Three-dimensional pressure sensing fabric with spacer woven structures and method for preparing three-dimensional spacer pressure sensing fabric

A three-dimensional, pressure technology, applied in the direction of fabric, multi-strand fabric, textile, etc., can solve the problems of low carbon nanotube content, uneven dispersion, low degree of orientation, etc., to achieve light weight, high sensing sensitivity, high sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

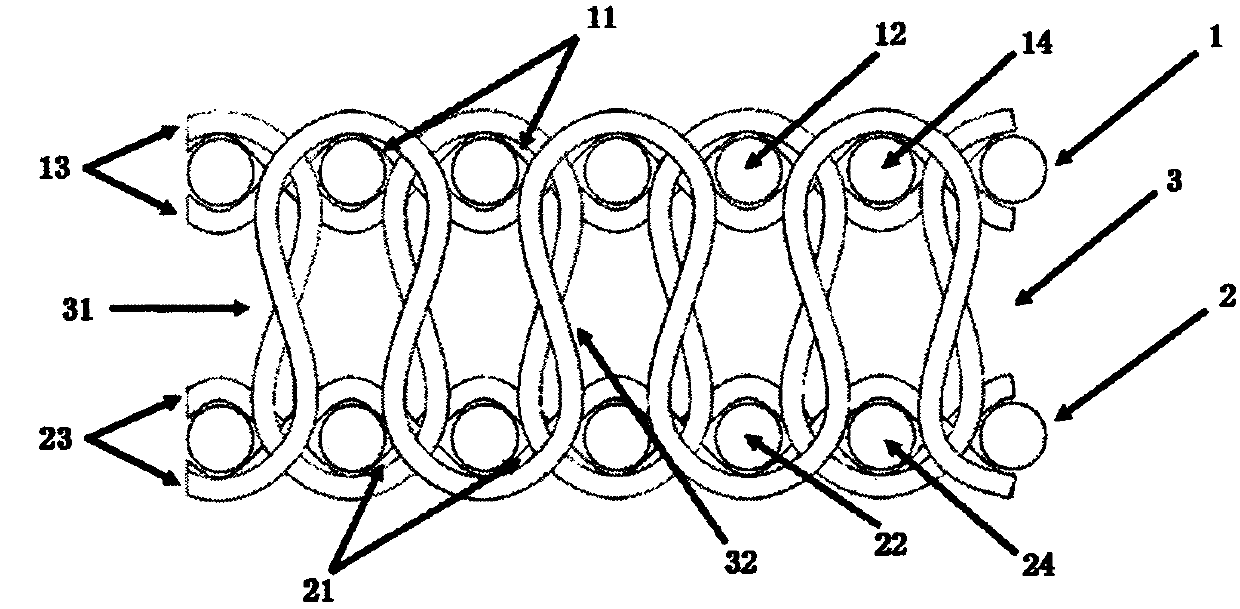

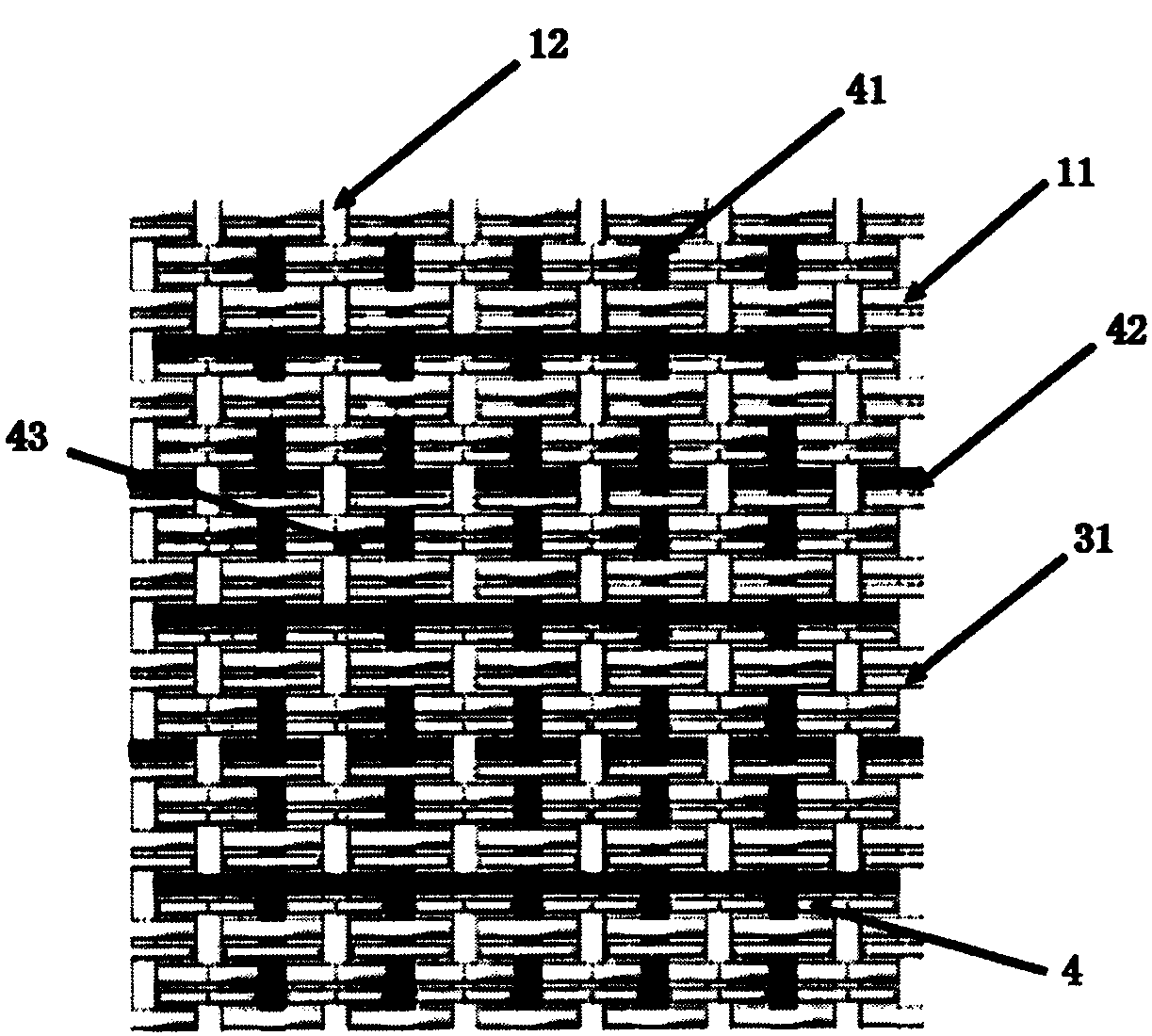

[0028] A method for preparing a three-dimensional interval woven structure pressure sensing fabric for detecting the pressure position and force value in the low pressure range (1-10kPa):

[0029] Using three-dimensional woven weaving technology, two layers of upper warp threads 11 and two layers of lower warp threads 21 respectively penetrate into the heald frame equipped with binocular healds, one layer of upper weft threads 12 and one layer of lower weft threads 22 penetrate into the modified multi-layer arrow shaft Weft insertion device, the spacer yarn 31 penetrates the common heald frame; the upper warp yarn layer formed by interweaving two layers of upper warp yarns 11 and one layer of upper weft yarns 12 1 3 and the upper weft yarn layer 14 jointly form the upper yarn layer 1, and the lower warp yarn layer 23 and the lower weft yarn layer 24 formed by the interweaving of two layers of lower warp yarns 21 and one layer of lower weft yarn yarns 22 jointly form the lower y...

Embodiment 2

[0042] A preparation method of a three-dimensional interval woven structure pressure sensing fabric for detecting the pressure position and force value under the medium pressure range (10-100kPa):

