Method for coextracting uranium, plutonium and neptunium

An extraction and neptunium co-extraction technology, applied in the field of co-extraction of plutonium, uranium and neptunium, can solve the problems of increasing the salt content of radioactive waste, increasing the difficulty and cost of nuclear waste disposal, and the low extraction rate of neptunium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

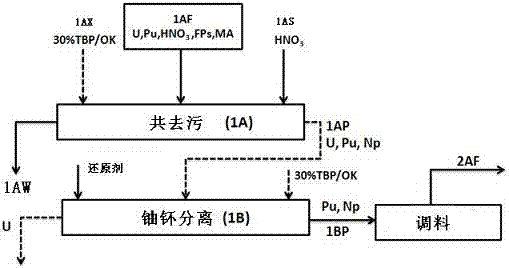

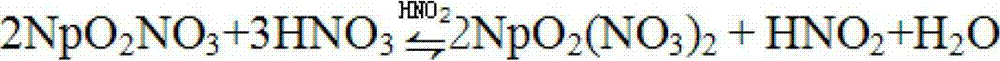

[0035] A method of co-extraction of uranium, plutonium, and neptunium. This method is to co-extract neptunium with uranium and plutonium in the co-decontamination section to make it enter the organic phase 1AP. The key is to oxidize Np(V) into energy in the 1A extractor. Np(VI) extracted by the extractor.

[0036] figure 1 Schematic diagram of the co-decontamination separation cycle. The total decontamination section is divided into two parts, 1AX to 1AF are extraction sections, and 1AF to 1AS are washing sections.

[0037] 1AF is a nuclear fuel solution, which is an aqueous solution of nitric acid containing uranium, plutonium, neptunium, sub-actinium MA (neptunium, americium, curium), shard elements, etc., 1AF is fed from the middle of the extractor; 1AX is an extractant with the composition 30% TBP / kerosene, the extractant is fed from the outlet stage of the aqueous raffinate of the extractor; 1AS is the detergent, which is an aqueous solution of nitric acid, fed from the orga...

Embodiment 2

[0040] A method of co-extraction of uranium, plutonium, and neptunium. This method is to co-extract neptunium with uranium and plutonium in the co-decontamination section to make it enter the organic phase 1AP. The key is to oxidize Np(V) into energy in the 1A extractor. Np(VI) extracted by the extractor.

[0041] figure 1 It is a schematic diagram of the co-decontamination separation cycle, where the nitric acid concentration in 1AF is 3.50 mol / L, and the nitric acid concentration in 1AS is 3.0 mol / L. The concentration of nitrous acid in the water phase of the extraction section is 1×10 -4 mol / L. 1AX:1AS (organic phase: water phase) flow ratio range is 3: 1 uranium saturation is 60%, the operating temperature of extraction section and washing section are 50℃ and 20℃ respectively.

[0042] UV-UV-Visible spectrophotometer was used to analyze the uranium concentration and nitrous acid concentration in the sample, and the yield of uranium product was greater than 99.99%. The plutoni...

Embodiment 3

[0044] The method is the same as that used in Example 2, except for the process parameters. The nitric acid concentration in 1AF is 4.50 mol / L, and the nitric acid concentration in 1AS is 3.5 mol / L. The concentration of nitrous acid in the water phase of the extraction section is 8×10 -4 mol / L. The 1AX:1AS flow ratio range is 5:1. The uranium saturation is 65%, and the operating temperatures of the extraction section and the washing section are 40℃ and 25℃ respectively.

[0045] UV-UV-Visible spectrophotometer was used to analyze the uranium concentration and nitrous acid concentration in the sample, and the yield of uranium product was greater than 99.99%. The plutonium concentration and neptunium concentration in the sample were analyzed by α spectrum, and the yield of plutonium was greater than 99.9%. , The yield of neptunium is greater than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com