Slide valve type vacuum pump applicable to tile vacuum extruder

A technology of vacuum extruder and vacuum pump, which is applied to components of pumping devices for elastic fluids, rotary piston type/swing piston type pump components, pumps, etc. The effect is not ideal, the working performance of the vacuum pump changes, etc., to achieve the effect of eliminating oil droplet spray and oil mist diffusion, avoiding pump oil loss and environmental pollution, and maintaining stable working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

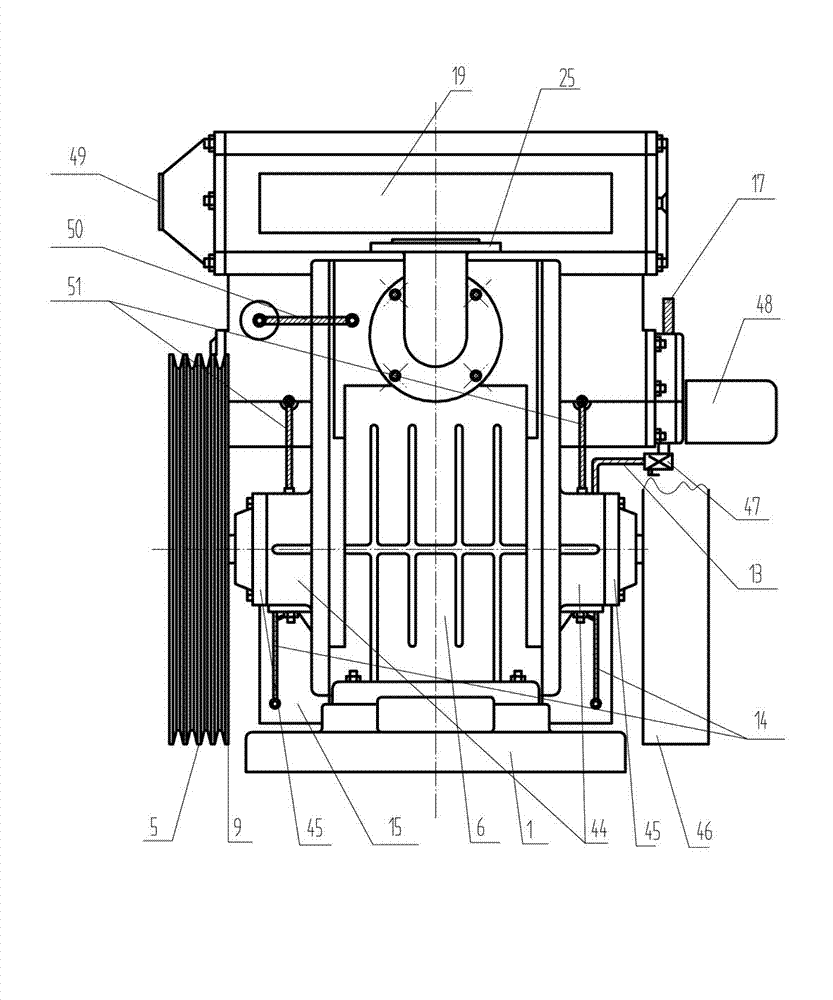

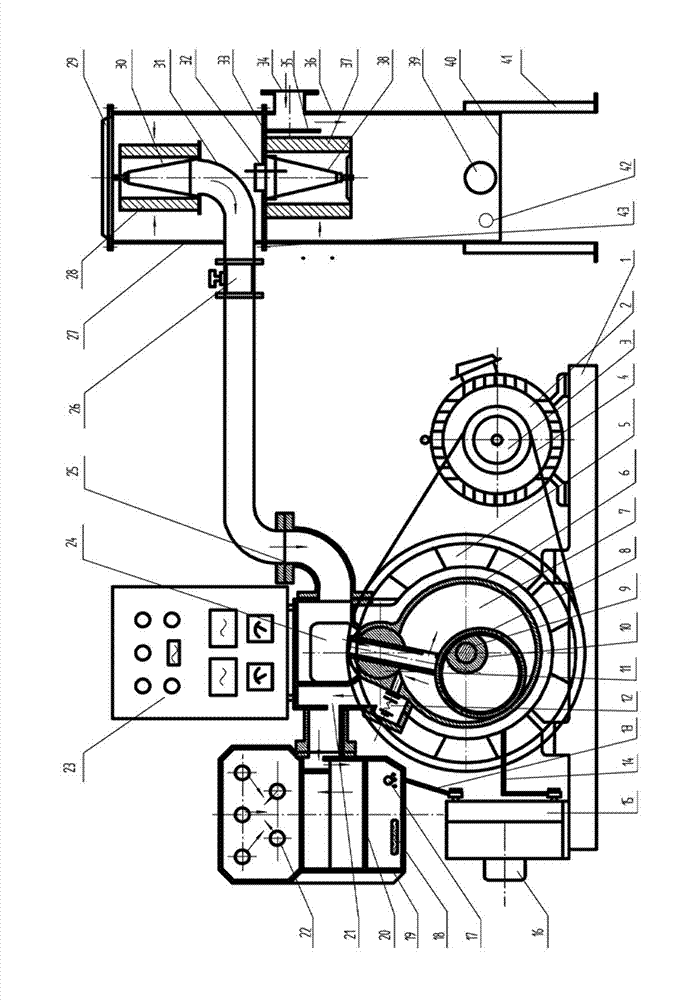

[0026] Refer to attached figure 1 , 2 , a sliding valve vacuum pump suitable for brick vacuum extruders, including an air inlet filter, a pump body 6, a sliding valve sleeve 8 (sliding sleeve with a sliding rod), an eccentric wheel 10, a sliding block 11, and a main shaft 9 , pulley 5, belt 4, motor 2, exhaust valve 12, side-mounted oil tank 19, exhaust oil mist filter 22, pump oil circulation and oil temperature control device, base 1 and electrical control box 23.

[0027] The intake filter is installed on one side of the vacuum pump, and the intake filter includes an upper cylinder body 27 , a lower cylinder body 36 , a baffle plate 35 , a coarse filter element 37 and a fine filter element 28 . The upper cylinder 27 is installed on the upper part of the lower cylinder 36, an O-ring 43 is installed between the upper cylinder 27 and the lower cylinder 36, and the upper part of the lower cylinder 36 is equipped with a coarse filter element fixing bracket 38, and the coarse fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com