Earthen sanitary ware blank and preparation method thereof

A sanitary ware and green body technology, applied in the field of ceramics, can solve problems such as shrinkage and large deformation, achieve low deformation, improve crack resistance, and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The embodiment of the present application provides a body of pottery sanitary ware. The raw materials of the body include: 10-40% by weight of southern black mud, 10-30% by weight of southern kaolin, and 10-30% by weight of southern pyrophyllite. The percentage is 5-20%, the weight percentage of quartz is 10-25%, the weight percentage of calcined kaolin is 10-30%, the weight percentage of waste porcelain powder is 0-15%, and the weight percentage of wollastonite is 0-20%. 15%, 0-8% by weight of dolomite, 0-10% by weight of talc, electrolyte.

[0029] Specifically, the main raw materials used in the green body of the present invention include southern black mud, southern kaolin, southern pyrophyllite, quartz, calcined kaolin, waste porcelain powder of our factory, wollastonite, dolomite, talc, electrolyte, etc. The physical and chemical properties of the raw materials used are shown in Table 1, Table 2, and Table 3.

[0030] Table 1 raw material chemical composition (%)...

Embodiment 2

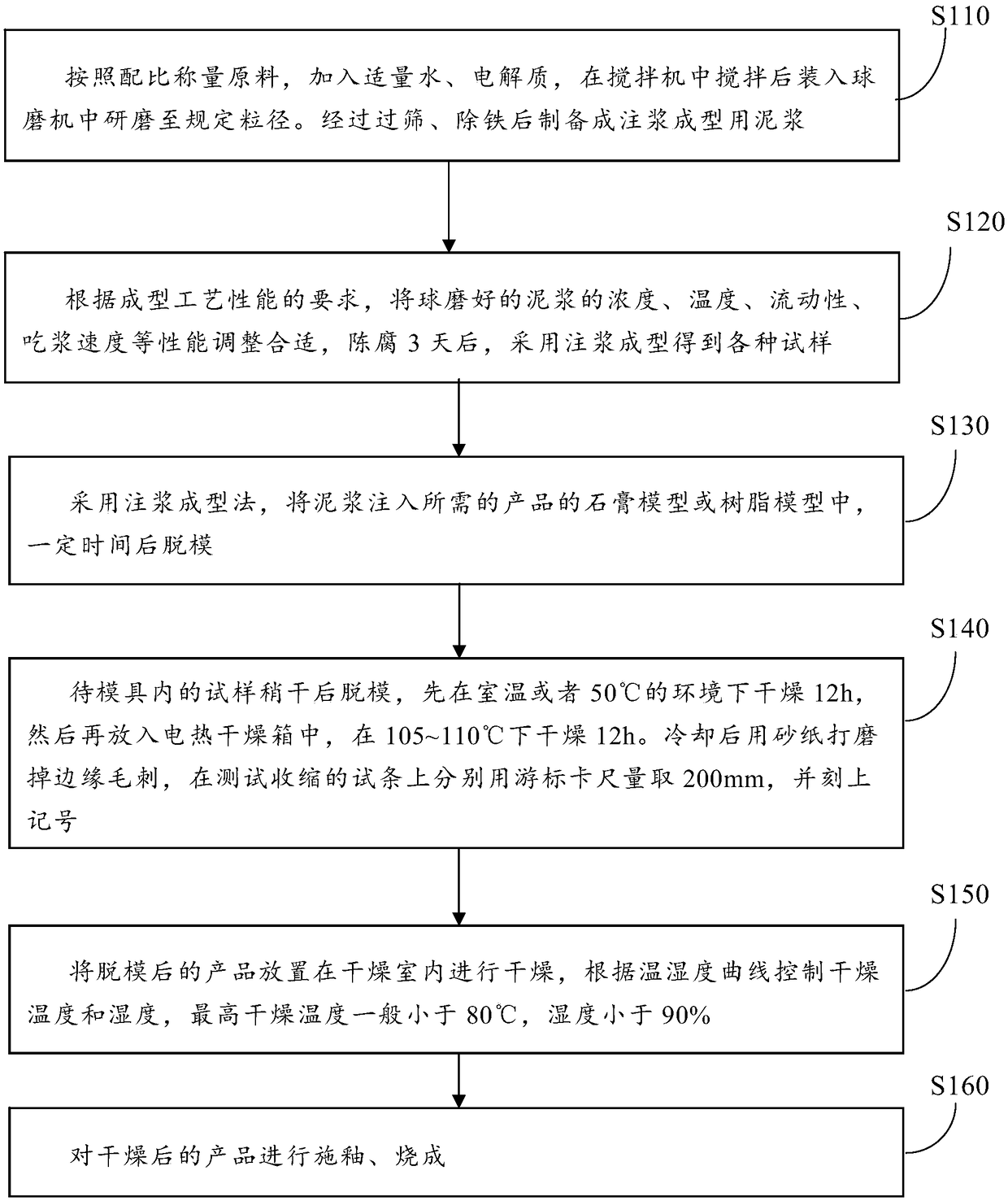

[0063] The embodiment of the present application also provides a method for preparing the body of ceramic sanitary ware, which is used to prepare the body of ceramic sanitary ware according to claims 1-7, such as figure 1 As shown, the method includes:

[0064] Step 110: Weigh the raw materials according to the proportion, add appropriate amount of water and electrolyte, stir in the mixer, put into the ball mill and grind to the specified particle size. After sieving and removing iron, it is prepared into slurry for grouting;

[0065] Step 120: According to the performance requirements of the molding process, the concentration, temperature, fluidity, and slurry feeding speed of the ball-milled slurry are properly adjusted. After 3 days of aging, various samples are obtained by grouting;

[0066] Step 130: Using the grouting method, inject the mud into the plaster model or resin model of the desired product, and demould after a certain period of time;

[0067] Step 140: After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com