Patents

Literature

33results about How to "Good for transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

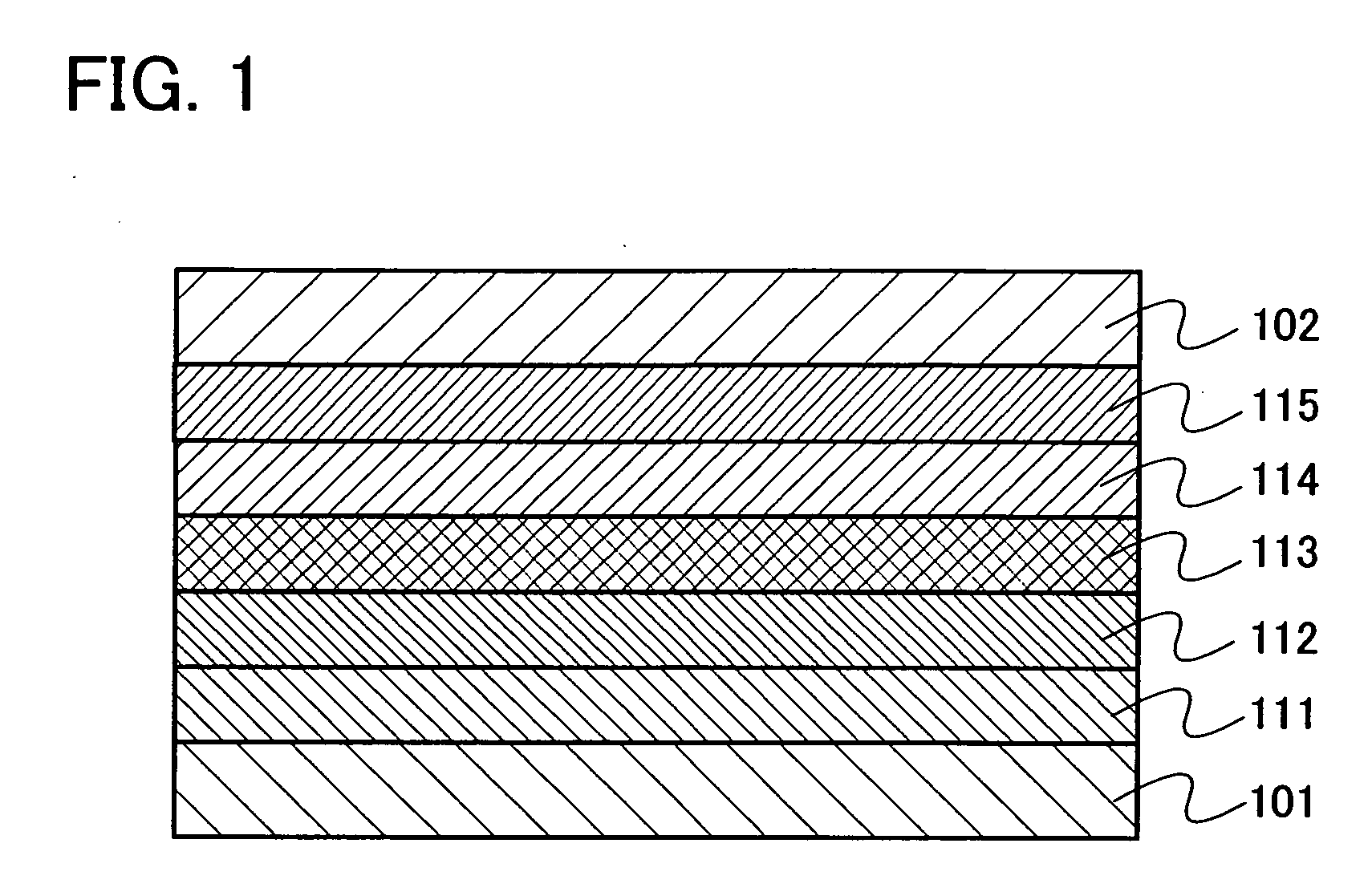

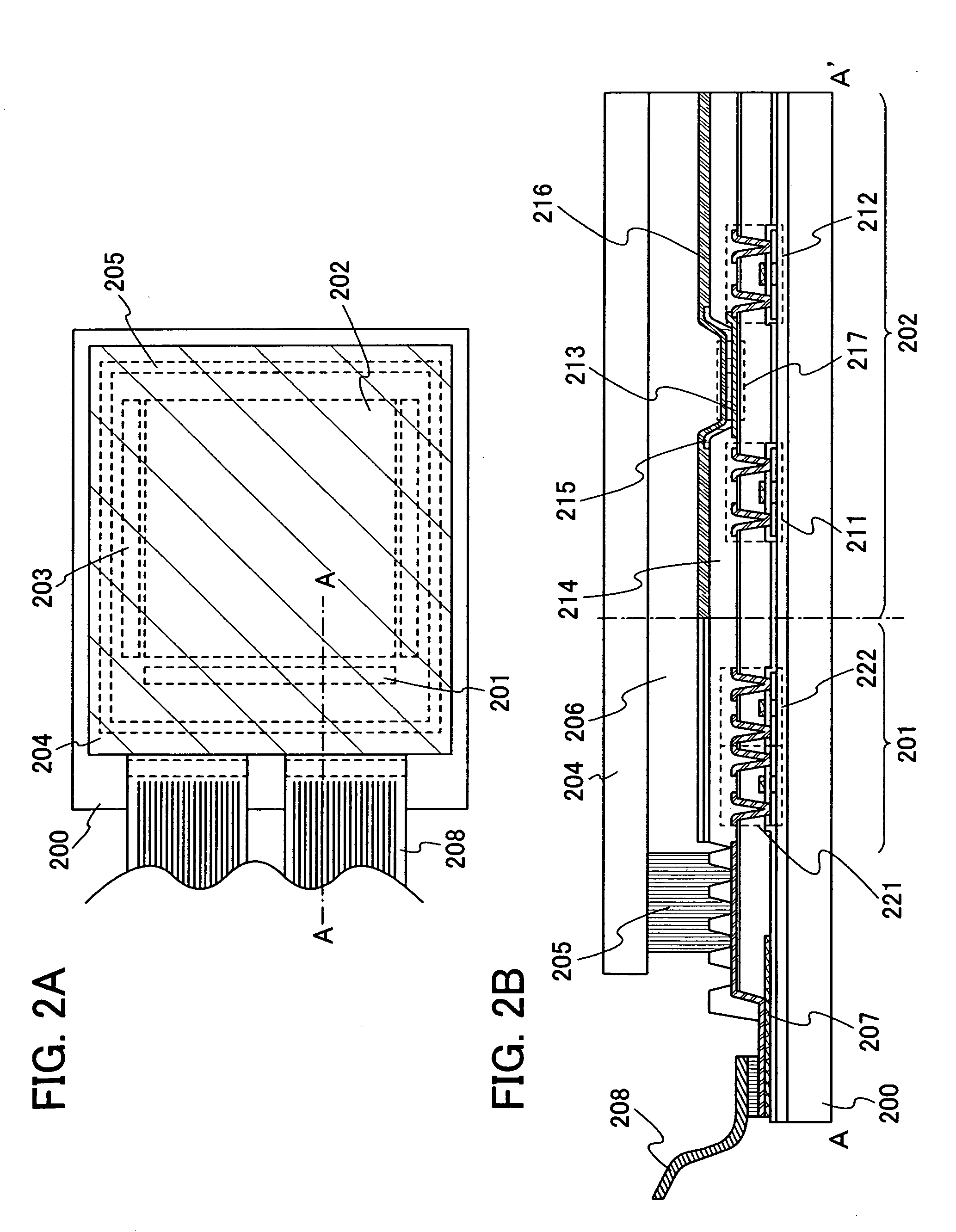

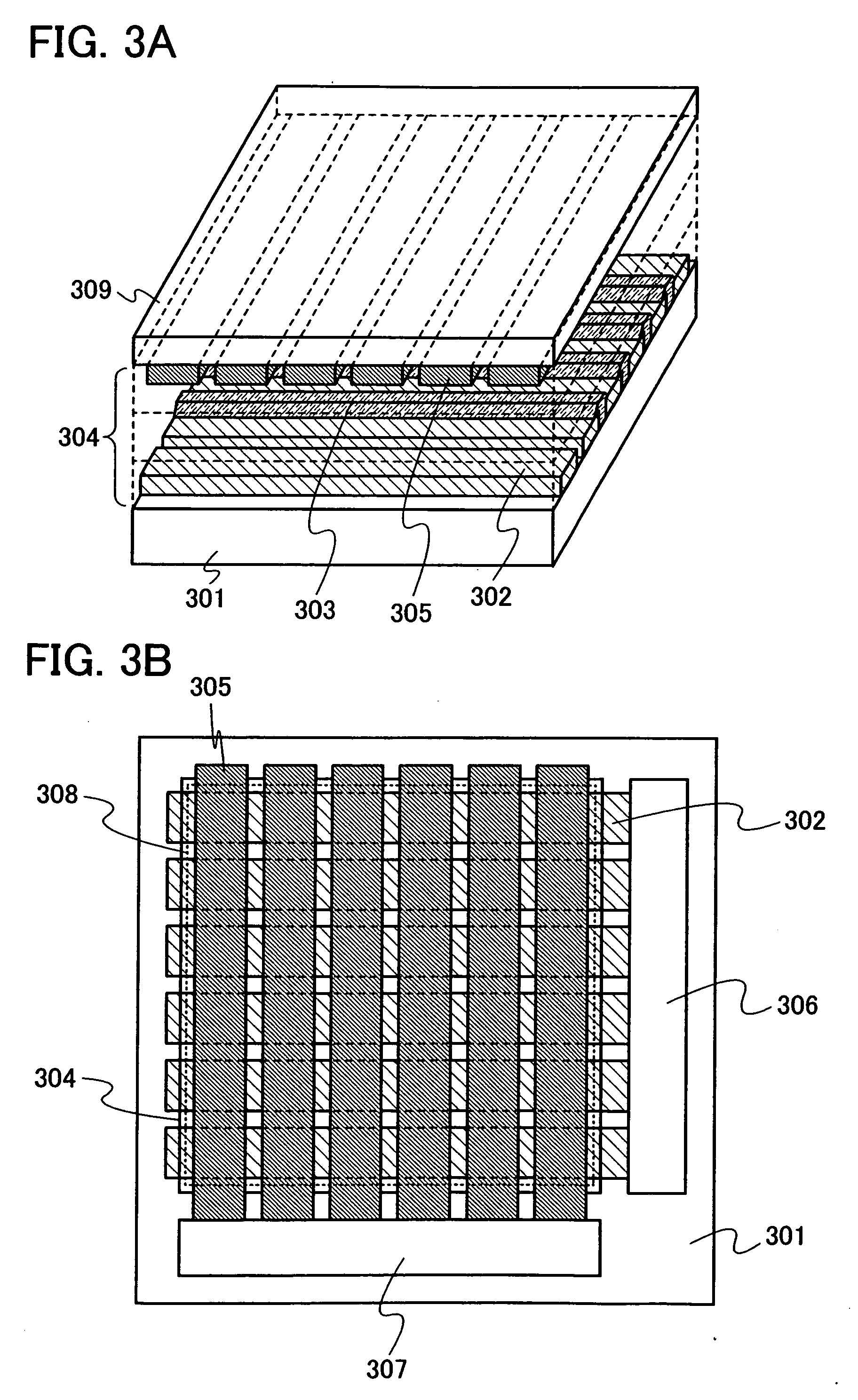

Anthracene derivative and hole transporting material, light emitting element, and electronic appliance using the same

InactiveUS20070049778A1Good for transportationReduce driving voltageOrganic chemistryDischarge tube luminescnet screensVoltageCarbon atom

It is an object of the present invention to provide a substance capable of contributing to obtaining a light emitting element with a low driving voltage and long lifetime. An anthracene derivative represented by a general formula (1) is provided. In the general formula (1), each of R1 to R8 represents hydrogen or an alkyl group having 1 to 4 carbon atoms. Further, each of R9 to R17 represents hydrogen, an alkyl group having 1 to 4 carbon atoms, or a substituted or unsubstituted aryl group. Such an anthracene derivative can be hardly crystallized, and can be superior in a carrier transporting property. Therefore, by using the anthracene derivative, a light emitting element with a low driving voltage and long lifetime can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

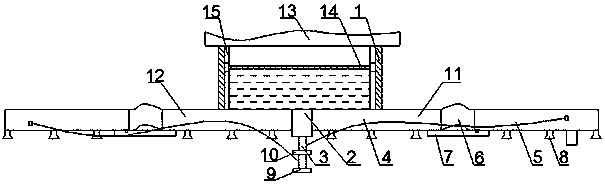

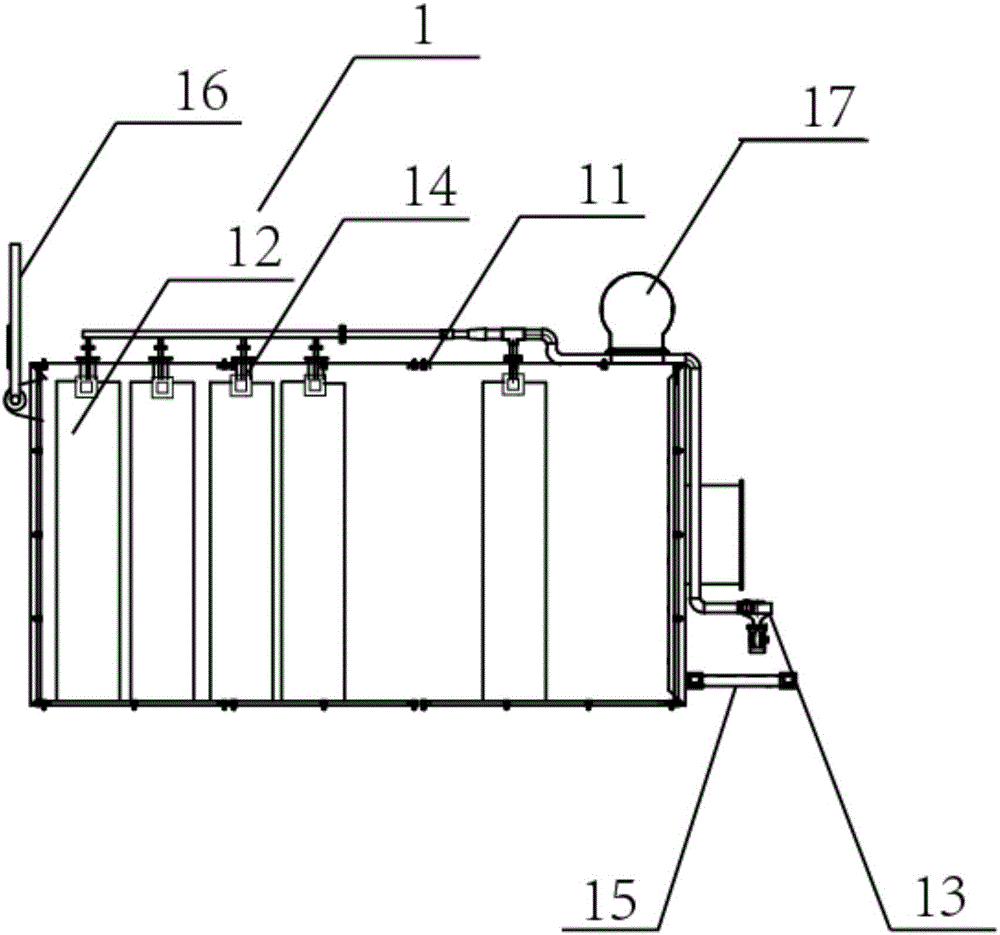

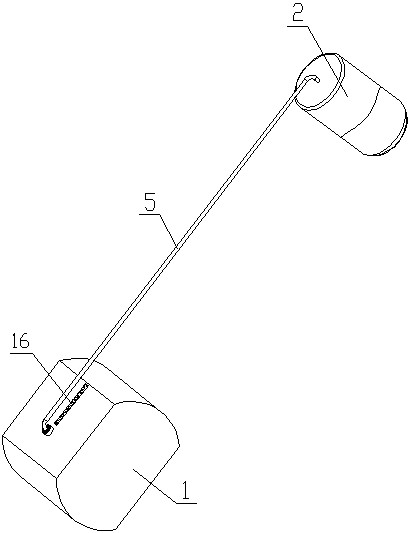

Anti-sloshing spraying unmanned aerial vehicle

InactiveCN108275276AGood for transportationExpand the scope ofAircraft componentsInsect catchers and killersEngineeringMechanical engineering

The invention discloses an anti-sloshing spraying unmanned aerial vehicle. The anti-sloshing spraying unmanned aerial vehicle comprises a containing box used for containing medicine, a first sprayingassembly and a second spraying assembly, wherein the containing box is detachably arranged on an unmanned aerial vehicle body, the bottom of the containing box is fixedly provided with a motor, a shaft front end of the motor is connected to a rotating shaft, the structure of the first spraying assembly is same as that of the second spraying assembly, the first spraying assembly and the second spraying assembly are arranged symmetrically, the first spraying assembly comprises a first spraying rod, a second spraying rod, a hose, a supporting part and a rope, a cavity penetrating through one sideend face of the first spraying rod is formed into an opening A, a cavity penetrating through one side end face of the second spraying rod is formed into an opening B, the containing box is communicated with the cavity of the first spraying rod, one end, close to the opening A, of the first spraying rod is fixedly connected to the supporting part, the supporting part is hinged with the second spraying rod, the two ends of the hose are respectively communicated with the opening A and the opening B, and the two ends of the rope are respectively and fixedly connected with the second spraying rodand the rotating shaft. The anti-sloshing spraying unmanned aerial vehicle has the advantages that the structure is simple, the parking is convenient, and the spraying range is increased.

