Patents

Literature

111results about How to "Resolve shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

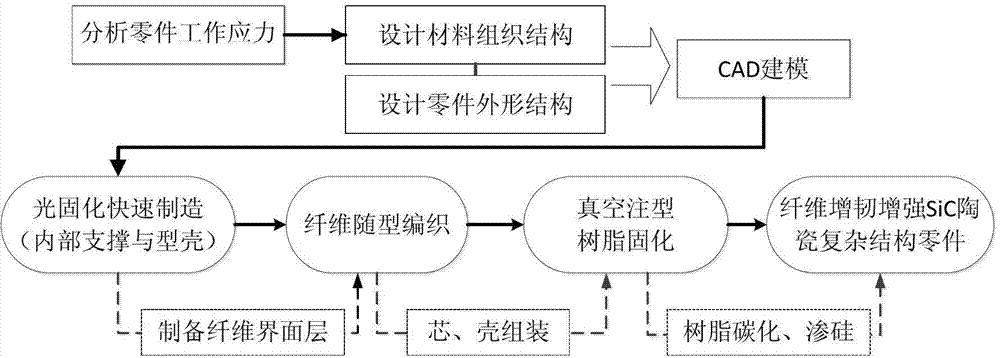

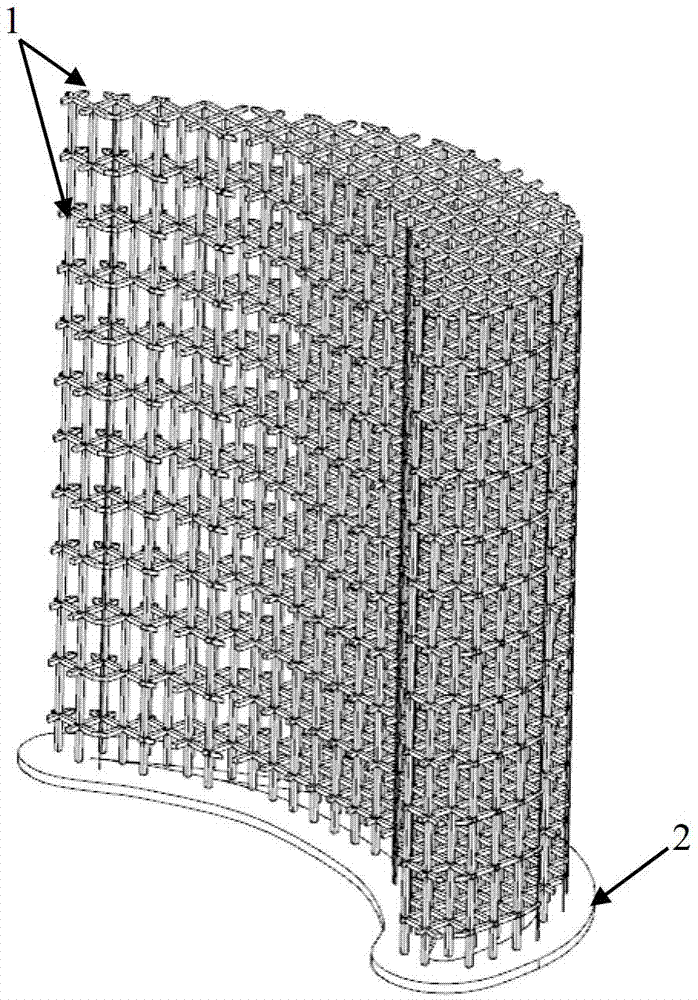

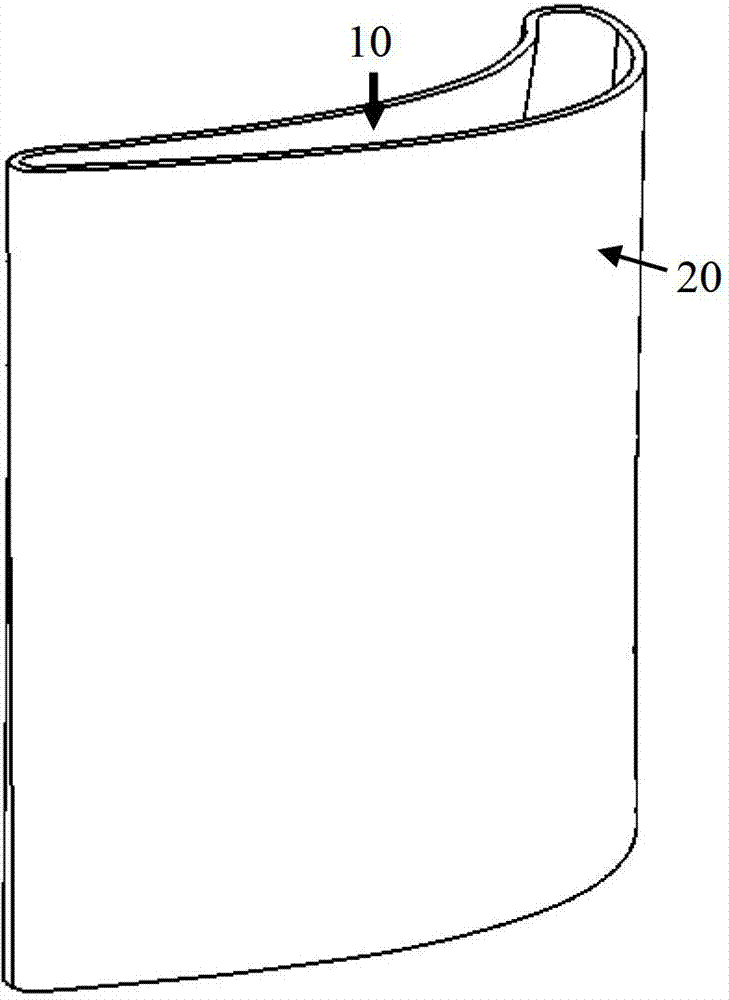

Preparation method of SiCf/SiC ceramic matrix composite turbine blades

InactiveCN103113123AMeet preparation requirementsImprove silicon corrosion resistanceYarnStress distribution

The invention discloses a preparation method of SiCf / SiC ceramic matrix composite turbine blades, which is characterized in that through analyzing the stress distribution of a blade in an application state, based on this point, a performance-controllable SiCf / SiC ceramic matrix composite turbine blade is manufactured through the designing and adopting of processes such as rapid forming, high-performance continuous yarn braiding, gel-casting, reactive sintering, and the like. According to the method, parts such as blades and the like are manufactured by using heterogeneous materials, the contradiction between the uniformity and nonuniform loaded structure of materials is solved, and the performances of materials can be set flexibly according to the bearing needs of manufactured parts; and prepared SiCf / SiC ceramic matrix composite turbine blades have the characteristics of near-net forming variable-cross-section complex structure, controllable material performance, flexible machining, short production cycle, low cost, and the like, and can be applied to the development and manufacturing of high-temperature-resistant complex structured parts for aerospace and the like.

Owner:XI AN JIAOTONG UNIV

Water-borne epoxy resin modified cement grouting material

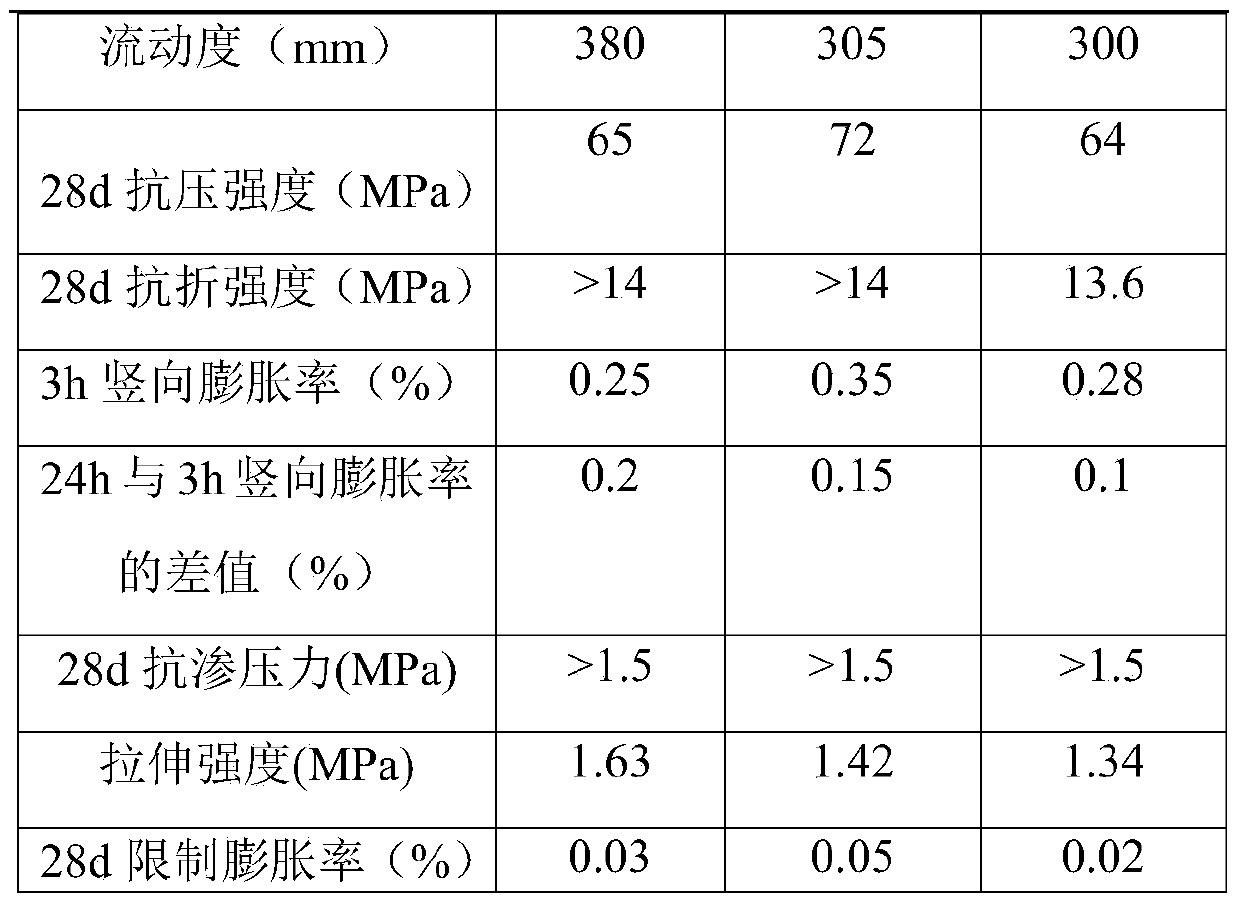

The invention provides a water-borne epoxy resin modified cement grouting material. The material is prepared by the following raw materials in parts by weight: 5-10 parts of water-borne epoxy resin, 30-50 parts of cement, 5-30 parts of quartz powder, 0-40 parts of quartz sand, 5-10 parts of calcium carbonate powder, 5-10 parts of a composite expanding agent, 0.01-0.03 parts of low-viscosity cellulose, 0.5-1 parts of asphalt powder, 0.2-0.6 parts of a water reducer, and 0.001-0.03 parts of a retarder. The material overcomes the deficiency in prior art, the composite expanding agent is used for compensating shrinkage in plastic stage, density of grouting is increased, and interspace structure is effectively filled; at the same time, fluidity is good, and settlement phenomenon disappears; the material is suitable for common cement grouting, and is suitable for repairing and strengthening, duct grouting, crack repairing, and other engineering occasions; furtherly, the materials has the advantages of good fluidity, adhesive property, shrinkage compensation performance and corrosion resistance.

Owner:天津天盈新型建材有限公司

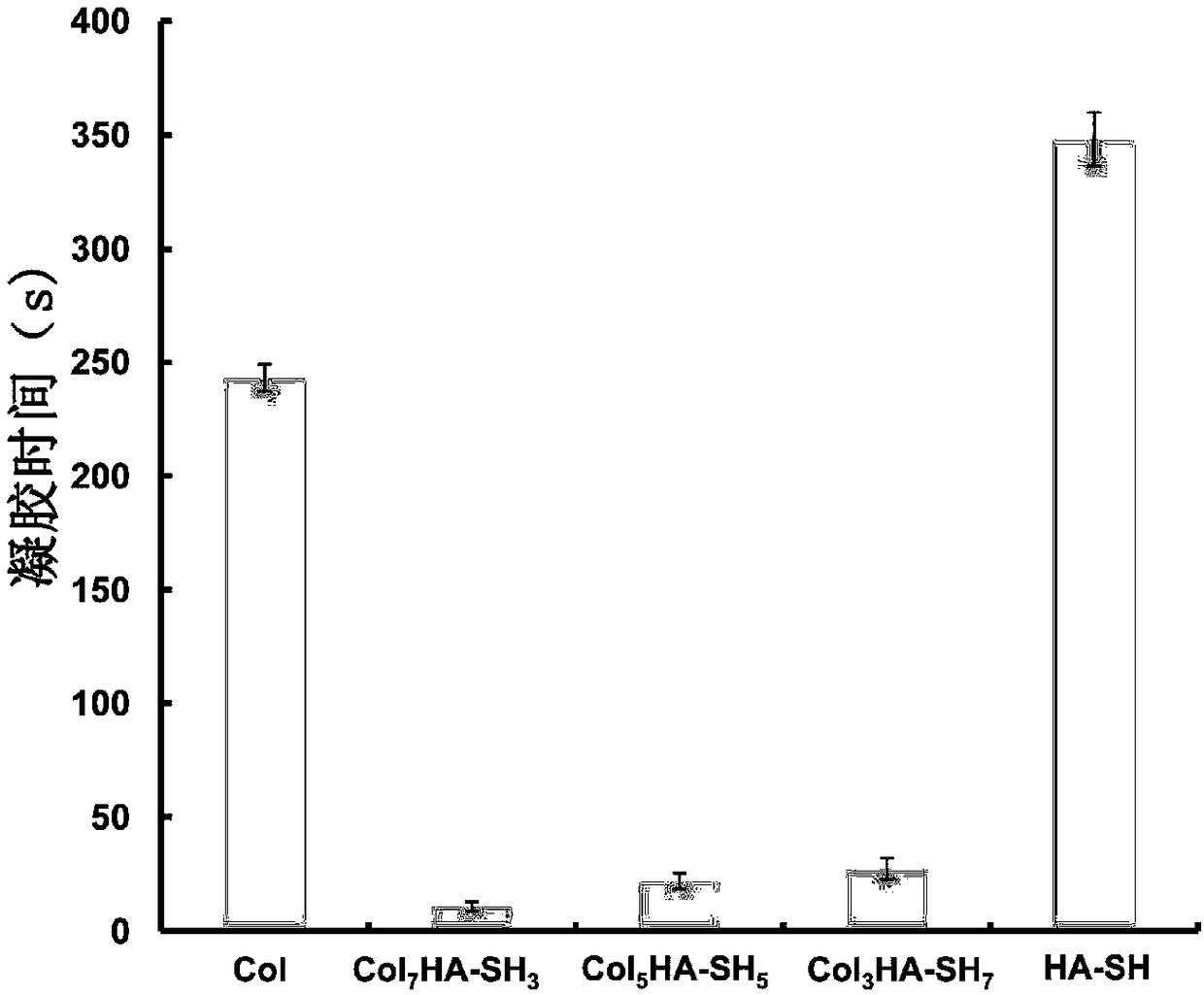

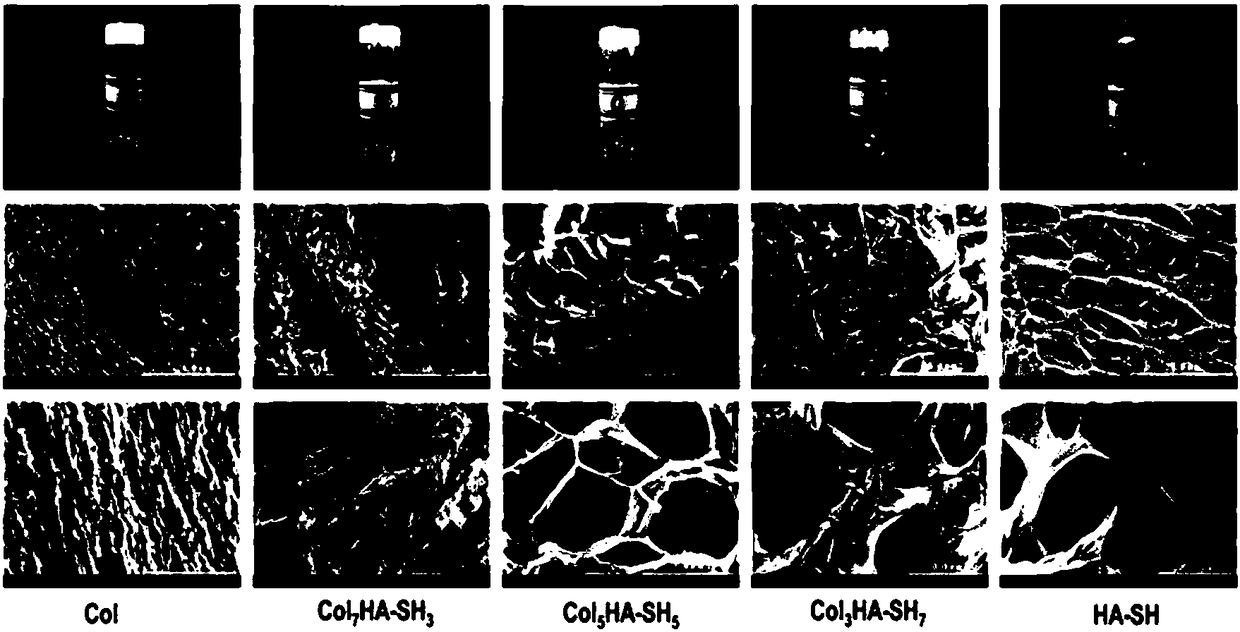

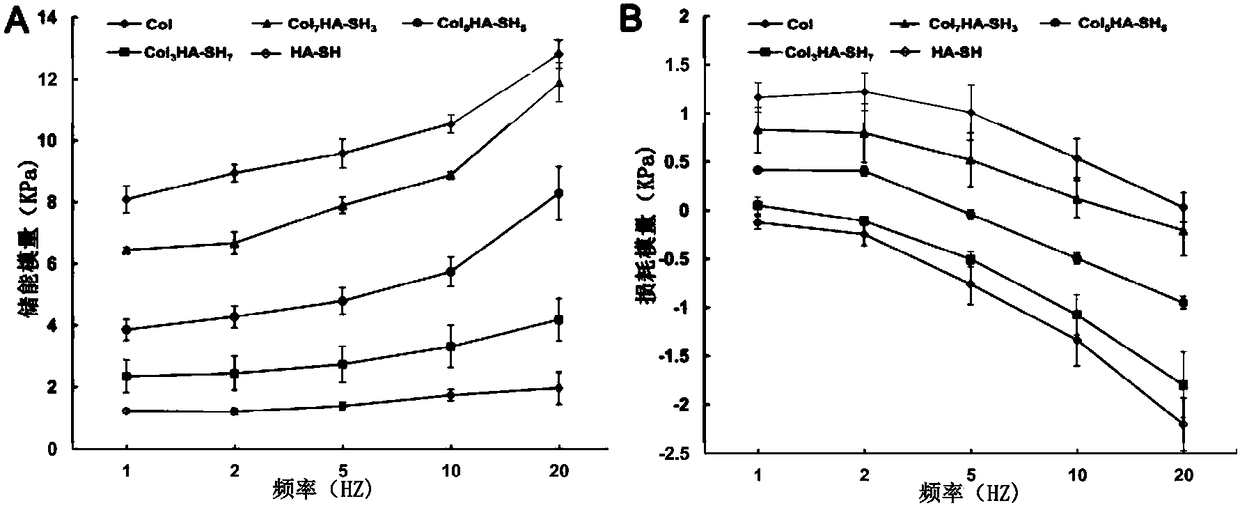

Controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as preparation method and application thereof

ActiveCN108084461AGood biocompatibilityGood biodegradabilityPharmaceutical delivery mechanismTissue regenerationCell adhesionChemistry

The invention provides controllable self-crosslinking sulfhydrylated hyaluronic acid-collagen composite hydrogel as well as a preparation method therefore. The composite hydrogel is prepared from hyaluronic acid hydrogel and I-type collagen or II-type collagen; the I-type collagen or II-type collagen is distributed in a three-dimensional crosslinking network structure. The composite hydrogel has rigidity and elasticity, is high in mechanical property, can promote spreading growth of cartilage cells, is favorable for phenotype maintaining for cells, can relieve the shortcomings that an existinggel material for cartilage reparation is easy to shrink and low in cell adhesion, and has an important application value in the field of cartilage injury reparation.

