Production process for continuously producing high-hydrogen-content silicone oil

A high hydrogen-containing silicone oil and production process technology, applied in the field of fine chemicals, can solve the problems of high production cost, low hydrogen content, solvent pollution, etc., and achieve the effects of reducing production cost, improving yield, and reducing the number of washings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

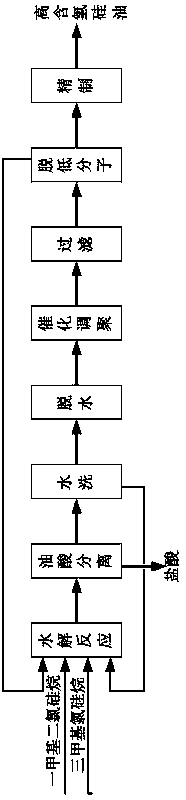

Method used

Image

Examples

Embodiment 1

[0023] A production process for continuous production of high hydrogen-containing silicone oil comprises the following steps:

[0024] 1) Add trimethylchlorosilane, methylhydrogendichlorosilane, dilute hydrochloric acid with a concentration of 1wt%, and low molecular weight into the hydrolysis cycle reaction system in proportion, with an average residence time of 20 minutes and a temperature of 8°C; the trimethylsilane The mass ratio of methylchlorosilane and methylhydrogendichlorosilane is 1:10, and the mass ratio of the chlorosilane mixture composed of trimethylchlorosilane and methylhydrogendichlorosilane and the concentration of 1wt% dilute hydrochloric acid is 1:30 ;

[0025] 2) The oleic acid mixture obtained through the hydrolysis reaction is separated in the oleic acid separation system, the upper layer is the hydrolyzate, and the lower layer is 16wt% dilute hydrochloric acid; the lower layer dilute acid enters the hydrolysis reaction system for recycling; the upper la...

Embodiment 2

[0028] A production process for continuous production of high hydrogen-containing silicone oil comprises the following steps:

[0029] 1) Add trimethylchlorosilane, methylhydrogendichlorosilane, dilute hydrochloric acid with a concentration of 3wt%, and low molecular weight into the hydrolysis cycle reaction system in proportion, with an average residence time of 40 minutes and a temperature of 12°C; the trimethylsilane The mass ratio of methylchlorosilane to methylhydrogendichlorosilane is 1:20, and the mass ratio of the chlorosilane mixture composed of trimethylchlorosilane and methylhydrogendichlorosilane to the concentration of 3wt% dilute hydrochloric acid is 1:40 ;

[0030] 2) The oleic acid mixture obtained through the hydrolysis reaction is separated in the oleic acid separation system, the upper layer obtains the hydrolyzate, and the lower layer obtains 20wt% dilute hydrochloric acid; the lower layer dilute acid enters the hydrolysis reaction system for recycling; the...

Embodiment 3

[0033] A production process for continuous production of high hydrogen-containing silicone oil comprises the following steps:

[0034] 1) Add trimethylchlorosilane, methylhydrogendichlorosilane, dilute hydrochloric acid with a concentration of 5wt%, and low molecular weight into the hydrolysis cycle reaction system in proportion, with an average residence time of 30 minutes and a temperature of 20°C; the trimethylsilane The mass ratio of methylchlorosilane to methylhydrogendichlorosilane is 1:30, and the mass ratio of the chlorosilane mixture composed of trimethylchlorosilane and methylhydrogendichlorosilane to concentration of 5wt% dilute hydrochloric acid is 1:80 ;

[0035] 2) The oleic acid mixture obtained through the hydrolysis reaction is separated in the oleic acid separation system. The upper layer obtains the hydrolyzate, and the lower layer obtains 22wt% dilute hydrochloric acid. The residence time of the hydrolyzate in the oleic acid separation system is 100min; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com