Carbon nanotube fabric with multi-scale pore structure and preparation method thereof

A technology of carbon nanotubes and carbon nanotube fibers, which is applied in the field of nanometers, can solve the problems of small specific surface area, poor flexibility, high substrate strength, high flexibility, high conductivity and high specific surface area, and achieve high specific surface area, high flexibility, The effect of high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

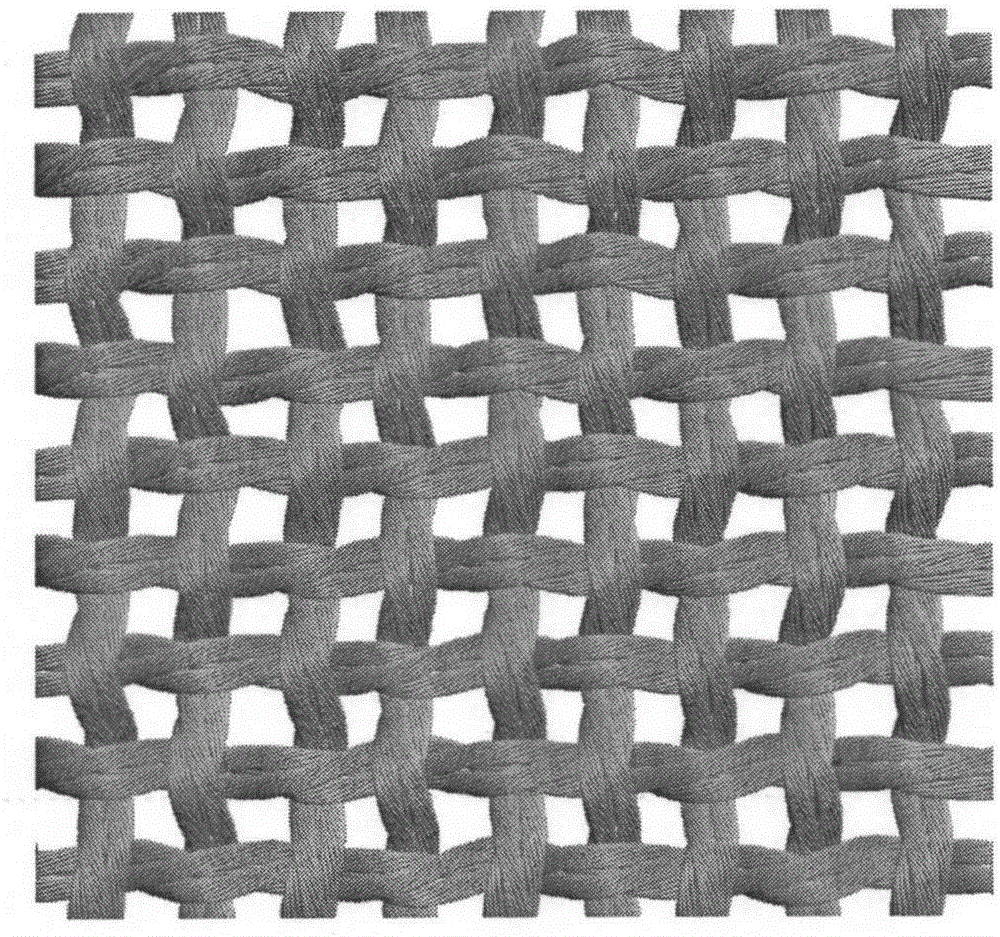

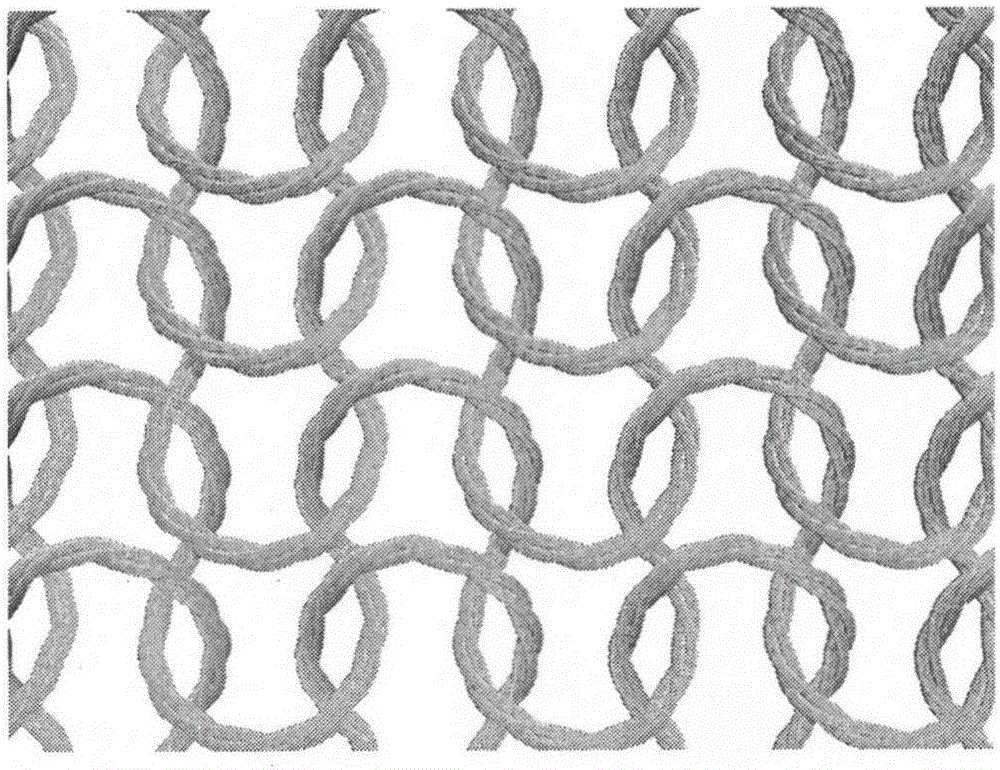

[0025] A carbon nanotube fabric with a multi-scale hole structure is composed of carbon nanotube yarns, the carbon nanotube yarns are composed of carbon nanotube fibers, and the carbon nanotube fibers are composed of carbon nanotubes. The preparation method is as follows: holes with a diameter of 5-8 nm are formed between the carbon nanotube fibers in the carbon nanotube fiber, and holes with a diameter of 50-100 nm are formed between the carbon nanotube fibers in the carbon nanotube yarn. holes, the carbon nanotube yarns form holes of 5-10 μm.

[0026] (1) Growth of carbon nanotubes by chemical vapor deposition:

[0027] Sequential deposition of Al on silicon substrates by electron beam evaporation process 2 o 3 layer and Fe layer, Al 2 o 3 layer is located between the Si substrate and the Fe layer, the Al 2 o 3 The layer thickness is 5nm, as a buffer layer, and the Fe layer thickness is 1.2nm, as a catalyst; by chemical vapor deposition, ethylene is used as carbon sour...

Embodiment 2

