Patents

Literature

304results about "Cable conductor construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

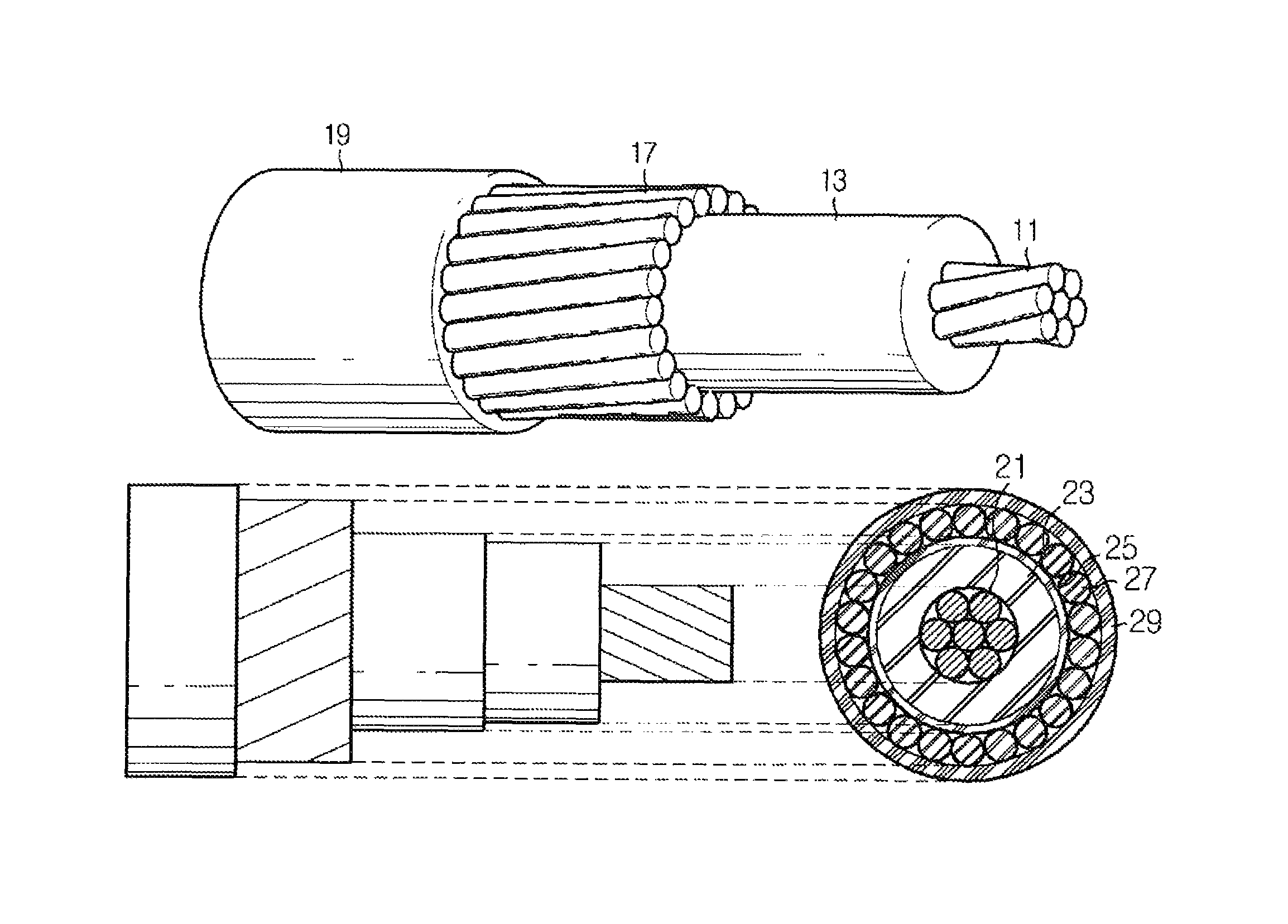

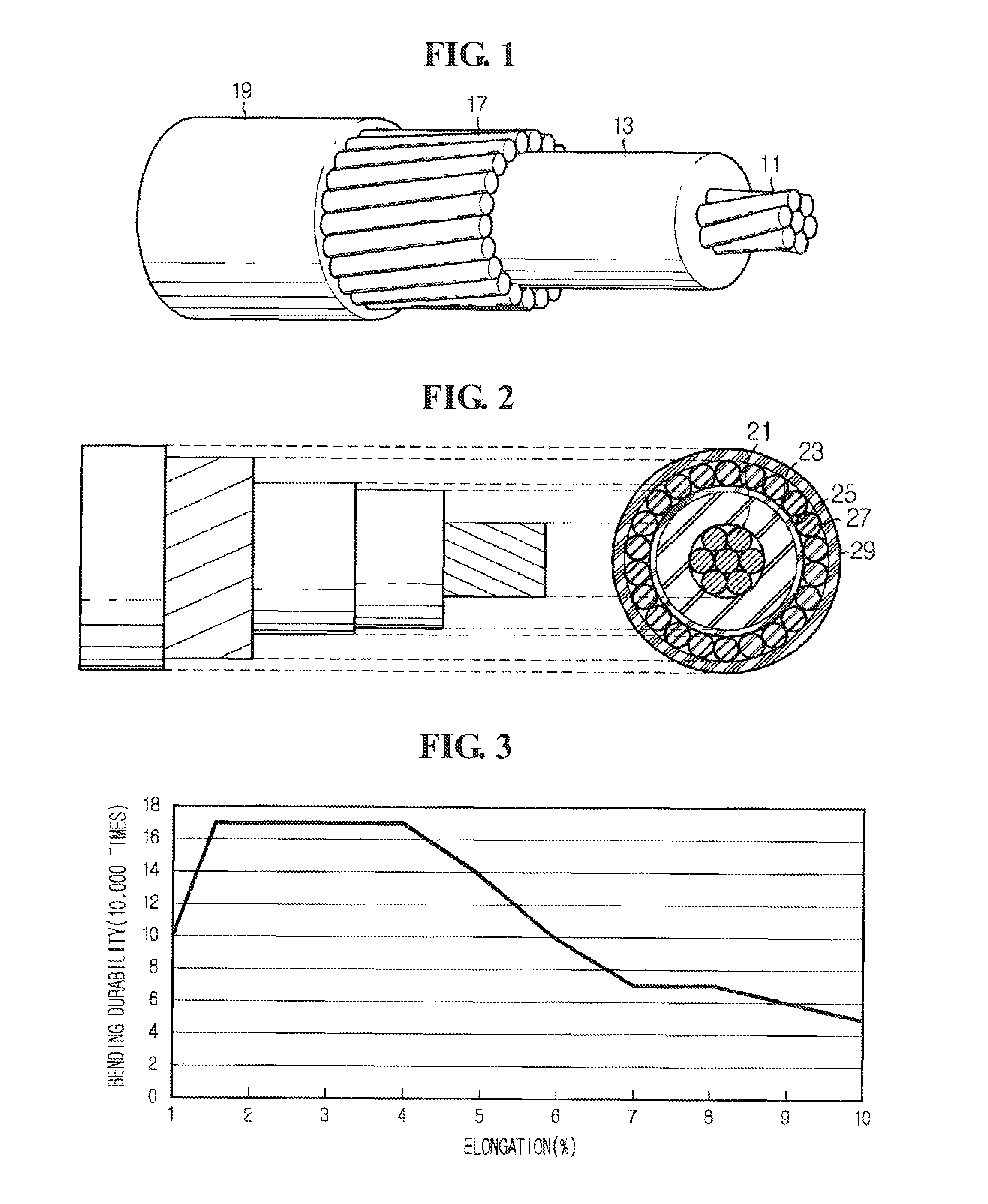

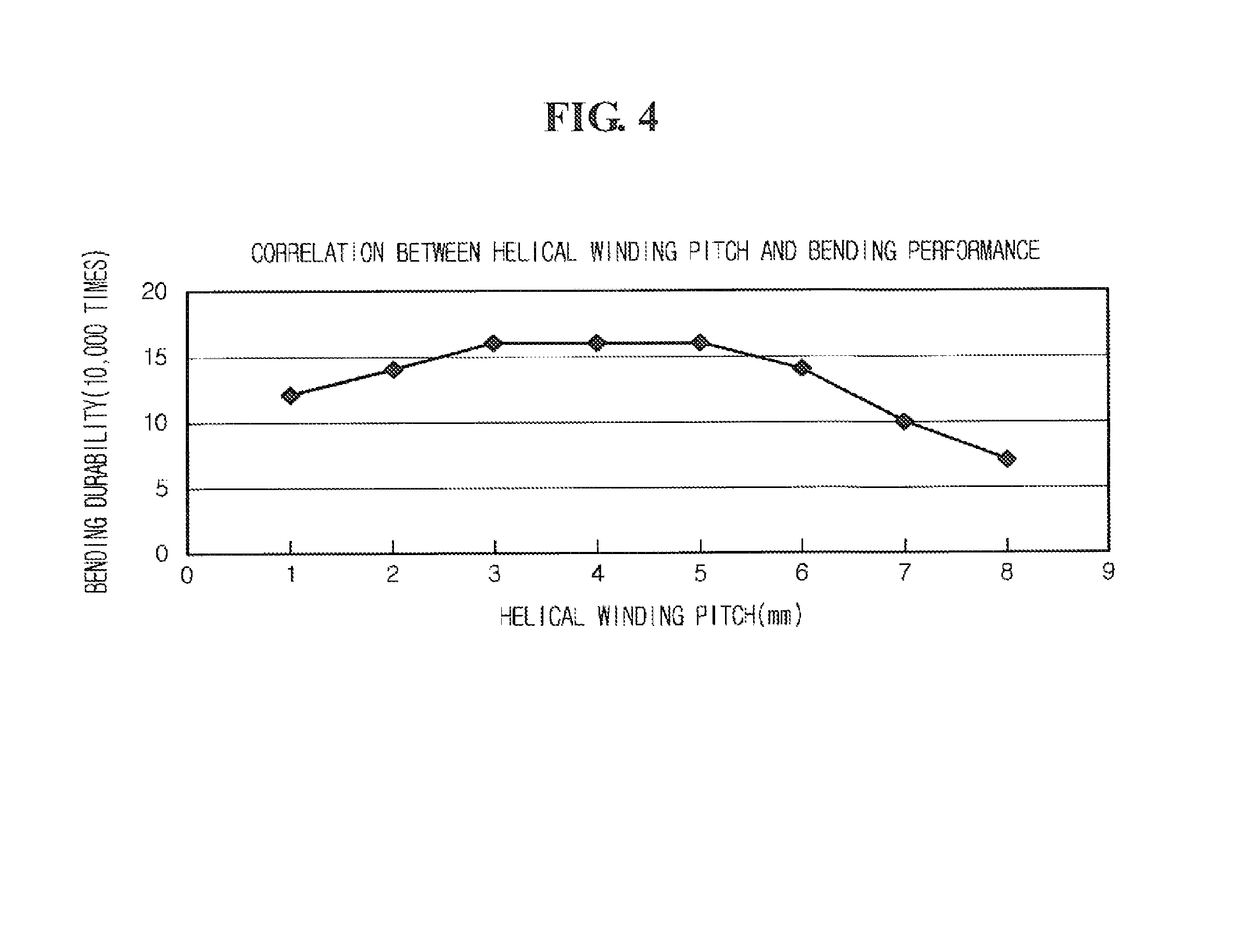

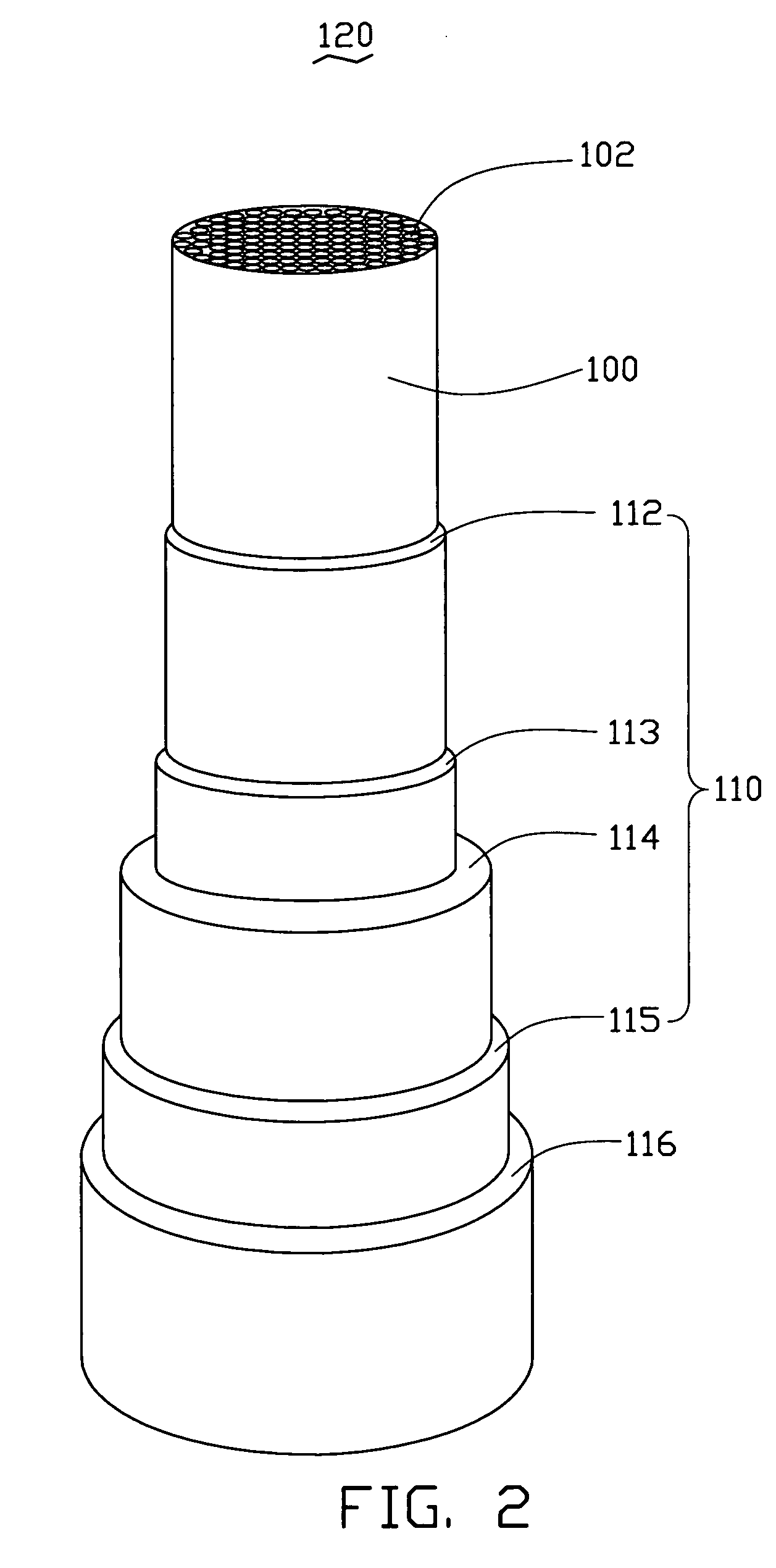

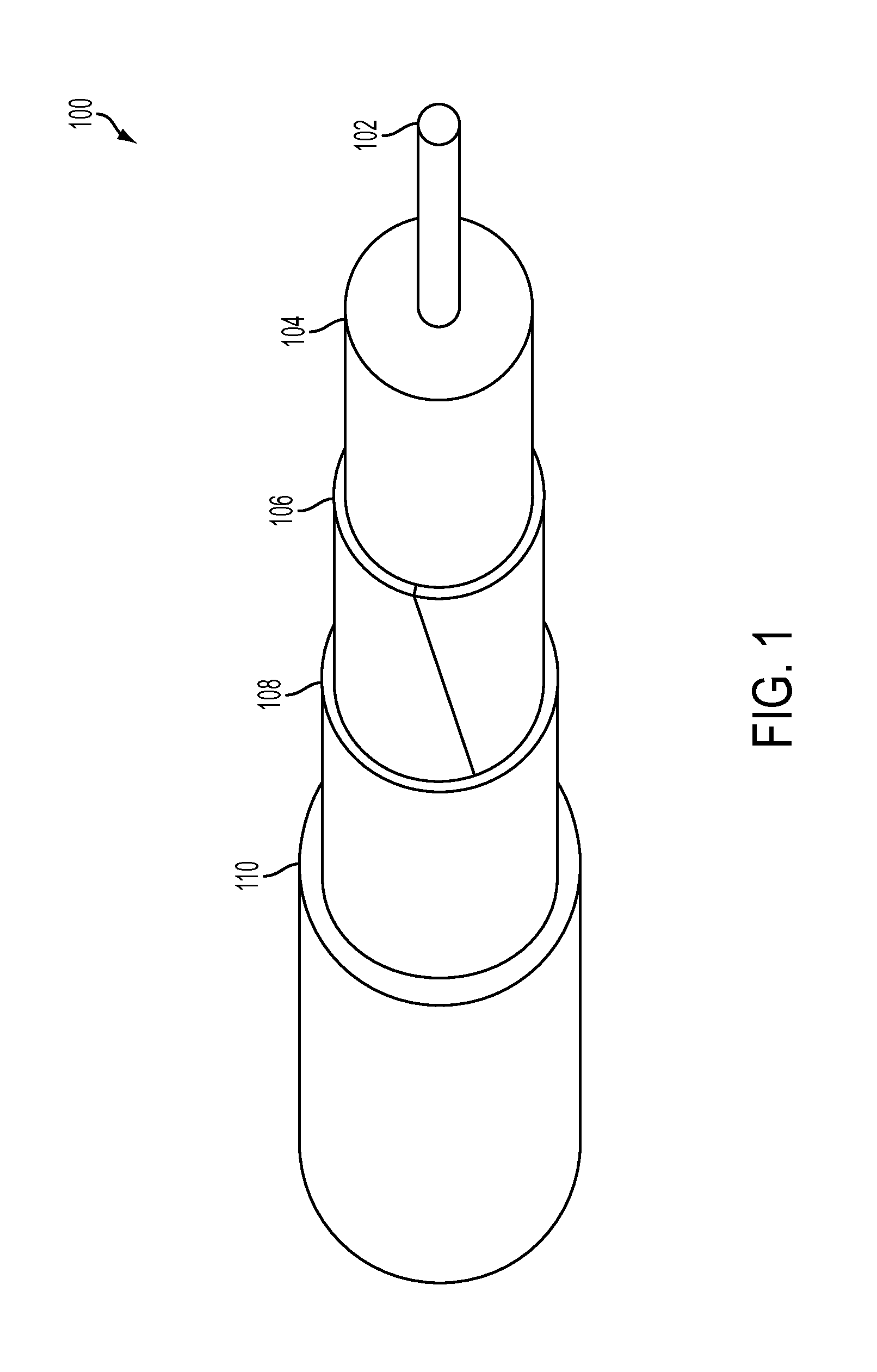

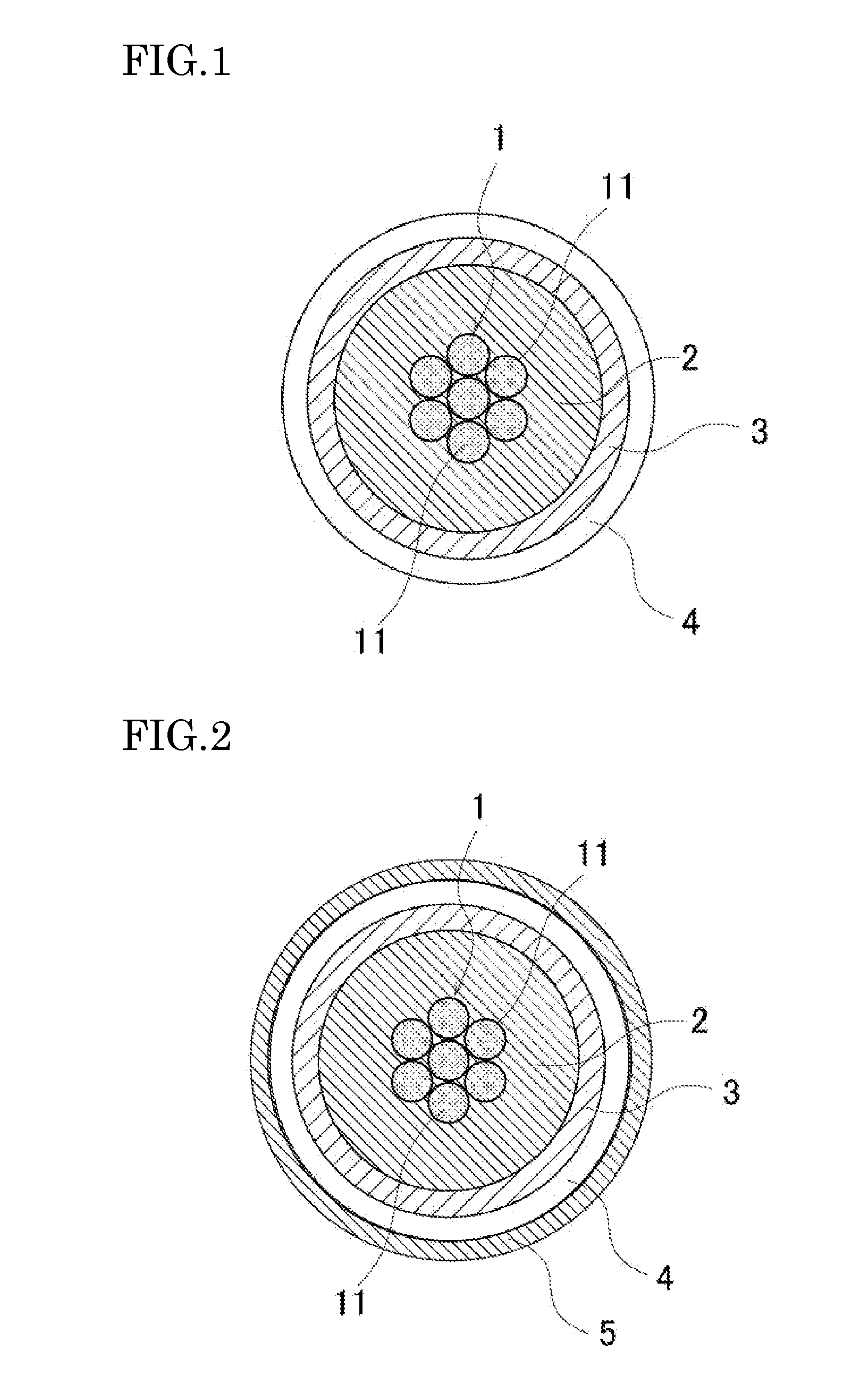

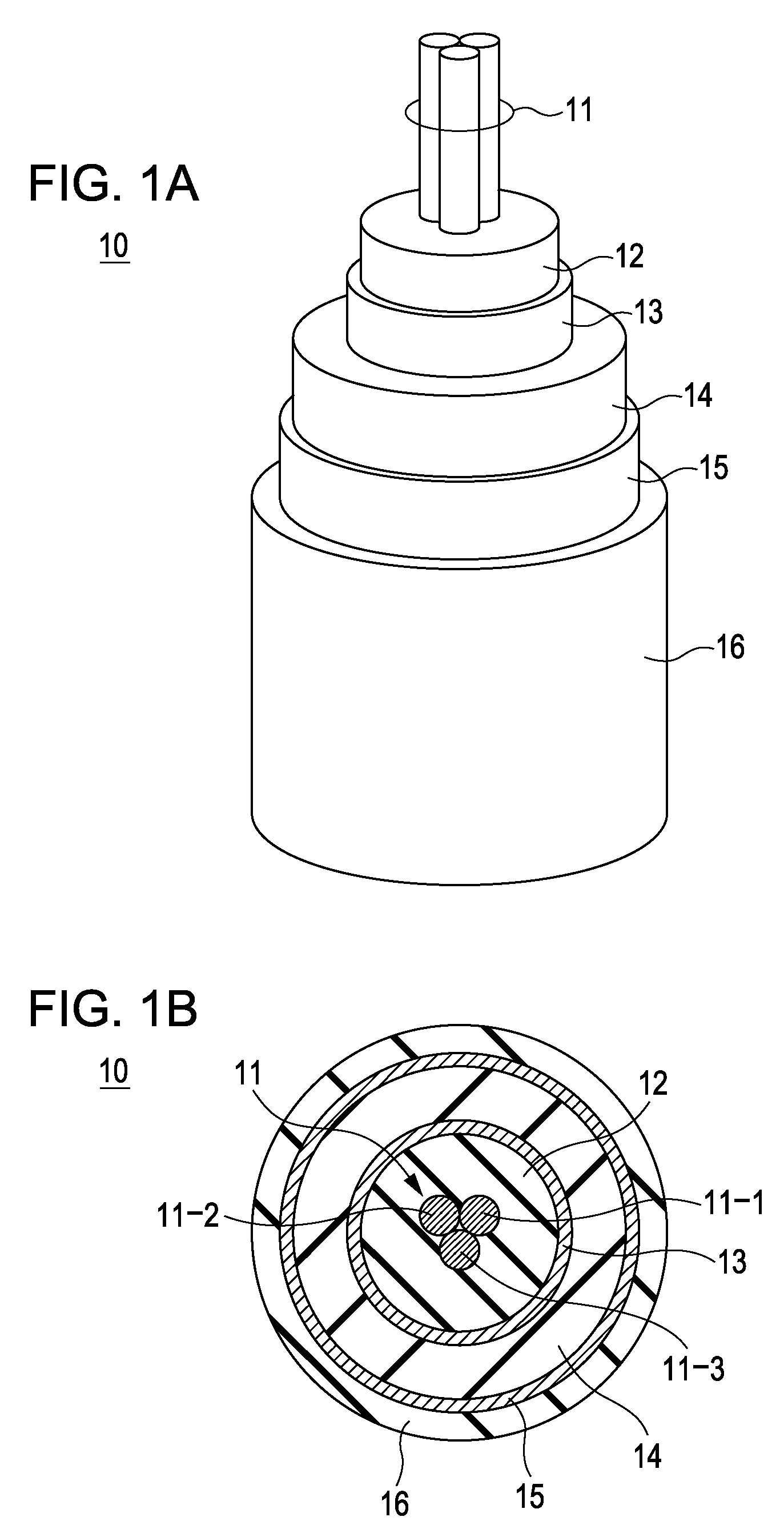

Micro coaxial cable for high bending performance

ActiveUS8242358B2Improve bending performanceLong-term reliabilityCable conductor constructionPower cables with screens/conductive layersElectrical conductorCoaxial cable

A micro coaxial cable with a high bending performance, having an inner conductor; an insulating layer configured to surround the inner conductor, and a helical winding conductor configured to surround the insulating layer and having an elongation of 1.5 to 4% and a pitch of 3.0 to 5.0 mm.

