Patents

Literature

457results about "Manufacturing co-axial cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coaxial cable

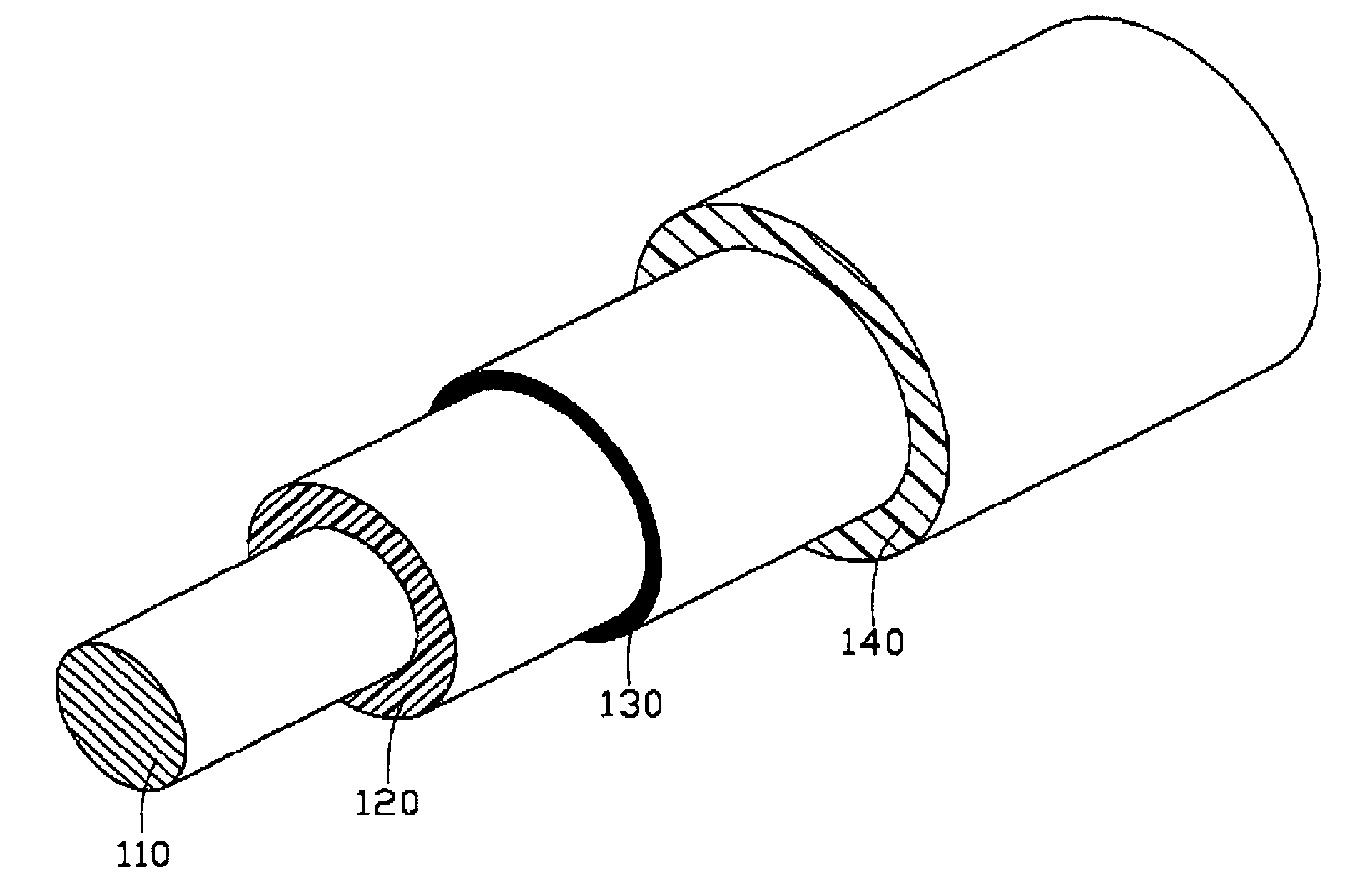

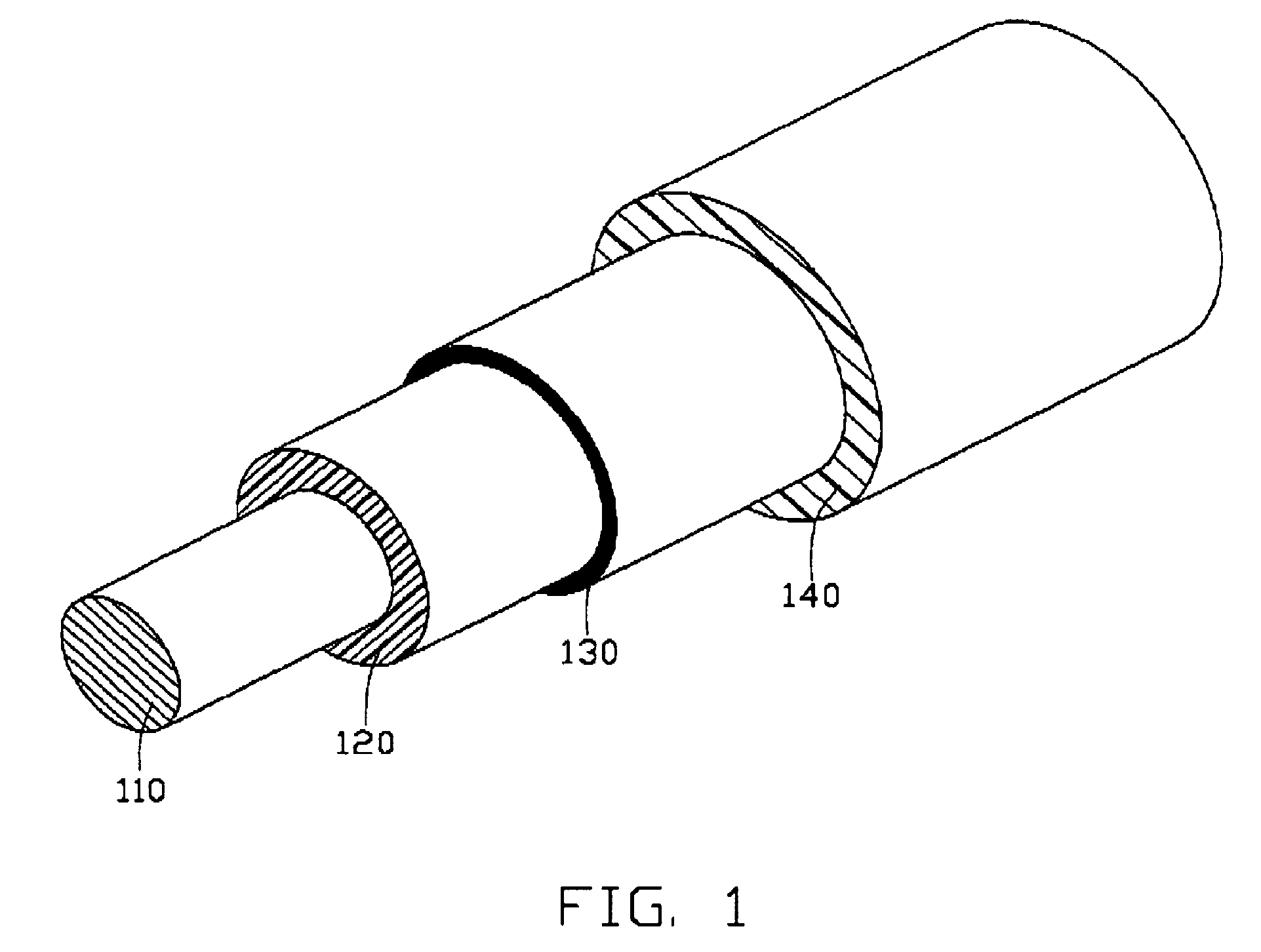

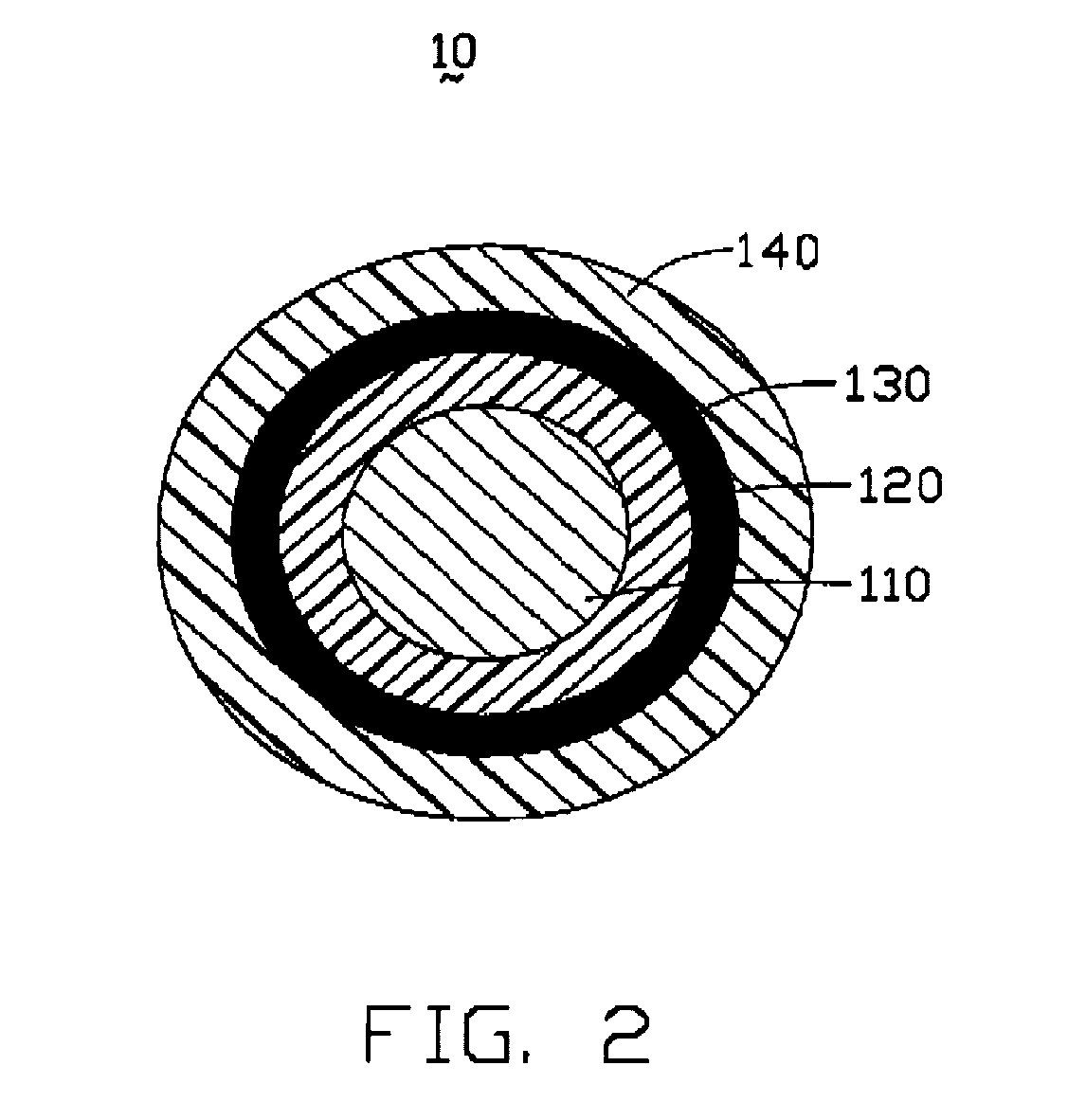

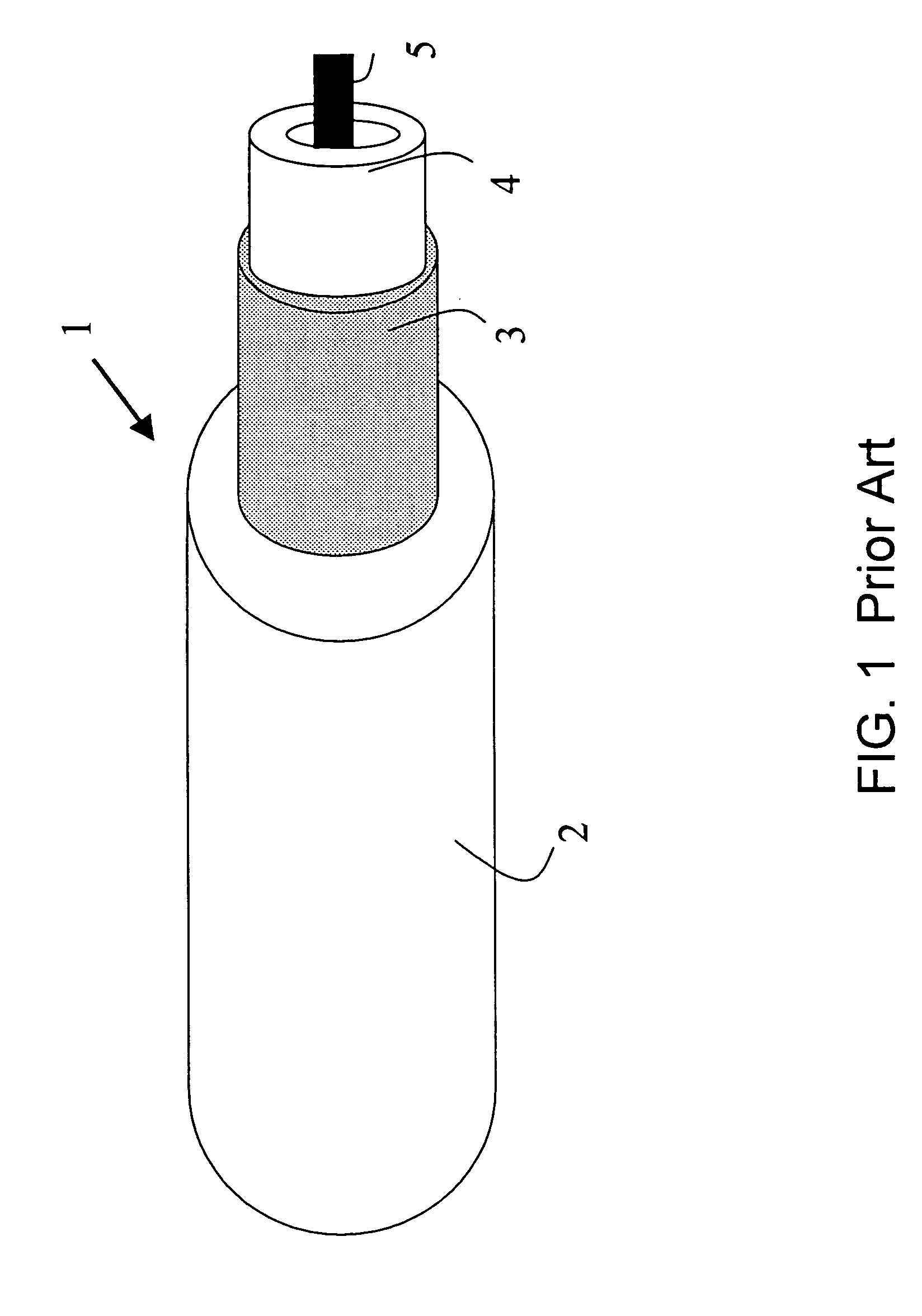

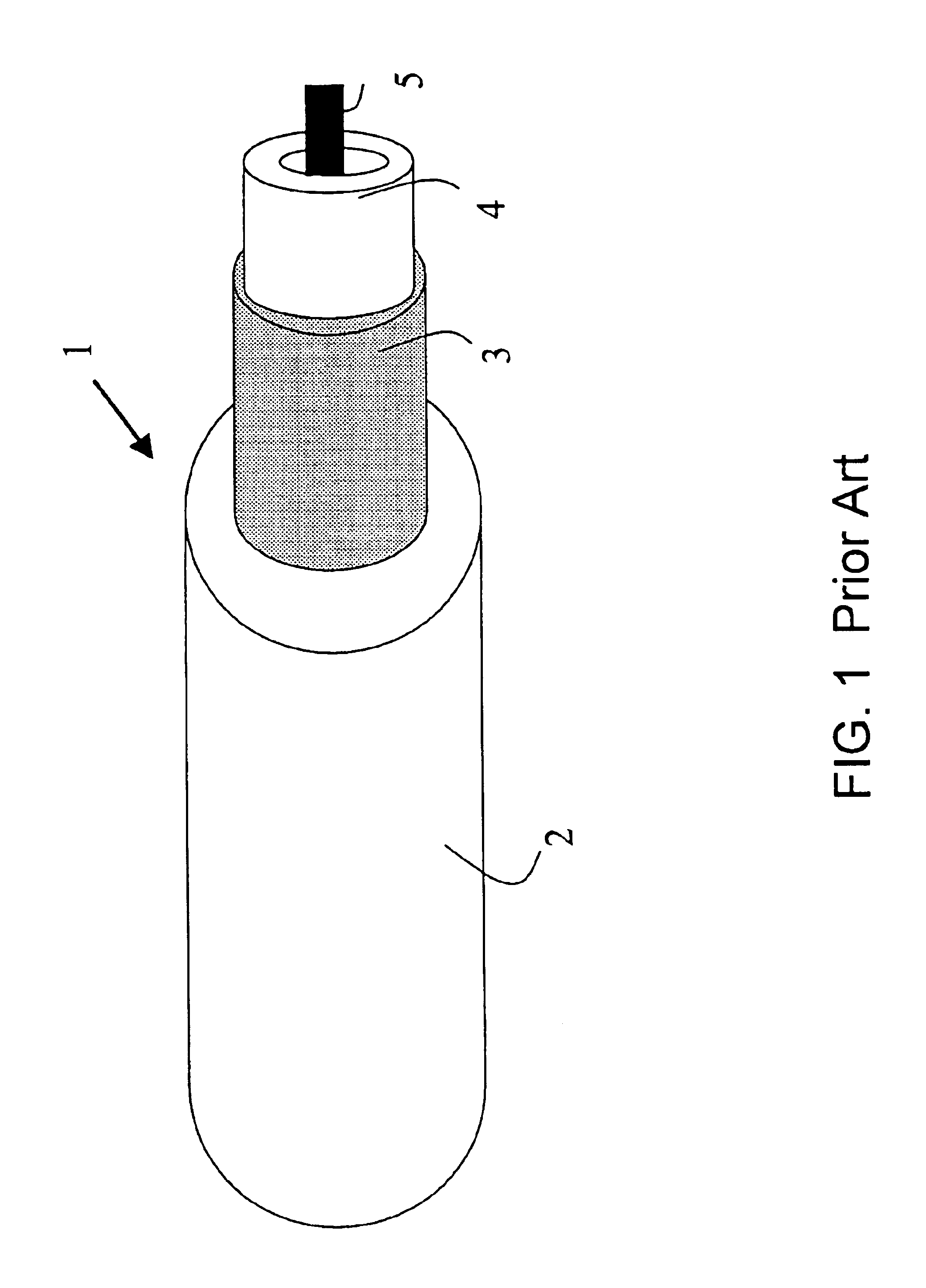

ActiveUS7459627B2Improve effectivenessSuitable for low-cost mass productionCable conductor constructionPower cables with screens/conductive layersCoaxial cableCarbon nanotube

