Picosecond pulse laser cutting preparation method for grid-control traveling wave tube grid mesh

A laser cutting and picosecond pulse technology is applied in the field of preparation of traveling wave tube fittings, which can solve the problems of difficulty in guaranteeing the accuracy of the coaxiality of the spoke width, the inconsistency of the electric discharge machining grid, and the unstable quality of the traveling wave tube. , to achieve the effect of narrow processing line width, good edge quality and small heat affected area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

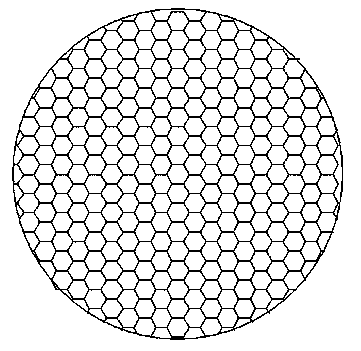

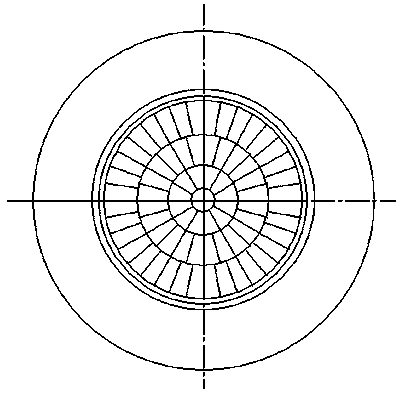

[0024] Example 1 Preparation of Molybdenum Honeycomb Grid

[0025] A preparation method for picosecond pulse laser cutting of a honeycomb grid, which comprises the following steps:

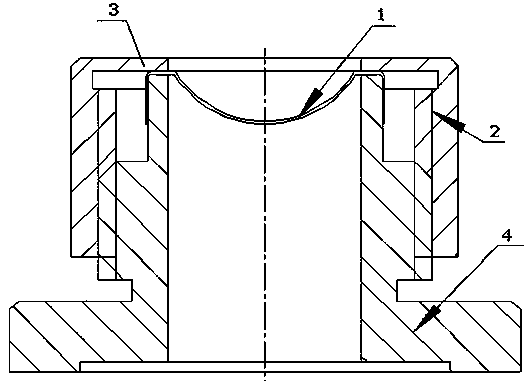

[0026] a. Take the molybdenum grid material with a thickness of 0.03 mm and blank it with a die, clean and remove the oil on the surface of the grid material, then place the grid material in a hydrogen burning furnace, and perform hydrogen annealing treatment at 800 ° C for 15 minutes, then Place the grid material on a convex spherical mold and press it into a spherical round block with a convex center with a punch to obtain a spherical grid blank;

[0027] b. Take the spherical grid blank obtained in step a and clean it with sodium hydroxide solution first, then wash it with chromic acid solution, then place the cleaned spherical grid blank in a hydrogen furnace, and perform hydrogen annealing treatment at 800°C 15 minutes; remove the stress generated during molding to obtain a stress-removed sp...

Embodiment 2

[0030] Example 2 Preparation of grid of oxygen-free copper

[0031] A preparation method for picosecond pulse laser cutting of a honeycomb grid, which comprises the following steps:

[0032] a. After blanking the oxygen-free copper grid material with a thickness of 0.1mm, clean and remove the oil stain on the surface of the grid material, then place the grid material in a hydrogen burning furnace, and perform hydrogen annealing treatment at 650°C for 15 minutes. Then place the grid material on a convex spherical mold and press it into a spherical round block with a convex center with a punch to obtain a spherical grid blank;

[0033] b. Take the spherical grid blank obtained in step a and clean it with sodium hydroxide solution first, then clean it with chromic acid solution, then place the cleaned spherical grid blank in a hydrogen furnace, and anneal it at 650 °C by burning hydrogen Process for 15 minutes; remove the stress generated during molding to obtain a stress-remove...

Embodiment 3

[0036] Example 3 Preparation of Molybdenum-Rhenium Grid

[0037] A preparation method for picosecond pulse laser cutting of a honeycomb grid, which comprises the following steps:

[0038]a. After blanking the molybdenum-rhenium grid material with a thickness of 0.08mm, clean and remove the oil stain on the surface of the grid material, then place the grid material in a hydrogen burning furnace, and anneal hydrogen burning at 900°C for 20 minutes, and then Place the grid material on a convex spherical mold and press it into a spherical round block with a convex center with a punch to obtain a spherical grid blank;

[0039] b. Take the spherical grid blank obtained in step a and clean it with sodium hydroxide solution first, then clean it with chromic acid solution, then place the cleaned spherical grid blank in a hydrogen furnace, and anneal it at 900°C Process for 15 minutes; remove the stress generated during molding to obtain a stress-removed spherical grid blank, for subse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com