Owner:HITACHI METALS LTD

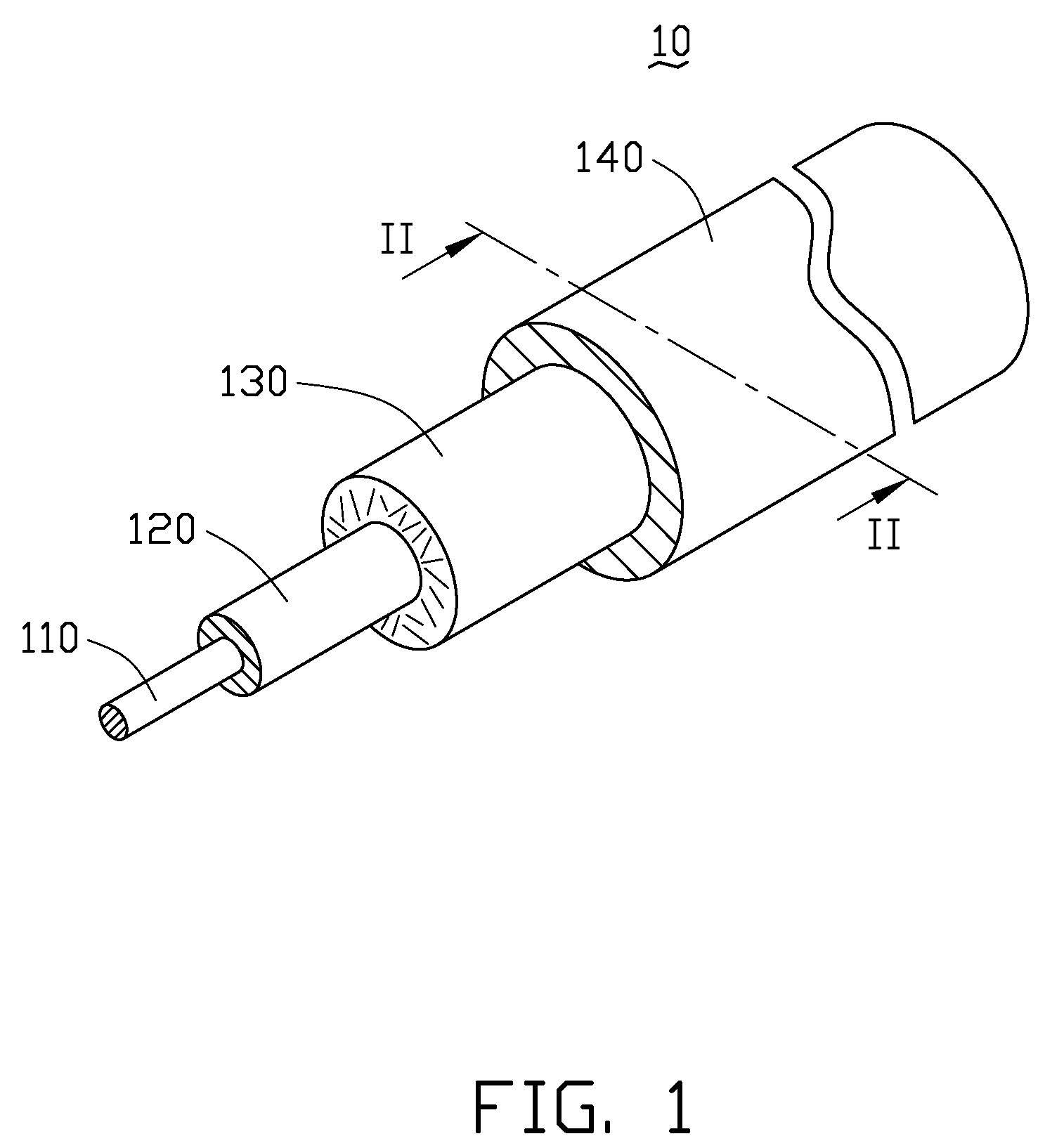

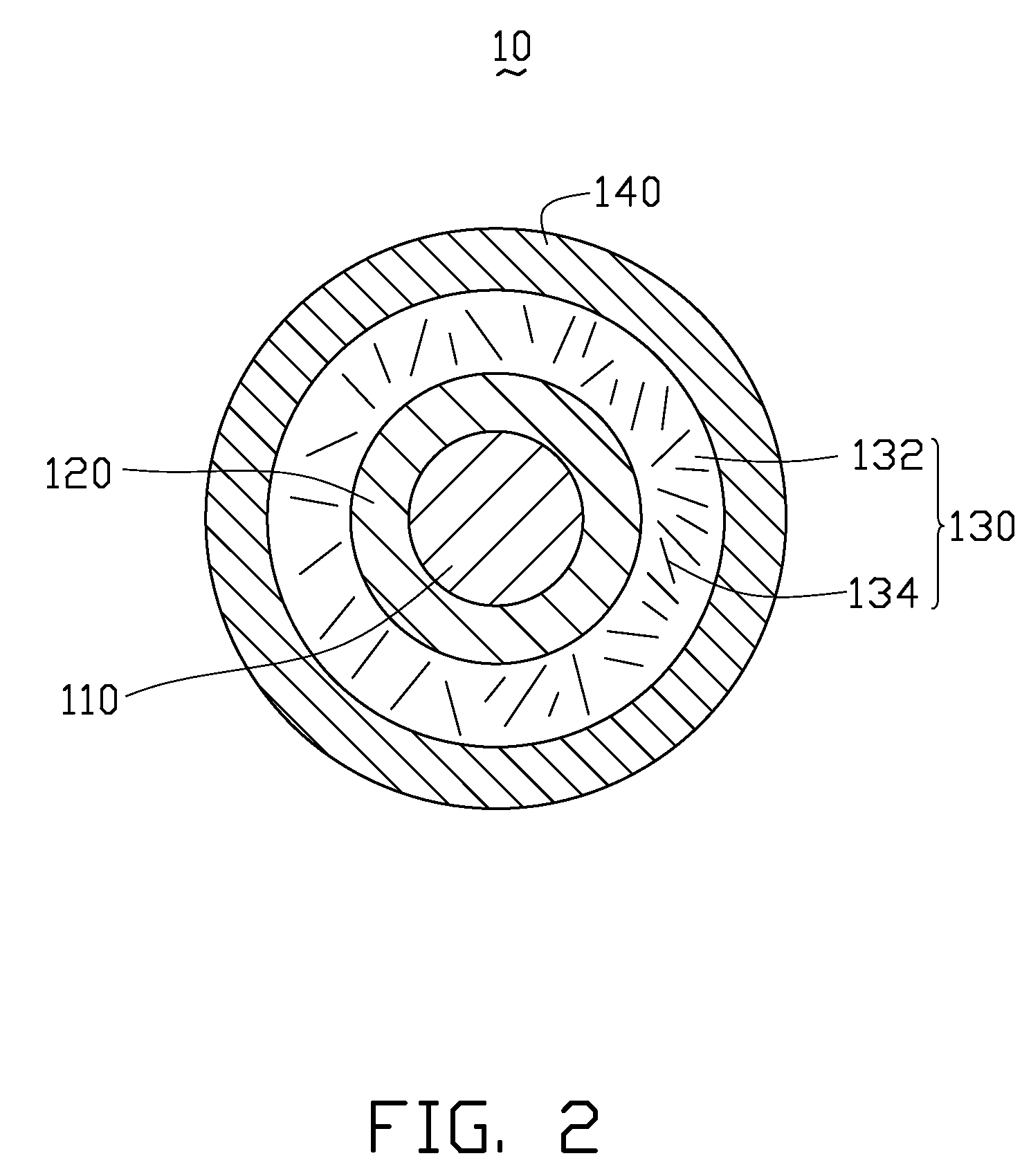

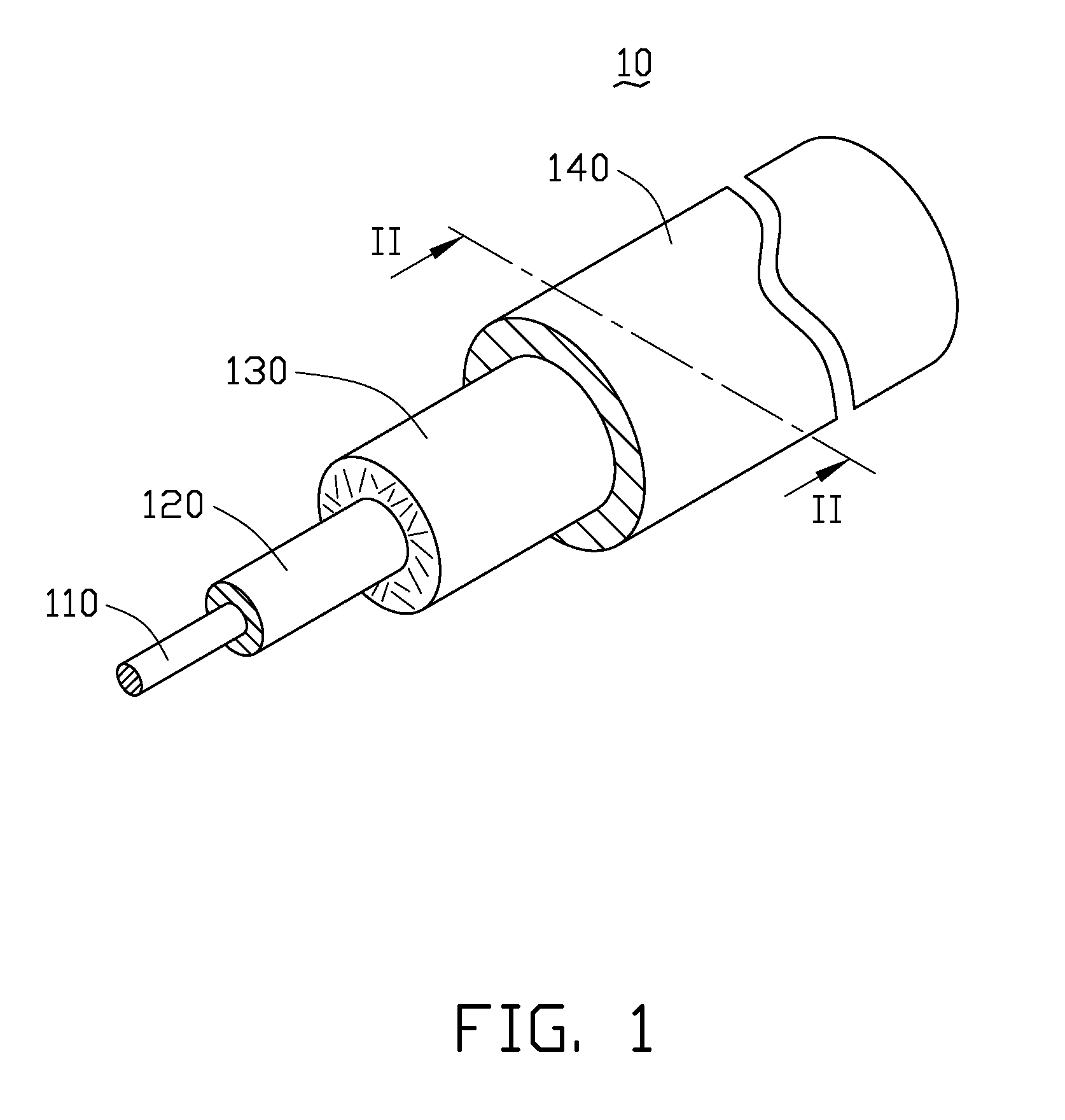

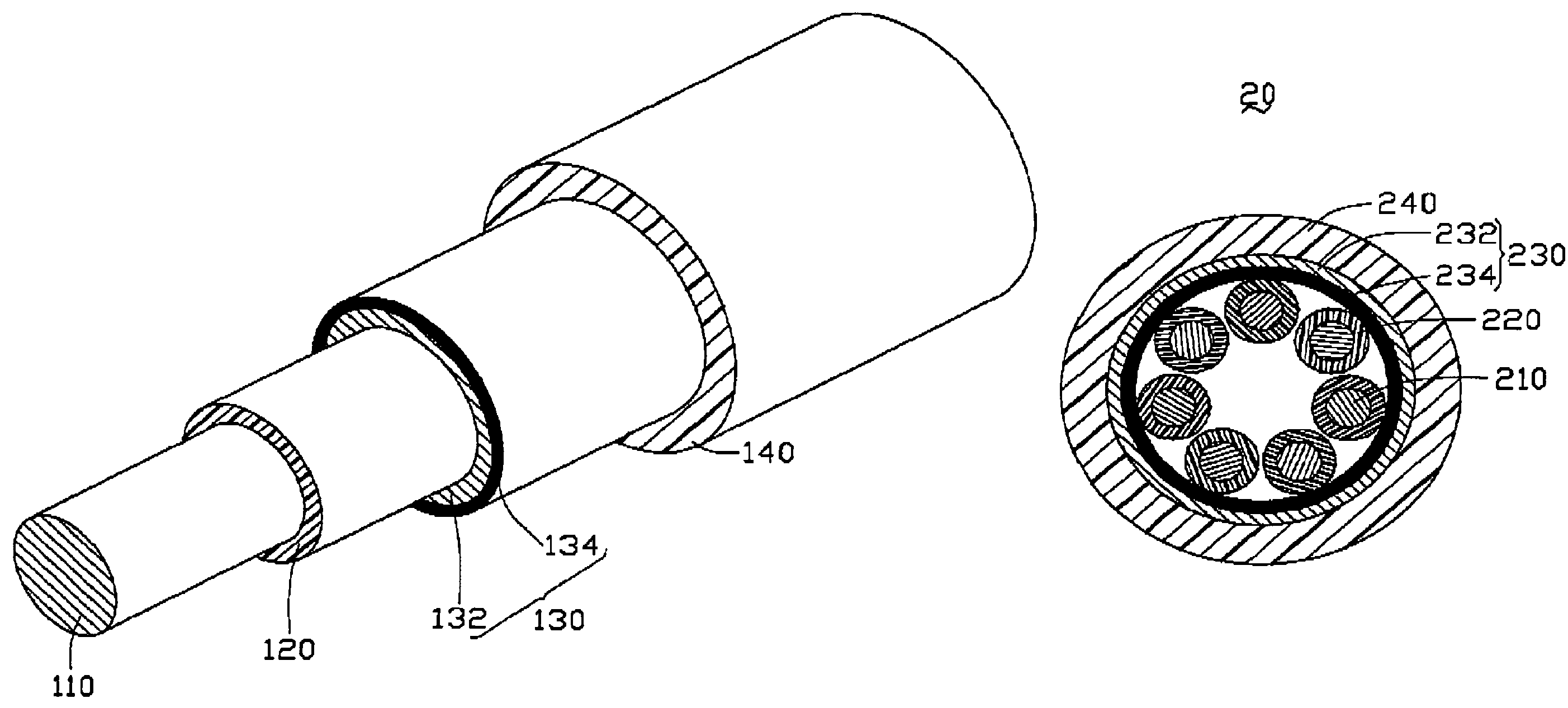

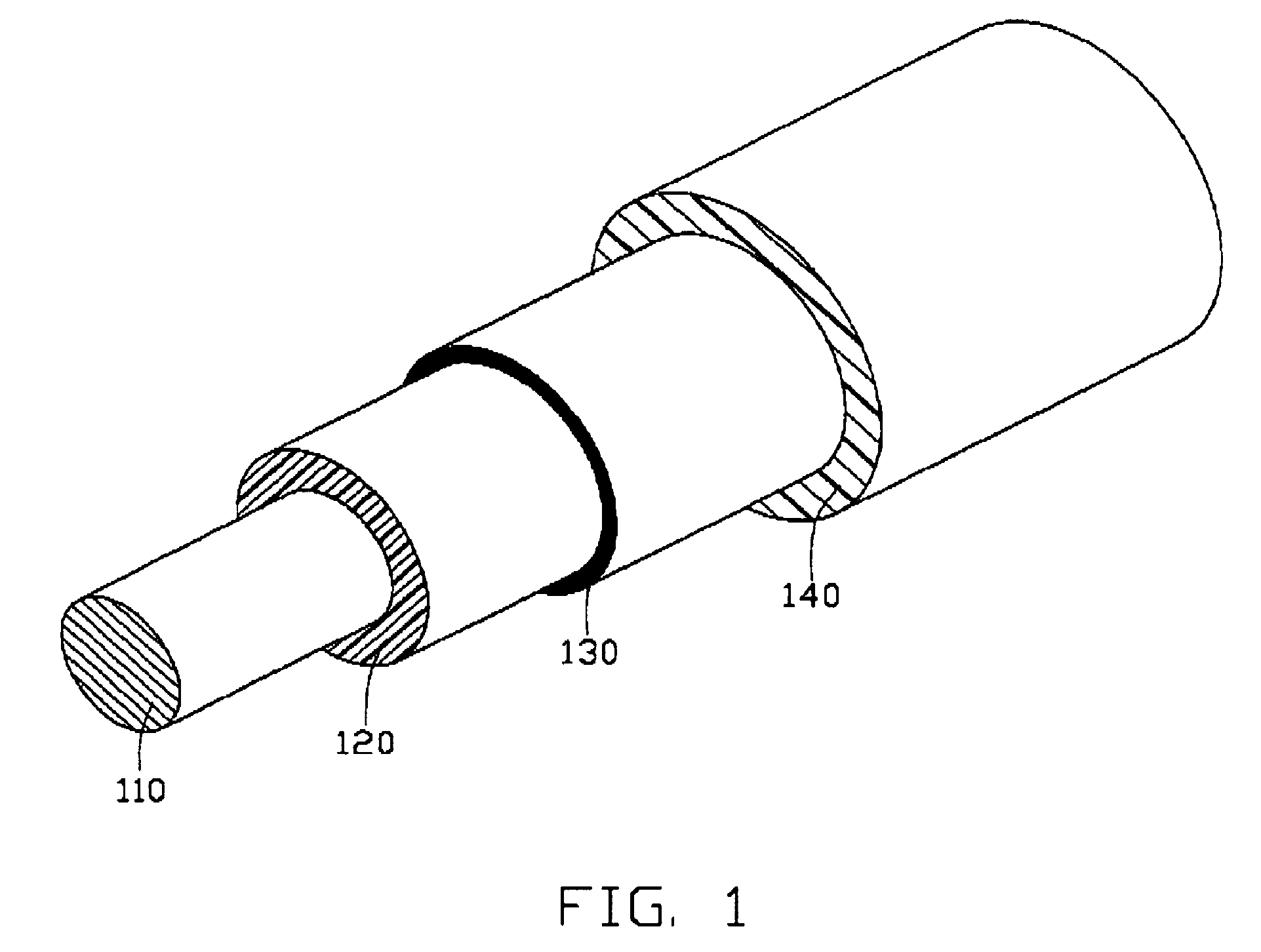

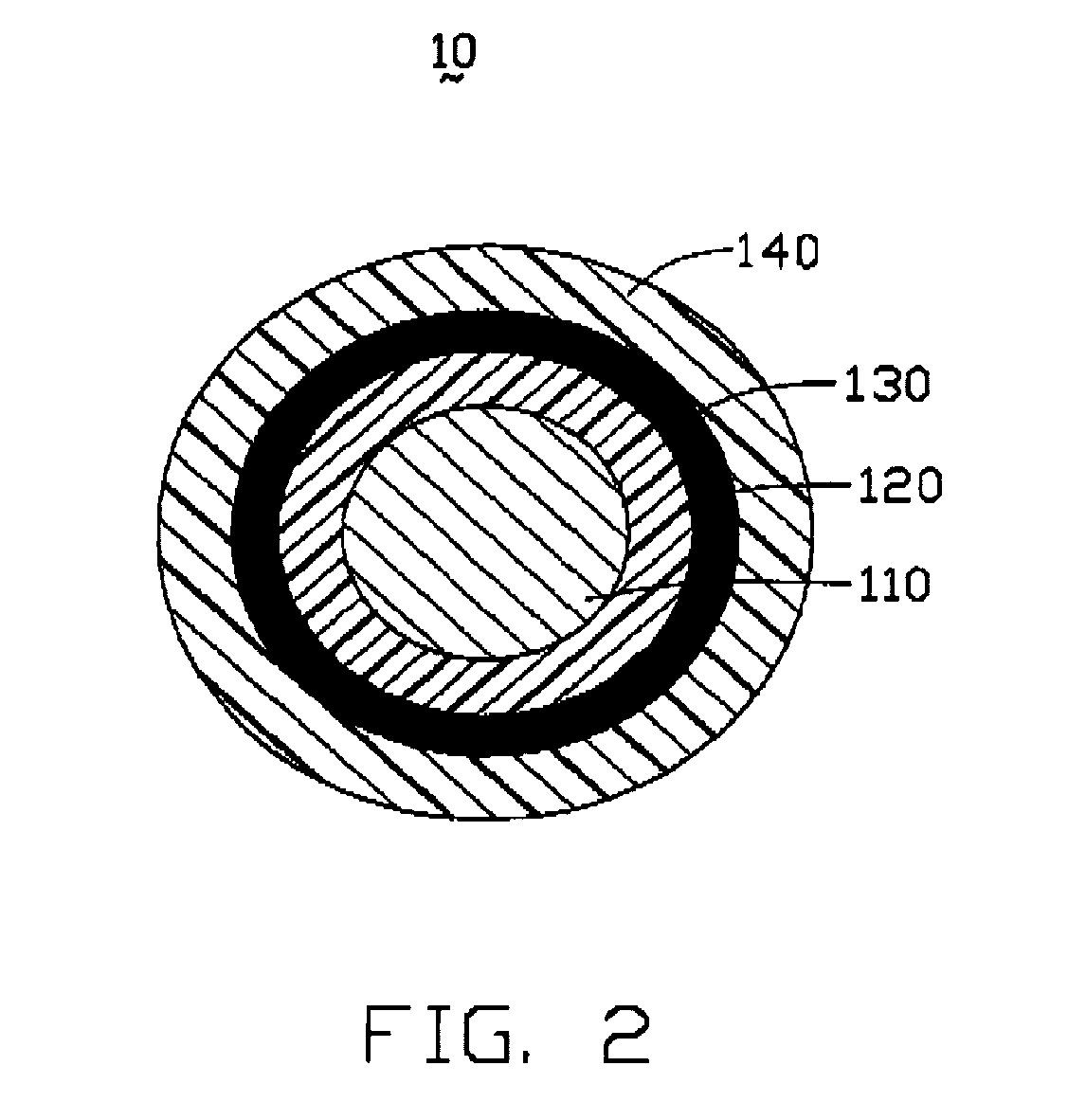

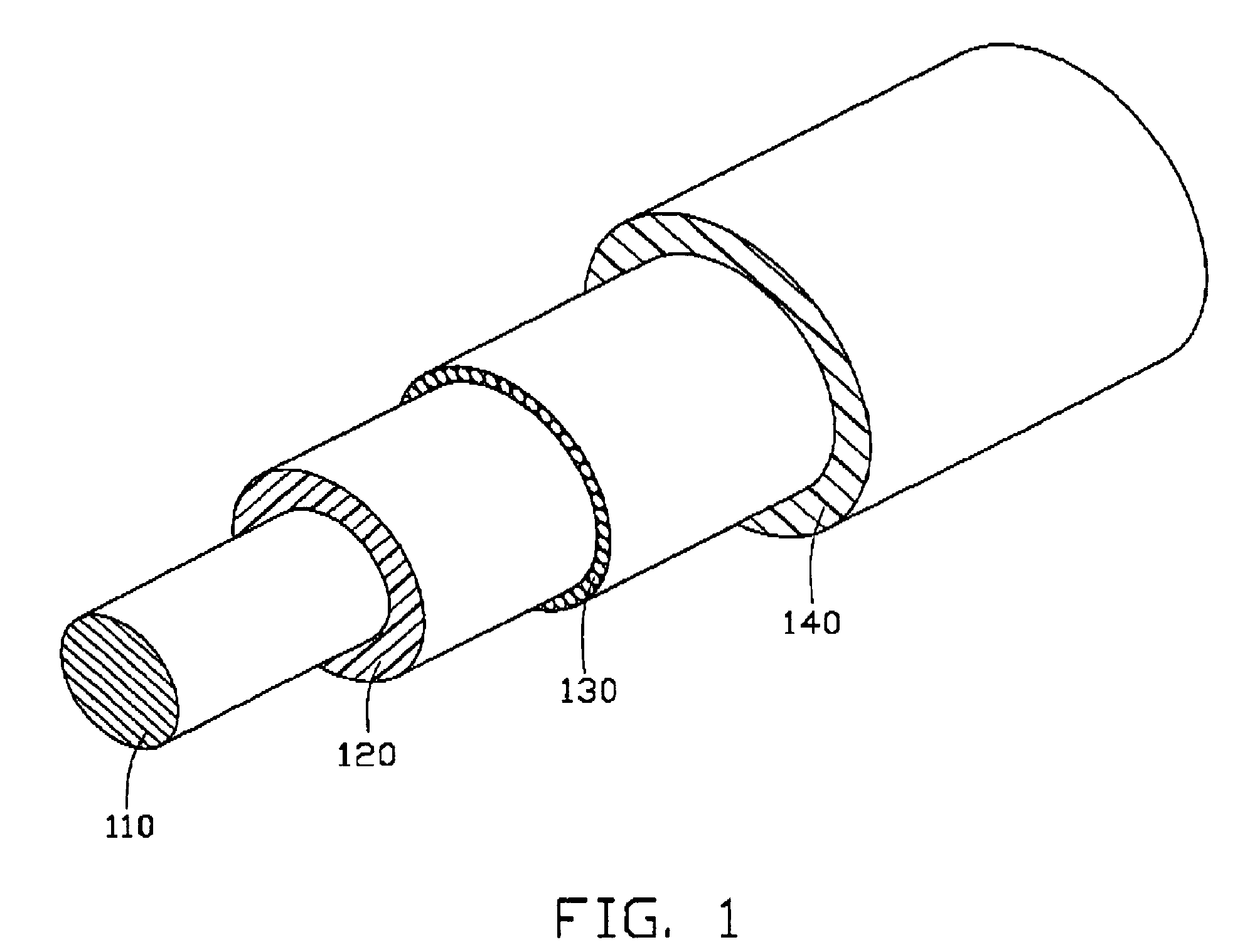

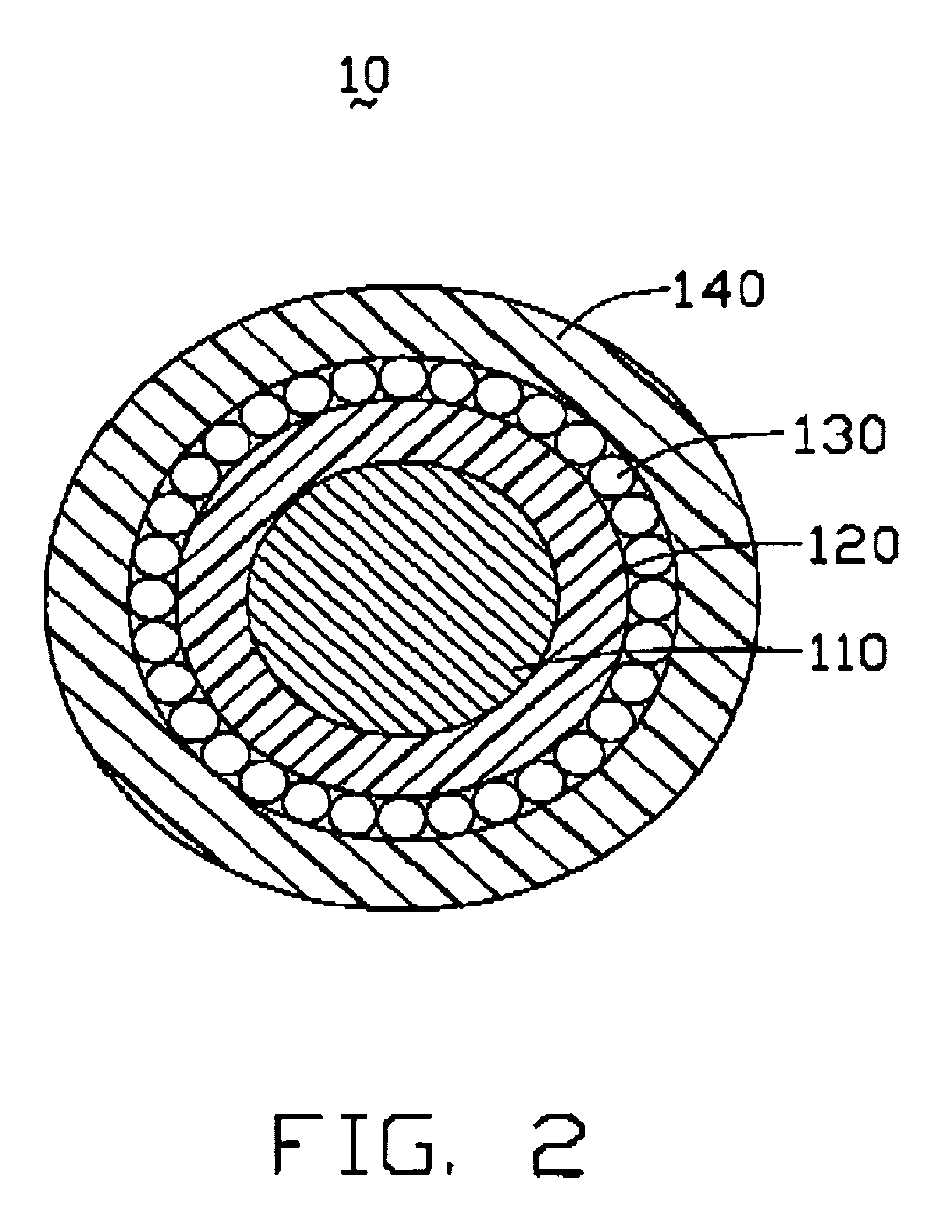

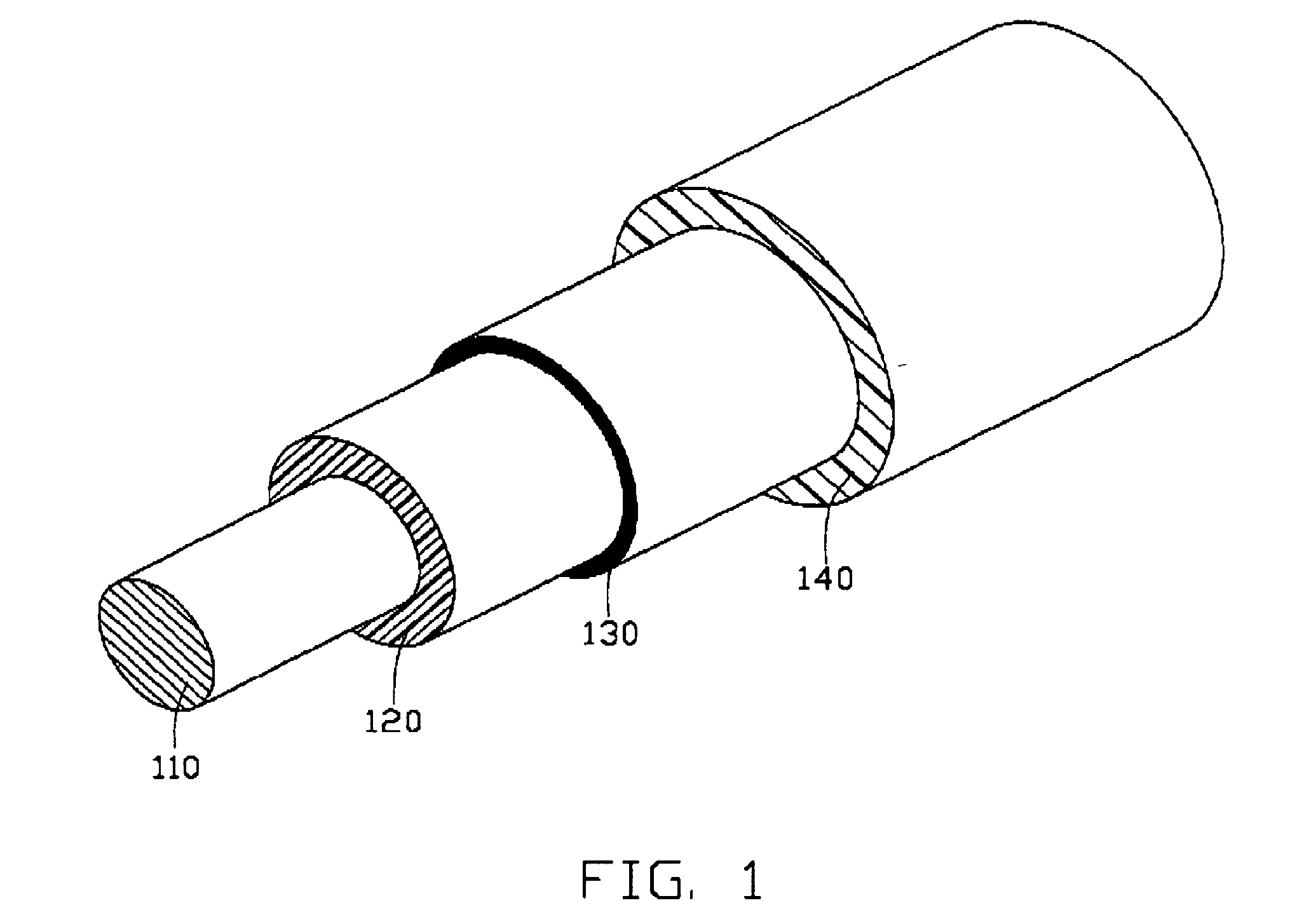

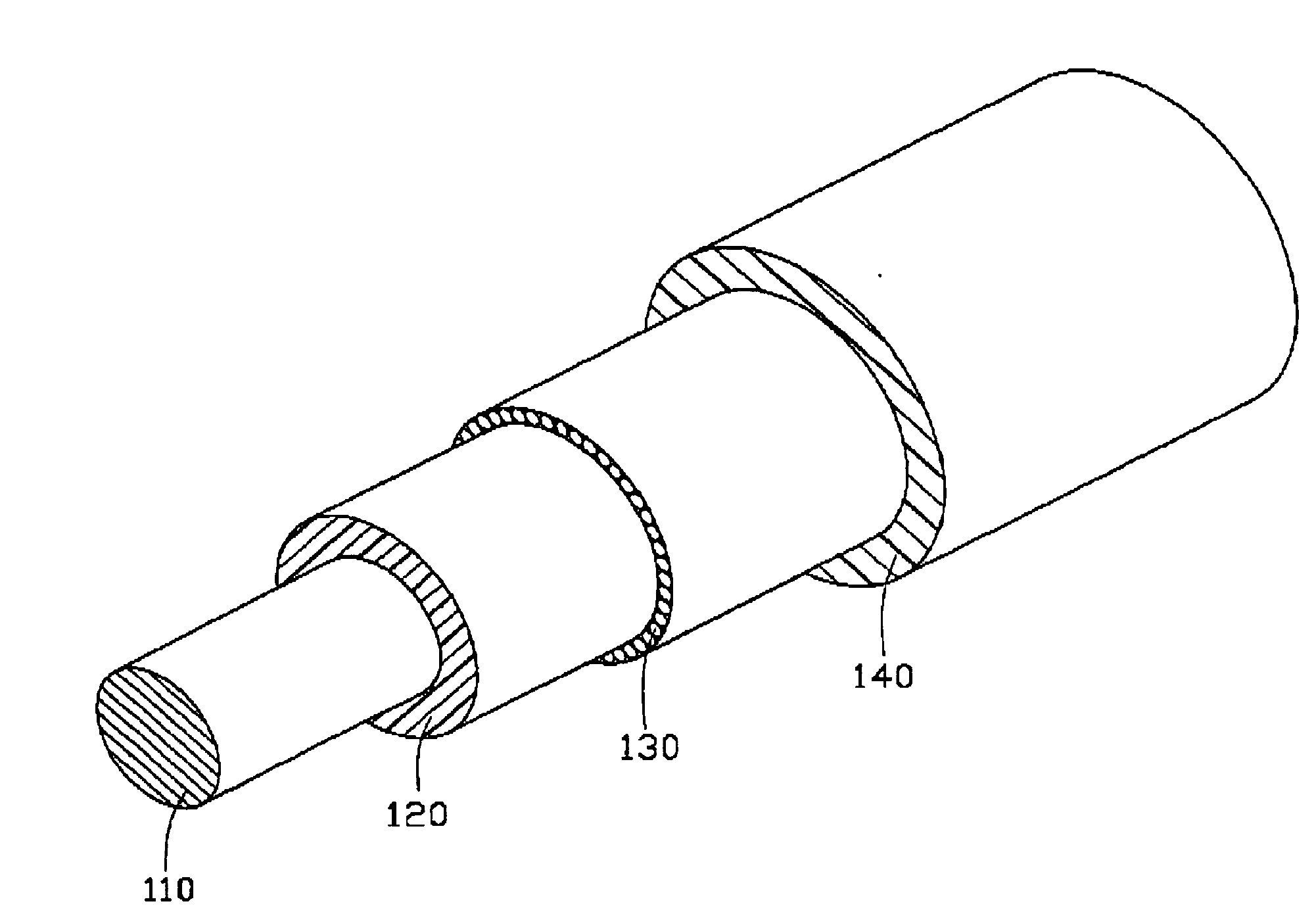

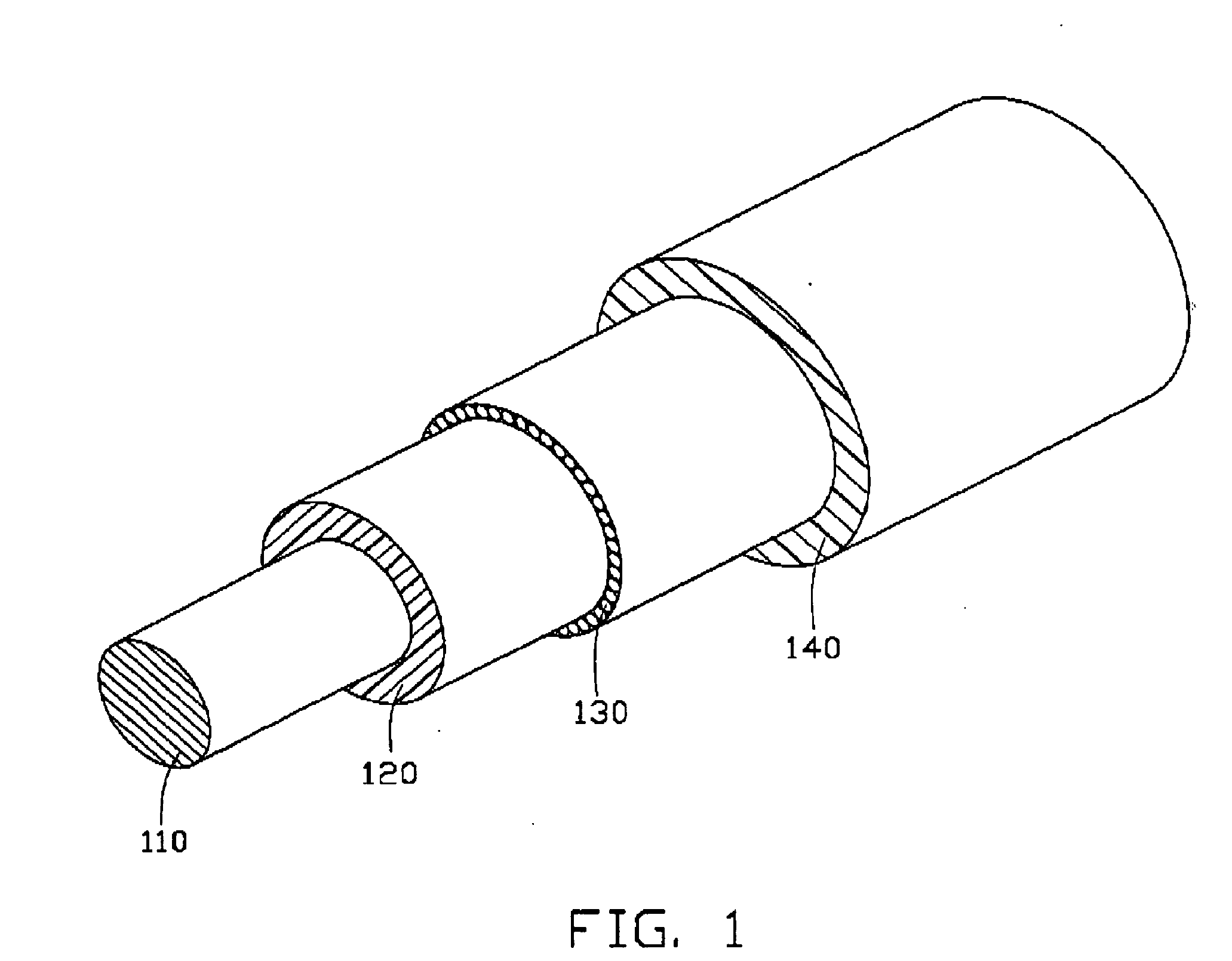

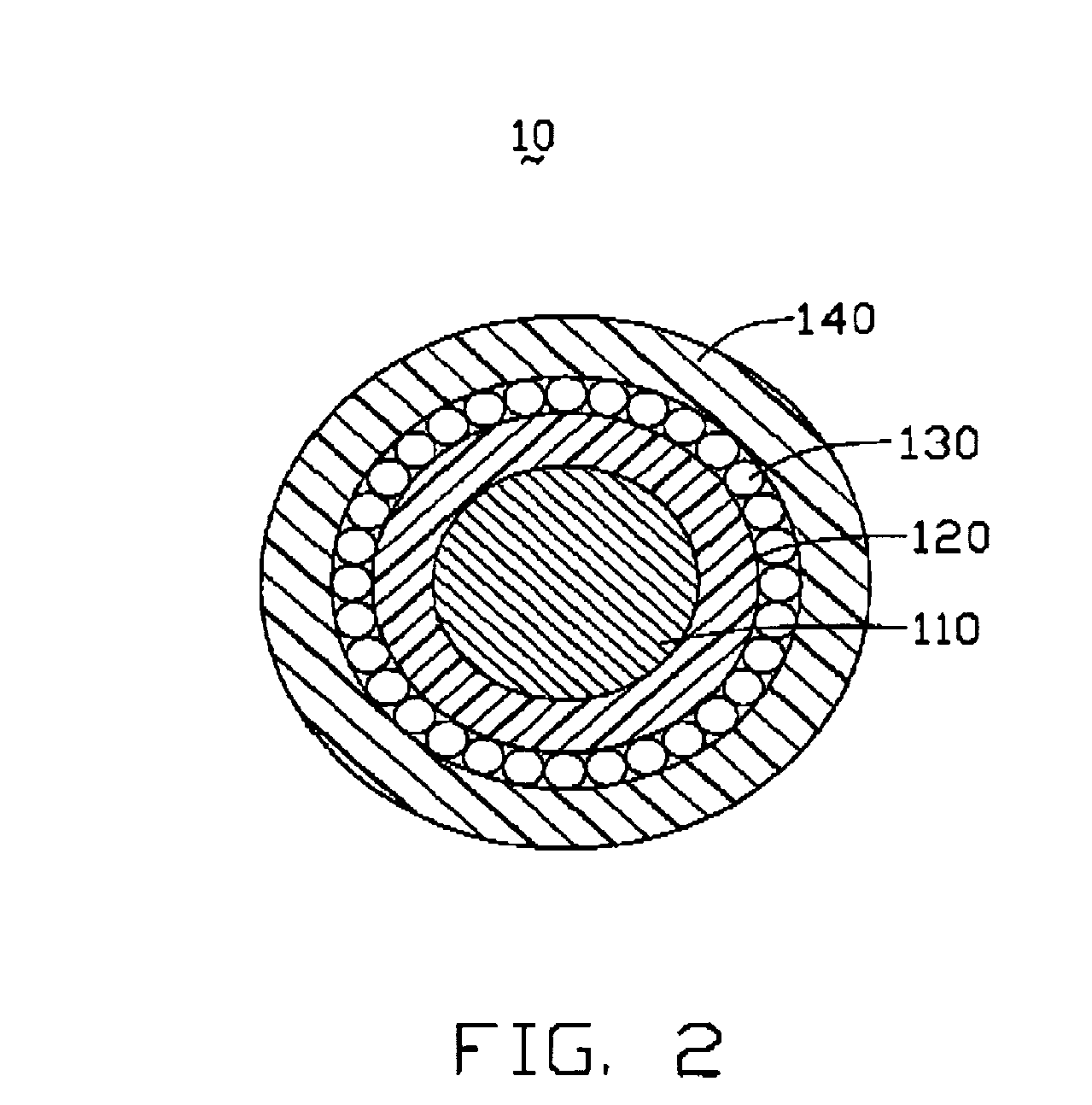

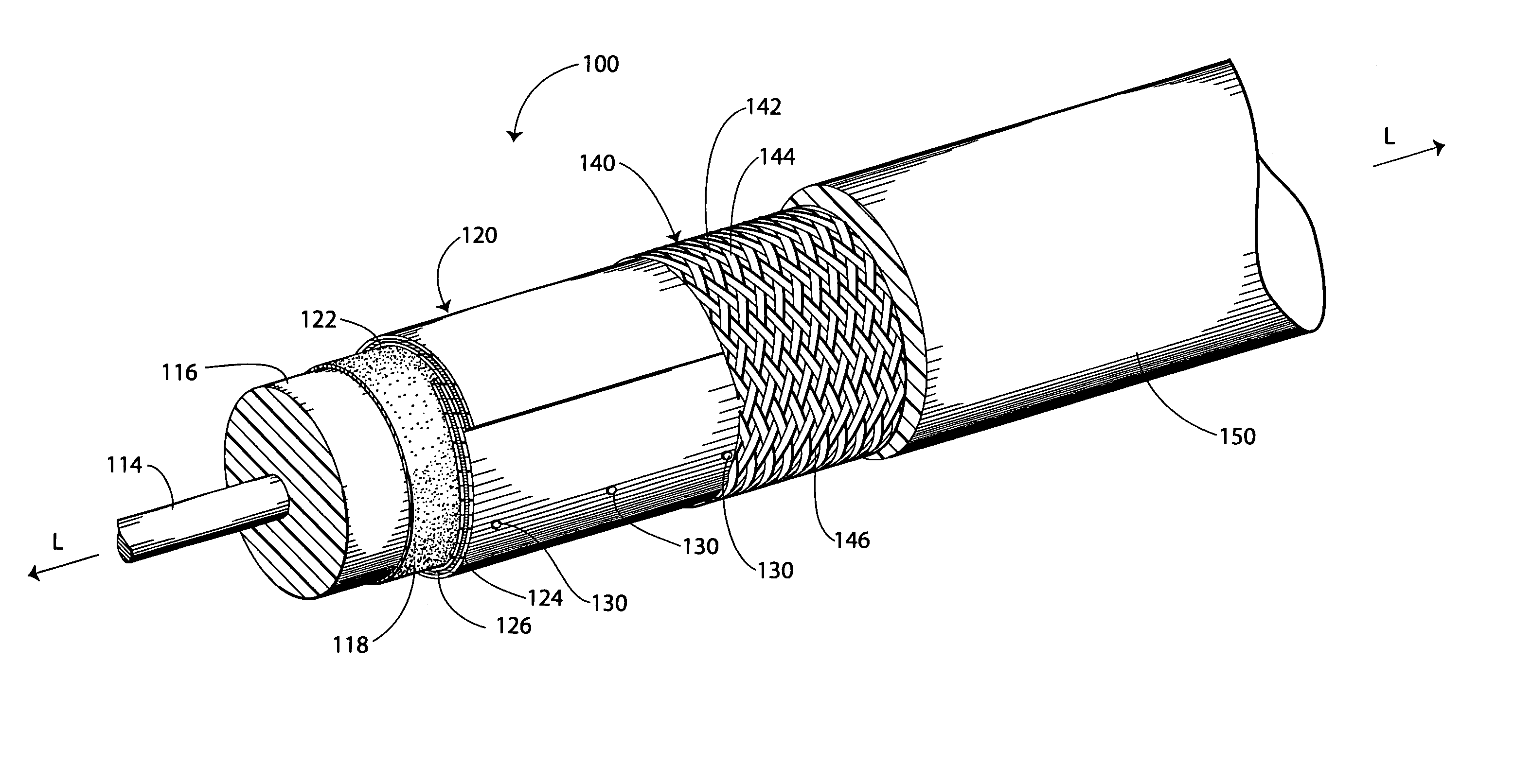

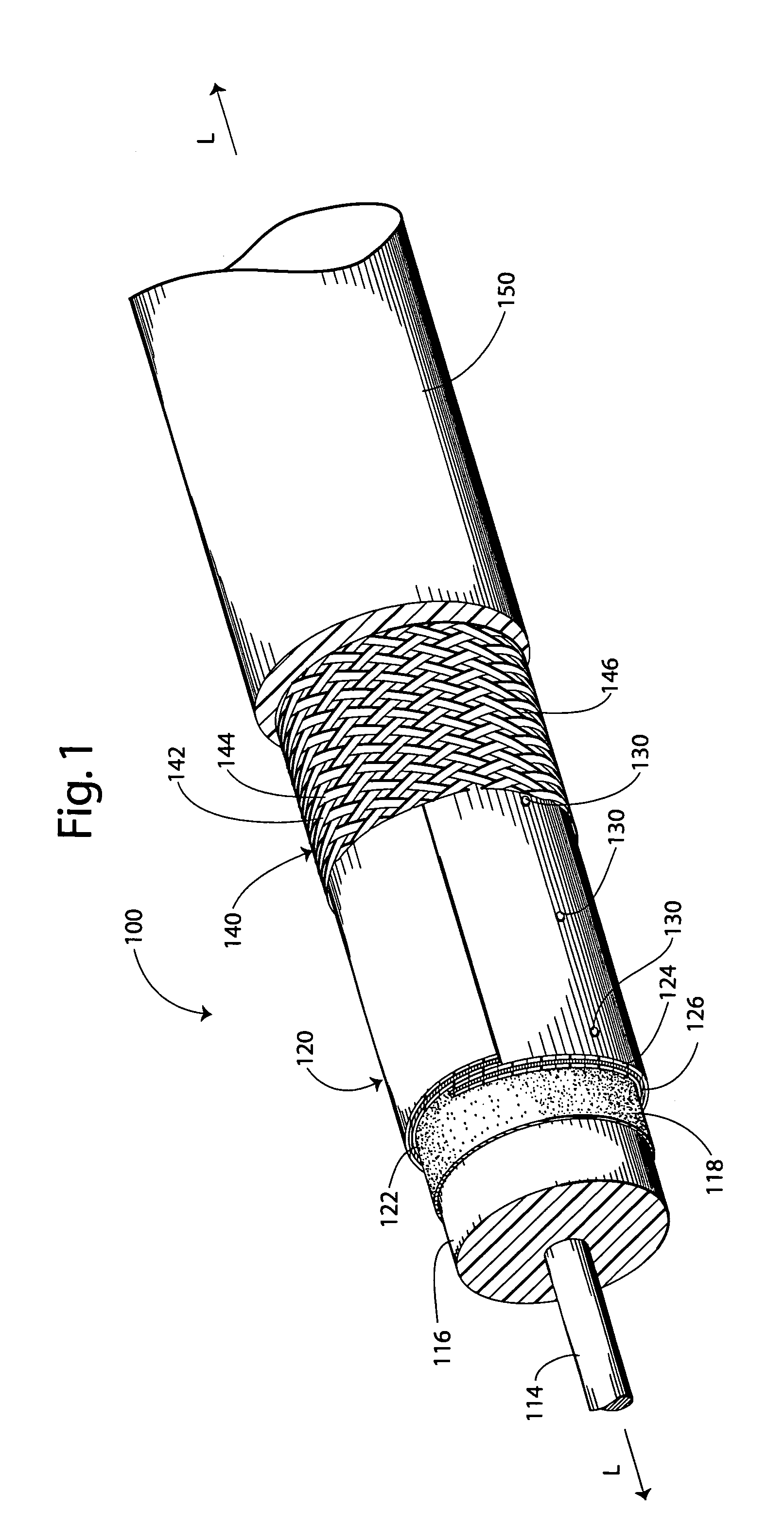

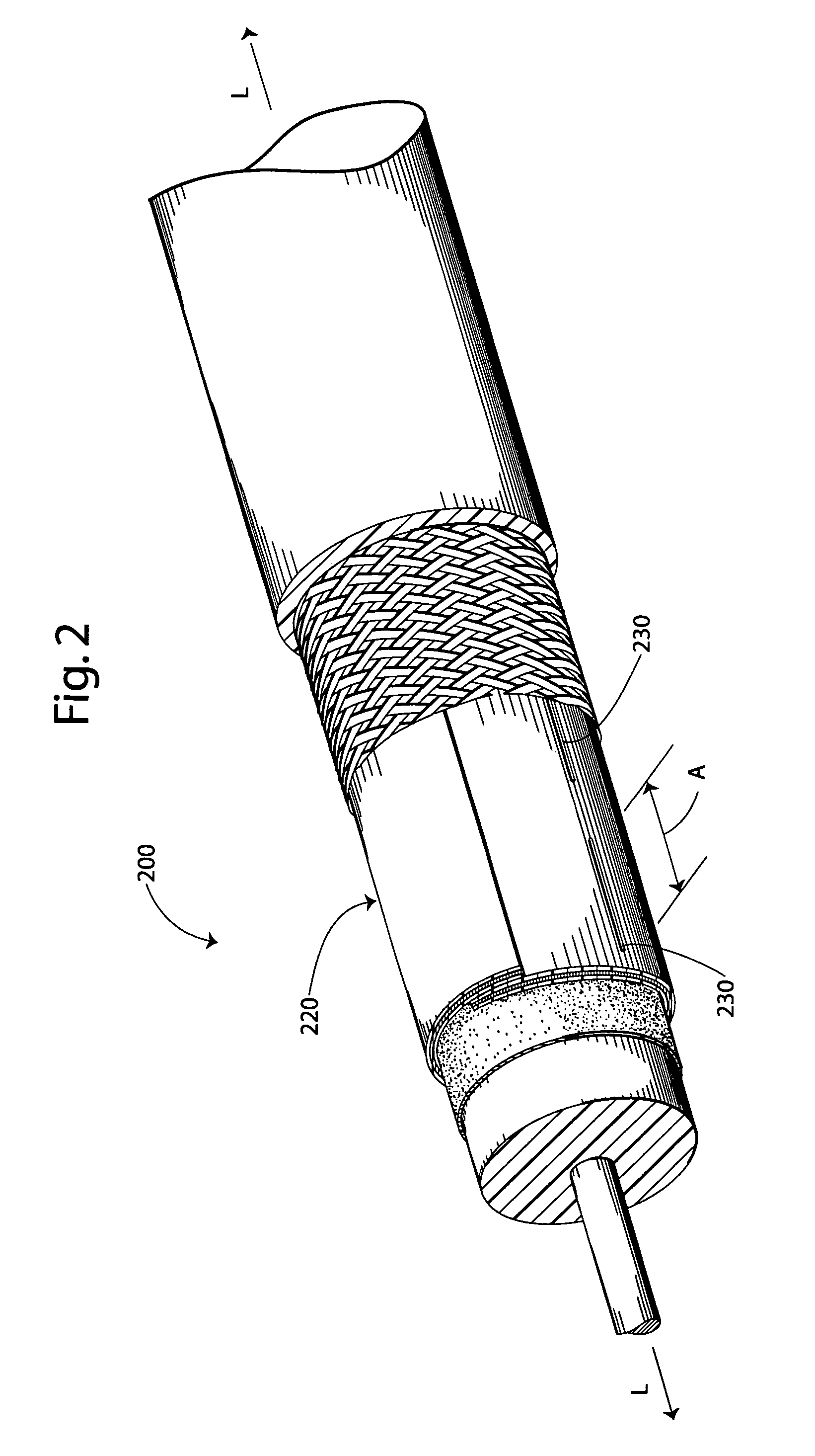

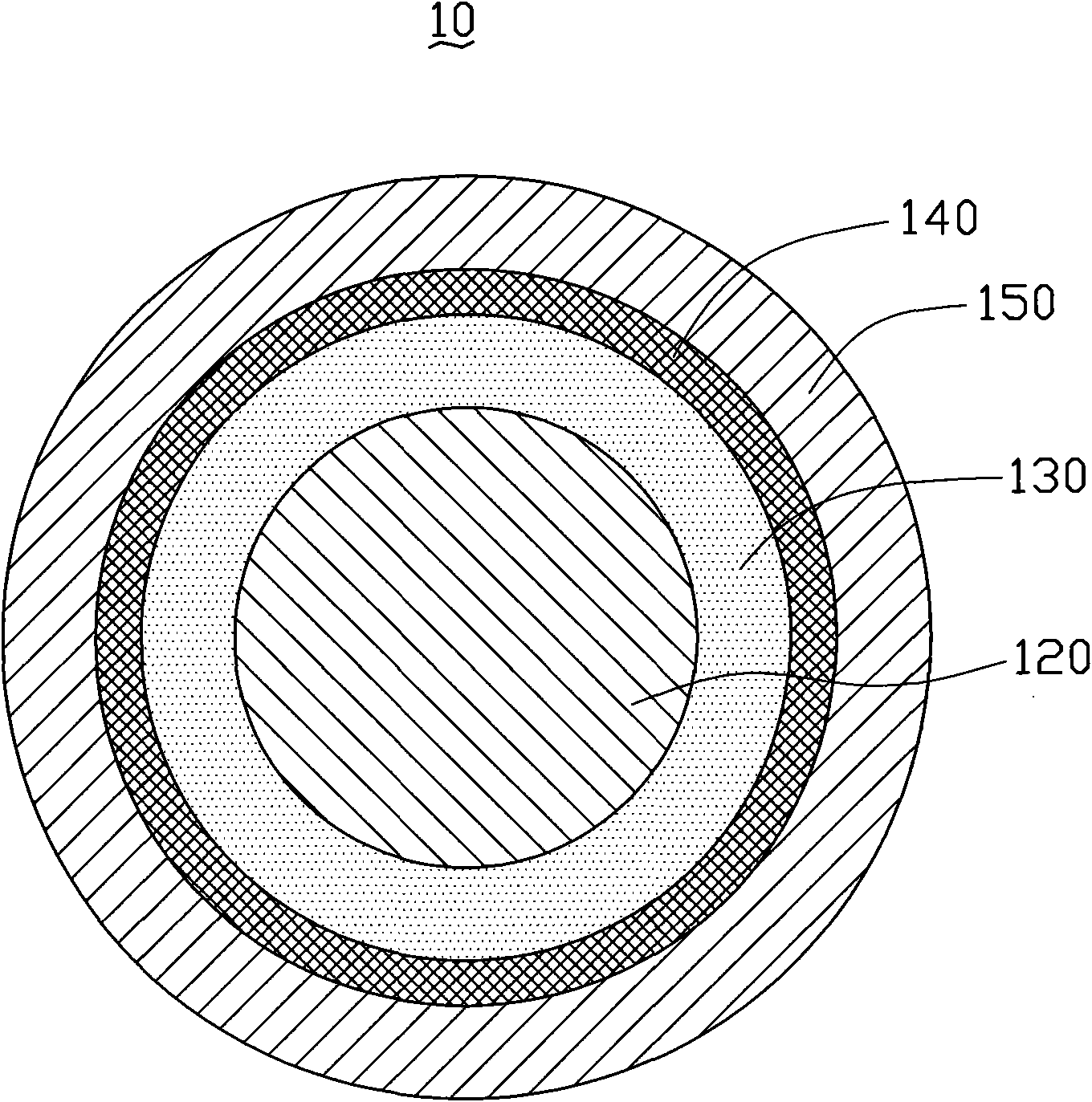

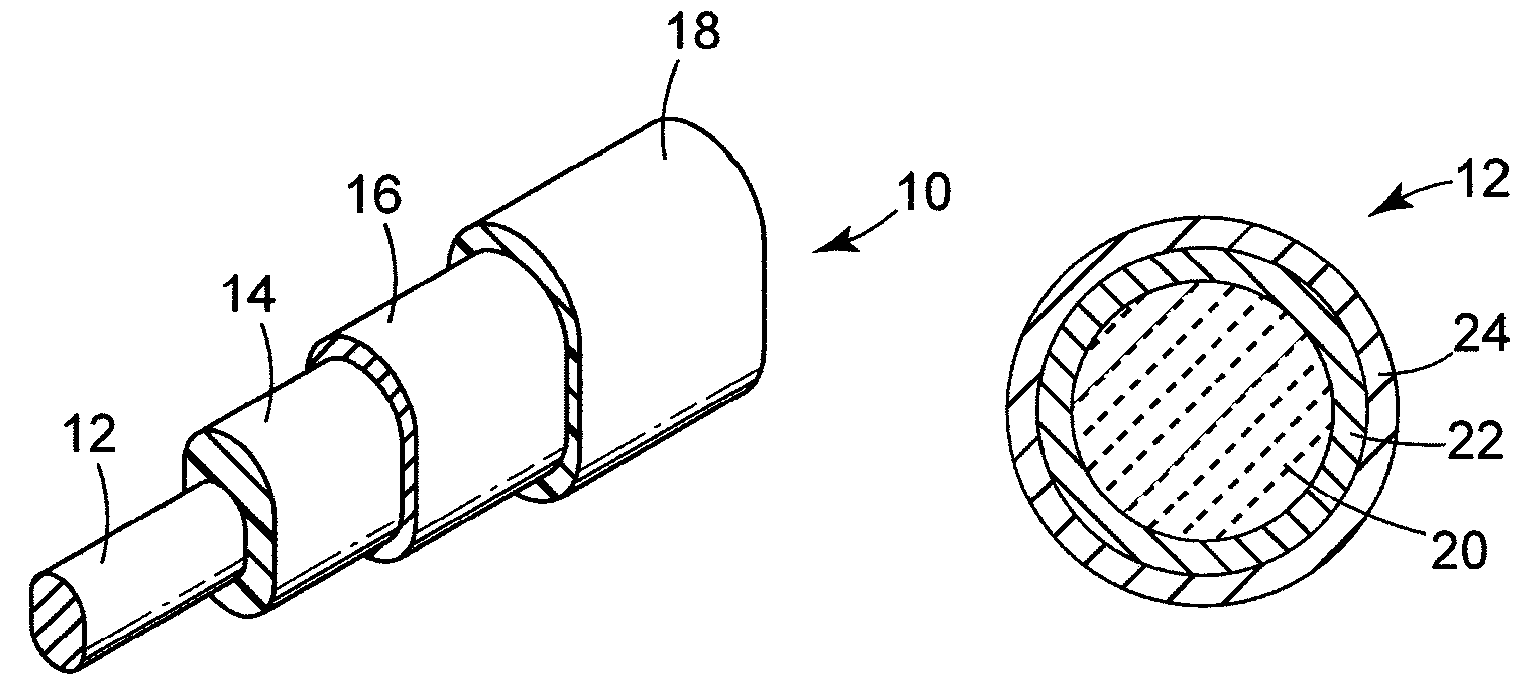

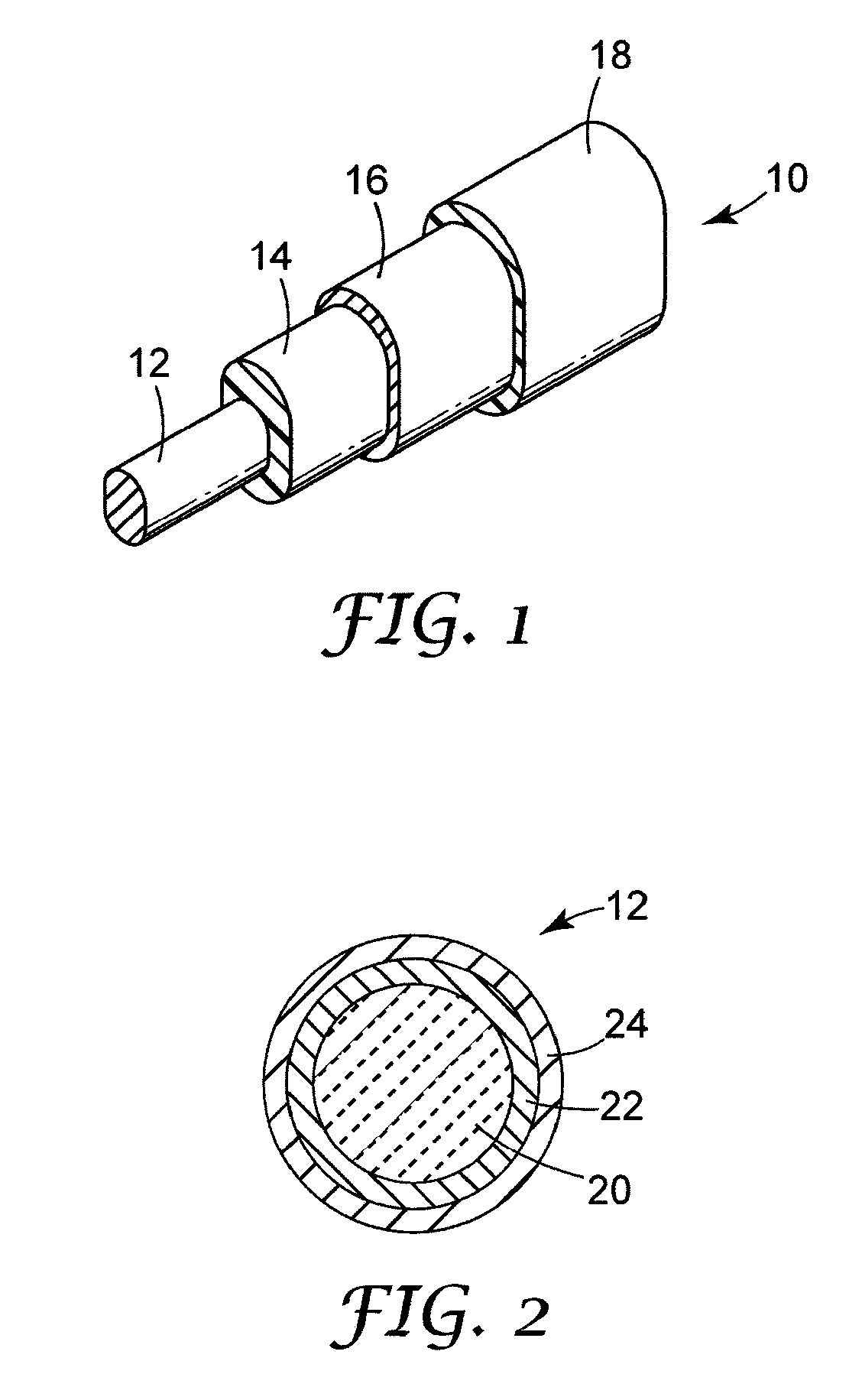

Composite coaxial cable employing carbon nanotubes therein

ActiveUS7413474B2Improve effectivenessSuitable for low-cost mass productionElectrically conductive connectionsCable conductor constructionShielded cableCoaxial cable

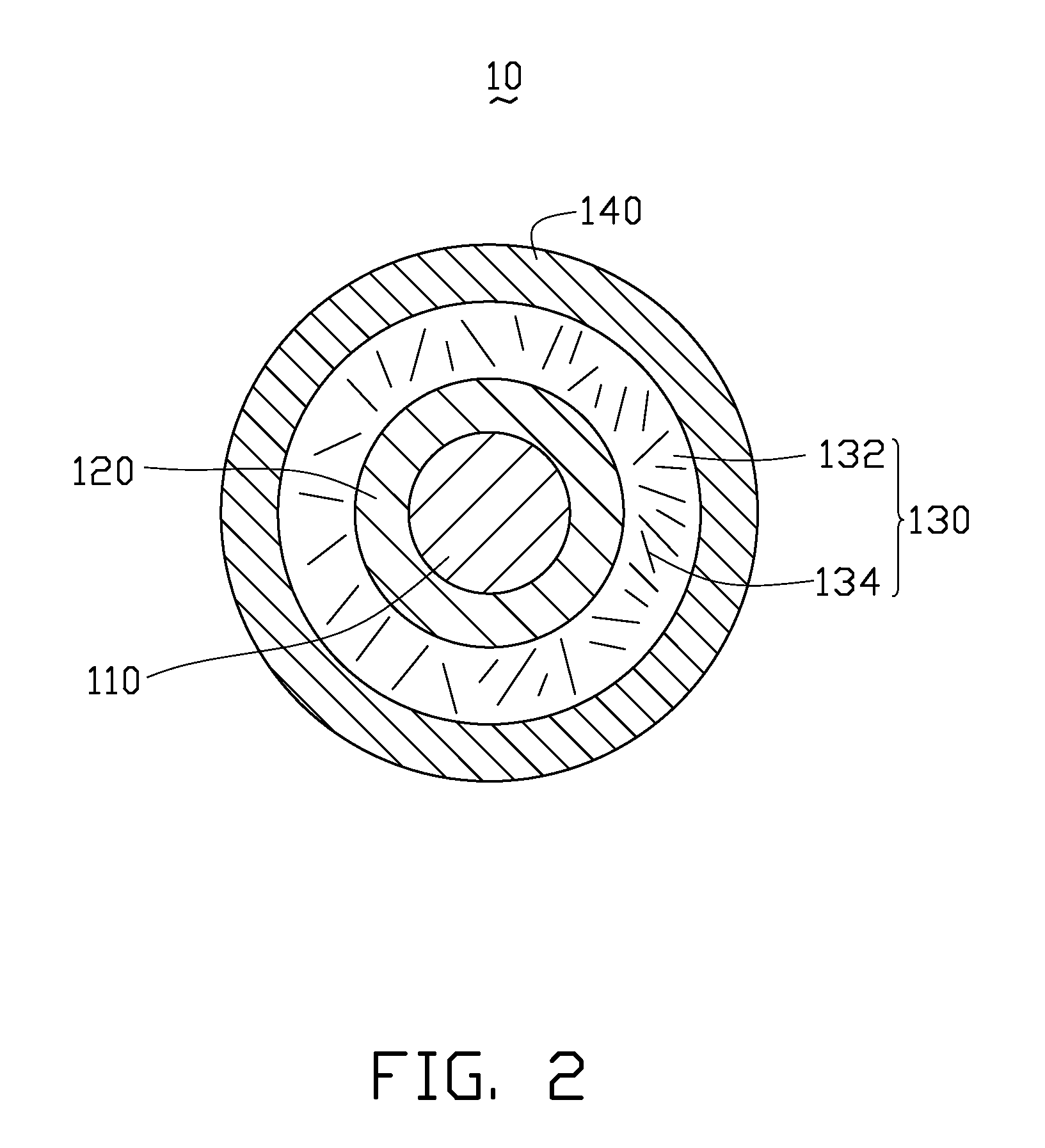

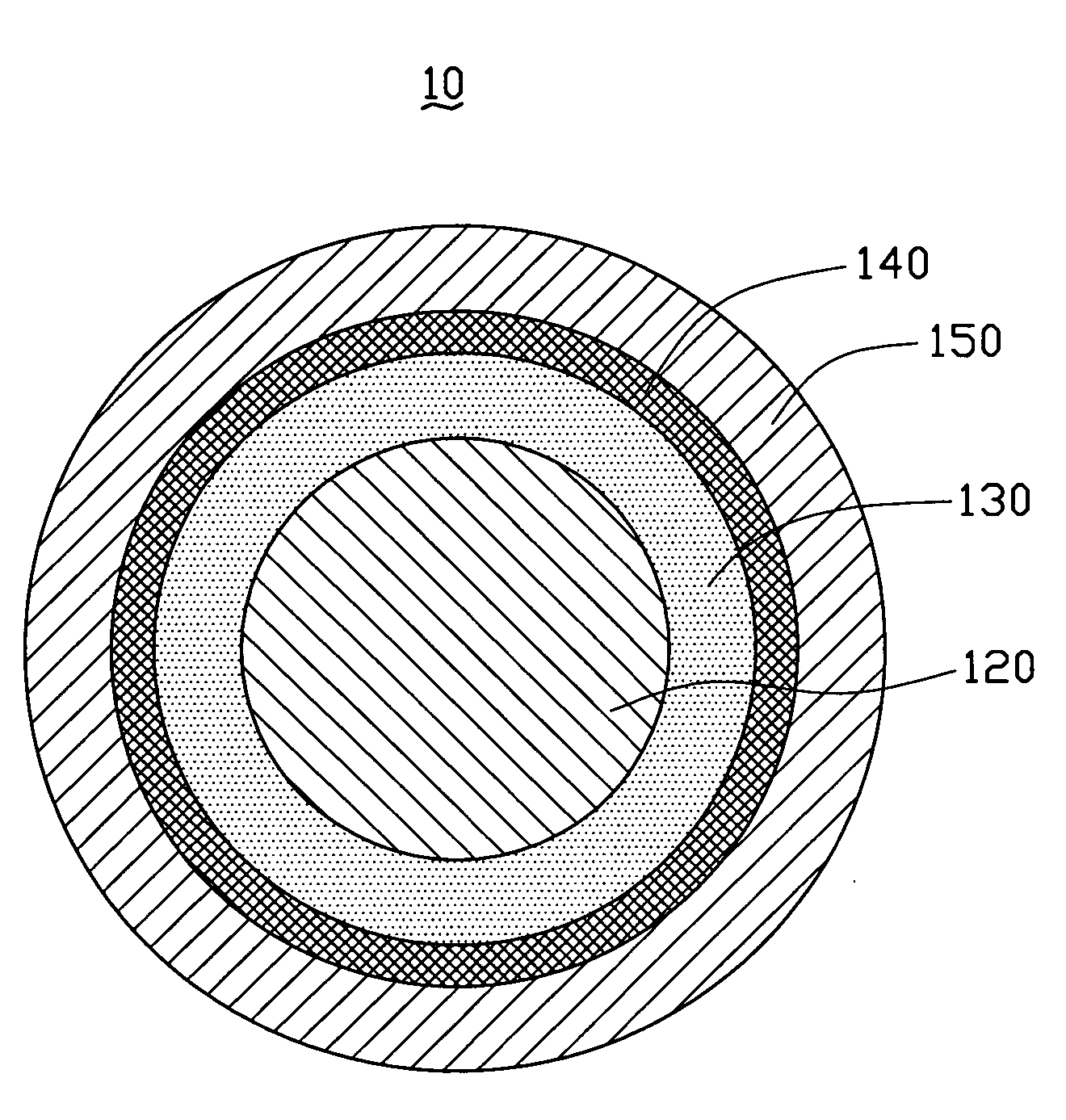

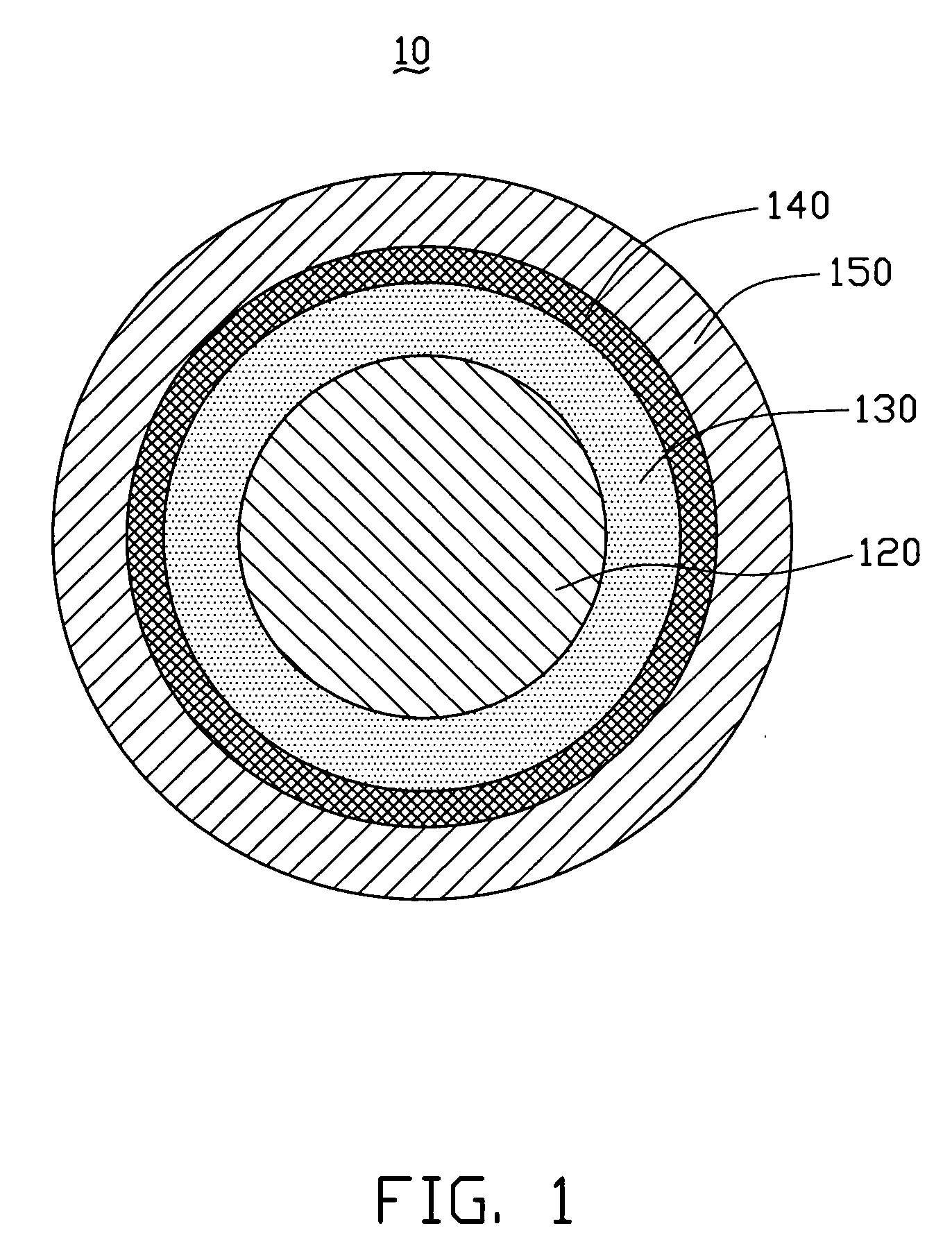

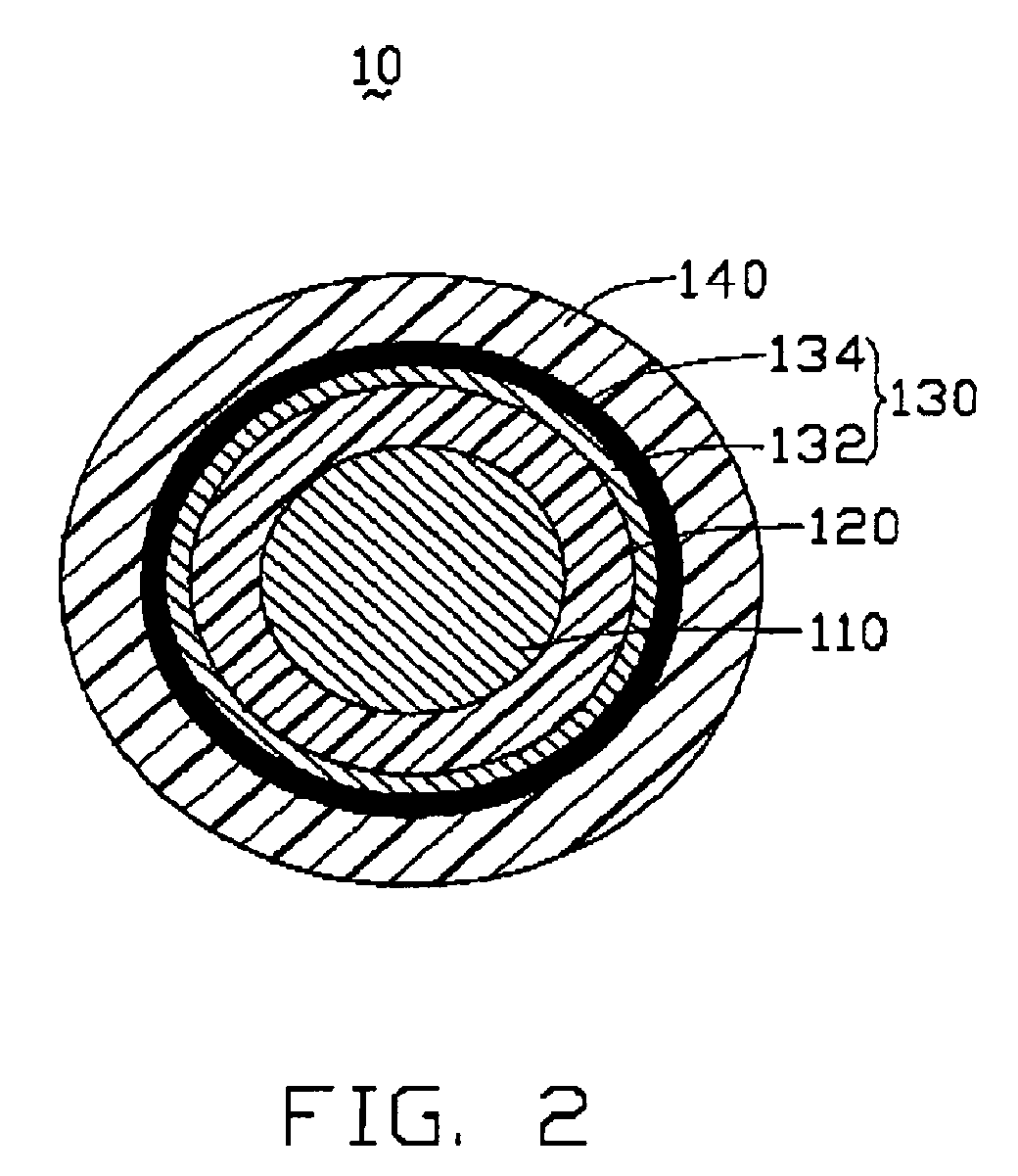

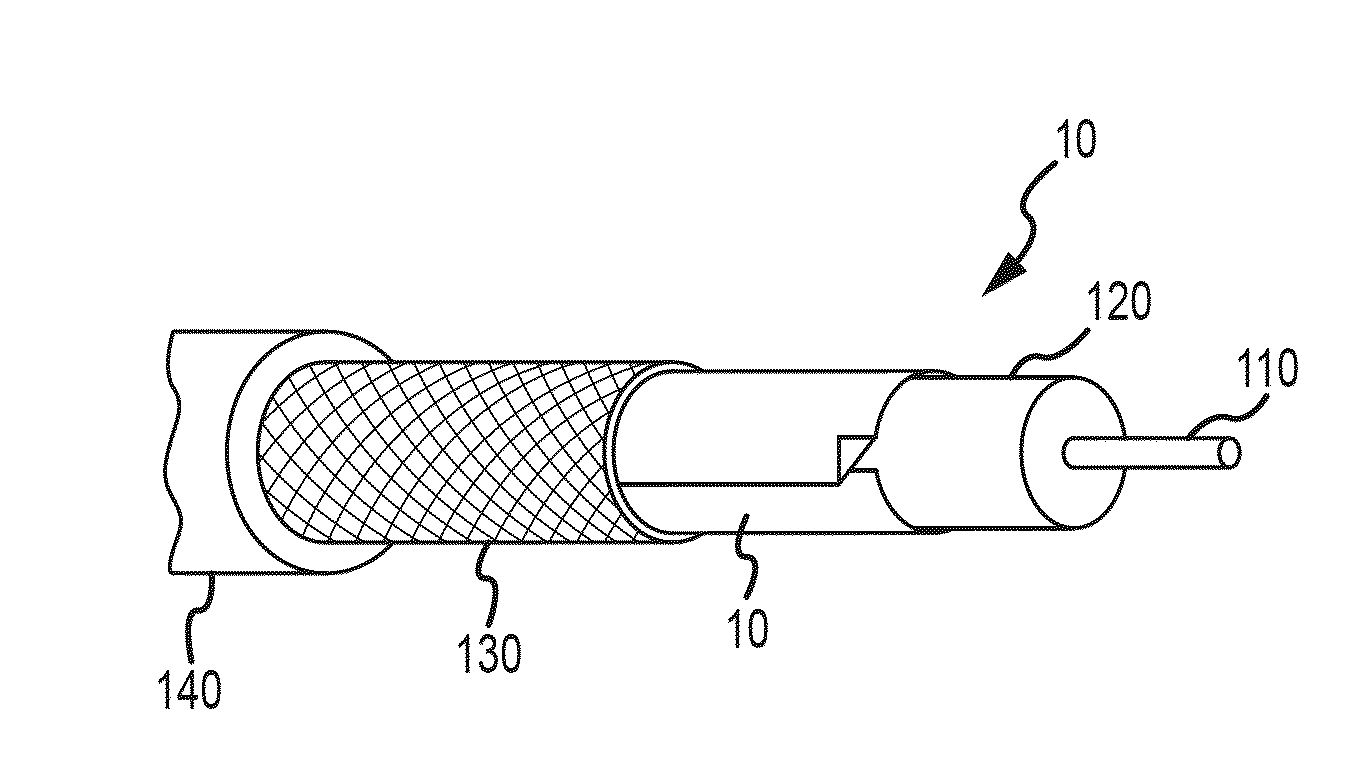

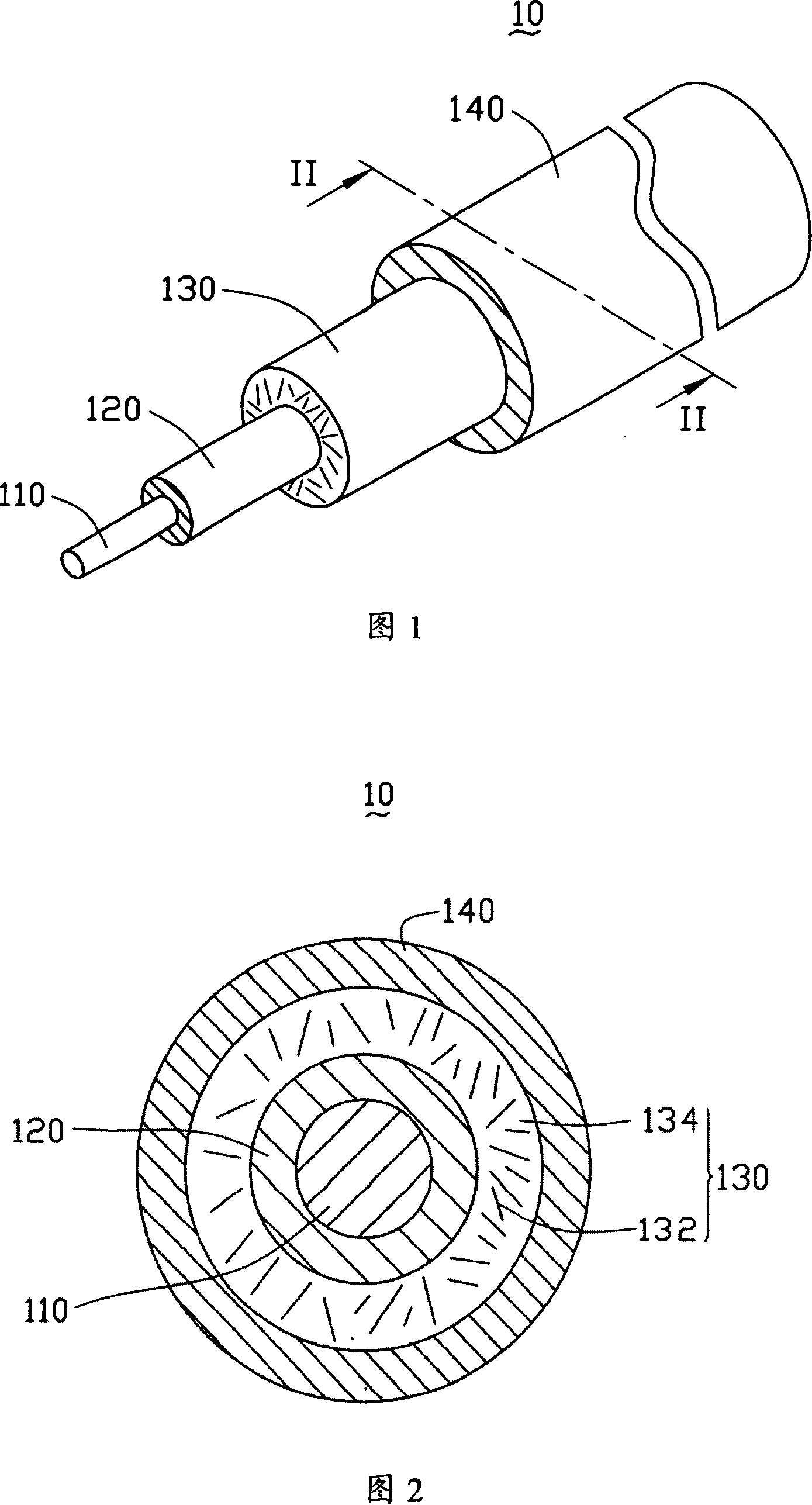

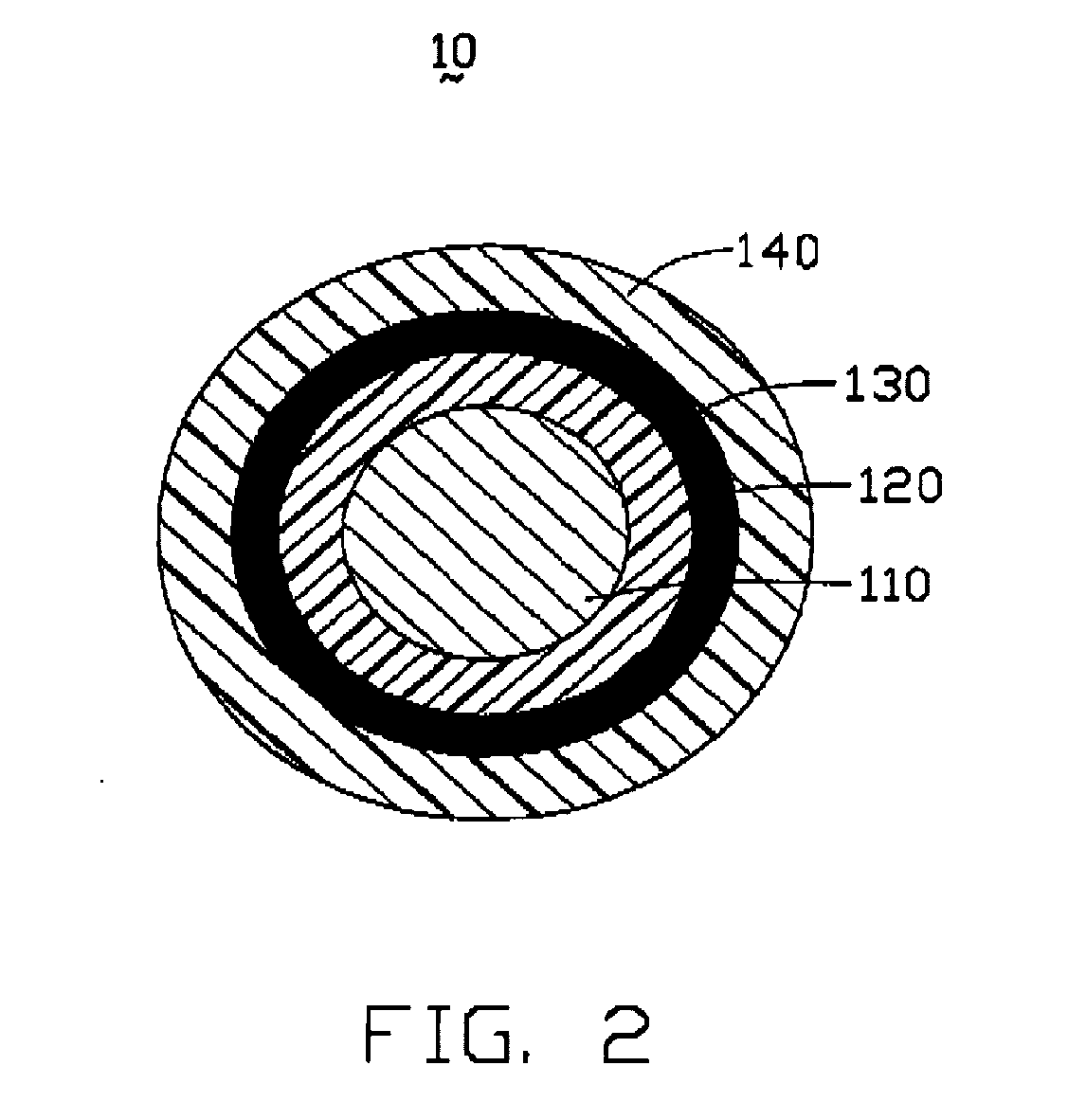

