Patents

Literature

159results about How to "Good biodegradability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

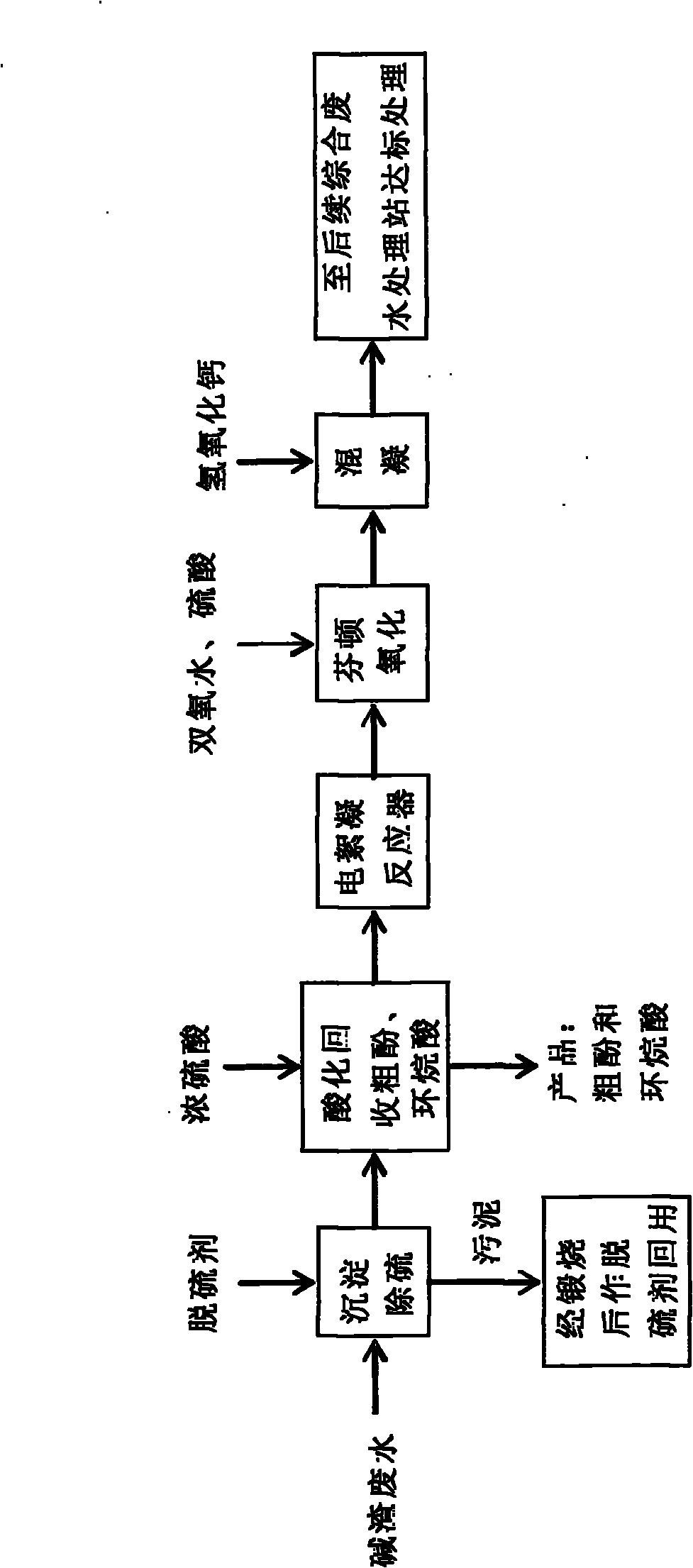

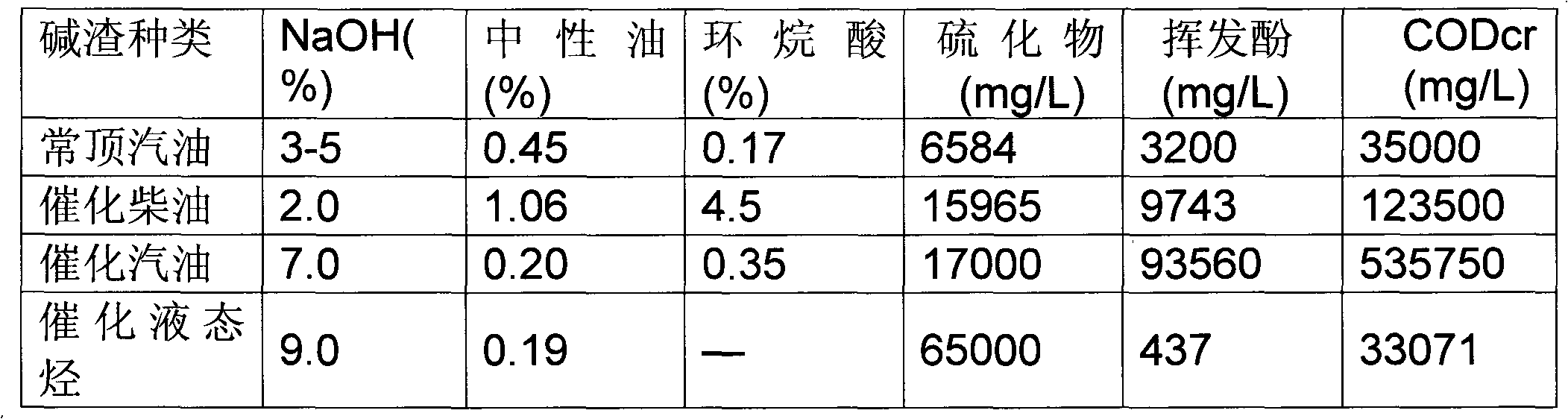

Treatment method for high-concentration sulfur-containing caustic sludge wastewater from oil refinery

InactiveCN101985379AGood biodegradabilitySimple processOrganic compound preparationMultistage water/sewage treatmentEnvironmental chemistrySulfide

The invention relates to a treatment method for high-concentration sulfur-containing caustic sludge wastewater from an oil refinery. The main process comprises precipitation, acidification, electrocoagulation and Fenton reagent oxidation. The method comprises the following steps of: adding a precipitator into the high-concentration sulfur-containing caustic sludge wastewater refined from the oil refinery so as to remove sulfide, sulfur ether, sulfur alcohol and other malodorants, greatly reduce odor of caustic residue and reduce toxicity of water body; then acidifying and recovering crude phenol and naphthenic acid; and performing oxidation treatment through an electrocoagulation-Fenton reagent so as to remove most of the polluted and nonbiodegradable organic matters from the wastewater. The limit of COD concentration and sulfur content of water inlet is improved to the greatest degree, the need of a large amount of dilution water is saved in the conventional operation process, the crude phenol and naphthenic acid in the caustic residue wastewater are effectively recovered, and no secondary pollution is produced in the operation process.

Owner:惠州TCL环境科技有限公司

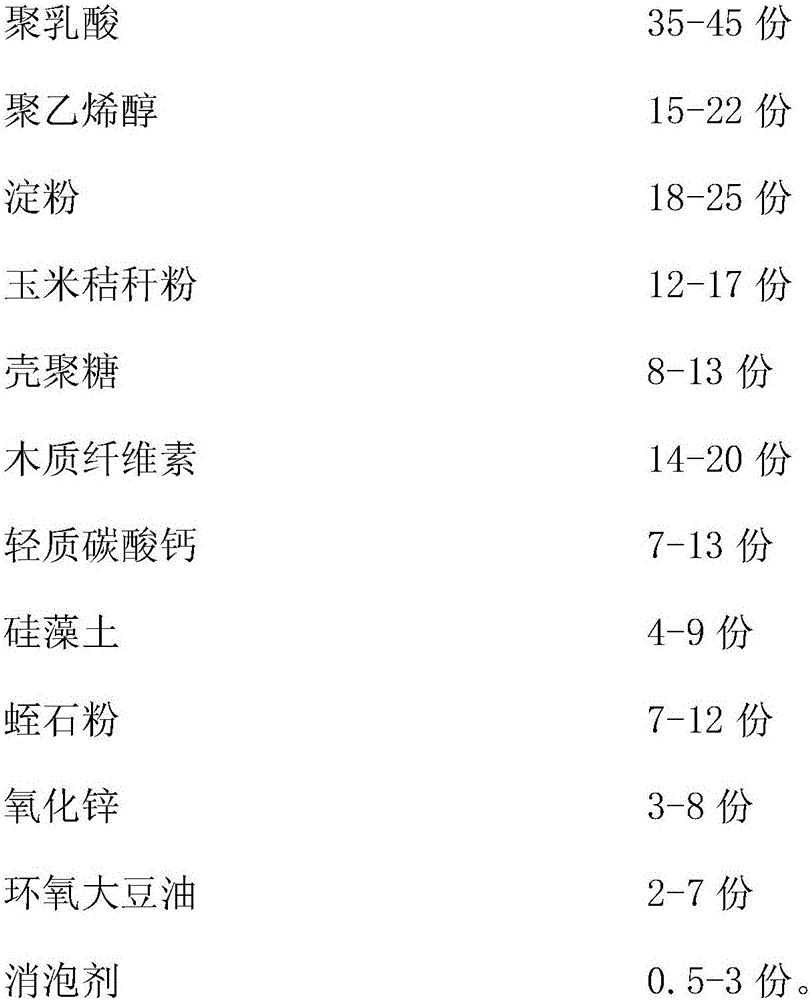

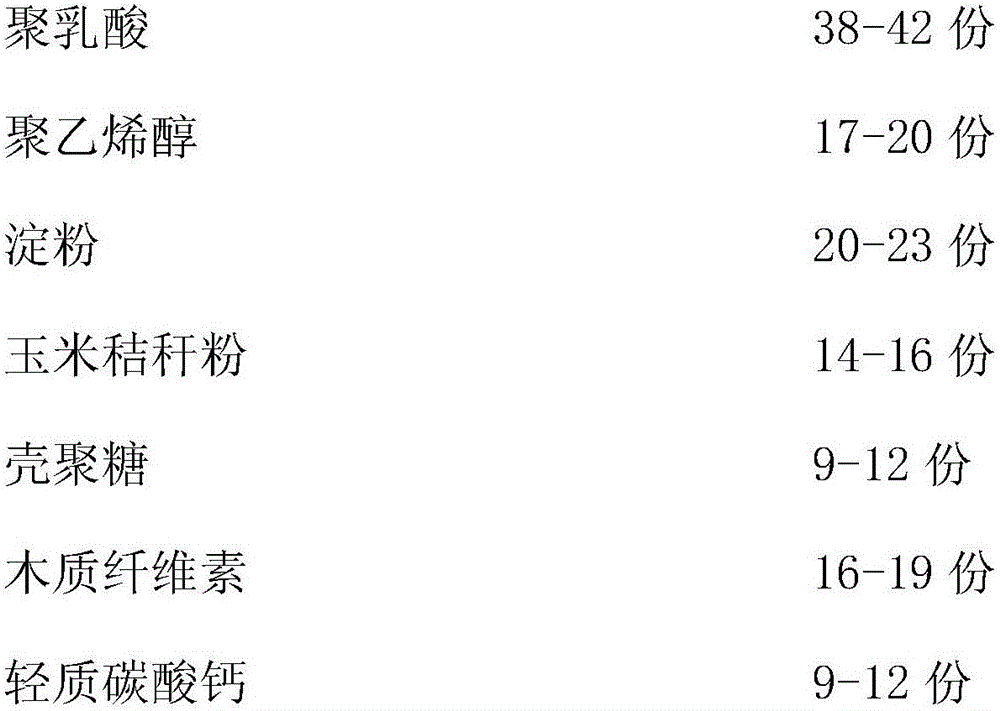

Degradable composite film and preparation method thereof

The invention relates to a degradable composite film and a preparation method thereof. The degradable composite film comprises, by weight, 35-45 parts of polylactic acid, 15-22 parts of polyvinyl alcohol, 18-25 parts of starch, 12-17 parts of corn stalk powder, 8-13 parts of chitosan, 14-20 parts of lignocelluloses, 7-13 parts of light calcium carbonate, 4-9 parts of diatomite, 7-12 parts of vermiculite powder, 3-8 parts of zinc oxide, 2-7 parts of epoxidized soybean oil and 0.5-3 parts of defoamers. The degradable composite film and the preparation method thereof have the advantages that the film is mainly prepared from the polylactic acid, and the starch, the corn stalk powder, the chitosan and the lignocelluloses are added compatibly, so that the film has high biological degradability and is safe and environment friendly, and white pollution is avoided; the zinc oxide, the diatomite and the vermiculite powder serve as activating agents, strength and tenacity of the film can be improved, and migration rate of plasticizers can be lowered; the raw materials are easy to get, the price is low, the preparation process is simple, and good economic benefit is achieved.

