Method for non-saponification extraction and separation of light rare earth elements

A light rare earth element, non-saponifiable technology, applied in the field of hydrometallurgy, can solve the problems of poor fluidity, long phase separation time, and large system viscosity, and achieve the effects of reducing production cost, shortening phase separation time, and enhancing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

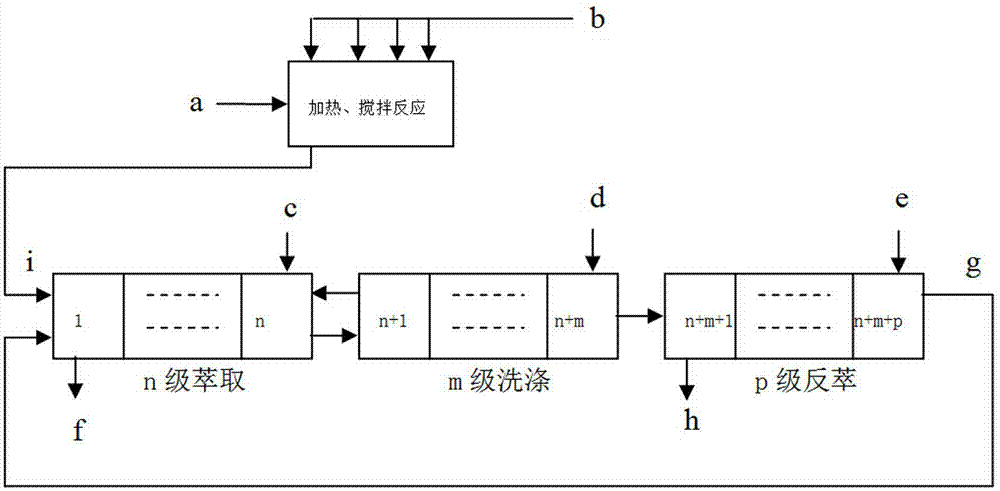

[0026]Add P507—N235-200# solvent oil composite type extractant in airtight stirred kettle, wherein the volume percentage of P507 is 30%, the volume percentage of N235 is 35%, and the volume percentage of 200# solvent oil is 35%; At 45°C, add a solvent consisting of tributyl phosphate and isooctyl alcohol at a flow rate of 0.03L / min, wherein the volume percentage of tributyl phosphate is 80%, and the volume percentage of isooctyl alcohol is 20%; the solvent is added The total amount is 15% of the compound extraction dosage, and stirred for 1 hour. Stop stirring, introduce the mixed organic phase into the extraction tank, and chlorinate light rare earth feed liquid (feed liquid concentration: La 41g / L, Ce 4g / L, Pr 10 g / L, Nd 36 g / L; feed liquid pH: 1.5) Carry out LaCe / PrNd extraction grouping, as follows figure 1 The process shown is for extraction, washing, and stripping operations, wherein the ratio of the extraction section (organic phase: water phase) is controlled at 1:1, ...

Embodiment 2

[0031] Add P204—N1923-260# solvent oil composite type extractant in airtight stirred tank, wherein the volume percentage of P204 is 40%, the volume percentage of N1923 is 30%, the volume percentage of 260# solvent oil is 30%; At 70°C, add a solvent consisting of trioctyl phosphate and n-amyl alcohol flowing in at a flow rate of 0.05L / min, wherein the volume percentage of trioctyl phosphate is 60%, and the volume percentage of n-amyl alcohol is 40%; The amount is 10% of the compound extraction dosage, and stirred for 0.5h. Stop stirring, introduce the mixed organic phase into the extraction tank, and mix the rare earth chloride feed solution containing La and Ce (the concentrations of La and Ce are 45g / L and 3g / L respectively, and the pH of the feed solution: 1.9) according to the attached figure 1 The process shown is for extraction, washing, and back-extraction operations, wherein the ratio of the extraction section (organic phase: water phase) is controlled to 2:1, the extra...

Embodiment 3

[0036] Add P507—N235-200# solvent oil compound type extractant in airtight stirred tank, wherein the volume percentage of P507 is 50%, the volume percentage of N235 is 25%, and the volume percentage of 200# solvent oil is 25%; 35°C, add a solvent composed of trioctyl phosphate and isooctyl alcohol at a flow rate of 0.01L / min, wherein the volume percentage of trioctyl phosphate is 90%, and the volume percentage of isooctyl alcohol is 10%; the solvent is added The total amount is 20% of the compound extraction dosage, and stirred for 4 hours. Stop stirring, introduce the mixed organic phase into the extraction tank, and mix the rare earth chloride feed liquid containing Pr and Nd (wherein the concentrations of Pr and Nd are 9g / L and 35g / L respectively, and the pH of the feed liquid: 4) according to the attached figure 1 The shown flow process carries out extraction, washing, stripping operations, wherein, the ratio of extraction section (organic phase: water phase) is controlled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com