A coaxial cable (10) includes at least one conducting wire (110), at least one insulting layer (120) coating a respective conducting wire, at least one shielding layer (130) surrounding the at least one insulting layer, and a single sheath (140) wrapping the at least one shielding layer. The shielding layer includes a polymer material (134) and a plurality of carbon nanotubes (132) embedded in the polymer material. The coaxial cable is, advantageously, an electromagnetic interference (EMI) shield cable.

Owner:BEIJING FUNATE INNOVATION TECH +1

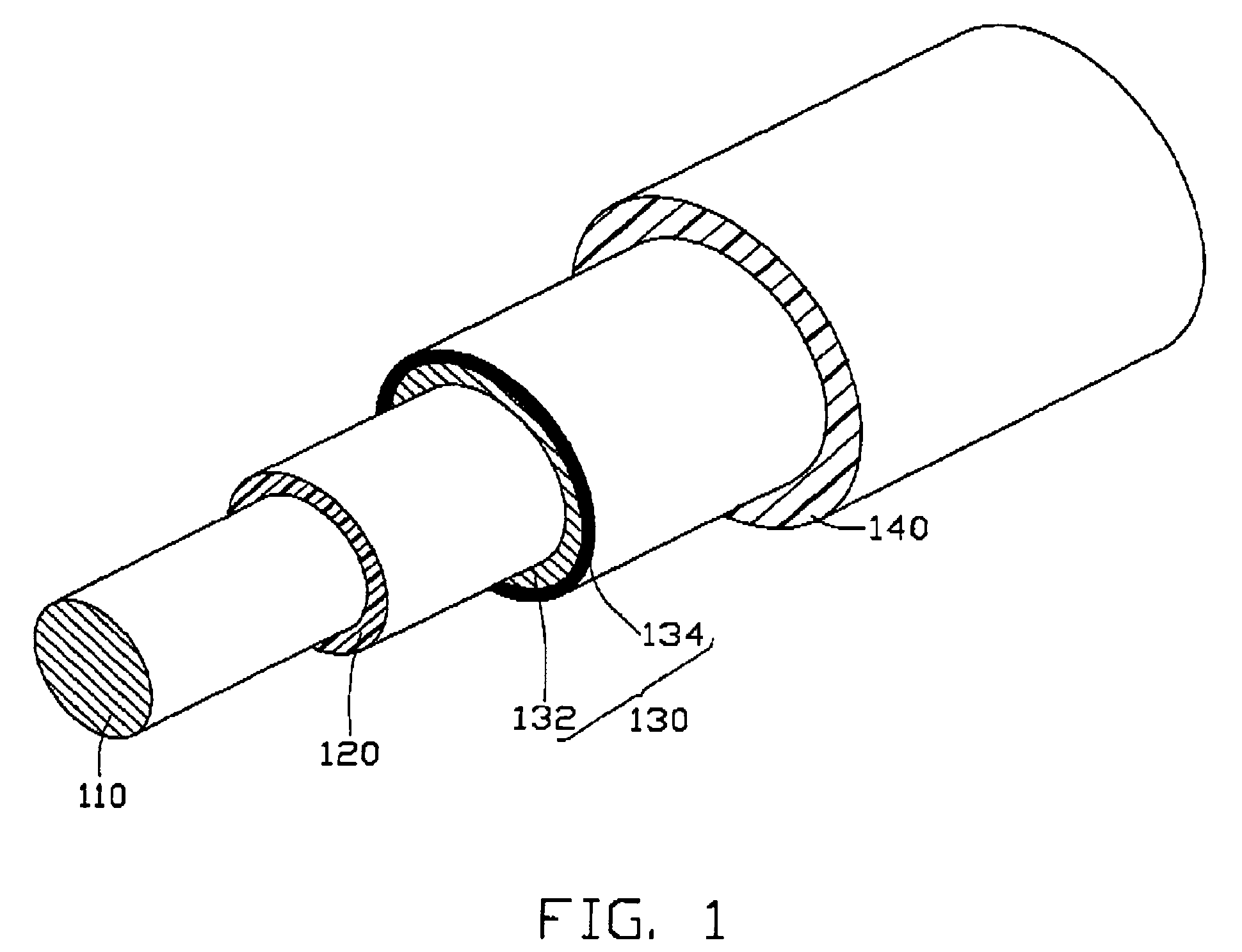

Coaxial cable

ActiveUS20070293086A1Great shield effectivenessSuitable for low-cost mass productionElectrically conductive connectionsCable conductor constructionShielded cableCoaxial cable

A coaxial cable (10) includes at least one conducting wire (110), at least one insulting layer (120) coating a respective conducting wire, at least one shielding layer (130) surrounding the at least one insulting layer, and a single sheath (140) wrapping the at least one shielding layer. The shielding layer includes a polymer material (134) and a plurality of carbon nanotubes (132) embedded in the polymer material. The coaxial cable is, advantageously, an electromagnetic interference (EMI) shield cable.