Owner:安徽省天乐塑业有限公司

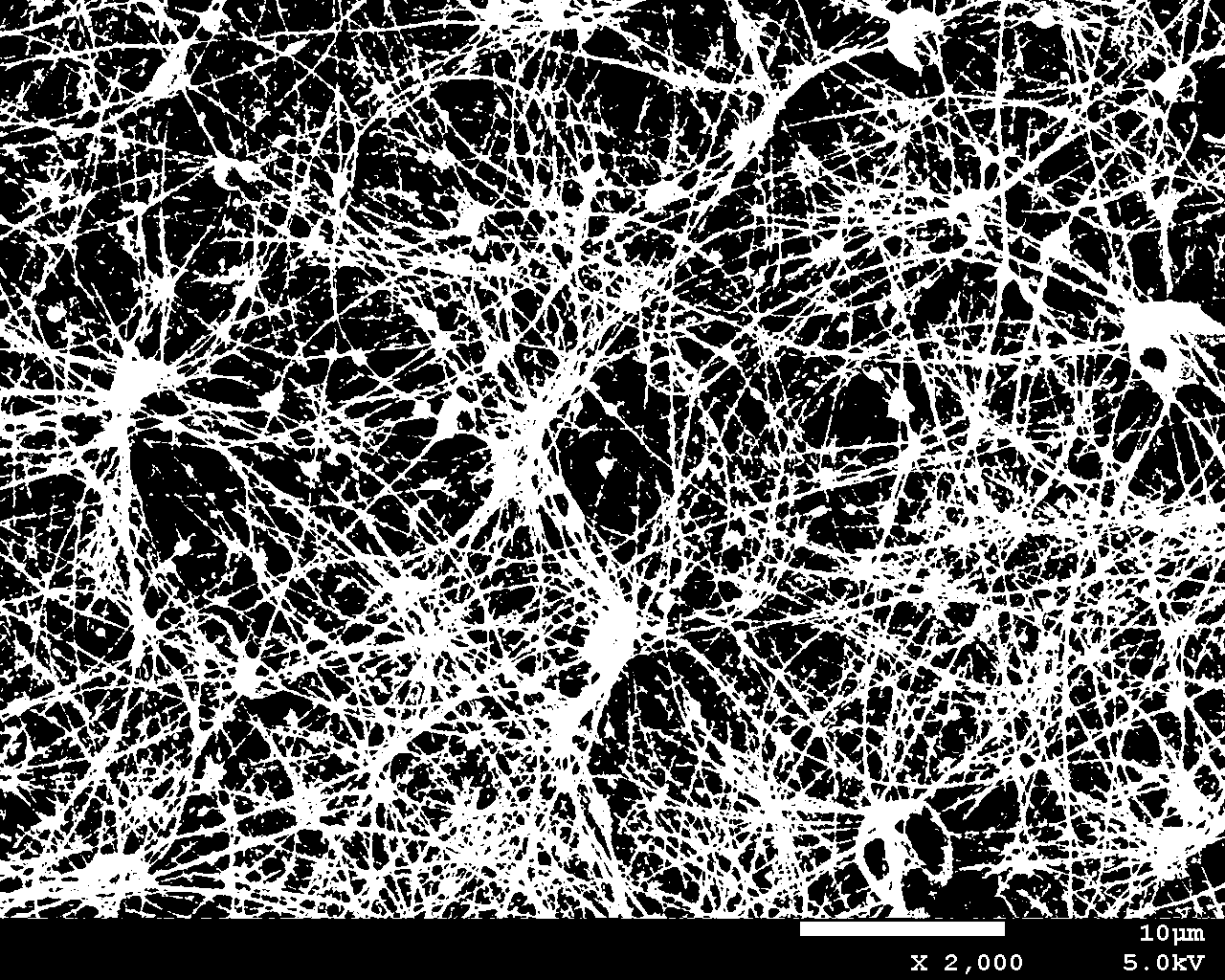

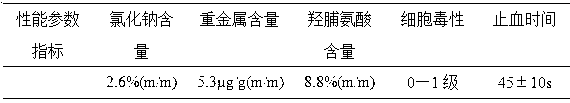

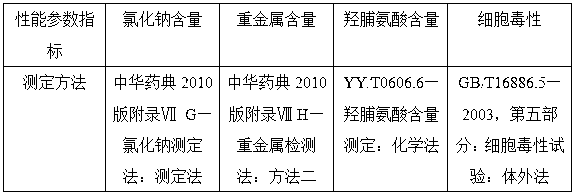

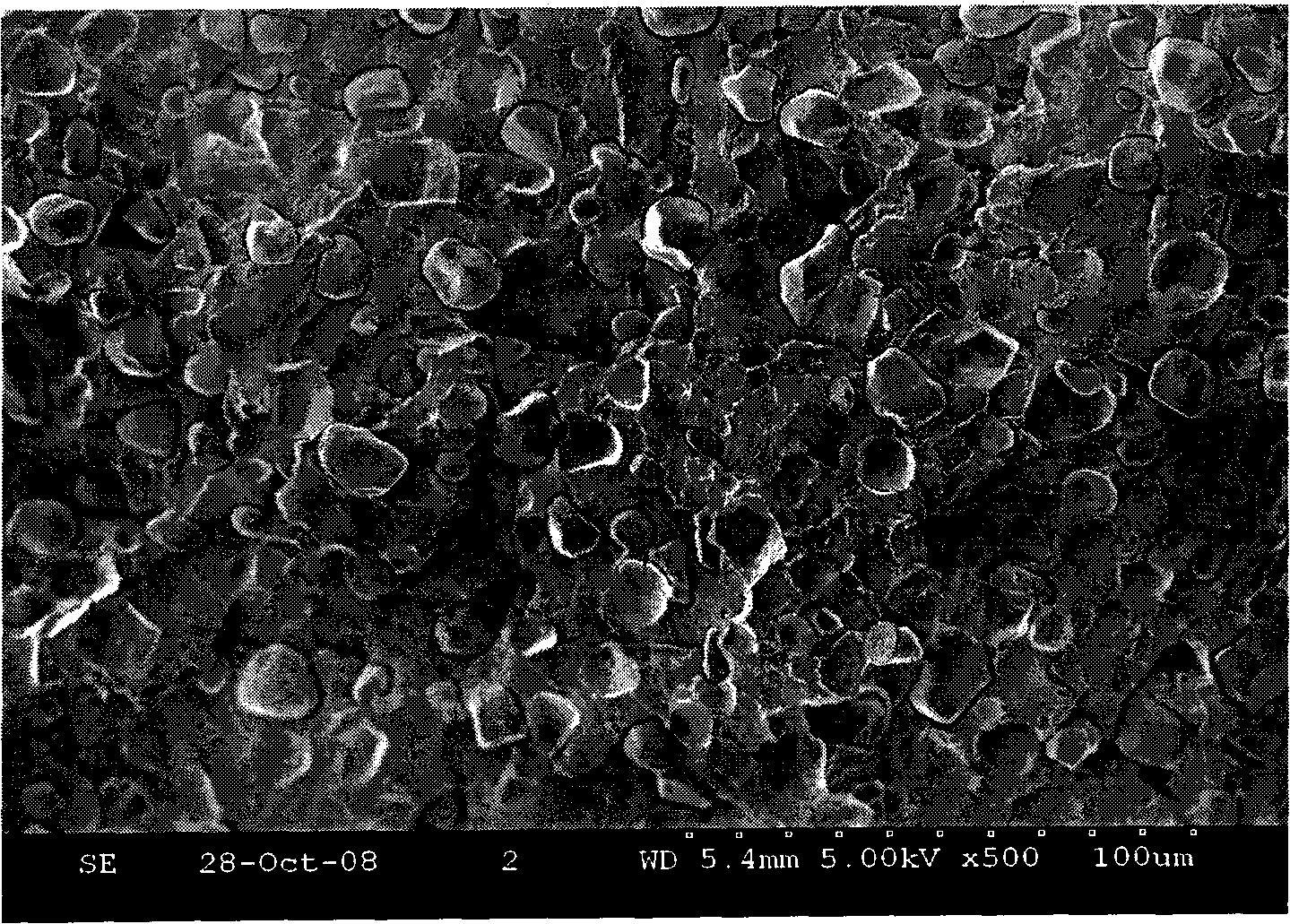

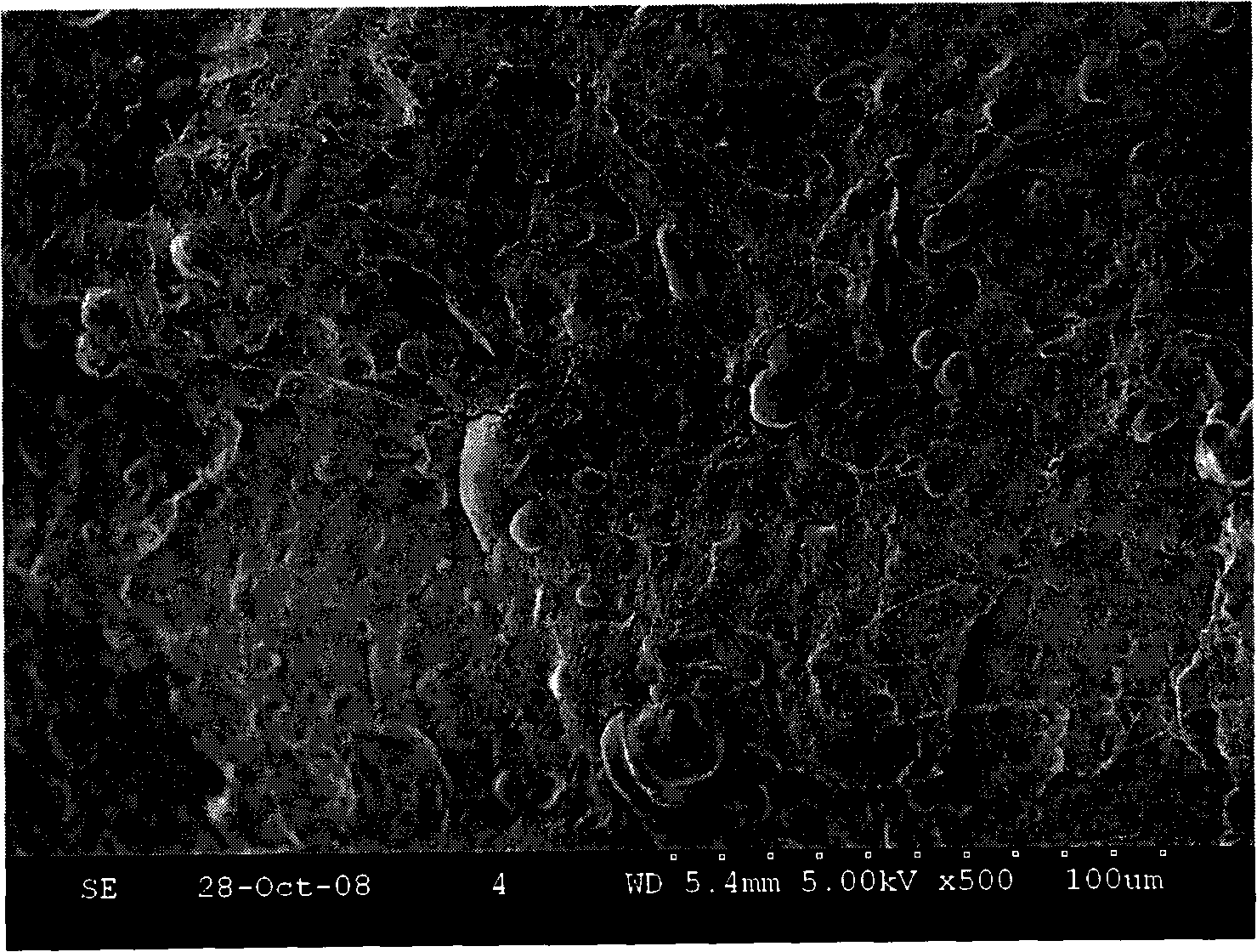

Collagen/chitosan micro-nano fiber composite hemostatic membrane material and preparation method thereof

ActiveCN103230617AGood biocompatibilityGood biodegradabilityAbsorbent padsBandagesElectrospinningAnti-inflammatory

The invention discloses a collagen / chitosan micro-nano fiber composite hemostatic membrane material and a preparation method thereof. The preparation method is characterized by comprising the following steps of: extracting a medical biological skin sheet serving as a raw material by an ultrasonic technology to prepare I type collagen; mixing hexafluoroisopropanol and acetic acid according to different volume ratios to prepare a spinning solvent; mixing the prepared I type collagen and chitosan in a certain mass ratio and adding the mixture into the spinning solvent; stirring in an ultrasonic cleaner at room temperature until the material is transparent to prepare electrostatic spinning mother liquid at the concentration of 4 to 10 percent; injecting the electrostatic spinning mother liquid into an electrostatic spinning machine and performing electrostatic spinning to obtain a collagen / chitosan micro-nano fiber composite membrane; soaking the collagen / chitosan micro-nano fiber composite membrane into natural biomacromolecules and Chinese herbal medicines sequentially; and freeze-drying to obtain the collagen / chitosan micro-nano fiber composite hemostatic membrane material. The collagen / chitosan micro-nano fiber composite hemostatic membrane material has excellent biocompatibility, biodegradability, adhesion property and the like, can quickly stop bleeding, resist inflammation, ease pain and promote wound healing, and can be applied to trauma hemostasis and repair and general civil hemostasis emergency treatment.

Owner:SICHUAN UNIV

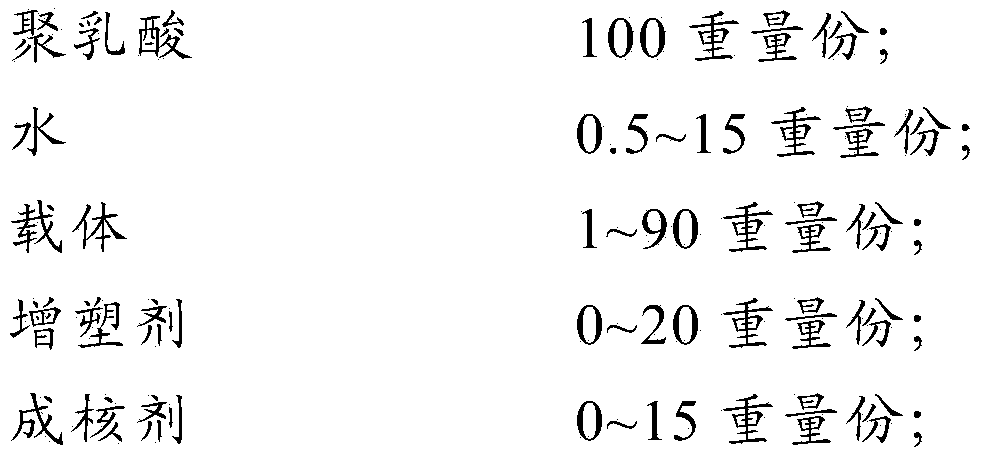

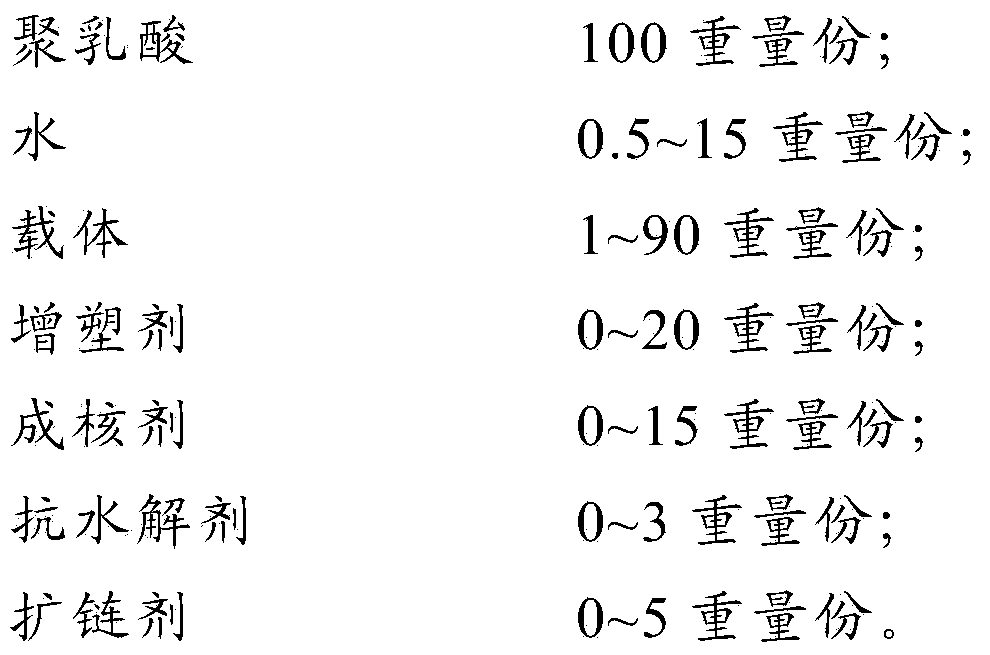

Polylactic acid foam material and preparation method thereof

ActiveCN103642185AGood biodegradabilityThe preparation process is safe and environmentally friendlyPlasticizerPolylactic acid

The invention provides a polylactic acid foam material, which is obtained by foaming of a mixture. The mixture comprises by weight 100 parts of polylactic acid, 0.5-15 parts of water, 1-90 parts of a carrier, 0-20 parts of a plasticizer, 0-15 parts of a nucleating agent, 0-3 parts of an anti-hydrolysis agent and 0-5 parts of a chain extender. The polylactic acid foam material in the application uses water as a foaming agent rather than an organic foaming agent, so that the foaming of polylactic acid is safe and environment-friendly. The application uses polylactic acid as a matrix for the foam material to endow the foam material with good biodegradability, thus realizing biodegradation of the polylactic acid foam material. The application also provides a reparation method of the polylactic acid foam material.

