Method and special mold for constructing multi-channel cavernous nerve conduit by two-time molding

A technology for forming molds and sponge nerves, which can be used in home appliances, other home appliances, applications, etc. It can solve problems such as difficult to accurately control the size of the inner and outer diameters, and wrong guidance, so as to improve the efficiency and accuracy of insertion, and solve the problem of shrinkage Problems, size controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Solution preparation and first molding

[0059] ① Dissolve cellulose and soybean protein in sodium hydroxide / urea solution respectively to prepare a polymer solution with a mass concentration of 2-10%;

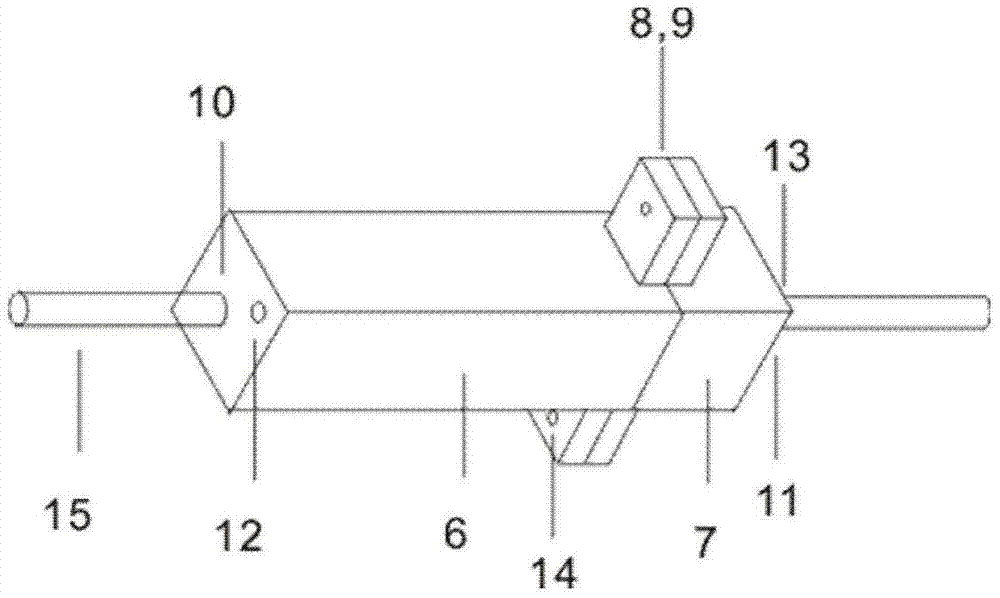

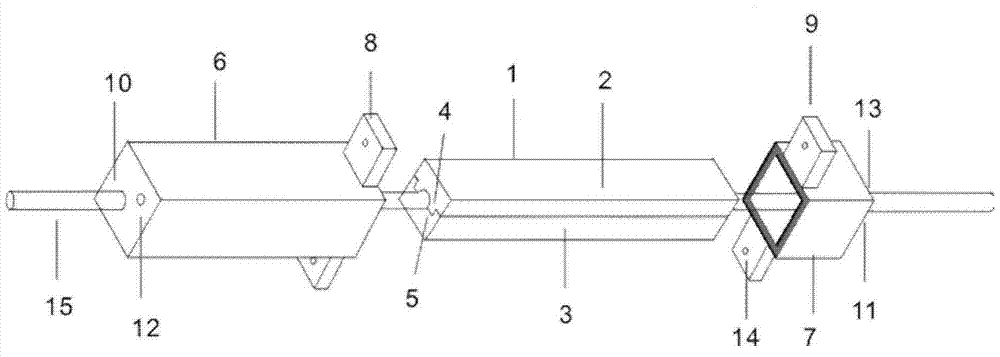

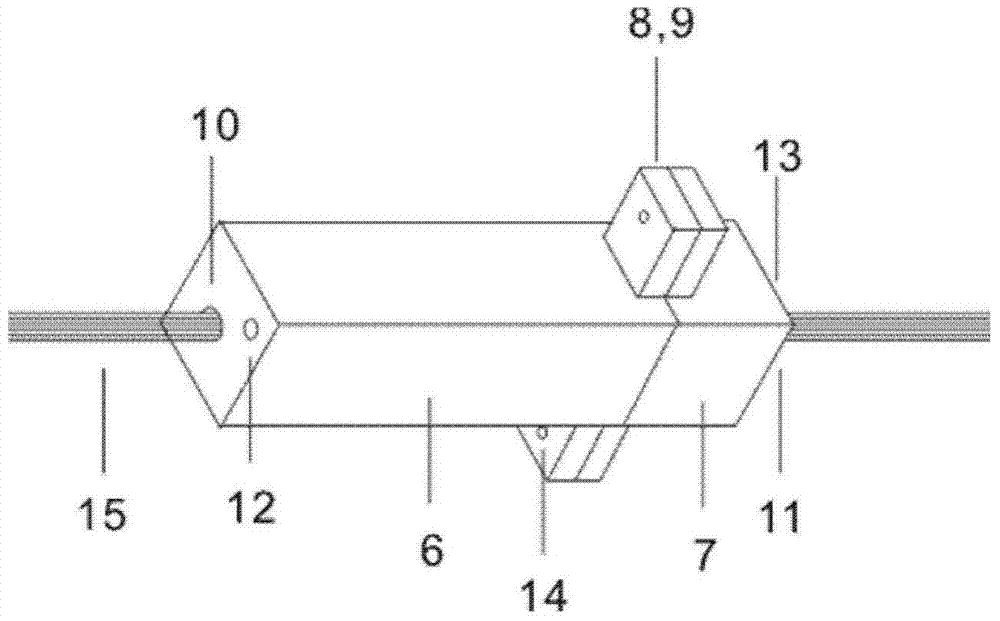

[0060] ② Assemble the mold (single channel) ( figure 1 ), placed in a room temperature environment, so that there is no temperature difference between parts of the mold;

[0061] ③ Inject the polymer solution into the mold, cool down to -20°C (10h), and freeze the polymer solution in the mold cavity;

[0062] ④ Place the frozen polymer mixture and the mold in ③ quickly in a freeze dryer, and freeze-dry at about -50°C to obtain a single mold with an inner diameter of 1.5-2.0mm, an outer diameter of 2.5-3.0mm, and a length of 40mm. Channeled cavernous nerve conduits.

[0063] (2) Second forming

[0064] ① Dissolve cellulose and soybean protein in sodium hydroxide / urea solution respectively to prepare a polymer solution with a mass concentration of 2-10%;

[0065]...

Embodiment 2

[0069] (1) Preparation and first molding of 7-channel sponge nerve conduit solution