Owner:SICHUAN UNIV

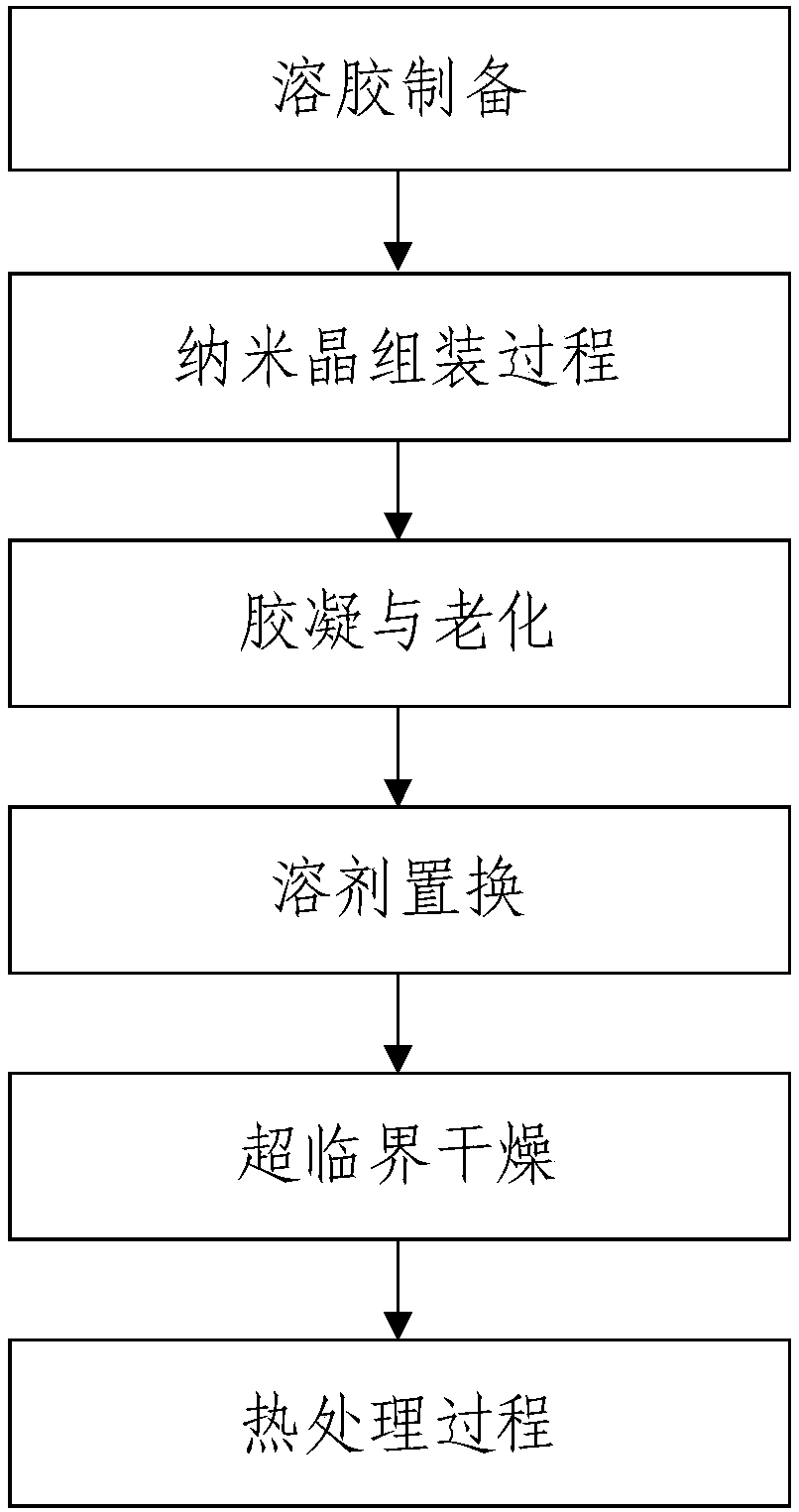

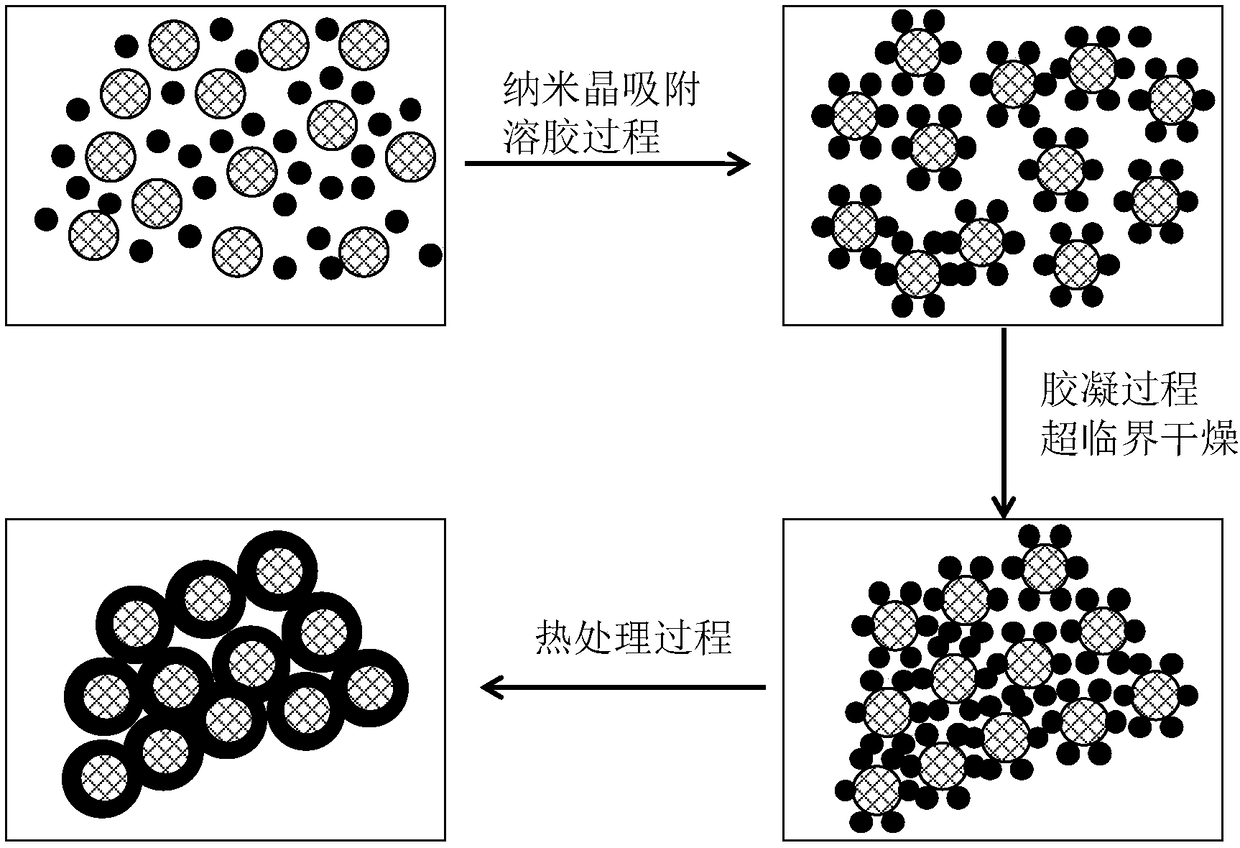

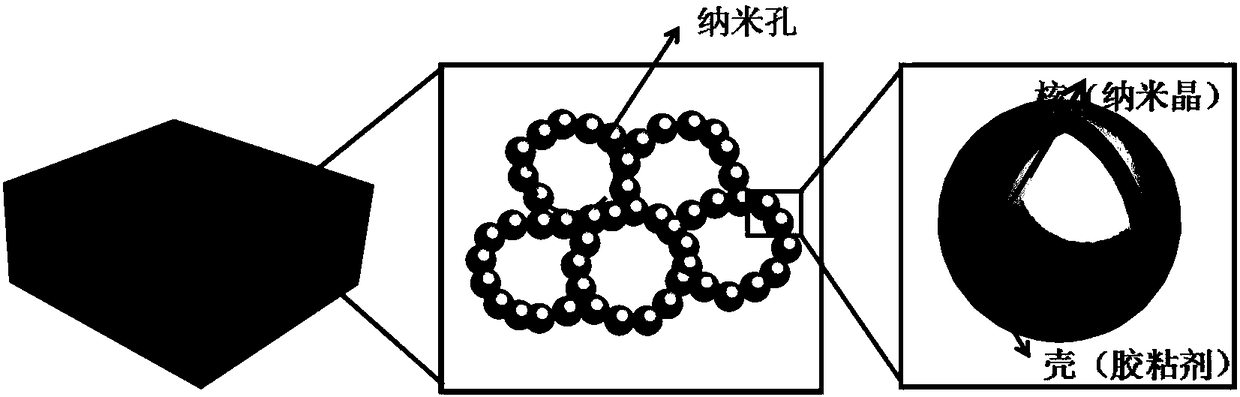

Preparation method of high-temperature-resisting aerogel material

The invention relates to a preparation method of a high-temperature-resisting aerogel material. The method comprises the following steps: (1) preparing sol; (2) carrying out a nano-crystal assemblingprocess to prepare aerogel wet gel which takes an oxide nano-crystal as a framework; (3) preparing an aerogel material; (4) carrying out a heat treatment process to prepare the high-temperature-resisting aerogel material. According to the preparation method provided by the invention, a nano-crystal assembling technology and heat treatment are combined to prepare the high-temperature-resisting aerogel material with a microcosmic core-shell structure; the core-shell structure forms a network framework under high temprature so that the growth of the oxide nano-crystal is inhibited and the shrinkage problem caused by the fact that the structure of oxide aerogel collapses in a high-temperature utilization process is effectively solved. The aerogel material prepared by the preparation method hasa good high-temperature-resisting property; the heat-resisting temperature is 1000 DEG C or more and the high-temperature-resisting aerogel material even can bear the high temperature of 1300 DEG C or more.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

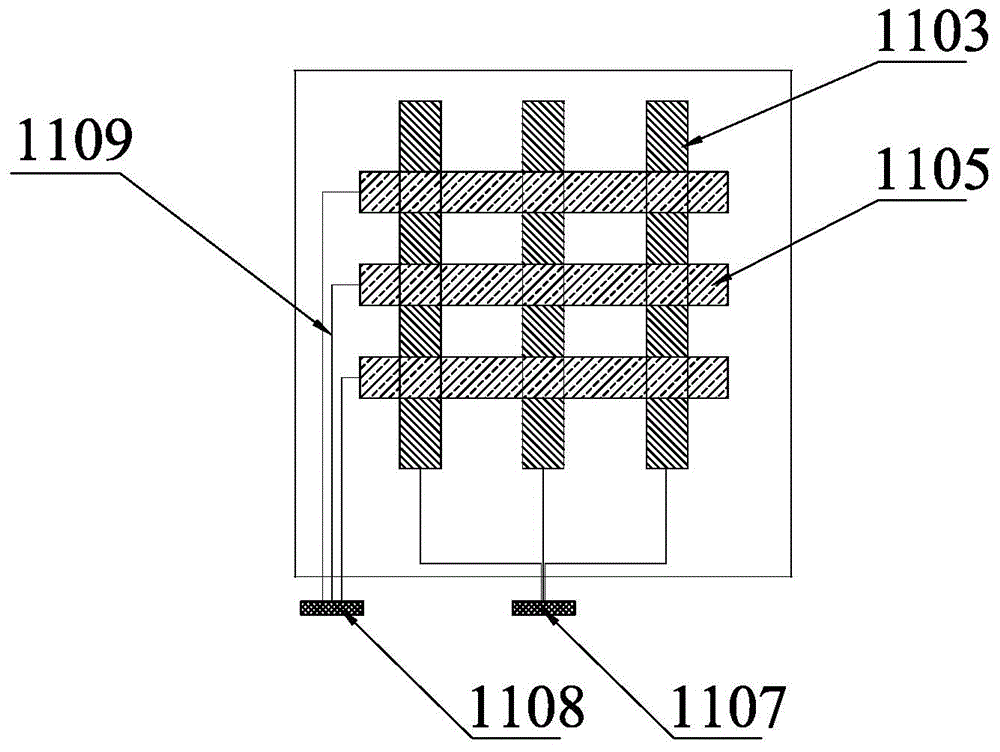

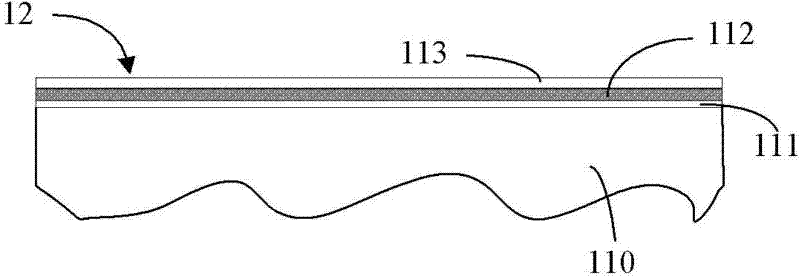

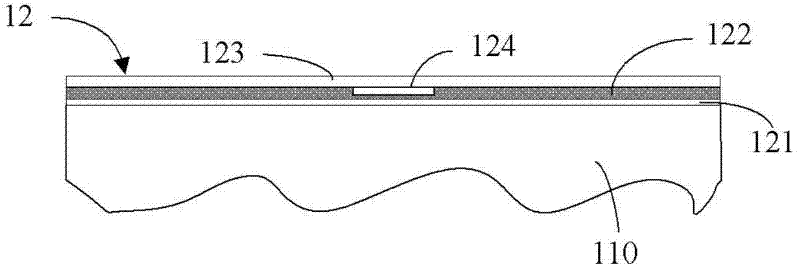

Capacitive touch control panel

ActiveCN105183246AImprove touch sensitivityReduce light transmissionInput/output processes for data processingElectrical and Electronics engineeringElectrode

