Method for preparing carbon nano tube fabric electrode and yarn electrode and application of electrode

A technology of carbon nanotubes and fabric electrodes, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor multiplier performance of fabric electrodes and yarn electrodes, decreased electrochemical performance of flexible electrodes, and complex processes. , to achieve the effects of outstanding electrochemical performance and mechanical stability, outstanding cycle stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

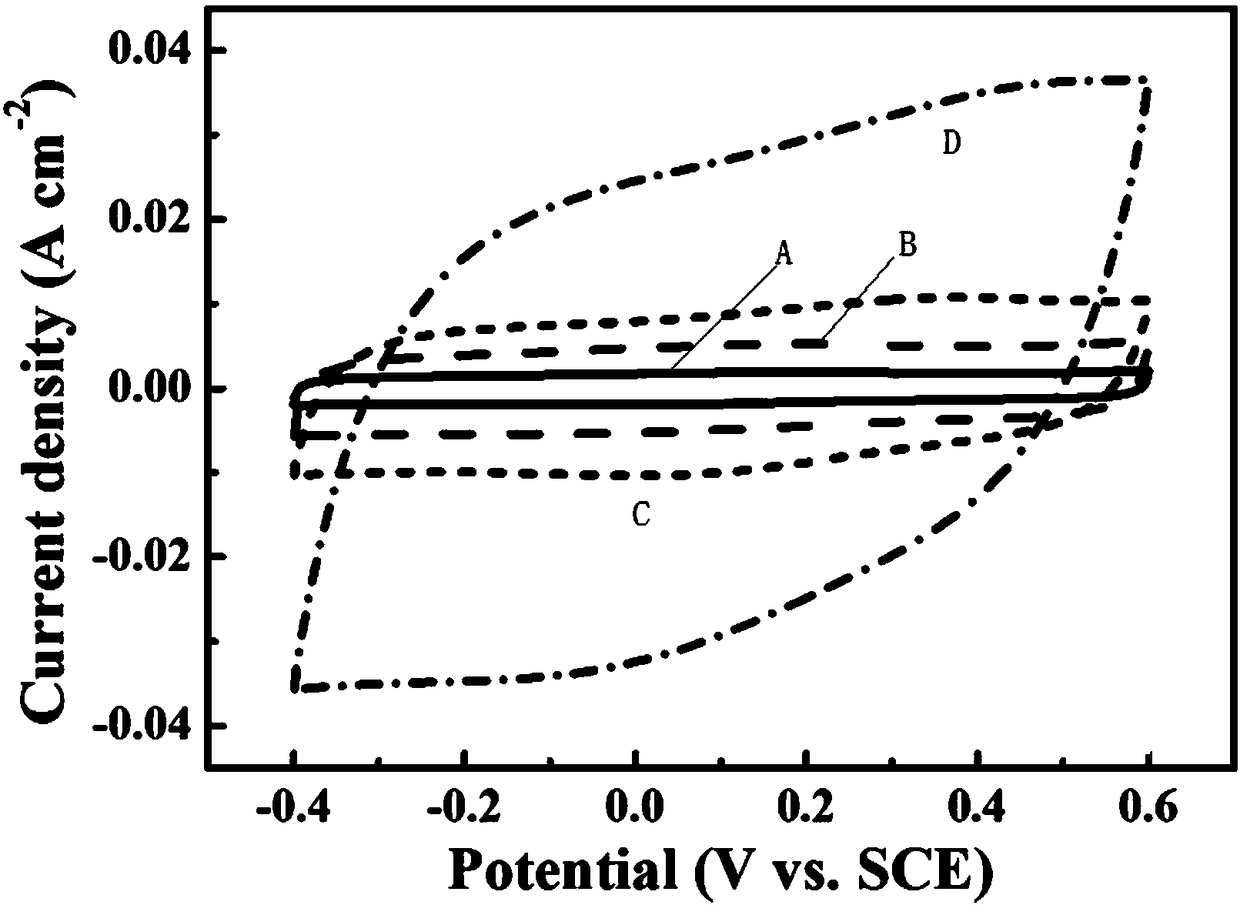

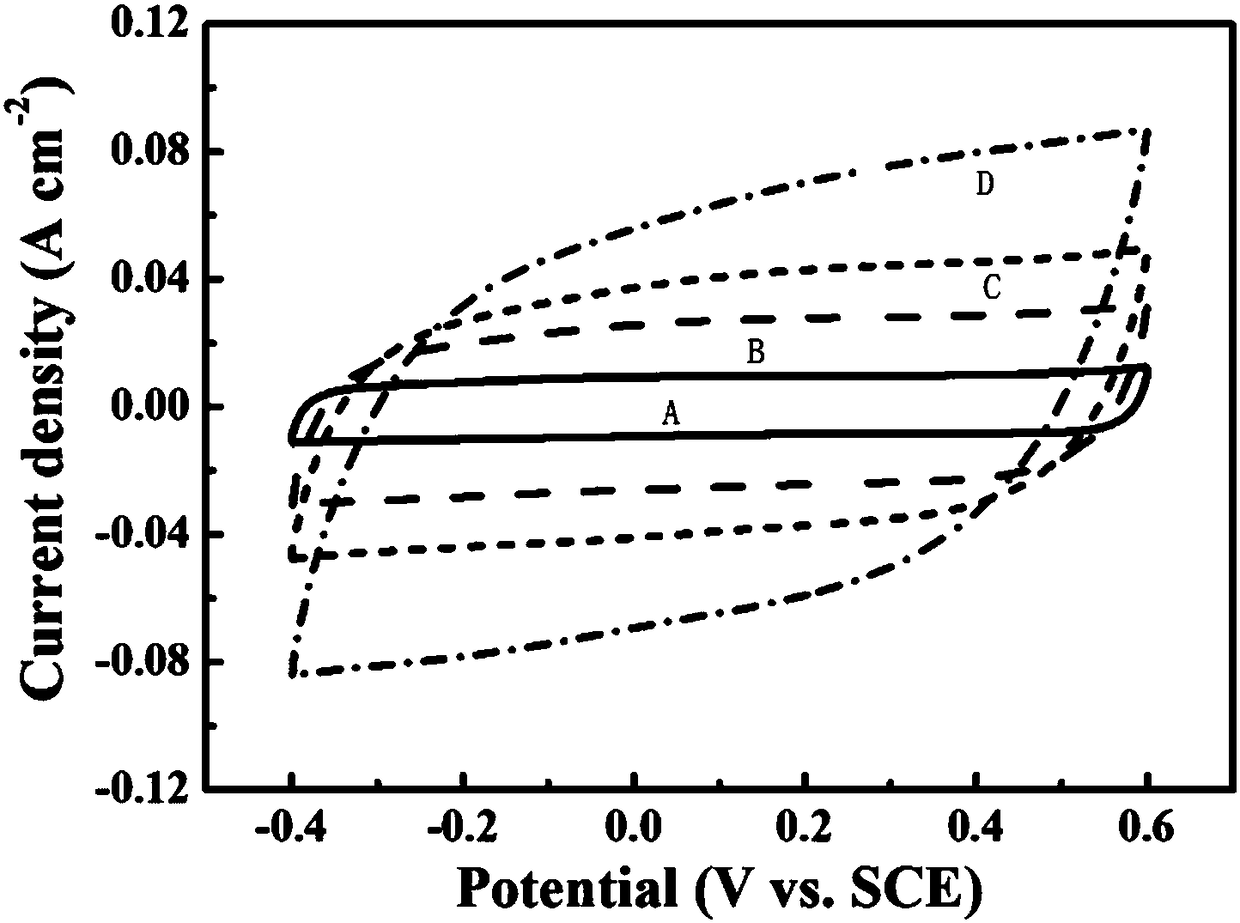

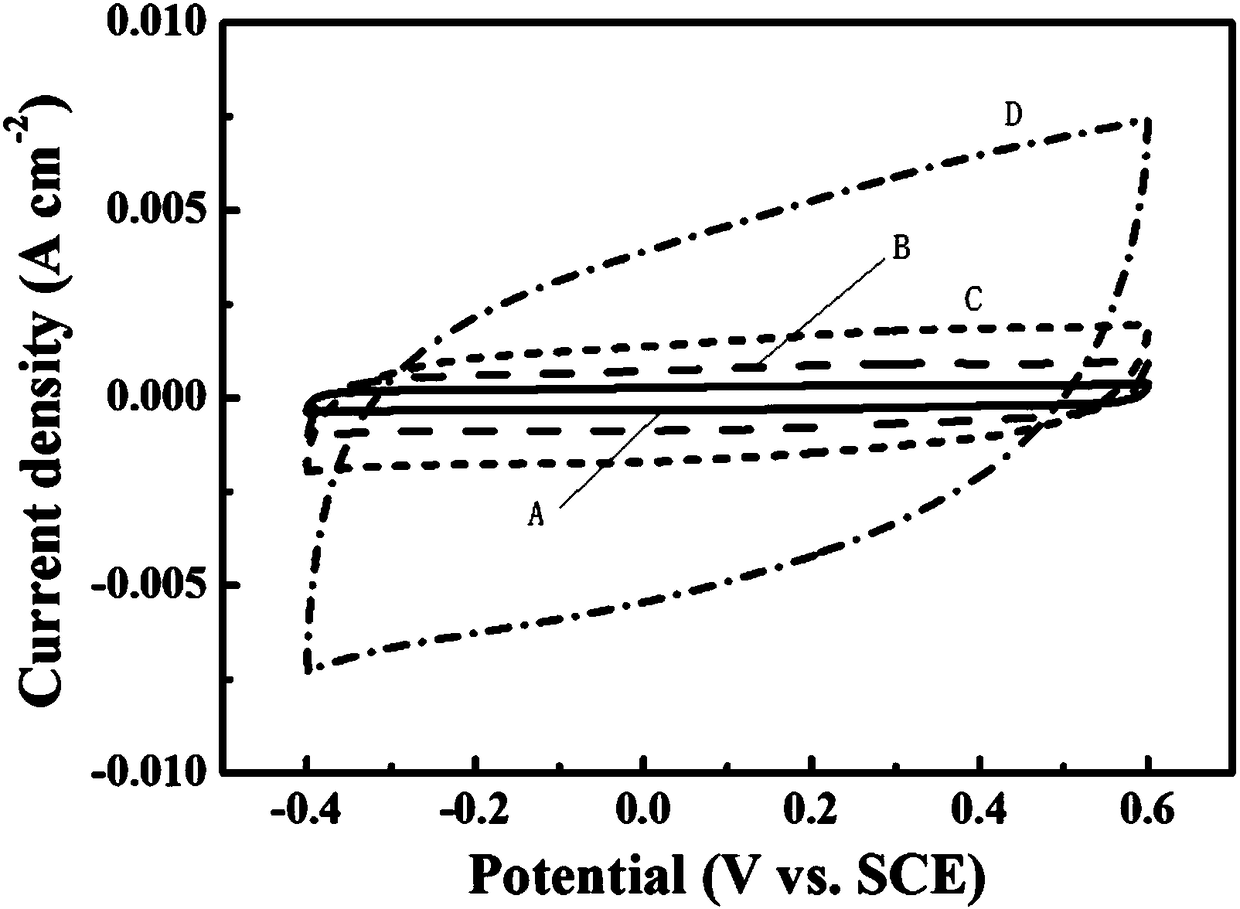