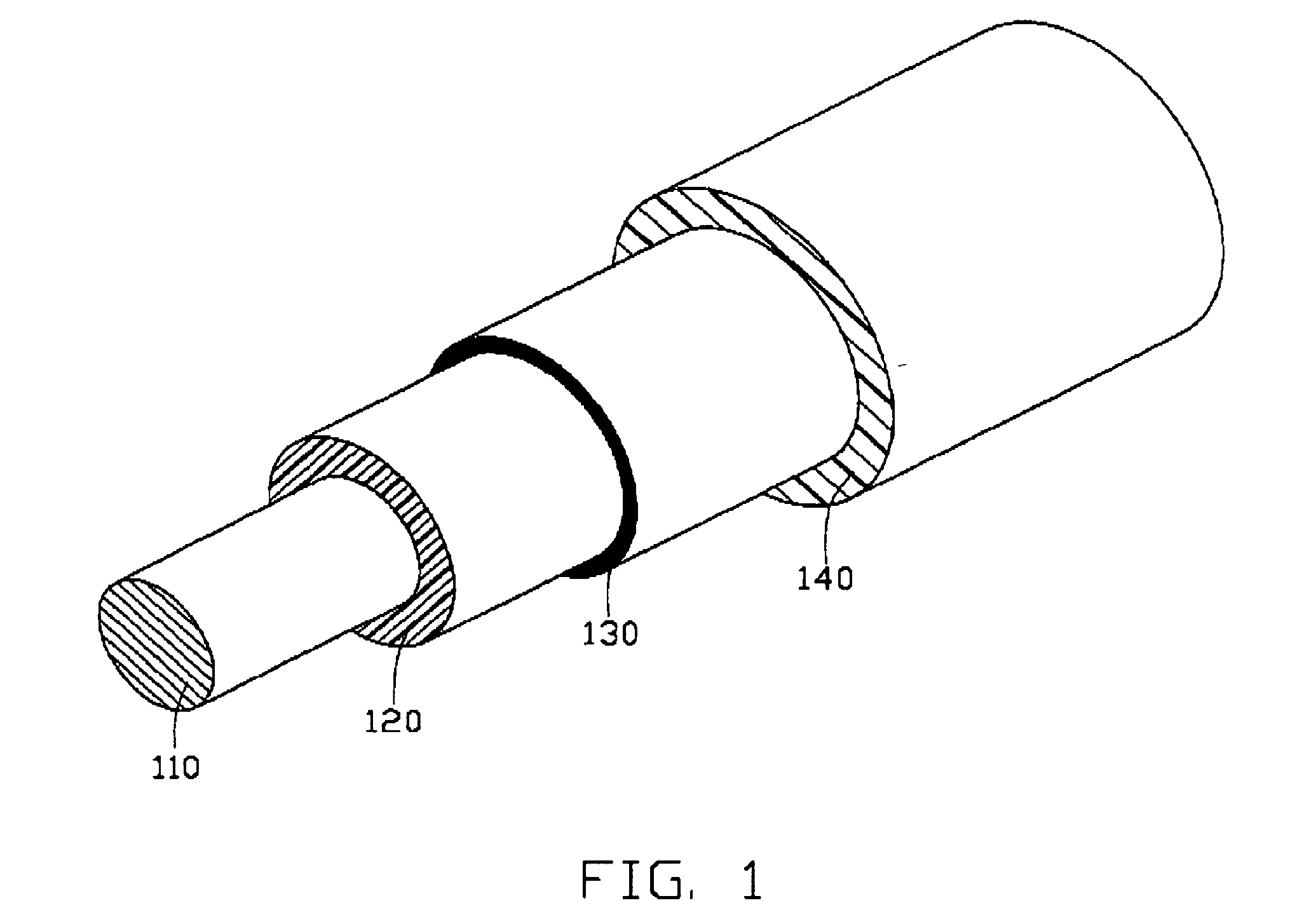

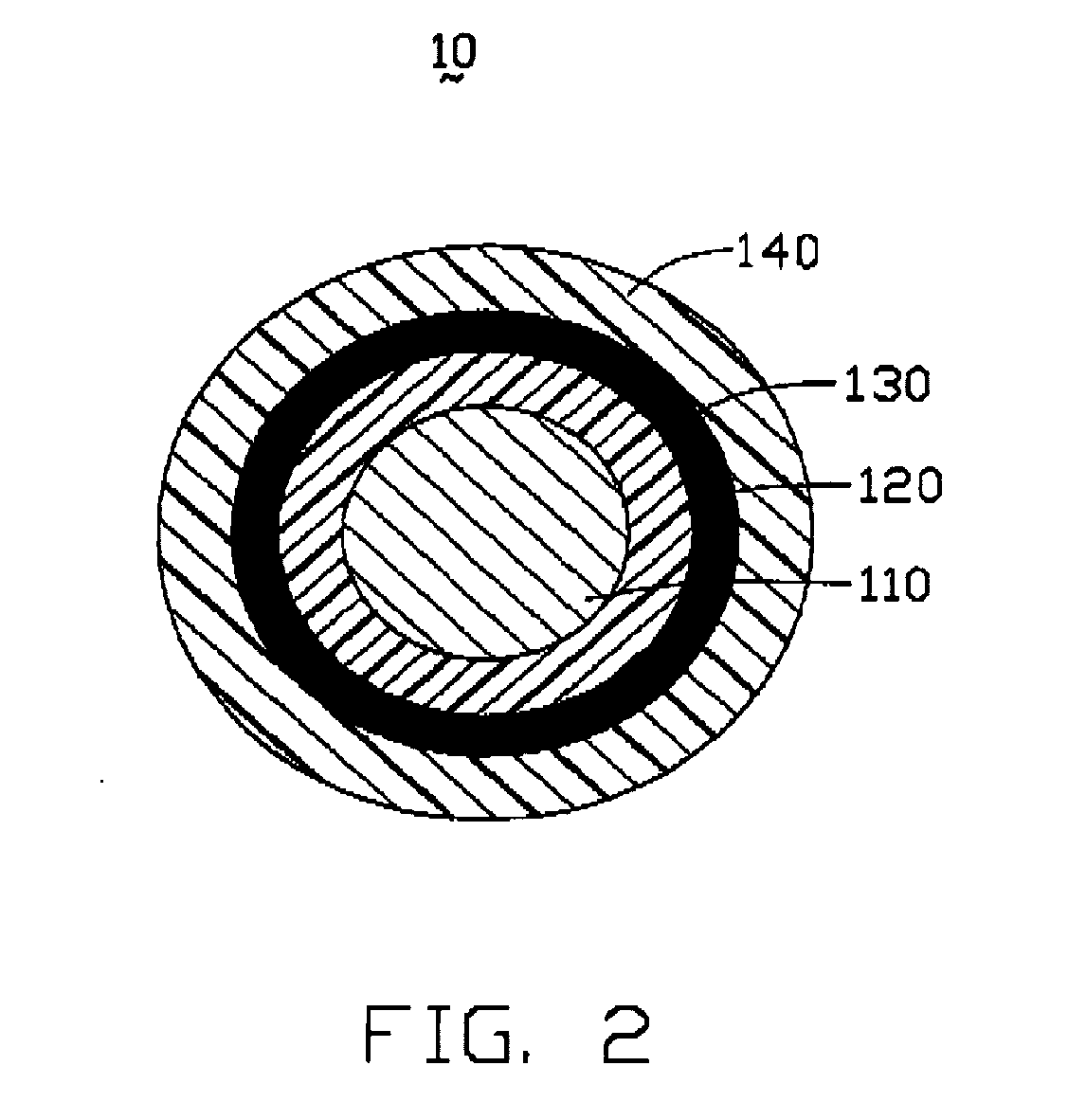

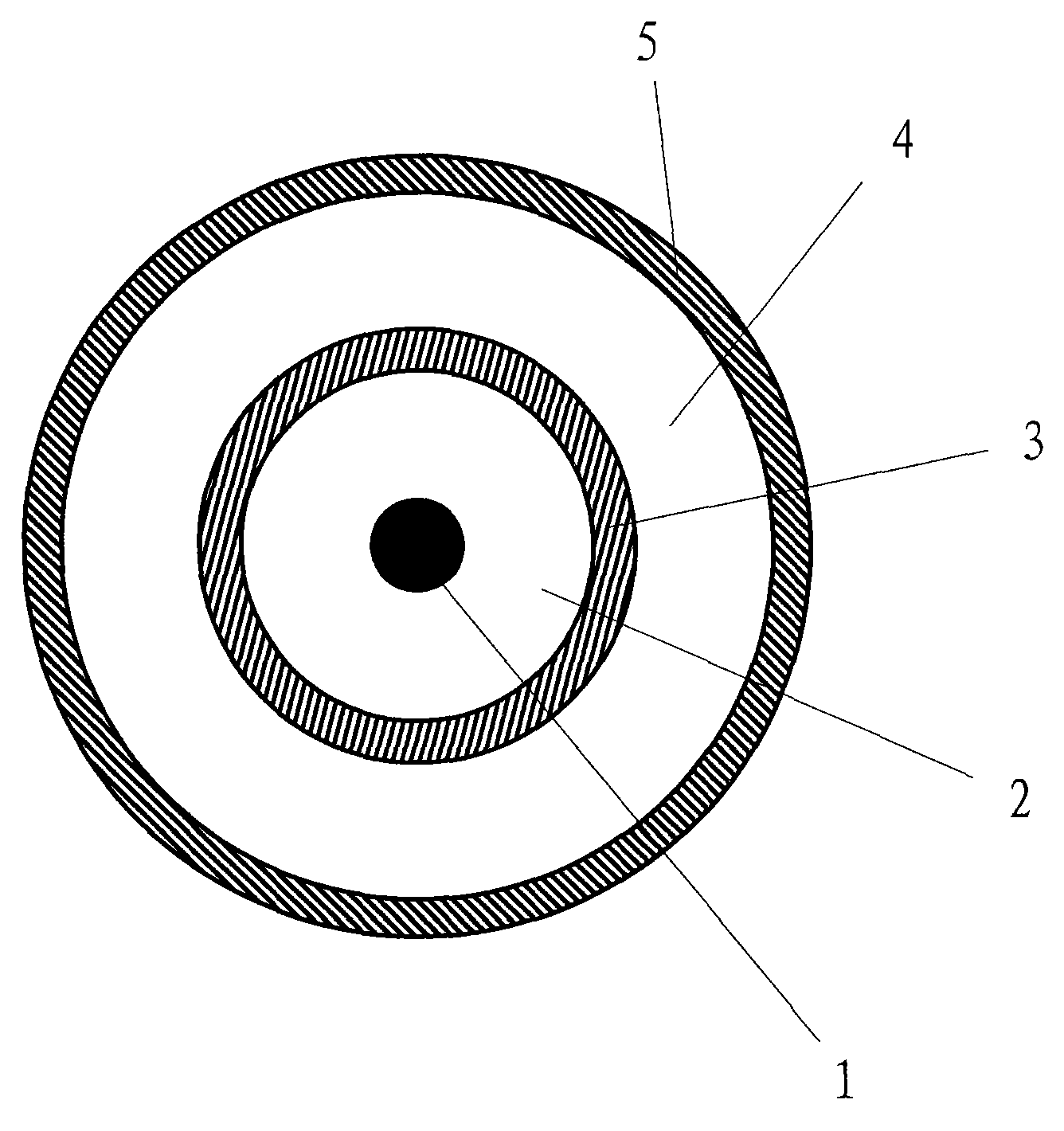

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) is a carbon nanotube film.