Owner:CHENGDU RAINPOO TECH CO LTD

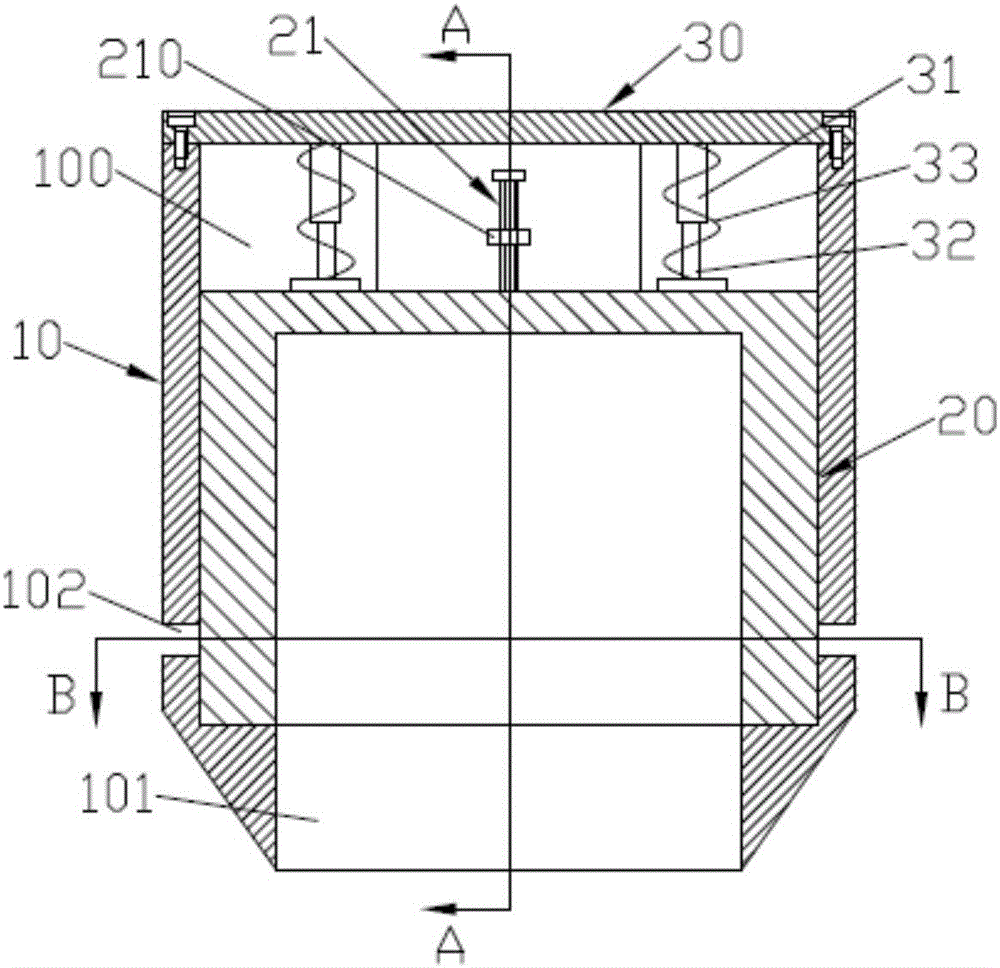

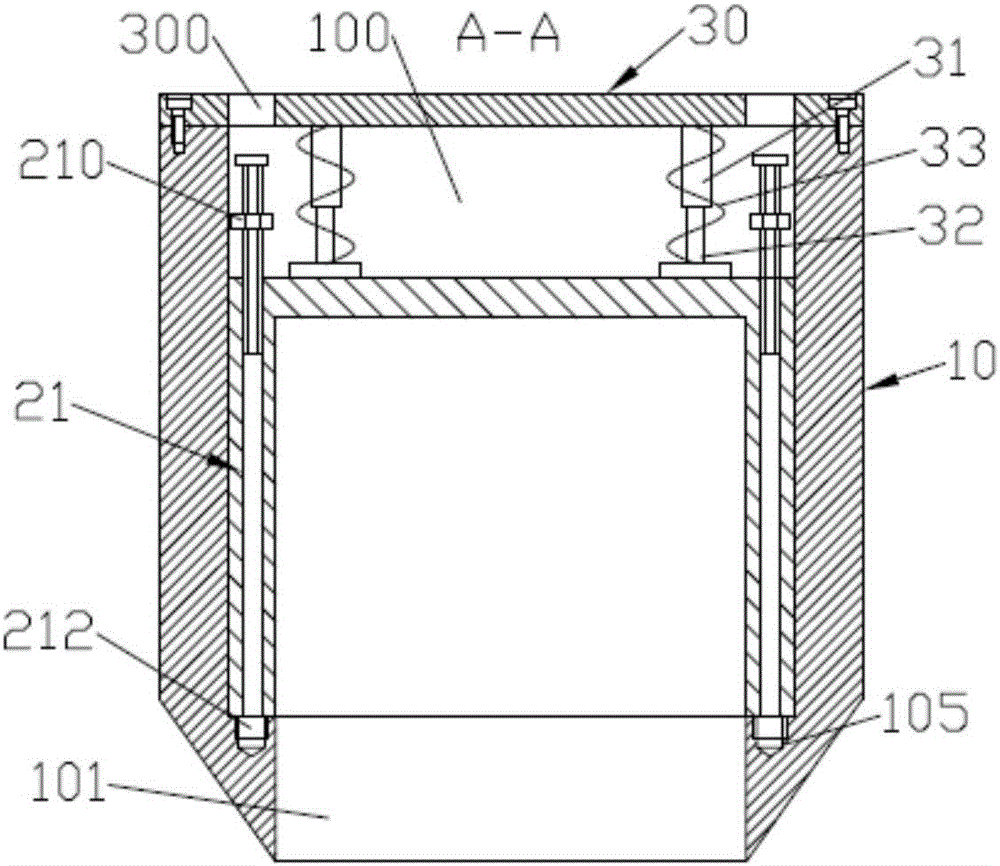

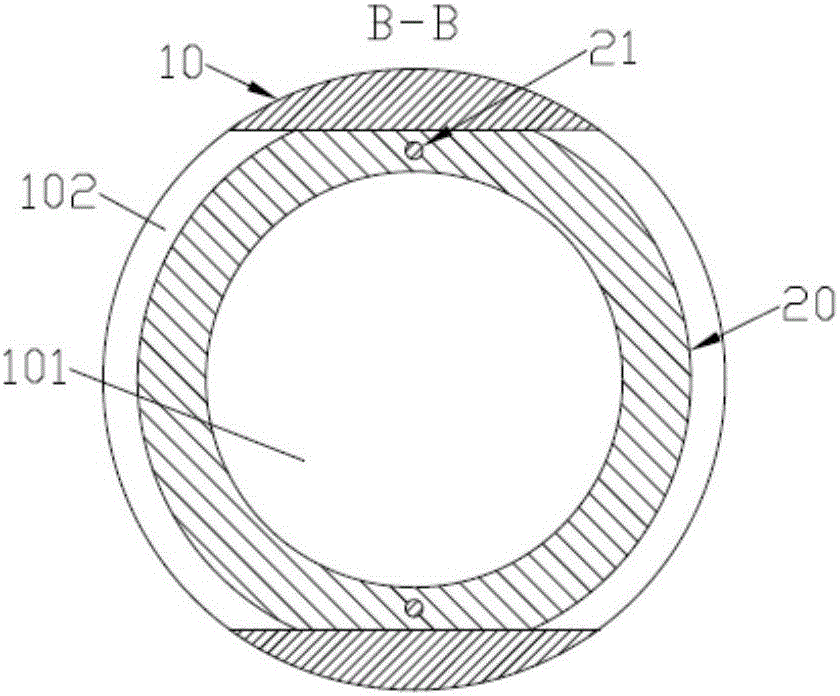

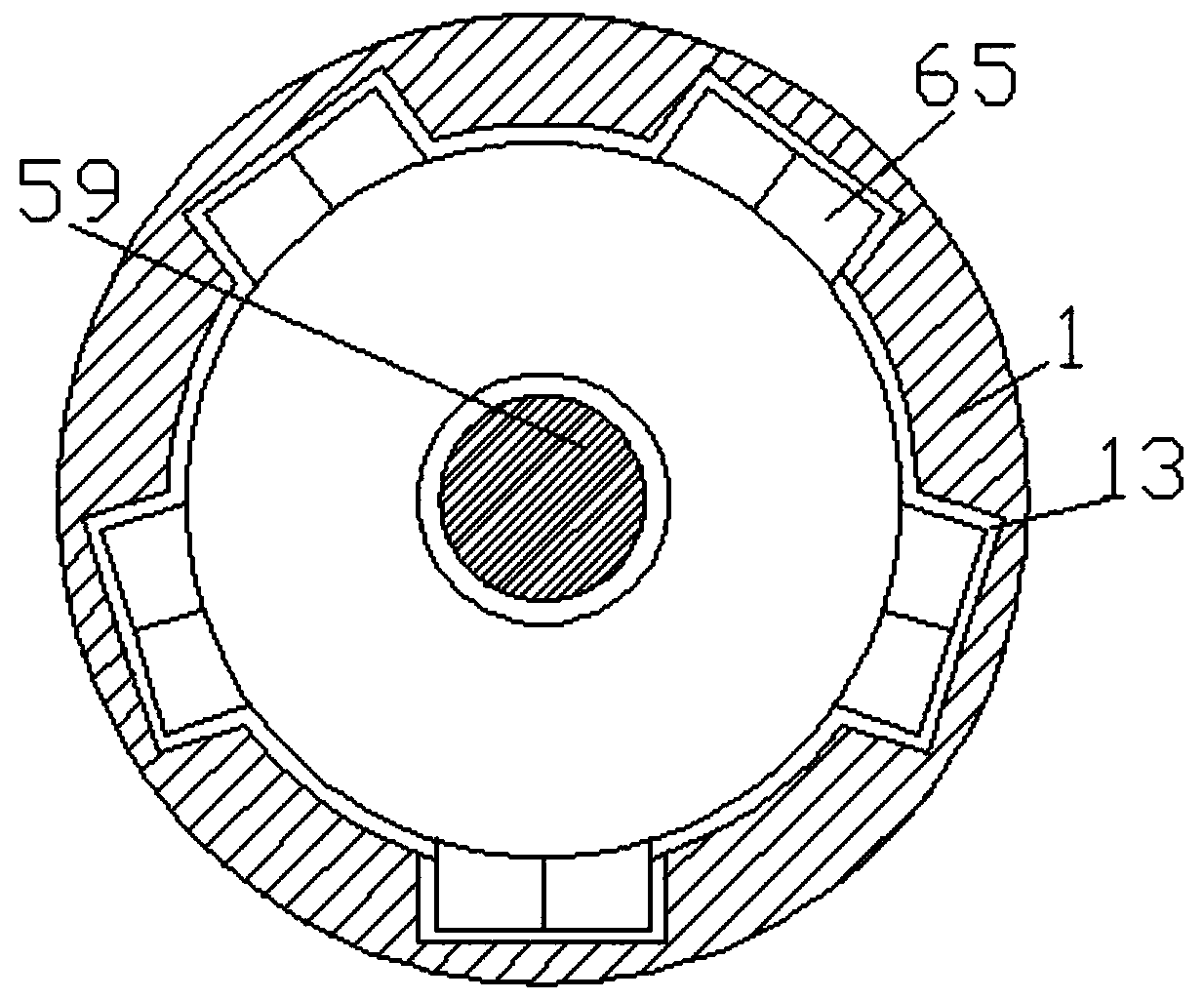

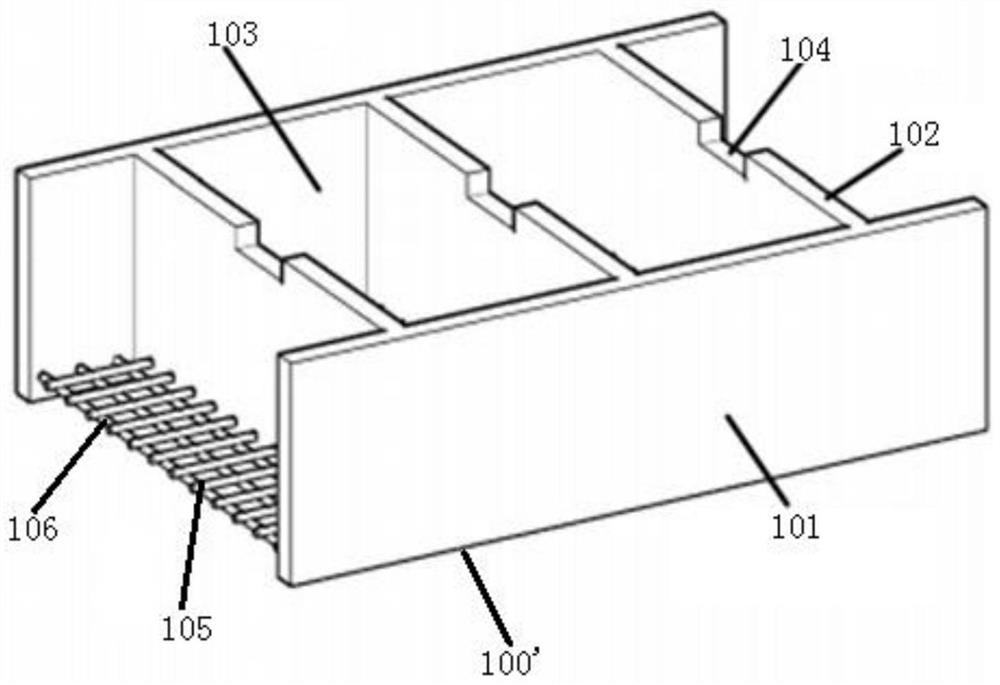

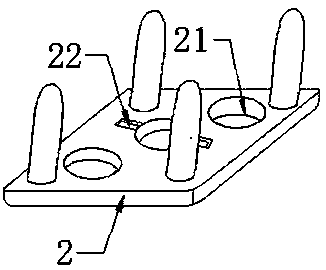

Sampling and storage integrated undisturbed soil sampling tool

InactiveCN106769194AGood for transportationEasy to transportWithdrawing sample devicesEngineeringConical surface

The invention discloses a sampling and storage integrated undistributed soil sampling tool. The sampling and storage integrated undisturbed soil sampling tool comprises a sampling tool body, a storage seat, an upper cover plate and a cut-off closing tool; the sampling tool body is an annular tool body with a lower end surface being molded into a conical surface and a cylindrical sampling groove penetrating through the sampling tool body formed in the middle portion; a long-hole-shaped installation groove is formed in the upper end surface of the sampling tool body; a radius of the installation groove is greater than the radius of the sampling groove; the storage seat is arranged in the installation groove of the sampling tool body in a lifting manner; a cut-off groove with a long-hole-shaped cross section penetrating through the sampling tool body is formed in the middle portion of the sampling tool body; the upper cover plate is screwed onto the upper end surface of the sampling tool body; the cut-off closing tool can be arranged in the cut-off groove in a sliding manner; and the cut-off closing tool is detachably fixed on the lower end surface of the storage seat. The cut-off closing tool and the storage seat are detachably assembled and combine; when the cut-off closing tool and the storage seat are separated, the sampling tool is used for collecting the soil; and when the cut-off closing tool and the storage seat are combined, the sampling tool can be used for storage, so that the original state of an undisturbed soil sample is maximally maintained, and the transportation is facilitated.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

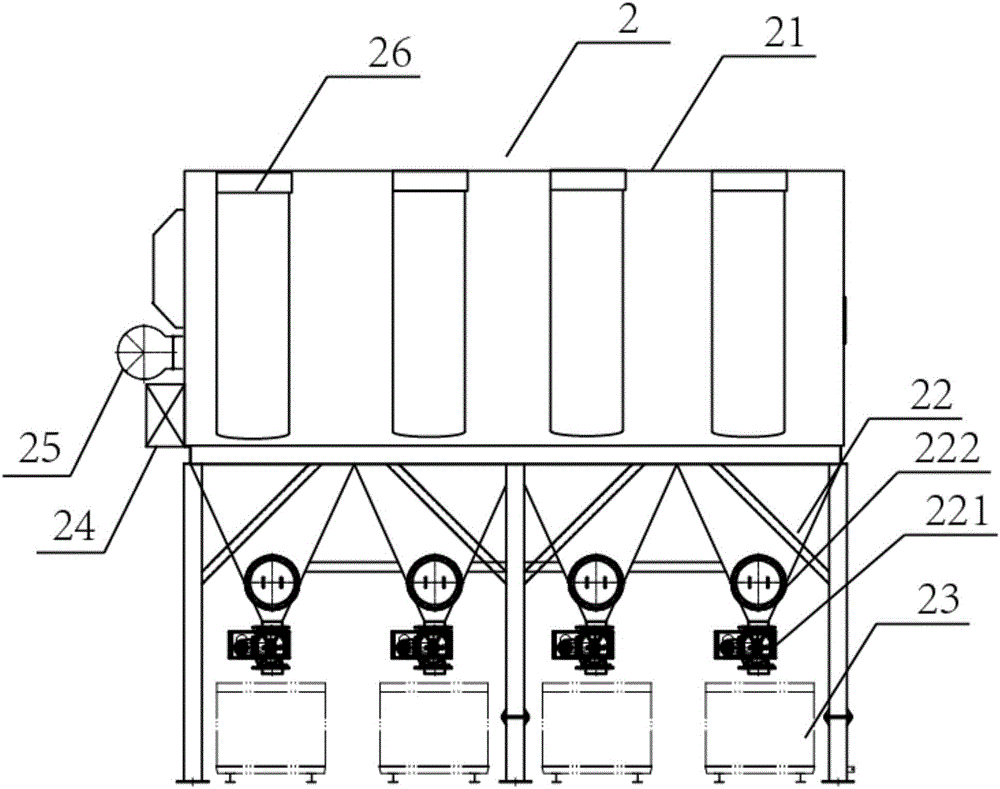

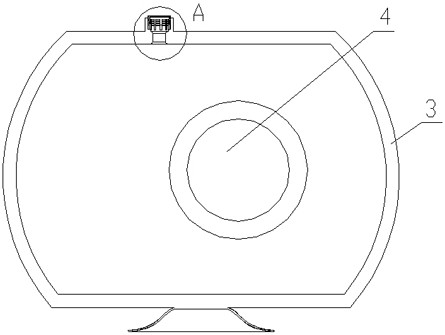

Coal-fired flue gas treatment method

ActiveCN106215561AGood for transportationReasonable stepsHuman health protectionDispersed particle filtrationAir pollutantsFlue gas

The invention discloses a coal-fired flue gas treatment method. The coal-fired flue gas treatment method comprises the steps that after undergoing heat exchange, the coal-fired flue gas undergoes dust removal treatment; then the coal-fired flue gas is exhausted from an exhaust device after being treated with an adsorbent, wherein the adsorbent comprises quicklime; dust removal treatment is carried out in a pulse type dust collector; the pulse type dust collector comprises a square shell and dust hoppers; the dust hoppers are installed below the square shell; openings are formed in the bottom surface of the square shell and the top surfaces of the dust hoppers; the square shell is communicated with the dust hoppers; filters are installed inside the square shell; dust outlets are formed in the bottoms of the dust hoppers; the adsorbent is arranged in a dry chemical catalytic treater; the dry chemical catalytic treater comprises a hollow shell, catalytic treatment boxes and an atomizer; the catalytic treatment boxes are arranged inside the hollow shell; atomization nozzles are connected above the catalytic treatment boxes and are communicated with the atomizer by an atomization pipe; and an air inlet pipe is arranged on the side wall of the hollow shell. After the coal-fired flue gas is treated, various indexes completely satisfy the Emission Standard of Air Pollutants for Boiler (GB 13271-2014).

Owner:苏州贝捷环保设备有限公司

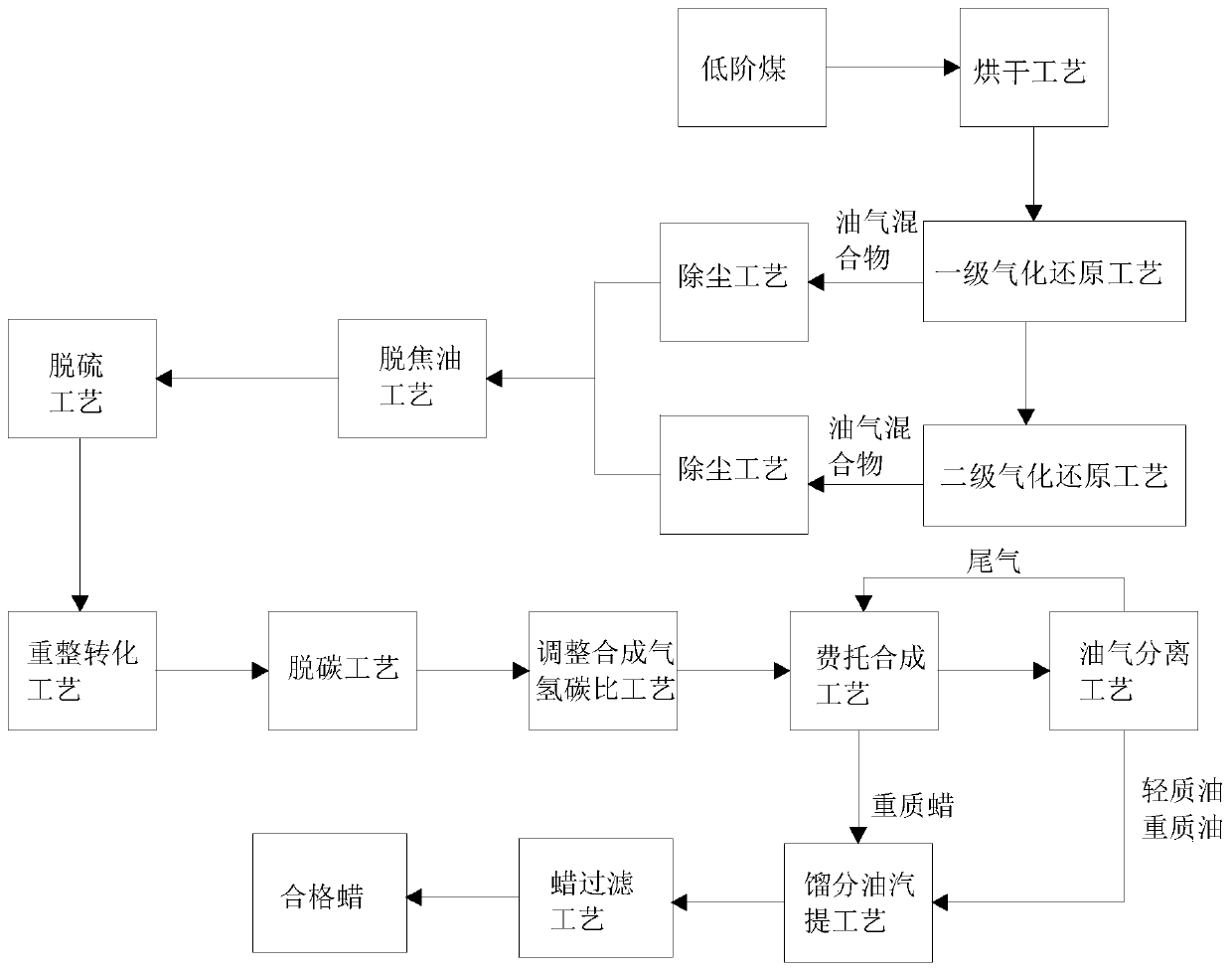

Method for synthesizing wax by using volatile components in low-rank coal by fischer-tropsch synthesis

PendingCN109880654AIncrease added valueGood for transportationLiquid hydrocarbon mixture productionMineral wax recovery/refiningChemistryFischer–Tropsch process

The invention provides a method for synthesizing wax by using volatile components in low-rank coal by fischer-tropsch synthesis, low-rank coal sequentially is subjected to drying and gasification reduction treatment to obtain an oil-gas mixture, wherein the gasification reduction process is a chemical reaction process for heating the dried low-rank coal under oxygen-free or micro-oxygen conditions; an oil-gas mixture is purified to obtain a mixed gas; the mixed gas is subjected to partial hydrocarbon reforming conversion process to obtain a reforming conversion gas containing CO and H2, CO2 isremoved from the reforming conversion gas, and the reforming conversion gas is supplemented with CO or H2 to obtain a synthesis gas with the hydrogen-carbon ratio of 1.5-2.2; the synthesis gas is subjected to fischer-tropsch synthesis under the action of a catalyst and is subjected to oil-gas separation to obtain a hydrocarbon mixture and tail gas, and the hydrocarbon mixture is subjected to distillate oil stripping and the like so as to obtain wax, heavy oil and naphtha. According to the invention, the volatile components in the low-rank coal are used for producing light oil, the heavy oil and the wax by using a fischer-tropsch synthesis technology, transport is facilitated, the utilization rate of resources is improved; moreover, the raw material sources are wide, the process energy consumption is low, and the production cost is reduced.

Owner:浙江天禄环境科技有限公司

Simulation experiment method for drilling-blocking prevention of rock drill in cave

InactiveCN102926683AEnsure normal drilling workHigh movement precisionConstructionsRotary-drilling machinesEngineeringDrill

The invention discloses a simulation experiment method for drilling-blocking prevention of a rock drill in a cave. The method comprises the following steps of: firstly, controlling a rod-disassembling mechanism to pressurize a drilling rod to cause a pressure value of rotary pressure to be stabilized to 12MPa; in the process of the simulation of drilling rocks by a down-the-hole drill, controlling a propulsion handle in an operator cab to pressurize a propulsion mechanism to cause a pressure value of propulsion pressure to be stabilized to 8MPa, and simulating a normal propulsion state of the down-the-hole drill in the process of drilling the rocks; controlling the propulsion handle to depressurize the propulsion mechanism to reduce the propulsion pressure to 5MPa suddenly, and simulating a drilling-blocking phenomenon in the cave and wherein a setting value of a pressure relay of a propulsion circuit is 3MPa, which is less than a critical propulsion pressure value of the drilling-blocking prevention in the cave; and drawing a change curve of the propulsion pressure with changes with time in the process. The method provided by the invention has the beneficial effects that the drilling-blocking problem is solved, the normal drilling operation of the rock drill is ensured, the service life of the rock drill is prolonged, and the body of the rock drill can be assisted to be stressed.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

