Bauxite-based low-creep mullite product

A mullite and low-creep technology, which is applied in the field of high-quality alumina-based low-creep mullite products, can solve the problems of difficulty in popularization and large-scale application, dependence on artificial synthetic materials, high production costs, etc., and achieve excellent high temperature Volume stability, improving the value of comprehensive utilization of resources, and improving the effect of grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

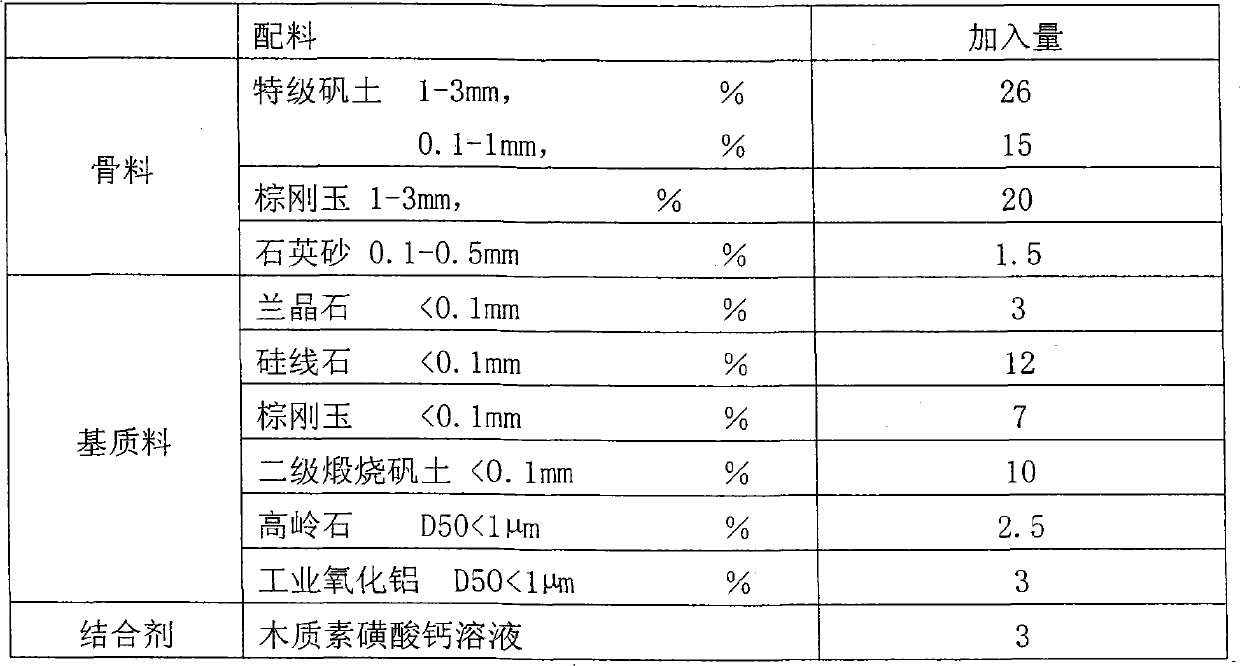

[0020] Preparation of alumina-based low-creep mullite products: first prepare materials according to Table 1:

[0021]

[0022] After the raw materials are selected, crushed and processed to a qualified particle size, the ingredients are proportioned according to the ratio listed in the above table. Put the base material in the ball mill for co-grinding for 20 minutes to achieve the purpose of homogenization, then pour the aggregate, base material and binder into the wet mill and mix thoroughly (the binder is added at the end), according to the designed specifications It is molded on a brick press, dried and placed in a downdraft kiln for sintering at 1650 °C under normal pressure to make alumina-based low-creep mullite products.

