Different-shrinkage polyester filament yarn dyeing uniformity test method

A polyester filament and inspection method technology, which is applied in the inspection of textile materials, textiles and papermaking, etc., can solve the problems of inability to judge normally, achieve good shaping effect and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

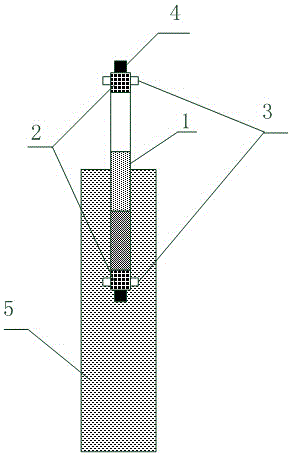

[0018] In conjunction with Fig. 1, the present invention is made a specific explanation:

[0019] The first step of hosiery knitting process: According to the requirements of the national standard polyester filament dyeing uniformity inspection method, different shrinkage polyester filaments are used for hosiery knitting, and three socks tubes formed by three kinds of different shrinkage polyester filaments are knitted together to form a For the sock sample 1, weave a 5cm-long isolation pattern 2 on both sides of the sock sample 1.

[0020] The second step is to wear the shaped frame process: insert the special shaped frame 3 into the formed sock sample 1, the special shaped frame 3 is in the shape of a strip, its length is slightly longer than that of the sock sample 1, and its width is about 0.5 cm wider than the sock sample.

[0021] The third step is to fix the sock sample process: fix the sock sample 1 worn on the special shaping frame 3, that is, fix the isolated weaving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com