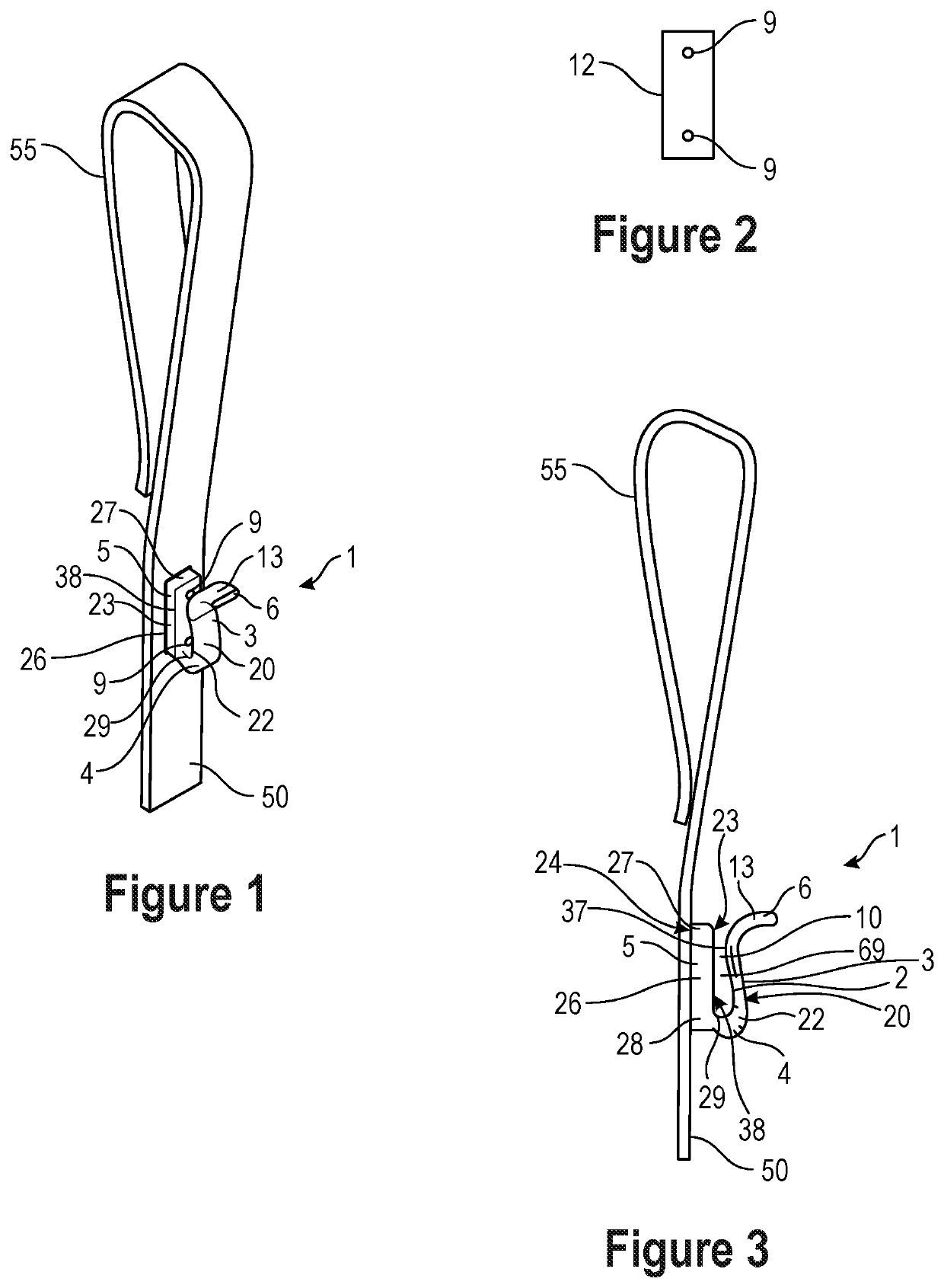

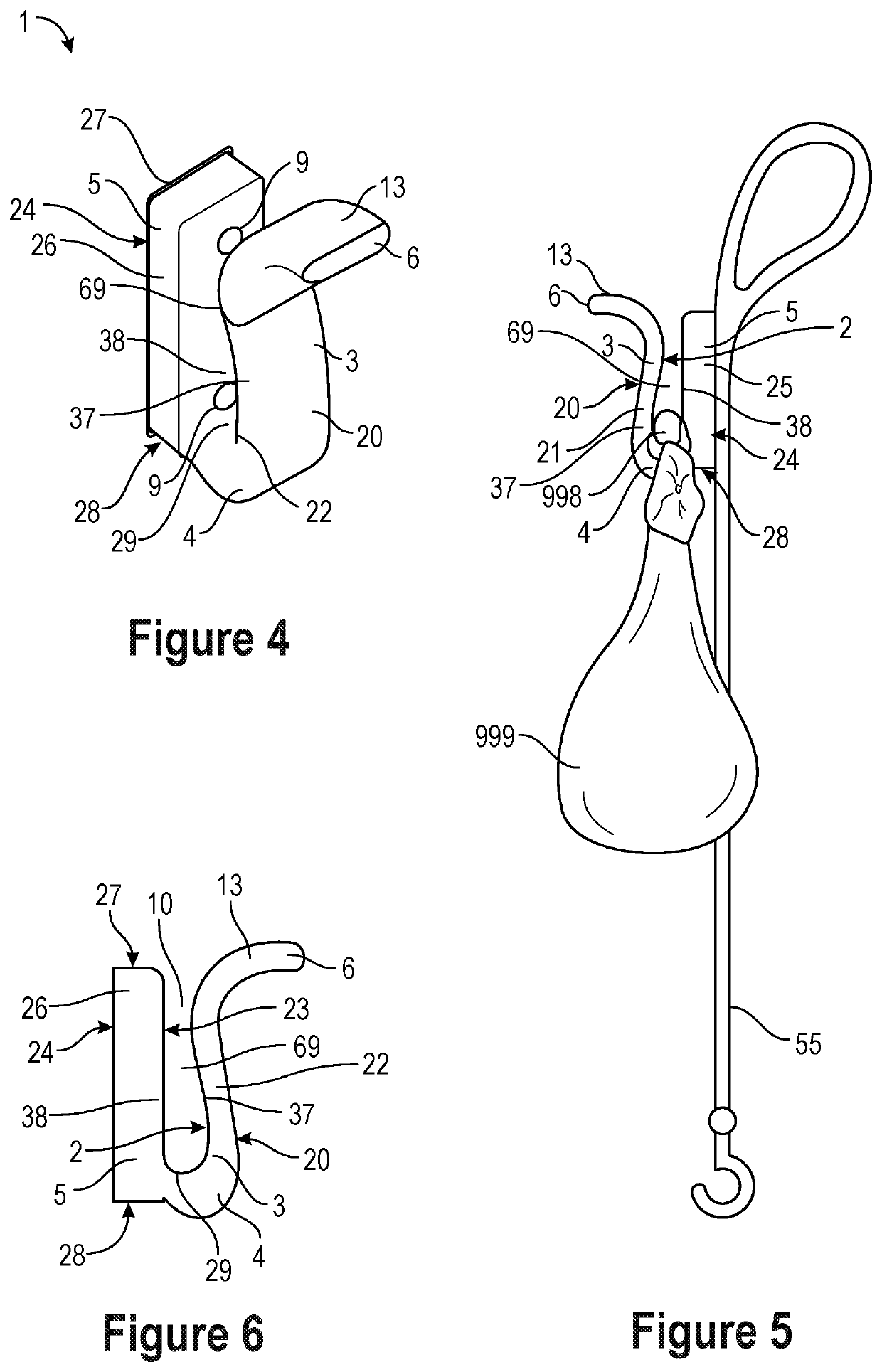

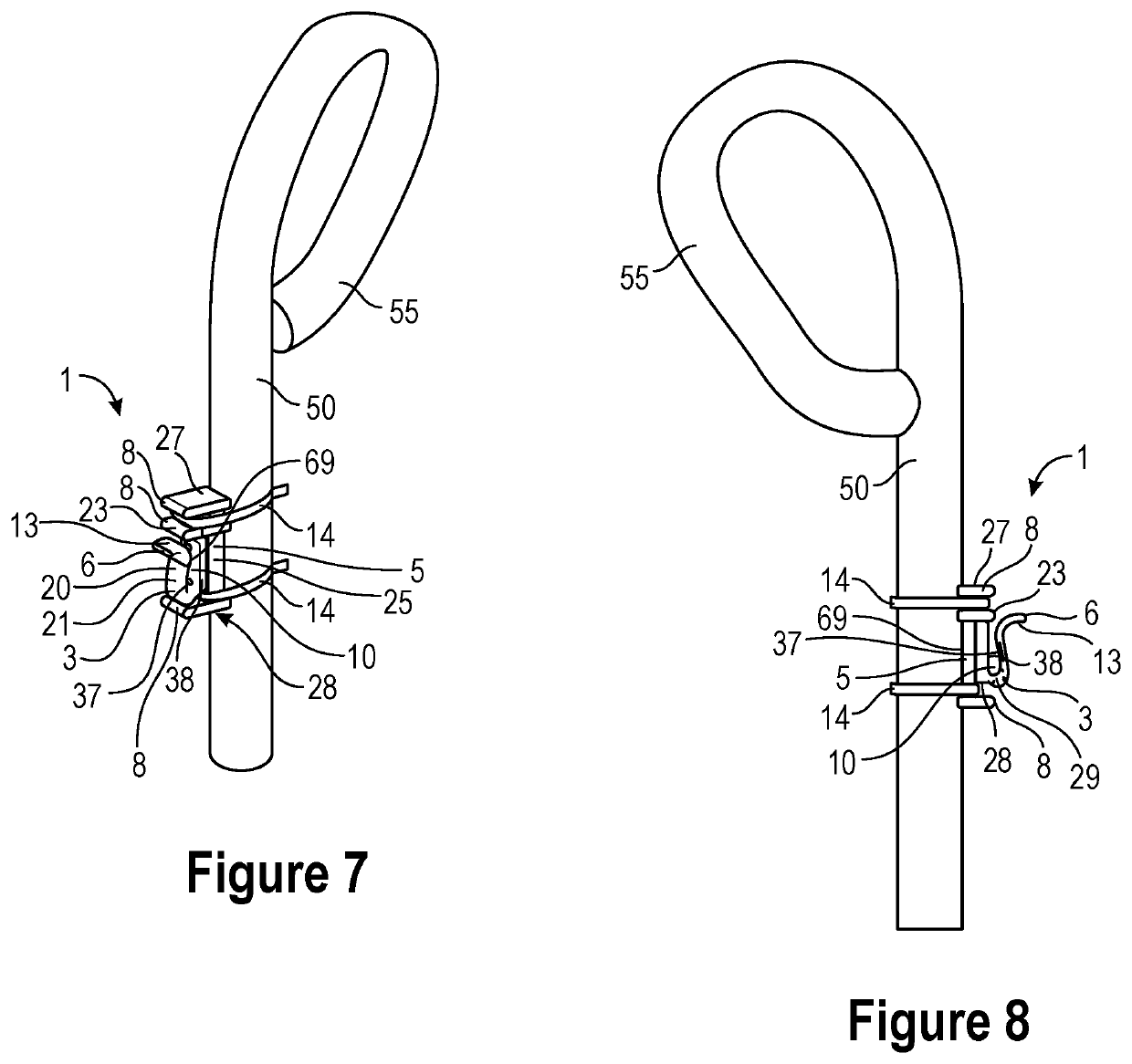

Clip for pet waste bags

ActiveUS20200045937A1Good for transportationNegates needRoad cleaningTaming and training devicesEngineeringEnvironmental geology

A narrow channel created by one or more channel walls. The channel is engineered with narrow dimensions so as to carry out its function of supporting small bags filled with waste. The channel may be formed as a single body, attached to another body, or formed or incorporated into another body or device, such as, but not limited to, animal leashes, retractable animal leashes, pet waste bag dispensers, pet harnesses, and pooper scoopers. Bags containing animal waste may be inserted into the channel. The bags may be supported by the channel. Additional small bodies including but not limited to rings or cord loops may be inserted into and supported by the channel.

Owner:WESTON BRYAN

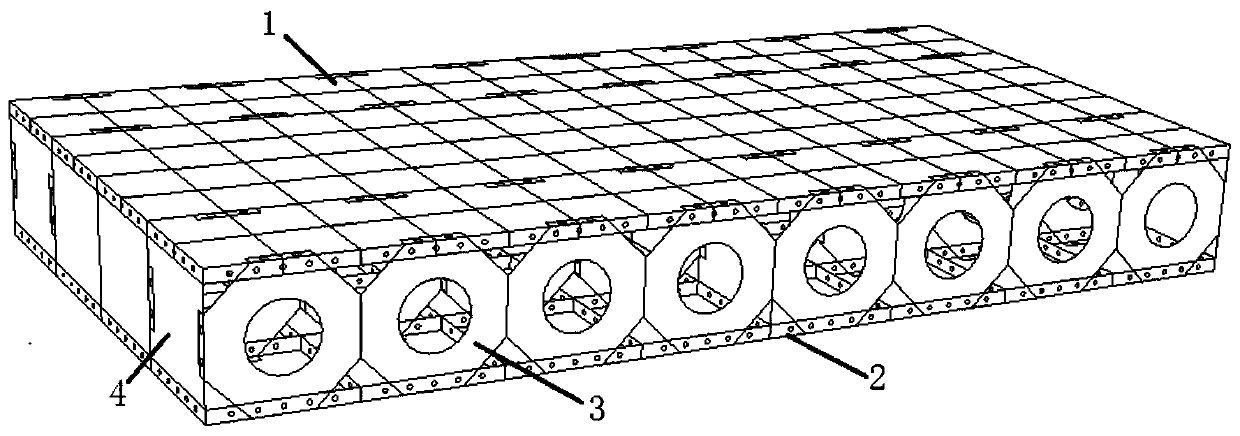

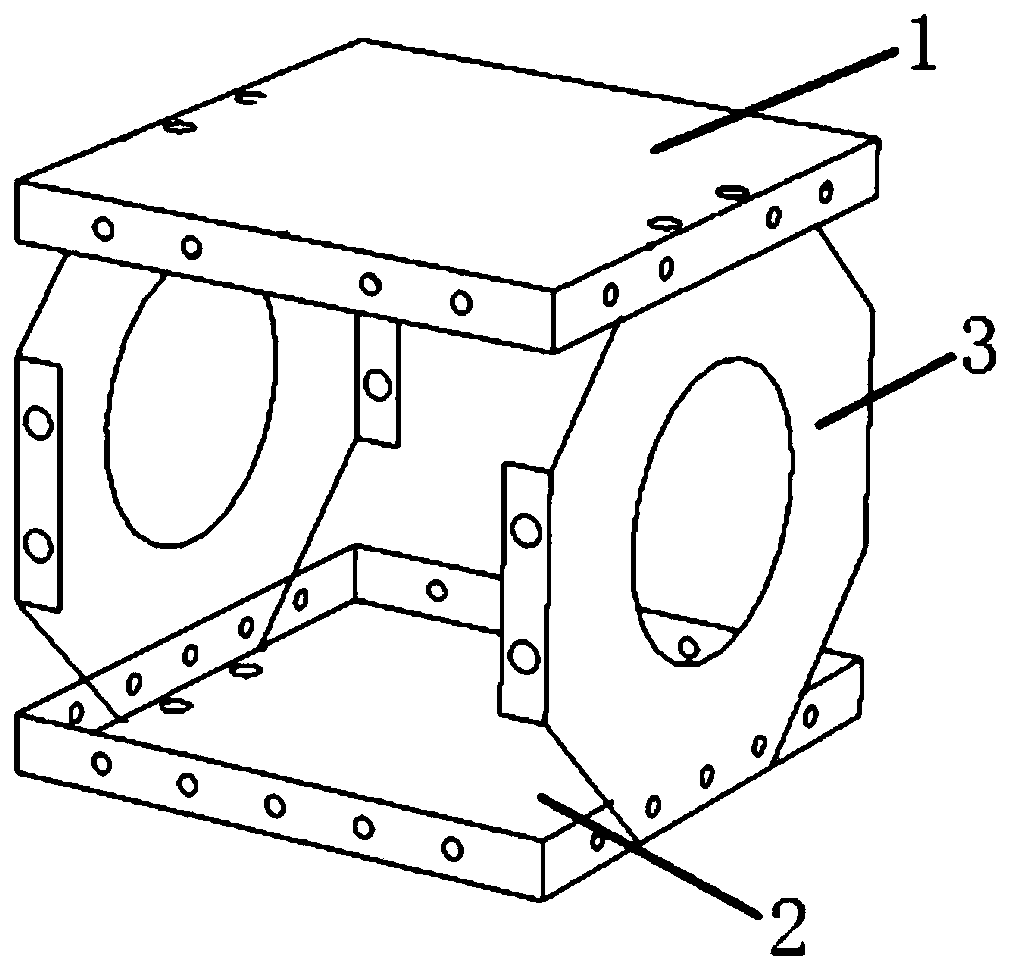

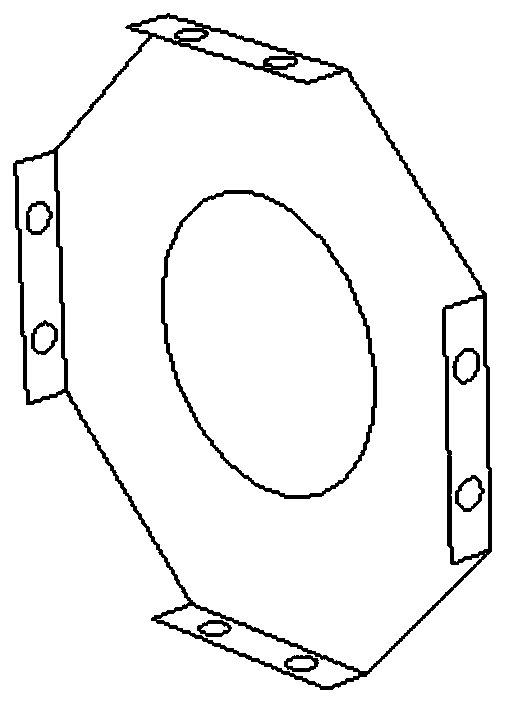

Emergency bridge structure capable of being quickly assembled and constructed and construction method thereof

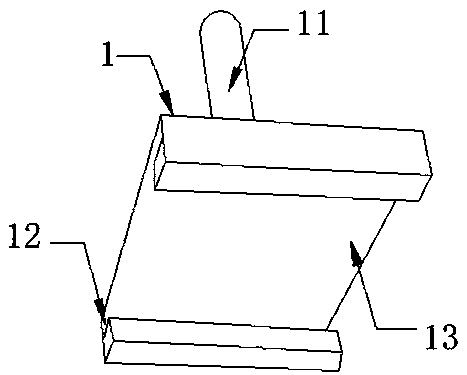

InactiveCN110878519AControl construction qualityGood for transportationConstructionsSteel platesArchitectural engineering

The invention discloses an emergency bridge structure capable of being quickly assembled and constructed and a construction method thereof. The structure comprises a plurality of structural units which are mutually spliced in the transverse bridge direction or the longitudinal bridge direction. Each structural unit comprises an upper steel plate and a lower steel plate which correspond to each other up and down, and two longitudinal belly steel plates are arranged in the structural units located on the two sides of the transverse bridge direction and fixed to the two sides of the transverse bridge direction of the upper steel plate and the lower steel plate respectively. Compared with the prior art, the steel structure bridge has the remarkable advantages of being convenient to construct,easy to replace and convenient to transport. The bridge can be used as an overpass, a landscape gallery bridge and the like, and can also be used as a temporary bridge.

Owner:SOUTHEAST UNIV

Speed adjusting method of hydraulic system transmission mechanism

InactiveCN102954055AMeet the process requirementsHigh movement precisionServomotorsHydraulic motorLogical combination

The invention discloses a speed adjusting method of a hydraulic system transmission mechanism, and the speed adjusting method is characterized by comprising the following steps of installing and determining a hydraulic actuation element, adopting a reversing valve or a logic control unit to control the direction, and adopting a logical combination structure of a cartridge valve and a pilot control valve; adopting a quantitative pump to supply oil, utilizing a flow control valve to change the flow inputting or outputting from the hydraulic actuation element to adjust the speed, and adjusting the speed by changing the displacement of a hydraulic pump or a hydraulic motor; a variable pump is used for supplying the oil in the volume throttling speed adjusting process, utilizing the flow control valve to adjust the flow inputted into or outputted from the hydraulic actuation element, ensuring the oil supply quantity to be equivalent to the oil demand quantity, and determining a circulating form of a loop; and adopting an open circulating way to make the hydraulic pump suck oil from an oil tank, and returning the pressure oil back to the oil tank after releasing the energy through the system. The method has the beneficial effects that different technique requirements of a pressing workpiece can be completely and accurately satisfied, the movement precision of the machine is improved, the abrasion situation is reduced, the service life is prolonged, and the stress of the machine body is assisted.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

Connecting method of load control dual-pressure system for high-speed punching machine

The invention discloses a connecting method of a load control dual-pressure system for a high-speed punching machine. The connecting method comprises the following steps: firstly, double pressure pumps, namely a high-pressure large-flow pump and a low-pressure small-flow pump, are respectively arranged inside a hydraulic system; an energy accumulator is additionally arranged on an oil path between the low-pressure small-flow pump and a hydraulic cylinder; meanwhile, another energy accumulator is additionally arranged on the oil path between the high-pressure large-flow pump and the hydraulic cylinder as an auxiliary power source; then the set load control dual-pressure system is adopted; rapid movement and punching action of the hydraulic cylinder are achieved by alternative use of the double pumps; simultaneously, a differential connection circuit is additionally arranged on the hydraulic system, and a hydraulically operated direction control valve is additionally arranged to achieve the on / off the differential connection circuit and the unloading of a low-pressure pump. The connecting method has the beneficial effects that the system is stable to move, the speed is easy to adjust, the travel is controllable and the noise is low; the stamping frequency is improved, and the service life is prolonged. Meanwhile, the operation controllability can be improved, and the labor intensity is reduced.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

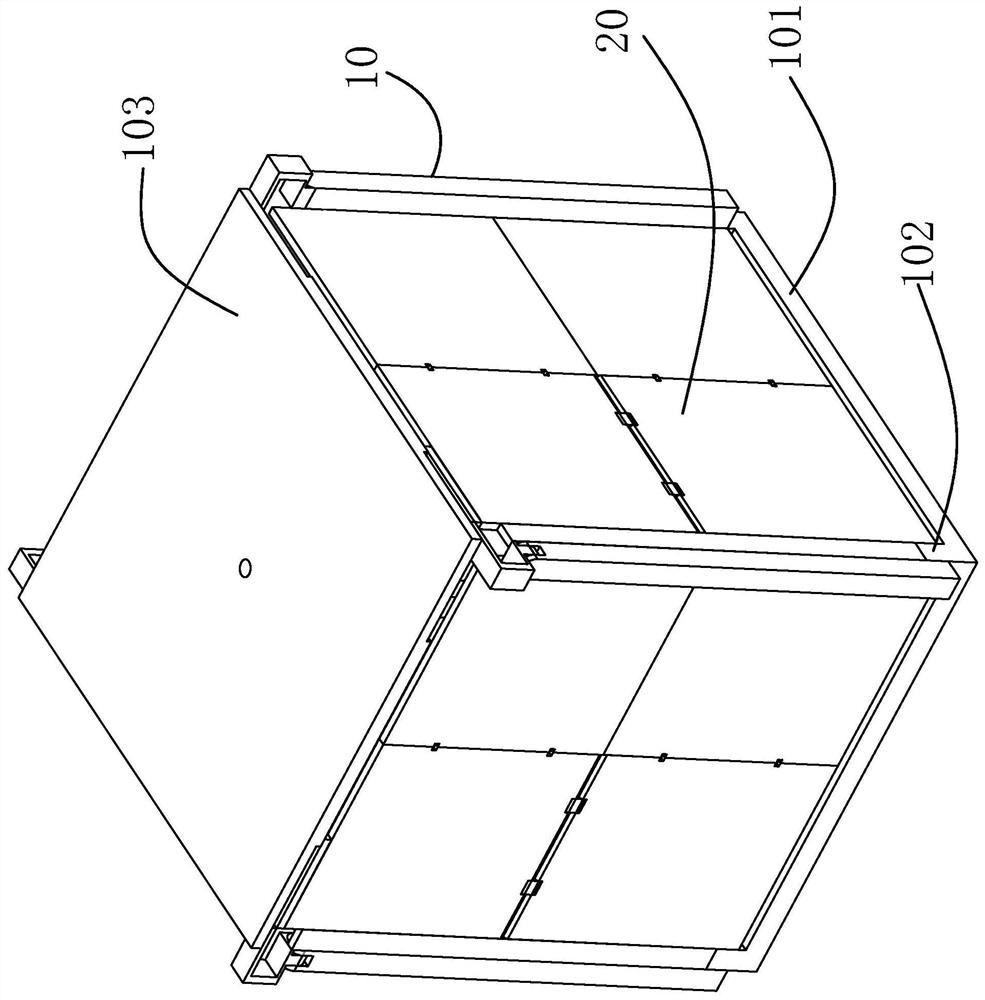

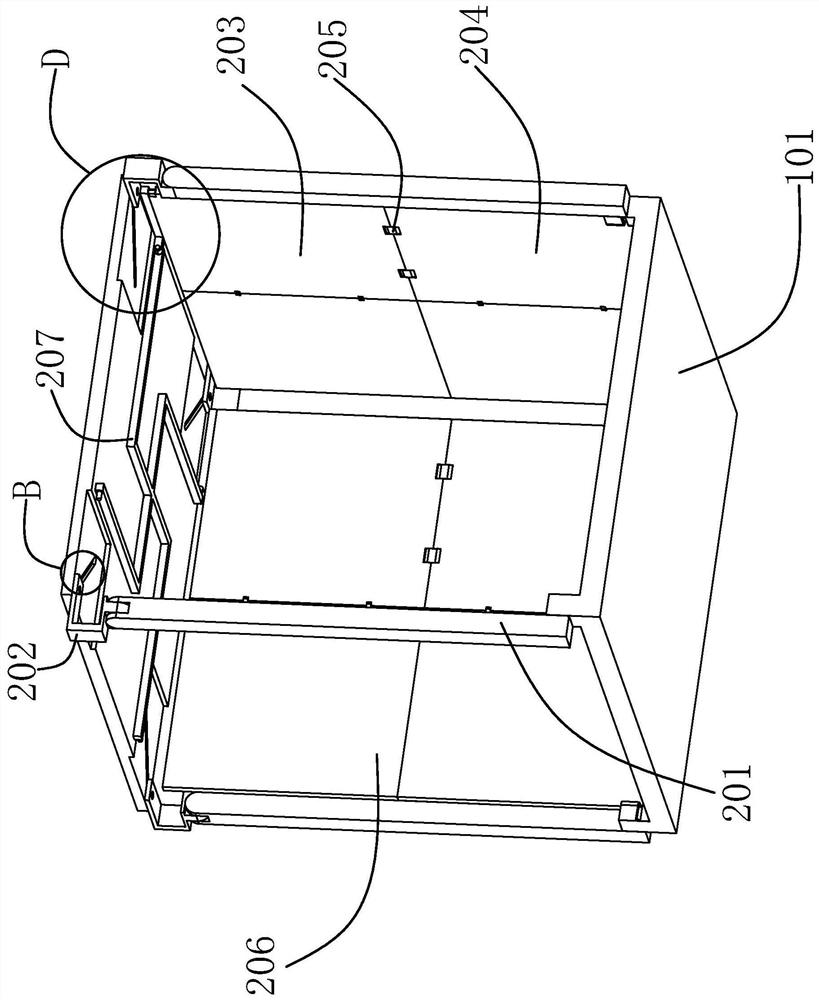

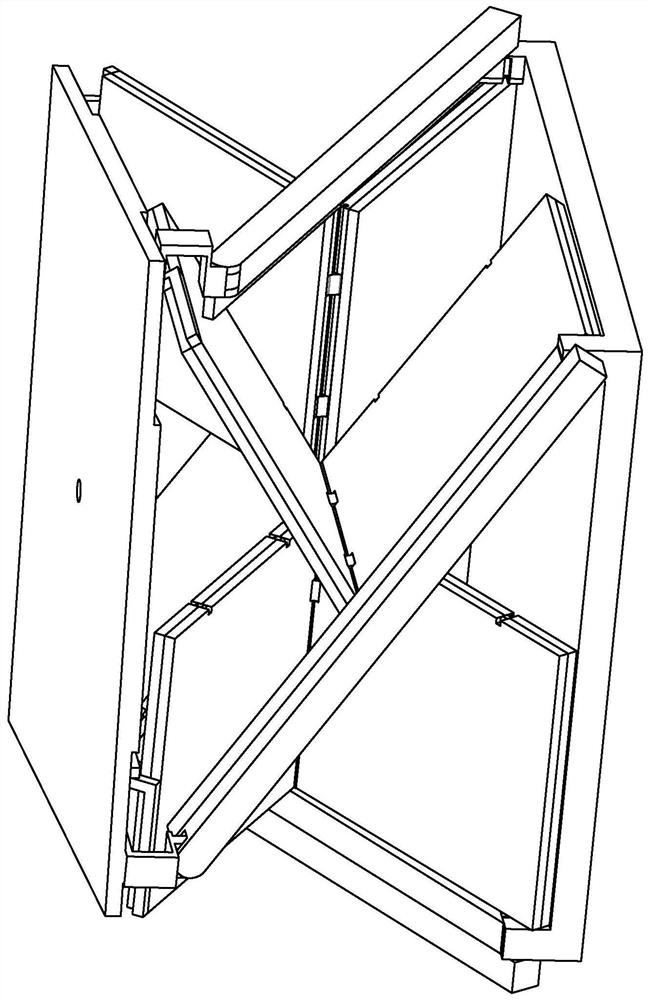

Folding board room

ActiveCN112196110AGood for transportationExpand quicklyBuilding constructionsStructural engineeringMechanical engineering