Owner:TSINGHUA UNIV +1

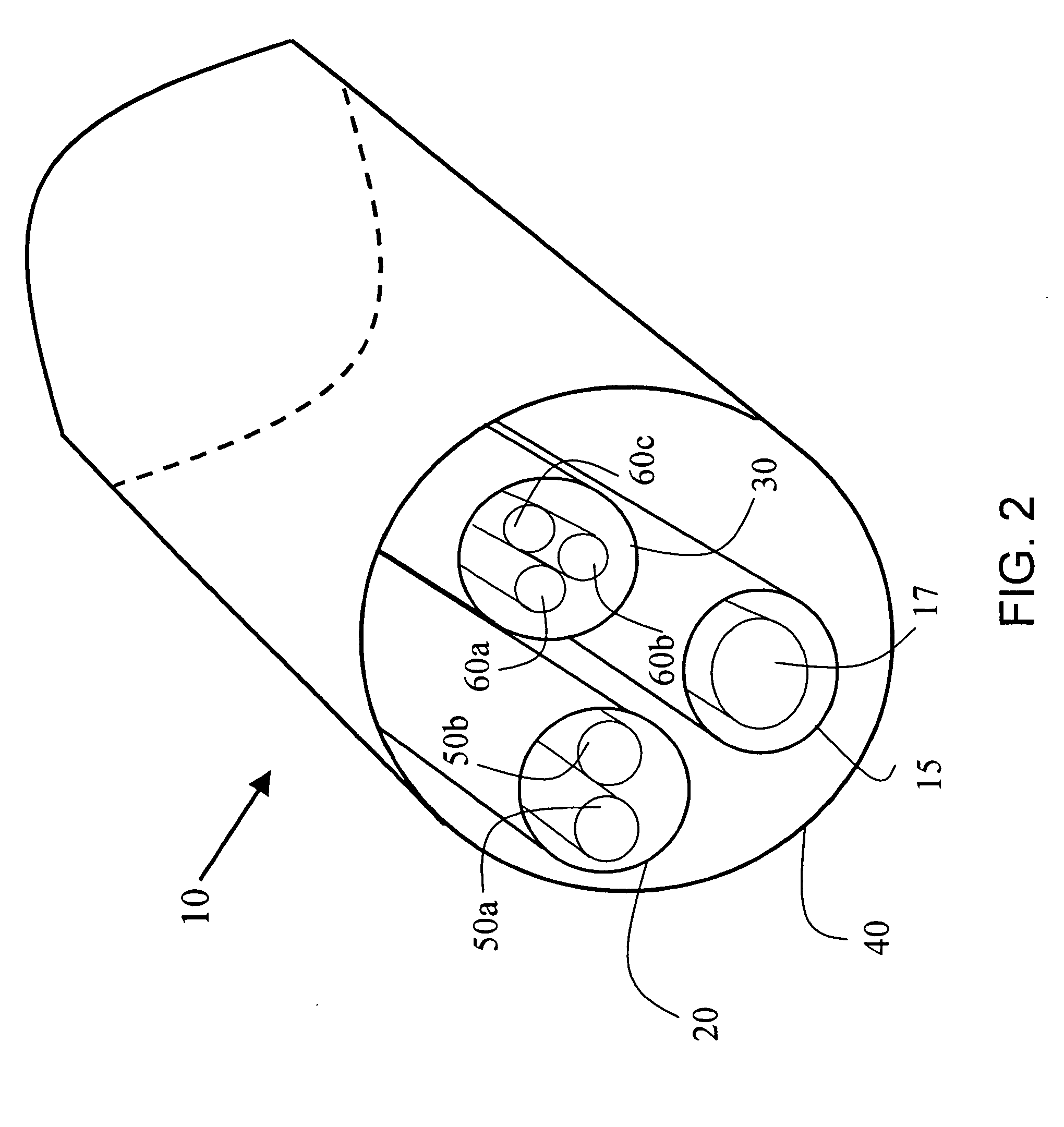

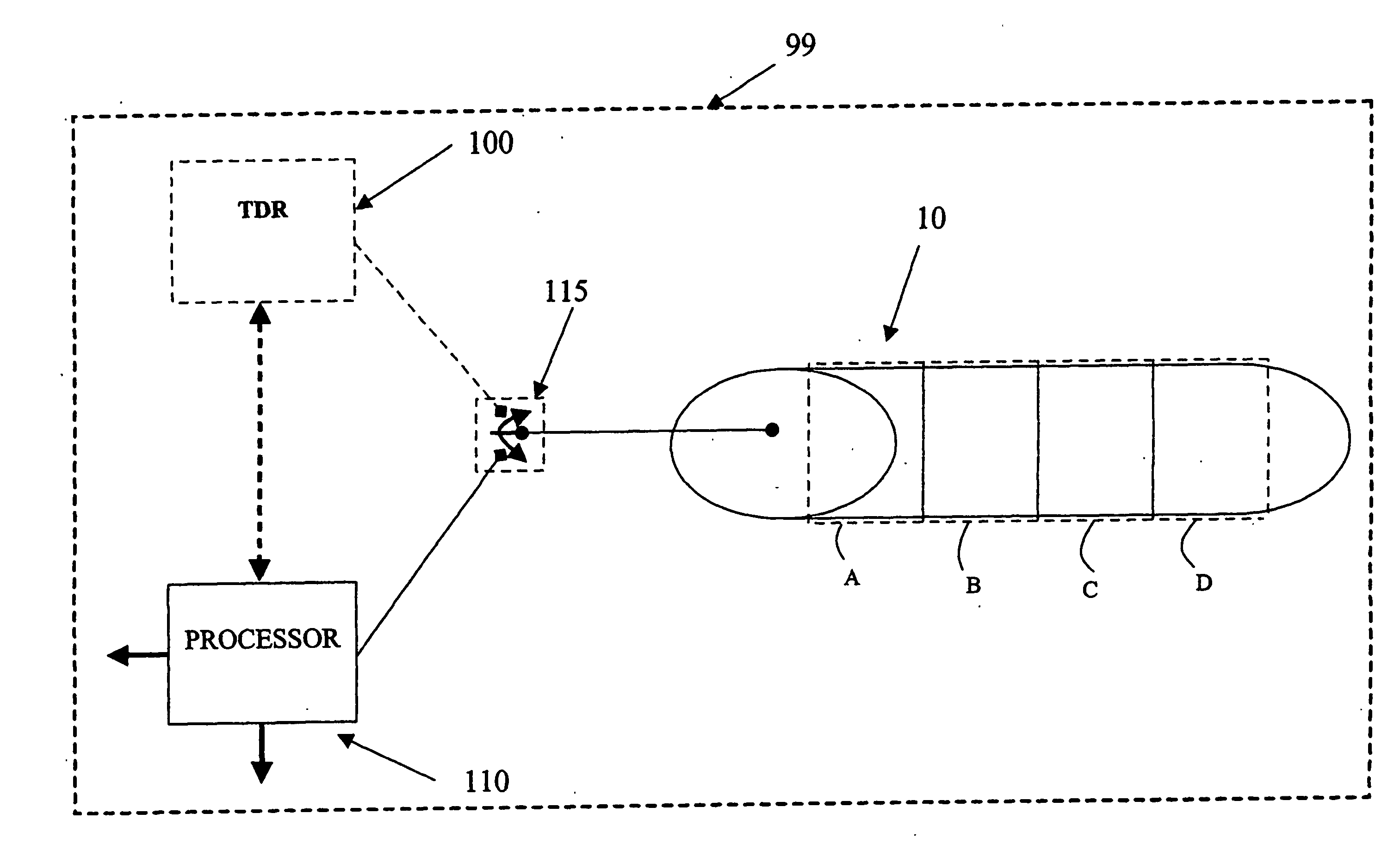

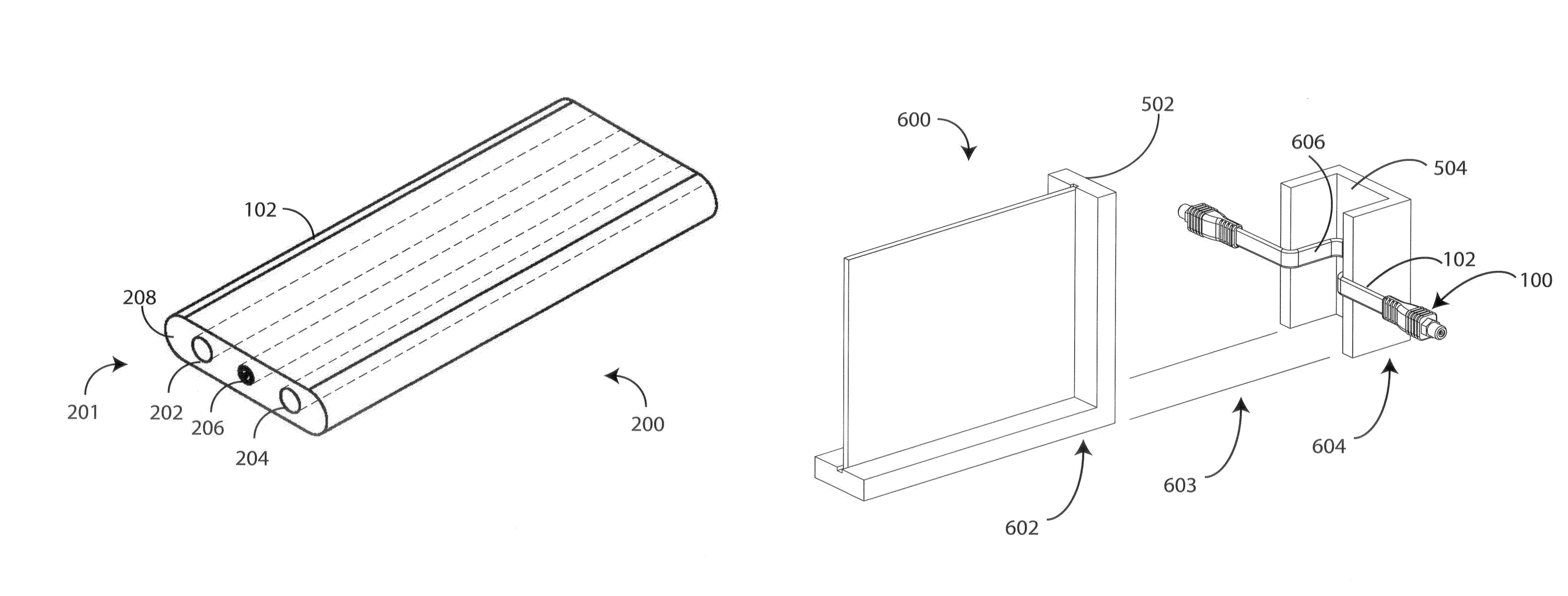

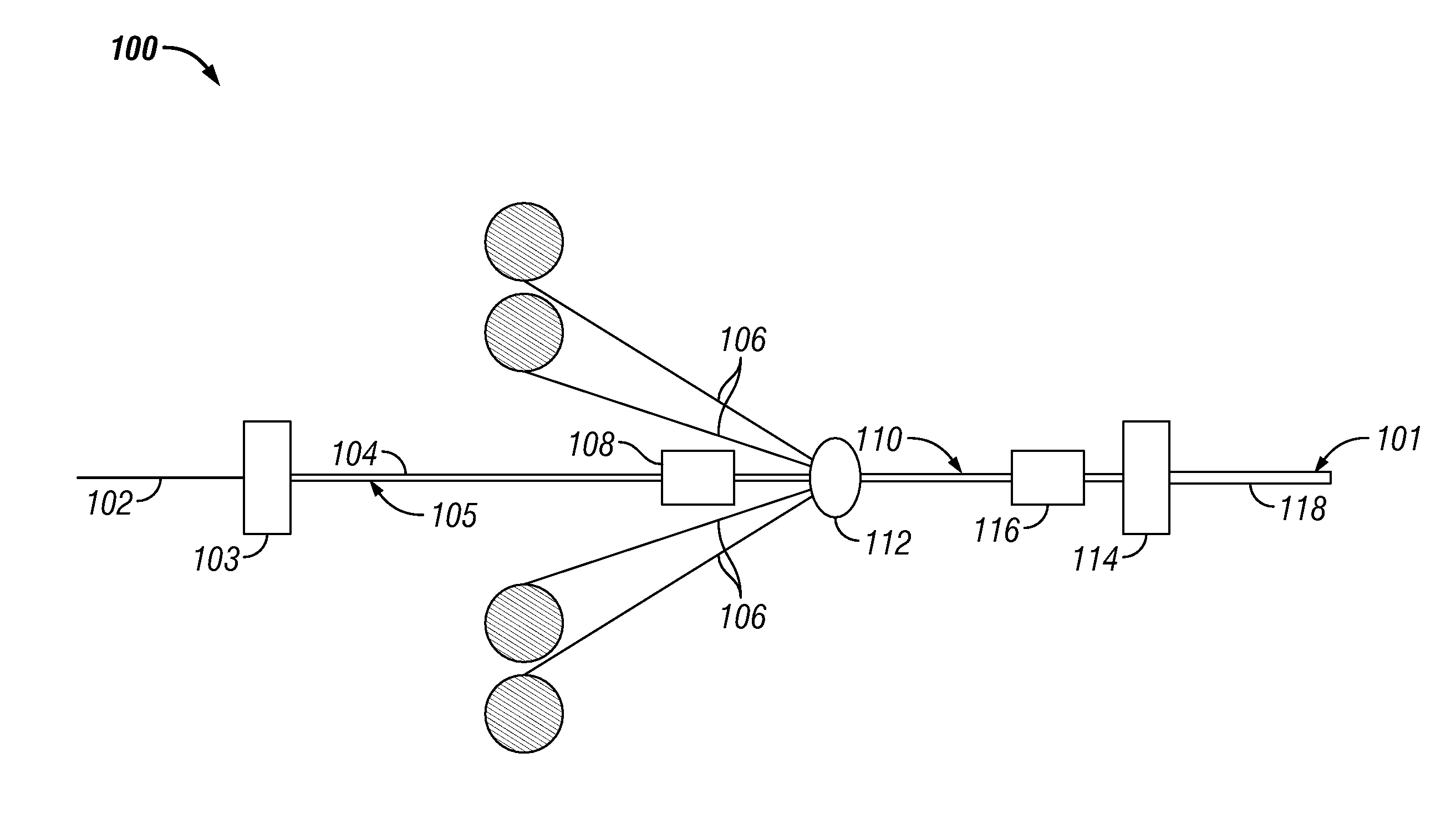

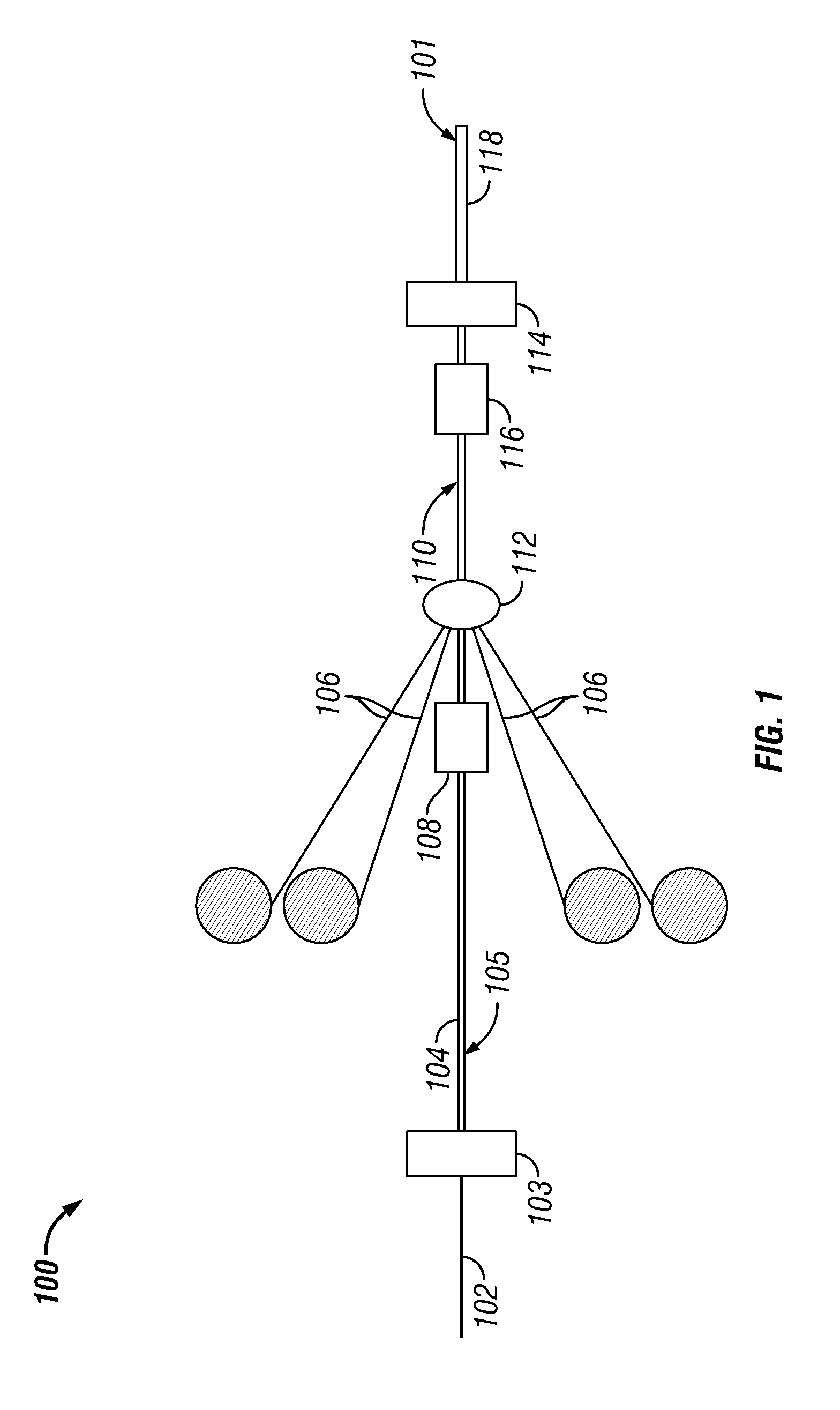

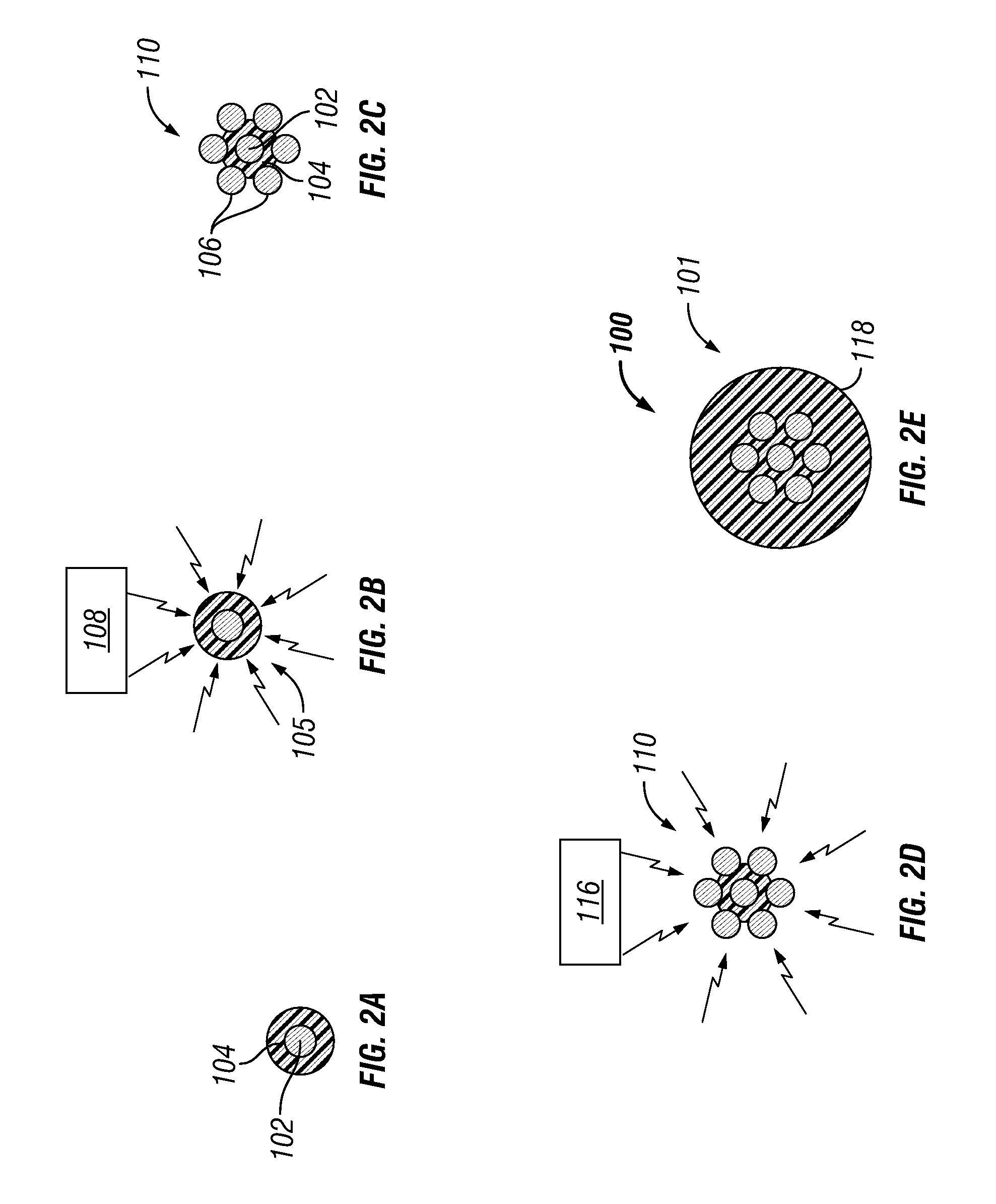

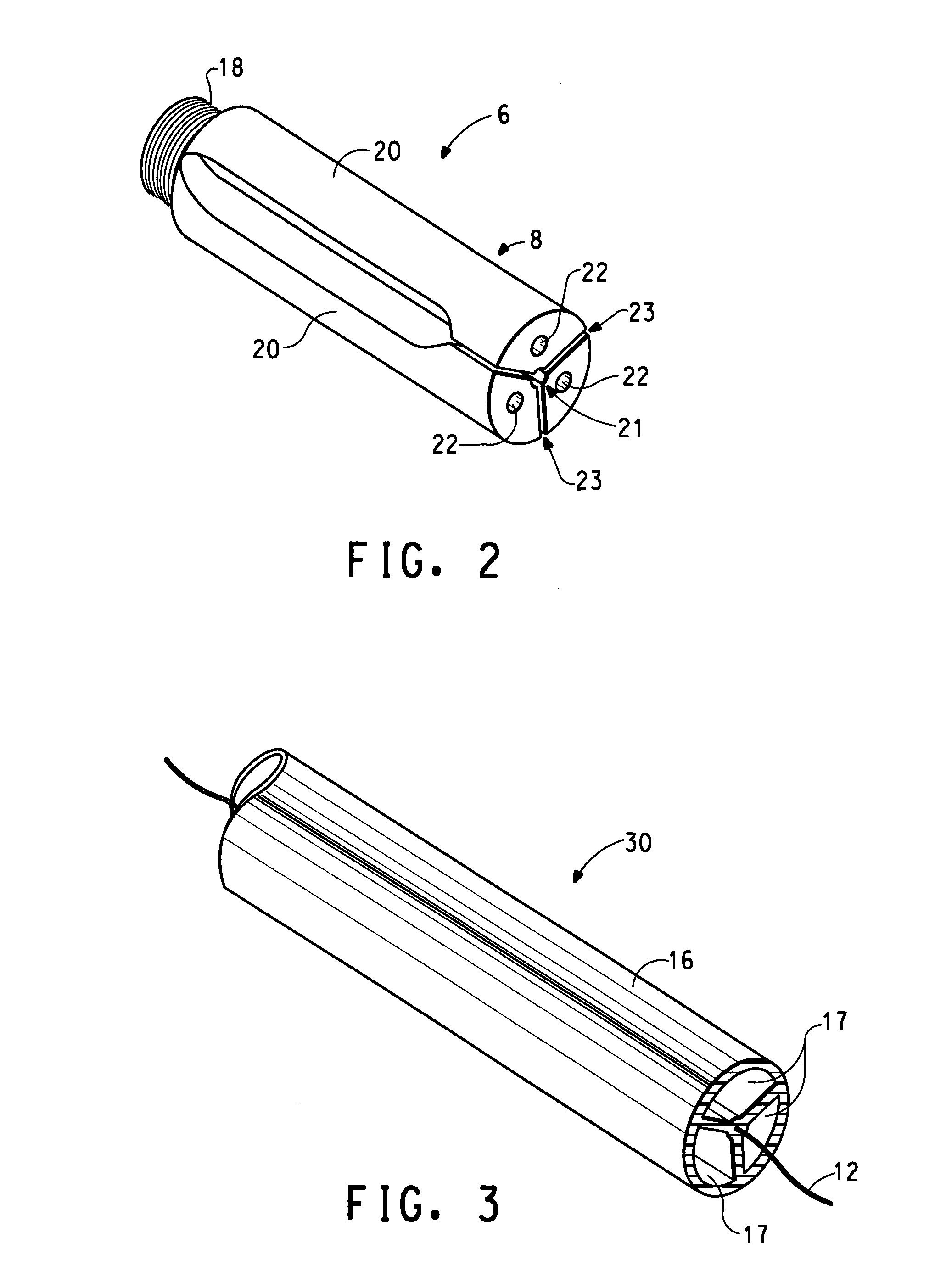

Integrated sensor cable for ranging

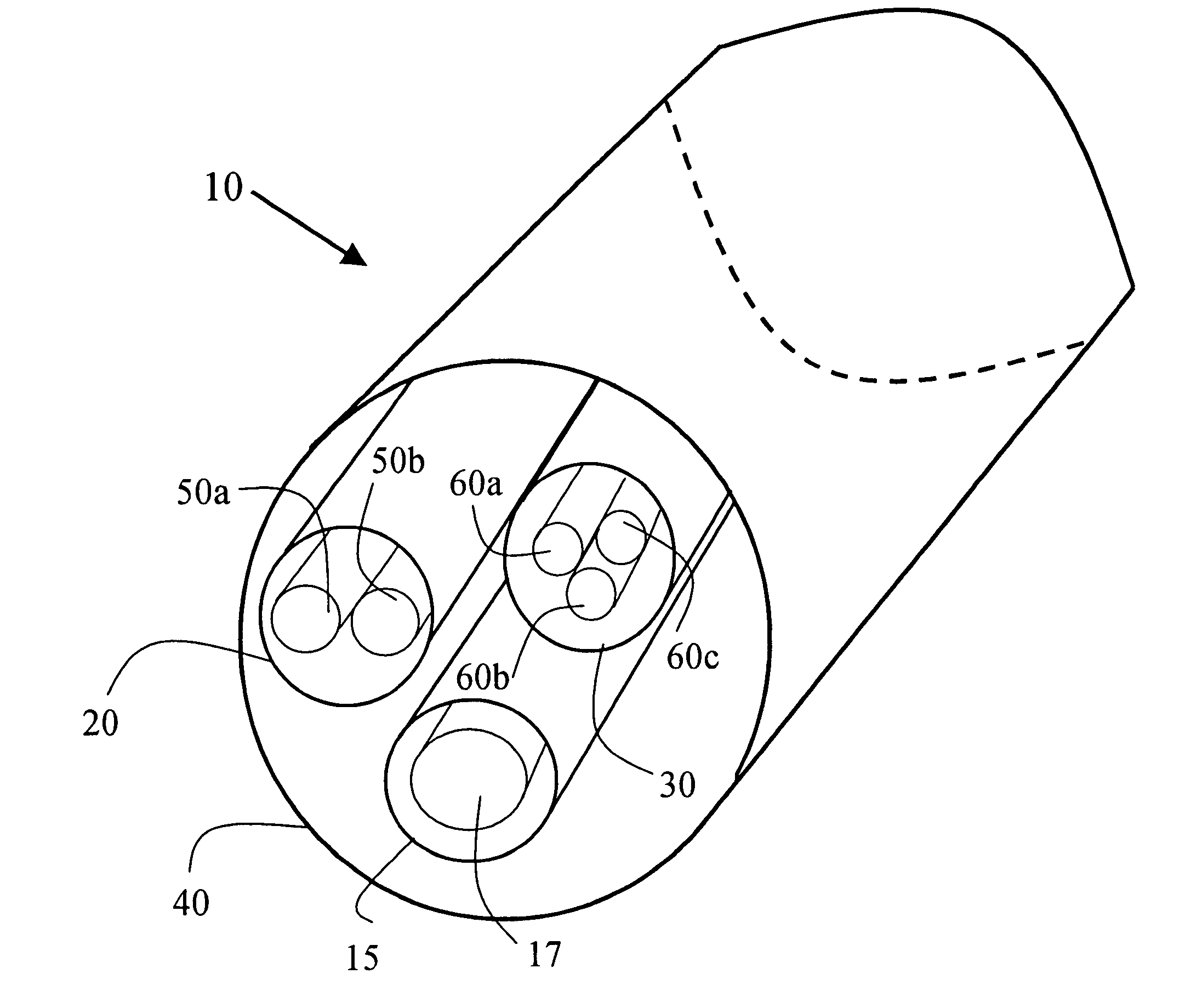

An intrusion detection system provides the function of an “active” ranging sensor cable system utilized for identification of the location of the intruder, with that of a “passive” cable detection system, in an integrated cable configuration. This dual function is provided with a single conventional sensing cable optimized for both “active” and “passive” sensing, or in combination with other parallel sensing cables for a “passive” cable component. The “active” cable component includes a coaxial sensor cable having a loosely disposed conductor. A signal is injected into the sensor cable such that a reflection is altered when an intrusion disturbs the cable. Based on the timing of the reflection, a processor, or a reflectometer, identifies the location of the disturbance. The “passive” cable component can be sensitized to detect intrusion via some other sensing phenomenology, such as the triboelectric effect, for triboelectric effect sensing.