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

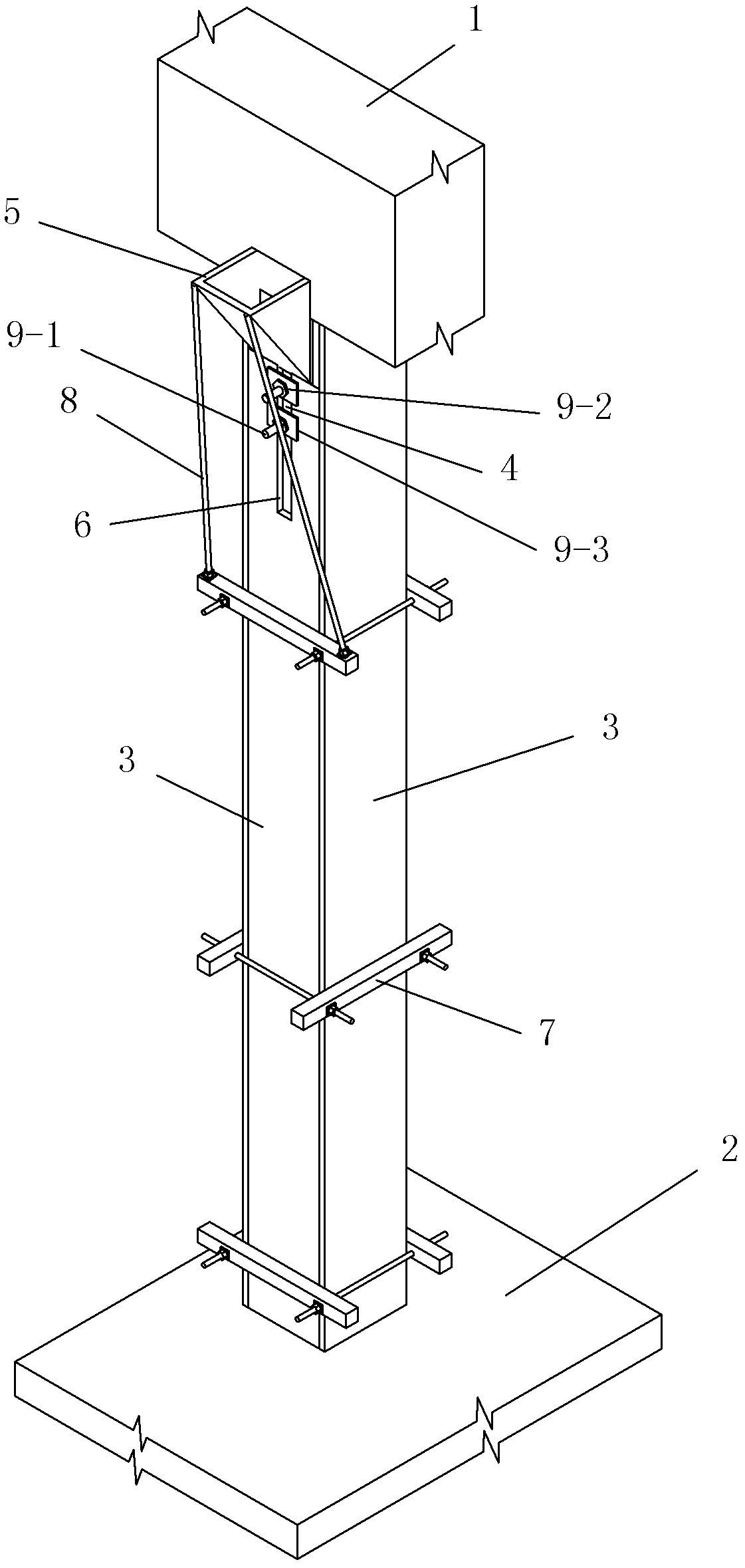

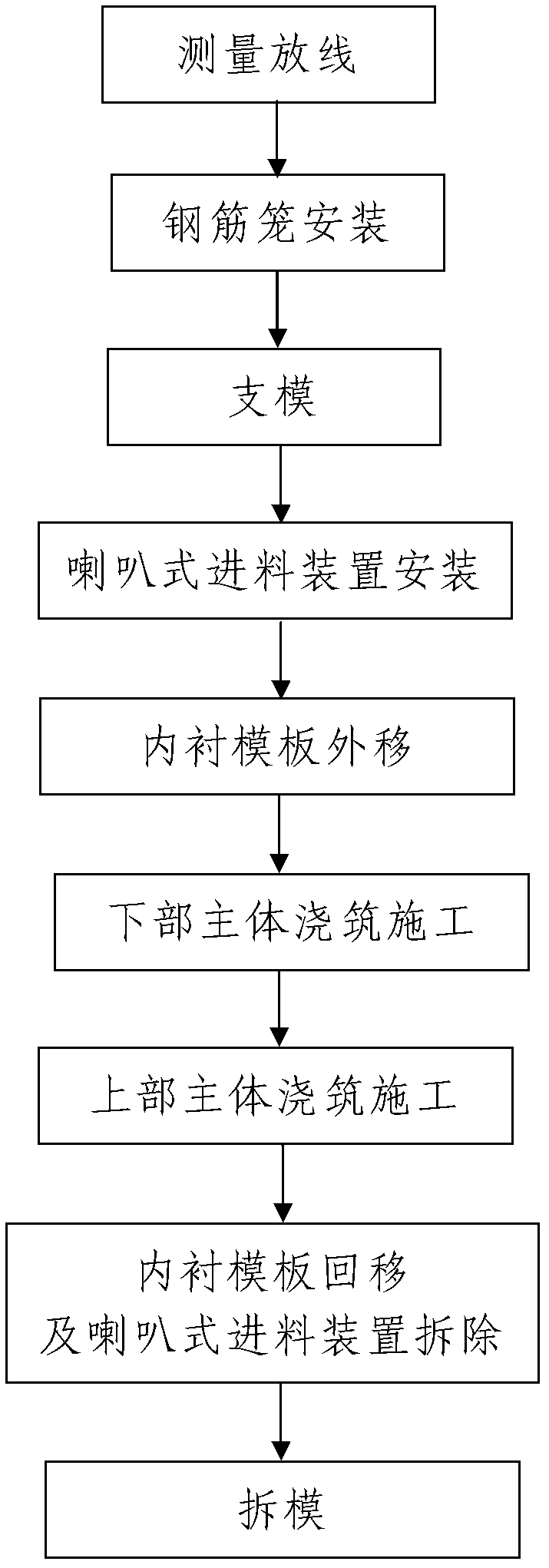

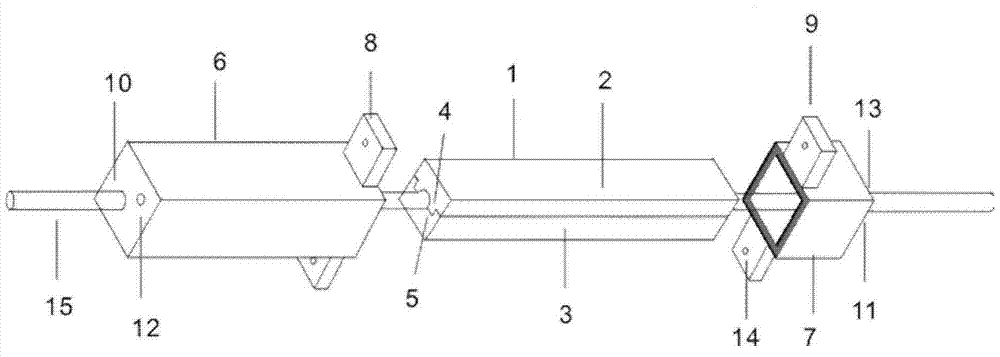

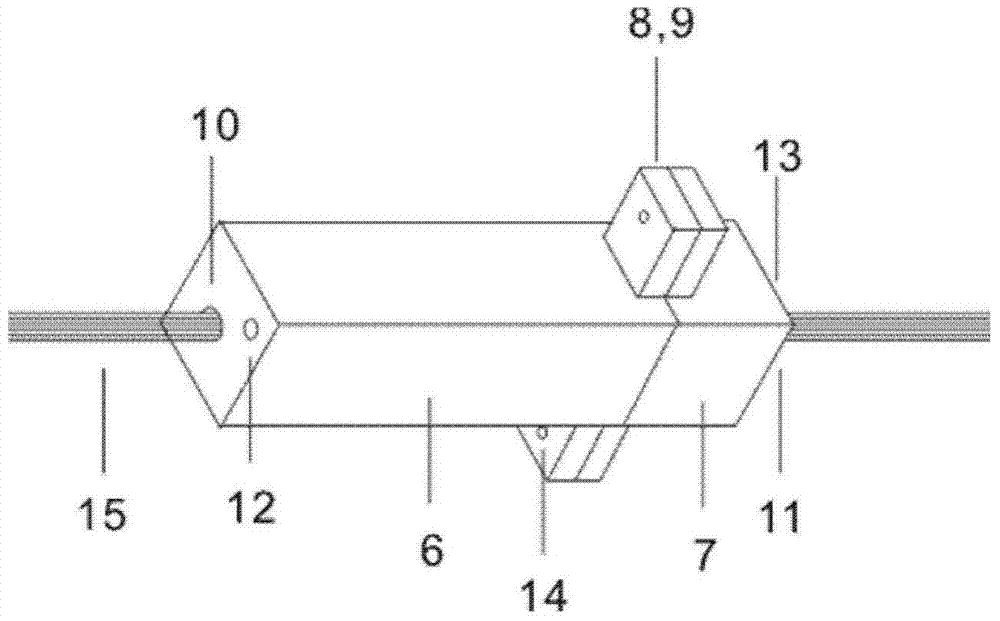

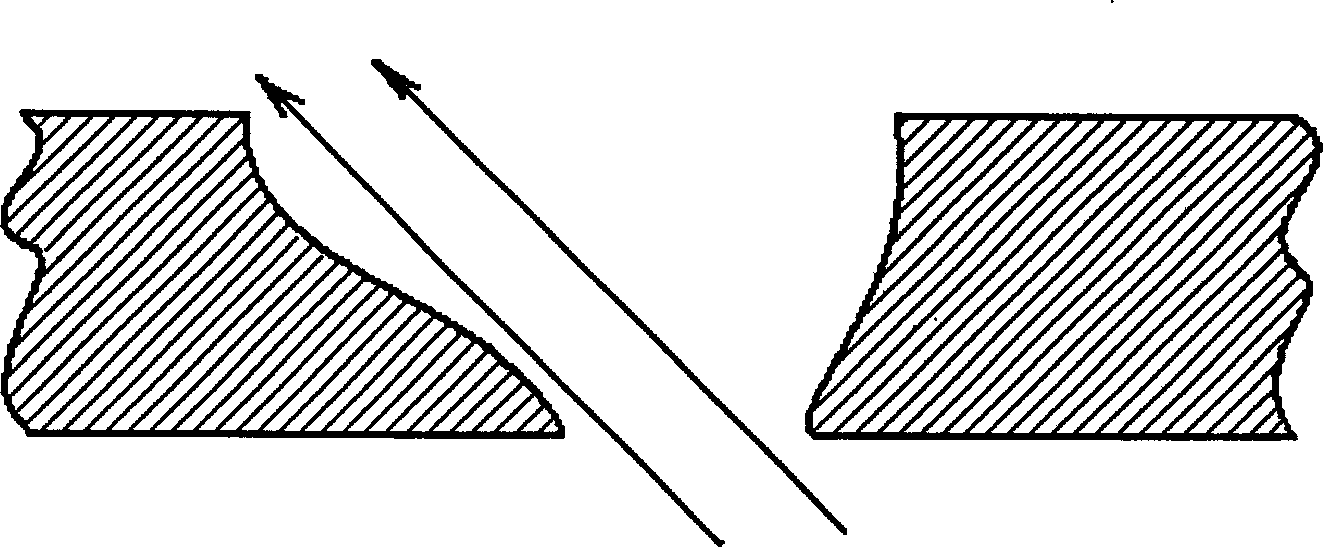

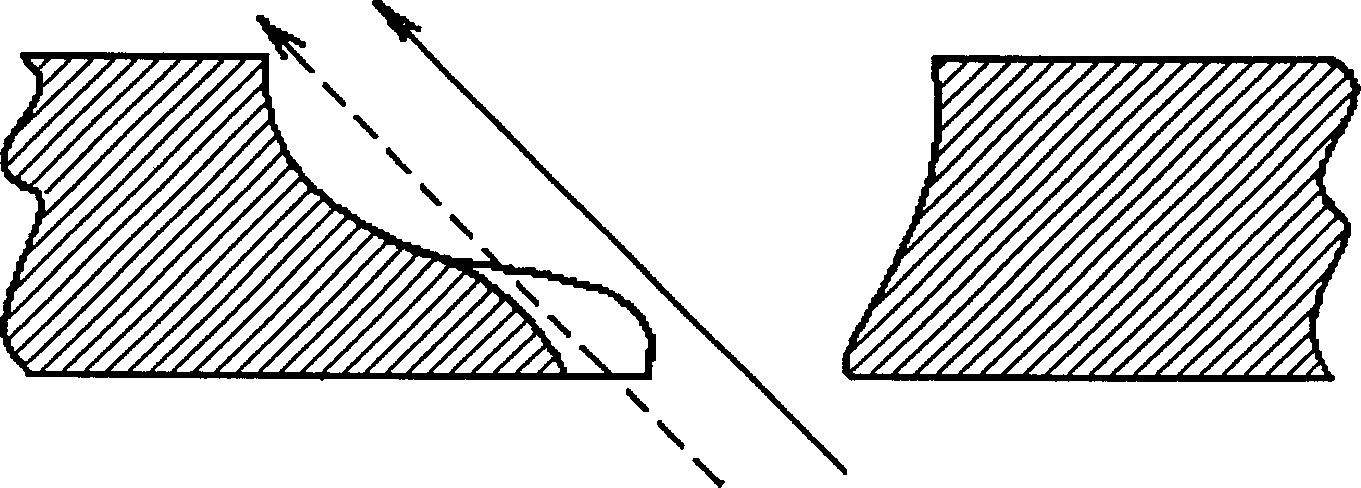

Casting molding template and casting molding process for constructional columns of infilled walls

InactiveCN102561681ASimple structureReasonable designForms/shuttering/falseworksBuilding material handlingMaterials scienceBuilding construction

The invention discloses a casting molding template and a casting molding process for constructional columns of infilled walls. The molding template comprises a lining template and a principal template, wherein the upper end part of the principal template is provided with a lining template installing slot for installing the lining template, the lining template and the principal template are assembled so as to form a constructional column template; and the lining template installing slot is provided with a horn-type feeding device, the lining template is a movable template which can carry out up-and-down motions or left-and-right motions on the inner wall of the principal template, and a template moving component is arranged on the outside surface of the lining template; and the molding process comprises the steps of 1, carrying out survey layout; 2, installing a reinforcement cage; 3, erecting the template; 4, installing the horn-type feeding device; 5, moving the lining template outwards; 6, carrying out casting construction; 7, moving back the lining template and removing the horn-type feeding device; and 8, removing the template. The casting molding template disclosed by the invention is reasonable in structure, simple in operation, economic, practical, time-saving, labor-saving and good in application effect, and can effectively solve various actual problems existing in the current construction on constructional columns of infilled walls.

Owner:陕西建工集团有限公司

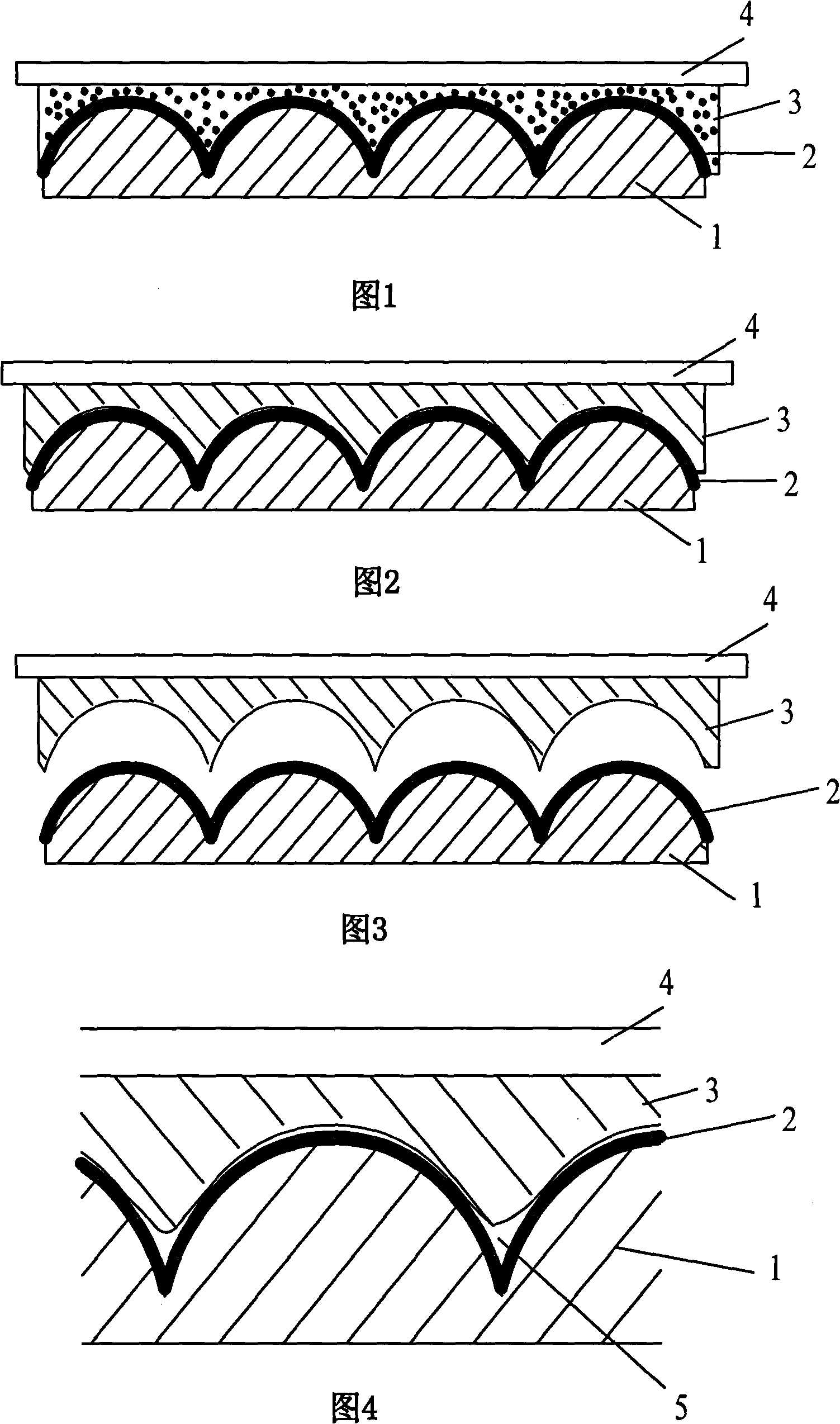

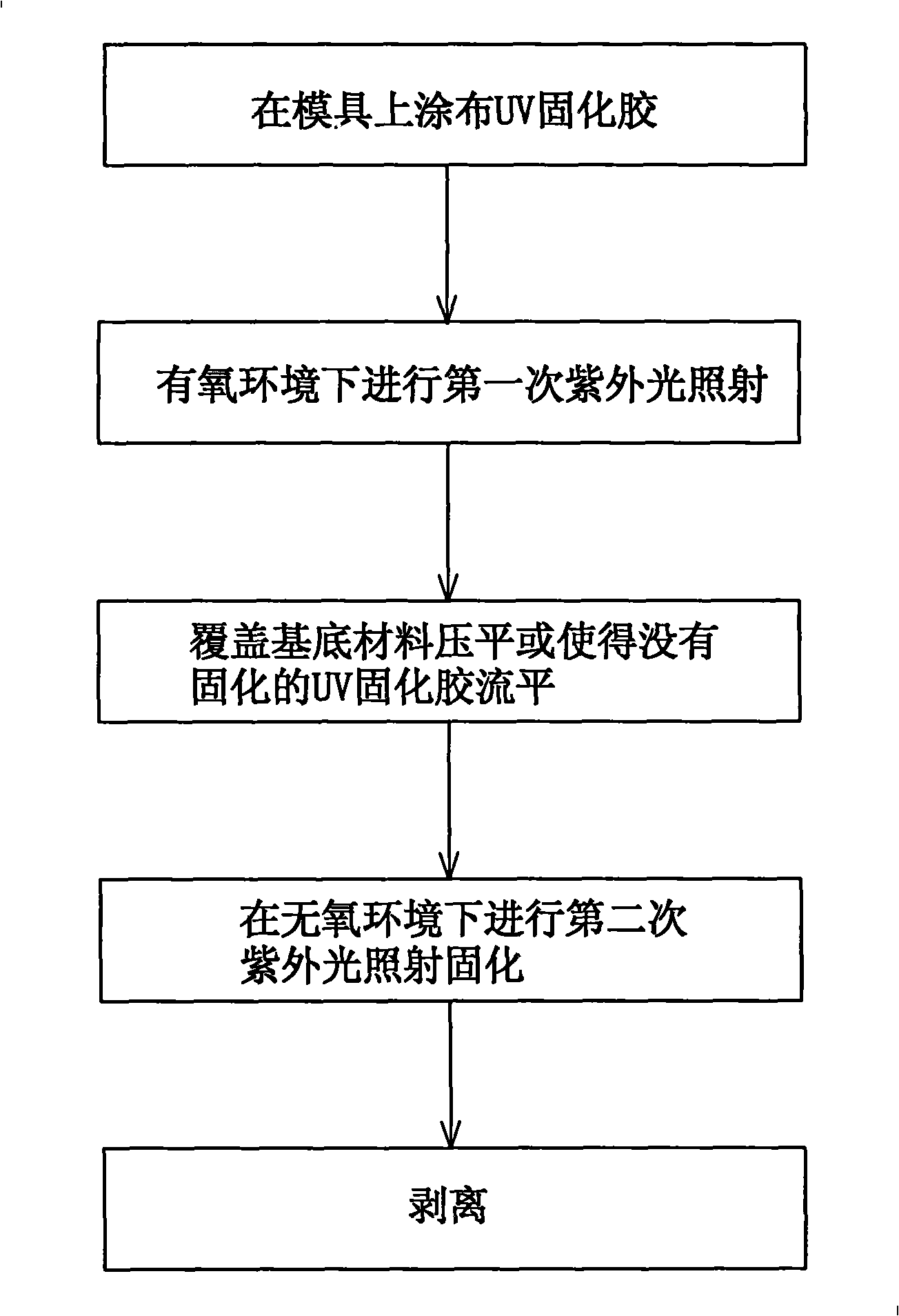

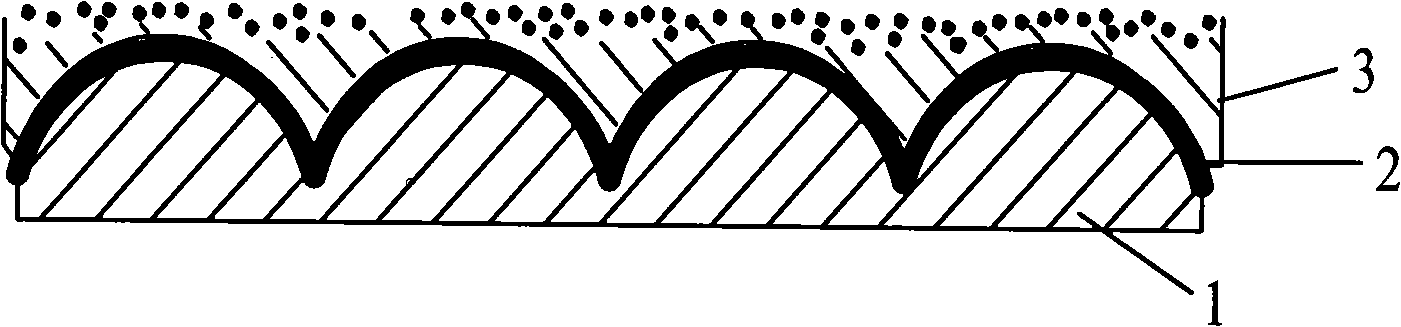

Method for manufacturing microlens array

ActiveCN101303421AResolve shrinkageArch height limitOptical articlesPretreated surfacesUV curingAdhesive

The invention discloses a preparation method for a micro-lens array, which comprises the following steps: Step 1, a UV curing adhesive is coated and distributed on a mold; Step 2, the mold coated and distributed with the UV curing adhesive is put in a polymerization inhibition atmosphere for ultraviolet radiation for the first time; Step 3, ultraviolet radiation for the second time is carried out in an atmosphere without polymerization inhibition; Step 4, peeling is carried out. A step of covering a substrate material can be included between the Step 2 and the Step 3. The UV curing adhesive can be a UV curing adhesive of oxygen polymerization inhibition type. The mold can be a columnar low arched parallel array mold or a columnar slightly concave parallel array mold; the method adopts a secondary ultraviolet curing method, which can well solve the problem of shrinkage of the UV curing adhesive when a columnar slightly concave lens array is prepared and is not limited by the arc height of a columnar micro-lens array.

