Patents

Literature

96 results about "Carbon nanotube yarn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fabricating carbon nanotube yarn

ActiveUS20040053780A1Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

Method for fabricating carbon nanotube yarn

ActiveUS7045108B2Material nanotechnologyCatalyst activation/preparationFurnace temperatureCarbon nanotube yarn

A method of fabricating a long carbon nanotube yarn includes the following steps: (1) providing a flat and smooth substrate; (2) depositing a catalyst on the substrate; (3) positioning the substrate with the catalyst in a furnace; (4) heating the furnace to a predetermined temperature; (5) supplying a mixture of carbon containing gas and protecting gas into the furnace; (6) controlling a difference between the local temperature of the catalyst and the furnace temperature to be at least 50° C.; (7) controlling the partial pressure of the carbon containing gas to be less than 0.2; (8) growing a number of carbon nanotubes on the substrate such that a carbon nanotube array is formed on the substrate; and (9) drawing out a bundle of carbon nanotubes from the carbon nanotube array such that a carbon nanotube yarn is formed.

Owner:HON HAI PRECISION IND CO LTD +1

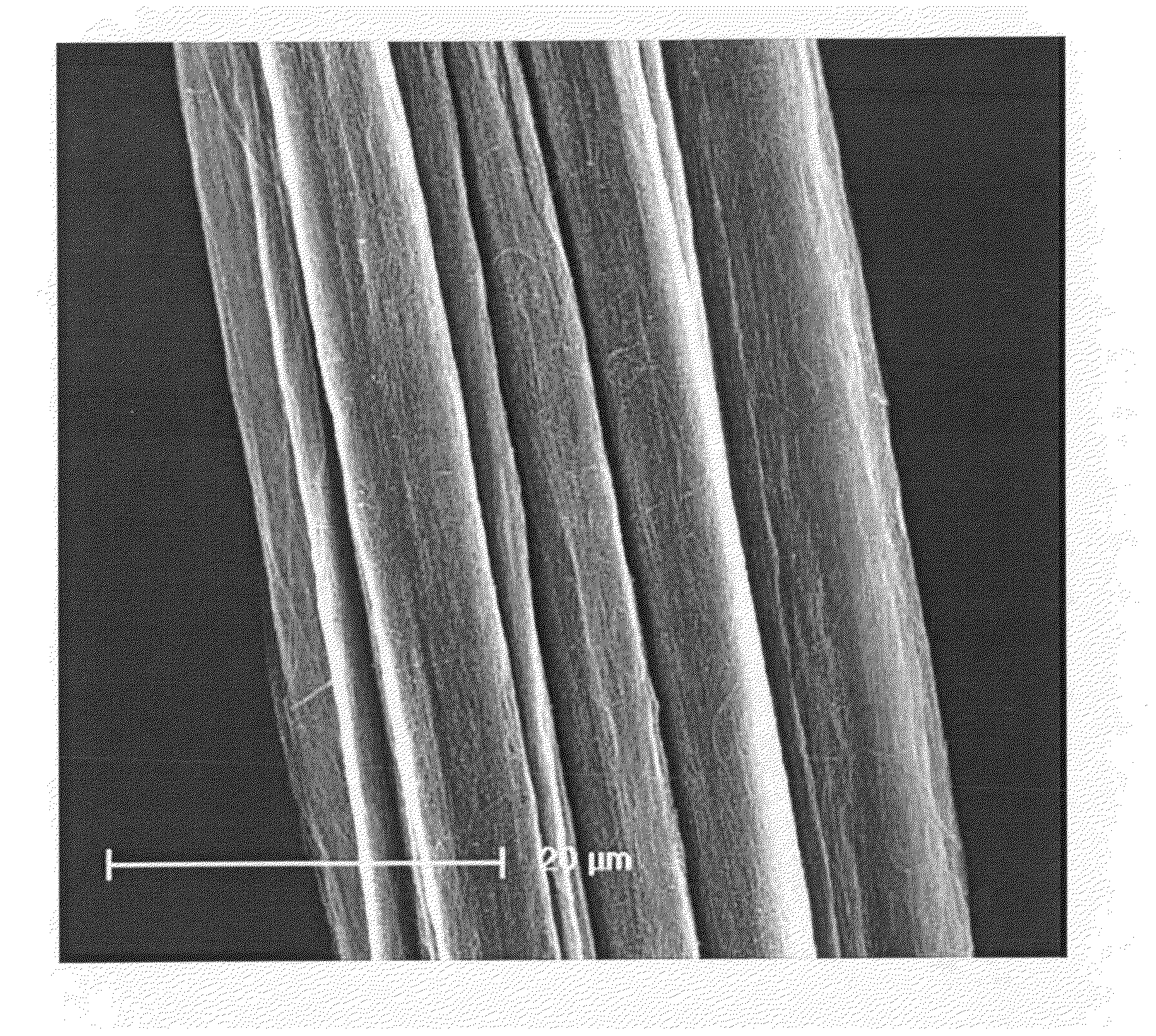

Carbon nanotube yarn and method for making the same

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

Method for making carbon nanotube yarn

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV

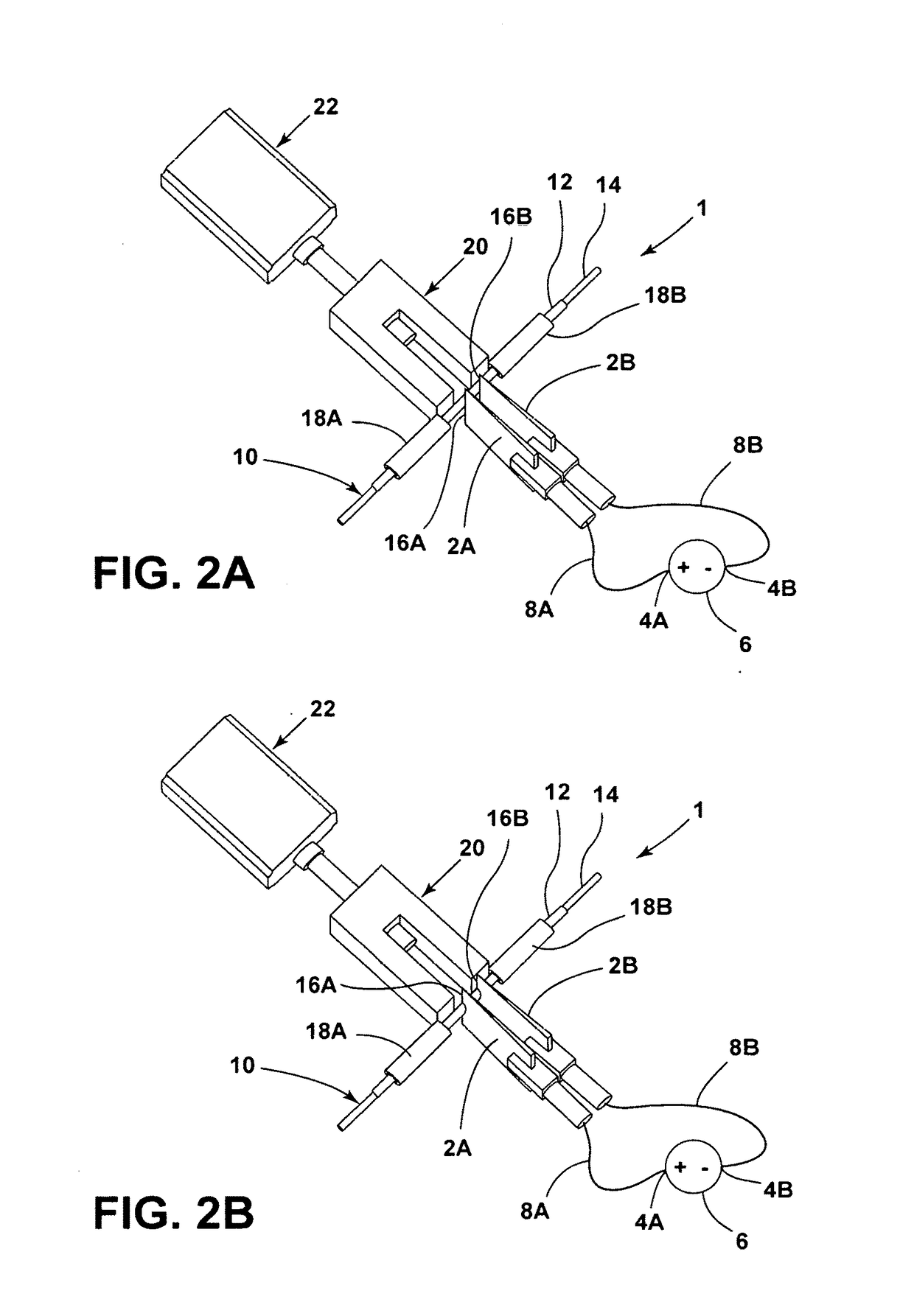

Cutting mechanism for carbon nanotube yarns, tapes, sheets and polymer composites thereof

ActiveUS20170129182A1Easy to cutRobust cutting method3D object support structuresManufacturing data aquisition/processingPower flowCarbon nanotube yarn

A cutting mechanism includes electrodes that are utilized to cut or score a non-conductive outer material of a filament or sheet. The electrodes contact a conductive reinforcing material of the filament or sheet to complete an electric circuit. Electric current flows through and heats the conductive material to oxidize or otherwise separate / cut the conductive material and any remaining non-conductive material.

