Scandium element extraction method

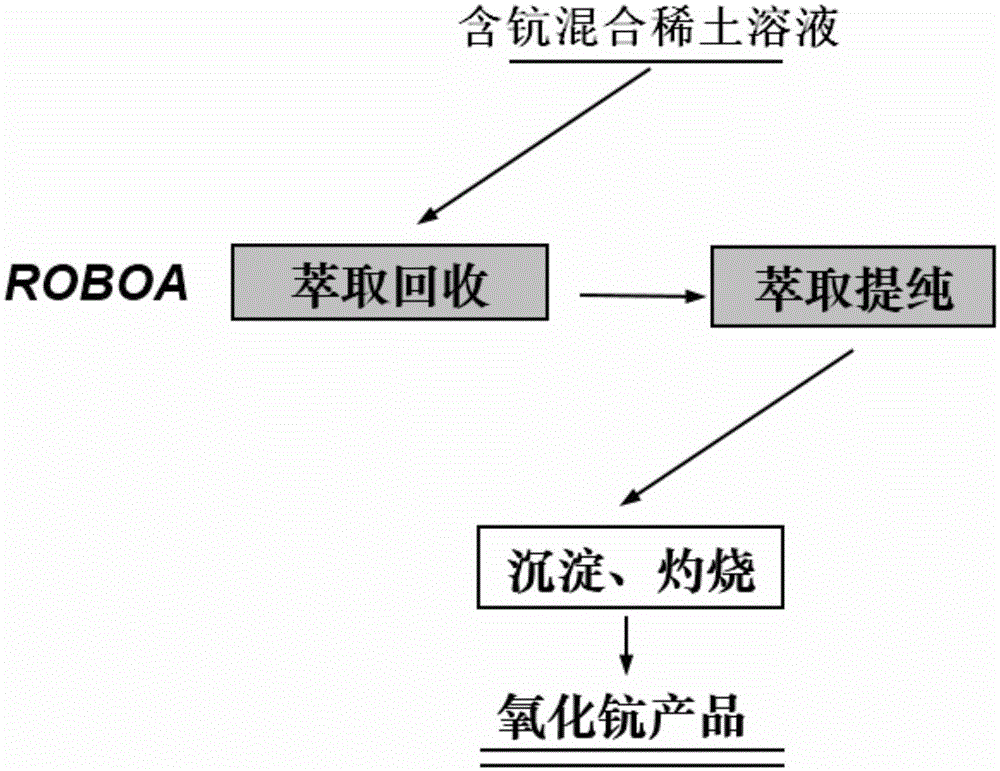

A scandium element and extraction technology, which is applied in the field of rare earth hydrometallurgy, can solve the problems of scandium recovery and purification processes that have not seen major innovations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The analysis of rare earth elements adopts the ICP-MS method (refer to GB / T 18114.8-2010 Chemical Analysis Methods of Rare Earth Concentrates, Part 8, Determination of 15 Rare Earth Element Oxides).

[0054] When the volume of the aqueous phase and the organic phase are equal, the calculation formulas for the extraction rate E, distribution ratio D, and separation coefficient β are as follows:

[0055] Extraction rate E=(C total -C aq ) / C total ;

[0056] Distribution ratio D=E / (1-E);

[0057] Separation coefficient β=D RE1 / D RE2 .

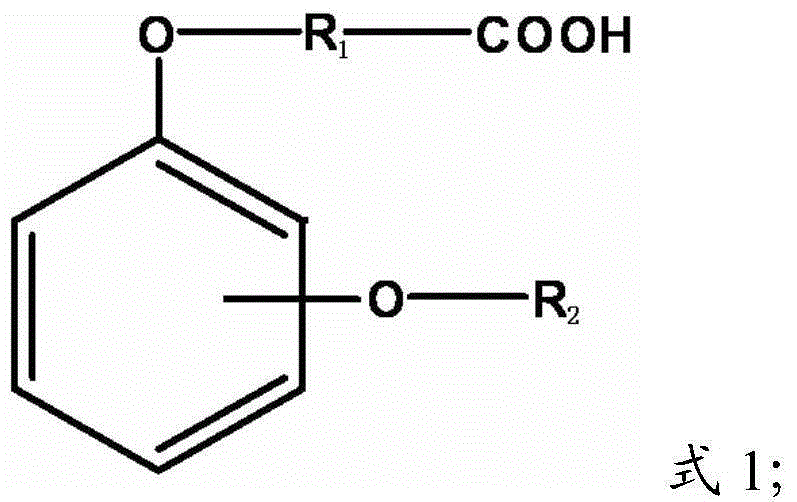

[0058] Synthesis and characterization of extractant: using o-chlorophenoxyacetic acid and 3,5,5-trimethylhexanol as raw materials, o-3,5,5-trimethylhexanol was prepared by Williamson reaction Phenyloxyacetic acid (code name ROBOA-1), its purity was measured to be 98%, and its pKa value was 4.80.

[0059] Prepare the organic phase: take 20 mL of o-3,5,5-trimethylhexyloxyphenoxyacetic acid (code ROBOA-1) extractant, 10 mL of tributyl...

Embodiment 2

[0065] Prepare the organic phase: Dissolve 100mL of commercial m-2,4,4-trimethylpentyloxyphenoxyacetic acid (code ROBOA-2) extractant in toluene, 100mL of tributyl phosphate (TBP), And dilute to 1000mL, the volume concentration of extractant is 10% at this moment.

[0066] Preparation of raw material solution: take tungsten slag leaching solution and adjust it into scandium-containing mixed rare earth solution, its composition is: scandium 54ppm, pH value is 3. The main impurities are iron, aluminum, titanium, zirconium and rare earth.

[0067] Fractional extraction: The whole extraction process uses a separatory funnel array for fractional extraction, including 4-stage extraction, 2-stage washing and 2-stage stripping. The organic phase is added from the first stage; the scandium-containing mixed rare earth solution is added from the fourth stage; the washing solution is 0.2 mol / liter nitric acid, which is added from the sixth stage; the stripping acid is 2.0 mol / liter nitri...

Embodiment 3

[0069] Prepare the organic phase: take 500mL of commercialized p-n-nonyloxyphenoxypropionic acid (code ROBOA-3) extractant and dissolve it in 260# solvent oil (purchased from Luoyang Aoda Chemical Co., Ltd.), TBP200mL, And dilute to 2000mL, the volume concentration of extractant is 25% at this moment. Add 37.5 milliliters of concentrated ammonia water for saponification, and the degree of saponification is 70%.

[0070] Prepare the raw material solution: take crude scandium with a grade of 35%, dissolve it with nitric acid, and adjust it into a mixed rare earth solution containing scandium. The main impurities are rare earths.

[0071] Fractional distillation extraction: The whole extraction process uses a mixed-settler tank for fractional distillation extraction, including 6-stage extraction, 4-stage washing and 3-stage stripping. The organic phase is added from the first stage; the scandium-containing mixed rare earth solution is added from the sixth stage; the washing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com