Owner:SUPERD CO LTD

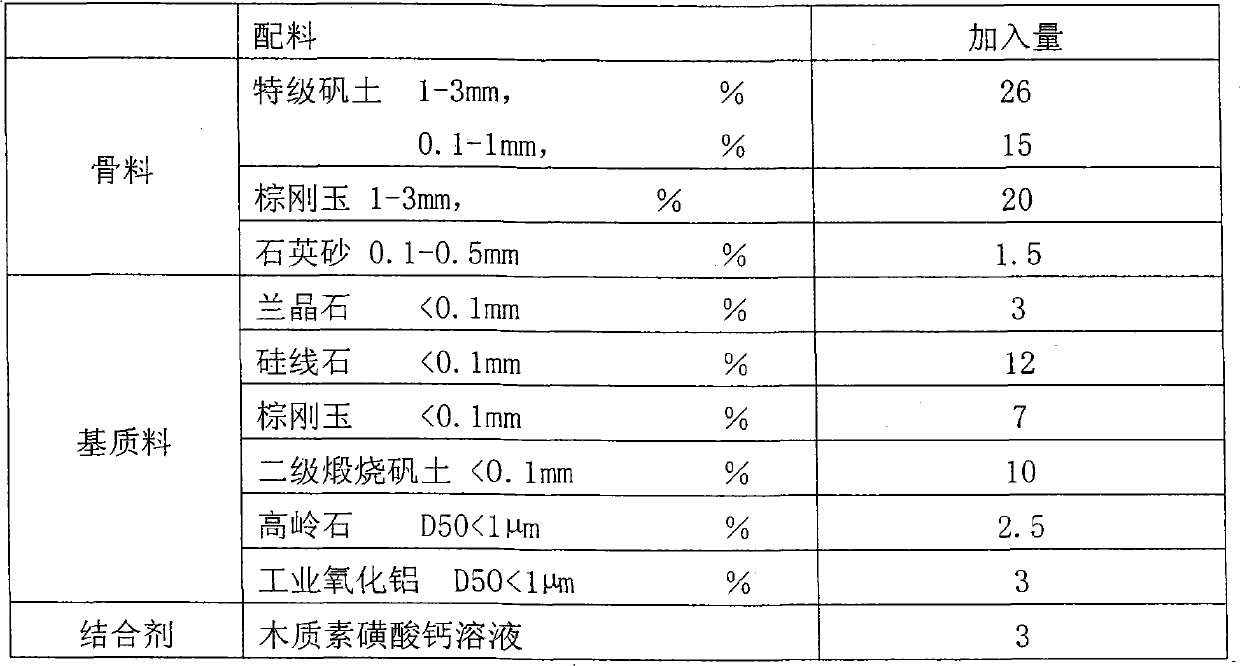

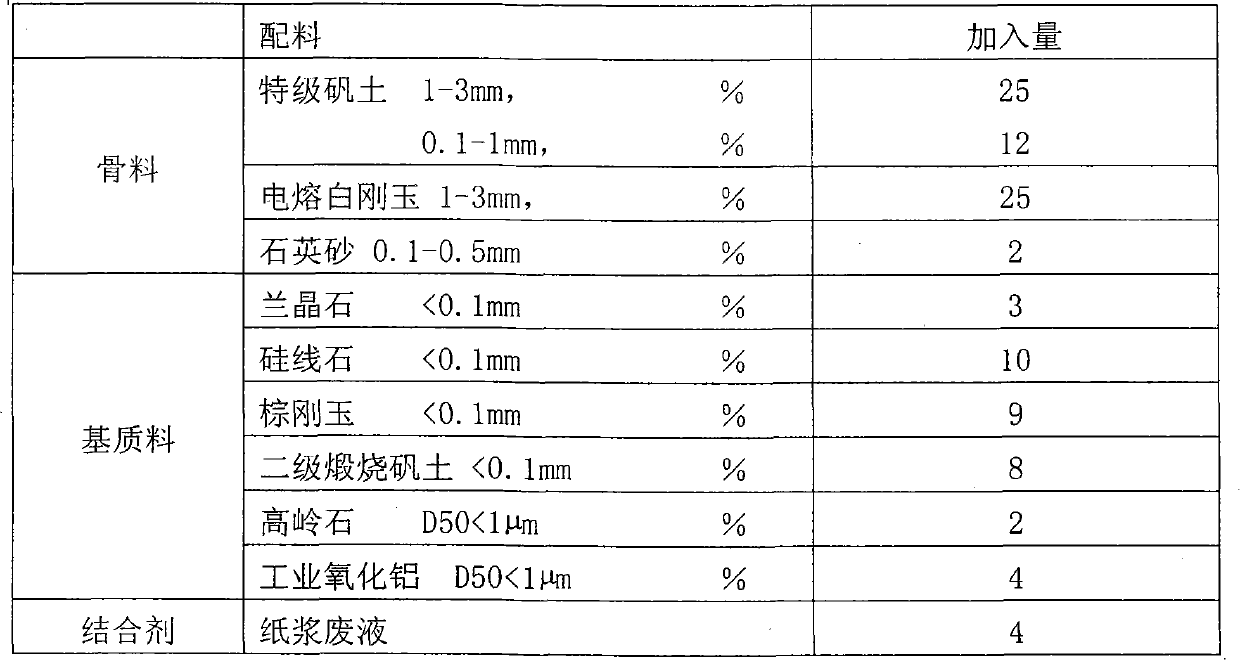

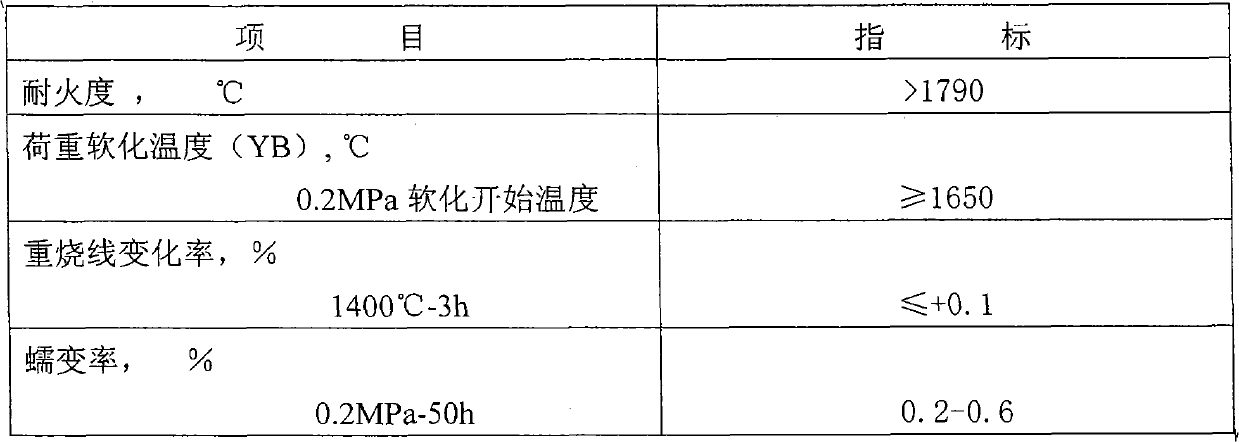

Bauxite-based low-creep mullite product

The invention provides a bauxite-based low-creep mullite product, which belongs to the field of fire-resistant materials. The bauxite-based low-creep mullite product is prepared by the following steps of: adding quartz sand, a sillimanite mineral, corundum, industrial aluminum oxide, kaolin and the like into high-alumina bauxite serving as a base material; proportioning, homogenizing, mixing, shaping and drying the mixture; and sintering the mixture at the temperature of 1,650 DEG C under the normal pressure to obtain the low-cost and high-grade bauxite-based low-creep mullite fire-resistant product. In the preparation, a composite technology route is adopted, the mineral composition is optimized and the mullitization during the production and use is effectively controlled, so the high-grade fire-resistant material product can be obtained, the superior high temperature performance of the mullite is brought into full play and the creep is small and the expansion is slight in the use of the product; and the preparation of the product can fully utilize the available resources of China, improve the comprehensive utilization value of the resources and optimize the product structure. The product can be widely applied to the parts, such as heat storage chambers, small furnaces, feeding ports, material passage systems and the like, of glass melting furnaces and other high temperature industrial furnaces.

Owner:山西高科耐火材料股份有限公司

Shell and manufacturing method thereof

InactiveCN102365007AResolve shrinkageDiversifiedThin material handlingMetal layered productsMetal coatingPrinting ink

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

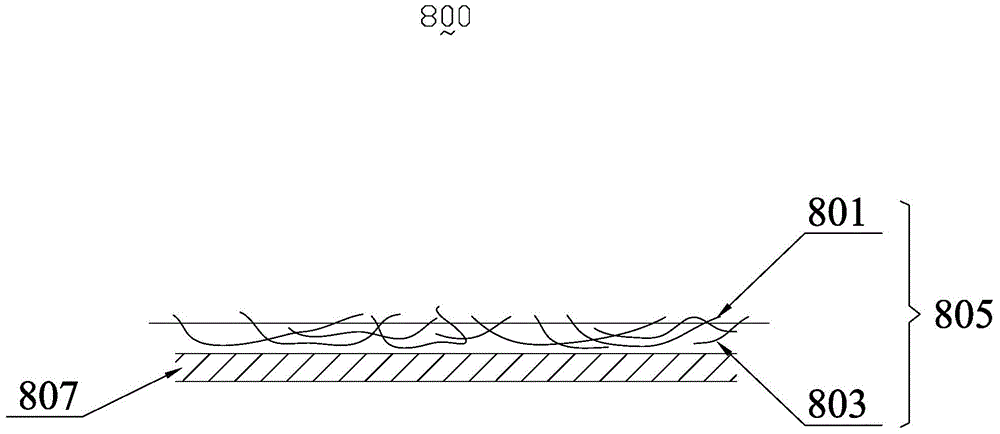

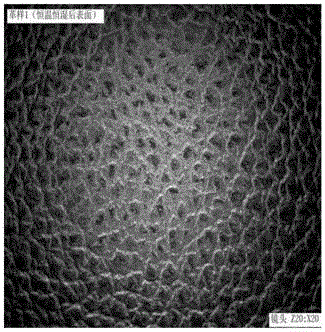

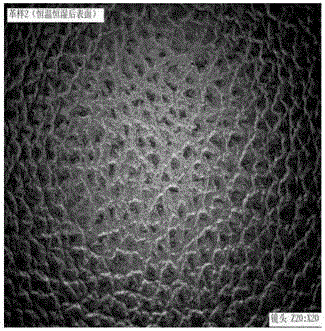

Soft sheepskin-imitating polyurethane resin, preparation method thereof, and method of producing sheepskin-imitating artificial leather therewith

ActiveCN105671989AImprove immersionMuch infiltrationGlovesPolyurea/polyurethane coatingsN dimethylformamideWear resistance

The invention relates to soft sheepskin-imitating polyurethane resin which includes the following components: wet-method polyurethane resin, N,N-dimethylformamide, paper pulp powder, a hand feeling agent, a permeation agent, an anti-crimping agent and an oily color material. The invention also relates to a method of producing sheepskin-imitating artificial leather with the soft sheepskin-imitating polyurethane resin, wherein the method includes the following steps: 1) impregnating a base cloth in a soft sheepskin-imitating polyurethane resin mixture liquid; 2) regulating sizing quantity through extrusion, and performing solidification, water washing, drying and polishing to prepare wet-method base; and 3) performing veneering and vacuum grain suction to the wet-method base to prepare the sheepskin-imitating artificial leather. The sheepskin-imitating artificial leather has a soft and light feel, has fine and elastic hand feeling, is high in tear strength and good in weather and wear resistance, has a soft and natural surface color, has full grains and has strong stereoscopic sense.

Owner:SHANGHAI HUIDE TECH CO LTD

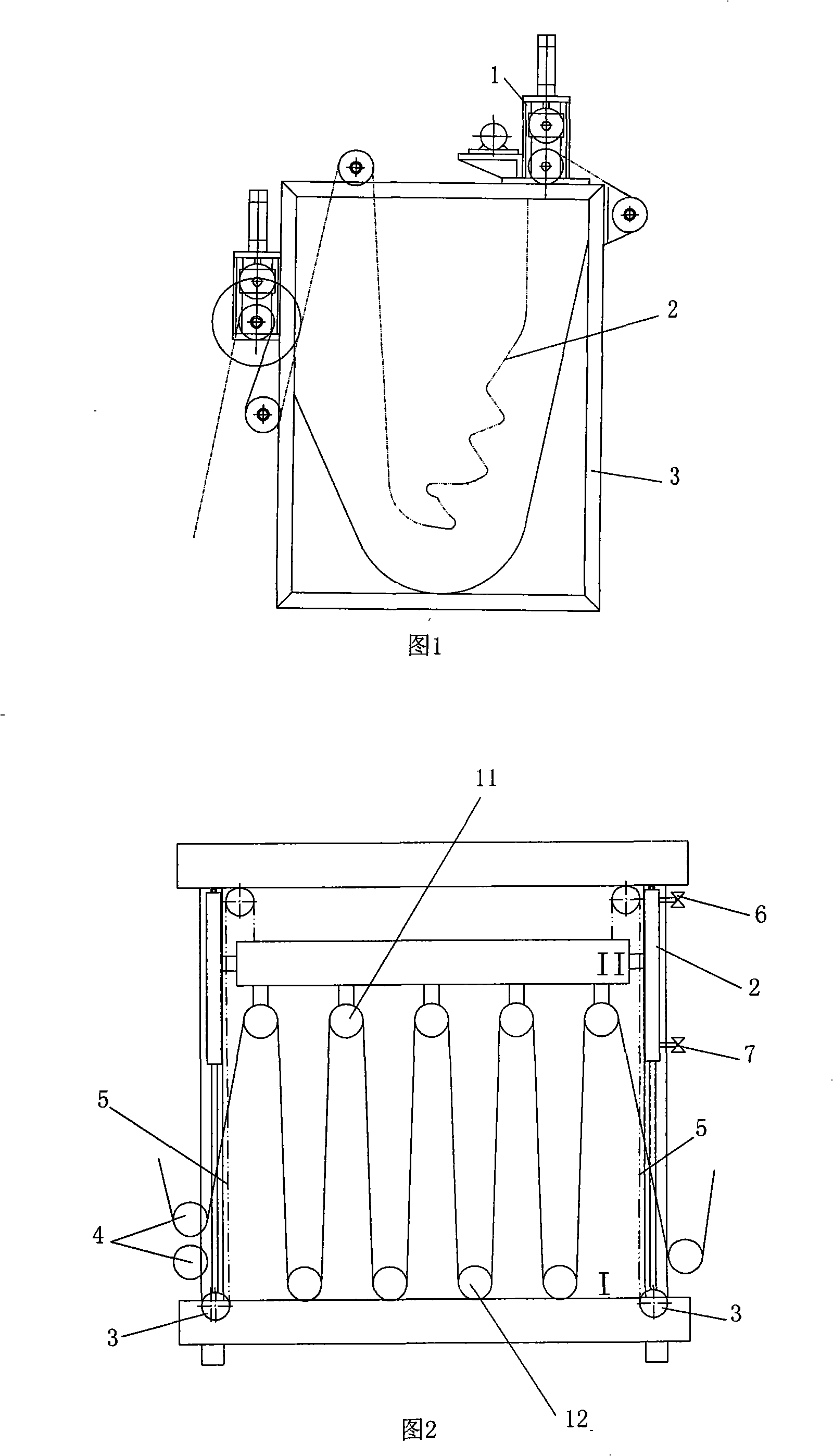

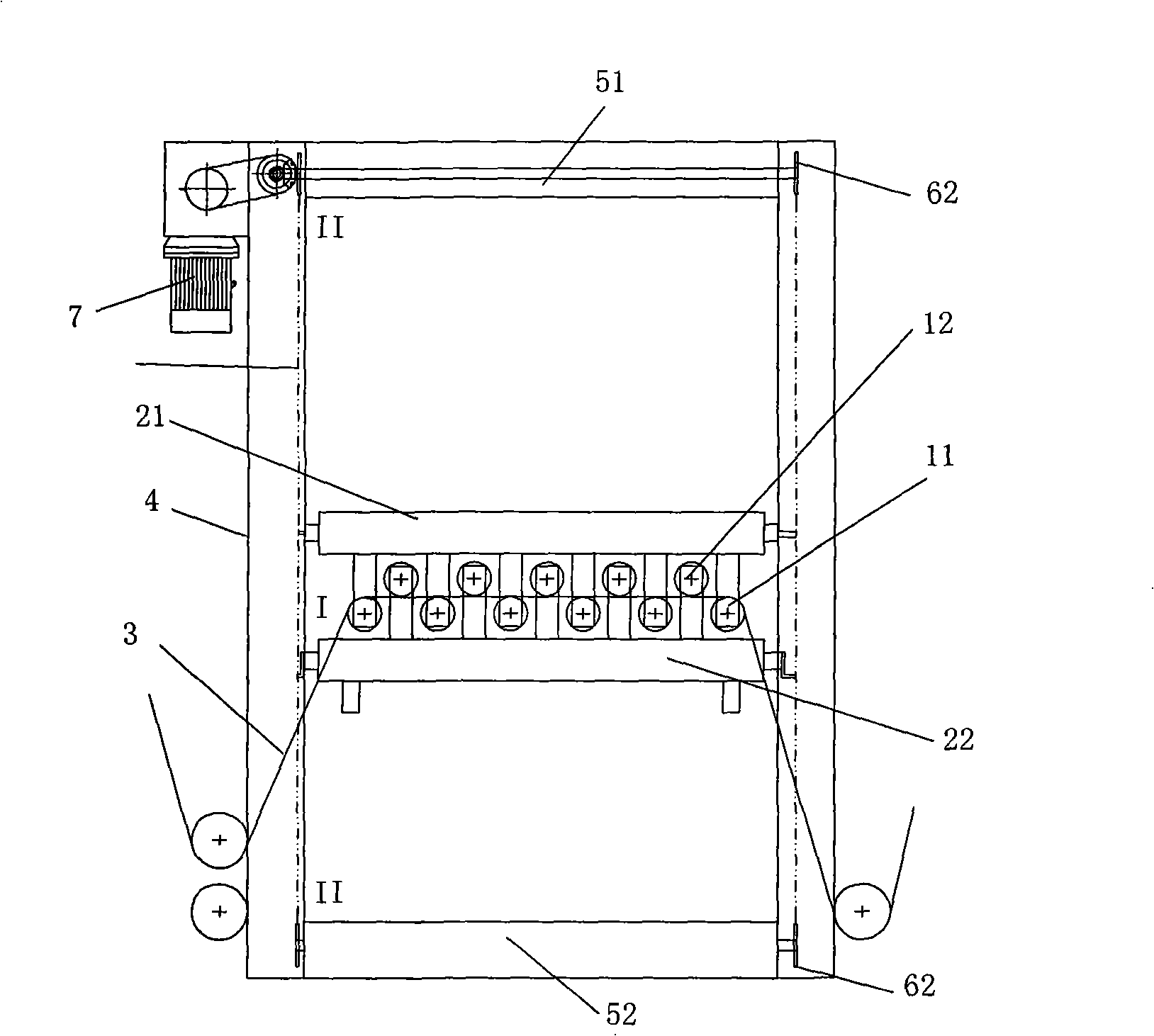

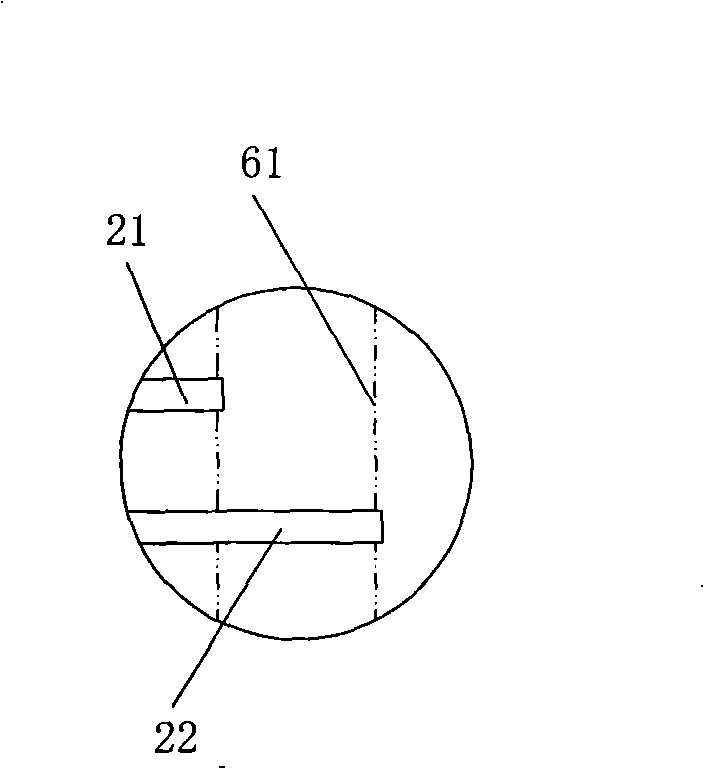

Self-tension cloth storage device

ActiveCN101353851AEasy to operateDoes not affect continuous operationTextile treatment carriersEngineeringSprocket