Owner:SENSTAR STELLAR CORP

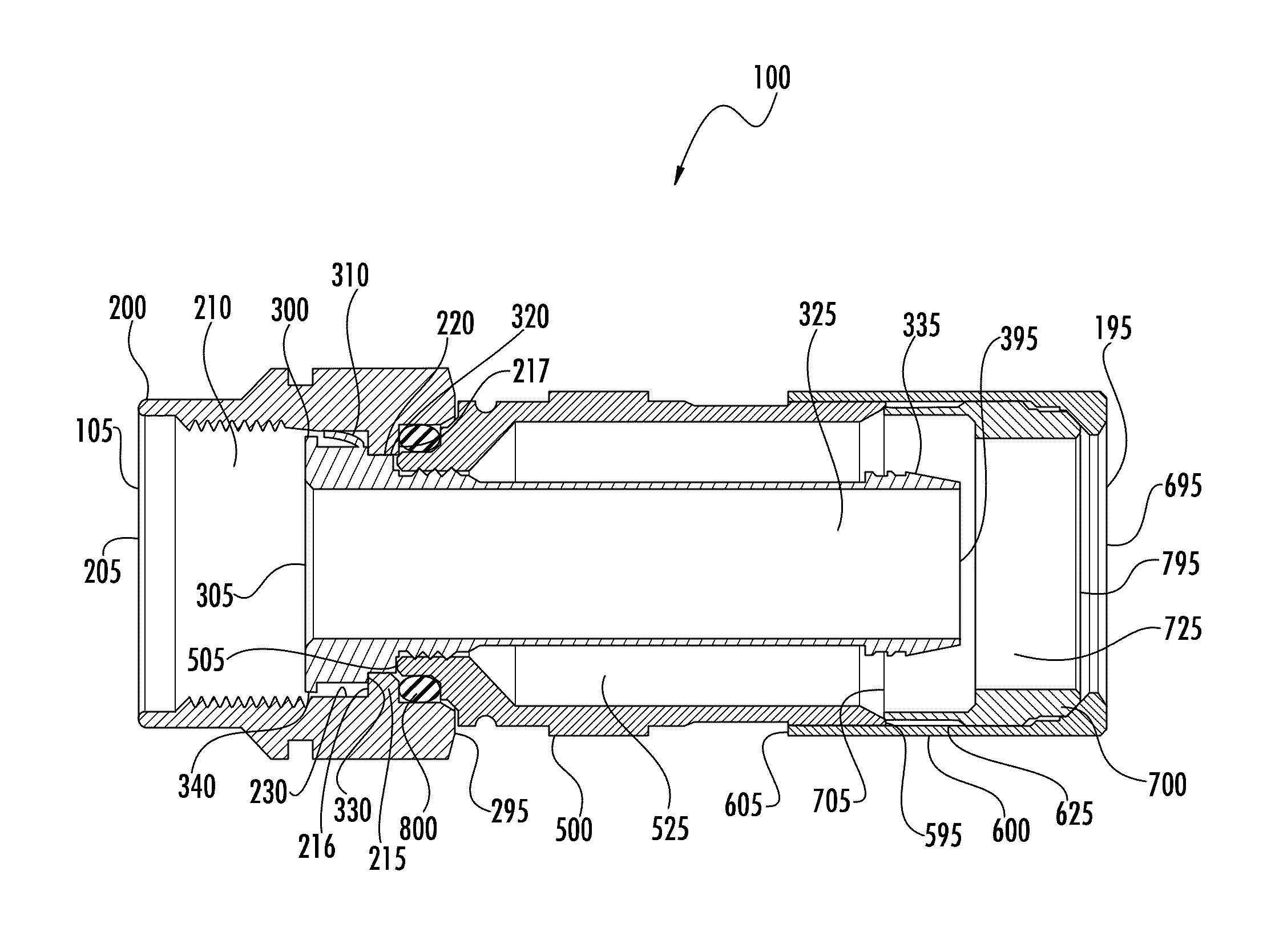

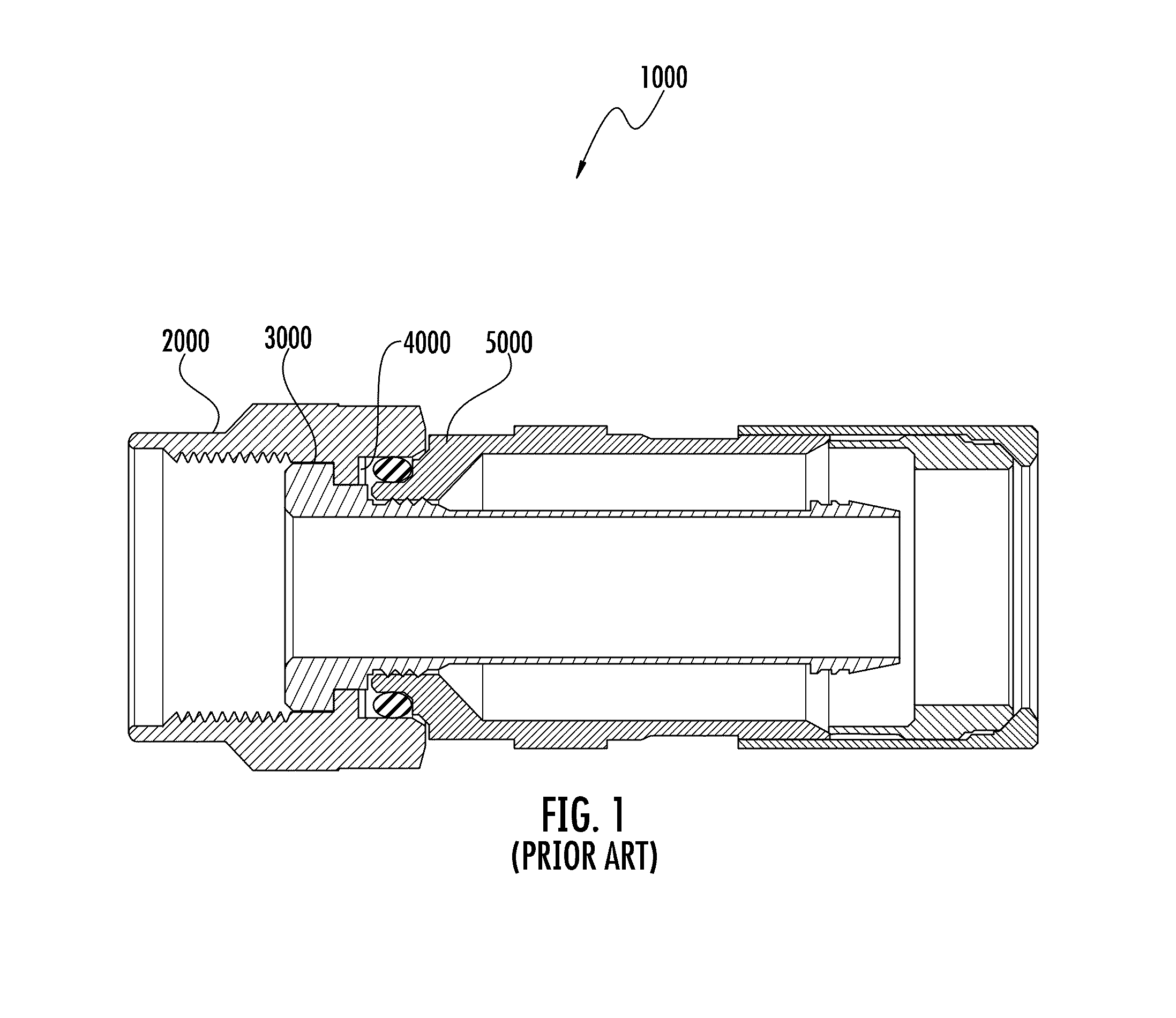

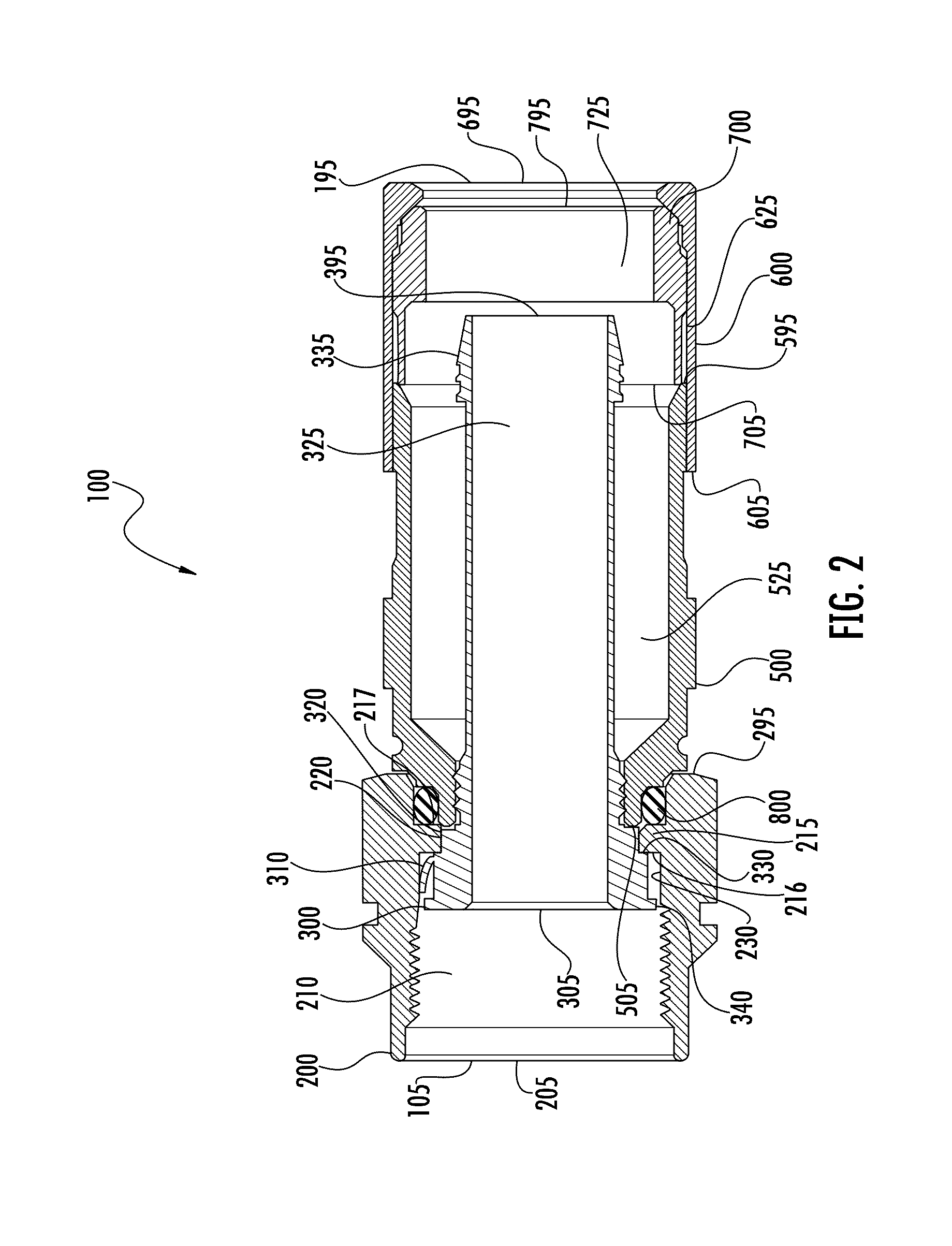

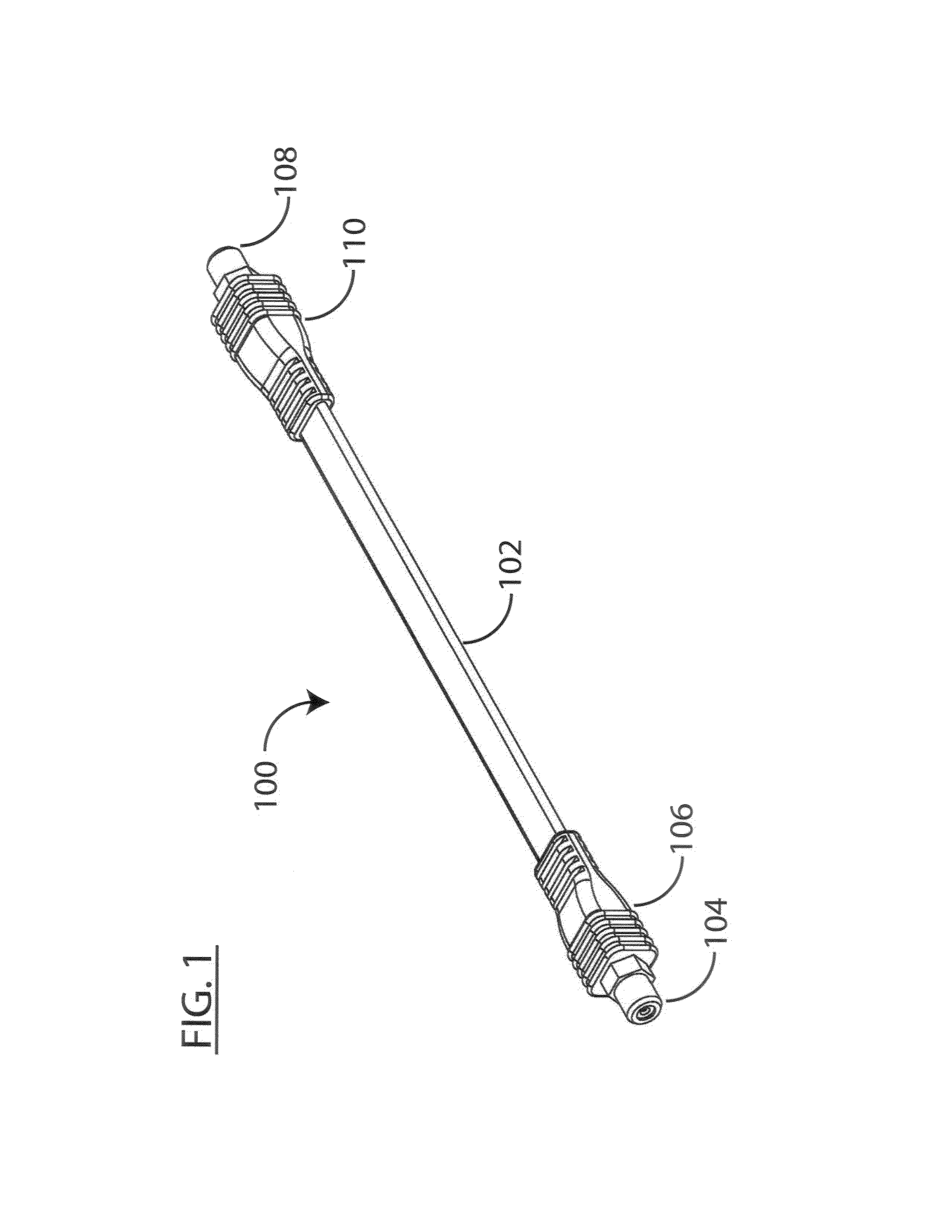

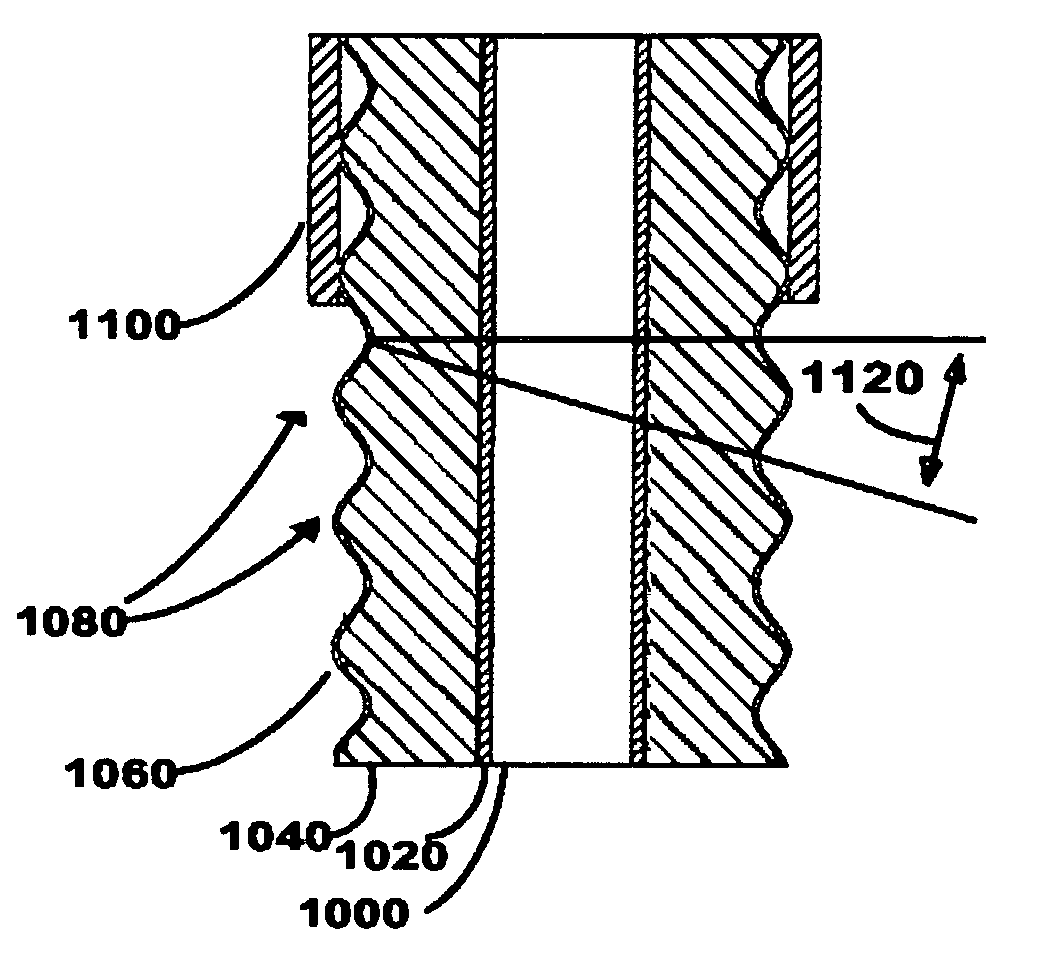

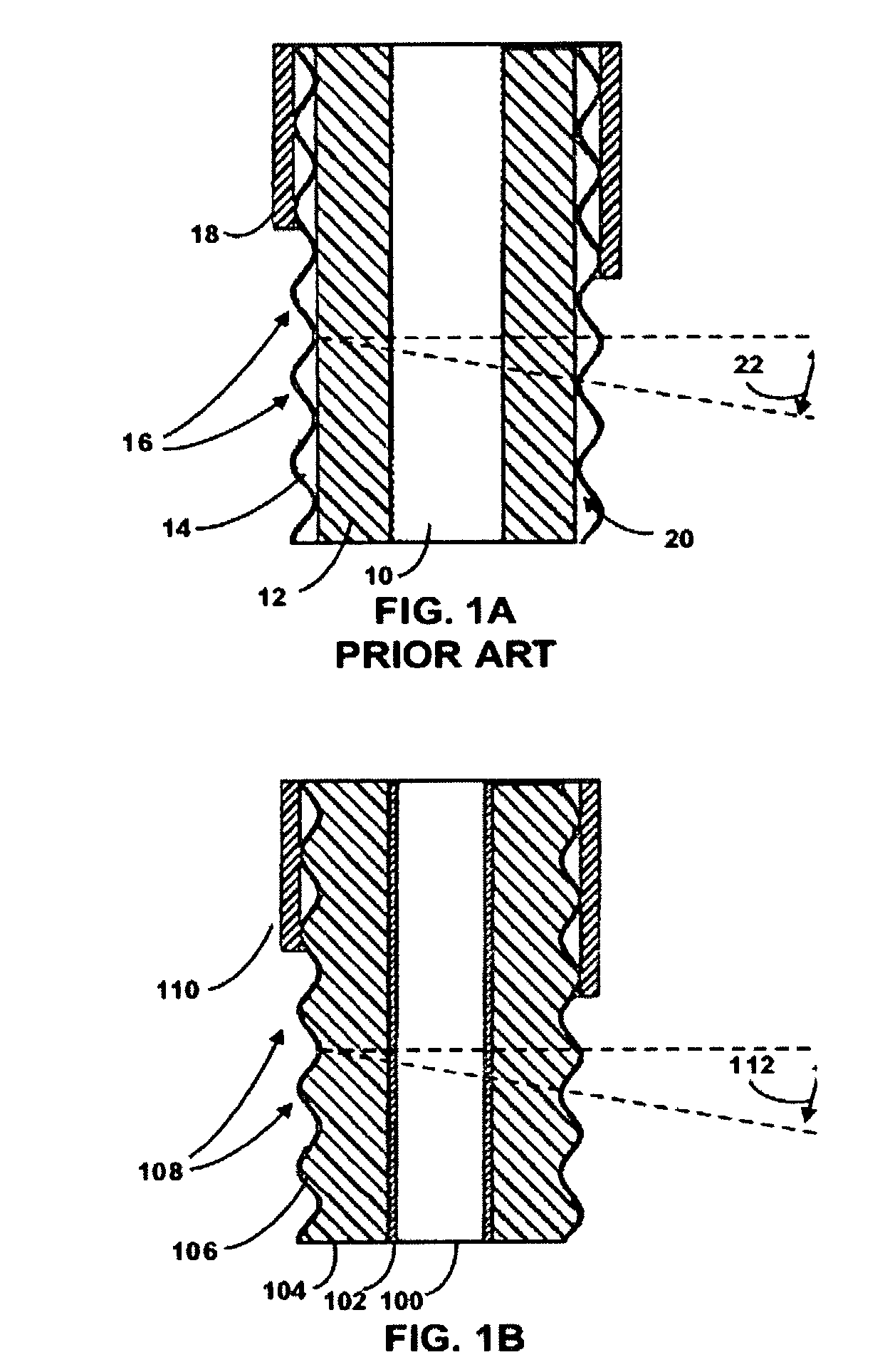

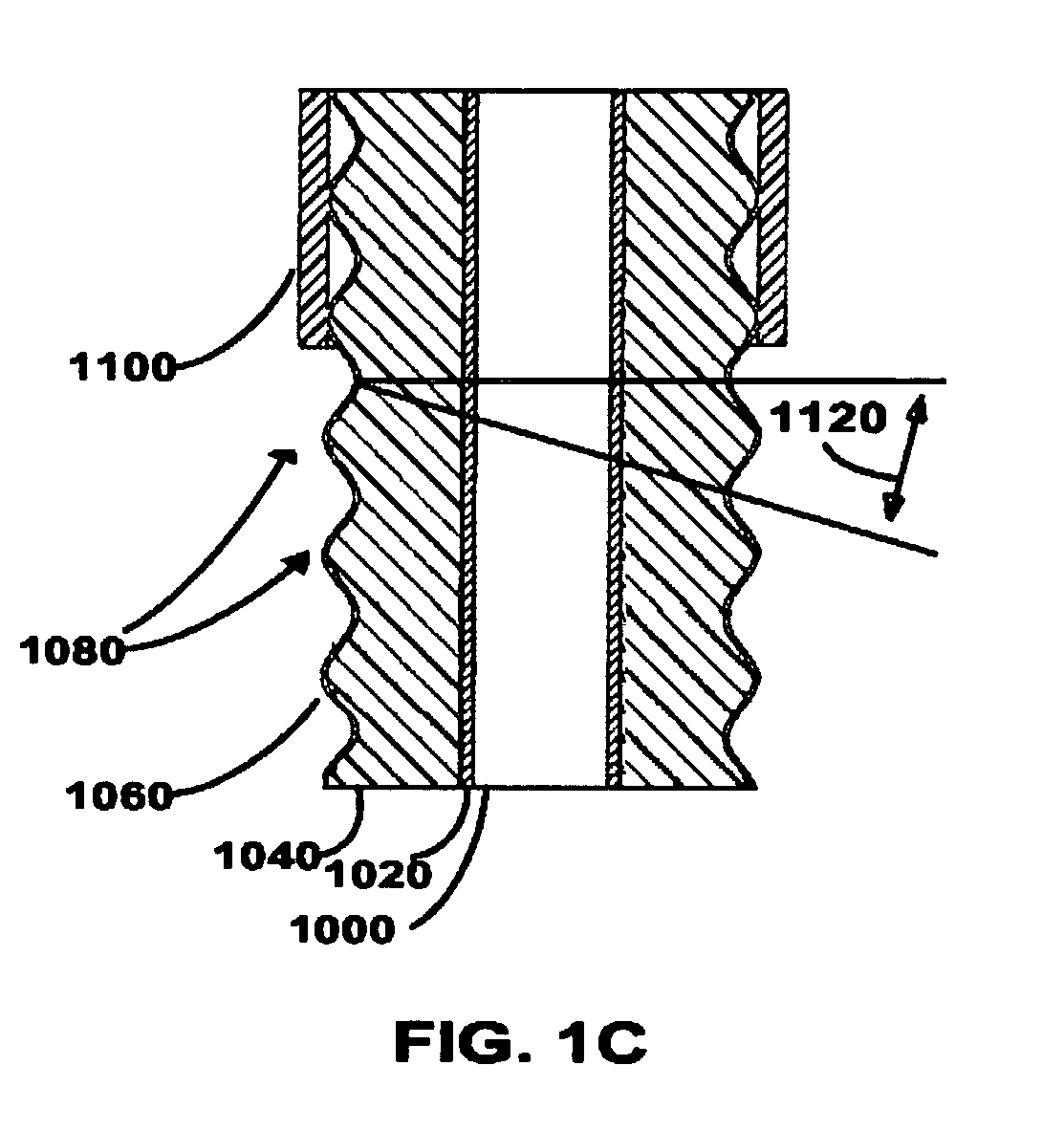

Coaxial cable connector with integral continuity contacting portion

ActiveUS20140106612A1Coupling device detailsClamped/spring connectionsElectrical conductorCoaxial cable

A coaxial cable connector for coupling an end of a coaxial cable to a terminal is disclosed. The connector has a coupler adapted to couple the connector to a terminal, a body assembled with the coupler and a post assembled with the coupler and the body. The post is adapted to receive an end of a coaxial cable. The coupler, the body or the post has an integral, monolithic contacting portion. When the connector is coupled to the terminal and a coaxial cable is received by the body, the contacting portion provides for electrical continuity from an outer conductor of the coaxial cable through the connector to the terminal other than by a separate component. The contacting portion is formable and forms to a contour of at least one of the body and the coupler when the body at least partially assembles with the coupler.

