Patents

Literature

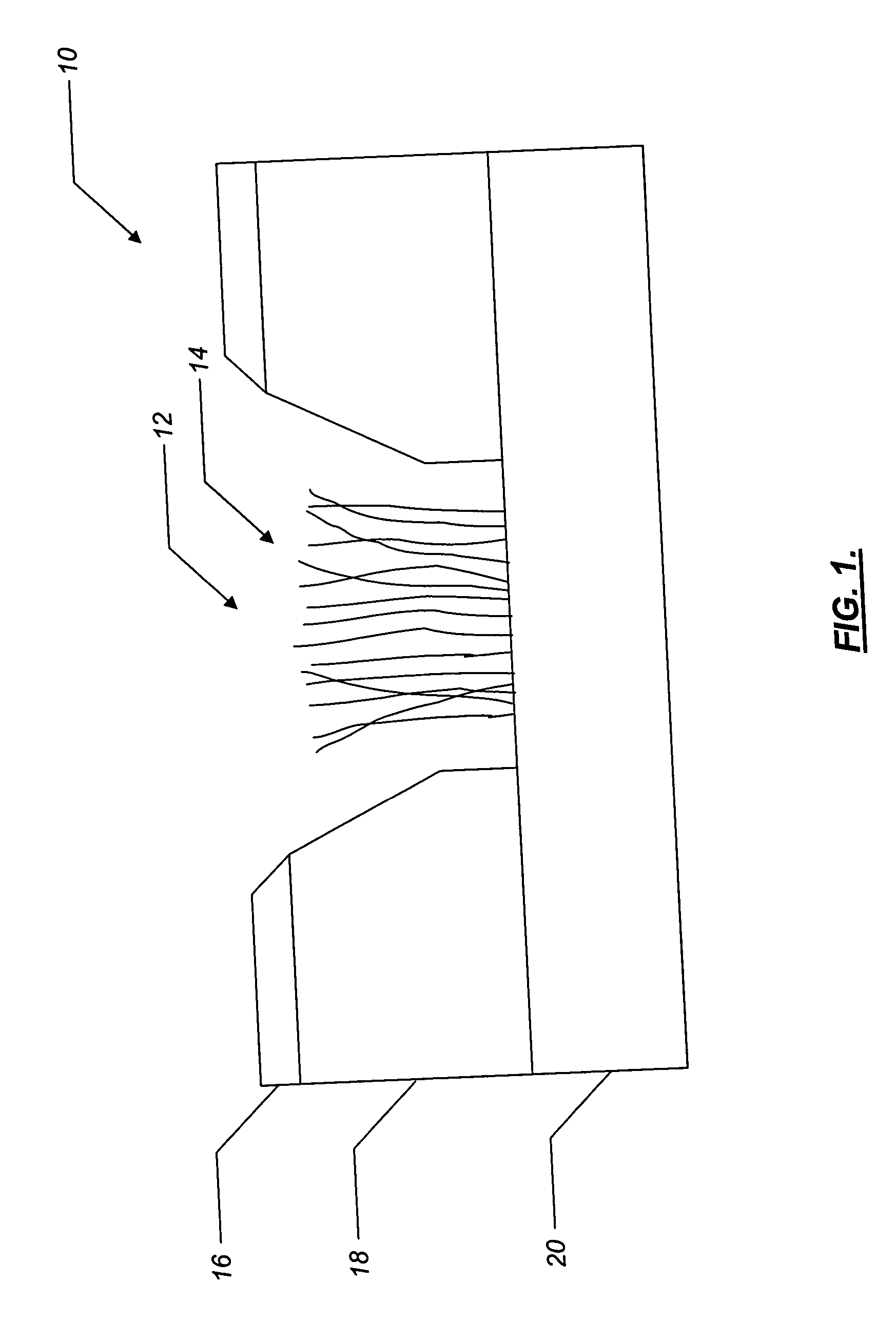

551results about "Non-emitting electrodes manufacture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

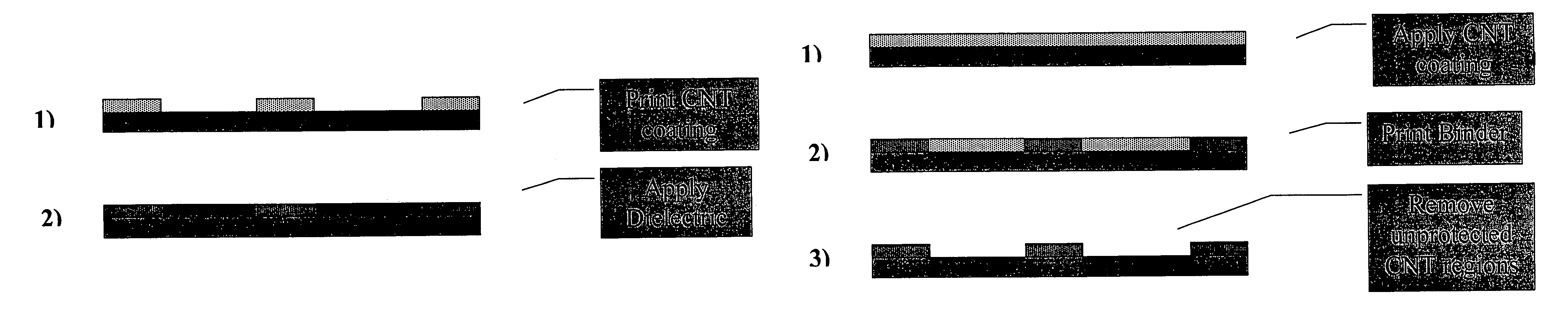

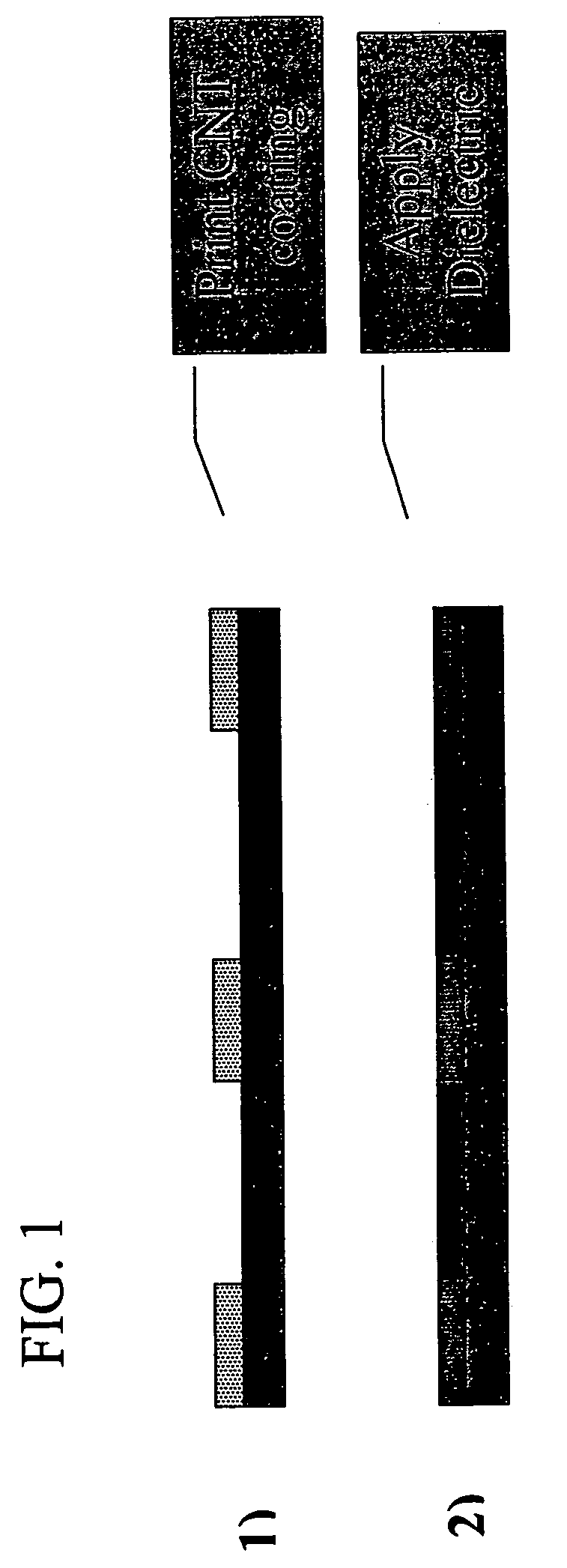

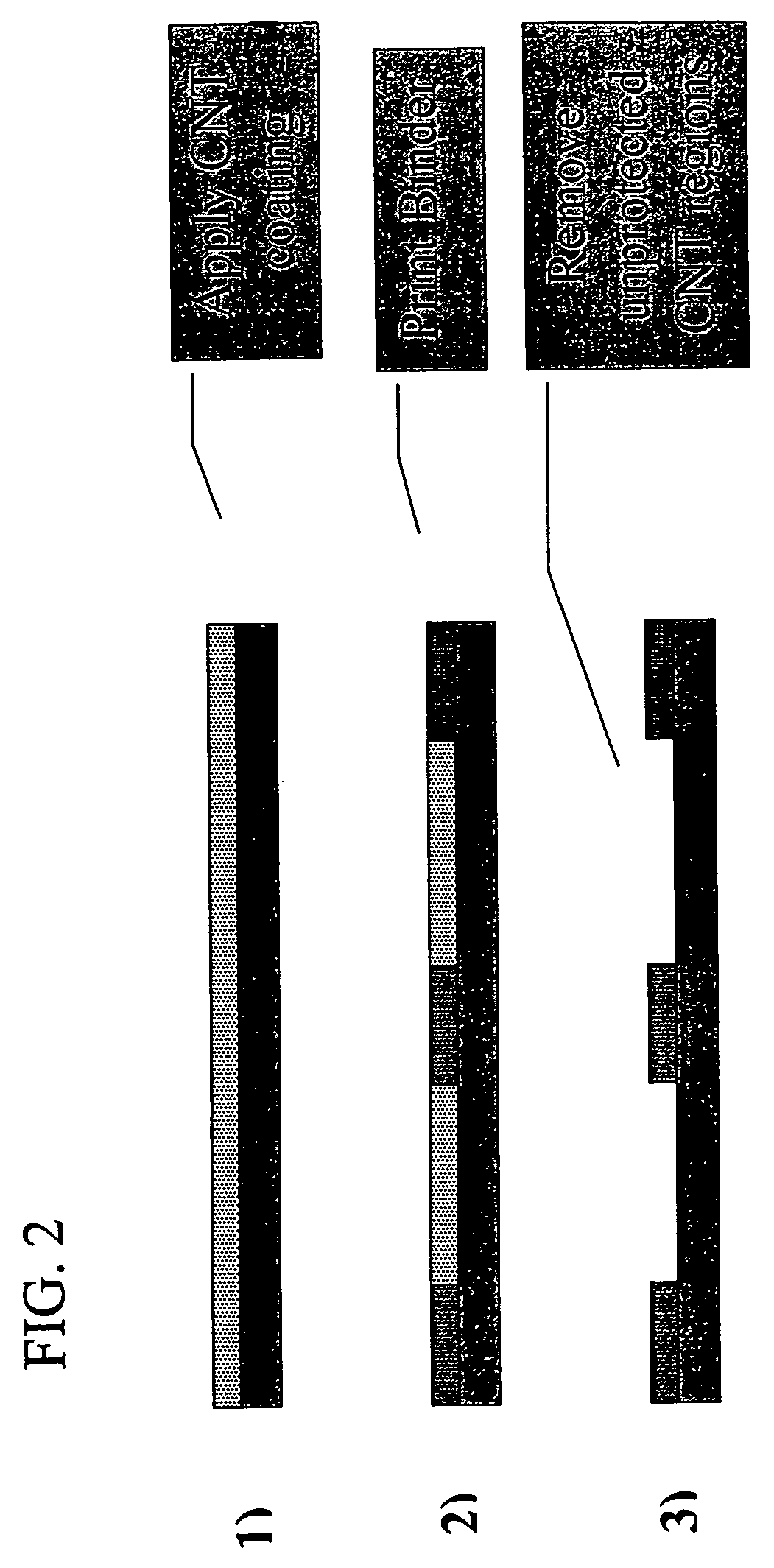

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:EIKOS

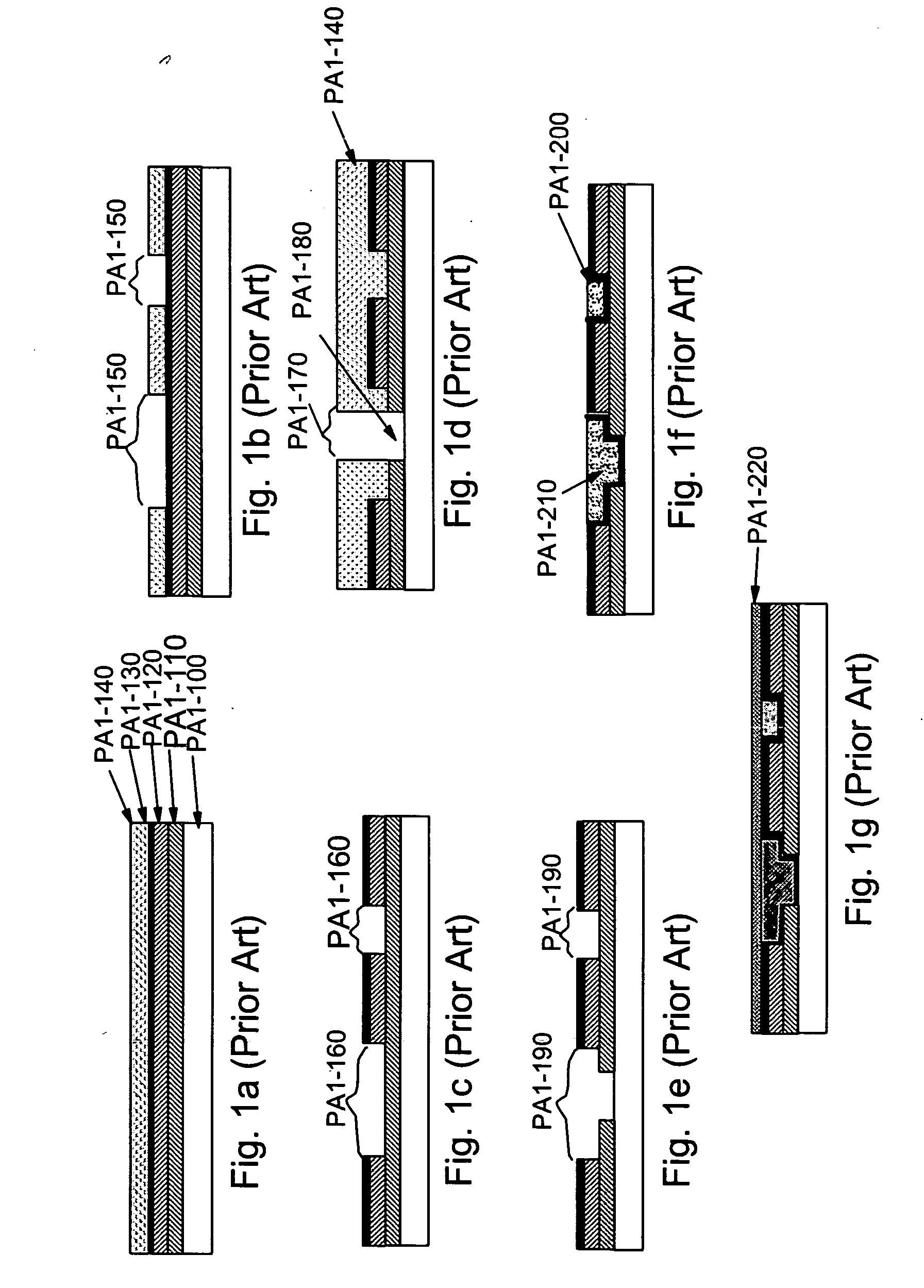

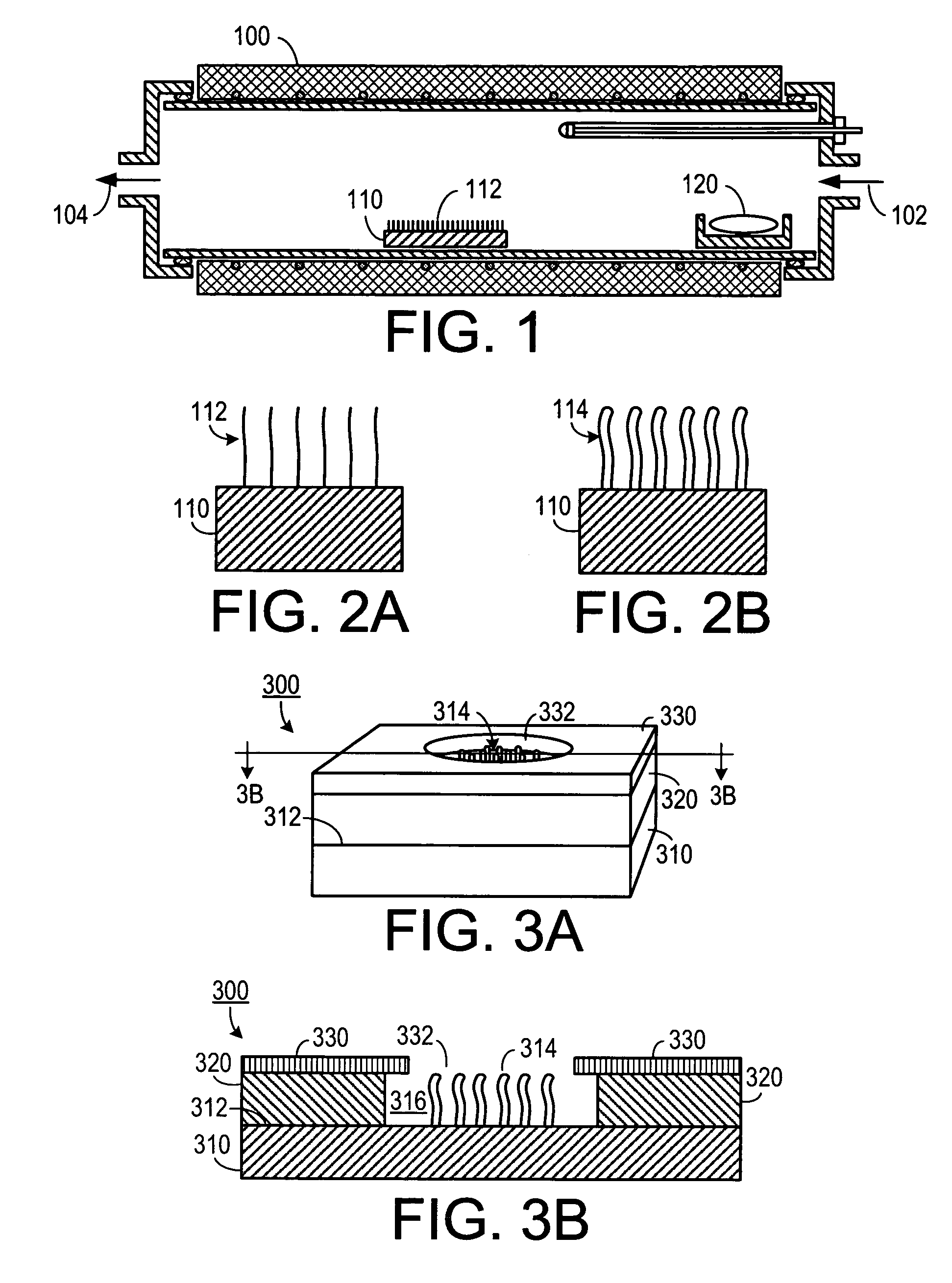

Methods for manufacture of self-aligned integrally gated nanofilament field emitter cell and array

InactiveUS6440763B1Clean and inert surfaceImprove stabilityElectric discharge tubesNanoinformaticsEngineeringNanometre

The present invention discloses a new field emitter cell and array consisting of groups of nanofilaments forming emitter cathodes. Control gates are microprocessed to be integrally formed with groups of nanofilament emitter cathodes on a substrate. Groups of nanofilaments are grown directly on the substrate material. As a result, the control gates and groups of nanofilaments are self-aligned with one another.

Owner:SEC OF THE NAVY AS REPRESENTED BY THE UNITED STATES OF AMERICA THE

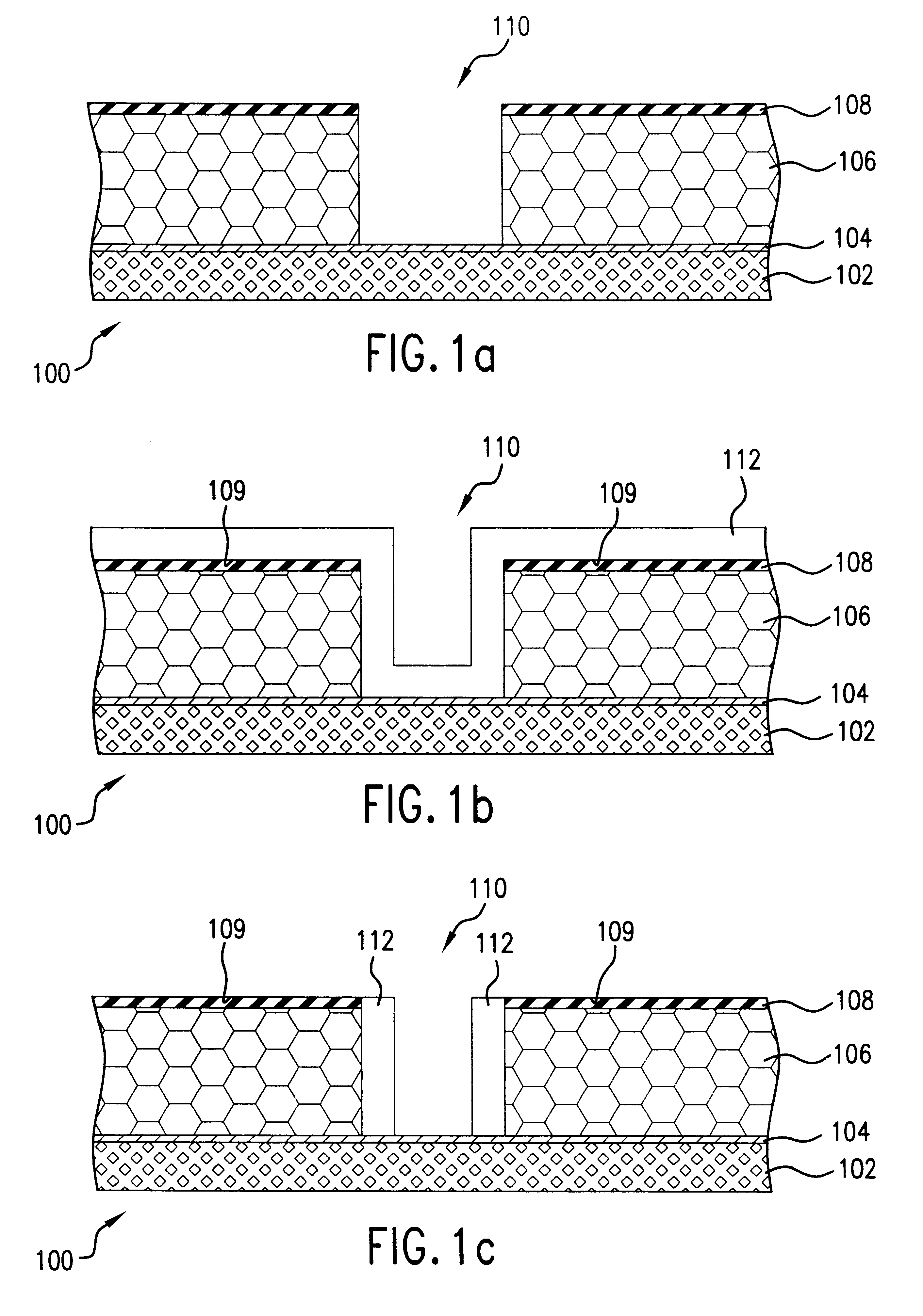

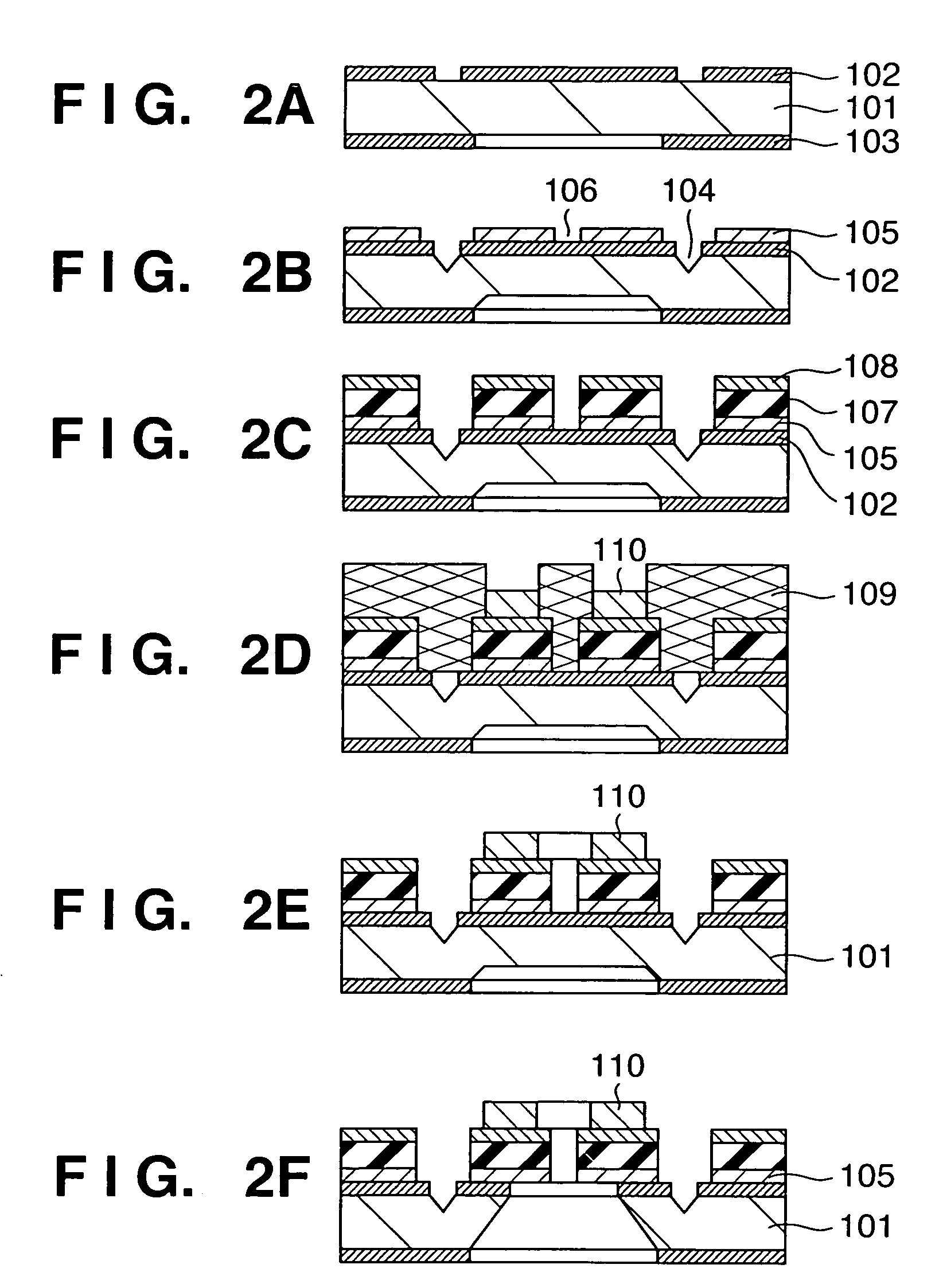

Method for fabricating a self-aligned nanocolumnar airbridge and structure produced thereby

ActiveUS20050208752A1Semiconductor/solid-state device detailsSolid-state devicesPorosityElectrical conductor

A method for fabricating a low k, ultra-low k, and extreme-low k multilayer interconnect structure on a substrate in which the interconnect line features are separated laterally by a dielectric with vertically oriented nano-scale voids formed by perforating it using sub-optical lithography patterning and etching techniques and closing off the tops of the perforations by a dielectric deposition step. The lines are supported either by solid or patterned dielectric features underneath. The method avoids the issues associated with the formation of air gaps after the fabrication of conductor patterns and those associated with the integration of conventional low k, ultra-low k and extreme low k dielectrics which have porosity present before the formation of the interconnect patterns.