Owner:BEIJING FUNATE INNOVATION TECH +1

Coaxial cable

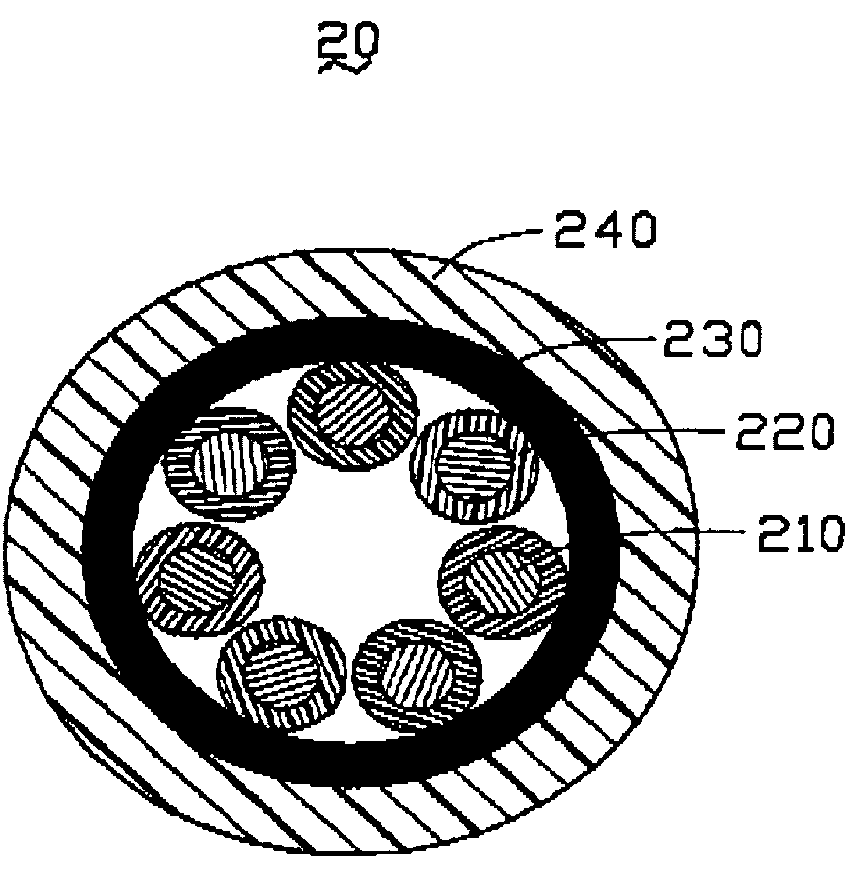

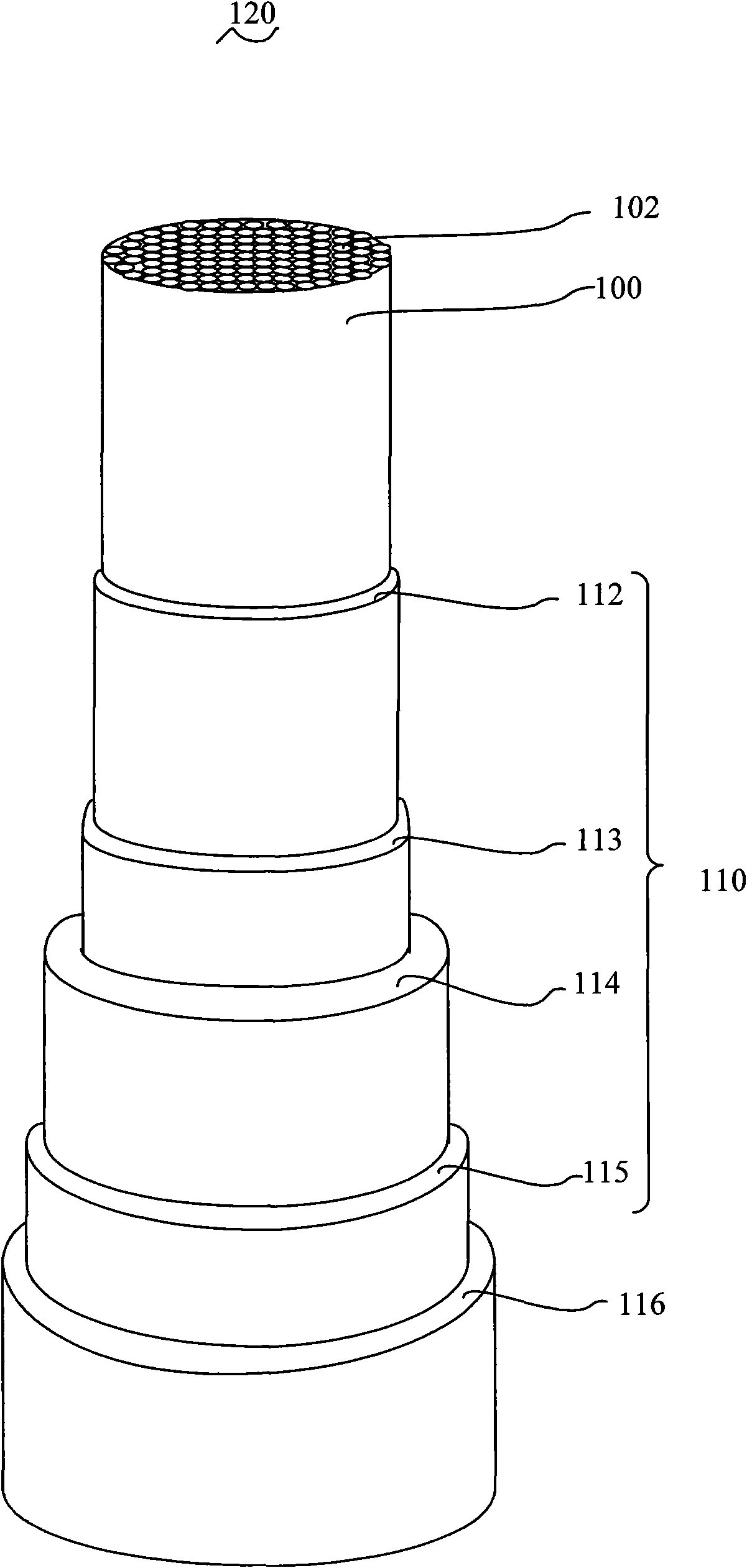

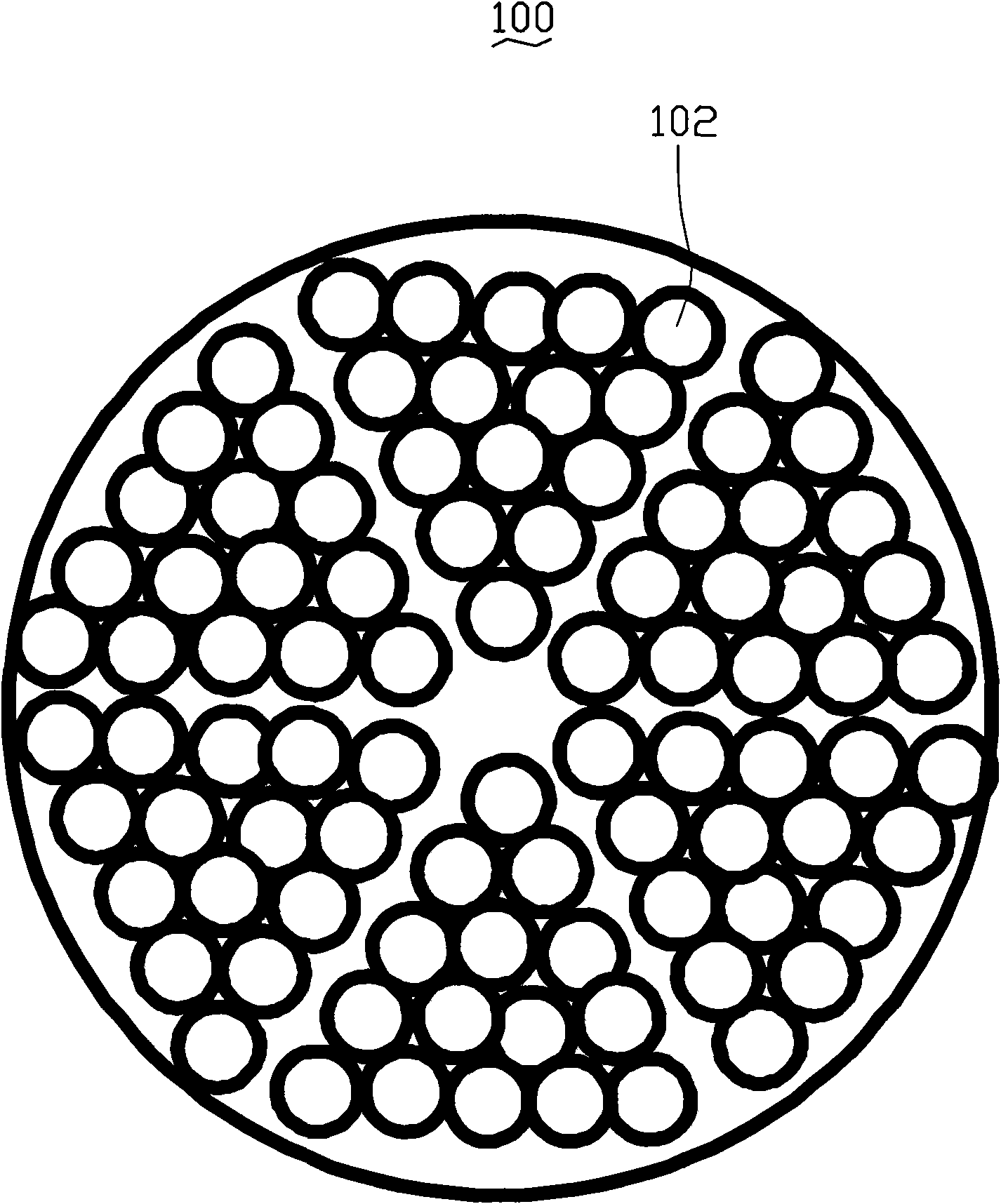

ActiveUS20090255706A1Reduce intensityGreat weight and diameterNon-insulated conductorsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable includes a core, an insulating layer, a shielding layer, and a sheathing layer. The core includes a carbon nanotube wire-like structure and at least one conductive material layer is disposed on the outside surface of the carbon nanotube wire-like structure. The carbon nanotube wire-like structure includes a plurality carbon nanotubes orderly arranged.

Owner:TSINGHUA UNIV +1

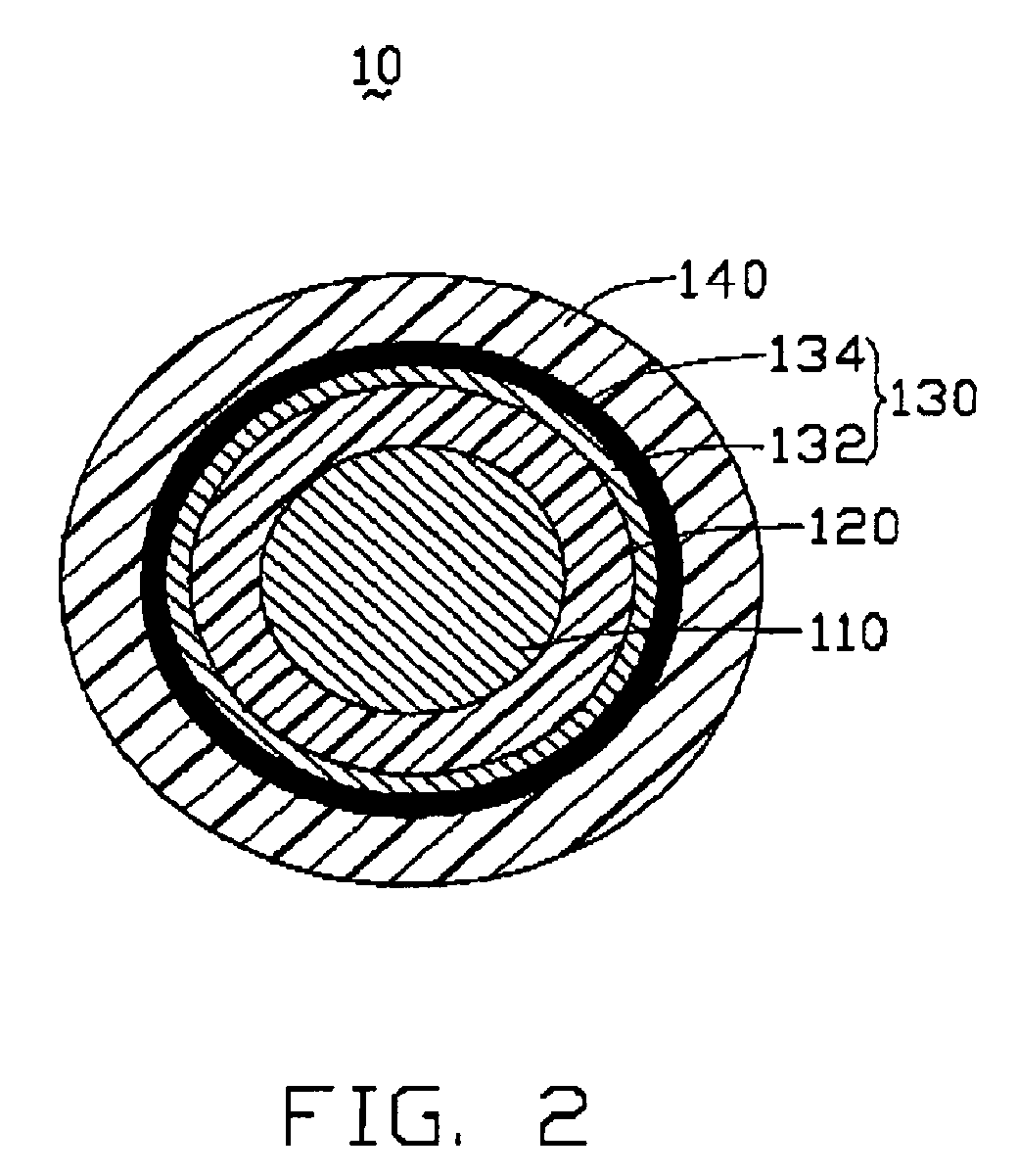

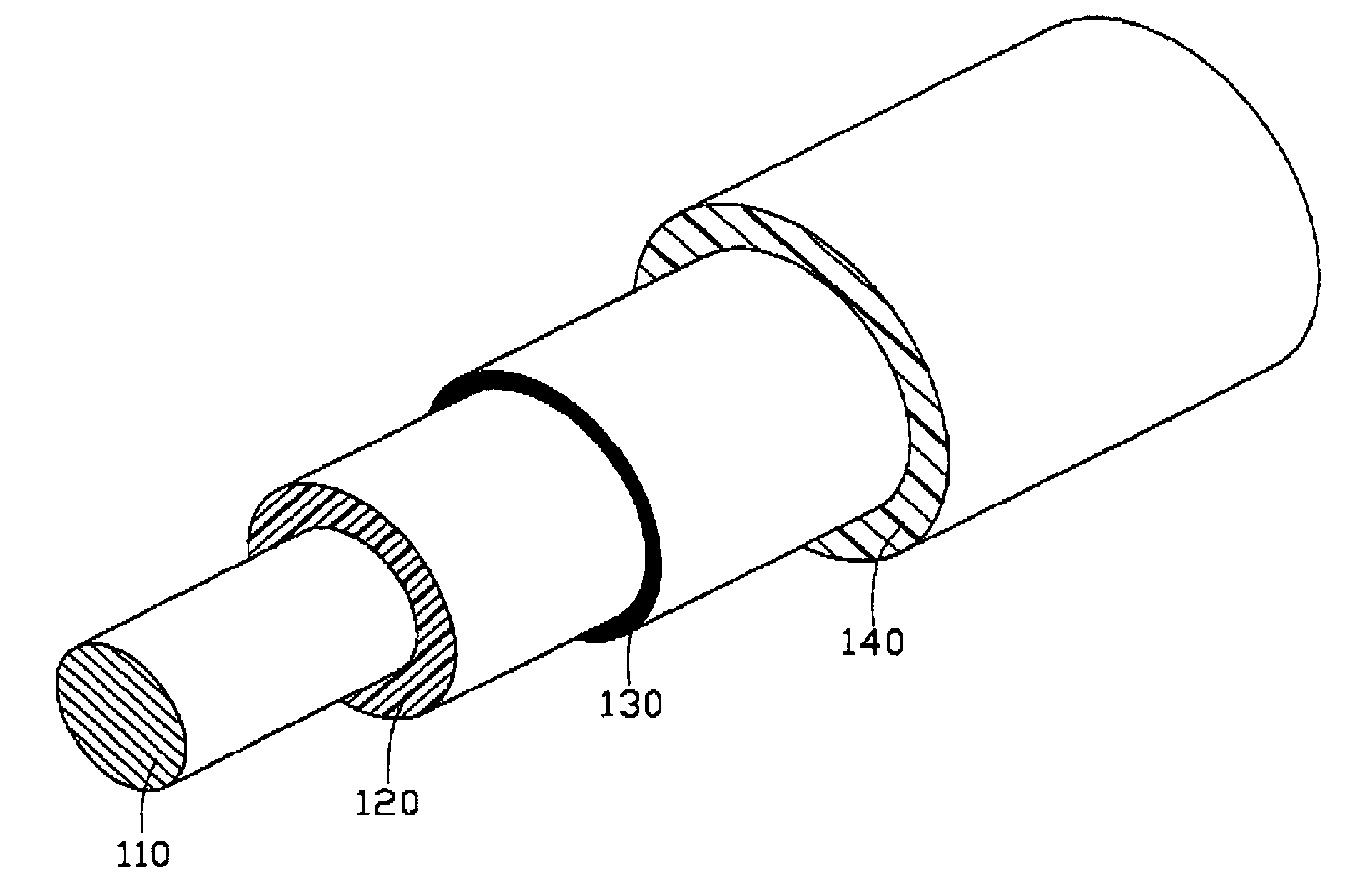

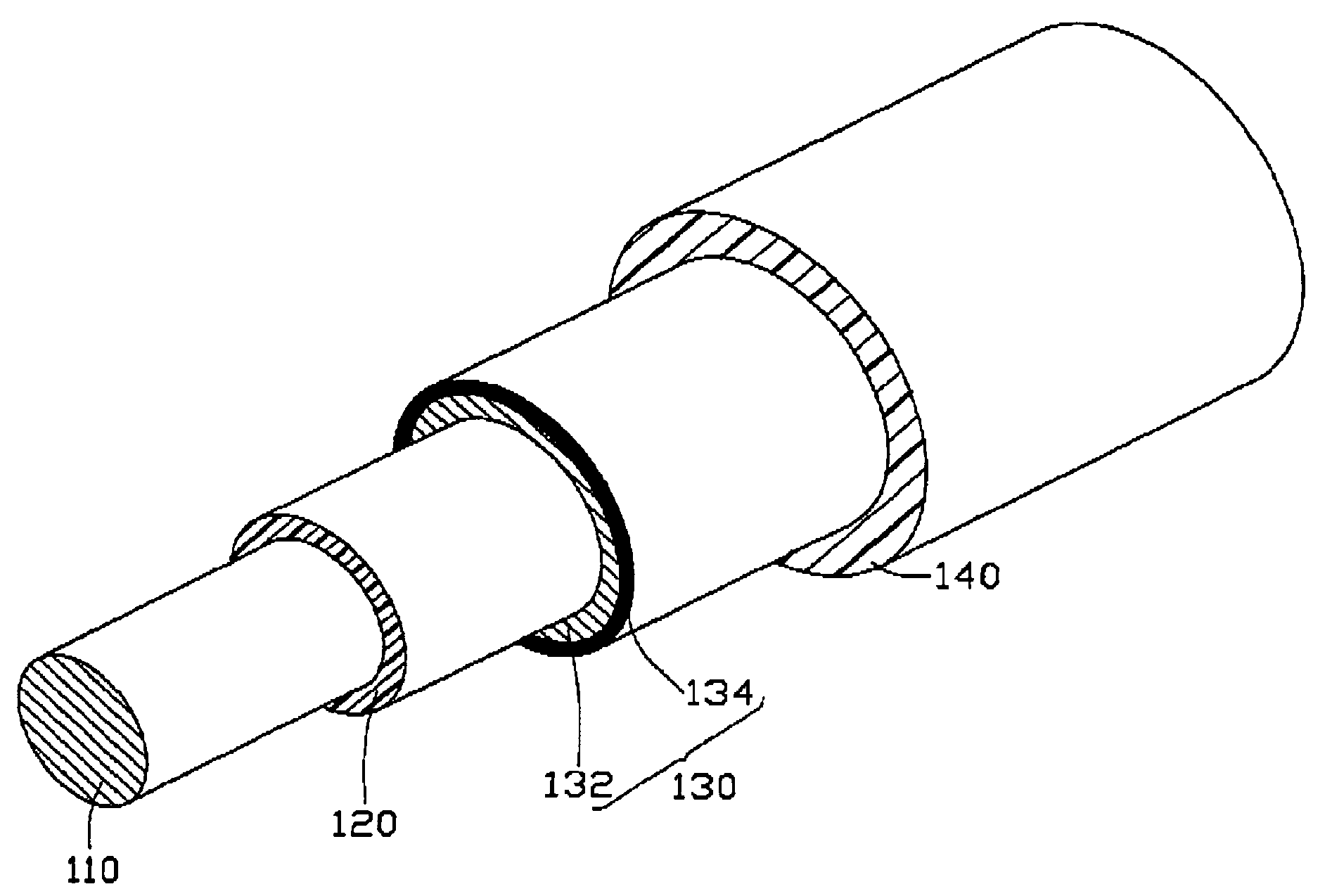

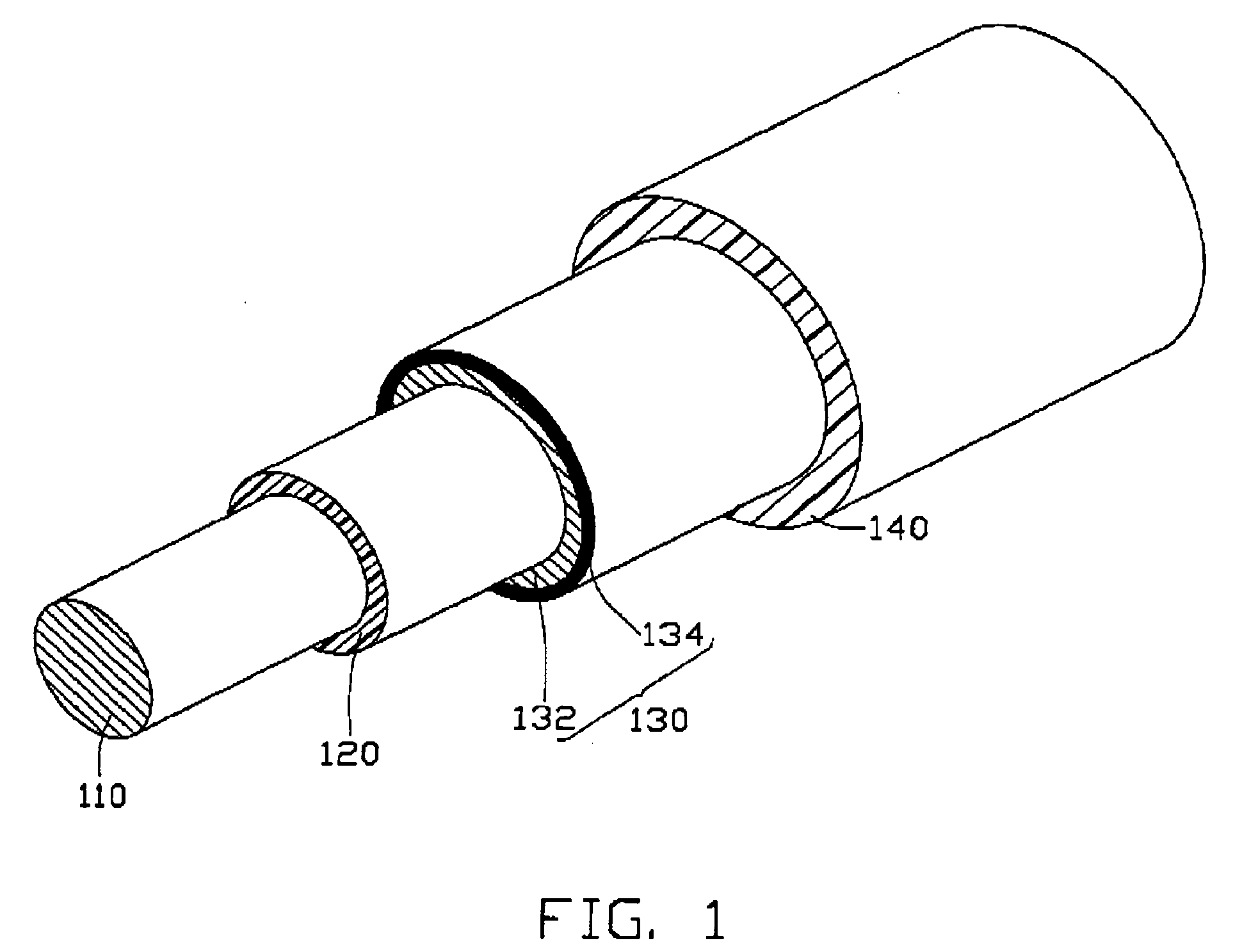

Coaxial cable

ActiveUS7491883B2Improve effectivenessSuitable for low-cost mass productionElectrically conductive connectionsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a metal layer and a carbon nanotube film.

Owner:TSINGHUA UNIV +1

Coaxial cable

ActiveUS7459627B2Improve effectivenessSuitable for low-cost mass productionCable conductor constructionPower cables with screens/conductive layersCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) is a carbon nanotube film.

Owner:TSINGHUA UNIV +1

Coaxial cable

ActiveUS20080254675A1Great shield effectivenessLow cost mass productionElectrically conductive connectionsCable conductor constructionCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a metal layer and a carbon nanotube film.

Owner:TSINGHUA UNIV +1

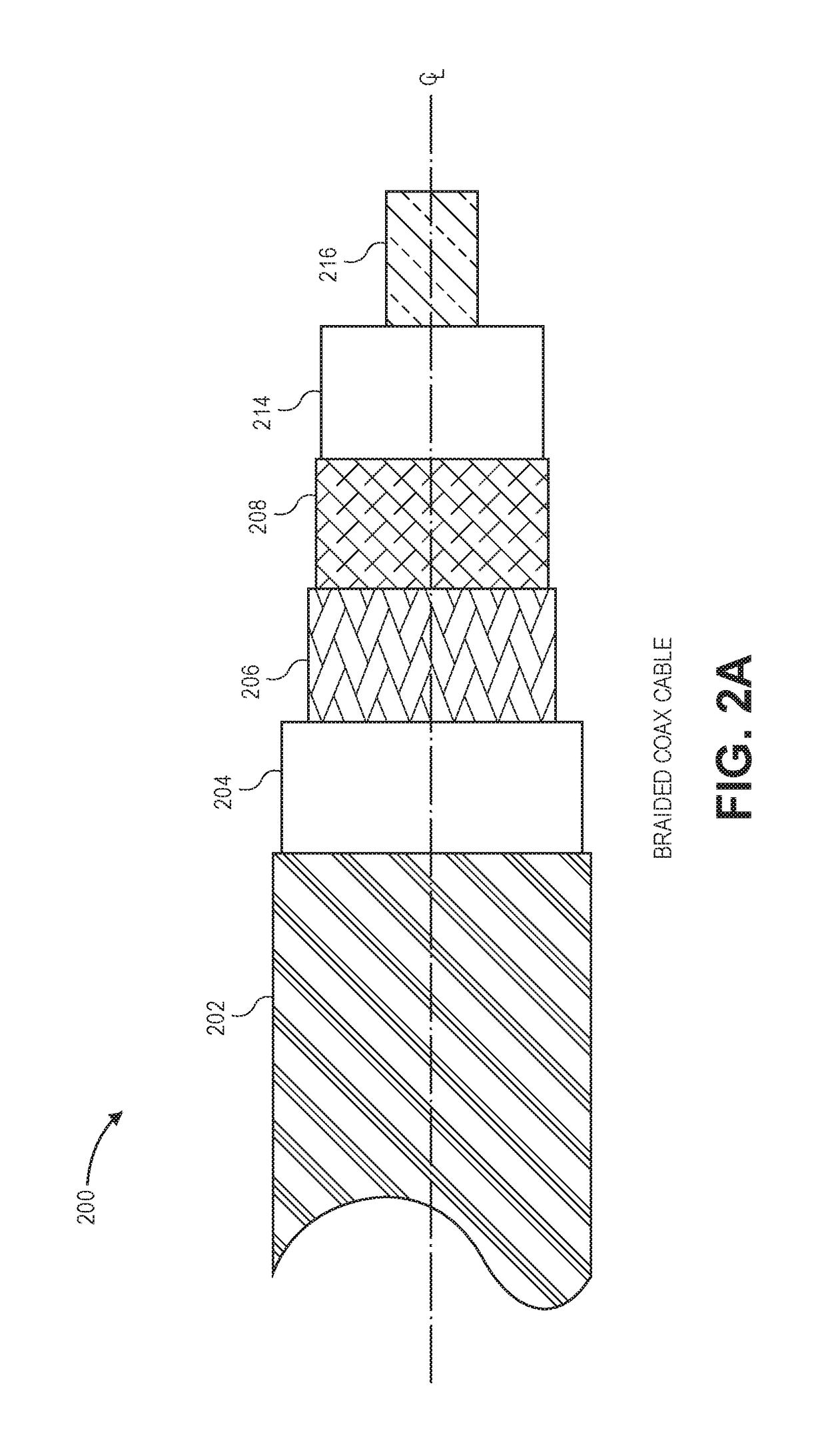

Shielding tape with multiple foil layers

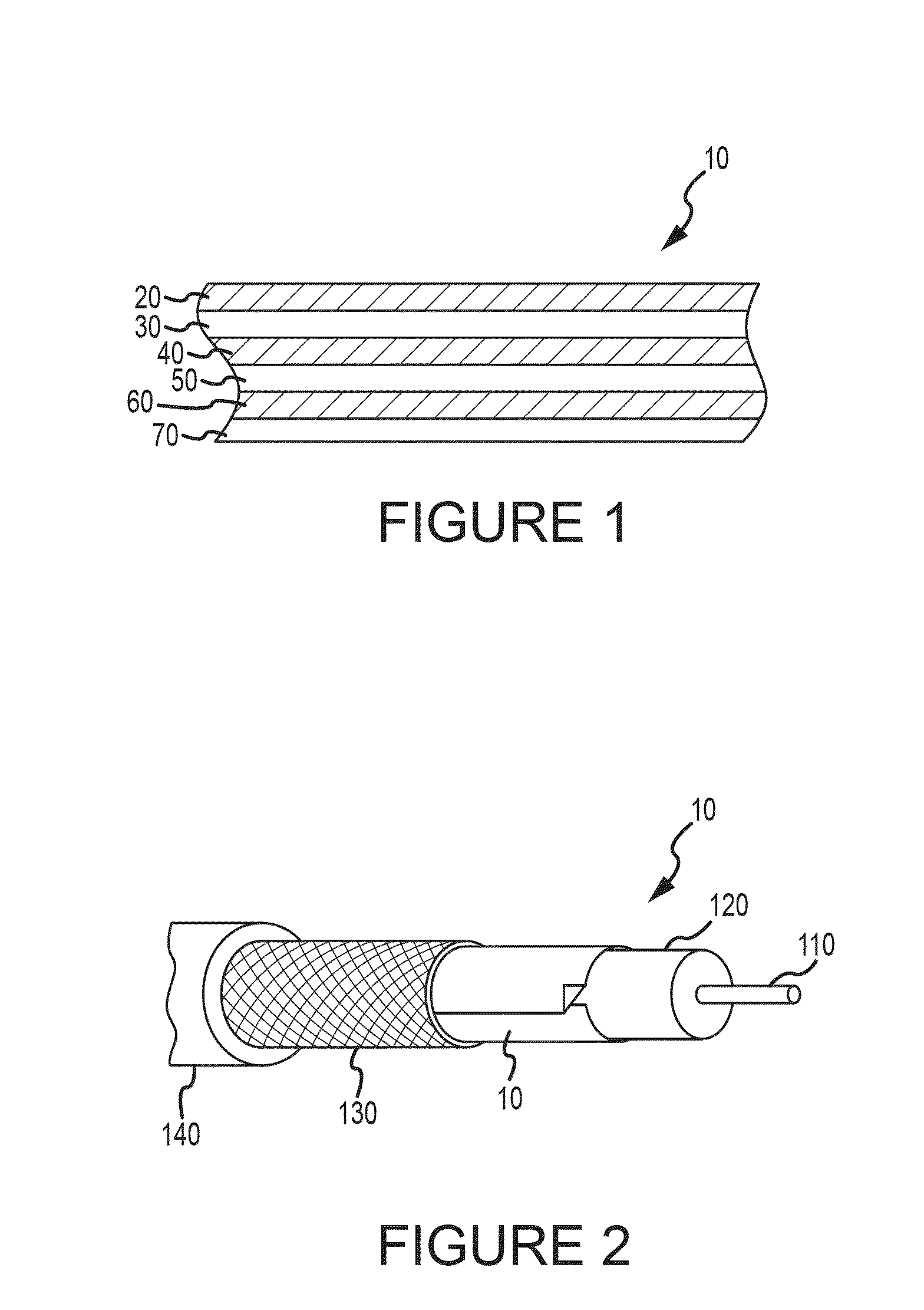

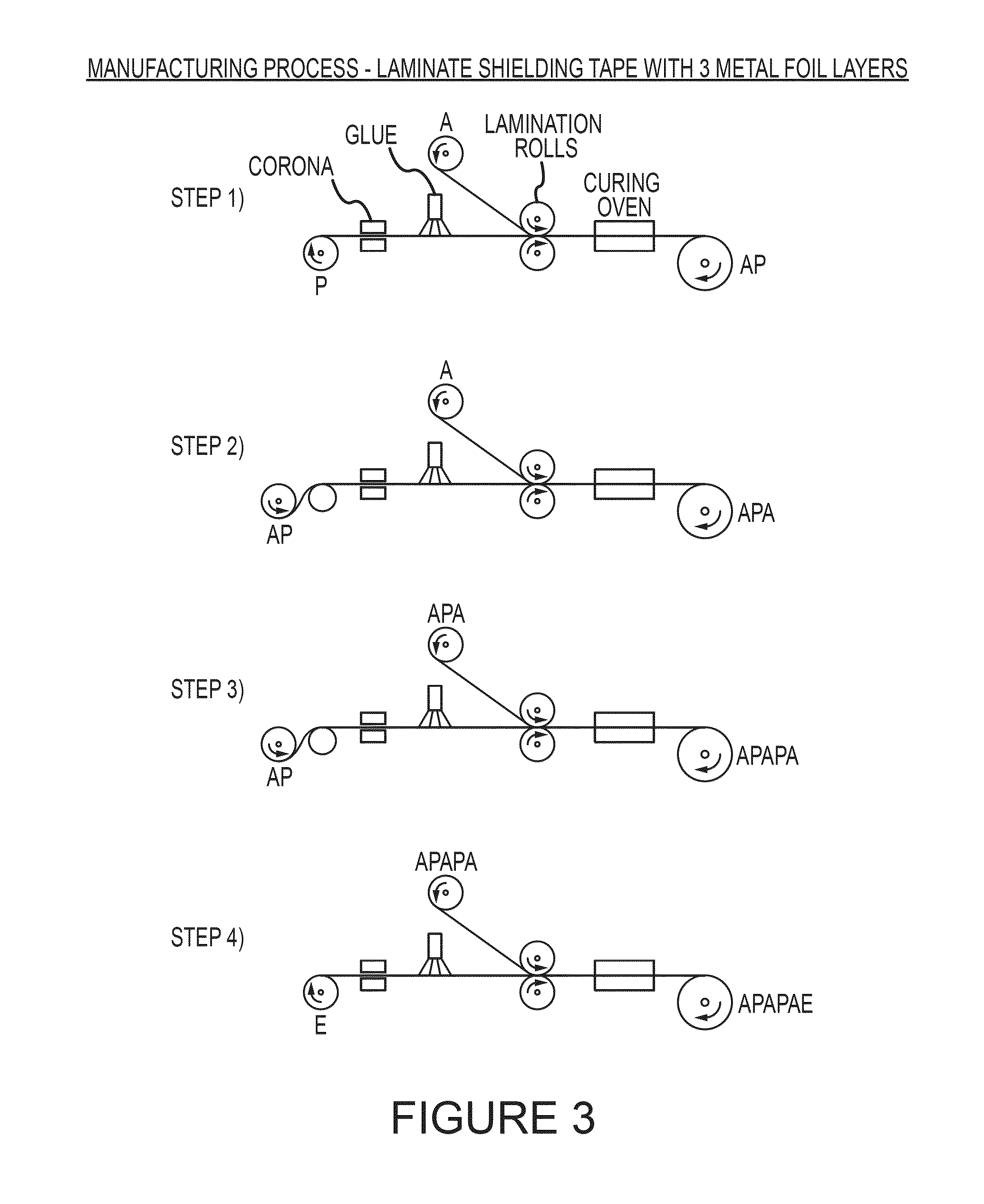

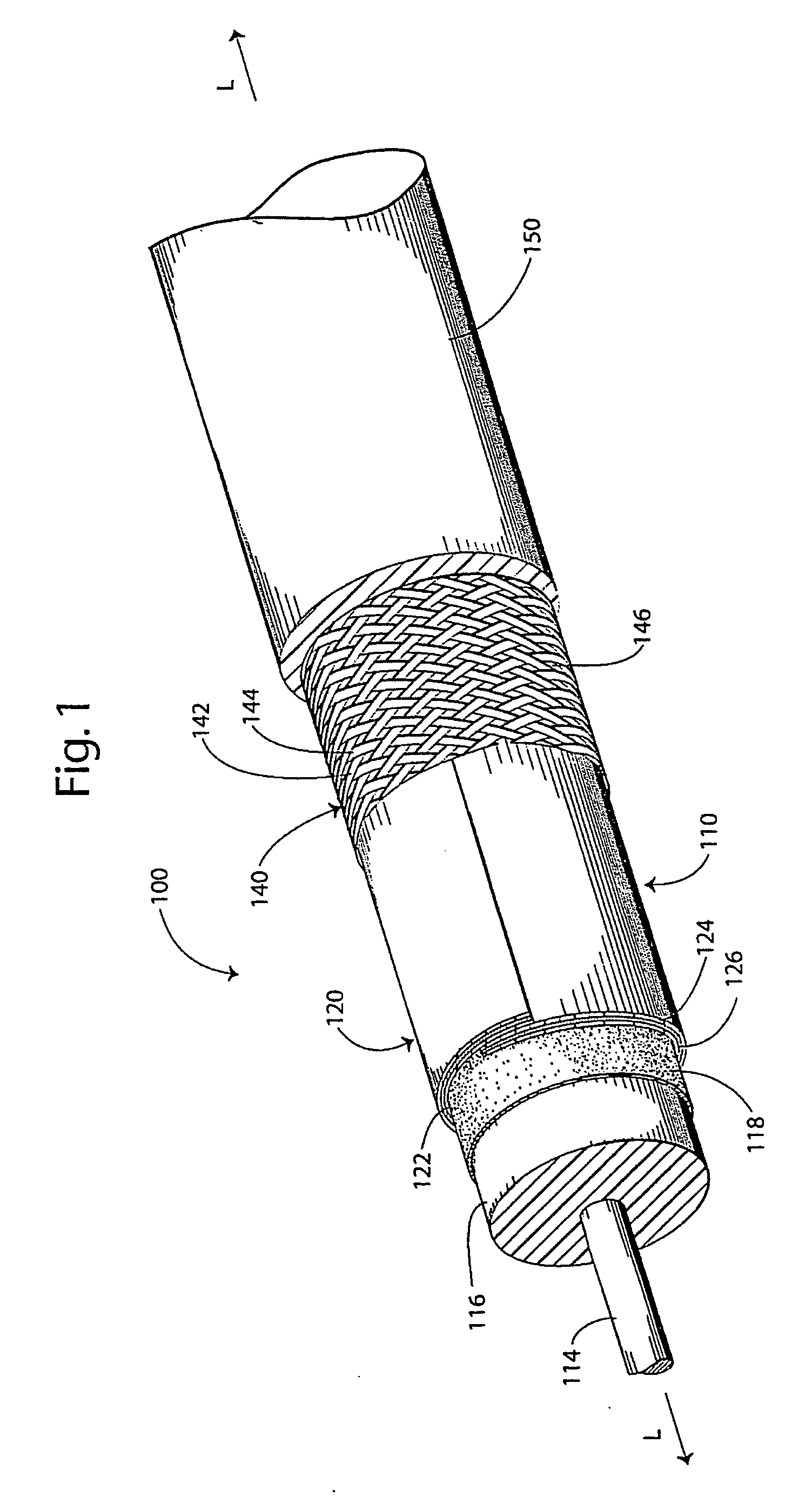

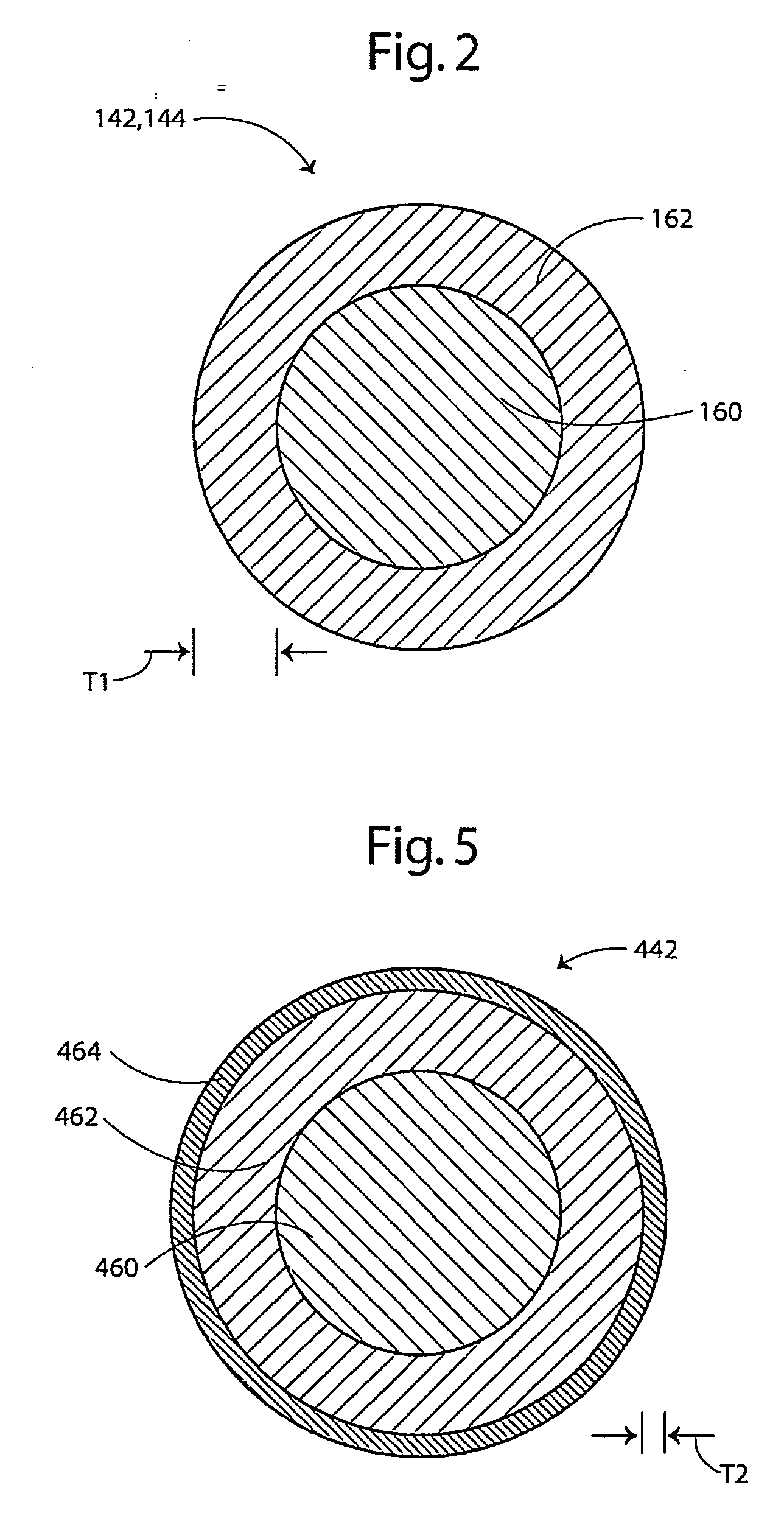

ActiveUS20110011639A1Extend elastic lifeReducing signal egressCable conductor constructionMagnetic/electric field screeningDielectricCoaxial cable

A coaxial cable of the present invention comprises a center conductor, a dielectric surrounding the center conductor, a shielding tape surrounding the dielectric, a braided metal surrounding the shielding tape, and an outer jacket surrounding the braided metal. The shielding tape comprises: (i) a first shielding layer bonded to a first separating layer; (ii) a second shielding layer bonded to the first separating layer and a second separating layer; and (iii) a third shielding layer bonded to the second separating layer. The present invention eliminates the potential problem of the outer shielding structures separating and interfering with connector attachment. Furthermore, the use of three or more shielding layers in the shielding tape of the present invention improves the flex life of the shield tape by covering micro-cracks in the metal layers with additional shielding layers, thus reducing signal egress or ingress. Accordingly, the present invention provides cost savings and / or an improvement in shielding performance.