Owner:NAT INST AEROSPACE ASSOC +1

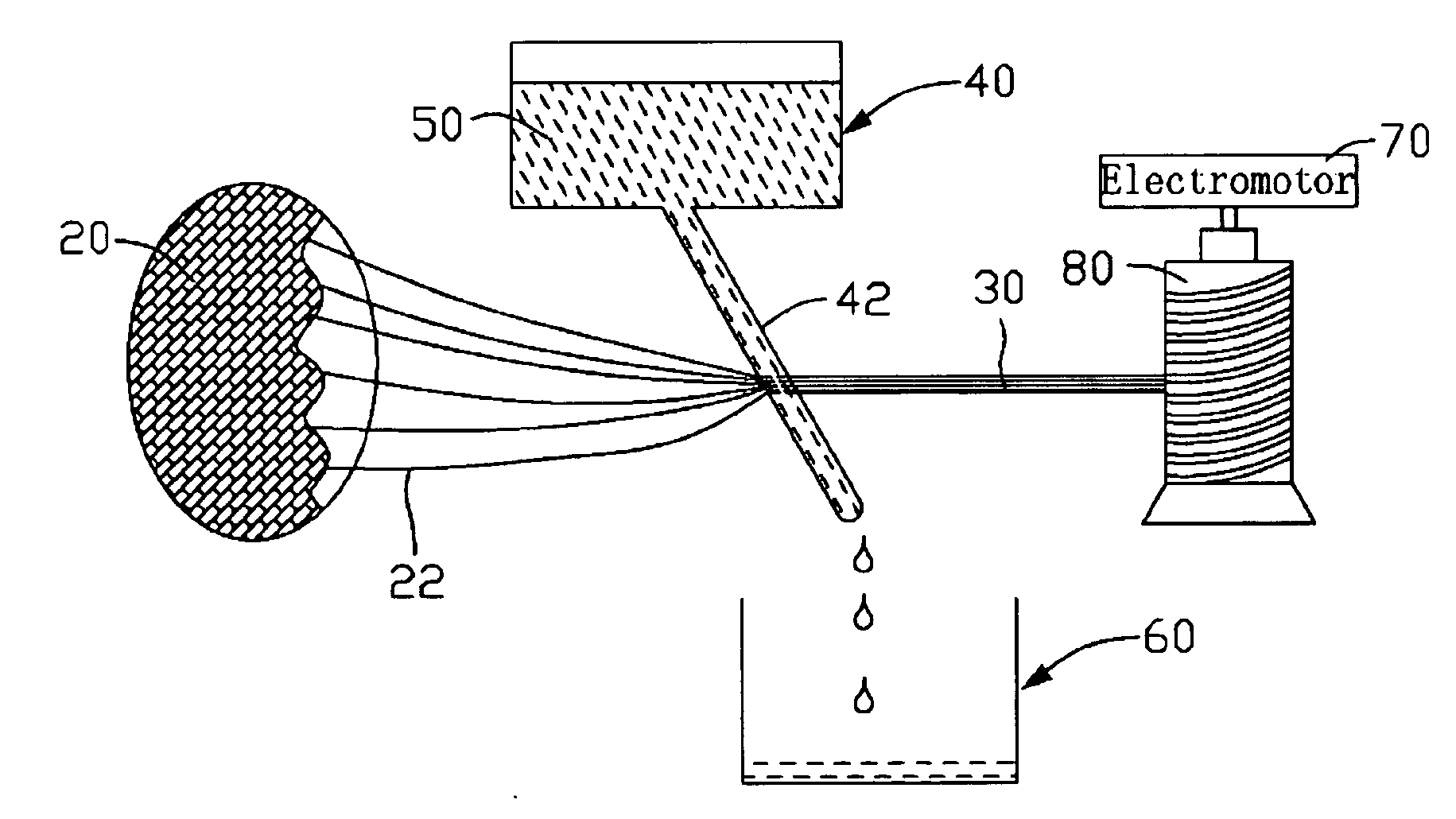

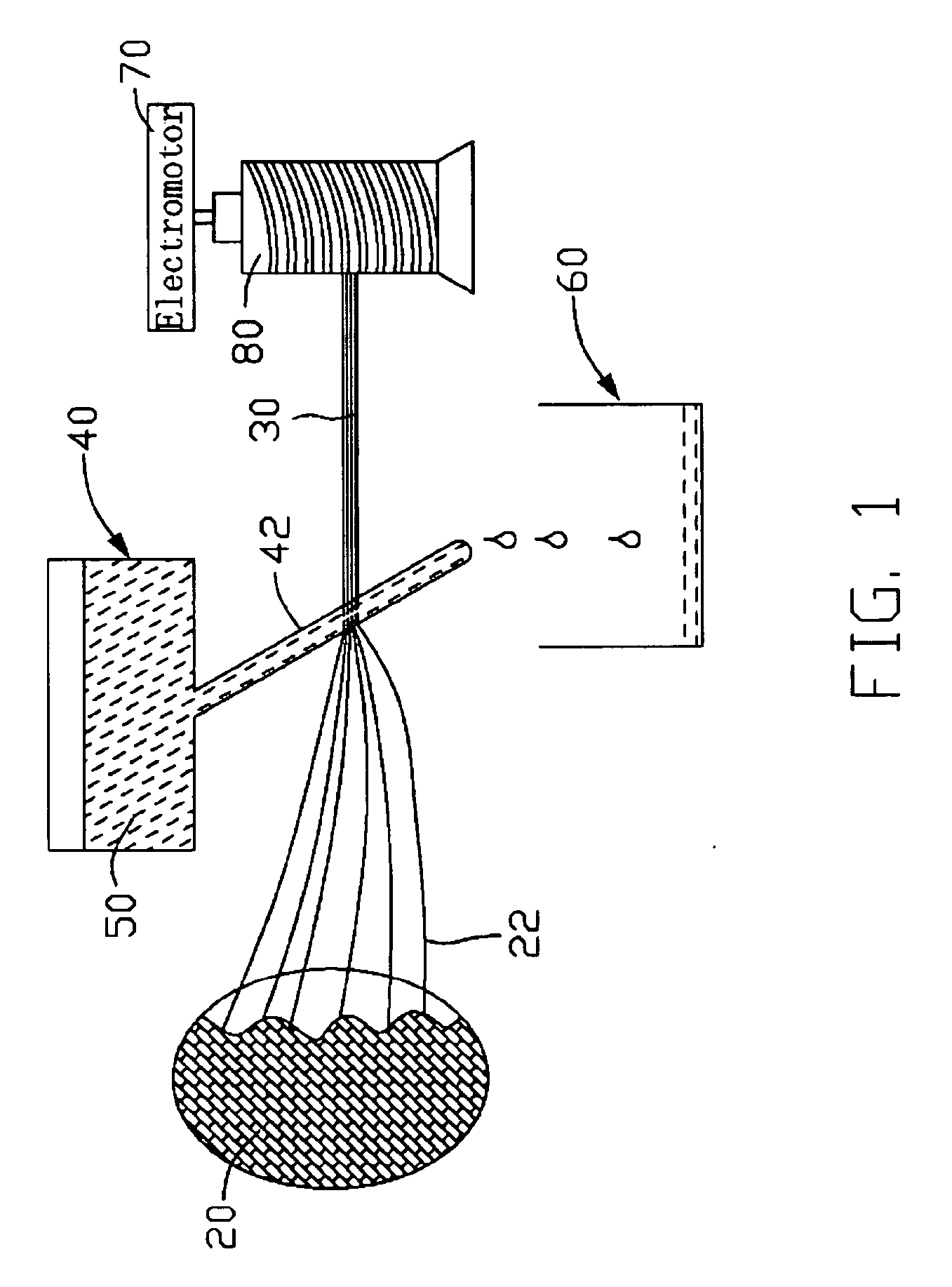

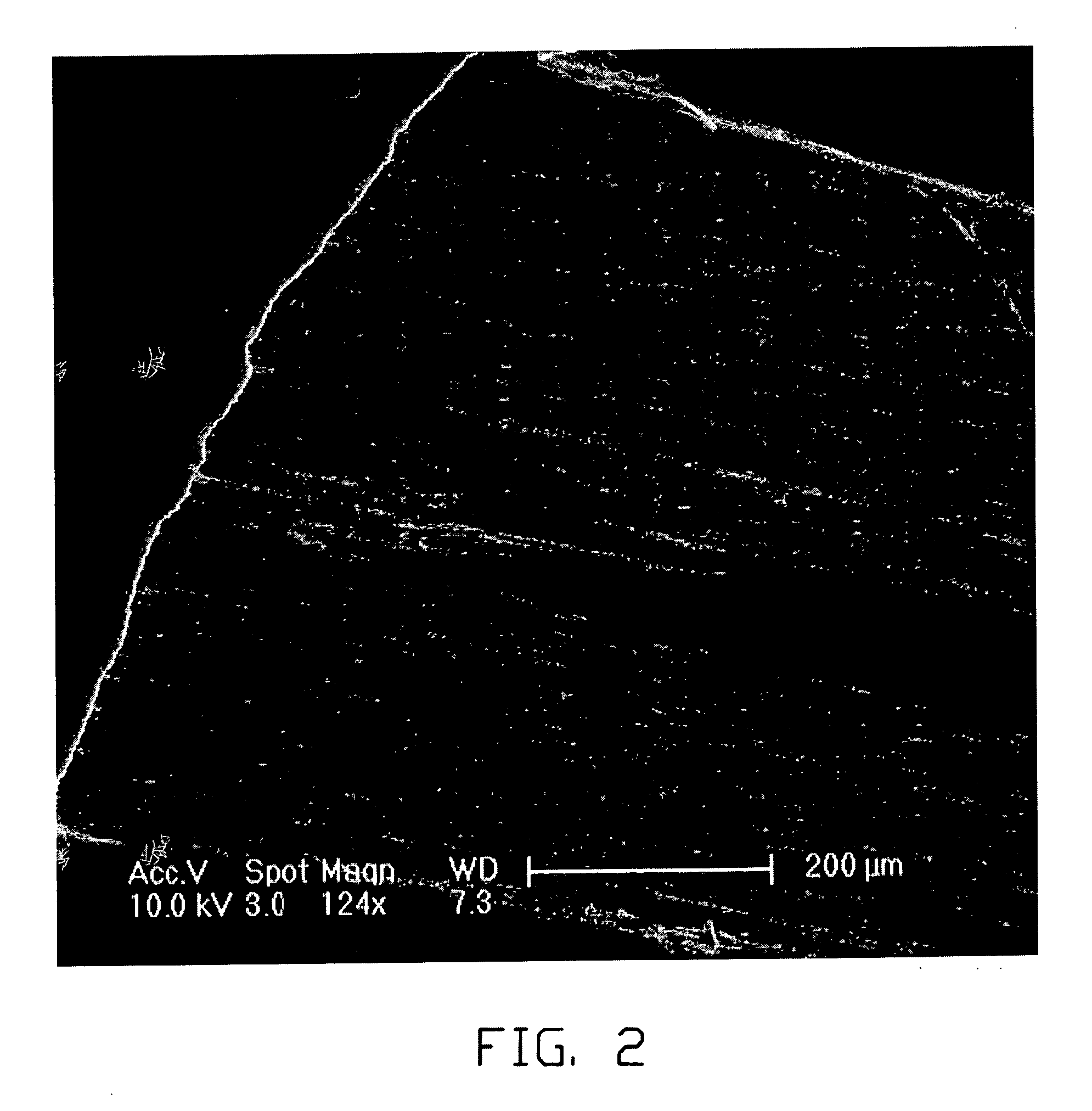

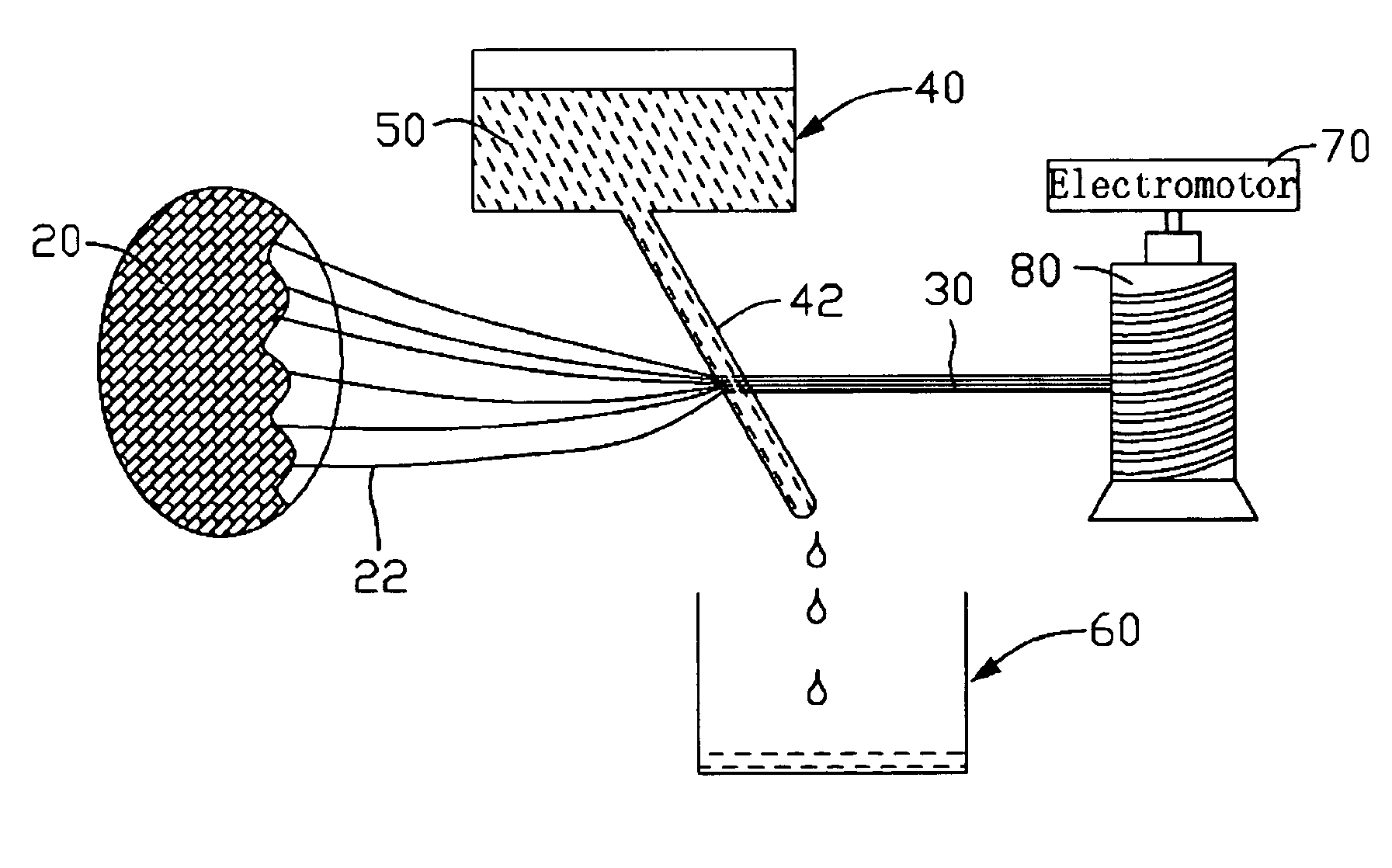

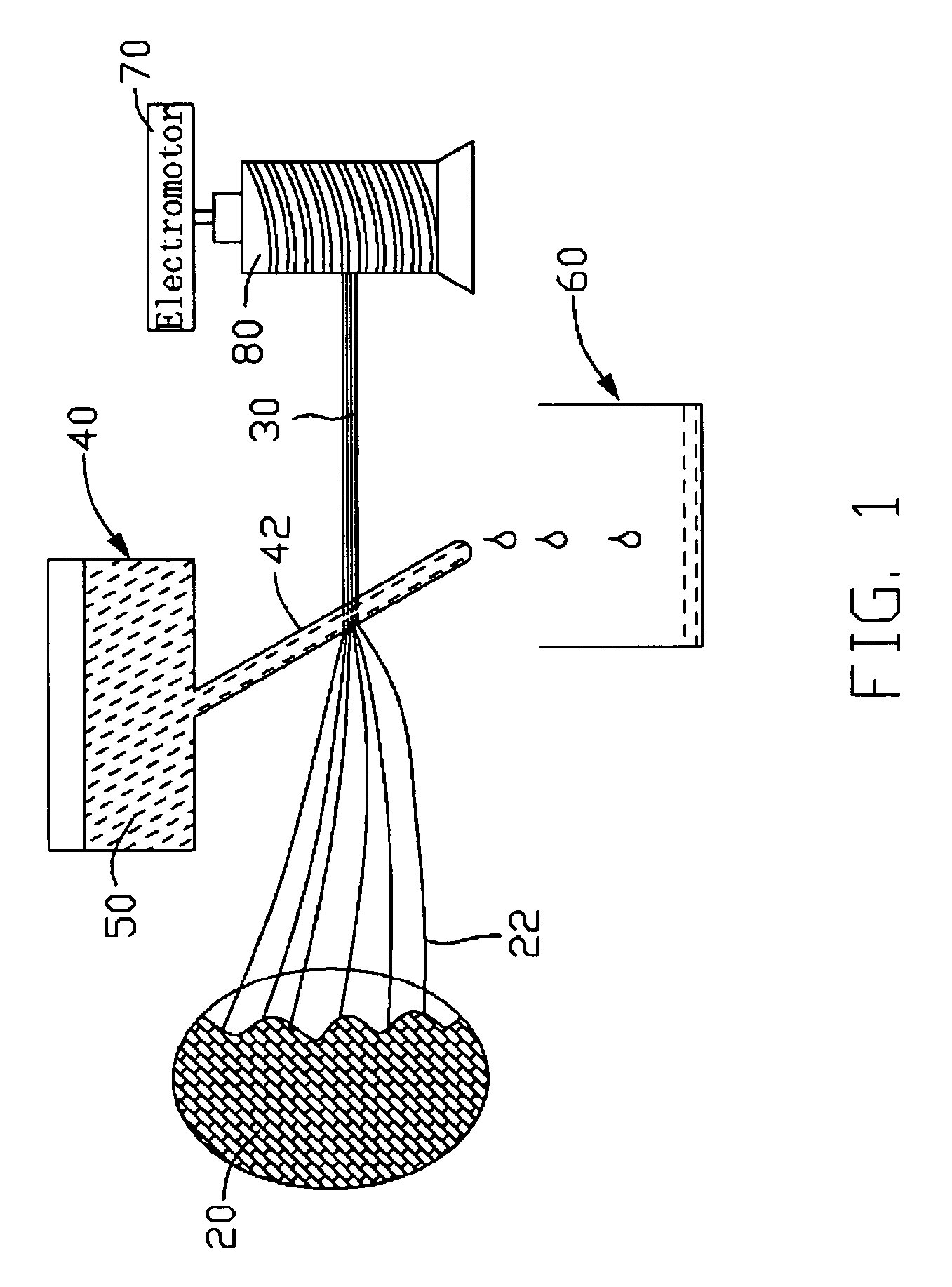

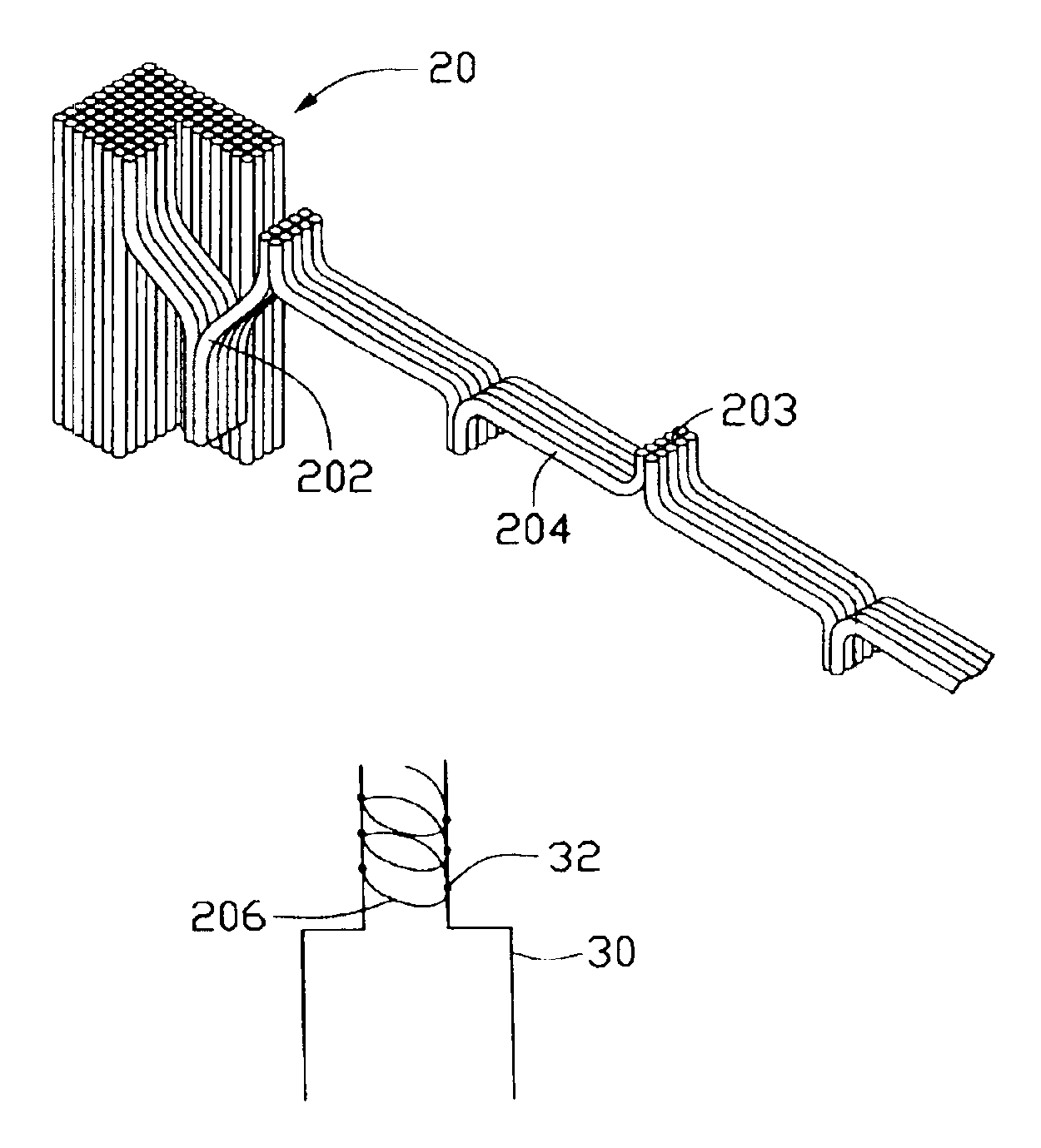

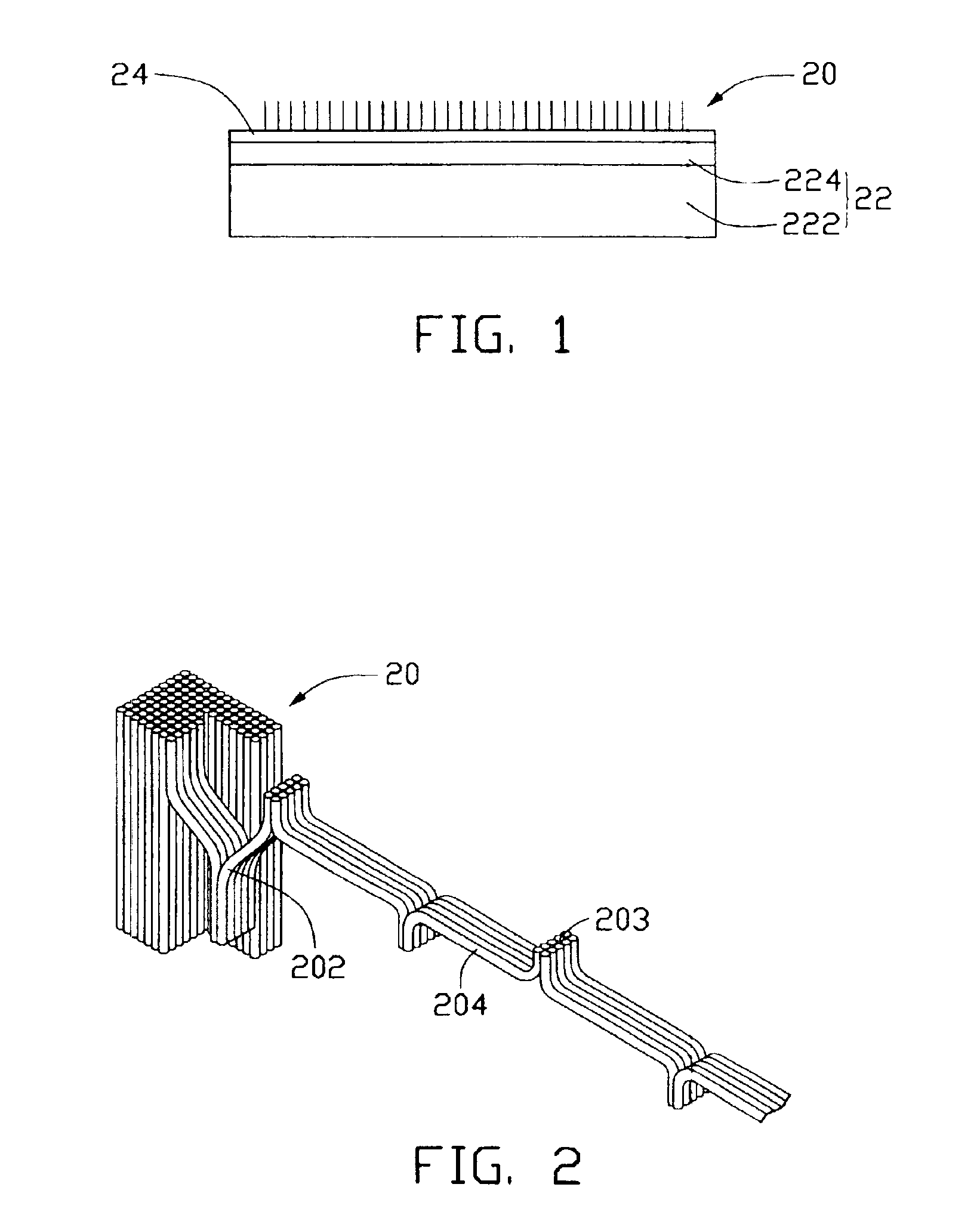

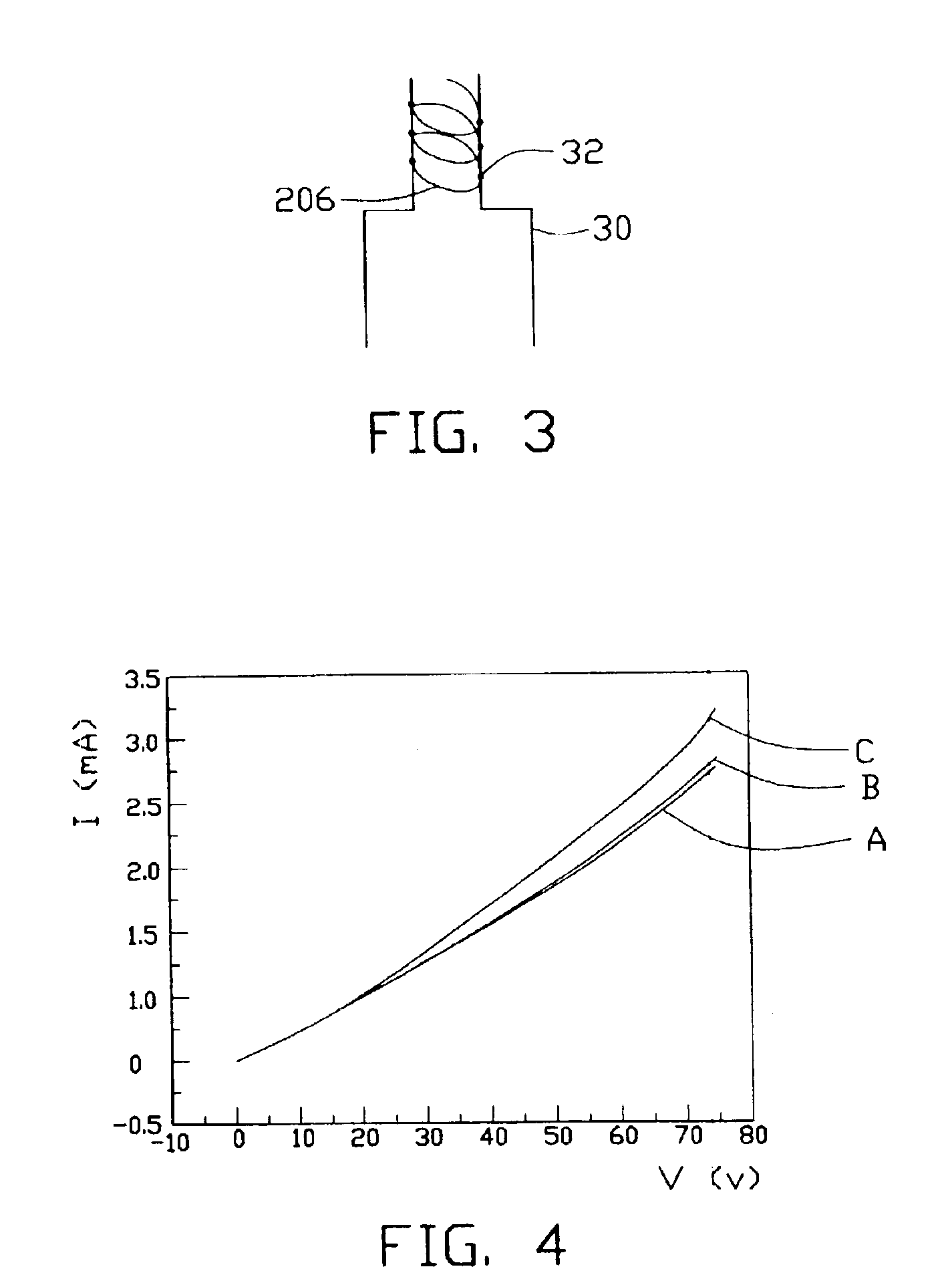

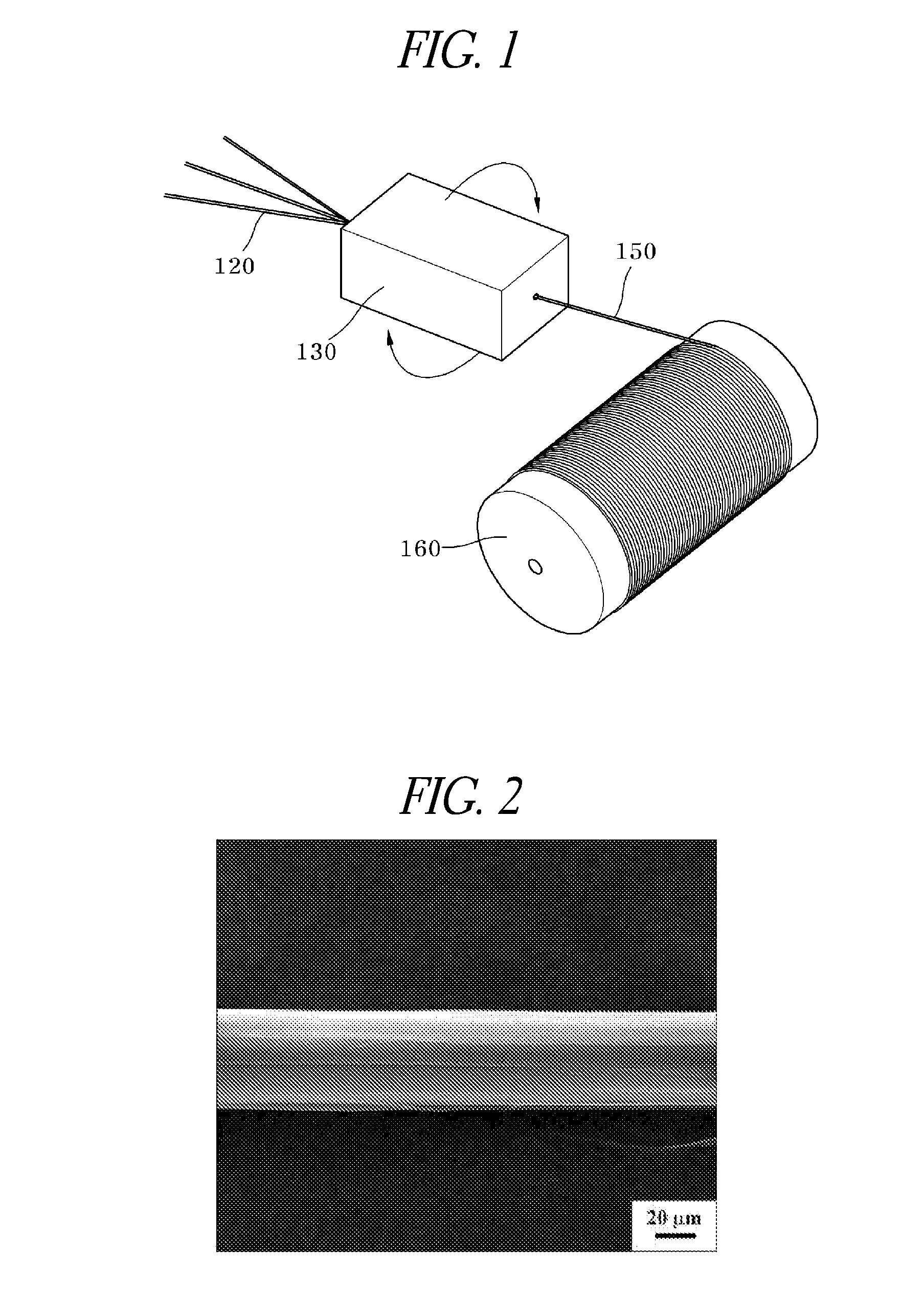

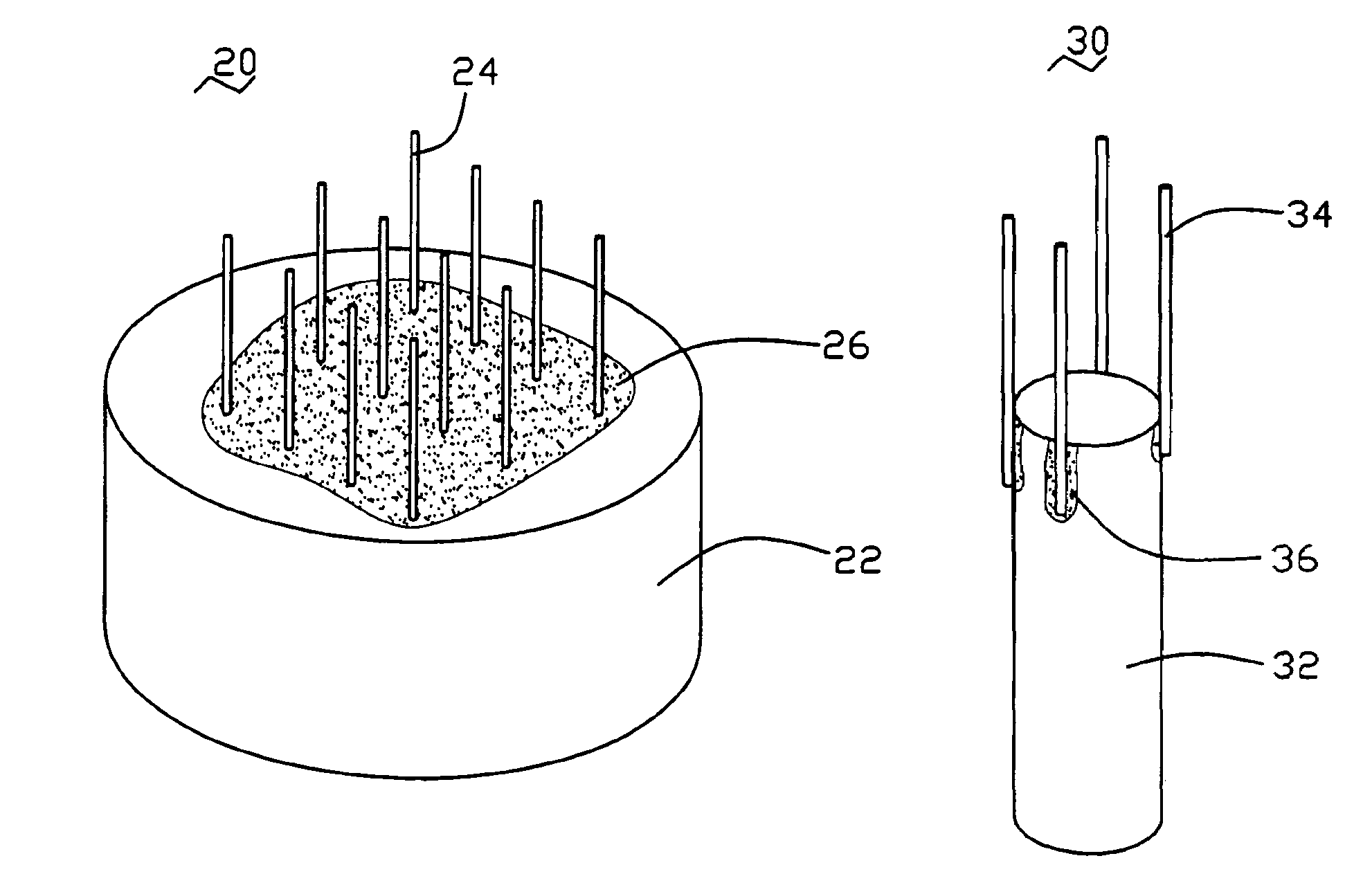

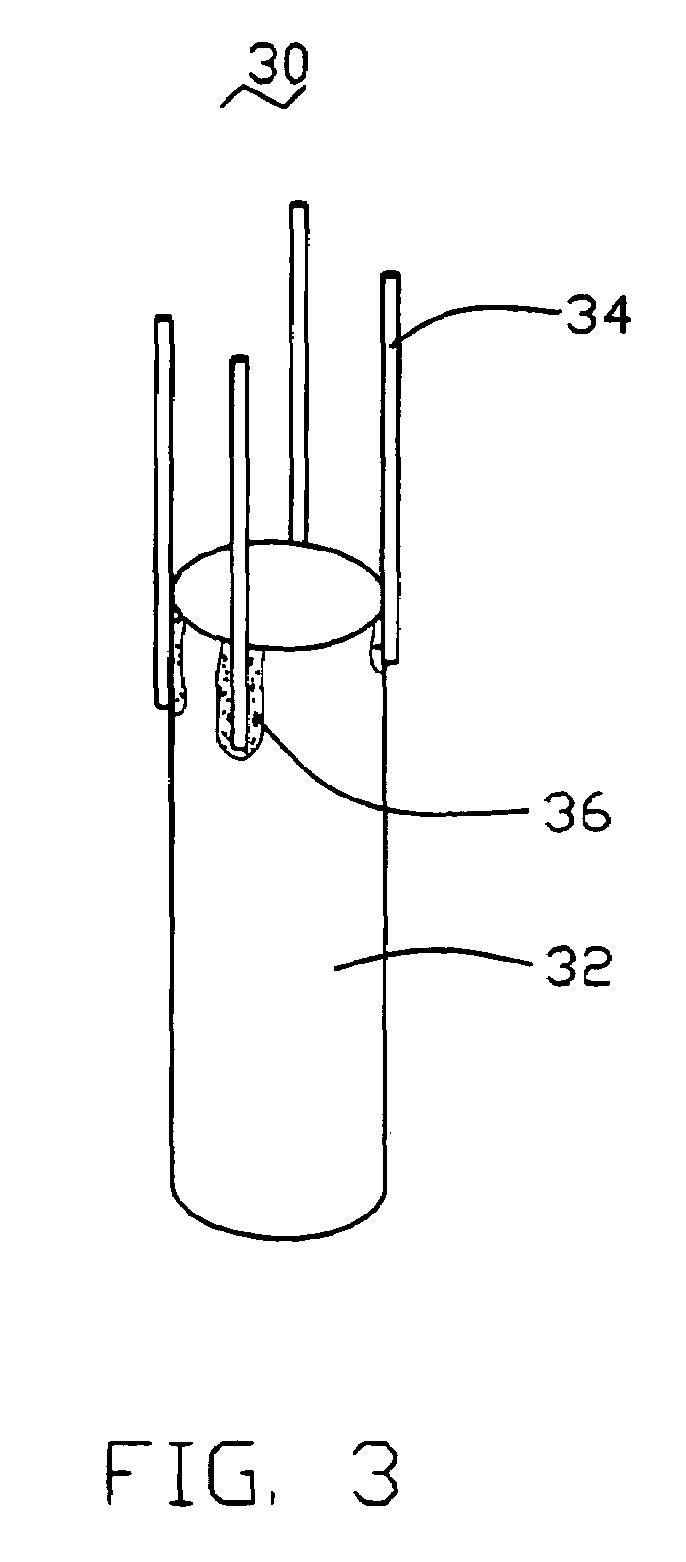

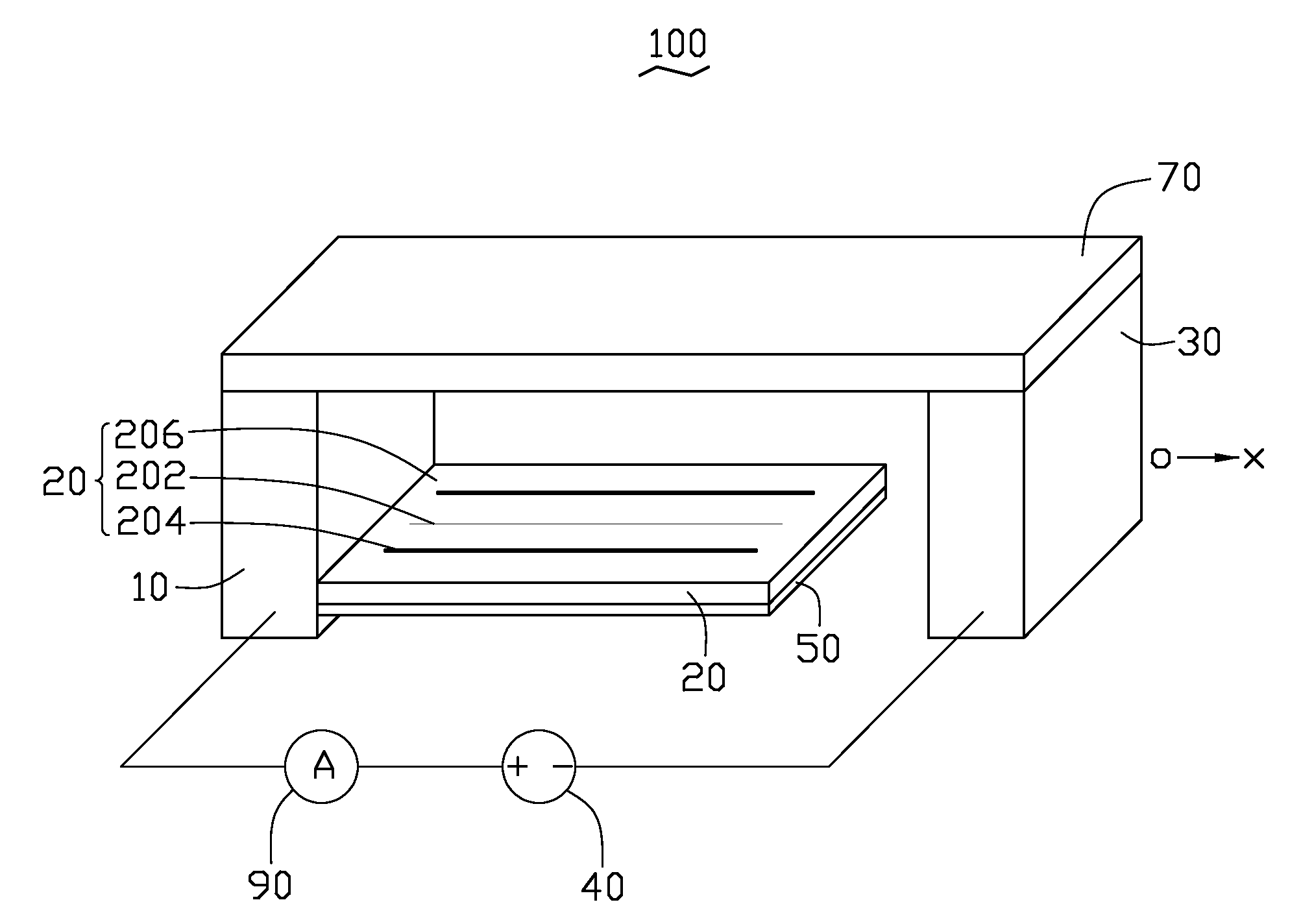

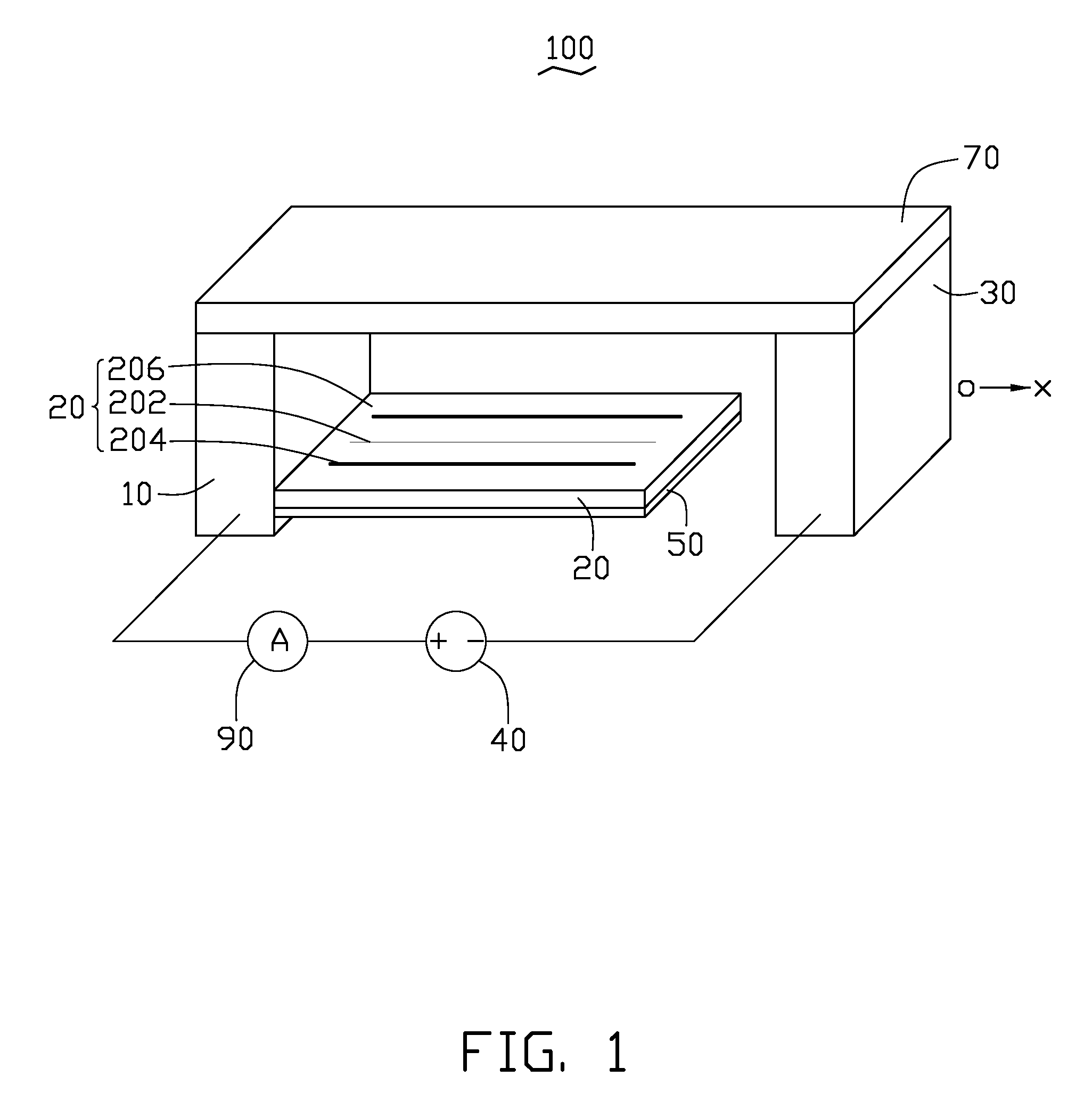

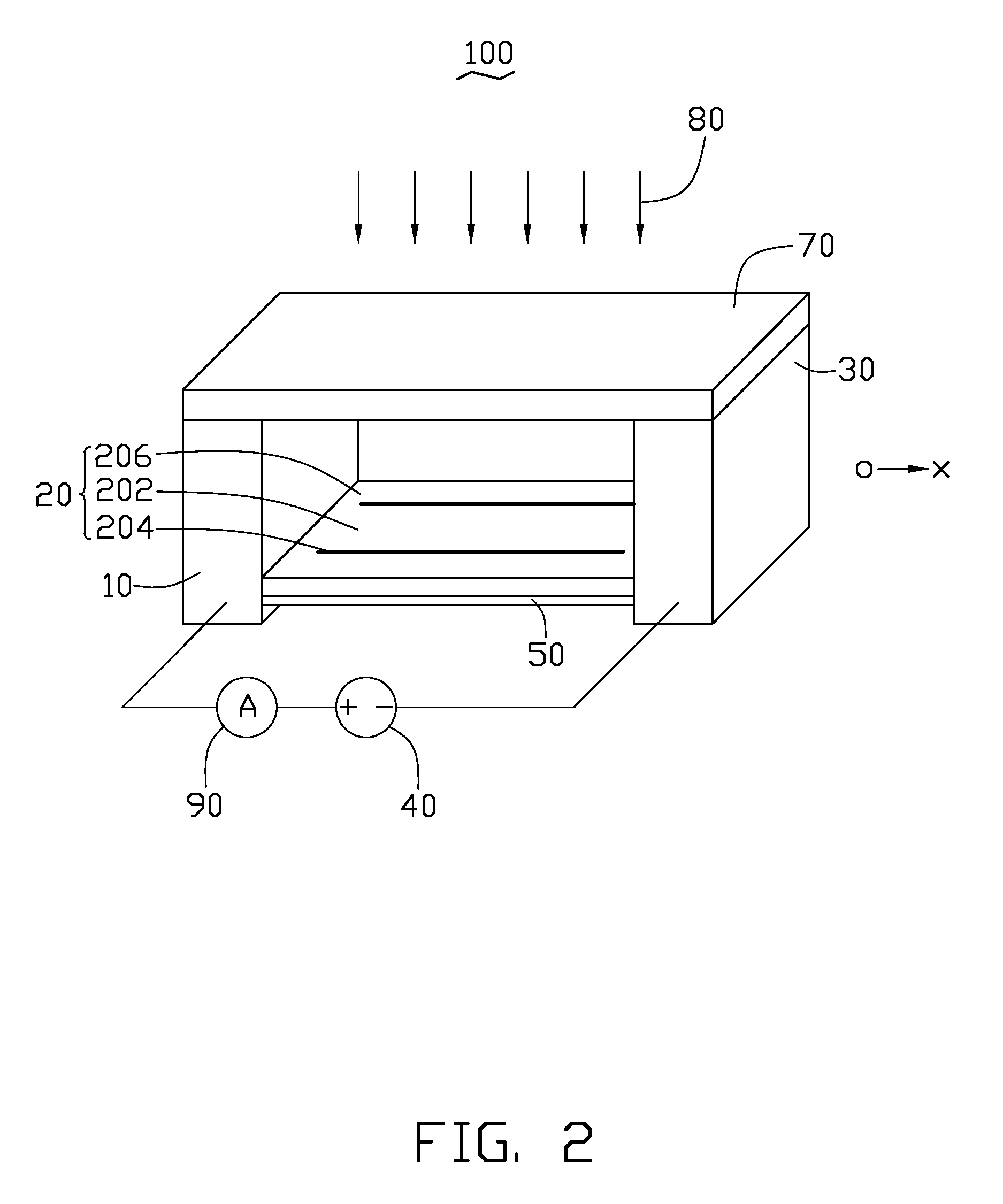

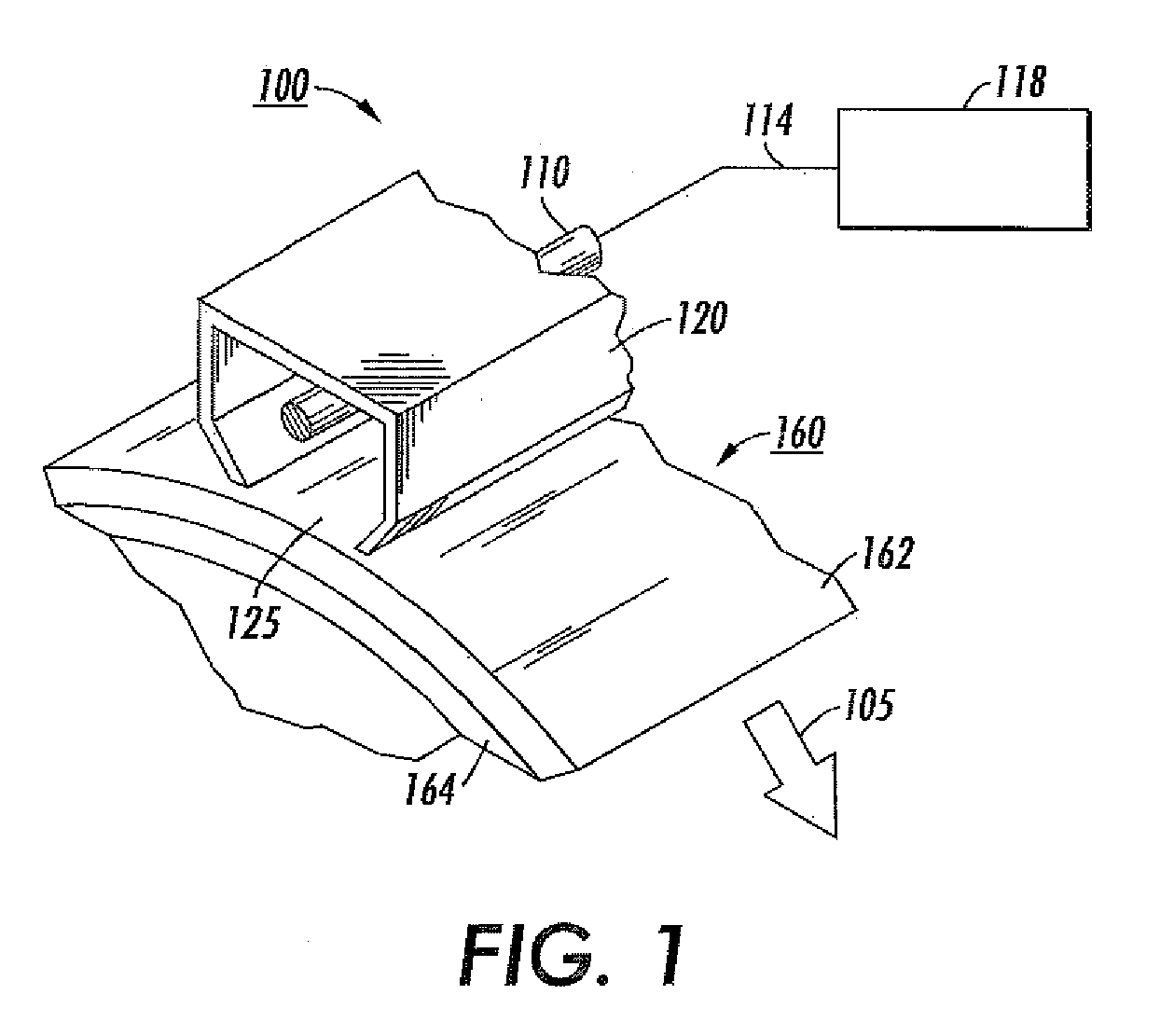

Method of manufacturing a light filament from carbon nanotubes

InactiveUS6957993B2Large specific surface areaIncreased durabilityMaterial nanotechnologyNanoinformaticsCarbon nanotube yarnCarbon nanotube fet

A light filament (206) formed from carbon nanotubes is characterized by high mechanical strength and durability at elevated temperatures, a high surface area to volume ratio, and high emissivity. Additionally, electrical resistance of the light filament does not increase with increasing temperature as much as electrical resistance of metallic light filaments. Accordingly, power consumption of the light filament is low at incandescent operating temperatures. A method for making a light filament made of carbon nanotubes includes the steps of: forming an array of carbon nanotubes (20); pulling out carbon nanotube yarn (204) from the carbon nanotube array; and winding the yarn between two leads (30) functioning as electrodes to form the light filament.

Owner:HON HAI PRECISION IND CO LTD +1

Method for making carbon nanotube-based device

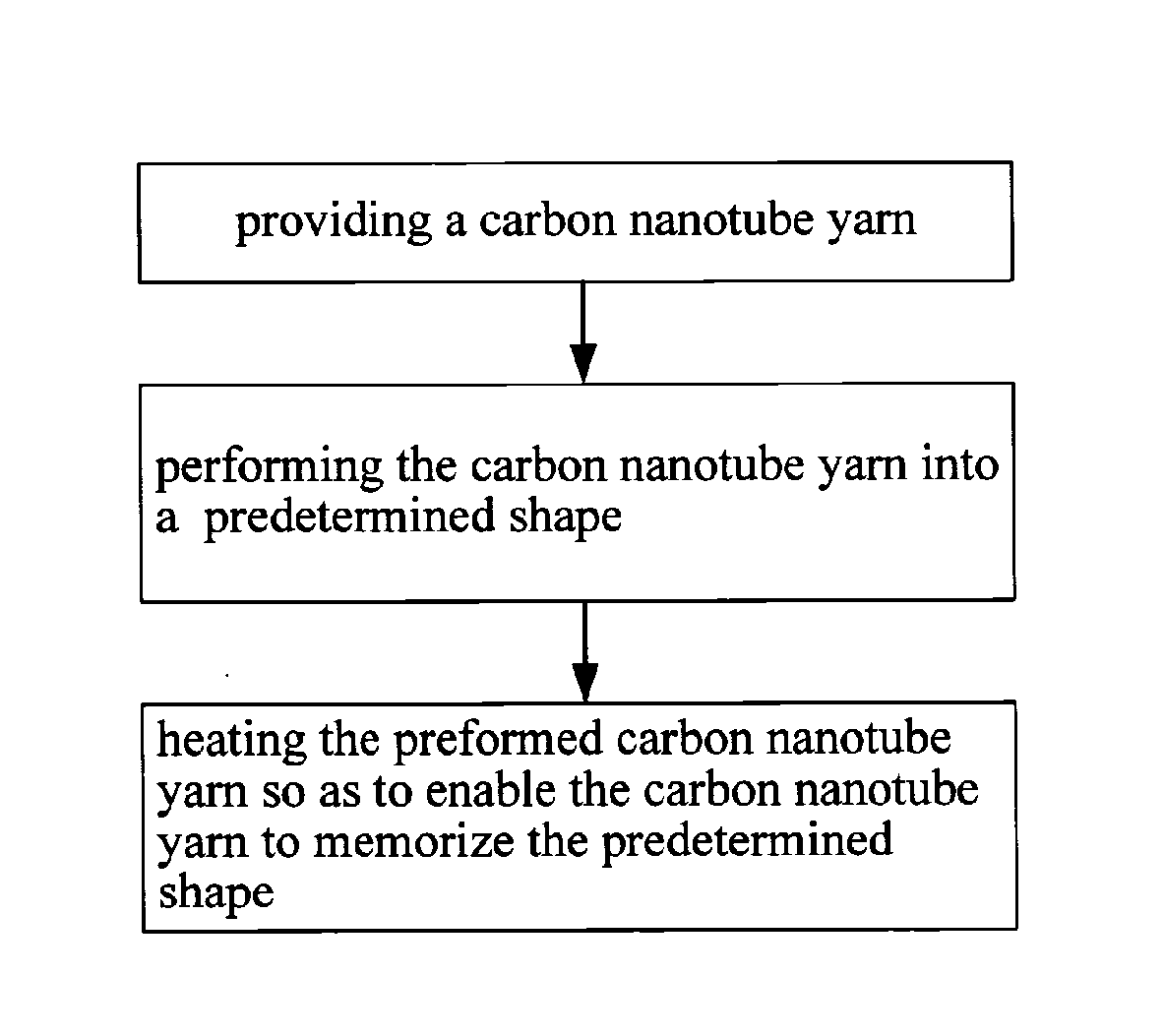

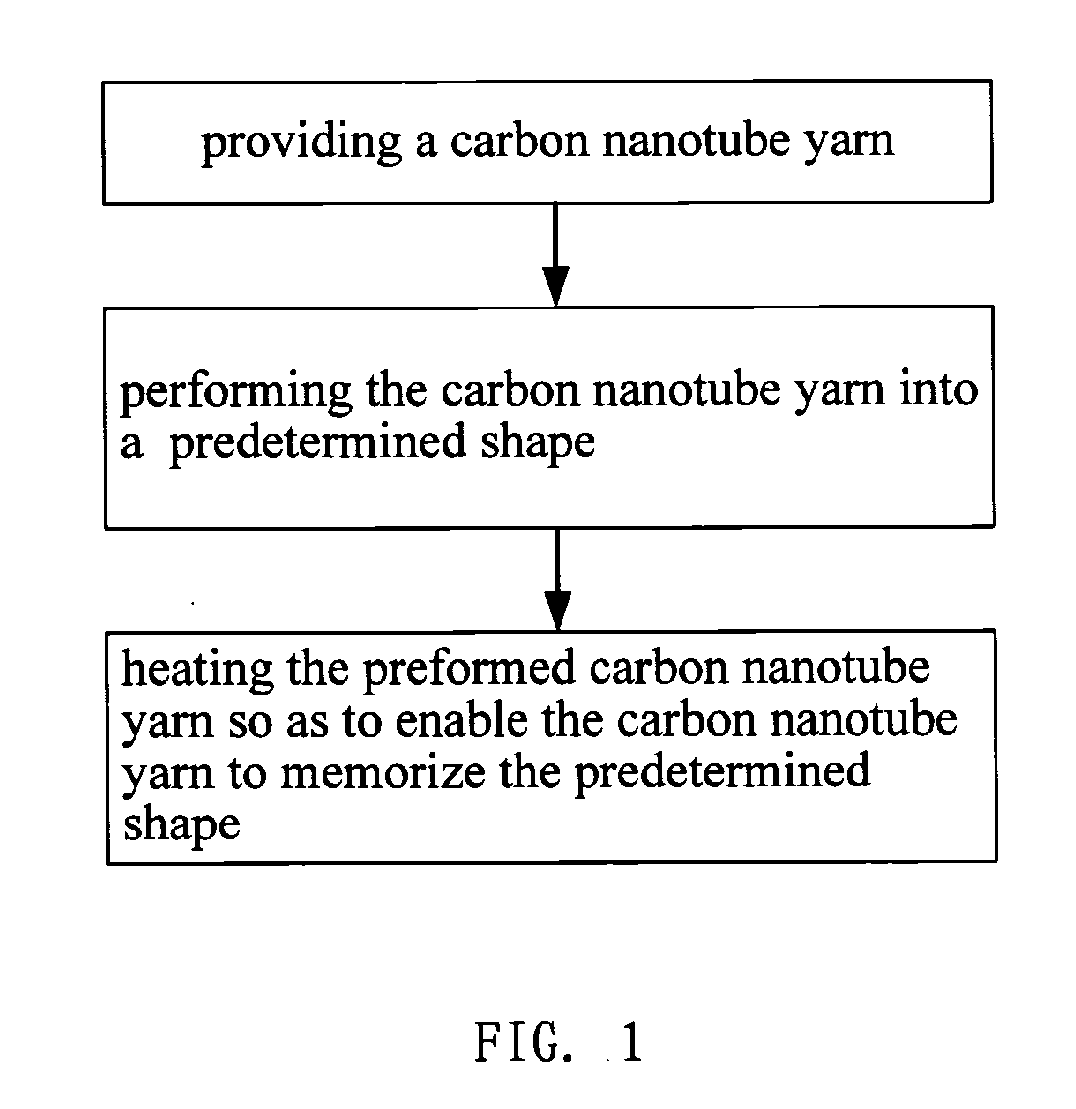

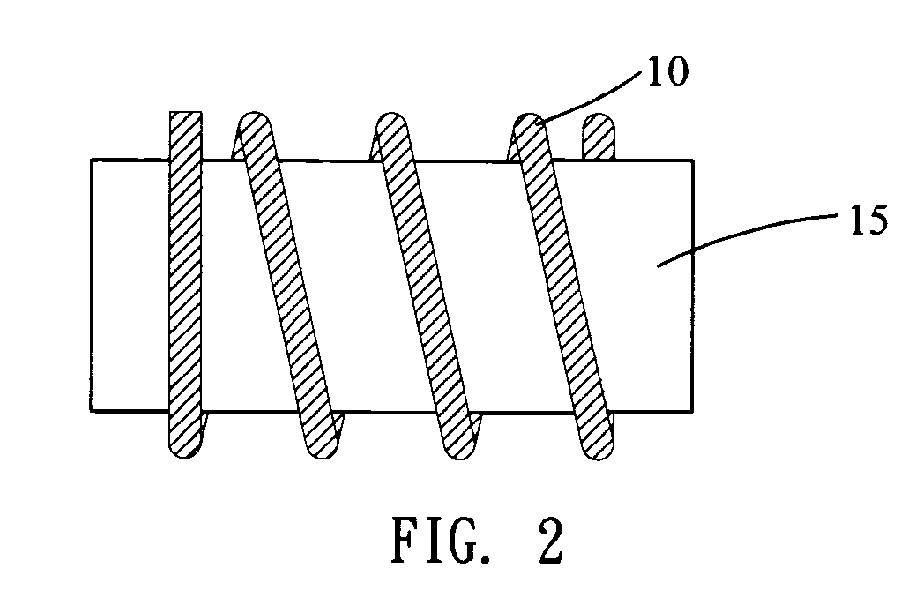

ActiveUS20070237952A1High mechanical strengthNanostructure manufactureElectric discharge heatingCarbon nanotube yarn

A method for making a carbon nanotube-based device includes the steps of: providing a carbon nanotube yarn; preforming the carbon nanotube yarn into a predetermined shape; and heating the preformed carbon nanotube yarn so as to enable the carbon nanotube yarn to memorize the predetermined shape.