Owner:东营市东达机械制造有限责任公司

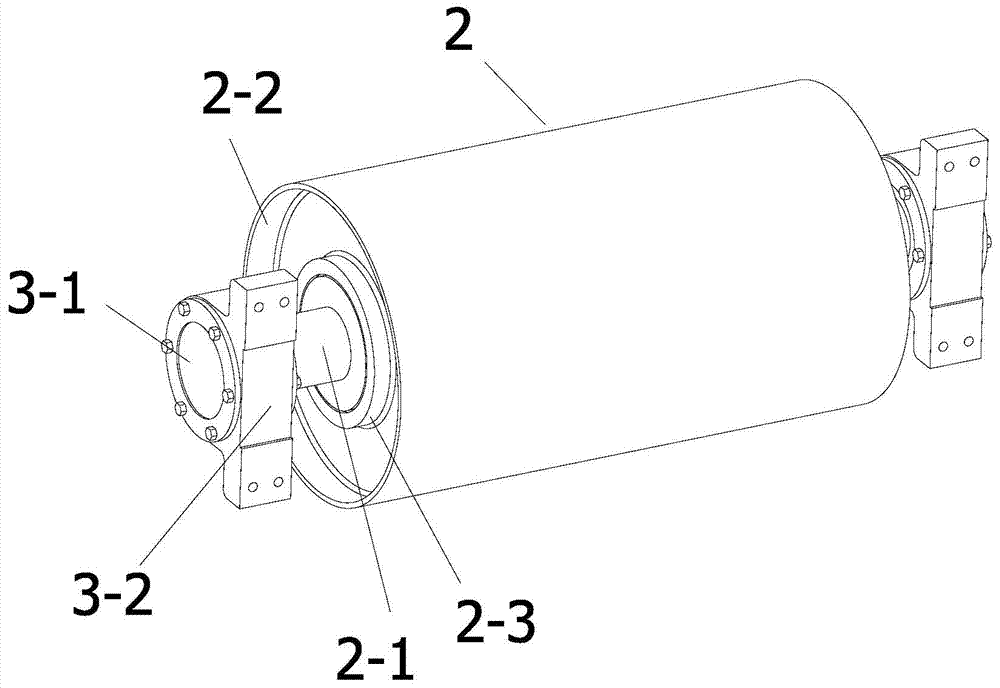

Waste conveying belt reeling recovery device and method

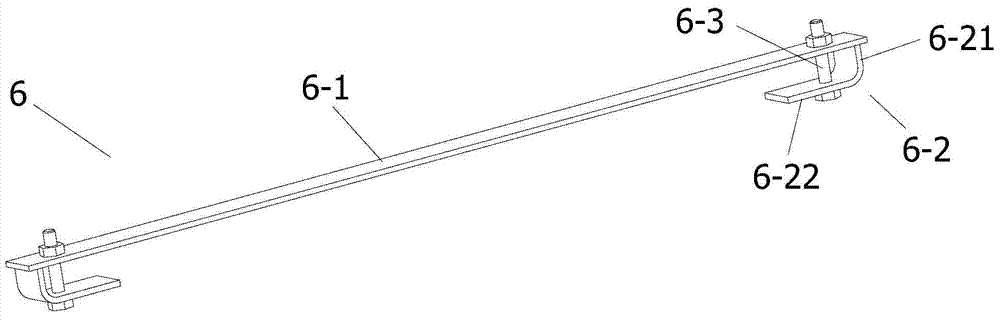

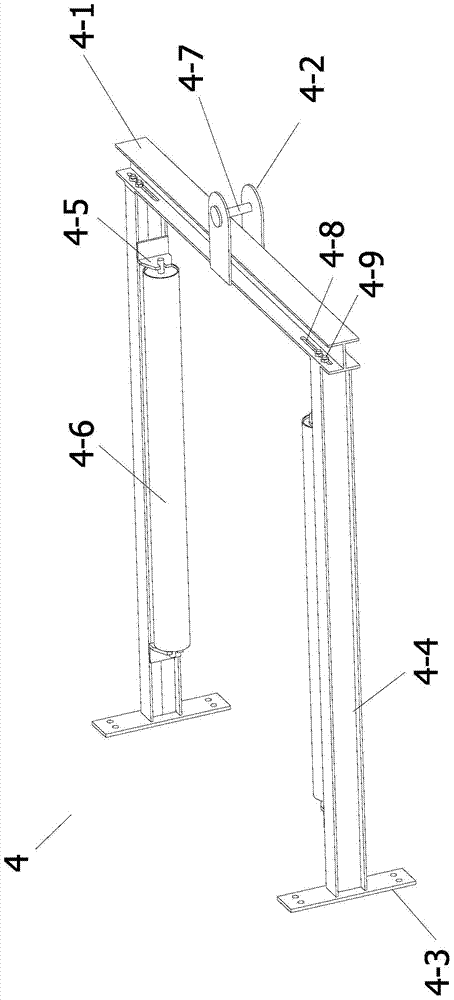

ActiveCN103935796AGood for transportationConvenient coiling and recyclingWebs handlingHorizontal diameterMechanical engineering

The invention relates to a waste conveying belt reeling recovery device and method. The device comprises a roller used for rolling up a conveying belt. A clamp used for clamping the belt head of the conveying belt is arranged on the outer side of the side wall of the roller. Roller shafts at the two ends of the roller are connected with corresponding bearing pedestals respectively in a rotating mode, hanging plates are arranged on the same sides of the two bearing pedestals respectively, and all the hanging plates are fixedly connected with a traction frame. The traction frame is provided with a cross bar parallel to the axis of the roller, and a traction end allowing a traction rope to penetrate through is arranged on one side, far away from the roller, of the cross bar. The method includes the steps that the waste conveying belt is tiled, the clamp is used for clamping the belt head, and the conveying belt is rolled up and recovered through traction of a traction vehicle. By means of the waste conveying belt reeling recovery device and method, the waste conveying belt can be conveniently rolled up and recovered to the roller, so that transportation, storage and recycle after width reducing treatment of the waste conveying belt are promoted, and therefore the purposes of improving the utilization rate of the conveying belt and saving cost can be achieved.

Owner:NANJING MEISHAN METALLURGY DEV +1

Creation method for simulation model of anti-jamming hydraulic control system of rocker driller

InactiveCN102996109AEnsure normal drilling workHigh movement precisionAutomatic control for drillingAnti jammingEngineering

The invention discloses a creation method for a simulation model of an anti-jamming hydraulic control system of a rocker driller, comprising the following steps of: firstly, setting an analogue load input value of a feed mechanism and an analogue input value of a slewing mechanism to cause the feed mechanism and the slewing mechanism to work in a normal state, and to cause feed pressure to stabilize at 8MPA and slewing pressure to stabilize at 12MPA; inputting a process that the feed pressure is reduced from a normal value into the analogue load of the feed mechanism to carry out cave jammed drilling simulation, wherein when the feed pressure is reduced to a setting value of a pressure relay signal of a feeding loop, an electromagnetic reversing valve acts, a multi-way valve changes direction to push a motor to slew, and the feed mechanism retreats; observing whether the anti-jamming hydraulic control system is capable of preventing cave jammed drilling; and inputting a process that the slewing pressure is increased slowly from a normal value into the analogue load of the slewing mechanism to carry out simulated slow varying jammed drilling. The method disclosed by the invention has the beneficial effects that the method is conductive to solving the problem of jammed drilling, ensures normal drilling work of the rock driller, and is conductive to prolonging service life and assisting driller stressing.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

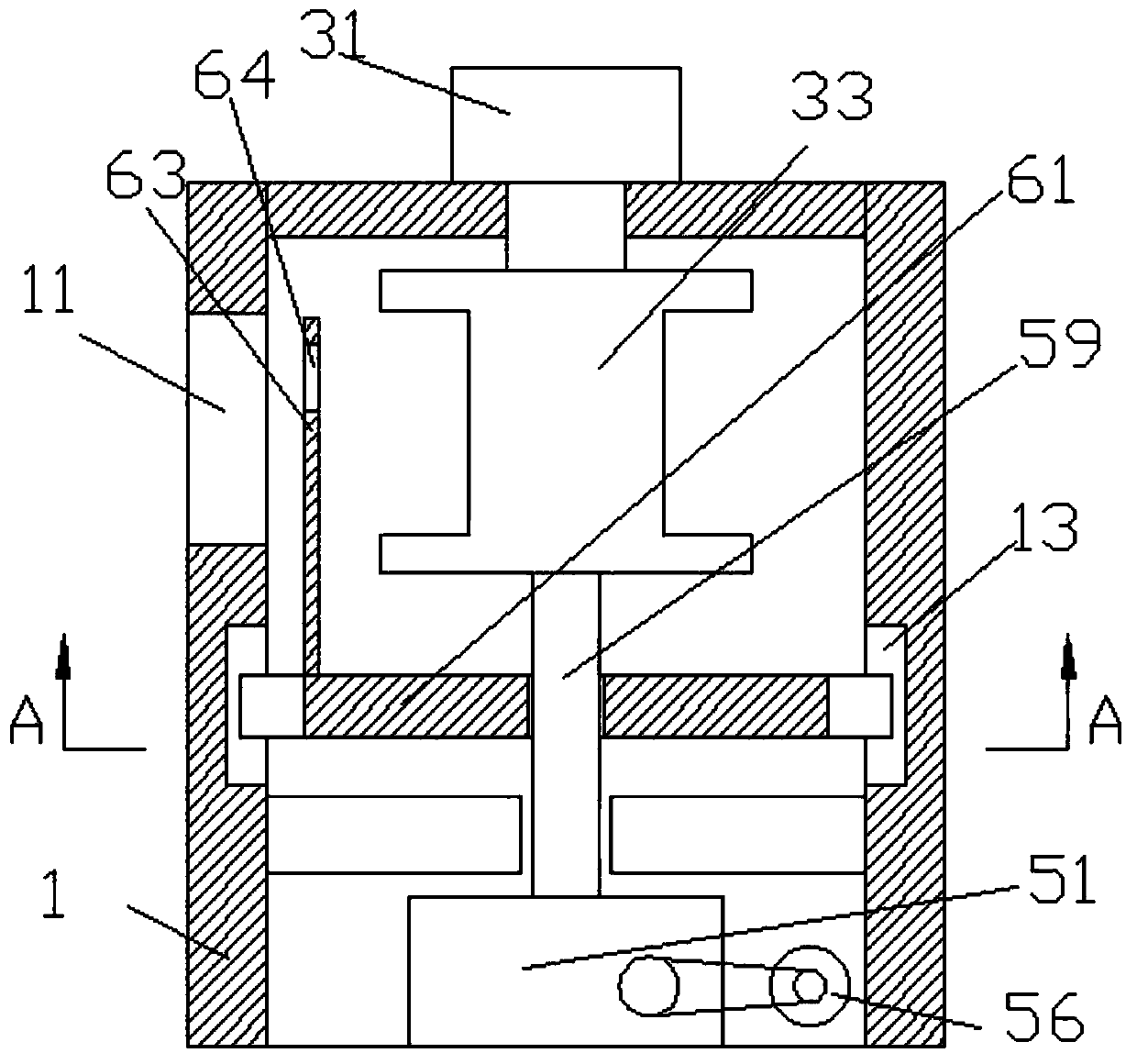

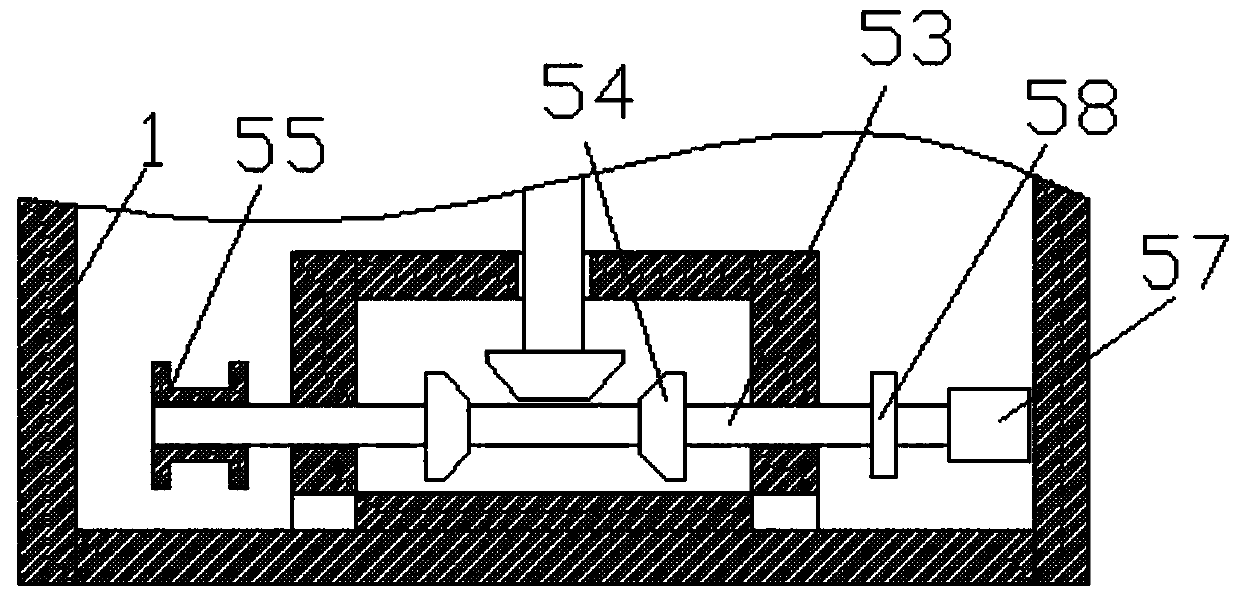

Cable reel

The invention discloses a cable reel, and relates to the field of cables. The cable reel comprises a shell, a cable reel assembly and a shifting assembly, wherein a wire inlet is formed in the side wall of the shell; the cable reel assembly is rotationally arranged in the shell, the cable reel assembly comprises a cable reel body and a motor, the motor is arranged at the top of the shell, and theextending end of the motor is inserted into the shell; the cable reel body is arranged at the end part of the motor and used for winding the cables; and the shifting assembly is used for controlling the cable winding position. Preferably, the cable reel body is fixedly connected to the motor. The problem of cable knotting is solved.

Owner:安徽瑞之星电子科技集团有限公司

Method for selecting hydraulic power source of hydraulic system

InactiveCN102966640AMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsFiltrationHydraulic circuit

The invention discloses a method for selecting a hydraulic power source of a hydraulic system. The method comprises the following steps that firstly, a working medium of the hydraulic system is supplied by the hydraulic source, a throttle speed adjusting system is supplied with hydraulic fluid by a quantitative pump, the hydraulic fluid supply quantity of a hydraulic pump is greater than the quantity of hydraulic fluid required by the system, and the excessive redundant hydraulic fluid flows back to a hydraulic tank through an overflow valve; a volume speed adjusting system is supplied with hydraulic fluid by a variable pump, the maximum pressure of the system is limited by a safety valve, the hydraulic fluid supply quantity of the hydraulic pump is matched with the quantity of hydraulic fluid required by the system, and in each phase of work circulation, the hydraulic fluid is supplied by multiple pumps; an accumulator is additionally arranged and is used as an auxiliary hydraulic source, an inlet of the pump is provided with a coarse filter, and according to the requirements of protected elements, the hydraulic fluid entering the system is subjected to secondary filtration by a corresponding fine filter; and a magnetic filter is arranged on a hydraulic circuit, and according to the environments of the hydraulic equipment and the requirements of on temperature raising, the heating and cooling measures are additionally carried out. The method has the beneficial effects that the running precision of the machine is favorably improved, the abrasion is reduced, the service life is prolonged, the force on the machine body is assisted, and the like.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