The invention provides a cloth accumulator with self tension, which is provided with upper rollers and lower rollers reversely. The cloth moves in a Z-shaped way alternately on the upper and the lower rollers. The cloth accumulator with self tension is characterized in that: a transmission mechanism is arranged in a cloth storage box in rectangular frame shape; the top frame and the bottom frame of the rectangular frame are provided with a top rob and a bottom rob that are provided with sprocket wheels respectively; an annular gearing chain which forms the chain and sprocket transmission mechanism with the sprocket wheels which are positioned at the corresponding positions of the ends of the top and the bottom robs is arranged on the frames at the two sides of the rectangular frame. An upper roller shelf and a lower roller shelf are hung and arranged at the different sides of the annular gearing chain to form reverse movement between the upper roller shelf and lower roller shelf. The invention can solve not only the problem of tension in the consecutive production process of the cloth, but also the constriction problem of the textiles in production, thus improving the cloth accumulating speed and simplifying the operation process.

Owner:ANHUI ANLI MATERIAL TECH

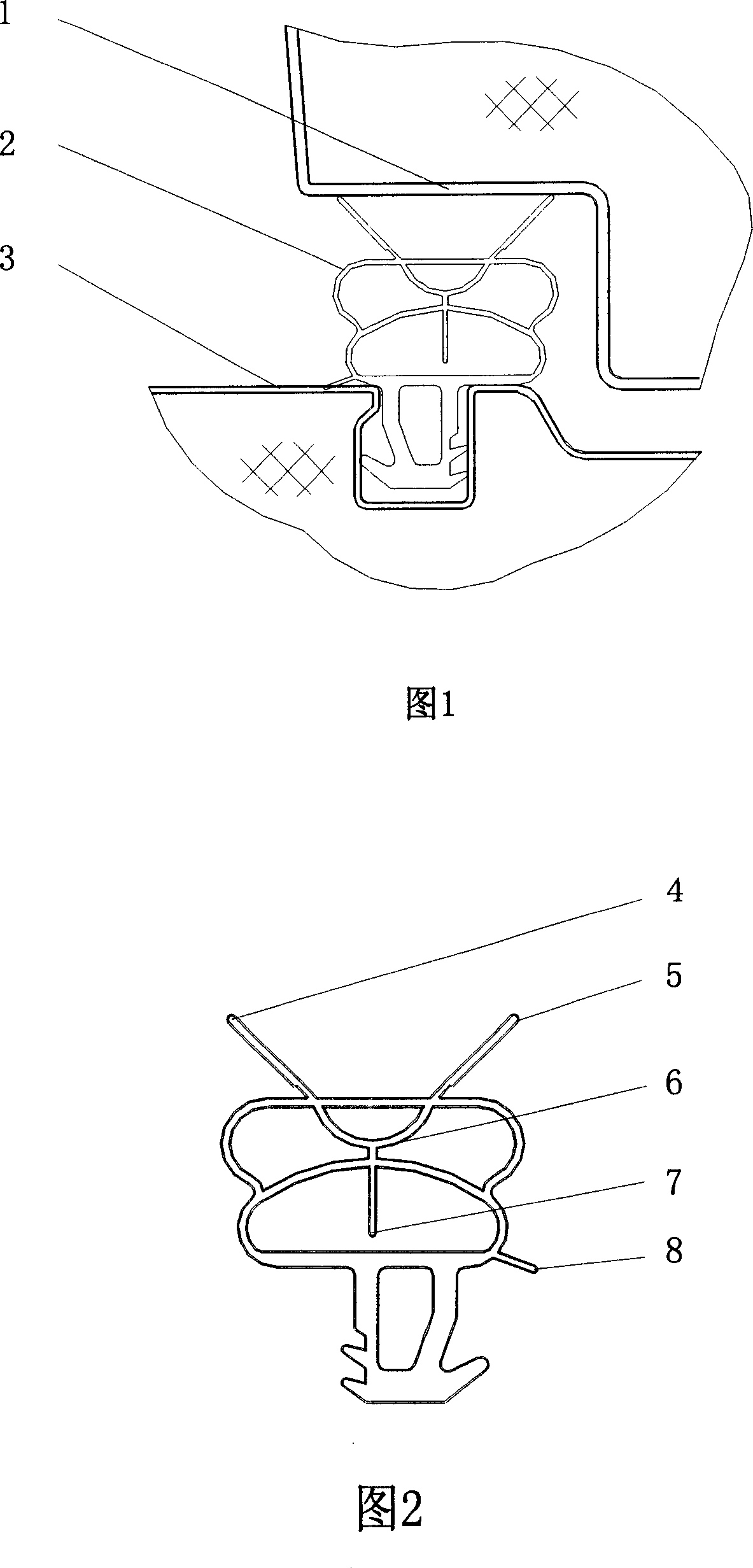

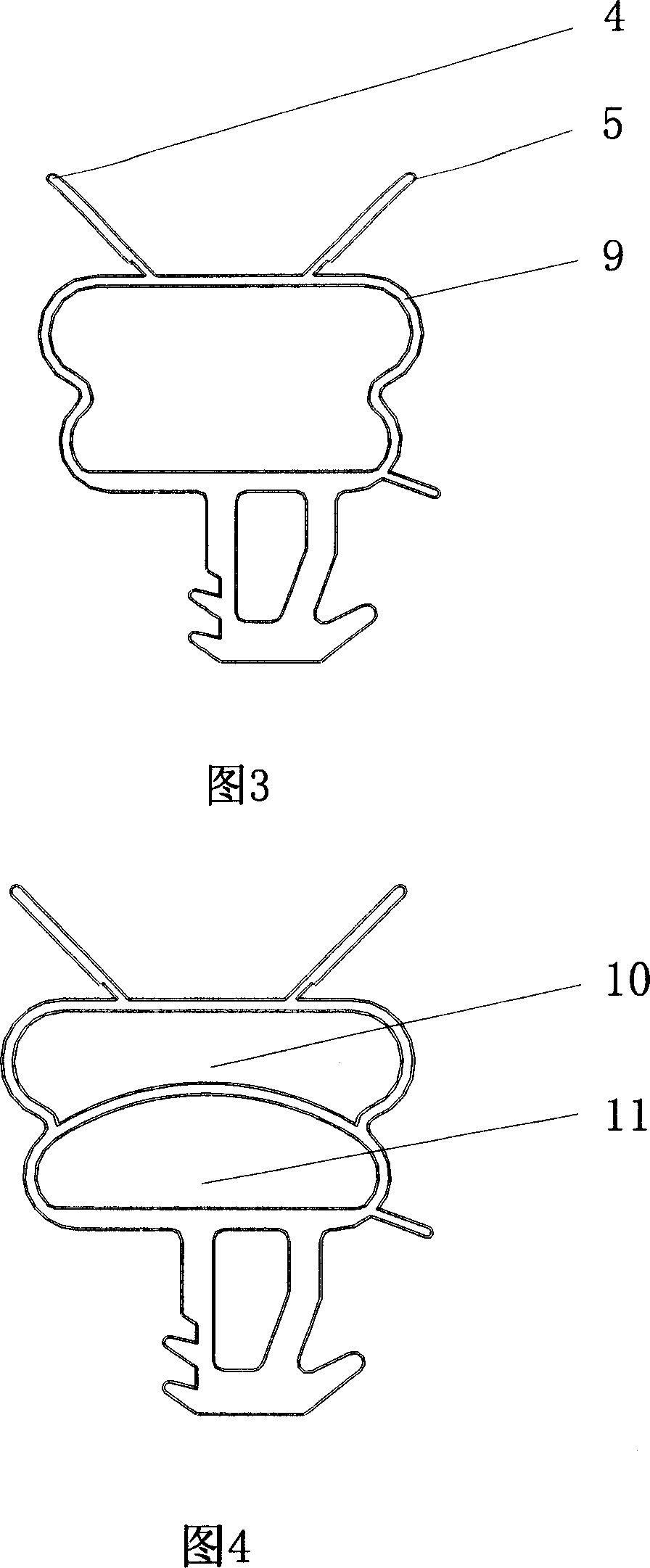

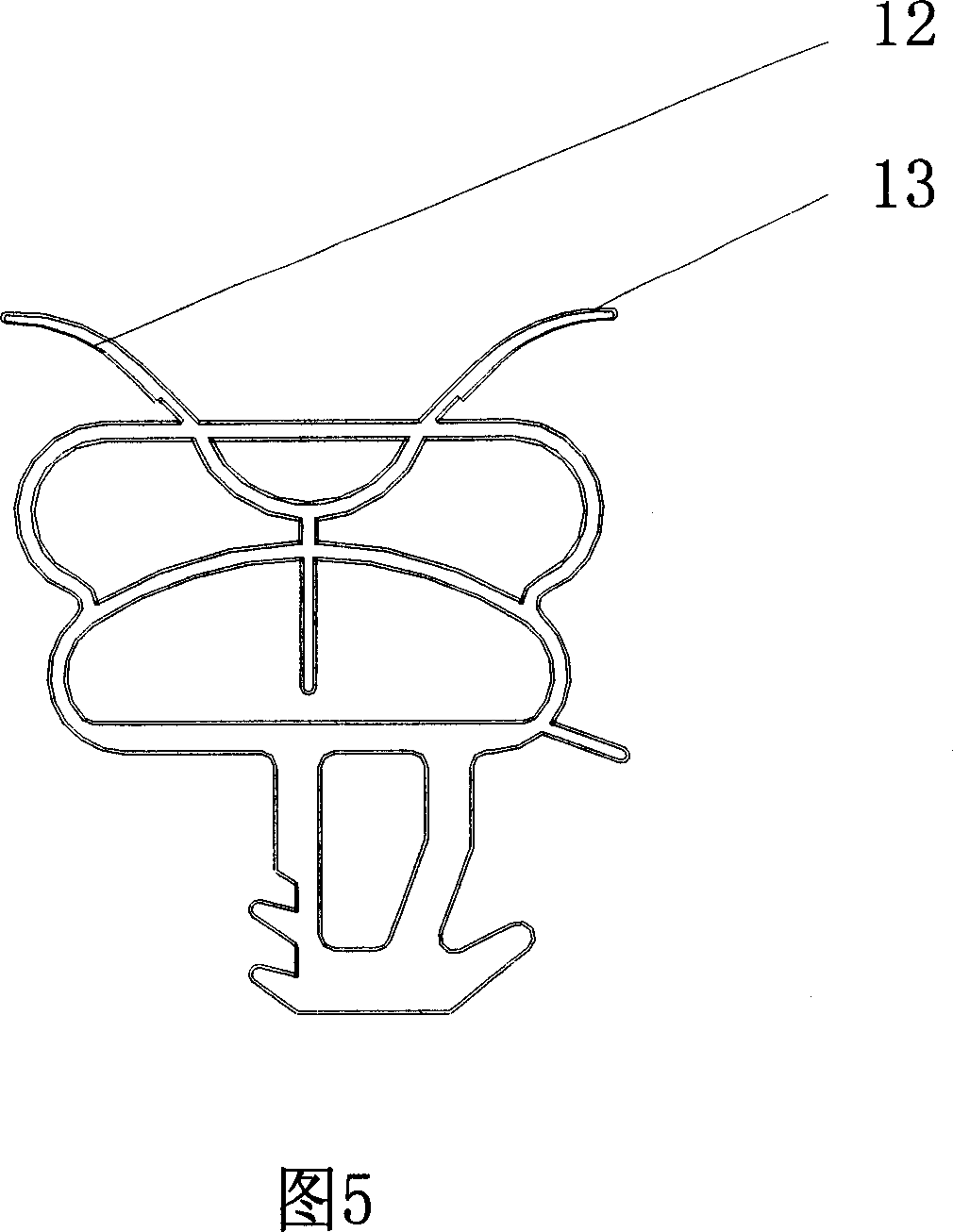

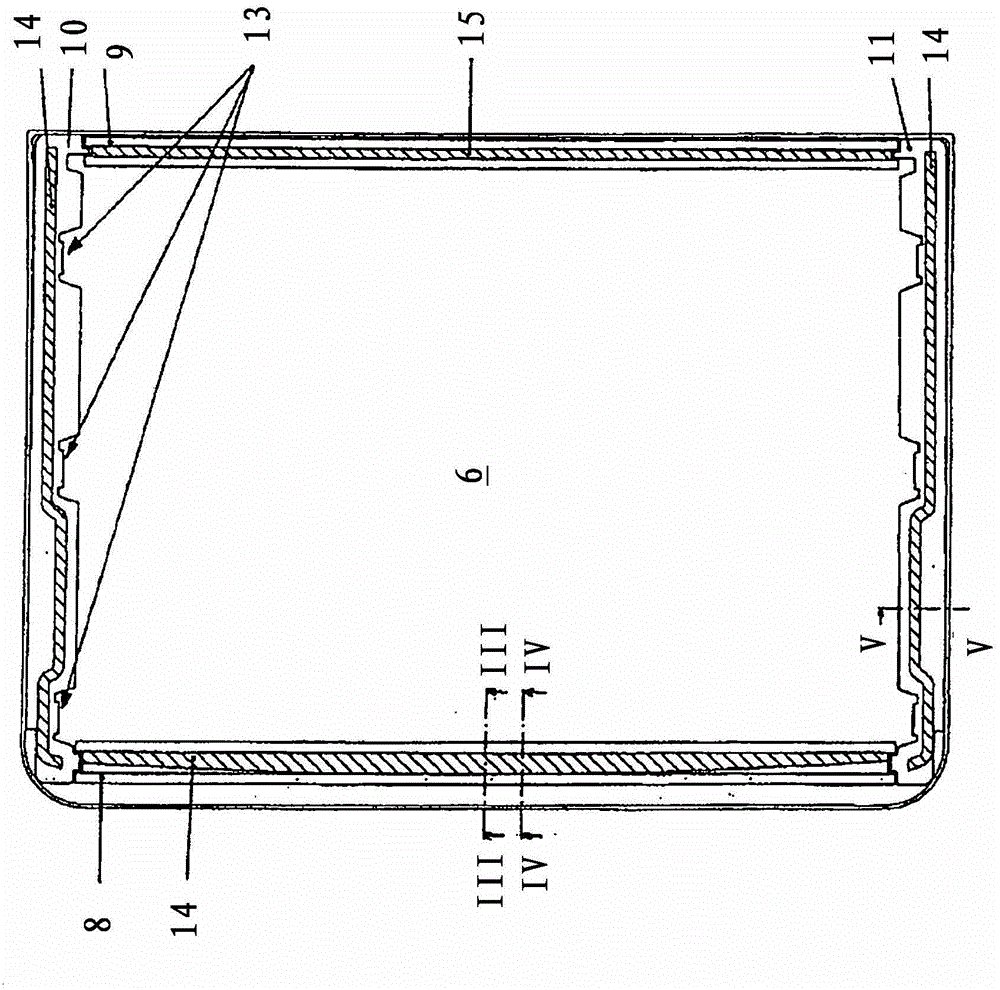

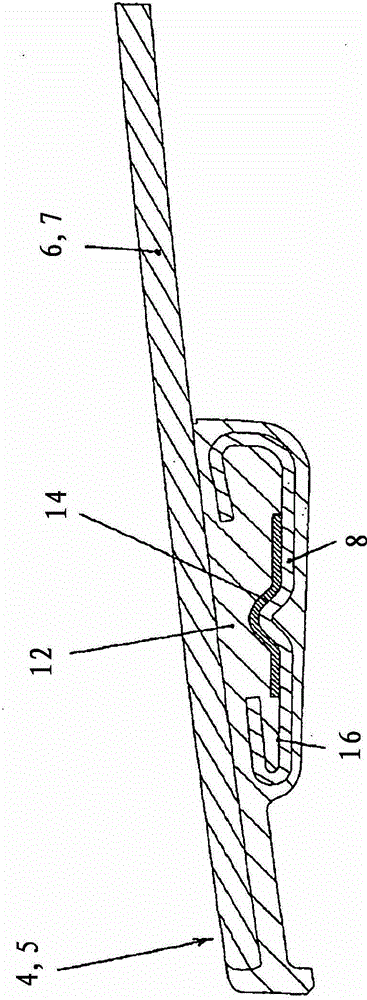

Door seal structure in refrigerator

ActiveCN101086408AIncrease elasticityImprove adaptabilityDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

The invention discloses an inner door sealing structure of fridge, which comprises the following parts: air bag, assembling foot on the door of fridge, wherein the inner door seal is set at inner side of main door seal; the fin is set on the external end face of air bag to seal; the thickness of root of fin is less than the thickness of wing part. The invention seals the inner door of fridge effectively without insufficient elastic and weak adaptation problem, which improves the energy-saving effect of fridge greatly.