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: a kind of preparation method of carbon nanotube fabric electrode and yarn electrode, this method is carried out as follows:

[0026] 1. Dip the polyester fiber fabric or yarn in acetone for ultrasonic washing, then immerse in ethanol for ultrasonic washing, and finally immerse in deionized water for ultrasonic washing to obtain a polyester fiber fabric or yarn with impurities removed;

[0027] 2. Add tin protochloride to the mixed solvent, and then add HCl to obtain a sensitization solution; immerse the impurity-removed polyester fabric or yarn in the sensitization solution with stirring to obtain a sensitized polyester fabric or Yarn; wherein, the mixed solvent is mixed by methanol and deionized water by equal volume;

[0028] 3. Ultrasonic dispersion of carbon nanotubes in deionized water after acidification treatment to obtain a carbon nanotube dispersion;

[0029] 4. Immerse the sensitized polyester fiber fabric or yarn in the carbon nanotu...

specific Embodiment approach 2

[0031] Specific embodiment two: this embodiment is the same as specific embodiment one: the concentration of the carbon nanotube dispersion liquid described in step one is 2g L -1 ~20gL -1 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: this embodiment is the same as specific embodiment one: the concentration of stannous chloride in the sensitization process described in step two is 0.005mol L -1 ~0.2mol L -1 , the concentration of HCl is 0.02mol L -1 ~0.5molL -1 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com