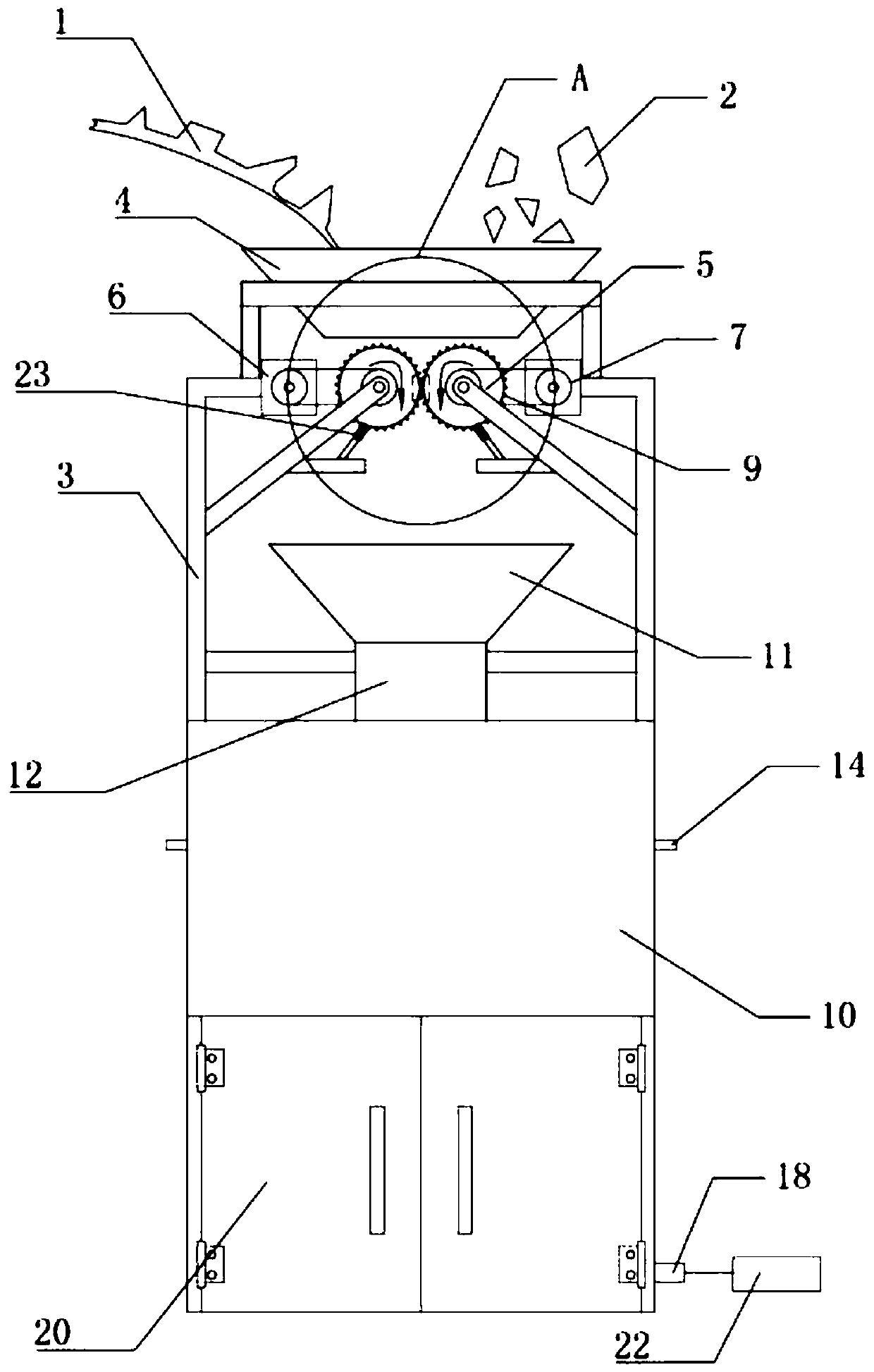

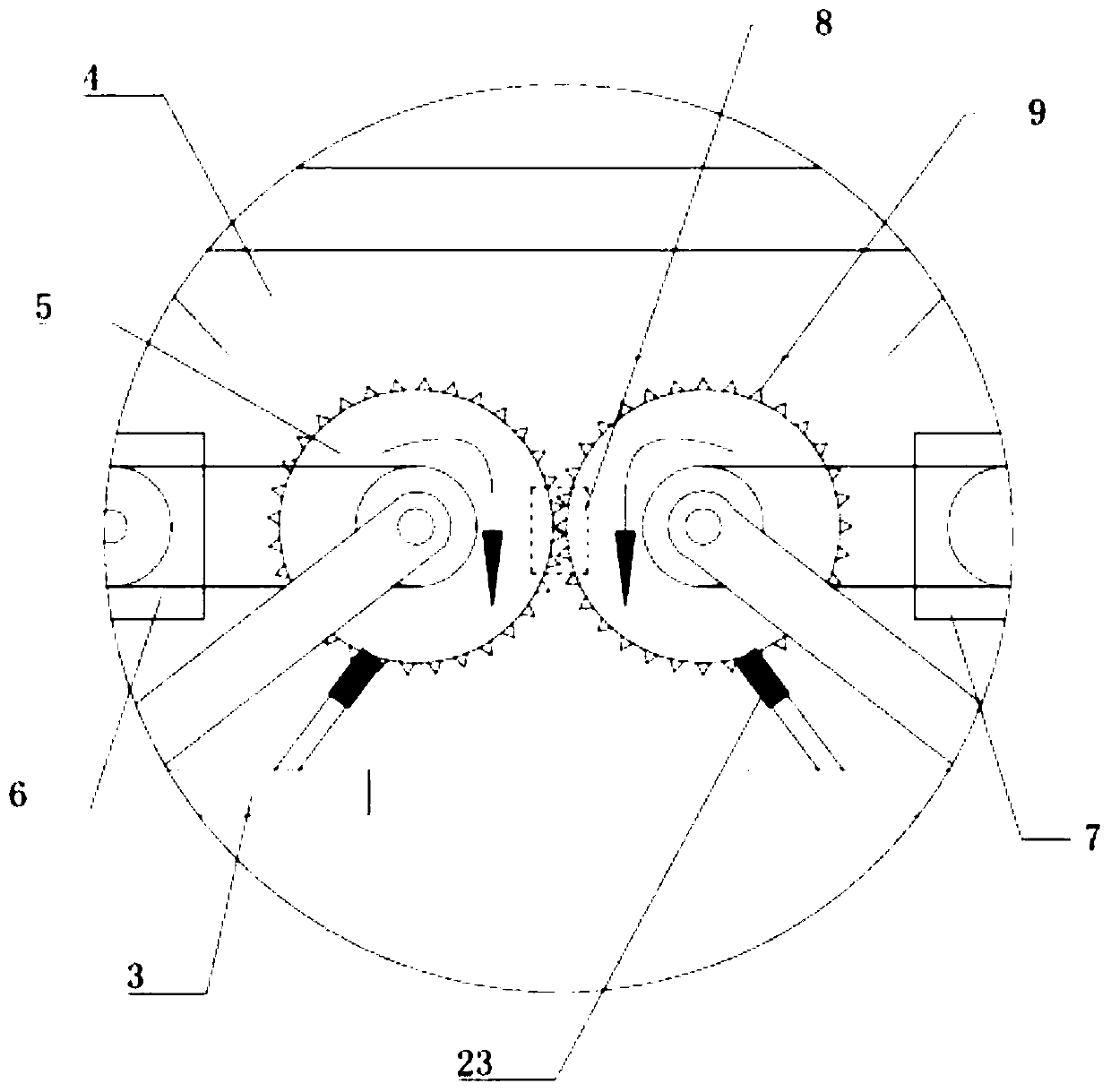

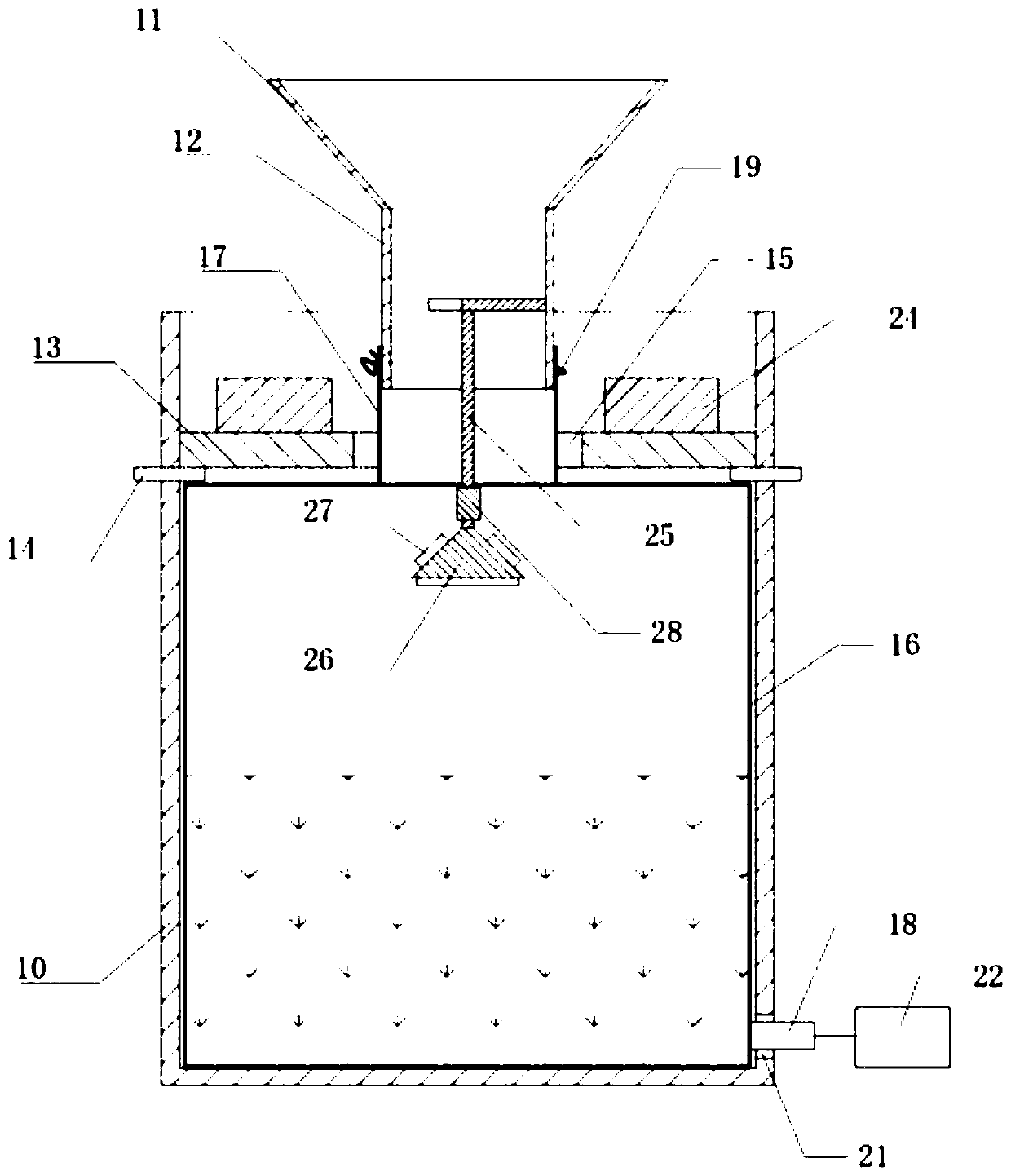

Waste material recovering and packaging device for face mask machine

InactiveCN111301730ASmall footprintGood for transportationPlastic recyclingSolid materialElectric machineryDrive motor

The invention discloses a waste material recovering and packaging device for a face mask machine, and is used for recovering and packaging bar-shaped waste materials and block-shaped waste materials generated in a face mask machine production process. The device comprises a rack, a material guiding hopper, a driving and breaking mechanism and a recovering and packaging mechanism, wherein the driving and breaking mechanism comprises two driving rollers, a first driving motor and a second driving motor; each driving roller is evenly provided with cutoff teeth; the recovering and packaging mechanism comprises a waste material recovery tank, a material collection hopper and a material collection tube; a slippage block is in slippage connection in the waste material recovery tank, and a switchbolt is arranged; the slippage block is provided with an installation hole; a plastic recovery bag is arranged in the waste material recovery tank and comprises an installation tube, an air outlet check valve and a knotting rope; a movable door and an air outlet are arranged on the bottom of the waste material recovery tank; and the air outlet check valve is connected with a negative pressure airsource. Through the above arrangement, waste materials generated by the face mask machine can be recovered and are subjected to closed packaging, so that the waste materials are free from being directly polluted by external environment, and the waste materials can be directly recovered and used without being cleaned.

Owner:无为市泉康防护用品厂

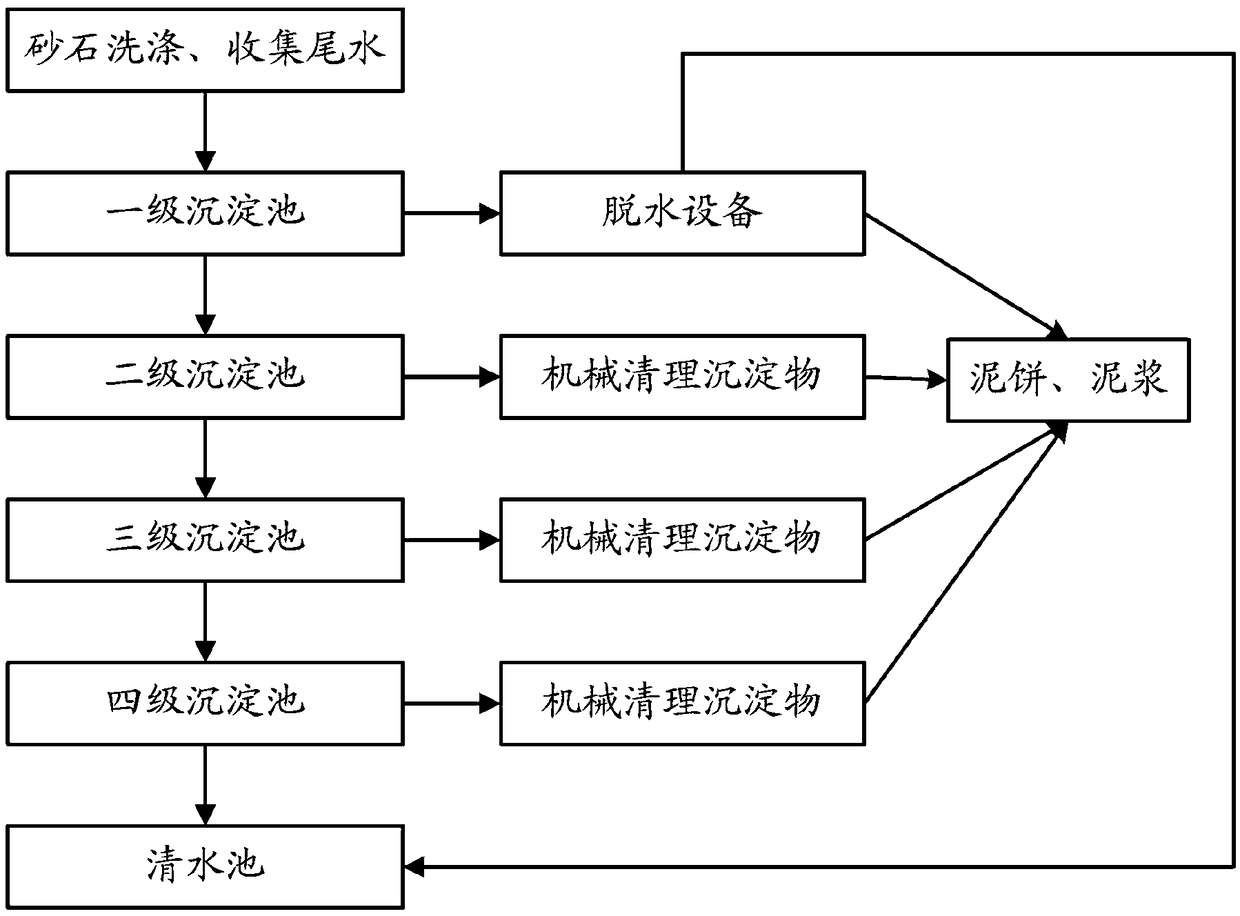

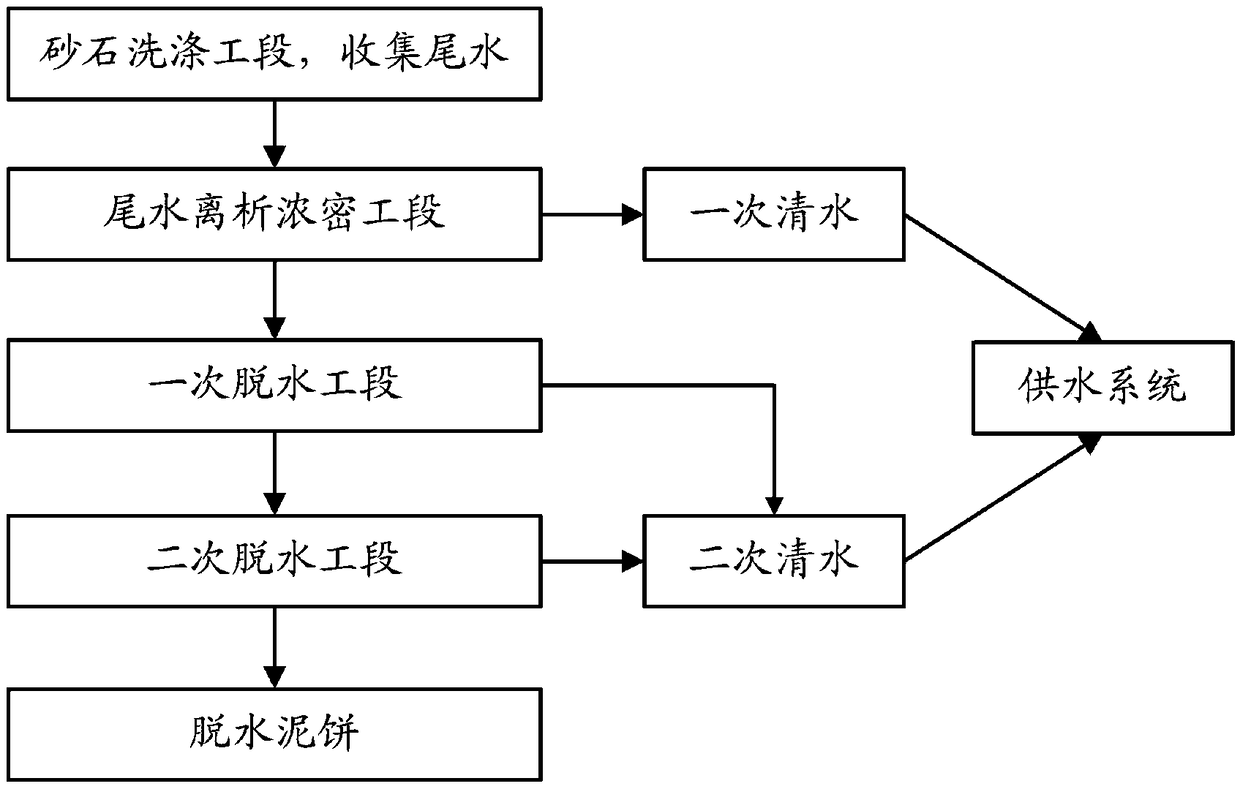

Environment-friendly control technology for tail water of sandstone factory

InactiveCN108793354AEliminate drug residue hazardsGood for transportationSludge treatment by de-watering/drying/thickeningNature of treatment waterWater supplyLand resources

The invention discloses an environment-friendly control technology for tail water of a sandstone factory. The environment-friendly control technology comprises the following steps of (1) washing of sandstone: washing the sandstone for building engineering, and collecting the tail water after washing; (2) separating and concentrating: separating and settling the tail water in step (1) by concentrating equipment, producing mud containing fine particles and siltized matter and primary clean water, conveying the mud into dewatering equipment of a press filter to make cakes, and returning the primary clean water back to a water supply system for further use; (3) primary dewatering and cake making: dewatering the settled mud in step (2) for the first time by a primary belt type press filter, andproducing primary dewatering mud cake and secondary clean water; (4) secondary dewatering and cake making: dewatering the primary dewatering mud cake in step (3) for the second time by a secondary belt type press filter, and producing secondary dewatering mud cake and secondary clean water; selecting a land for the secondary dewatering mud cake, storing for further use, and returning the secondary clean water back to the water supply system for further use. The environment-friendly control technology has the advantage that the pollution to the environment by the tail water and the occupationof land resources are fundamentally eliminated.

Owner:乔静梅

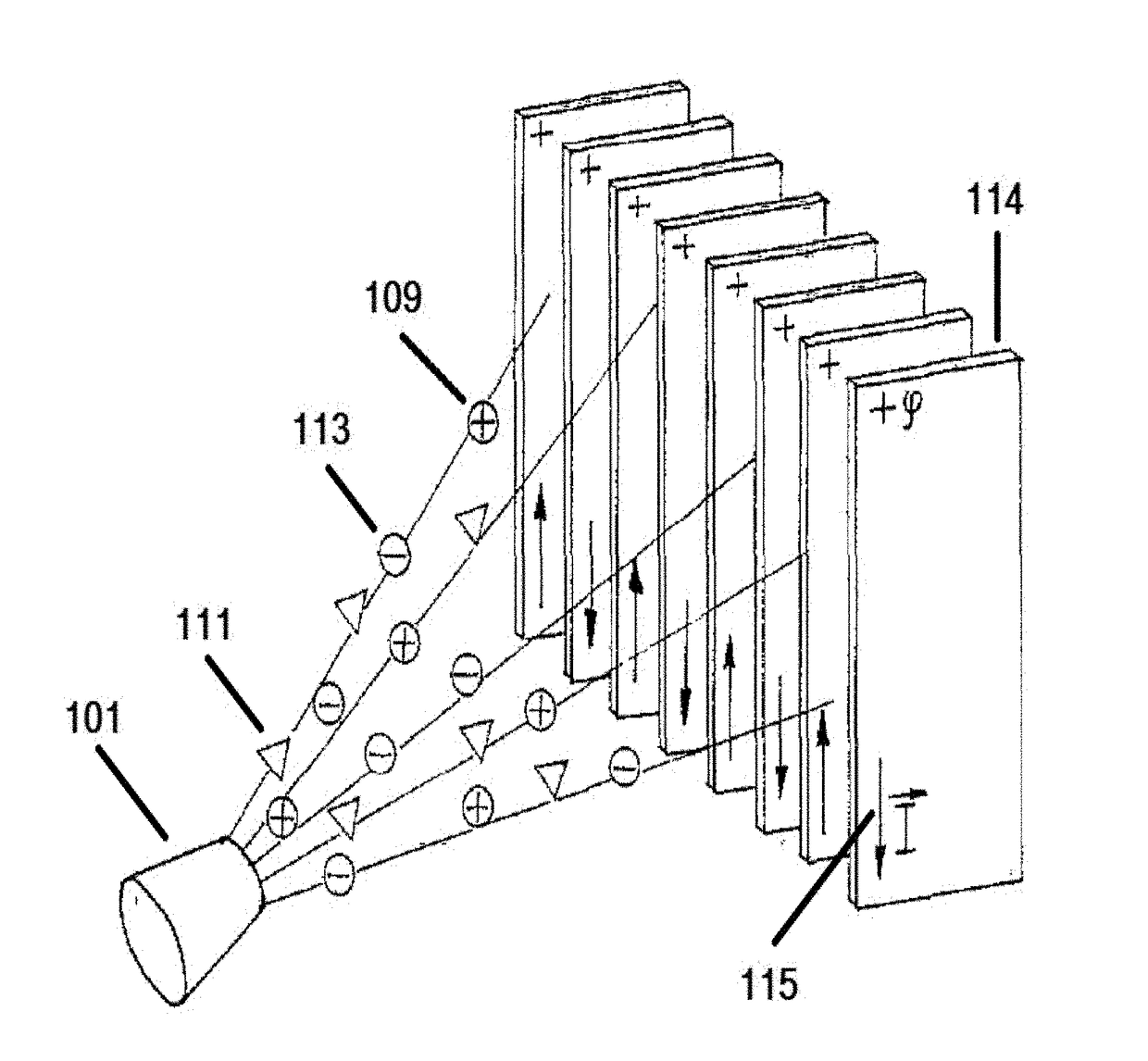

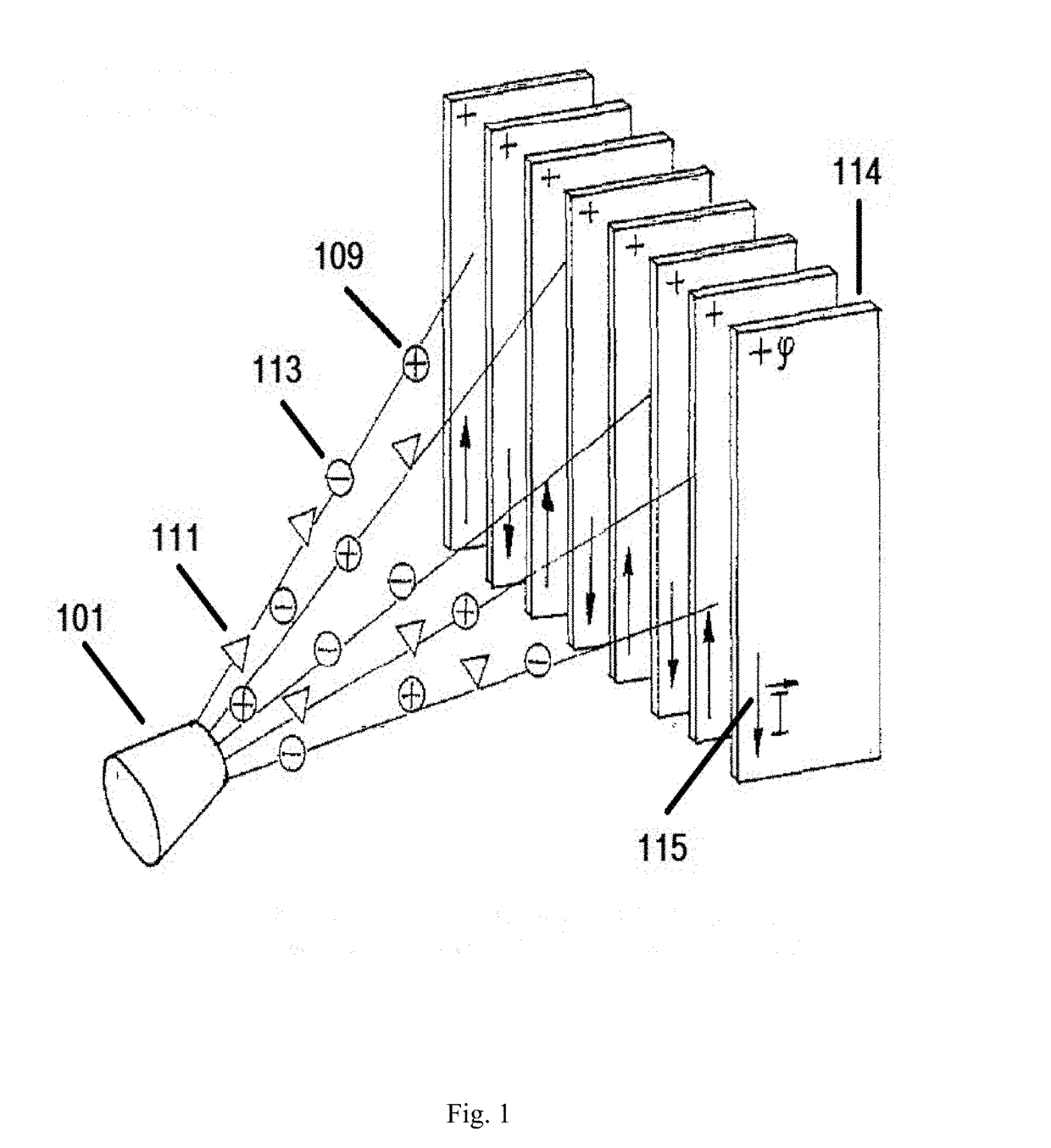

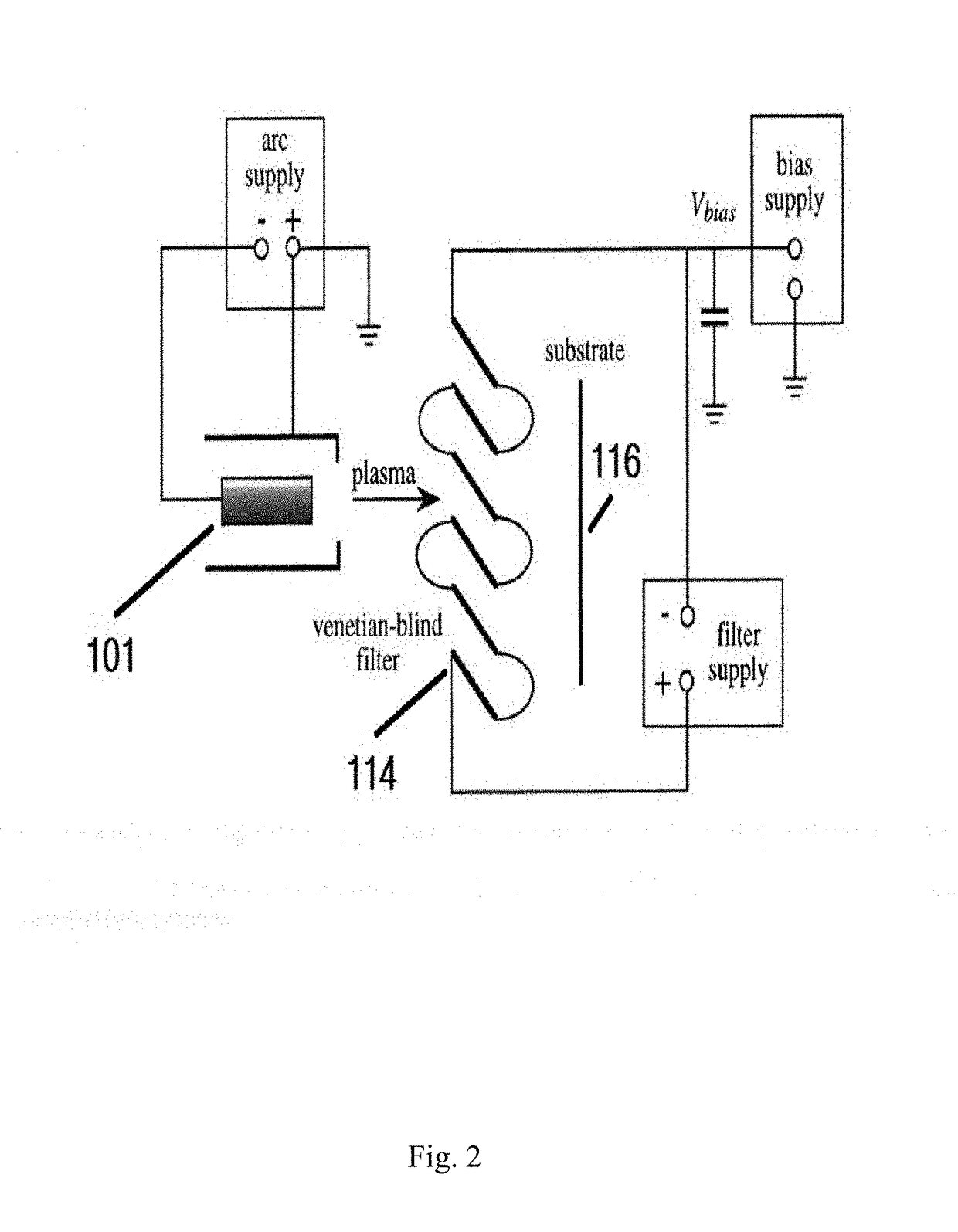

Filter apparatus for arc ion evaporator used in cathodic arc plasma deposition system