Owner:HISENSE HOME APPLIANCES GRP CO LTD

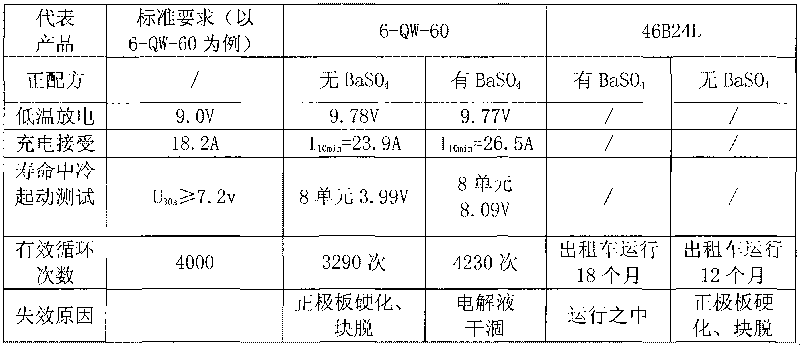

Storage battery anode lead plaster capable of enhancing SAE standard high temperature service life and preparation method

InactiveCN101707249AMeet the requirements of high temperature lifeResolve shrinkageLead-acid accumulator electrodesPorosityFiber

The invention discloses a storage battery anode lead plaster capable of enhancing SAE standard high temperature service life and a preparation method, aiming at solving the problem of high temperature service life of lead-acid storage batteries. The technical scheme is that the lead plaster raw materials are prepared by the following substances in parts by weight: 100 of lead powder, 0.05-0.1 of fiber, 0.1-1.0 of superfine barium sulfate, 0.05-0.2 of carbon black, and 0.1-0.4 of magnesium sulfate. The invention selects superfine barium sulfate as anode additive, thus delaying contraction and rigidification of anode plate under high temperature and prolonging service life of the storage battery; magnesium sulfate and carbon black improve the porosity of the anode active substance, facilitates dispersion of sulfuric acid and is beneficial for starting performance of the storage battery. Proved by test data, main technical performance index can perfectly achieve and surpass the standard requirement, and satisfy the requirement of the automobile on the high temperature service life of the storage battery.

Owner:中国船舶重工集团动力股份有限公司

Micromachining method for manufacturing polymer cylindrical microlens by electric field induction

InactiveCN102253435AEasy to processReduce processing costsPhotomechanical apparatusLensElectrical field strengthUltraviolet lights

The invention discloses a micromachining method for manufacturing a polymer cylindrical microlens by electric field induction. The method comprises the following steps of: machining on a SiO2 substrate to form a transparent conductive grid structure, spinning an SU-8 photoresist, photoetching and developing a circle of bracket to form a cylindrical electric field contour surface, and evaporating a conductive indium tin oxide (ITO) layer at the bottom of the SiO2 substrate; spinning ultraviolet curing polymer, and pressing a transparent template on the ultraviolet curing polymer to make the bracket made of the SU-8 photoresist pressed into a polymer film; making the conductive grid structure of the plane generate the cylindrical electric field contour surface on the surface of the polymer film by using a direct current power supply, and forming a cylindrical microlens structure; keeping polymer rheology under an electric field with a stabilized voltage value to form the cylindrical microlens structure; and finally, exposing the curing polymer through ultraviolet light, and removing the template to obtain a needed polymer cylindrical microlens array. The method has the advantages of high production efficiency, simple process and low cost.

Owner:XI AN JIAOTONG UNIV

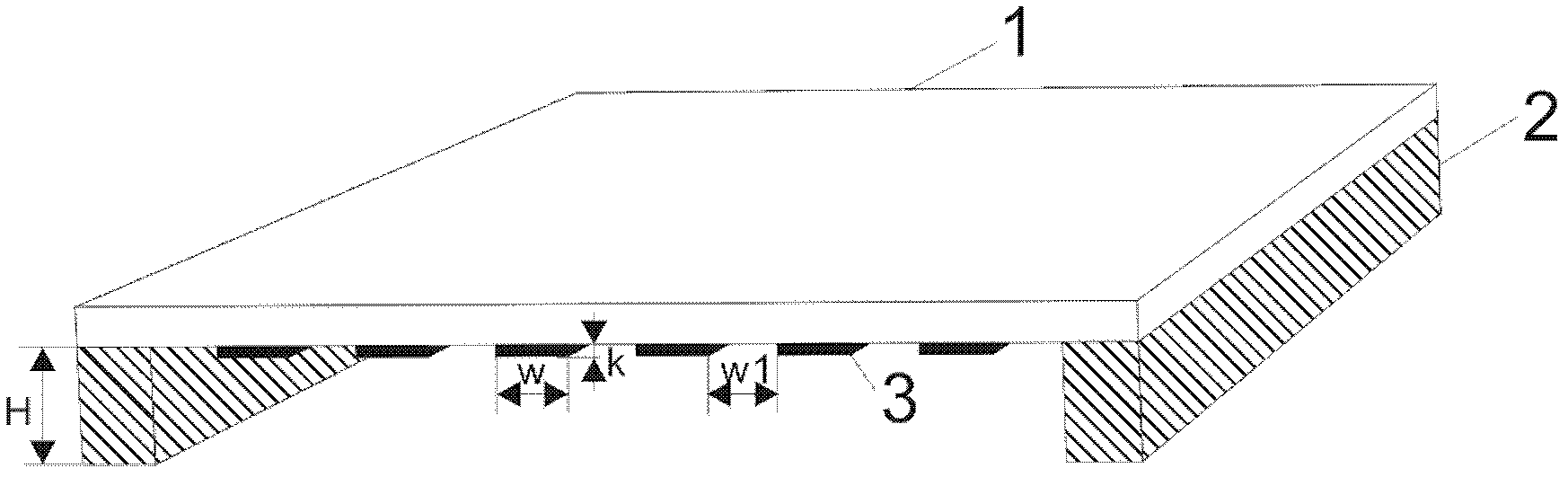

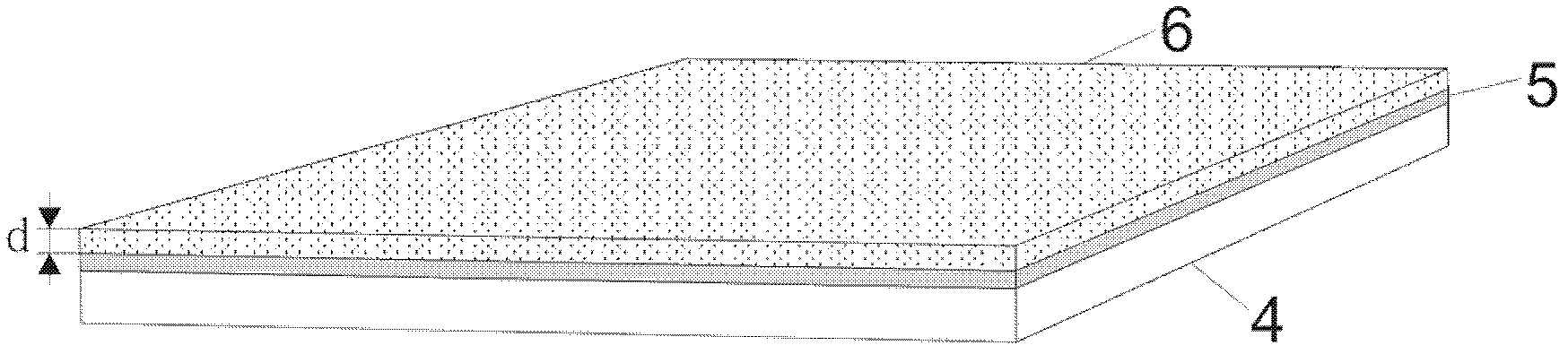

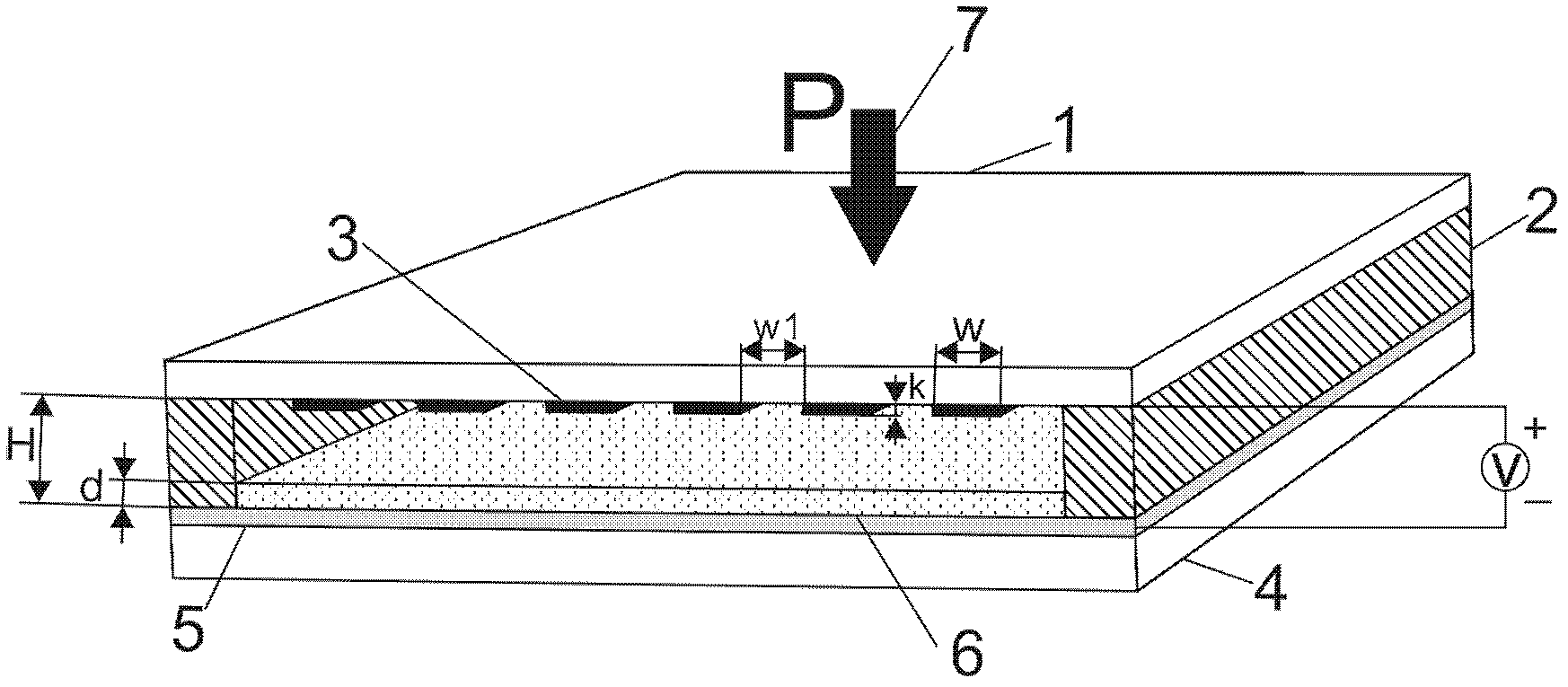

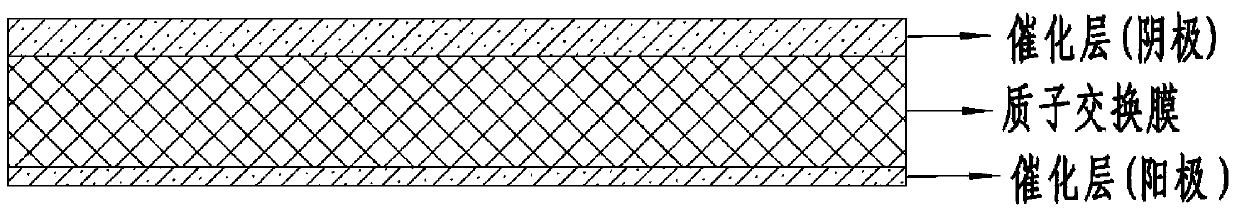

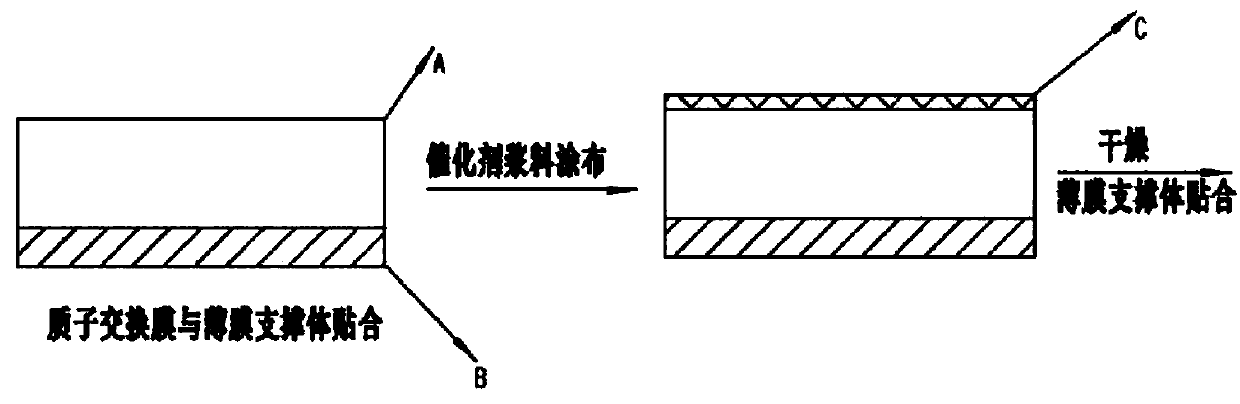

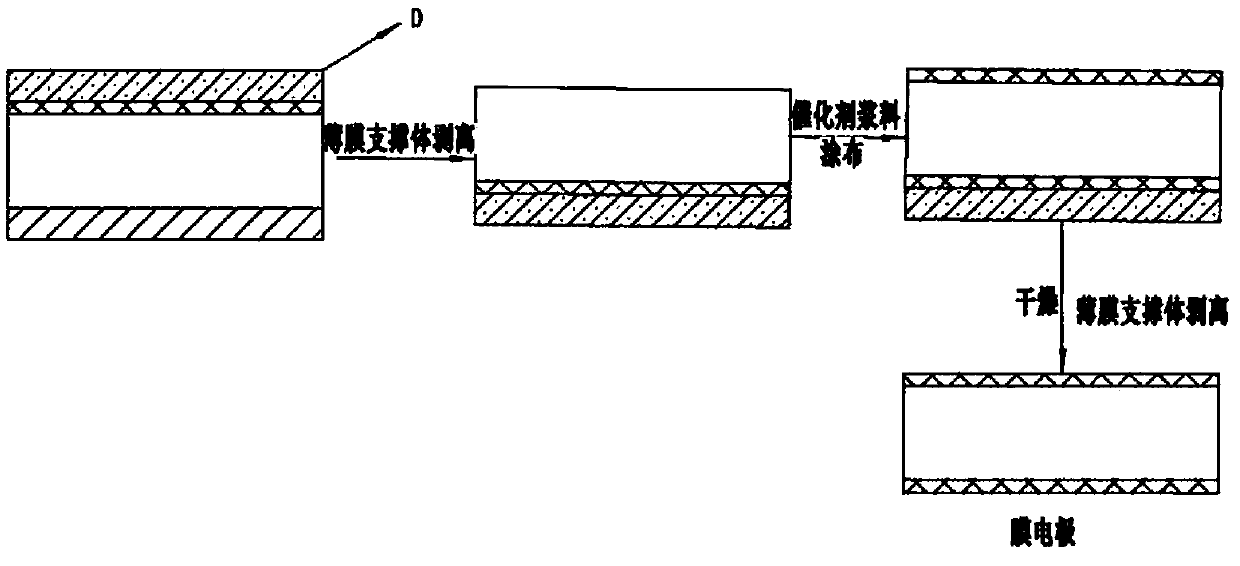

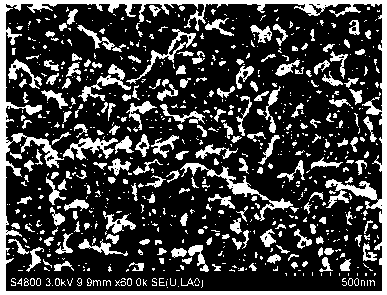

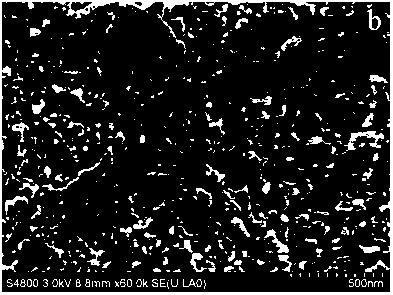

Preparation method of membrane electrode assembly of proton exchange membrane fuel cell

InactiveCN109585859AResolve shrinkageSolve the swelling problemFinal product manufactureCell electrodesProtonProton exchange membrane fuel cell

The invention discloses a preparation method of a membrane electrode assembly of a proton exchange membrane fuel cell. The preparation method comprises the steps of firstly, attaching a layer of a thin film support body onto one side of a proton exchange membrane, coating catalyst paste on the other side, and performing drying to obtain a catalyst layer; secondly, attaching the thin film support body onto one side of the catalyst layer, and stripping the thin film support body at the other side; thirdly, coating the catalyst paste on the side, and performing drying to obtain the catalyst layer; and removing the remaining thin film support body, thereby obtaining the membrane electrode assembly. By the method, the defects of swelling and deformation of the proton exchange membrane during direct coating of the catalyst paste are effectively overcome, the method has the advantages of simple and rapid process, low production cost and the like, and mass production is easy.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

Fly-ash-base filling material

The invention relates to a building material applied to construction industry, particularly a fly-ash-base filling material, belonging to an inorganic Portland cement material. The fly-ash-base filling material is prepared from the following components in parts by weight: 30-40 parts of desulfurized gypsum, 40-50 parts of fly ash, 5-10 parts of ordinary Portland cement, 1 part of curing agent, 0.5 part of expanding agent and 0.5 part of setting accelerator. The curing agent is lime, the setting accelerator is sodium sulfate or potassium sulfate, and the expanding agent is common air entraining agent. The fly-ash-base filling material has the advantages of reasonable design, absolute flame retardancy, high safety and lower cost.

Owner:山西凝固力新型材料股份有限公司

Active regeneration artificial cornea graft and preparation method thereof

InactiveCN101380486AUnsuitable for transplantationSolve the strength problemEye implantsPolyvinyl alcoholBiocompatibility Testing

The invention belongs to the technical field of artificial cornea production and more particularly provides an active regenerating artificial cornea implant and a preparation method thereof. The artificial cornea implant comprises 5-30 shares of chitosan, 5-30 shares of collagen, 0.1-0.5 share of chondroitin-sulfuric acid, 5-10 shares of polyethylene glycol, 5-25 shares of polyvinyl alcohol and 15-80 shares of triple-distilled water; preferably the artificial cornea implant also comprises appropriate amount of cornea cell growing factor, fibronectin and laminin. The preparation method of the active regenerating artificial cornea implant is as below: dissolving the chitosan, the collagen and the chondroitin-sulfuric acid in hydrochloric acid, acetic acid and water respectively, and then infusing the mixture of the components which are agitated uniformly at the room temperature into a mould for drying, and then obtaining the product after water immersion, cleaning and drying. The artificial cornea implant has good biocompatibility, high substance rigidity and good transparency; the preparation method is easy to be operated, the raw materials are easy to be obtained and are cheap, and large-scale industrialized production can be performed.

Owner:JINAN UNIVERSITY

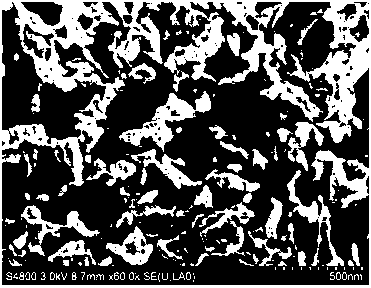

Enhanced hydroxypropyl cellulose microporous film and preparation method thereof

The invention discloses an enhanced hydroxypropyl cellulose microporous film and a preparation method thereof. The preparation method comprises the following steps: dissolving hydroxypropyl cellulose into an alkaline water-soluble solvent system subjected to precooling treatment to obtain a hydroxypropyl cellulose solution; causing the obtain solution to form a film through tape casting, and solidifying in an acid coagulation bath; carrying out cross-linking and plasticizing processing after water washing, and continuing to water vapor boiling under atmospheric pressure or freezing or water vapor boiling under the atmospheric pressure and then freezing; and drying in the air to obtain the enhanced hydroxypropyl cellulose microporous film. The hydroxypropyl content of the hydroxypropyl cellulose is 2-20 percent by weight. The toughness, the tensile strength and the air and water permeability of the film are improved, and the biodegradable homogeneous microporous film is obtained. The microporous film can be widely applied to the film separation process and can be used as packaging films, film electrodes or biomedical materials.

