Hydraulic oil

A technology of hydraulic oil and extreme pressure anti-wear agent, applied in the field of hydraulic oil, can solve the problems of low flash point, refractory degradation, high toxicity, etc., achieve good low temperature performance, good foam tendency and foam stability, and good foam resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention has no special limitation on the preparation method of the hydraulic oil, which can be prepared by mixing the components of the hydraulic oil described in the above technical solution. In an embodiment of the present invention, the preparation method of the hydraulic oil may be:

[0061] mixing polyalphaolefin, diester compound, viscosity modifier, antioxidant, antirust agent, extreme pressure antiwear agent and coloring agent to obtain a mixture;

[0062] The mixture is mixed with an antifoaming agent to obtain a hydraulic oil.

[0063] In the present invention, the types, sources and parts by weight of the polyalphaolefins, diester compounds, viscosity modifiers, antioxidants, rust inhibitors, extreme pressure antiwear agents, dyeing agents and antifoaming agents are the same as The types, sources and parts by weight of the polyalphaolefins, diester compounds, viscosity modifiers, antioxidants, rust inhibitors, extreme pressure and antiwear agen...

Embodiment 1

[0077] 89g of PAO2, 11g of dioctyl sebacate, 15g of VX7510, 0.4g of 2,6-di-tert-butyl-p-cresol, 0.4g of N-phenyl-1-naphthylamine, 2.0g of TCP Stir and mix with 0.005g of oily red at 80°C for 0.5 hours to obtain a mixture; filter the mixture with diatomaceous earth, mix and stir the filtered mixture and methyl silicone oil evenly to obtain hydraulic oil, and the methyl silicone oil The mass content in the hydraulic oil is 25 μg / g.

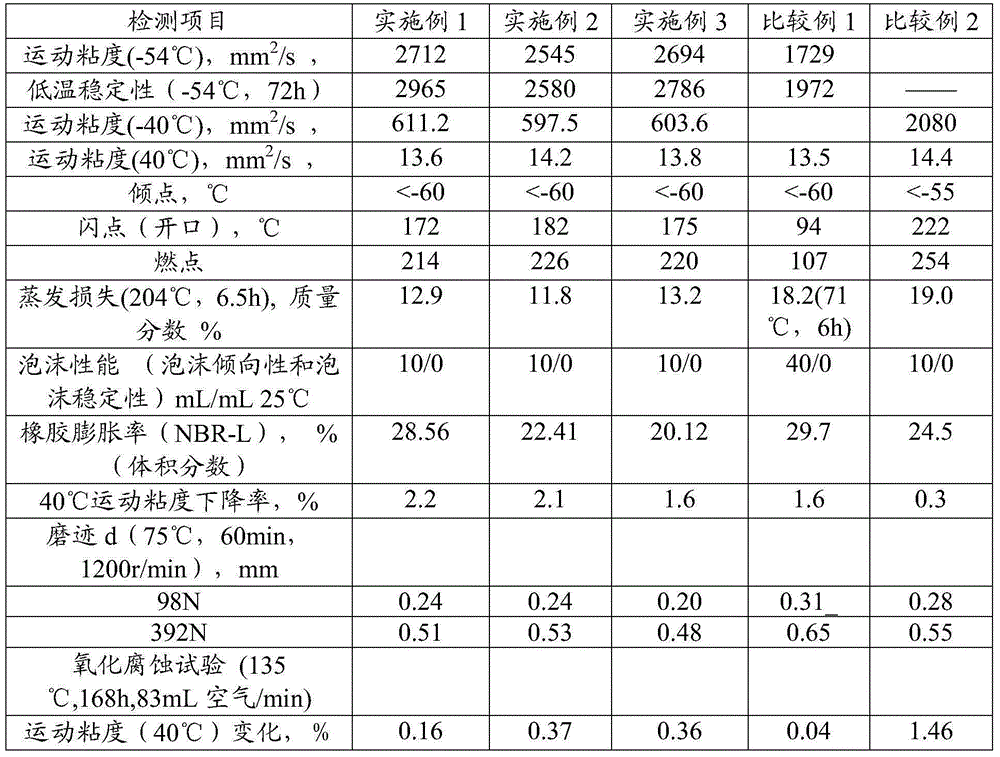

[0078]According to the method described in the above technical solution, the kinematic viscosity, low temperature stability, pour point, flash point, ignition point, evaporation loss, wear performance, and oxidation corrosion of the hydraulic oil prepared in Example 1 of the present invention were tested. The test results are shown in the table 1, Table 1 shows the performance test results of the hydraulic oils provided by the embodiments of the present invention and comparative examples.

Embodiment 2

[0080] 80g of PAO2, 20g of dioctyl sebacate, 15g of YC750, 0.5g of β-(3.5-di-tert-butyl-4 hydroxyphenyl) methyl propionate, 0.5g of N-phenyl-1 -Naphthylamine, 1.5g of TCP, 0.05g of Span-80 and 0.005g of Oily Red were stirred and mixed for 1 hour at 80°C to obtain a mixture; the mixture was filtered with diatomaceous earth, and the filtered mixture was mixed with formazan The base silicone oil was mixed and stirred evenly to obtain a hydraulic oil, and the mass content of the methyl silicone oil in the hydraulic oil was 20 μg / g.

[0081] According to the method described in the above technical solution, the kinematic viscosity, low temperature stability, pour point, flash point, ignition point, evaporation loss, wear performance, and oxidation corrosion of the hydraulic oil prepared in Example 2 of the present invention were tested. The test results are shown in the table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com