ActiveUS20170229294A1Lessens disadvantage pointGood for transportationElectric discharge tubesVacuum evaporation coatingPhysicsIon

A filter apparatus for arc ion evaporator used in the cathodic arc plasma deposition system according to this invention is characterized by a set of multiple straight tubes placing in parallel to one another wherein the size and / or amount of large particles, which could contaminate the plasma beam, can be controlled. The filter apparatus further comprises a set of solenoid coils which coil around the filter to generate a magnetic field to drive plasma to the targeting object or material.The filter apparatus of this present invention can reduce a number of large particles in the plasma beam and can further be designed into compacted shapes with high flexibility for adaptation in order to suit engineering demands. In addition, the filter apparatus according to this invention does not hinder the line of sight and is in consistent with the direction of plasma movement so that large number of plasma can be obtained, resulting in a reduced electrical consumption for driving the plasma and a faster deposition rate to enable quick, high volume production of quality products at a reasonable cost.

Owner:SURINPHONG SURASAK

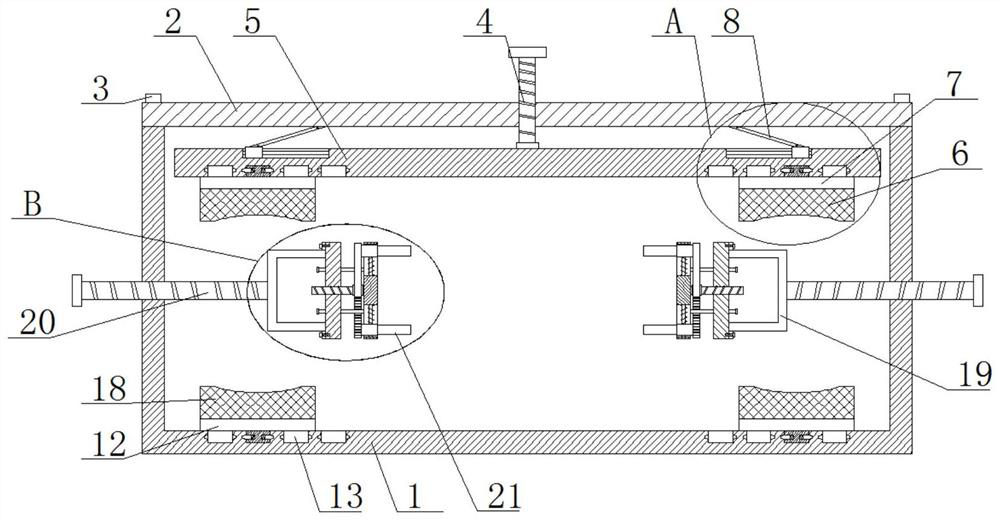

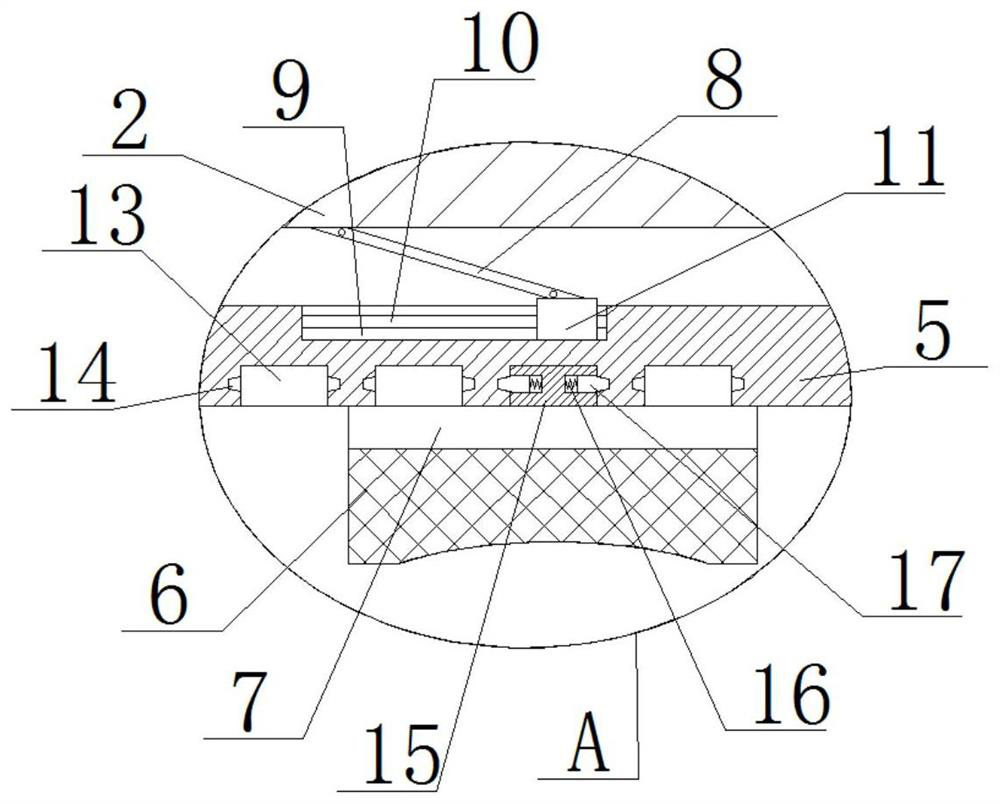

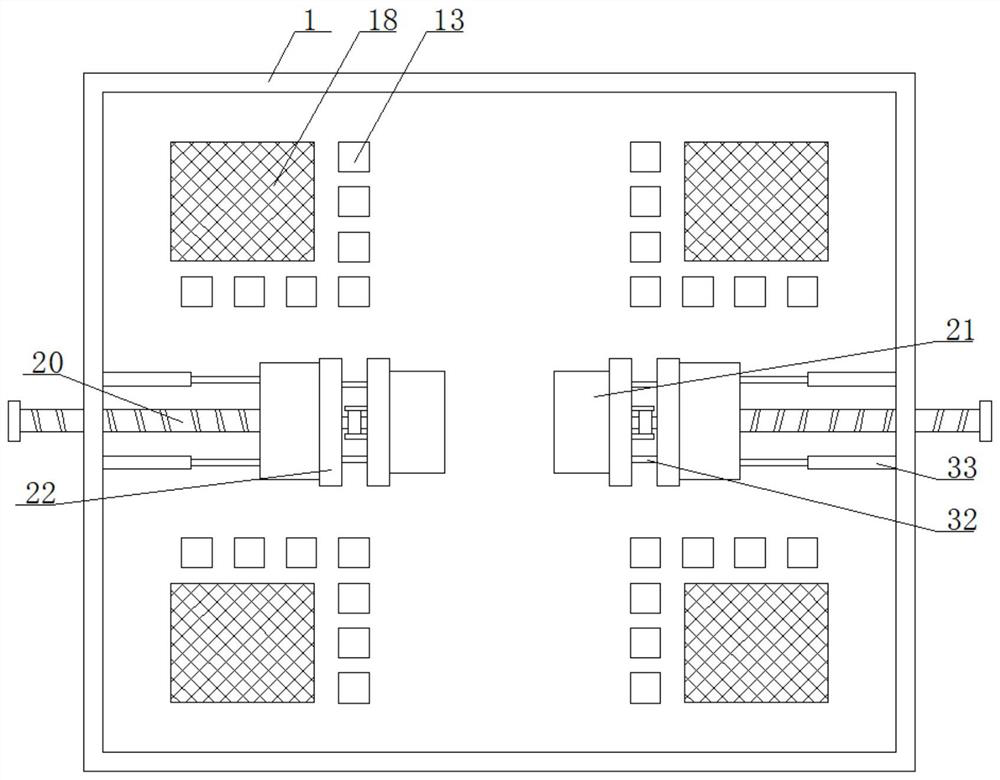

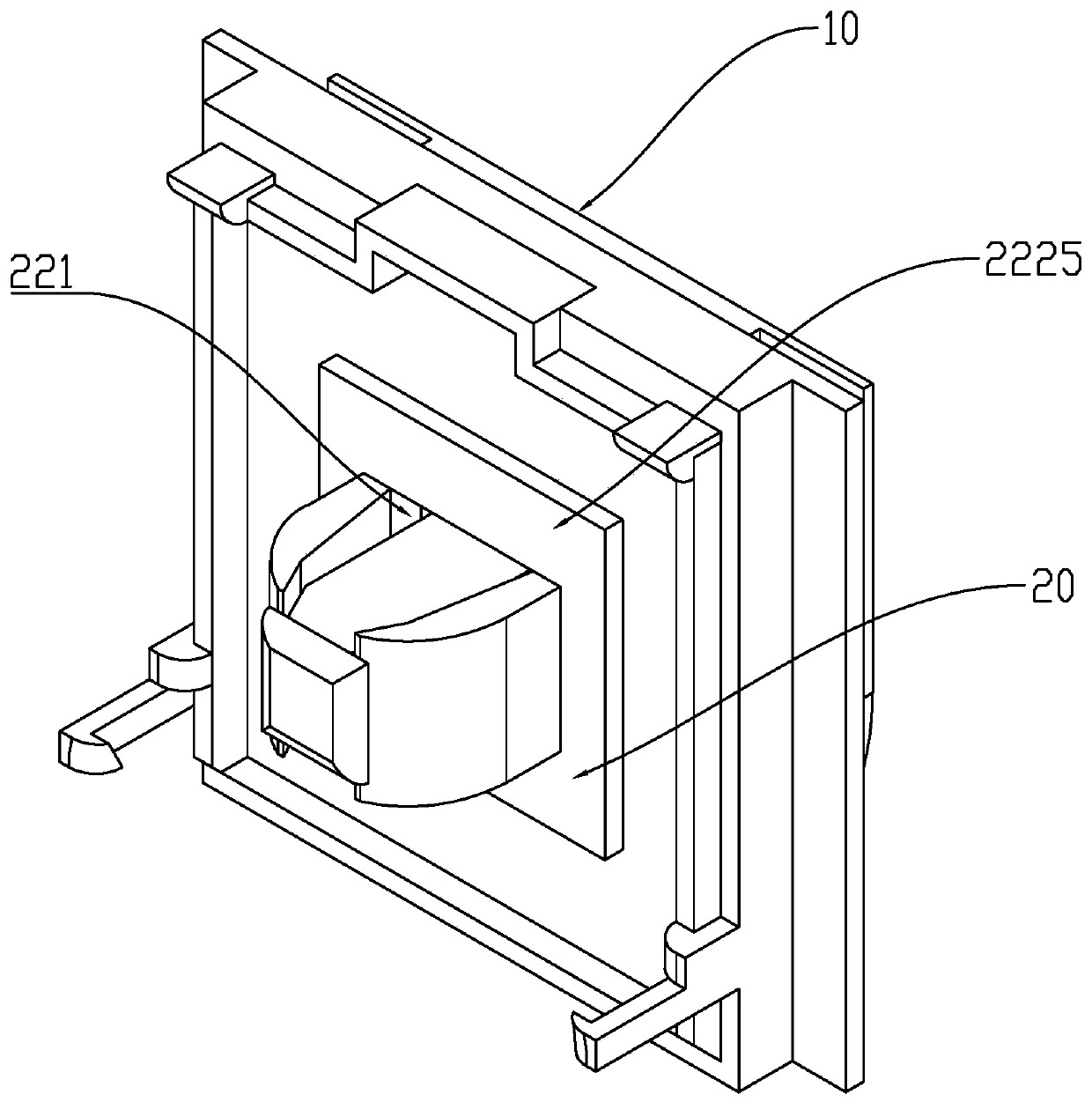

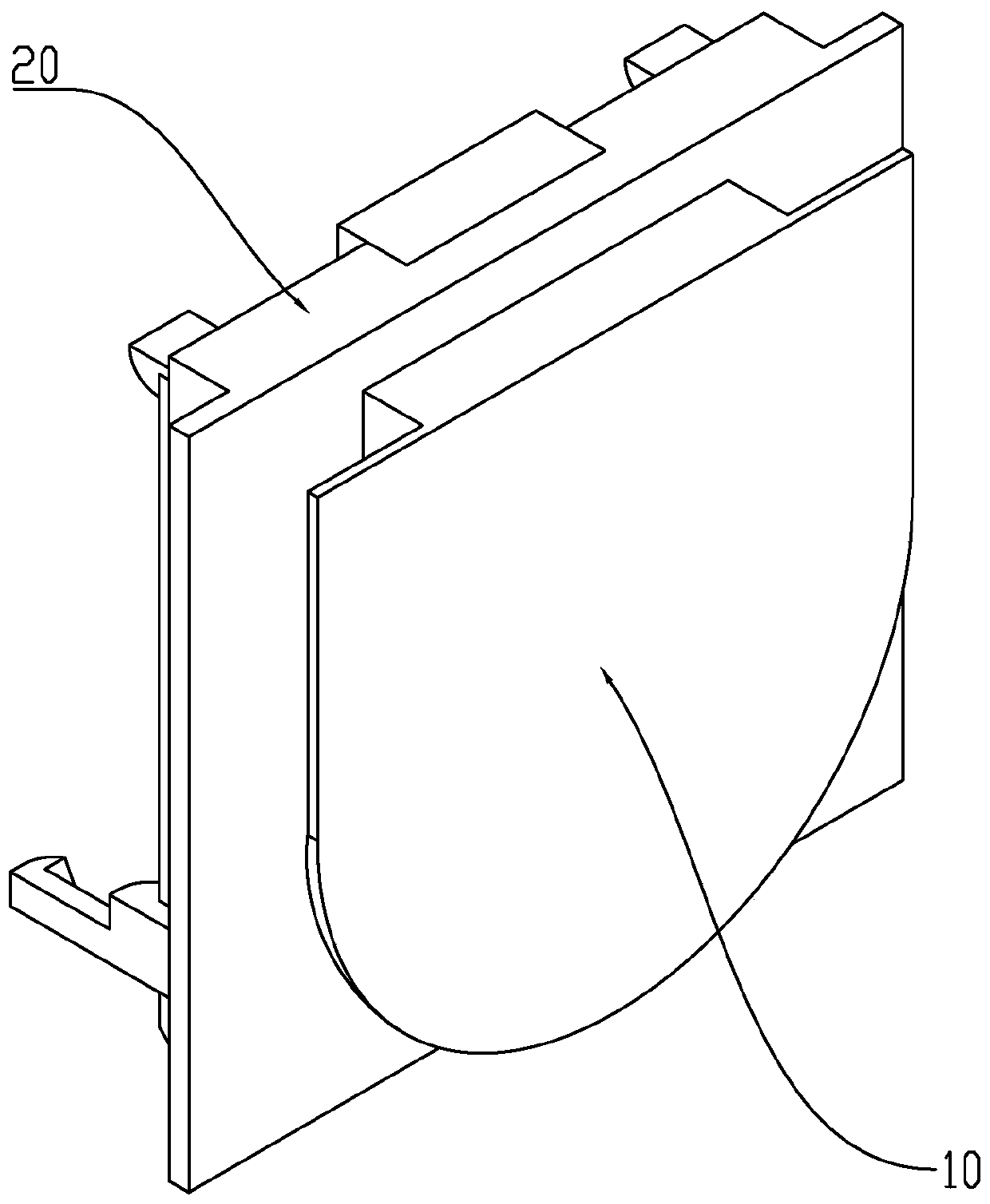

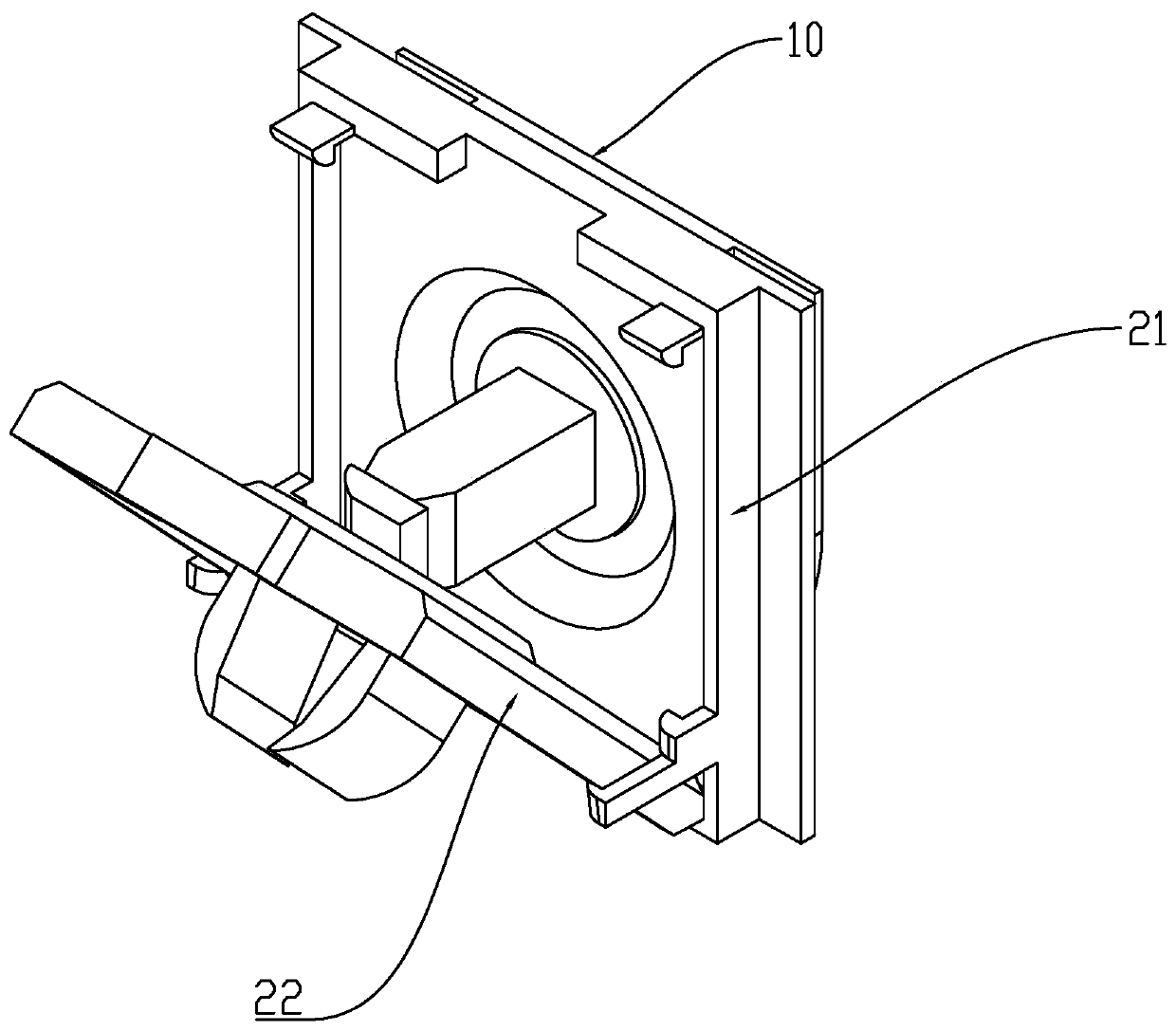

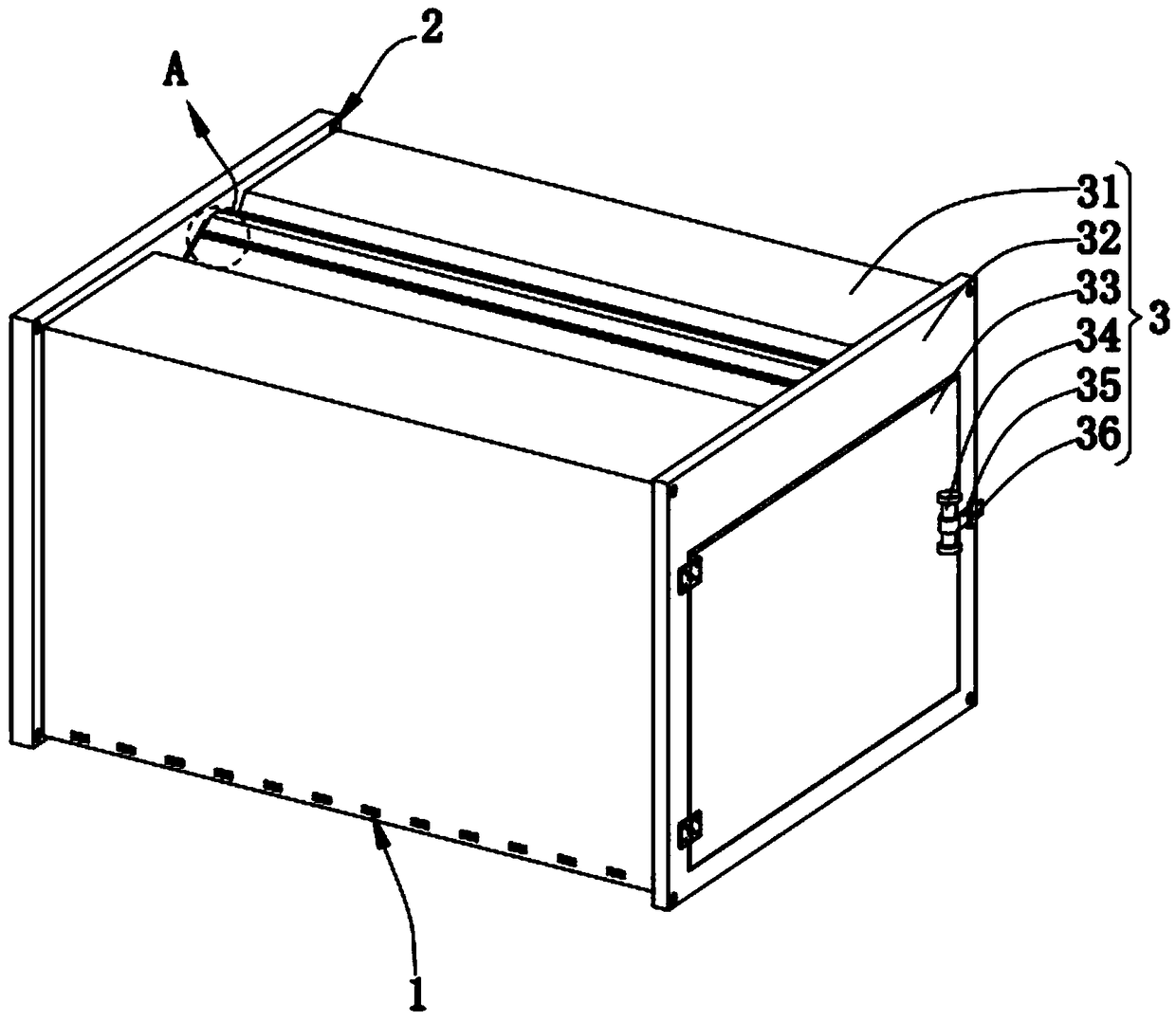

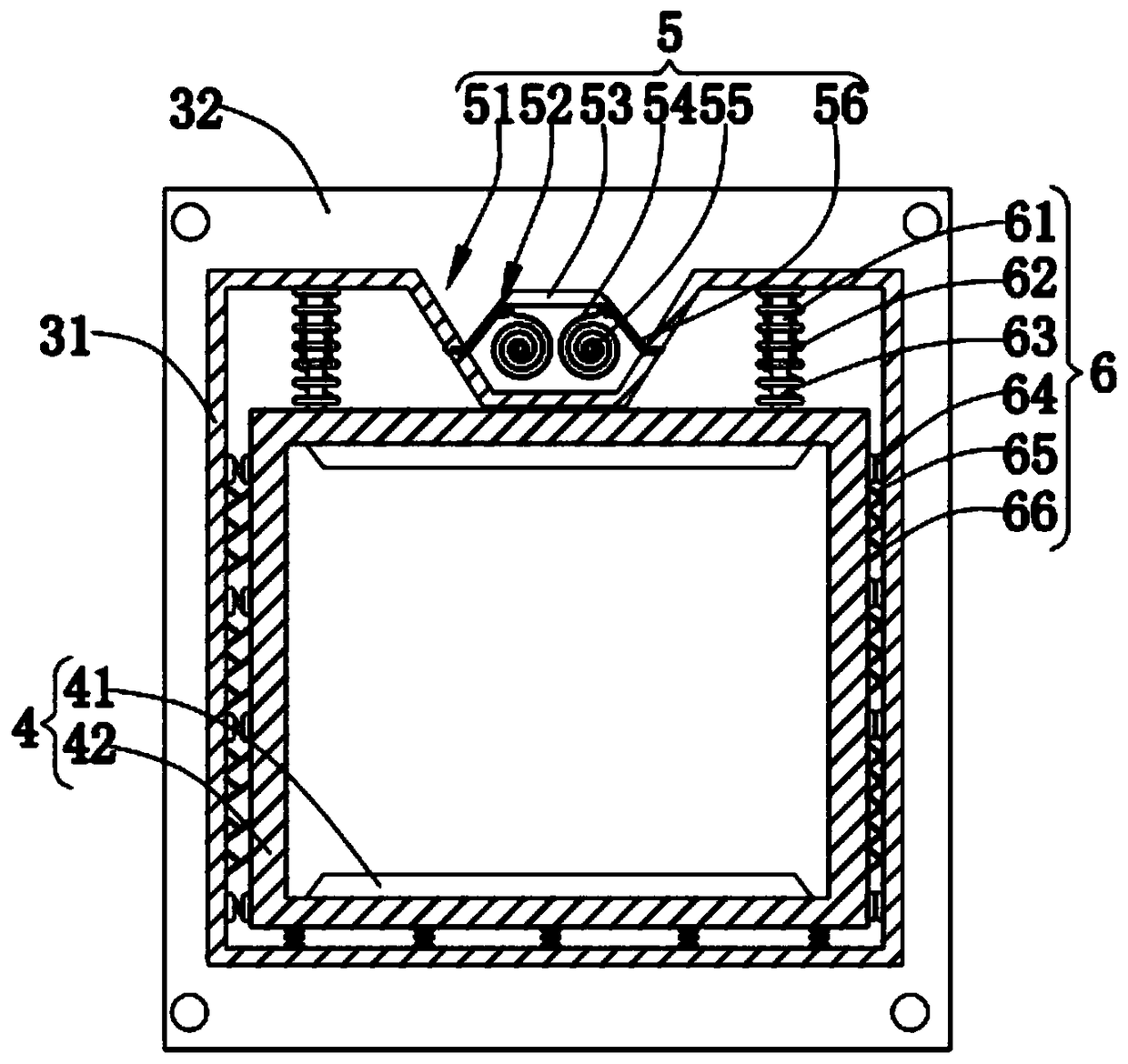

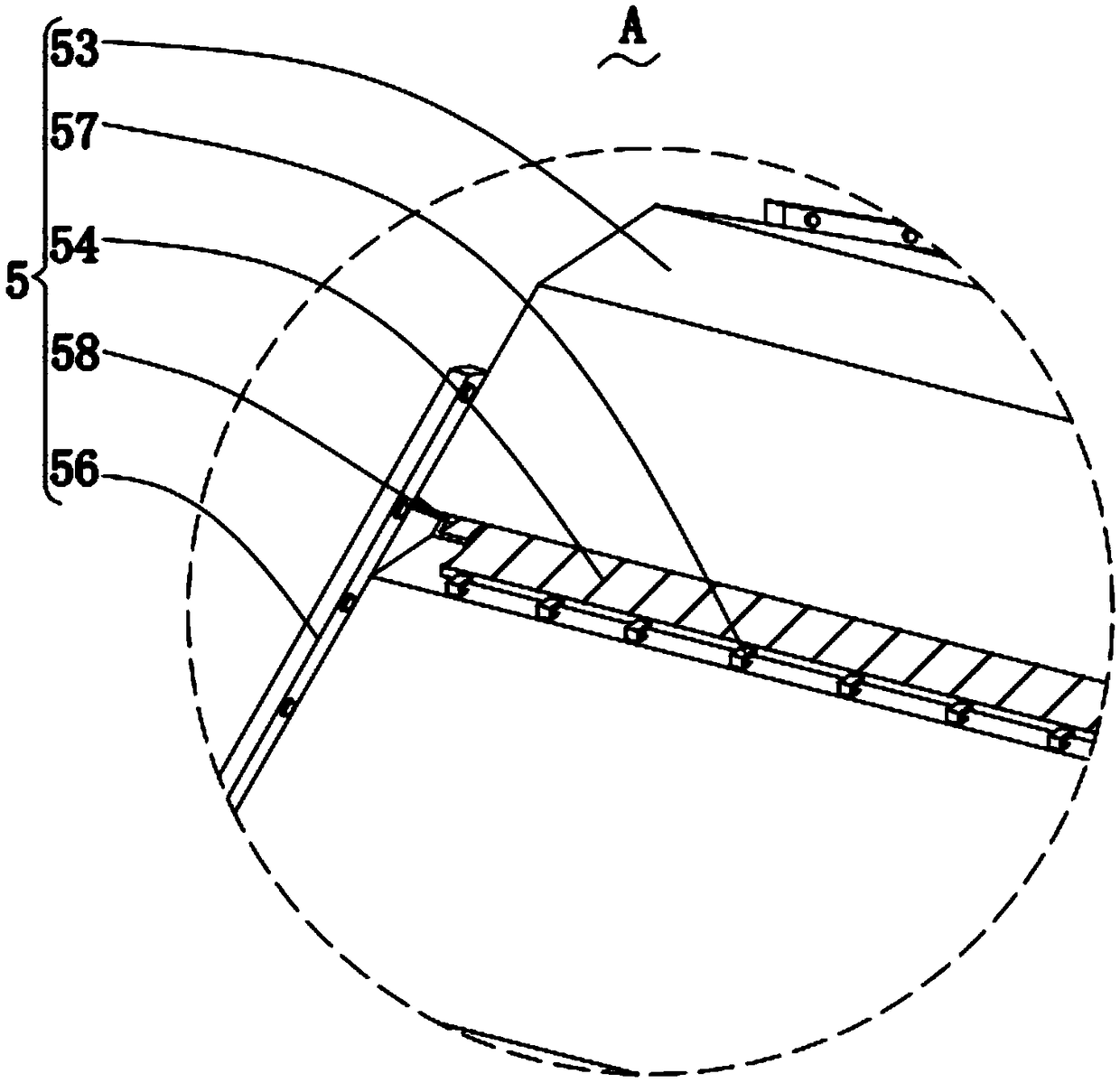

Logistics box for unmanned aerial vehicles

InactiveCN111977146AAvoid shakingGood for transportationPackaging vehiclesContainers for machinesStructural engineeringElectrical and Electronics engineering

The invention belongs to the technical field of modern logistics, and discloses a logistics box for unmanned aerial vehicles. The logistics box for the unmanned aerial vehicles includes a box body, the box body is provided with a box cap, the box cap is detachably and fixedly connected with the box body, a screw rod is connected with the top of the box body in a threaded mode, an extrusion board is connected with the bottom of the screw rod in a rotating mode, four top press boards are connected with a base board of the extrusion board in a moving mode, four bottom press boards are connected with the inner wall of the bottom of the box body in a moving mode, four top elastic pads and four bottom elastic pads are connected with the sides of the four top press boards and the four bottom press boards close to each other respectively, spiral rods are connected with two sides of the box body in a threaded mode, connecting frames are connected with the ends of the two spiral rods close to each other in a rotating mode, and stable boards are fixedly connected with the ends of the two connecting frames close to each other. The logistics box for the unmanned aerial vehicles can fix the unmanned aerial vehicles conveniently, and is suitable for the fixing of the unmanned aerial vehicles with different size, the fixing strength can be adjusted, the shaking can be prevented, and the transporting of the unmanned aerial vehicles can be facilitated.

Owner:北京碳云科技有限公司

Advanced mathematics plotter

The invention discloses an advanced mathematics plotter. The advanced mathematics plotter comprises a calibration rope mounting part and a calibration fixing part, wherein the calibration rope mounting part comprises a shell and a spring reel arranged in the shell, a first suction cup is arranged at the bottom of the shell, a calibration rope is arranged on the spring reel, the free end of the calibration rope is fixedly connected with the calibration fixing part, the calibration fixing part is detachably connected with a suction cup fixing part or a chalk clamping part, a second suction cup is arranged on the suction cup fixing part, and the chalk clamping part is used for clamping chalk; and a locking mechanism for locking the calibration rope is arranged on the calibration rope mounting part. The device is simple in structure, convenient to operate, small in occupied space and convenient to transport.