Owner:TSINGHUA UNIV +1

Carbon nanotube yarn and method for making the same

A carbon nanotube yarn includes a number of carbon nanotube yarn strings bound together, and each of the carbon nanotube yarn strings includes a number of carbon nanotube bundles that are joined end to end by van der Waals attractive force, and each of the carbon nanotube bundles includes a number of carbon nanotubes substantially parallel to each other. A method for making the carbon nanotube yarn includes soaking the at least one carbon nanotube yarn string drawn out from a carbon nanotube array in an organic solvent to shrink it and then collecting it.

Owner:TSINGHUA UNIV +1

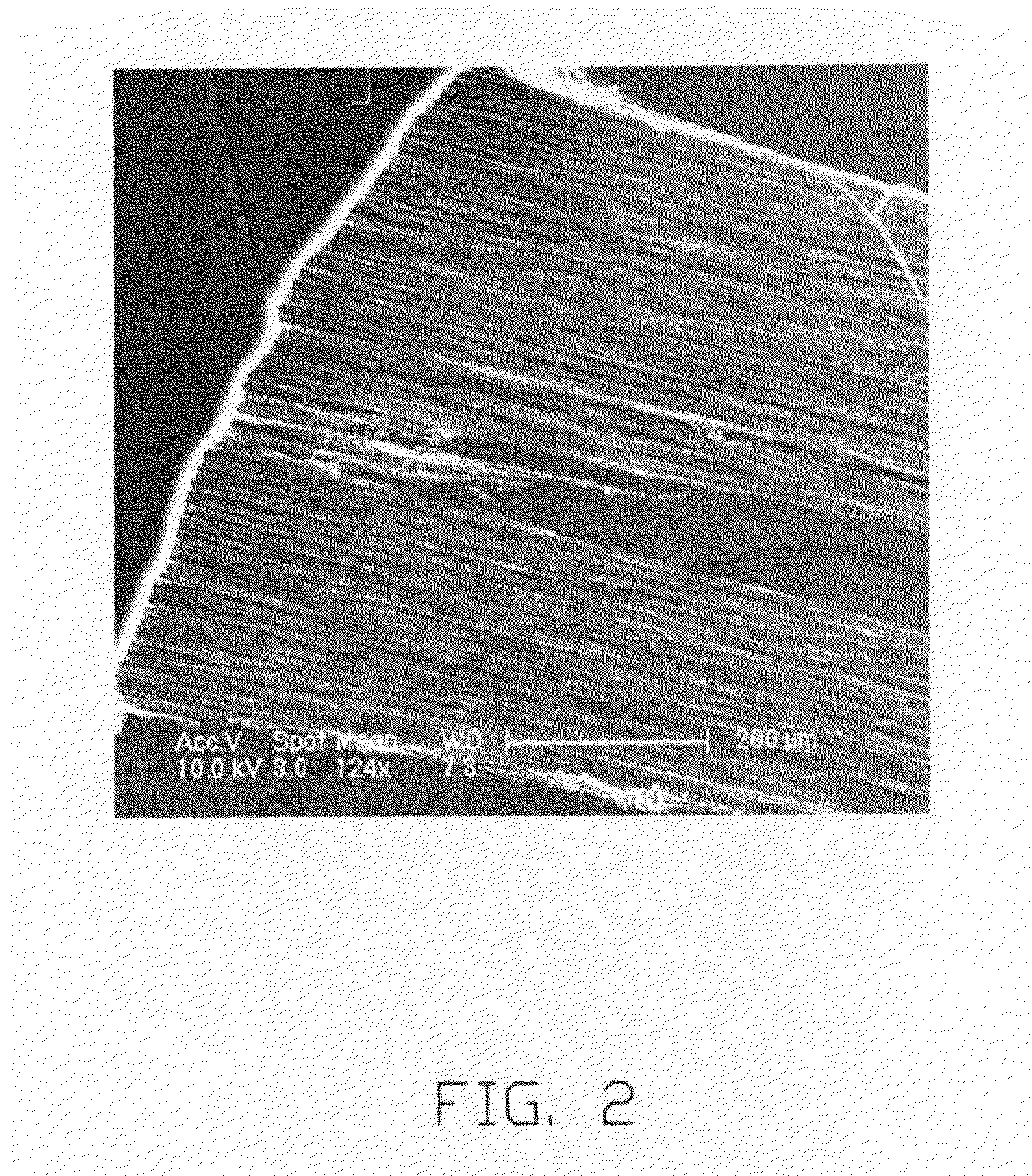

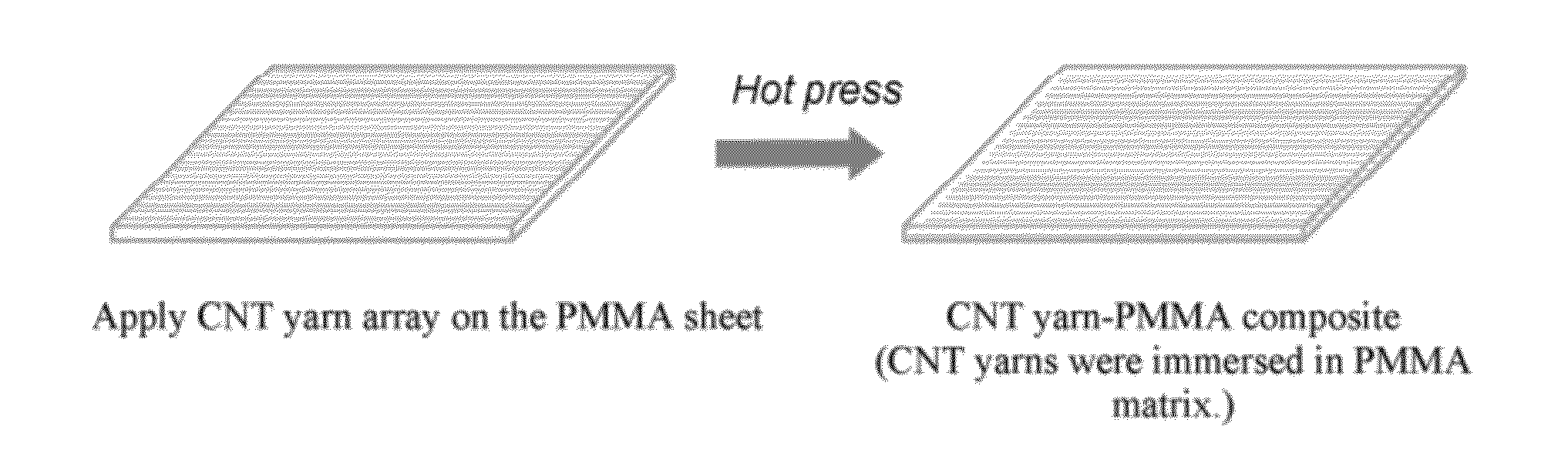

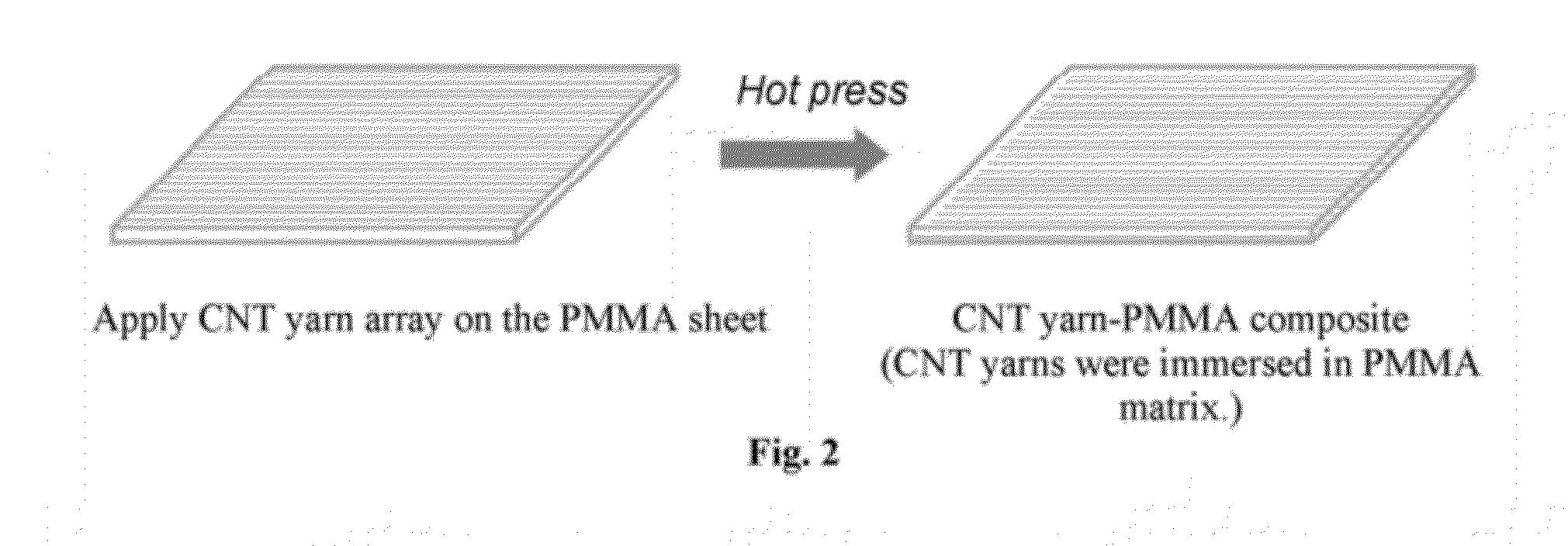

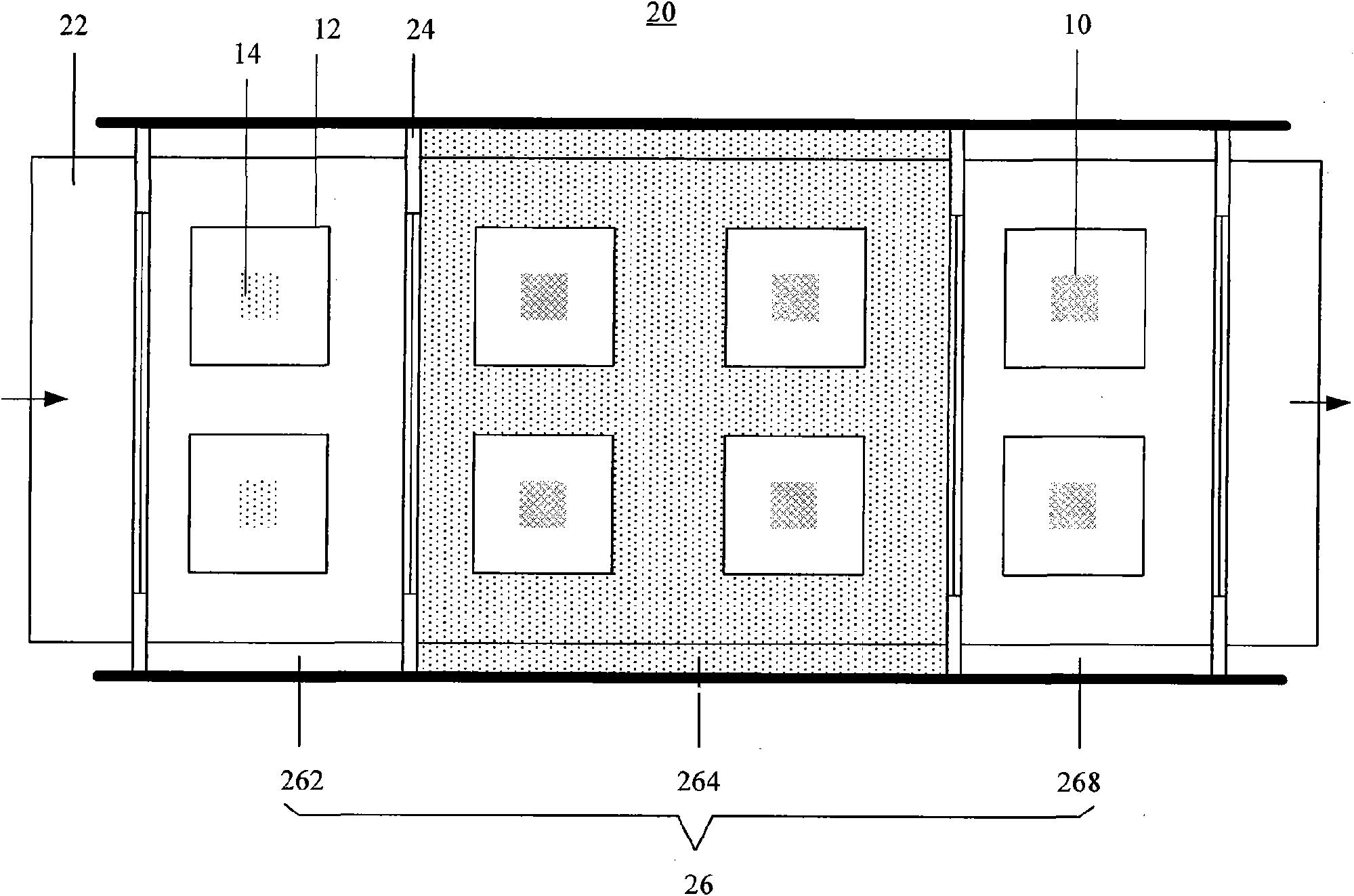

Composite Materials Reinforced with Carbon Nanotube Yarns

ActiveUS20120085970A1Material nanotechnologyNon-fibrous pulp additionCarbon nanotube yarnMaterials science

Composite materials are provided that include one or more CNT yarns embedded in a matrix material. The composite materials may be transparent. Methods for making the composite materials are also provided. The composite materials may be made by arranging at least one CNT yarn into a desired pattern and embedding the at least one CNT yarn into a matrix material.