Owner:天津佰盛环保科技有限公司

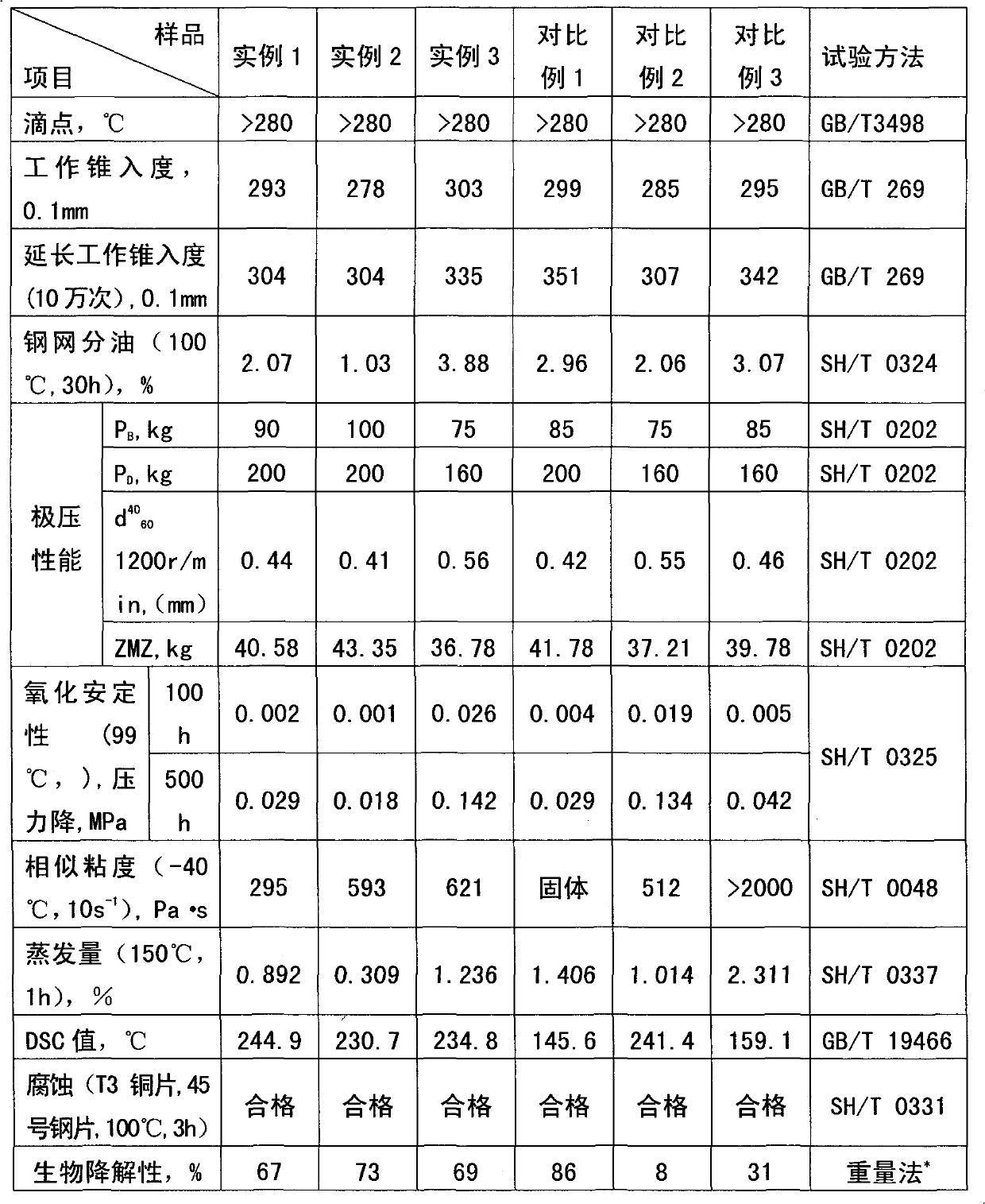

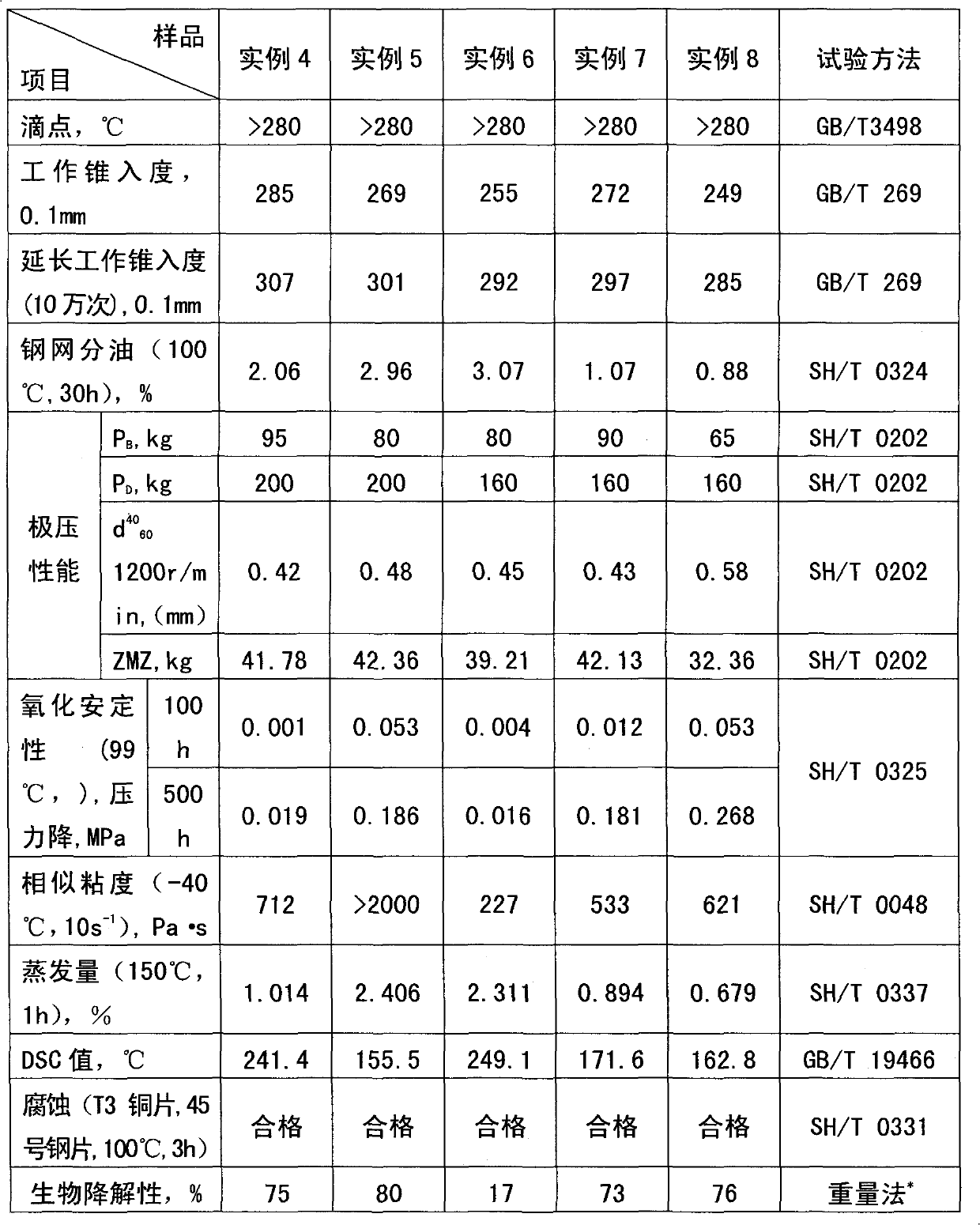

Environmental protection type lubricating grease composition and method for preparing same

ActiveCN102199471AWide high and low temperature adaptabilityGood biodegradabilityLubricant compositionChemistryAntioxidant

The invention provides an environmental protection type lubricating grease composition. The composition comprises basic grease and an additive, wherein the basic grease comprises the following ingredients in percentage by weight: 60 to 95 percent of basic oil and 5 to 40 percent of composite lithium soap thickener; and the additive comprises the following ingredients based on the 100 weight percent of the basic oil: 0.05 to 2 percent of antioxidant, 0.5 to 10 percent of extreme pressure anti-wear agent and 0.1 to 2 percent of anti-rusting agent. The environmental protection type lubricating grease composition has high high-low temperature adaptability, high biodegradability, excellent an anti-oxidation, shear resistance and extreme pressure wear resistance and high anti-rusting property and corrosion inhibition, and is suitable to be used as the lubricating grease for bearings of electromotors of rail locomotives.

Owner:CHINA PETROLEUM & CHEM CORP +1

Adsorbable internal fixing material for bone fracture and its preparing process

An absorbable internal fixing material for bone fracture is prepared from polylactic acid (50-90 wt.%), tricalcium phosphate (1-40 wt.%) and hydroxylapatitie (1-40 wt.%) through mixing then and then hot die pressing at 80-1230 deg.C and under 0.11-25 MPa or hot extruding at 80-230 deg.c. The granulality of hydroxylapatite and tricalcium phosphate is less than 100 microns. Its advantages are high strength, high strength, high X-ray visualization and high biocompatibility.

Owner:SOUTHEAST UNIV

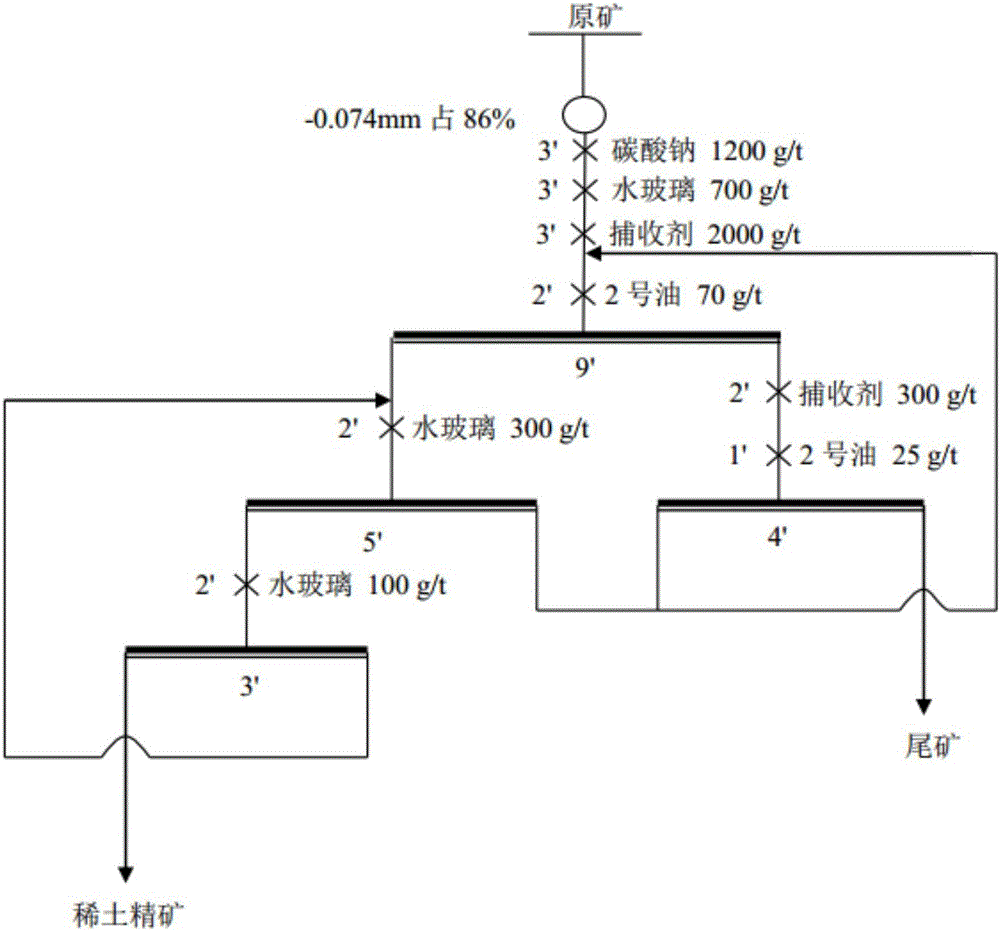

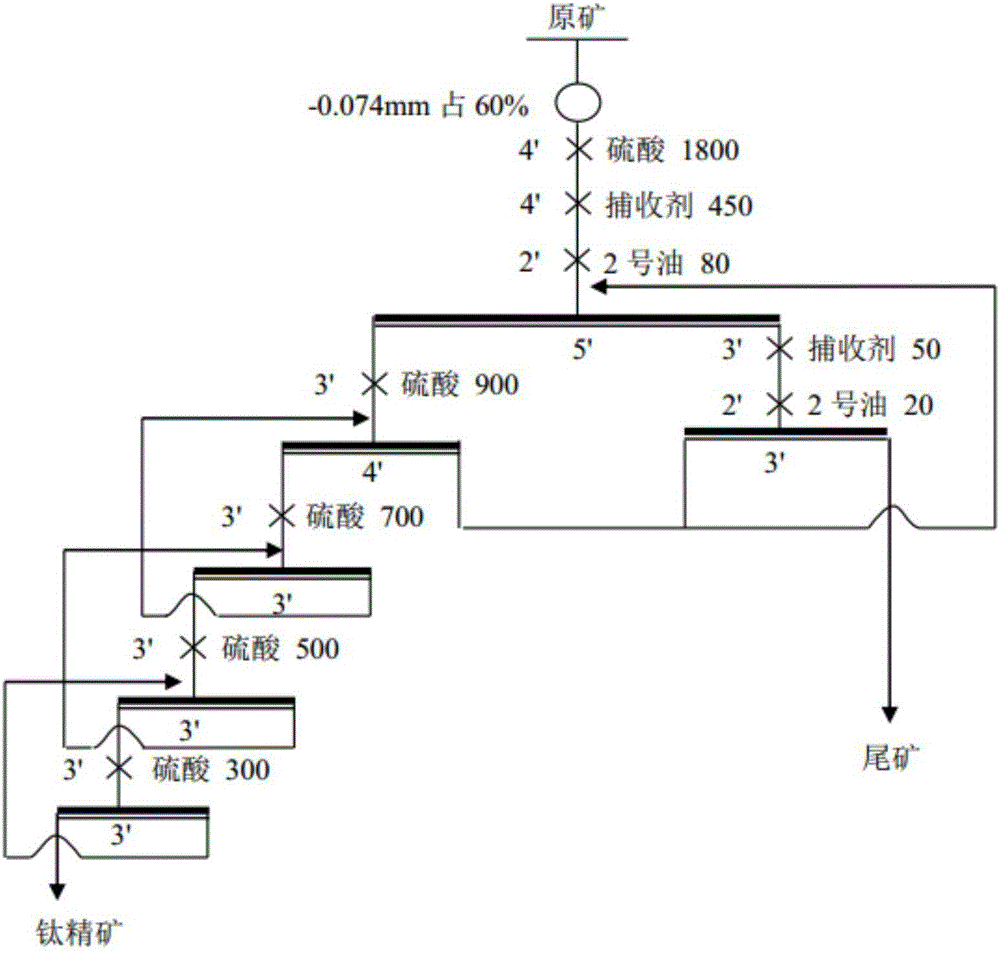

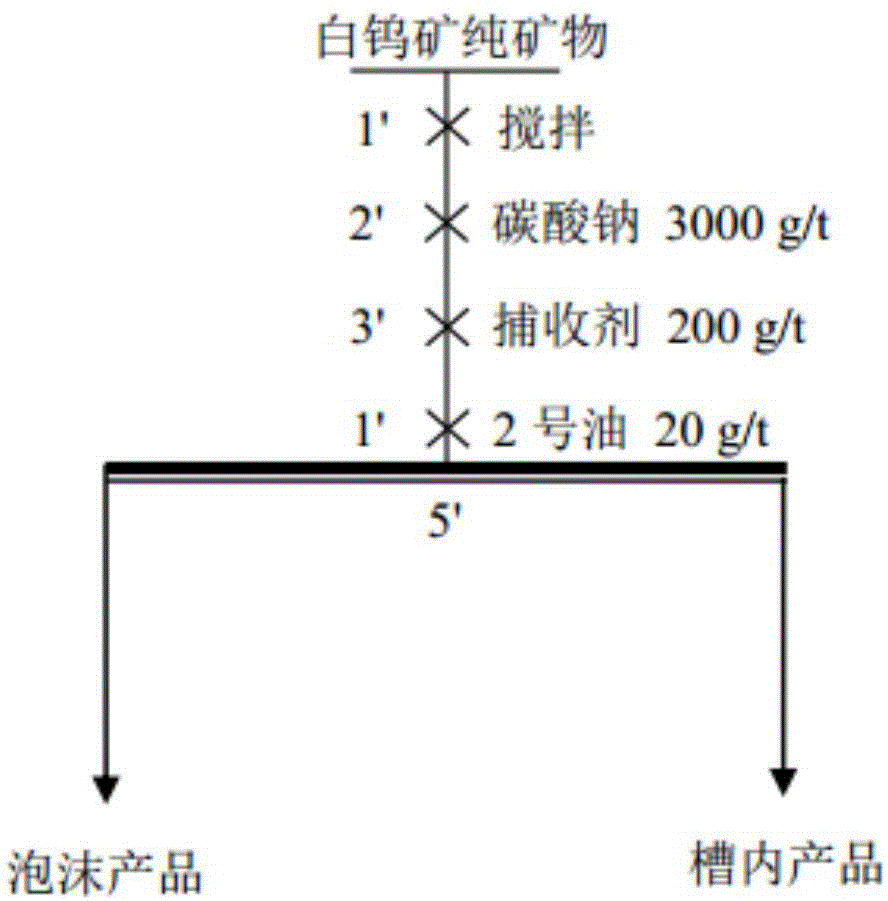

Application method of ester-based hydroximic acid collecting agent to mineral flotation

The invention provides an application method of an ester-based hydroximic acid collecting agent to mineral flotation, and belongs to the technical field of mineral flotation. The structure of the ester-based hydroximic acid collecting agent is shown in the formula I shown in the specification, wherein in the formula I, R is a C1-C17 alkane base or C2-C17 alkylene. Due to the fact that the molecule of the ester-based hydroximic acid collecting agent contains an ester base and a hydroximic acid base, more ligating atoms and more coordinating groups are obtained, through chelation and metal ions, the more stable complex compound can be formed or strong adsorption is formed on the surfaces of metal oxide minerals, and floatation recycling of rare earth ores, titanic iron ores, scheelite, wolframite, scheelite and wolframite mixture ores or tin ores ca be strengthened; compared with an existing hydroximic acid collecting agent, due to the fact that the ester base exists in the molecule, the beneficial effects of being good in biodegradability, small in poisonousness and friendly to the environment are achieved.