Owner:电子科技大学成都学院

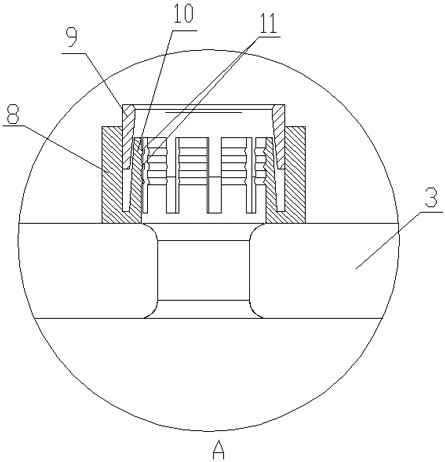

Fischer-Tropsch synthesis method for wax by utilizing low-rank coal

PendingCN109762604AIncrease added valueGood for transportationLiquid hydrocarbon mixture productionMineral wax recovery/refiningCoal waterWax

The invention provides a Fischer-Tropsch synthesis method for wax by utilizing low-rank coal. The Fischer-Tropsch synthesis method comprises the following steps: drying the low-rank coal to obtain dried low-rank coal and waste gas; removing dust from the waste gas to obtain coal powder; gasifying and reducing the dried low-rank coal under an oxygen-free or micro-aerobic condition to obtain an oil-gas mixture and quality-improved coal; preparing the oil-gas mixture into mixed gas and wastewater; reforming and transforming the mixed gas to prepare synthetic gas; preparing coal water slurry through the wastewater, the coal powder and a coal water slurry additive and then preparing synthetic gas; preparing synthetic gas by utilizing the quality-improved coal; after mixing the three types of synthetic gas, removing CO2 and supplementing H2 or CO to adjust a hydrogen-carbon ratio of the synthetic gas to be 1.5 to 2.2; carrying out distillate oil steam stripping and the like on a product, which is obtained by carrying out Fischer-Tropsch synthesis reaction on the synthetic gas, to obtain wax, heavy oil and naphtha. According to the Fischer-Tropsch synthesis method provided by the invention, the low-rank coal is used for producing light oil, the heavy oil and the wax through a Fischer-Tropsch synthesis technology and is convenient to transport, and the utilization rate of resources isimproved; the source of raw materials is wide, the energy consumption of the technology is low, wastes are utilized and the production cost is easy to save.

Owner:浙江天禄环境科技有限公司

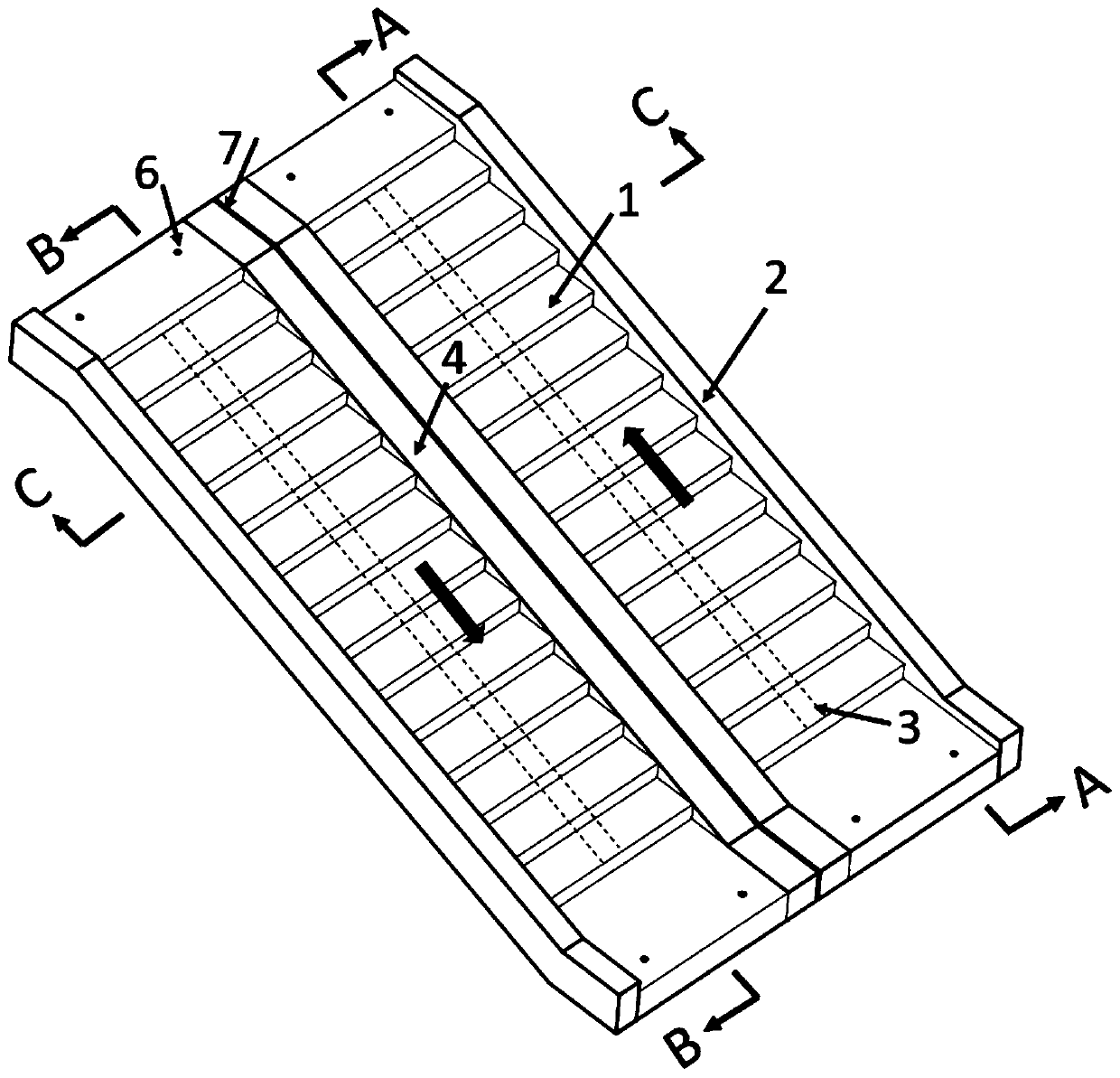

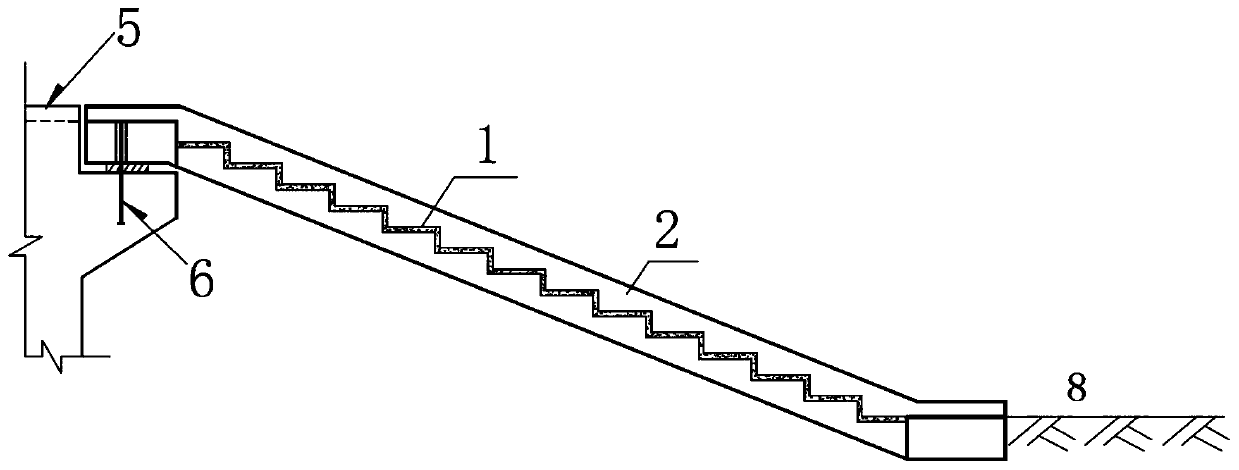

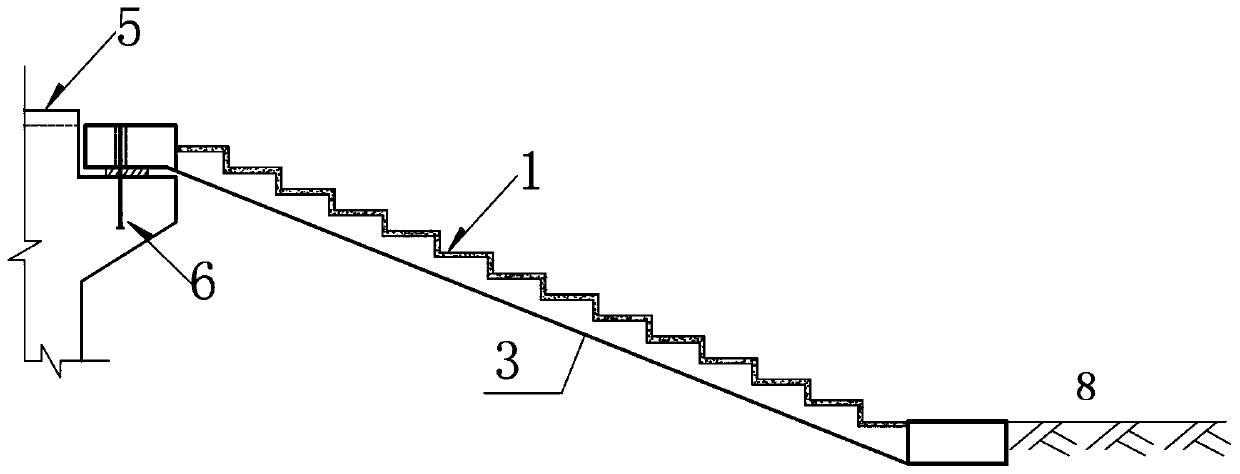

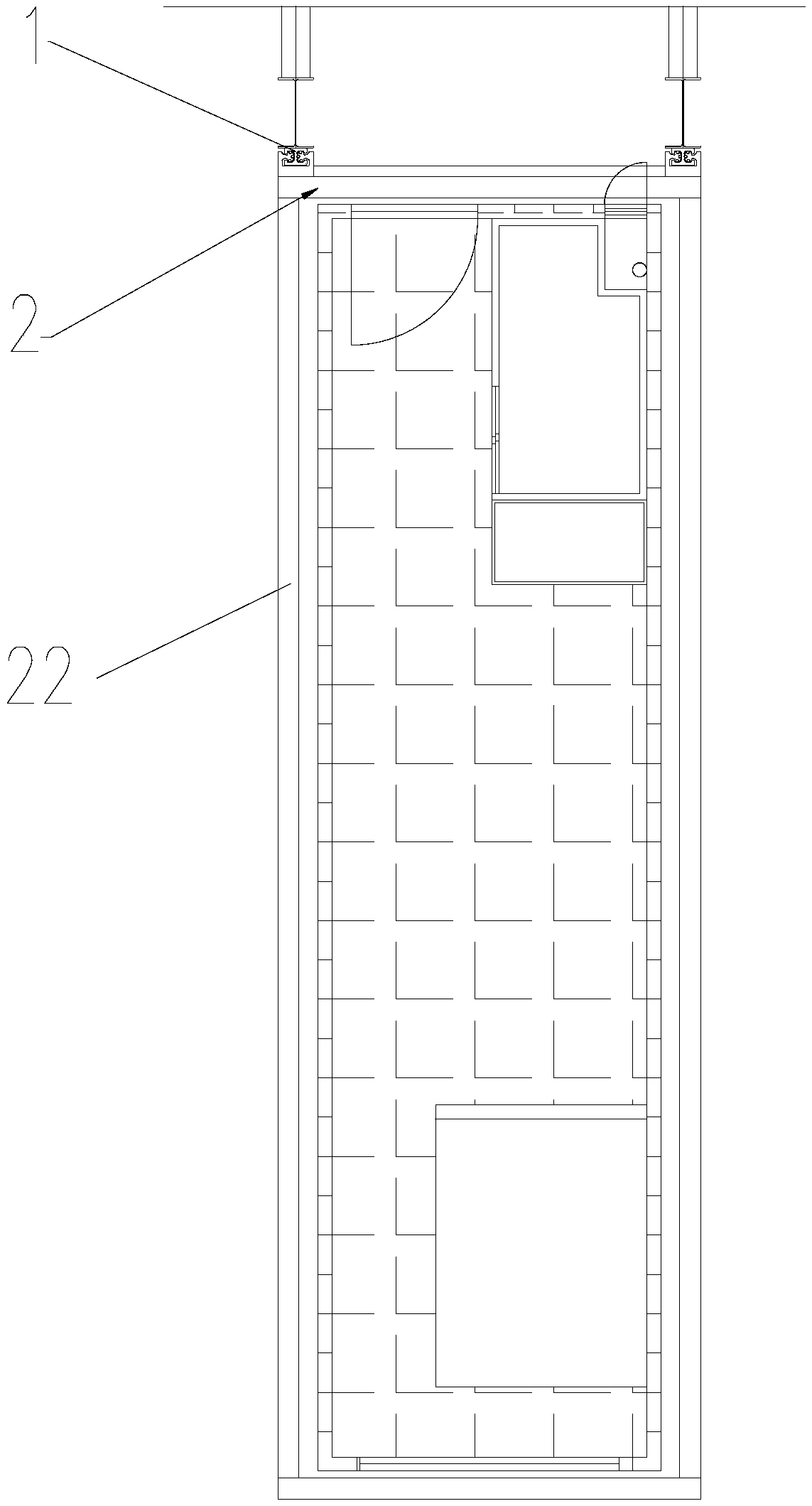

Urban fabricated platform bridge stair adopting UHPC and implementation method thereof

PendingCN110820511AGood for transportationShort production cycleBridge structural detailsRebarTreadle

The invention relates to an urban fabricated platform bridge stair adopting UHPC, and belongs to the technical field of municipal engineering fabrication. The urban fabricated platform bridge stair adopting the UHPC comprises a stair unit; the stair unit comprises two side beams, at least one middle beam, step ladder pedals, an upper platform and a lower platform; the two side beams are located onthe left side and the right side in parallel, the middle beams are located between the two side beams and are parallel to the side beams, the step ladder pedals are located between the two side beamsand located over the middle beams, the upper platform is arranged at the upper ends of the step ladder pedals, and the lower platform is arranged at the lower ends of the step ladder pedals; and thestair unit is of a beam plate type structure which is overall poured through the UHPC, stressed steel bars are arranged in the upper platform, the lower platform, the side beams and the middle beams,and steel bar nets are arranged in the step ladder pedals. The invention further relates to an implementation method of the urban fabricated platform bridge stair adopting the UHPC. The problems thatthe maintenance cost of a prefabricated steel stair is high, and the self weight of a prefabricated common concrete stair is large are solved.