Owner:GLOBALFOUNDRIES US INC

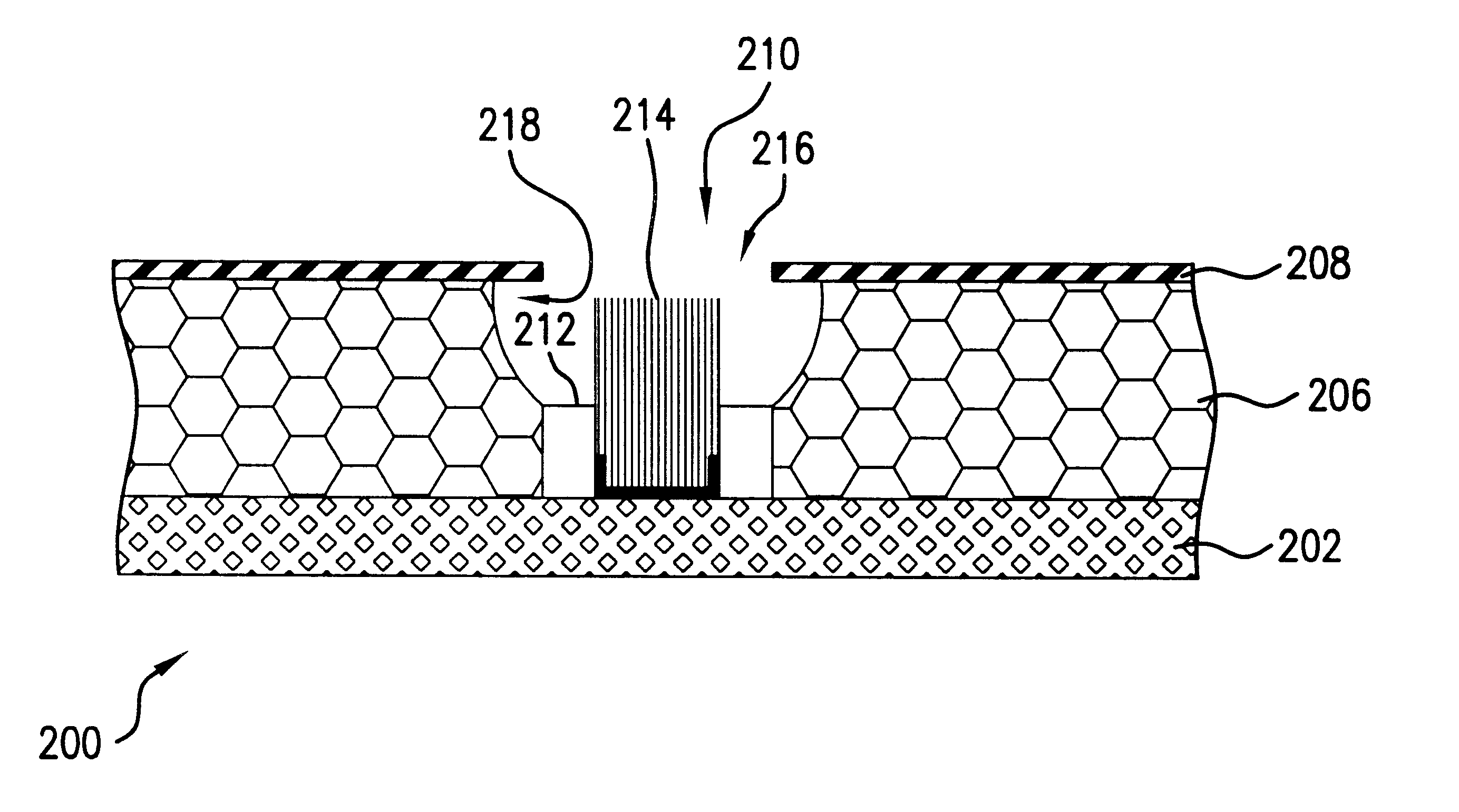

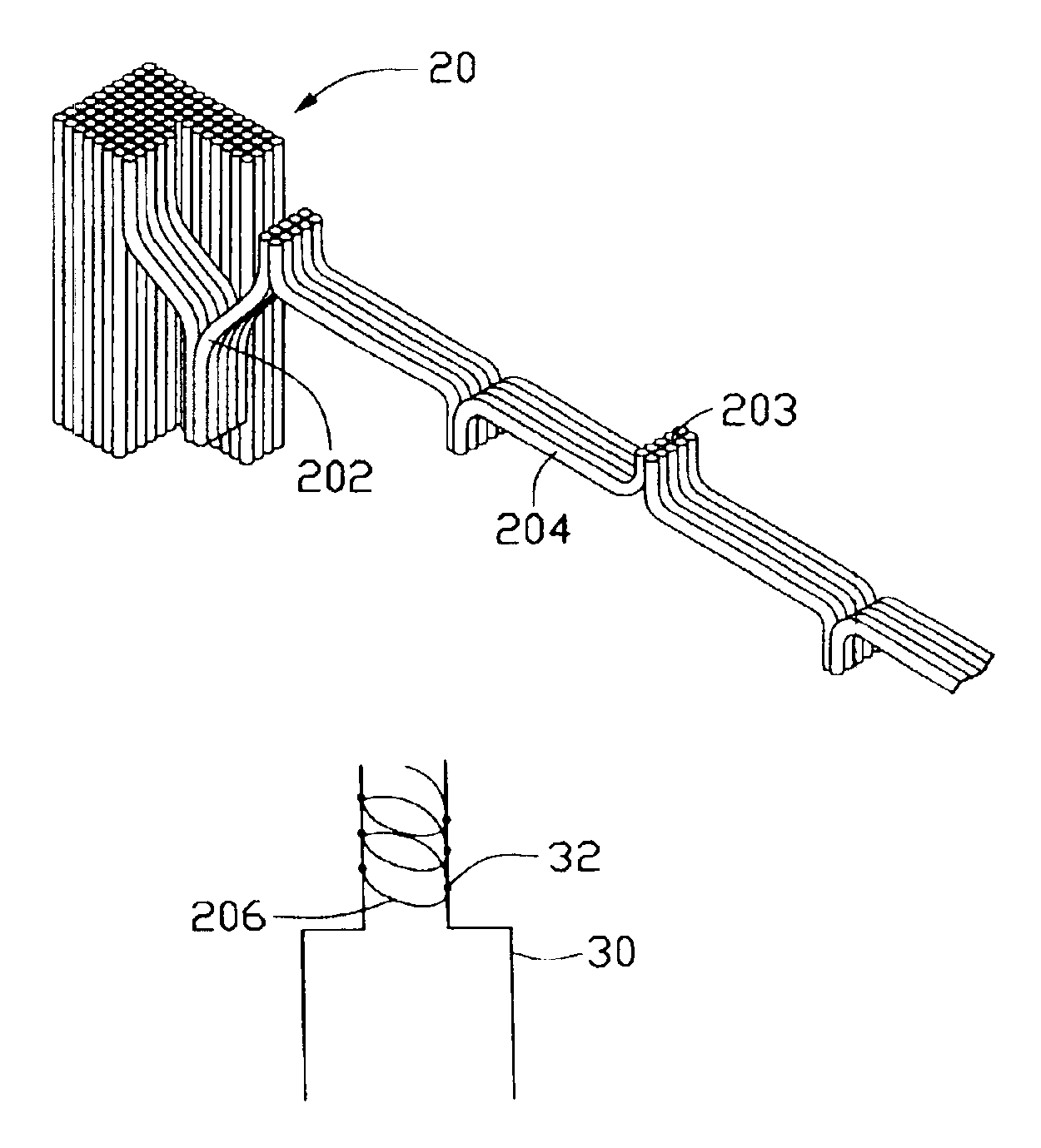

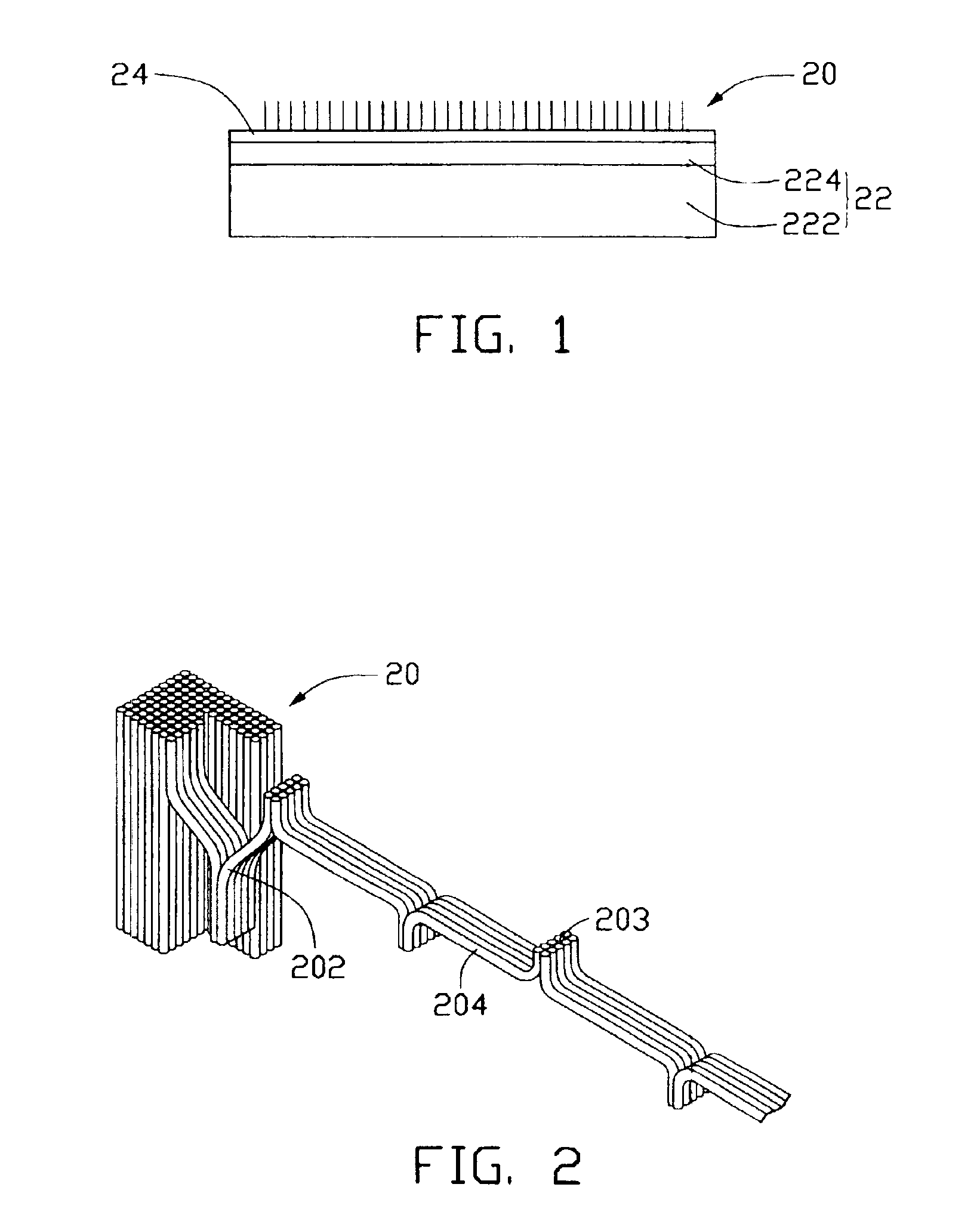

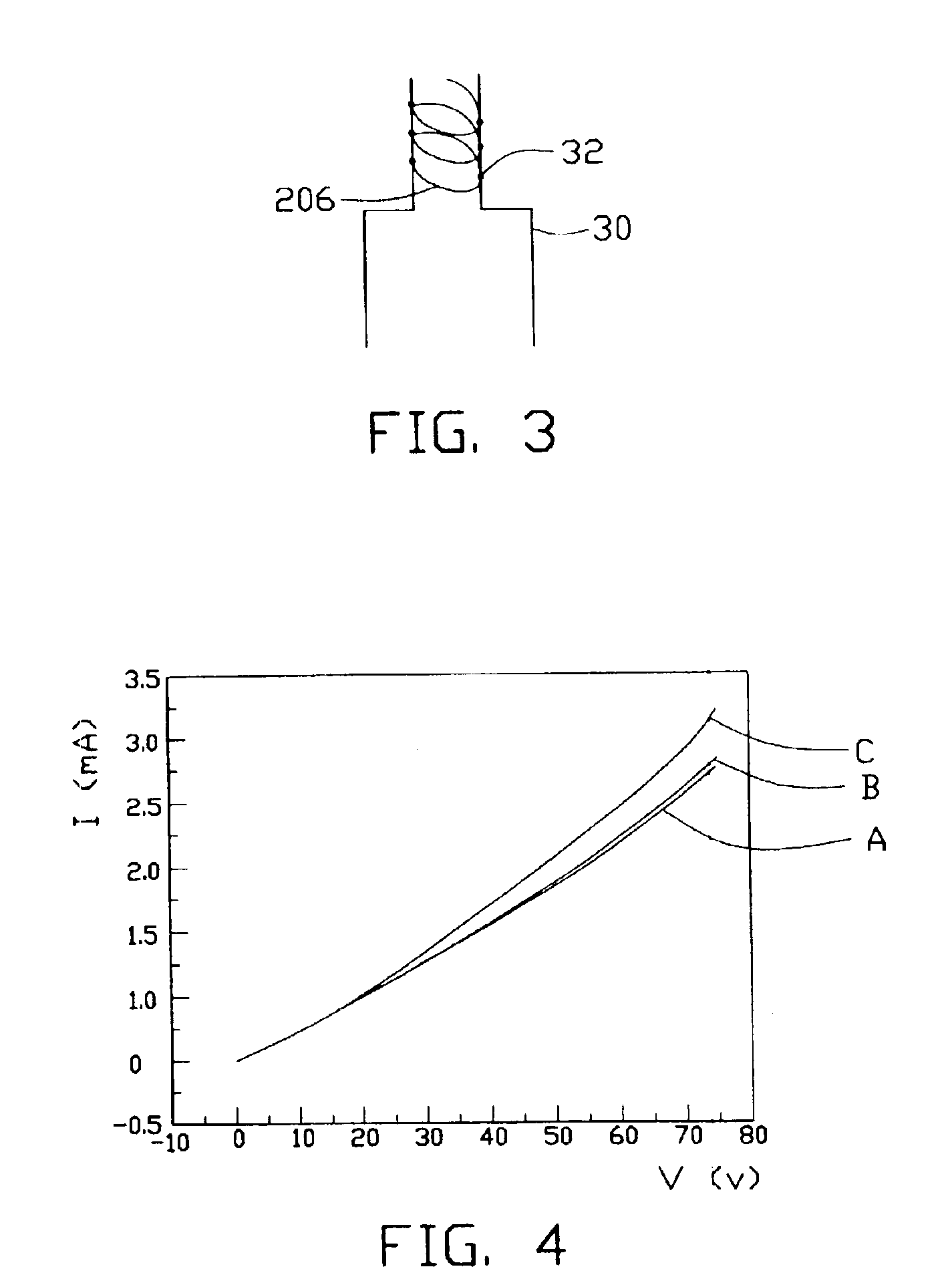

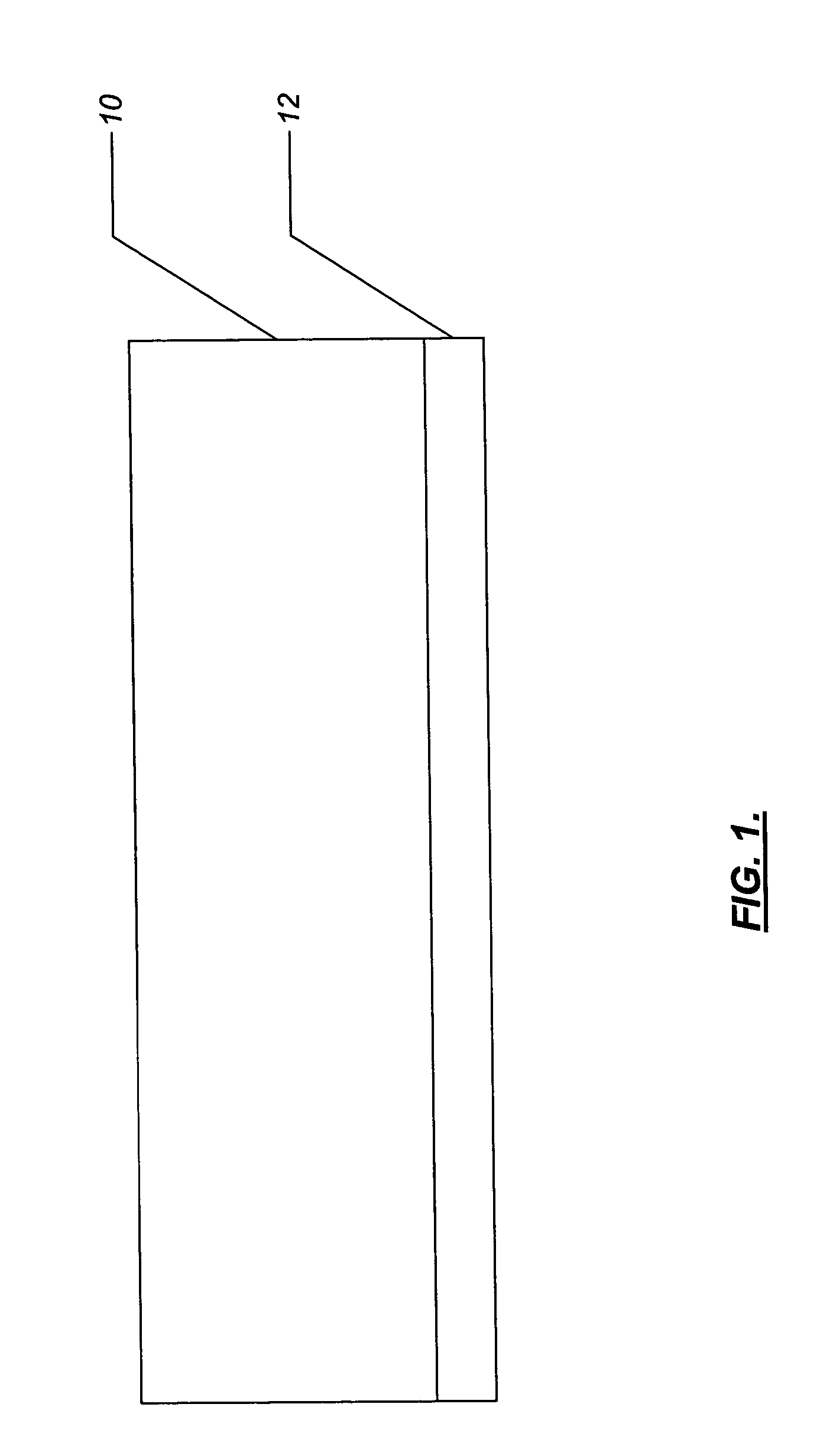

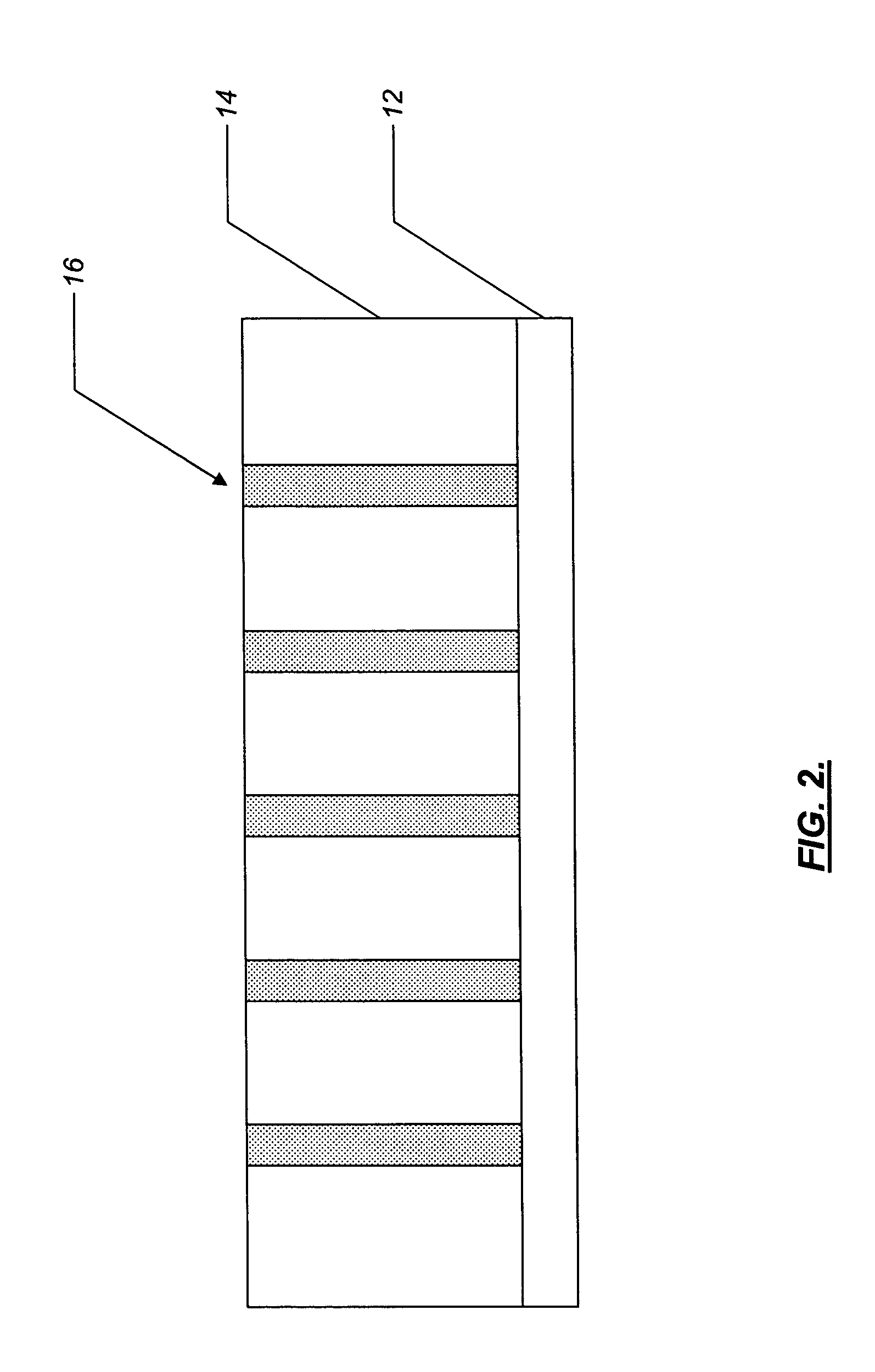

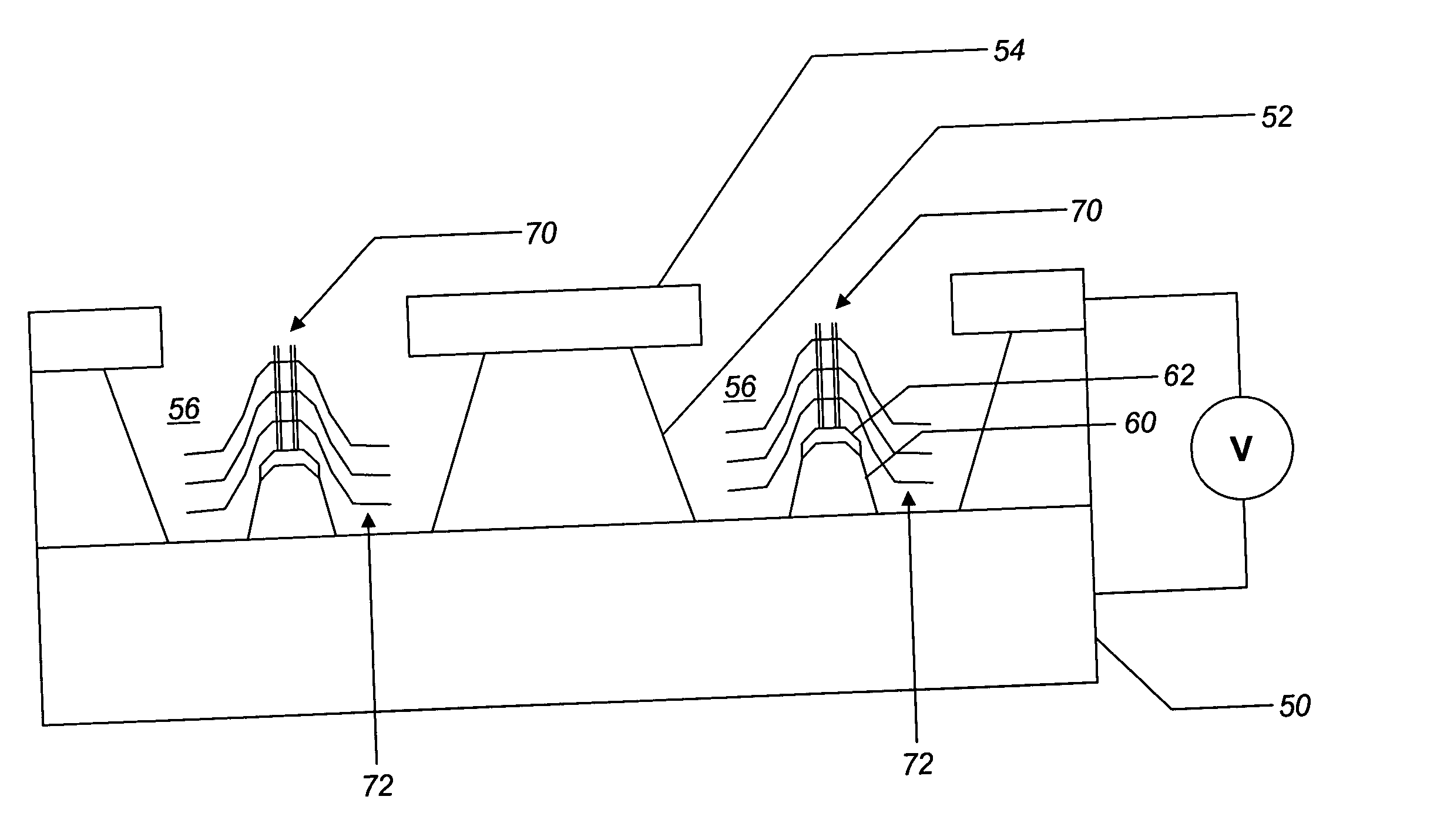

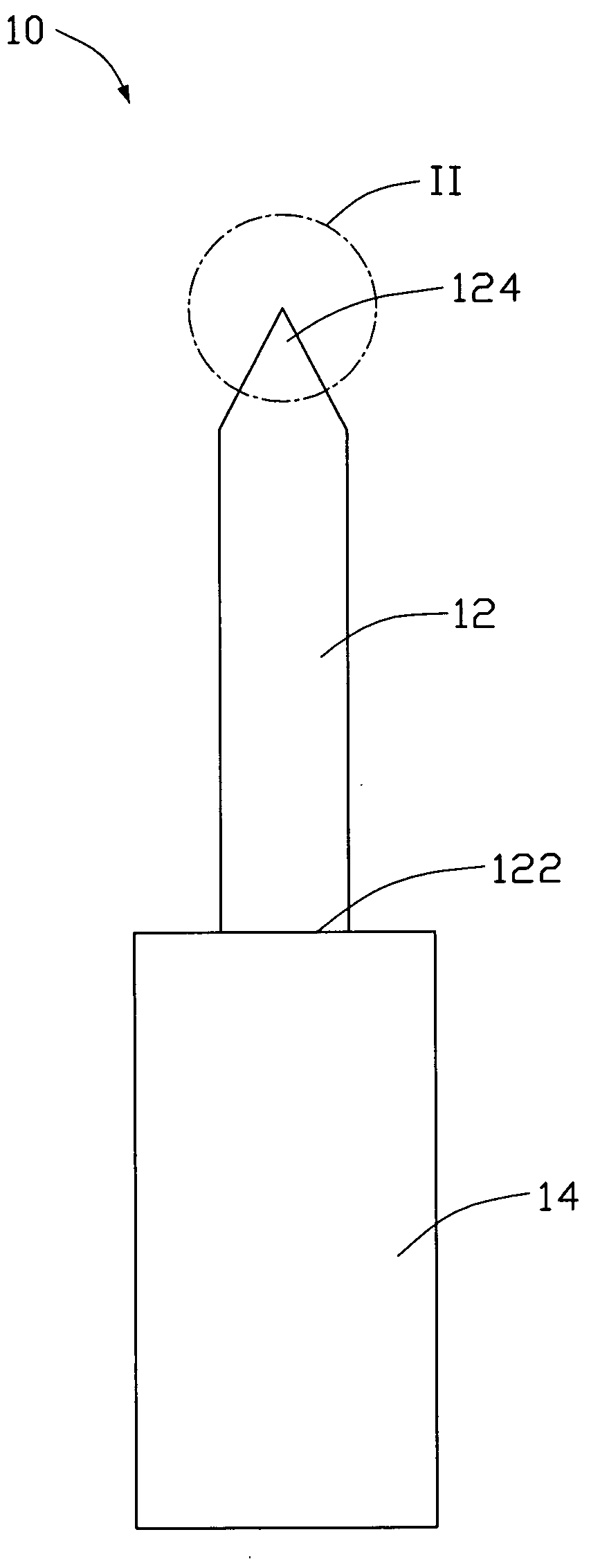

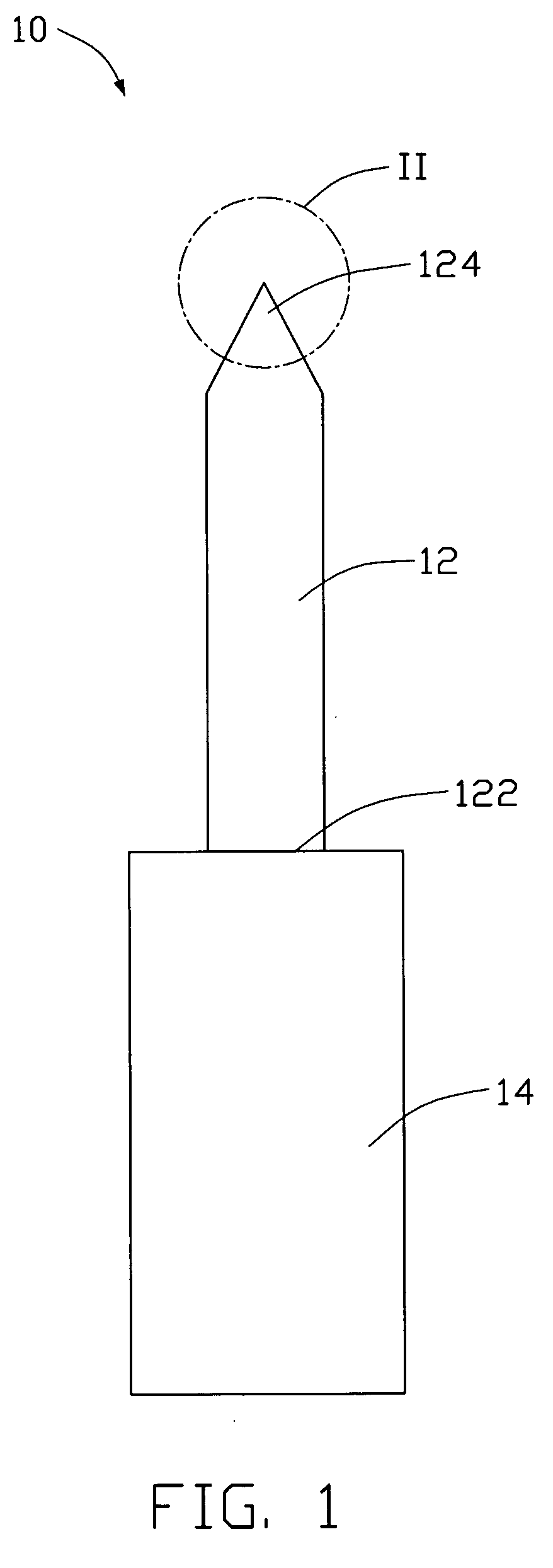

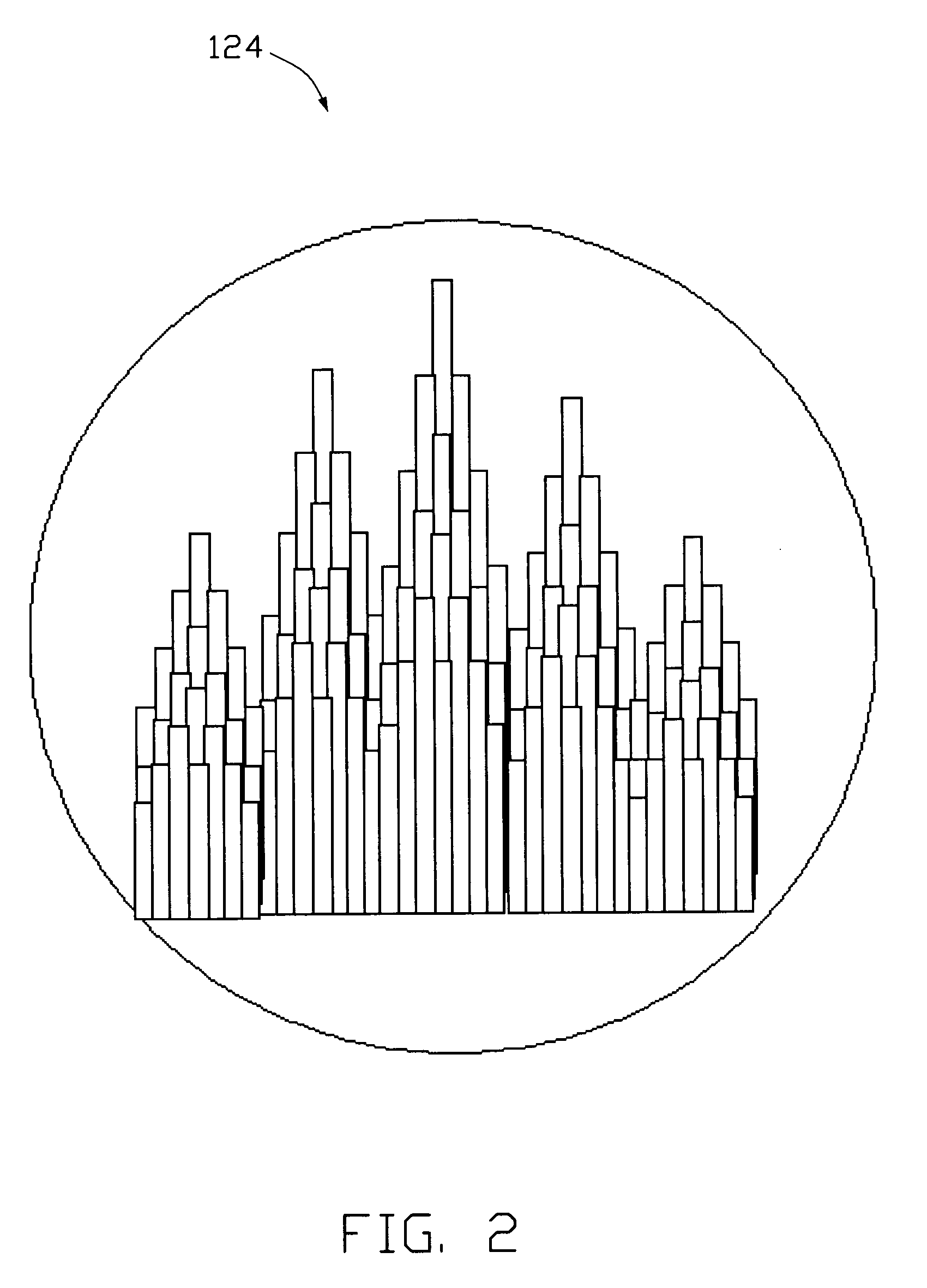

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

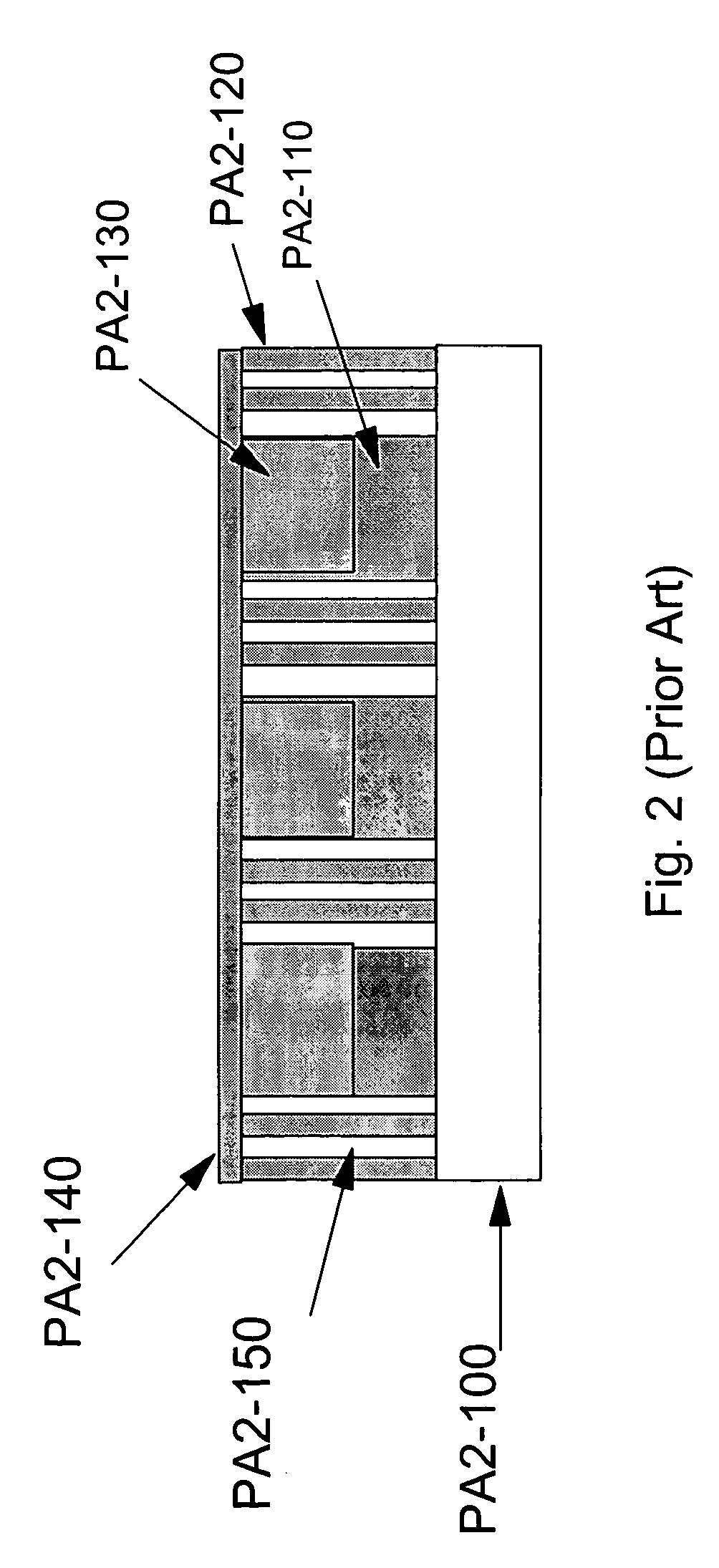

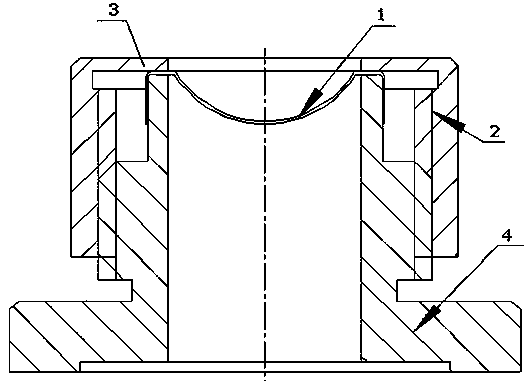

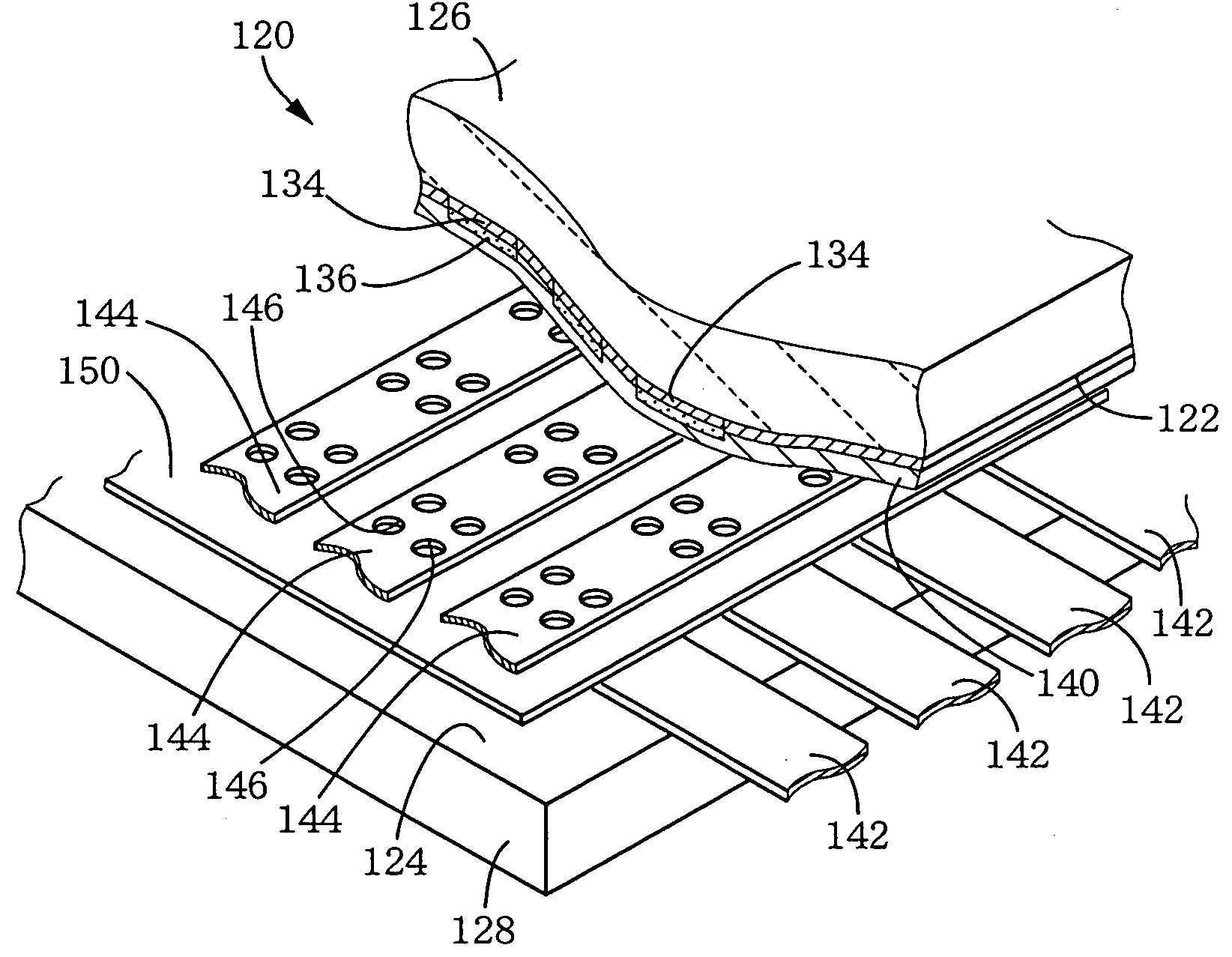

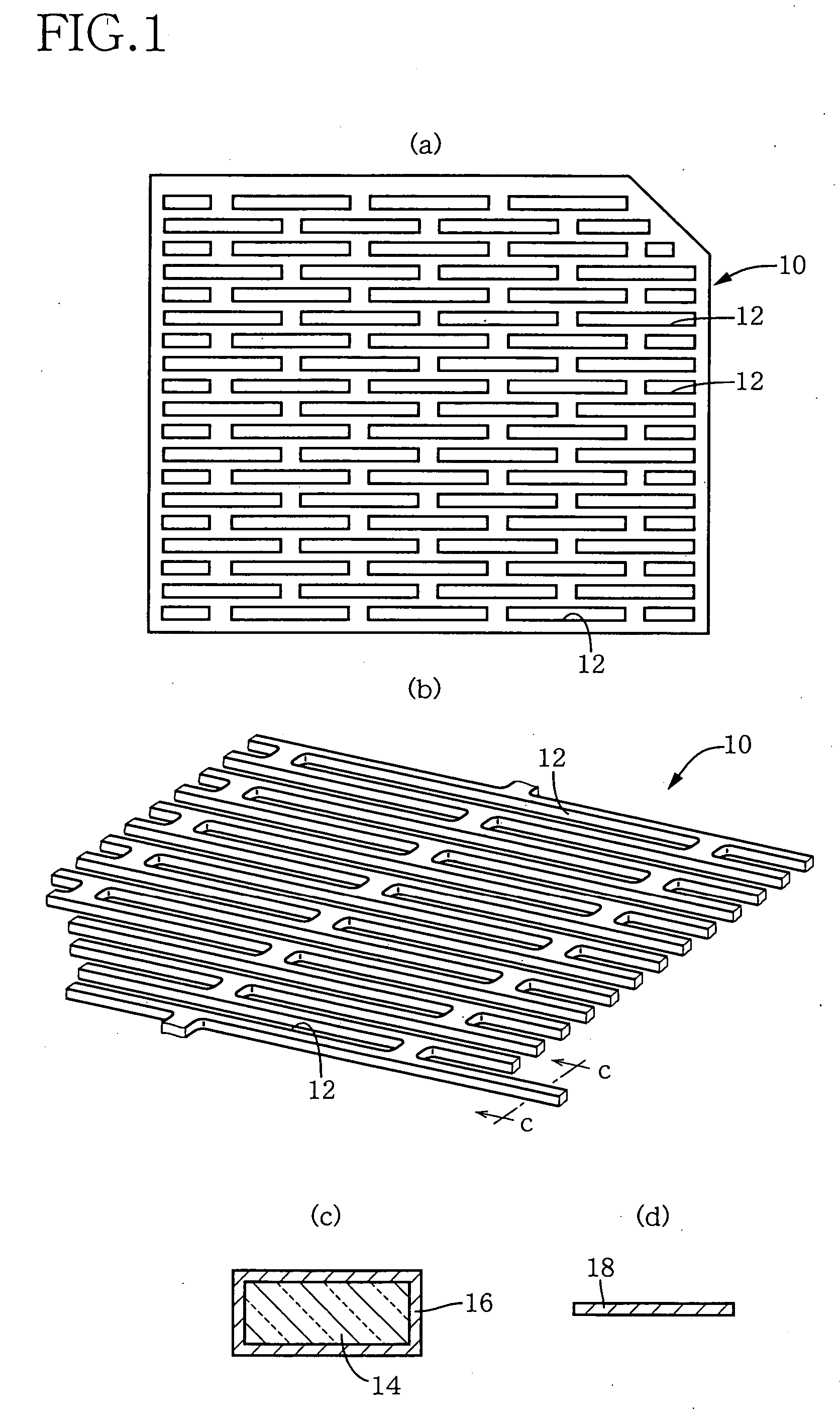

Deposition mask, method of manufacturing the same, and method of manufacturing electroluminescent display device having the same

InactiveUS20080118743A1Preventing a mask sheet from bendingElectroluminescent light sourcesVacuum evaporation coatingOrganic filmEngineering

A mask for depositing an organic film includes a mask sheet having at least two openings with different sizes and a blocking part formed in a region where the at least two openings are not formed. A supporting frame is formed on a back side of the mask sheet to support the mask sheet, and a mask frame receives a peripheral region of the supporting frame and supports a vertical pressure applied to the supporting frame and the mask sheet.

