Integrated hydro-pneumatic spring device

An oil-pneumatic spring and integrated technology, which is applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc., can solve problems such as the limitation of the application of electromechanical simulation theory, improve driving comfort and handling stability, and improve Suspension sprung mass, effect of reducing confinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

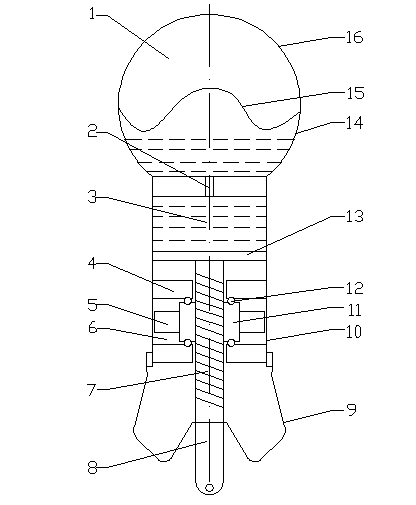

[0029] figure 1Shown is an integrated oil-gas spring device, including an inerter working part, a damping working part, and an outer protection part. The outer protection part includes a protective cover 9 and a working cylinder 10, and the lower end of the working cylinder 10 is fixed with the protective cover 9 through a sealing structure; The working part of the inerter includes a piston 13, an upper limit ring 4, a lower limit ring, a flywheel 5 and a ball screw structure 7. The ball screw structure 7 includes a piston rod 8, a ball screw nut 11 and a ball 12. The piston rod 8 passes through the ball The screw nut 11, and the ball screw nut 11 and the screw rod part of the piston rod 8 are screw fit, the contact surface between the ball screw nut 11 and the upper limit ring 4 and the lower limit ring is provided with a ball ring groove, and the balls 12 is placed in the ball ring groove, the flywheel 5 is coaxially fixed on the ball screw nut 11, the piston 13 is fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com