Owner:PPC BROADBAND INC

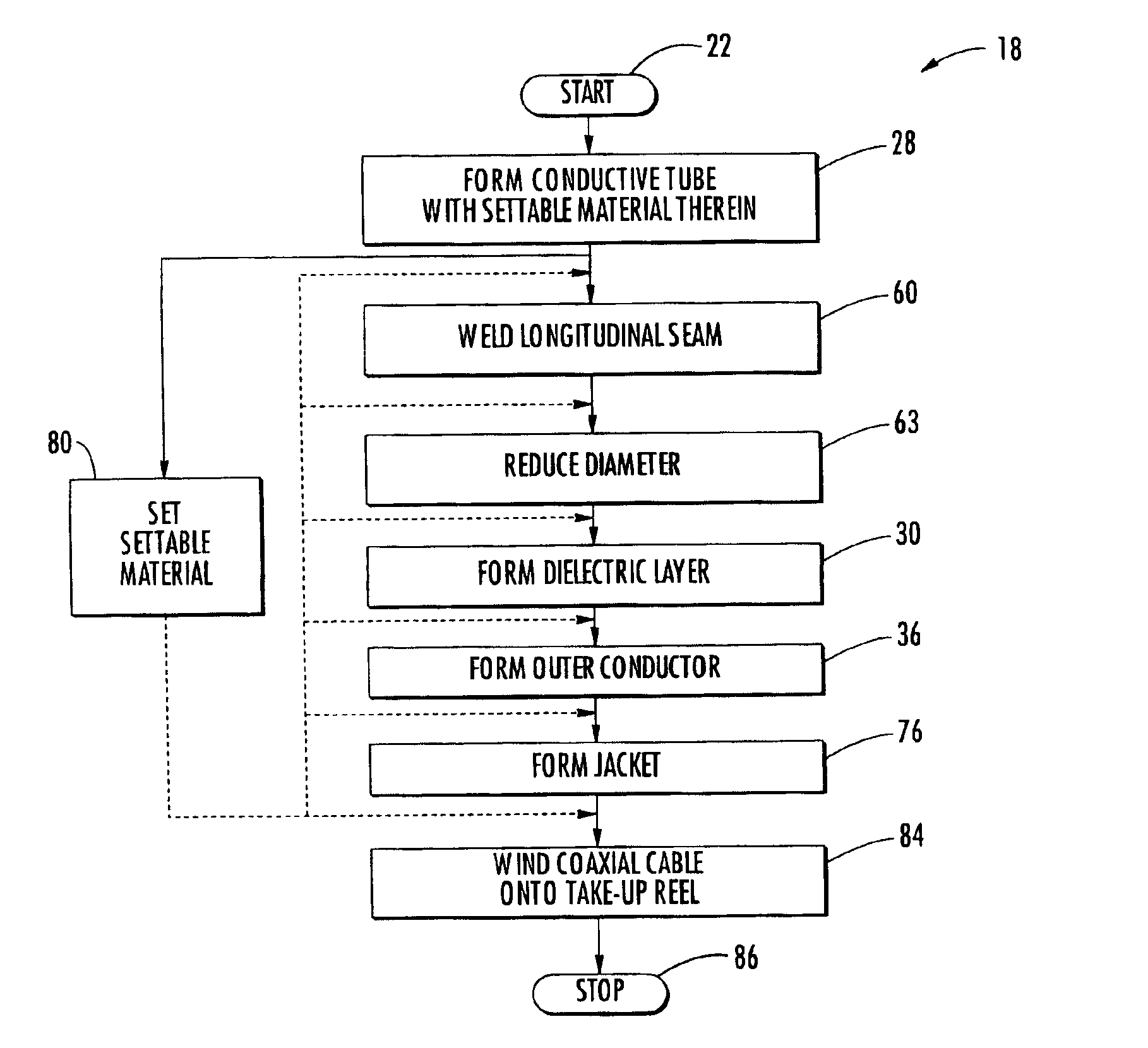

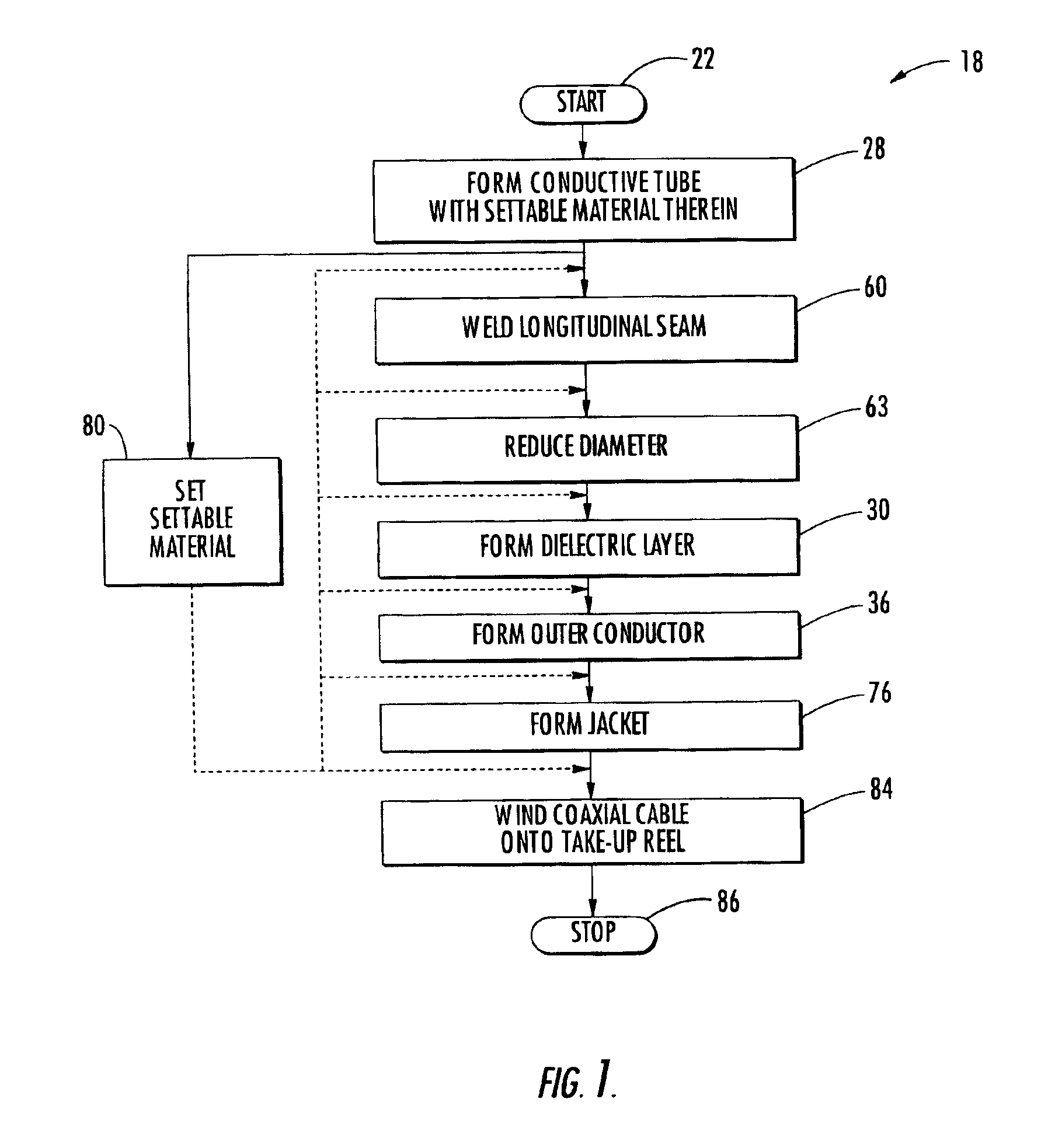

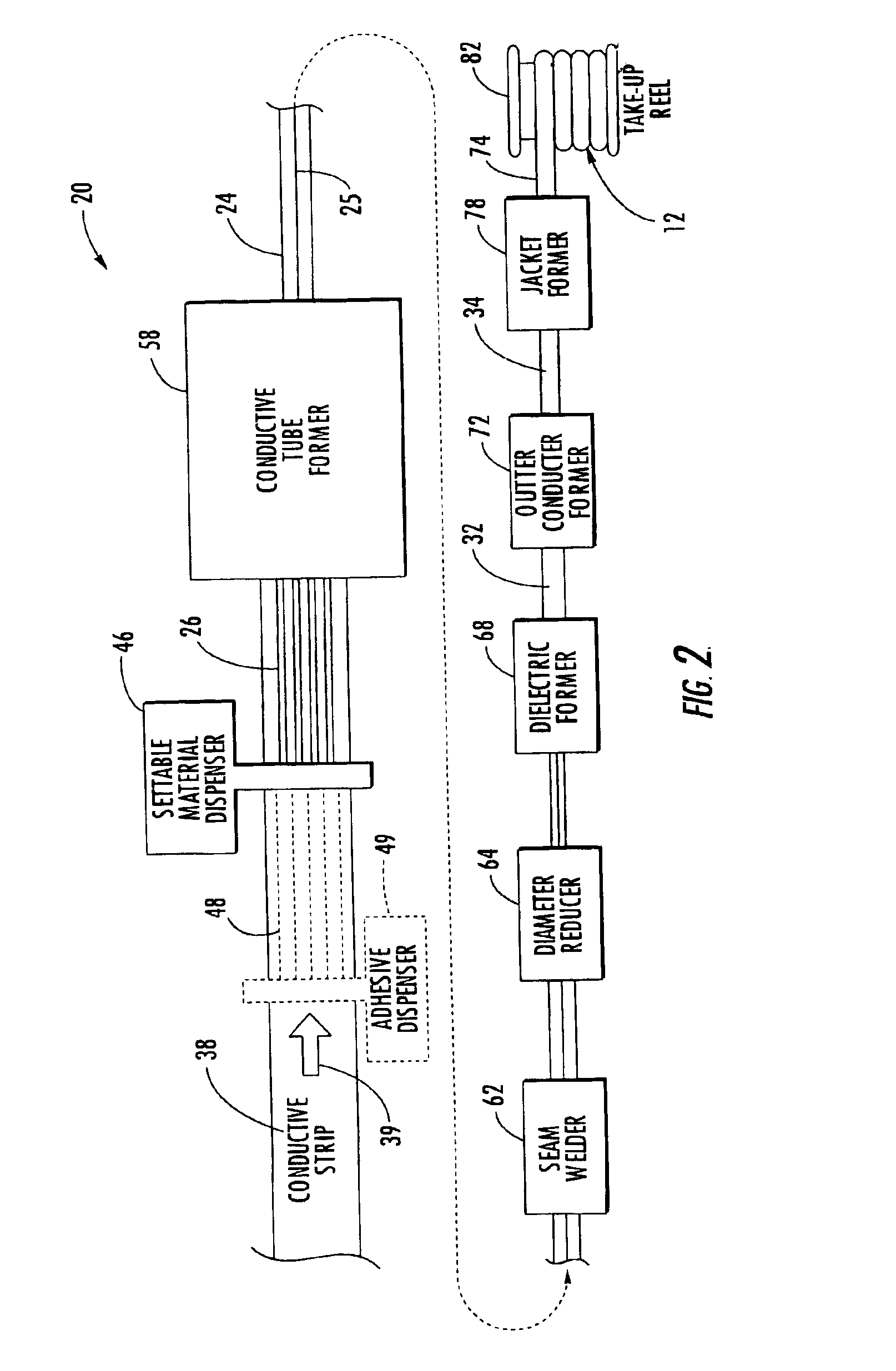

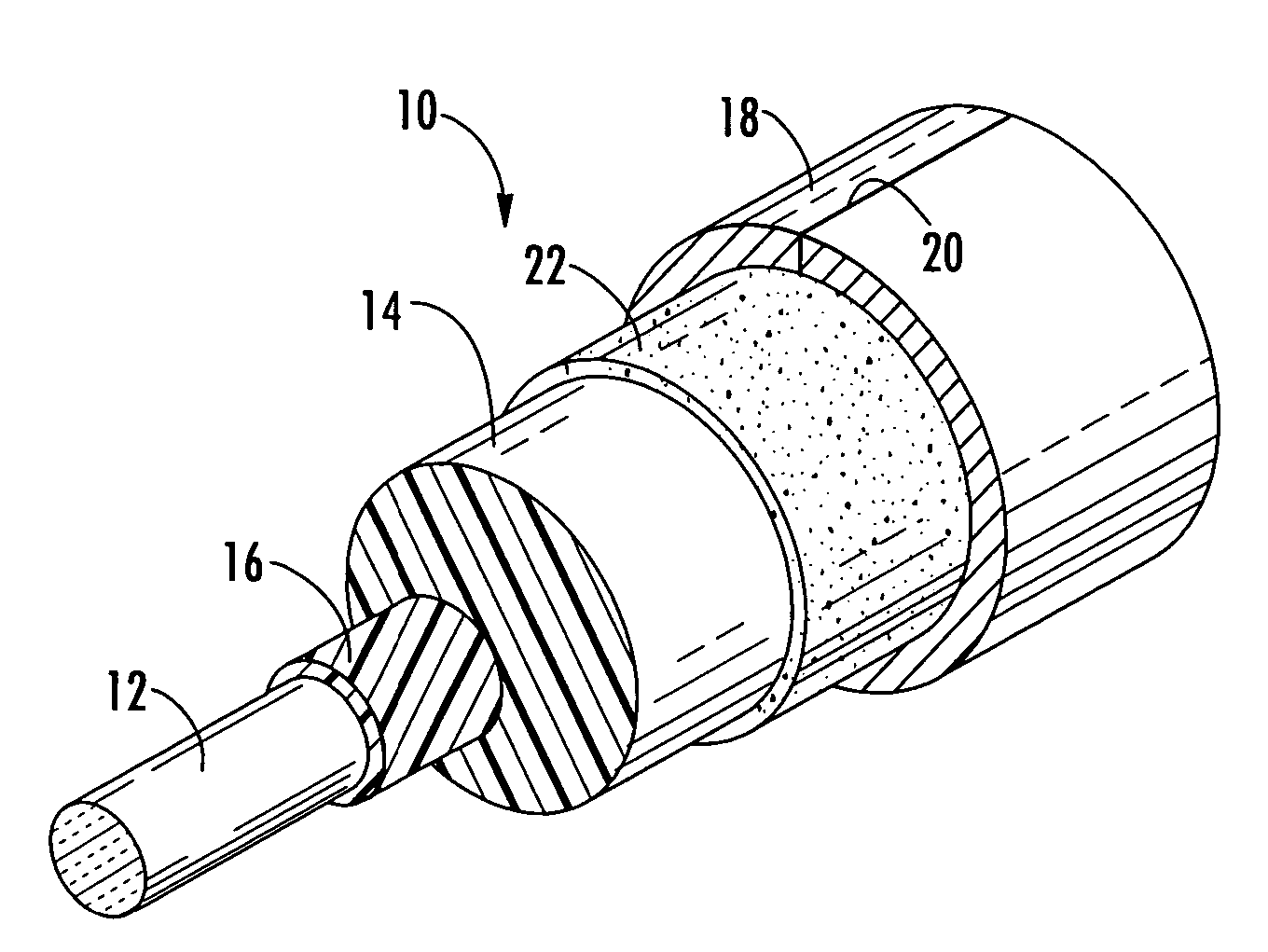

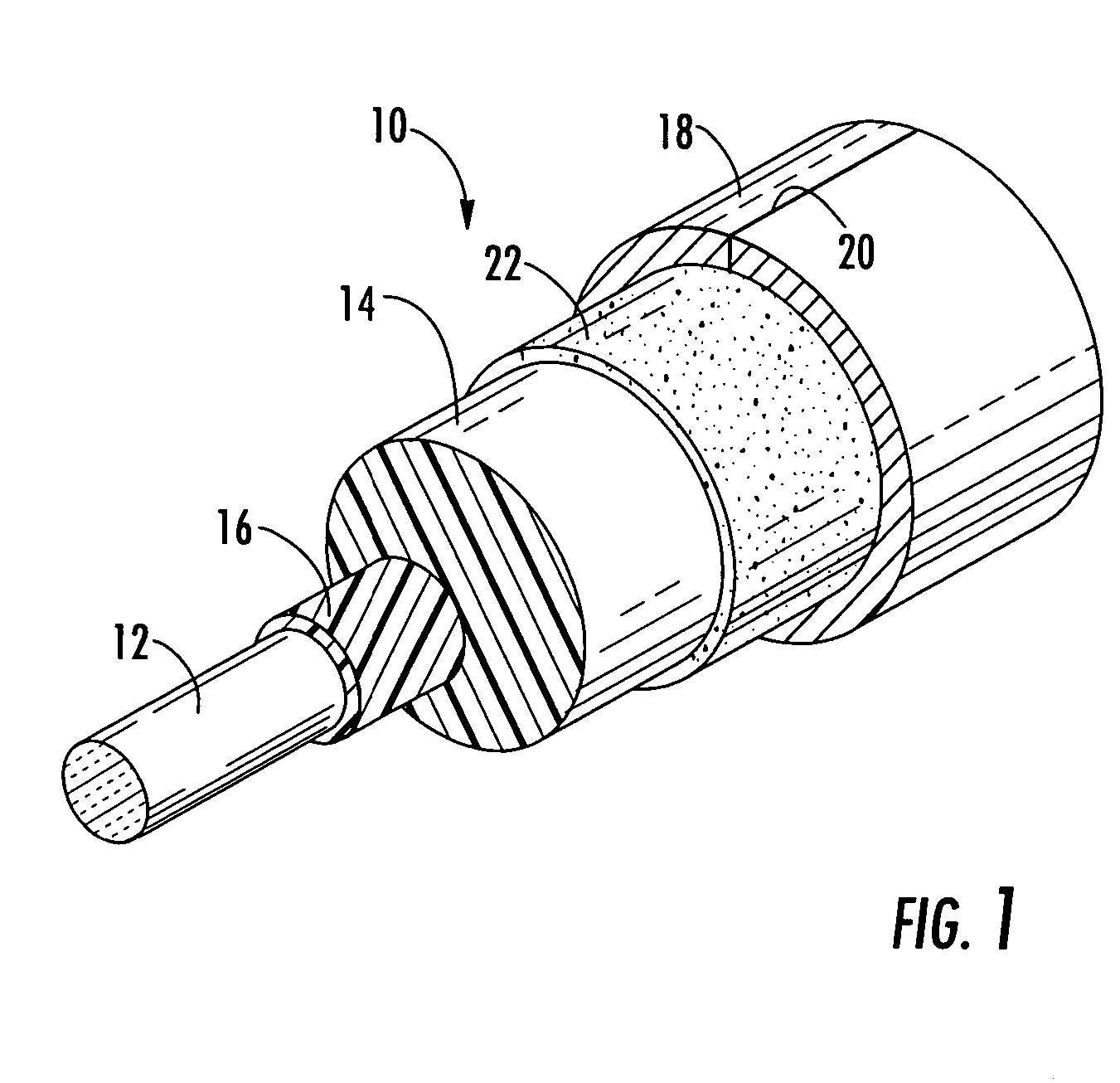

Method and apparatus for manufacturing coaxial cable with composite inner conductor

InactiveUS6915564B2Efficient preparationLow costLine/current collector detailsCable conductor constructionElectrical conductorCoaxial cable

A method of making a coaxial cable includes forming a conductive tube and setting a settable material therein to define an inner conductor. Forming may include advancing a conductive strip and bending it into a tube having a longitudinal seam. The settable material may be dispensed onto the conductive strip continuously with the forming. Alternately, the settable material may be dispensed onto the conductive strip prior to advancing. The dispensing may use a puller cord as the settable material or carrying some or all of the settable material. The method may further include forming a dielectric layer surrounding the inner conductor, and forming an outer conductor surrounding the dielectric layer.