Owner:PCT INT

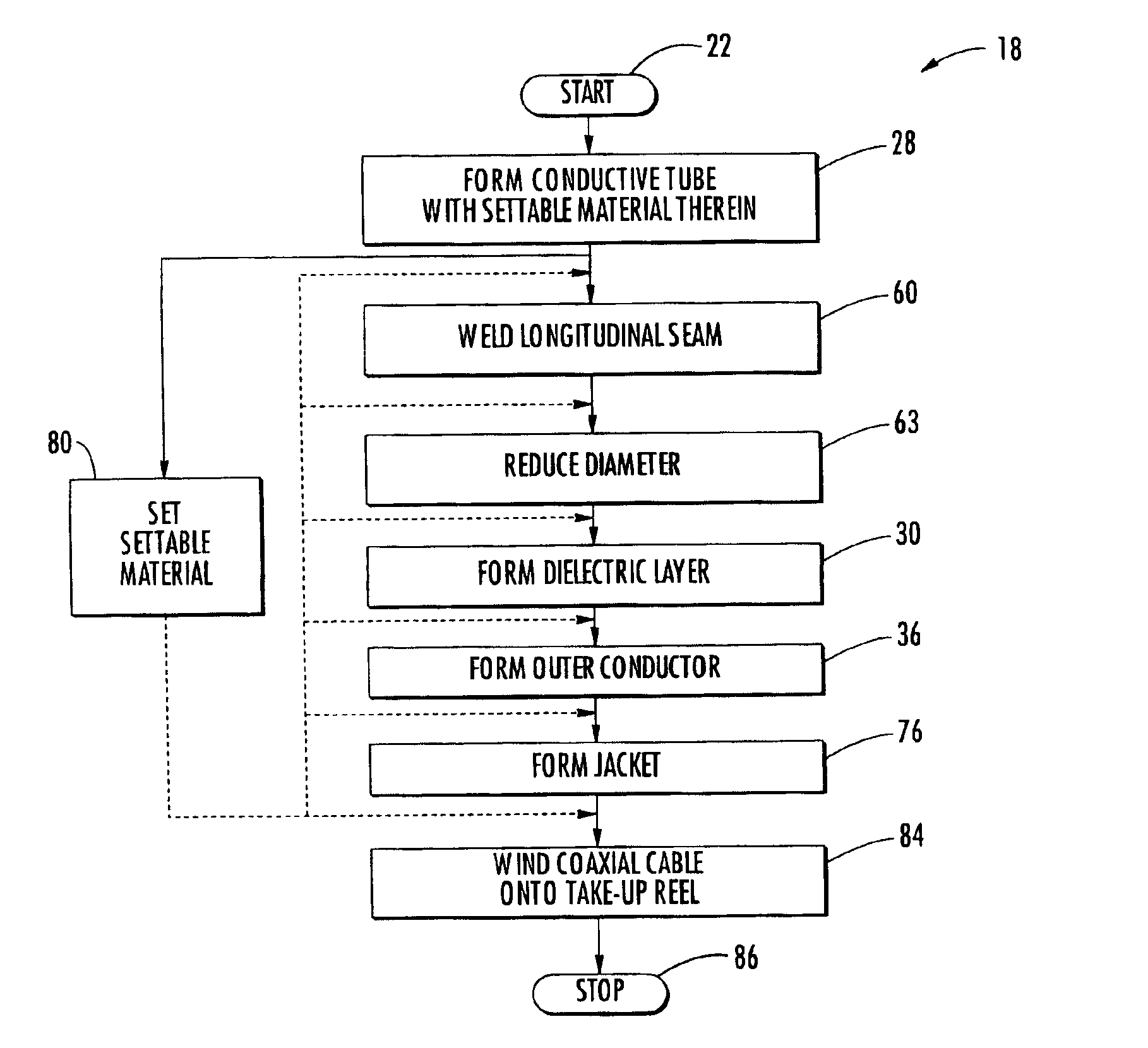

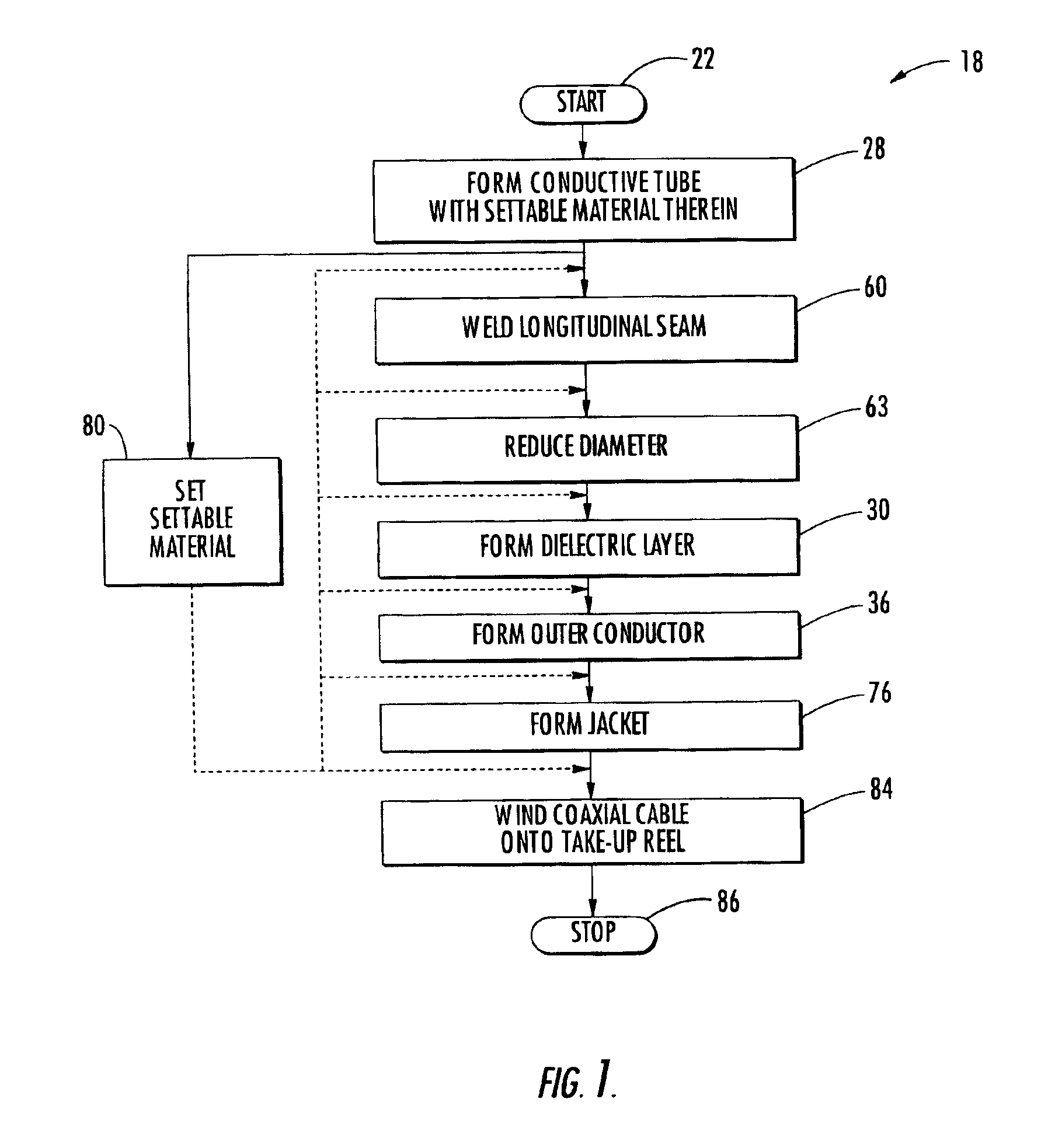

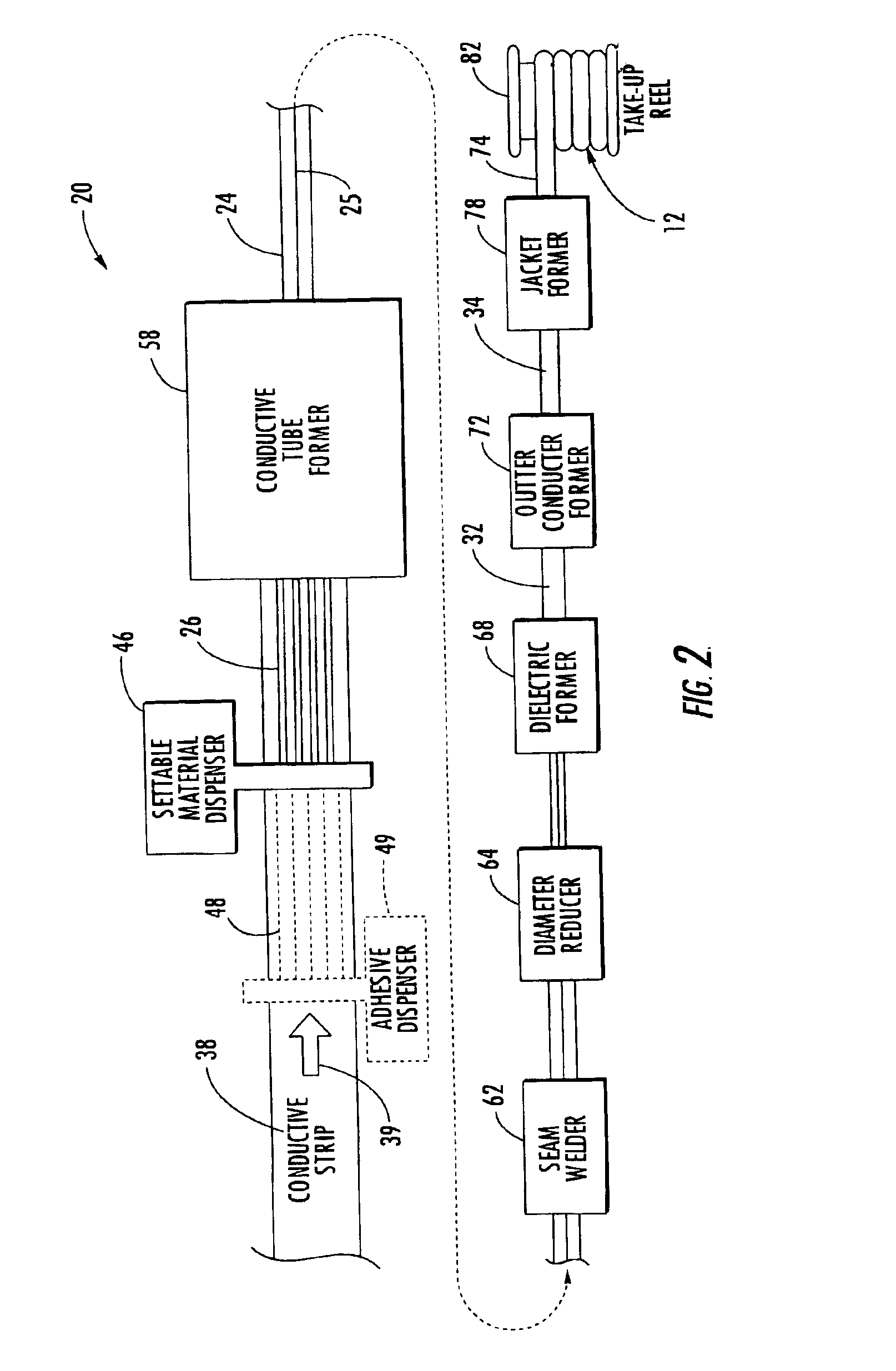

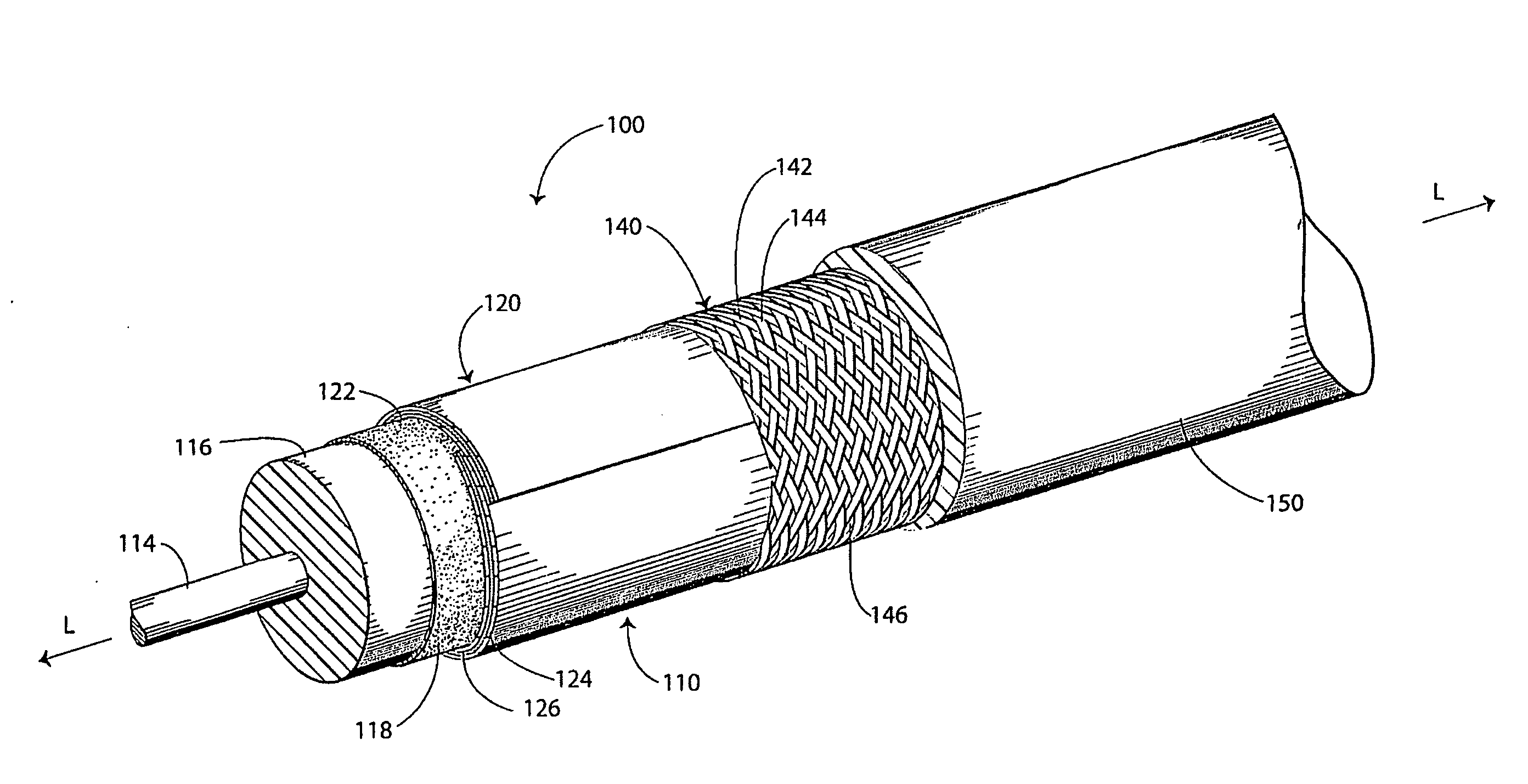

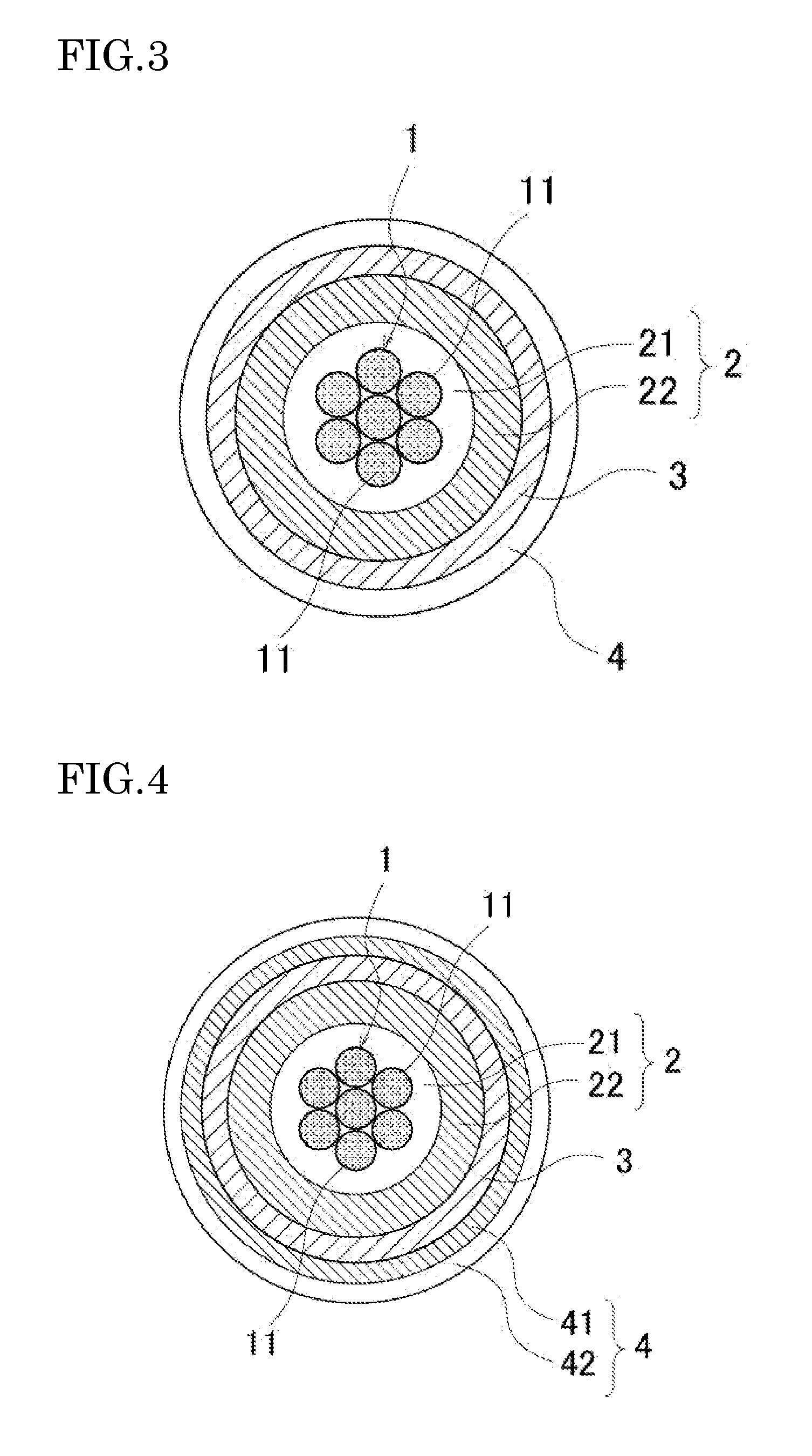

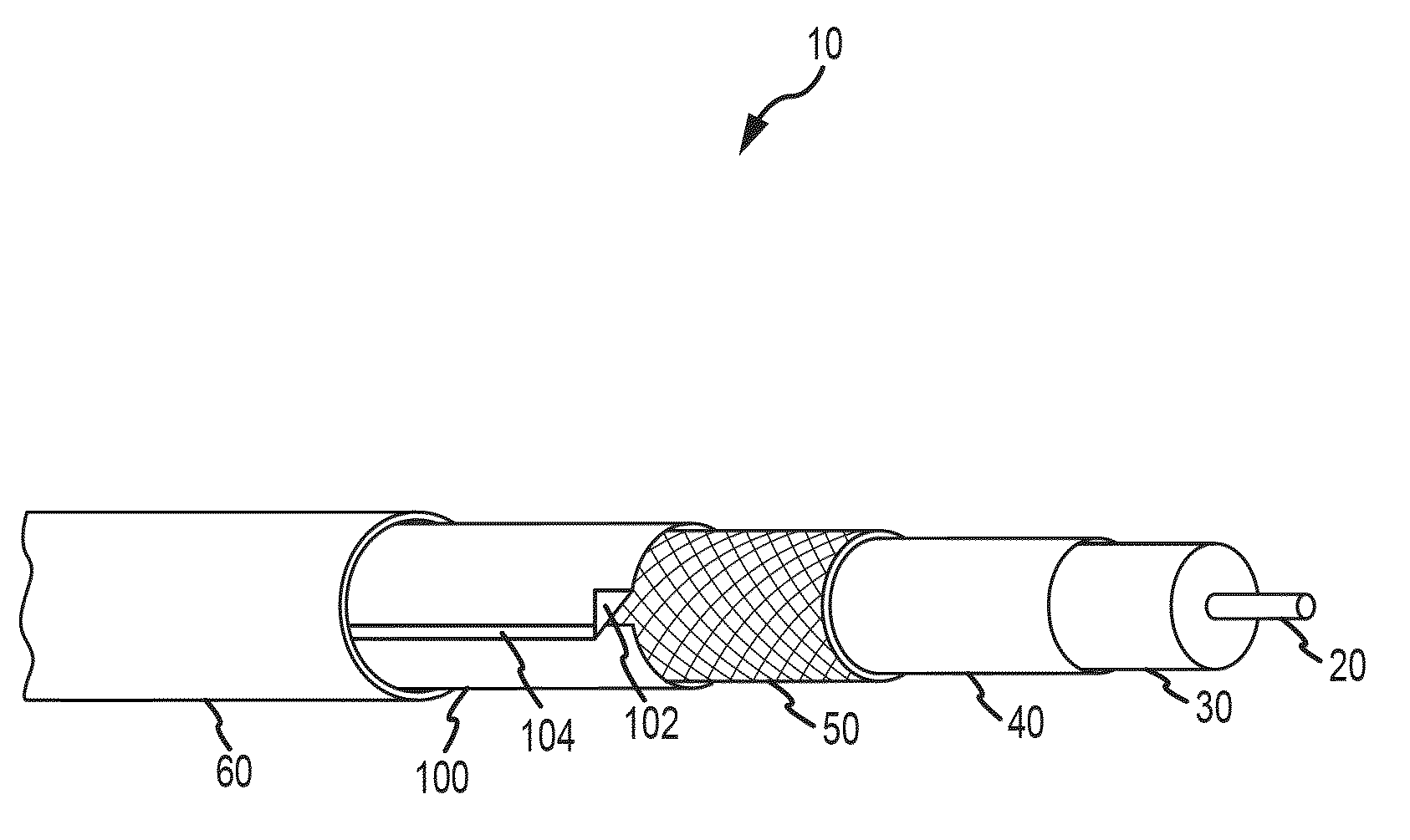

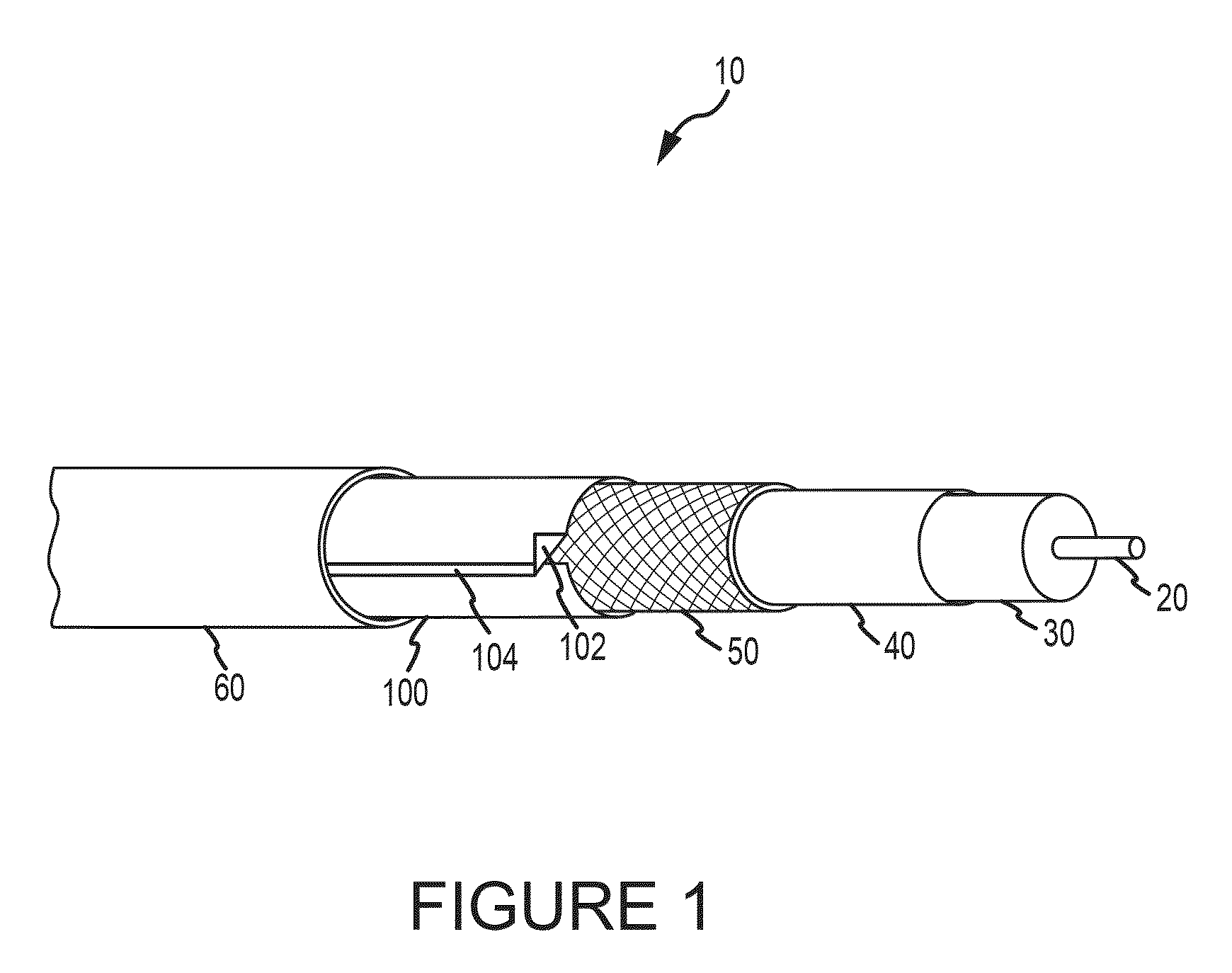

Method and apparatus for manufacturing coaxial cable with composite inner conductor

InactiveUS6915564B2Efficient preparationLow costLine/current collector detailsCable conductor constructionElectrical conductorCoaxial cable

A method of making a coaxial cable includes forming a conductive tube and setting a settable material therein to define an inner conductor. Forming may include advancing a conductive strip and bending it into a tube having a longitudinal seam. The settable material may be dispensed onto the conductive strip continuously with the forming. Alternately, the settable material may be dispensed onto the conductive strip prior to advancing. The dispensing may use a puller cord as the settable material or carrying some or all of the settable material. The method may further include forming a dielectric layer surrounding the inner conductor, and forming an outer conductor surrounding the dielectric layer.

Owner:COMMSCOPE INC

Shielded electrical transmission cables and methods for forming the same

InactiveUS20060254801A1Cable conductor constructionPower cables with screens/conductive layersElectrical conductorEngineering

A shielded electrical transmission cable includes an elongate inner conductor and an elongate shield member surrounding the inner conductor. The shield member is formed of at least one copper clad aluminum shield wire including a core including aluminum and a cladding surrounding the core and including copper.

Owner:COMMSCOPE INC

Electromagnetic shielded cable

ActiveCN101090011AImprove shielding effectSimple structurePlastic/resin/waxes insulatorsCable conductor constructionShielded cableCarbon nanotube

This invention relates to an electromagnetic screen cable including at least a core, at least one insulation dielectric layer wrapping the surface of the core, at least a screen layer wrapping at least one core and an outer jacket covering the screen layer, in which, the screen layer is made of polymer material scattered with carbon nanometer tubes.

Owner:BEIJING FUNATE INNOVATION TECH +1

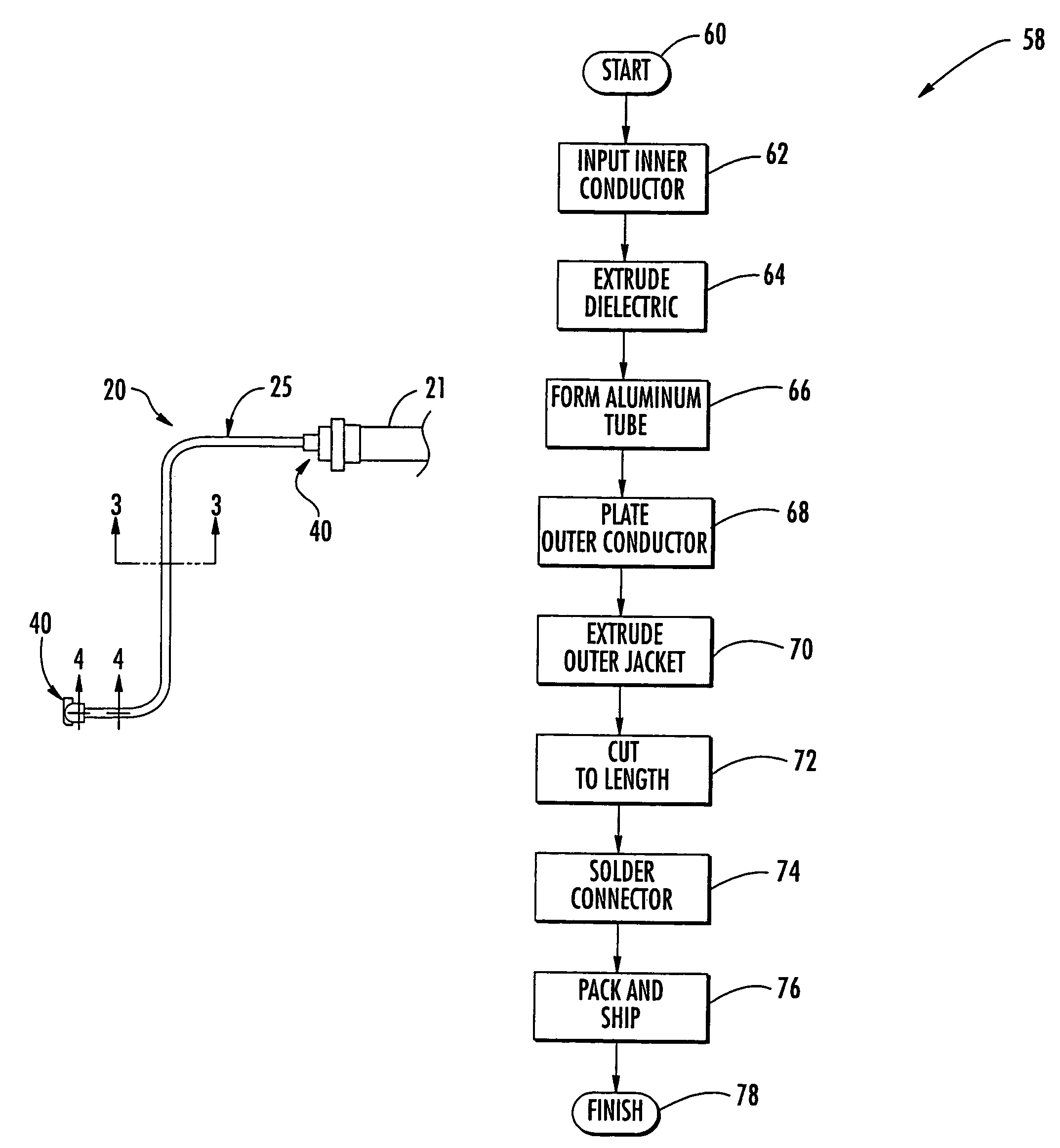

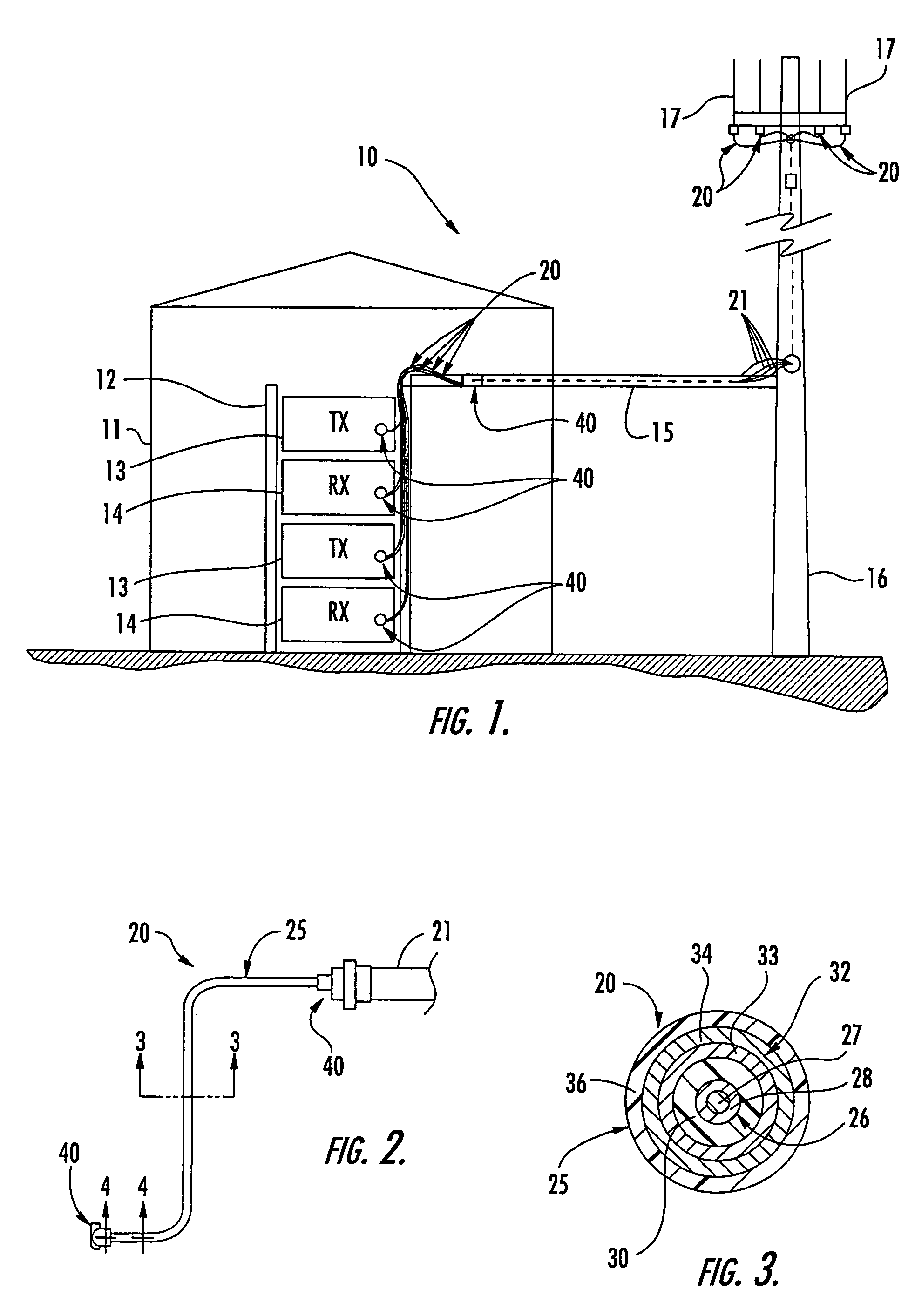

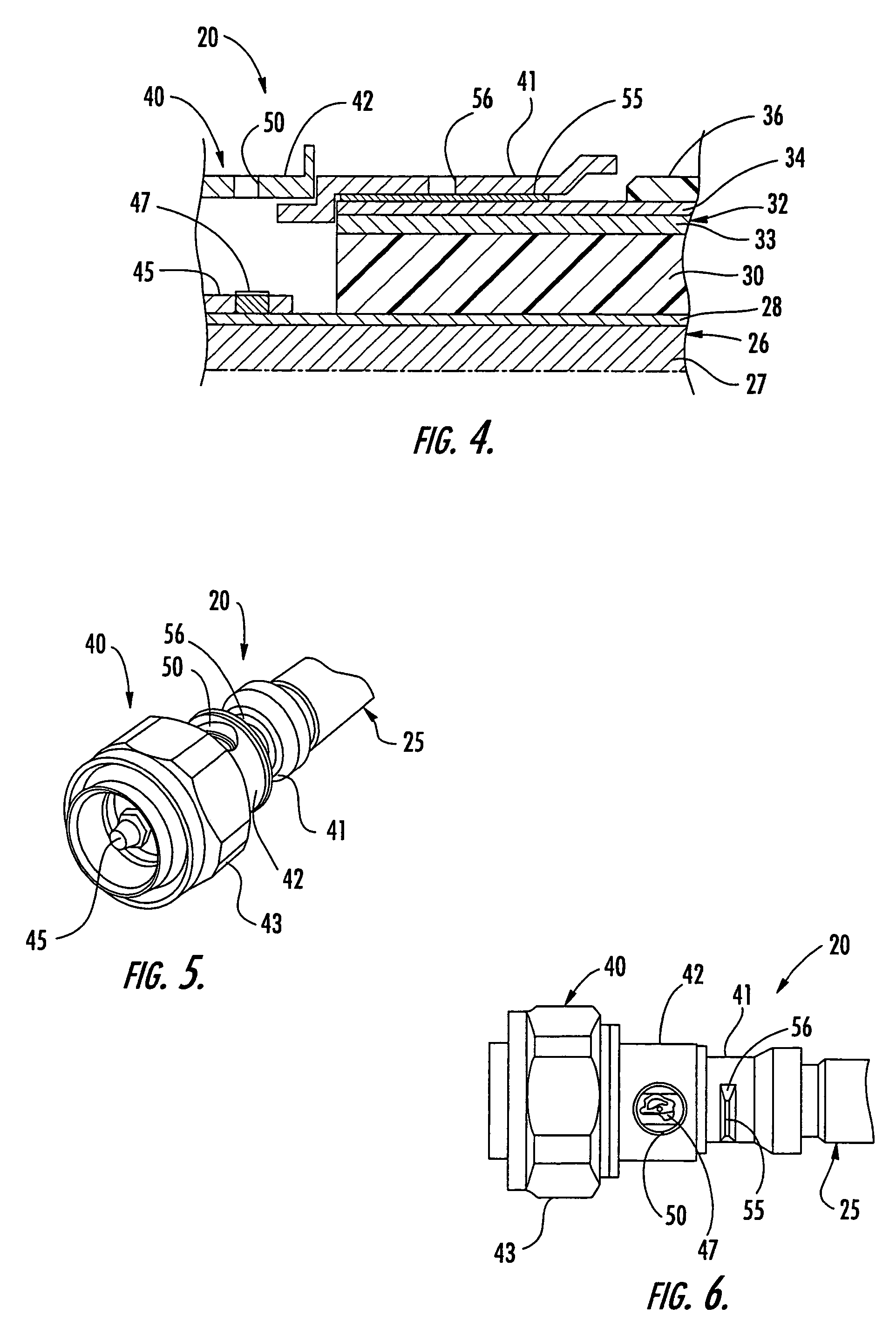

Method for marking coaxial cable jumper assembly including plated outer assembly

InactiveUS7127806B2Easy to manufactureShape-retaining qualityEngagement/disengagement of coupling partsPrinted circuit assemblingCoaxial cableElectrical conductor

A jumper coaxial cable assembly includes a jumper coaxial cable and at least one solder-type connector secured thereto. The cable may include an outer conductor, which, in turn, includes aluminum with a tin layer thereon. The tin layer permits an aluminum outer conductor to be used, yet facilitates soldering of the solder-type connector onto the outer conductor. The tin layer may be a tin alloy, such as a tin / lead alloy, for example. The outer conductor may have a continuous, non-braided, tubular shape, and the tin layer may extend continuously along an entire length of the outer conductor. The tin layer may be readily formed by tin plating during manufacturing of the jumper coaxial cable. The jumper coaxial cable assembly may be joined to a main coaxial cable and / or to electronic equipment.

