Coal-fired flue gas treatment method

A coal-fired flue gas and treatment method technology, which is applied in the field of coal-fired flue gas treatment and coal-fired boiler dust removal, can solve the problems of short filter bag life, heavy maintenance workload, and low purification efficiency, so as to reduce heat energy loss and step-by-step Reasonable and conducive to the effect of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

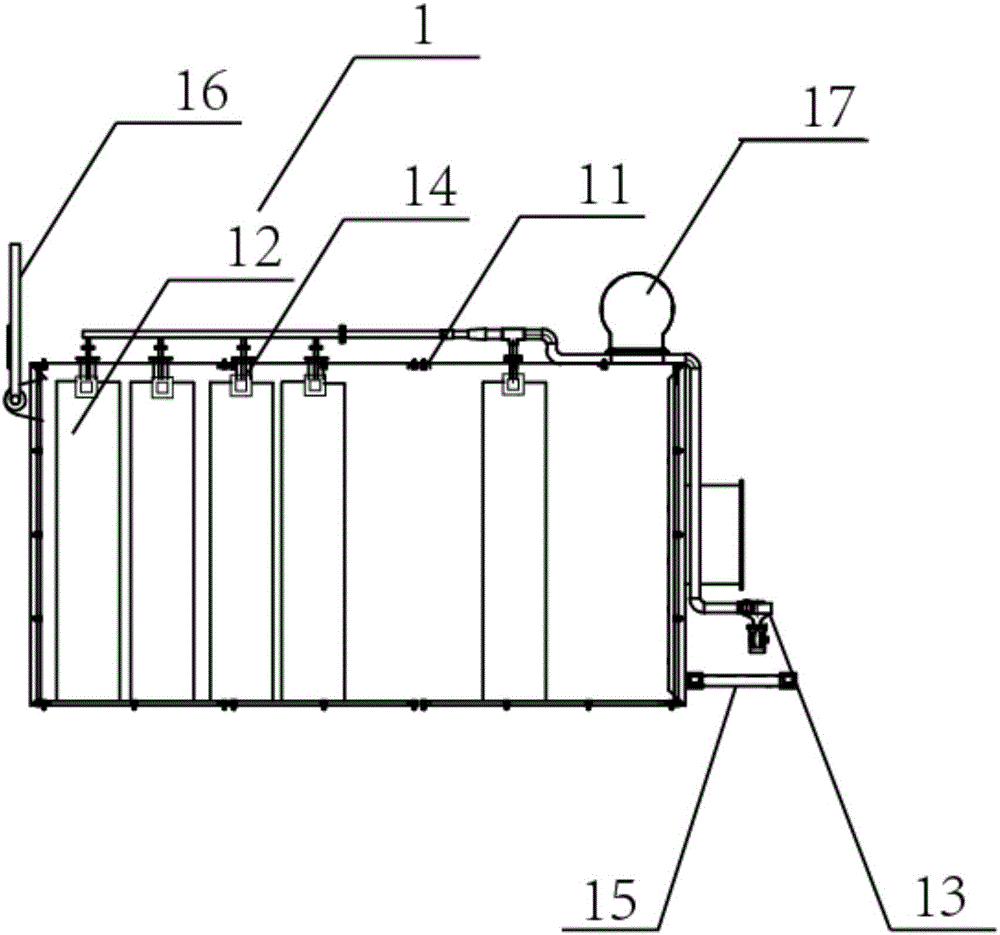

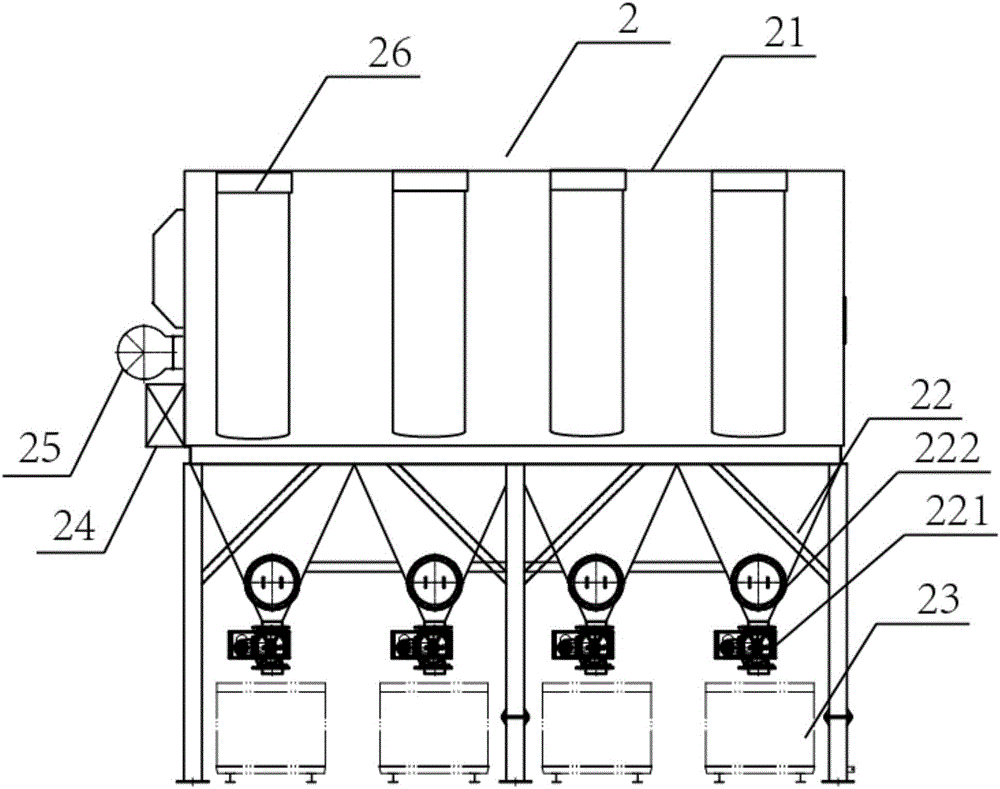

[0022]A method for treating coal-fired flue gas, comprising the following steps: the coal-fired flue gas is subjected to dust removal treatment after heat exchange; then it is discharged from the exhaust device after being treated by an adsorbent; the preparation of the adsorbent is as follows: nonylphenol polyoxyethylene Mix ether with sodium aluminosilicate, disodium hydrogen phosphate dodecahydrate, polyurea formaldehyde, and butyl acrylate, and treat at 120°C for 65 minutes to obtain a viscous fluid; bismuth nitrate pentahydrate, nickel oxide, and cetyltrimethyl chloride Ammonium chloride, diethyl phosphite, propargyl bromobutyrate, and polyvinyl butyral are mixed; after ball milling for 4 hours, put in a muffle furnace, sinter at 700-800°C for 45 minutes, and then sinter at 1100-1200°C 15 minutes; then naturally cool to obtain a porous material; immerse the porous material in methanol containing azobisisoheptanonitrile for 5 minutes; then dry to obtain a solid; pulverize t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com