Owner:SAMSUNG ELECTRONICS CO LTD

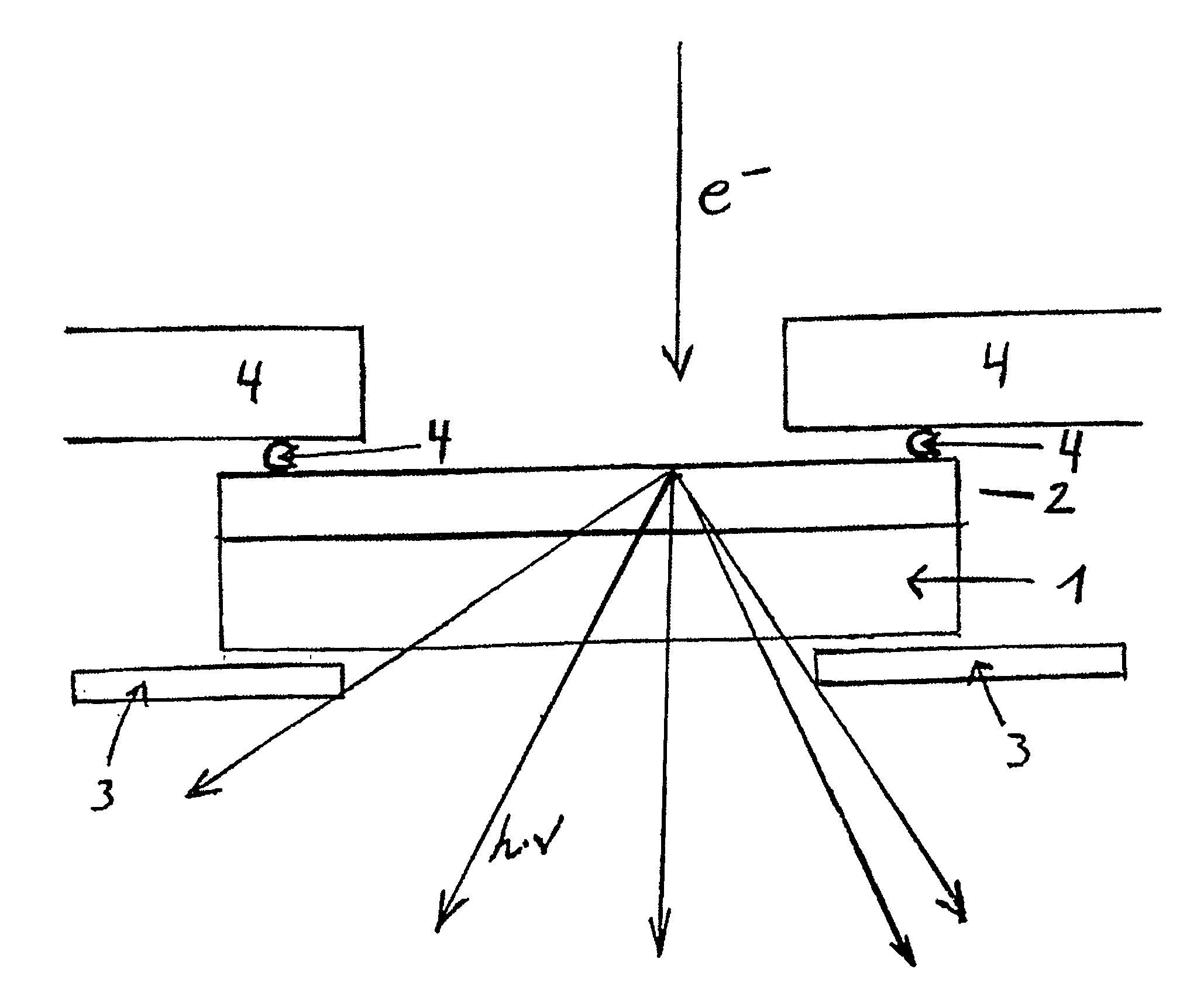

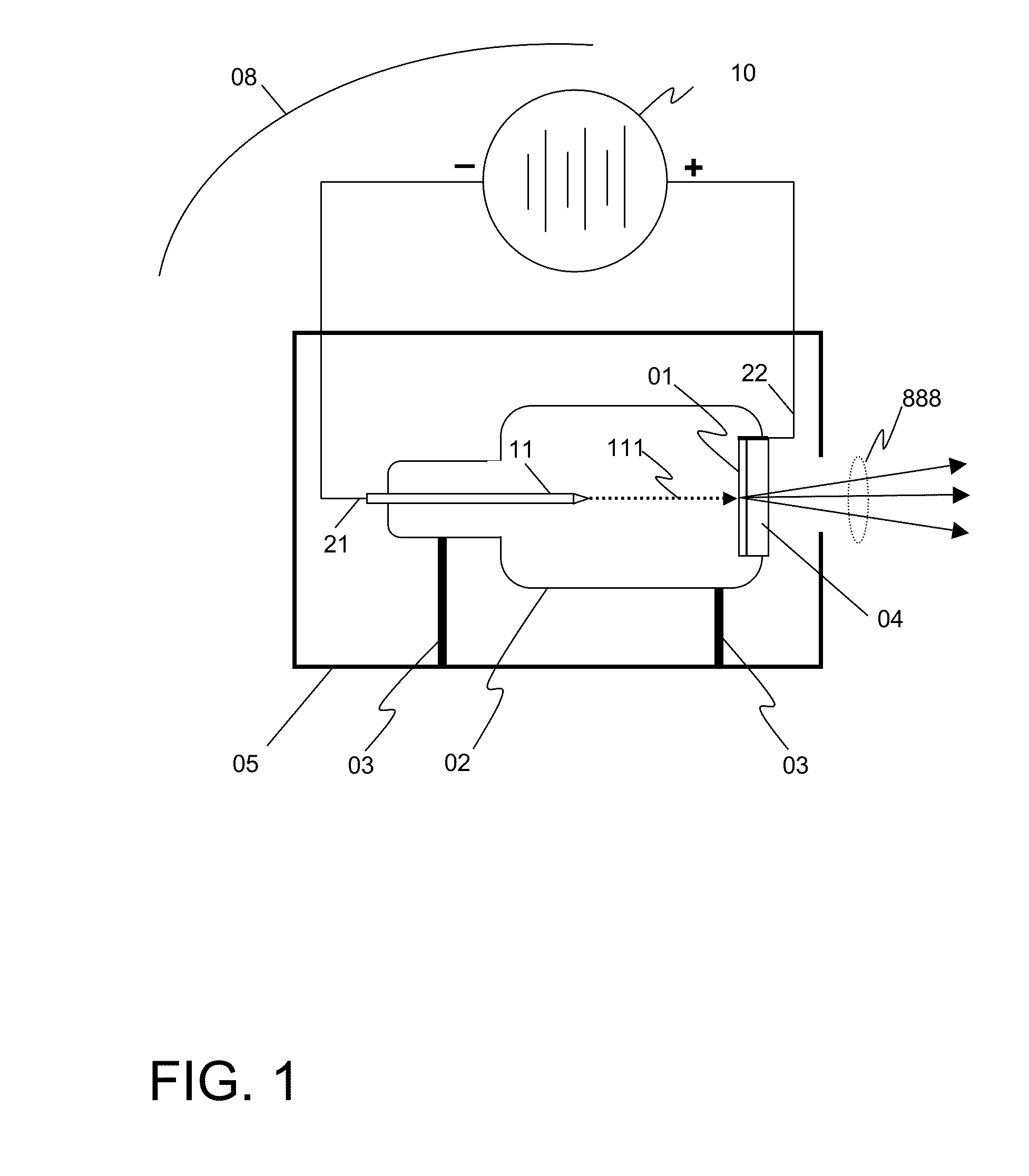

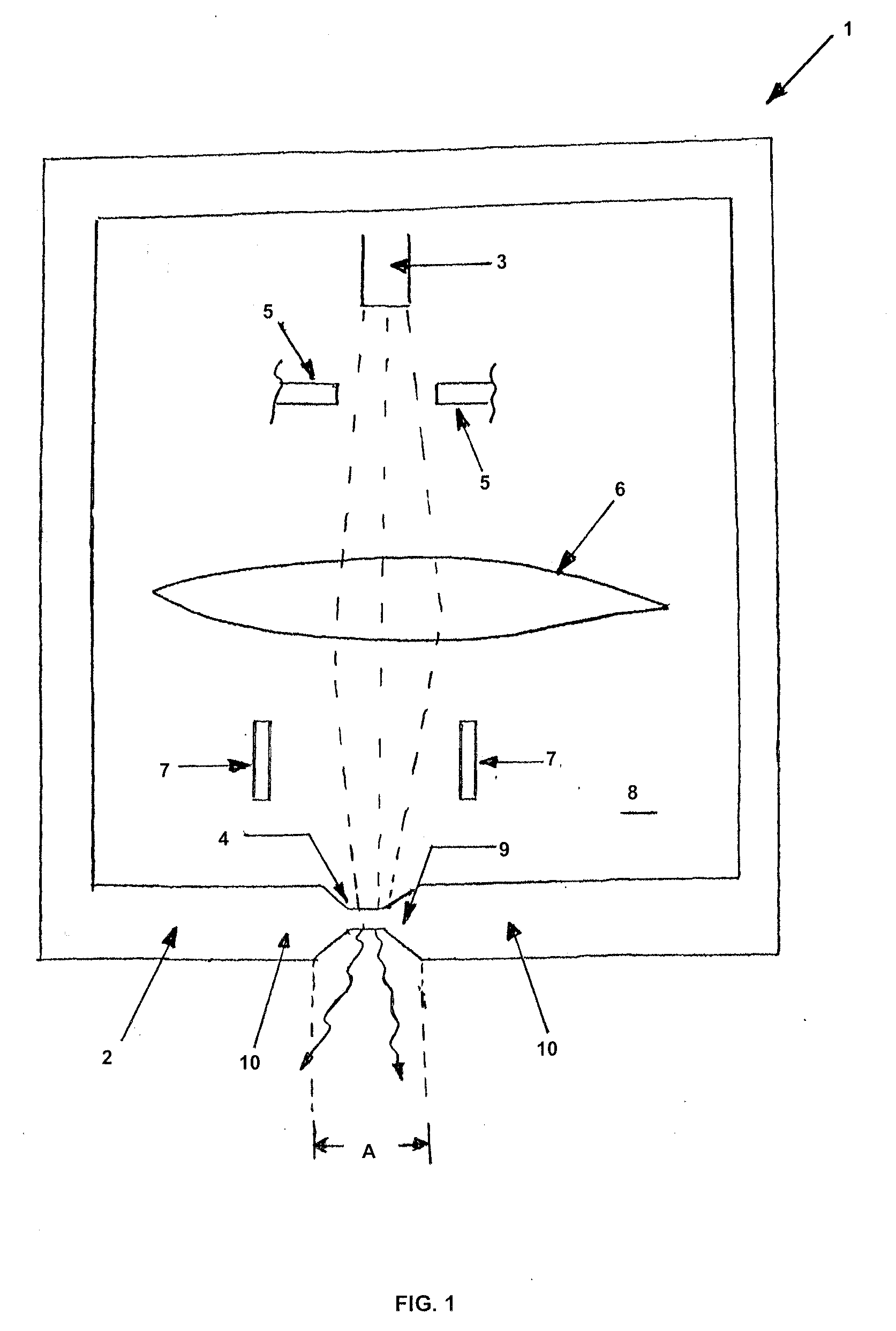

X-ray anode and process for its manufacture

InactiveUS6850598B1Improve the heating effectReduce absorptionRadiation/particle handlingX-ray tube electrodesSoft x rayImage resolution

The invention relates to an x-ray anode and a process for its manufacture. The x-ray anode is characterized in that the anode material is embodied as a layer on a diamond window. The x-ray anode is preferably used with x-ray units which require as selective as possible x-radiation production to achieve as high as possible radiation intensity. Use in x-ray microscopes in which a high radiation intensity guarantees the highest resolutions is particularly preferred.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Method for fabricating a self-aligned nanocolumnar airbridge and structure produced thereby

InactiveUS20050272341A1Semiconductor/solid-state device detailsSolid-state devicesPorosityElectrical conductor

A method for fabricating a low k, ultra-low k, and extreme-low k multilayer interconnect structure on a substrate in which the interconnect line features are separated laterally by a dielectric with vertically oriented nano-scale voids formed by perforating it using sub-optical lithography patterning and etching techniques and closing off the tops of the perforations by a dielectric deposition step. The lines are supported either by solid or patterned dielectric features underneath. The method avoids the issues associated with the formation of air gaps after the fabrication of conductor patterns and those associated with the integration of conventional low k, ultra-low k and extreme low k dielectrics which have porosity present before the formation of the interconnect patterns.

Owner:GLOBALFOUNDRIES INC

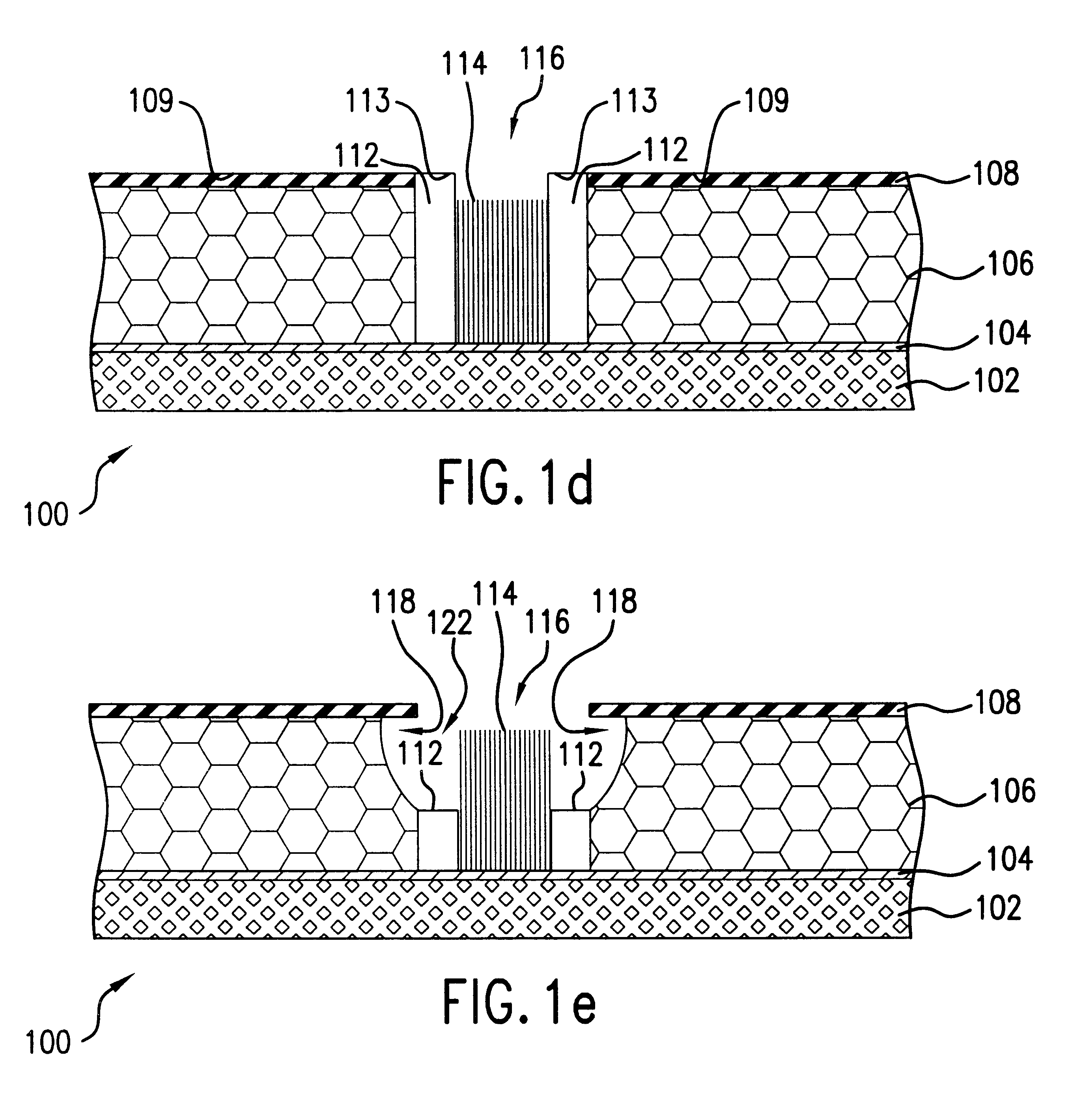

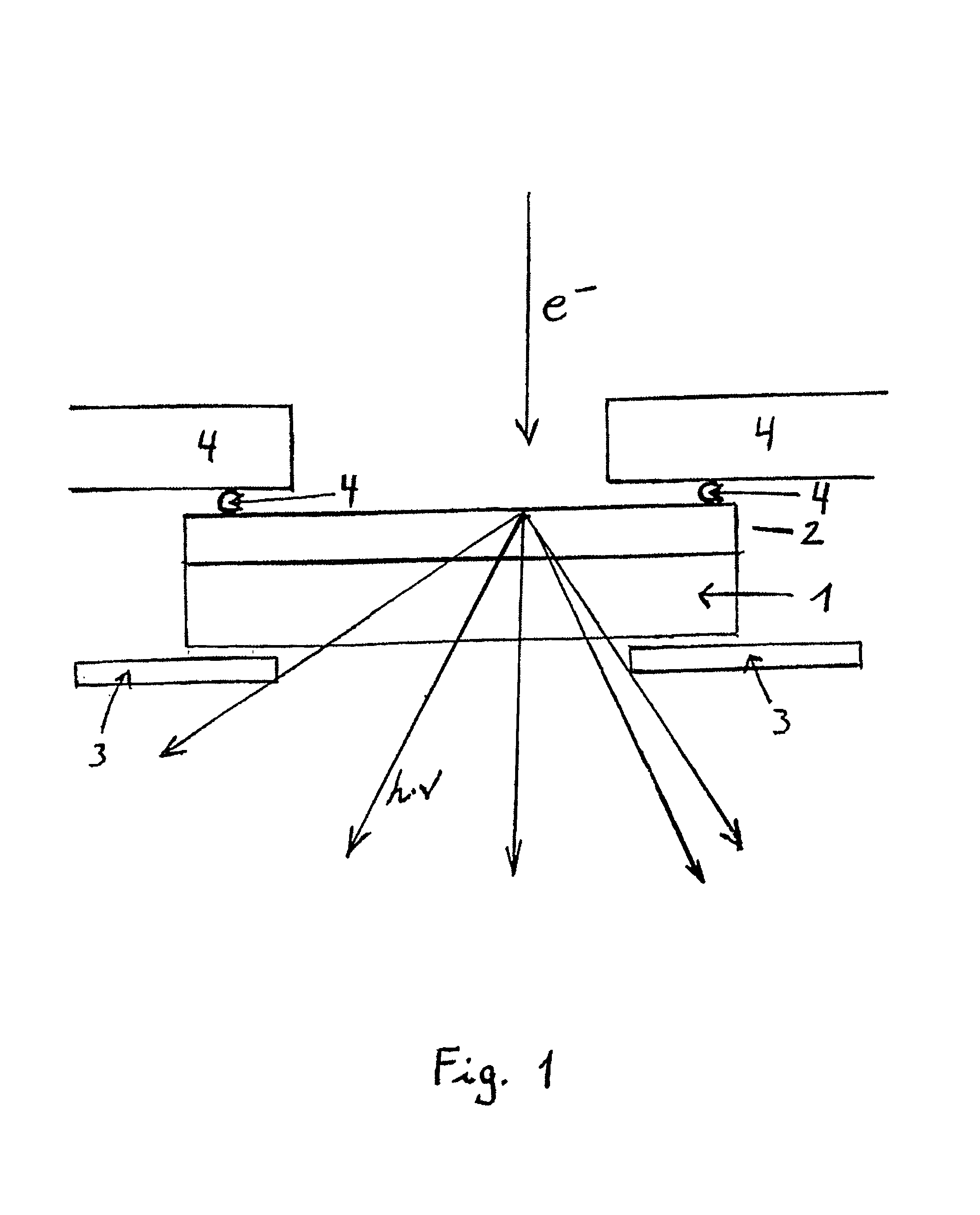

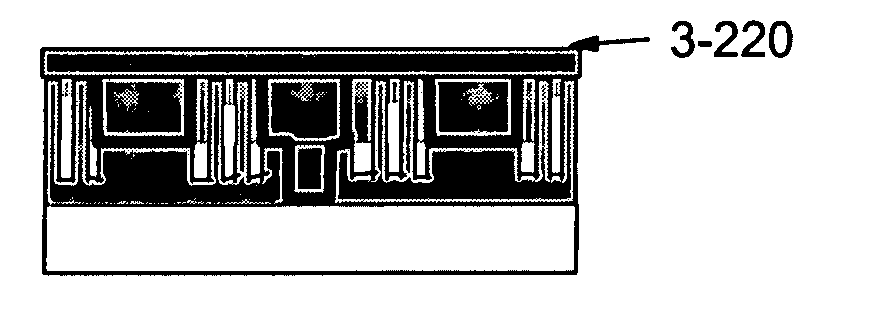

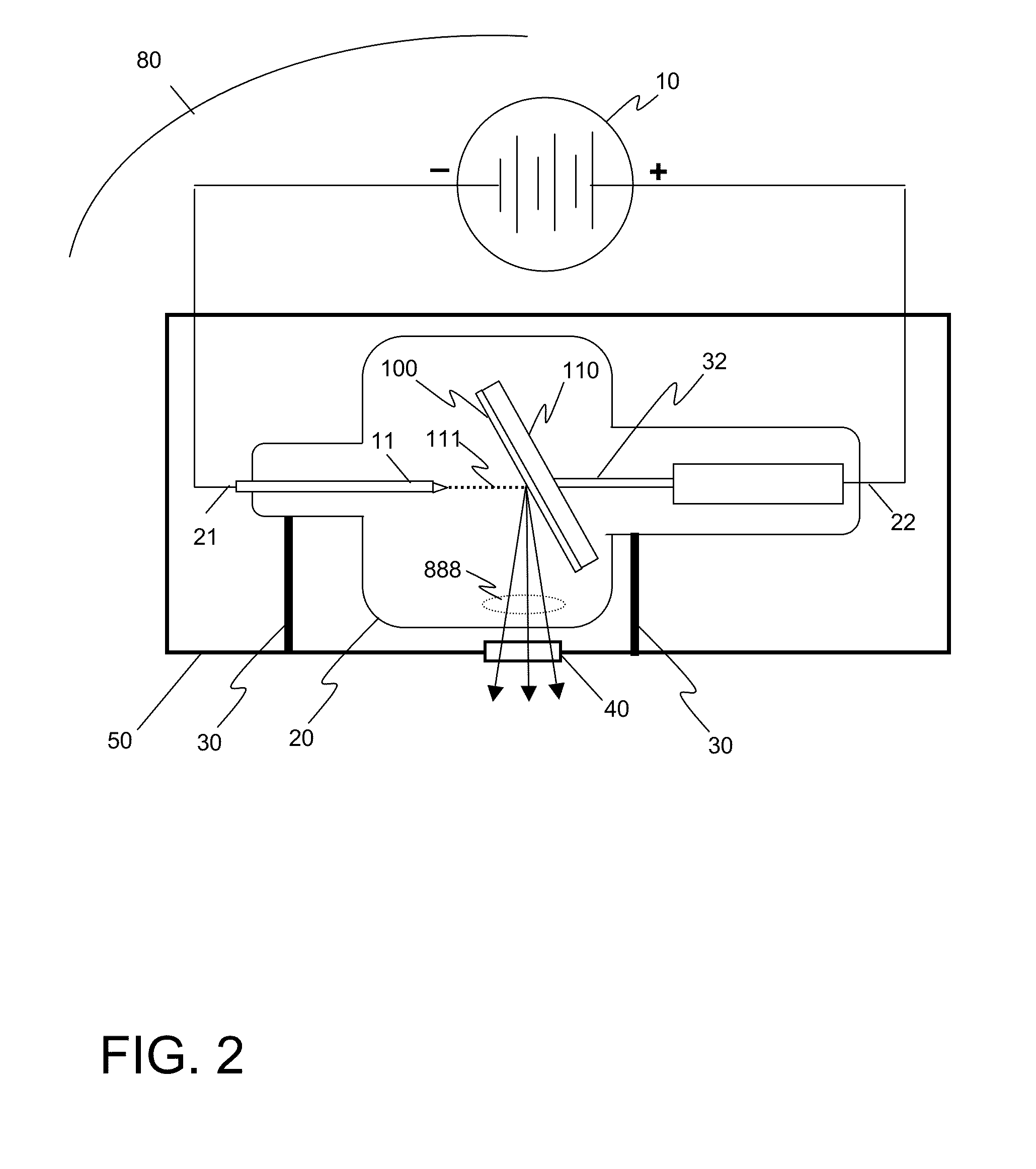

Structured targets for x-ray generation

InactiveUS20150092924A1Improve cooling effectHeat generationX-ray tube laminated targetsX-ray tube anode coolingMicron scaleHigh energy

We disclose targets for generating x-rays using electron beams, along with their method of fabrication. The targets comprise a number of microstructures fabricated from an x-ray target material arranged in close thermal contact with a substrate such that the heat is more efficiently drawn out of the x-ray target material. This in turn allows irradiation of the x-ray generating substance with higher electron density or higher energy electrons, which leads to greater x-ray brightness, without inducing damage or melting.The microstructures may comprise conventional x-ray target materials (such as tungsten) that are patterned at micron-scale dimensions on a thermally conducting substrate, such as diamond. The microstructures may have any number of geometric shapes to best generate x-rays of high brightness and efficiently disperse heat.In some embodiments, the target comprising microstructures may be incorporated into a rotating anode geometry, to enhance x-ray generation in such systems.

Owner:SIGRAY INC

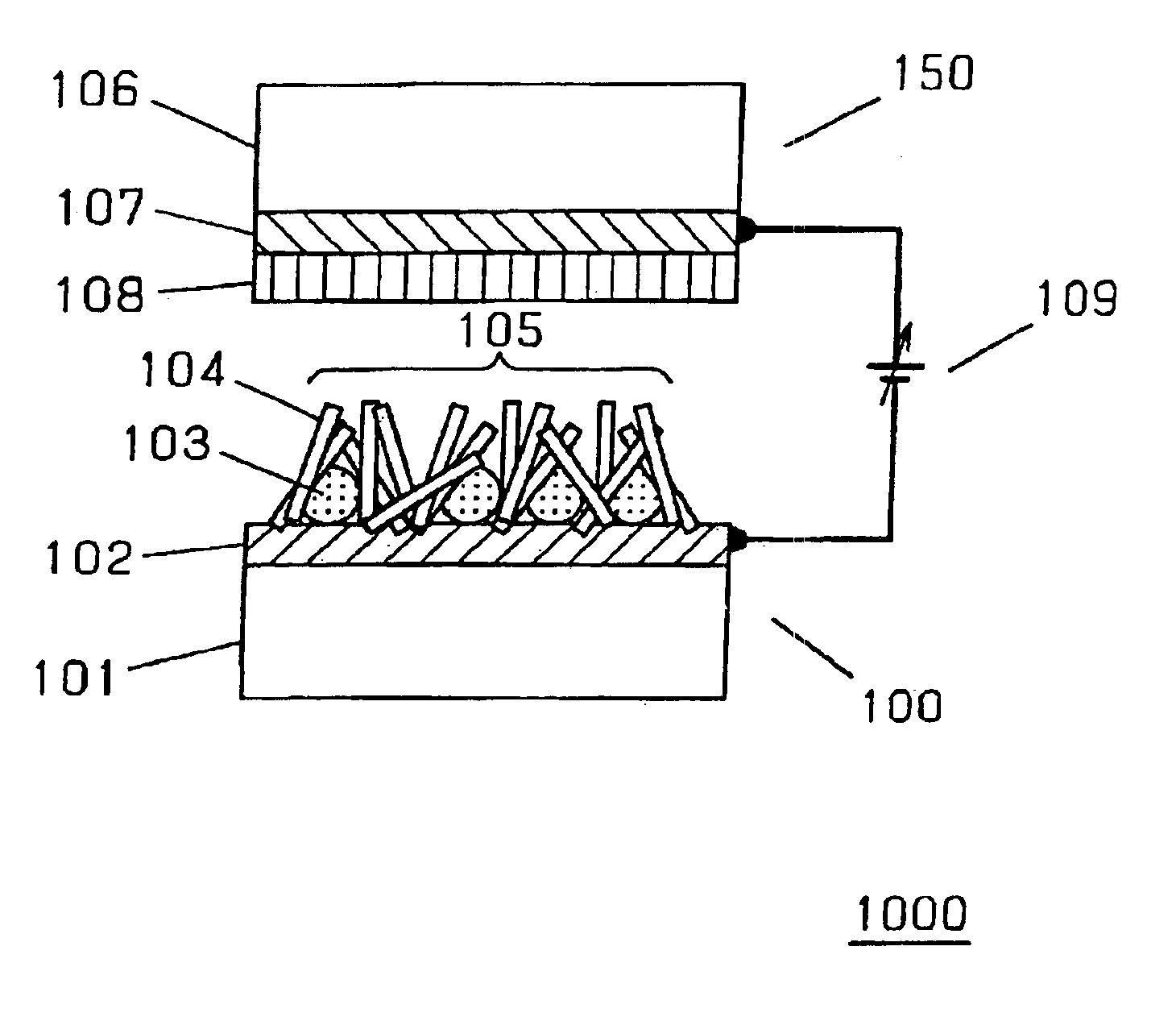

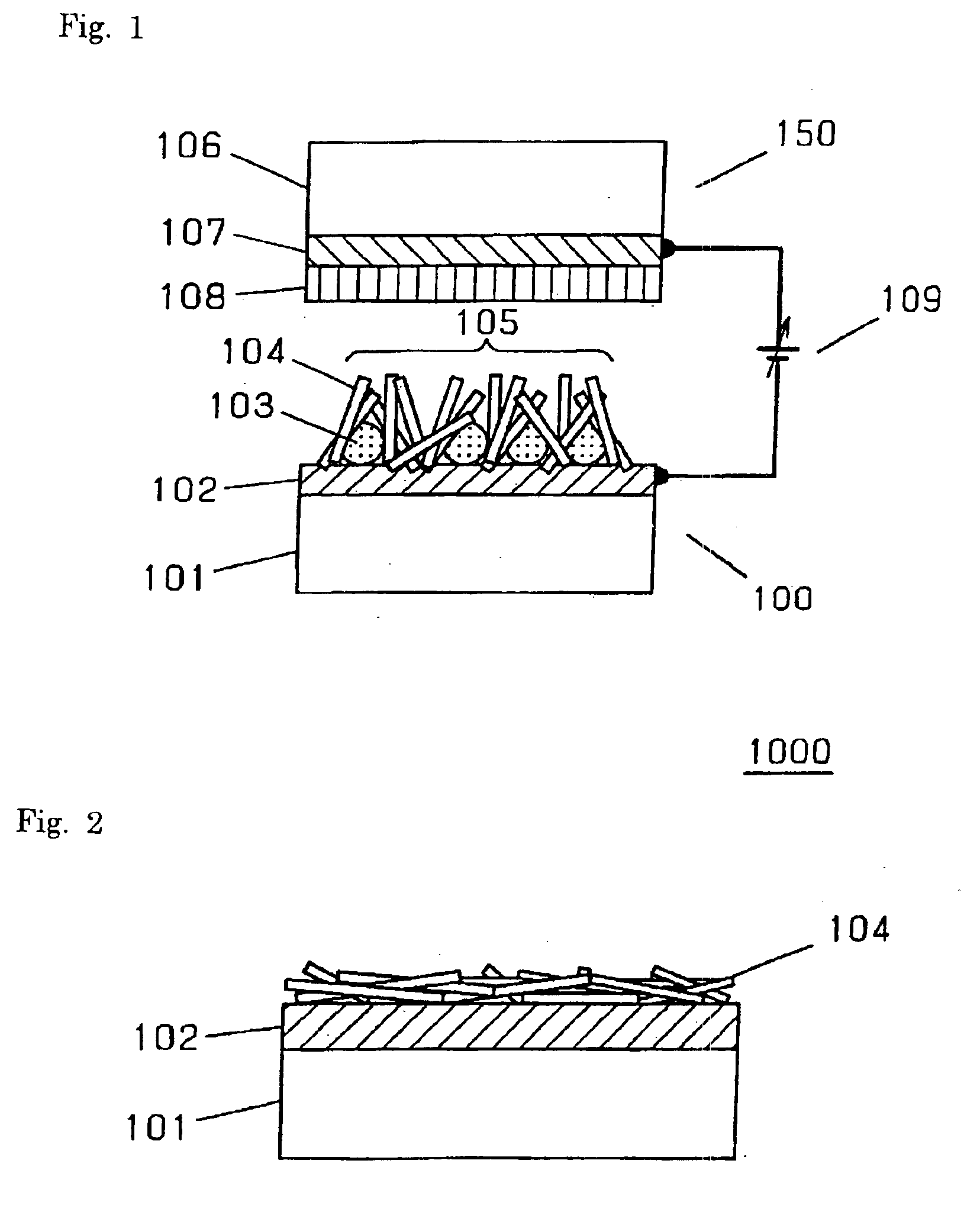

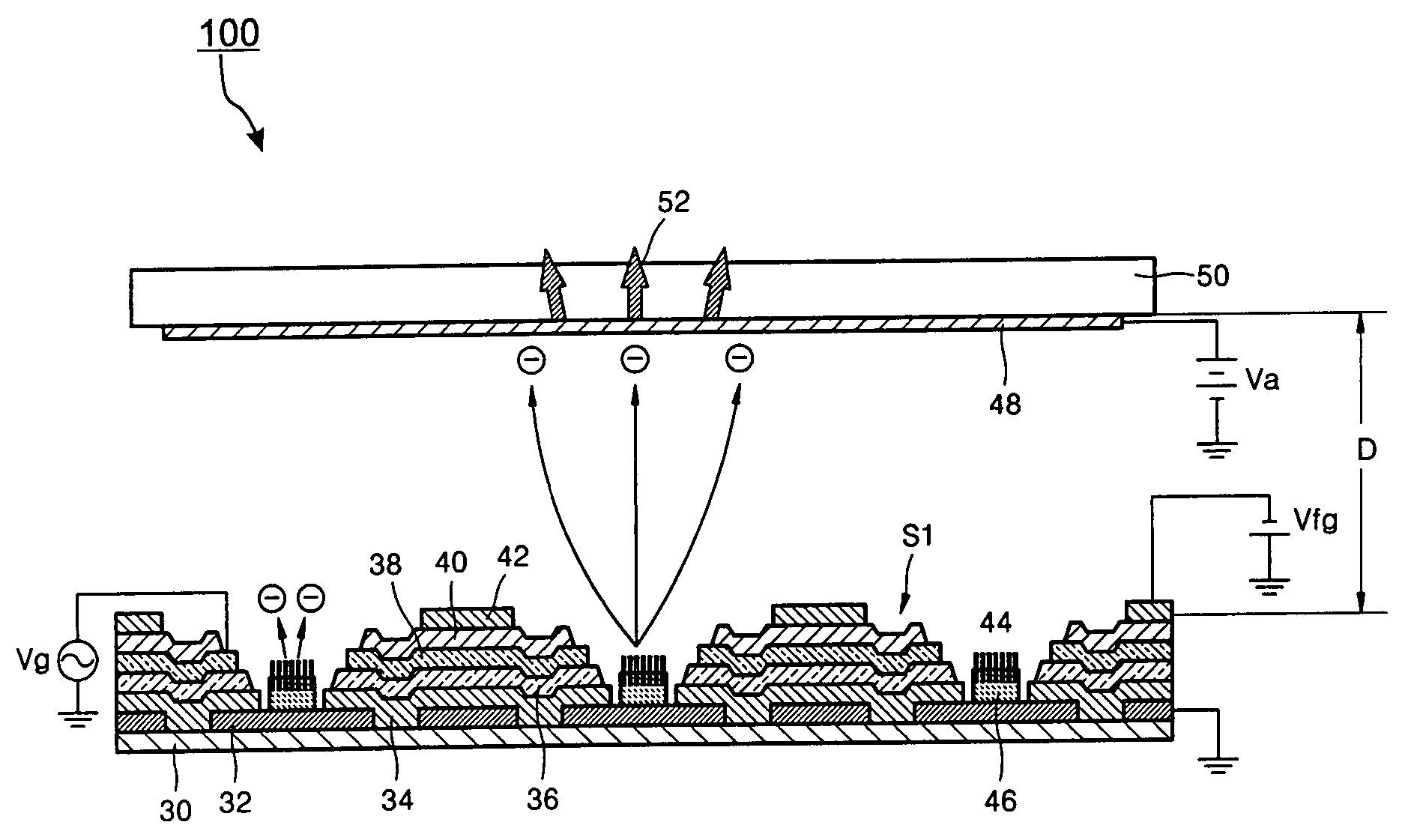

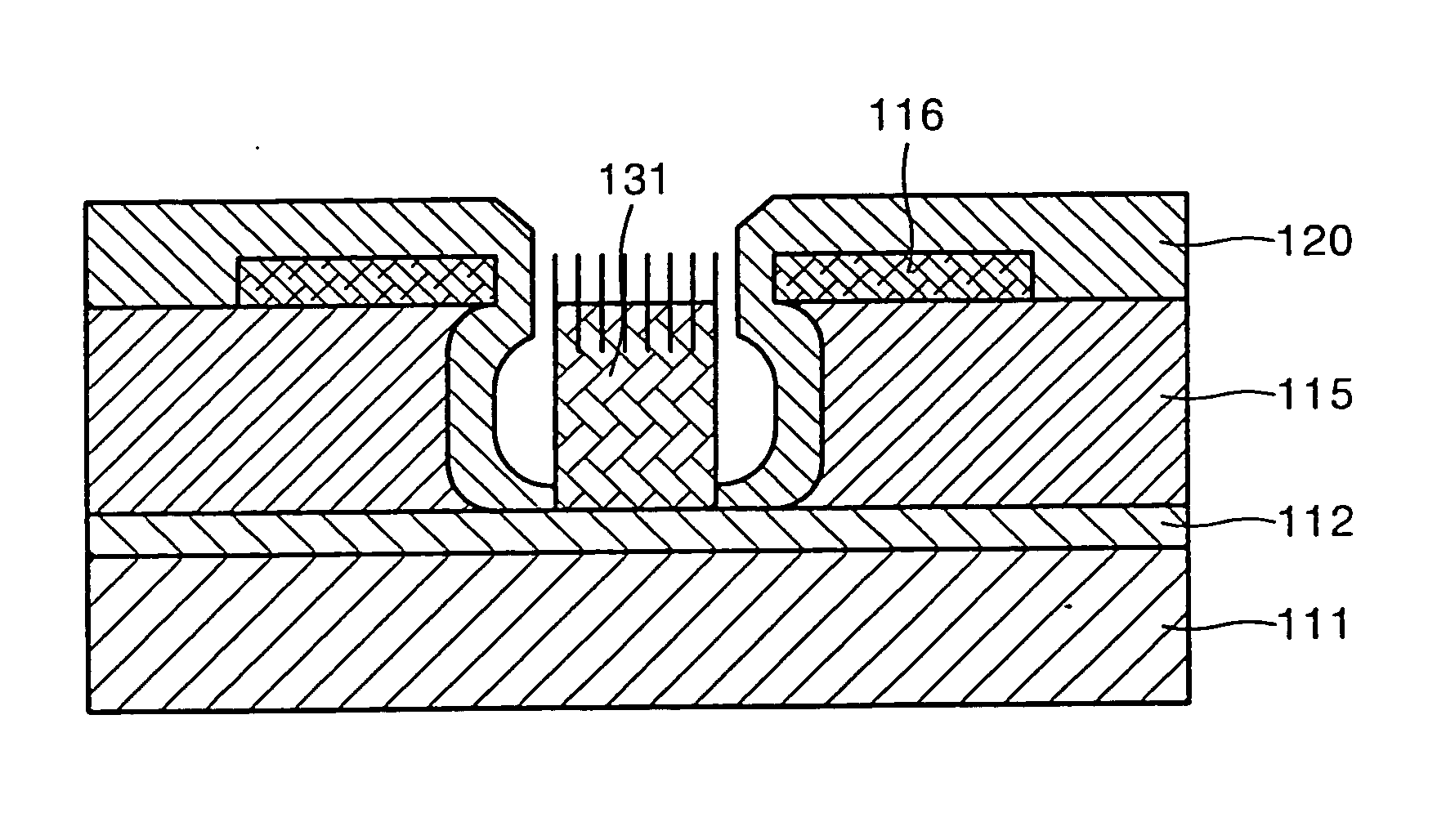

Electron-emitting element and electron source, field emission image display device, and fluorescent lamp utilizing the same and methods of fabricating the same

Disclosed are an electron-emitting element having a large operating current at a low operating voltage and excellent operation stability, and an electron source, an image display device and the like utilizing such an electron-emitting element, and further a method of fabricating such an element with few process steps at low cost. A cold cathode member is configured utilizing hybrid particle of a first particle serving to emit electrons into the space and a second particle being in the vicinity of the first particle and serving to control the position of the first particle. In this configuration, it is preferable that the first particle have a higher electron emission efficiency than the second particle and that the second particle be conductive.

