Rotary-vane vacuum pump suitable for tile vacuum extruder

The technology of a rotary vane vacuum pump and a vacuum extruder is applied to the components of the pumping device for elastic fluid, the rotary piston pump, the rotary piston/oscillating piston pump, etc., which can solve the problem of gas filtration equipment. The purification effect is not ideal, the working performance of the pump is reduced, and the pumping efficiency is low, so as to avoid the loss of pump oil and environmental pollution, maintain stable working performance, and eliminate the spread of oil mist.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

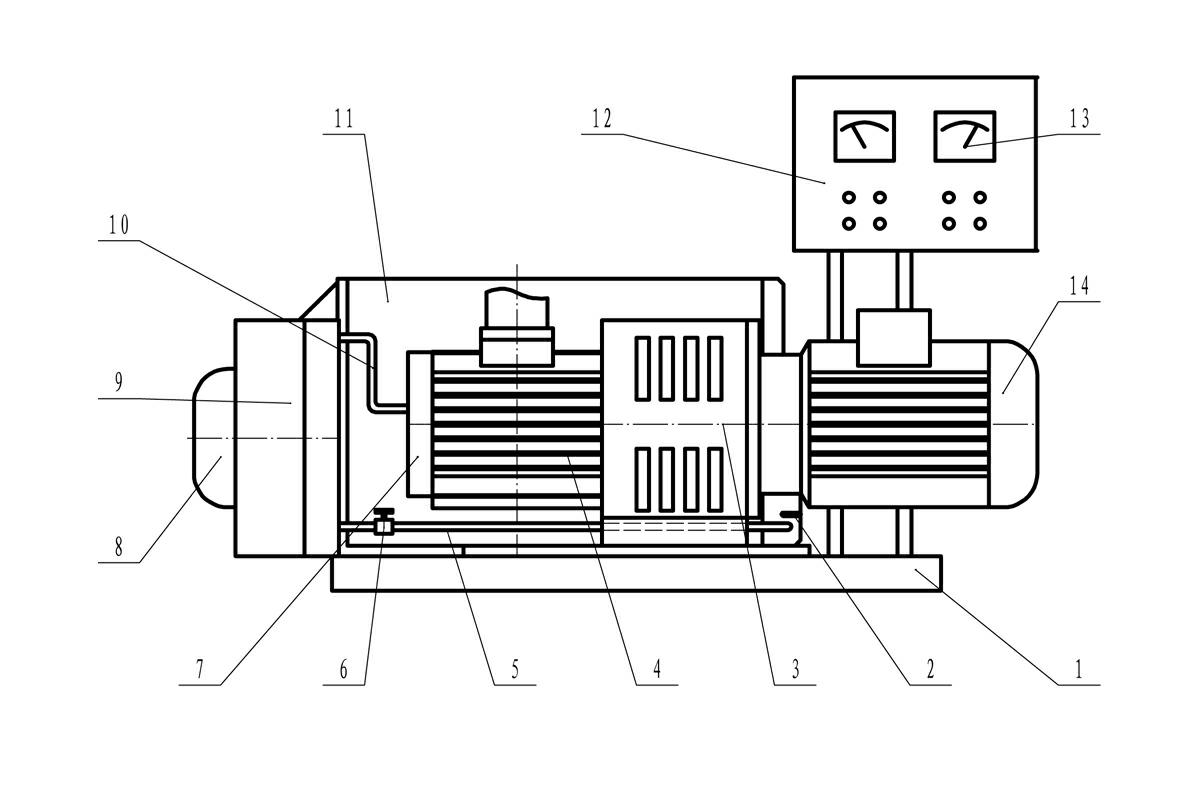

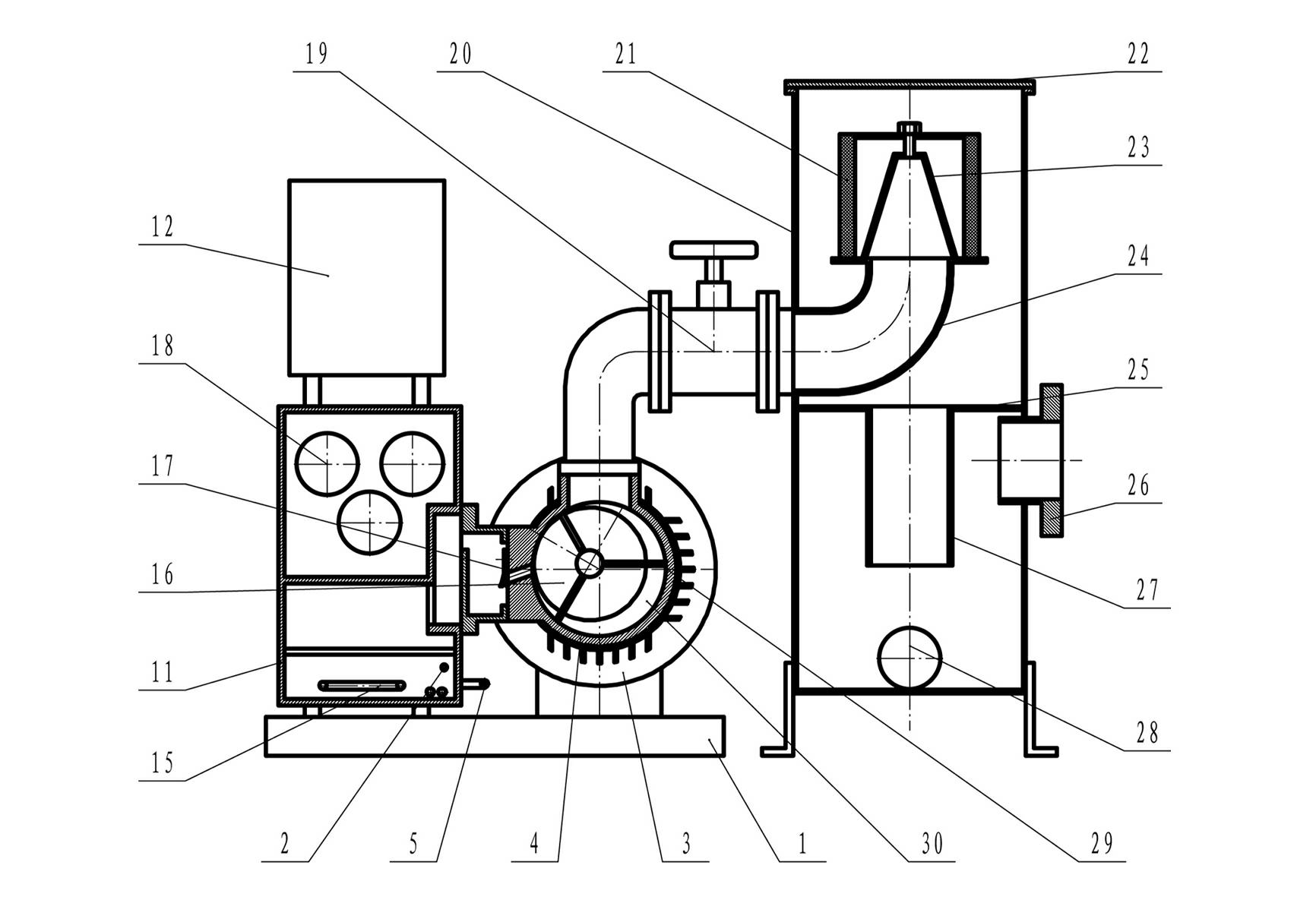

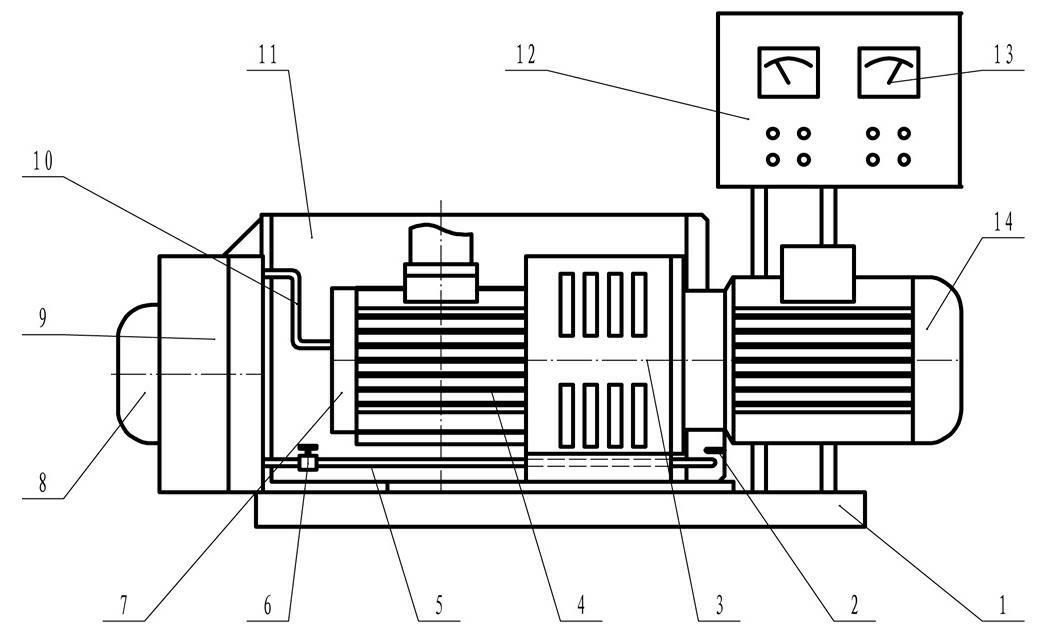

[0017] Refer to attached figure 1 , 2 , a kind of rotary vane vacuum pump suitable for tile vacuum extruder provided by the present invention, the specific structure of its embodiment is as follows:

[0018] like figure 1 and figure 2 As shown, a rotary vane vacuum pump suitable for brick and tile vacuum extruders of the present invention includes a pump body stator 4 with air-cooled fins, a front end cover 7, a rear end cover 30, a rotor 16, a rotary vane 29, a row Air valve assembly 17, side-mounted oil tank 11, exhaust oil mist filter 18, oil temperature control system, motor support base 3, motor 14, electrical control box 12, and necessary connecting parts and accessory parts. The connection relationship of each component is as follows: in the closed pump cavity formed by the front end cover 7, the pump body stator 4 and the rear end cover 30, the rotor 16 is installed eccentrically at an angle of 30° upward, and the rotor 16 has three rotary vane grooves. Rotary van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com