[0070] ① Dissolve 7g of cellulose and 3g of soybean protein in 190g of sodium hydroxide / urea solution (13.3g of sodium hydroxide, 22.8g of urea, and 153.9g of water) to prepare cellulose and soybean protein with concentrations of 3.5% and 3.5% respectively. 1.5% polymer solution;

[0071] ② Assemble the mold (single channel) ( figure 1 ), placed in a room temperature environment, so that there is no temperature difference between parts of the mold;

[0072] ③ Inject the polymer solution into the mold, cool down to -20°C (10h), and freeze the polymer solution in the mold cavity;

[0073] ④ Quickly place the frozen polymer mixture and mold in ③ into a freeze dryer, freeze-dry at about -50°C, and obtain a single-channel sponge nerve conduit with an inner diameter of 2.0 mm, an outer diameter of 3.0 mm, and a length of 40 mm. .

[0074] (2) Second forming

[0075] ① Dissolve 7g of cellulose ...

Embodiment 3

[0082] (1) Solution preparation and first molding

[0083] ① Dissolving chitosan in acetic acid with a mass concentration of 2% is prepared into a chitosan solution with a chitosan mass concentration of 3%;

[0084] ② Assemble the mold (single channel) ( figure 1 ), placed in a room temperature environment, so that there is no temperature difference between parts of the mold;

[0085] ③ Inject the polymer solution into the mold, cool down to -20°C (10h), and freeze the polymer solution in the mold cavity;

[0086] ④ Place the frozen polymer mixture and the mold in ③ quickly in a freeze dryer, and freeze-dry at about -50°C to obtain a single mold with an inner diameter of 1.5-2.0mm, an outer diameter of 2.5-3.0mm, and a length of 40mm. Channeled cavernous nerve conduits.

[0087] (2) Second forming

[0088] ① Dissolving chitosan in acetic acid with a mass concentration of 2% is prepared into a chitosan solution with a mass concentration of 3%;

[0089] ② Put the mold (3 to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com