Controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as preparation method and application thereof

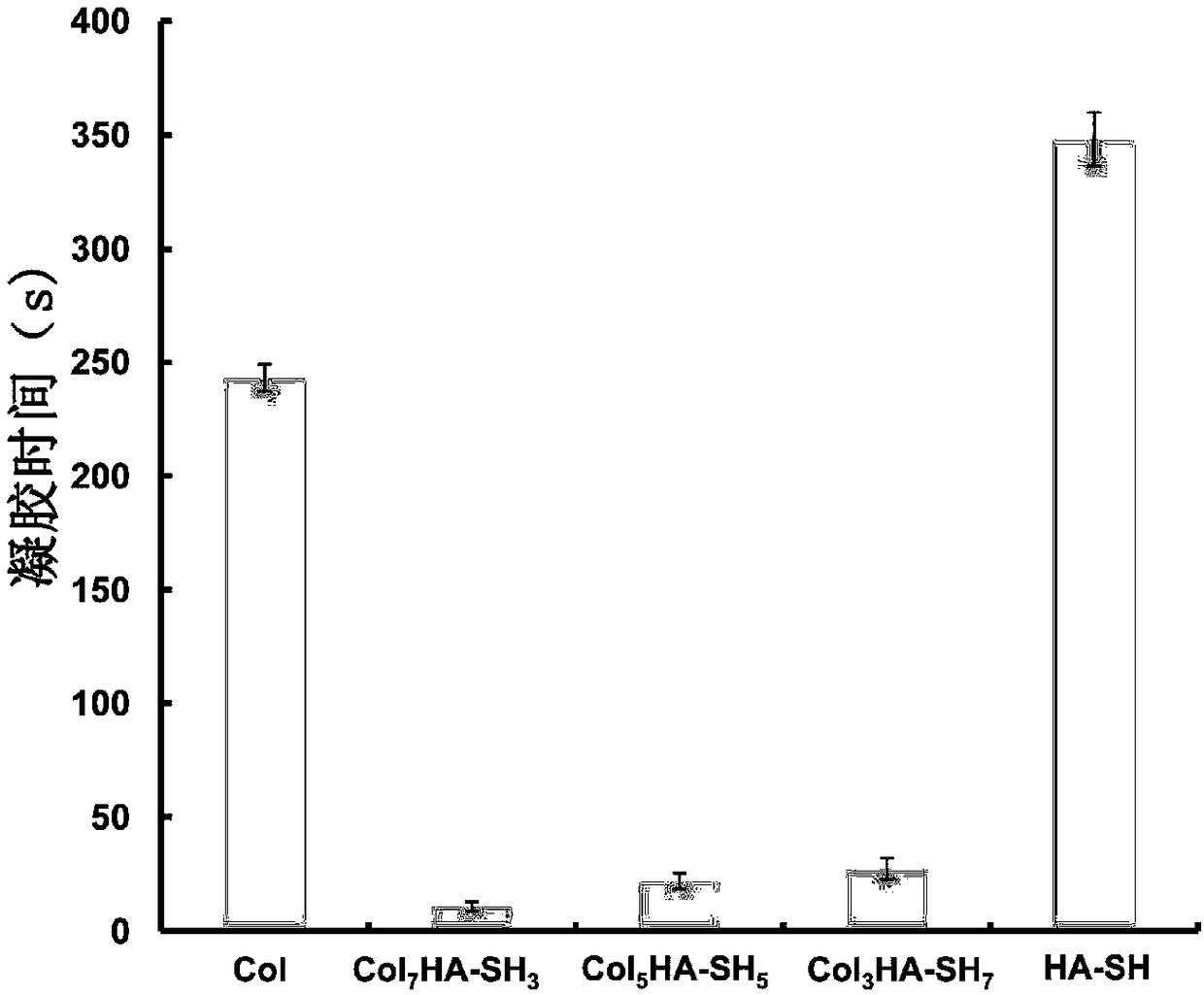

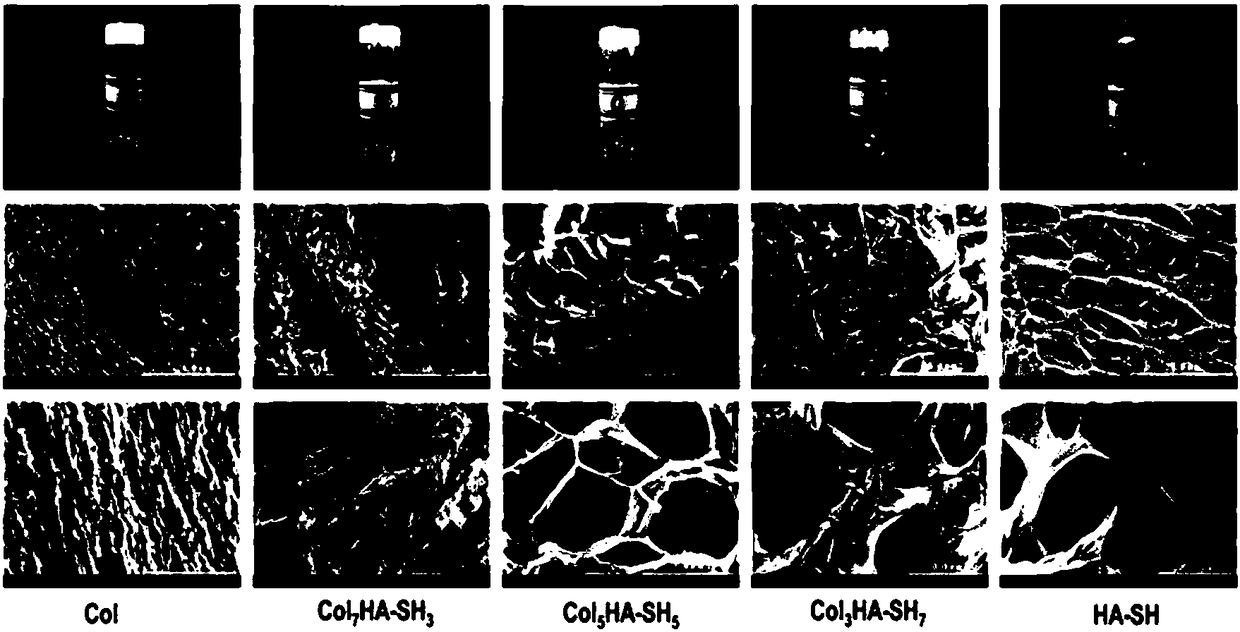

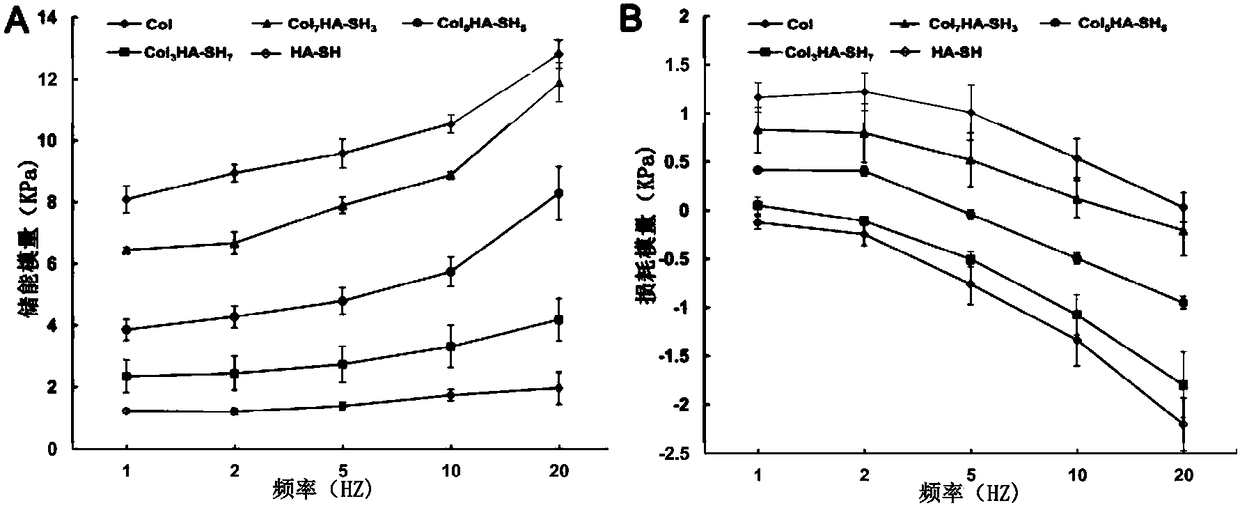

A technology of composite hydrogel and hyaluronic acid, which is applied in the fields of pharmaceutical formula, medical science, prosthesis, etc., can solve the problems of easy-to-shrink cell adhesion, achieve good biodegradability, low loss modulus, good The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this example, the preparation of mercaptolated hyaluronic acid, the steps are as follows:

[0047] (1) Dissolve sodium hyaluronate with a molecular weight of 0.3MDa in deionized water, add N-hydroxysuccinimide (NHS), fully dissolve, and then add 1-ethyl-(3-dimethylaminopropyl ) carbodiimide hydrochloride (EDC HCl), fully dissolved, adjust the pH value of the mixture to 4.75 with 1mol / L NaOH solution and 1mol / L HCl solution, react at room temperature for 2h, and then add cysteine Ammonia hydrochloride (CSH·HCl) solution was reacted at room temperature for 24 h, and then the pH value of the reaction solution was adjusted to 8.5 with 1 mol / L NaOH solution, and dithiothreitol (DTT) solution was added to react at room temperature for 12 h.