Owner:广州市市政工程机械施工有限公司 +1

Light solid wood sectional material and manufacturing method thereof

InactiveCN108202376AGood for transportationEasy to installWood treatment detailsThermal wood treatmentWater contentElastic modulus

The invention discloses a light solid wood sectional material which comprises a paulownia solid wood sectional material with the thickness being 2 to 6mm. The paulownia solid wood sectional material is prepared from 20 to 40 percent by weight of polymer resin with the porosity being 8 to 20vol percent, the density being 0.32 to 0.56g / cm<3> when the water content is 6 percent, the static bending intensity being 30 to 40MPa, and the elasticity modulus being 4100 to 4500Mpa. The light solid wood sectional material provided by the technical scheme of the invention has the characteristics of convenience in transportation, high strength, and good decorative effect.

Owner:中山市大涌镇生产力促进中心

Method for increasing energy utilization rate of hydraulic system in field of ship building

InactiveCN102963025AHigh movement precisionMeet the process requirementsPressesWorking fluidEngineering

The invention discloses a method for increasing the energy utilization rate of a hydraulic system in the field of ship building. In the aspect of operation, a piston type main work cylinder is arranged for hydraulic press and return; a floating ejector cylinder is arranged for reversely pulling a hydraulic flange and respectively carrying out micro adjustment operation, manual operation and semiautomatic operation; in the aspect of travel speed, the assisting time is saved by quick idle running motion and a pressure-maintaining and time-delaying system is required to be arranged so as to meet the specific process requirement; the pressure of work fluid is maintained at 25-30MPa or a lower work pressure value or higher work pressure value of an interval is selected according to the difference of unit deformation pressure of a workpiece; the a hydraulic pressure is subjected to pressure classification; and finally, pressure pre-relieving is carried out on the main cylinder so as to reduce the impact vibration during return. The method disclosed by the invention has the beneficial effects that due to the adoption of the mode, various process requirements of pressed workpieces can be met comprehensively and accurately, the improvement of the motion precision of the machine and the reduction of wear conditions are facilitated, the service life can be prolonged, the stress of the machine body is assisted and the like.

Owner:WUXI YANGGONG MACHINERY MFG

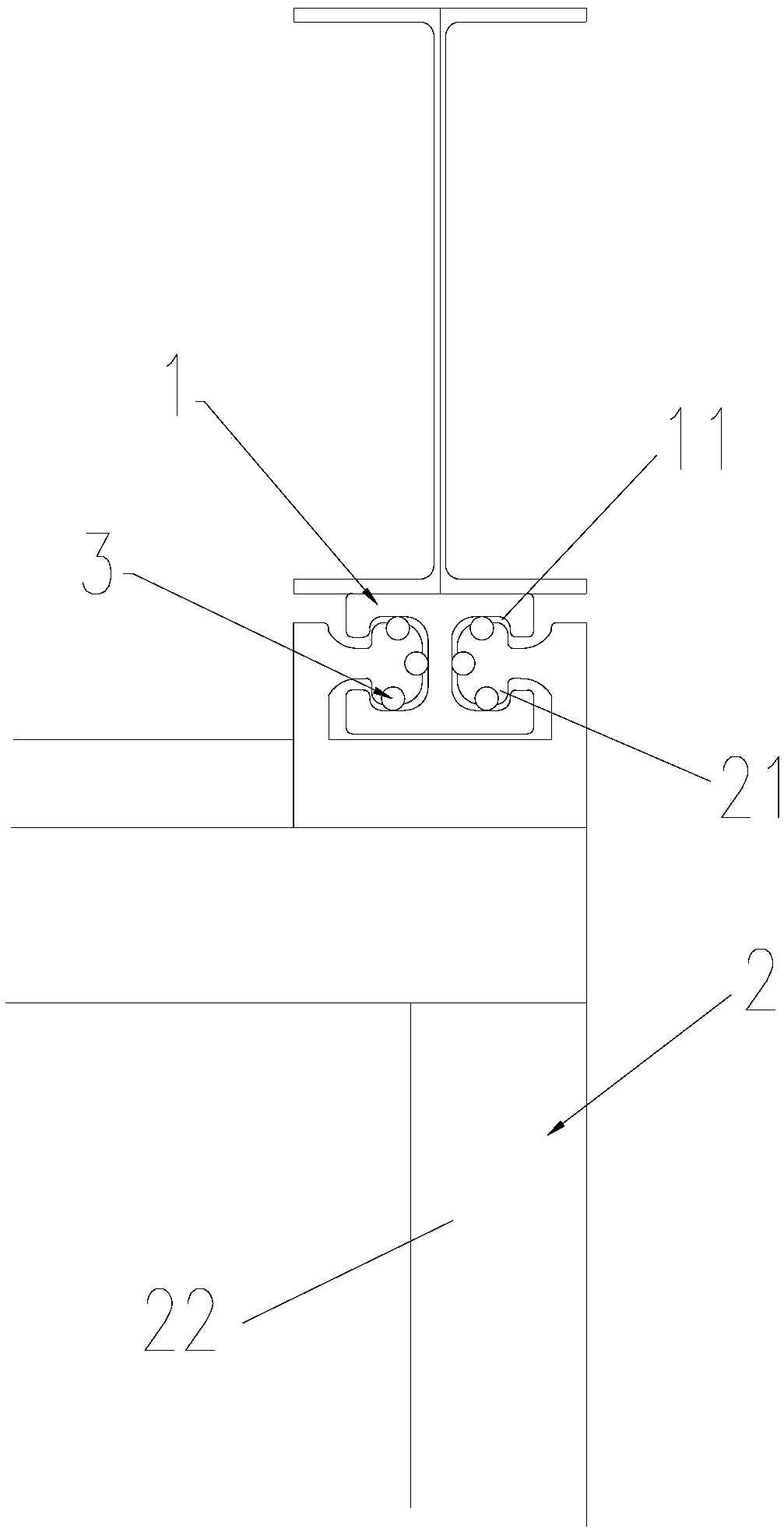

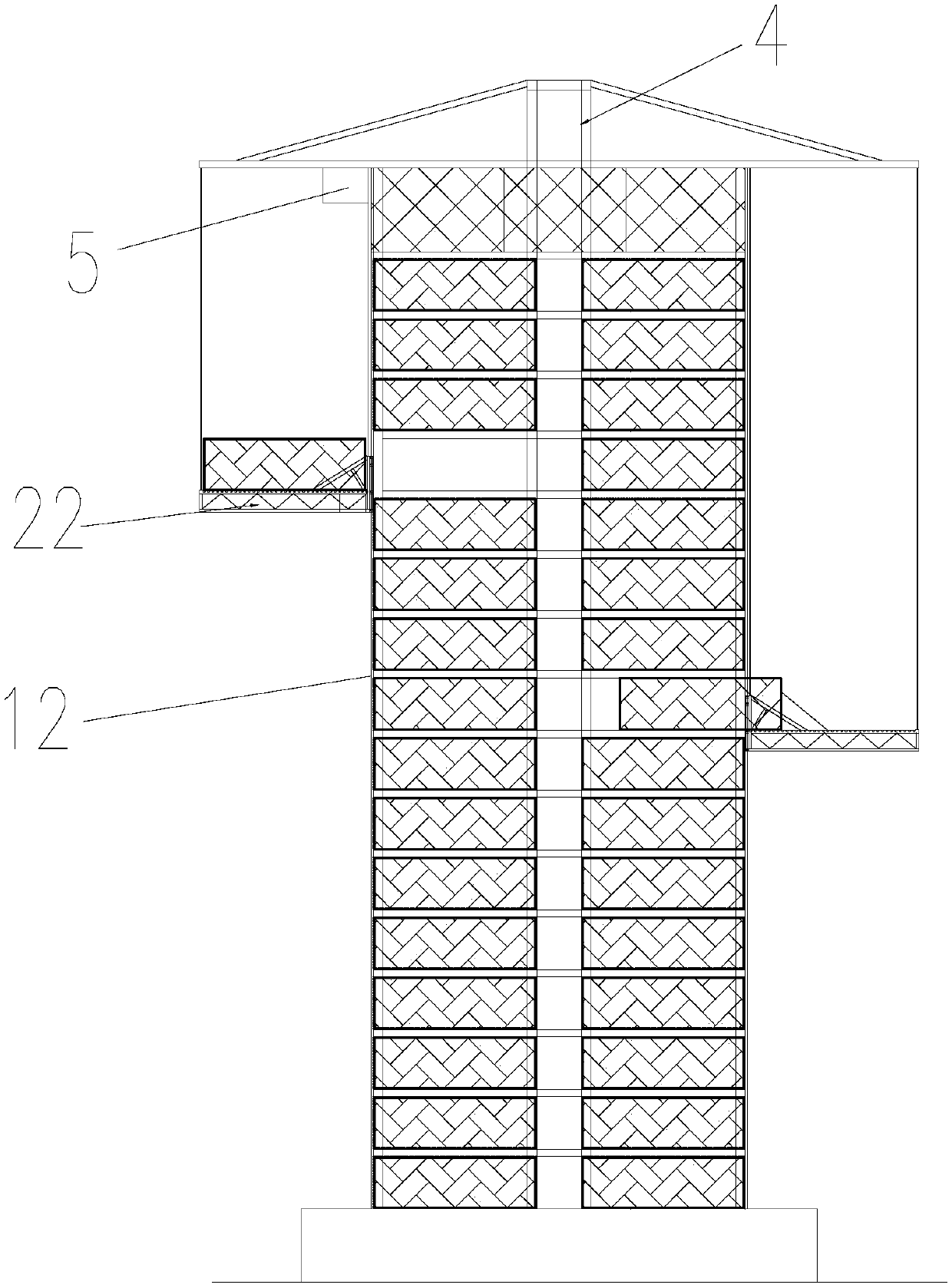

Track system of load-bearing building

The embodiment of the invention is applicable to the technical field of buildings and provides a track system of a load-bearing building. The track system of the load-bearing building comprises tracksand a moving device. The tracks are fixed to an outer wall of the load-bearing building. The tracks are provided with embedment grooves. The moving device is provided with embedment parts. The embedment parts can movably penetrate through the embedment grooves. According to the track system, the tracks are mounted on the load-bearing building, and the embedment parts of the moving device can movably penetrate through the embedment grooves of the tracks; a room module is placed on the moving device and moves along the tracks, transportation of the room module is facilitated, labor is saved inthe transportation process of the room module, and accordingly, the assembly efficiency of a combined house is higher.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Method for setting up integrated block of hydraulic device

ActiveCN102954065AMeet the process requirementsHigh movement precisionFluid-pressure actuator componentsSuperimpositionEngineering

The invention discloses a method for setting up an integrated block of a hydraulic device, and the method is characterized by comprising the following steps that cast iron or forged steel is adopted as an integrated material, a block body is machined into a cubic structure, and a superimposition form of multiple integrated blocks is adopted for the situation that the hydraulic system is complicated and multiple control valves exist; an upper surface and a lower surface of each superimposed integrated block are respectively set as a superimposition joint surface and simultaneously provided with a common pressure oil hole, a leak oil hole and three bolt holes; and one side surface of four surfaces of the integrated block is communicated with an oil pipe of a hydraulic actuation element, the other three side surfaces are used for installing a hydraulic valve, and a hole which is communicated with each valve is drilled inside the block body according to the requirement of a system diagram; and the installation position of the valve makes the communicated oil holes stay on the same horizontal plane as far as possible. The method has the beneficial effects that the movement precision of the machine is improved, the service life is prolonged, and the stress of the machine body is assisted; and the operation controllability is improved, and the labor intensity is alleviated.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

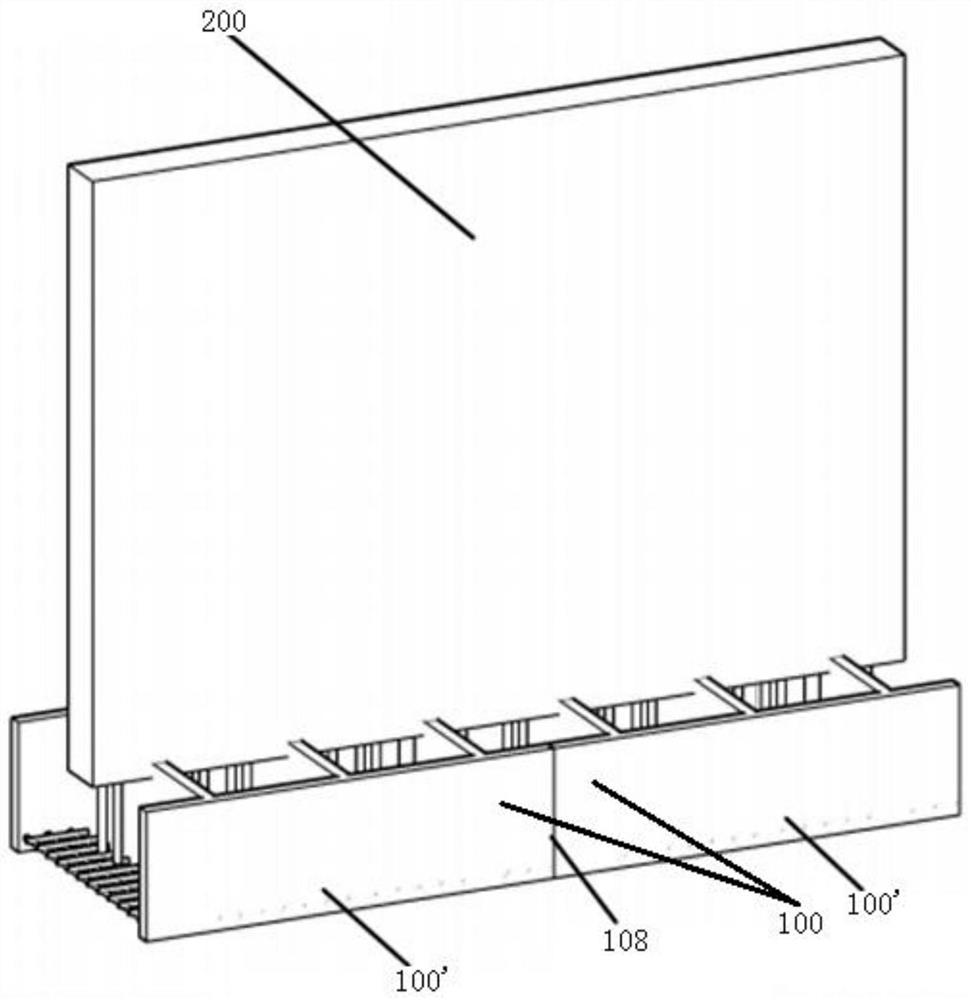

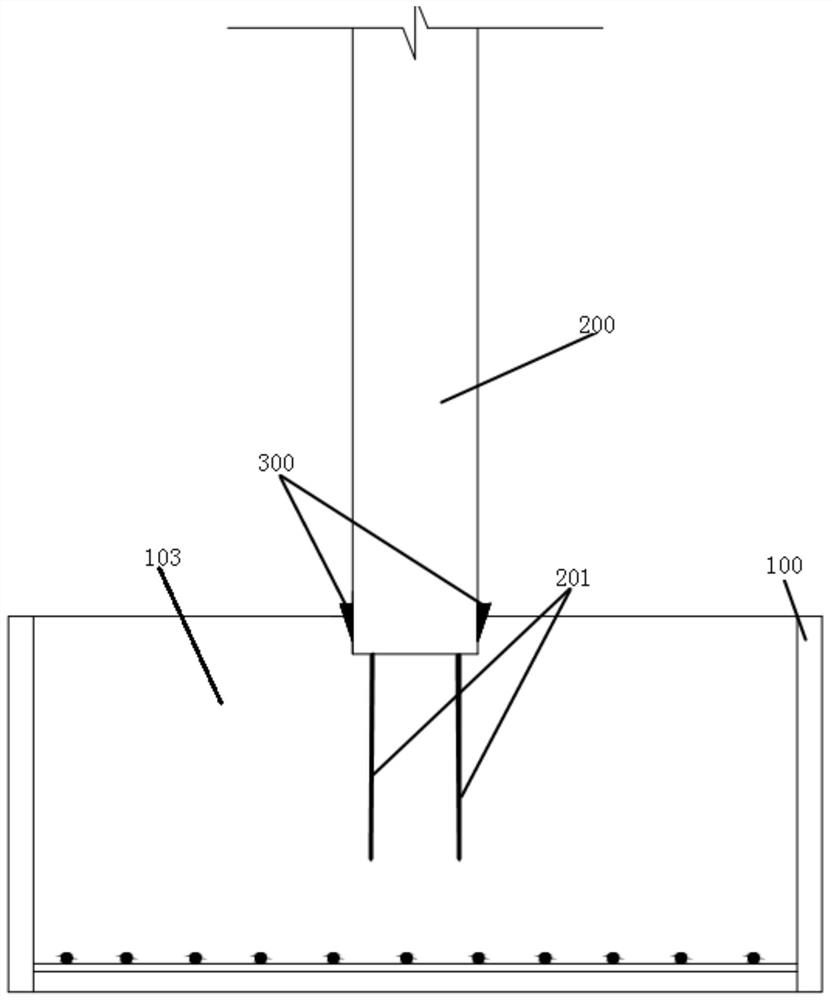

Connecting system and connecting method for prefabricated composite foundation and full-prefabricated shear wall

The invention discloses a connecting system and a connecting method for a prefabricated composite foundation and a full-prefabricated shear wall, and belongs to the field of prefabricated buildings. The prefabricated concrete composite foundation comprises a peripheral wall protecting plate and at least one inner partition plate arranged in the peripheral wall protecting plate, wherein the inner partition plate divides the inner part of the peripheral wall protecting plate into a plurality of cavities; a positioning groove is formed in the top of each inner partition plate; reserved longitudinal ribs are arranged on the bottom of the full-prefabricated shear wall; the bottom edge of the full-prefabricated shear wall is blocked into the positioning grooves; the reserved longitudinal ribs are inserted into the cavities; and concrete is poured into the cavities, so that the prefabricated concrete composite foundation and the full-prefabricated shear wall are connected into an integer. Theconnecting system solves the problems that the prefabricated concrete foundation is too great in dead weight, foundation reserved lap joint reinforcing steel bars are difficult to position, precisionrequirements are high and the like in transportation, hoisting and connecting processes; and concrete construction does not need to support a template, a scaffold and the like, so that efficiency ishigh, and quality is guaranteed.

Owner:SHANDONG UNIV

Folding anti-counterfeiting buckle structure

PendingCN111268277ASave spaceGood for transportationLocking devicesStructural engineeringPackaging Case

Owner:SHENZHEN YUTO PACKAGING TECH

Logistics container

ActiveCN109368063AGood for transportationQuick storageLarge containersTank wagonsEngineeringLogistics management

Owner:安徽壹度品牌运营股份有限公司

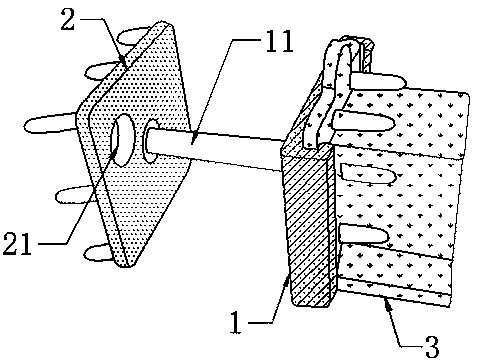

Detachable simulation plant wall hanger

ActiveCN108284700AReduced packaging volumeGood for transportationSpecial ornamental structuresEngineeringMachining

The invention discloses a detachable simulation plant wall hanger. The detachable simulation plant wall hanger comprises a screw rod base, a gasket and a flower arrangement core; a screw rod is arranged in the bottom center of the screw rod base, and is movably connected with the gasket; stop ports are fixed on the two sides of the upper part of the screw rod base; a notch is formed between the stop ports; the flower arrangement core is inserted in the notch through the stop ports and fixed on the screw rod base; a socket base is fixed on the flower arrangement core; a mounting base is fixed on the side of the socket base; insertion pieces are distributed on the two sides of the socket base and the mounting base, and are movably connected with the screw rod base; an insertion hole is formed in the center of the surface of the socket base; and a simulation plant is inserted in the flower arrangement core through the insertion hole. Through detachable assembly of the screw rod base, thegasket and the flower arrangement core, the detachable simulation plant wall hanger has the advantages of easy machining, convenience to assemble, scale production, convenience to clean and convenience to replace, and facilitates improvement of sale of the simulation plant.

Owner:上海亮贝宠物用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com