Owner:COMMSCOPE INC

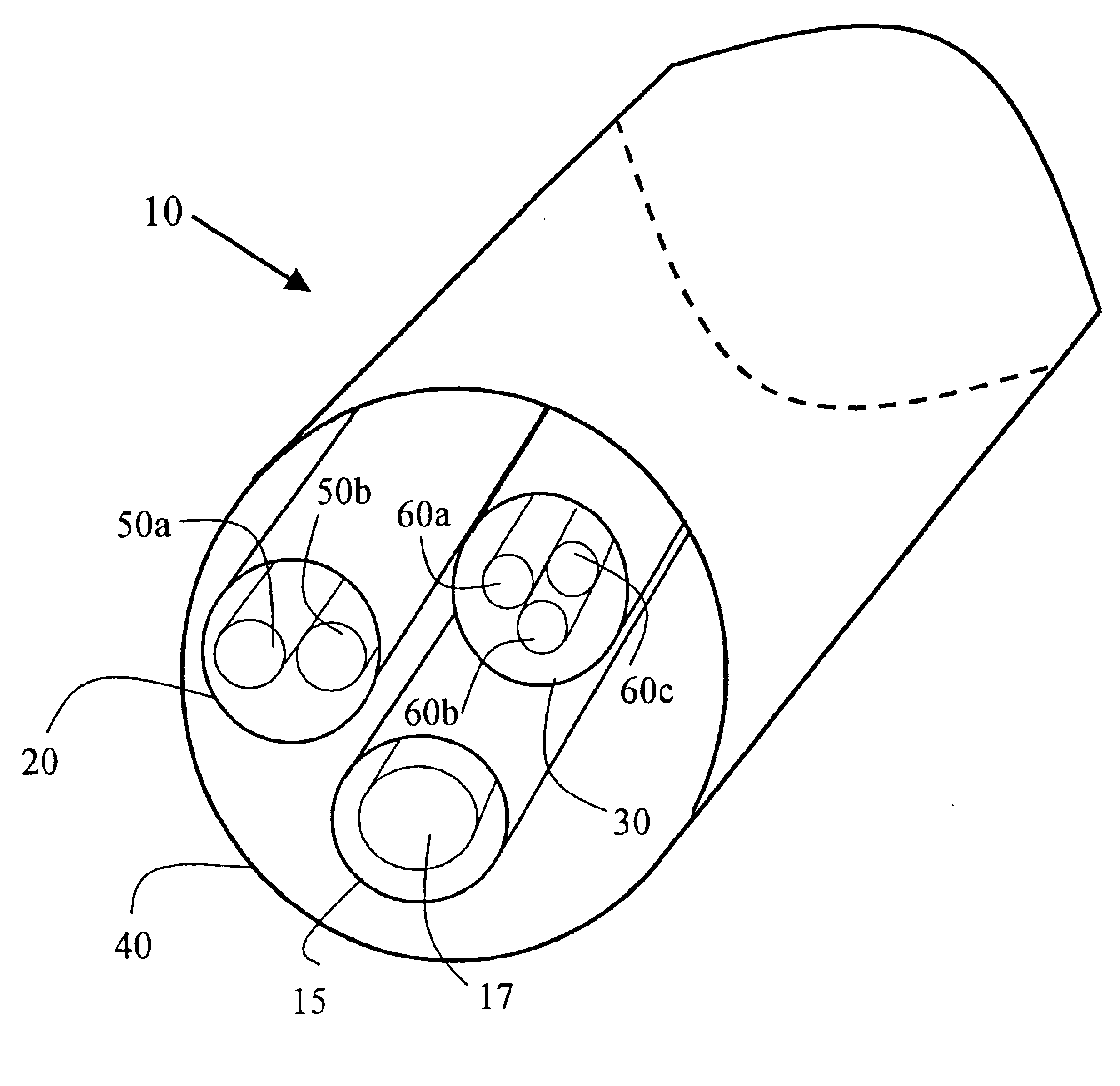

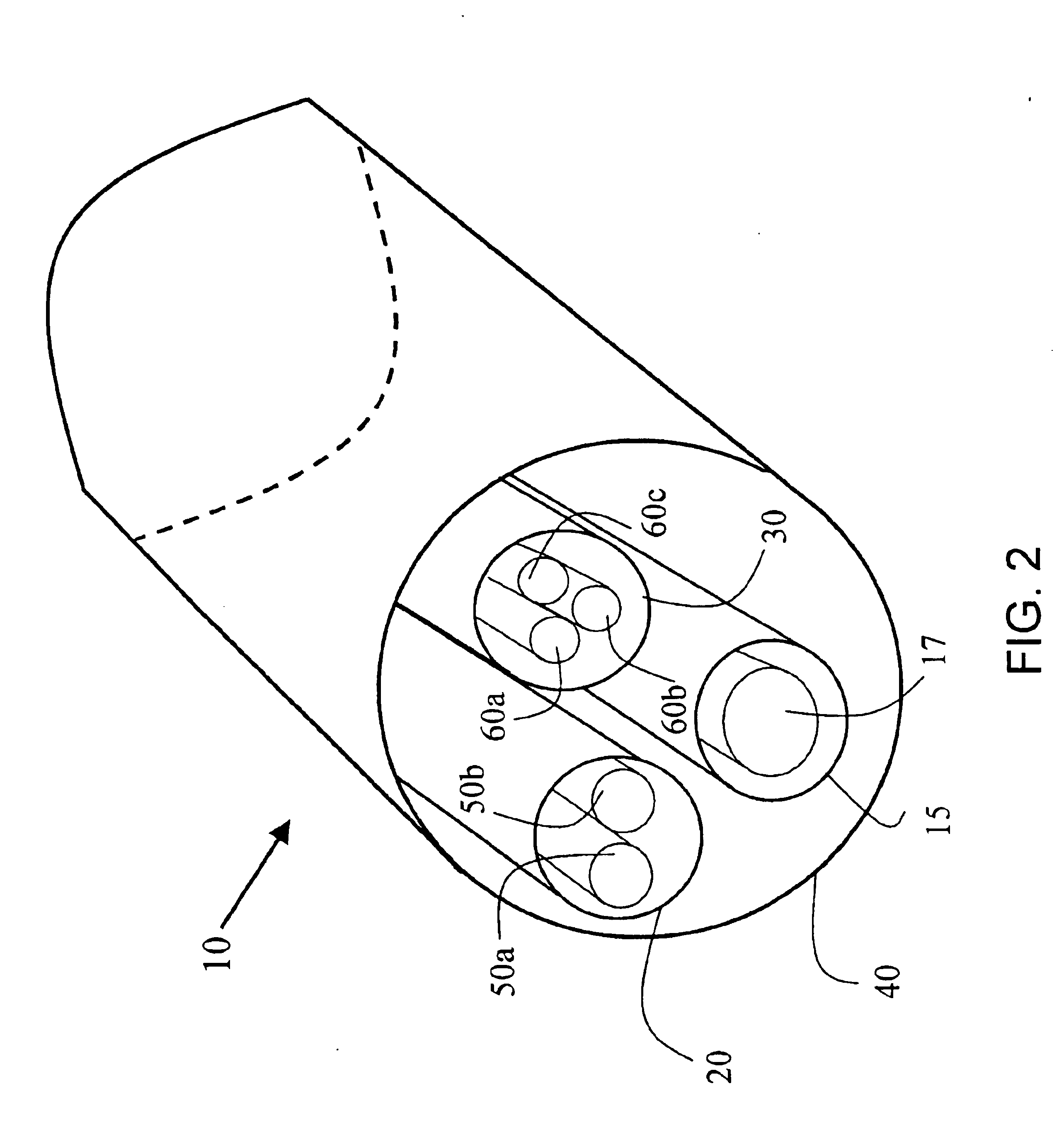

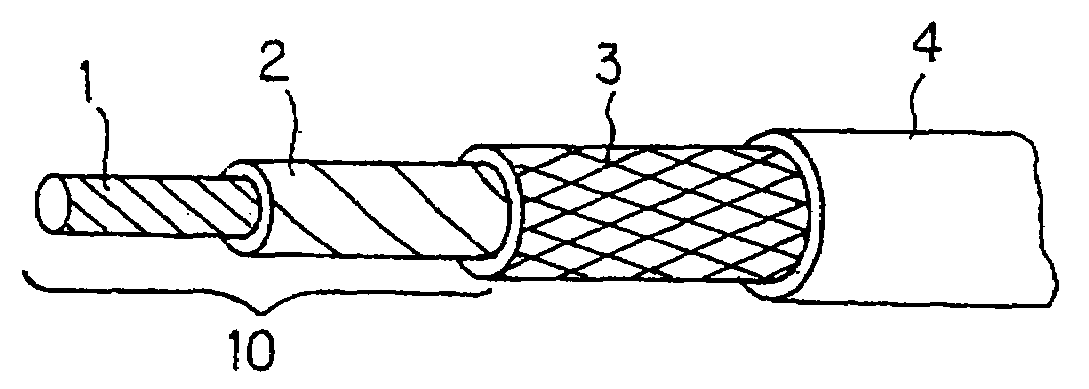

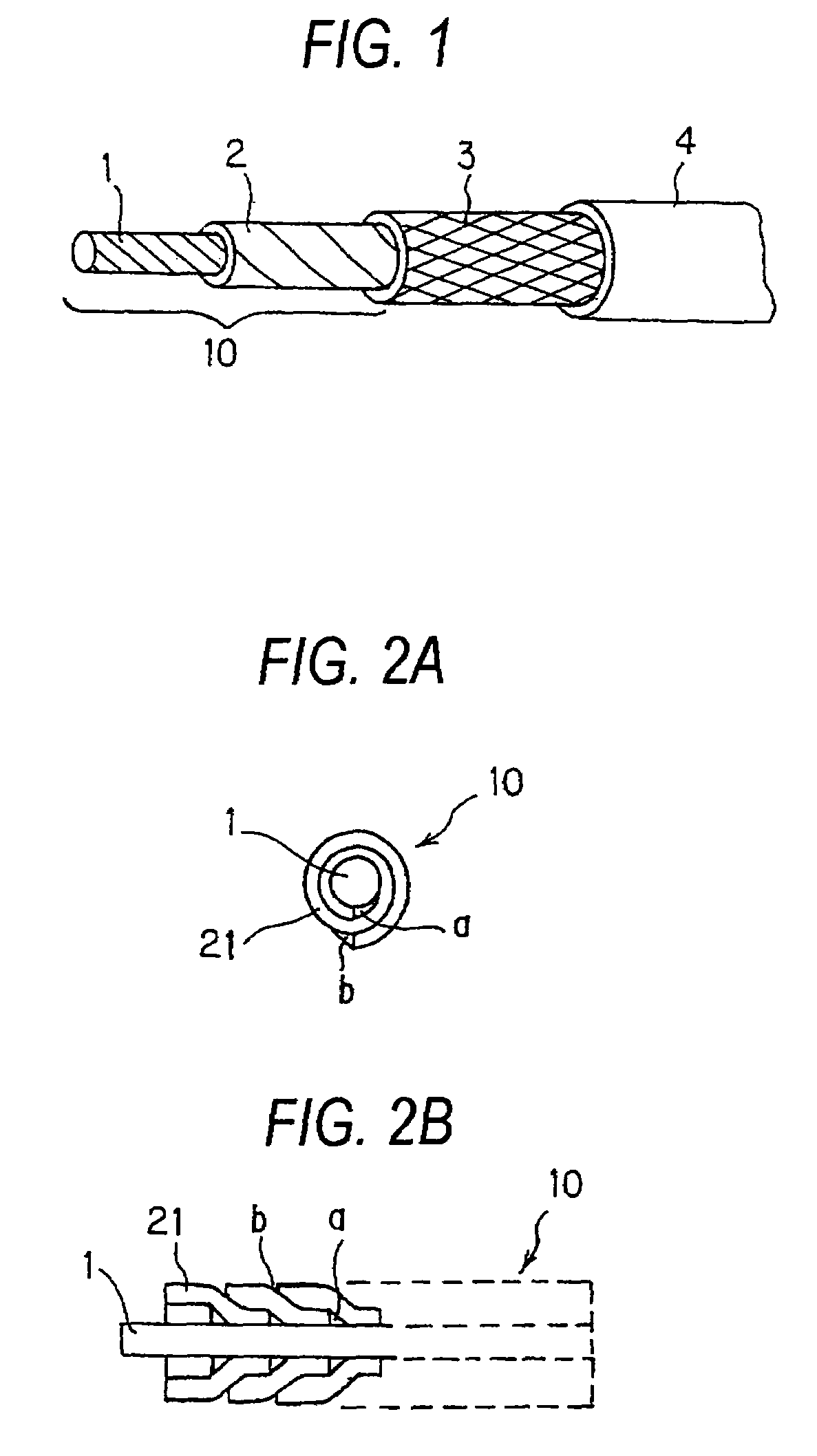

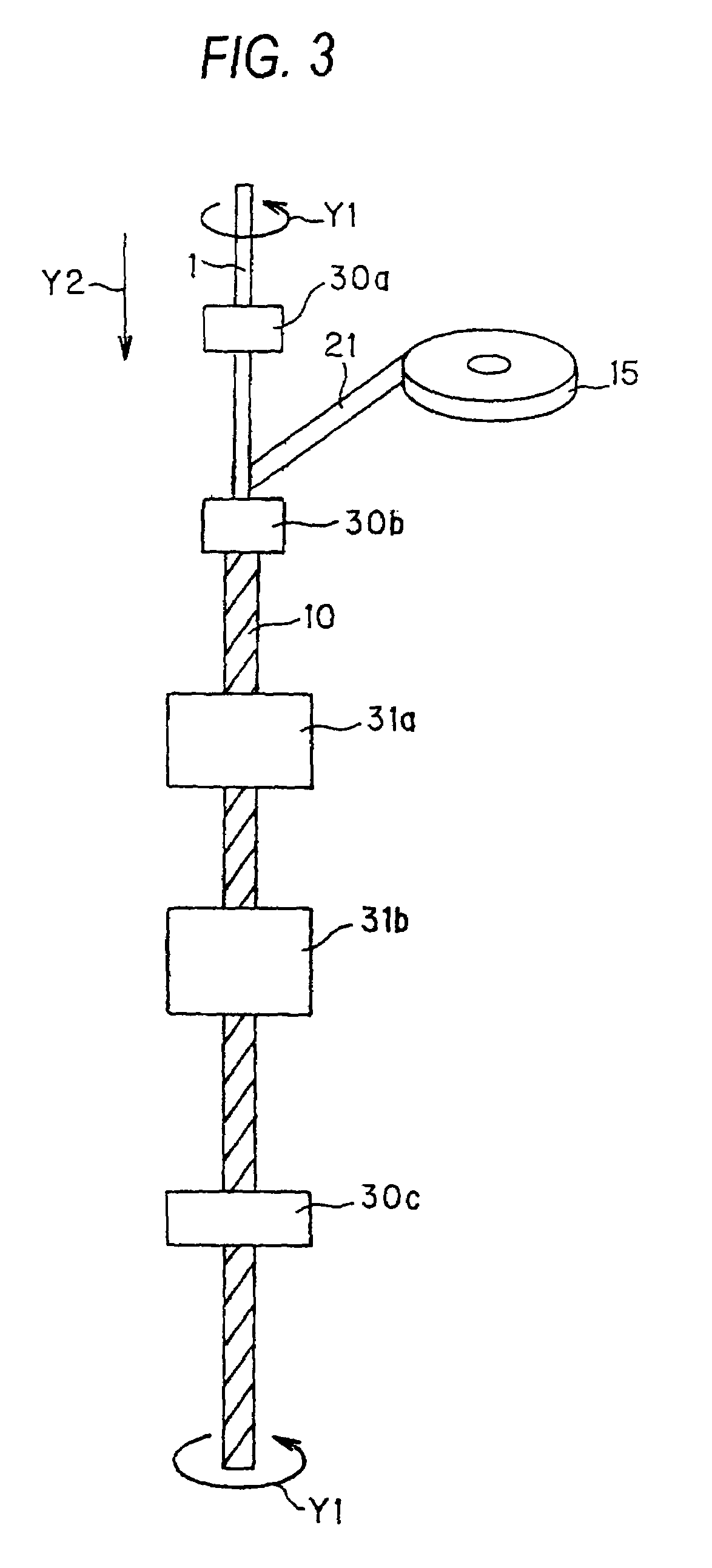

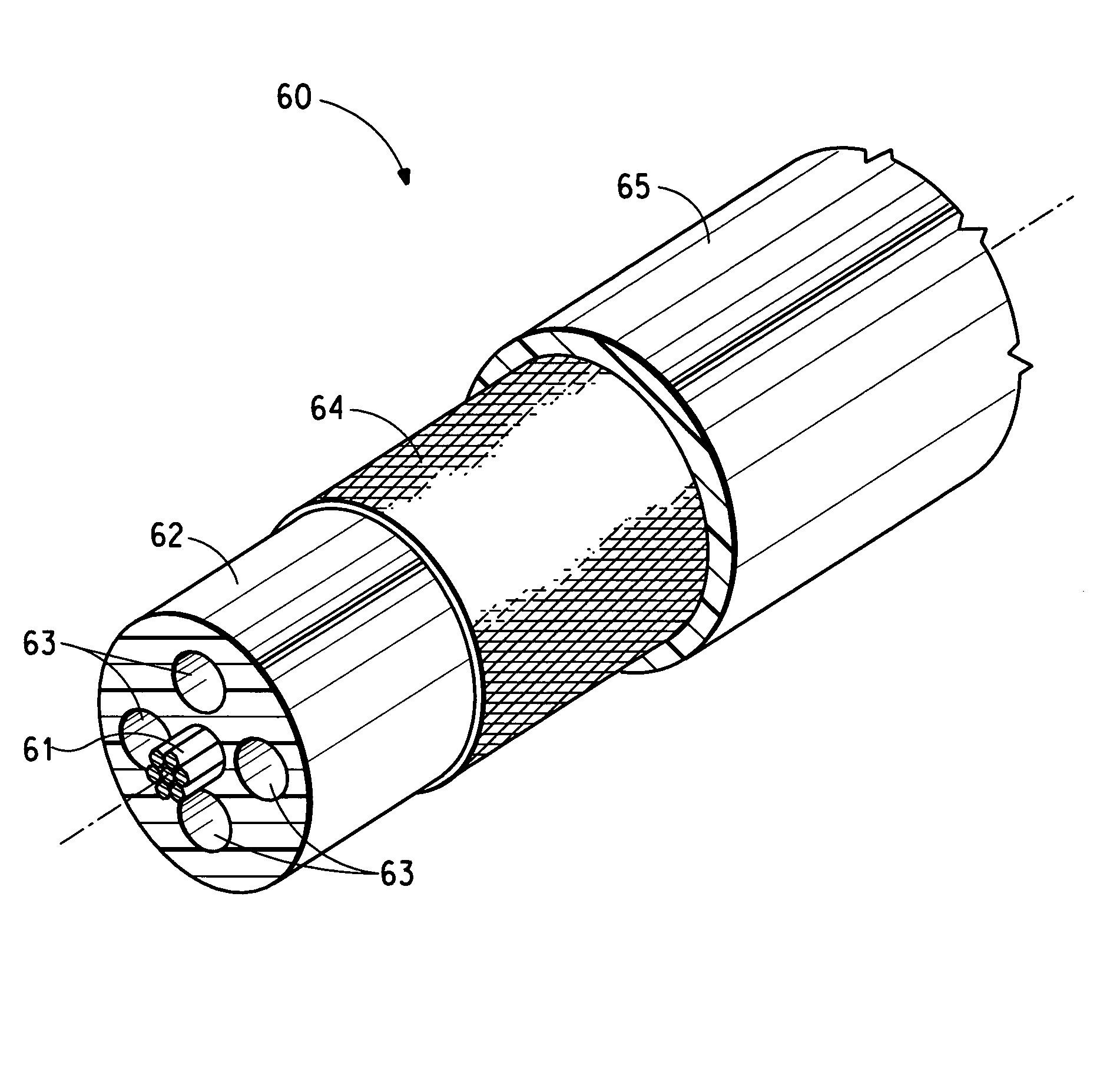

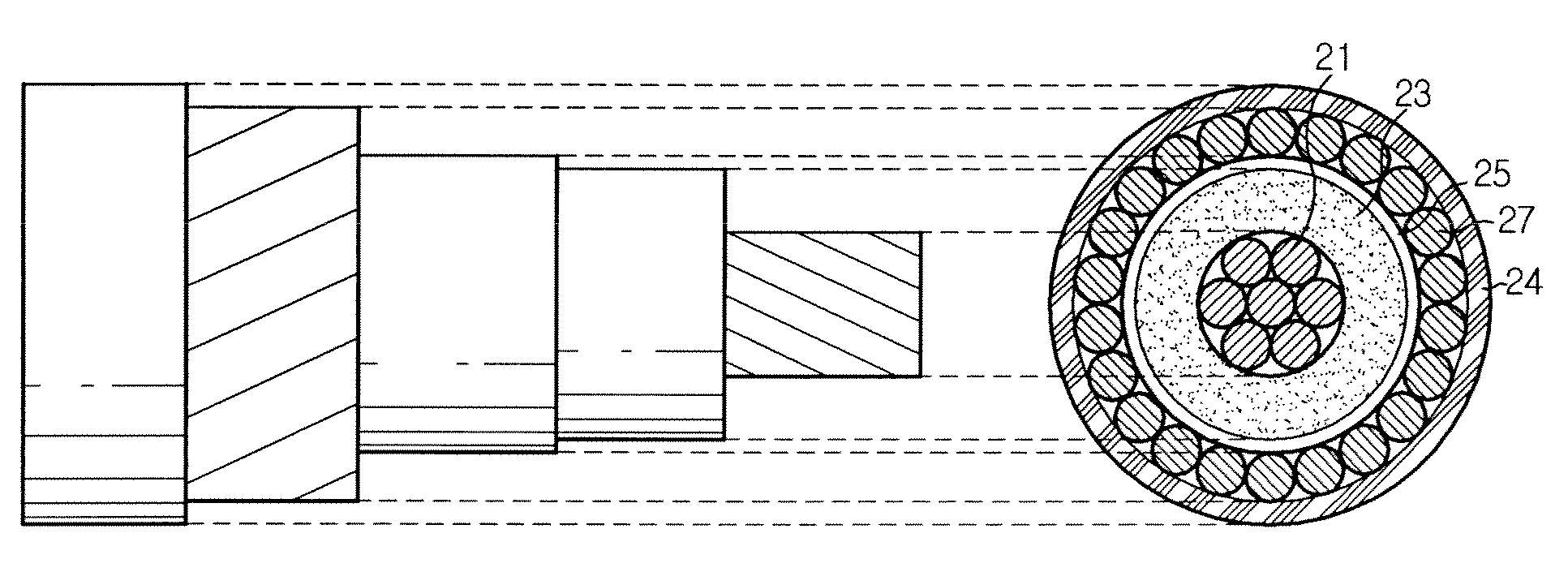

Extra-fine copper alloy wire, extra-fine copper alloy twisted wire, coaxial cable, multi-core cable and manufacturing method thereof

ActiveCN1988055AImprove heat resistanceHigh strength propertiesCoaxial cables/analogue cablesSingle bars/rods/wires/strips conductorsMulticore cableElectrical conductor

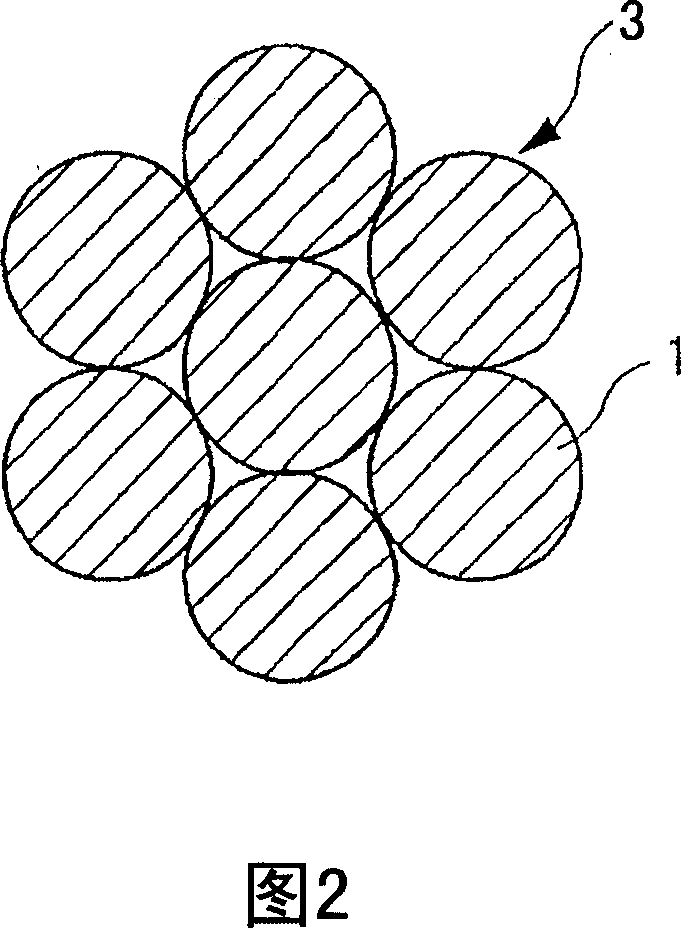

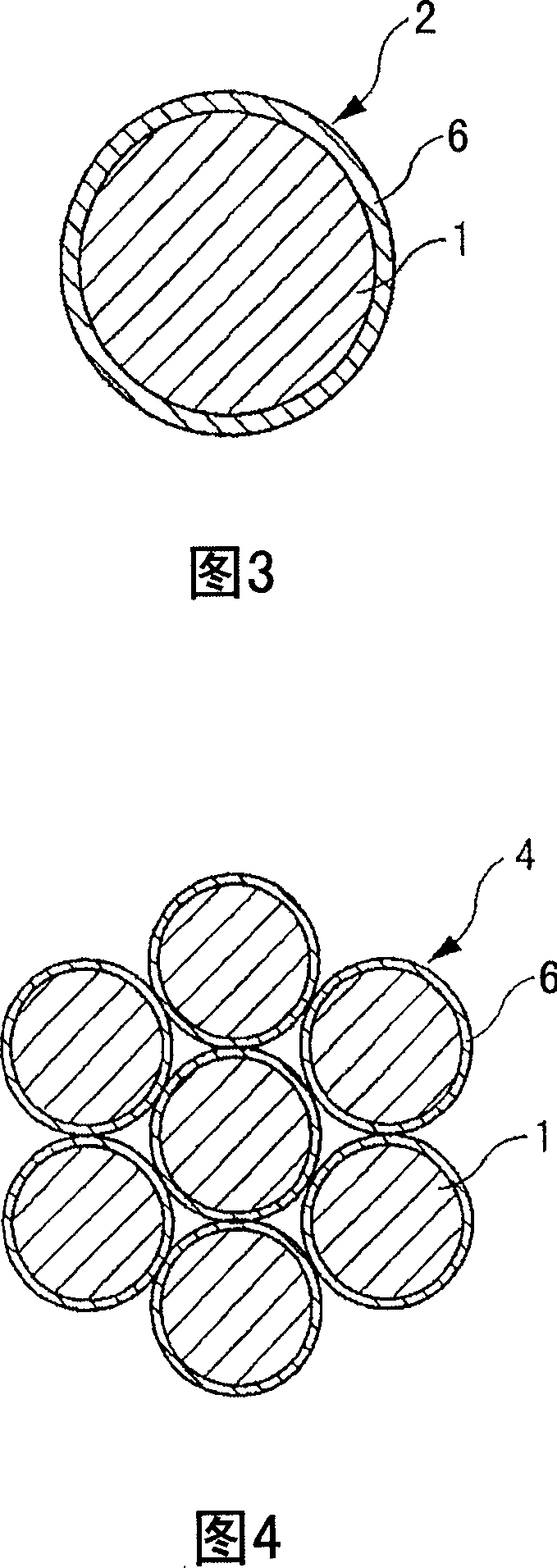

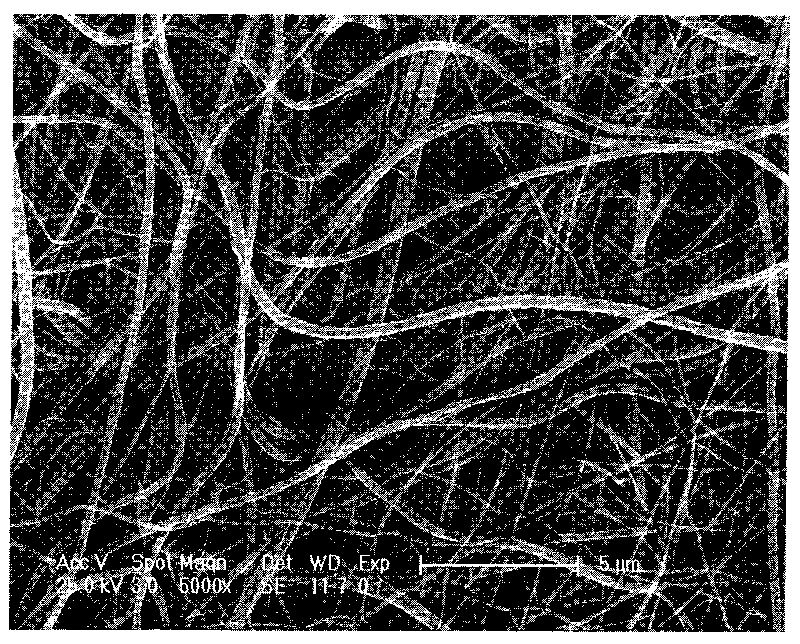

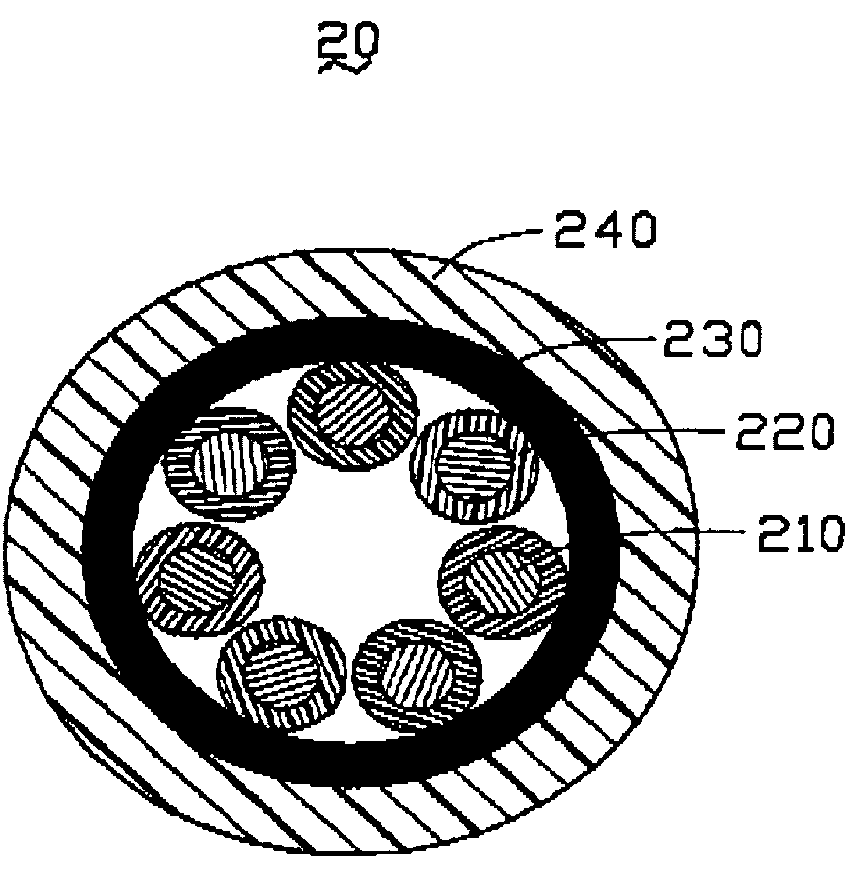

The object of the invention is to provide an extra-fine copper alloy wire, an extra-fine copper alloy twisted wire, an extra-fine insulated wire, a coaxial cable having high intensity, low resistance and high heat tolerance, their manufacturing method and a multicore cable thereof. The extra-fine copper alloy wire has 1 to 3 weight % of silver in the copper, a wire diameter less than 0.025 mm, and a tensile strength of more than 850 MPa, an electrical conductivity of more than 85% IACS after heat treatment; the coaxial cable (20A) is configured that, an inner conductor is formed by an extra-fine copper alloy twisted wire (3) twisted from seven extra-fine copper alloy wires (1), the inner conductor is then peripherally envelopped with a solid insulator (5a) to form an extra-fine insulated wire (10), a plurality of conductor wires (13) are winding in a screw shape on the periphery of the extra-fine insulated wire along a length direction of the extra-fine insulated wire to form an outer conductor (15), thereafter, the outer conductor is envenlopped with a protection layer (17).