Owner:JIANGXI UNIV OF SCI & TECH

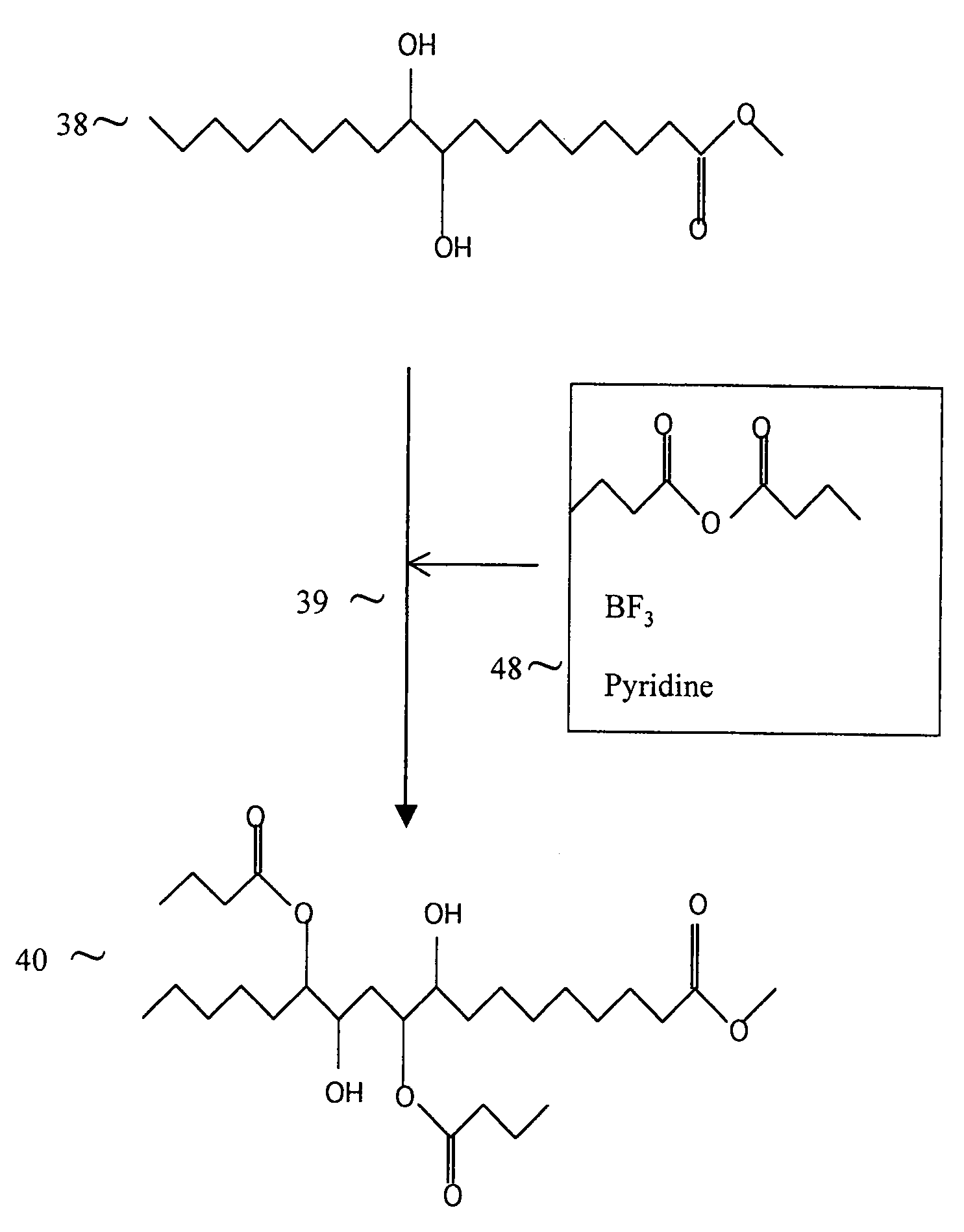

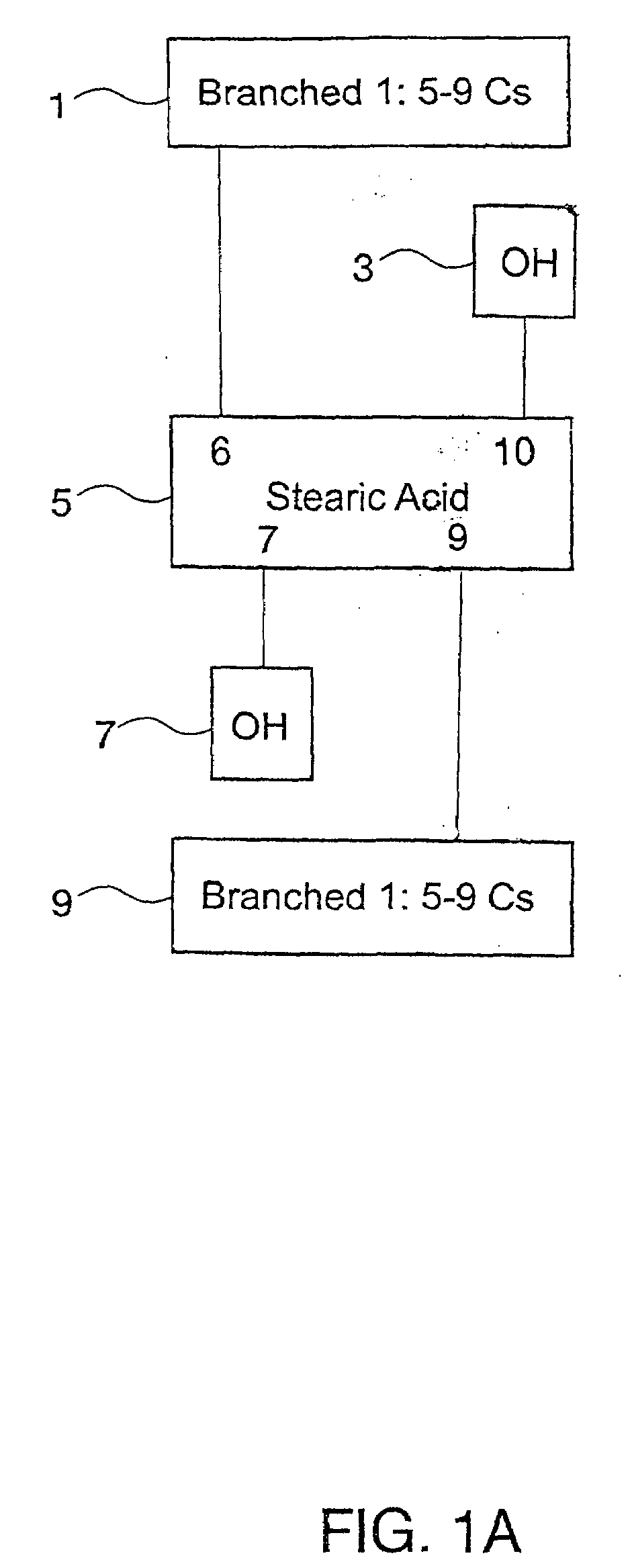

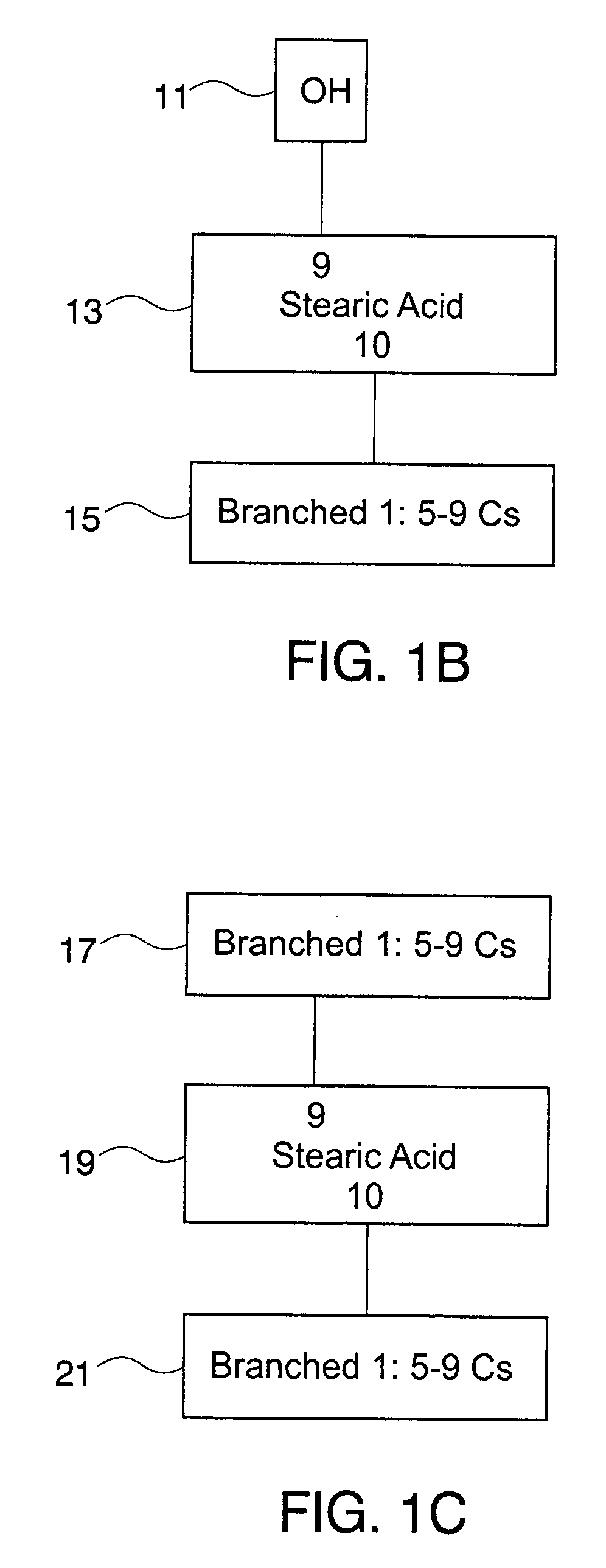

Synthesizing and compounding molecules from and with plant oils to improve low temperature behavior of plant oils as fuels, oils and lubricants

InactiveUS20080227993A1Good biodegradabilityLow ecotoxicityFatty acid esterificationOrganic compound preparationViscosity indexVegetable oil

The present invention is a method for making a class of molecules synthesized from unsaturated plant oils, and the synthesized class of molecules, such that when compounded with saturated plant oils they improve the physical properties such as low temperature behavior, measured as cold filter plug point and cloud point for biodiesel fuels and pour point for oils and lubricants, as well as other physical properties including viscosity and viscosity index, so that the physical properties of the combined materials approach the physical properties of unsaturated plant oils and find use as base material feed stocks for “Green” fuel, oil, and lubricant products.

Owner:ZUCKERMAN MATTHEW MARK

Biodegradable composition and method of producing the same

InactiveUS20020061583A1Good biodegradabilityAdd to effectFungiDyeing processBiodegradable plasticFertilizer

Disclosed is a biodegradable composition characterized by compounding yeast (A) and biodegradable plastic (B) at a particular proportion. The purpose is to provide a biodegradable composition having very good biodegradability and additional fertilizer effect, making good use of the characteristics of yeast.

Owner:NIPPON PAPER IND CO LTD

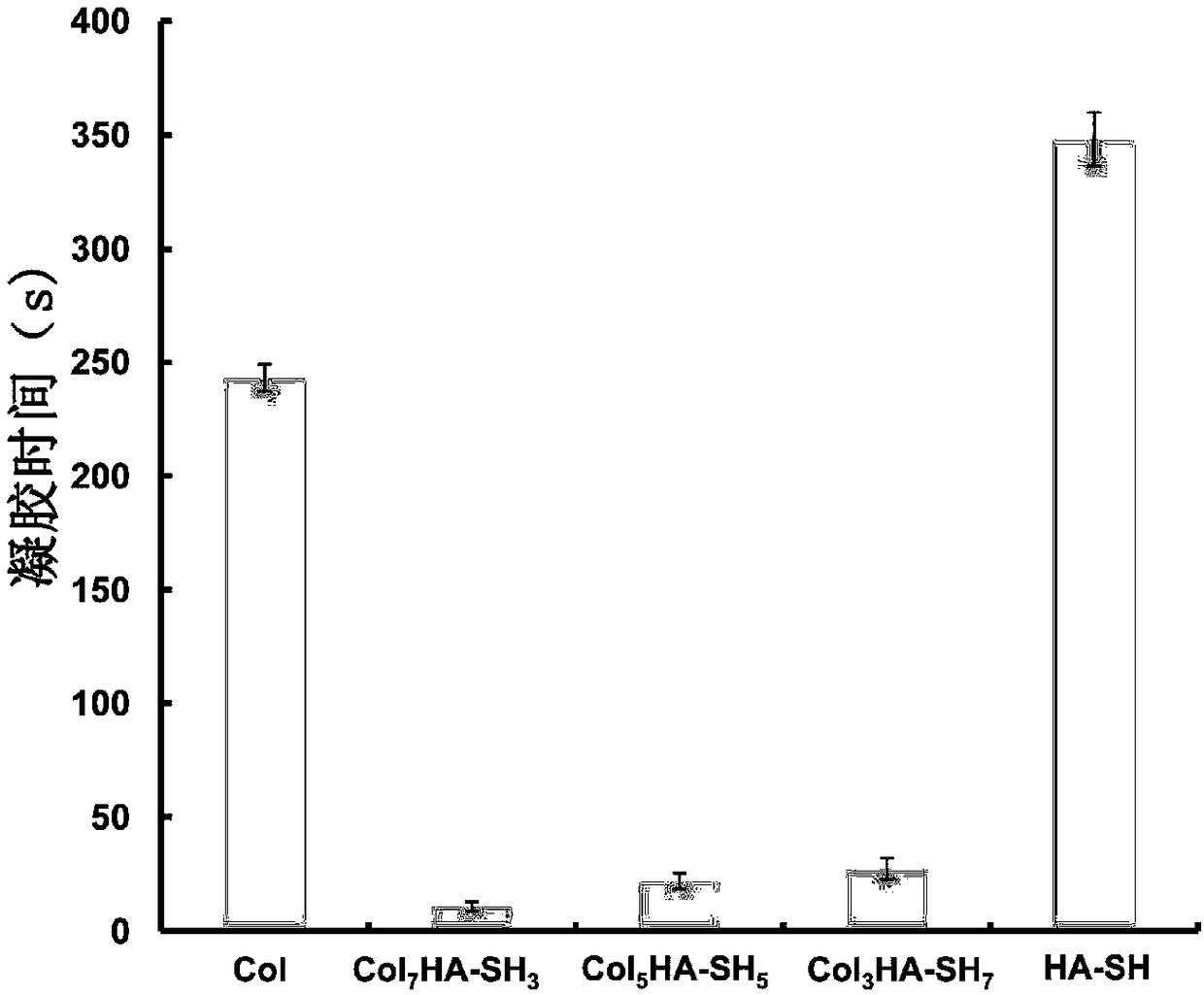

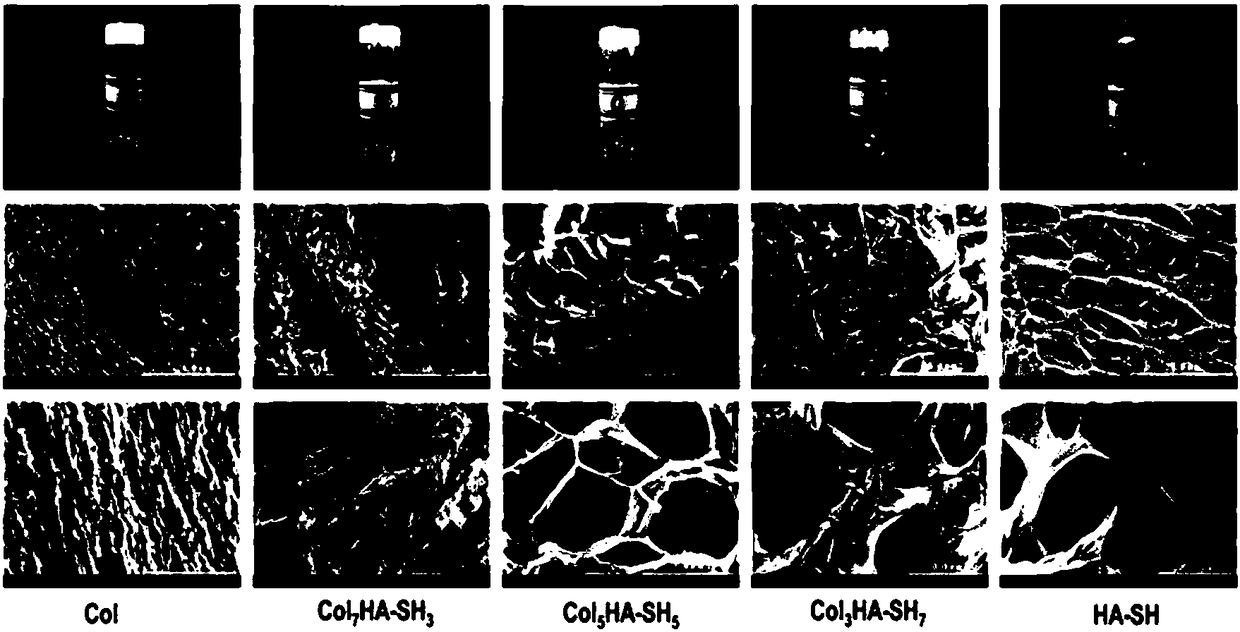

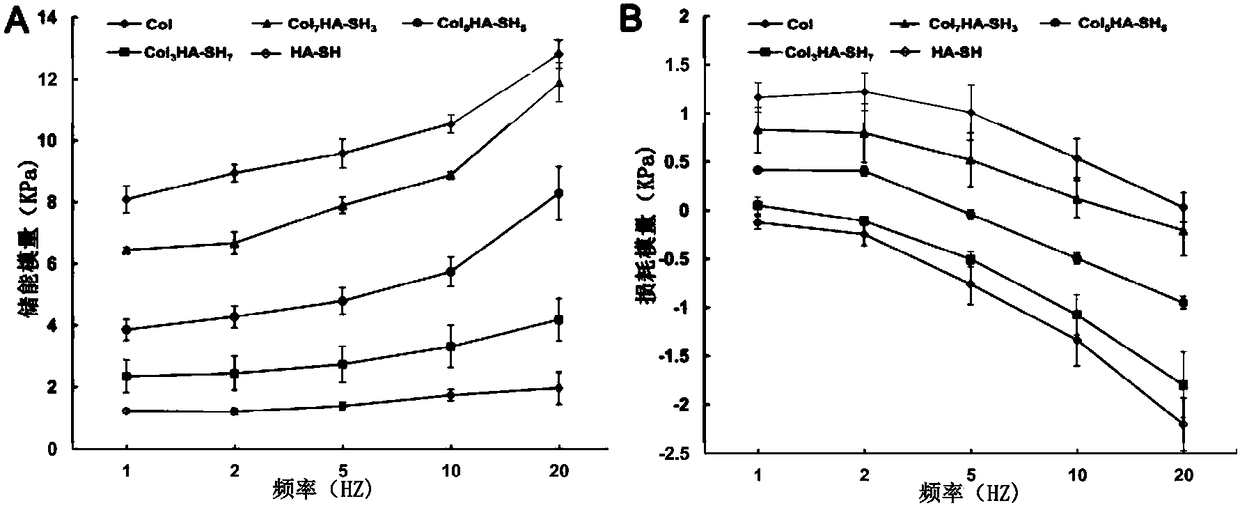

Controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as preparation method and application thereof

ActiveCN108084461AGood biocompatibilityGood biodegradabilityPharmaceutical delivery mechanismTissue regenerationCell adhesionChemistry

The invention provides controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as a preparation method therefore. The composite hydrogel is prepared from hyaluronic acid hydrogel and I-type collagen or II-type collagen; the I-type collagen or II-type collagen is distributed in a three-dimensional crosslinking network structure. The composite hydrogel has rigidity and elasticity, is high in mechanical property, can promote spreading growth of cartilage cells, is favorable for phenotype maintaining for cells, can relieve the shortcomings that an existinggel material for cartilage reparation is easy to shrink and low in cell adhesion, and has an important application value in the field of cartilage injury reparation.

