Slide-valve vacuum pump suitable for vacuum extrusion of tiles

A technology of vacuum extruder and vacuum pump, which is applied to parts of pumping devices for elastic fluids, rotary piston pumps, rotary piston/swing piston pump components, etc., which can solve pump wear and tear, pump work Performance degradation, pollution of vacuum pump oil and other problems, to achieve the effect of avoiding condensation, ensuring work performance and avoiding failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

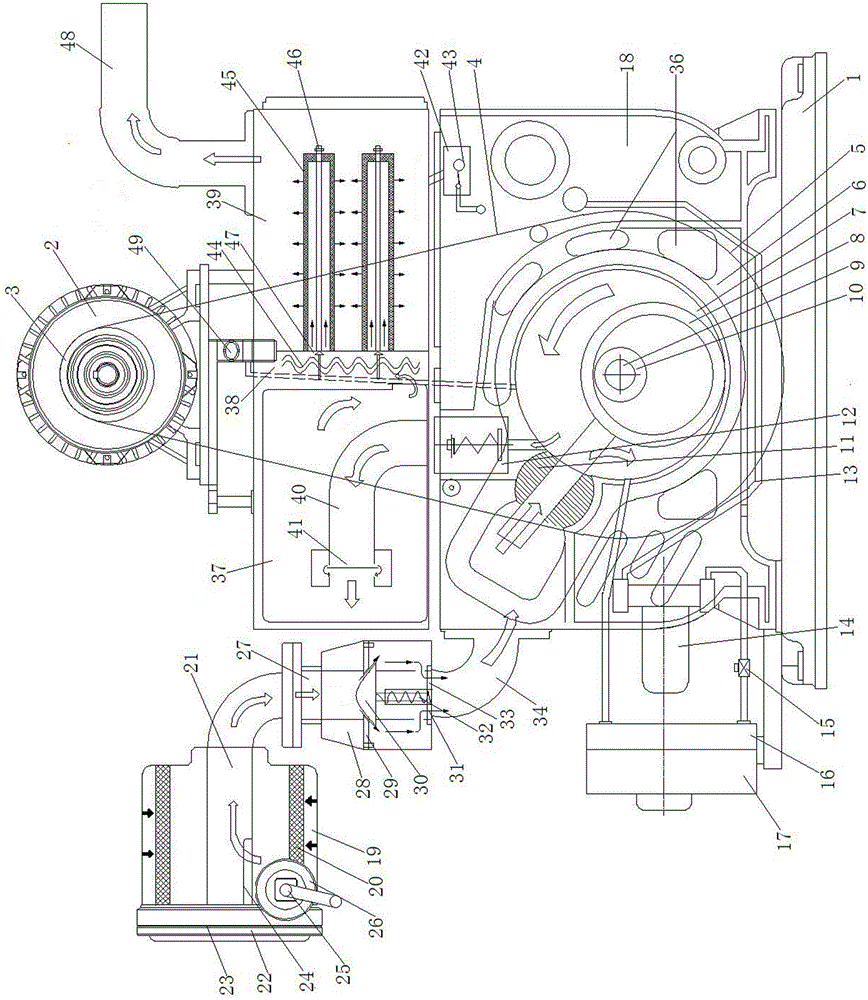

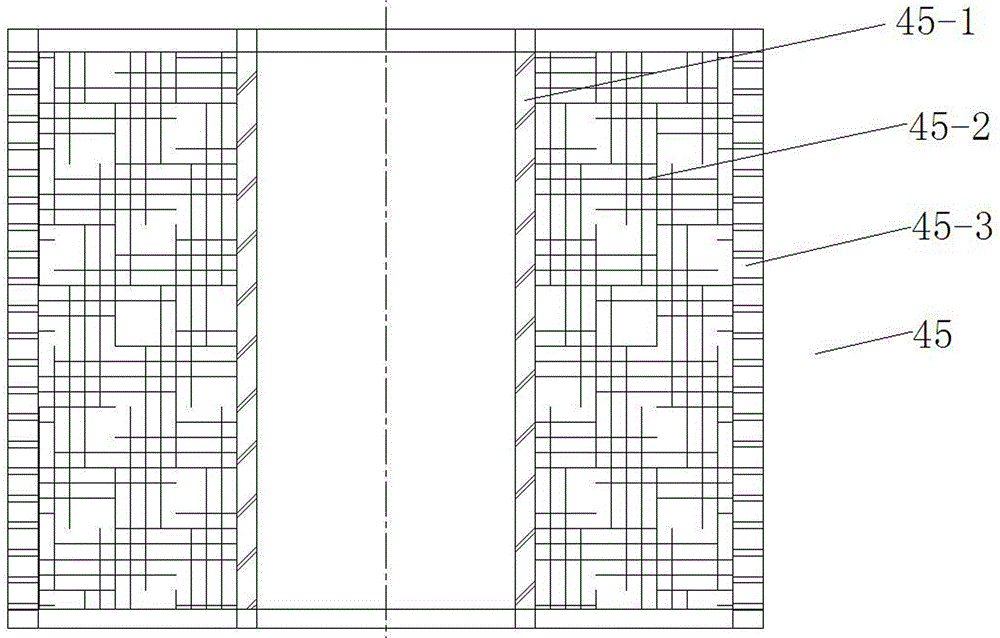

[0039] Refer to attached Figure 1~4 , the sliding valve vacuum pump suitable for brick vacuum extruder includes air inlet fine filter, one-way check valve, pump body 6, sliding valve sleeve 8, eccentric wheel 10, one-piece slider 11, main