Owner:PANASONIC CORP

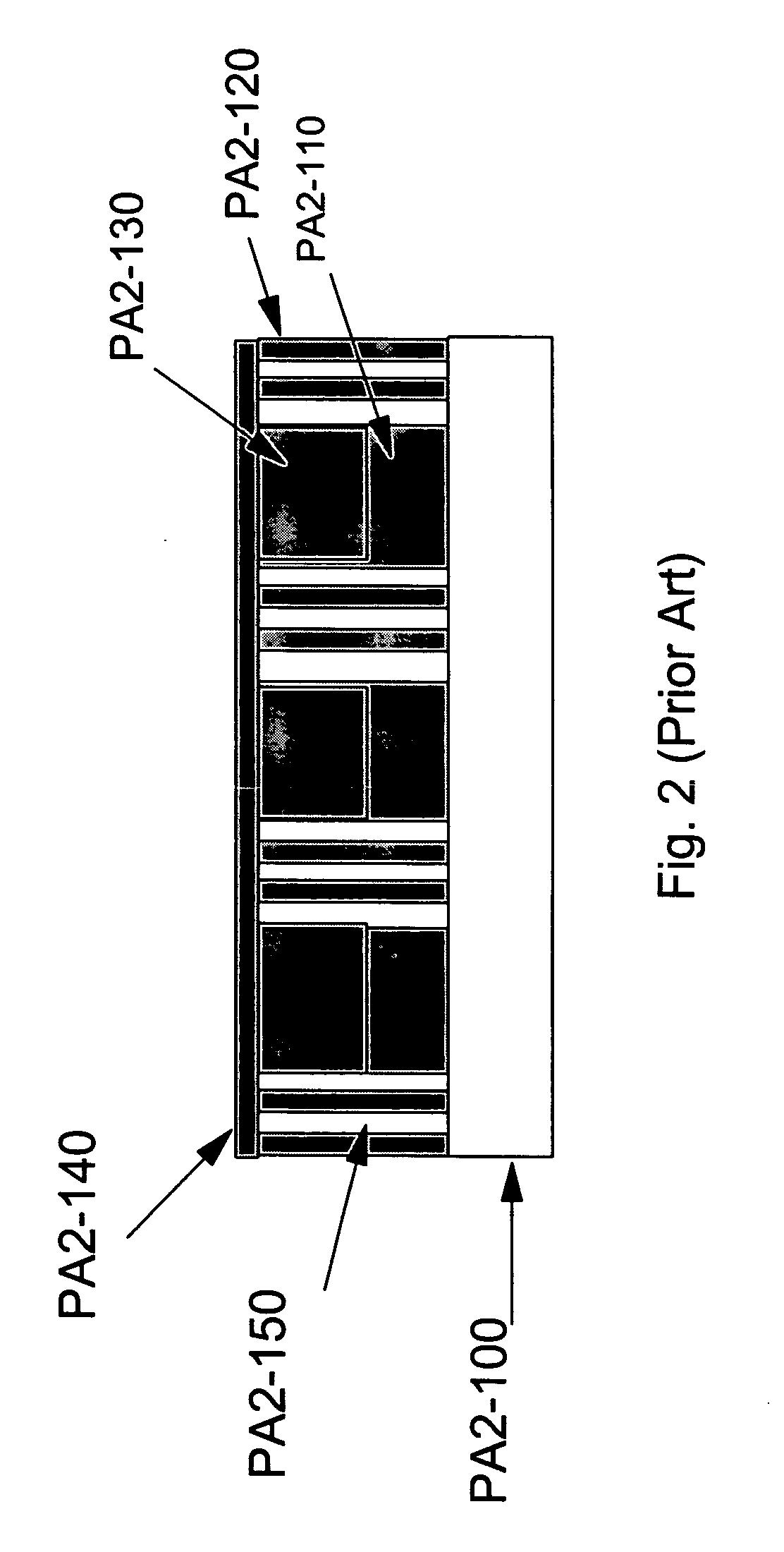

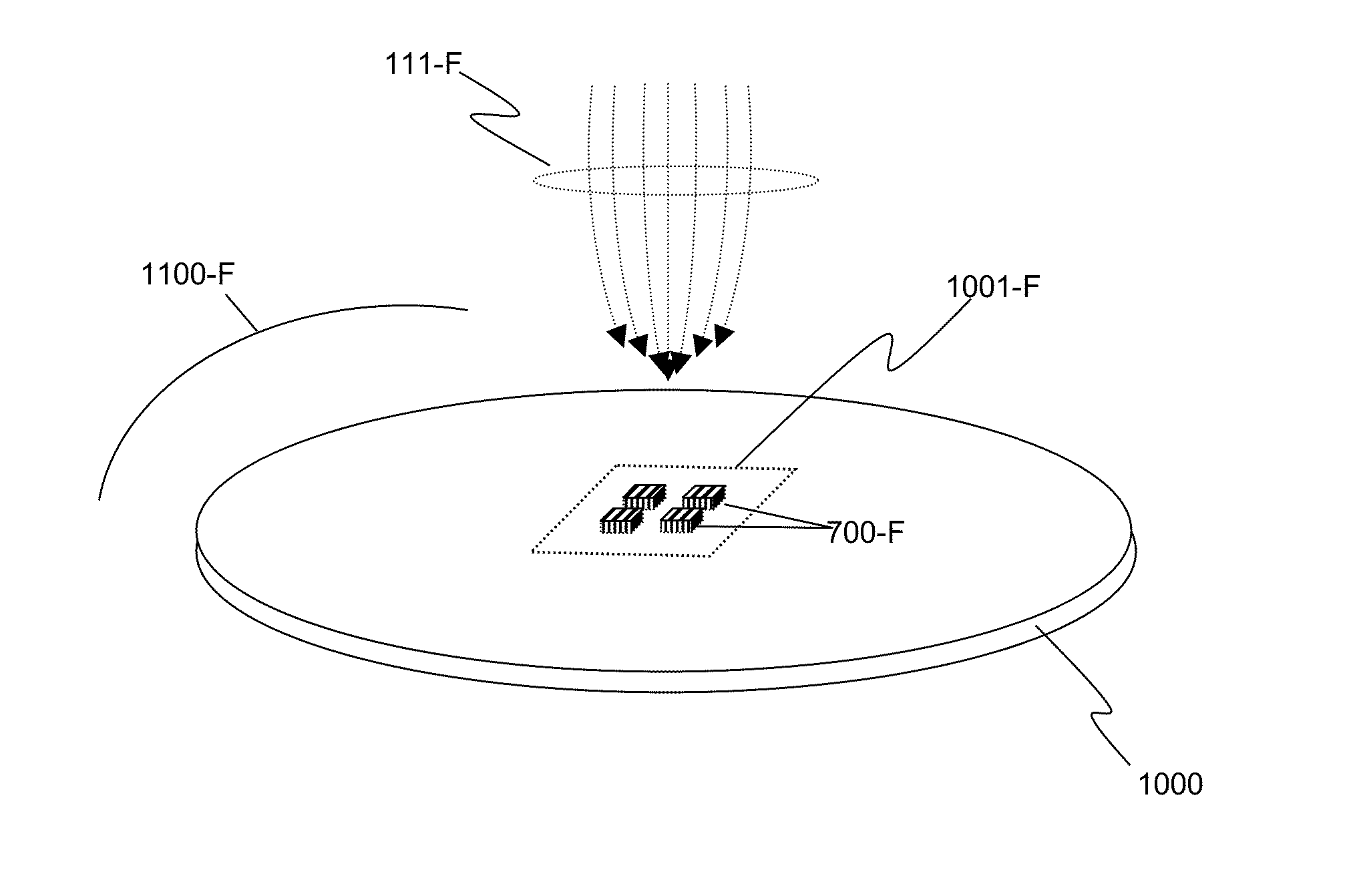

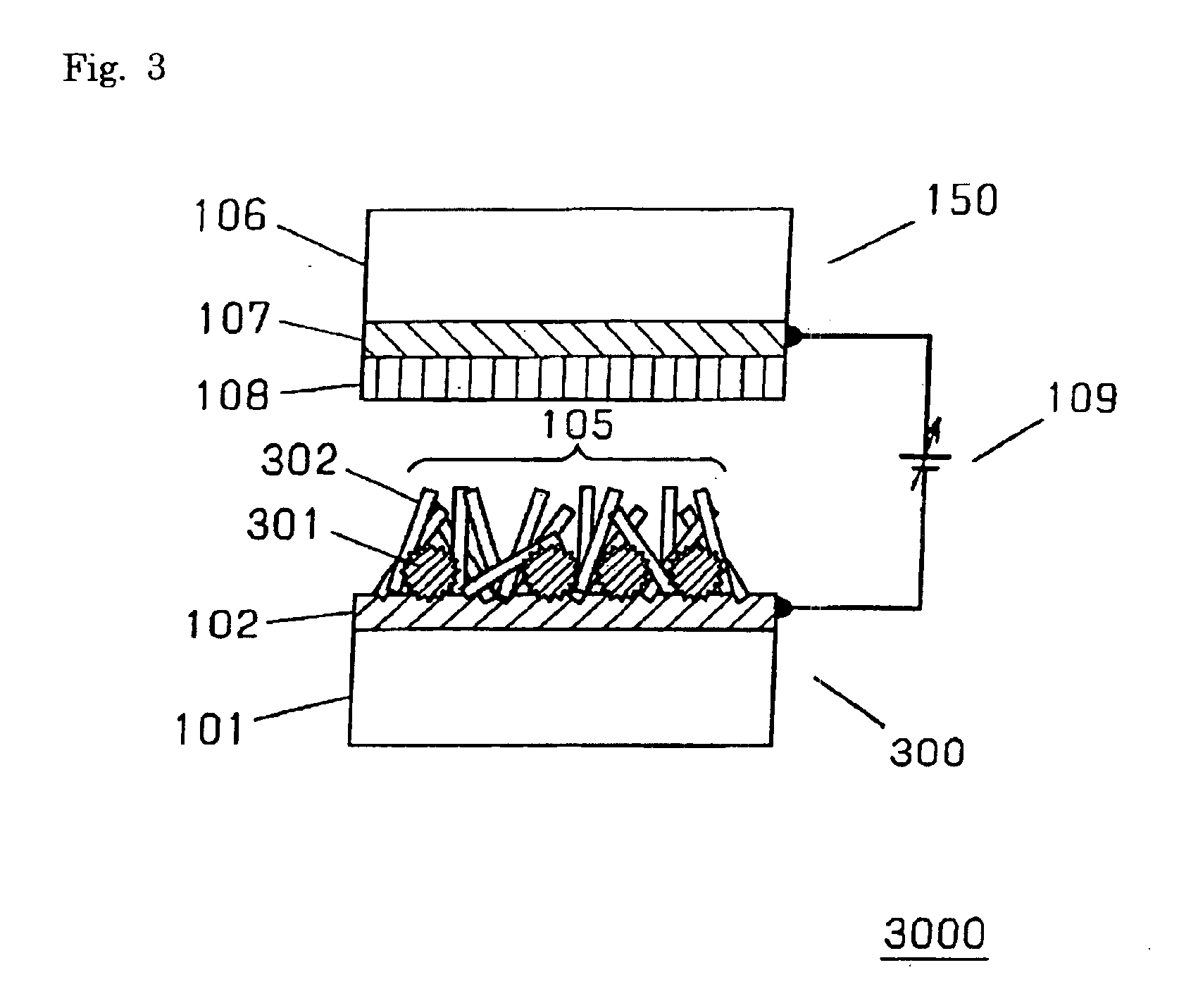

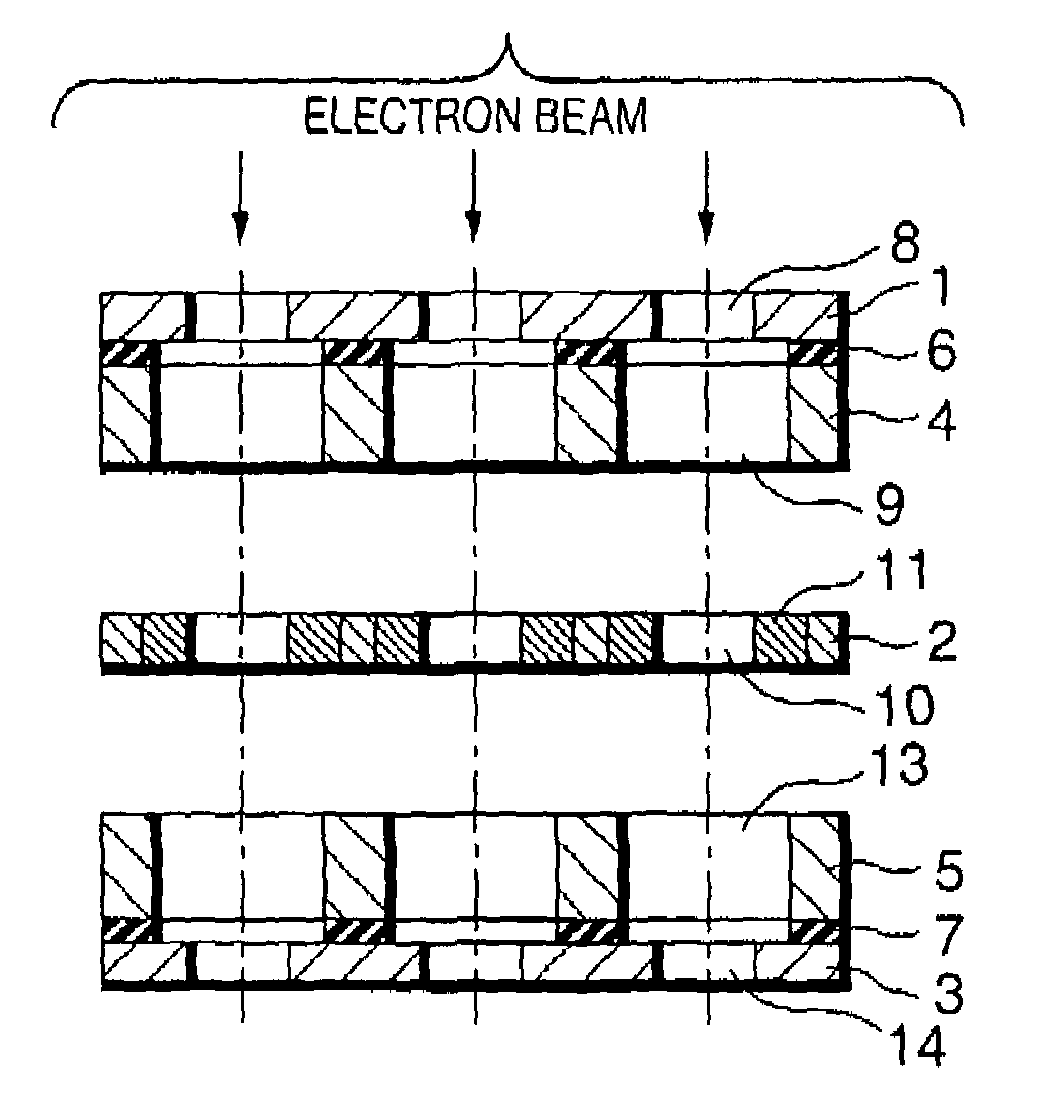

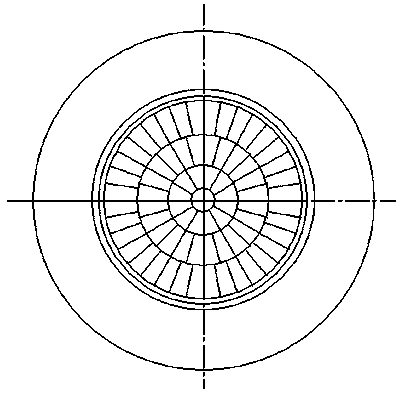

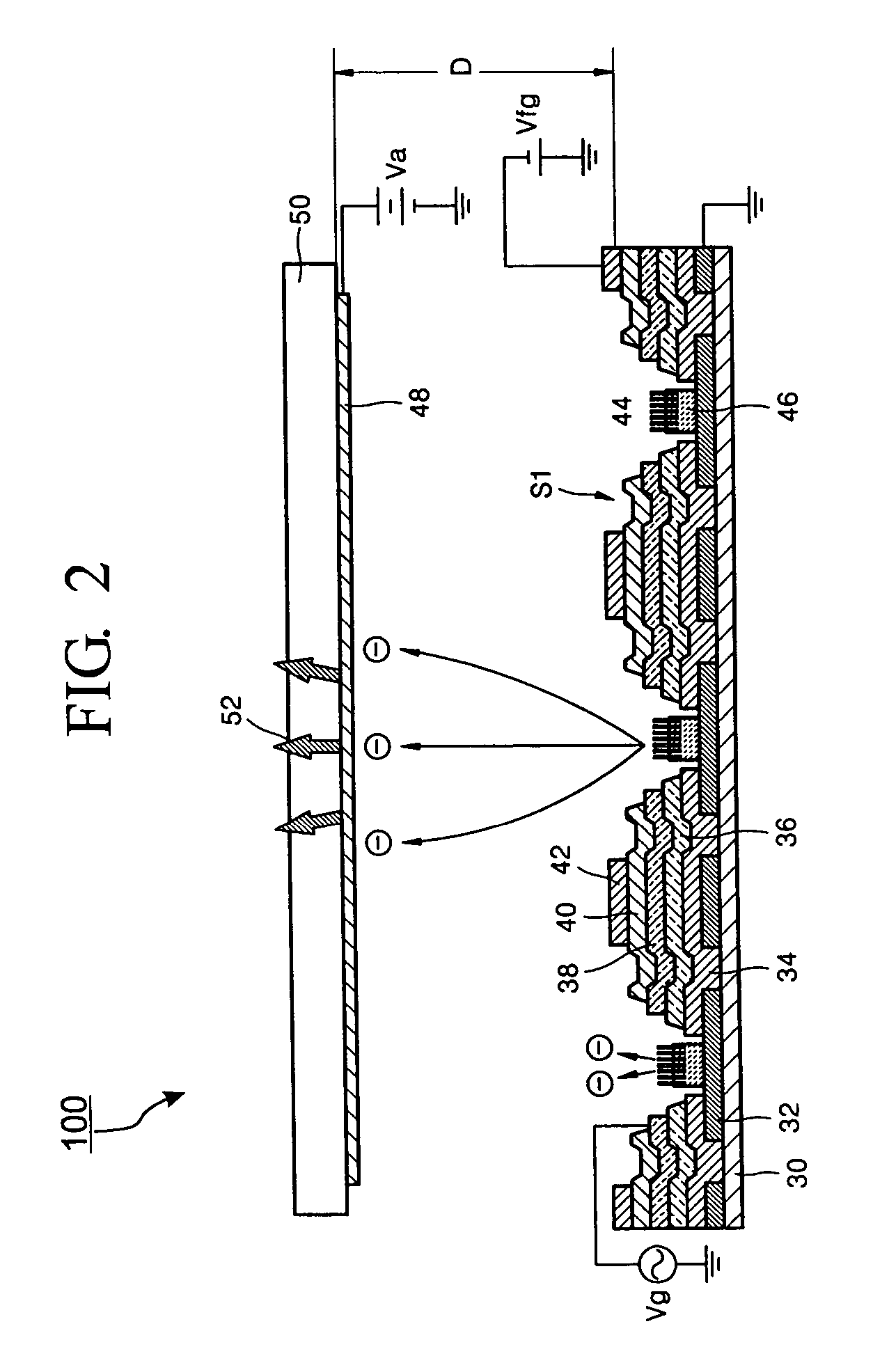

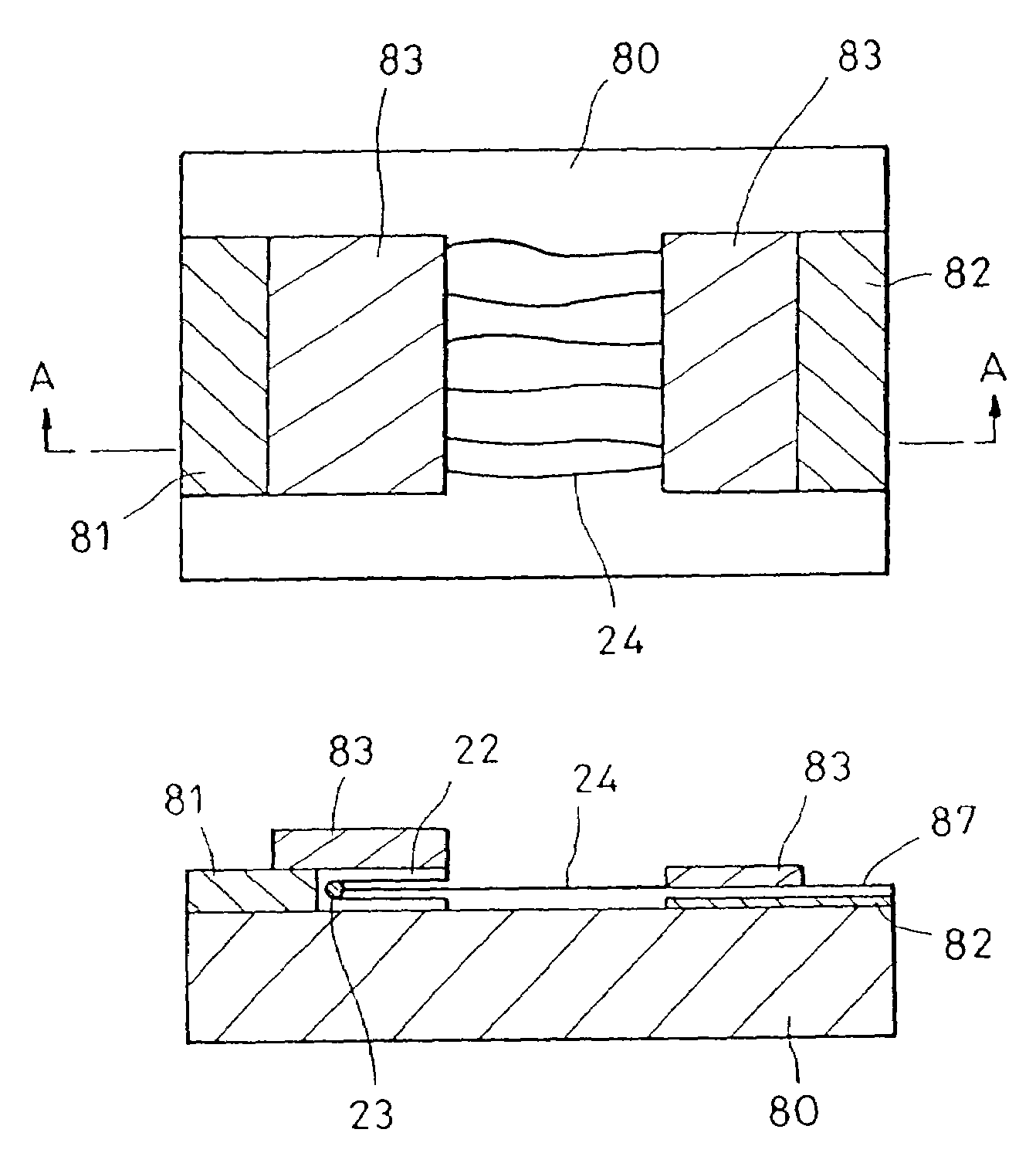

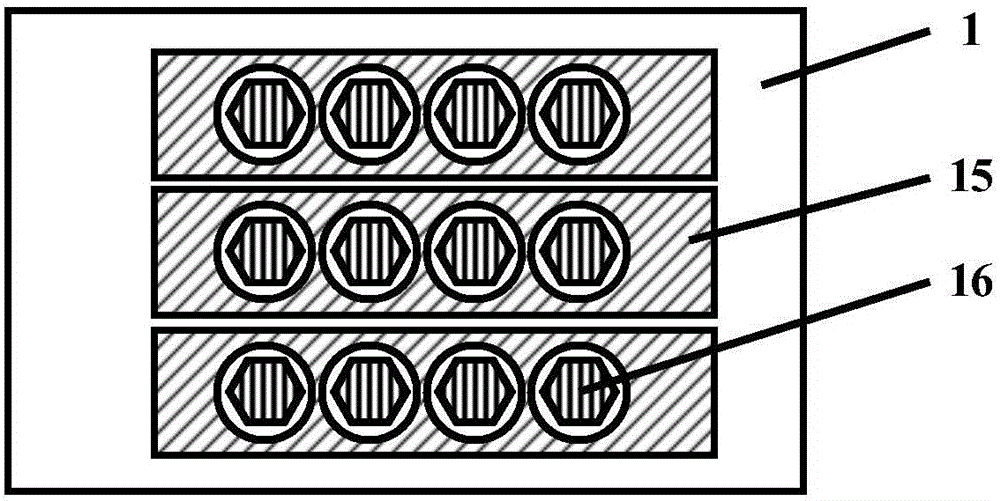

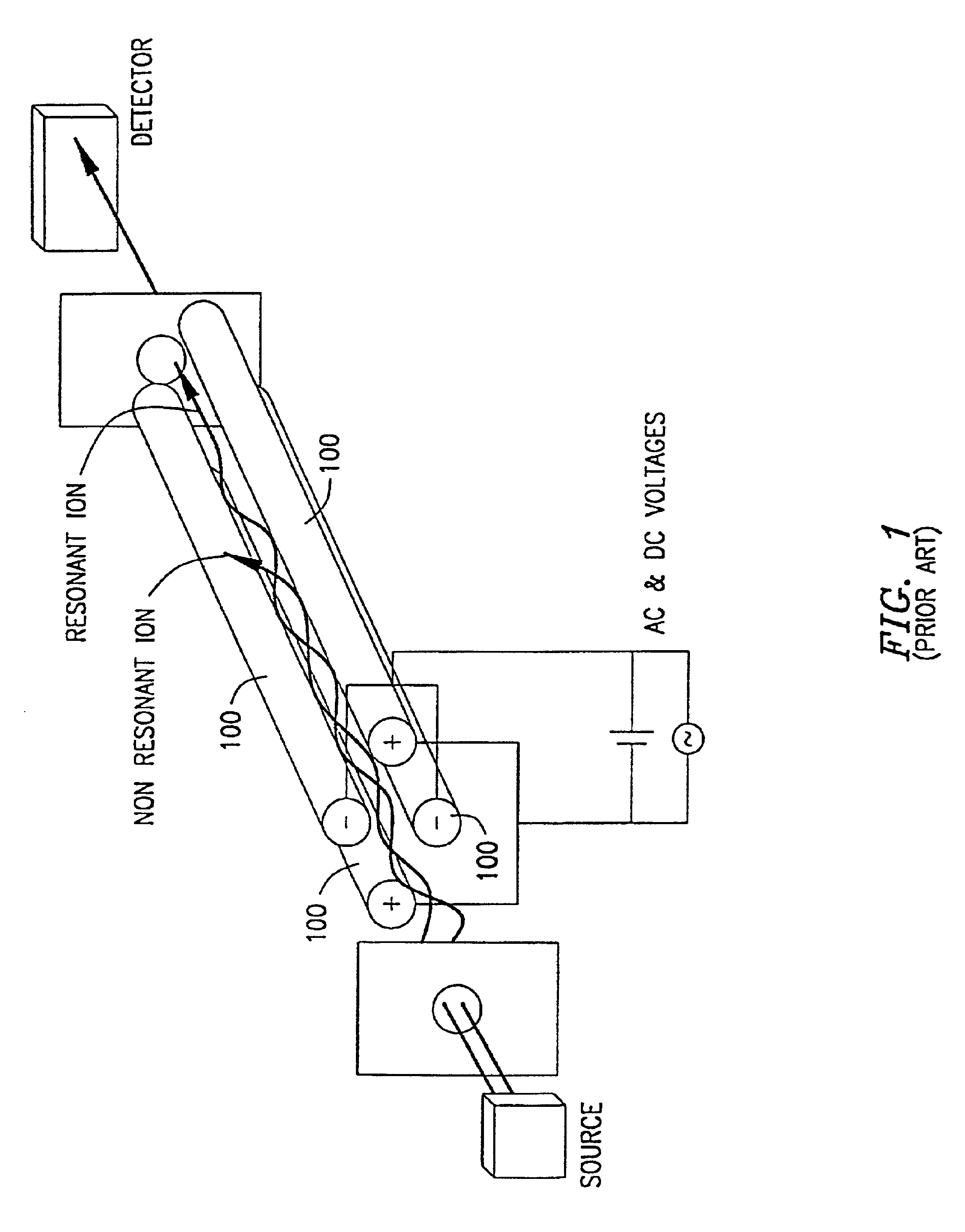

Electrooptic system array, charged-particle beam exposure apparatus using the same, and device manufacturing method

InactiveUS6965153B1Reduce crosstalkImprove accuracySemiconductor/solid-state device detailsSolid-state devicesNuclear engineeringElectron lenses

This invention relates to an electrooptic system array having a plurality of electron lenses. The electrooptic system array includes upper, middle, and lower electrodes arranged along the paths of a plurality of charged-particle beams, the upper, middle, and lower electrodes having pluralities of apertures on the paths of the plurality of charged-particle beams, an upper shield electrode which is interposed between the upper and middle electrodes and has a plurality of shields corresponding to the respective paths of the charged-particle beams, and a lower shield electrode which is interposed between the lower and middle electrodes and has a plurality of shields corresponding to the respective paths of the charged-particle beams.

Owner:CANON KK

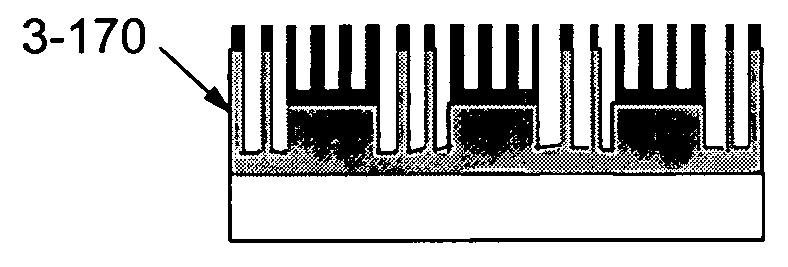

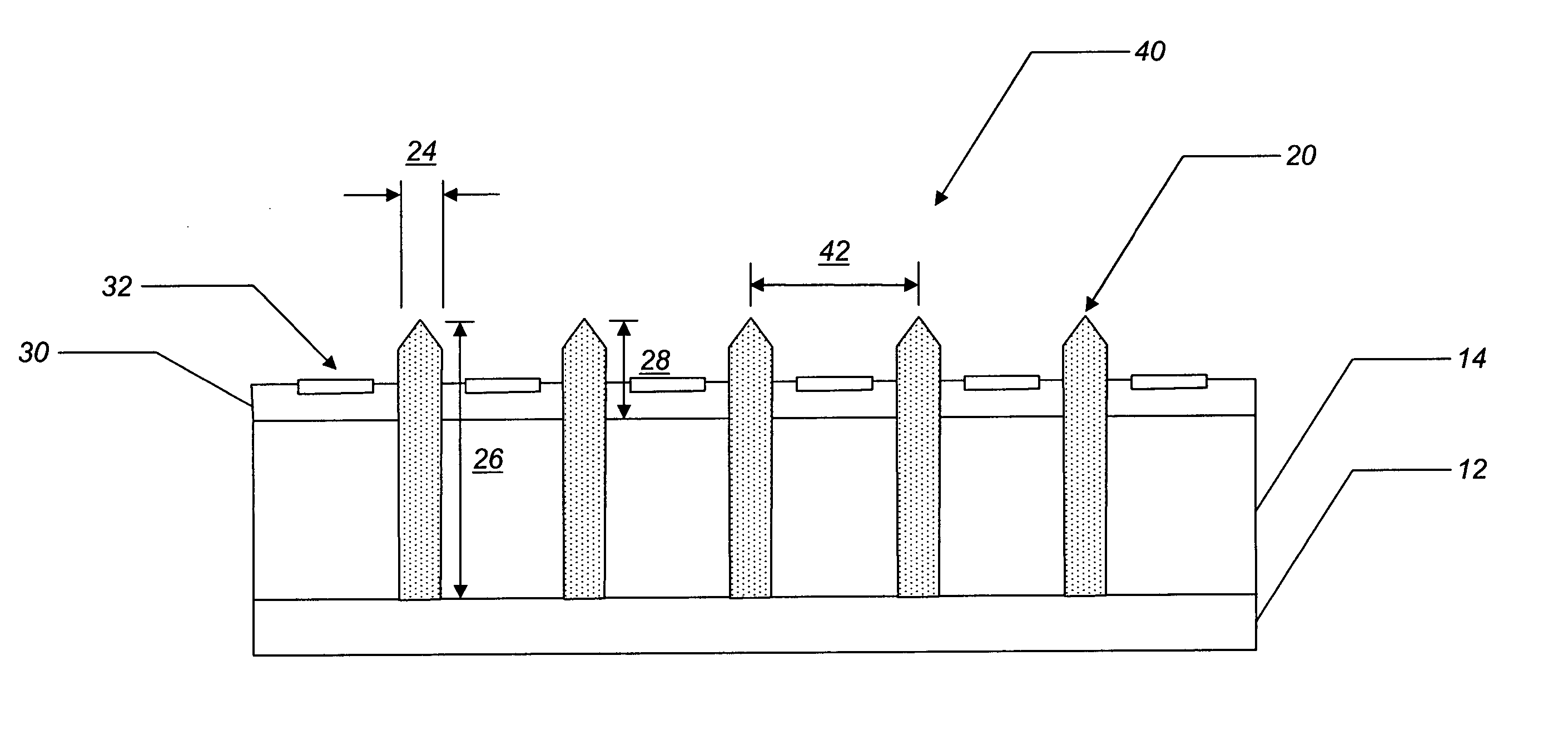

Self-aligned gated rod field emission device and associated method of fabrication

ActiveUS20050067935A1Discharge tube luminescnet screensLamp detailsCylindrical channelField emission device

A self-aligned gated field emission device and an associated method of fabrication are described. The device includes a substrate and a porous layer disposed adjacent to the surface of the substrate, wherein the porous layer defines a plurality of substantially cylindrical channels, each of the plurality of substantially cylindrical channels aligned substantially parallel to one another and substantially perpendicular to the surface of the substrate. The device also includes a plurality of substantially rod-shaped structures disposed within at least a portion of the plurality of substantially cylindrical channels defined by the porous layer and adjacent to the surface of the substrate, wherein a portion of each of the plurality of substantially rod-shaped structures protrudes above the surface of the porous layer. The device further includes a gate dielectric layer disposed on the surface of the porous layer, wherein the gate dielectric layer is disposed between the plurality of substantially rod-shaped structures. The device still further includes a conductive layer selectively disposed on the surface of the gate dielectric layer, wherein the conductive layer is selectively disposed between the plurality of substantially rod-shaped structures.

Owner:GENERAL ELECTRIC CO

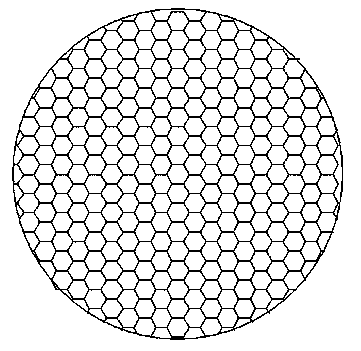

Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

ActiveCN103531414AHigh dimensional accuracyImprove consistencyNon-emitting electrodes manufacturePicosecond laserPicosecond pulsed laser

The invention discloses a picosecond pulse laser cutting preparation method for a grid-control traveling wave tube grid mesh. The method comprises the following steps of performing cleaning, hydrogen burning and annealing on a grid mesh material, then pressing the grid mesh material through a die on a punching machine to form a spherical grid mesh blank with high curvature radius precision, performing destressing hydrogen burning on the blank to eliminate stress during processing to guarantee the stability of the curvature radius of a spherical cap of a grid mesh, and finally cutting the grid mesh by adopting picosecond pulse laser of an optimized technology to prepare the grid-control traveling wave tube grid mesh with high size precision and high consistency. According to the preparation method for the grid mesh of a grid-control traveling wave tube, specific technical parameters of picosecond laser cutting are screened through a large number of experiments, the operability is high, the technical design is reasonable, and the application range is large; the prepared grid mesh is high in size precision, high in consistency, high in yield and high in reliability and has an important application value; the shortcoming of an existing electric spark grid mesh processing technology can be effectively overcome.