Owner:SICHUAN UNIV

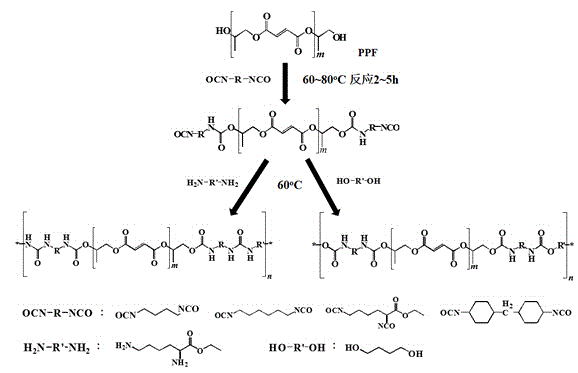

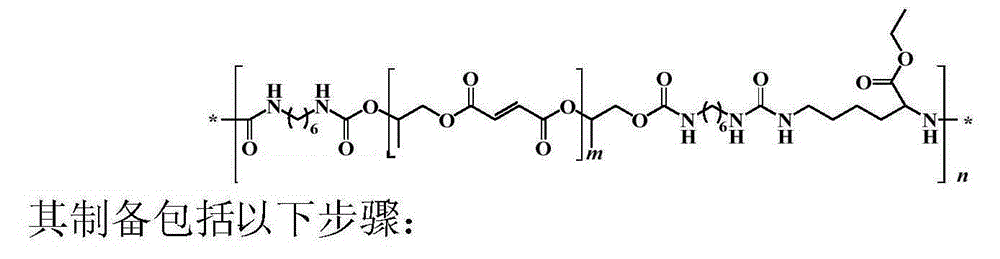

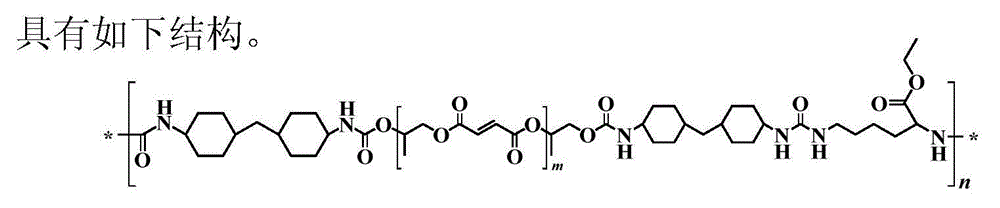

Biodegradable unsaturated polyurethane material and preparation method thereof

The invention discloses a biodegradable unsaturated polyurethane material comprising a soft segment and a hard segment, wherein the soft segment comprises unsaturated polyester polyol polypropylene fumarate, and the hard segment comprises saturated aliphatic isocyanate and a small molecule glycol chain extender or a small molecule diamine chain extender. The material is prepared by taking polypropylene fumarate as large molecule dihydric alcohol, saturated aliphatic isocyanate as a raw material and small molecule glycol or small molecule diamine as a chain extender, and adopting a two-step chain extension method. The polyurethane elastomer namely the biodegradable unsaturated polyurethane material prepared by the preparation method disclosed by the invention has biodegradability, the material and a degradation product are harmless to human bodies, and the material has good biocompatibility. A polyurethane main chain structure comprises a lot of unsaturated electron-deficient double bonds to facilitate further modification of the material, and the material has a good application prospect.

Owner:ZHEJIANG UNIV

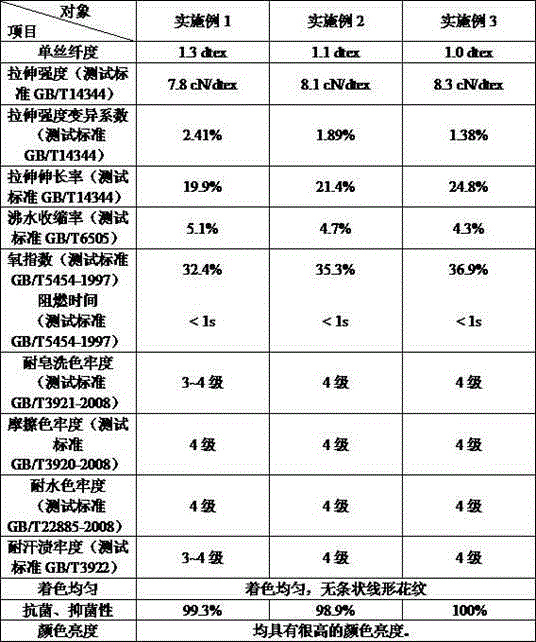

Preparation method of colorful polyester fiber

ActiveCN105200551ASpinnability improvementImprove flame retardant performancePigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to the technical field of a chemical fiber textile flame-retardant material, particularly to a preparation process of a colorful polyester fiber. The preparation process comprises the following steps: drying, grinding, mixing, melting, spinning, after-processing and shaping raw materials to obtain a finished product. The colorful polyester fiber prepared by adopting the process has good spinning property, good flame-retardant effect, high decomposition temperature, good heat stability and excellent dyeing property; the color is brighter compared with the ordinary dyeing fiber, and the color fastness is high.

Owner:JIEDONG PARIS WANZHU SHAHUA TEXTILES CO LTD

Cleaning agent for silicon materials and method for cleaning silicon materials

InactiveCN102010797AGood biodegradabilityMeet cleaning requirementsInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIonTriethanolamine

The invention discloses formulas of a cleaning agent SEH-1, a cleaning agent SHE-2 and a cleaning agent SHE-3, wherein the cleaning agent SEH-1 comprises the following components in parts by weight: 5-25 parts of fatty alcohol polyoxyethylene ether, 3-15 parts of alkyl phenyl polyoxyethylene ether, 2-8 parts of alkylolamide, 0.5-7 parts of ethylene glycol alkyl ether, 0.1-5 parts of chelating agent, 5-10 parts of chloracid, 0.5-5 parts of H2O2 (hydrogen peroxide) and the balance of deionized water, and the total number of parts is 100; the cleaning agent SHE-2 comprises the following components in parts by weight: 4-15 parts of coconut oil alkyl amide phosphate, 3-15 parts of triethanolamine oleic soap, 1-5 parts of triethanolamine, 0.1-5 parts of aminotriacetic acid, 1-5 parts of potassium hydroxide and the balance of the deionized water, and the total number of parts is 100; and the cleaning agent SHE-3 comprises the following components in parts by weight: 5-10 parts of acetic acid, 0.5-10 parts of citric acid, 0.1-5 parts of sorbitol and the balance of the deionized water, and the total number of parts is 100. The invention further discloses a method for cleaning silicon materials by utilizing the three cleaning agents. The method is completely in line with the cleaning requirement for production of solar grade single crystal silicon and does not pollute the environment.

Owner:LONGI GREEN ENERGY TECH CO LTD

Cleaning agent for machinery for food industry

InactiveCN1970713AGood biodegradabilityLow application costNon-ionic surface-active compoundsOther dairy technologyAdjuvantPOLYOXYETHYLENE ETHER

The invention discloses a food mechanic abluent of on-site food machine and pipe line, which comprises the following parts: 1-8% at least one component of proteinase, lipase or amylase, alkyl glycoside as surface activator, food-grade C12-C18, water loss sorbitol acid grease, polyoxyethylene water loss sorbitol acid grease, 0.5-1% at least one component of polyglycerol fatty acid ester or geoceric acid polyoxyethylene ester, 10-75% at least one component or two components of sodium carbonate or sodium hydrogen carbonate of alkali adjuvant.

Owner:沈阳宏迪科技有限公司

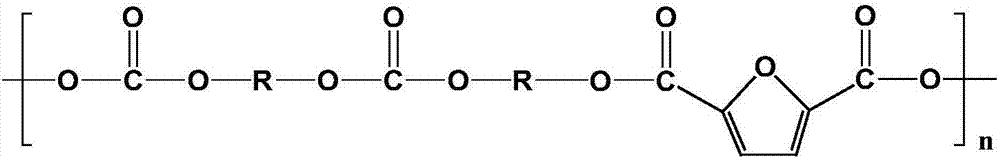

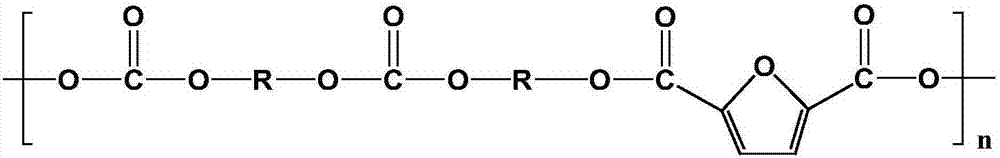

Aliphatic polycarbonate copolyester and preparation method thereof

ActiveCN107474229AImproved thermodynamic properties and processabilityShorten transesterification reaction timeCarbonic acidGlass transition

The invention discloses a high molecular weight aliphatic polycarbonate copolyester and a preparation method thereof, and relates to a multi-step ester exchange reaction and a high-temperature high-vacuum polycondensation reaction of aliphatic polyhydric alcohols, 2,5-furandicarboxylic acid and carbonic acid aryl esters. The ester exchange reaction and the polycondensation reaction are implemented continuously, so that the ester exchange reaction time is shortened, the equipment utilization rate is improved, no extra catalyst is needed before polycondensation, and thus the experiment steps are simplified. According to the copolyester disclosed by the invention, furandicarboxylic acid polyester structure units or chain segments are introduced into aliphatic polycarbonate main chains, so that the copolyester has the biodegradation of the aliphatic polycarbonate and excellent thermodynamic and processing proprieties of the furandicarboxylic acid polyester simultaneously, defects that the aliphatic polycarbonate is low in glass-transition temperature, low in melting temperature, low in crystallization temperature and the like are overcome, and requirements of different industries are met.