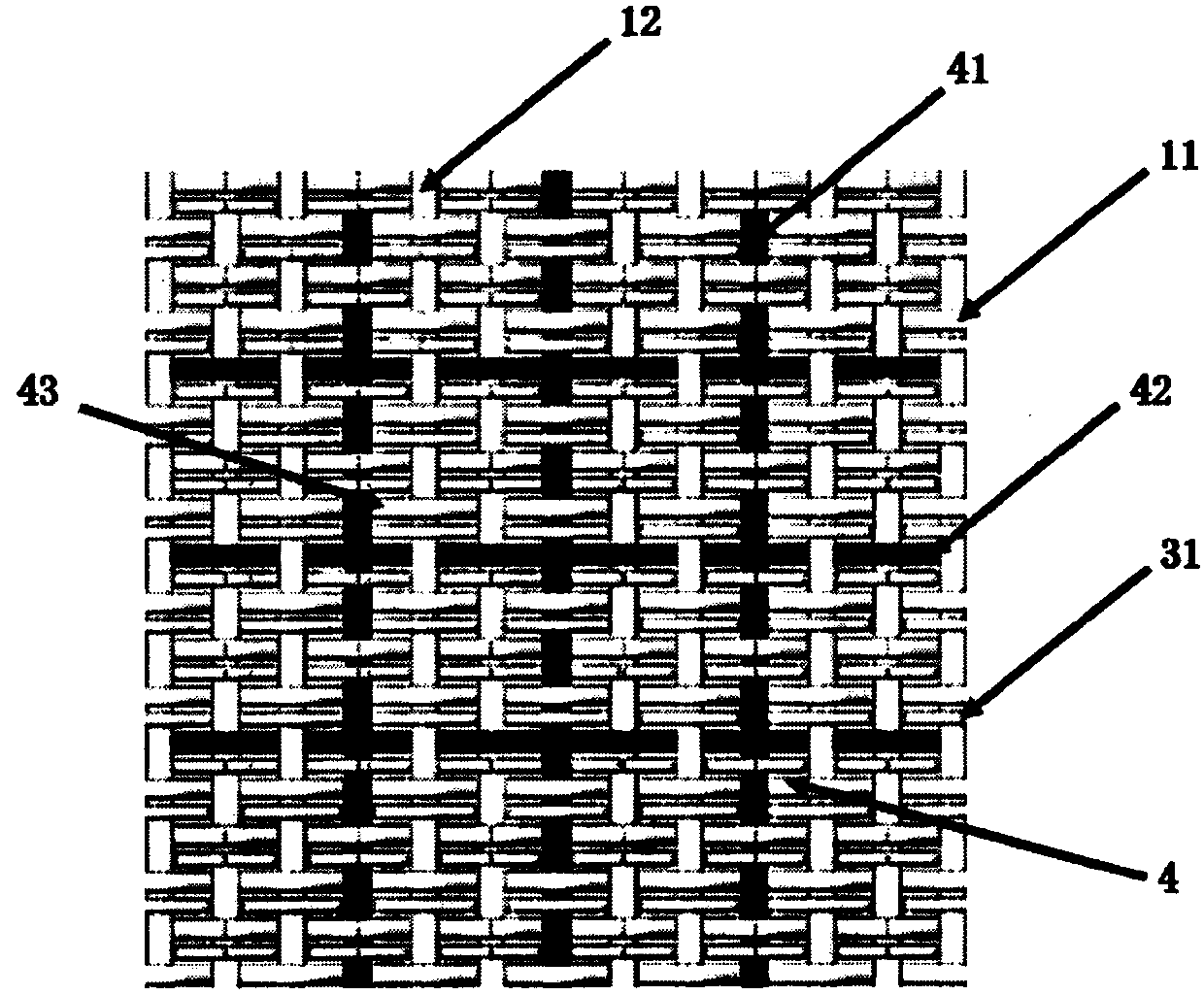

[0043] The weaving method of the lightweight three-dimensional carbon nanotube pressure-sensing fabric is the same as in Example 1, except that carbon nanotube yarns with different sensing performance parameters are used, the height of the spacer layer 3 is changed, and the pressure-sensing layer 4 conducts electricity. Network 43 size, type of elastic resin, three-dimensional interval woven structure pressure sensing fabric designed to detect the pressure position and force value under the medium pressure range (10 ~ 100kPa), such as image 3 shown.

[0044] The upper warp thread 11, the upper weft thread 12, the lower warp thread 21, the lower weft thread 22 and the spacer yarn 31 are all high-strength high-modulus polyethylene fibers with a fineness of 300 tex.

[0045] The hei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com