Owner:NANJING SANLE GROUP

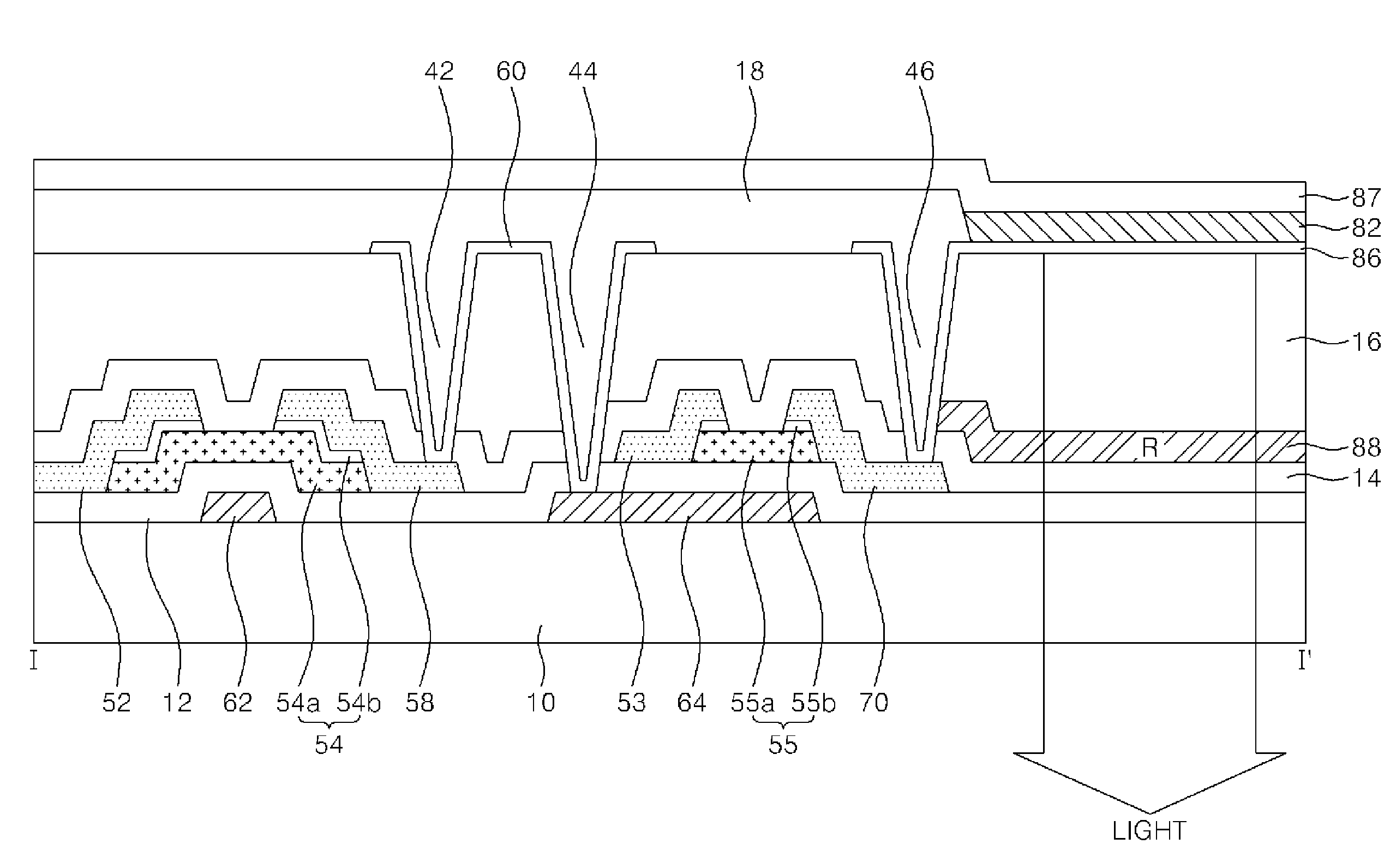

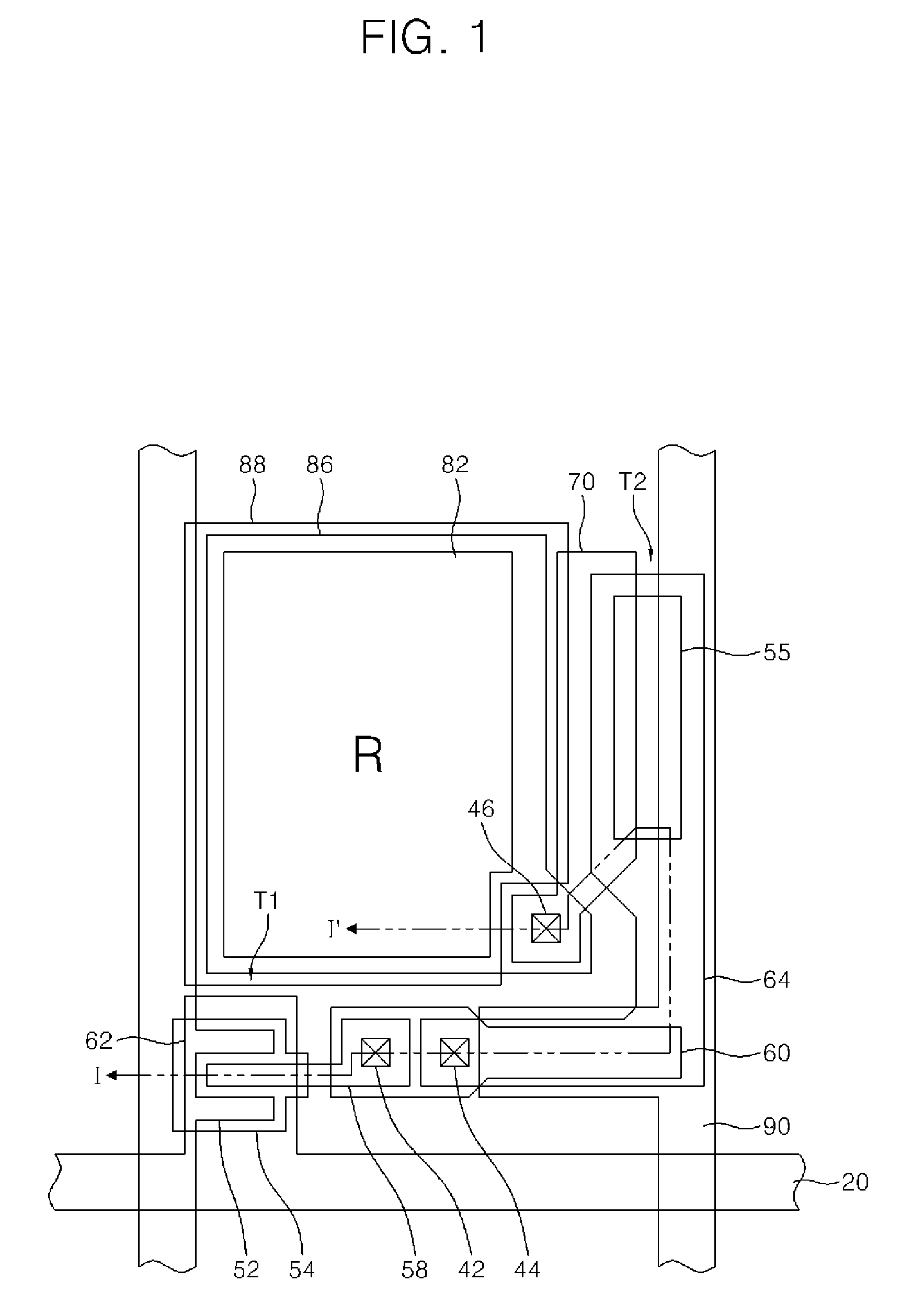

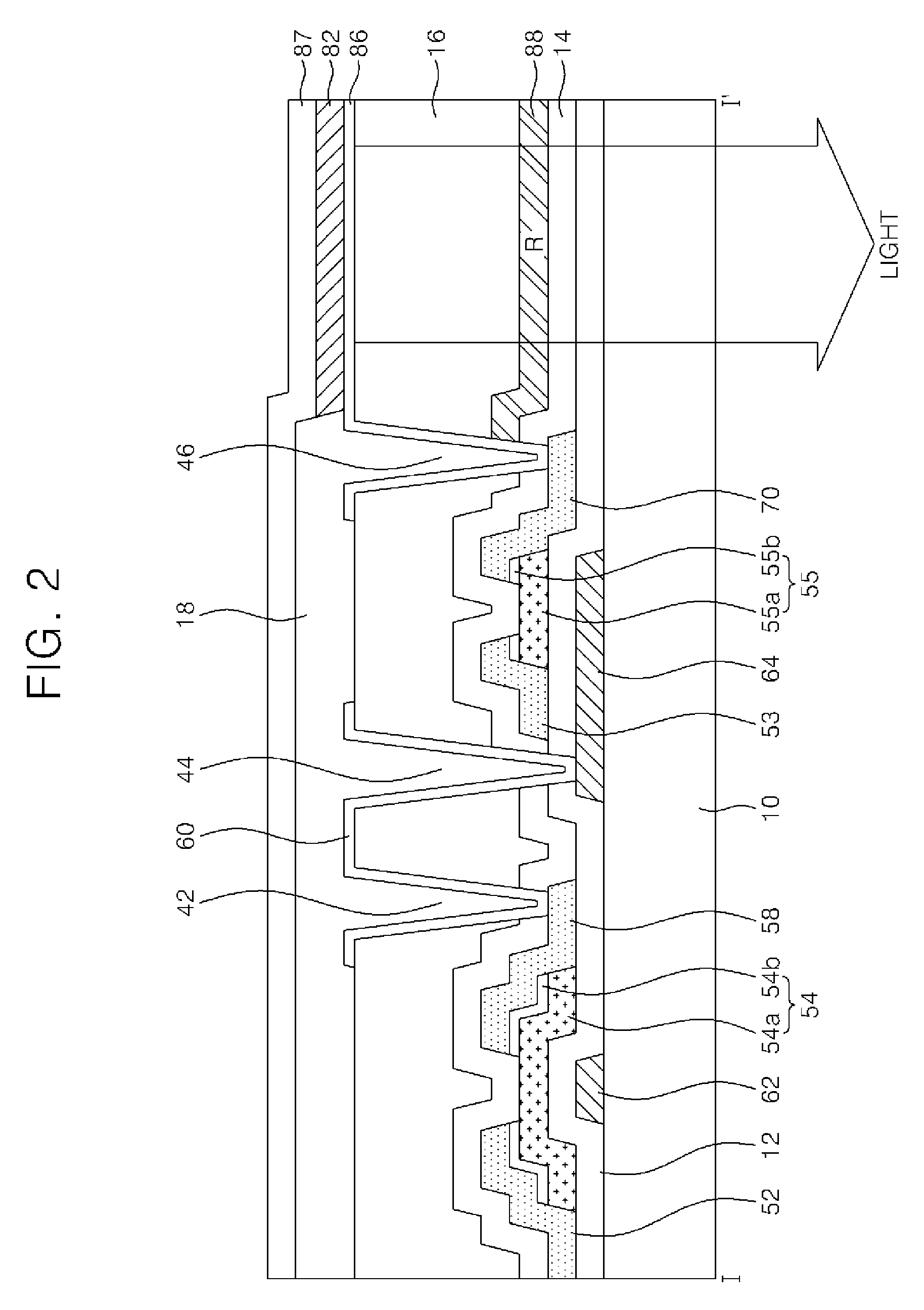

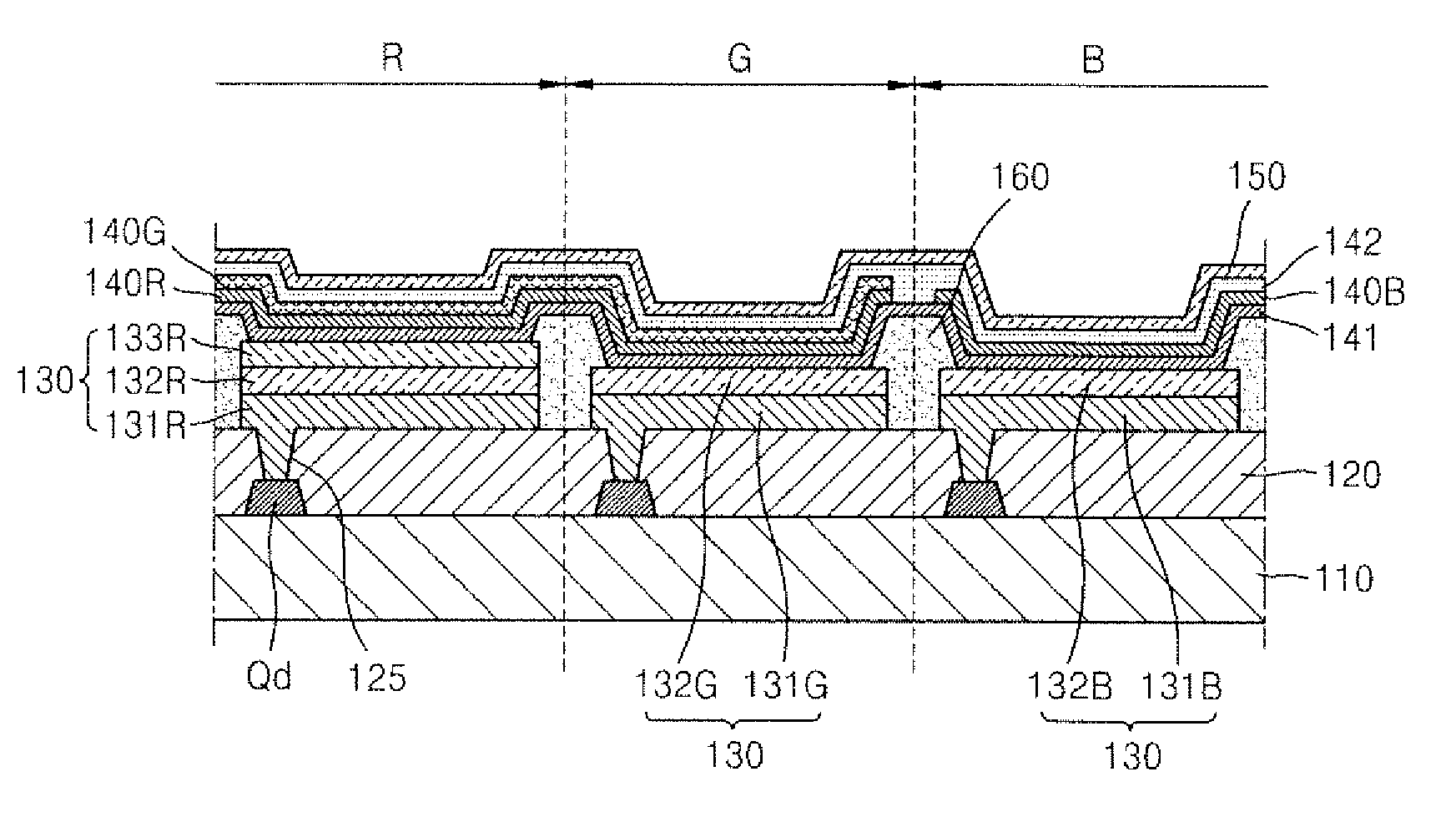

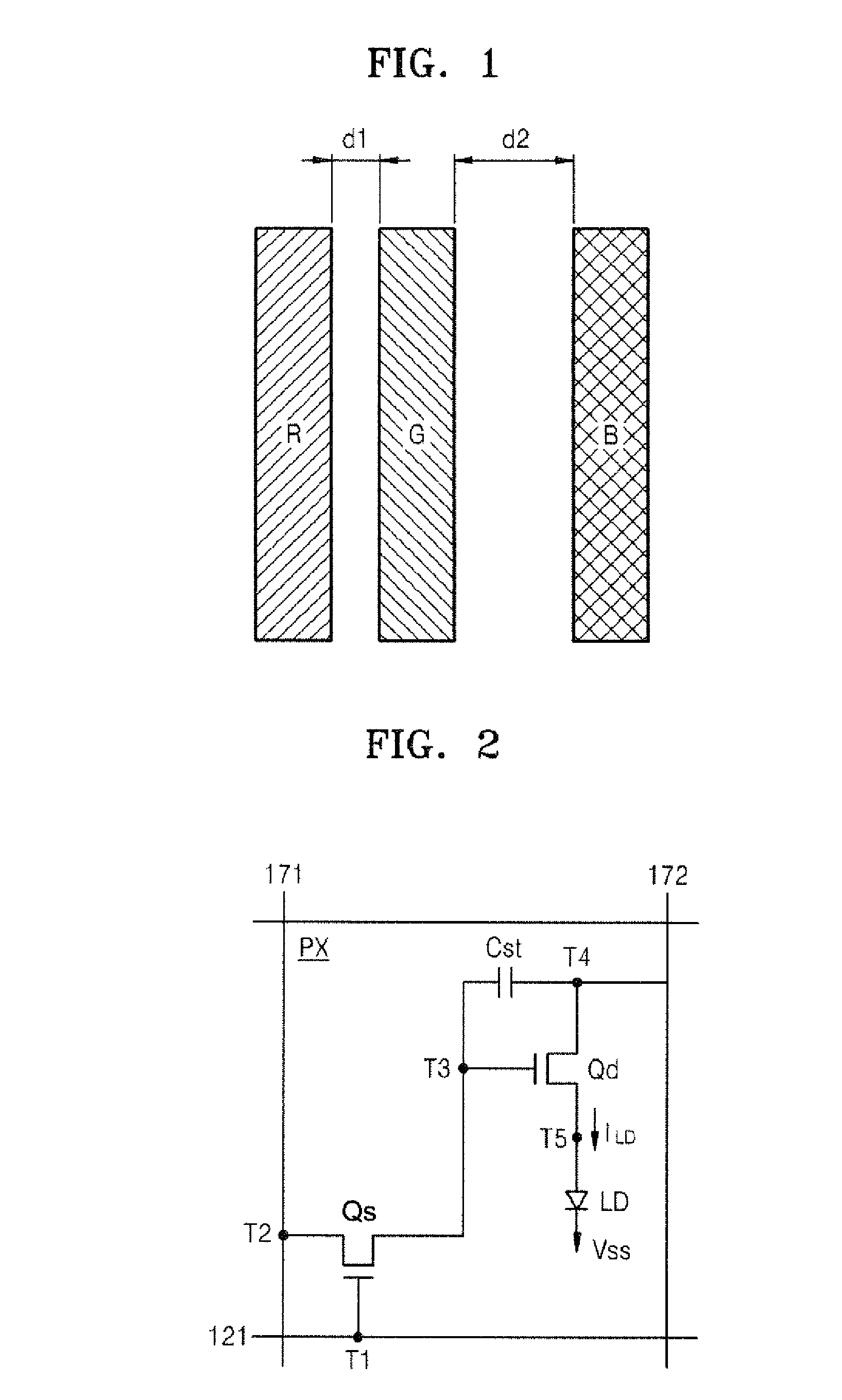

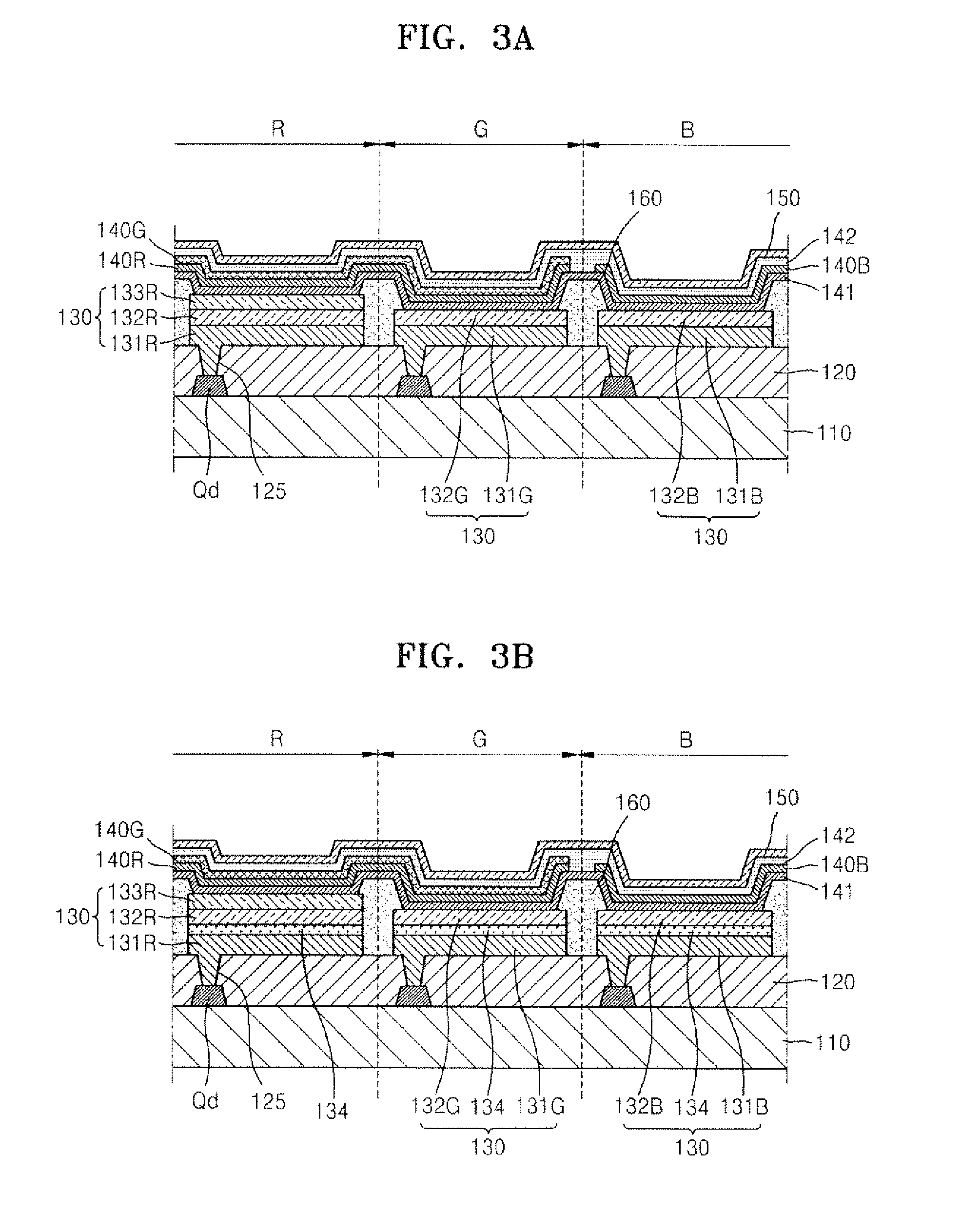

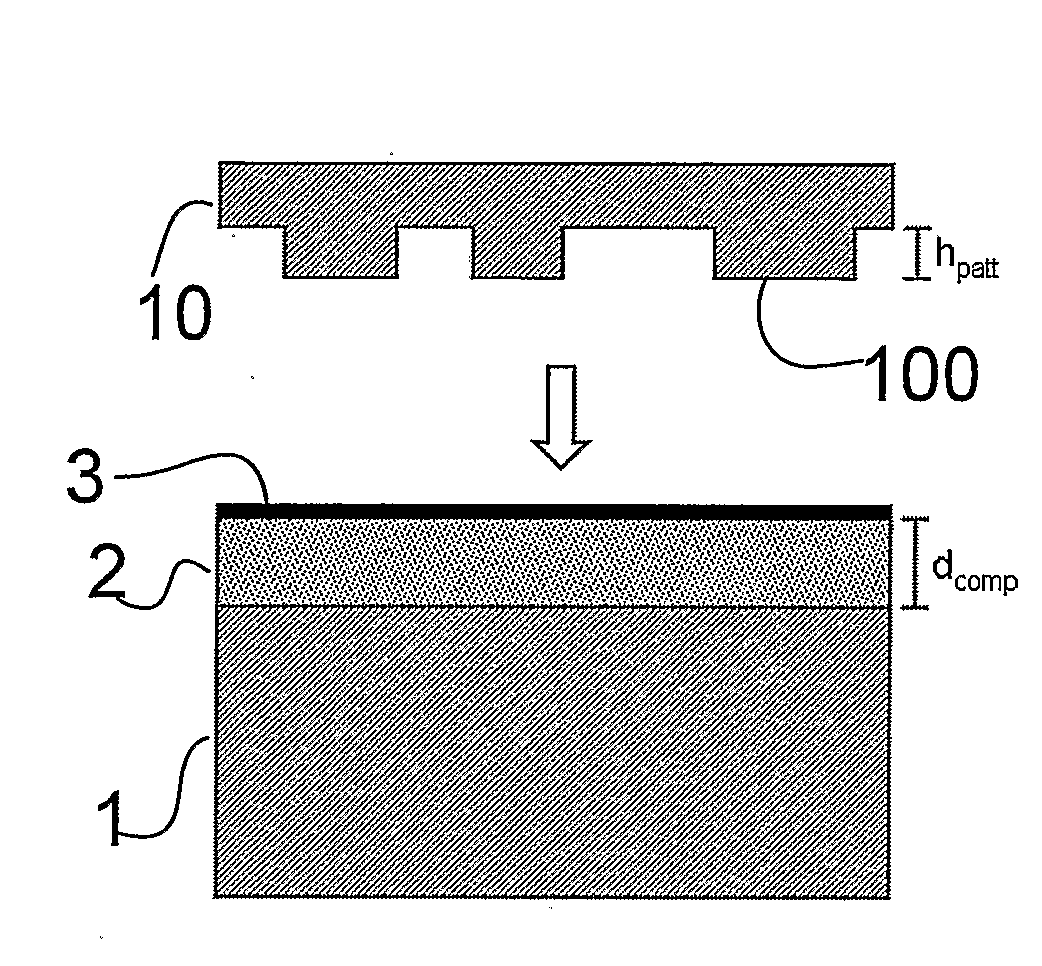

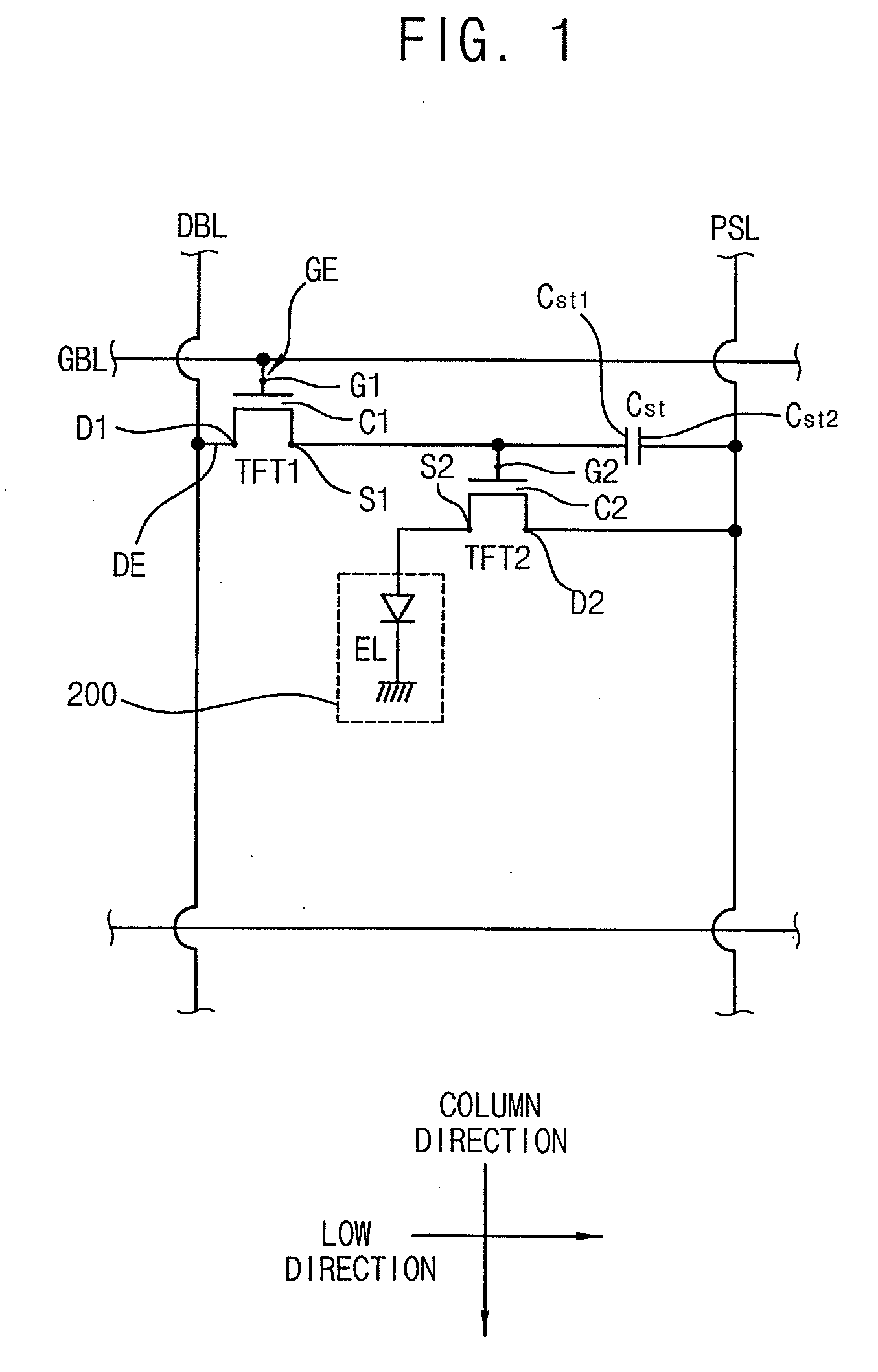

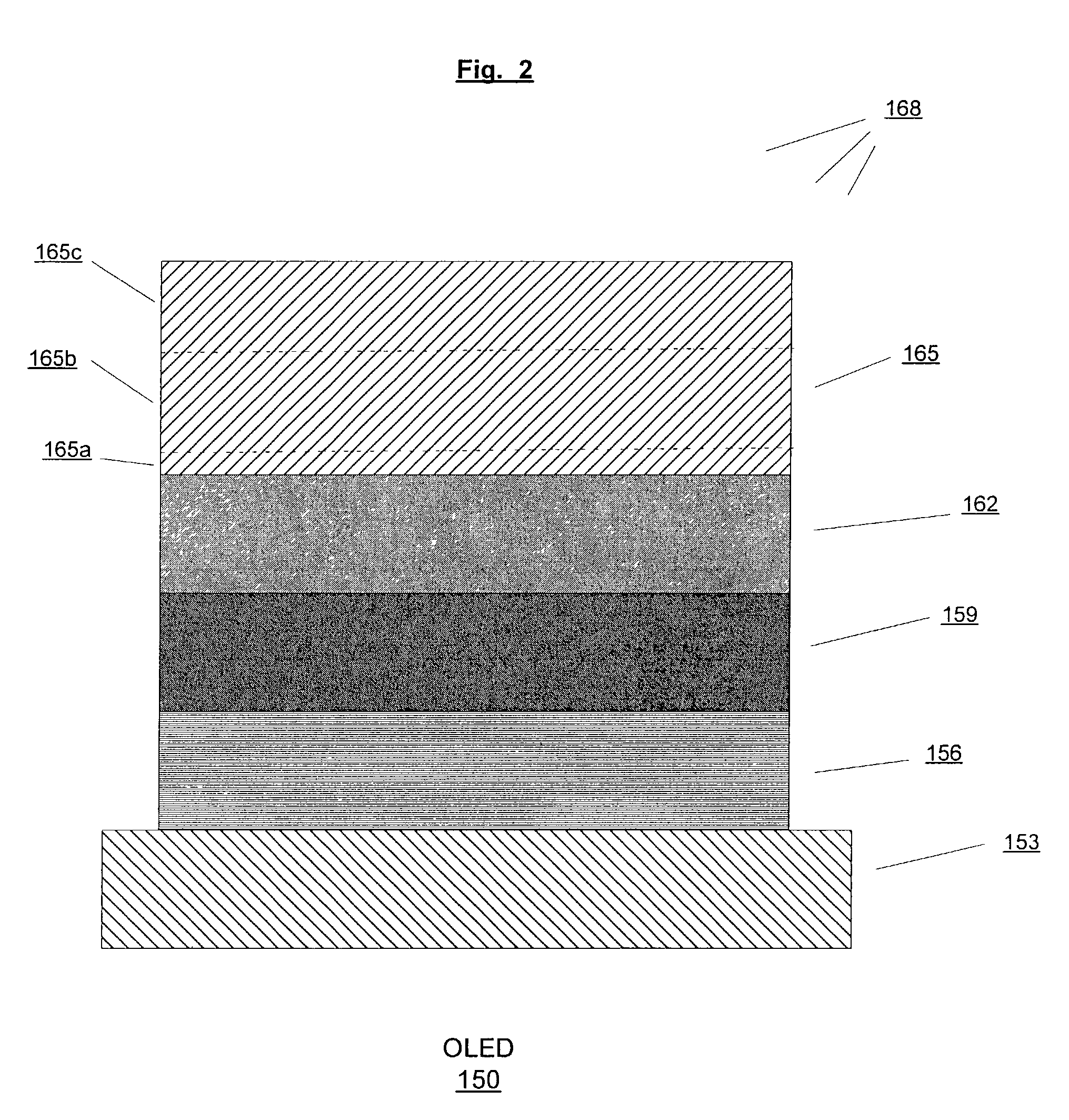

Organic Light Emitting Display Apparatus and Method of Manufacturing the Same

ActiveUS20120176025A1Improve productivityReduce distanceDischarge tube luminescnet screensLamp detailsOptoelectronicsCavity method

An organic light emitting display apparatus using a micro cavity method comprises a first sub pixel, a second pixel and a third pixel, each of which emits different color from an emission layer interposed between two electrodes. The first sub pixel, the second sub pixel and the third sub pixel form a unit pixel. Emission layers of the first and second sub pixels are formed so as to have the same pattern throughout the first and second sub pixels, and an emission layer of the third sub pixel is formed so as to have a pattern separate from the first and second sub pixels. In this structure, three-colored emission layers may be formed using two mask processes so that productivity is improved due to process simplification, and high-resolution is realized due to a decrease in the distance between deposited patterns.