Embodiment 2

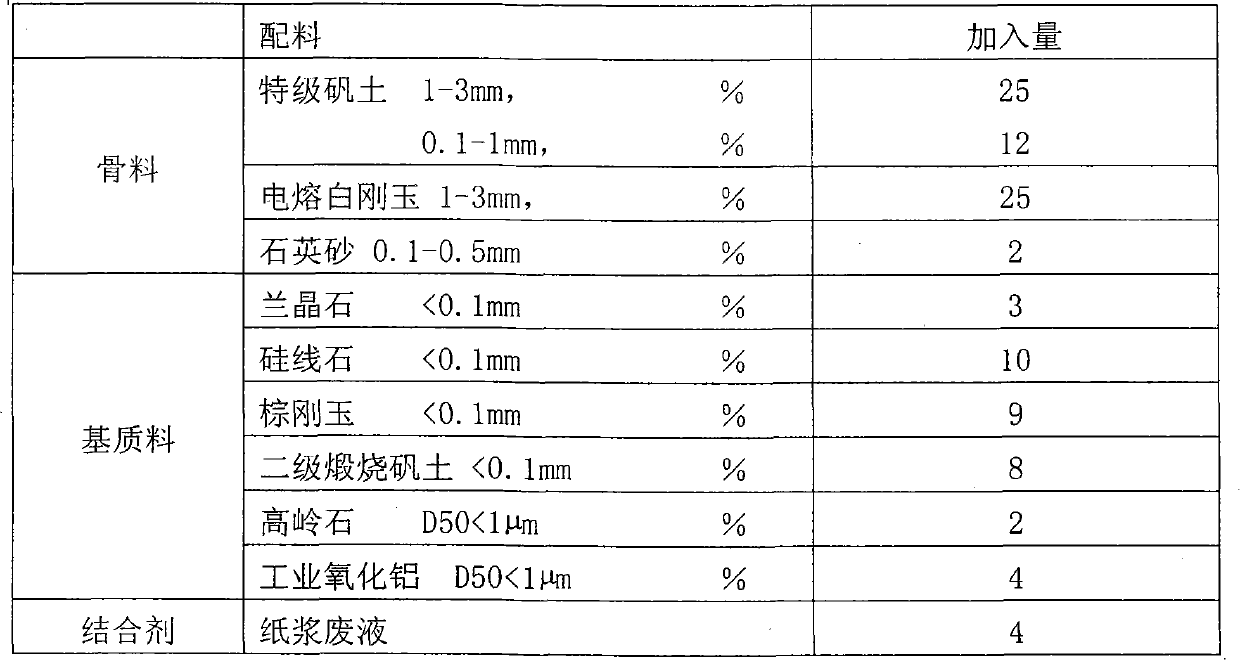

[0024] Preparation of alumina-based low-creep mullite products: first prepare materials according to Table 1:

[0025]

[0026] After the raw materials are selected, crushed and processed to a qualified particle size, the ingredients are proportioned according to the ratio listed in the above table. Put the base material in the ball mill for co-grinding for 20 minutes to achieve the purpose of homogenization, then pour the aggregate, base material and binder into the wet mill and mix thoroughly (the binder is added at the end), according to the designed specifications It is molded on a brick press, dried and placed in a tunnel kiln for sintering at 1650°C under normal pressure. After cooling, it can be made into alumina-based low-creep mullite products.

Embodiment 3

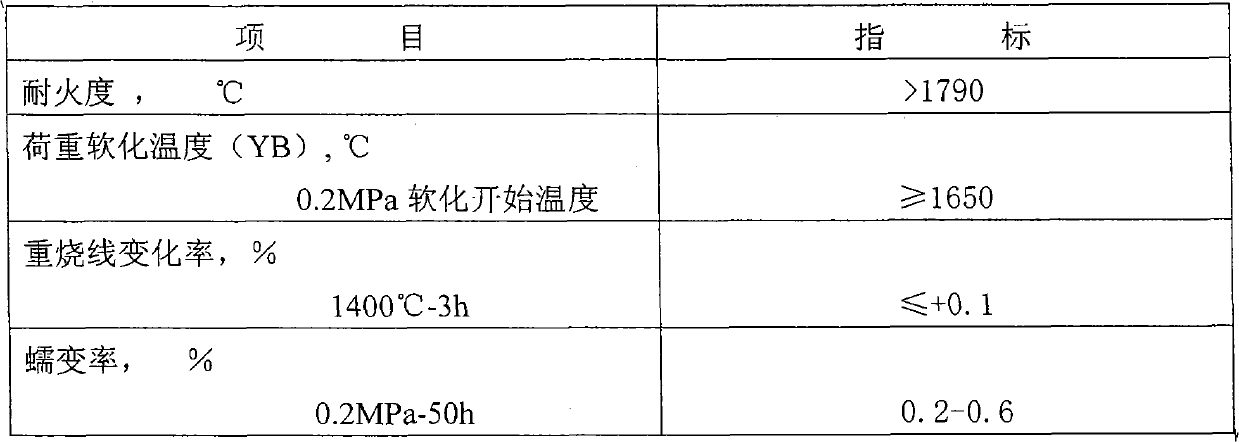

[0028] Preparation of alumina-based low-creep mullite products: first prepare materials according to Table 1:

[0029]

[0030] After the raw materials are selected, crushed and processed to a qualified particle size, the ingredients are proportioned according to the ratio listed in the above table. Put the base material in the ball mill for co-grinding for 20 minutes to achieve the purpose of homogenization, then pour the aggregate, base material and binder into the wet mill and mix thoroughly (the binder is added at the end), according to the designed specifications It is molded on a brick press, dried and placed in a downdraft kiln for sintering at 1650 °C under normal pressure to make alumina-based low-creep mullite products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com