Owner:FLORIDA STATE UNIV RES FOUND INC

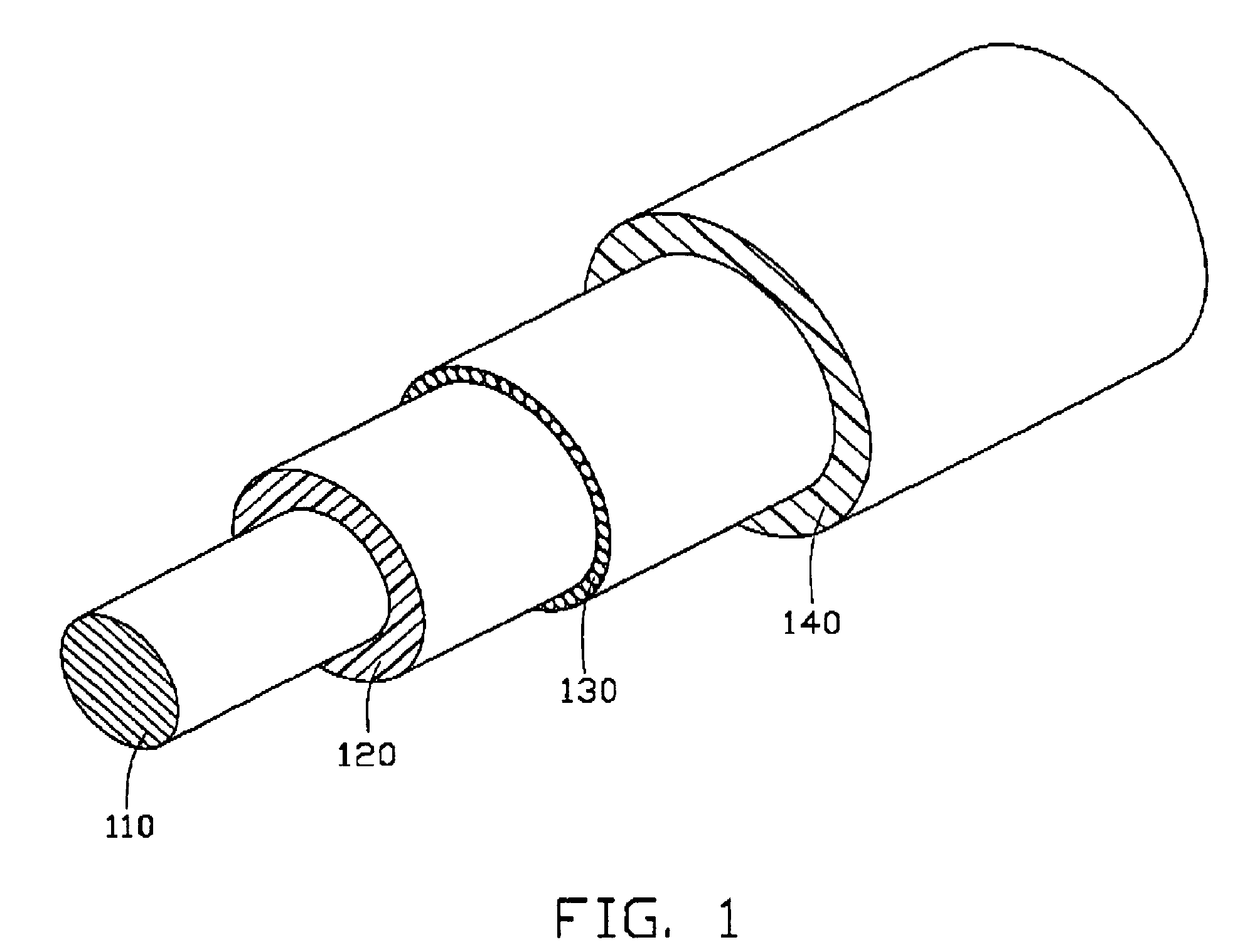

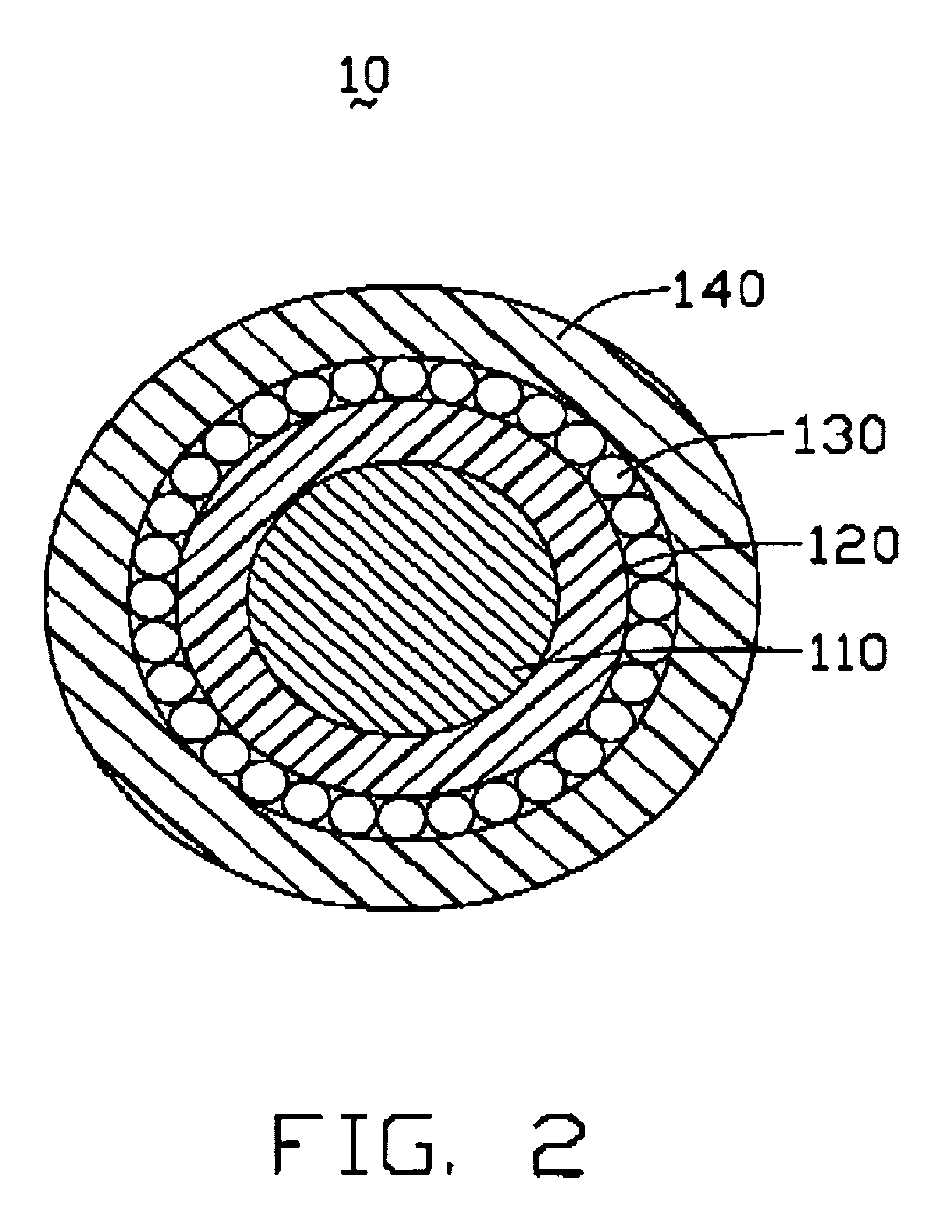

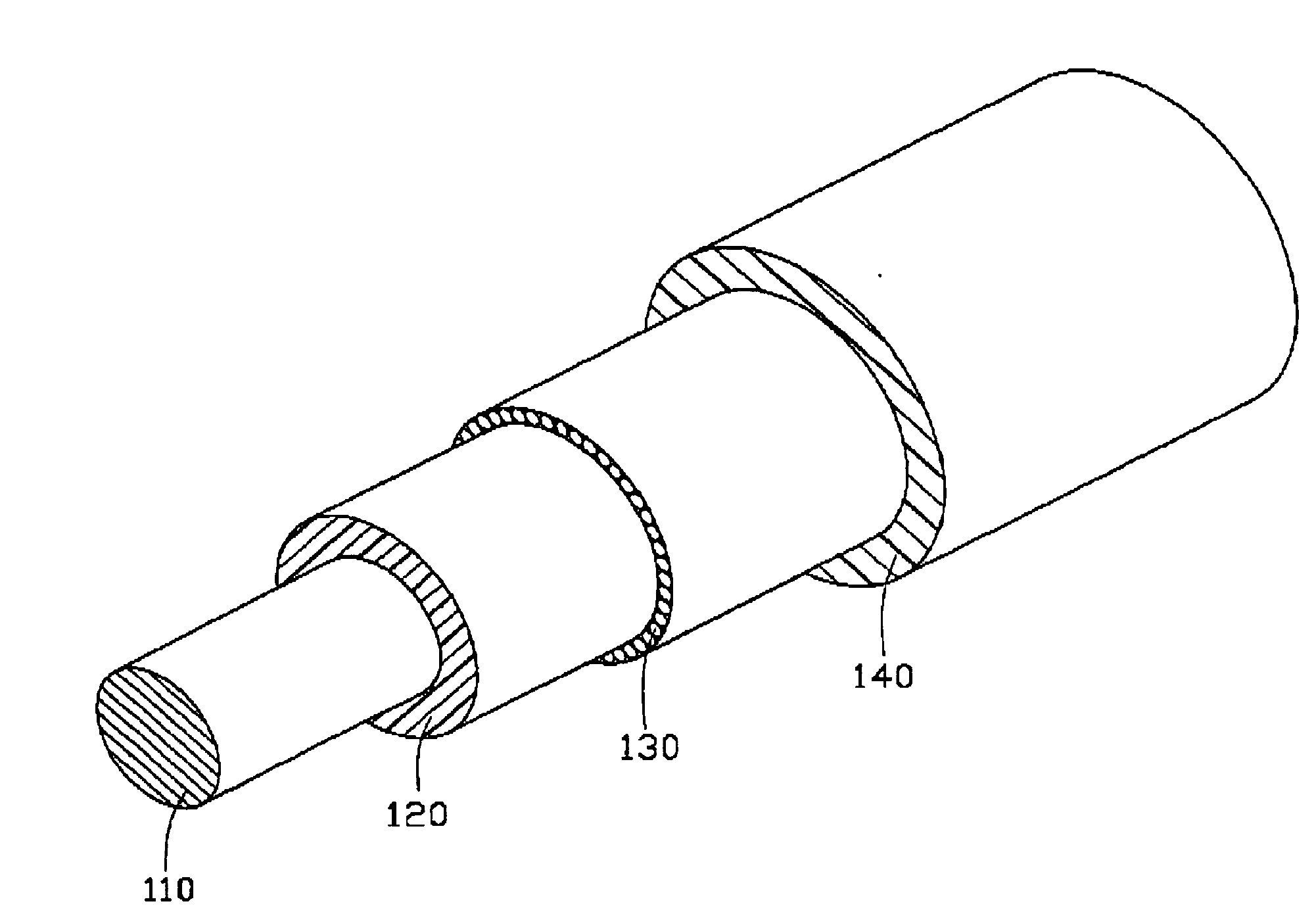

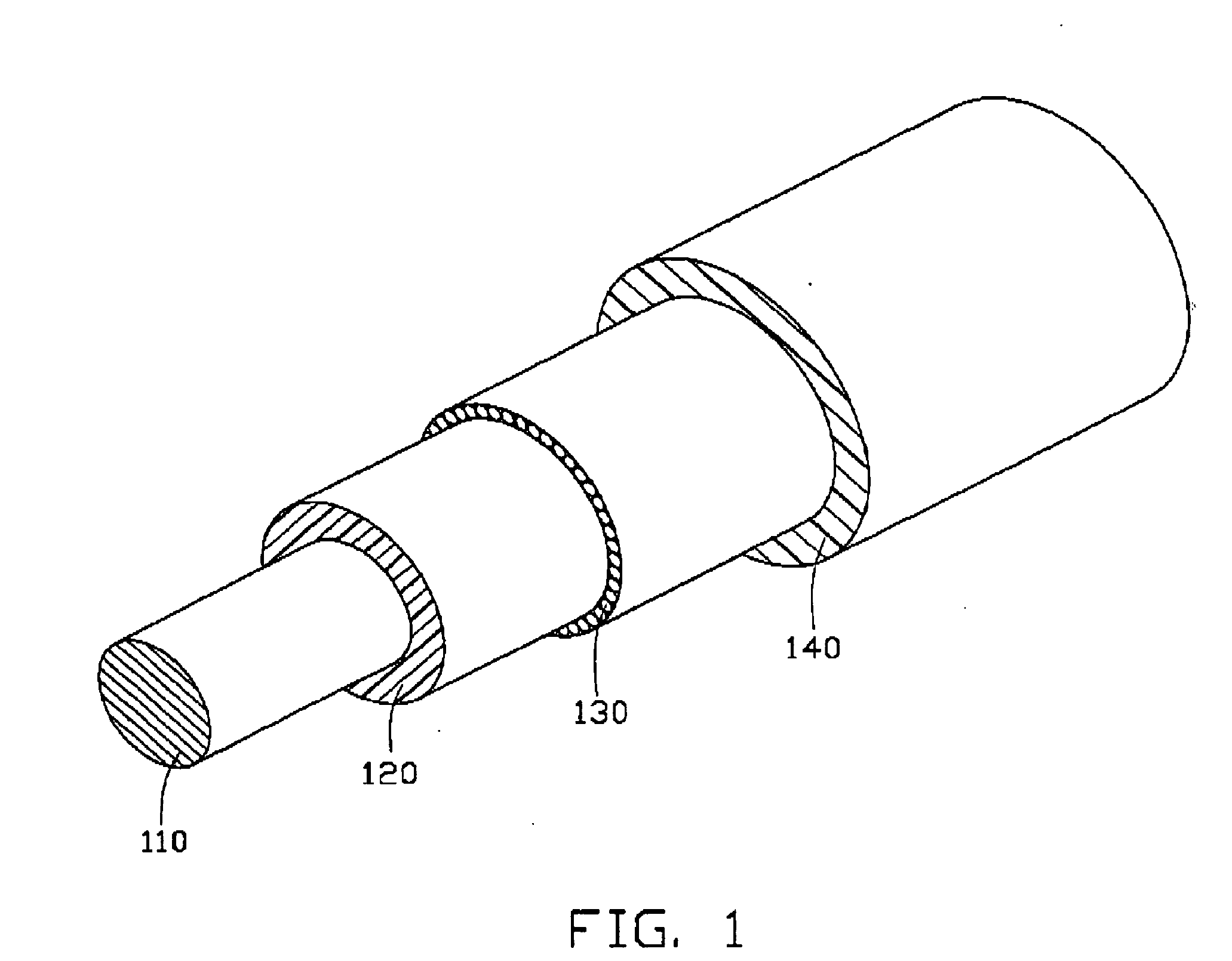

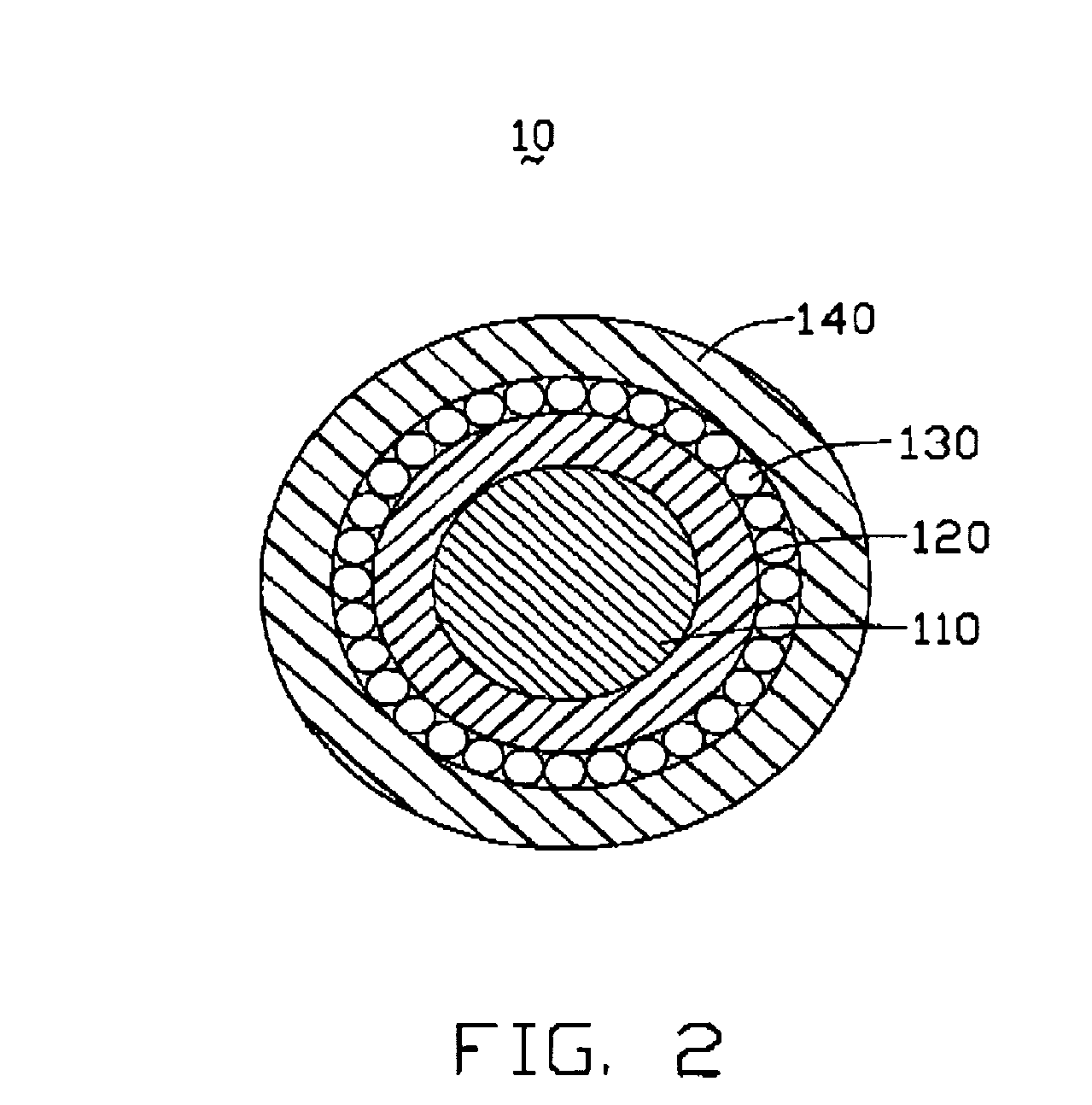

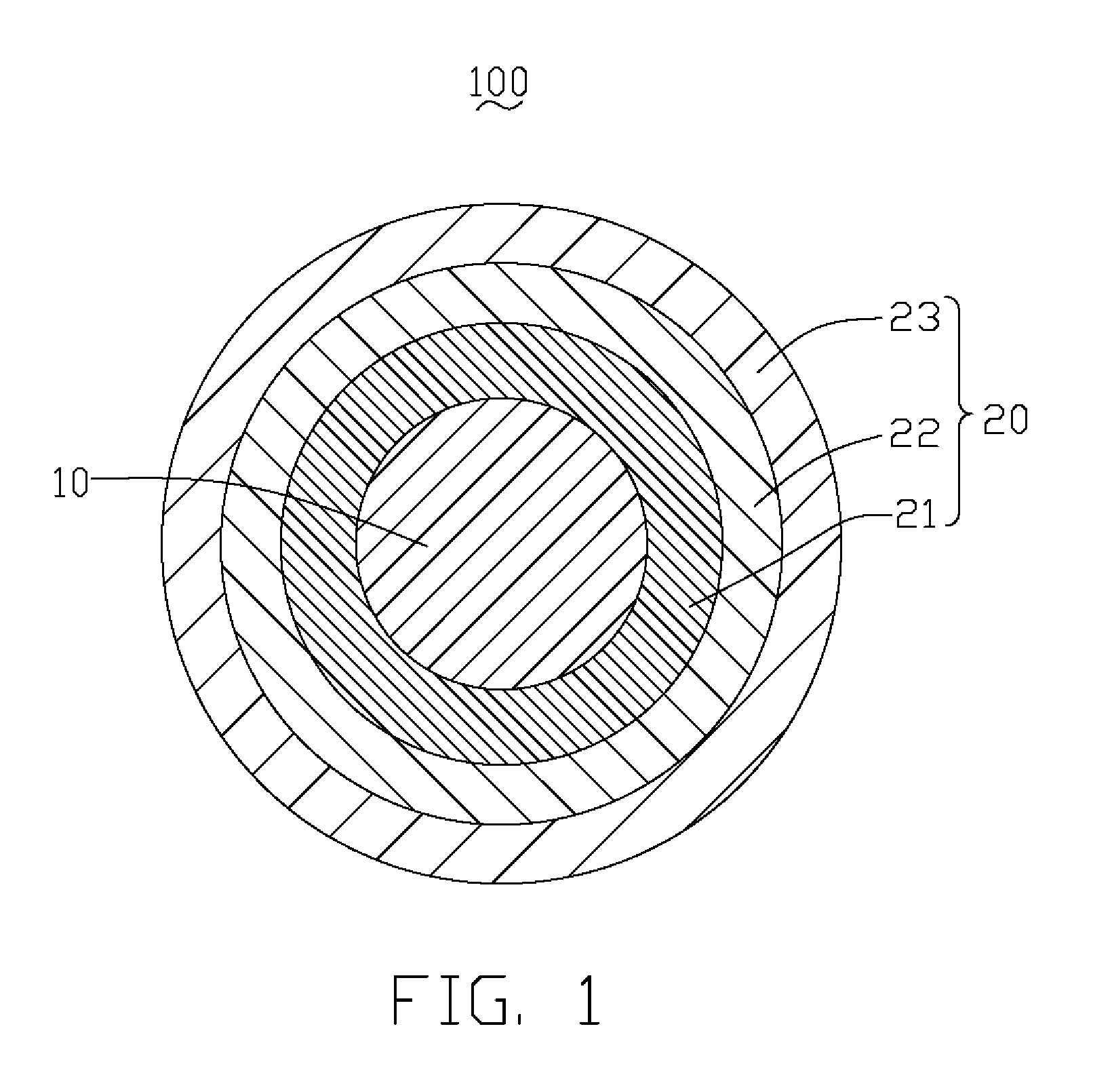

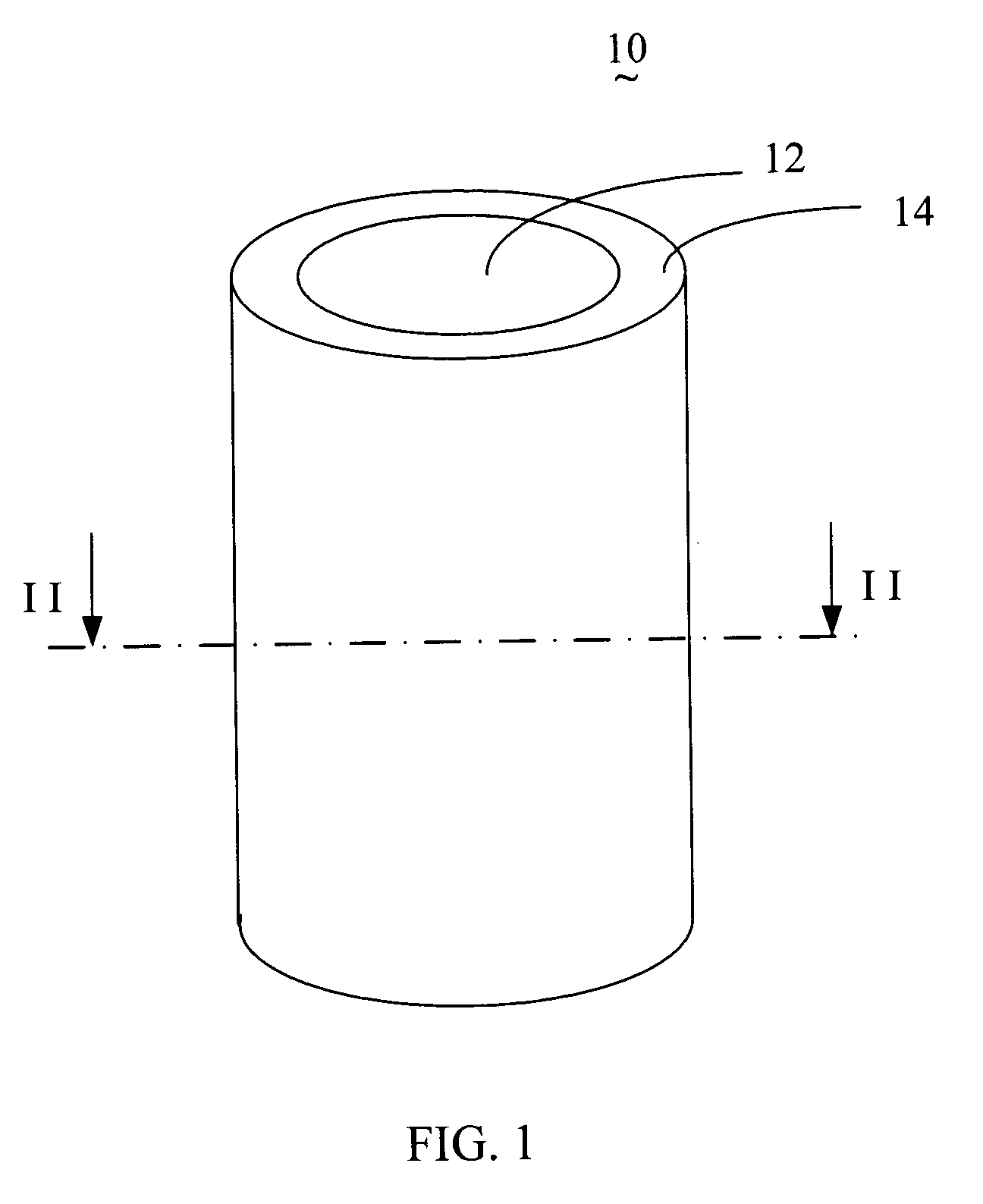

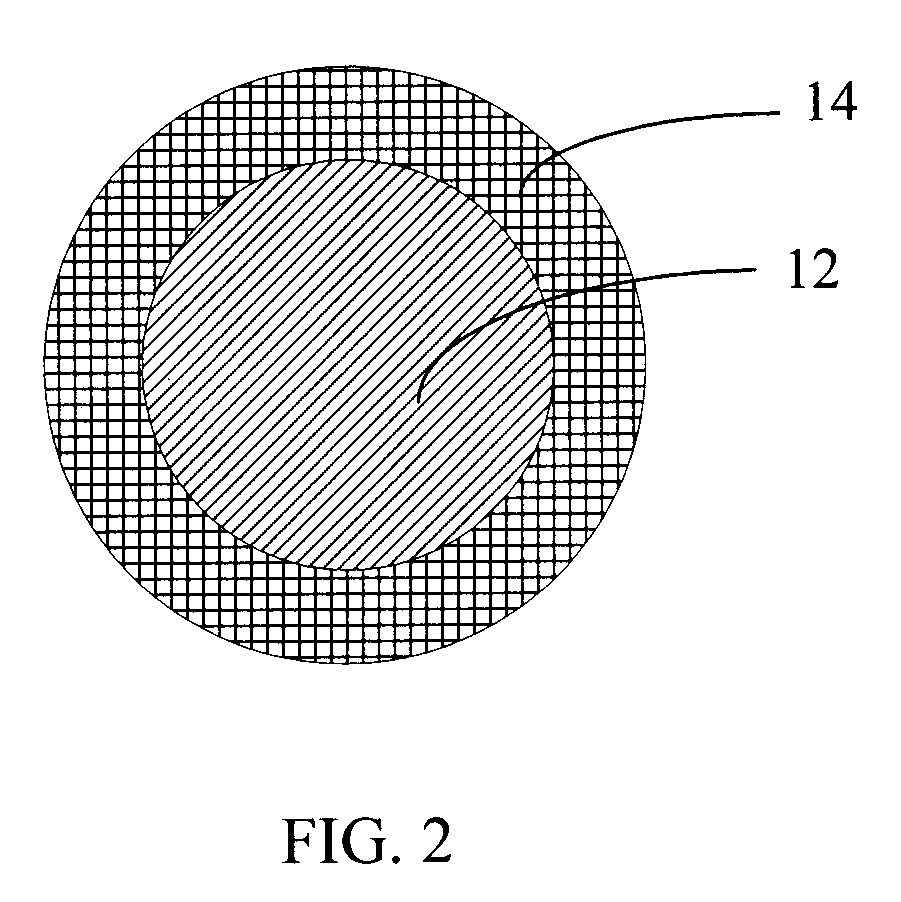

Coaxial cable

ActiveUS7449631B2Improve effectivenessSuitable for mass productionCable conductor constructionMagnetic/electric field screeningCoaxial cableCarbon nanotube yarn

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a number of carbon nanotube yarns.

Owner:TSINGHUA UNIV +1

Coaxial cable

ActiveUS20080251270A1Improve effectivenessSuitable for low-cost mass productionCable conductor constructionMagnetic/electric field screeningCoaxial cableCarbon nanotube yarn

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a number of carbon nanotube yarns.

Owner:TSINGHUA UNIV +1

Electrical composite conductor and electrical cable using the same

InactiveUS7345242B2Good electrical conductorImprove mechanical propertiesPlastic/resin/waxes insulatorsConductive materialElectrical conductorCarbon nanotube yarn

Owner:HON HAI PRECISION IND CO LTD

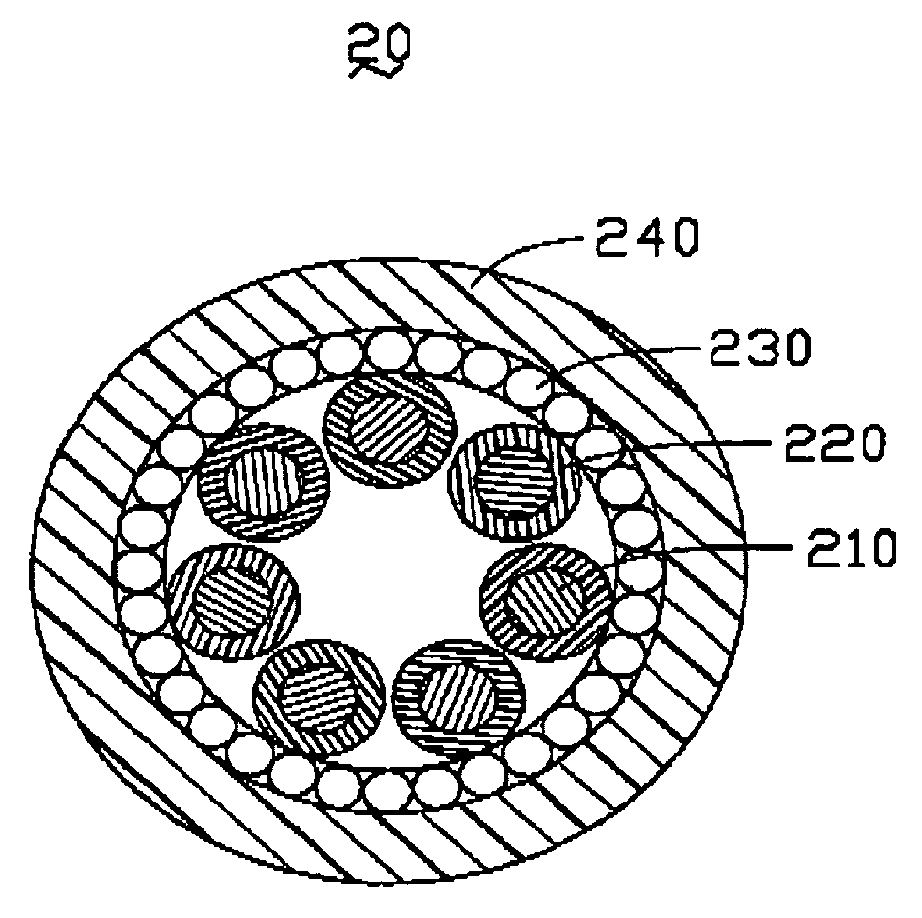

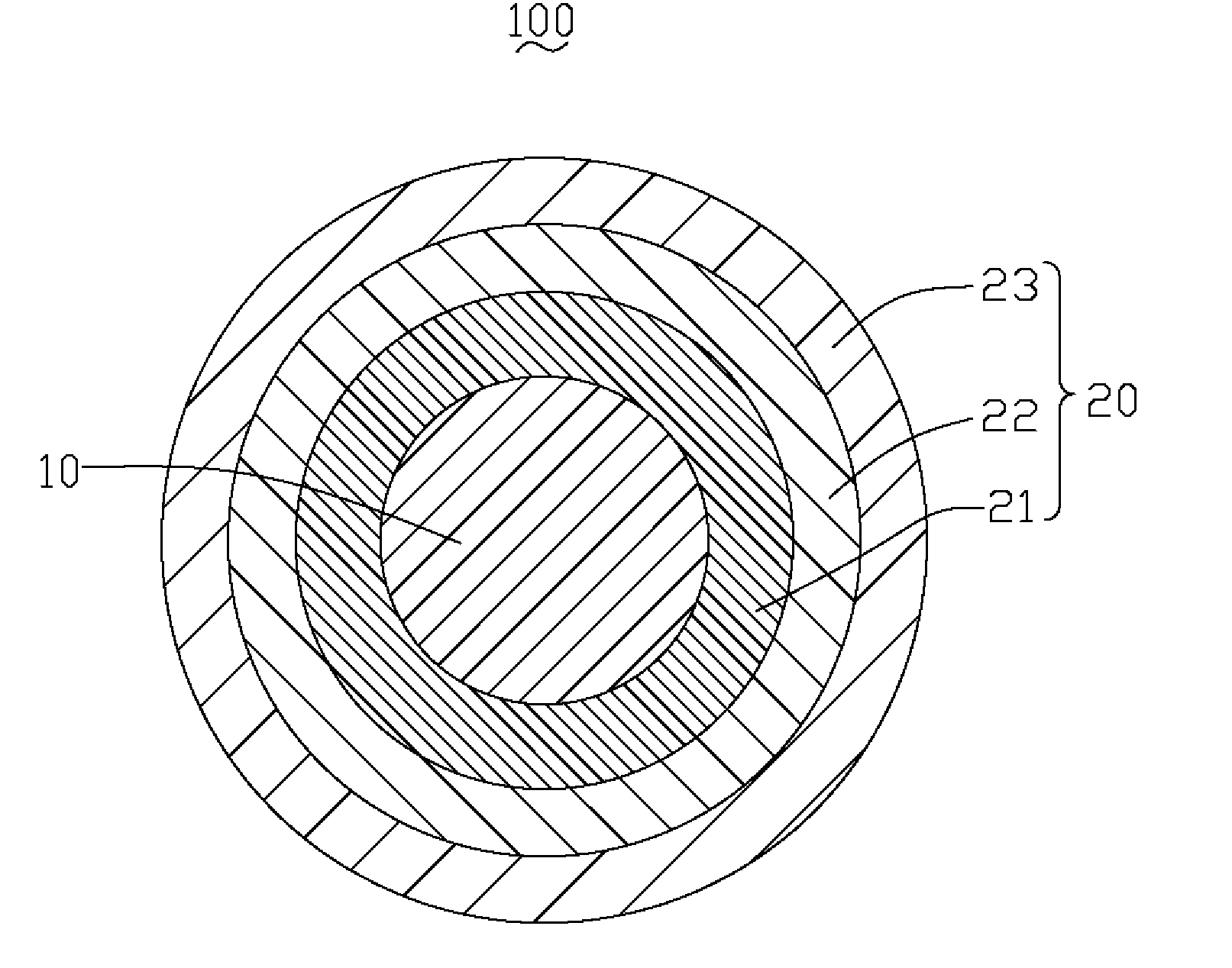

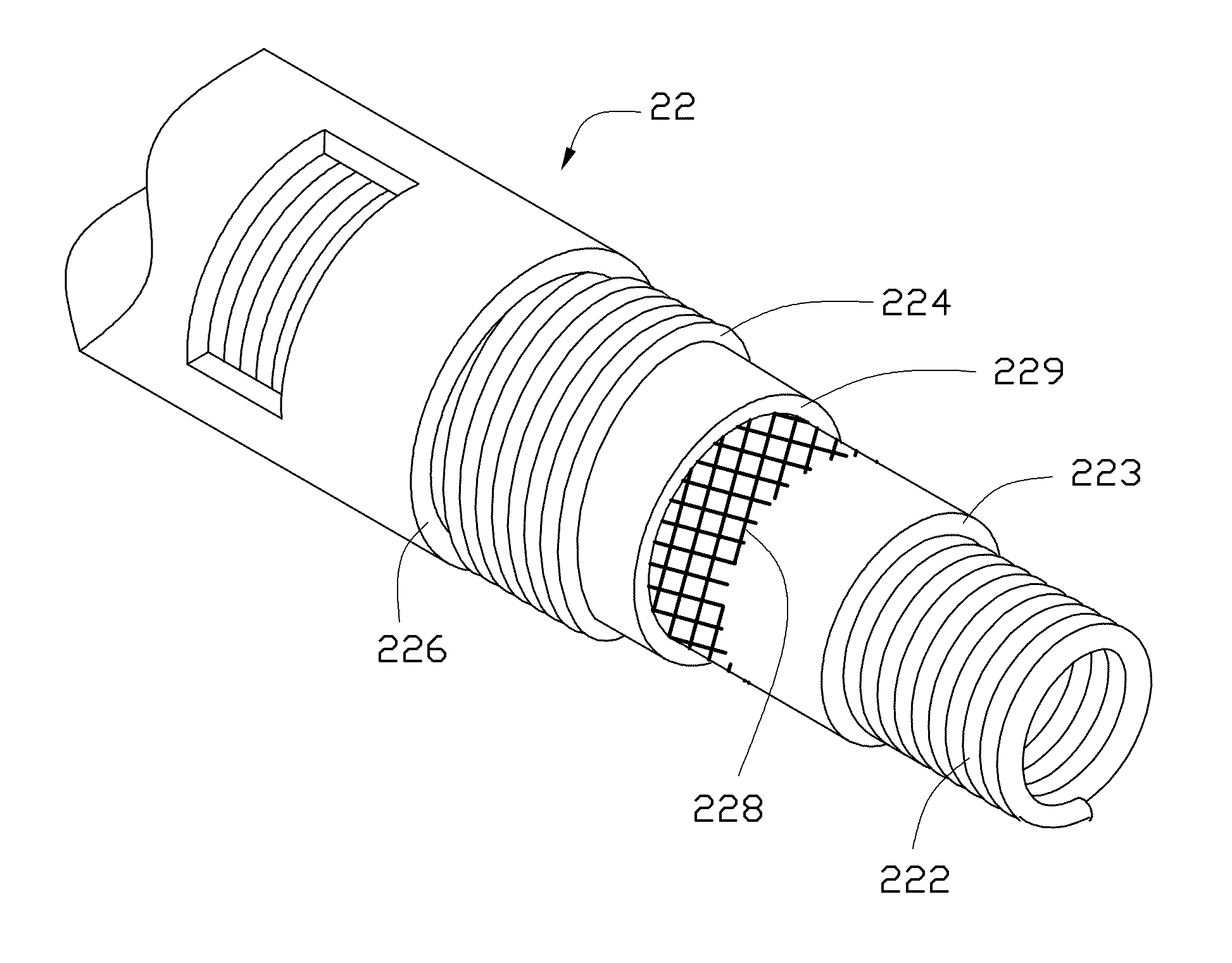

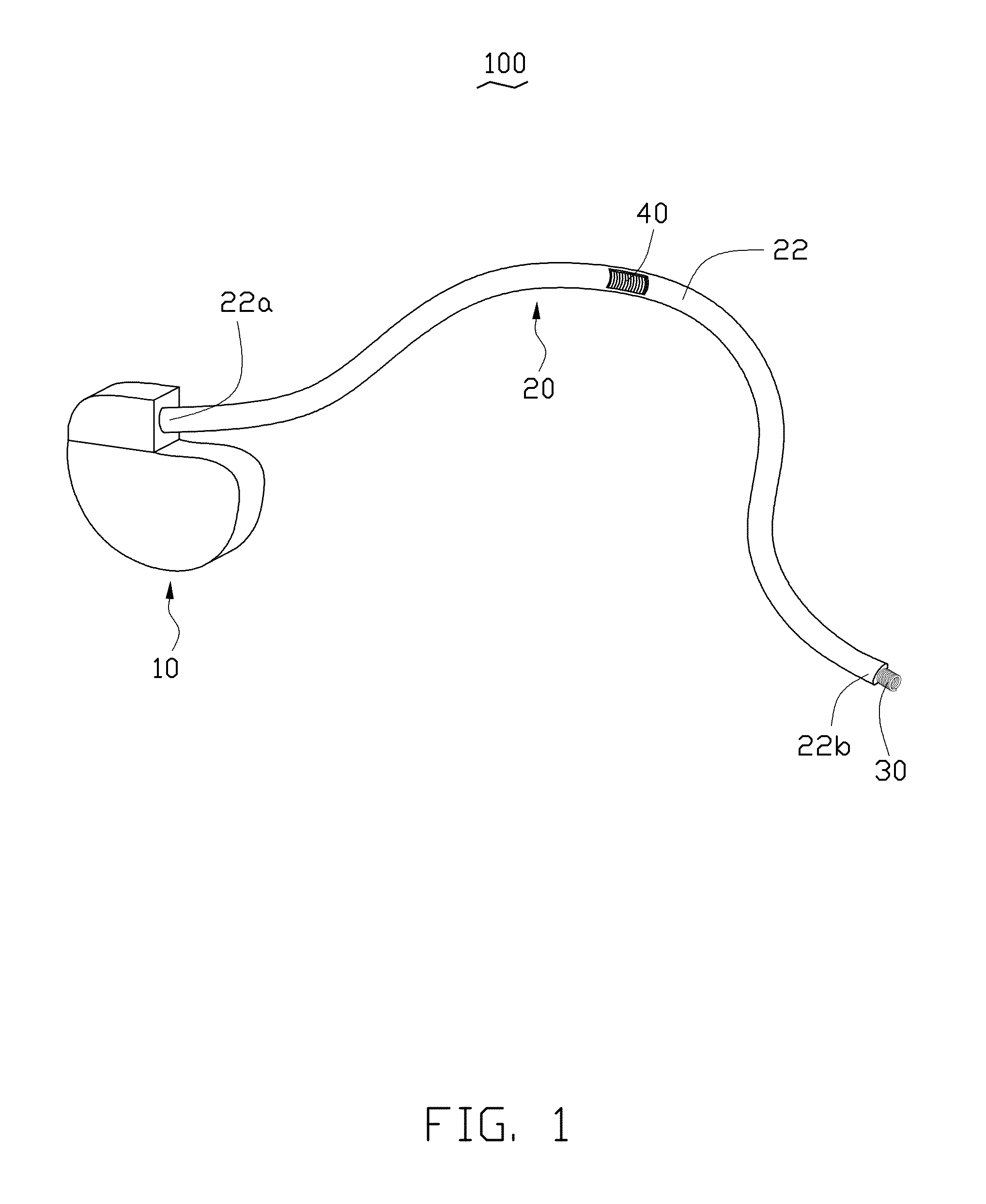

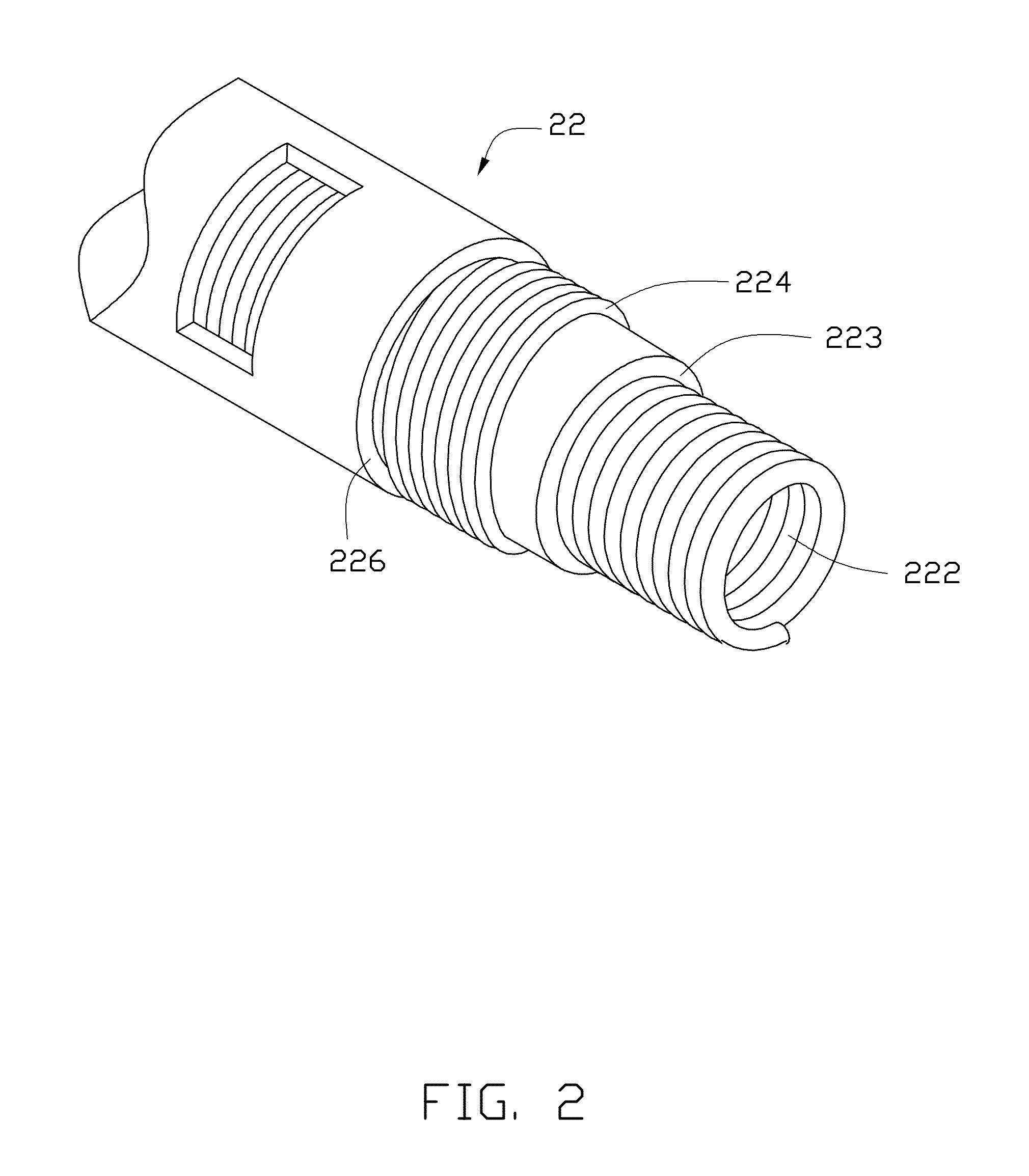

Electrode lead of pacemaker and pacemaker using the same

ActiveUS20130110215A1High strengthImprove toughnessTransvascular endocardial electrodesNanomedicineCarbon nanotube yarnMaterials science

An electrode lead of a pacemaker includes at least one lead wire. The at least one lead wire includes at least one conductive core, a first insulating layer coated on an outer surface of the at least one conductive core, at least one carbon nanotube yarn spirally wound on an outer surface of the first insulating layer, and a second insulating layer coated on the surface of the at least one carbon nanotube yarn. One end of the at least one conductive core protrudes from the first insulating layer to form a naked portion. The at least one carbon nanotube yarn includes a number of carbon nanotubes joined end to end by van der Waals attractive forces. A pacemaker includes a pulse generator and the electrode lead electrically connected with the pulse generator.