Owner:SAMSUNG DISPLAY CO LTD

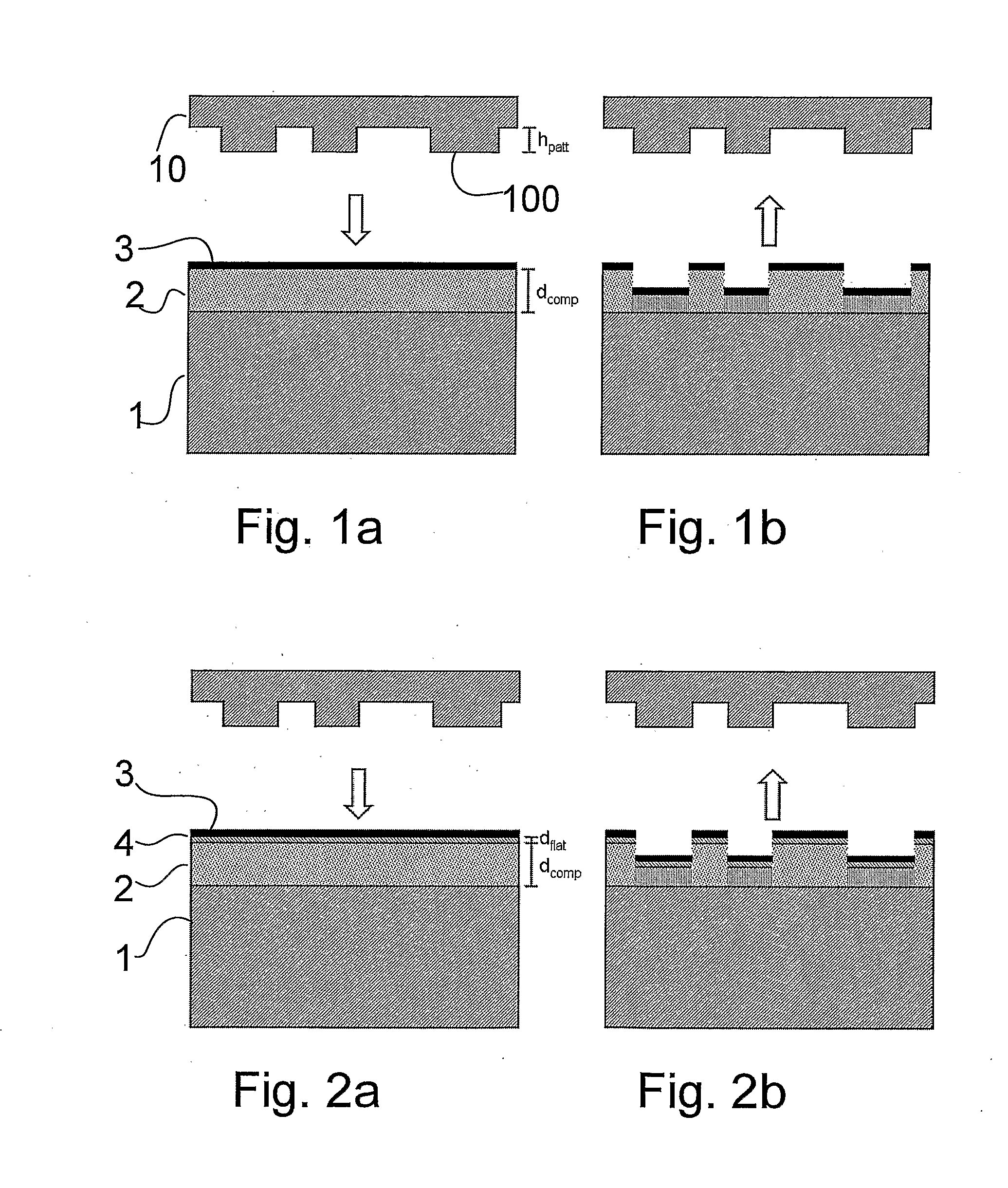

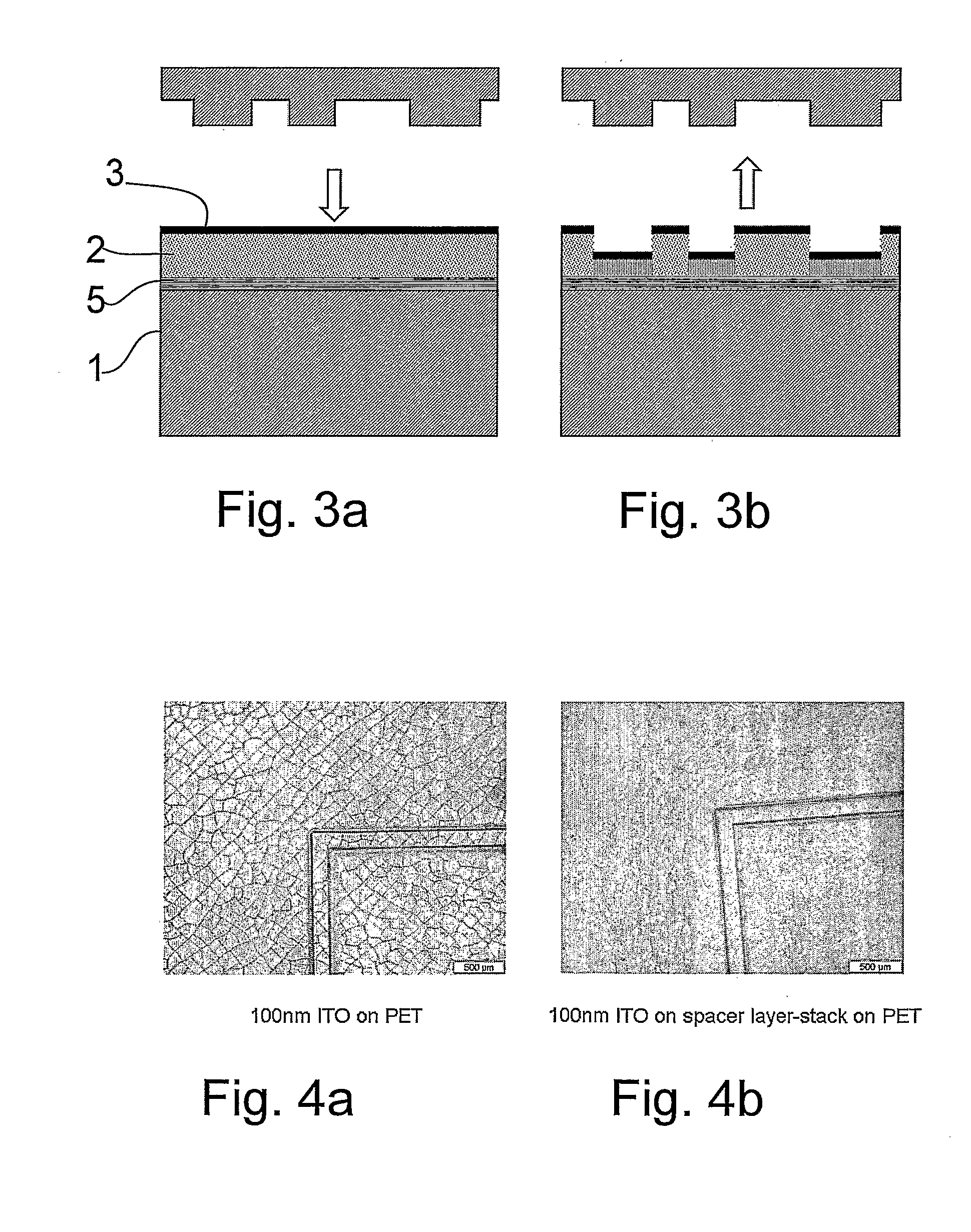

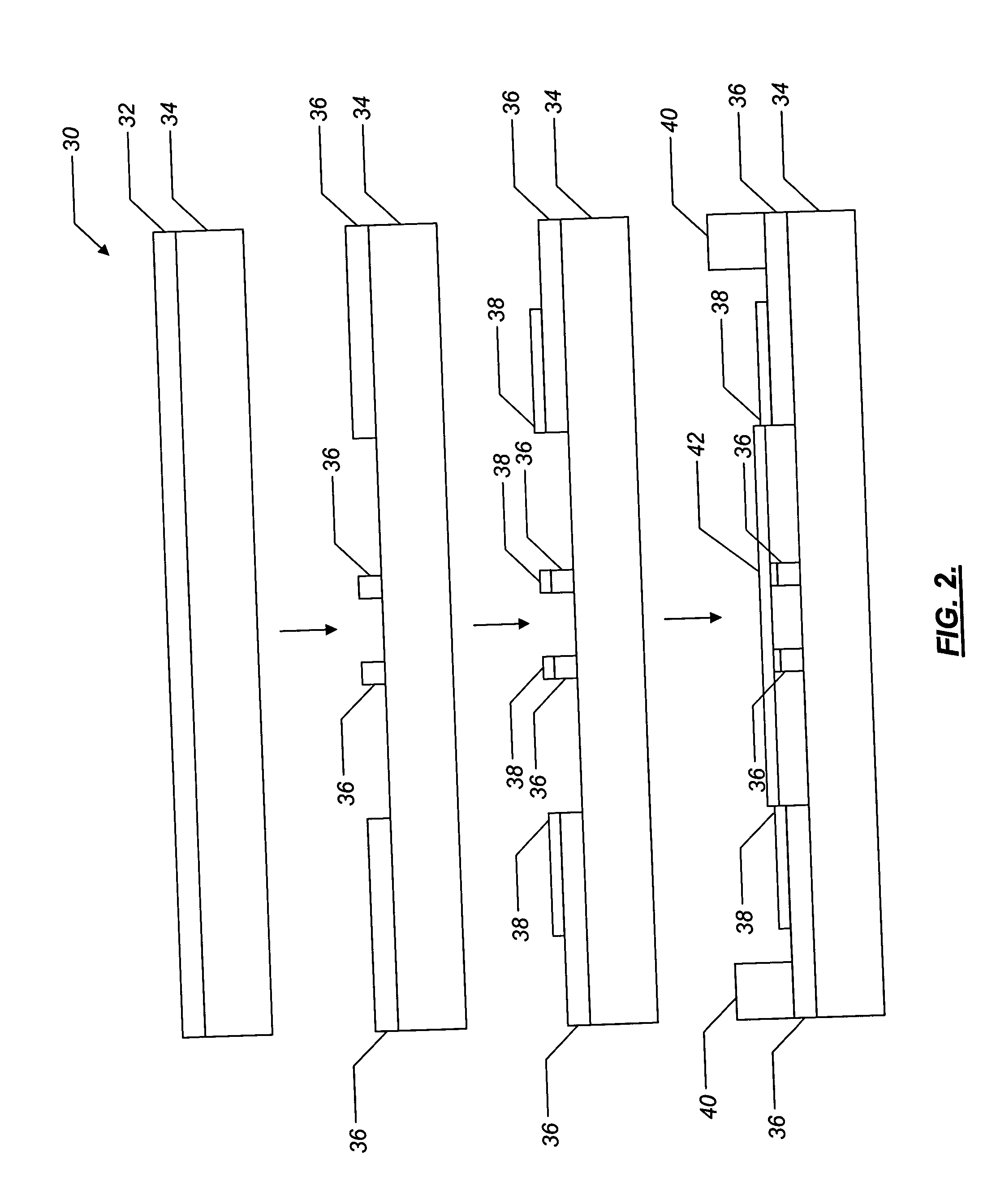

Method and Apparatus for Patterning a Conductive Layer, and a Device Produced Thereby

InactiveUS20090038683A1Drawback can be obviatedLarge-area productionMechanical working/deformationSolid-state devicesEngineeringElectrical and Electronics engineering

A device is fabricated by a method in which a conductive layer or layer stack is formed over a compressible layer or layer stack, and contacted with an embossing tool. Raised portions of the embossing tool compress the compressible layer or stack and countersink the conductive layer or stack into the compressible layer or stack.

Owner:CIBA SPECIALTY CHEM CORP

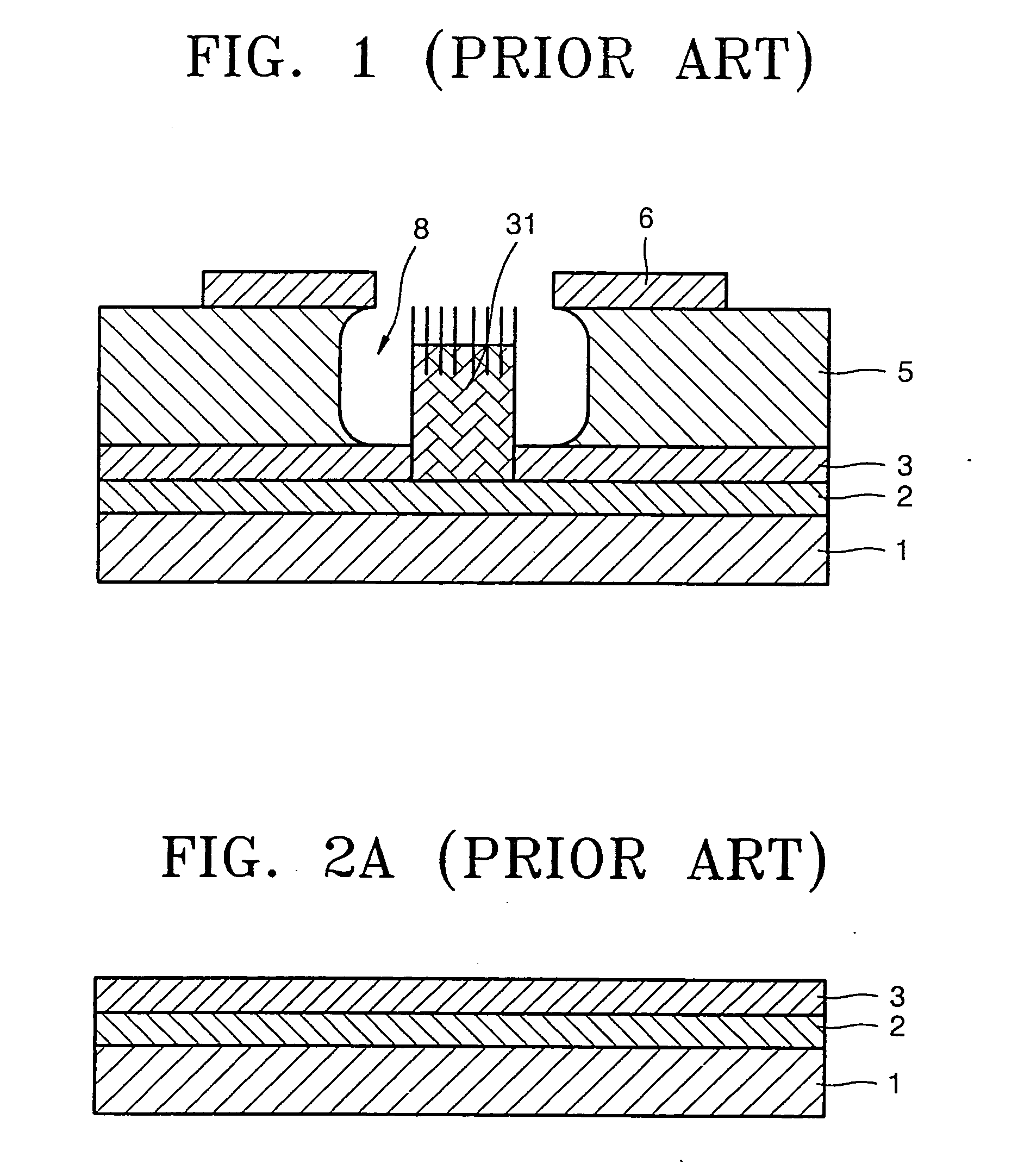

Field emission display having carbon nanotube emitter and method of manufacturing the same

InactiveUS20050035701A1Good step coverageReduce leakage currentNanoinformaticsElectrode and associated part arrangementsSilanesCarbon nanotube

Provided is a field emission display (FED) with a carbon nanotube emitter and a method of manufacturing the same. A gate stack that surrounds the CNT emitter has a mask layer that covers an emitter electrode adjacent to the CNT emitter, and a gate insulating film, a gate electrode, a focus gate insulating film (SiOx, X<2), and a focus gate electrode formed on the mask layer. The focus gate insulating film has a thickness 2 μm or more, and preferably 3˜15 μm and is preferably made using PECVD. A flow rate of silane and nitric acid for forming the focus gate insulating film and / or the gate insulating film are maintained at 50˜700 sccm and 700˜4,500 sccm, respectively. By doing so and by making the oxide thick, the oxide is less apt to crack and thus less apt to generate a leakage current.

Owner:SAMSUNG SDI CO LTD

Method for manufacturing ultrafine carbon fiber and field emission element

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing an electronic device containing a carbon nanotube

InactiveUS6979244B2Improve directivityImprove performanceMaterial nanotechnologyNanoinformaticsCarbon nanotubeElectron

A method of manufacturing an electronic device in which a substrate with a pair of electrodes is provided and a carbon nanotube is formed or arranged to electrically connect the electrodes.

Owner:CANON KK

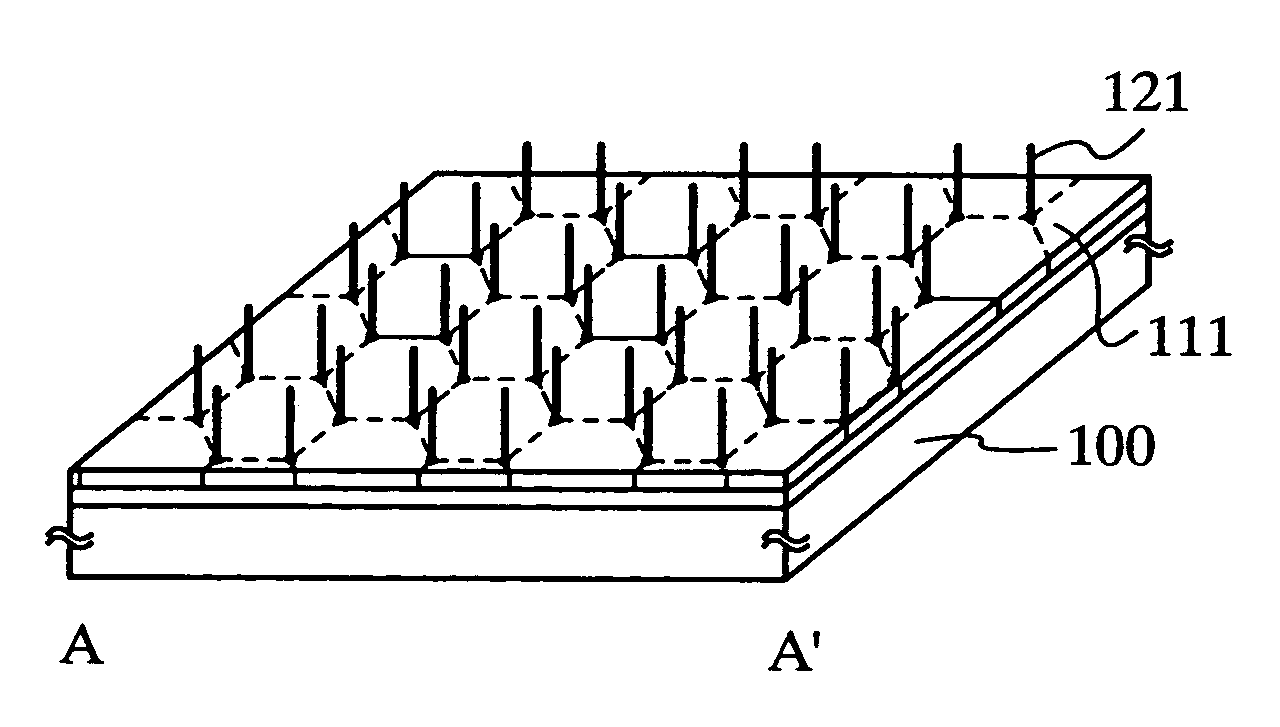

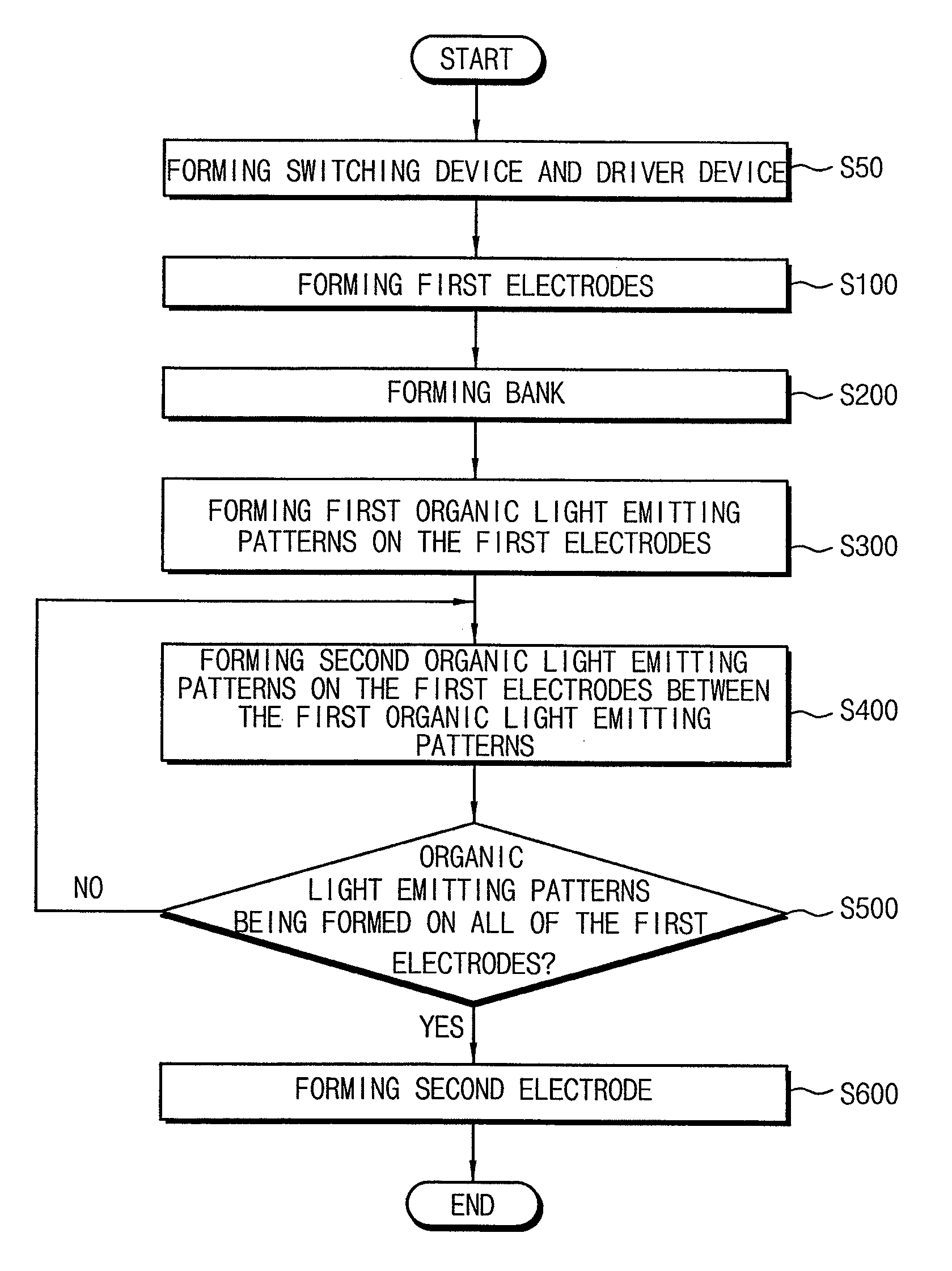

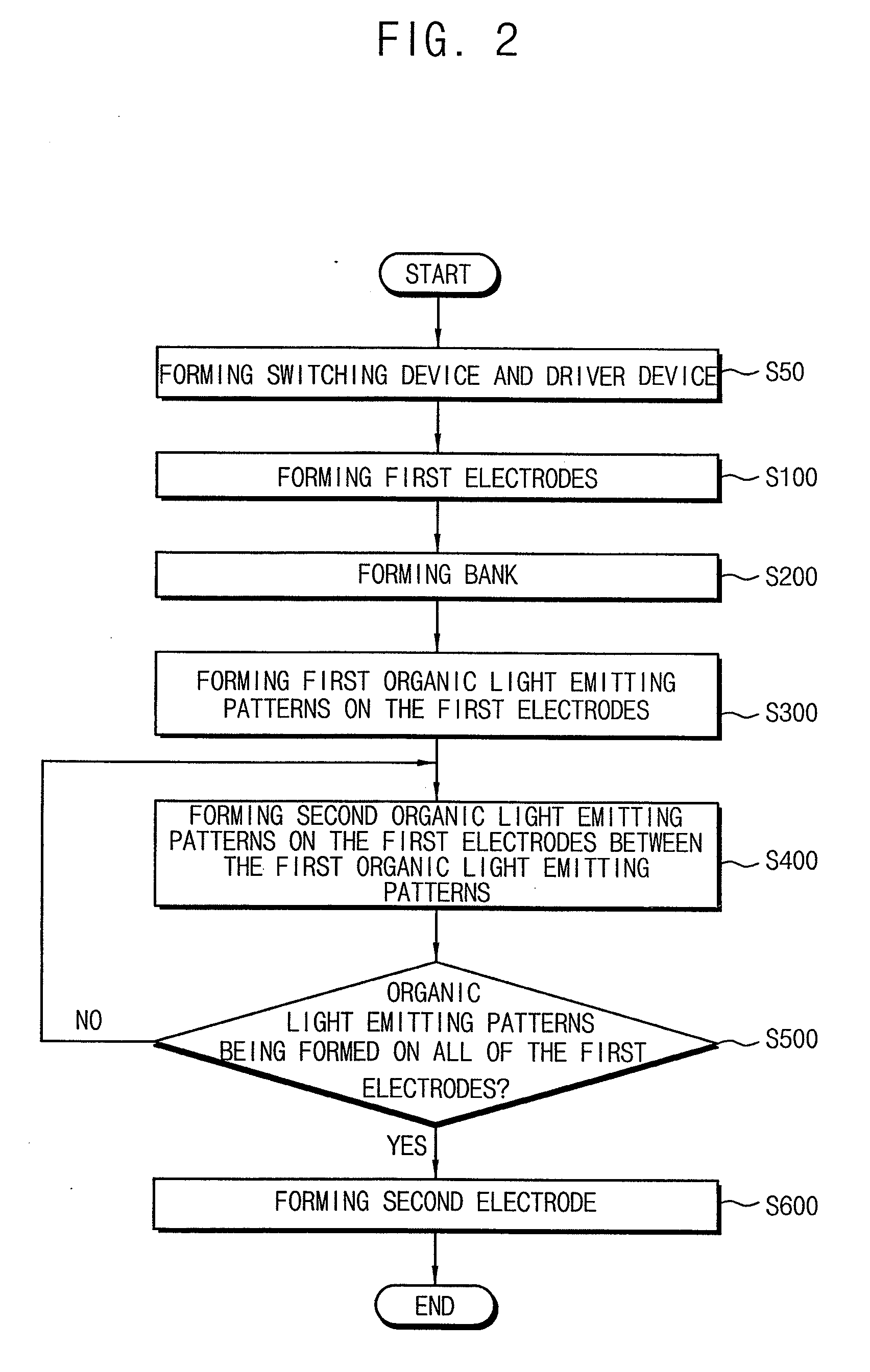

Method of manufacturing light emitting element and method of manufacturing display apparatus having the same

InactiveUS20080090484A1Improving luminance and uniformity of luminanceImprove luminanceElectroluminescent light sourcesSolid-state devicesEngineeringLuminescent material

In a method of manufacturing a light emitting element, a plurality of first electrodes arranged in a matrix shape is formed on a pixel area of a base substrate. A bank is formed between the first electrodes. A light emitting material is ejected on a portion of the first electrodes spaced apart from one another to form a plurality of first light emitting patterns. The light emitting material is erected on a portion of the first electrodes between the first light emitting patterns to form a plurality of second light emitting patterns. A second electrode is formed on the first and second light emitting patterns. Therefore, a luminance of the light emitting element is improved and uniformized.

Owner:LEE DONG WON +2

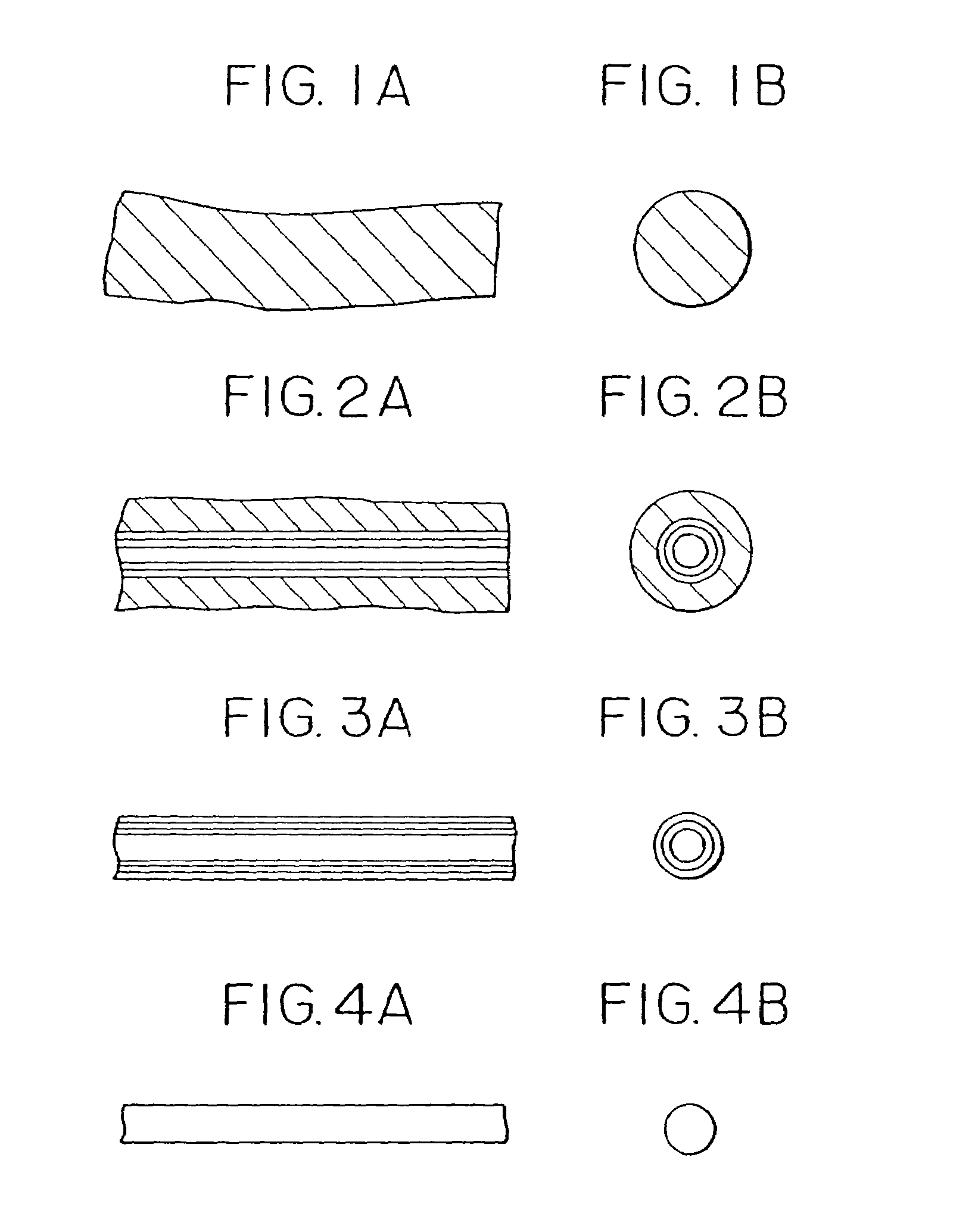

Thick-film sheet member its applied device and methods for manufacturing them

InactiveUS20050122030A1Well formedIncrease freedomPretreated surfacesVessels or leading-in conductors manufactureTherapeutic effectFilm material

A thick-film sheet member provided by a thick film which has a predetermined thickness and a predetermined thickness and a predetermined plan configuration, without the thick film being fixed to a substrate. This thick-film sheet member can be produced by (a) forming a paste film having a predetermined thickness, on a predetermined film formation surface in a predetermined pattern, and (b) peeling the paste film from the predetermined film formation surface after subjecting the paste film to a firing treatment effected at a predetermined temperature. The paste film is constituted by a thick-film material in the form of particles which are bonded together with a resin and which are sintered at the predetermined temperature.

Owner:NORITAKE CO LTD

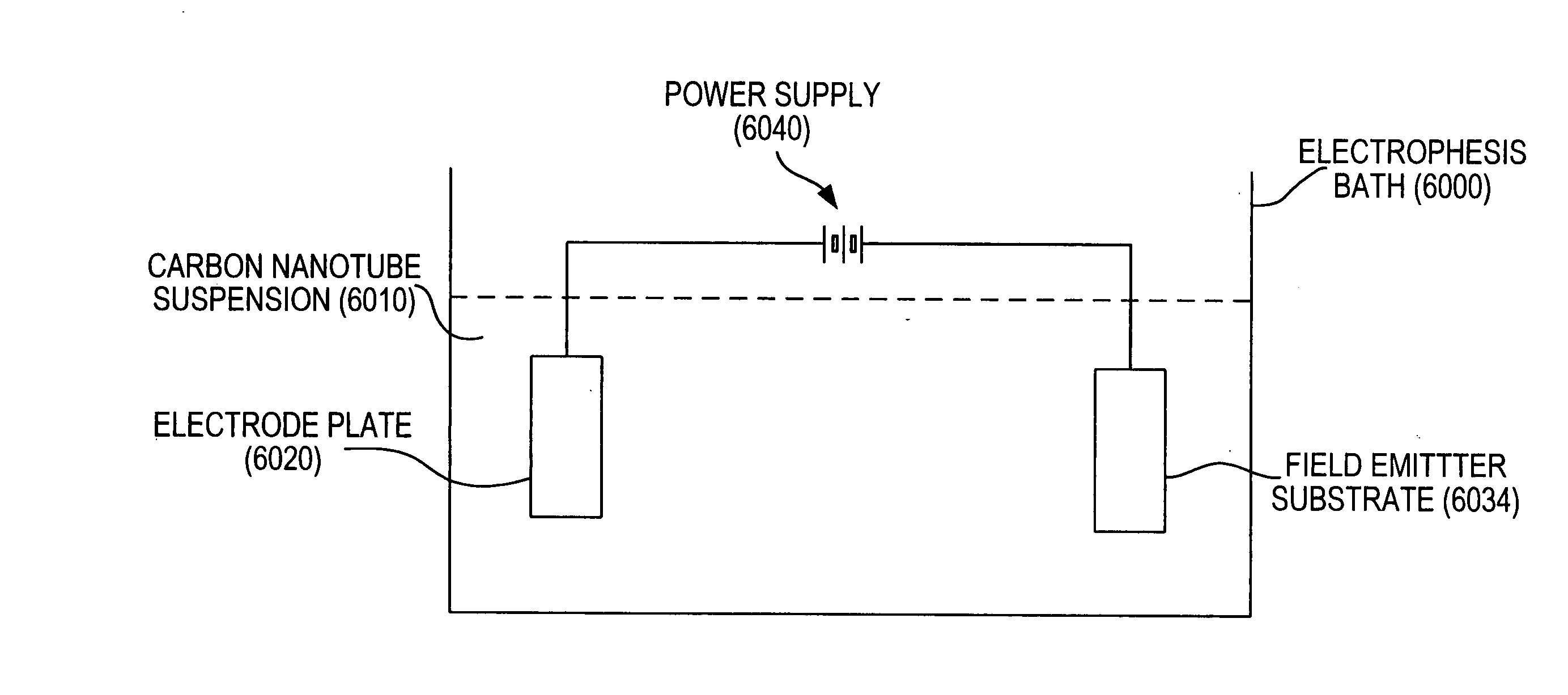

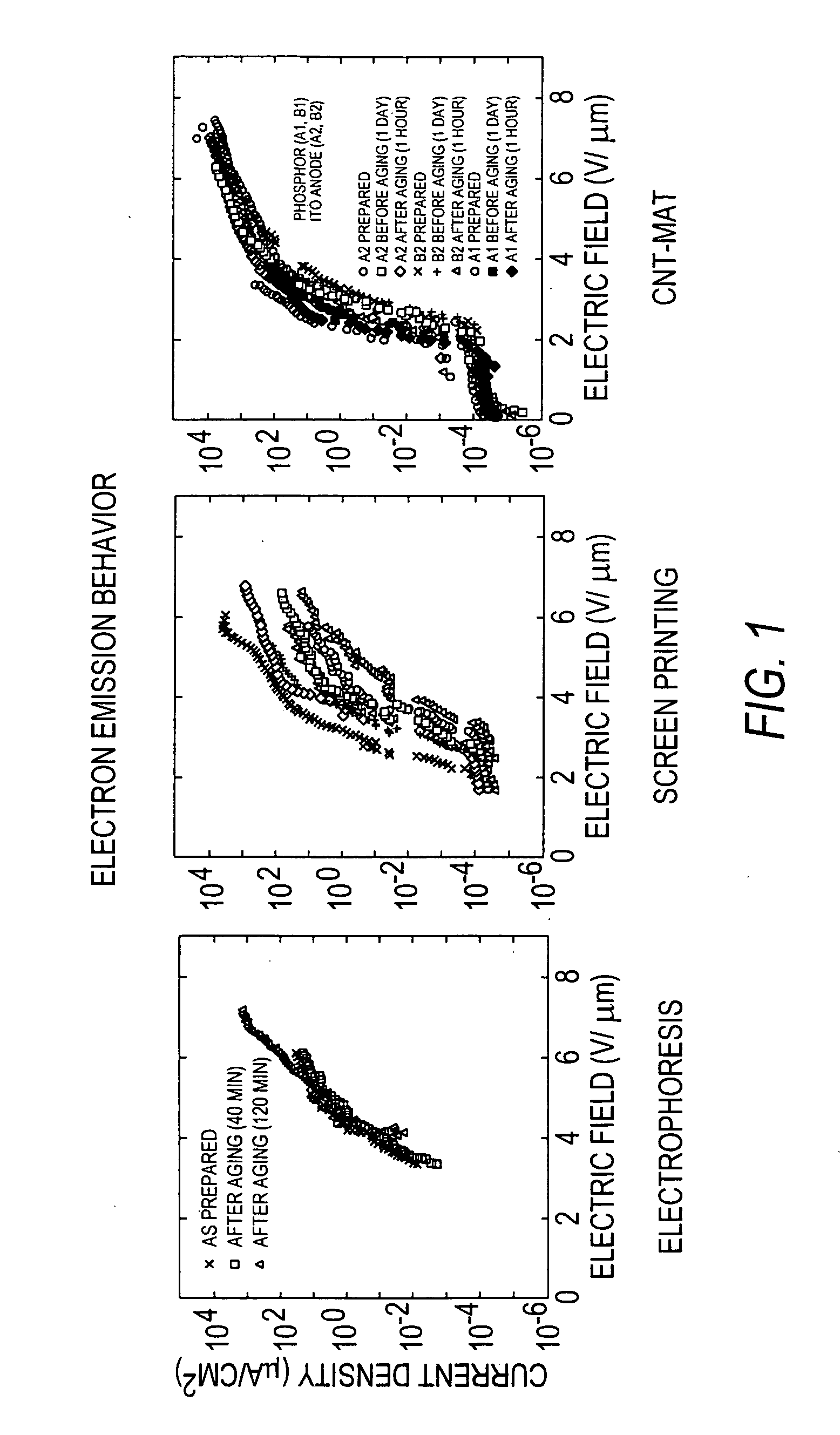

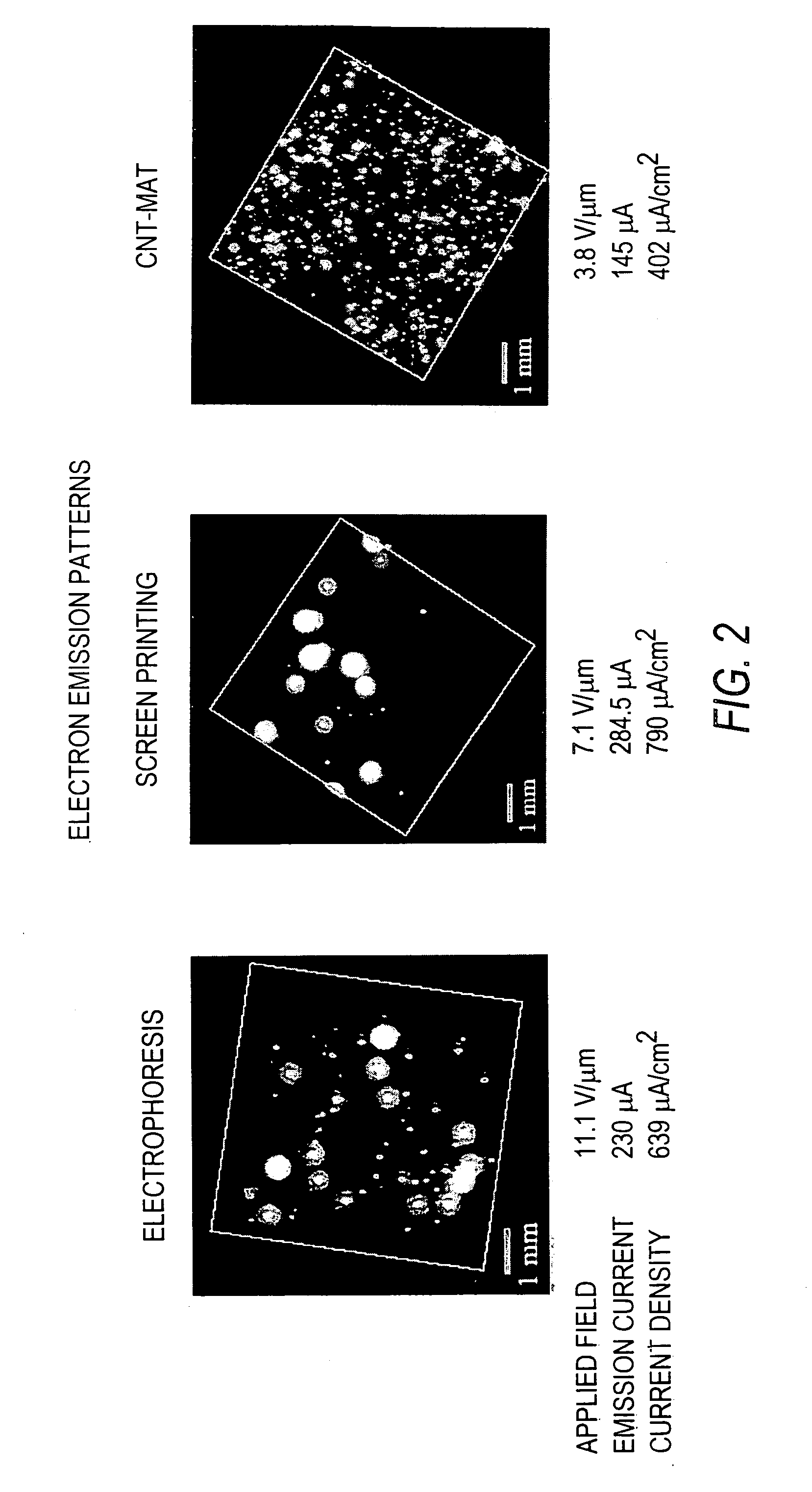

Field emission devices made with laser and/or plasma treated carbon nanotube mats, films or inks

InactiveUS20050156504A1Improve cathode emission current densityLaunch evenlyDischarge tube luminescnet screensElectric discharge tubesField emission deviceFibril

Field emission devices comprising carbon nanotube mats which have been treated with laser or plasma are provided. Mats are formed from carbon nanotubes, also known as carbon fibrils, which are vermicular carbon deposits having diameters of less than about one micron. The carbon nanotube mats are then subjected to laser or plasma treatment. The treated carbon nanotube mat results in improved field emission performance as either a field emission cathode or as part of a field emission device.