Owner:CHANGZHOU INST OF CHEM

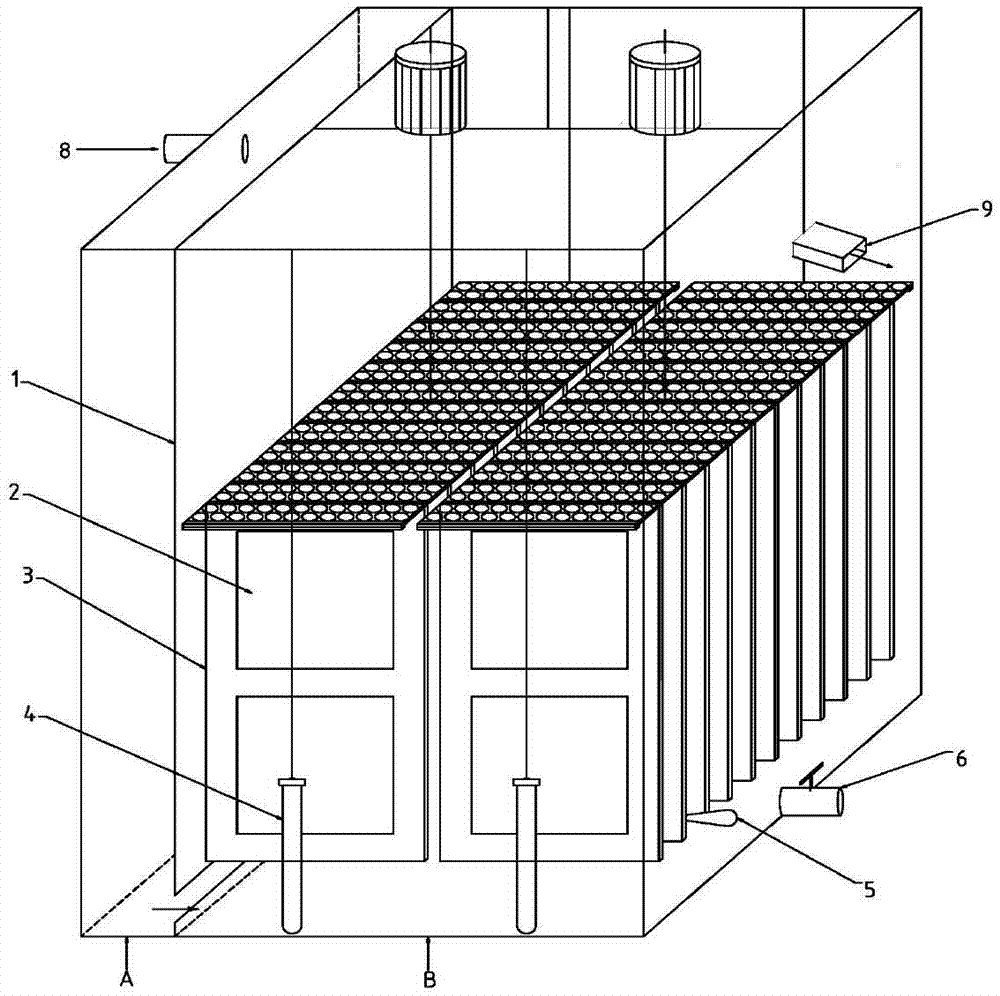

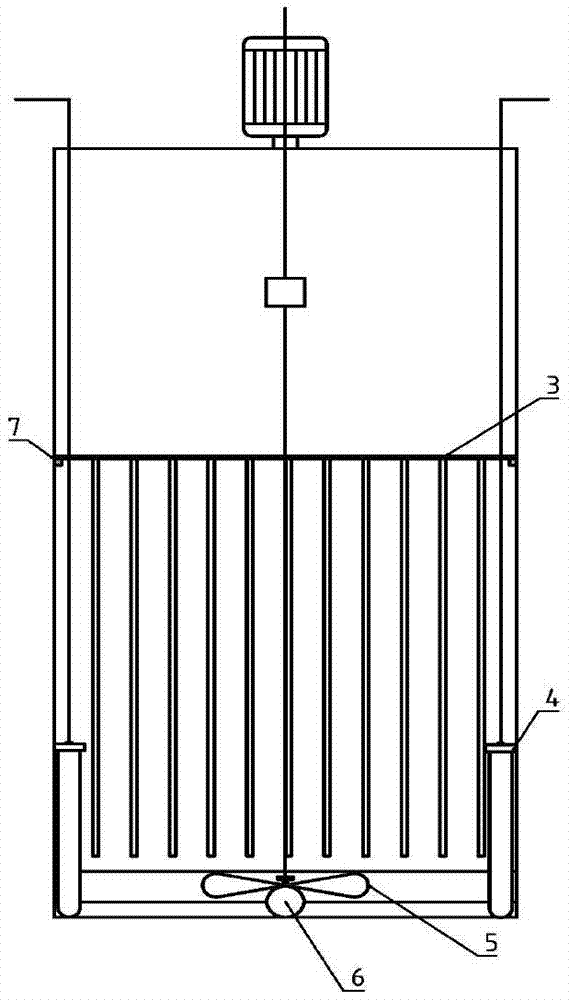

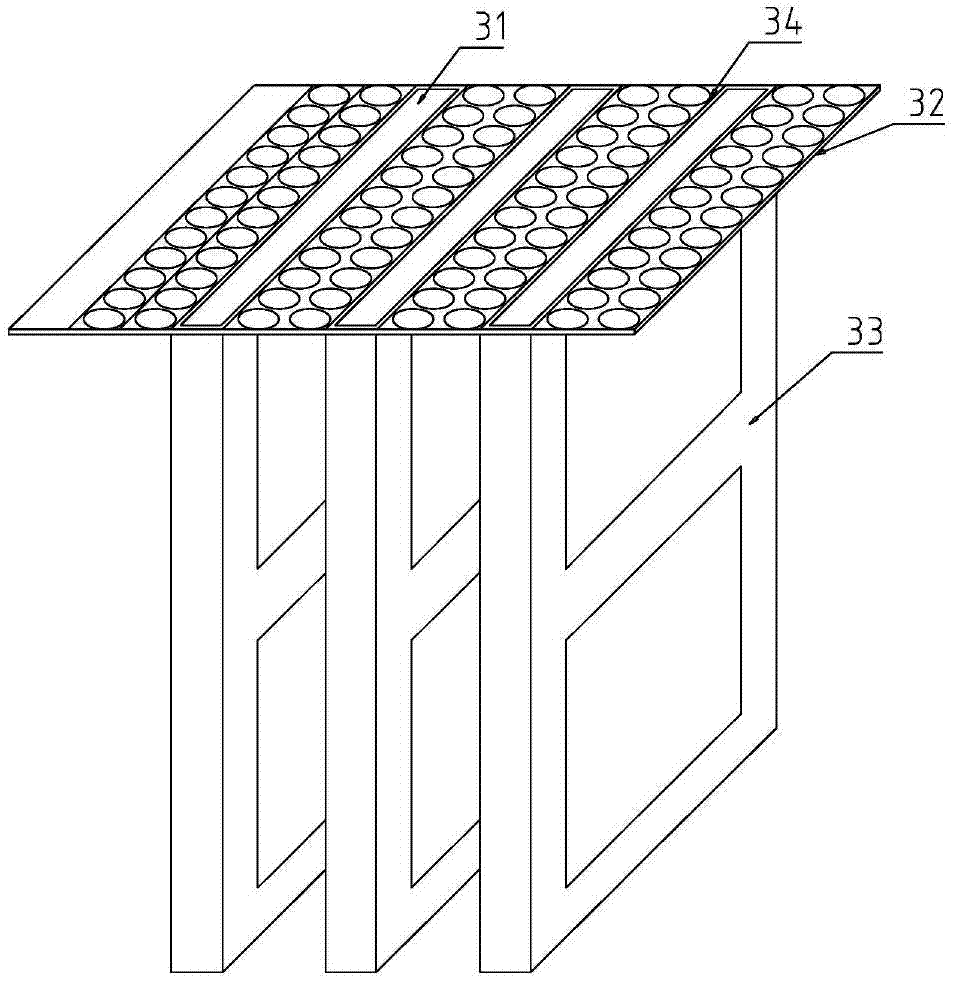

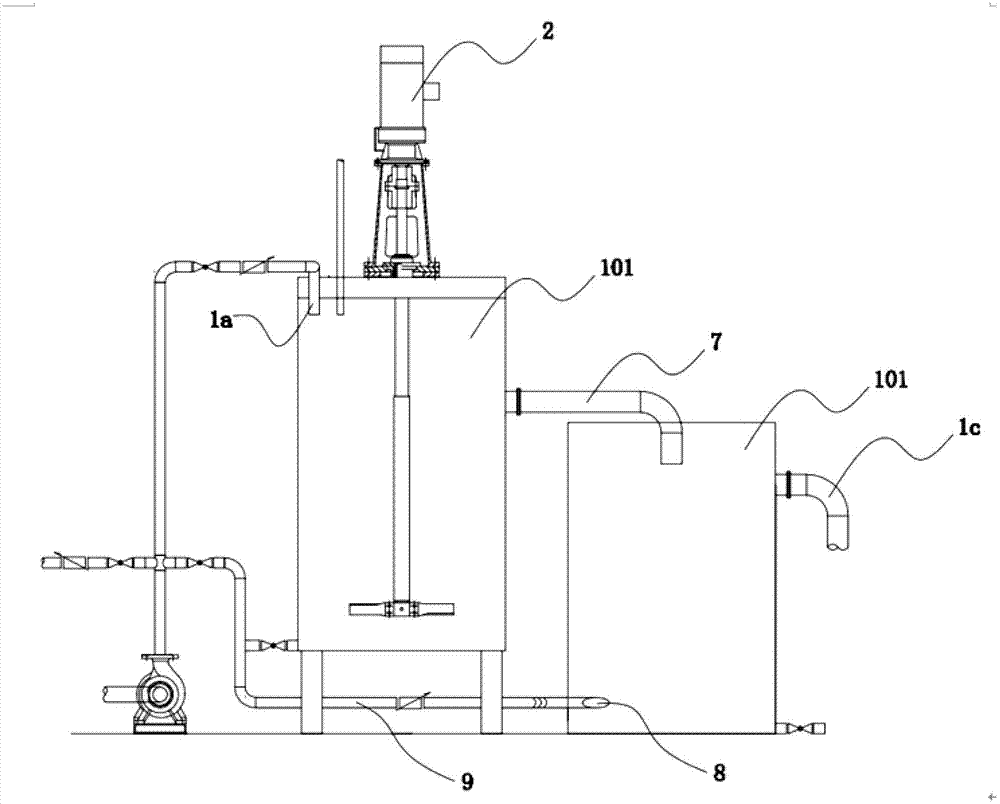

Up-flow solid carbon source biofilm carrier denitrification bioreactor

ActiveCN103172172AGood biodegradabilitySimple system structureTreatment with anaerobic digestion processesChemistryFixed frame

Owner:CHONGQING UNIV

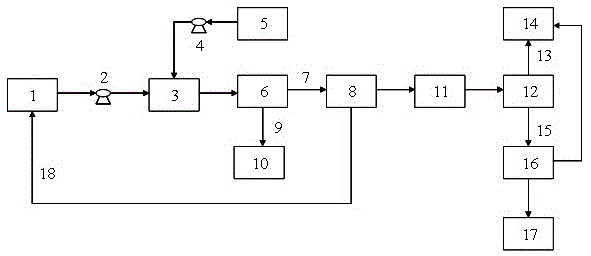

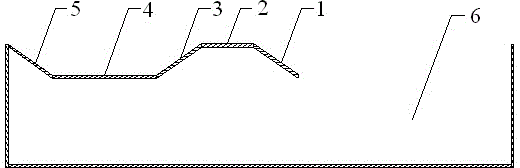

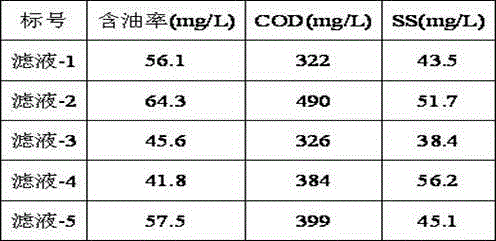

Oily sludge advanced treatment technology

ActiveCN104649563AGood demulsification effectGood biodegradabilitySludge treatment by de-watering/drying/thickeningFatty/oily/floating substances removal devicesPetroleumSludge dewatering

The invention discloses an oily sludge advanced treatment technology which comprises the following contents: oily sludge in a raw material storage sludge-tank enters a sludge mixing tank; a demulsifier is added to carry out demulsification treatment; demulsified oily sludge enters screw-type sludge dewatering equipment to undergo solid-liquid separation so as to obtain a filtrate and sludge cake; the filtrate enters a two-phase cyclone to be separated; after two-phase separation, excess sludge at the lower layer flows back to the raw material storage sludge-tank, a mixed liquor at the upper layer is sent into a gas-liquid mixing tank to be mixed with the air and then enters a separation pond to carry out primary separation of sump oil and sewage; sump oil is recovered to a sump oil tank by the use of a sludge scraper; sewage enters a filter to separate suspended particles and residual sump oil in the sewage from water; sump oil separated from the top of the filter is recovered to a sump oil recovery tank; and sewage discharged from the filter is sent to a sewage treatment plant to undergo subsequent processing. By the technology, water content of the oily sludge can be reduced from 80-98% to about 50%, and most crude oil in the oily sludge can be recovered. Thus, sludge subsequent processing difficulty is greatly reduced. The technology provided by the invention has a wide range of application, is especially suitable for processing of oily sludge at the bottom of an oil-tank, dross and activated sludge as well as processing of various oily sludge generated from oil exploitation and storage transportation enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waterproof paper-plastic compound bag and preparation method thereof

ActiveCN104925355AGood waterproof performanceGood biodegradabilityBio-packagingBagsChemistryOrganosilicon

The invention discloses a waterproof paper-plastic compound bag and a preparation method thereof. The waterproof paper-plastic compound bag comprises a plastic layer and a paper layer, wherein the plastic layer is arranged on the surface of the paper layer; the plastic layer comprises starch, polyvinyl alcohol, poly-beta-polyhydroxybutyrate, modified polyacrylate, high density polyethylene, dicumyl peroxide, polyisobutene, polyester fiber, lactose, glycerol, dimethyl phthalate and epoxy resin; the modified polyacrylate comprises a modifying agent and polyacrylate that are mutually compounded; and the modifying agent comprises one or more of organosilicon, organic fluorine and polyurethane. The preparation method of the waterproof paper-plastic compound bag is simple in step, and the raw materials are easy to obtain, so that large-scale industrial production of the waterproof paper-plastic compound bag can be conducted.

Owner:TONGLING FOUNDER PLASTICS TECH

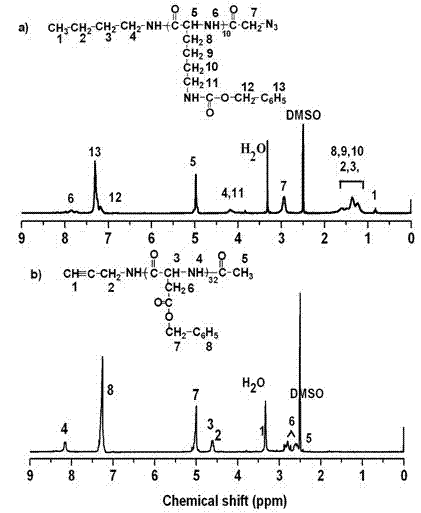

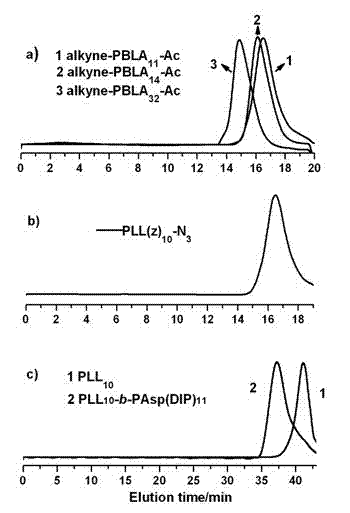

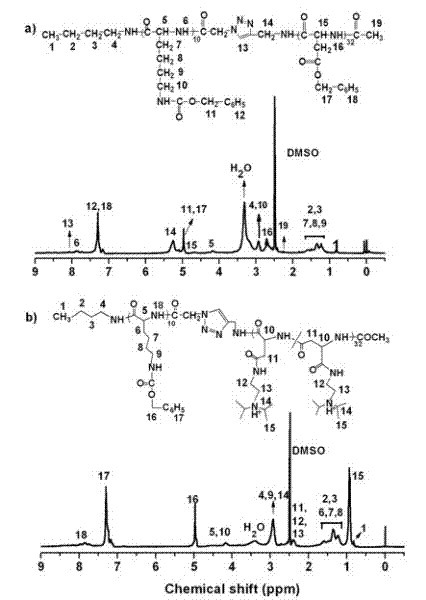

Degradable acid-sensitive macromolecular amphipathic cationic block copolymers and micellar particles and preparation method thereof

InactiveCN102516552AGood biocompatibilityGood biodegradabilityGenetic material ingredientsPharmaceutical delivery mechanismDoxorubicinPolyaspartic acid

The invention discloses degradable acid-sensitive macromolecular amphipathic cationic block copolymers and micellar particles and a preparation method thereof. The hydrophilic / hydrophobic segments of the macromolecular amphipathic block copolymers disclosed by the invention are respectively formed by polylysines and polyaspartic derivatives with acid-sensitive groups. The preparation method of the macromolecular amphipathic block copolymers disclosed by the invention comprises the following steps of: using a micromolecular amine initiator for initiating the ring opening polymerization of N-carboxylic anhydrides of L-amino benzyl esters with active side groups; interconnecting the hydrophilic and hydrophobic segments by click chemistry; introducing the acid-sensitive groups by further ammonolysis reaction; and taking off benzyl blocking groups under acidic conditions to obtain a target product. The copolymers disclosed by the invention have excellent acid sensitivity, biocompatibility and biodegradability and can self-assemble and form nanoscale micelles in an aqueous solution, and the micelles can simultaneously load anti-cancer drugs, such as doxorubicin, and groups, such as BCL-2siRNA and can realize the intelligent controlled release of loads at tumor positions.

Owner:SUN YAT SEN UNIV

Amphoteric wool grease leather fatliquoring agent and preparation method thereof

InactiveCN101864500AEnvironmentally friendlyGood biodegradabilityLeather impregnationWoolPolymer chemistry

The invention relates to an amphoteric wool grease leather fatliquoring agent and a preparation method thereof. At present, the existing wool grease modifying mode is mainly modification reaction based on hydroxy in wool grease, has direct influence on the quality of leather-making and fur products and has non-ideal effect on the improvement of performance. The amphoteric wool grease leather fatliquoring agent and the preparation method thereof comprise the steps of wool grease amidation reaction, condensation reaction of amidated wool grease and sodium chloroacetate in sequence, specificallytaking down materials in parts by weight for mixing, heating to 40-60 DEG C, insulating and stirring for 25-35min to lead oil phases to be mixed uniformly, then mixing 15-20 parts of water, 0.8-1.2 parts of penetrating agent JFC, 4-6 parts of Tween-80, heating the mixture to be 60-70 DEG C, then adding the obtained mixture into a product of step 3 by times, continuing to heat and stir for 15-25min and discharging. The invention is environment-friendly, has wide application range and simultaneously and greatly improves leather property.

Owner:SHAANXI UNIV OF SCI & TECH

Biodegradable hard water-resistant water-soluble metalworking liquid

The invention discloses biodegradable hard water-resistant water-soluble metalworking liquid. The biodegradable hard water-resistant water-soluble metalworking liquid consists of organic acid, organic amine, corrosion inhibitor, synthetic lubricant, surfactant, water and defoamer. The biodegradable hard water-resistant water-soluble metalworking liquid is high in biodegradability, hard water resistance, lubricity, rust prevention property and corrosion resistance and long in service life and is friendly to people and environment.

Owner:QIDONG YUSHIRO CHEMICAL INDUSTRY CO LTD +1

Traditional Chinese medicine wastewater treatment process

ActiveCN102923921AGood biodegradabilityImprove processing efficiencyMultistage water/sewage treatmentAnaerobic treatmentChinese herbology

The invention discloses a traditional Chinese medicine wastewater treatment process. The process has the following beneficial effects: after the traditional Chinese medicine wastewater is pretreated and the pH value of the traditional Chinese medicine wastewater is adjusted to be 8-9, the traditional Chinese medicine wastewater is subjected to anaerobic treatment, biochemical reflux treatment and filter and drain treatment; by combining the treatment methods, the traditional Chinese medicine wastewater can be effectively treated, so that the effluent of the treated traditional Chinese medicine wastewater can reach the primary standard (GB8978-1996); and the process has good environmental and economic benefits.