Owner:TSINGHUA UNIV +1

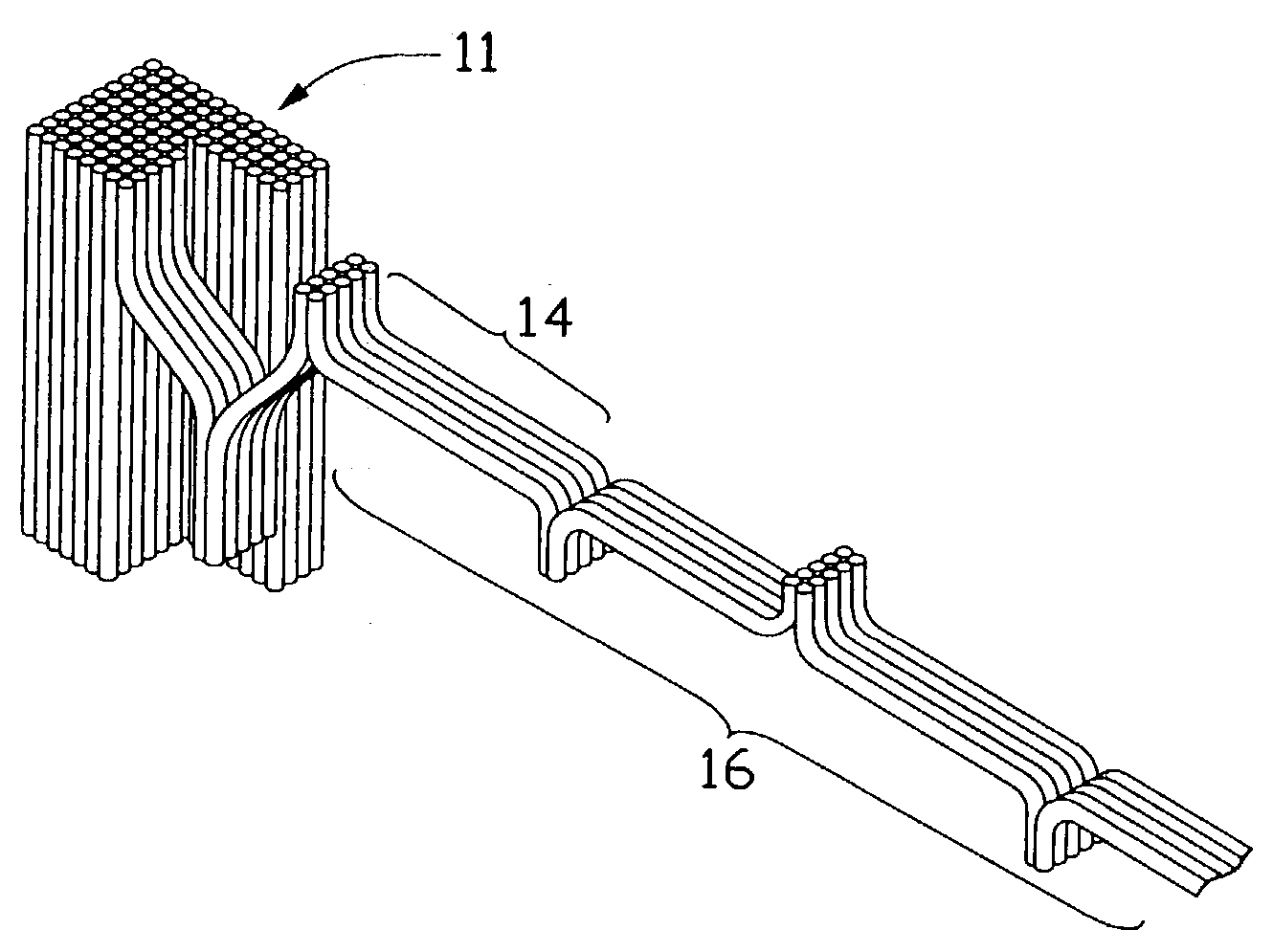

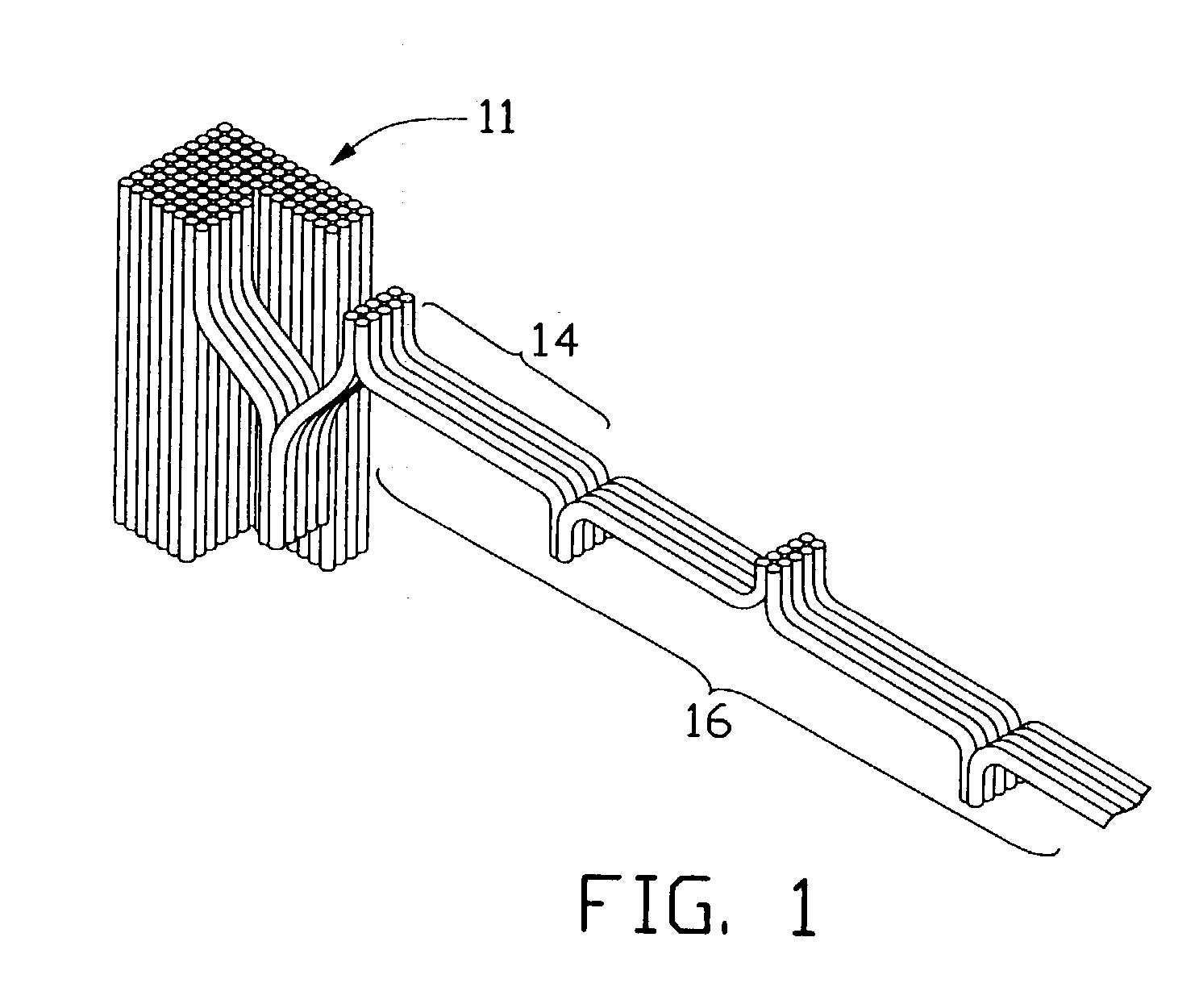

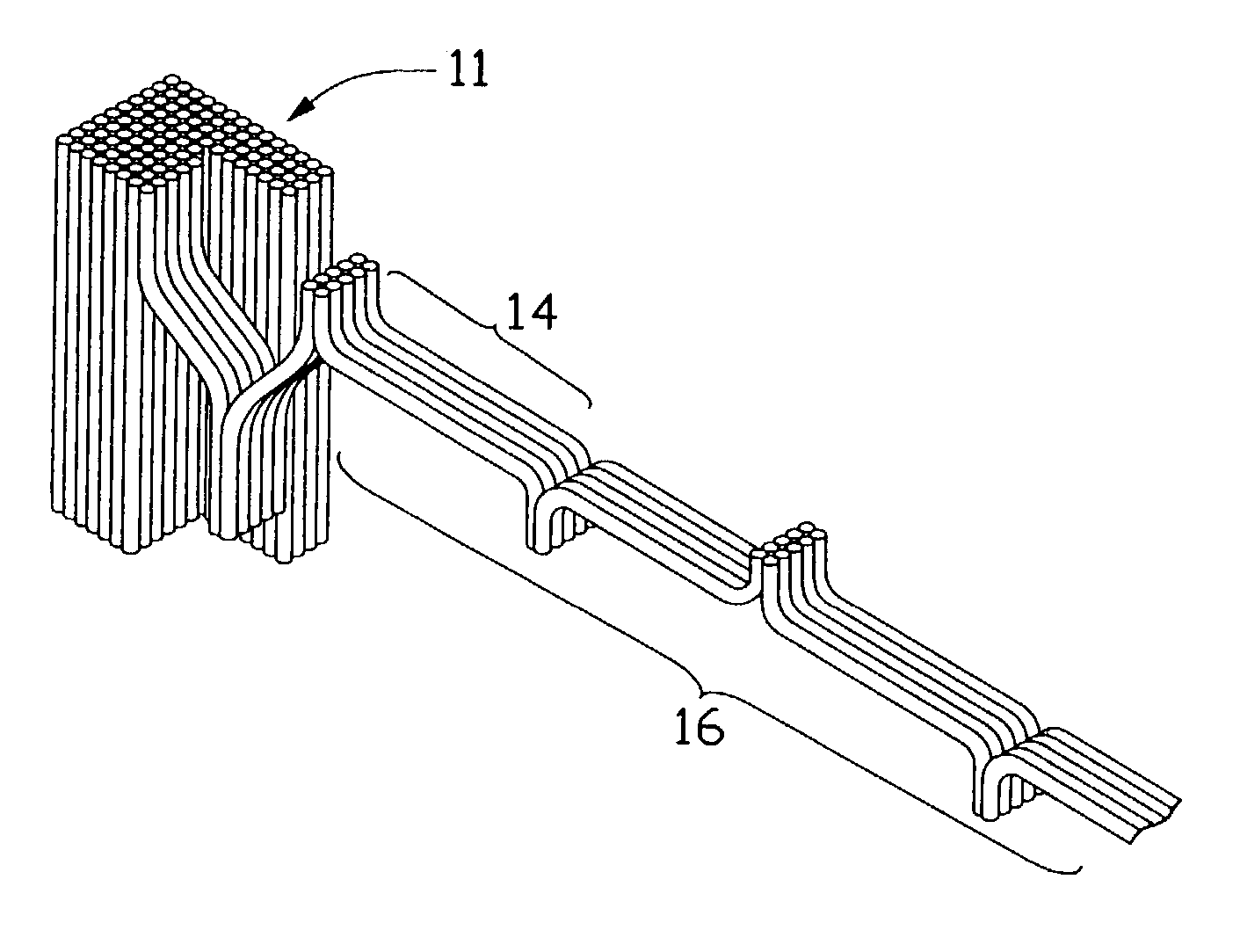

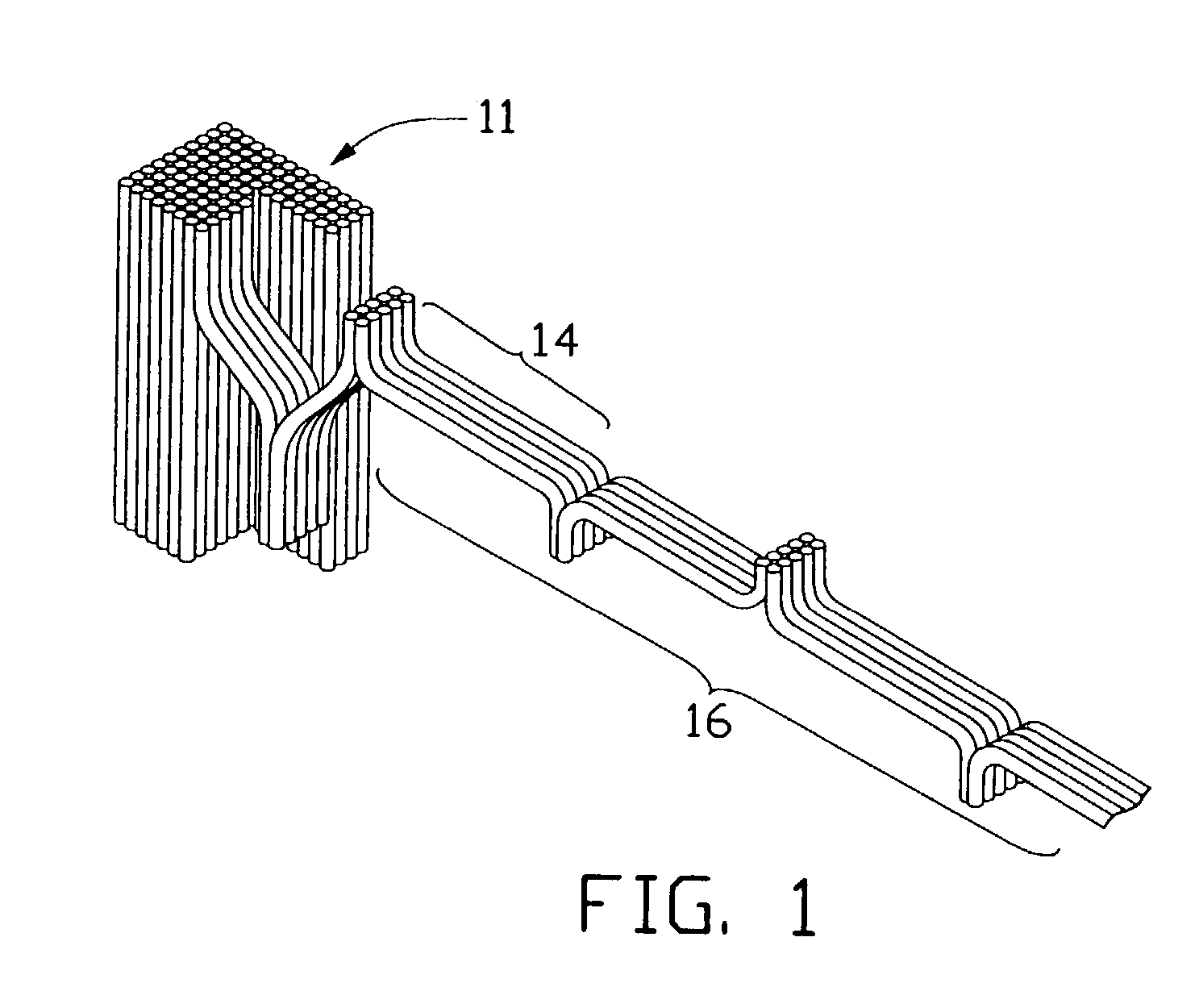

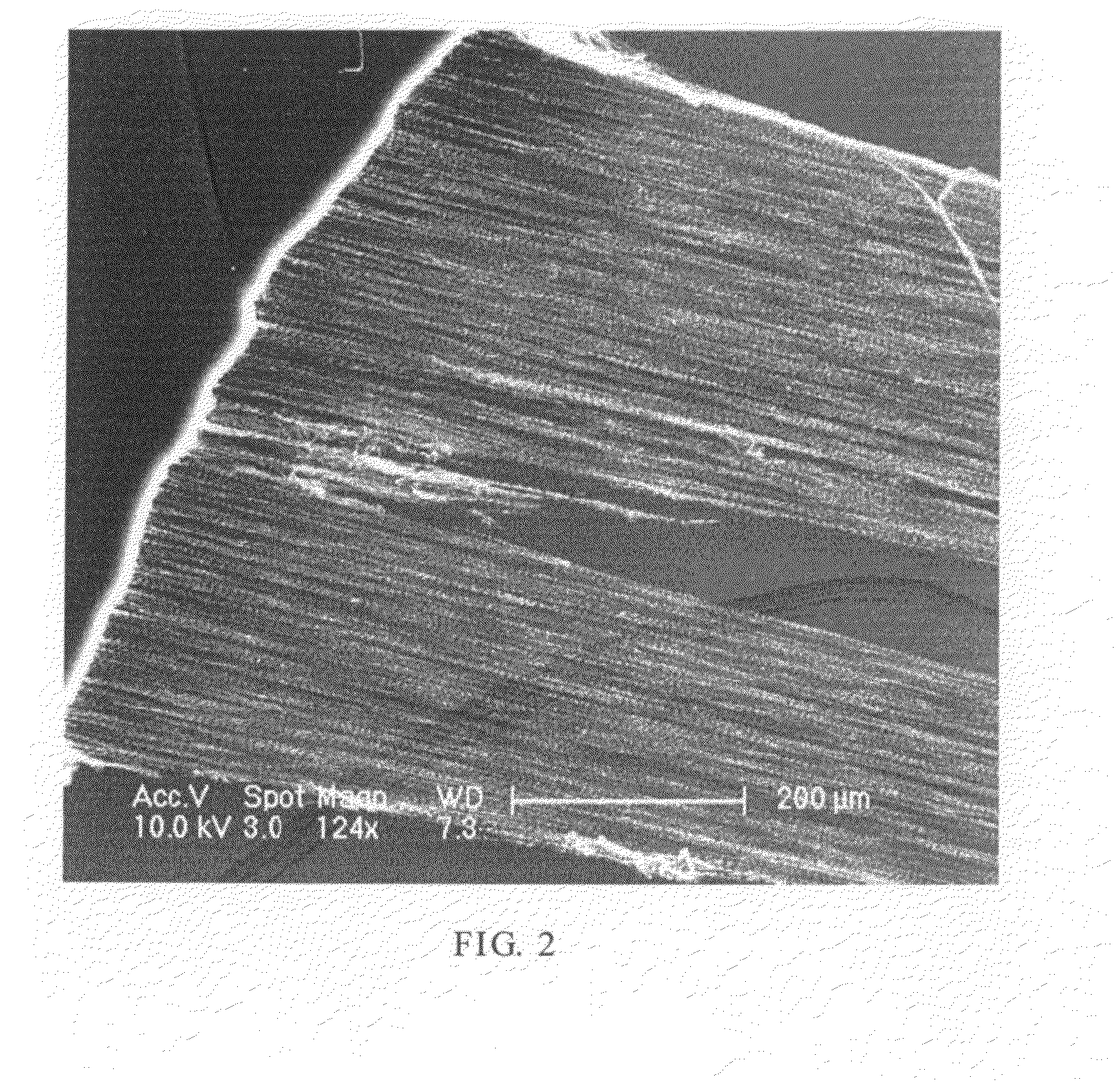

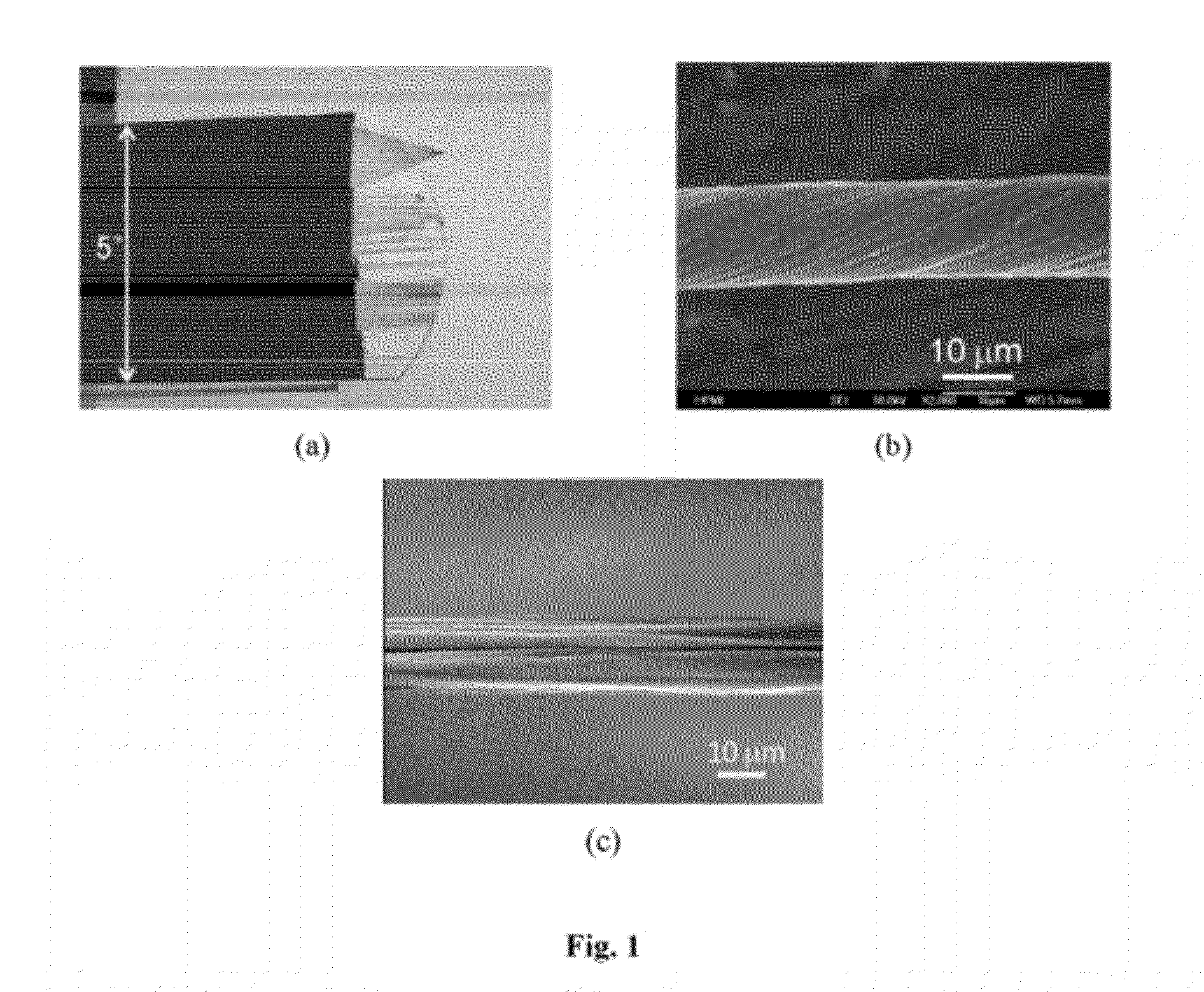

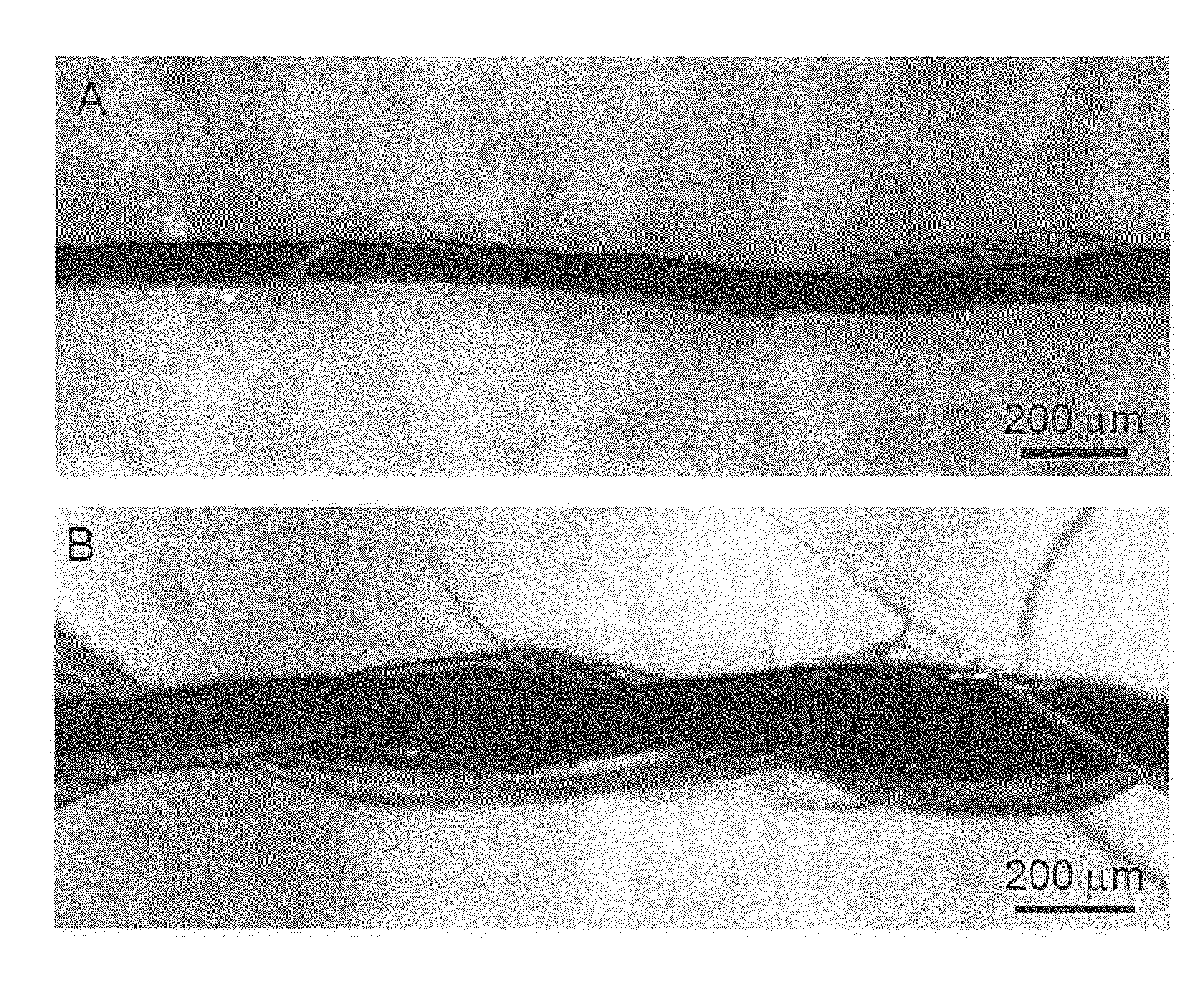

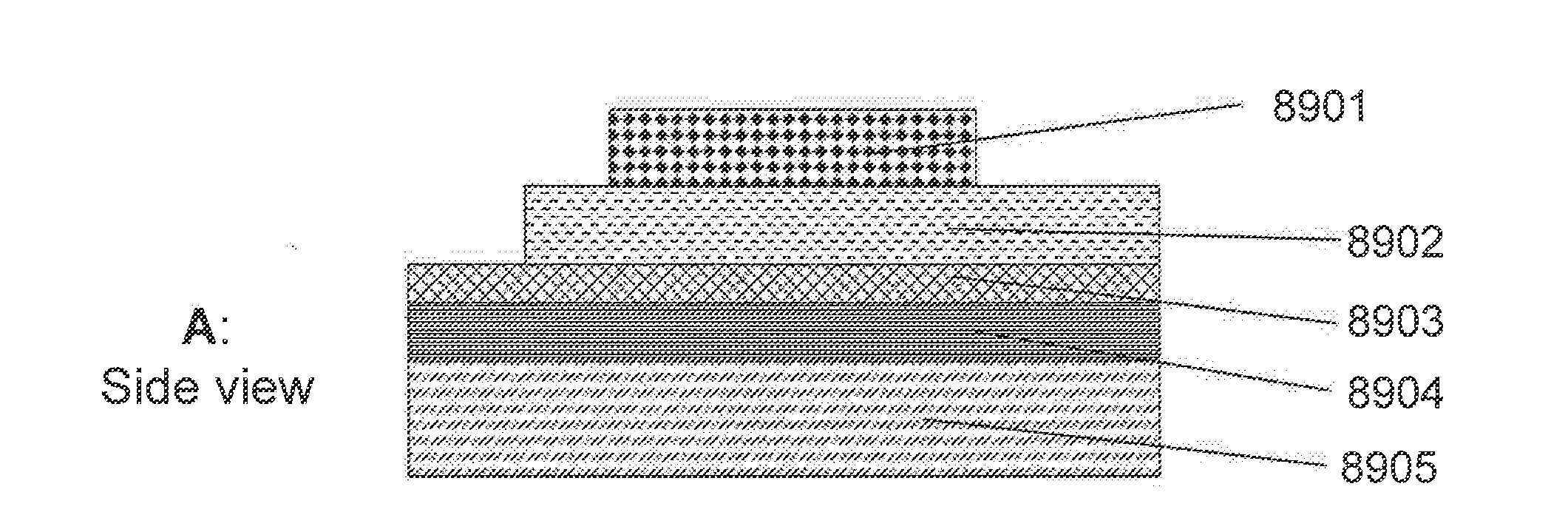

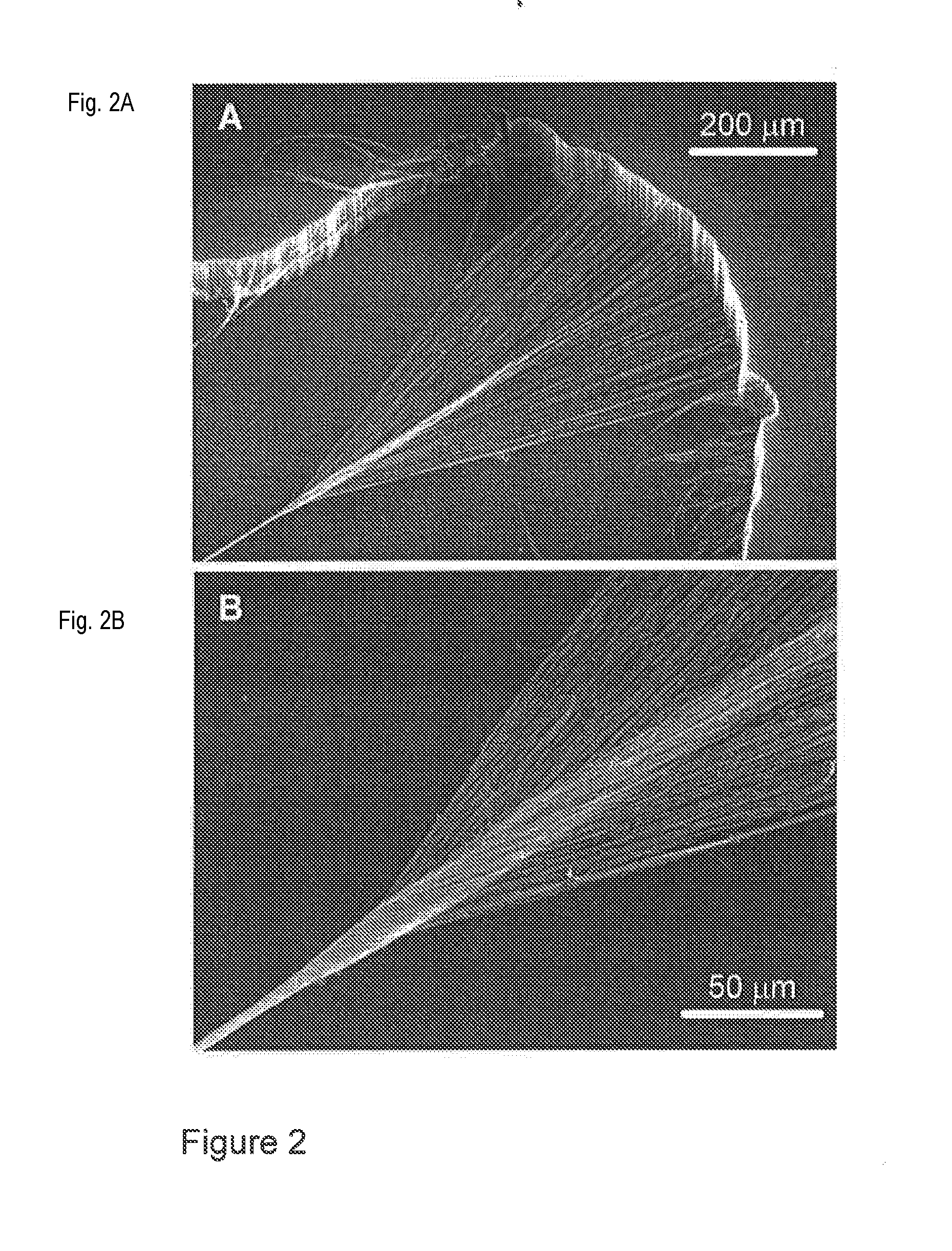

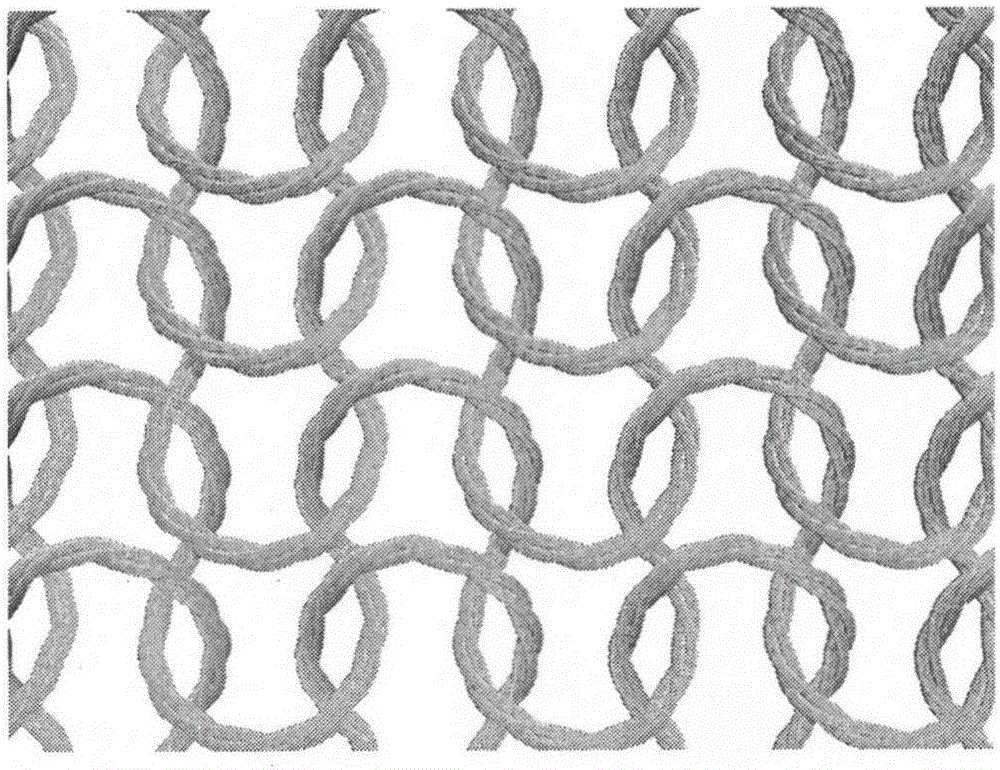

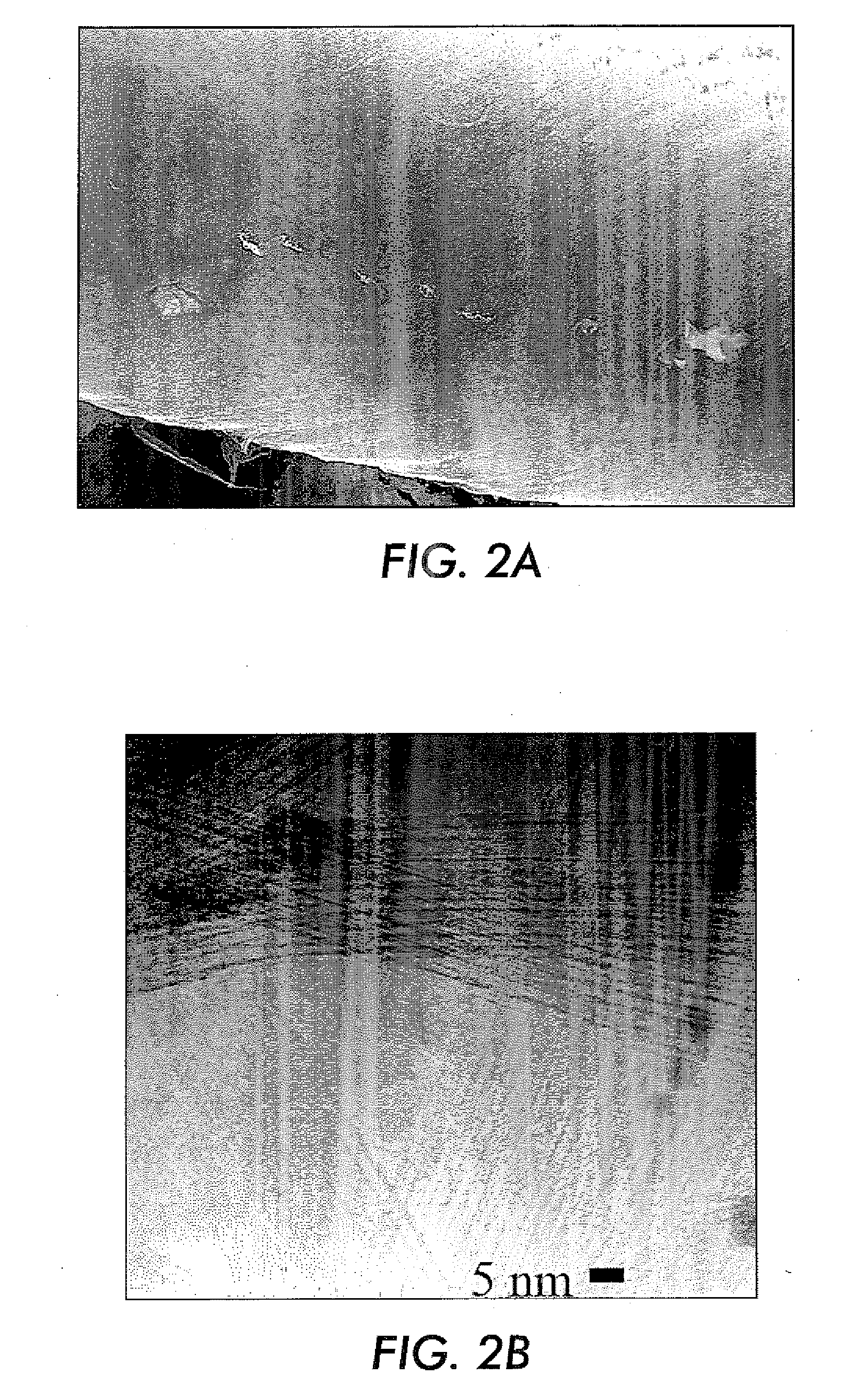

Fabrication and application of nanofiber ribbons and sheets and twisted and non-twisted nanofiber yarns

ActiveUS20150308018A1High strengthImprove yarn strengthMaterial nanotechnologyNon-insulated conductorsFiberHigh resistance

The present invention is directed to nanofiber yarns, ribbons, and sheets; to methods of making said yarns, ribbons, and sheets; and to applications of said yarns, ribbons, and sheets. In some embodiments, the nanotube yarns, ribbons, and sheets comprise carbon nanotubes. Particularly, such carbon nanotube yarns of the present invention provide unique properties and property combinations such as extreme toughness, resistance to failure at knots, high electrical and thermal conductivities, high absorption of energy that occurs reversibly, up to 13% strain-to-failure compared with the few percent strain-to-failure of other fibers with similar toughness, very high resistance to creep, retention of strength even when heated in air at 450° C. for one hour, and very high radiation and IJV resistance, even when irradiated in air. Furthermore these nanotube yarns can be spun as one micron diameter yarns and plied at will to make two-fold, four-fold, and higher fold yarns. Additional embodiments provide for the spinning of nanofiber sheets having arbitrarily large widths. In still additional embodiments, the present invention is directed to applications and devices that utilize and / or comprise the nanofiber yarns, ribbons, and sheets of the present invention.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