Owner:HYPERION CATALYSIS INT

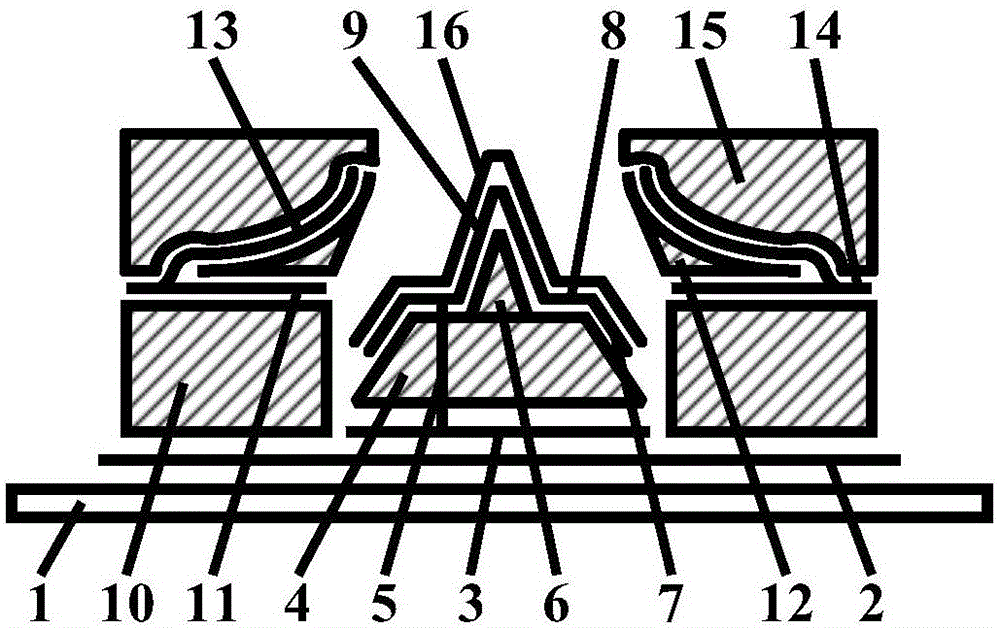

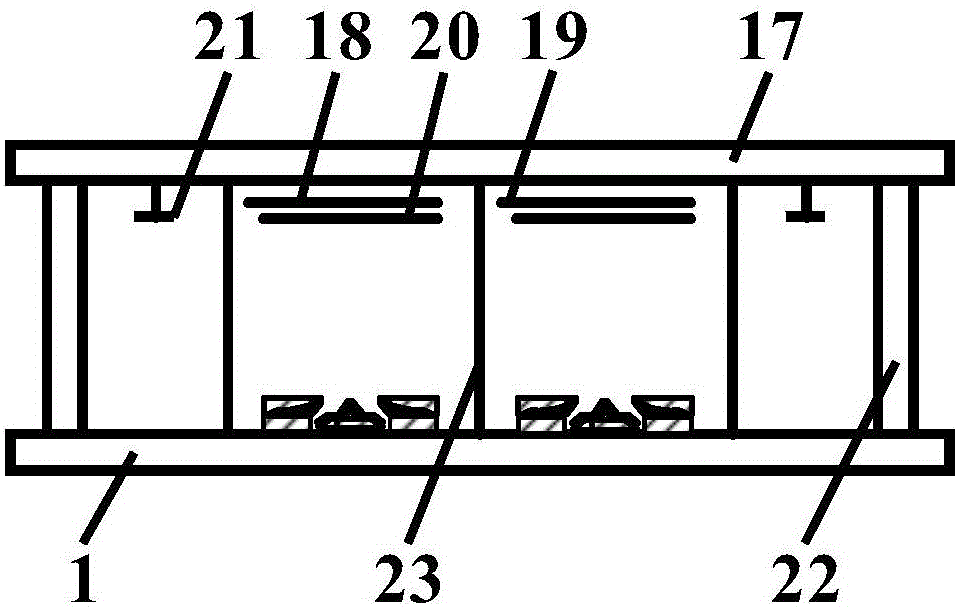

Light-emitting display with branched silver gate-controlled staggered multi-edge plane composite cathode structure

ActiveCN106128920ASignificant progressReduce manufacturing costElectrode and associated part arrangementsImage/pattern display tubesManufacturing technologyComposite cathode

The invention discloses a light-emitting display with a branched silver gate-controlled staggered multi-edge plane composite cathode structure. The light-emitting display comprises a vacuum chamber, and getters and a support wall auxiliary element which are located in the vacuum chamber, wherein the vacuum chamber comprises a front glass panel, a rear glass panel and transparent glass frames; the front glass panel is provided with anode membrane electrode layers, cathode outer lead layers connected with the corresponding anode membrane electrode layers and fluorescent powder layers prepared on the corresponding anode membrane electrode layers; and the rear glass panel is provided with reversely opposite slant double gate-controlled staggered square ring strip cathode structures. The light-emitting display has the advantages that the manufacturing cost is low, the manufacturing technology is simple and the luminance of the display is high.

Owner:山东千沐云物联科技股份有限公司

Carbide nanostructures and methods for making same

A structure includes a substrate and a metallized carbon nano-structure extending from a portion of the substrate. In a method of making a metallized carbon nanostructure, at least one carbon structure formed on a substrate is placed in a furnace. A metallic vapor is applied to the carbon nanostructure at a preselected temperature for a preselected period of time so that a metallized nanostructure

Owner:GENERAL ELECTRIC CO

Micro x-ray source

InactiveUS20080170668A1Avoid divergenceHigh resolutionX-ray tube electrodesCathode ray concentrating/focusing/directingElectron sourceMetal foil

A micro X-ray source comprising a target acting as anode, and a cathode, which during operation interacts with the target and functions as electron source, wherein the target is embodied as a metal foil possessing a spot where the electrons from the electron source arrive, and the metal foil being locally thinner at the spot.

Owner:TECH UNIV DELFT

Triode structure field emission display device using carbon nanotubes and method of fabricating the same

InactiveUS20050040752A1Short circuit can be preventedBlocking may occurControl electrodesNanoinformaticsInsulation layerField emission display

A field emission display device and a method of fabricating the same are provided. The field emission display device includes a substrate, a transparent cathode layer, an insulation layer, a gate electrode, a resistance layer, and carbon nanotubes. The transparent cathode layer is deposited on the substrate. The insulation layer is formed on the cathode layer and has a well exposing the cathode layer. The gate electrode is formed on the insulation layer and has an opening corresponding to the well. The resistance layer is formed to surround the surface of the gate electrode and the inner walls of the opening and the well so as to block ultraviolet rays. The carbon nanotube field emitting source is positioned on the exposed cathode layer. An alignment error between the gate electrode and the cathode is removed, and carbon nanotube paste is prevented from remaining during development, thereby preventing current leakage and short circuit between the electrodes and diode emission. Accordingly, the performance of the field emission display device can be improved.

Owner:SAMSUNG SDI CO LTD

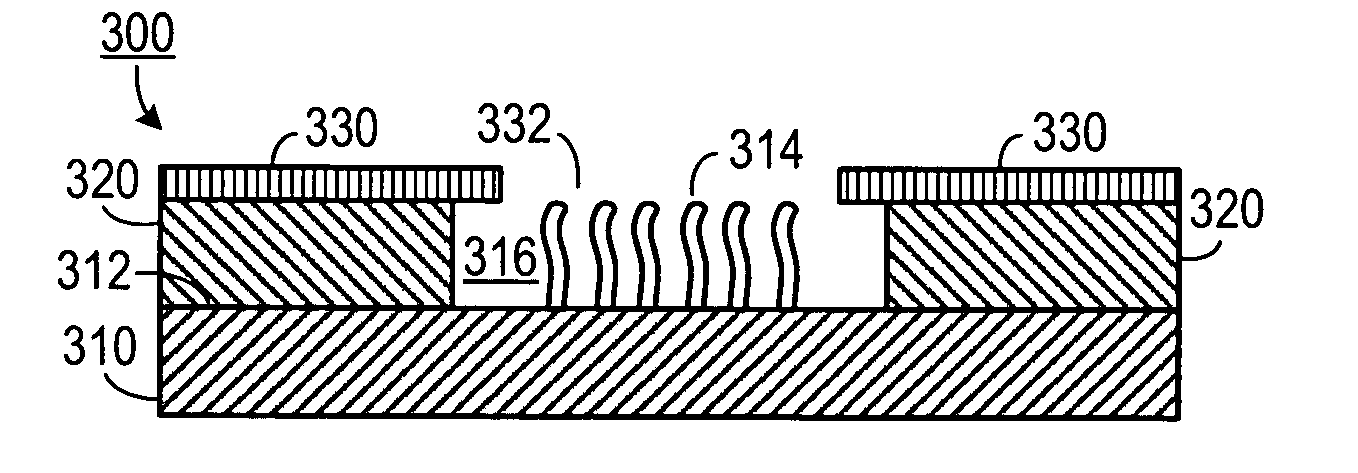

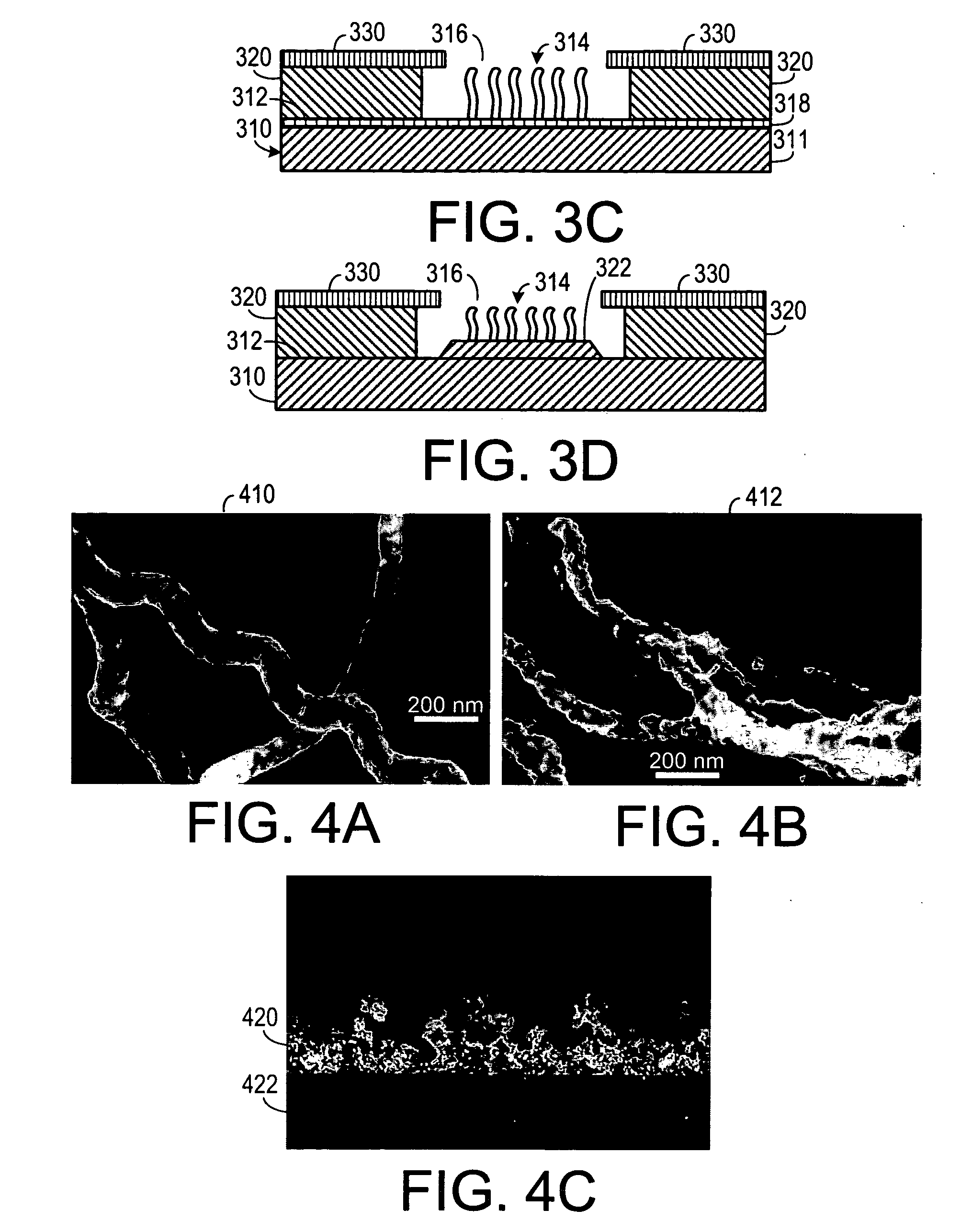

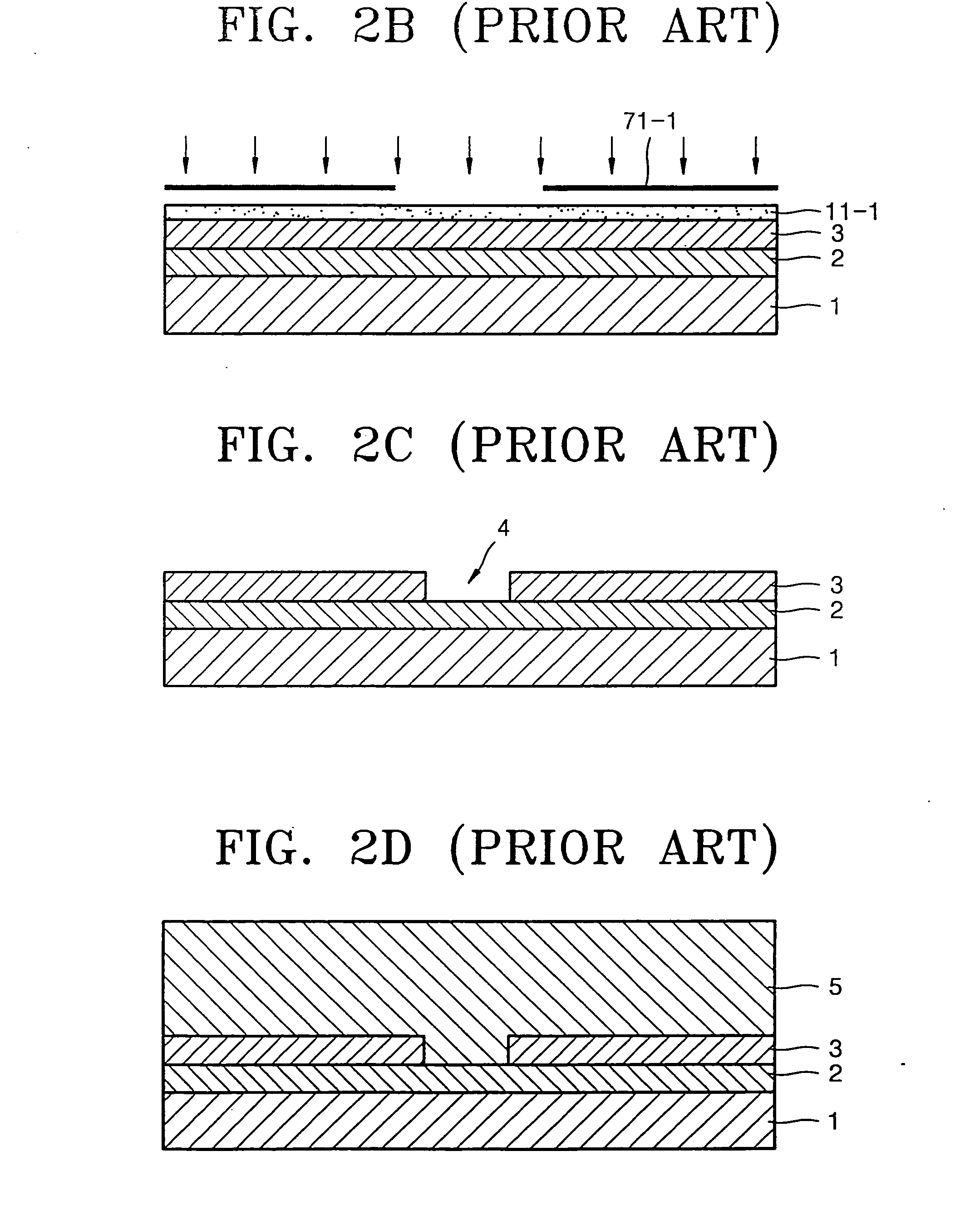

Self-aligned gated carbon nanotube field emitter structures and associated methods of fabrication

InactiveUS20050067936A1Simple and cost-effective and efficientDischarge tube luminescnet screensElectric discharge tubesElectrical conductorField line

A method for fabricating a self-aligned gated carbon nanotube field emitter structure includes providing a substrate, depositing a dielectric material on the surface of the substrate and depositing a conductor layer on the surface of the dielectric material. The method also includes selectively etching the conductor layer to form an opening and selectively etching the dielectric material to form a micro-cavity. The method further includes depositing a base layer structure in the micro-cavity adjacent to the surface of the substrate, wherein the base layer structure has a substantially conical shape, and depositing a catalyst on a portion of the surface of the base layer structure, wherein the catalyst is suitable for growing at least one carbon nanotube. The method still further includes applying an electrical potential to the substrate and the conductor layer, wherein the electrical potential generates a plurality of electrical field lines that are deflected around the surface of the base layer structure, and wherein the plurality of electrical field lines have a strength that is greatest in a direction substantially perpendicular to the surface of the substrate. Finally, the method includes growing at least one carbon nanotube from the catalyst in the presence of the plurality of electrical field lines, wherein the at least one carbon nanotube is grown in a direction substantially perpendicular to the surface of the substrate.

Owner:GENERAL ELECTRIC CO

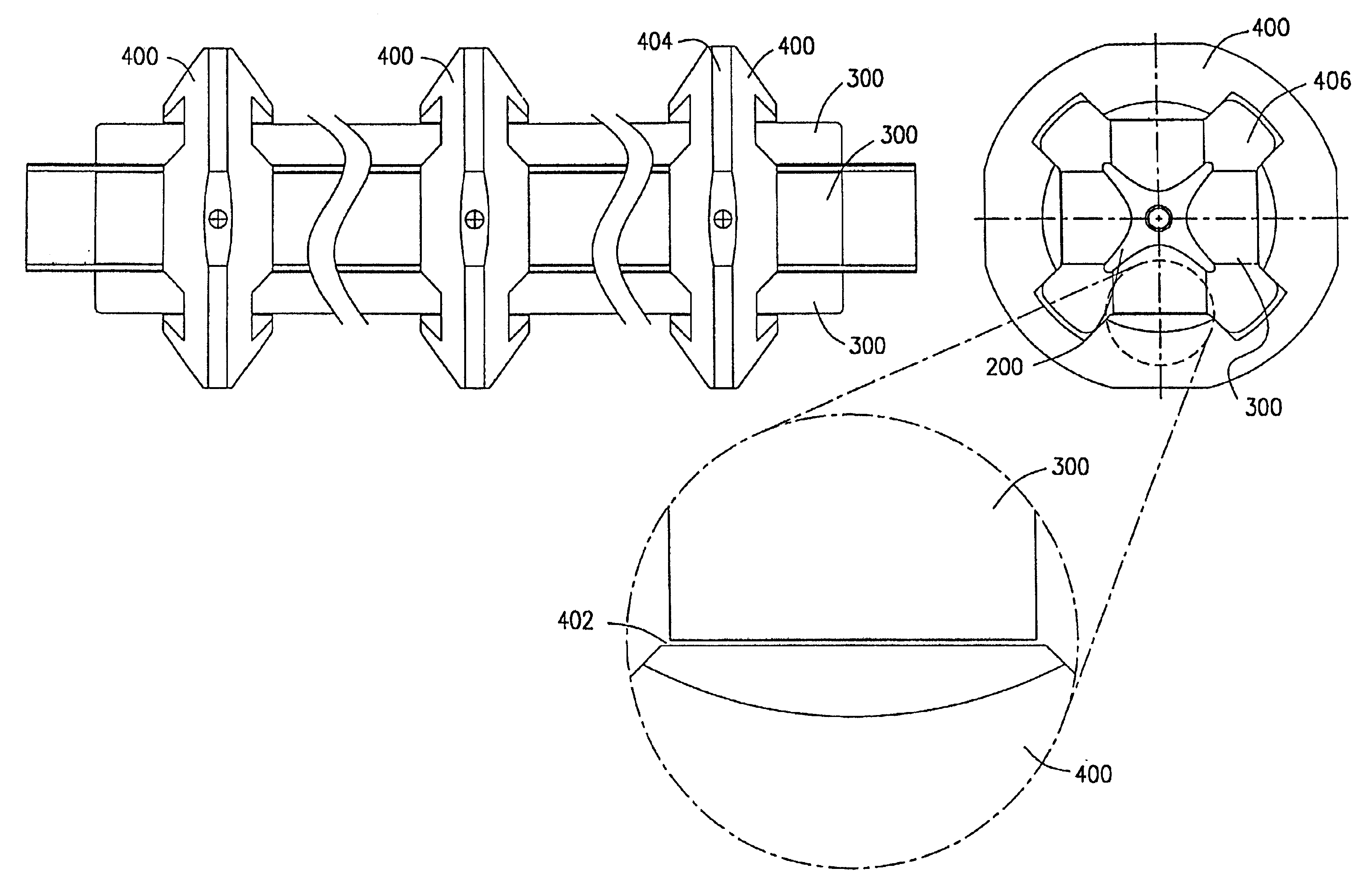

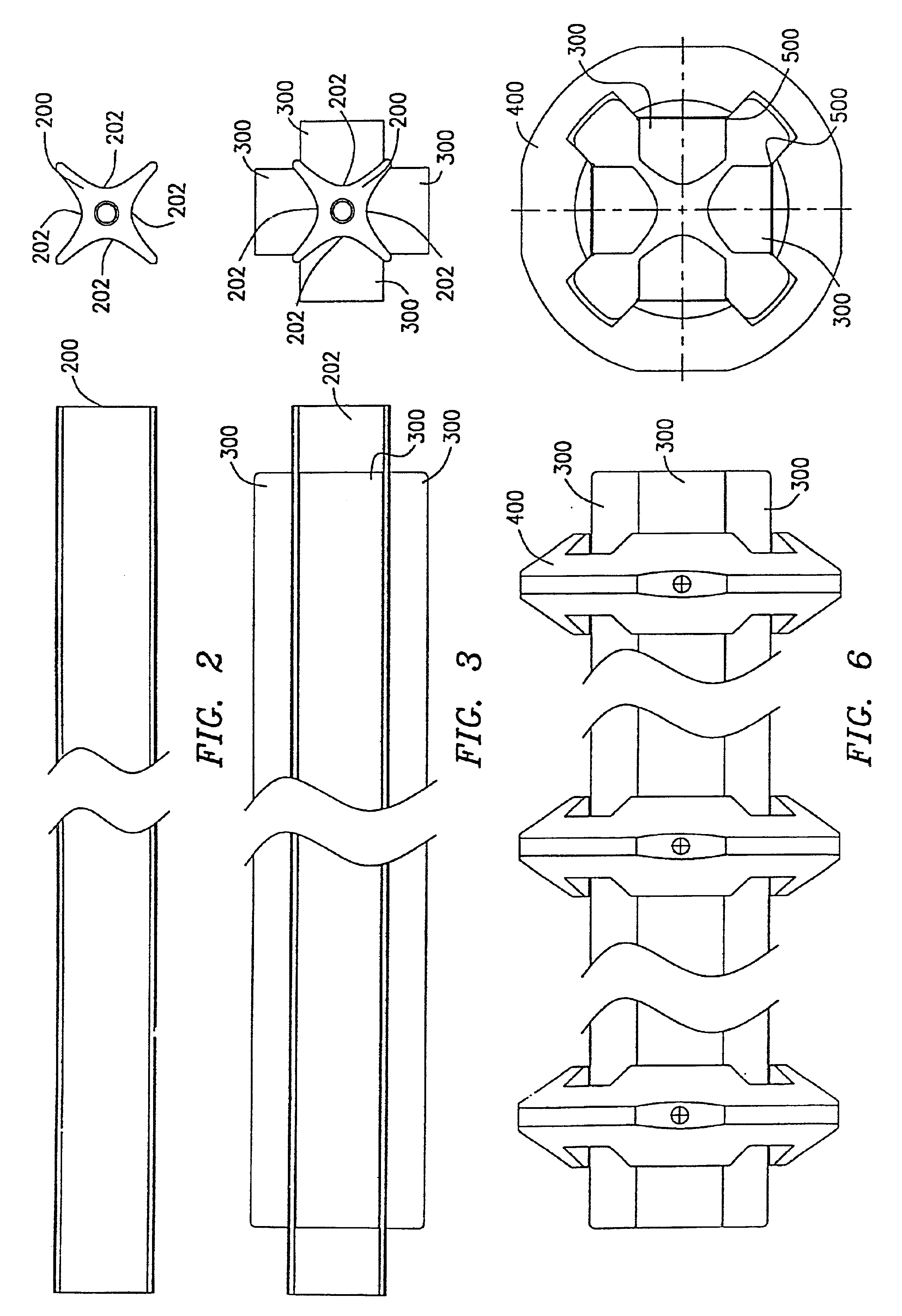

Manufacturing precision multipole guides and filters

InactiveUS6926783B2Precise positioningImprove accuracyAdhesive processesStability-of-path spectrometersResidual gas analyzerParticle beam

A method for manufacturing a multipole assembly for use in mass spectrometers, residual gas analyzers, mass filters, ion containment apparatus and particle beam accelerators. A precision mandrel tool is utilized for positioning a plurality of electrode rods in position during the manufacturing process. The electrode rods are placed on the mandrel. At least one insulator is positioned about the mandrel-rod assembly such that the mandrel-rod assembly psses through the insulator. The rods are tightly clamped to the mandrel and adhesive is placed in a gap established between each rod and the insulator. The adhesive is cured such that it acts both as a rigid bond between the insulator and each rod, as well as a precision spacer for positioning each rod in a precision position after the mandrel is removed from the assembly.

