Preparation method of carbon nanotube yarn-based flexible supercapacitor composite electrode material

A technology of supercapacitors and carbon nanotubes, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of low capacitance and energy density, achieve excellent electrochemical performance, no steam emission, and simple process controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] refer to figure 1 , the specific implementation method adopts the following technical scheme: the preparation method of carbon nanotube yarn-based flexible supercapacitor composite electrode material, and its preparation steps are:

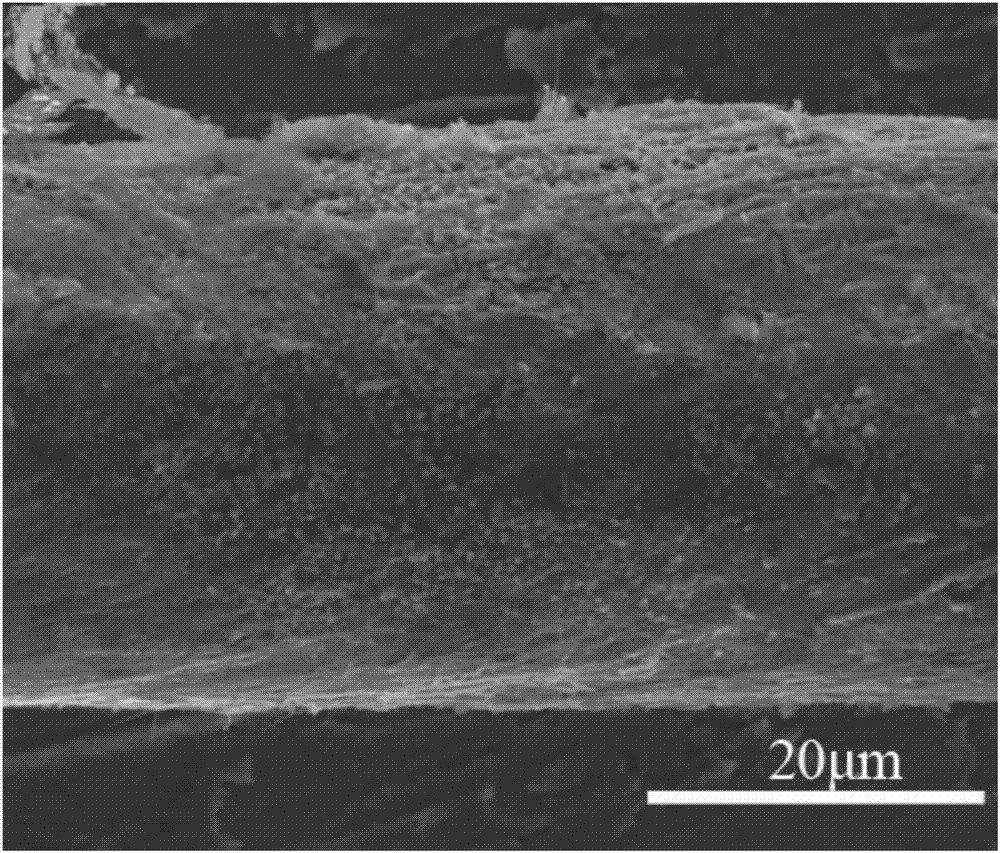

[0022] (1) Preparation of carbon nanotube (CNT) yarn by textile method: the carbon nanotube array prepared by chemical vapor deposition is pulled out from the array carbon nanotube by a motor under the condition that the spinning speed is controlled at 1000-5000rpm. Carbon nanotubes are rotated and twisted to obtain carbon nanotube yarns with a diameter of 20-50 μm;

[0023] (2) Electrodeposition compound preparation of electrode material crude product: adopt three-electrode electrodeposition, with the carbon nanotube yarn gained in step (1) as working electrode, Ag / AgCl is reference electrode, metal platinum is contrast electrode, Conducting electrodeposition in an electroplating solution containing a transition state metal salt to obtain...

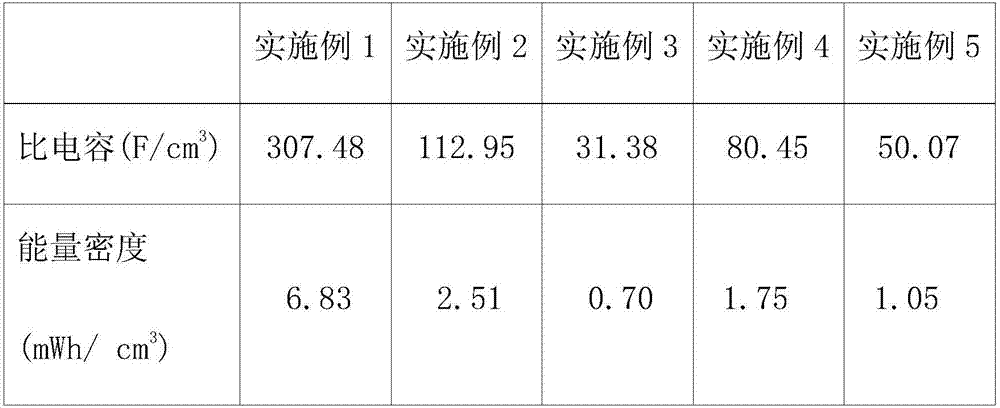

Embodiment 1

[0031] Embodiment 1: the preparation method of carbon nanotube yarn-based flexible supercapacitor composite electrode material, its preparation steps are: the carbon nanotube yarn with diameter of about 30 μ m is spun and prepared under the condition of rotating speed of 5000 rpm by self-made spinning equipment; The constant potential electrodeposition method uses the carbon nanotube yarn as a working electrode, Ag / AgCl as a reference electrode, metal platinum as a contrast electrode, and a plating solution containing 0.5mol / L Co(NO 3 ) 2 , 0.5mol / L Ni(NO 3 ) 2 , 0.1mol / L NaNO 3 The aqueous solution was deposited under 1.3V constant voltage condition for 10min. After the electrodeposition was completed, the carbon nanotube composite yarn was heated in a muffle furnace at 250°C for 150min to obtain the carbon nanotube yarn loaded with tricobalt tetroxide and nickel oxide ( CNT / Co 3 o 4 @NiO) composite material; soak the obtained composite material in the prepared graphene ...

Embodiment 2

[0032] Embodiment 2: the preparation method of carbon nanotube yarn-based flexible supercapacitor composite electrode material, its preparation steps are: spinning and preparing the carbon nanotube yarn of diameter about 35 μm under the condition of 5000rpm by spinning equipment; Potential electrodeposition method, with the carbon nanotube yarn as the working electrode, Ag / AgCl as the reference electrode, metal platinum as the reference electrode, and the plating solution contains 0.5mol / L Co(NO 3 ) 2 , 0.1mol / L NaNO 3 The aqueous solution was deposited under the condition of 1.3V constant voltage for 10min. After the electrodeposition was completed, the carbon nanotube composite yarn was heated in a muffle furnace at 250°C for 120min to obtain the carbon nanotube yarn loaded with tricobalt tetroxide (CNT / Co 3 o 4 ) composite material; the obtained composite material is immersed in the prepared graphene ink of 10mg / ml concentration for 10min, and then dried in an oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com