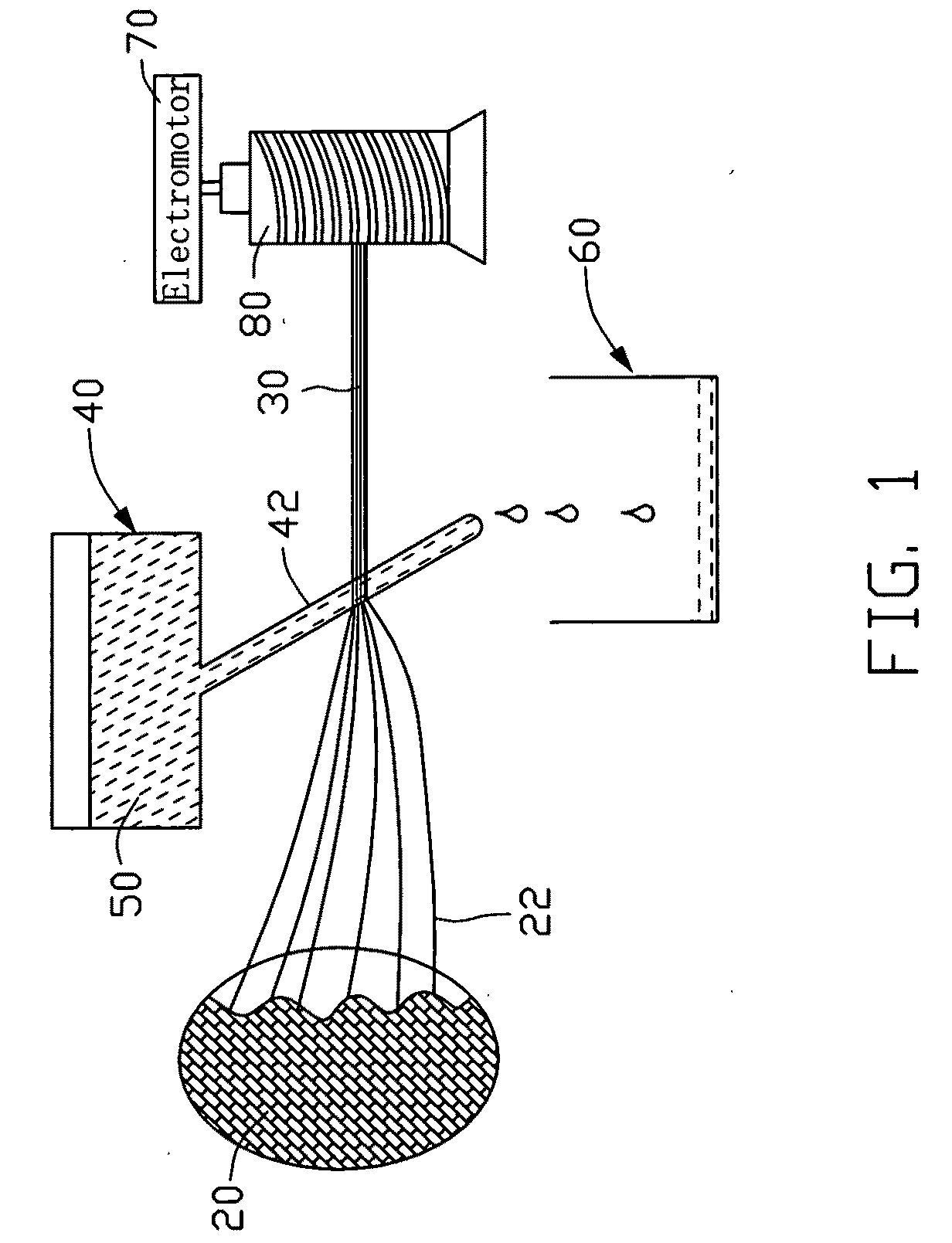

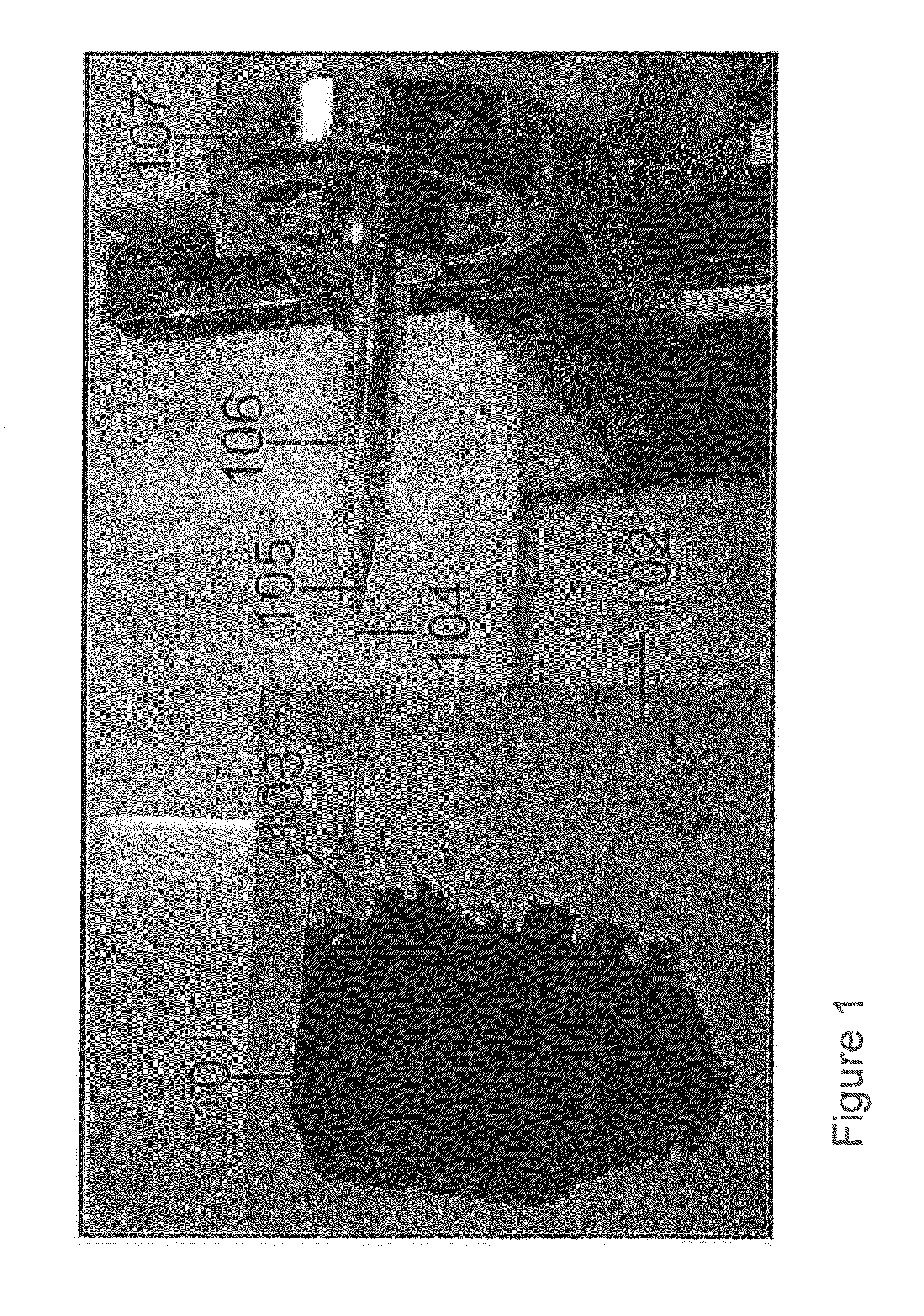

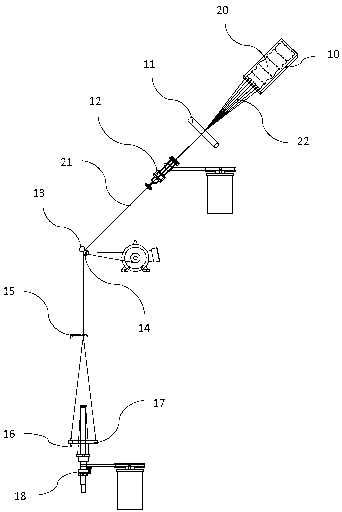

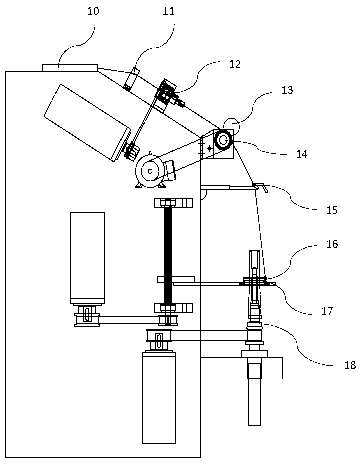

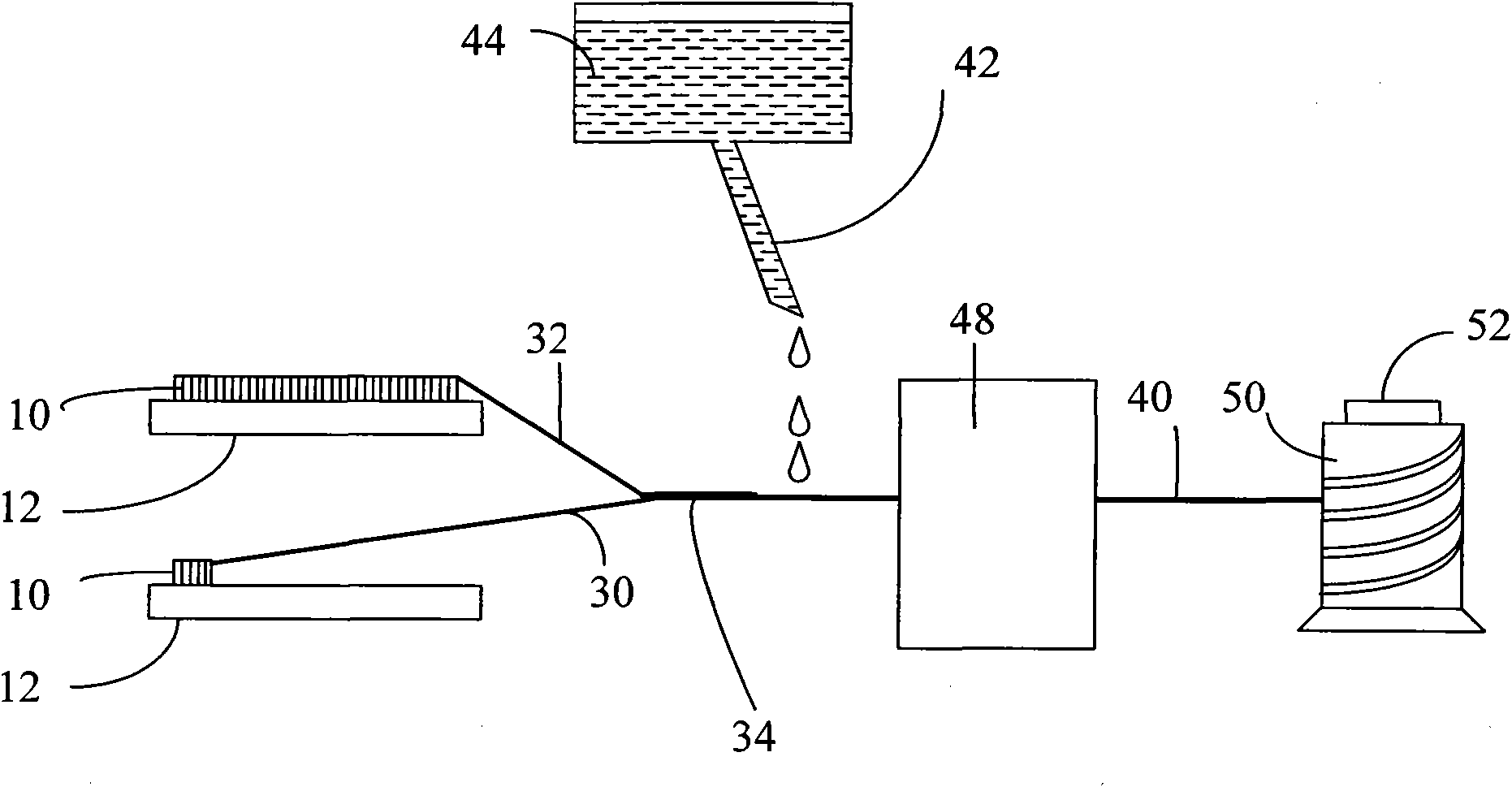

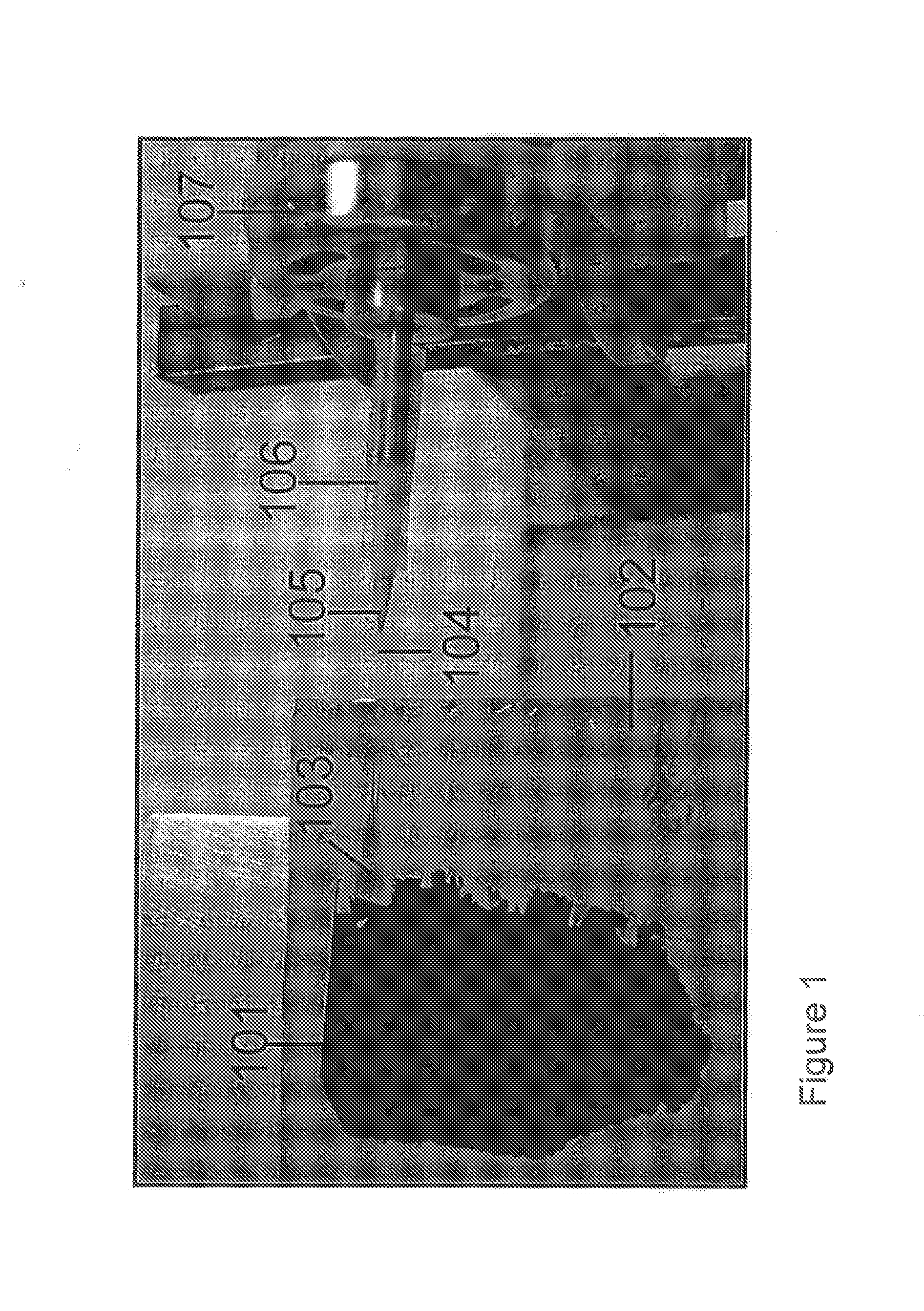

Carbon nanotube spinning machine and method for preparing carbon nanotube yarns by use of same

InactiveCN102953171AContinuous and stable productionContinuous wound-up machinesCarbon nanotube yarnCollection system

The invention discloses a carbon nanotube spinning machine which is used for spinning carbon nanotube films pulled out of a carbon nanotube array into carbon nanotube yarns. The spinning machine comprises a storage device, a soaking device, a false twisting device, a drafting system, a twisting collection system and a rack, wherein the storage device is used for placing the carbon nanotube array; the soaking device is used for soaking the films for shrinkage; the false twisting device performs false twisting of the carbon nanotube films; the drafting system is used for pulling the carbon nanotube films out of the carbon nanotube array; and the rack is integrated with a power system of the carbon nanotube spinning machine. According to the carbon nanotube spinning machine disclosed by the invention, the carbon nanotube films are subjected to false twisting by use of the false twisting principle of the false twisting device, and relatively long carbon nanotube yarns with better mechanical properties can be obtained; and meanwhile, large-batch industrial production can be realized.

Owner:SUZHOU CREATIVE CARBON NANOTECH

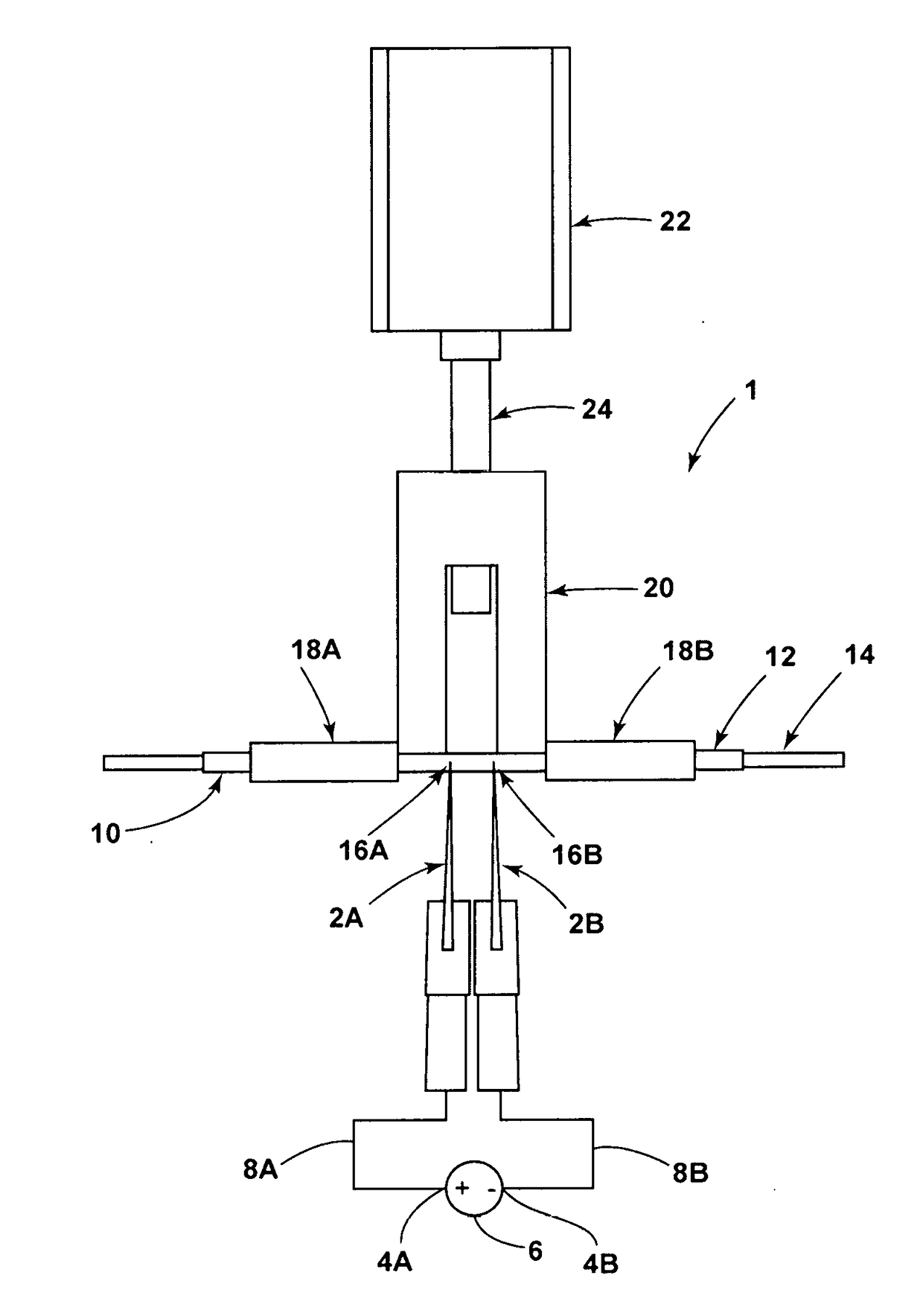

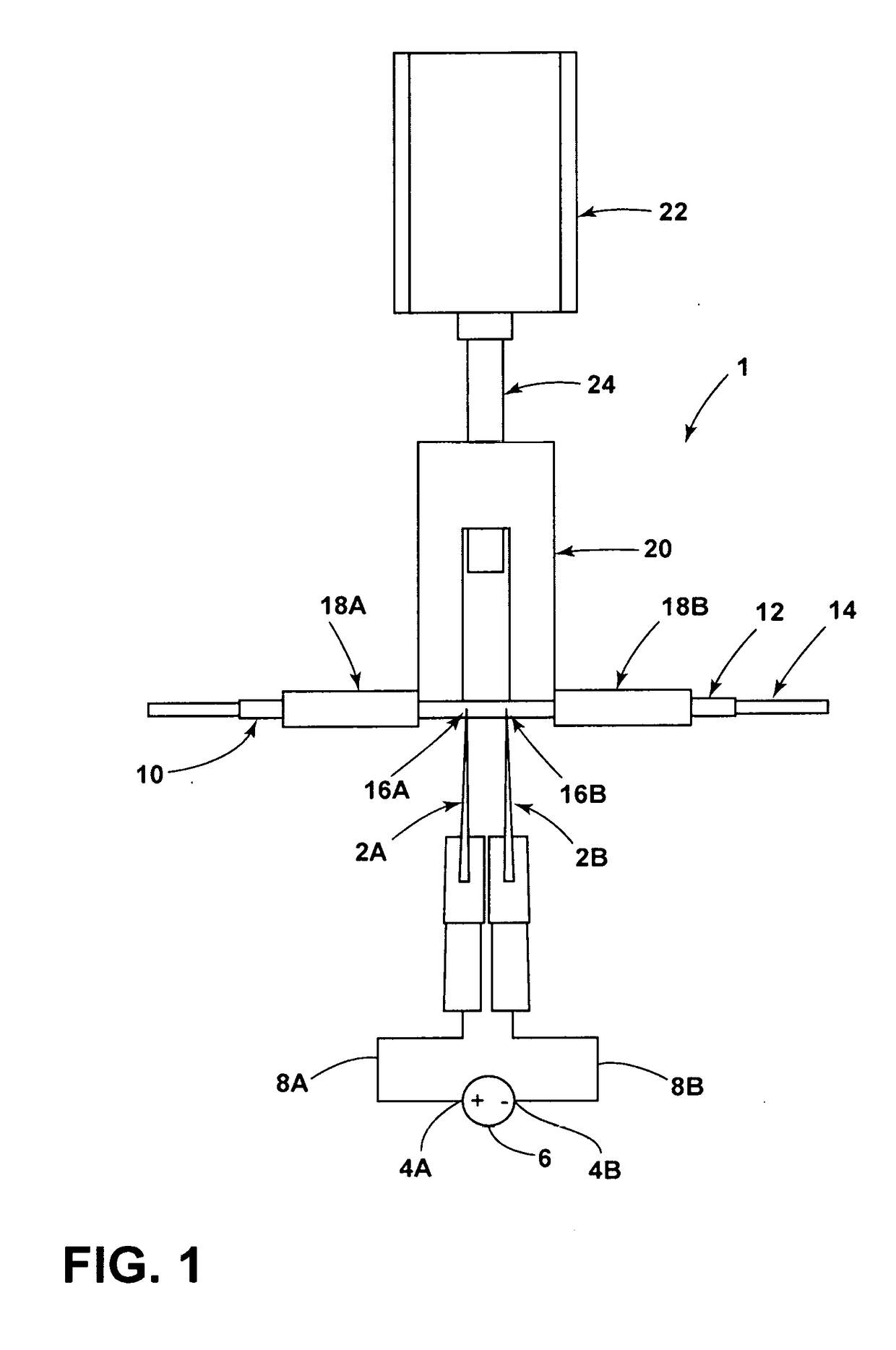

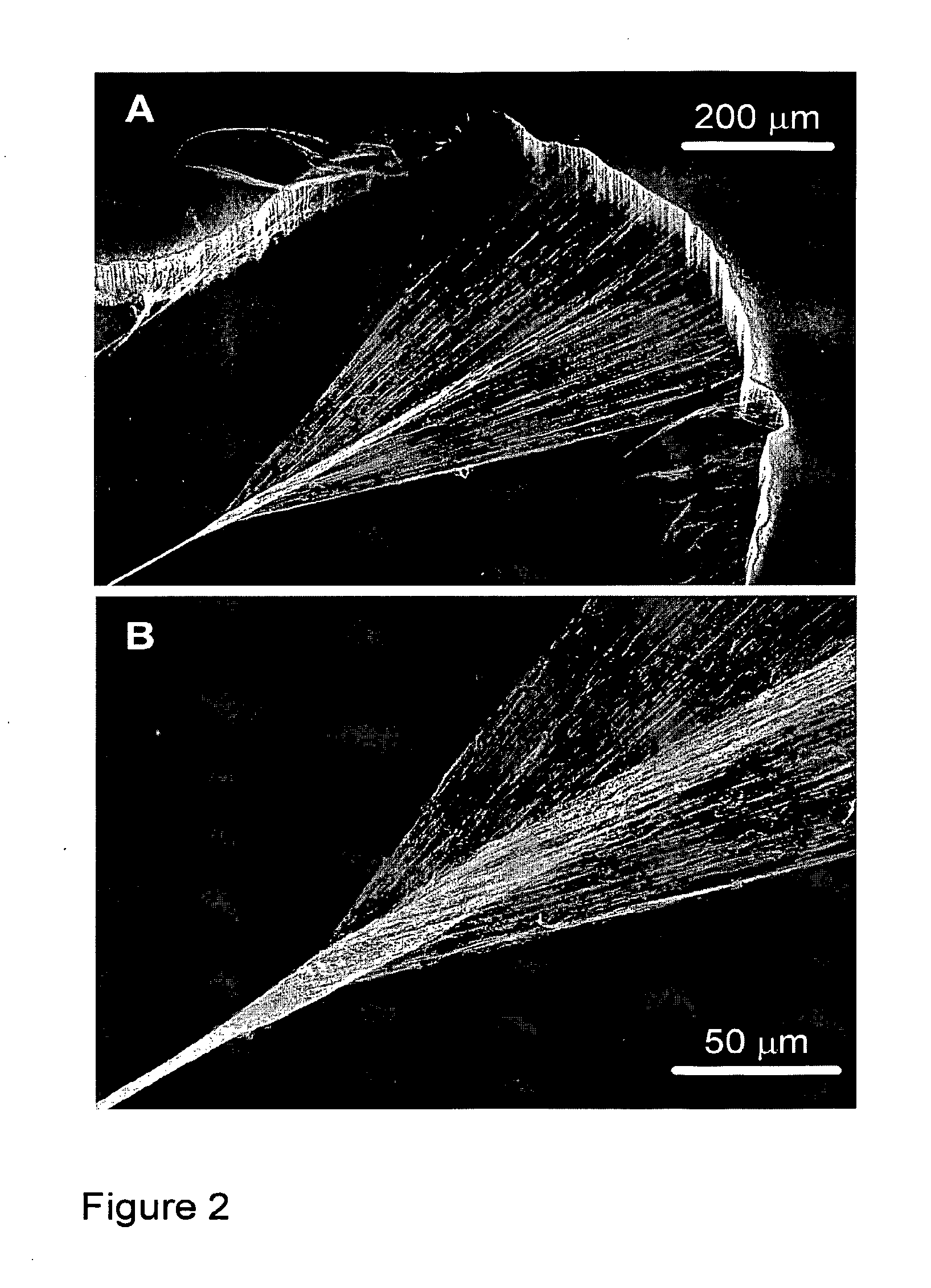

Surface field electron emitters using carbon nanotube yarn and method of fabricating carbon nanotube yarn thereof

ActiveUS20100181896A1Improve homogeneityGood reproducibilityCarbon fibresThermionic cathodesCarbon nanotube yarnLight emitting device

Surface field electron emitters using a carbon nanotube yarn and a method of fabricating the same are disclosed. To fabricate the carbon nanotube yarn for use in fabrication of simple and efficient carbon nanotube field electron emitters, the method performs densification of the carbon nanotube yarn during rotation of a plying unit and heat treatment of the carbon nanotube yarn that has passed through the plying unit without using organic or inorganic binders or polymer pastes. The method fabricates the carbon nanotube yarn with excellent homogeneity and reproducibility through a simple process. The carbon nanotube yarn-based surface field electron emitters can be applied to various light emitting devices.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND

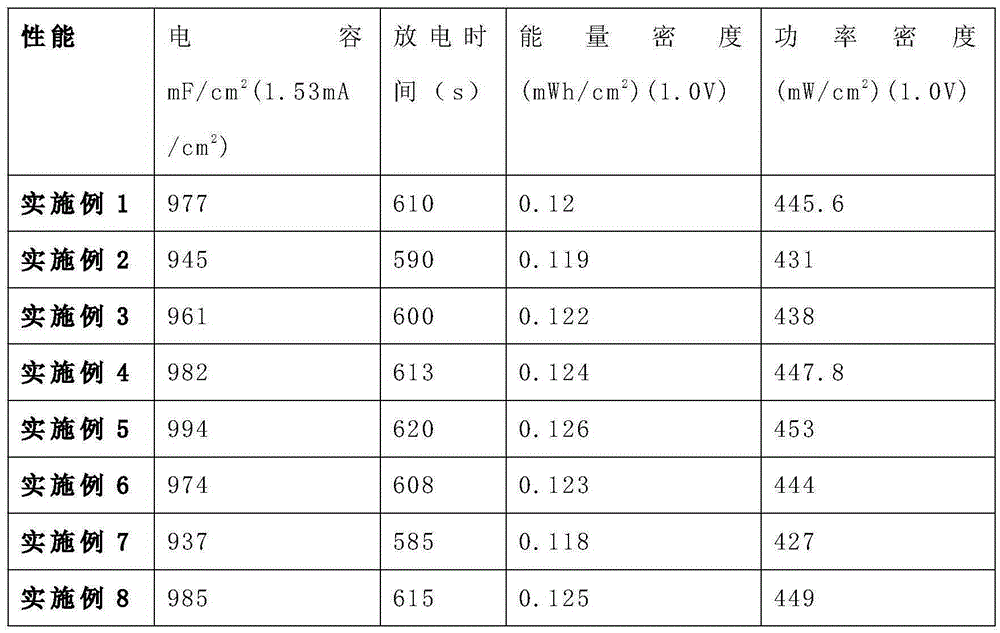

Method for preparing carbon nano tube fabric electrode and yarn electrode and application of electrode

InactiveCN108364797ALow priceSimple preparation processHybrid capacitor electrodesHybrid/EDL manufacturePolyesterCarbon nanotube yarn

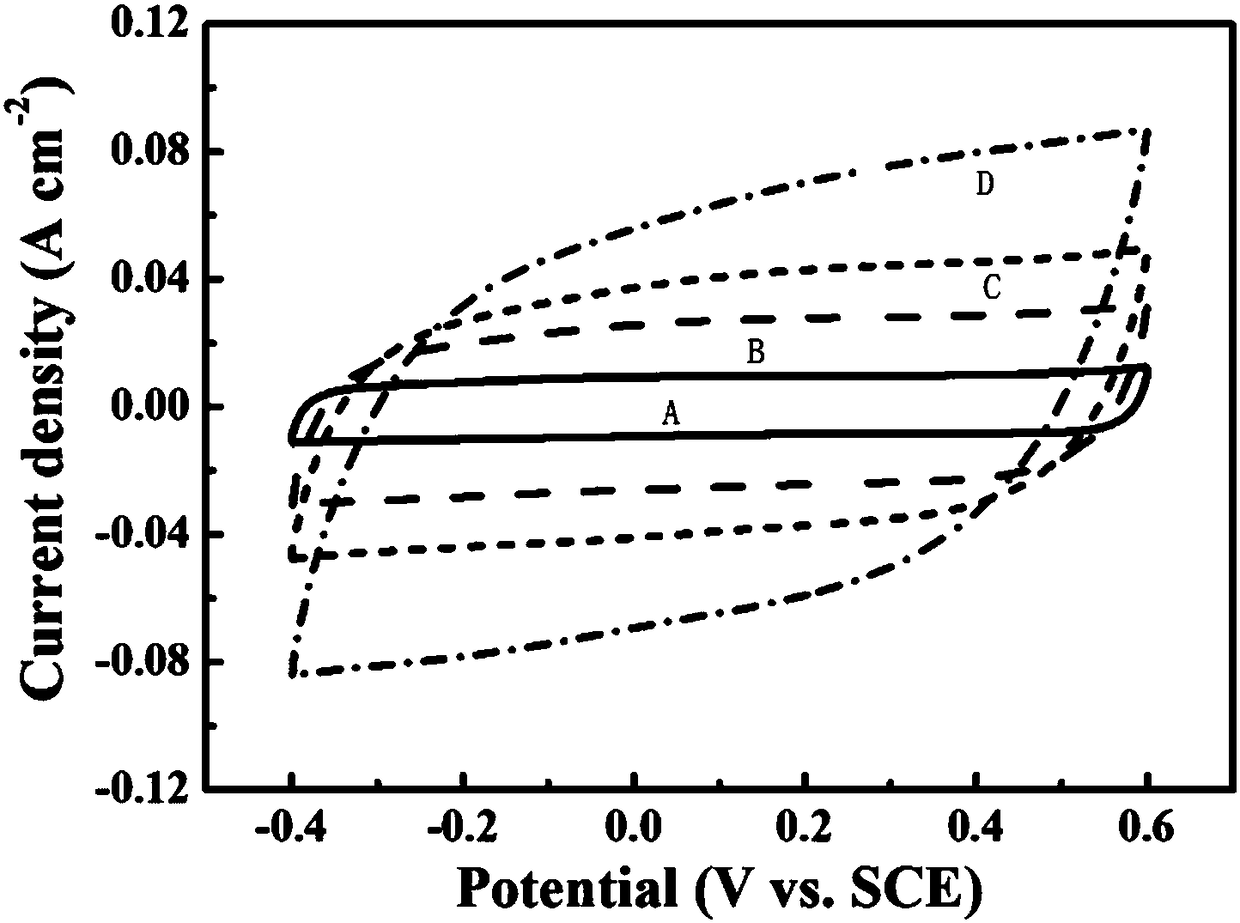

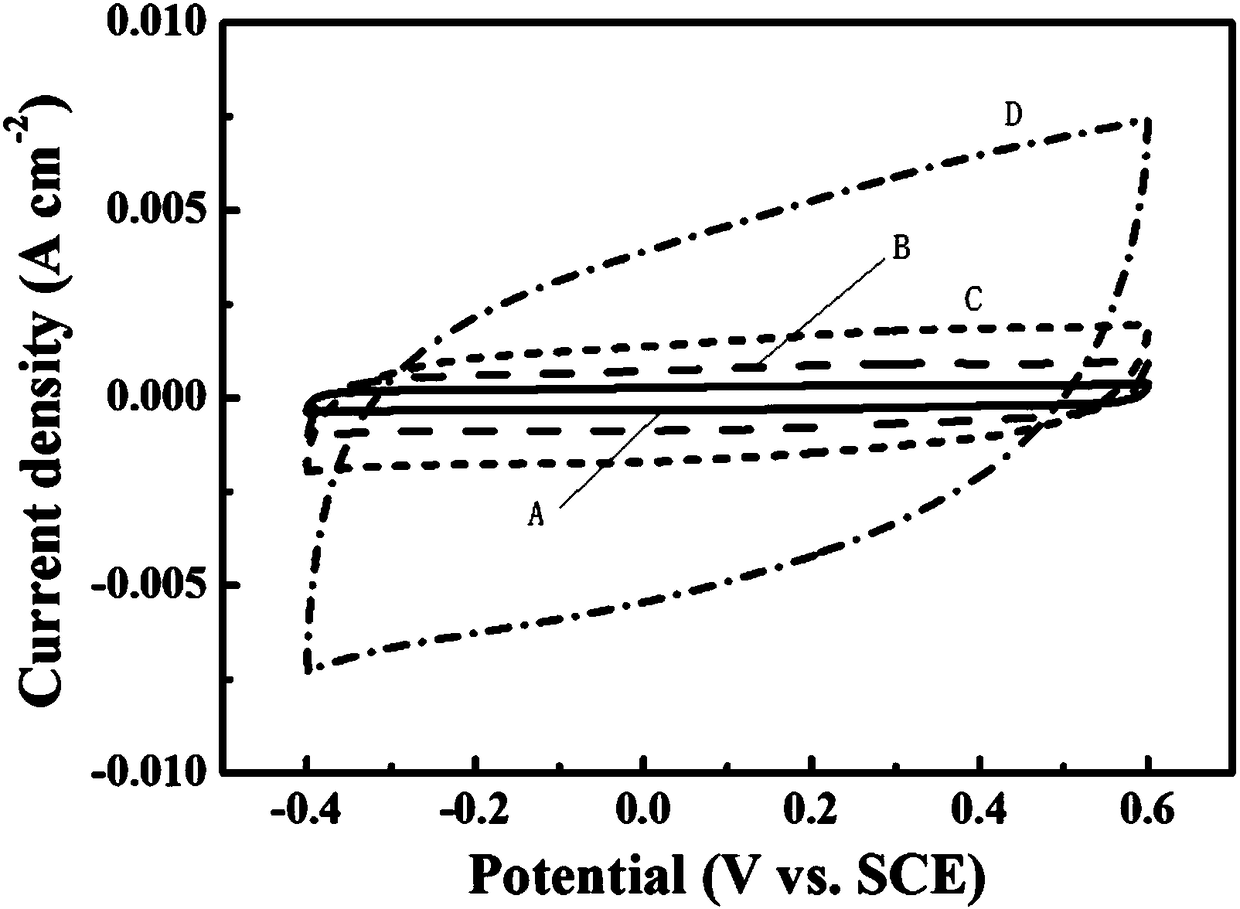

The invention relates to a method for preparing a carbon nano tube fabric electrode and a yarn electrode and application of the electrode, and relates to an electrode preparation method and application of the electrode, and solves the problem that no conventional method can simultaneously prepare a flexible electrode based on an ordinary textile fabric and yarns. The method comprises sensitizing apolyester fiber fabric and a yarn for an ordinary textile with stannous chloride, preparing a fabric / carbon nano tube fabric electrode and a yarn / carbon nano tube yarn electrode, preparing a conductive polymer / fabric / carbon nano tube fabric electrode and a conductive polymer / yarn / carbon nano tube yarn electrode and applying the same to a flexible super capacitor. The method of the invention has the advantages of simple process, low cost and universal applicability. The planar and fiber-type symmetric super capacitors in which the fabric electrode and the yarn electrode are assembled also achieve excellent electrochemical performance.