Owner:COMMSCOPE INC

Coaxial cable

ActiveUS7449631B2Improve effectivenessSuitable for mass productionCable conductor constructionMagnetic/electric field screeningCoaxial cableCarbon nanotube yarn

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a number of carbon nanotube yarns.

Owner:TSINGHUA UNIV +1

Coaxial cable

ActiveUS20080251274A1Great shield effectivenessSuitable for low-cost mass productionCable conductor constructionPower cables with screens/conductive layersCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) is a carbon nanotube film.

Owner:TSINGHUA UNIV +1

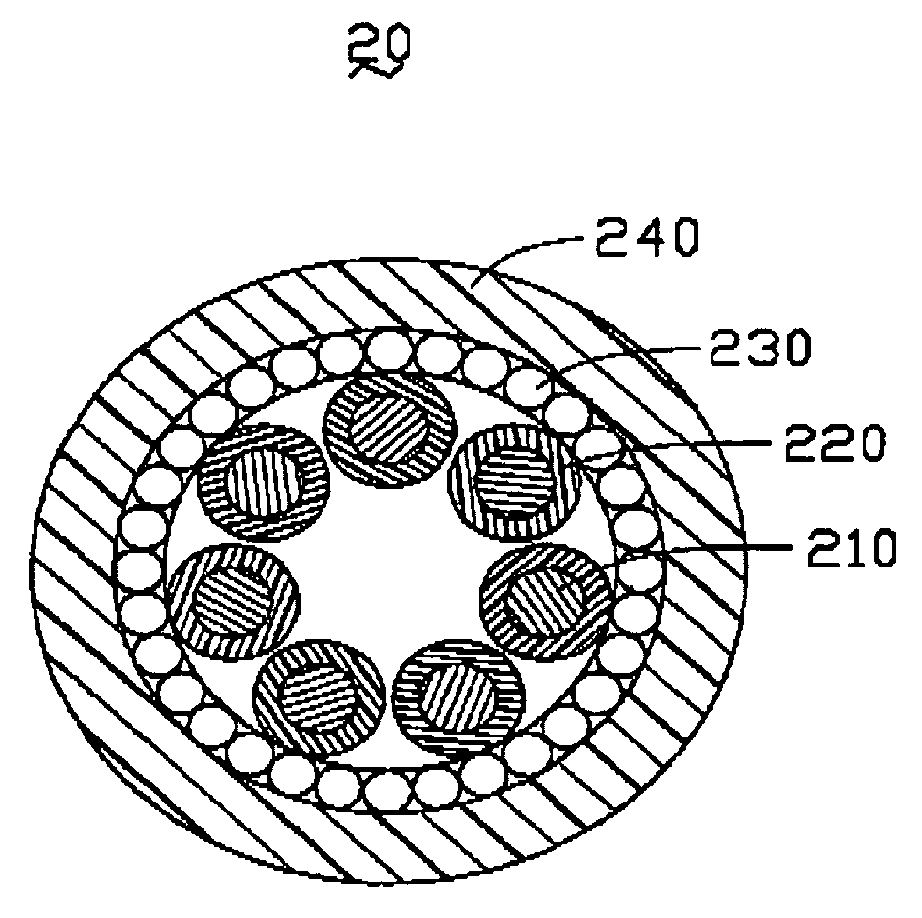

Shielded cable assembly

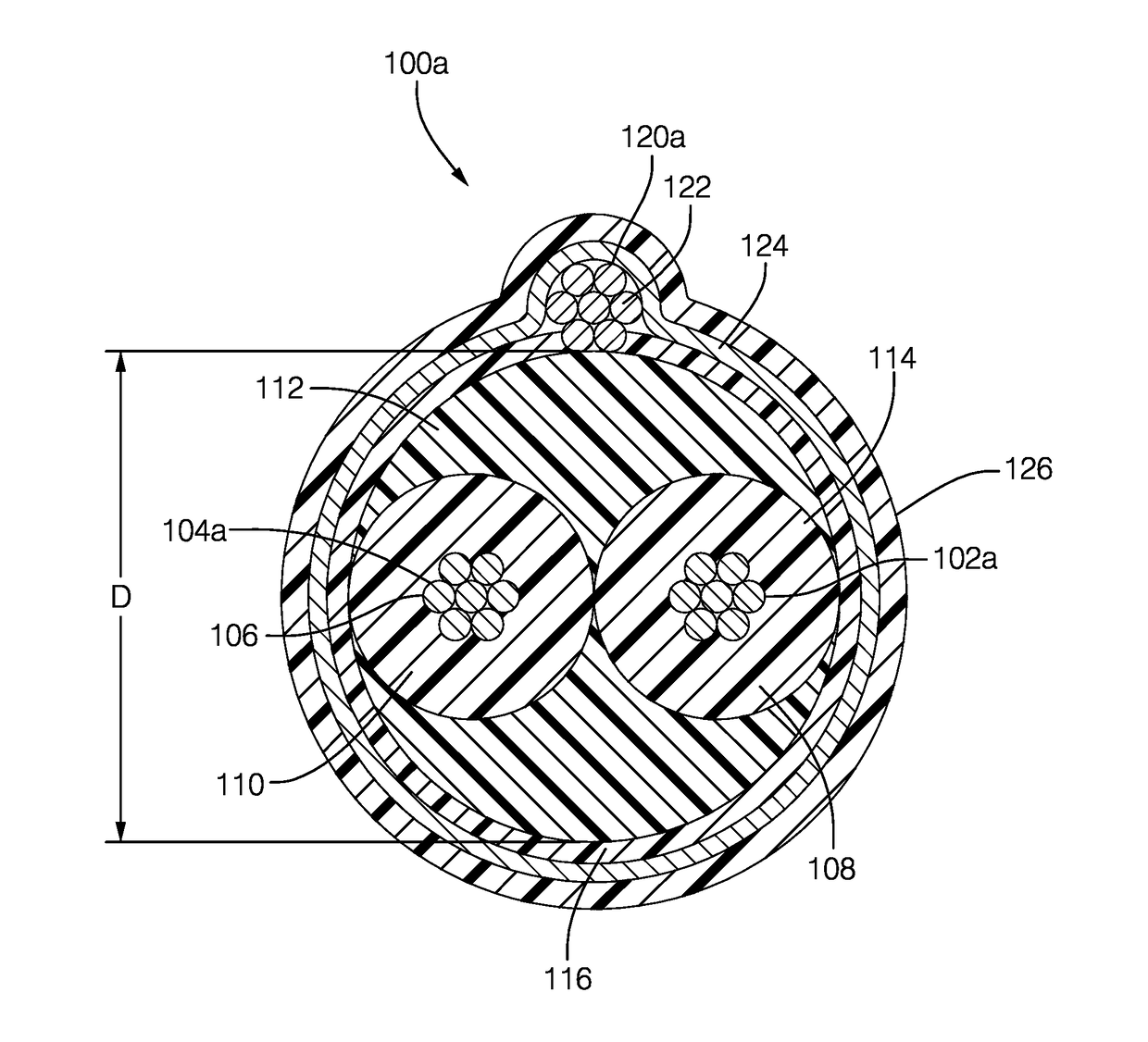

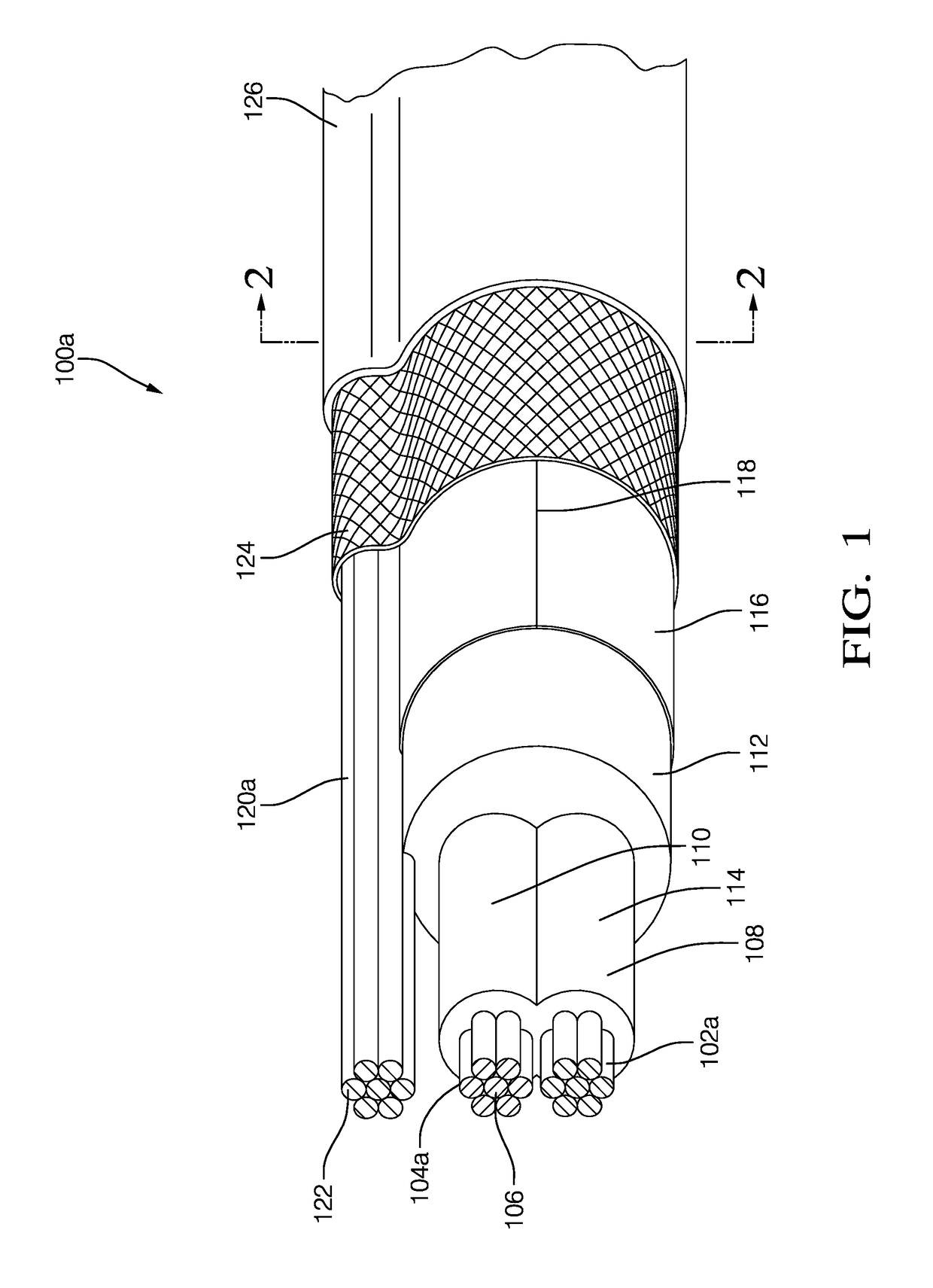

InactiveUS20170110222A1Electrically conductive connectionsPlastic/resin/waxes insulatorsShielded cableElectrical conductor

A wire cable assembly capable of transmitting signals at speeds of 5 Gigabits per second over a single pair or conductors. The cable has a characteristic impedance of 95 Ohms and can support transmission data according to either USB 3.0 or HDMI 1.3 performance specifications. The wire cable includes a pair of conductors, a shield surrounding the conductors, and a dielectric structure configured to maintain a first predetermined spacing between the conductors and a second predetermined spacing between said the conductors said shield. The shield includes an inner shield conductor enclosing the dielectric structure, a ground conductor external to the inner shield conductor, extending generally parallel to the pair of conductors, an outer shield conductor enclosing the inner shield conductor and the ground conductor.

Owner:APTIV TECH LTD

Coaxial cable

ActiveUS20080251270A1Improve effectivenessSuitable for low-cost mass productionCable conductor constructionMagnetic/electric field screeningCoaxial cableCarbon nanotube yarn

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) includes a number of carbon nanotube yarns.

