Airship airbag with shape-control frames

A skeleton and airbag technology, applied in the field of airships, can solve problems such as the difficulty of compressed air equipment, overturning of airships, poor heat dissipation of inner airbags, etc., to achieve strong expansion and scaling deformation rules, improve the space utilization rate in the boat, and make good use of space rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

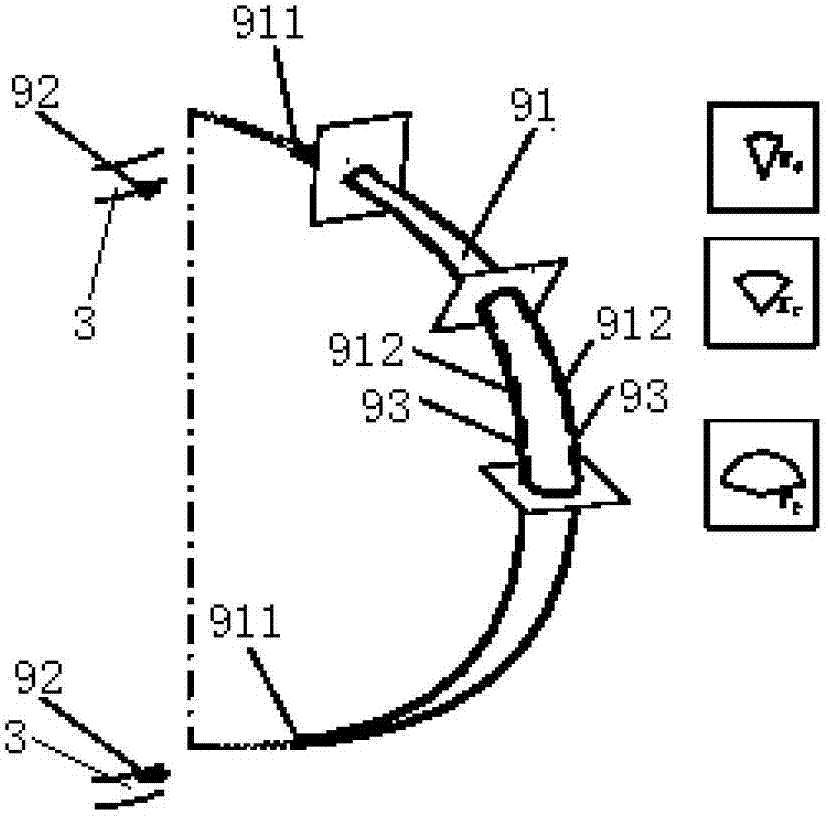

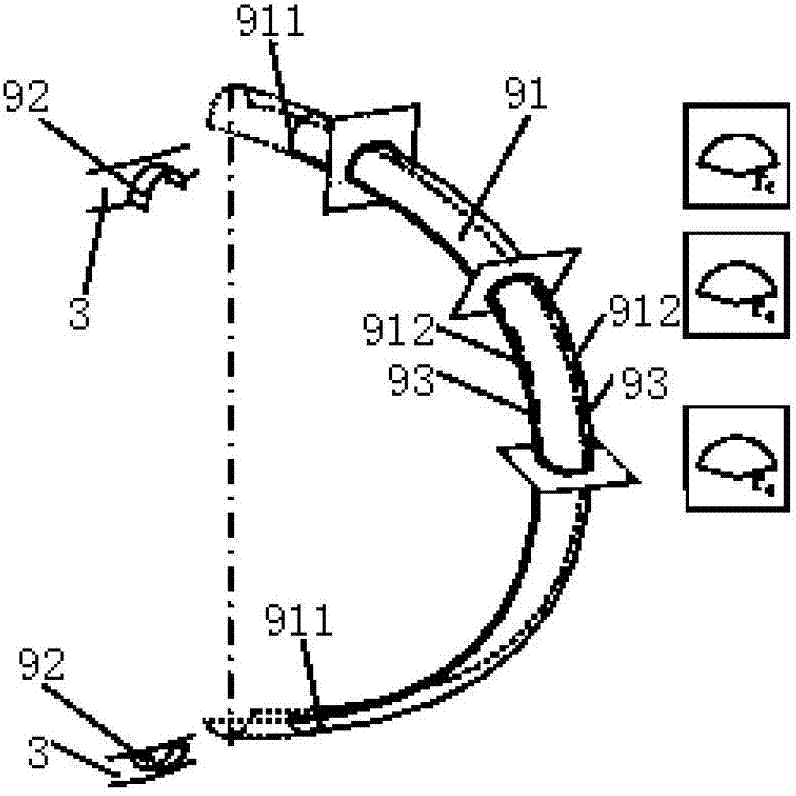

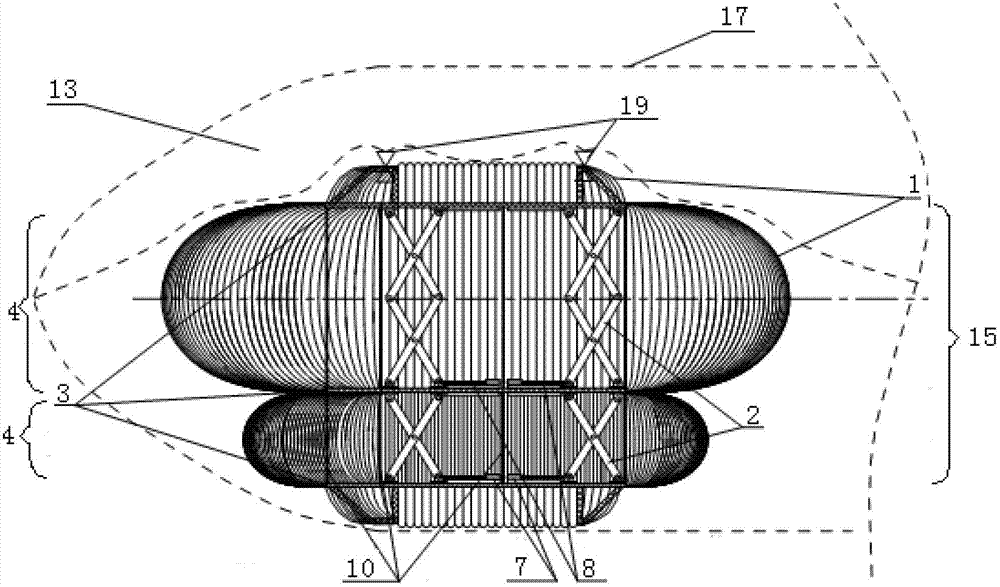

[0030] An airbag with a shape-controlling skeleton for an airship, comprising a capsule skin 1 and a shape-controlling skeleton such as Figure 1~3 As shown; wherein, the airtight flexible bladder skin 1 is located on the outer layer of the airbag, and is a laminated structure as a whole, consisting of a plurality of layered structures 4; the inside of the bladder skin 1 of each layered structure 4 is fixedly connected with a shape The control skeleton, the shape control skeleton of each layered structure 4 includes several pairs of vertically arranged retractable skeletons 2 and two sets of shaped skeletons 3 respectively hinged to the two ends of the retractable skeleton 2; The upper shaped skeleton 3 of the layered structure 4 is fixed, the lower top surface inside the capsule skin 1 is fixed with the lower shaped skeleton 3 of the bottom layered str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com