Owner:HARBIN INST OF TECH

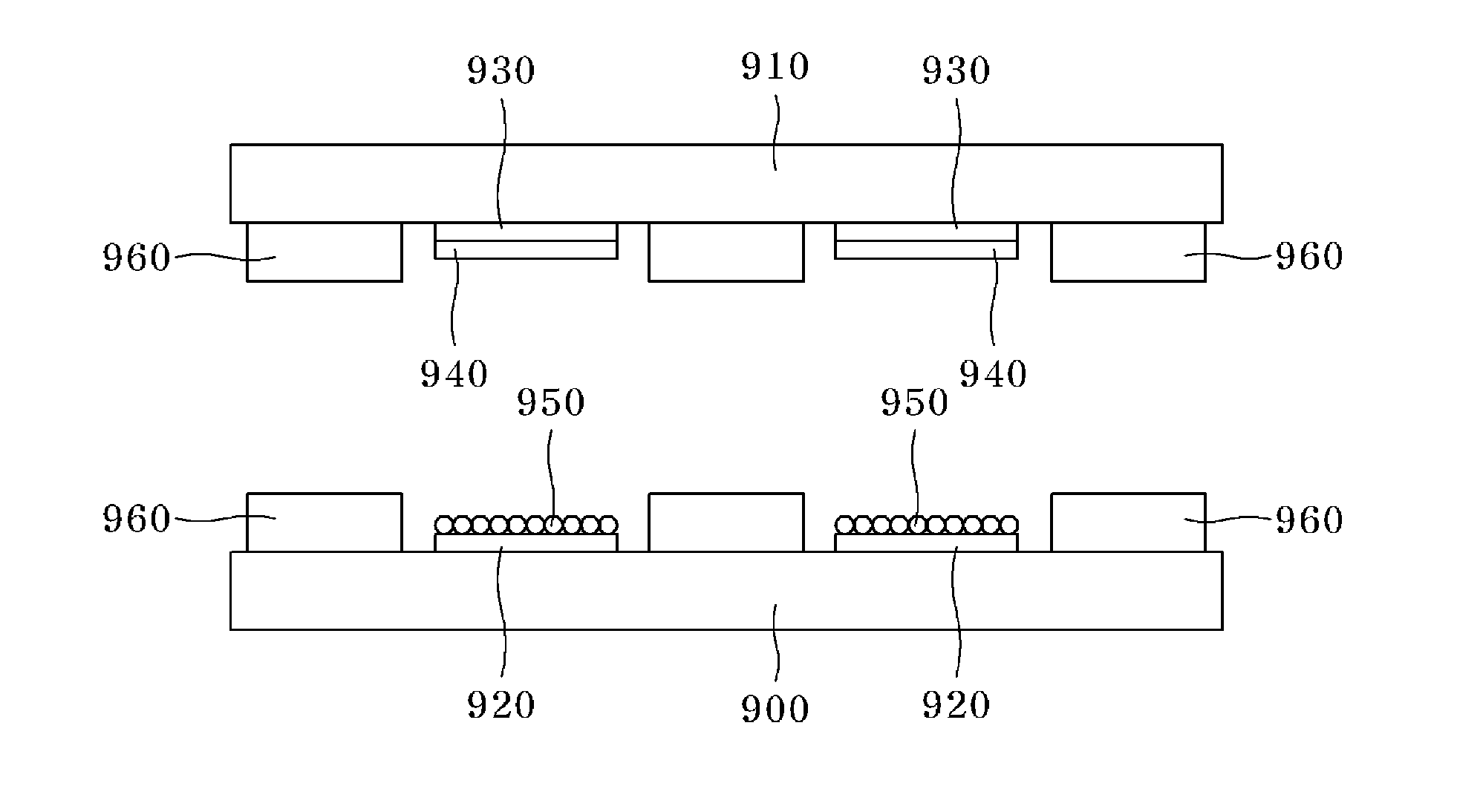

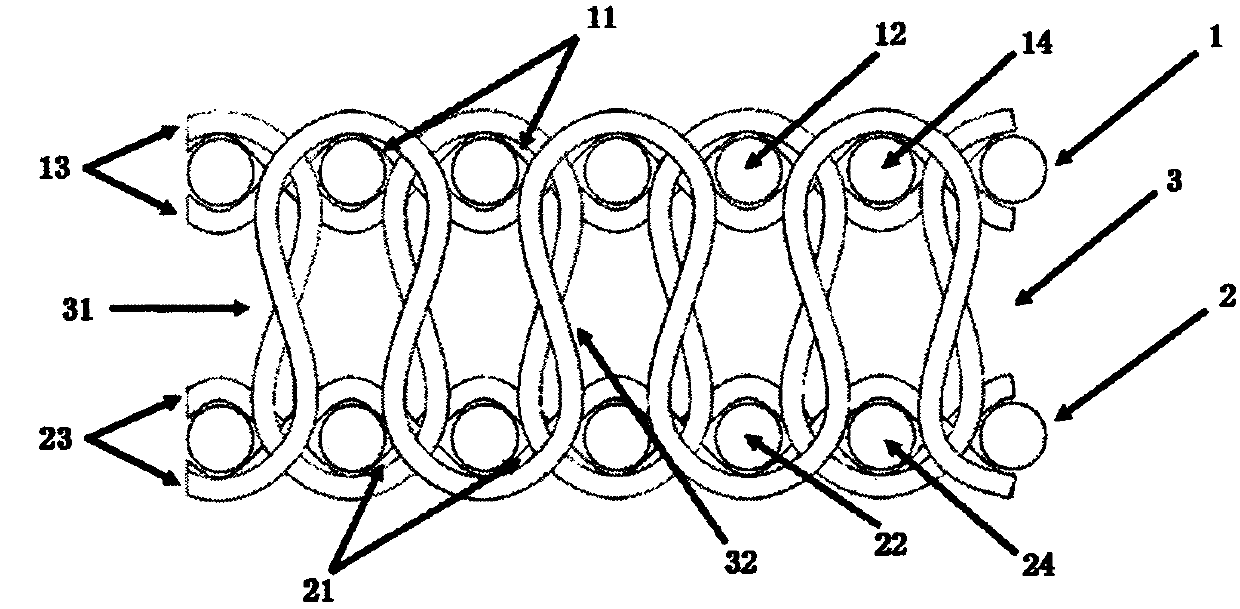

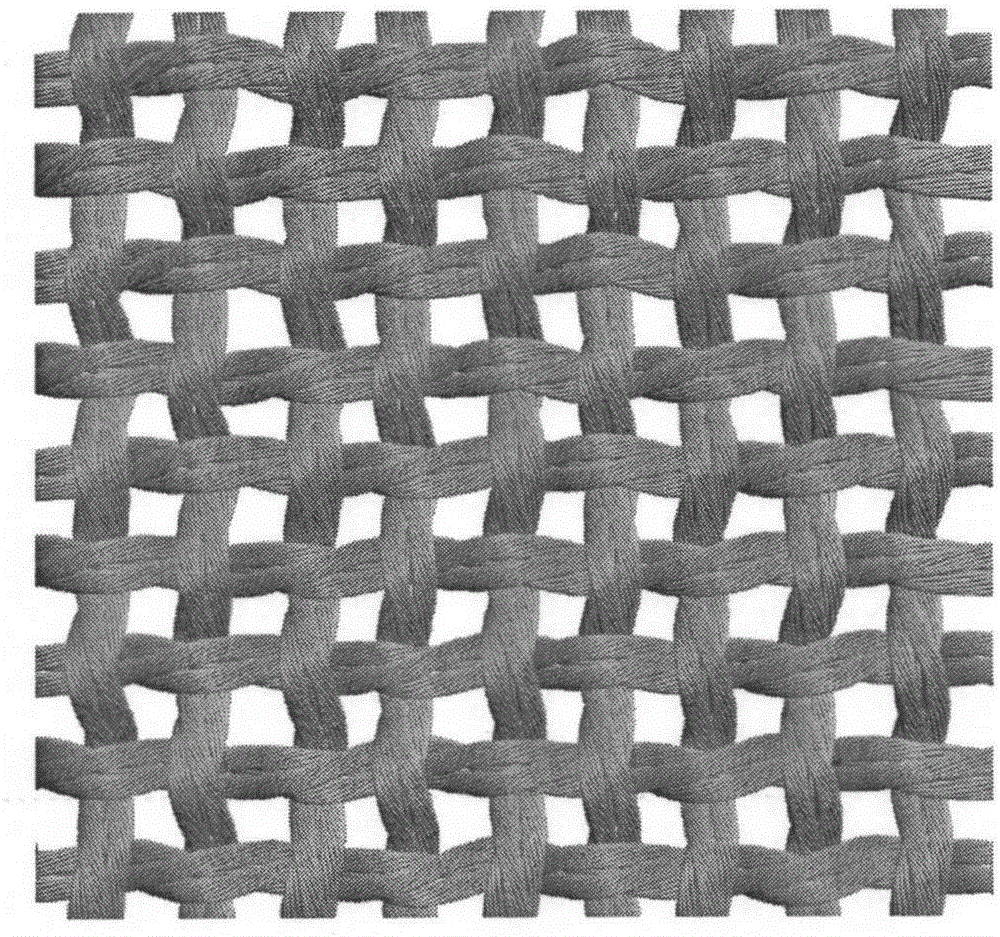

Three-dimensional pressure sensing fabric with spacer woven structures and method for preparing three-dimensional spacer pressure sensing fabric

InactiveCN108035032AHigh sensitivityRecoverable performance is goodOrnamental textile articlesForce measurementCarbon nanotube yarnPressure sense

The invention discloses a three-dimensional pressure sensing fabric with spacer woven structures and a method for preparing the three-dimensional pressure sensing fabric. The three-dimensional pressure sensing fabric comprises upper surface yarn layer and a lower surface yarn layer. The upper surface yarn layer and the lower surface yarn layer are integrally bound with each other by spacing yarns.The method includes weaving the upper surface yarn layer and the lower surface yarn layer by the aid of three-dimensional weaving processes; weaving carbon nano-tube yarns into the upper surface yarnlayer along warp and weft directions and interweaving the carbon nano-tube yarns and the upper surface yarn layer to form conductive networks which are pressure sensing layers; interweaving the uppersurface yarn layer and the lower surface yarn layer with each other by the aid of the spacing yarns to form the three-dimensional pressure sensing fabric which is a three-dimensional spacer sensing fabric. The three-dimensional pressure sensing fabric and the method have the advantages that the three-dimensional pressure sensing fabric with the spacer structures can greatly deform when pressuresare applied to the surfaces of the three-dimensional pressure sensing fabric, the carbon nano-tube yarns in the pressure sensing layers can deform, and accordingly electric resistance can be changed;the three-dimensional pressure sensing fabric is high in sensitivity under the low pressures and is good in recoverability under the high pressures, and the three-dimensional pressure sensing fabric and the method can be widely applied to engineering application and the intelligent wearable field.

Owner:DONGHUA UNIV

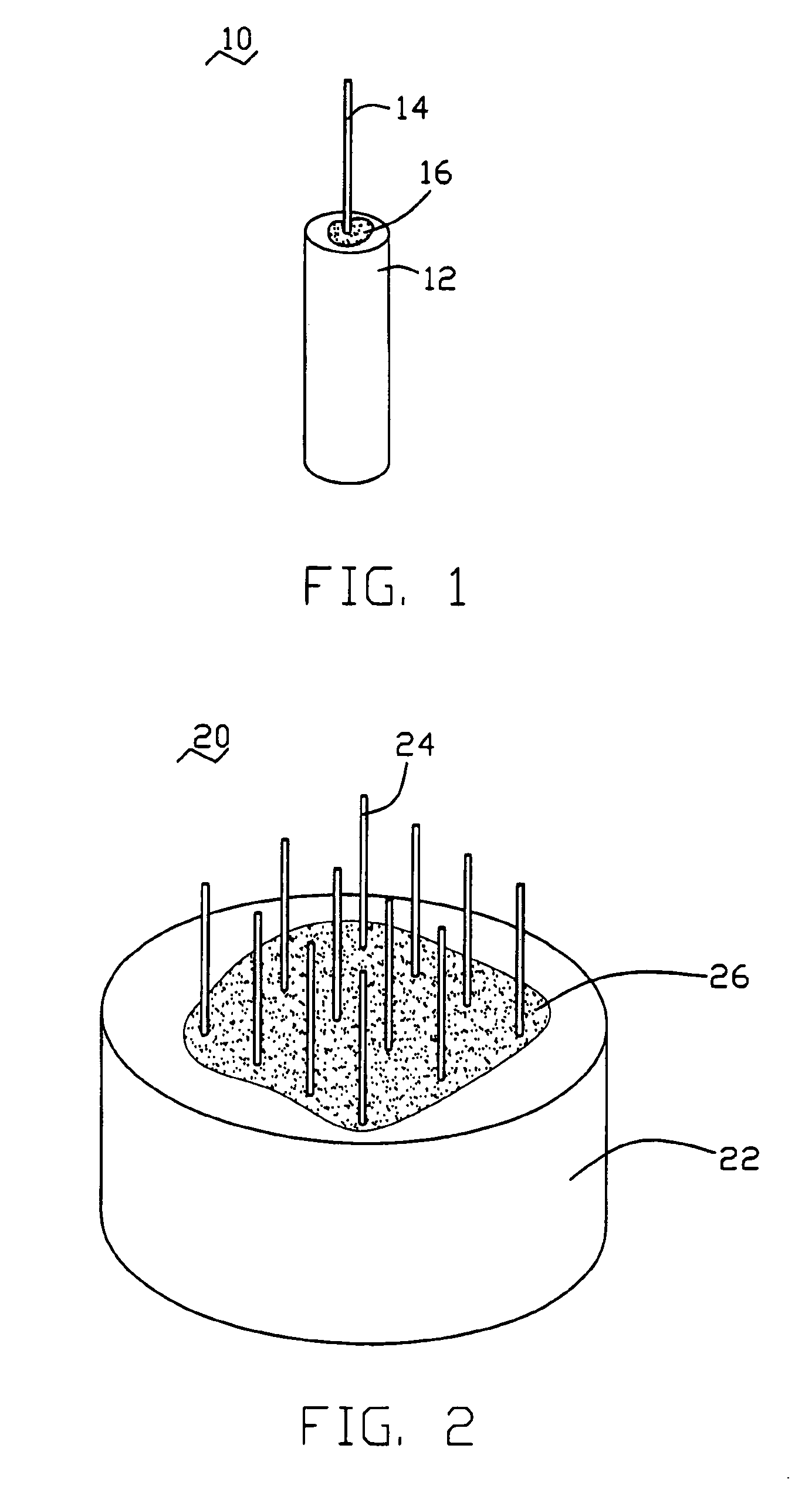

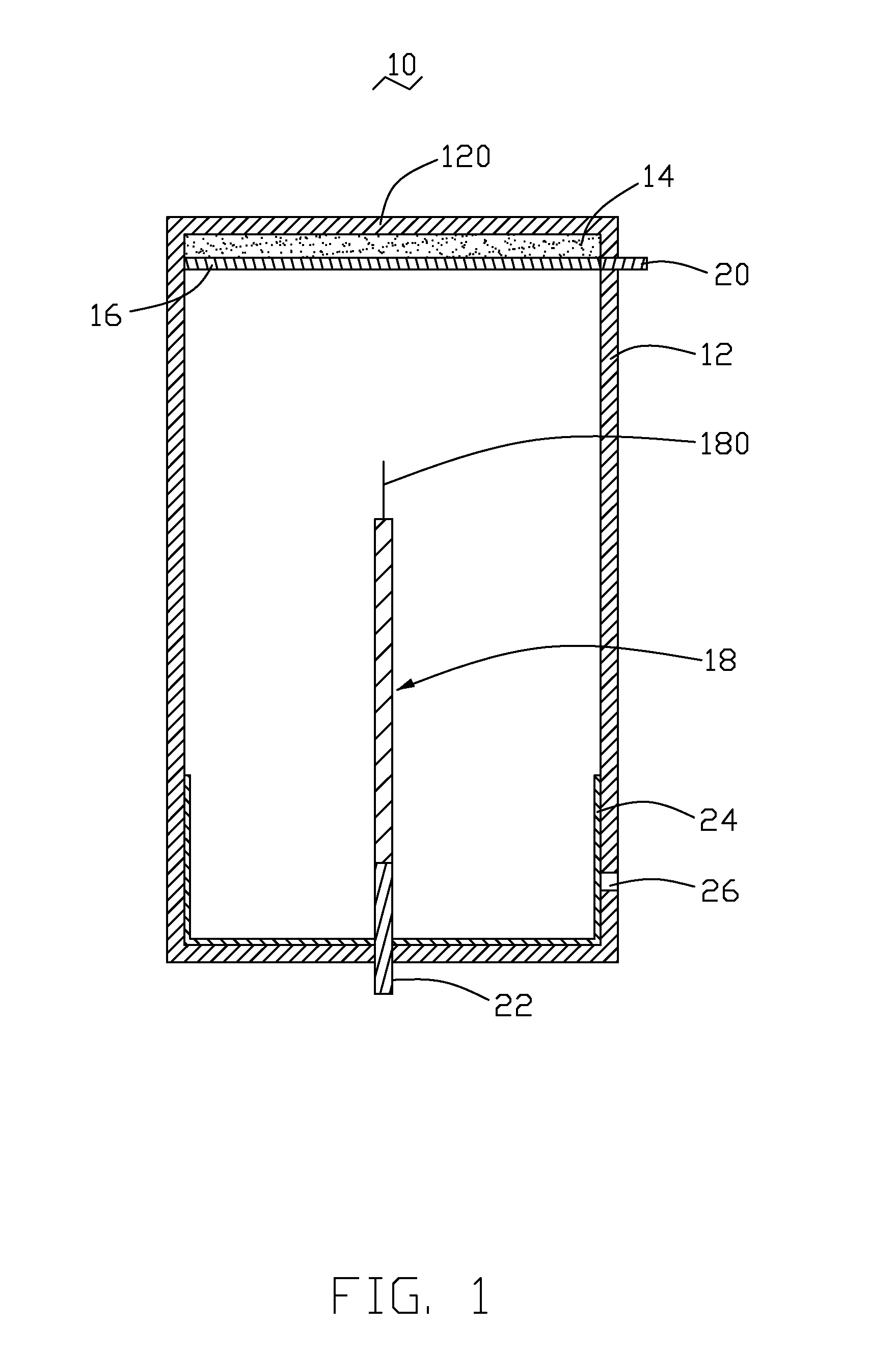

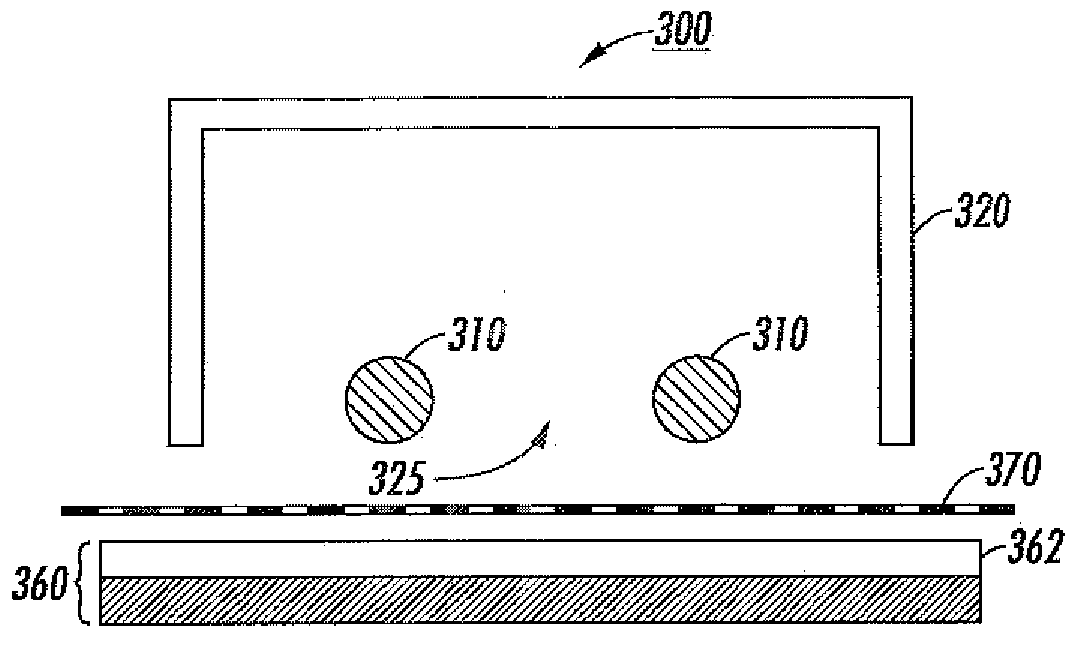

Field emission device and method for making the same

ActiveUS7586249B2Difficult to operateNanotechDischarge tube luminescnet screensField emission deviceConductive paste

A field emission device (10) includes a base (12), a conductive paste (16), and at least one carbon nanotube yarn (14). The at least one carbon nanotube yarn is attached to the base using the conductive paste. This avoids separation of the at least one carbon nanotube yarn from the base by electric field force in a strong electric field. A method for making the field emission device includes the steps of: (a) providing a base; (b) attaching at least one carbon nanotube yarn to the base using conductive paste; and (c) sintering the conductive paste to obtain the field emission device with the carbon nanotube yarn firmly attached to the base.

Owner:BEIJING FUNATE INNOVATION TECH +1

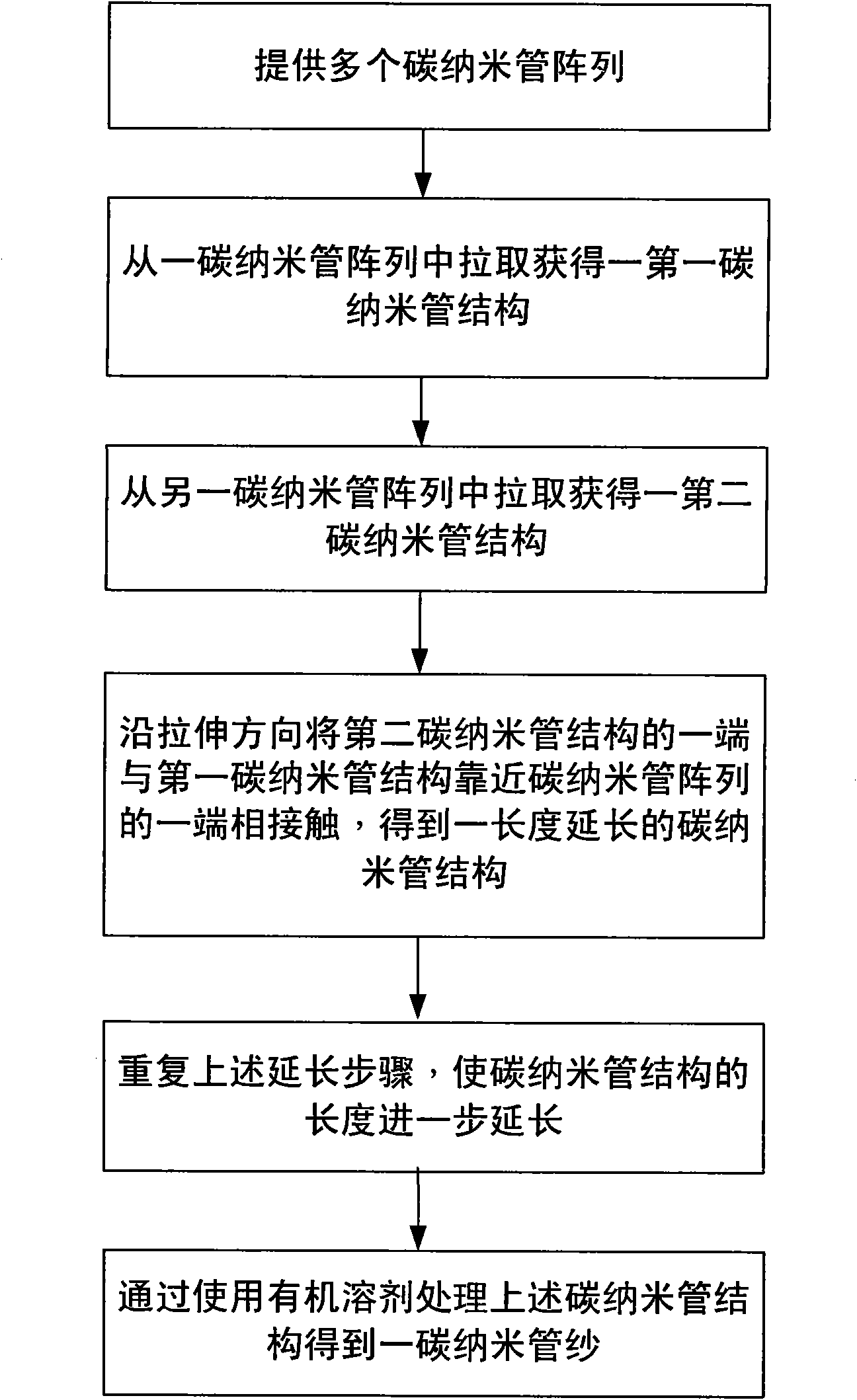

Method of producing carbon nano-tube yarn

ActiveCN101676452AIncrease the lengthEnough lengthFibre chemical featuresYarnOrganic solventCarbon nanotube yarn

The invention relates to a method of producing carbon nano-tube yarn, comprising the following steps: providing a plurality of carbon nano-tube arrays; drawing one carbon nano-tube array to obtain a first carbon nano-tube structure; drawing the other carbon nano-tube array to obtain a second carbon nano-tube structure; contacting one end of the second carbon nano-tube structure with one end of thefirst carbon nano-tube structure, which is close to the carbon nano-tube arrays, along the drawing direction to obtain a lengthened carbon nano-tube tube structure; repeatedly contacting one end of the second carbon nano-tube structure with one end of the first carbon nano-tube structure to further lengthen the carbon nano-tube tube structure; and processing the carbon nano-tube tube with organicsolvent to obtain the carbon nano-tube yarn.

Owner:TSINGHUA UNIV +1

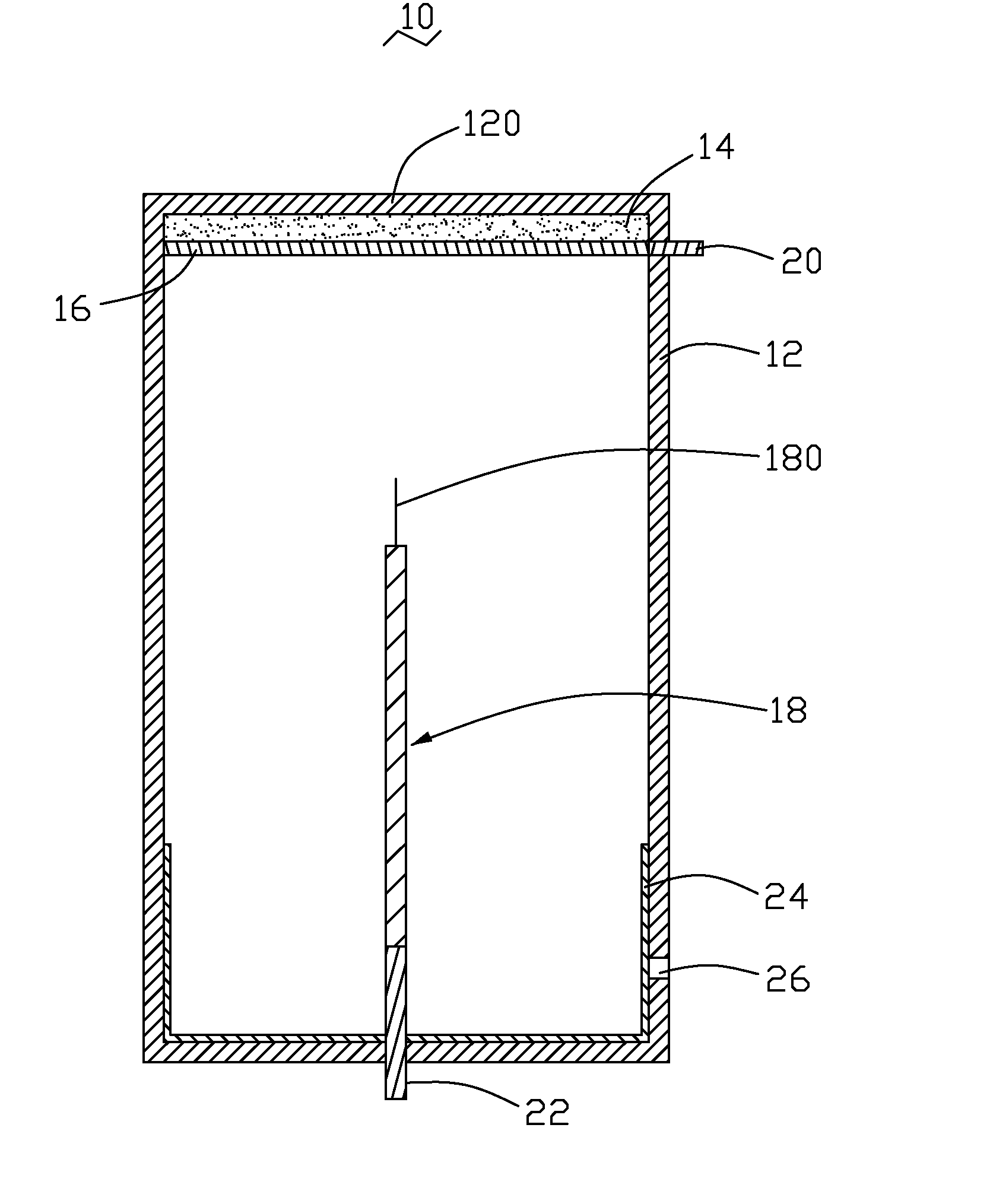

Field emission device

InactiveUS20080012466A1Powerful field emission enhancerSmall diameterDischarge tube luminescnet screensCathode ray tubes/electron beam tubesField emission deviceOrganic solvent

A field emission device (10) includes a sealed container (12) with a light permeable portion (120). A phosphor layer (14) and a light permeable anode (16) are coated on inside surface of the light permeable portion in succession. A cathode (18) is enclosed in the sealed container. A carbon nanotube yarn is attached to the cathode facing the light permeable portion. Before being embedded into the sealed container, the carbon nanotube yarn is processed in the following steps: providing a carbon nanotube array, drawing out at least one carbon nanotube yarn string from the carbon nanotube array, treating the at least one carbon nanotube yarn string using an organic solvent in a manner such that the at least one carbon nanotube yarn string is formed into a single strand of carbon nanotube yarn, and heating the single strand of the carbon nanotube yarn.

Owner:TSINGHUA UNIV +1

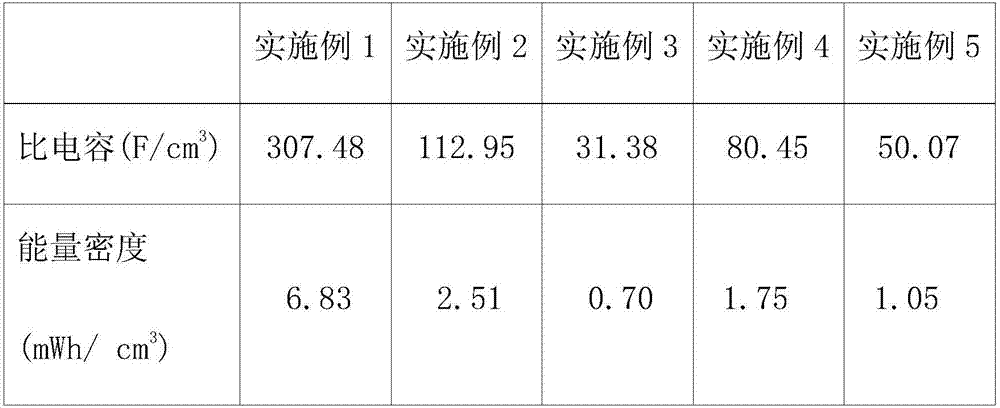

Preparation method for super capacitor obtained by carbon nanotube yarn compositing cobaltates metallic oxide nanowire

ActiveCN105244183ABeneficial technical effectHas a linear structureHybrid/EDL manufactureHybrid capacitor current collectorsCapacitanceNanowire

The invention belongs to the capacitor preparation technology field and discloses a preparation method for super capacitor obtained by carbon nanotube yarn compositing cobaltates metallic oxide nanowire. The carbon nanotube yarn composite cobaltates metallic oxide nanowire super capacitor is a one-dimension linear structure, comprising a metal filament, carbon nanotube yarn and cobaltates metallic oxide. The preparation method comprises steps of interwining the metal filament and the carbon nanotube yarn to form an M / CNT dual-strand yarn or a covering yarn structure M-CNT yarn, in which the metal filament is a core and the surface of the core is wrapped by the carbon nanotube yarn, hydrothermally growing cobaltates metallic oxide on the surface of the M / CNT or M-CNT to obtain a composite yarn M / CNT / ACo2O4 or M-CNT-ACo2O4, 3 immersing the M / CNT / ACo2O4 or the M-CNT-ACo2O4 into a polyving akohol-potassium hydroxide collosol to form a film on the surface and then interwining the two composite yarns to obtain a super capacitor. The obtained one-dimension linear super capacitor is high in capacitance, simple in technology and is applicable to weaving a wearable power supply.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

Fabrication and application of nanofiber ribbons and sheets and twisted and non-twisted nanofiber yarns

ActiveUS20160251778A1High strengthImprove yarn strengthMaterial nanotechnologyNon-insulated conductorsHigh resistanceFiber