Owner:四川省环保科技工程有限责任公司 +2

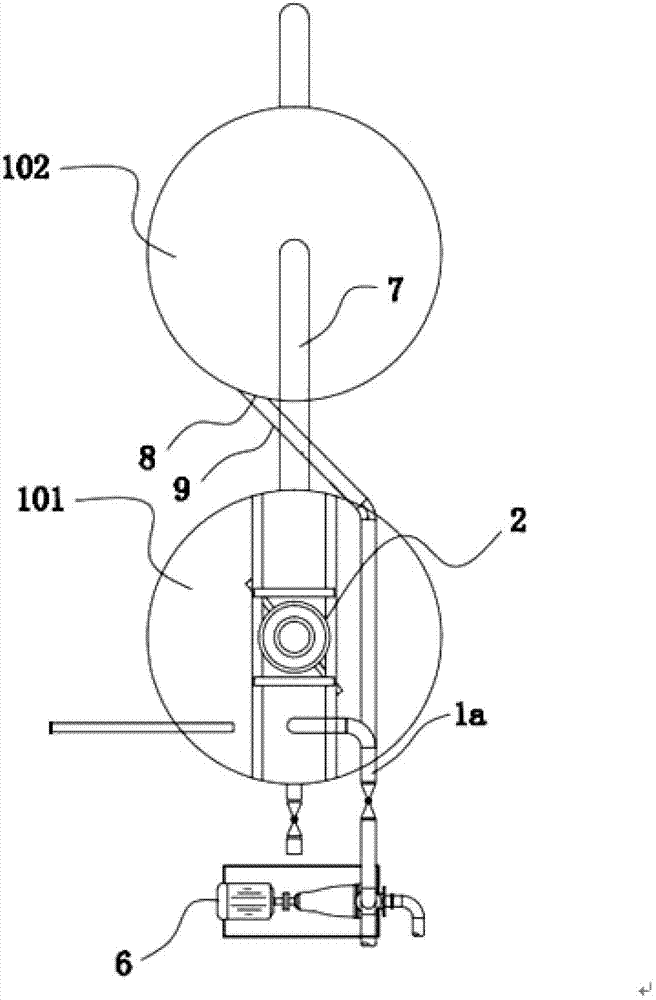

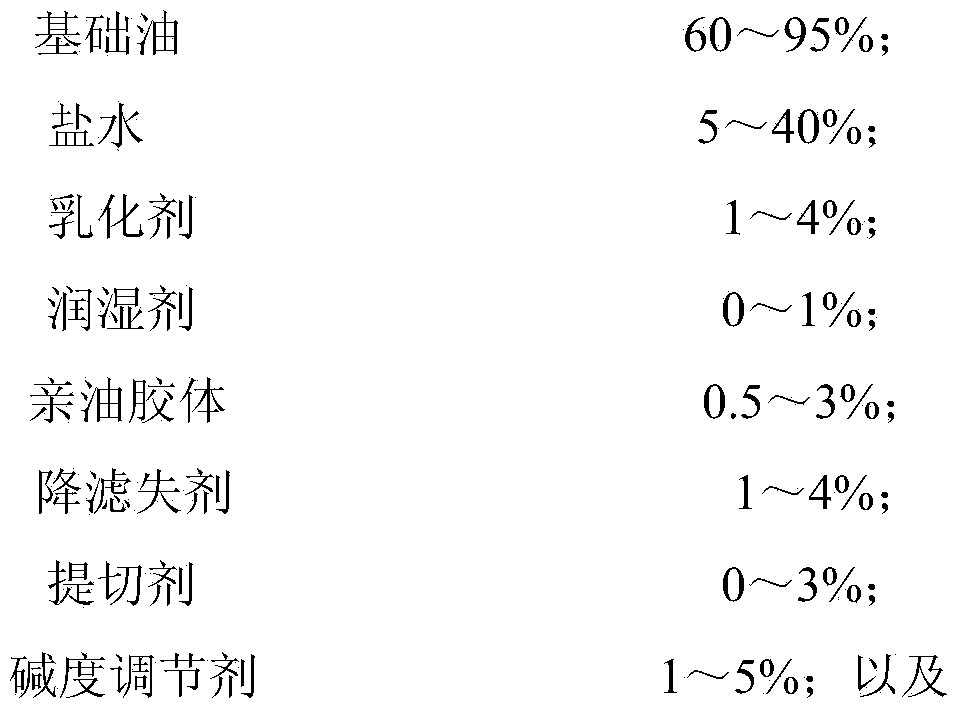

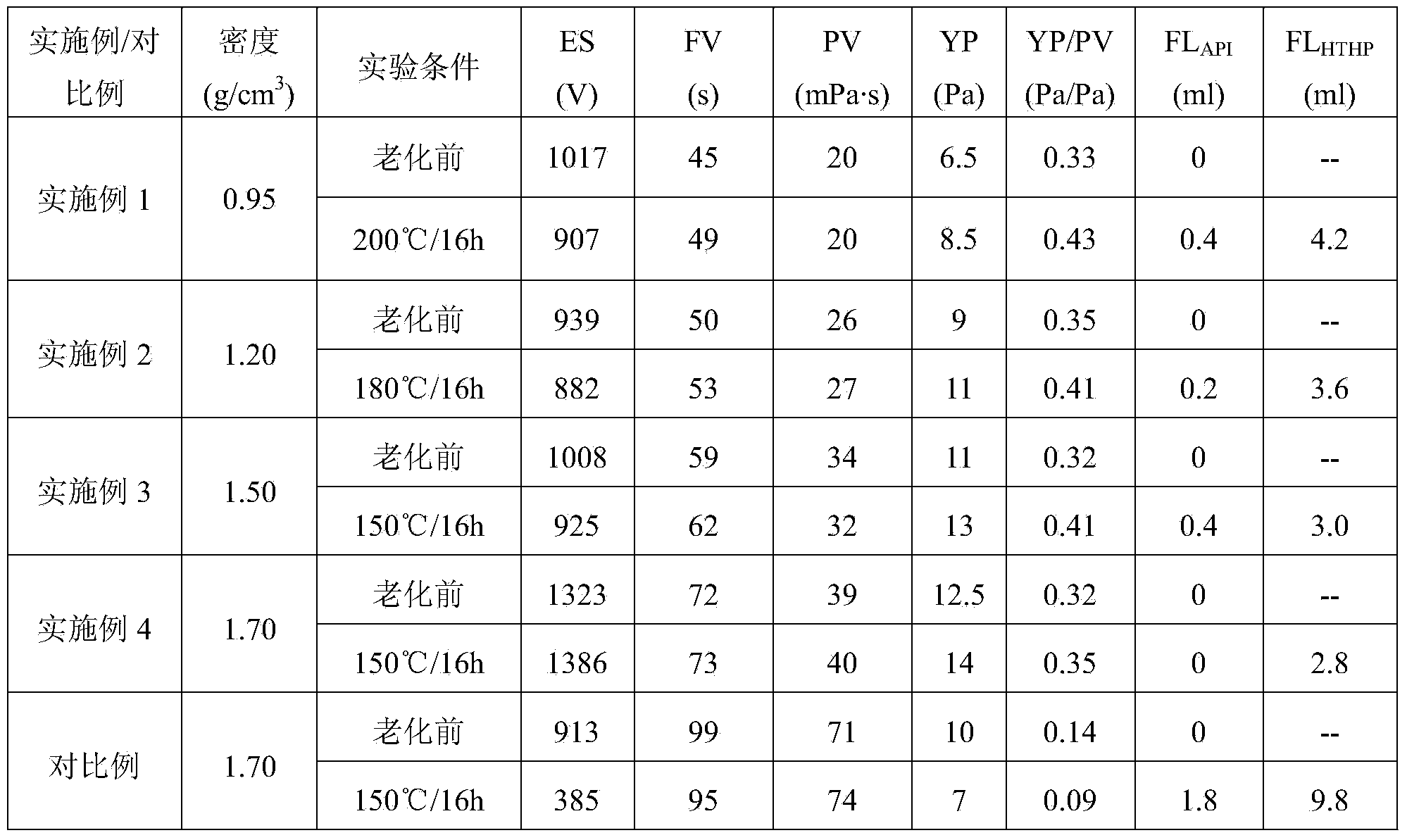

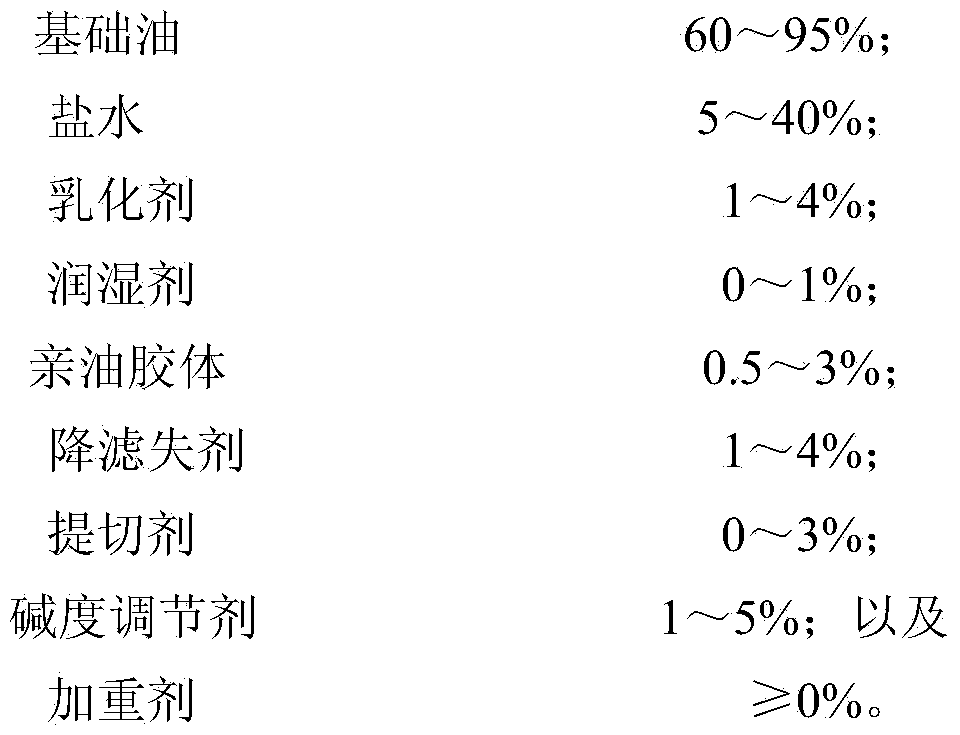

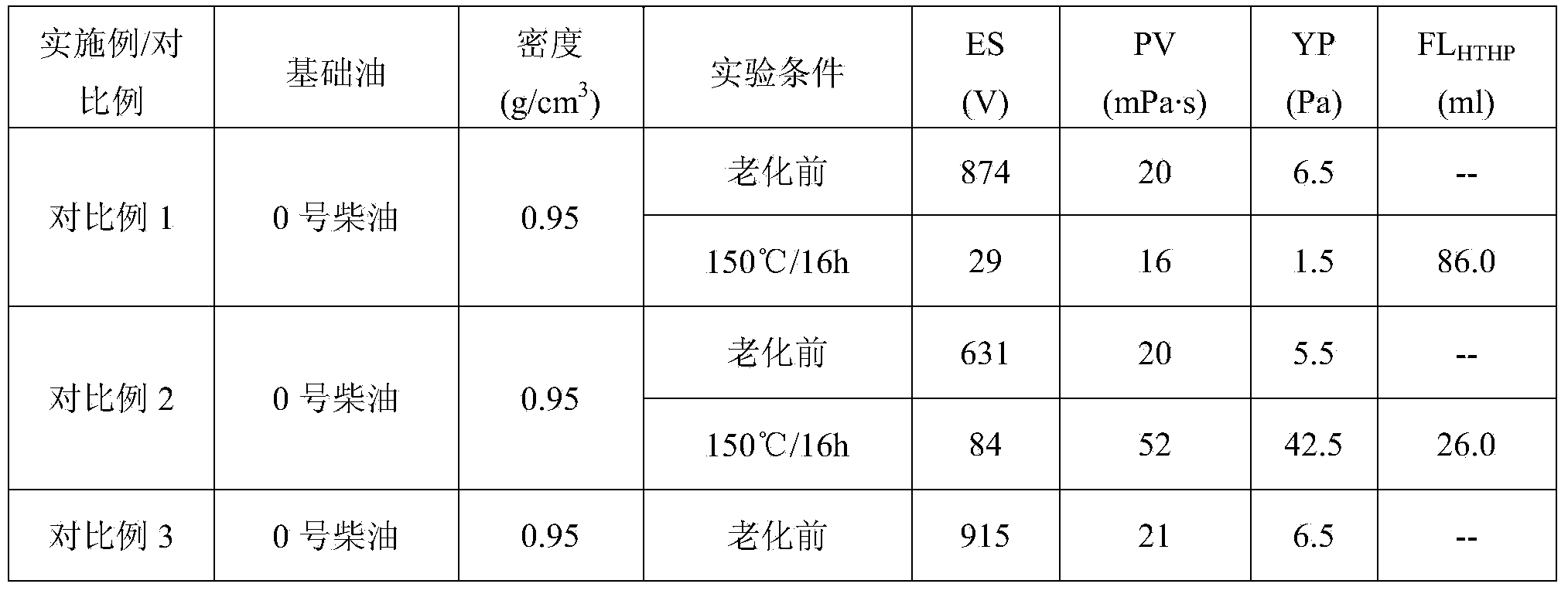

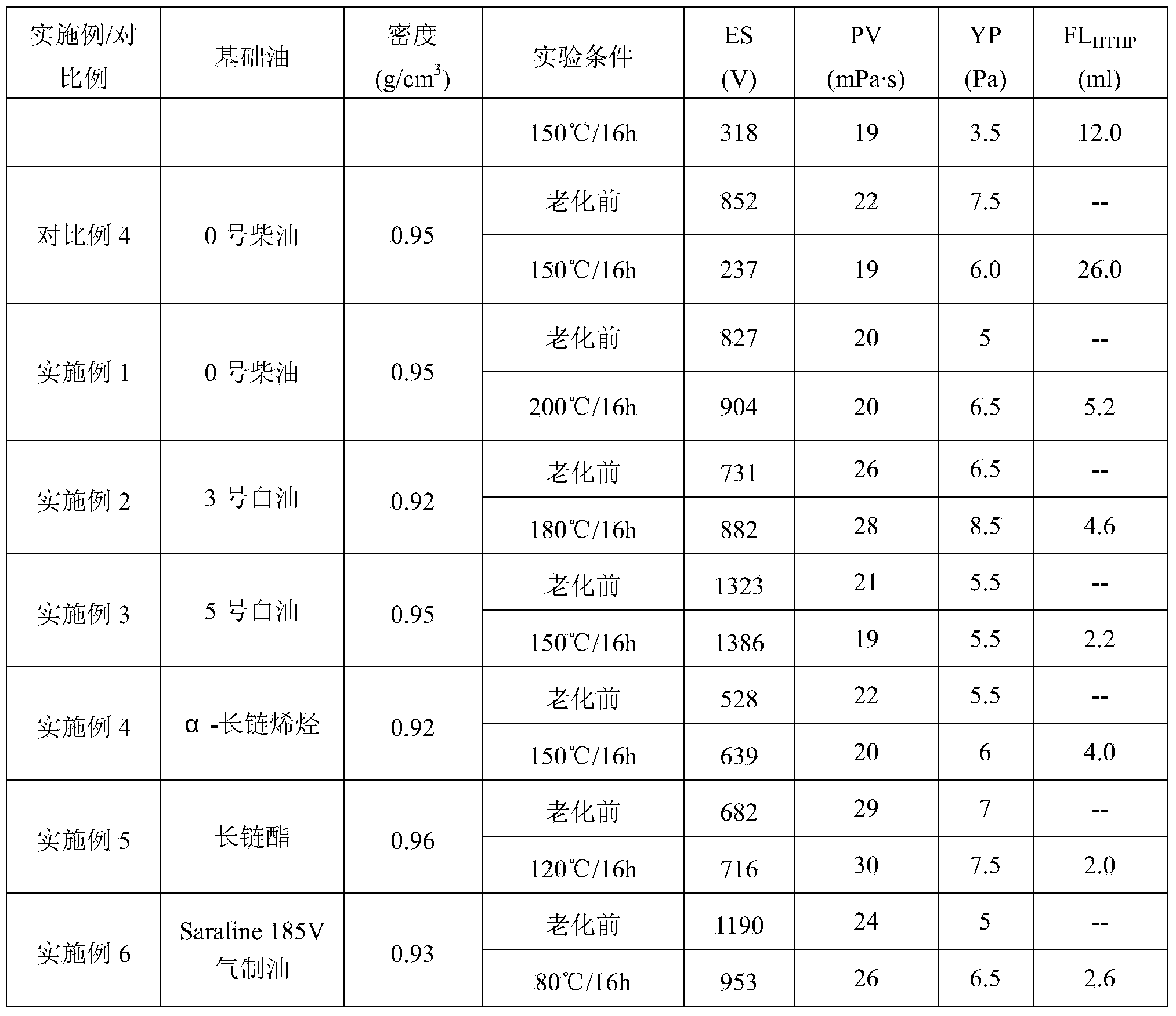

Invert-emulsion drilling fluid, preparation method and application thereof

The invention provides an invert-emulsion drilling fluid, which comprises basic oil, brine, an emulsifier, a wetting agent, lipophilic colloid, a fluid loss additive, a shearing potentiator, an alkalinity conditioning agent, and a weighting agent. The invert-emulsion drilling fluid has the characteristics of low funnel viscosity and plasticity viscosity, and high dynamic shearing force and static shearing force; the yield point / plastic viscosity ratio is more than or equal to 0.30, the drilling fluid can sustain a temperature as high as 200 DEG C, so the drilling fluid is suitable for being used in a high temperature deep well, and a plurality of oils such as diesel oil, white oil, gas-liquefied oil, and the like can be used to carry out construction. Solved are the technical problems that the funnel viscosity and plasticity viscosity of the conventional invert-emulsion drilling fluid system are too high, and the dynamic shearing force and the static shearing force are too low.

Owner:CHINA PETROLEUM & CHEM CORP +1

Natural hair dye prepared from fructus chebulae pigment and dyeing method thereof

InactiveCN106420499AGood biodegradabilityMeet individual needsCosmetic preparationsHair cosmeticsEnvironmental chemistryWater soluble

The invention discloses natural hair dye prepared from fructus chebulae pigment and a dyeing method thereof. The natural hair dye comprises an agent A and an agent B; the agent A is prepared from, by mass, 1-10% of fructus chebulae pigment, 2-8% of thickener, 1-5% of surfactant, 1-5% of dyeing accelerant and the balance water, and the pH value is adjusted to be 3-6; the agent B is prepared from, by mass, 1-10% of water-soluble metal salt, 2-8% of thickener, 1-5% of surfactant and the balance water, and the pH value is adjusted to be 3-6. The dyeing accelerant added in the agent A can promote swelling of the hair scale layer and is beneficial for the fructus chebulae pigment diffusing into hair, after the agent B is used, the durable hair dyeing effect can be achieved, and different colors are obtained after hair dyeing by using different water-soluble metal salts in the agent B. The fructus chebulae pigment has the advantages of being nontoxic, harmless and non-carcinogenic and not causing allergy to the skin or causing.

