Rotary vane high-efficiency energy-saving environmental protection vacuum pump

A high-efficiency, energy-saving, vacuum pump technology, which is applied in the direction of pumps, rotary piston/oscillating piston pump parts, pump components, etc., can solve the problem of reduced pump performance, dust that cannot be filtered out, affecting the cleanliness of pump oil, and changes in vacuum pump performance Eliminate oil drop spray and oil mist diffusion, avoid pump oil loss and environmental pollution, improve the use effect and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

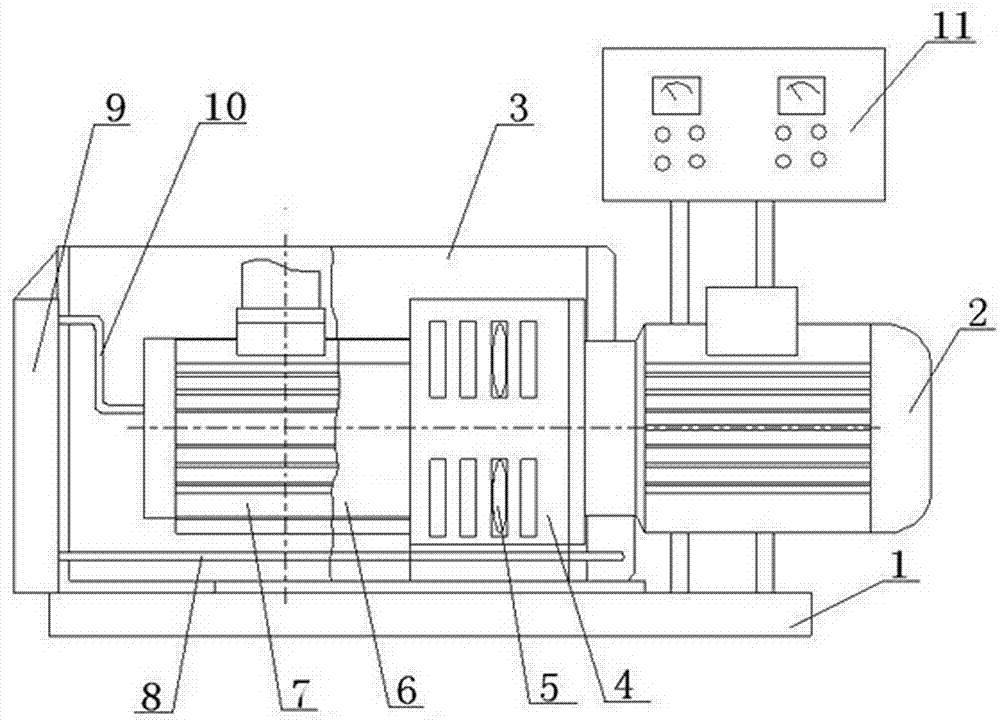

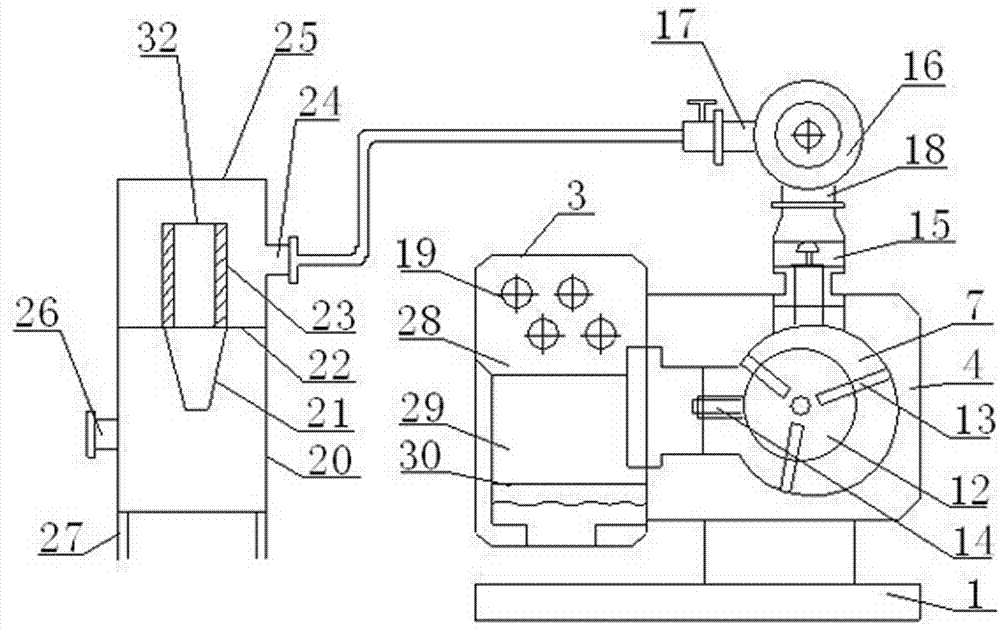

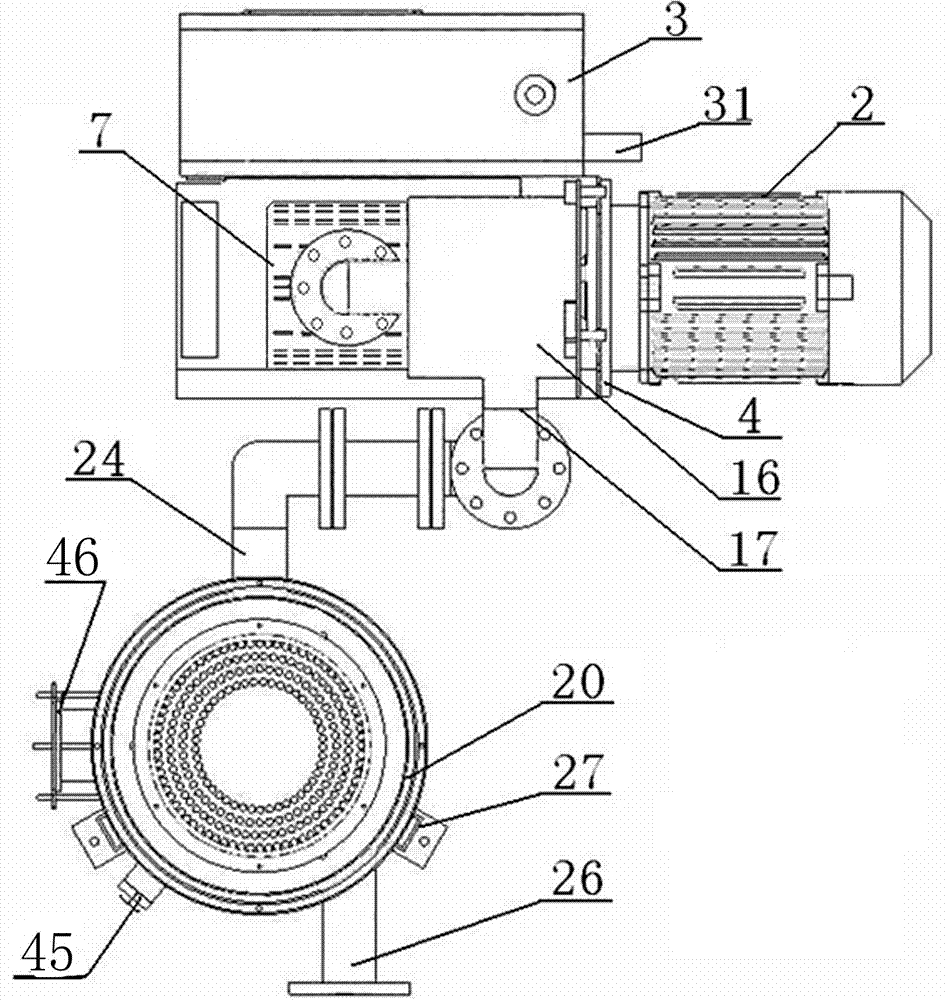

[0029] Refer to attached Figure 1~4 , Rotary vane high-efficiency energy-saving environmental protection vacuum pump includes air-water separator, air filter, pump body stator 7, rotor 12, rotary vane 13, exhaust valve assembly 14, side-mounted oil tank 3, air-cooled pump oil cooler 9, exhaust Air and oil mist filter, centrifugal fan 5, casing 6, frame 1 and motor 2.

[0030] The air-water separator is installed near the frame in an independent pattern, and the air-water separator includes a cylinder body 20, a partition plate 22, a mesh type filter screen cylinder 23, a conical diversion port 21, an upper cover 25, an air intake Port 26, air outlet 24 and sewage outlet. A partition 22 is installed in the middle of the cylindrical body 20 , and a mesh filter cylinder 23 is installed in the top of the partition 22 . The lower part of the dividing plate 22 is equipped with a conical diversion opening 21, and the upper part of the conical diversion opening 21 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com