[0035] A carbon nanotube fabric with a multi-scale hole structure is composed of carbon nanotube yarns, the carbon nanotube yarns are composed of carbon nanotube fibers, and the carbon nanotube fibers are composed of carbon nanotubes. The preparation method is as follows: holes with a diameter of 8-10 nm are formed between the carbon nanotubes in the carbon nanotube fiber, and holes with a diameter of 100-200 nm are formed between the carbon nanotube fibers in the carbon nanotube yarn. holes, the holes of 10-20 μm are formed between the carbon nanotube yarns.

[0036] (1) Growth of carbon nanotubes by chemical vapor deposition:

[0037] Sequential deposition of Al on silicon substrates by electron beam evaporation process 2 o 3 layer and Fe layer, Al 2 o 3 layer is located between the Si substrate and the Fe layer, the Al 2 o 3 The layer thickness is 5nm, as a buffer layer, and the Fe layer thickness is 1.2nm, as a catalyst; by chemical vapor deposition, ethylene is used...

Embodiment 3

[0045] A carbon nanotube fabric with a multi-scale hole structure is composed of carbon nanotube yarns, the carbon nanotube yarns are composed of carbon nanotube fibers, and the carbon nanotube fibers are composed of carbon nanotubes. The preparation method is as follows: holes with a diameter of 10-15 nm are formed between the carbon nanotubes in the carbon nanotube fiber, and holes with a diameter of 200-400 nm are formed between the carbon nanotube fibers in the carbon nanotube yarn. holes, the carbon nanotube yarns form holes of 20-40 μm.

[0046] (1) Growth of carbon nanotubes by chemical vapor deposition:

[0047] Sequential deposition of Al on silicon substrates by electron beam evaporation process 2 o 3 layer and Fe layer, Al 2 o 3 layer is located between the Si substrate and the Fe layer, the Al 2 o 3 The layer thickness is 5nm, as a buffer layer, and the Fe layer thickness is 1.2nm, as a catalyst; by chemical vapor deposition, ethylene is used as carbon source...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com