[0048] In this step, sodium hyaluronate, N-hydroxysuccinimide (NHS), 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), semi The molar ratio of cystine hydrochloride (CSH·HCl) to dithiothreitol (DTT) is 1:2:4:4:12....

Embodiment 2

[0052] In this example, the controllable self-crosslinking mercaptolated hyaluronic acid-collagen composite hydrogel was prepared, and the steps were as follows:

[0053] (1) The HA-SH prepared in Example 1 is sterilized and dissolved in α-MEM medium to form a 10wt.% HA-SH solution; the α-MEM medium is α-MEM basal medium The mixture of penicillin-streptomycin (double antibody) and ascorbic acid was added on the basis of α-MEM medium. The volume concentration of double antibody in α-MEM medium was 1%, and the concentration of ascorbic acid was 50 μg / mL.

[0054] (2) Dissolve type I collagen with 0.5mol / L acetic acid solution under ice bath, adjust the pH value to 7.4 with 5mol / L NaOH solution, and then add PBS buffer solution with a concentration of 0.01mol / L and a pH value of 7.4 Adjust the concentration of type I collagen to 10 mg / mL to obtain a collagen solution; the type I collagen is extracted from bovine tendons.

[0055] (3) Draw the collagen solution and HA-SH solution...

Embodiment 3

[0065] In this example, the controllable self-crosslinking mercaptolated hyaluronic acid-collagen composite hydrogel was prepared, and the steps were as follows:

[0066] (1) According to the method in Example 1, the molar ratio of EDCI and CSA·HCl and the molecular weight of sodium hyaluronate are adjusted to prepare HA-SH with a grafting ratio of cysteine of 33.54%, and the HA-SH Sterilize and dissolve in α-MEM medium to form a 1wt.% HA-SH solution; the α-MEM medium is based on the α-MEM basal medium by adding penicillin-streptomycin mixed solution ( double antibody) and ascorbic acid, the volume concentration of double antibody in α-MEM medium was 1%, and the concentration of ascorbic acid was 50 μg / mL.

[0067] (2) Dissolve type I collagen with 0.25mol / L acetic acid solution under ice bath, adjust the pH value to 7.8 with 5mol / L NaOH solution, and then add PBS buffer solution with a concentration of 0.01mol / L and a pH value of 7.8 Adjust the concentration of type I coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Loss modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com