Owner:SUZHOU UNIV +1

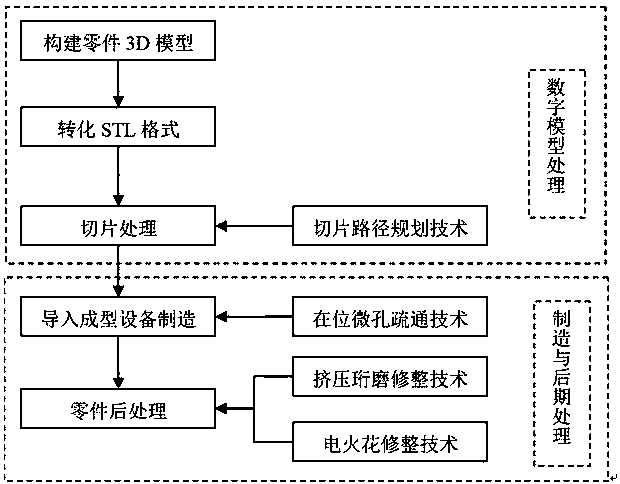

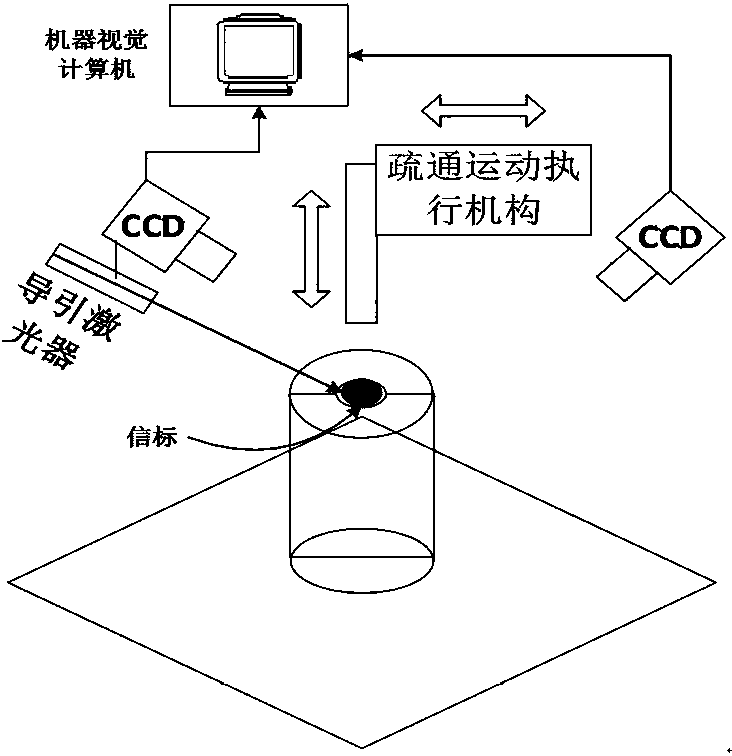

Compound processing method of micropore

ActiveCN108526824AResolve shrinkageSolve the problem of aliasing effectProgramme controlComputer controlUltrasound attenuationDiameter ratio

The invention discloses a compound processing method of a micropore. According to the compound processing method of the micropore, firstly, an additive manufacturing technique is adopted to preliminarily process the micropore, and then an extrusion honing finishing technique and an electric spark finishing technique are combined to perform postprocessing finishing, so that the surface roughness and the shape accuracy of the micropore can be increased, and the purpose of processing the micropore with an ultra-high depth-to-diameter ratio in pure metal with a high melting point is realized. Thecompound processing method of the micropore is a novel processing method of the micropore with the ultra-high depth-to-diameter ratio on the basis of additive and subtractive compound processing, andthe problems of difficulty in discharging electroerosion products, serious attenuation of energy spread to the bottom of a pore by laser, difficulty in guaranteeing the pore forming precision and thelike of a traditional micropore processing method during processing are solved. The compound processing method of the micropore can be used for processing circular micropores and can also be expandedin other processing fields of deep micropores with high melting points and in any complex shape.

Owner:INST OF MACHINERY MFG TECH CHINA ACAD OF ENG PHYSICS

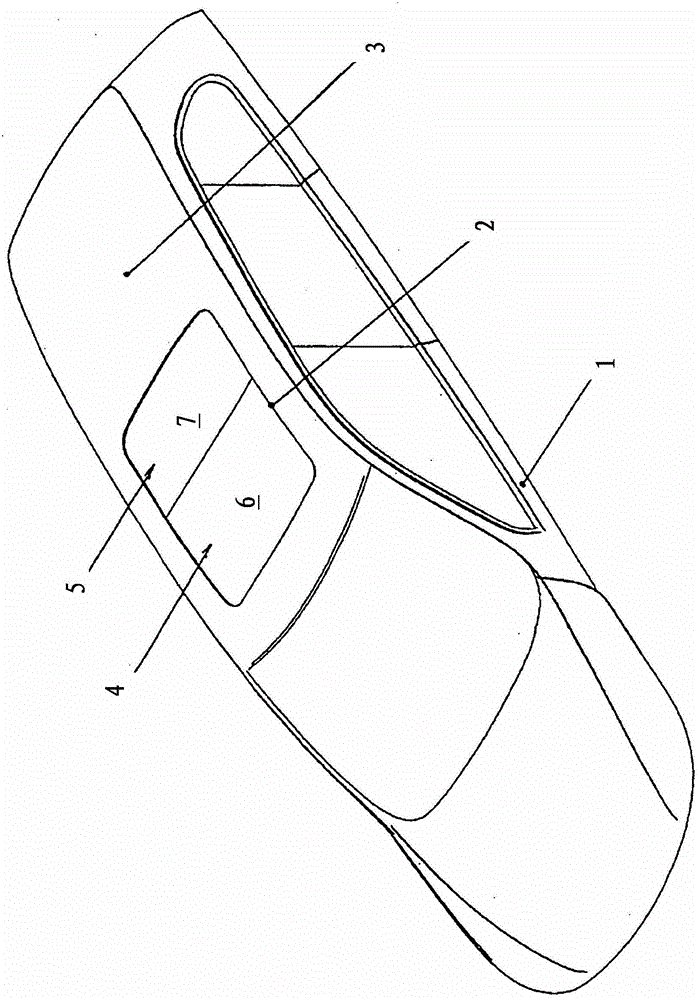

Roof panel and method of manufacturing said panel

ActiveCN102725160AQuality improvementReduce adhesionEngine sealsVehicle sealing arrangementsPlastic materialsBuilding construction

Owner:INALFA ROOF SYST GROUP

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

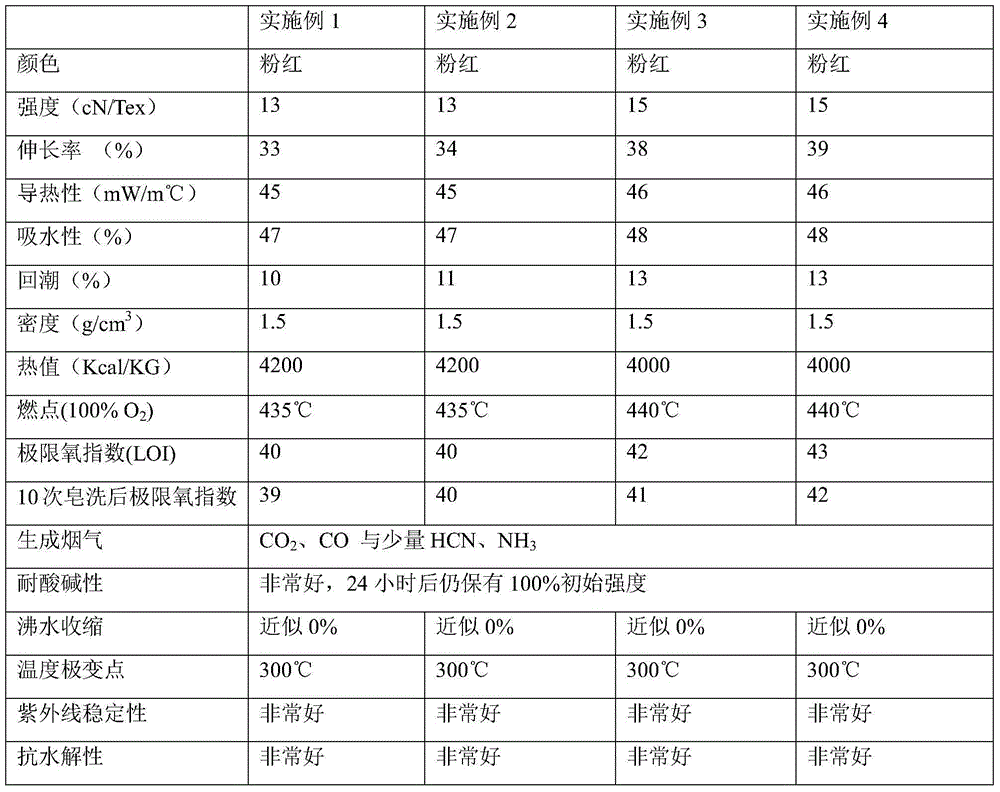

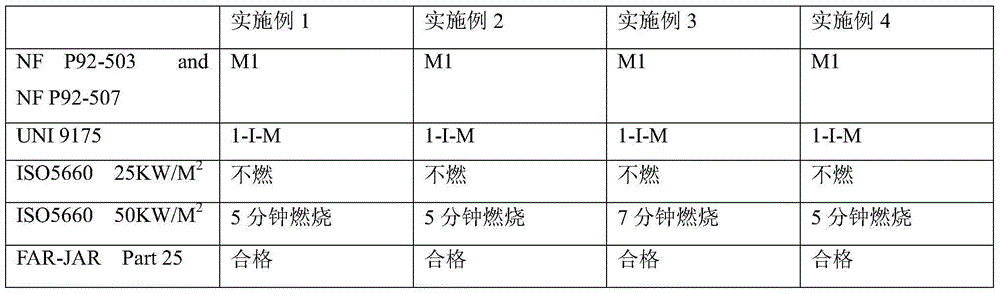

High temperature-resistant flame retardation polyacrylonitrile fiber and production method thereof

ActiveCN105986474AHigh limiting oxygen indexWon't meltFibre typesDyeing processPolymer scienceMoisture regain

The invention relates to a polyacrylonitrile fiber, and concretely relates to a high temperature-resistant flame retardation polyacrylonitrile fiber and a production method thereof. The method concretely comprises the following steps: processing a polyacrylonitrile fiber in a hydrazine solution with the concentration of 7-20wt%, processing the hydrazine processed fiber in an alkaline solution with the concentration of 3-10wt%, washing the alkali processed fiber with water until the fiber is neutral, processing the neutral fiber in an aqueous metal ion salt solution with the concentration of 3-10wt%, oiling the metal salt processed fiber, dehydrating the oiled fiber, and drying the dehydrated fiber to obtain the high temperature-resistant flame retardation polyacrylonitrile fiber. The flame retardation performance LOI of the flame retardation fiber obtained in the invention can reach 40-45, the flame retardation grade is M1, and the amount of smoke generated in the combustion process is very small, the grade of toxic gases is FO, and the smoke amount of the flame retardation fiber in the invention is lower than that of other flame retardation fibers. The flame retardation fiber in the invention has the advantages of high moisture regain rate, high water absorption rate, good dyeability and low shrinkage in boiling water.

Owner:JILIN ACRYLIC FIBERS CO LTD

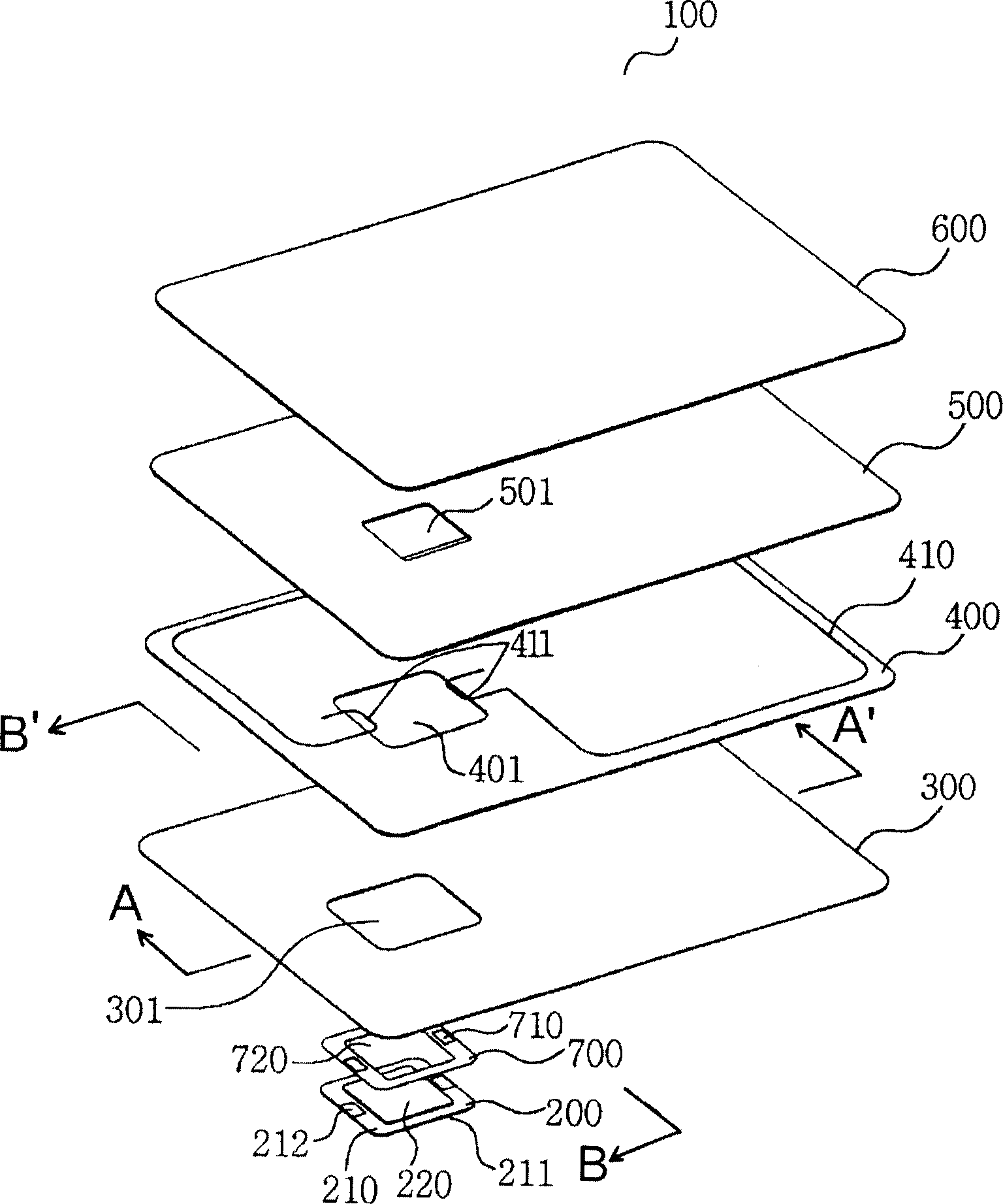

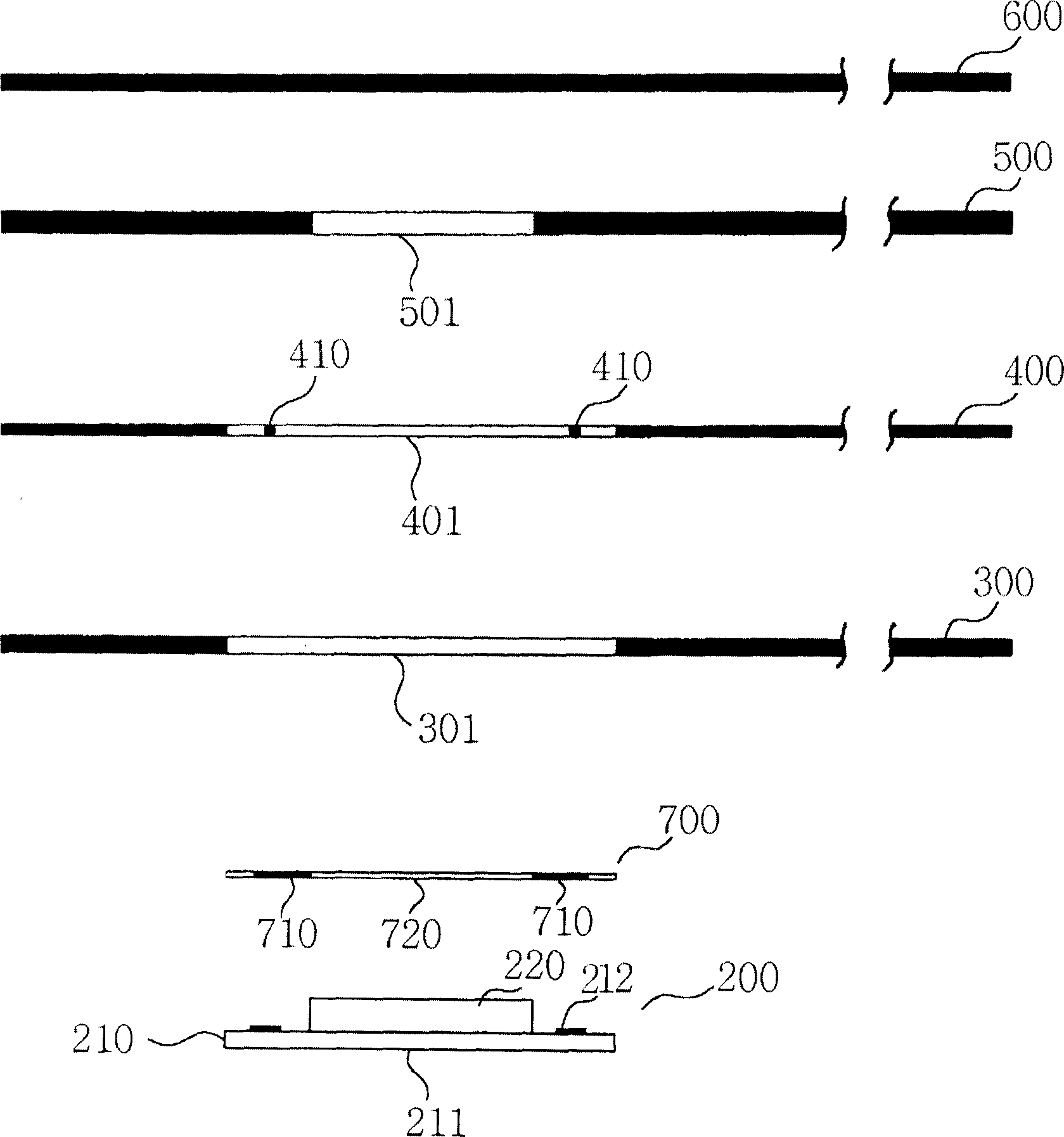

Method for manufacturing ic card by laminating a plurality of foils

InactiveCN1714368AManufacturing Method ImprovementsResolve shrinkageRecord carriers used with machinesOn boardEngineering

PURPOSE: A method for manufacturing an IC card by layering foils is provided to remove a step for digging out a groove again after layering the foils, firmly join the COB(Chip On Board) and a card plate, occur no gap between the COB and the card plate, and firmly join an electrode of the COB and an antenna. CONSTITUTION: The COB(200) is placed by facing an electrode surface of a terminal in the COB downwardly. At least more than two foils(300,400,500) having a hole(301) of the same area as the COB are layered by inserting the COB into the hole. A back side cover foil(600) having no hole is layered to an opposite side of the surface exposing the electrode surface of the terminal in the COB of the layered foils, and the foils are compressed.