shaft 9, pulley 5 , belt 4, motor 2, exhaust valve 12, first exhaust oil-air separation chamber 37, second exhaust oil-air separation chamber 38, third exhaust oil-air separation chamber 39, pump oil circulation cooling device and base 1.

[0040] The air intake fine filter is installed on the vacuum pump intake pipe 34 on one side of the pump body 5 through a one-way check valve.

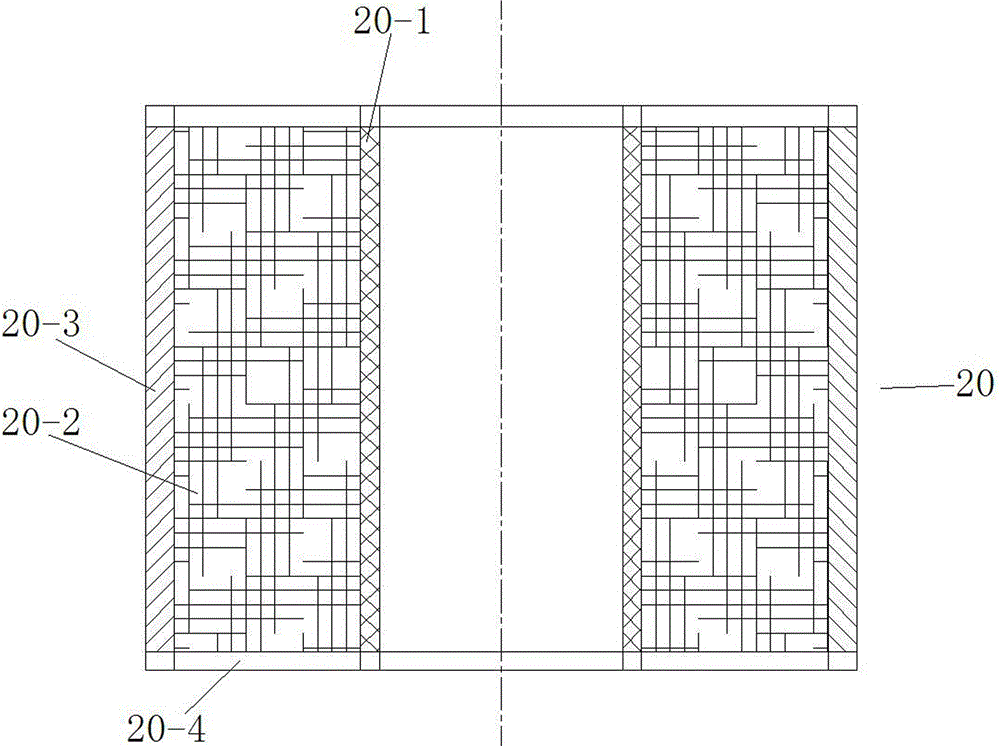

[0041] The intake fine filter includes a housing 19 , a fine filter element 20 , an air passage 21 , a cover plate 22 and a sealing ring 23 . One end of the housing 19 is sealed, the other end of the housing 19 is equipped with a cover plate 22, a sealing ring 23 is installed between the housing 19 and the cover plate 22, the housing 19 is equipped with a fine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com