Owner:TSINGHUA UNIV +1

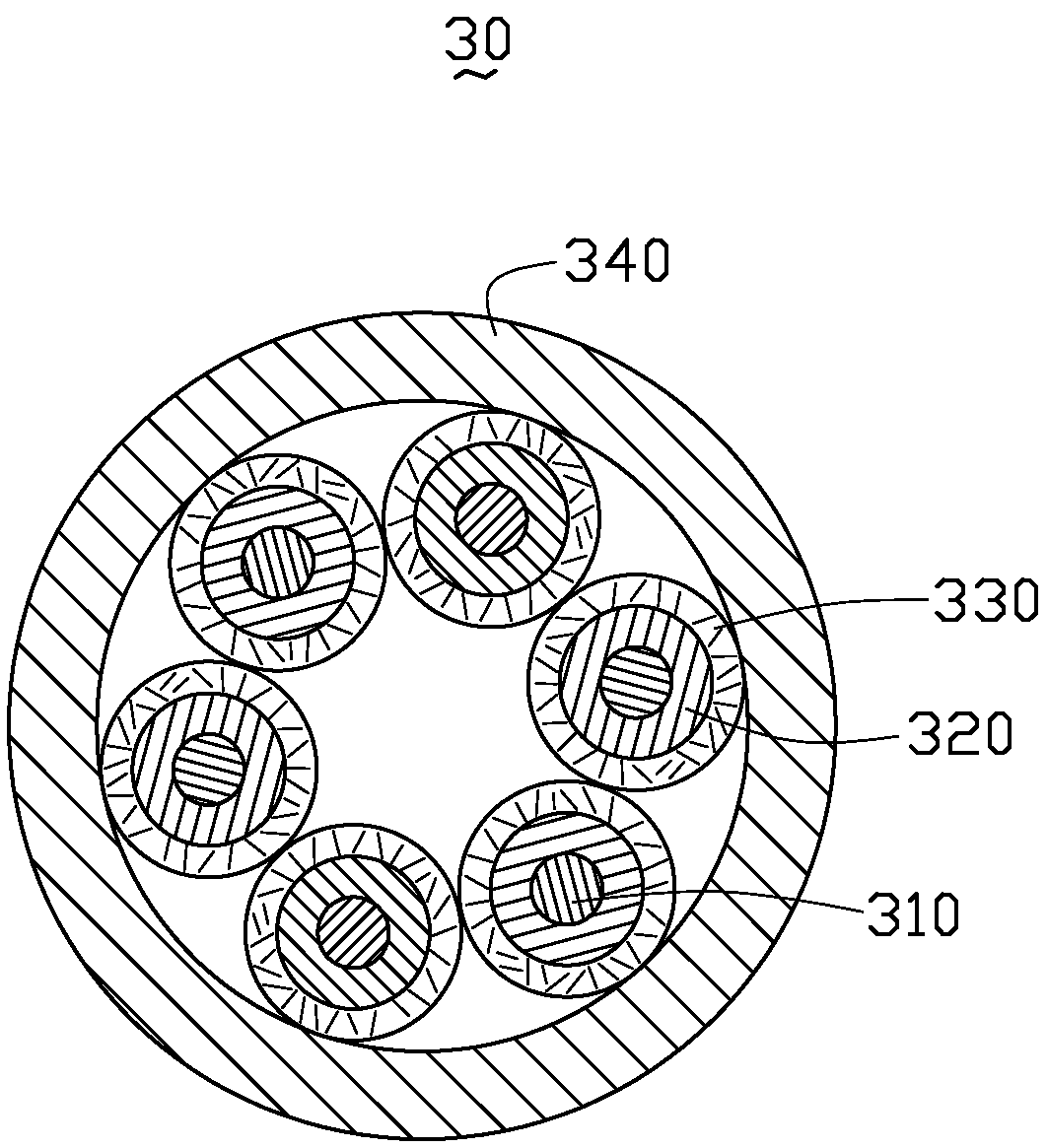

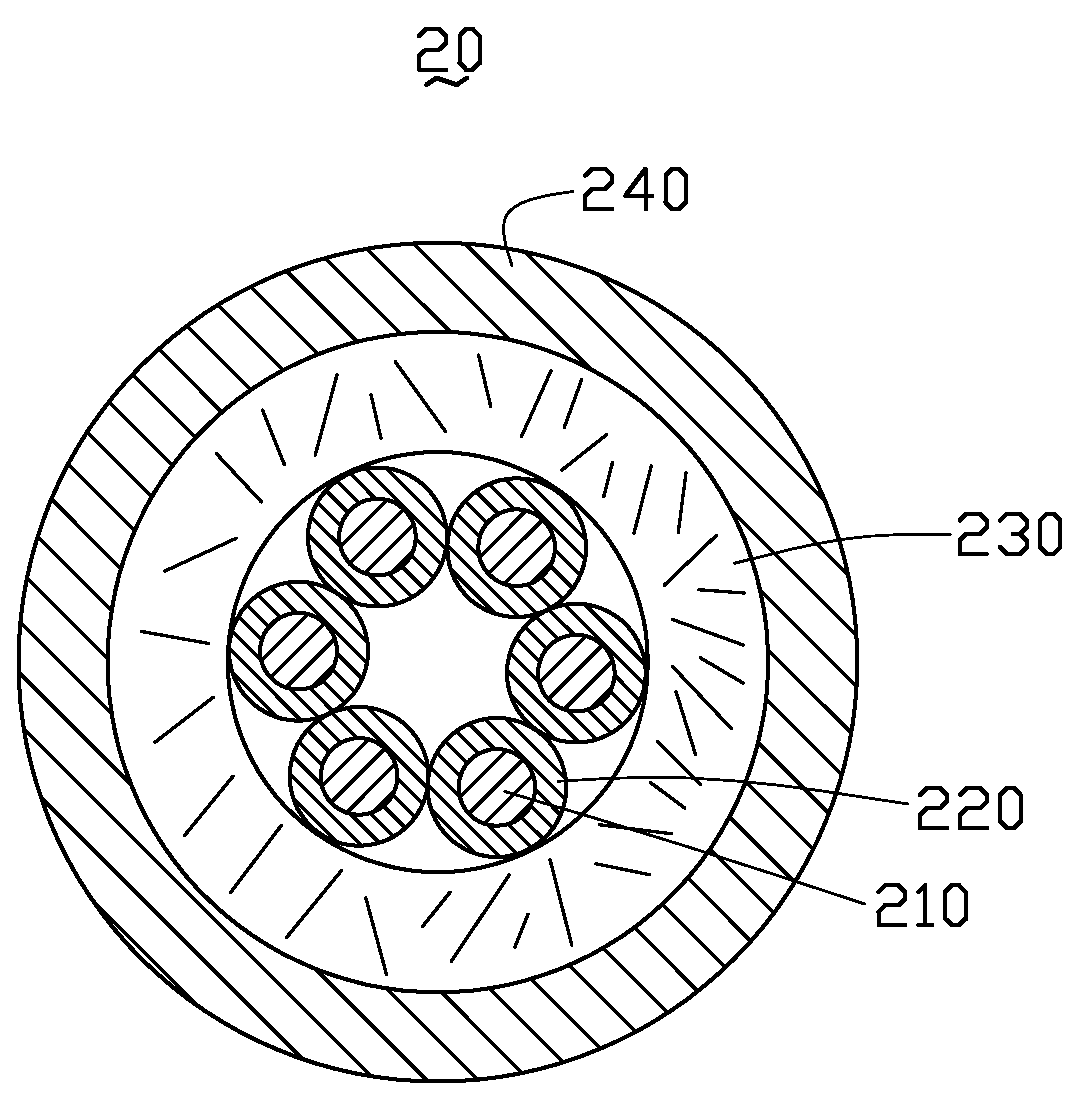

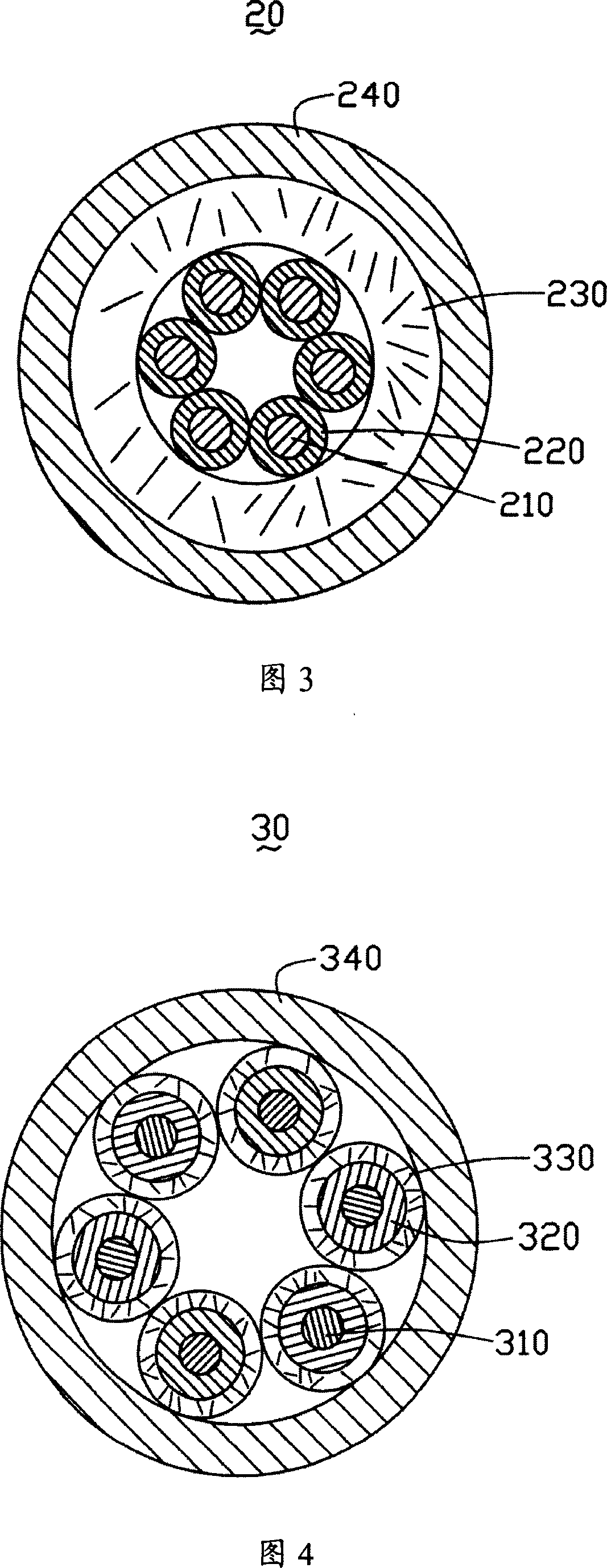

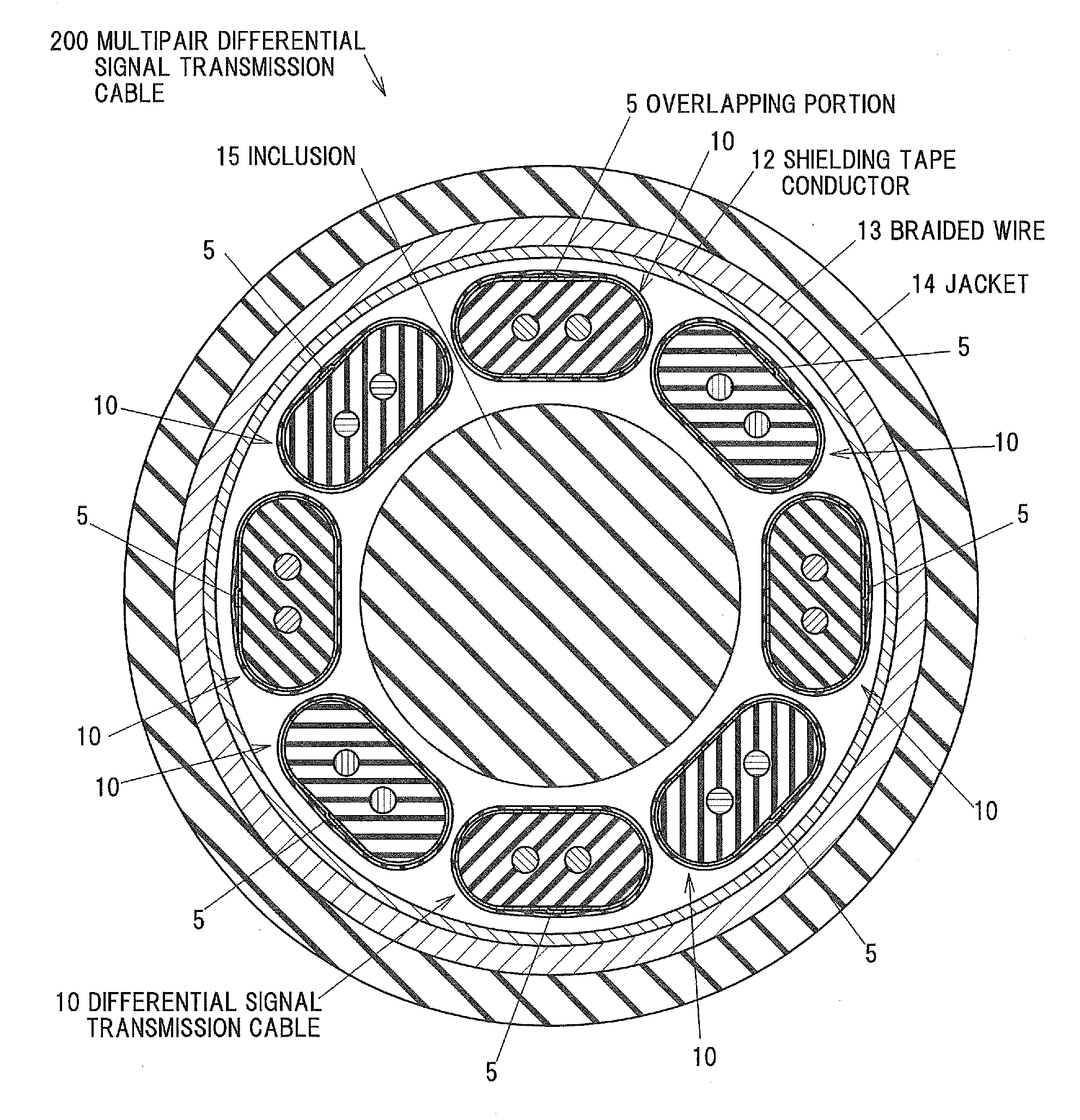

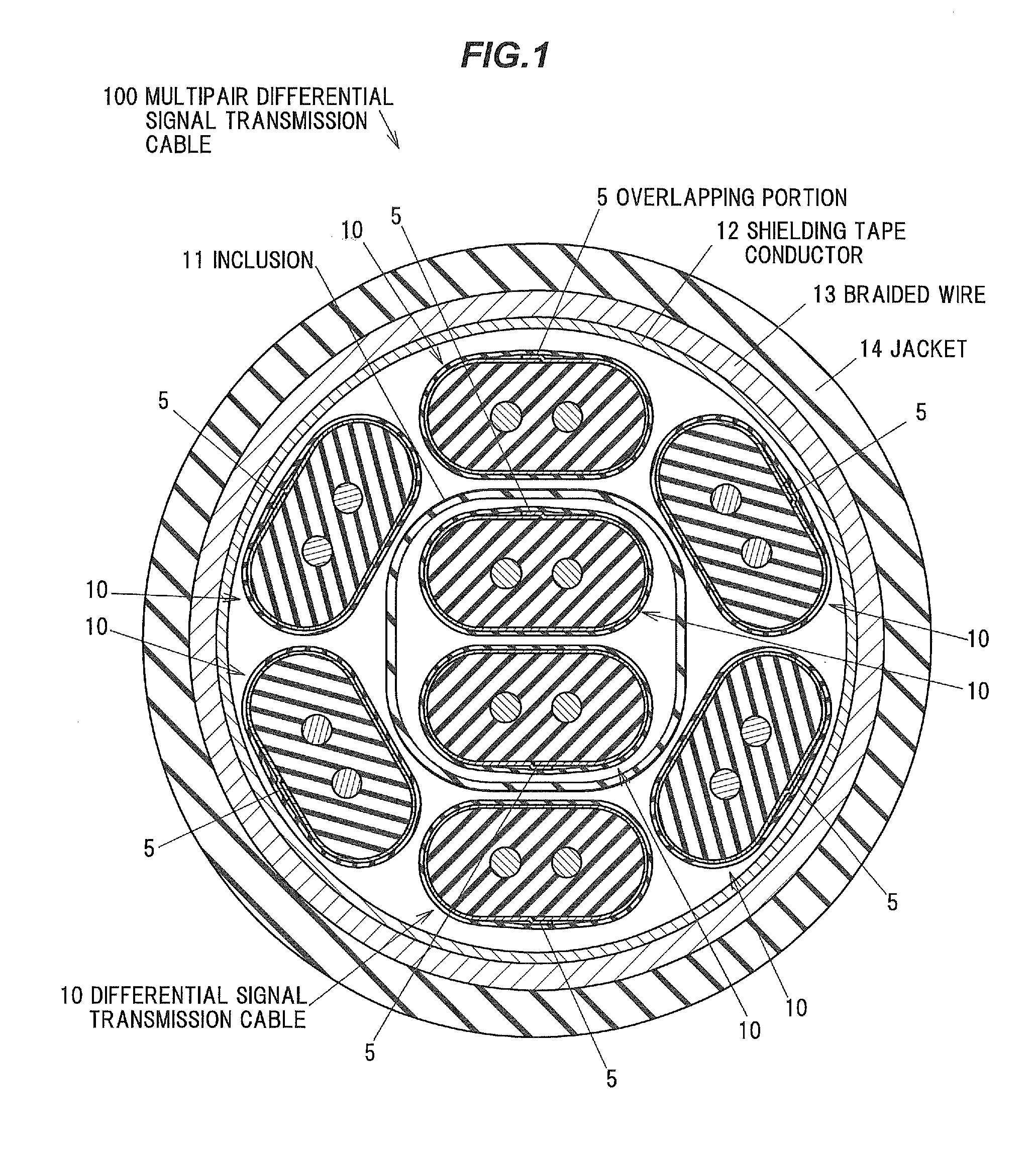

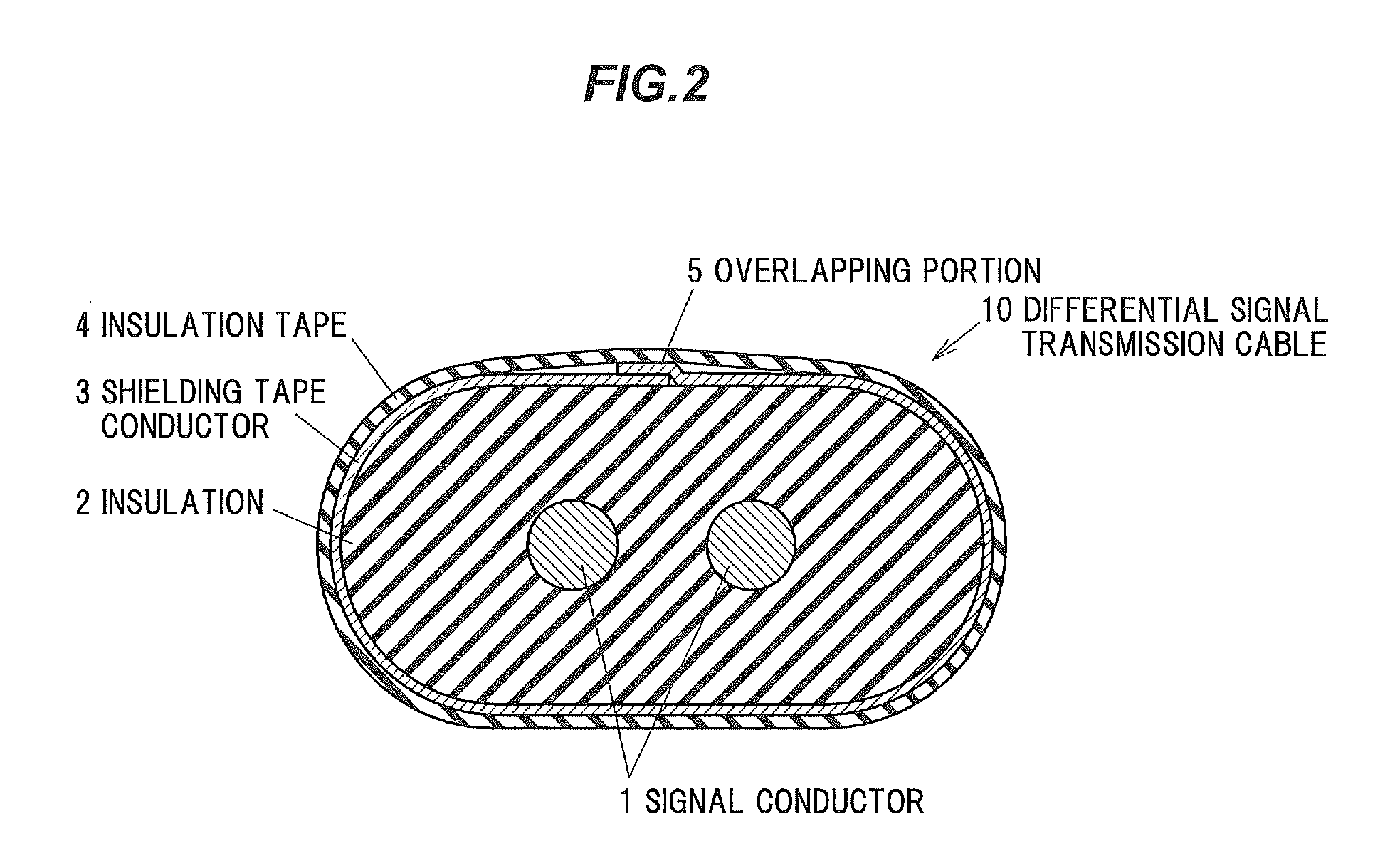

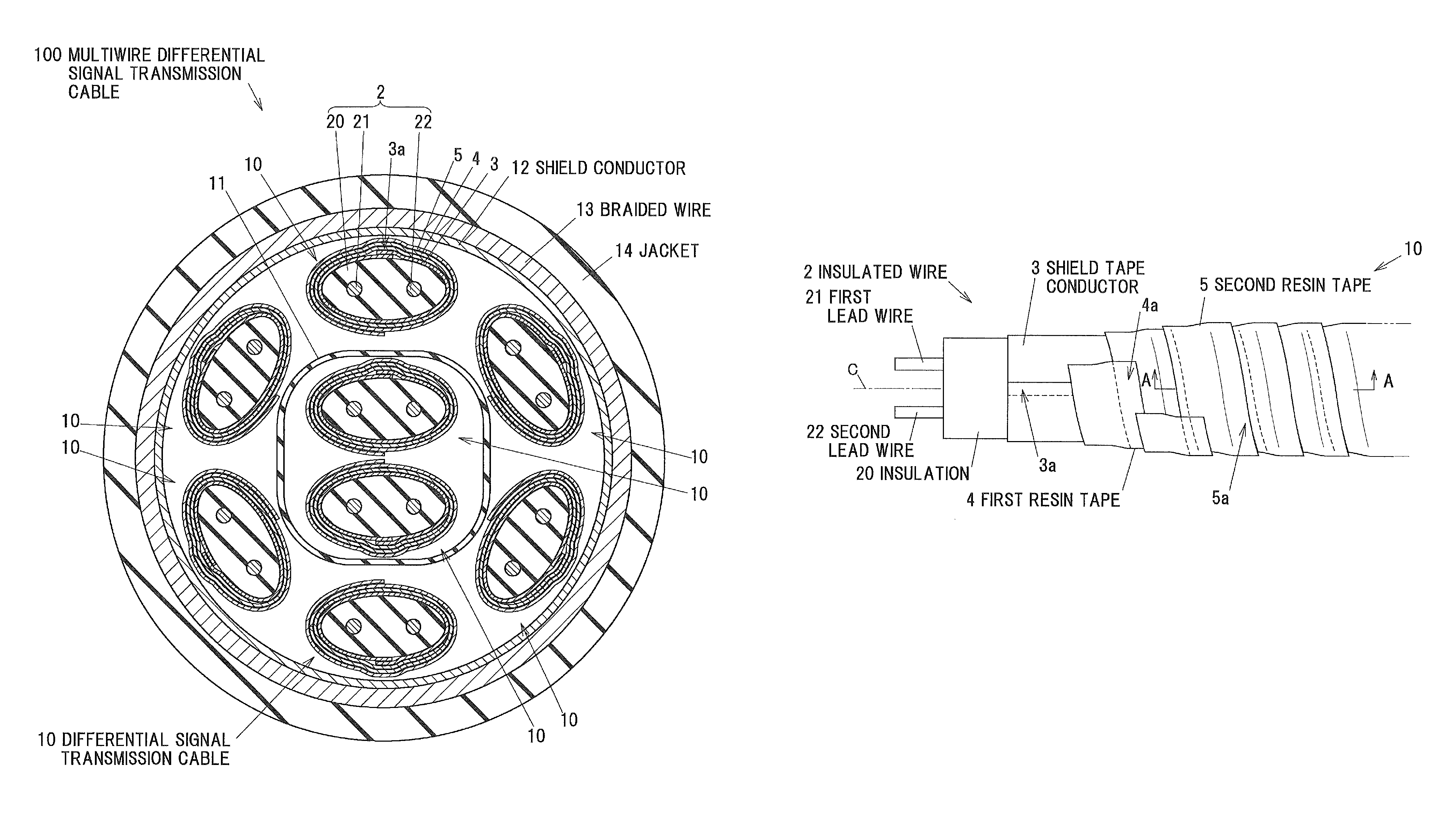

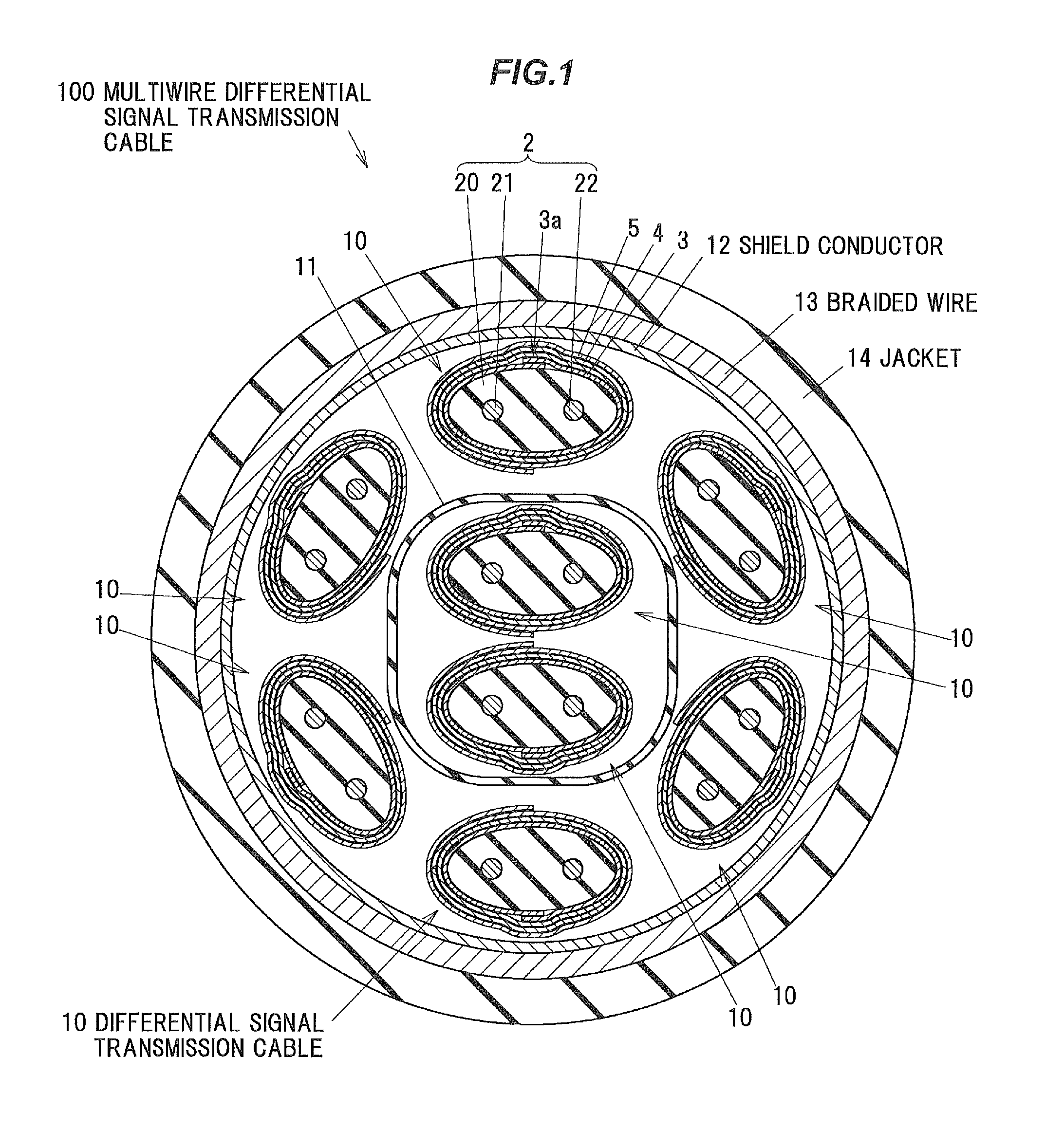

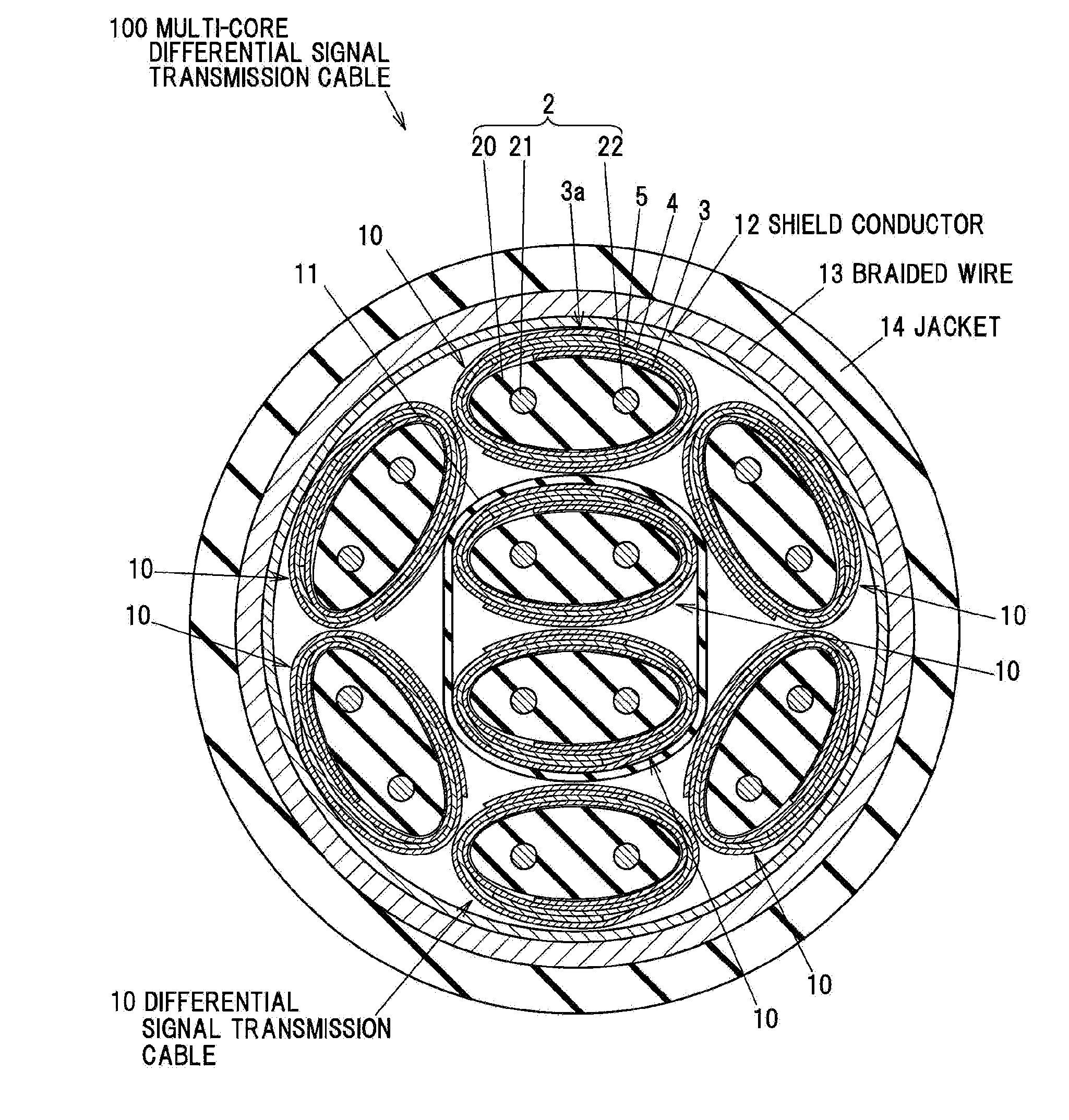

Multipair differential signal transmission cable

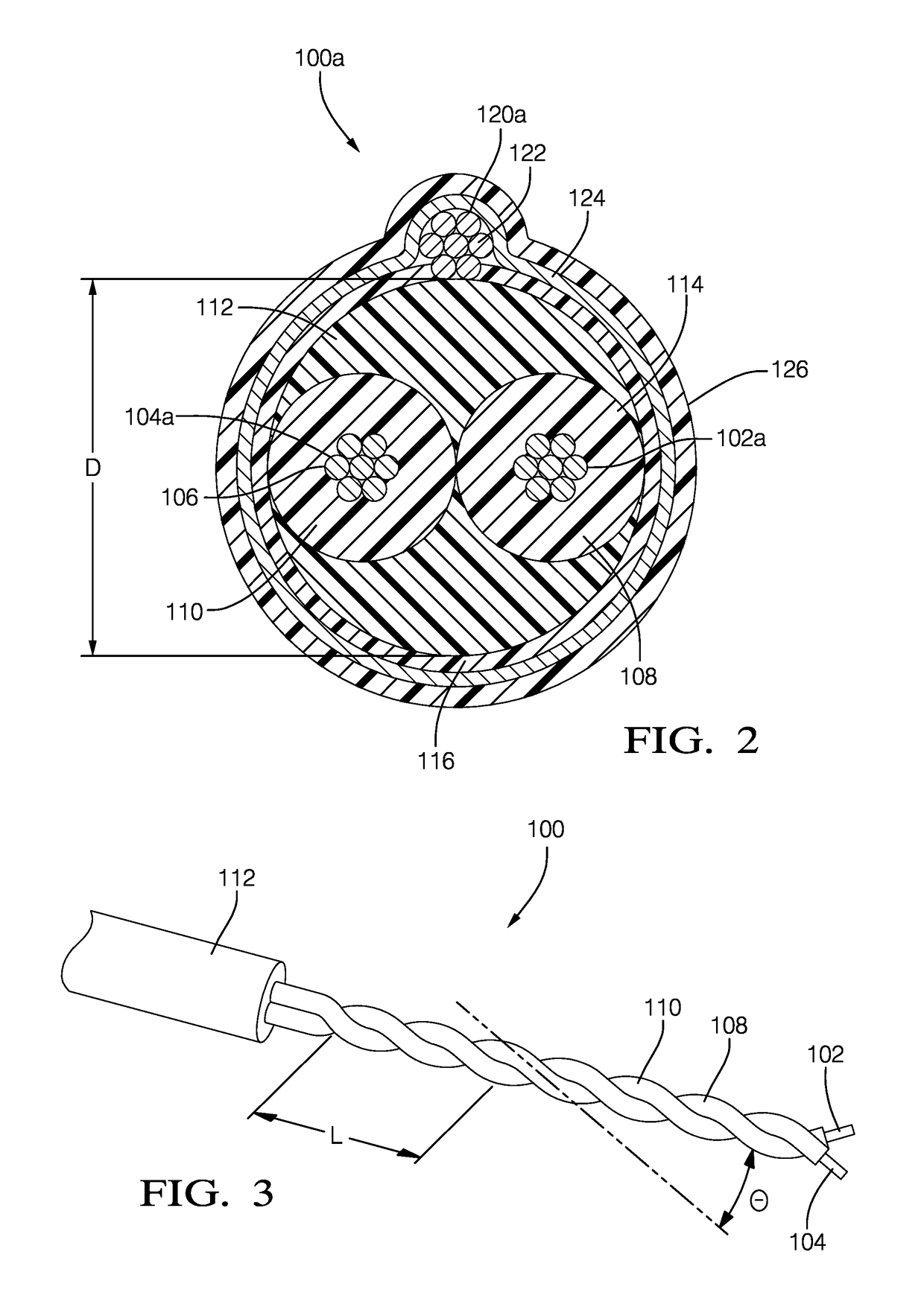

ActiveUS20130333913A1Reduce crosstalkCable conductor constructionCables with twisted pairs/quadsTelecommunicationsElectric cables

A multipair differential signal transmission cable includes a plurality of differential signal transmission cables being bundled and each including two signal conductors as a differential pair covered with an insulation and a first shielding tape conductor provided therearound. The first shielding tape conductor is longitudinally lapped so as to have an overlapping portion in a cable longitudinal direction. The plurality of differential signal transmission cables include at least one or more pairs of two adjacent differential signal transmission cables. The two adjacent differential signal transmission cables are arranged such that the overlapping portion of one of the two adjacent differential signal transmission cables does not face the other of the two adjacent differential signal transmission cables.

Owner:HITACHI METALS LTD

High accuracy foamed coaxial cable and method for manufacturing the same

InactiveUS6963032B2Exact impedanceImprove accuracyPlastic/resin/waxes insulatorsCable conductor constructionCoaxial cableElectrical conductor

Owner:HIRAKAWA HEWTECH +1

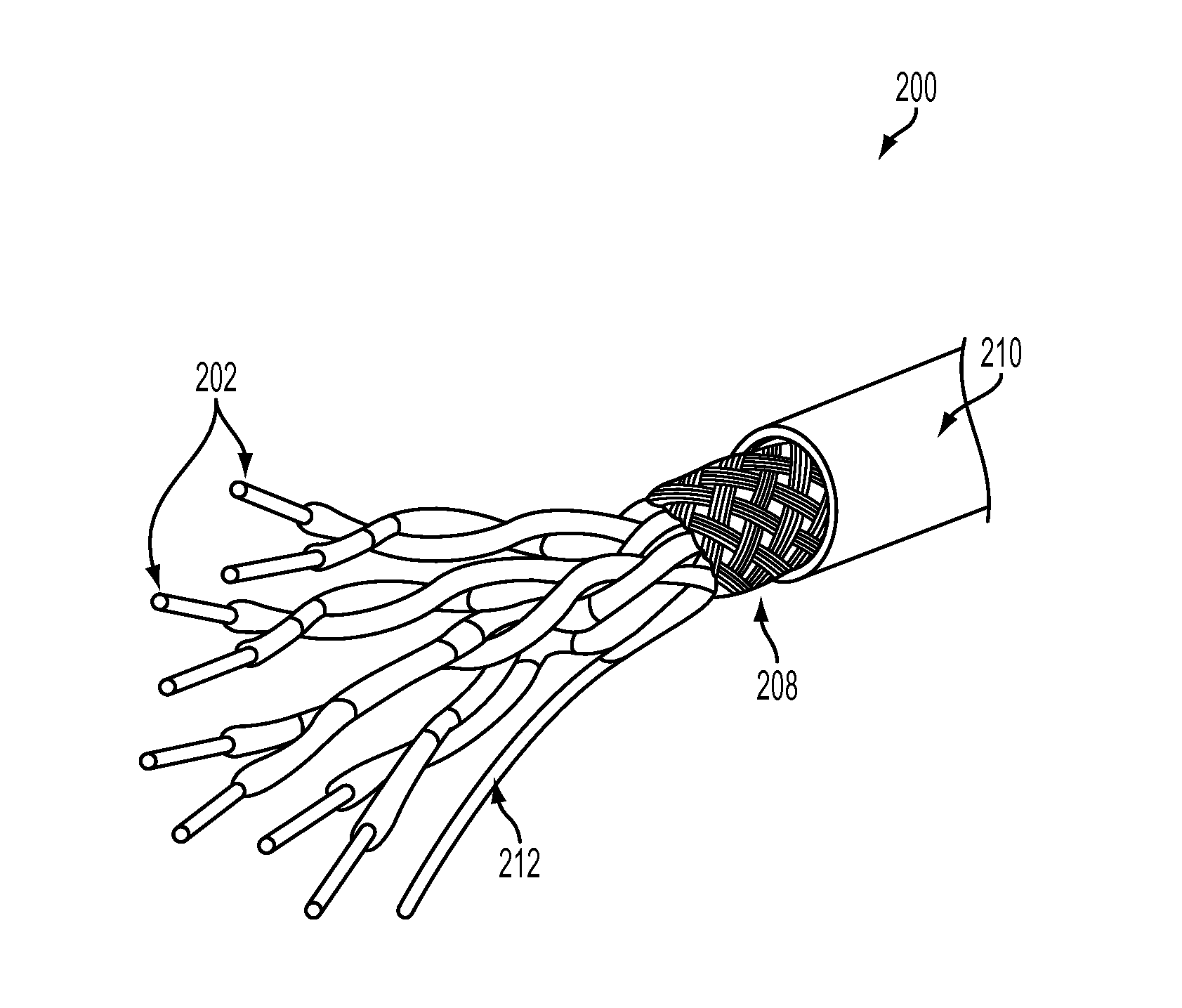

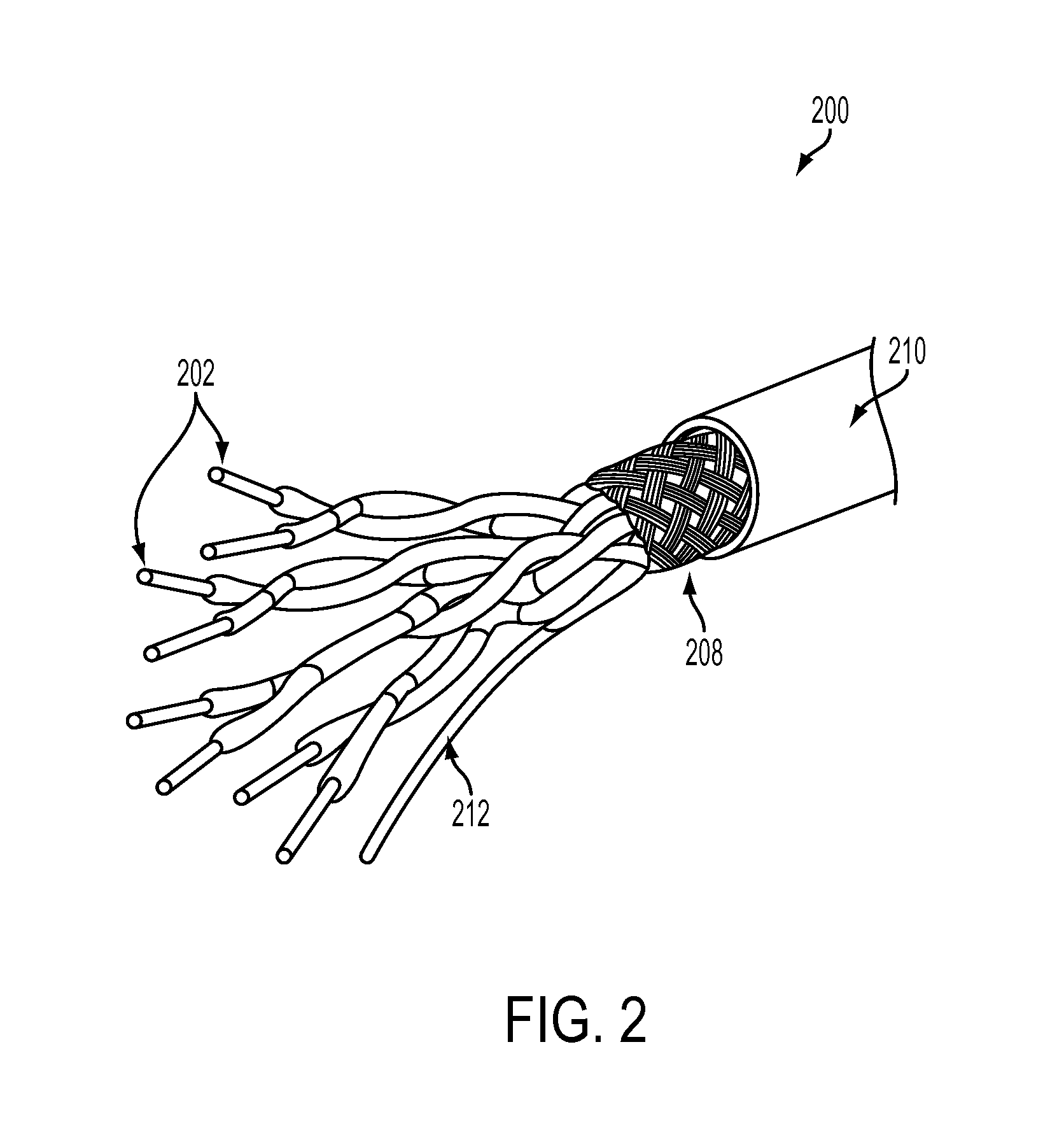

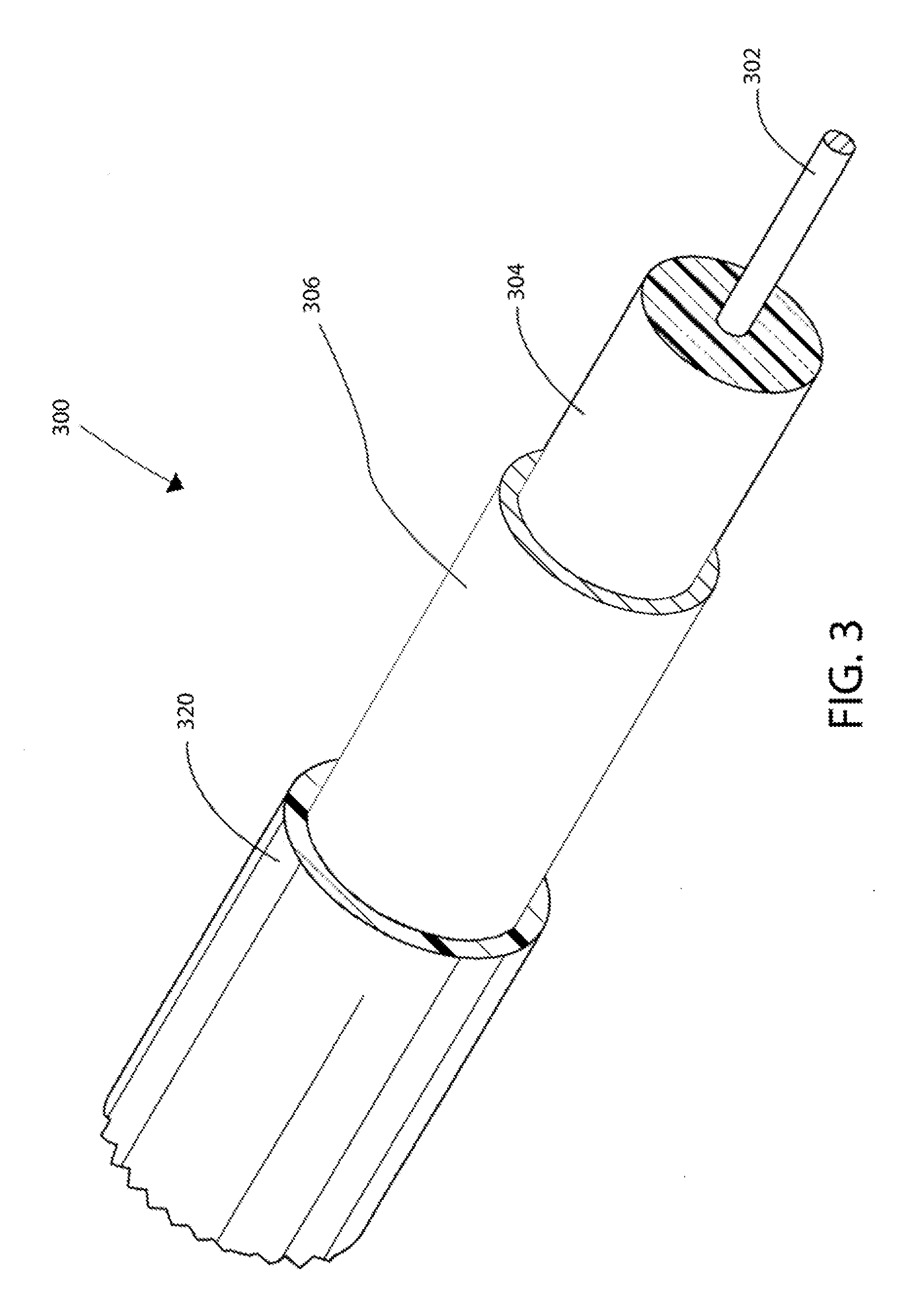

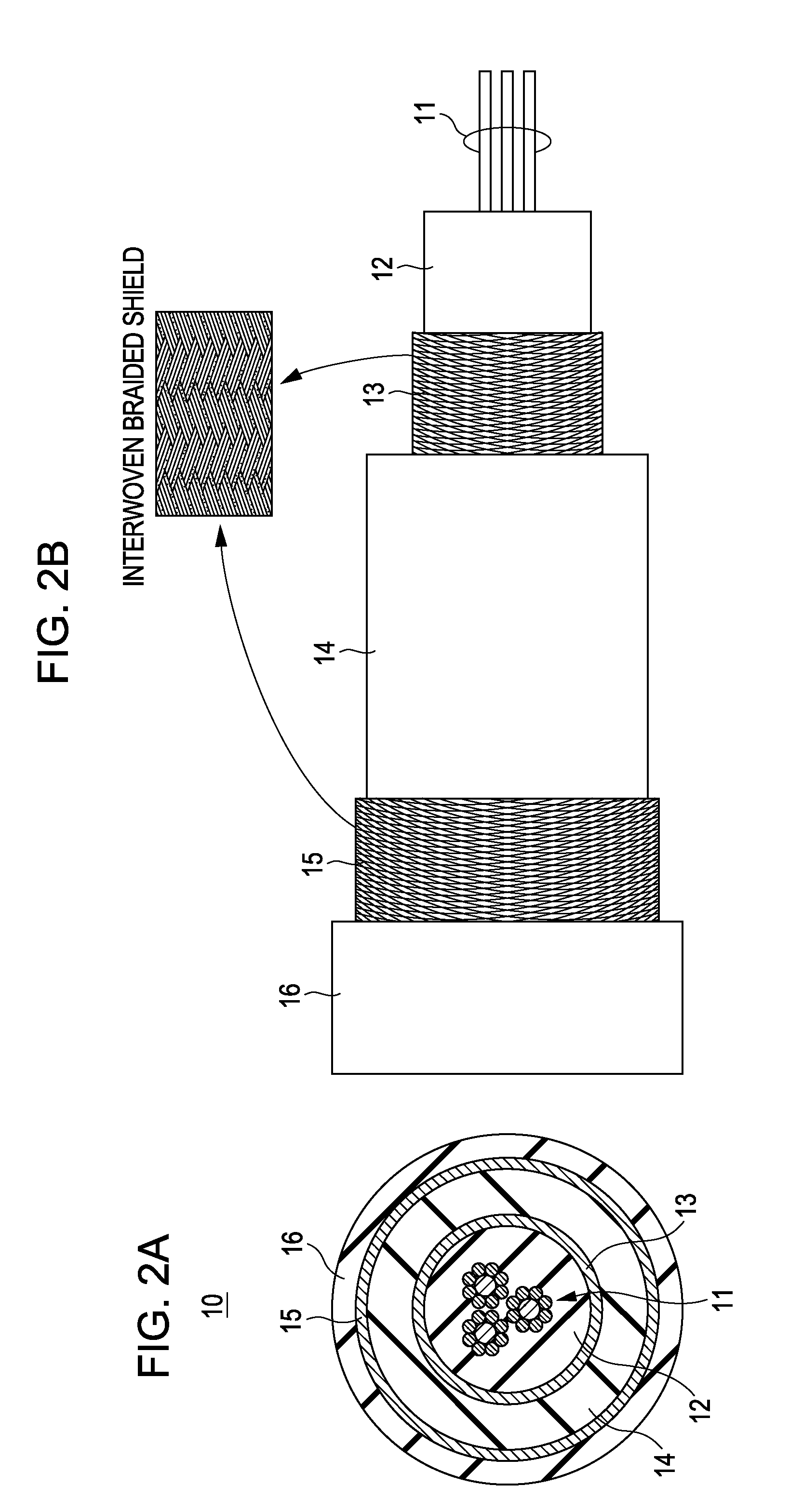

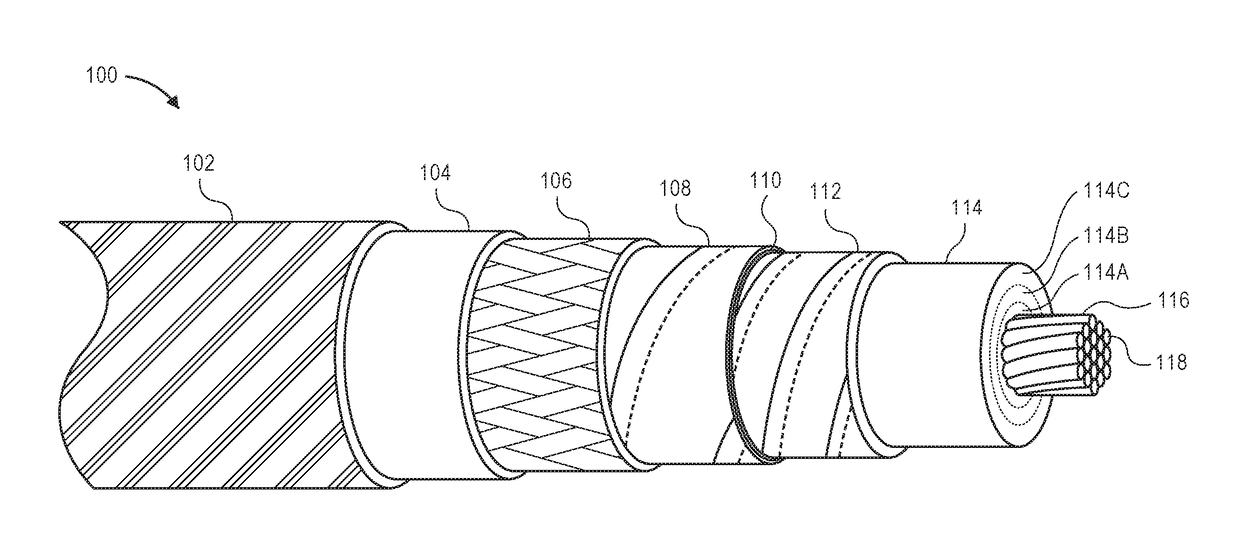

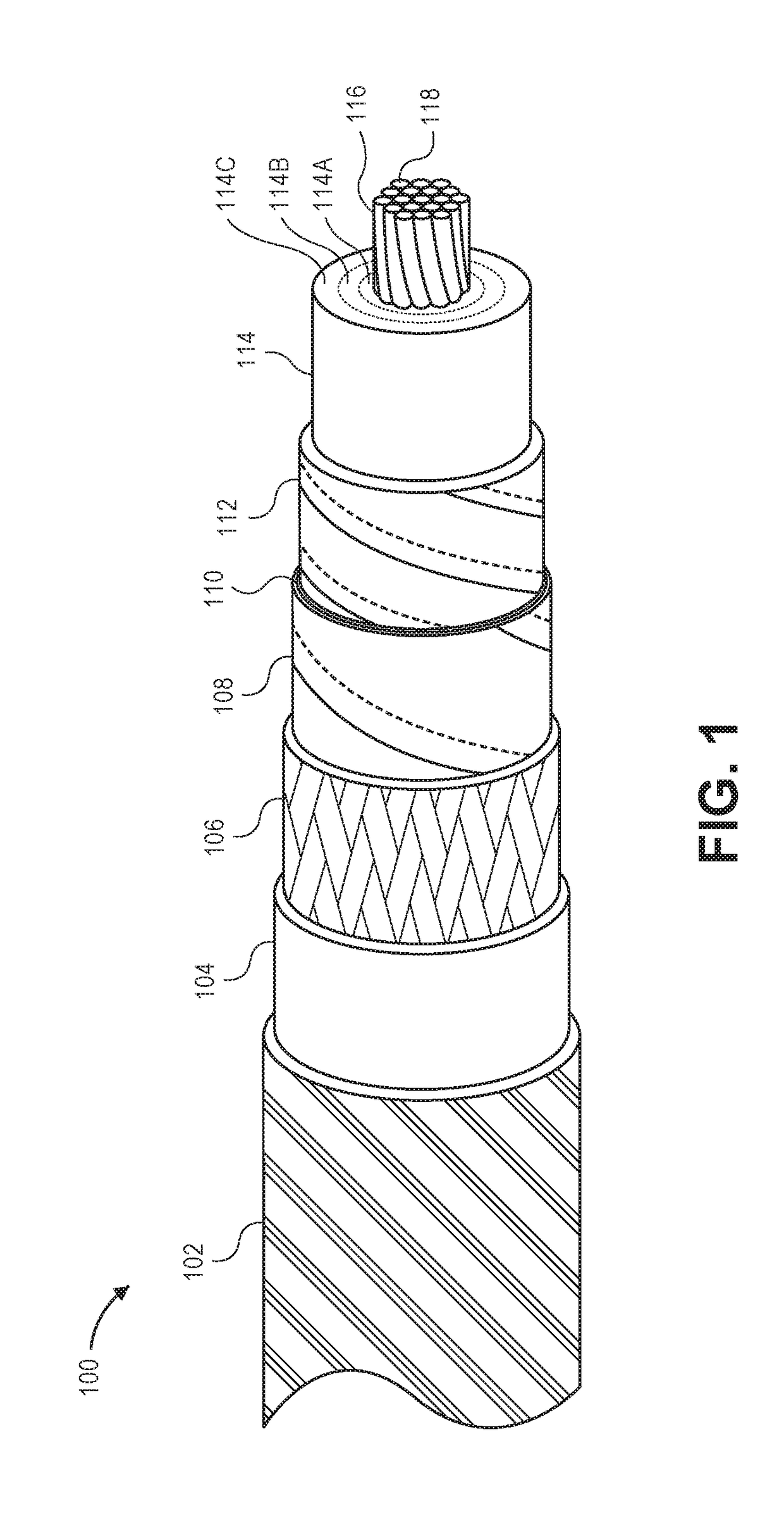

Light weight braid for cable shielding applications

A cable that includes at least one conductor, an insulation layer that surrounds the conductor, and a braid wrapped that is around the insulation layer. The braid is substantially formed of woven fiber. The woven fiber may include a metal coating.