Owner:JT

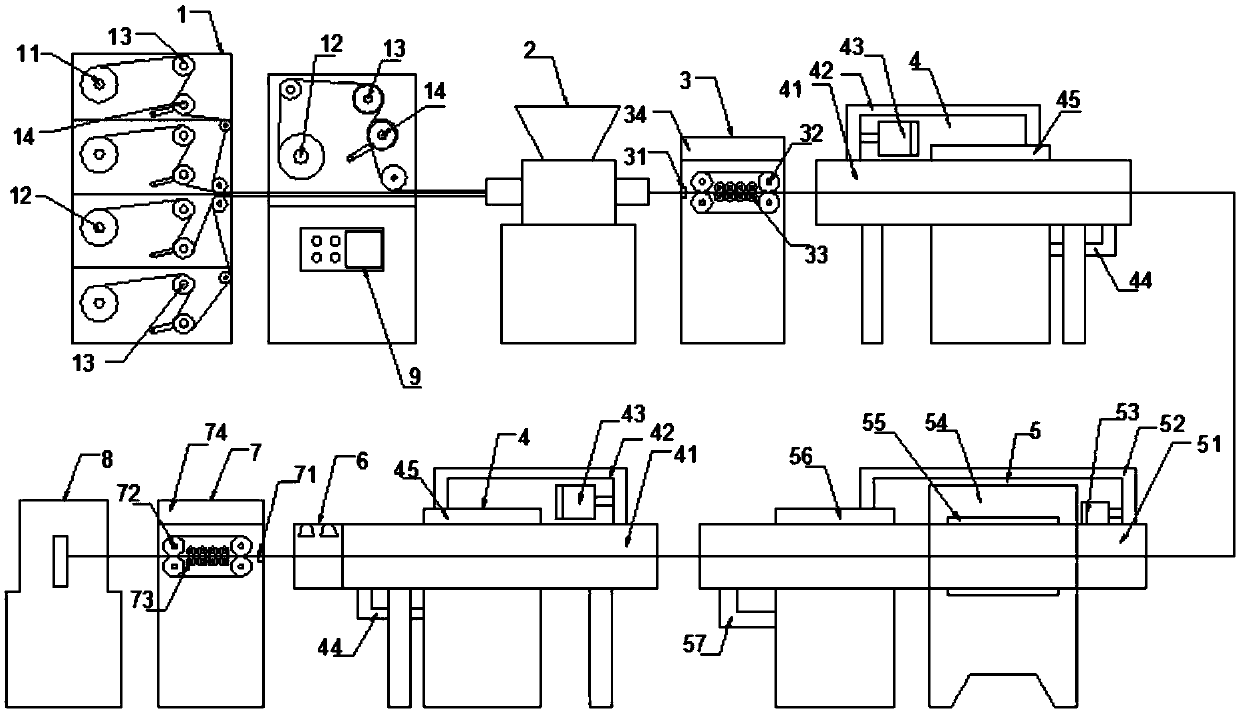

Automatic production equipment for processing cables

The invention provides automatic production equipment for processing cables. The automatic production equipment comprises a paying-off device, an extrusion molding device, a paying-off traction device, cooling devices, a heating device, a drying device, a take-up traction device, a take-up device and a control cabinet. According to the invention, the processes of cooling, heating and re-cooling are adopted for processing the cables, the two traction devices are arranged and are matched for carrying out on-line stress relief on the cables, and therefore the problem that external insulation skin of the cables shrinks can be solved.

Owner:TIANJIN OLYNNOK TELECOMM SCI CO LTD

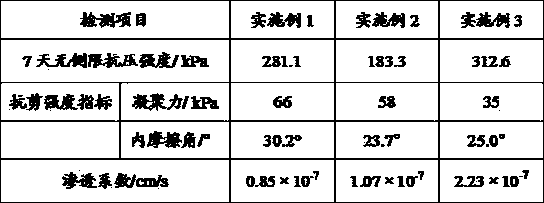

Curing agent for hydraulic filling of marine mud and curing method thereof

InactiveCN103964809AImprove cracking performanceResolve shrinkageSludge treatment by de-watering/drying/thickeningSolid waste managementSulfateFly ash

The invention discloses a curing agent for hydraulic filling of marine mud and a curing method thereof. The curing agent comprises the following raw materials in parts by weight: 8 to 23 parts of lime, 37 to 45 parts of fly ash, 0.2 to 0.5 part of triethanolamine, 18 to 23 parts of calcium sulfate, 2 to 5 parts of strong base, and 10-16 parts of water glass. The curing method comprises the following steps: the water content of an undisturbed mud sample is controlled by a cutter-suction pump in the range of 80% to 90%, and according to the mechanical stress borne by a soil mass in practical engineering, the curing agent is admixed; the admixture is then maintained for 6 to 8 days under a natural curing condition after admixing. According to the curing agent disclosed by the invention, lime and fly ash are mainly adopted as the main curing agents, auxiliary curing agents are added to improve the cracking property of the lime-fly ash stabilized soil, clay soil with higher plastic index are the main targets for curing, and the problem of greater shrinkage of the lime-fly ash stabilized soil used on the clay soil with higher plastic index is solved.

Owner:ZHEJIANG INST OF HYDRAULICS & ESTUARY +2

Different-shrinkage polyester filament yarn dyeing uniformity test method

ActiveCN104088126AResolve shrinkageImprove setting timeInspecting textilesWater bathsNational standard

The invention aims to provide a different-shrinkage polyester filament yarn dyeing uniformity test method. The method includes the following processes that (1) sock weaving is conducted on different-shrinkage polyester filament yarn according to requirements in the national standard polyester filament yarn dyeing uniformity test method to enable multiple sock legs formed by the various kinds of different-shrinkage polyester filament yarn to be weaved together so as to form a sock sample; (2) a special forming frame is inserted into the formed sock sample, the special forming frame is of a strip shape, the length of the special forming frame is equal to or larger than that of the sock sample, and the width of the special forming frame is matched with that of the sock sample; (3) the sock sample on the special forming frame is fixed through a clamping object; (4) the fixed sock sample is put into a thermostat water bath to be shaped; (5) dyeing and color judgment are conducted on the sock sample processed through heat shaping according to the national standard polyester filament yarn dyeing uniformity test method. The different-shrinkage polyester filament yarn dyeing uniformity test method has the advantages that by means of the method, the dyeing uniformity of the different-shrinkage polyester filament yarn can be tested according to the national standard normally in the different-shrinkage polyester filament yarn dyeing uniformity test process.

Owner:XUZHOU SILK FIBER TECH

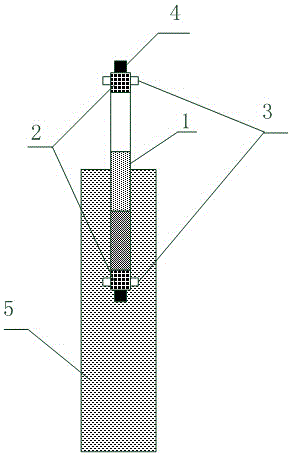

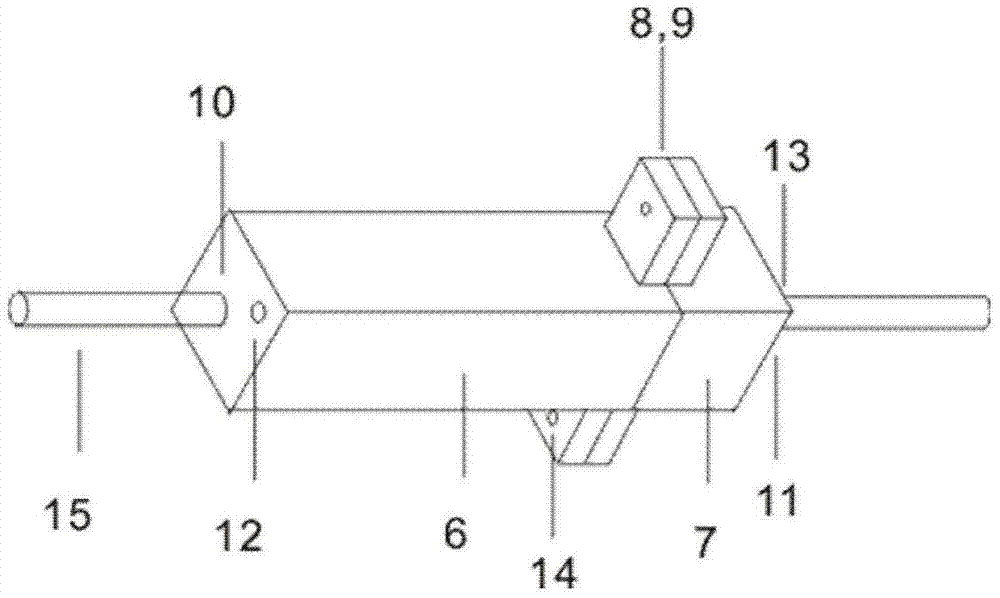

Method and special mold for constructing multi-channel cavernous nerve conduit by two-time molding

The invention discloses a method and a special mold for constructing a multi-channel cavernous nerve conduit by two-time molding. The mold comprises a single-channel molding mold and a multi-channel molding mold, wherein the single-channel molding mold and the multi-channel molding mold have the same main body structure and respectively comprise a mold body and an outer mold; each mold body is provided with a tubular mold cavity; each outer mold is provided with a cavity which is completely matched with the corresponding mold body; fixed holes are formed in the two sides of each outer mold or pore plates are arranged on the two sides of each outer mold (fixed holes are formed in each pore plate); when a single fixed hole or a plurality of fixed holes are formed, to the corresponding molding mold is a single-channel molding mold or a multi-channel molding mold; a material injection hole and an exhaust hole are formed in the two top ends of each outer mold. A biodegradable polymer solution is injected into the assembled single-channel molding mold and the assembled multi-channel molding mold, and the single-channel cavernous nerve conduit is obtained after freeze drying; the single-channel cavernous nerve conduit is inserted into the assembled multi-channel molding mold, the polymer solution is injected into the multi-channel molding mold, and the multi-channel cavernous nerve conduit is obtained after freeze drying. According to the method for constructing the multi-channel cavernous nerve conduit by two-time molding, which is disclosed by the invention, the problem of contraction when the multi-channel cavernous nerve conduit is molded is solved.

Owner:WUHAN UNIV

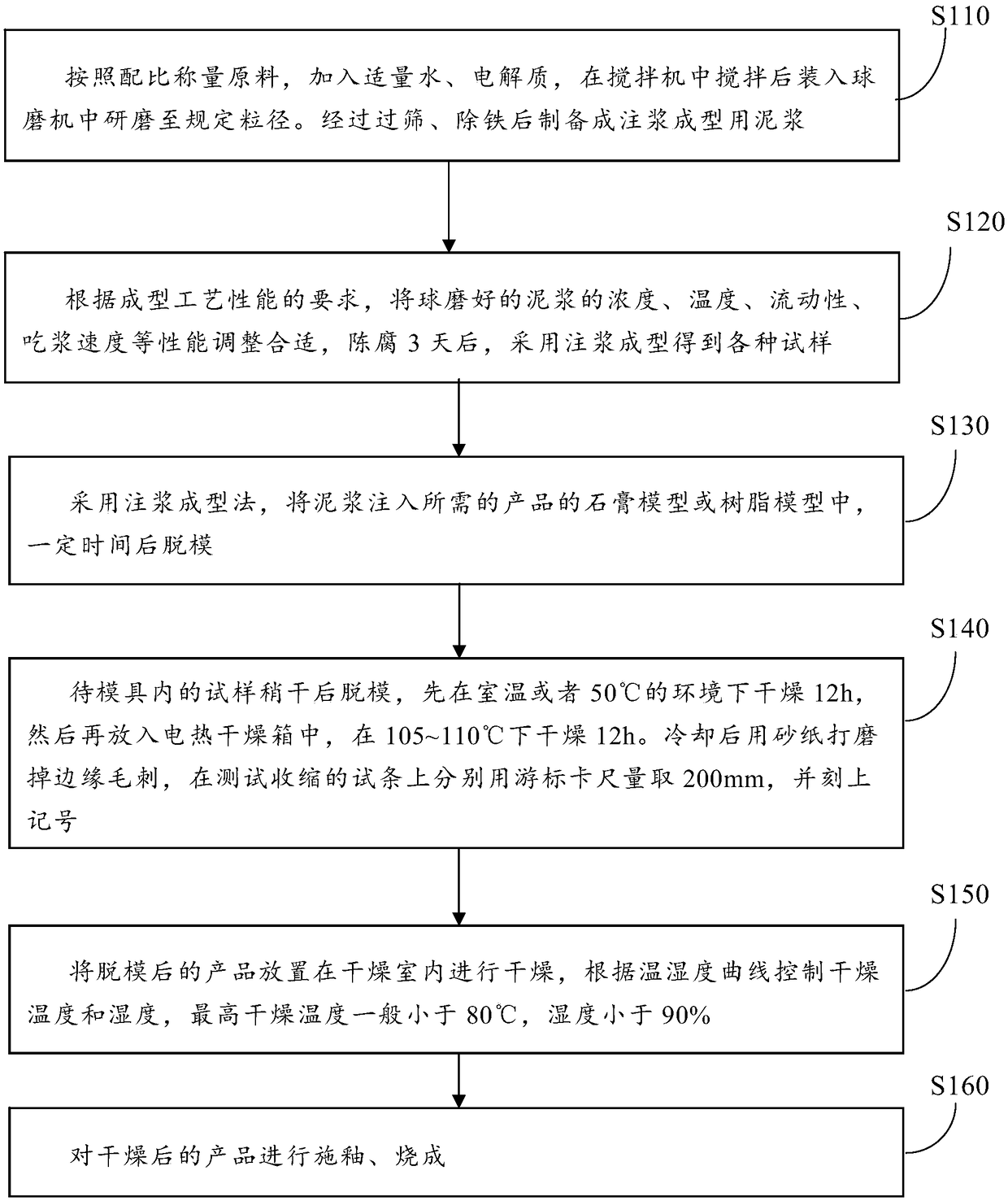

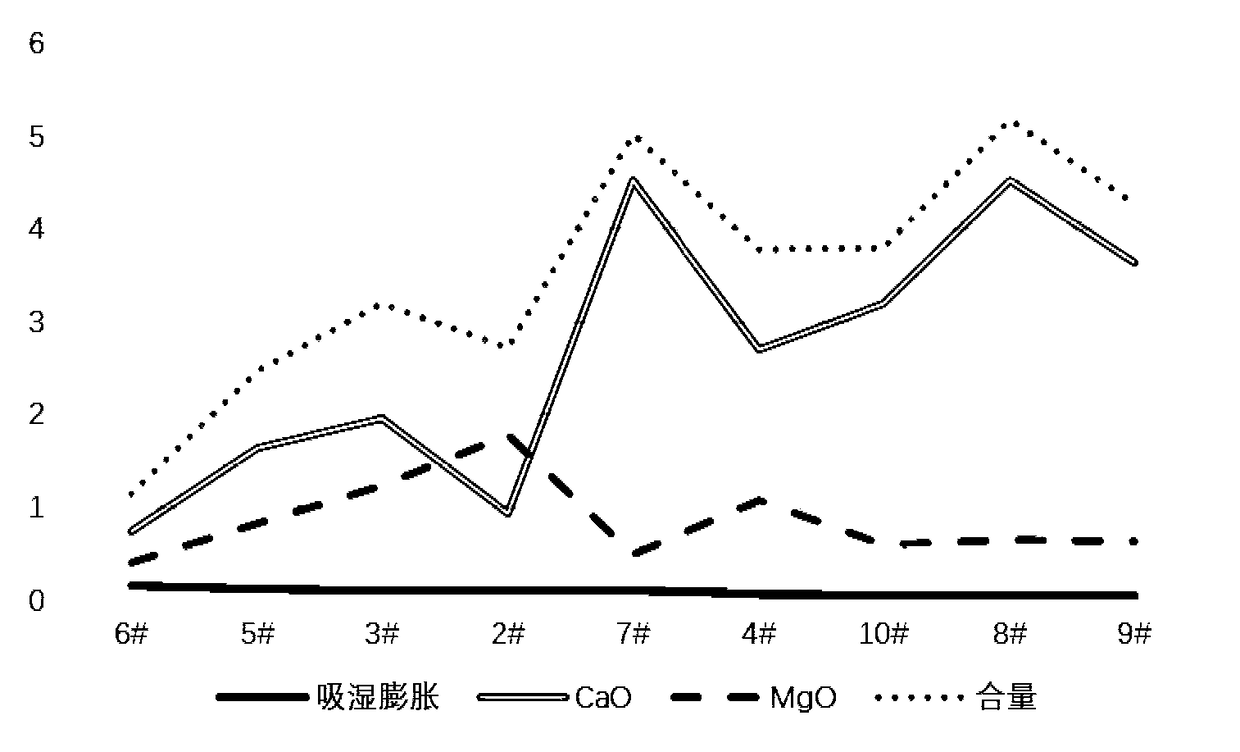

Earthen sanitary ware blank and preparation method thereof

PendingCN108975865AResolve shrinkageSmall overall deformationCeramic materials productionClaywaresThermal expansionQuartz

The invention provides an earthen sanitary ware blank and a preparation method thereof. A proper quantity of raw materials such as kaolin and quartz are introduced; the crystalline phase content of mullite, quartz and the like in the blank is controlled; the glass phase content of potassium oxide and sodium oxide is reduced; the high-temperature plastic deformation is reduced; the low deformationof earthen sanitary ceramics is realized. The thermal expansion coefficient of the blank at 200 to 300 DEG C is regulated, so that the thermal expansion coefficient of the blank is matched with the thermal expansion coefficient of glaze. The problem that the earthen sanitary ware blank cannot overcome shrinkage and great deformation is solved, so that the earthen sanitary ware does not use engobeand does not generate glaze checking; qualified products are produced according to an earthen sanitary ware production method.

Owner:平潭海创智汇科技有限公司

Alkaline-free anti-crack concrete shrinkage reducing agent

The invention discloses an alkaline-free anti-crack concrete shrinkage reducing agent comprising the following components in percentage by weight: 35-66% of I-grade coal ash, 8-18% of polypropylene staple fiber, 2-18% of polyethylene glycol, 3-17% of methacrylic acid, 2-15% of calcium formate, 3-16% of neopentyl glycol and 0.2-0.8% of sodium dodecyl benzene sulfonate. The invention provides possibility for realizing the comprehensive improvement of an additive technology, reducing concrete shrinkage, inhibiting non-loaded cracks and improving the durability of concrete through the research on and application as a shrinkage reducing additive and creates the environment-friendly alkaline-free anti-crack concrete shrinkage reducing agent. The technology is simple in feeding way, easily-controlled in production condition, simple in process and capable of producing the alkaline-free anti-crack concrete shrinkage reducing agent which is low in alkaline content and mixing amount and capable of effectively controlling the shrinkage of concrete. The alkaline-free anti-crack concrete shrinkage reducing agent has a relatively good social benefit and a relatively high economic benefit.

Owner:HUNAN CONSTR ENG GRP COR +1

Original edition for color display tube shadow mask printing

InactiveCN1858884APrevent shrinkageAvoid Neck Constriction ProblemsPhotomechanical apparatusNon-emitting electrodes manufactureComputer scienceLightness

This invention provides a shadow mask image-printing original edition of a color tube, which takes a concave hexagon as the compensation pattern to be spliced on a corner to be compensated of the rectangular shadow-mask aperture pattern to prevent contraction of the corner and the cervix in the process of etching and manufacture shadow-masks of particular hole shapes of square and bone.

Owner:烟台正海电子网板股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com