Method for extracting edible cornus wilsoniana seed oil from fresh cornus wilsoniana seed fruits at low temperature

A technology of smooth bark and tree seeds, which is applied in the field of extracting edible smooth bark seed oil from fresh fruits of light bark seeds at low temperature, can solve the problem of reducing oil safety, high oil acid value, high color and peroxide value, and large oil loss. and other problems, to achieve the effect of facilitating oil separation, maintaining characteristic flavor, and preventing oil emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

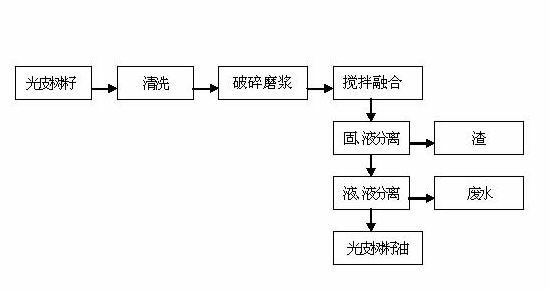

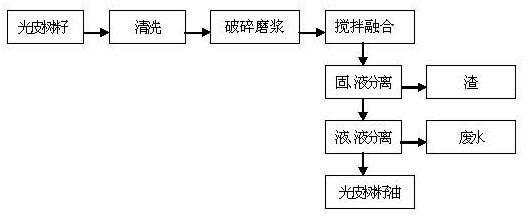

[0009] Example 1 : A method for extracting edible eucalyptus seed oil at low temperature from the fresh fruit of eucalyptus eucalyptus: wash 500 grams of fresh and ripe eucalyptus eucalyptus seeds to remove impurities, use a metal pulverizer to crush and refine pulp at a speed of 50 r / min, add Water with 100% raw material quality at 45°C was stirred and fused at 45°C and 60r / min for 2h, centrifuged at 3500r / min for solid-liquid separation, and then centrifuged at 9000r / min for liquid-liquid separation to obtain the eucalyptus seed oil.

Embodiment 2

[0010] Example 2 : A method for extracting edible eucalyptus seed oil at low temperature from fresh fruits of eucalyptus eucalyptus: wash 500g of fresh and mature eucalyptus eucalyptus seeds to remove impurities, use a grinding wheel pulverizer to crush and refine pulp at a speed of 20r / min, add 30 ℃ The water with 40% raw material quality is mixed at 30 ℃ and 30r / min for 1h, centrifuged at 2000r / min for solid-liquid separation, and then centrifuged at 15000r / min for liquid-liquid separation to obtain the eucalyptus seed oil.

Embodiment 3

[0011] Example 3 : A method for extracting edible eucalyptus seed oil from fresh fruit of eucalyptus at low temperature: wash 500g of fresh and mature eucalyptus eucalyptus seeds to remove impurities, use a ceramic pulverizer to crush and refine pulp at a speed of 80r / min, add 35 ℃ water with 150% raw material quality, stirred and fused at 35 ℃, 100r / min for 3 hours, centrifuged at 800r / min for solid-liquid separation, and then centrifuged at 20000r / min for liquid-liquid separation to obtain eucalyptus seed oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com