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

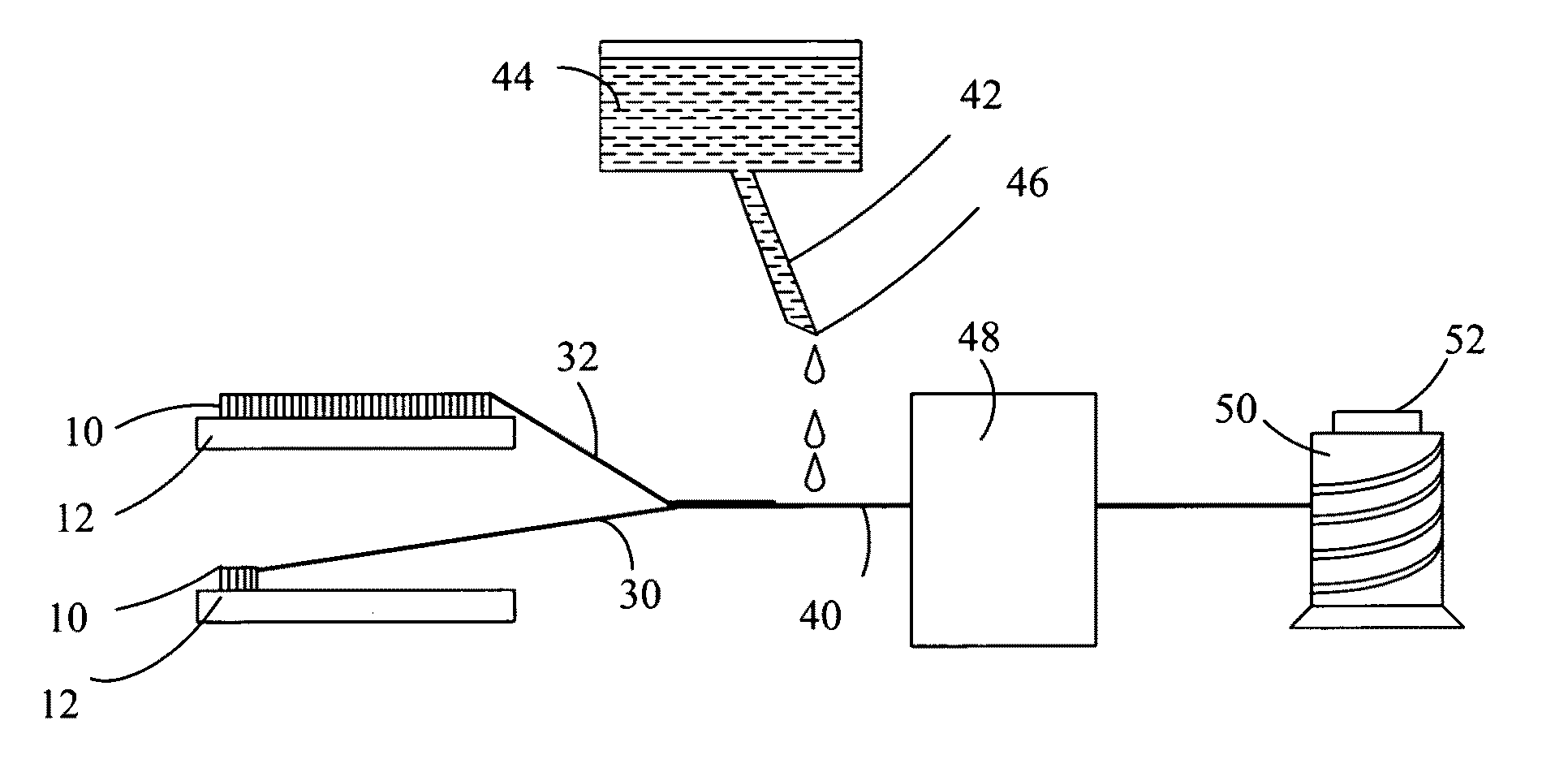

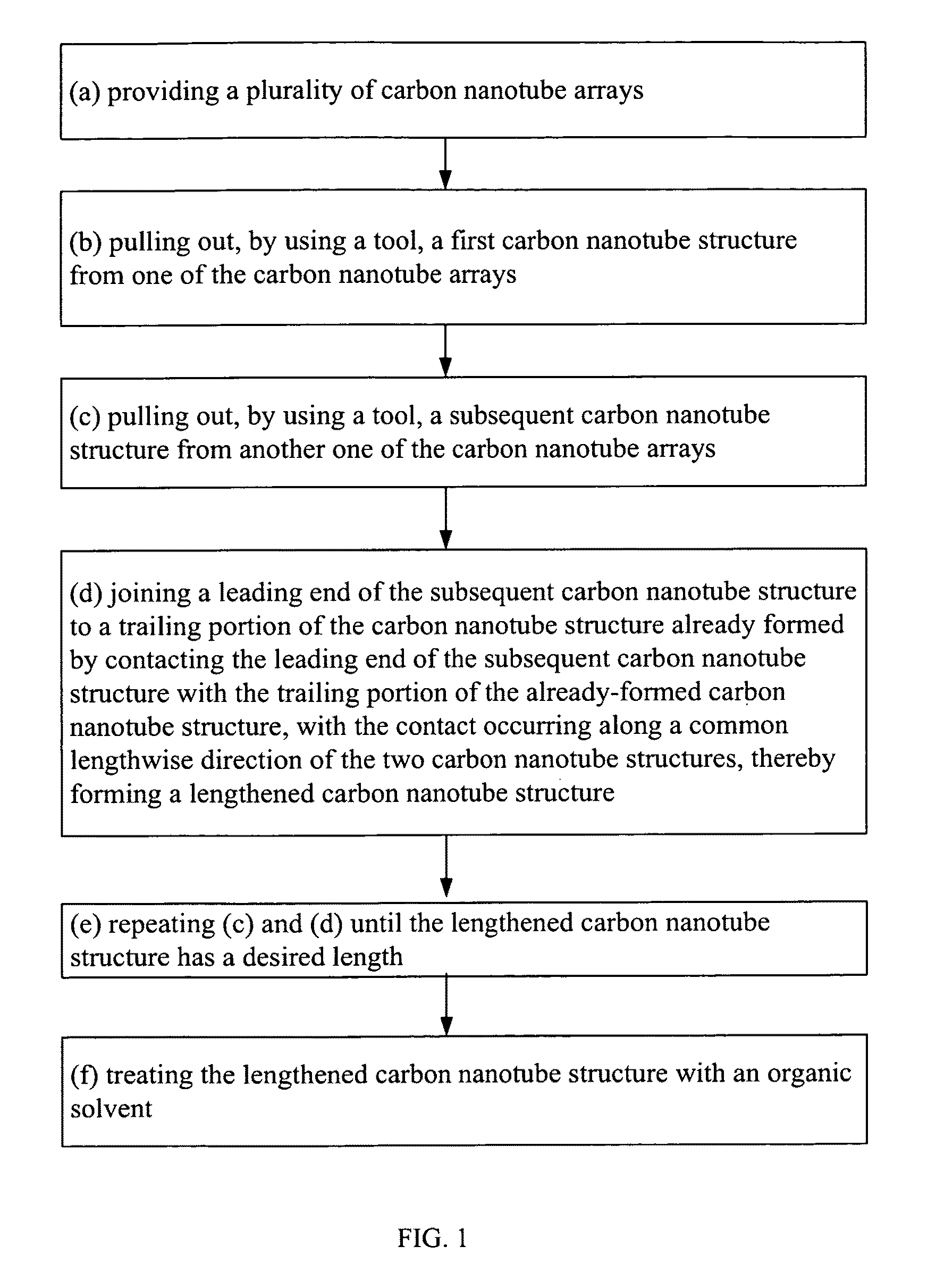

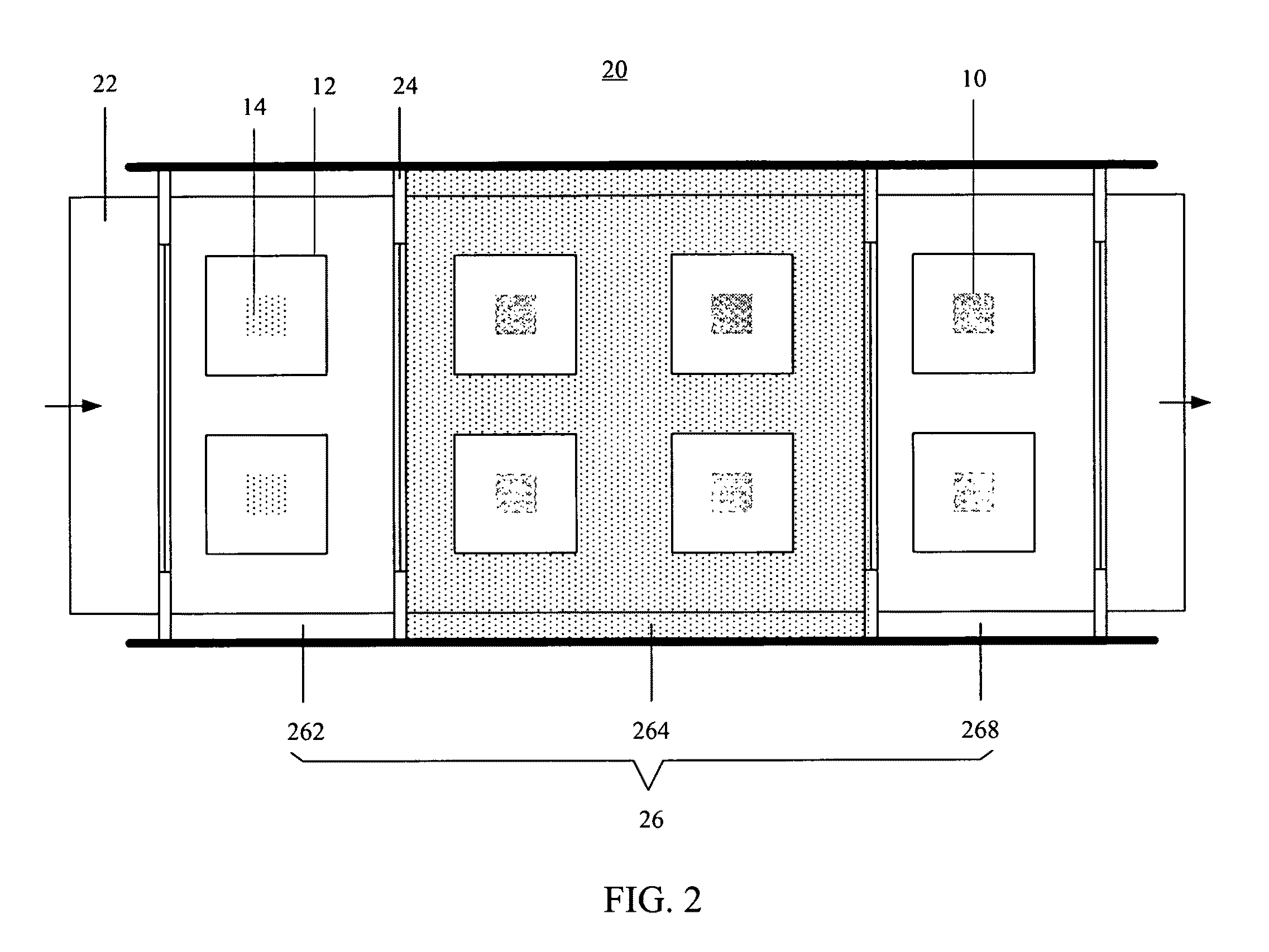

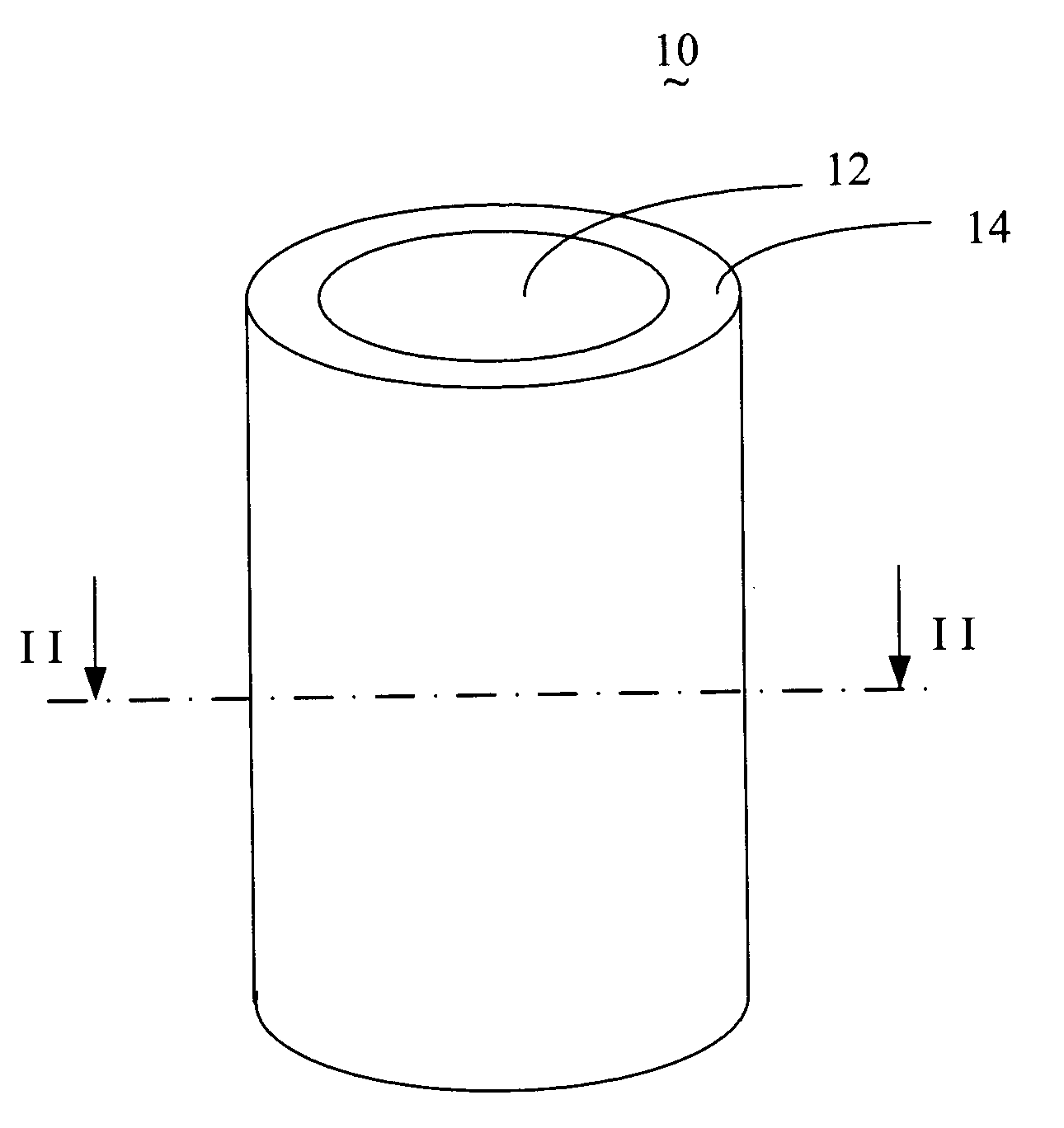

Method for fabricating carbon nanotube yarn

A method for fabricating a carbon nanotube yarn includes providing a plurality of carbon nanotube arrays; pulling out, by using a tool, a first carbon nanotube structure from one of the carbon nanotube arrays; pulling out a subsequent carbon nanotube structure from another one of the carbon nanotube arrays; joining a leading end of the subsequent carbon nanotube structure to a trailing portion of the carbon nanotube structure already formed by contacting the leading end of the subsequent carbon nanotube structure with the trailing portion of the already-formed carbon nanotube structure, with the contact occurring along a common lengthwise direction of the two carbon nanotube structures, thereby forming a lengthened carbon nanotube structure; repeating the pulling and the joining until the lengthened carbon nanotube structure has a desired length; and treating the lengthened carbon nanotube structure with an organic solvent.

Owner:TSINGHUA UNIV +1

Field emission element having carbon nanotube and manufacturing method thereof

ActiveUS20070296323A1Discharge tube luminescnet screensNanoinformaticsGlass compositesCarbon nanotube yarn

A given field emission element includes a carbon nanotube field emission wire and at least one supporting protective layer coating an outer surface of the carbon nanotube field emission wire. The carbon nanotube field emission wire is selected from a group consisting of a carbon nanotube yarn, a wire-shaped CNT-polymer composite, and a wire-shaped CNT-glass composite. A method for manufacturing the described field emission element includes the steps of: (a) providing one carbon nanotube field emission wire; (b) forming one supporting protective layer on an outer surface of the carbon nanotube field emission wire; and (c) cutting the carbon nanotube field emission wire to a predetermined length and treating the carbon nanotube emission wire to form the field emission element.

Owner:TSINGHUA UNIV +1

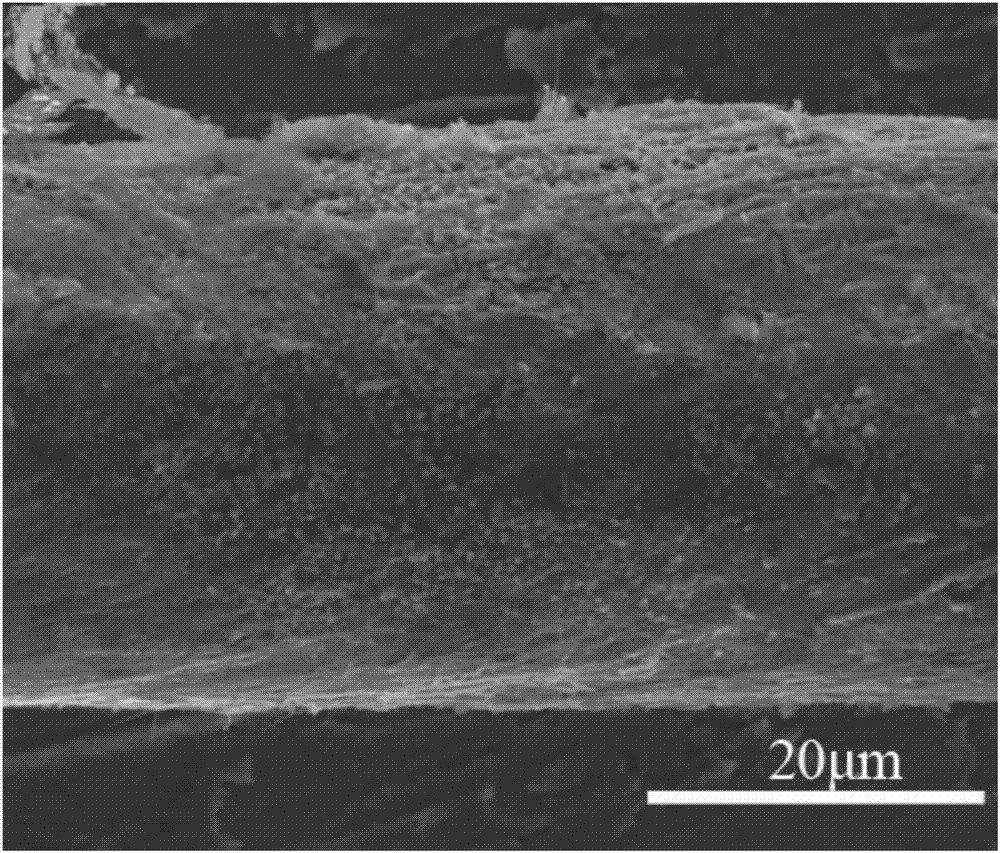

Preparation method of carbon nanotube yarn-based flexible supercapacitor composite electrode material

InactiveCN107248456AEasy to prepareImprove electrochemical performanceHybrid capacitor electrodesHybrid/EDL manufactureTransient stateComposite electrode

The invention discloses a preparation method of a carbon nanotube yarn-based flexible supercapacitor composite electrode material, and relates to the technical field of a supercapacitor electrode material. The preparation method comprises the steps of preparing carbon nanotube yarn by a spinning method, combing to prepare a rough product of the electrode material by an electroplating method, heating and purifying the electrode material, preparing graphene ink, performing graphene ink impregnation on the composite material, and finally obtaining a carbon nanotube (CNT) / transient-state metal oxide / graphene (GN) composite electrode material, wherein a transient-state metal oxide attached onto a carbon nanotube comprises Co3O4 nanoparticles, NiO nanoparticles or MnO2 nanoparticles. The preparation method has the characteristics of wide application prospect, excellent electrochemical performance and green and environmental-friendly process and is simple and practical, and promotion and application are easy.

Owner:江西省世道新能源科技有限公司

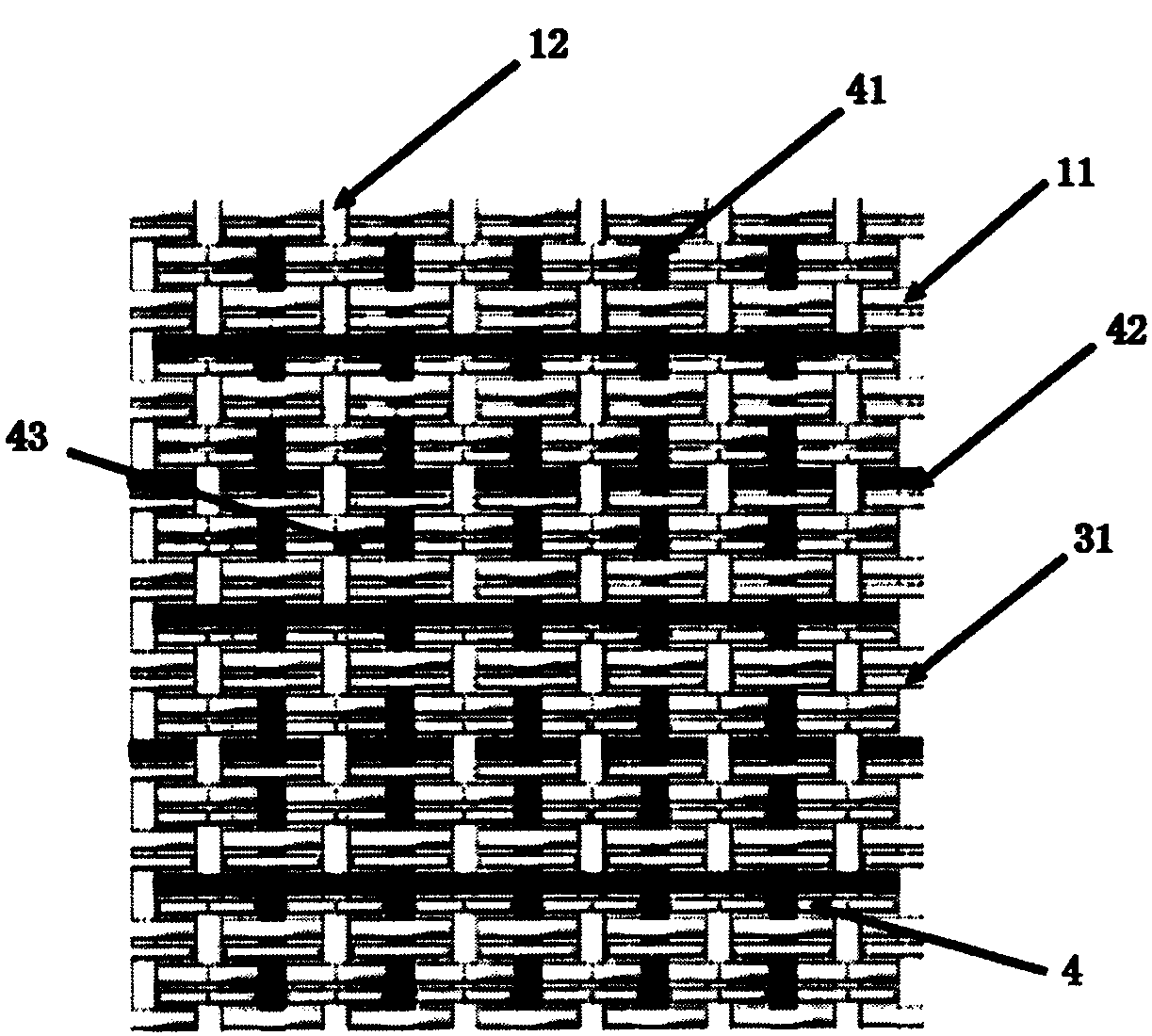

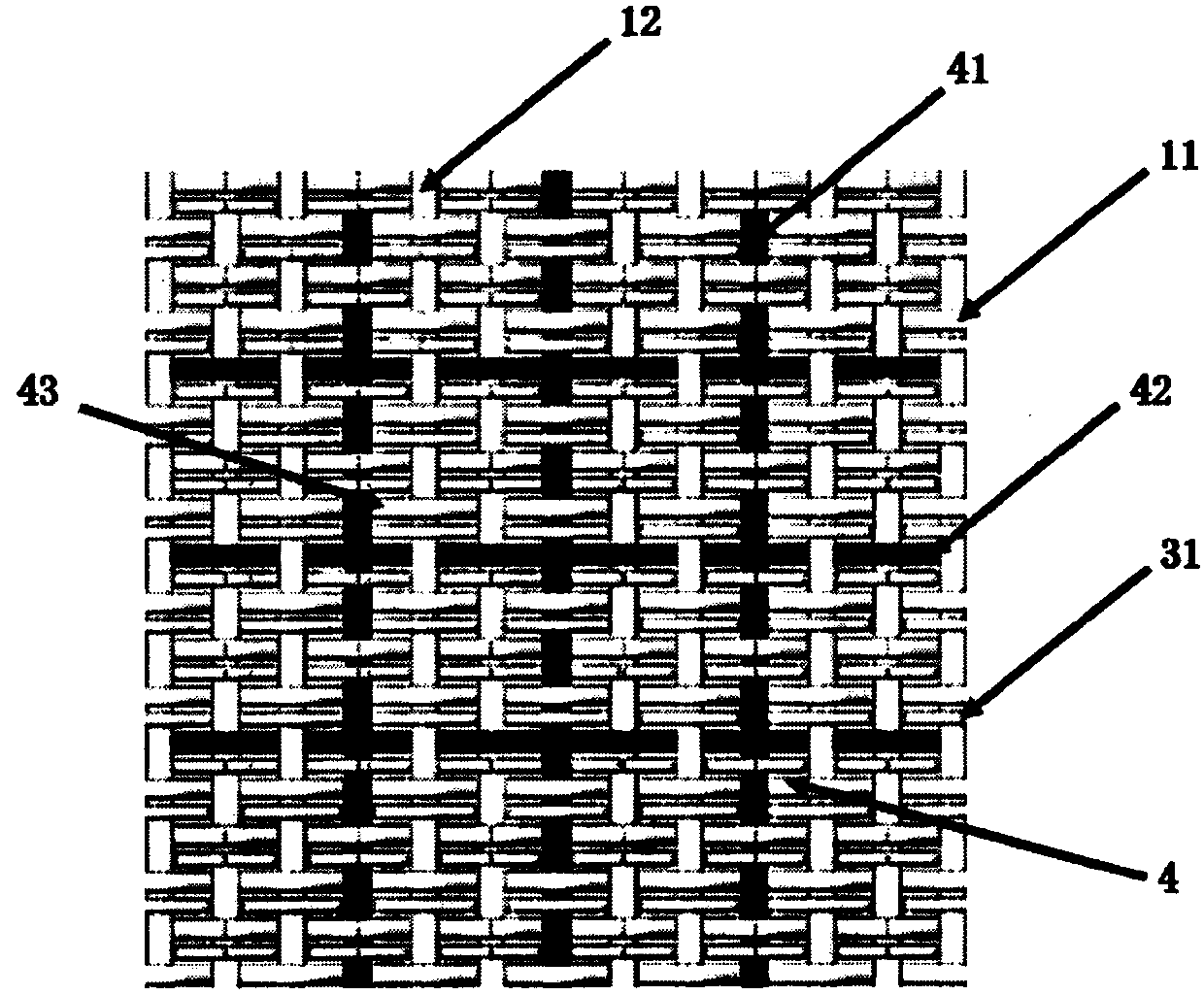

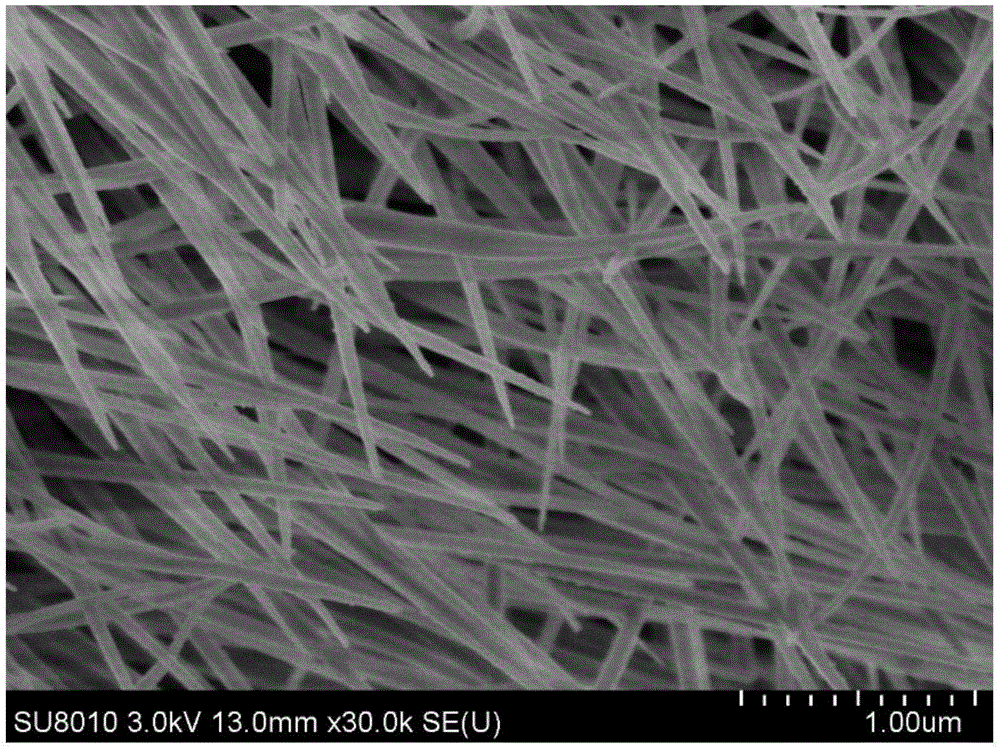

Carbon nanotube fabric with multi-scale pore structure and preparation method thereof

InactiveCN105780242AHigh strengthImprove flexibilityWeft knittingFilament/thread formingFiberMicrometer

The invention provides a carbon nanotube fabric with a multi-scale pore structure and a preparation method thereof. The carbon nanotube fabric with the multi-scale pore structure is characterized by consisting of carbon nanotube yarns, wherein each carbon nanotube yarn consists of carbon nanotube fiber; the carbon nanotube fiber consists of carbon nanotubes. The built carbon nanotube fabric has the multi-scale pore structure including several nanometers to tens of nanometers of pores between the carbon nanotubes, tens of nanometers to several hundreds of nanometers of pores between the carbon nanotube fiber and several micrometers to tens of micrometers of pores between the carbon nanotube yarns. The carbon nanotube fabric has the advantages of high strength, high flexibility, high electric conductivity, high specific surface area and good transparency, and is hopeful to be used in the fields of composite materials, flexible electronics and the like, such as flexible energy sources and sensing devices.

Owner:DONGHUA UNIV

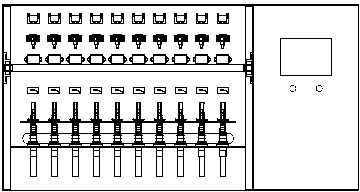

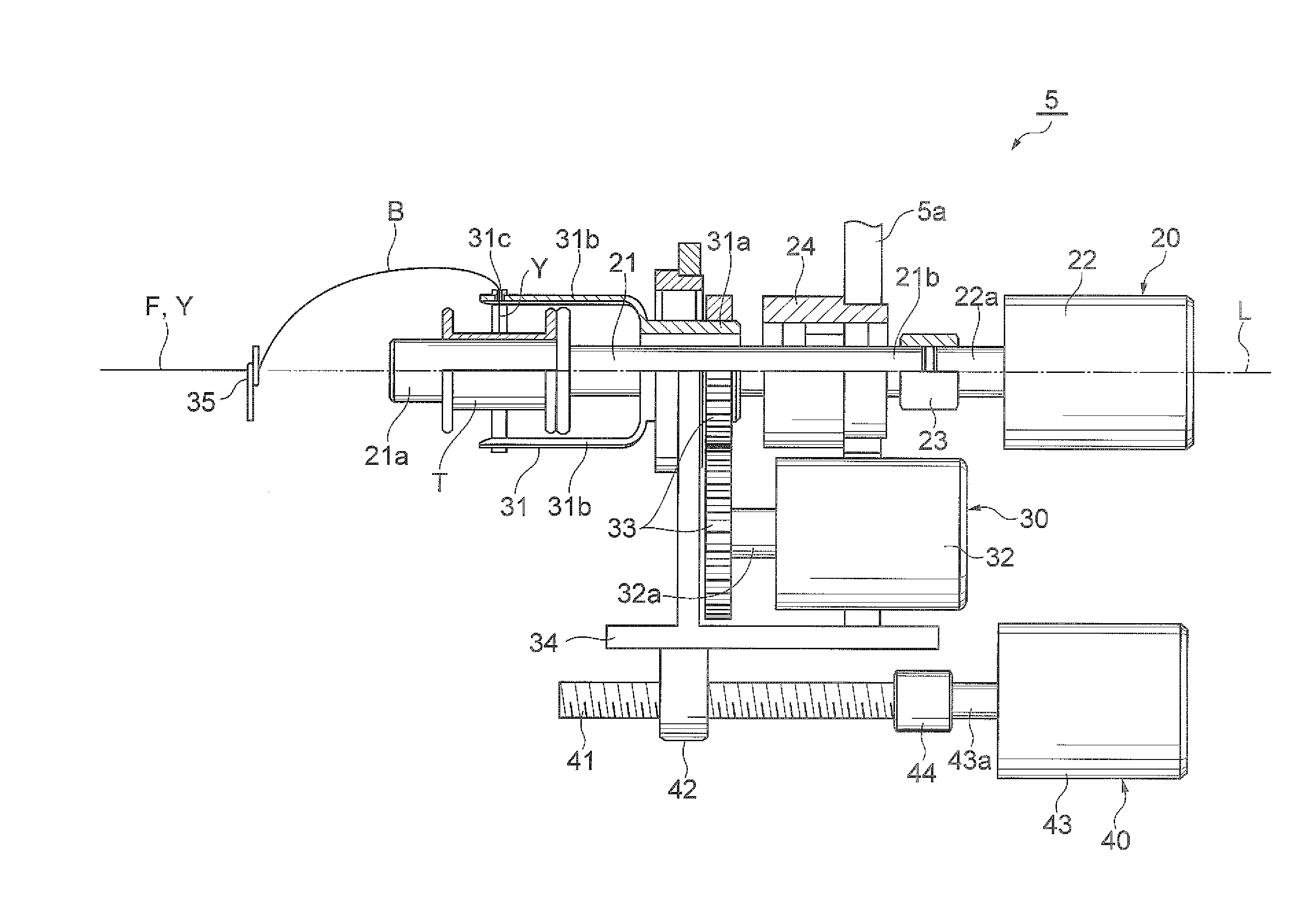

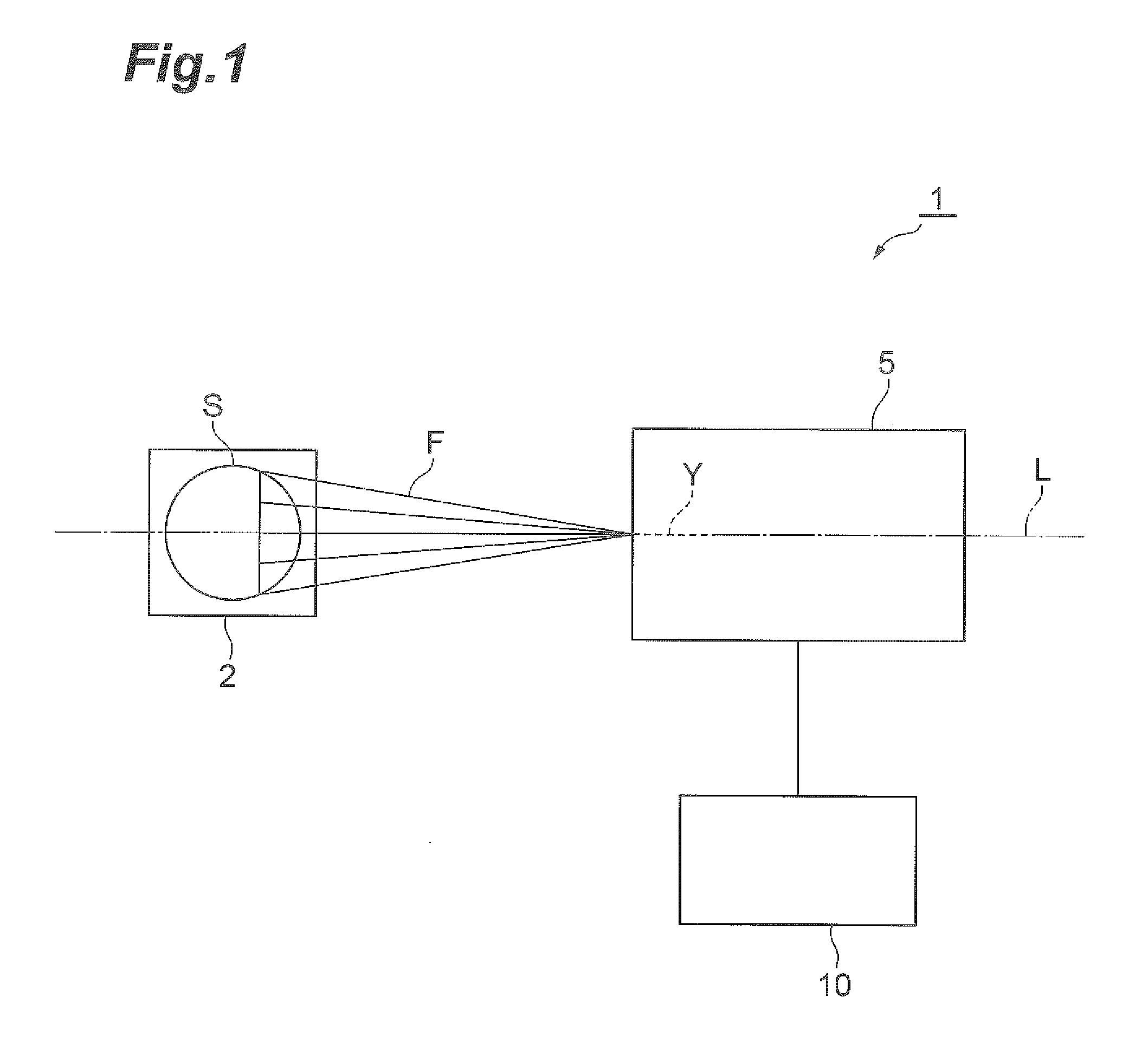

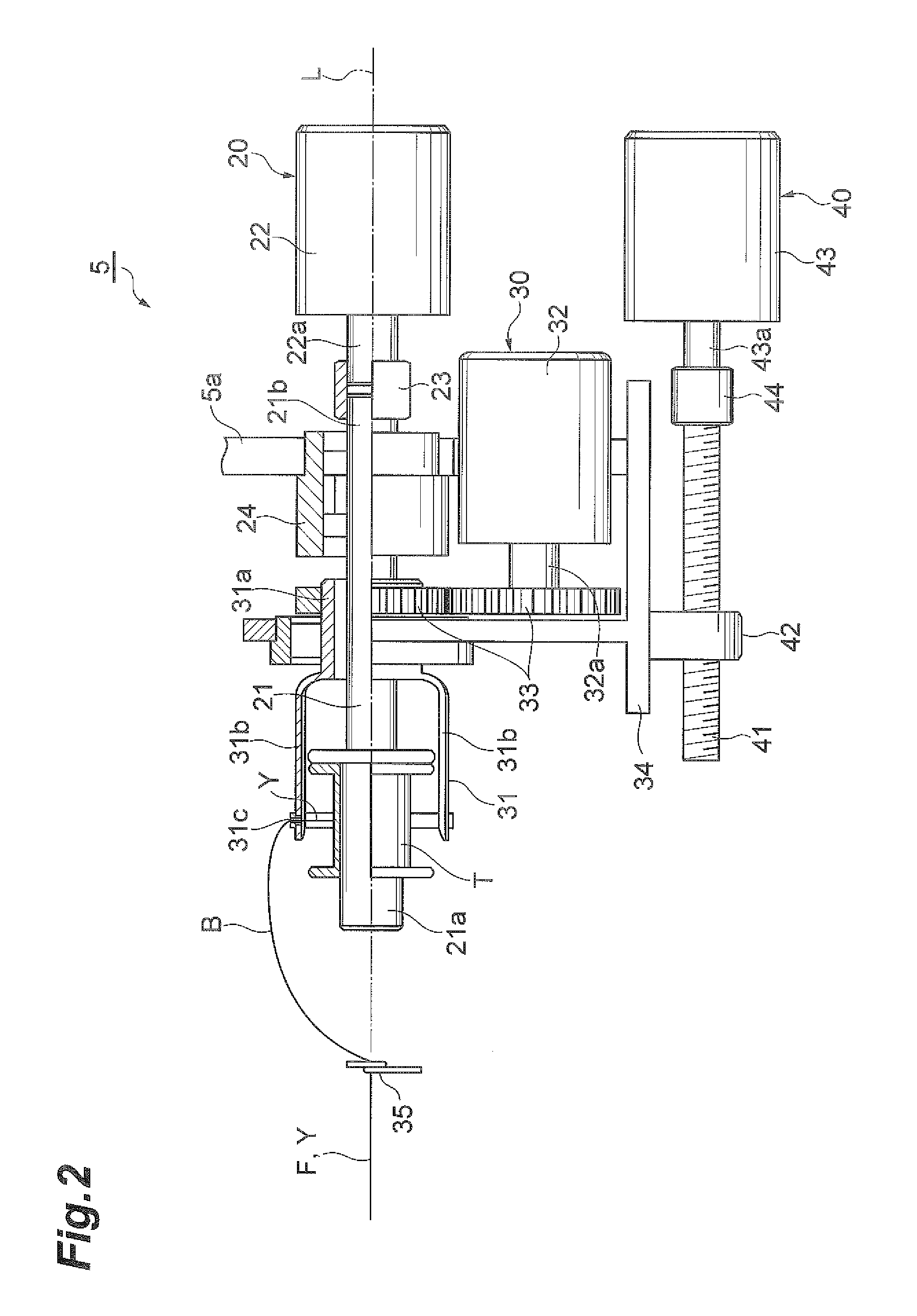

Thread production device

ActiveUS20160138202A1Sufficient performanceSolution value is not highFilament handlingDrafting machinesFiberWind driven

A yarn producing apparatus produces CNT carbon nanotube) yarn from CNT fibers while causing the CNT fibers to run. The yarn producing apparatus includes a wind driving mechanism that causes a winding shaft provided with a winding tube to rotate about a winding centerline of the winding shaft to wind the CNT yarn onto the winding tube, a twist driving mechanism that causes a guide to rotate around the winding tube and guide the CNT yarn to the winding tube, to twist the CNT fibers and produce the CNT yarn while causing the CNT fibers, CNT yarn, or both to swirl, and a traverse driving mechanism that causes the guide to reciprocate relative to the winding tube along the winding centerline of the winding shaft to cause the CNT yarn to traverse the winding tube.

Owner:MURATA MASCH LTD

Infrared detector with carbon nanotube yarns

An infrared detector based on CNT yarns includes a first electrode, a second electrode and a composite film between the first electrode and the second electrode. A first end of the composite film is electrically connected to the first electrode. A second end of the composite film and the second electrode cooperatively define a gap therebetween. The composite film is capable of extending in a direction towards the second electrode and, thereby forming an electrical connection between the first and the second electrodes when the composite film is illuminated by infrared light. The composite film includes a polymer layer, a plurality of semiconducting CNT yarns dispersed in the polymer layer, and a plurality of metallic CNT yarns dispersed in the polymer layer. Each semiconducting CNT yarn includes a plurality of twisted semiconducting CNTs. Each metallic CNT yarn includes a plurality of twisted metallic CNTs.

Owner:HON HAI PRECISION IND CO LTD

High strength, light weight corona wires using carbon nanotube yarns

ActiveUS20090252535A1Low working voltageMaterial analysis by optical meansElectrographic process apparatusCarbon nanotube yarnHigh intensity

Exemplary embodiments provide materials and devices for a corona charging. Specifically, carbon nanotube yarns can be used as corona wires (or coronode) in a corotron-type or scorotron-type charging device. The carbon nanotube yarns can provide small diameters, and desired electrical, mechanical and thermal properties. The carbon nanotube yarns can have a diameter of about 100 microns or less for a low operating voltage of the charging device.

Owner:XEROX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com