Urban fabricated platform bridge stair adopting UHPC and implementation method thereof

An implementation method and an assembled technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of self-heavy and high maintenance costs, and achieve the effects of short production cycle, short maintenance time, and favorable transportation and field operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

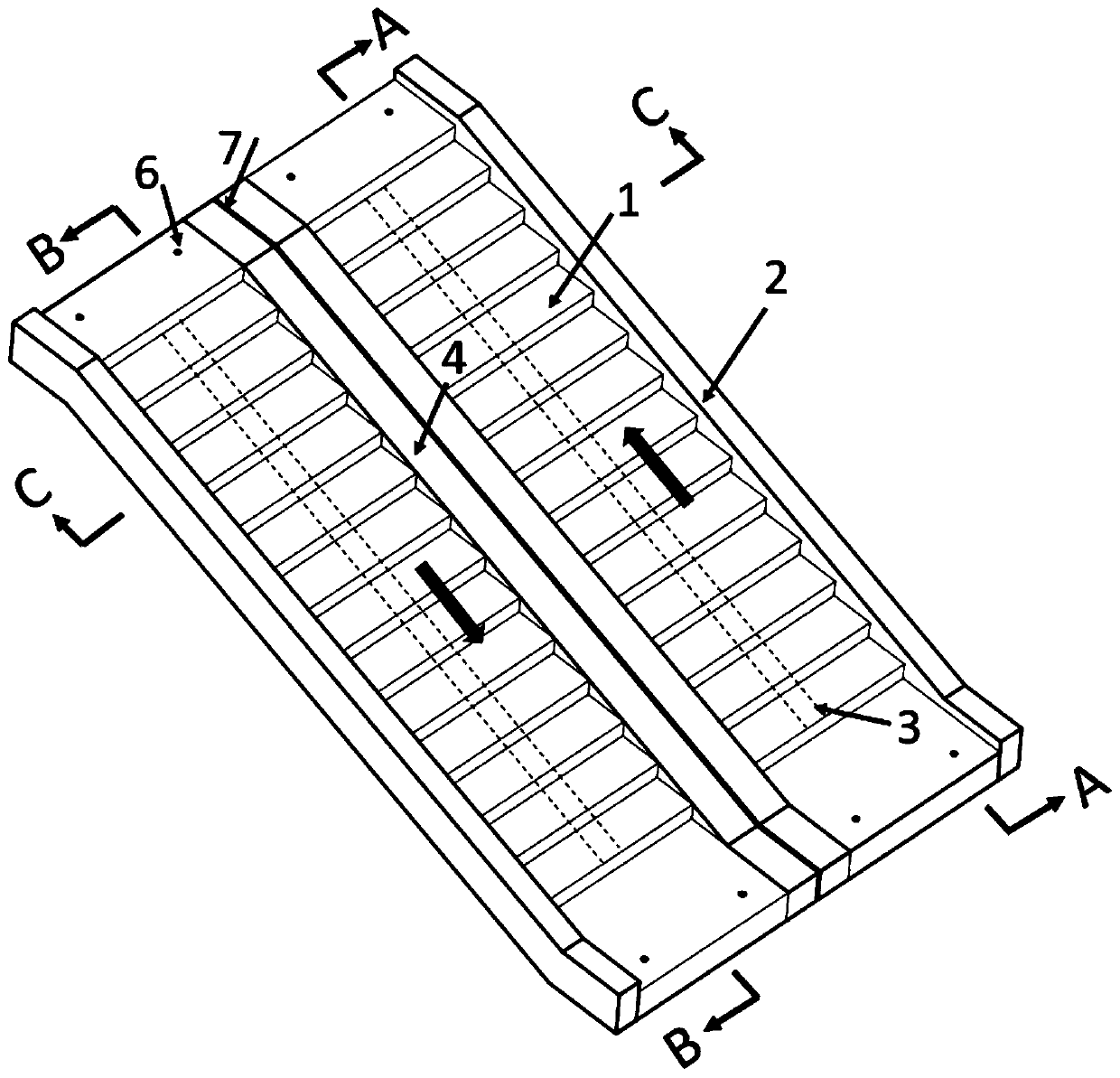

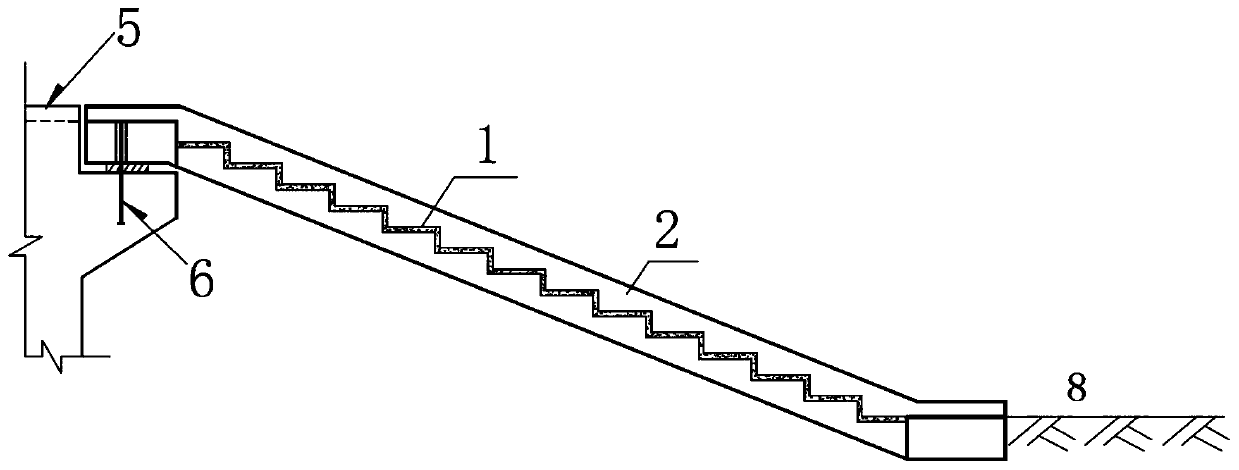

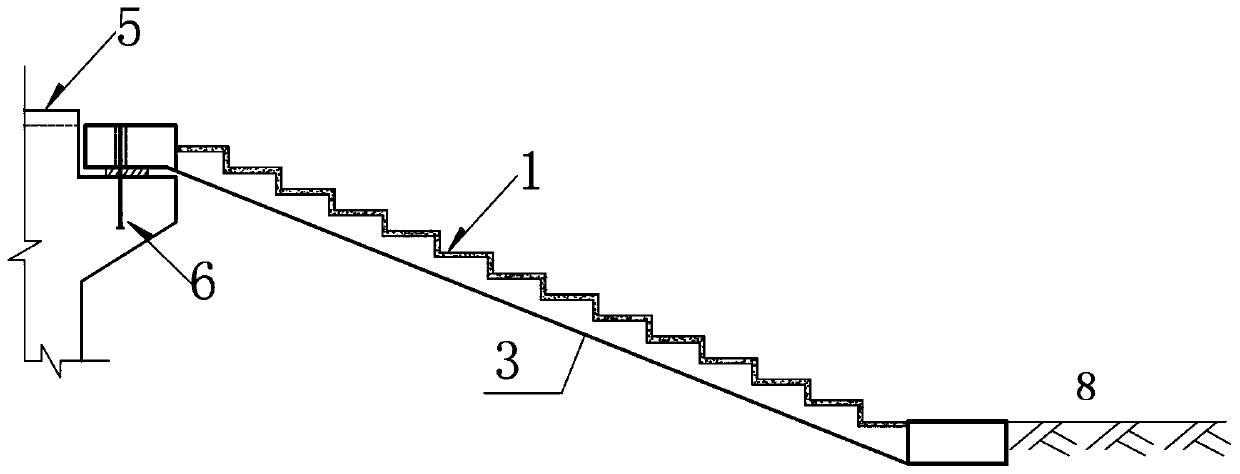

[0035] An urban prefabricated flyover staircase using UHPC includes a staircase unit; the staircase unit includes two side beams, at least one middle beam, step ladder treads, an upper platform and a lower platform. The two side beams are located on the left and right sides parallel to each other, the middle beam is located between the two side beams and parallel to the side beams, the step ladder pedal is located between the two side beams and above the center beam, the upper end of the step ladder pedal is the upper platform, and the step ladder pedal The lower end of the stair is the lower platform; the stair unit is integrally poured into a beam-slab structure through UHPC, the upper platform, the lower platform, the side beam and the middle beam are all provided with steel bars, and the step ladder treads are provided with steel mesh. After being assembled and bolted, the overpass stairs are subjected to external loads such as the self-weight of the structure and the crowd...

Embodiment approach

[0044] A method for implementing an urban prefabricated flyover staircase using UHPC, comprising the following steps:

[0045] (1) According to the size of the stair section of the real bridge, in the prefabricated factory, the formwork is supported, the reinforcement bars are bound, the reinforcement mesh of the step ladder treads is extended into the reinforcement frame of the side beam and the middle beam, and the stress steel bars of the side beam and the middle beam are connected with the upper and lower platforms. Effective anchoring, the same set of formwork is used for the ascending stairway and the descending stairway, the upper and descending stairways are prefabricated, and the materials are recycled, which meets the requirements of green construction.

[0046] (2) Pouring ultra-high performance concrete UHPC, so that the side beam, middle beam and step ladder treads are poured into an integral beam-slab structure.

[0047] (3) Maintenance of stair unit structure, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com