Owner:HENAN INST OF ENG

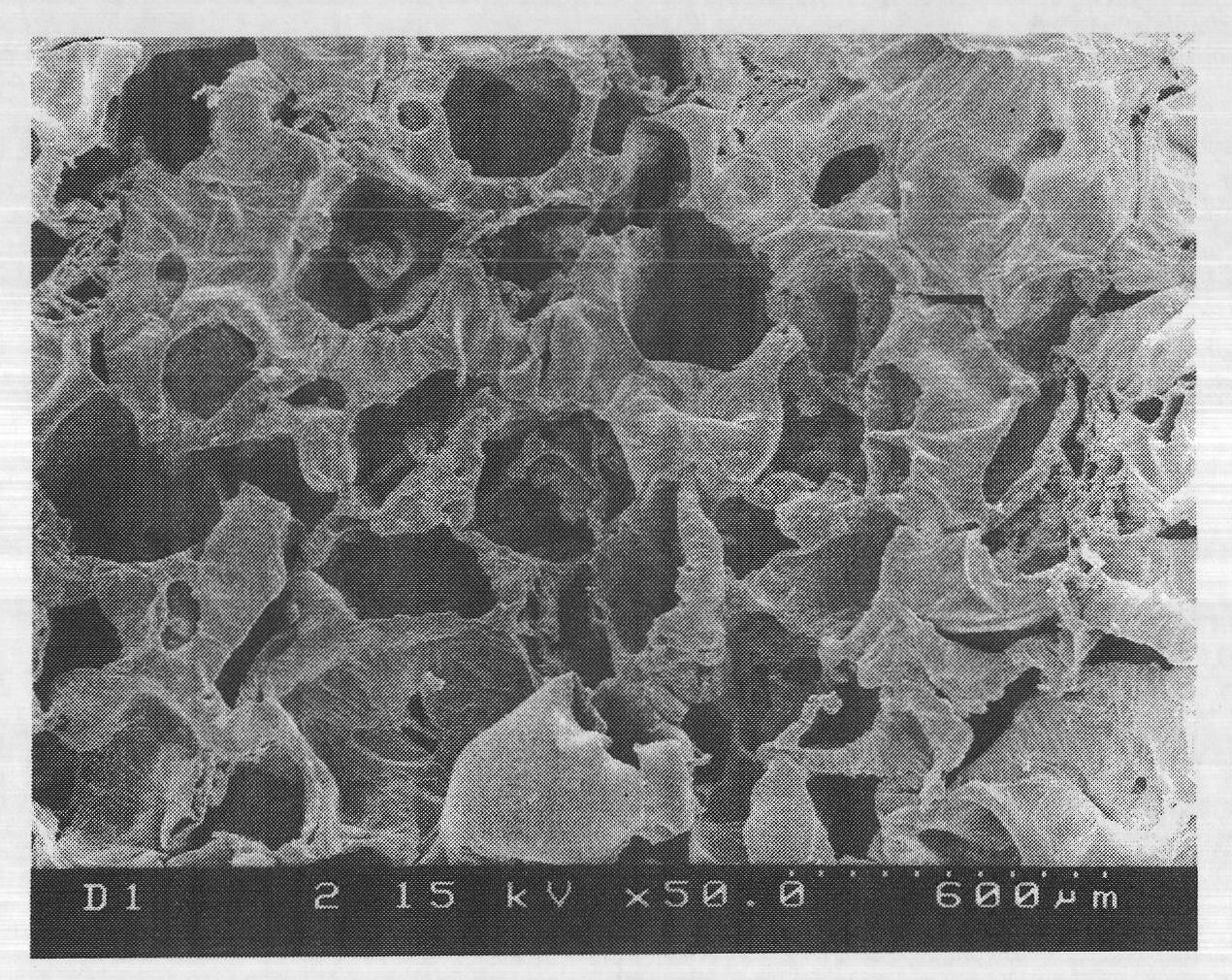

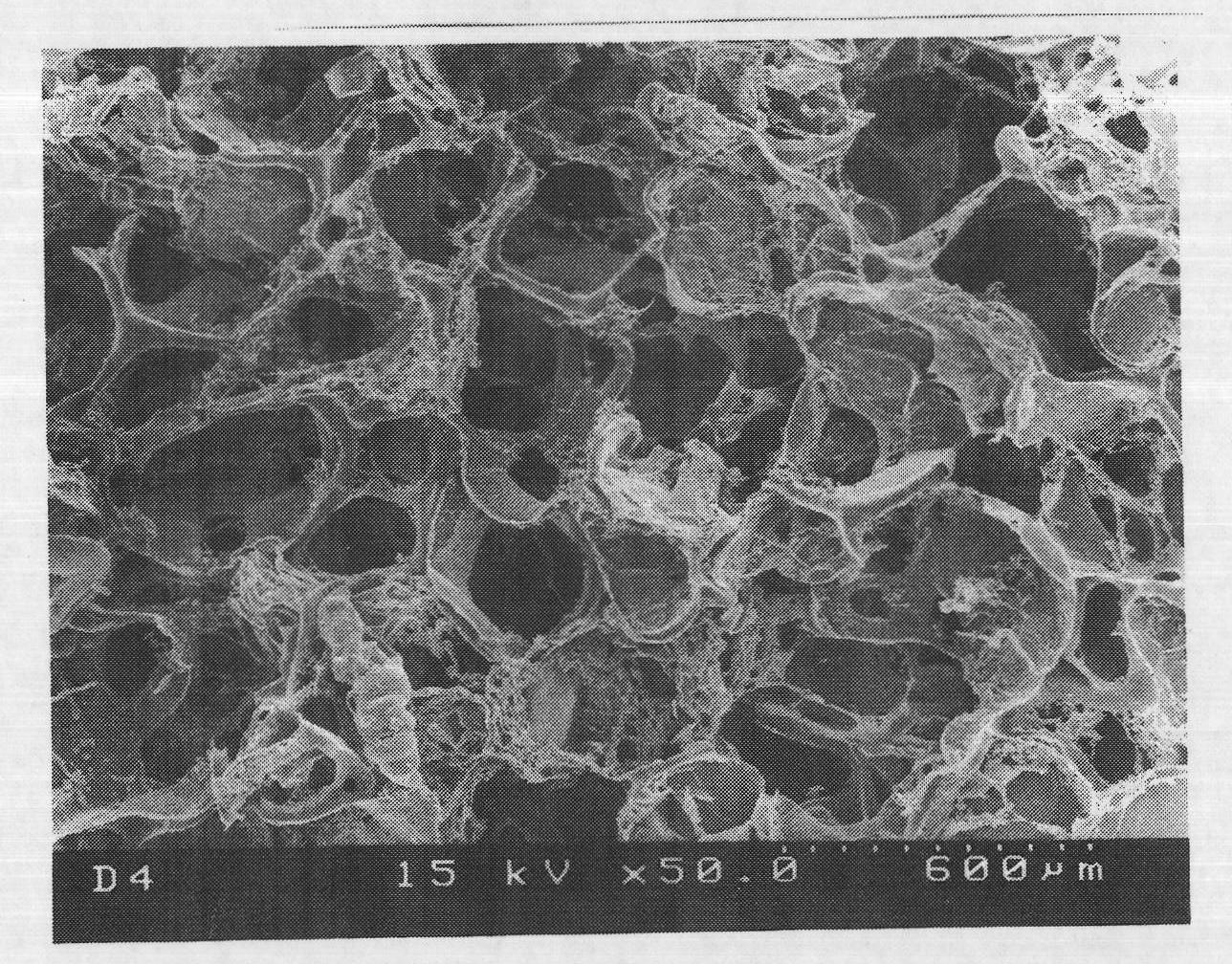

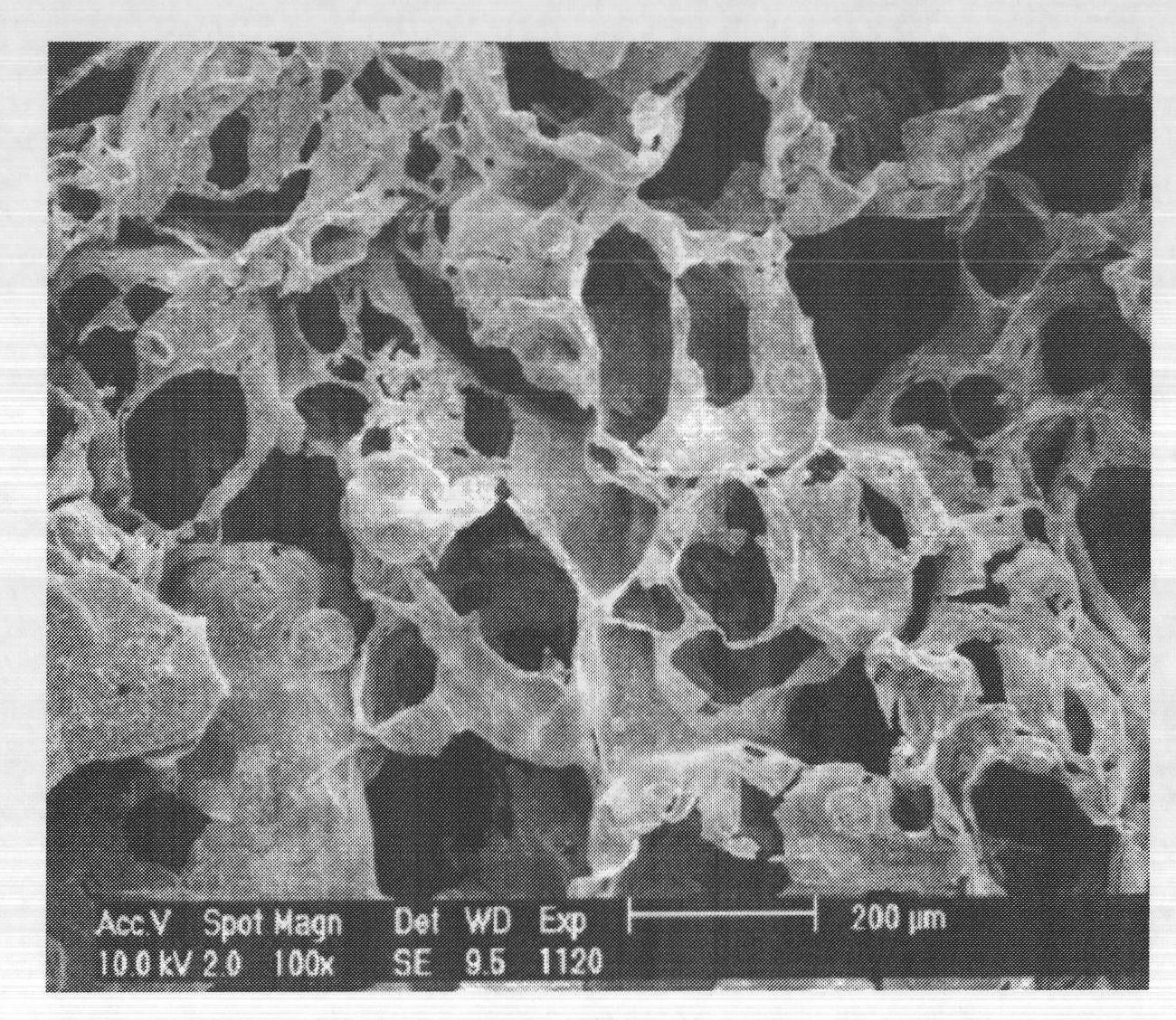

Porous biodegradable stent and preparation method thereof

The invention discloses a porous biodegradable stent and a preparation method thereof. The porous biodegradable stent mainly consists of a biodegradable polymer. The preparation method of the porous polymer stent comprises the following steps: dissolving the biodegradable polymer in an organic solvent; then stirring the mixture and soluble salt at normal temperature to form paste; pressurizing the paste in a die to form a semi-finished product; drying the semi-finished product; removing the organic solvent and desalting in pure water; and finally preparing the finished product by freeze drying pretreatment and freeze drying. The invention has the advantage that the porous biodegradable stent provided by the invention has the characteristics of good biodegradability, high porosity, specific pore size, high continuity, high ratio of superficial area to volume, histocompatibility, blood compatibility and the like and makes the human body have no foreign body sensation and have no immunological rejection. The invention is suitable for nose augmentation, breast augmentation, face-lifting and the like of the human body and tissue regeneration of tissue organ defect, cartilages of the human body, skeletons, liver, heart valves, ductus cysticus, alimentary canal and the like.

Owner:四川合泰新光医药有限公司 +1

Method for preparing modified soybean protein biological degradation plastic

The invention relates to a preparation method for modified soybean protein biodegradation plastic which comprises steps that: (1) soy protein isolate are mixed with corn protein powder or wheat gluten and glycerol or compound plasticizer for 10-50 min and then placed in a refrigerator with temperature of 2-6 DEG C for standing of 24-48 h; (2) the material obtained from step (1) is put into a self-made mould, and then hot pressed for 2-10 min under the circumstance of 110-160 DEG C and 5-40MPa so as to form plastic sheets, and then cooled and demolded. The invention has the advantages of simple production technique, no pollution, good waterproof property, good tensile strength and high elongation at break, and can be used for disposable tableware, agricultural and gardening tools, toy and outdoor sports equipment and so on.

Owner:SOUTH CHINA UNIV OF TECH

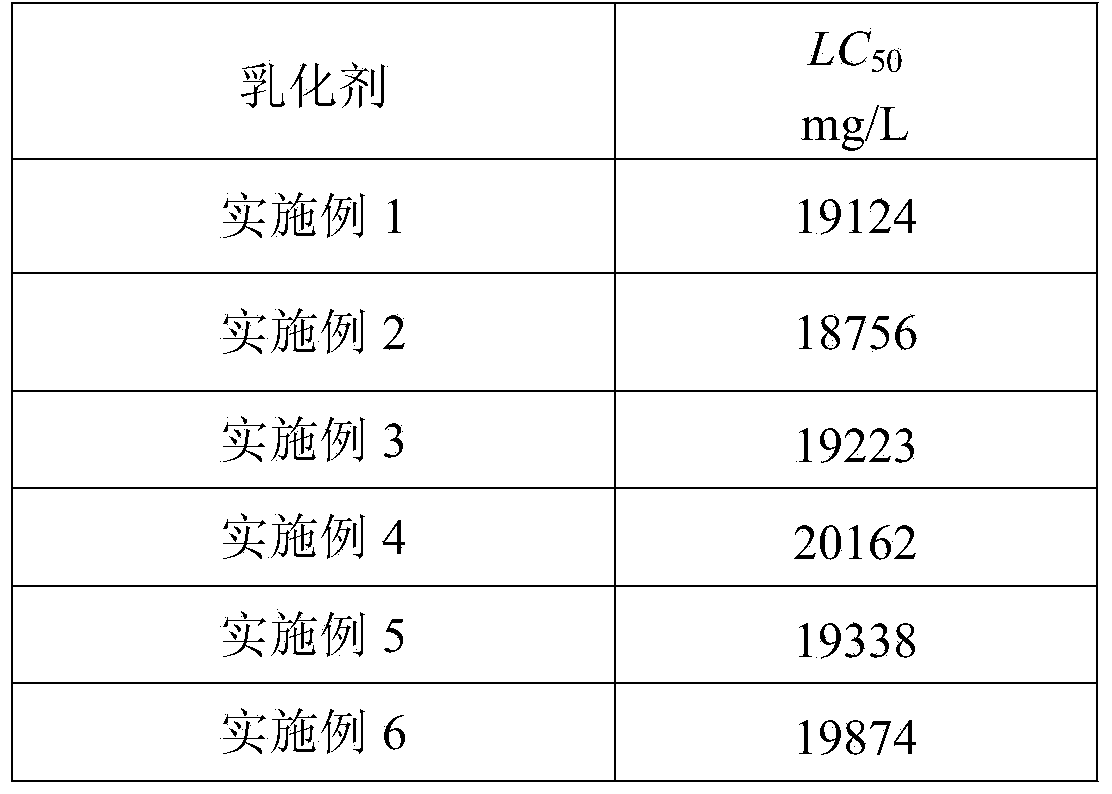

Emulsifier for oil-based drilling fluid as well as preparation method and application thereof

ActiveCN104140792ATurn waste into treasureLow costFatty acid chemical modificationDrilling compositionOil and greasePollution

The invention aims at providing an emulsifier for oil-based drilling fluid. The emulsifier is selected from any two or three types of waste oil and grease, a saponified substance of the waste oil and grease and amidate of the waste oil and grease, wherein the saponified substance of the waste oil and grease is obtained through reacting the waste oil and grease with alkali, and the amidate of the waste oil and grease is obtained through reacting the waste oil and grease with organic amine under the catalysis of alkali. The invention further provides a preparation method of the emulsifier and application of the emulsifier in the oil-based drilling fluid. The emulsifier has a good emulsifying effect; the biological toxicity is low, the cost of the emulsifier for the oil-based drilling fluid can be greatly reduced, the waste oil and grease can be changed into the valuable from the waste, and the environment pollution caused by the waste oil and grease is reduced, so that the environmental protection is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

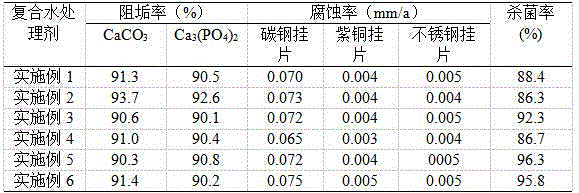

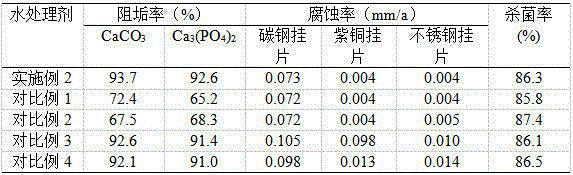

Environment-friendly composite water treatment agent and application thereof

ActiveCN104310600AGood biodegradabilityPromote degradationSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsEnvironmental chemistryPolyglutamic acid

The invention discloses an environment-friendly composite water treatment agent which is especially suitable for circulating cooling water of a central air conditioner. The water treatment agent comprises the following components by mass percent: 15-30% of polyepoxysuccinic acid, 10-20% of polyglutamic acid, 15-40% of sodium molybdate, 10-20% of sodium lauroyl sarcosinate, 10-25% of tetradecyl dimethyl benzyl ammonium chloride and the balance of water. When the dosage of the composite formula is 10mg / L, the scale inhibition rate reaches more than 90%, so that the corrosion rate of carbon steel is lower than 0.075mm / a, the corrosion rates of red copper and stainless steel are lower than 0.005mm / a, and the sterilizing rate reaches more than 85%.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST +1

Bodegradable manihot starch based material and product thereof

The present invention relates to a preparation of bio-degradative cassava starch group material for producing disposal plastic products, comprising cassava starch, polypropylene or polythylene, low-density high-pressure polythylene, linear low-density high-pressure polythylene, thylene-vinyl acetate copolymer, titanium white powder, etc. The present invention has the advantages of low cost of raw materials, good degradation effect, simple production process and easy promotion and application. The products made of the cassava starch group material include disposal catering container and utensil, packaging container, packaging membrane, medical equipment, agricultural membrane, etc.

Owner:吴同刚

Modification method for improving compatibility and interface associativity of polylactic acid/starch blend

InactiveCN101525449AGood biodegradabilityLow costFlat articlesTubular articlesIsocyanatePolylactic acid

The invention relates to a modification method for improving compatibility and interface associativity of a polylactic acid / starch blend. The modification method comprises the following steps: (1) mixing native starch with a compatibilizer according to the mass ratio of 60-90:10-40 in a high speed kneader for 10-30 minutes; and (2) mixing the powder with polylactic acid particles according to the mass ratio of 10-90:10-90, adding an isocyanate coupling agent, and forming polylactic acid / starch blended modified resin slices by blending, extrusion and granulation of a double screw extruder at the blending temperature of 150-230 DEG C and screw speed of 25-500rpm. The polylactic acid / starch blend prepared by the modification method has good biodegradability, the modification method has the advantages of low cost, improved compatibility, interface associativity, mechanical property and thermal property of the modified polylactic acid / starch blend, and the polylactic acid / starch blend replaces general-purpose plastics in certain simple application.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com