Owner:AGILENT TECH INC

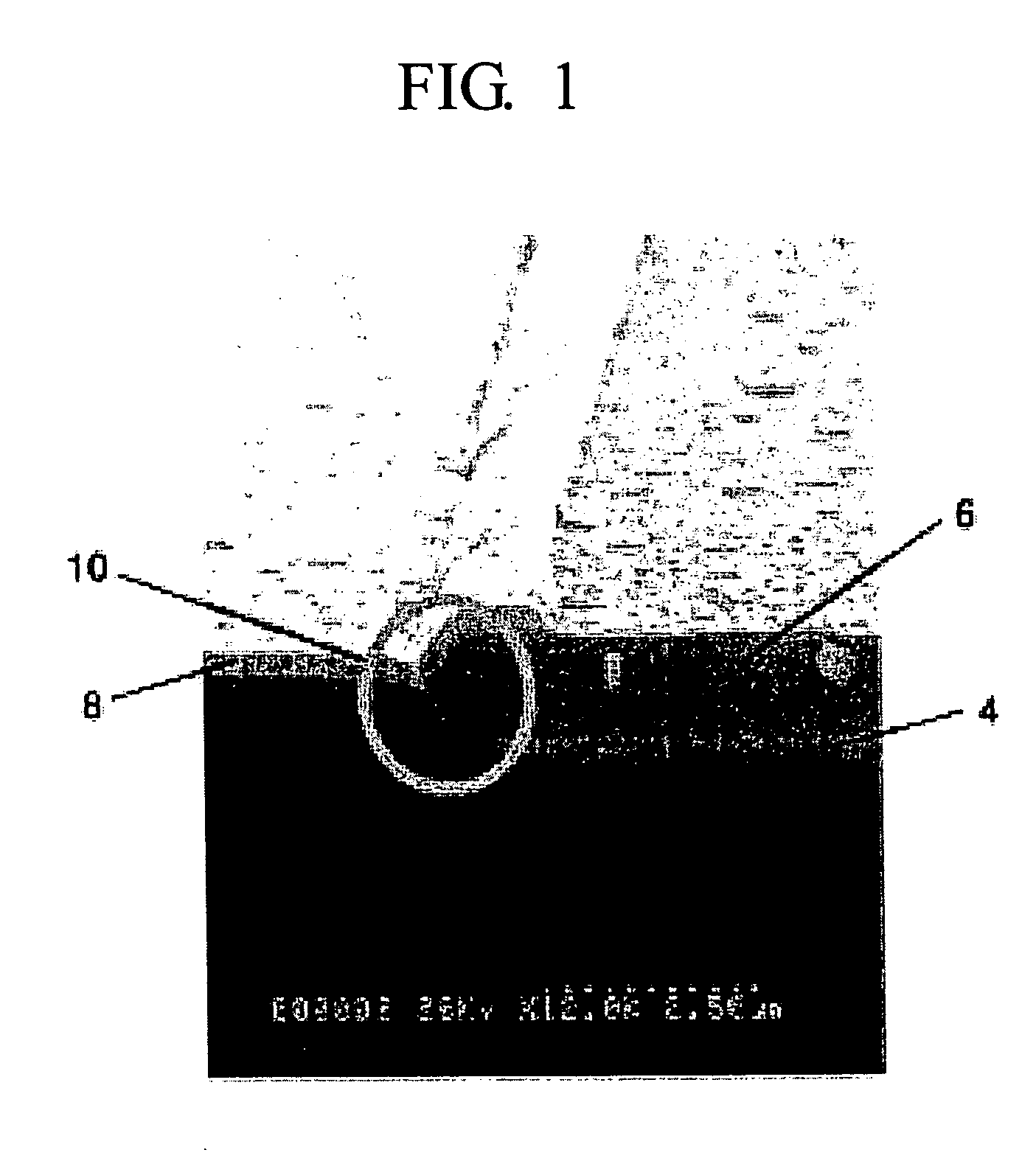

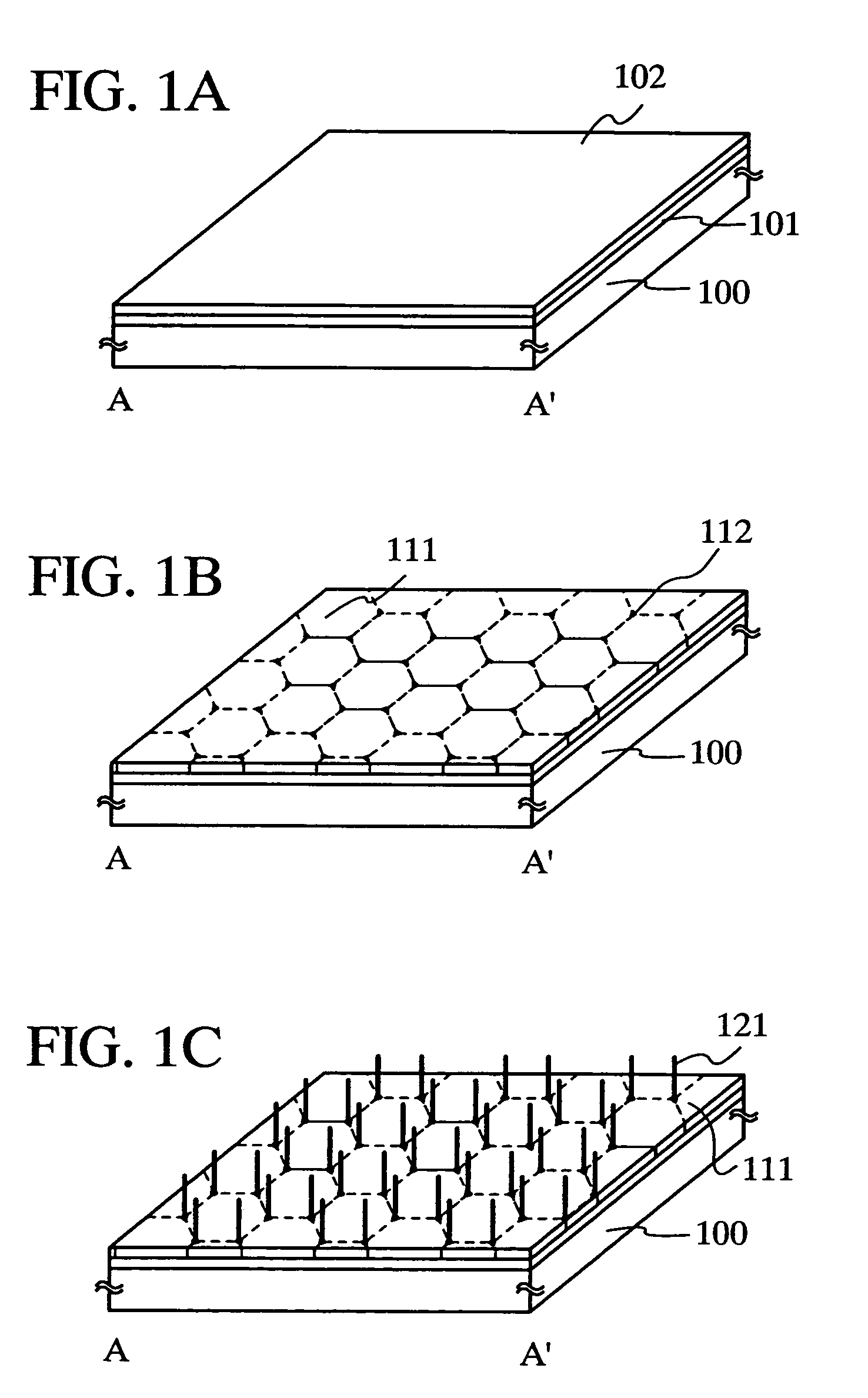

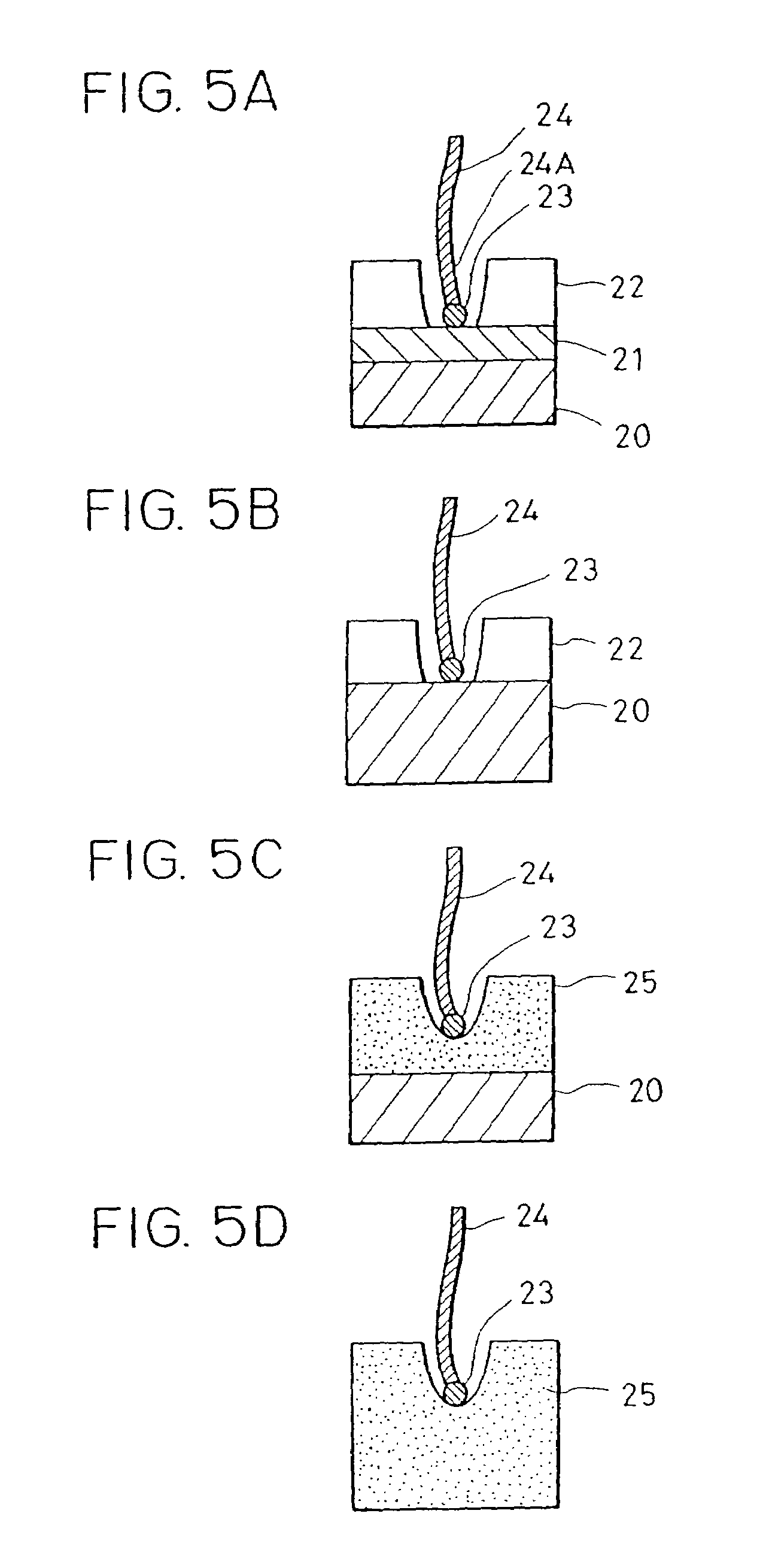

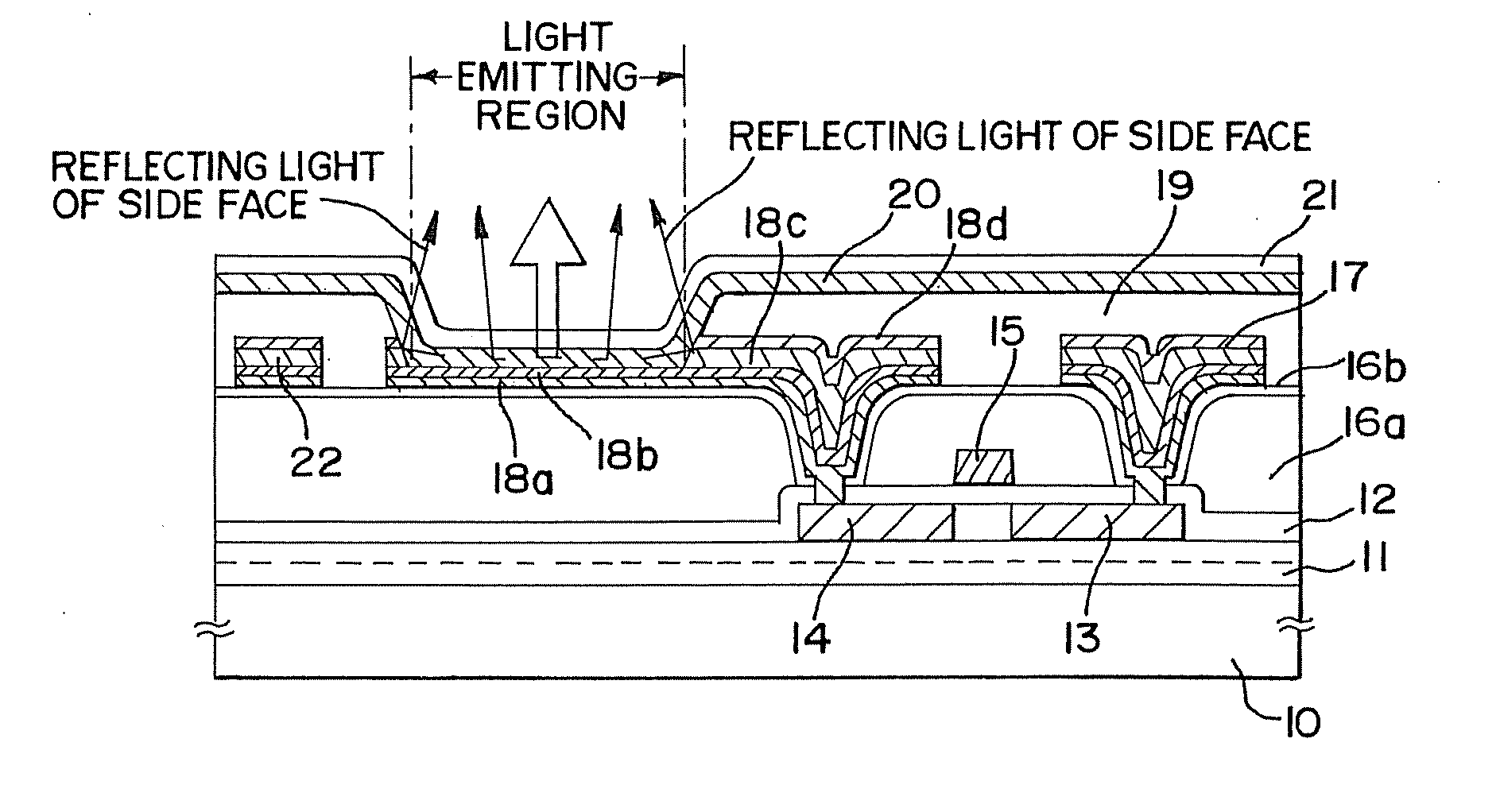

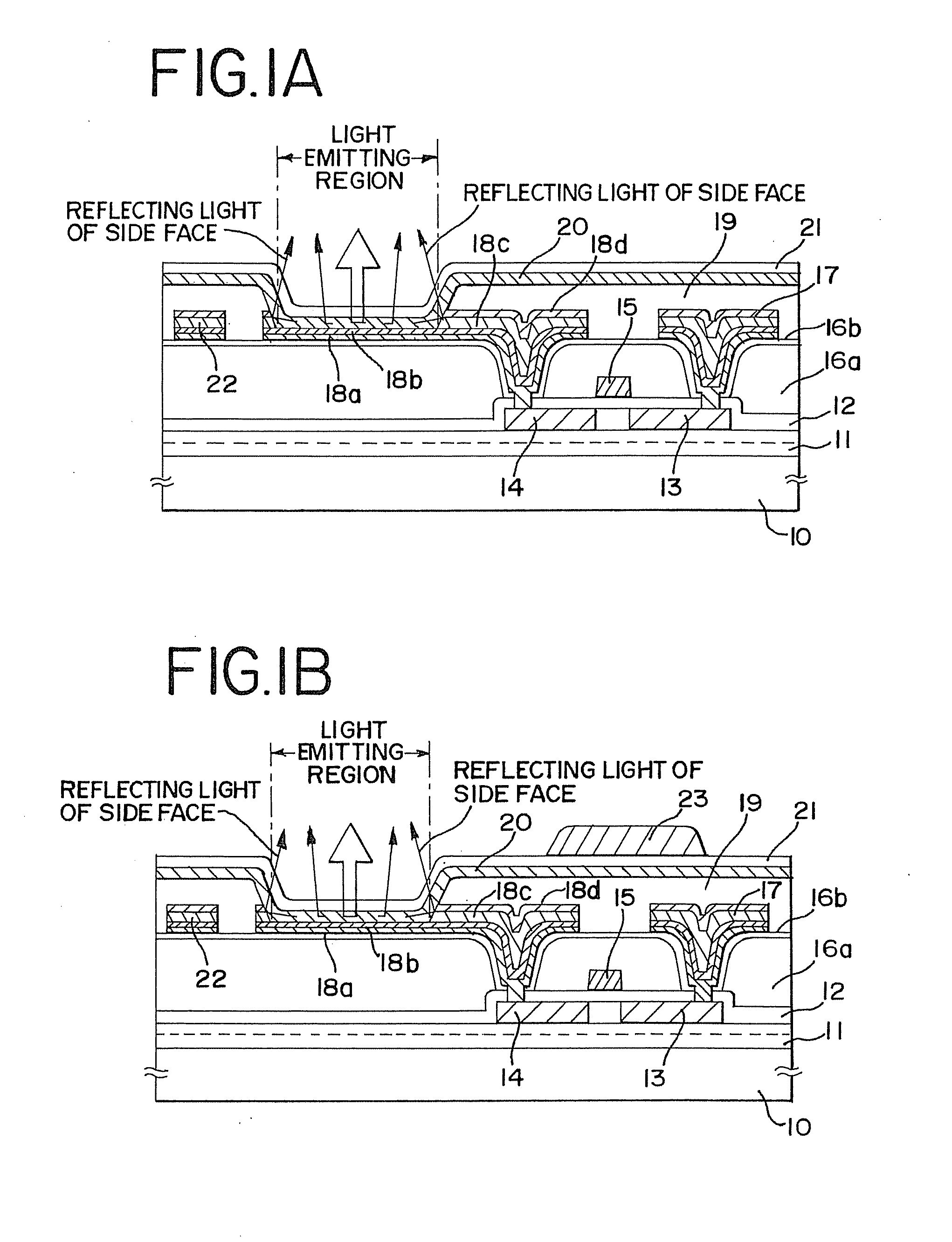

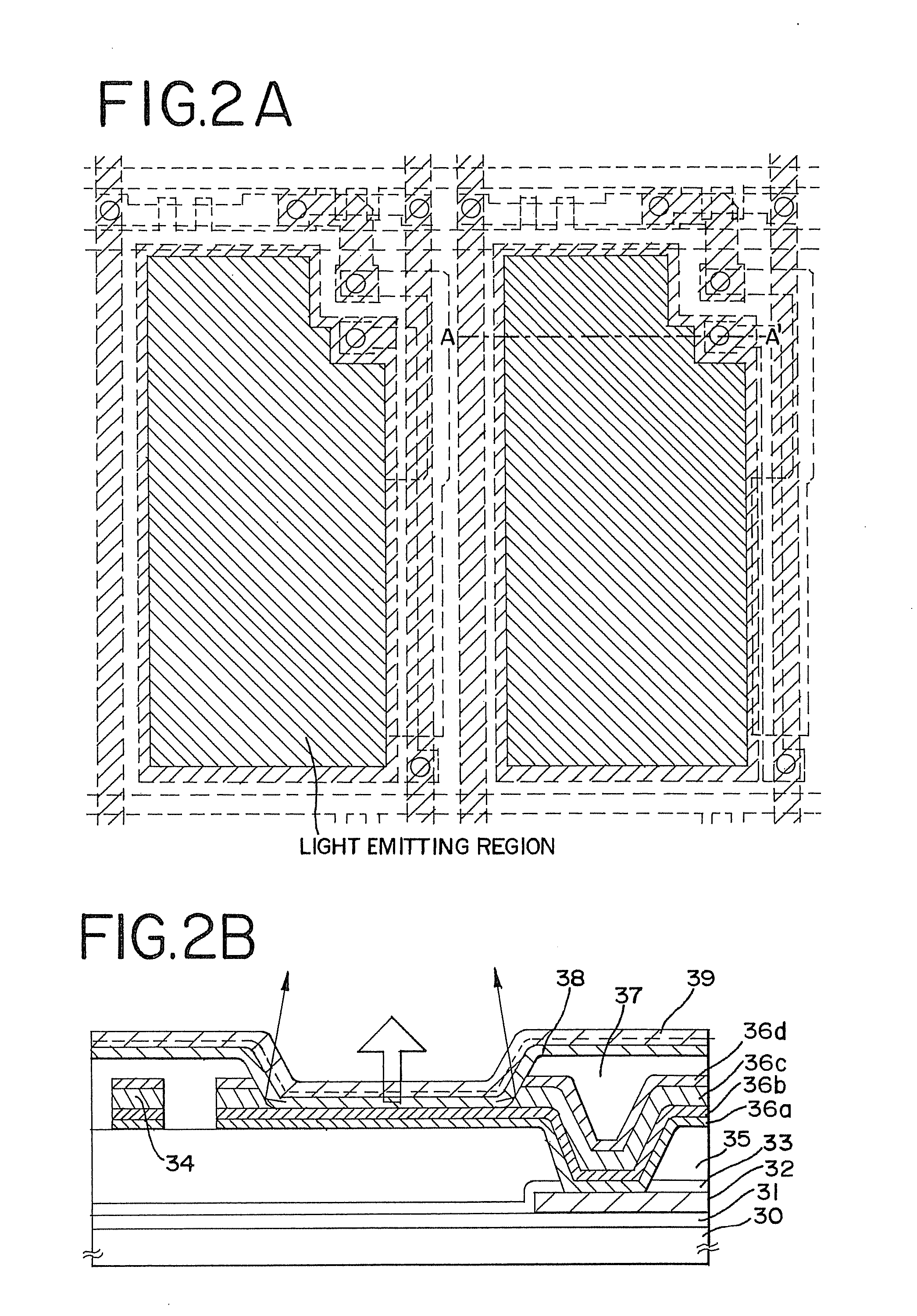

Light emitting device and method of manufacturing the same

InactiveUS20090298377A1Layer is smallReduce stray lightSolid-state devicesSemiconductor/solid-state device manufacturingOrganic compoundLight emitting device

All lights generated in an organic compound layer are not taken out towards a TFT from a cathode as a transparent electrode. For instance, the light is emitted in a lateral direction (direction parallel to the substrate surface) but the light emitted in the lateral direction is not taken out resultantly, which leads to a loss. Therefore, a light emitting device structured so as to increase the amount of light taken out in a certain direction is provided as well as a method of manufacturing this light emitting device. As a result of etching treatment, an upper edge portion of an insulator (19) is curved to have a radius of curvature, a slope is formed along the curved face while partially exposing layers (18c and 18d) of a first electrode, and a layer (18b) of the first electrode is exposed in a region that serves as a light emitting region. Light emitted from an organic compound layer (20) is reflected by the slope of the first electrode (layers 18c and 18d) to increase the total amount of light taken out in the direction indicated by the arrow in FIG. 1A.

Owner:SEMICON ENERGY LAB CO LTD

Field emission electron source having carbon nanotubes and method for manufacturing the same

ActiveUS20090115306A1Easy to controlFirmly connectedElectric discharge tubesDischarge tube main electrodesElectron sourceCarbon nanotube

A field emission electron source having carbon nanotubes includes a CNT string and a conductive base. The CNT string has an end portion and a broken end portion, the end portion is contacted with and electrically connected to the surface of the conductive base. The CNTs at the broken end portion form a tooth-shape structure, wherein some CNTs protruding and higher than the adjacent CNTs. Each protruding CNT functions as an electron emitter. Further, a method for manufacturing a field emission electron source is provided. The field emission efficiency of the field emission electron source is high.

Owner:TSINGHUA UNIV +1

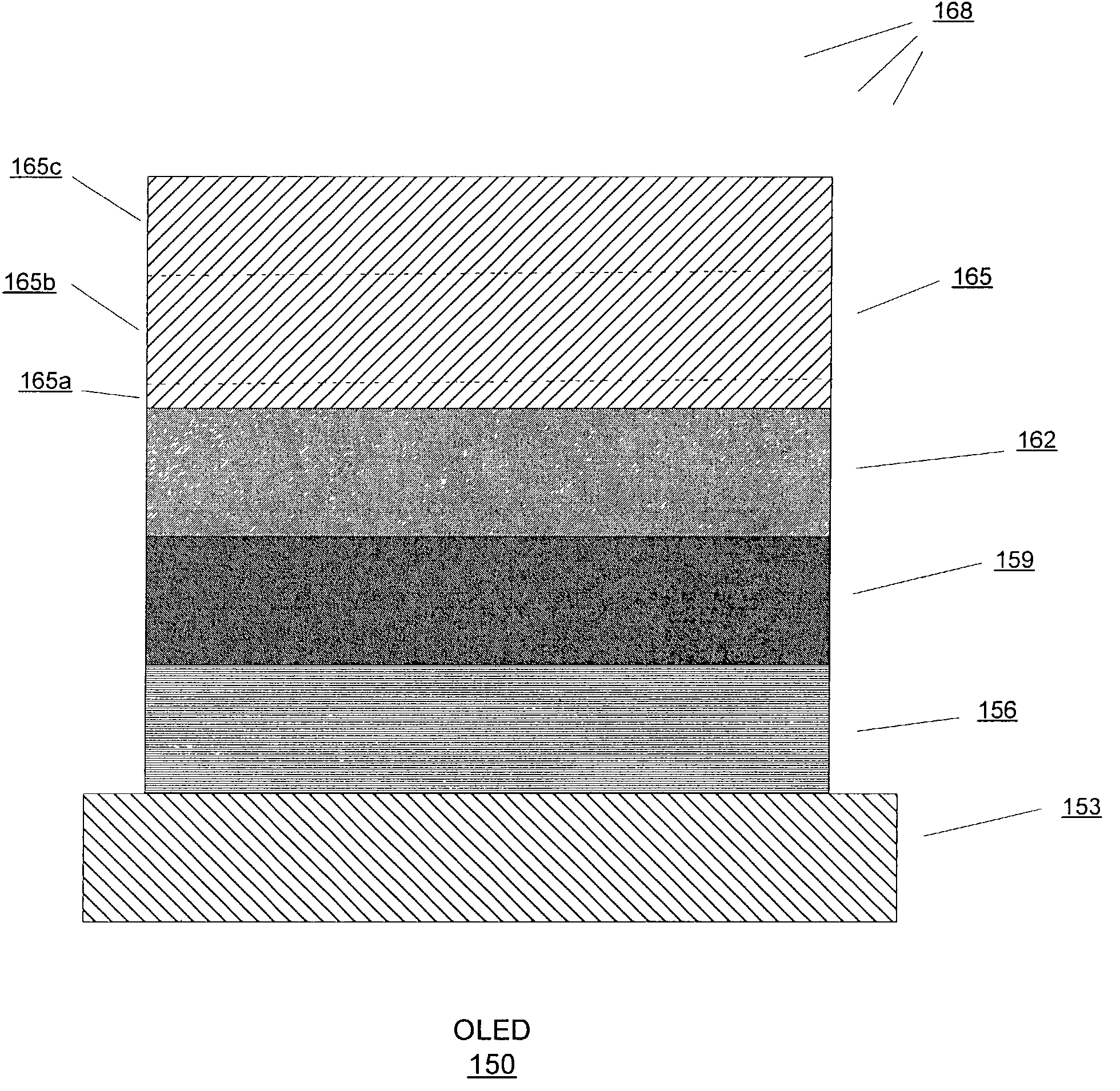

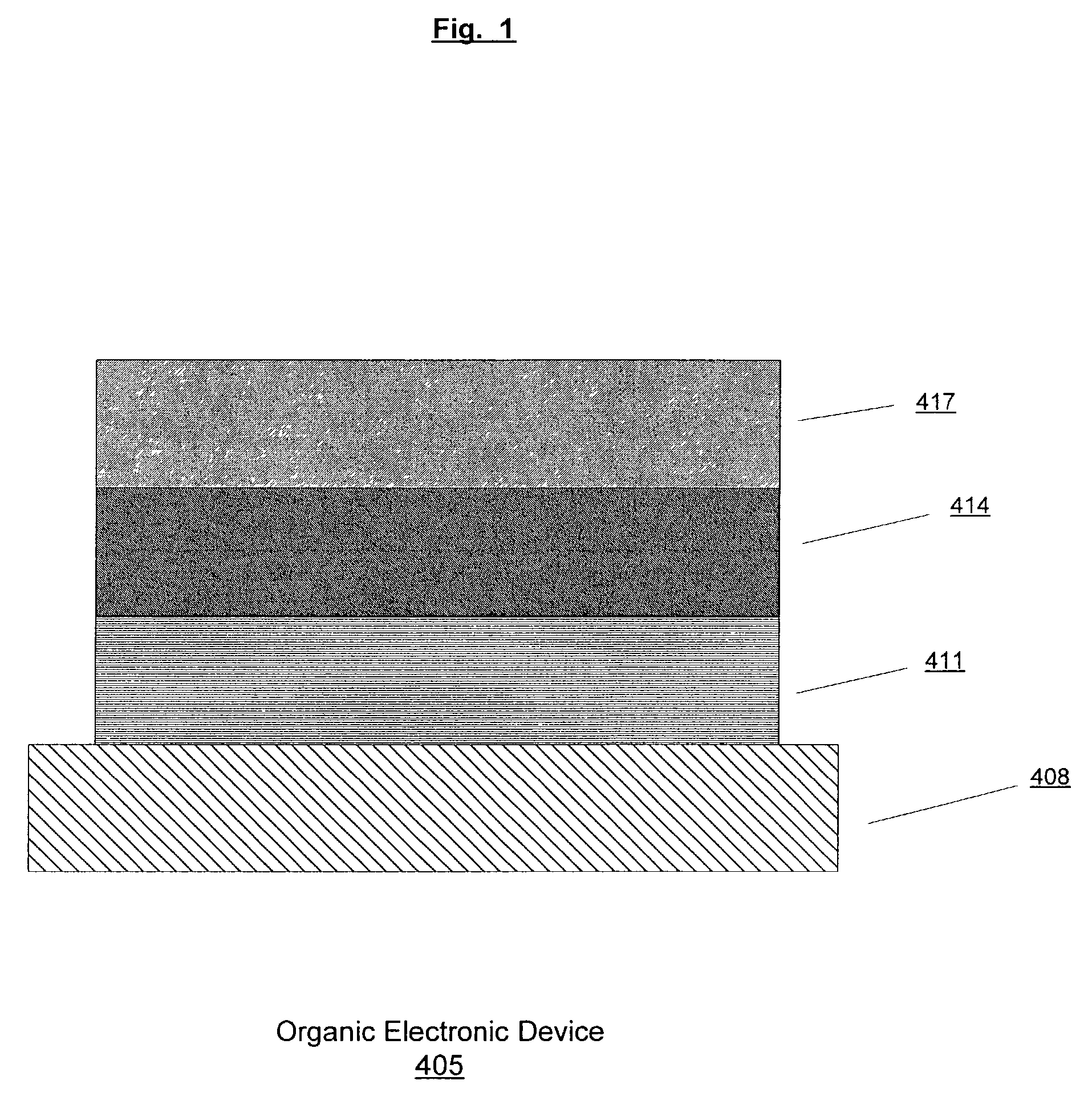

Electroluminescent devices and method of making transparent cathodes

InactiveUS7015639B2Discharge tube luminescnet screensElectroluminescent light sourcesElectronSecondary layer

An embodiment of the present invention pertains to an electrode that is substantially transparent and conductive and that is incorporated within an organic electronic device. This electrode includes a first layer and a second layer that is on the first layer. The electrode optionally includes a third layer on the second layer. The first layer, the second layer, and the third layer are exposed to a medium and reactions between various combinations of the first layer, the second layer, the third layer, and the medium produce the substantially transparent and conductive electrode.

Owner:PICTIVA DISPLAY INT LTD

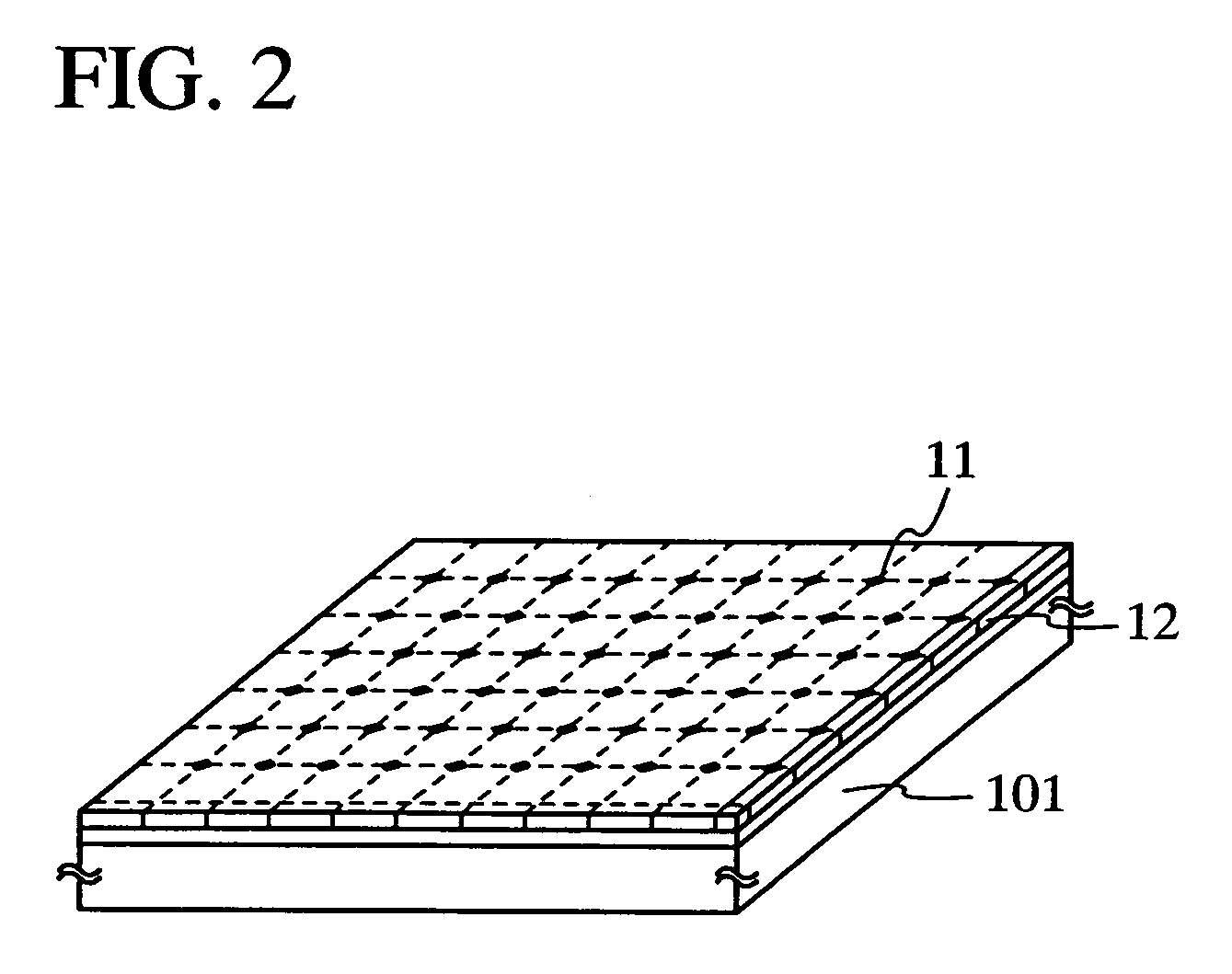

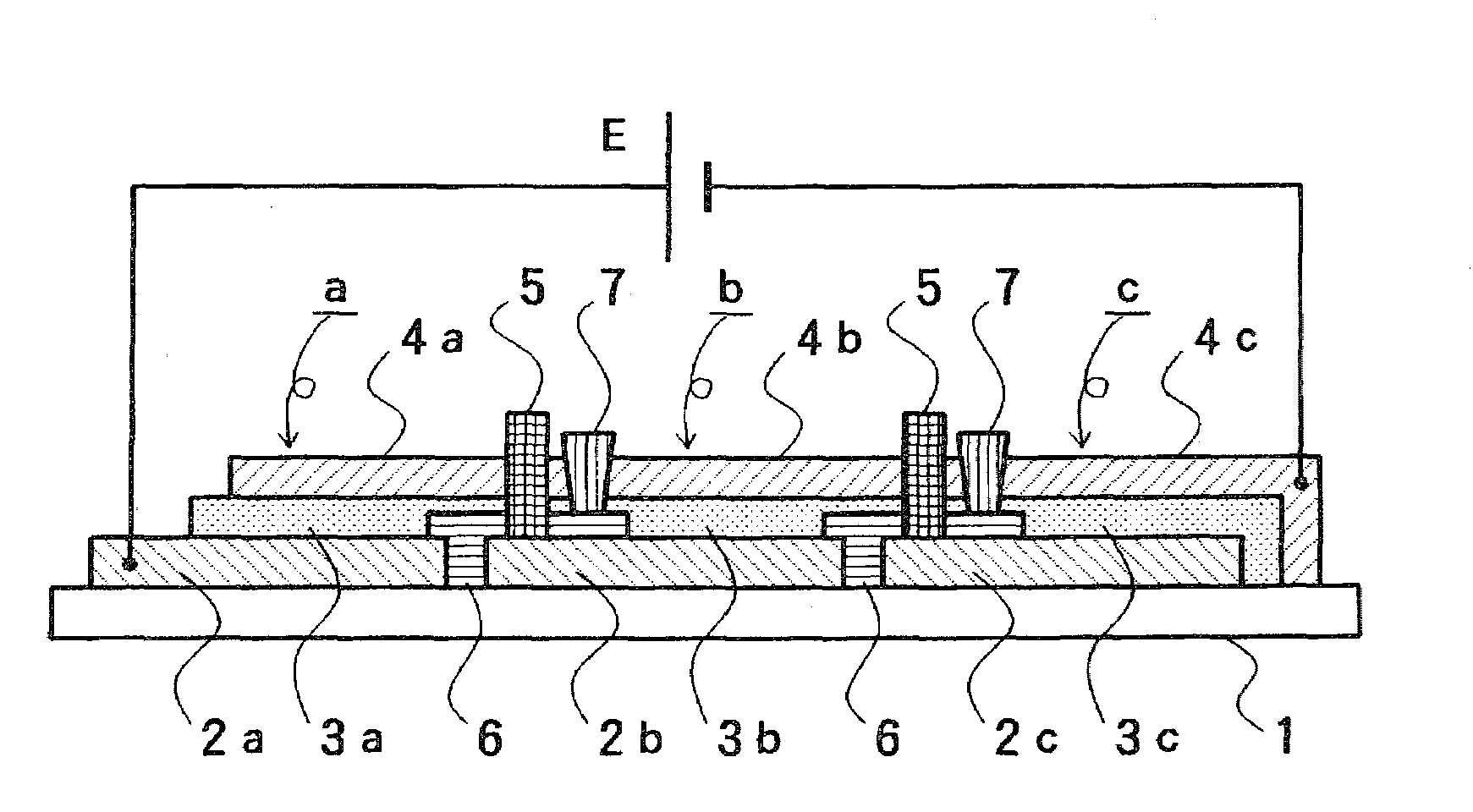

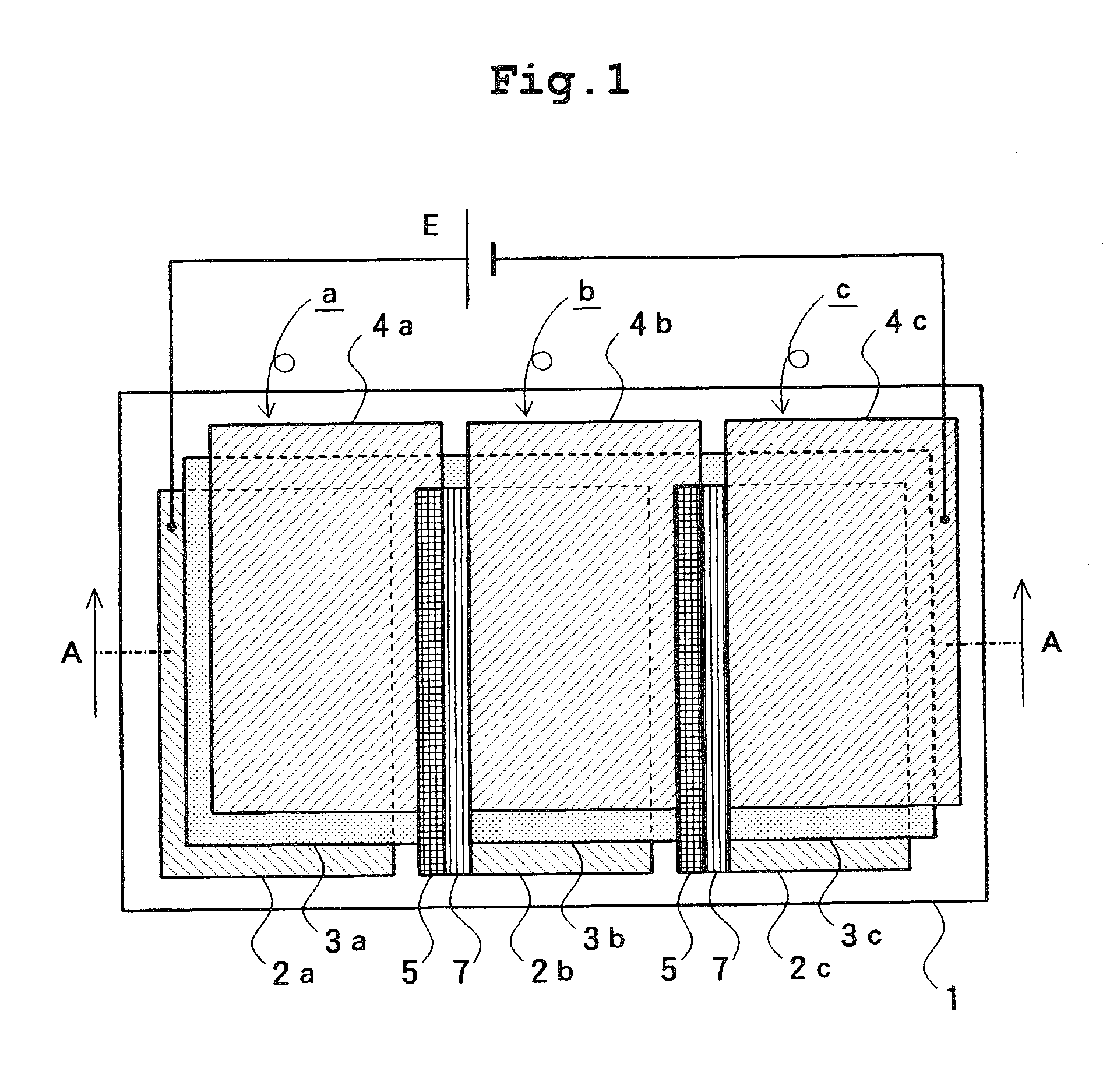

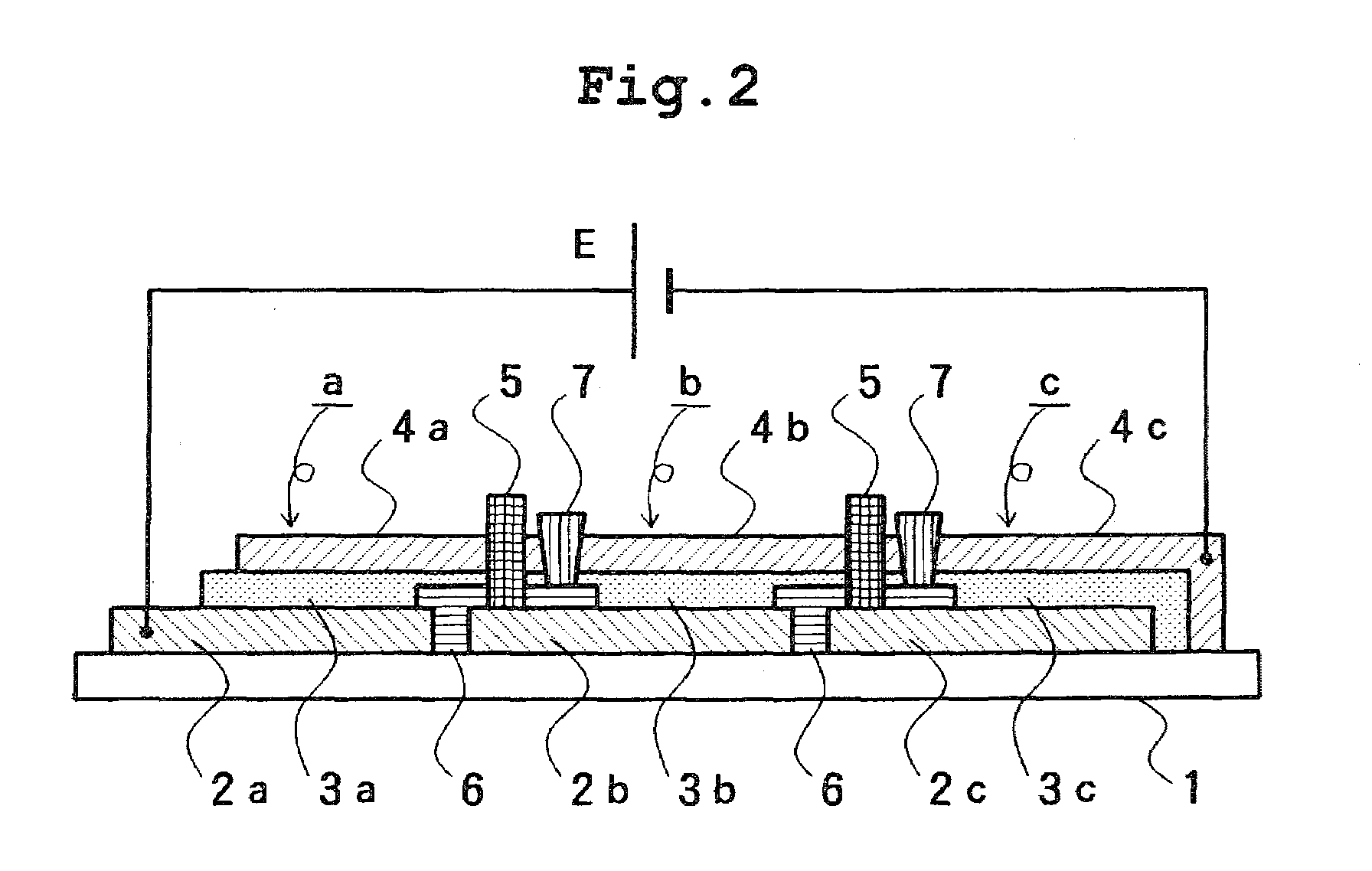

Organic el light emitting device and method for manufacturing the same

InactiveUS20080224606A1Efficient preparationImprove productivityDischarge tube luminescnet screensSemiconductor/solid-state device detailsLight emitting devicePhysics

An organic EL light emitting device, in which a plurality of divided light emitting segments are connected in series, is efficiently manufactured without separate coating of organic EL light emitting layers with the use of a vapor-deposition mask. Conductor parts 5 are respectively formed on first electrodes 2b and 2c in boundary parts of adjacent light emitting segments a, b and c. Organic light emitting layers 3a to 3c and second electrode 4a to 4c are respectively stacked on each of the first electrode 2a to 2c. The conductor part 5 has a function for electrically connecting the first electrodes and the second electrodes in the adjacent light emitting segments, whereby the light emitting segments are connected in series.

Owner:YAMAGATA PROMOTIONAL ORG FOR INDAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com