Owner:GENERAL CABLE TECH CORP

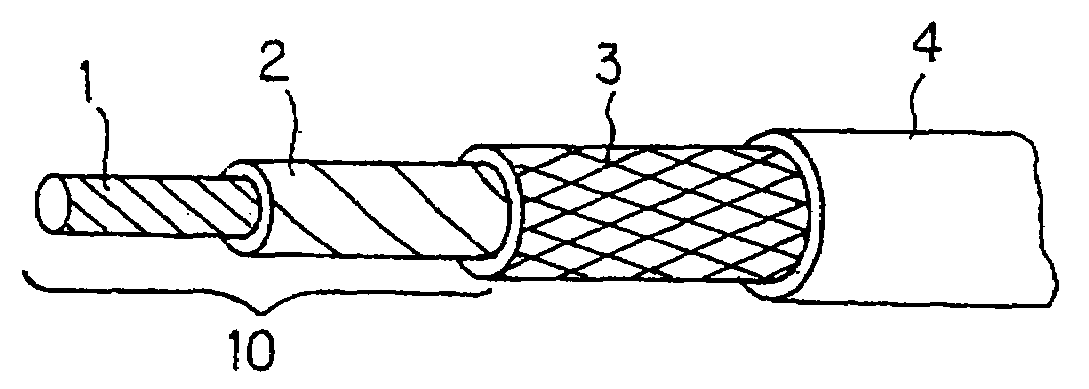

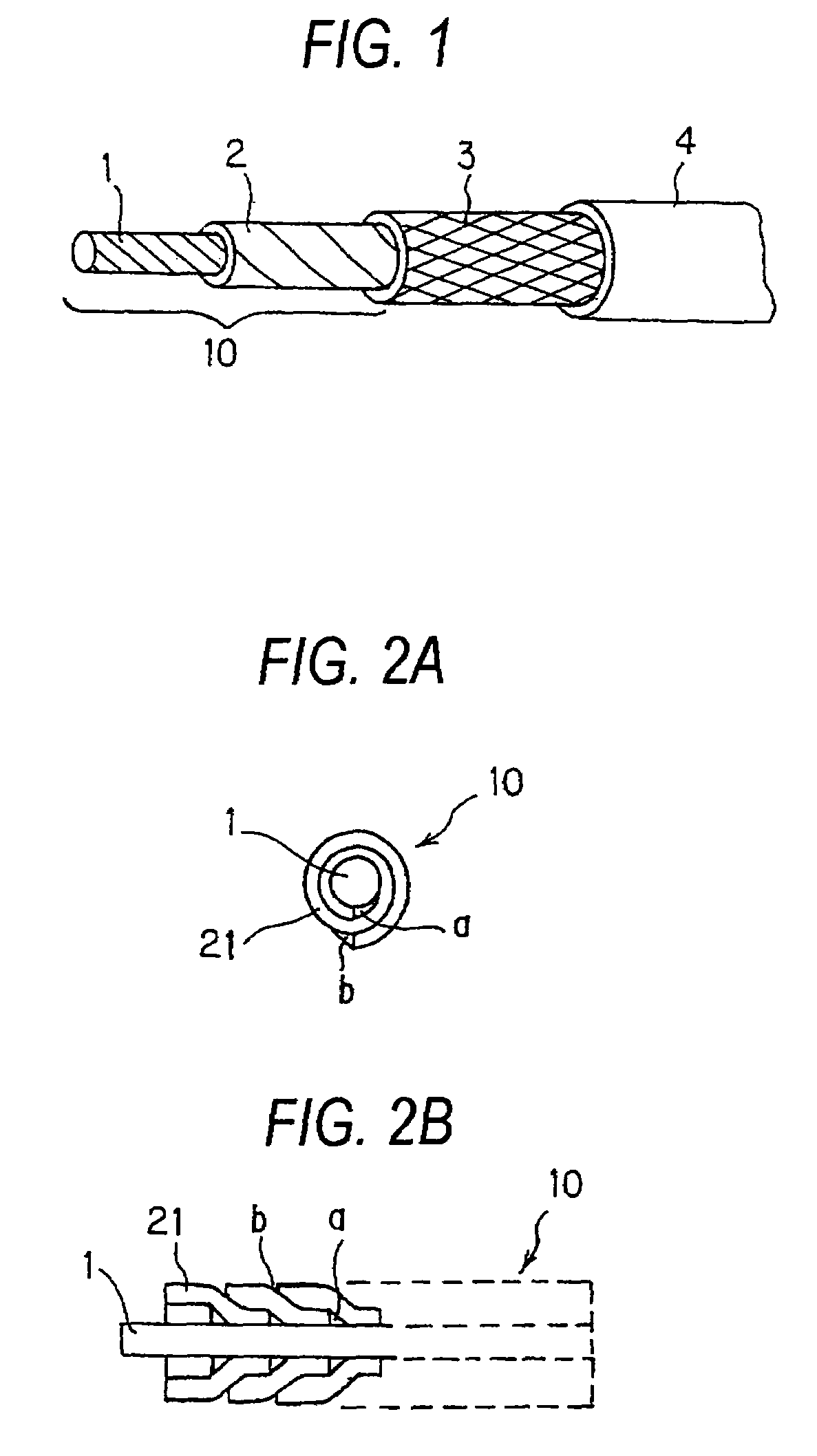

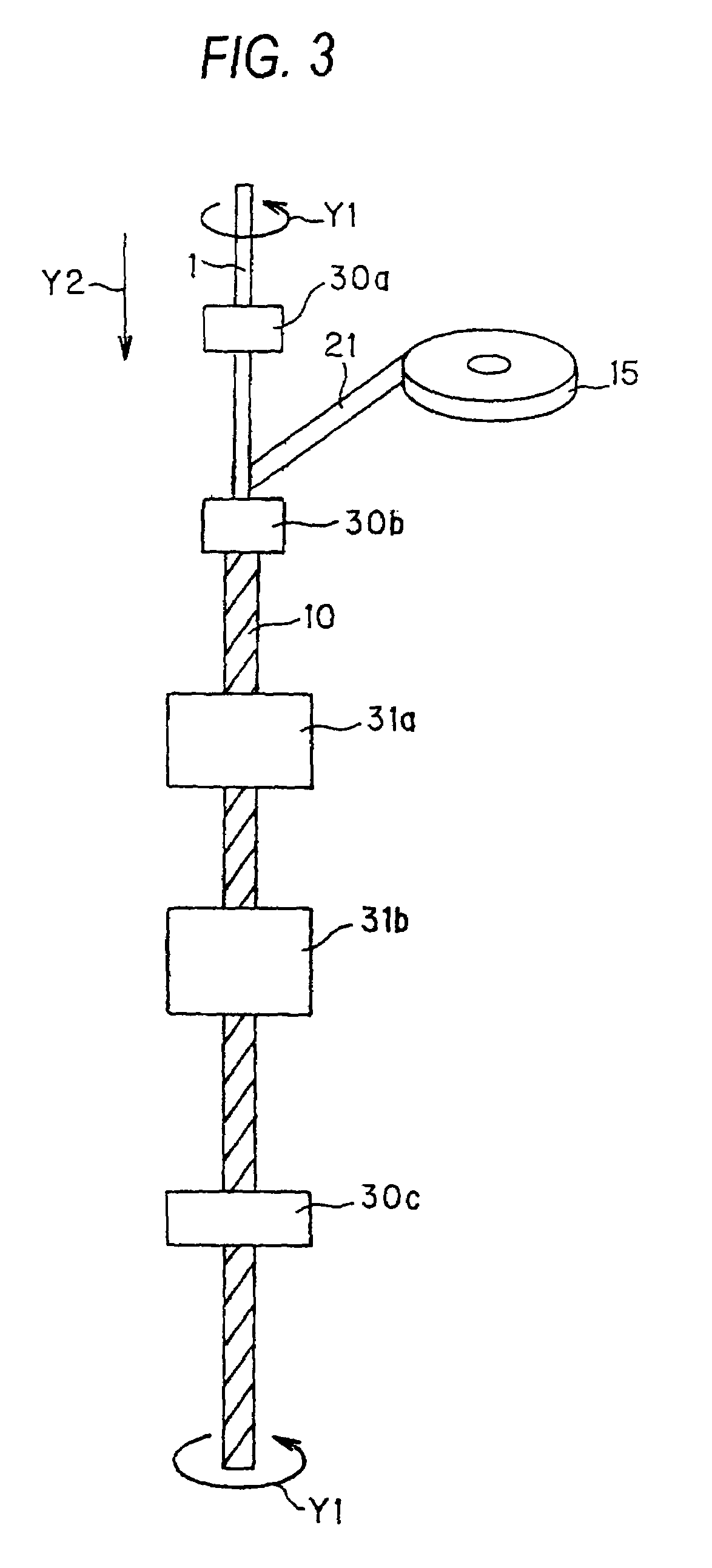

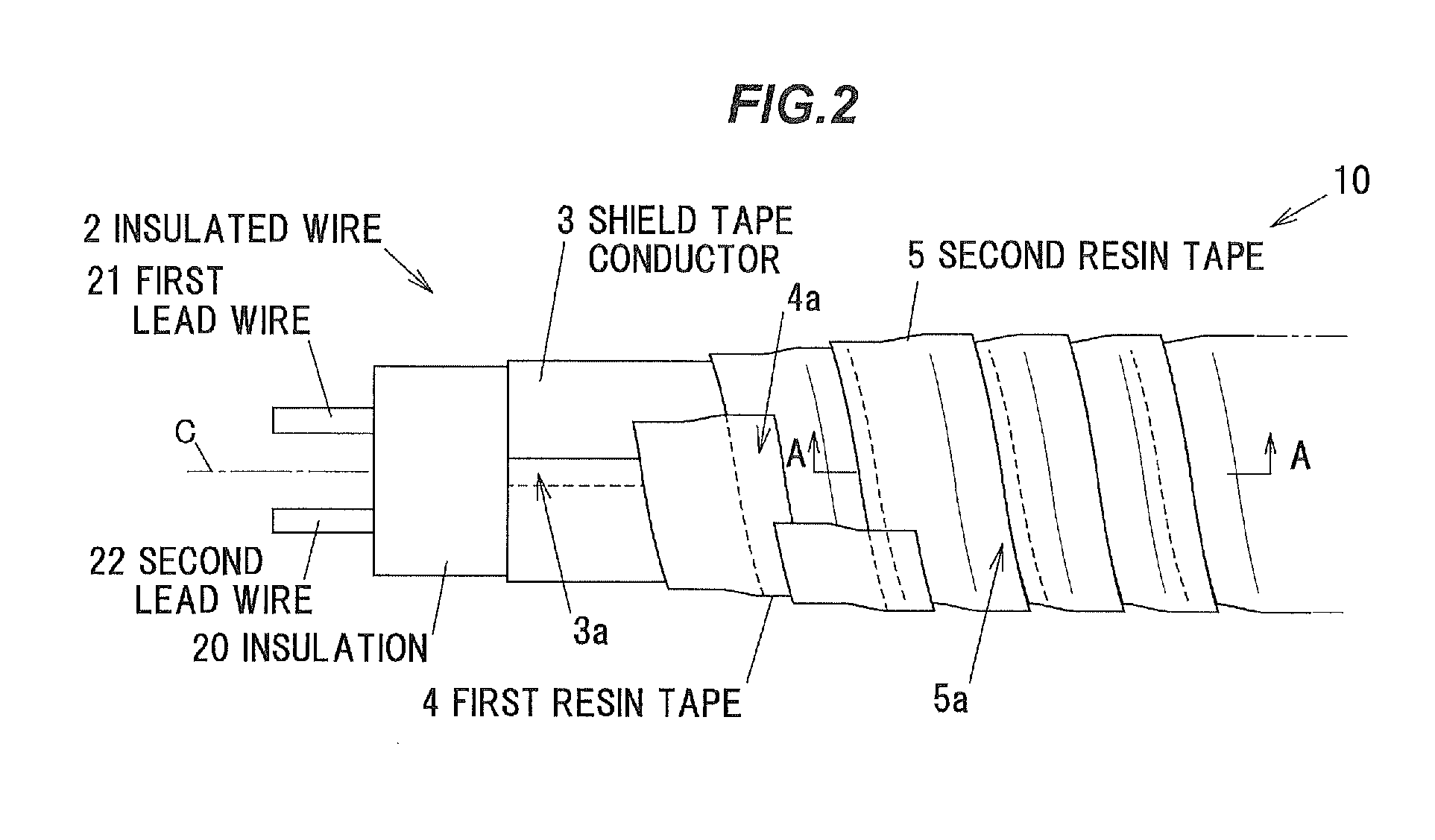

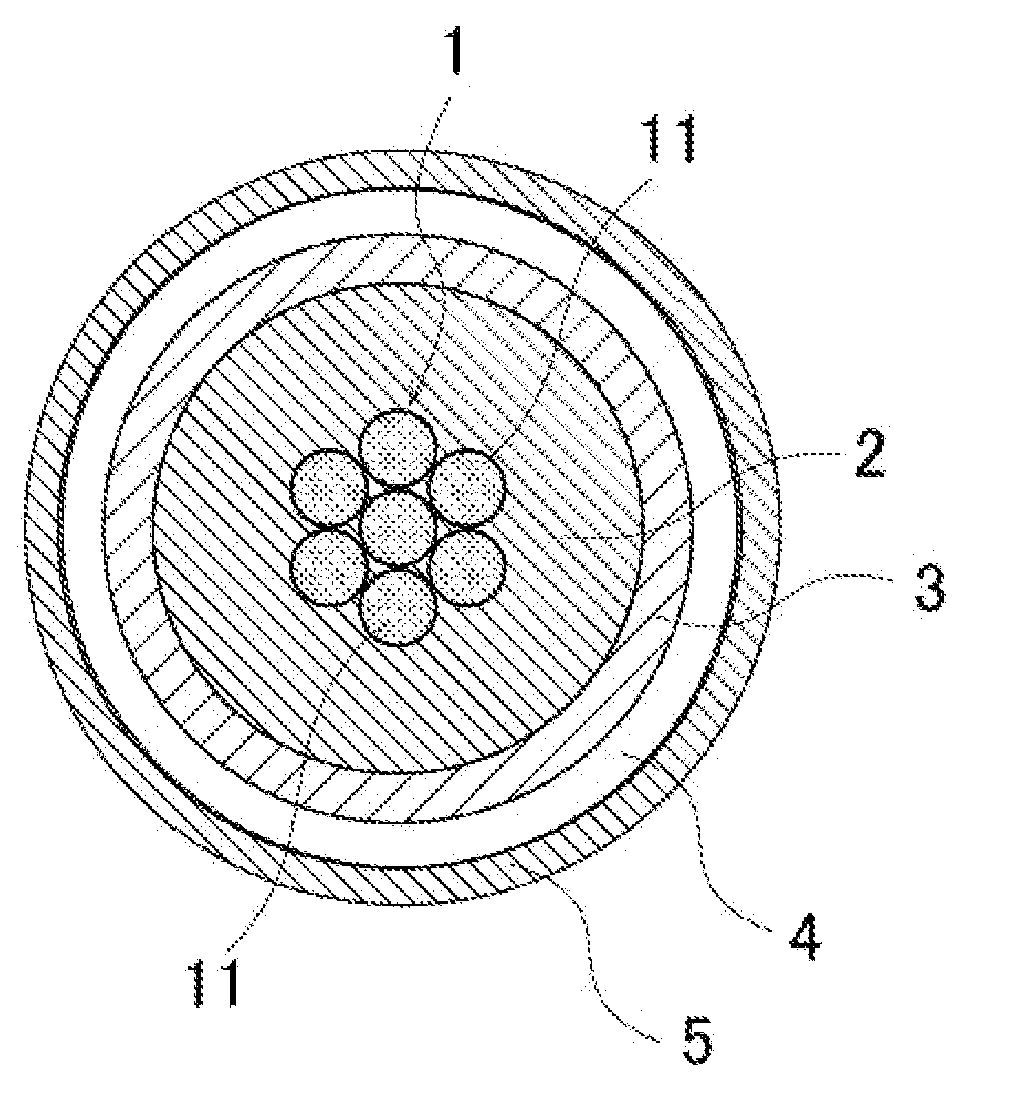

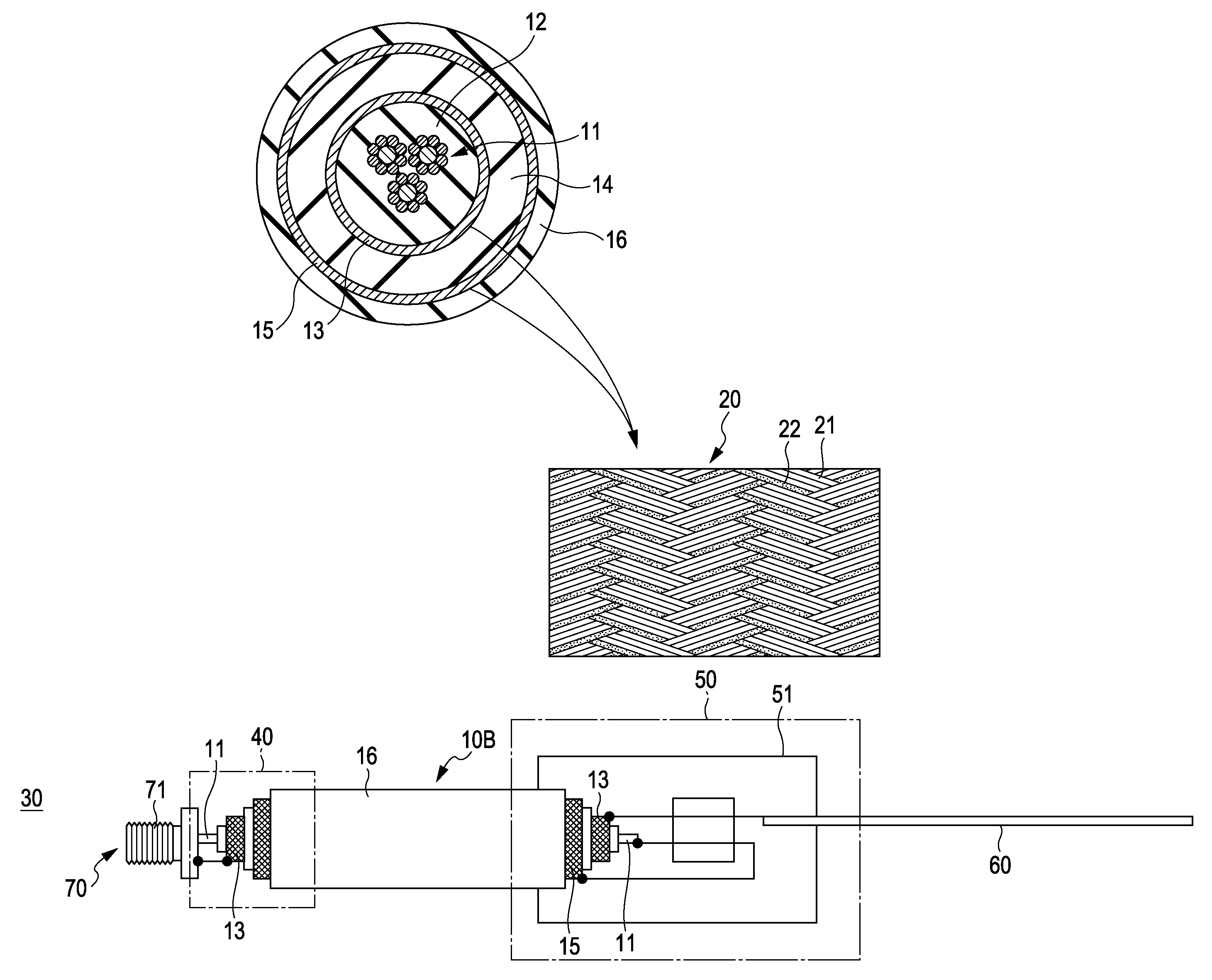

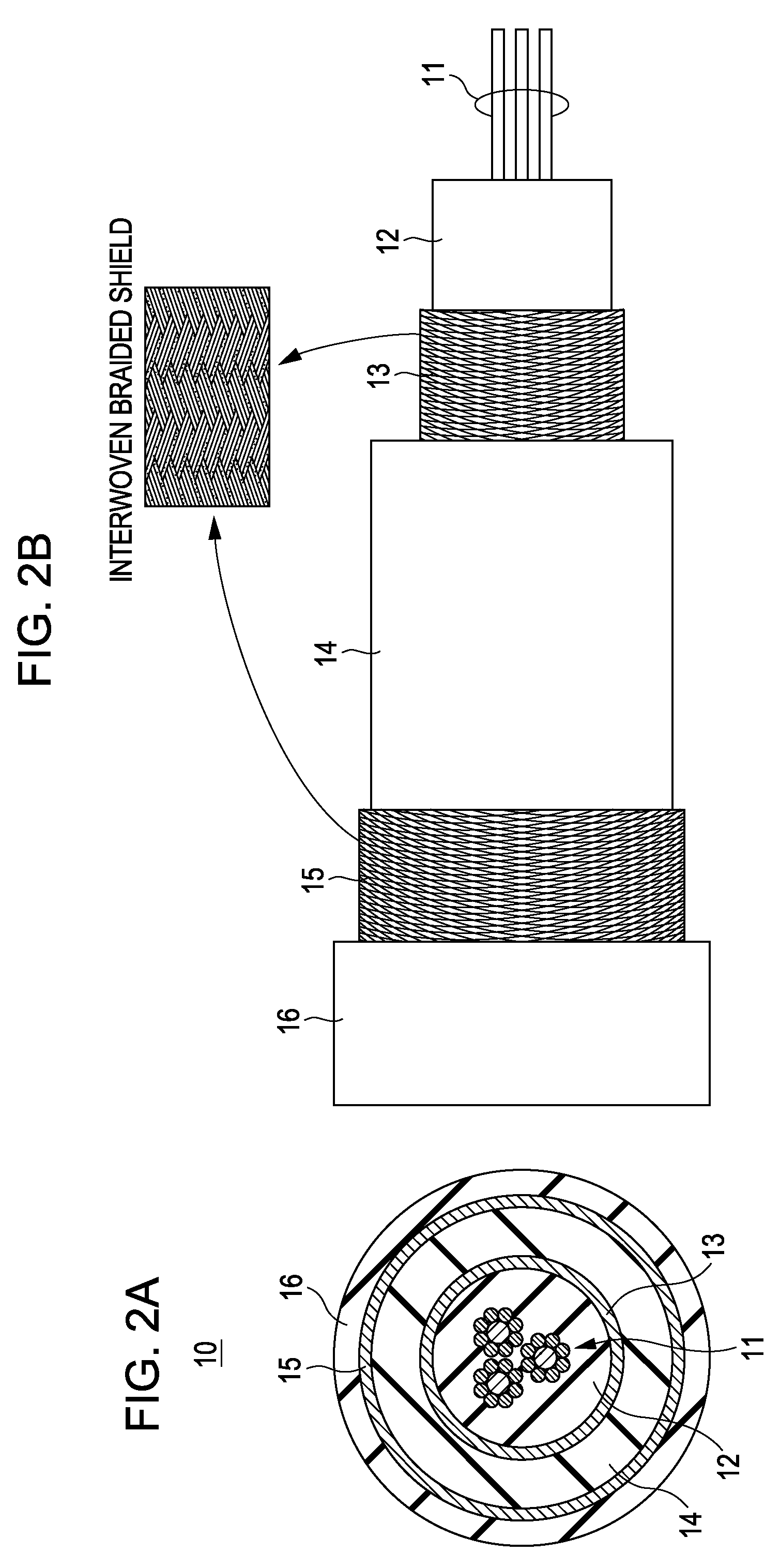

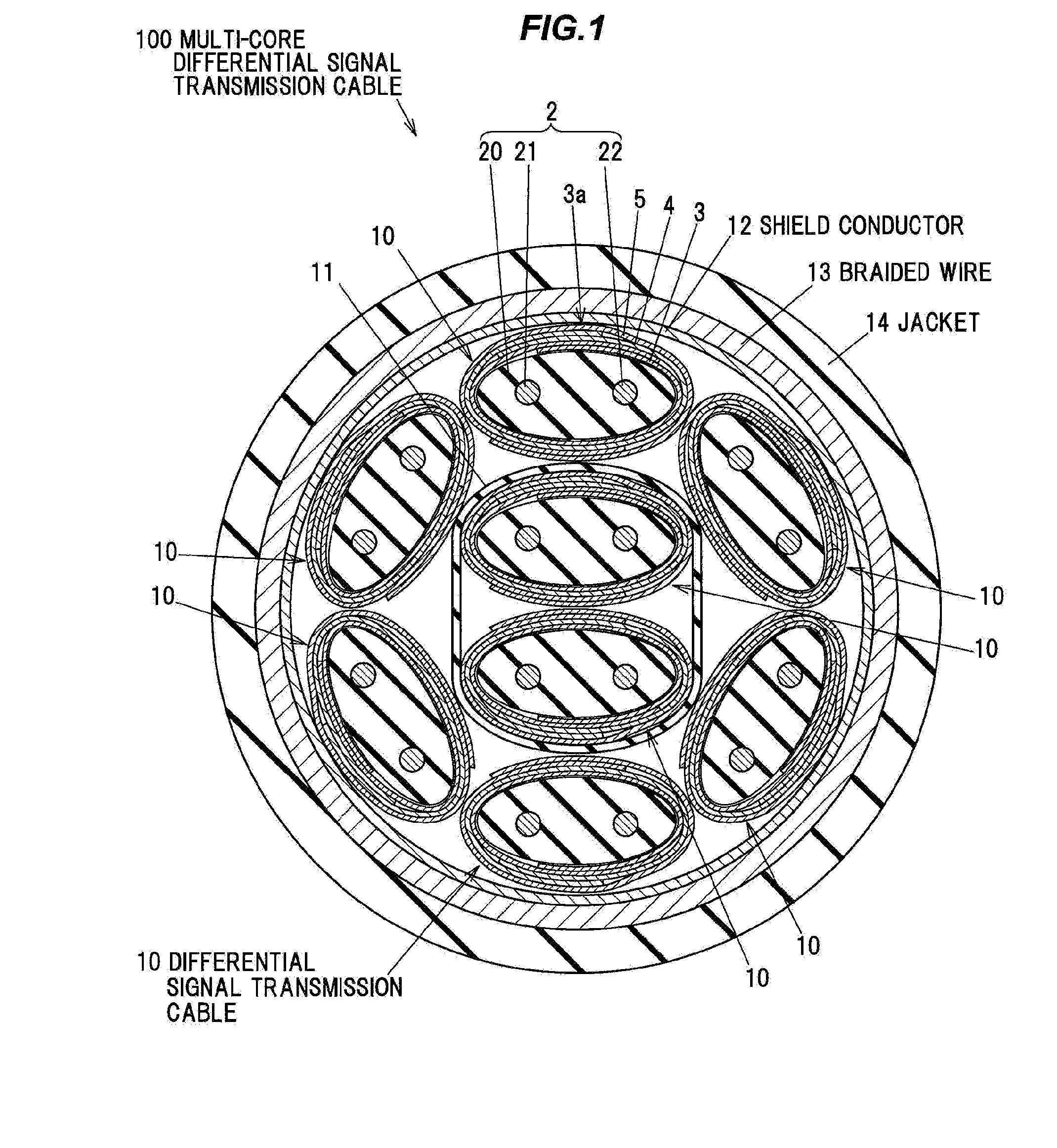

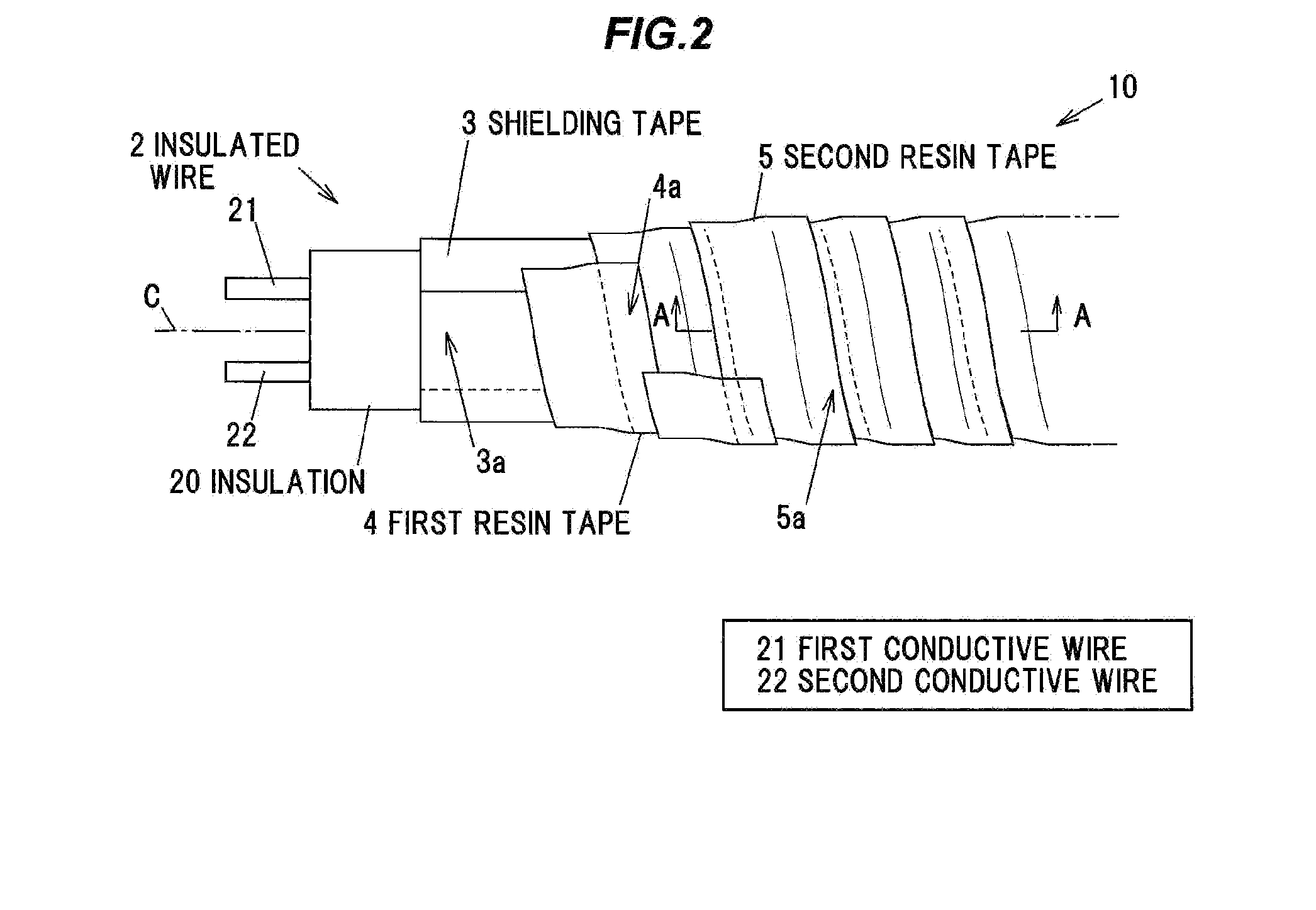

Differential signal transmission cable, multiwire differential signal transmission cable, and differential signal transmission cable producing method and apparatus

ActiveUS9136042B2Cable conductor constructionInsulated cablesElectrical conductorDifferential signaling

A differential signal transmission cable includes an insulated wire including a pair of differential signal transmission conductors coated with an insulation, a shield tape conductor made of a band-like member including an electrically conductive metal layer, and wrapped along an outer surface of the insulated wire so that its ends in a width direction are overlapped together, a first resin tape spirally wound along an outer surface of the shield tape conductor and around an outer side of the shield tape conductor, and a second resin tape spirally wound along an outer surface of the first resin tape and around an outer side of the first resin tape. The shield tape conductor, the first resin tape and the second resin tape are wound in a same circumferential direction around a center axis of the insulated wire.

Owner:HITACHI METALS LTD

Coaxial cable and manufacturing method of the same

InactiveUS20100139943A1Control deformationMaterial nanotechnologyCable conductor constructionCoaxial cableIrradiation

A coaxial cable includes an internal insulating layer formed on an outer periphery of an electric conductor, and a conductive layer formed on an outer periphery of the internal insulating layer, wherein the conductive layer is made of a metal nanoparticle paste sintered body obtained by sintering metal nanopraticles by irradiation of light toward a metal nanoparticle paste, and an external insulating layer is formed on an outer periphery of the conductive layer.

Owner:HITACHI METALS LTD

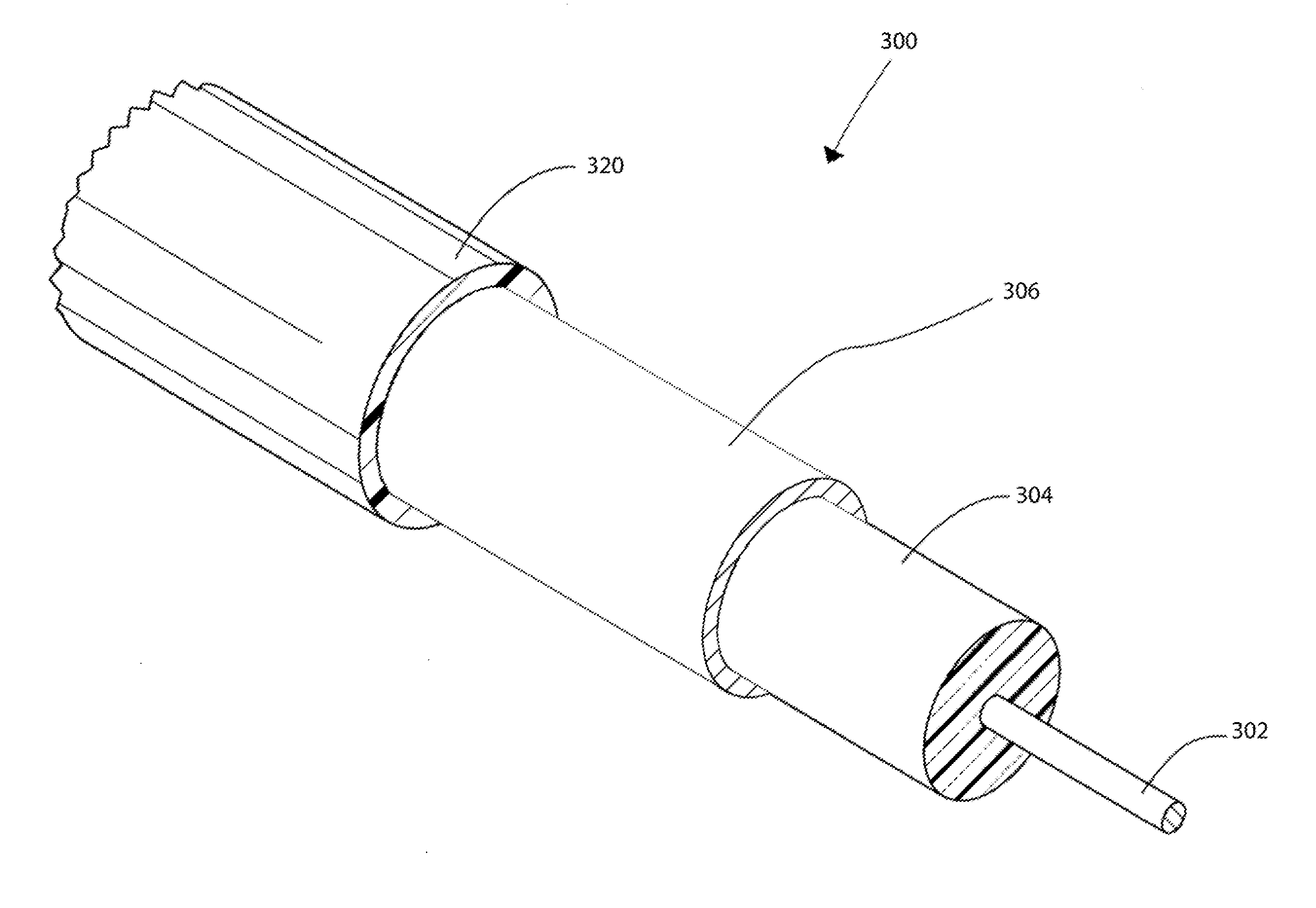

Conductive elastomer and method of applying a conductive coating to a cable

ActiveUS20110232937A1Application securityImprove bindingCable conductor constructionPower cables with screens/conductive layersElastomerConductive paste

A cable is provided, the cable includes: a conductor configured to propagate a signal; an elastomeric layer surrounding the center conductor; and a conductive topcoat layer surrounding and bonded to the elastomeric layer. The conductive topcoat layer includes a suspension of conductive particles. The conductive topcoat layer is formed by curing a topcoat and conductive paste mixture applied to the elastomeric layer.

Owner:PPC BROADBAND INC

Coaxial cables having improved smoke performance

ActiveUS7157645B2Cable conductor constructionPower cables with screens/conductive layersElectrical conductorCoaxial cable

A coaxial cable includes an elongate inner conductor. A dielectric layer surrounds the inner conductor. A first outer conductor surrounds the dielectric layer and has perforations defined therein. A second outer conductor surrounds the first outer conductor. A polymeric jacket surrounds the second outer conductor. The cable is adapted such that, when the dielectric layer is melted, at least a portion thereof and / or smoke therefrom can flow through the perforations in the first outer conductor. According to some embodiments, the second outer conductor defines a plurality of voids therein and, when the dielectric layer is melted, at least a portion thereof and / or smoke therefrom can flow through the perforations in the first outer conductor and into the voids. According to some embodiments, the second outer conductor is braided.

Owner:COMMSCOPE INC

Shielded cable

ActiveUS20100236810A1Low costExcellent in design propertyCable conductor constructionPower cables with screens/conductive layersShielded cableElectrical conductor

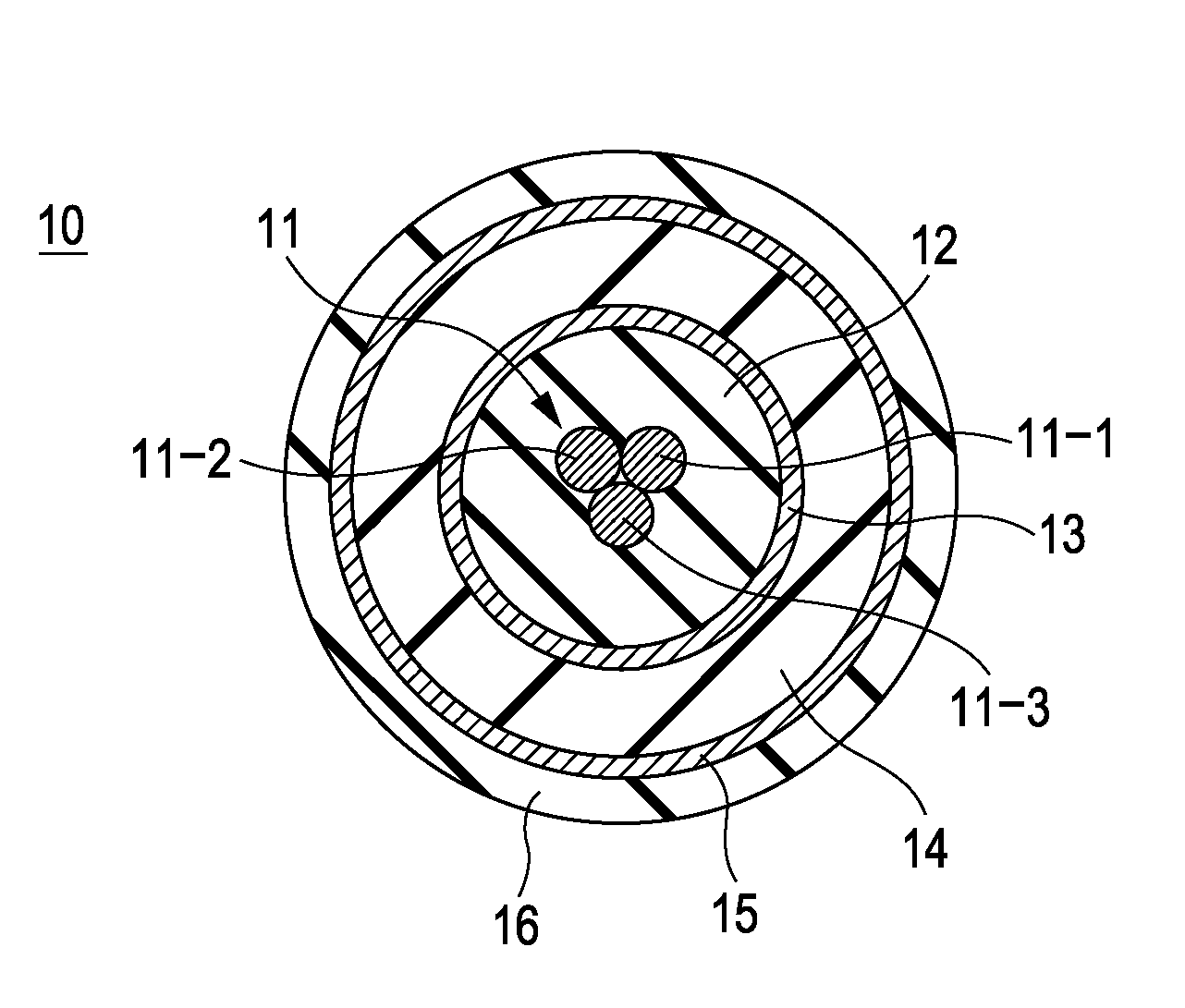

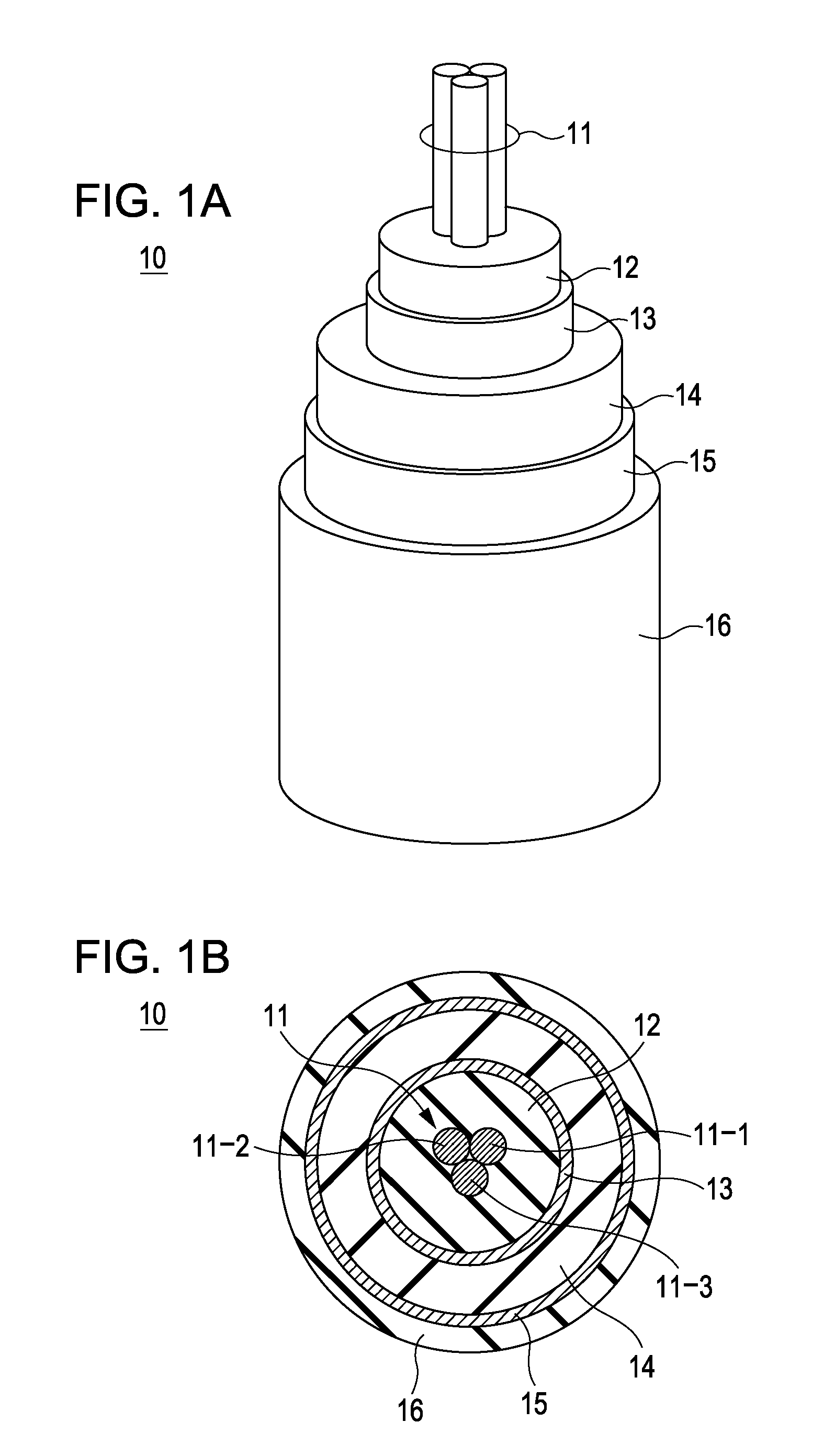

A shielded cable includes an inner conductor, a first insulator, a first outer conductor, a second insulator, and a second outer conductor, which are coaxially disposed in this order from an inner side, and has an outer circumference coated by an insulation sheath.

Owner:SONY CORP

Shielded cable

ActiveUS8080734B2Low costIncrease flexibilityElectrically conductive connectionsCable conductor constructionShielded cableElectrical conductor

Owner:SONY CORP

Differential signal cable and multi-core differential signal transmission cable

ActiveUS20160111187A1Avoid damageIncrease flexibilityCable conductor constructionPrinted circuit detailsElectric cablesSignal lines

A differential signal cable includes a pair of signal line conductors for transmitting differential signals, an insulation collectively covering the pair of signal line conductors, a shielding tape wrapped around the insulation, and an insulating tape wound around the shielding tape. A gap is formed between an outer peripheral surface of the insulation and an inner surface of the shielding tape such that the insulation is movable relative to the shielding tape.

Owner:HITACHI METALS LTD

Cable

ActiveCN101556839AHigh mechanical strengthLight in massCable conductor constructionInsulated cablesCarbon nanotubeEngineering

A cable comprises at least one cable core, at least one insulating medium layer coated out of the cable core, at least one shielding layer coated out of the insulating medium layer, and an outer sheath coated out of the shielding layer. The cable core comprises a carbon nano-tube long line structure and a conductive material layer which is coated on the surface of the carbon nano-tube long line structure.

Owner:TSINGHUA UNIV +1

Fire resistant coaxial cable and manufacturing technique

Fire-resistant coaxial cables are described as well as methods to manufacture them. The dielectric between the coax cable's central conductor and outer coaxial conductor ceramify under high heat, such as those specified by common fire test standards (e.g., 1850° F. / 1010° C. for two hours). The dielectric can be composed of ceramifiable silicone rubber, such as that having a polysiloxane matrix with inorganic flux and refractory particles. Because thick layers of uncured ceramifiable silicone rubber deform under their own weight when curing, multiple thinner layers are coated and serially cured in order to build up the required thickness. A sacrificial sheath mold is used to hold each layer of uncured ceramifiable silicone rubber in place around the central conductor while curing. The outer conductor can be a metal foil, metal braid, and / or corrugated metal. Another layer of extruded ceramifiable silicone dielectric or an outer wrap of ceramic fiber yarn surrounds the outer conductor and continues to insulate it from the outside if a low smoke zero halogen jacket burns away. Methods of testing and installation are described.

Owner:AMERICAN FIRE WIRE INC

Shielding tape with edge indicator

InactiveUS20110011638A1Precise positioningCable conductor constructionMagnetic/electric field screeningElectrical and Electronics engineeringEngineering

Owner:PCT INT

Metal/ceramic composite conductor and cable including same

InactiveUS7390963B2Non-insulated conductorsPlastic/resin/waxes insulatorsCeramic compositeConductive coating

A conductor cable includes an inner portion and a conductive coating. The inner portion is formed of a metal / ceramic composite. The conductive coating is coated on the inner portion.

Owner:3M INNOVATIVE PROPERTIES CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com