Owner:HITACHI CABLE

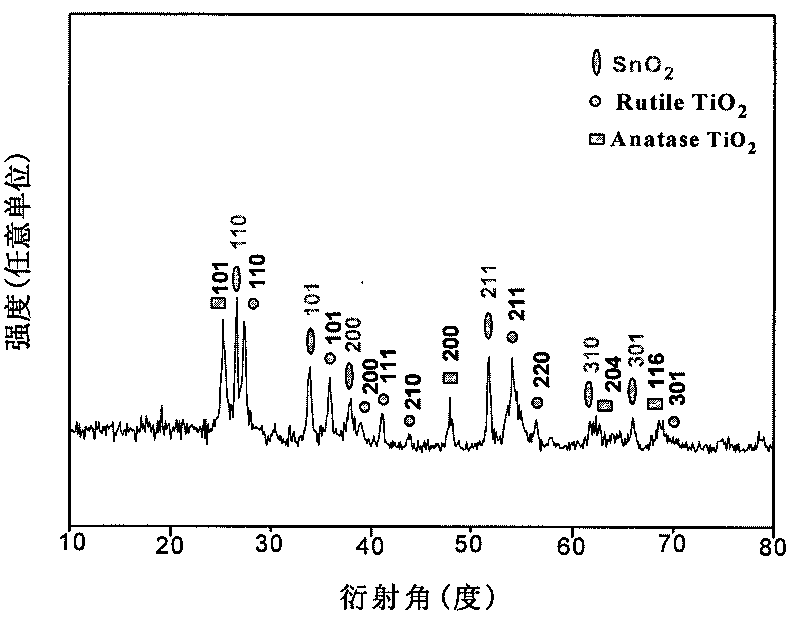

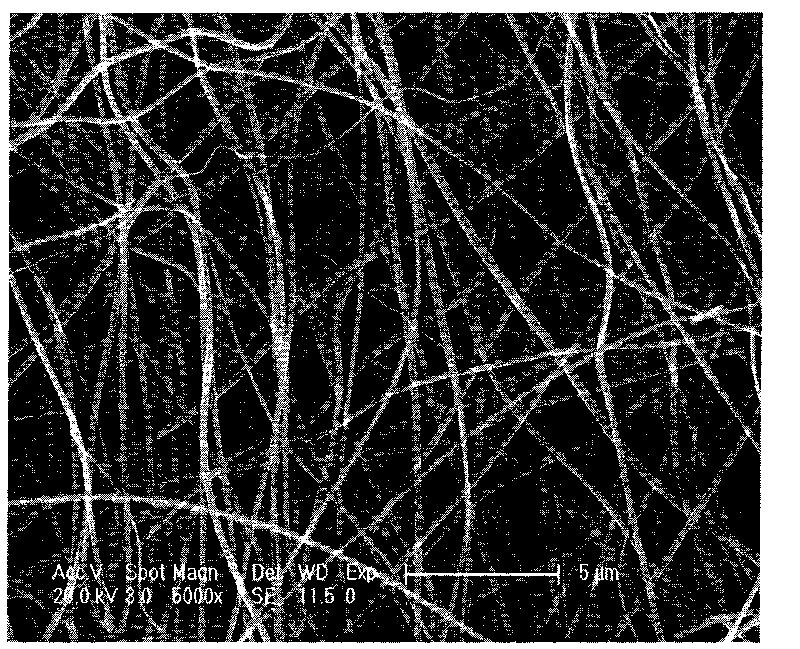

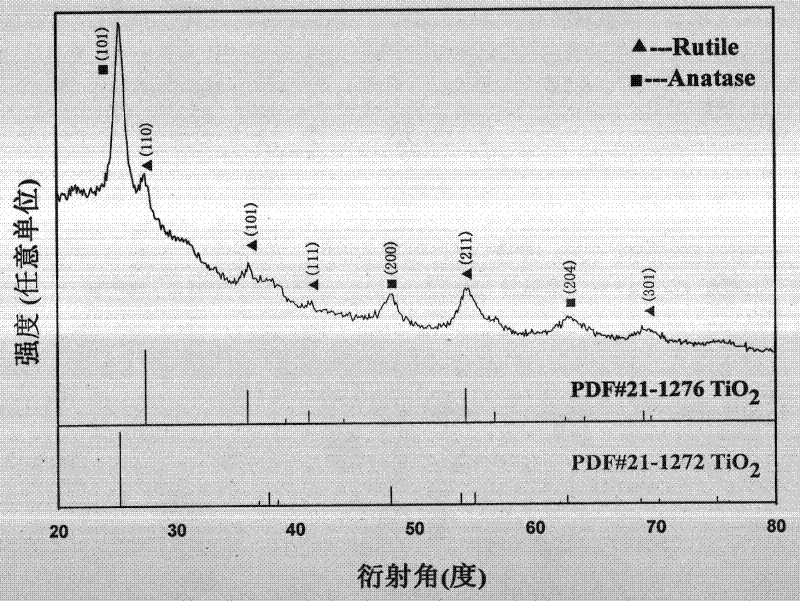

Method for preparing tin dioxide and titanium dioxide nano cable

The invention relates to a method for preparing a tin dioxide and titanium dioxide nano cable, which belongs to the technical field of nano material preparation. The method comprises the following three steps of: (1) preparation of spinning solution, adding stannic chloride and polyvinylpyrrolidone (PVP) into a mixed solvent of N, N-dimethylformamide and glycerin so as to prepare a core layer of the spinning solution, and adding PVP into a mixed liquid of butyl titanate and absolute ethyl alcohol so as to prepare a shell layer of the spinning solution; (2) preparation of (PVP+SnC14) and [PVP+Ti(OC4H9)] composite nano fiber by a coaxial electrostatic spinning technology under the condition that the voltage is 11.5-15 kV, the curing distance is 10-15 cm, the room temperature is 20-25 DEG C and the relative humidity is 45-50 percent; (3) preparation of SnO2 an TiO2 nano cable: carrying out heat treatment on the composite nano fiber to obtain the cable with cable diameter of 300-340 nm, core layer diameter of 200-220 nm, the shell layer thickness of 50-60 nm and length of more than 300 mu m.

Owner:CHANGCHUN UNIV OF SCI & TECH

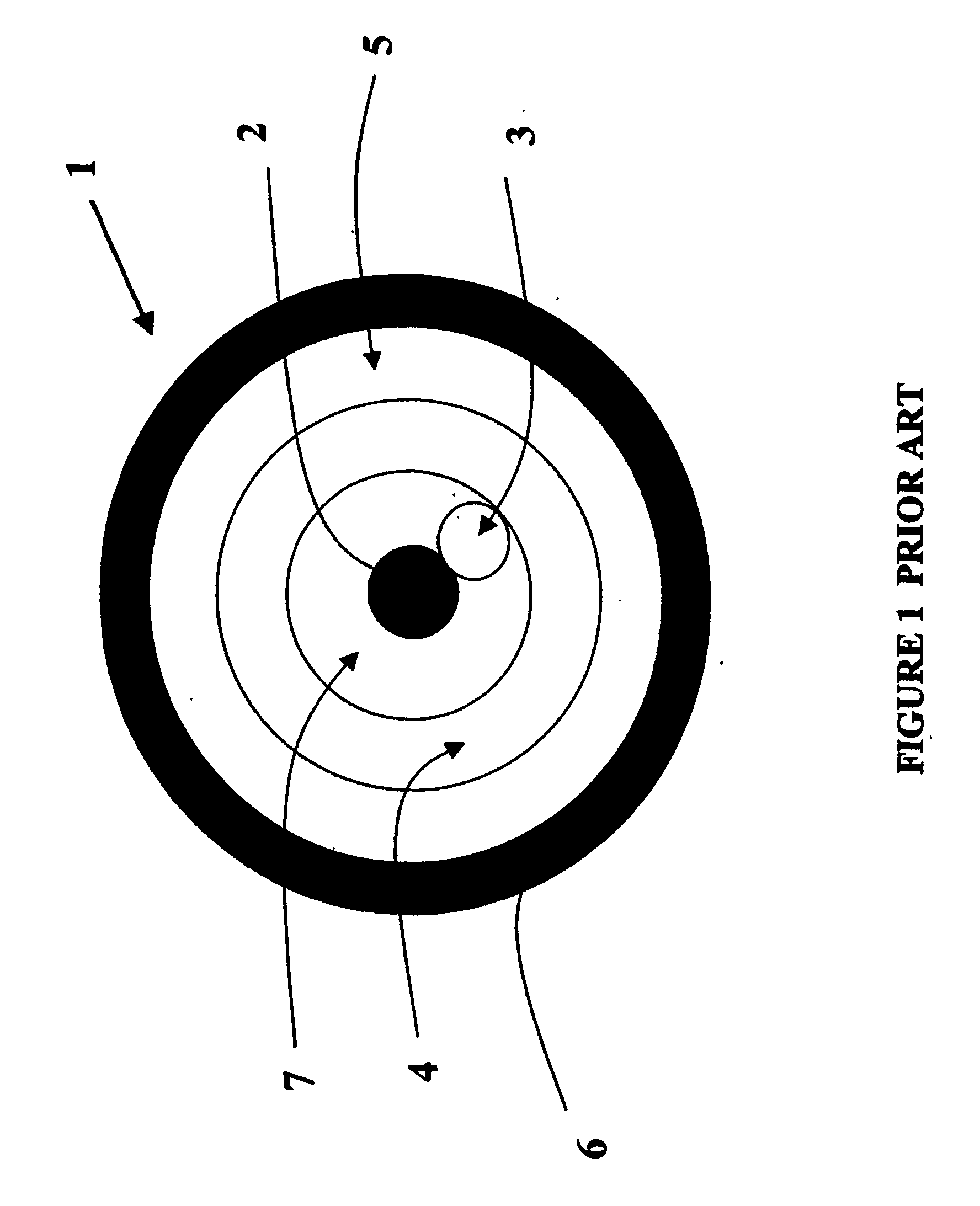

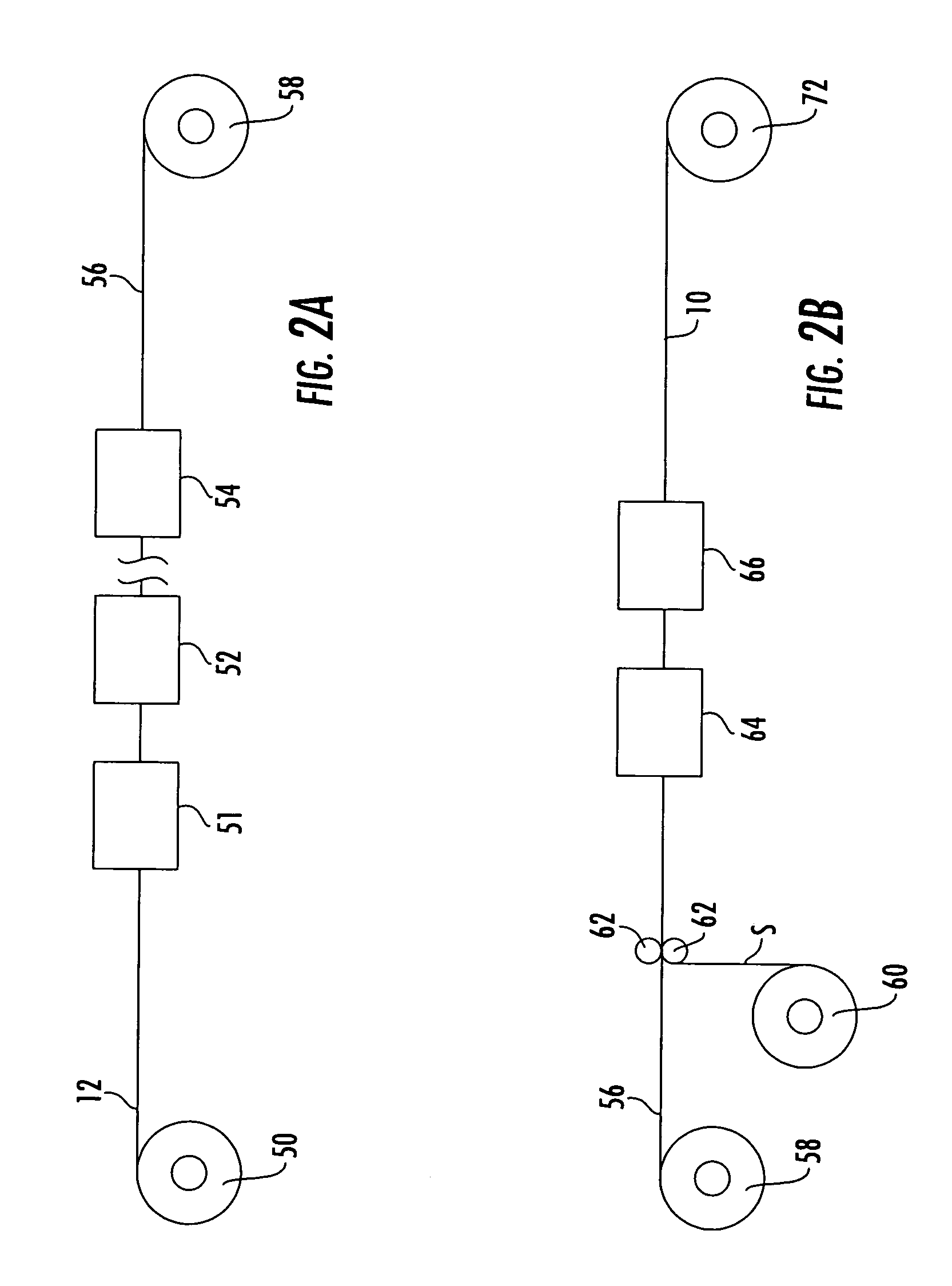

Triboelectric, Ranging, or Dual Use Security Sensor Cable and Method of Manufacturing Same

InactiveUS20080024297A1Easy constructionReadily availableCable insulation constructionInsulated cablesElectrical conductorTerminal voltage

The present invention provides an inexpensive security sensor cable, a method for manufacturing of same and an overall security system for using that sensor cable. The sensor cable consists of a central conductor, an air separator, a polyethylene dielectric tube, an outer conductor and an outer protective jacket. The central conductor is loosely centered in the coaxial cable and thus freely movable relative to the dielectric tube. The sensor cable has application either in a passive sensing system or in an active ranging sensing system to determine the location of an intrusion along the cable. For the passive sensing function, when the center conductor moves, it contacts a suitable dielectric material from the triboelectric series, such as polyethylene, which can be processed to produce a charge transfer by triboelectric effect that is measurable as a terminal voltage. In an active system, the central conductor moves within the dielectric in response to a vibration to provide an impedance change that can be sensed. Conventional radio grade cable may be modified in its construction by removing its dielectric thread to manufacture the sensor cable, thus enabling the center conductor to move freely in the air gap within the dielectric tube. An inexpensive method of manufacturing sensor cable is provided as the cable parts are readily available. Such a sensor cable is advantageous in that the passive triboelectric properties of the cable, in response to a disturbance, can provide a larger voltage response over prior art cables.

Owner:SENSTAR CORP

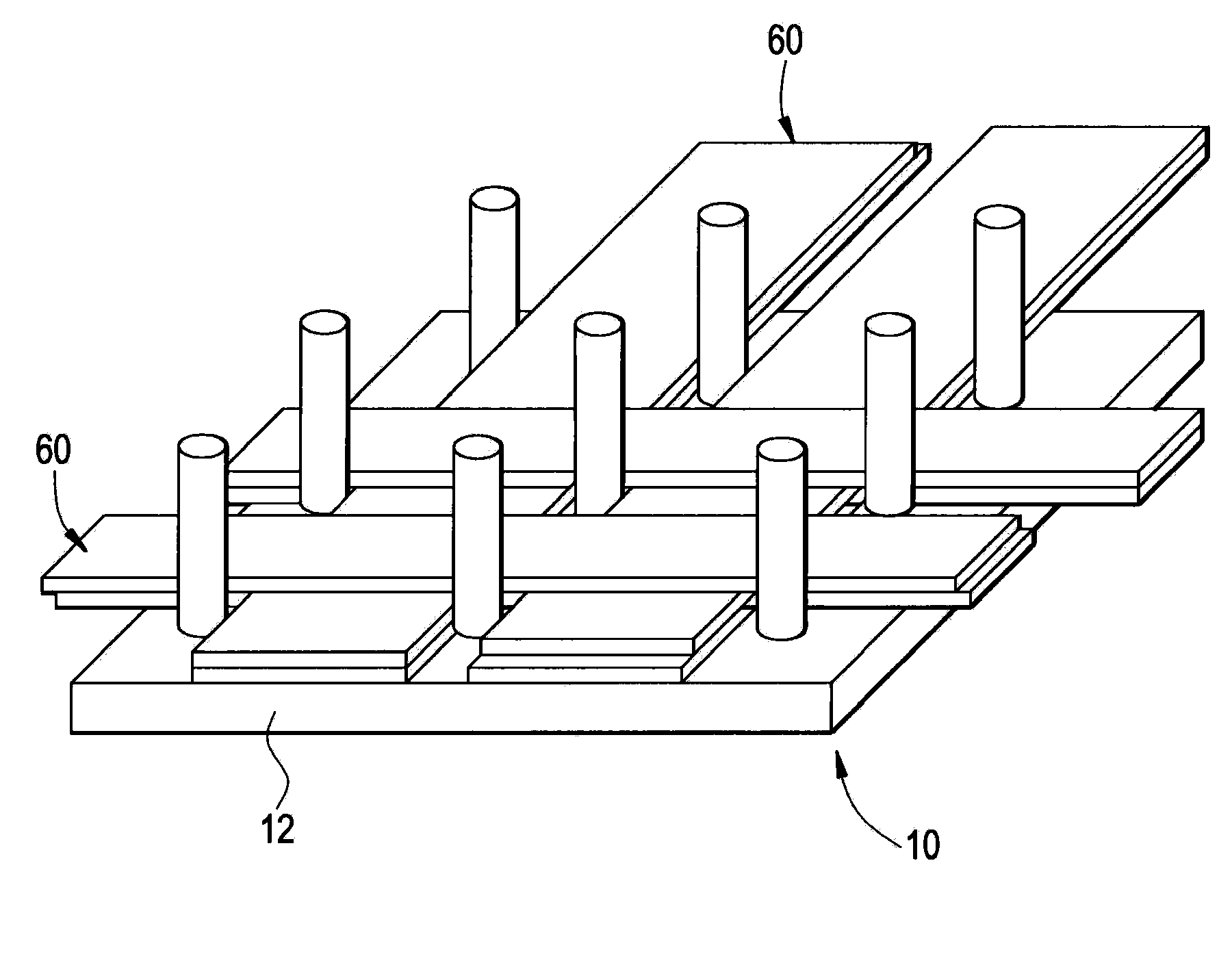

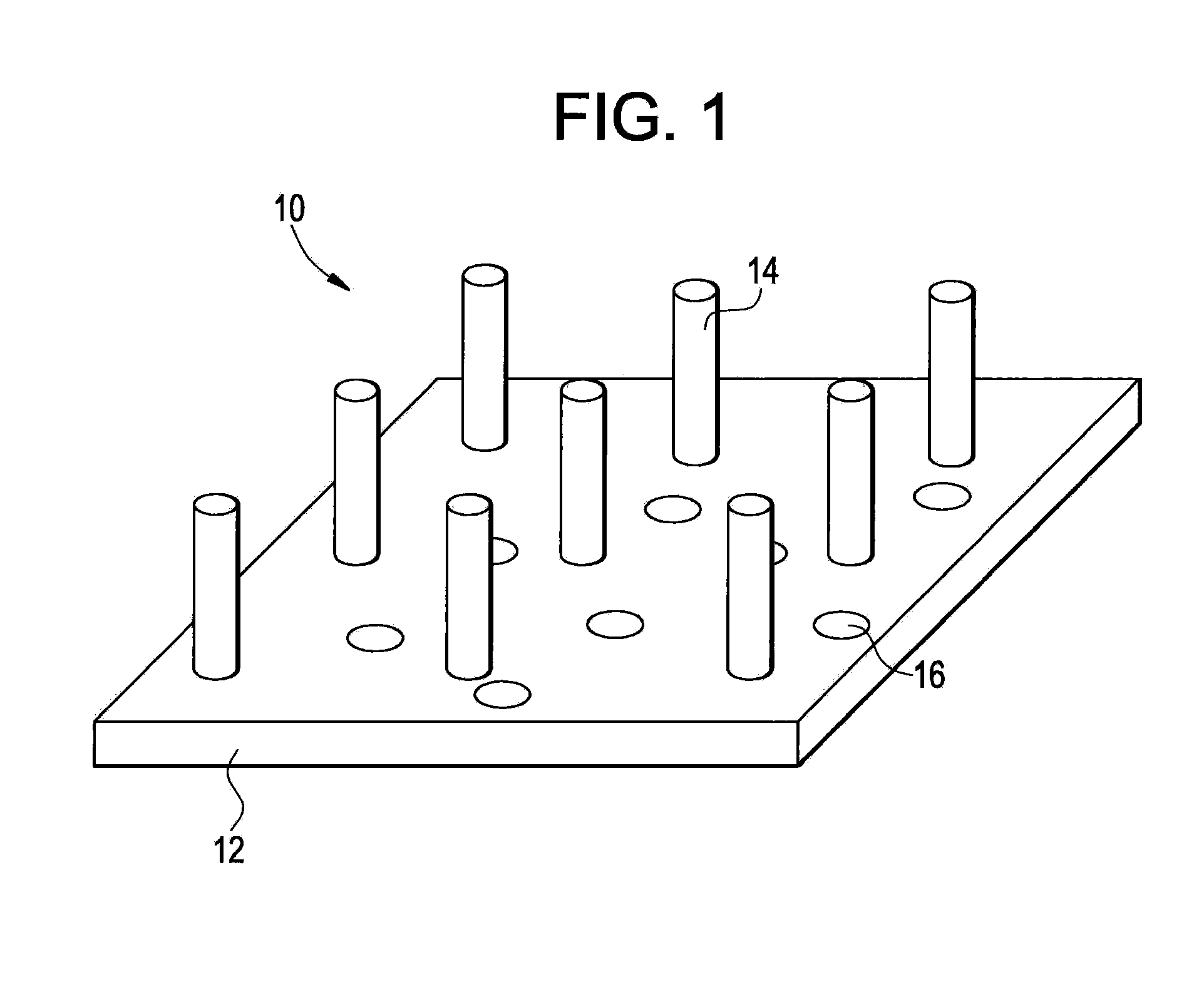

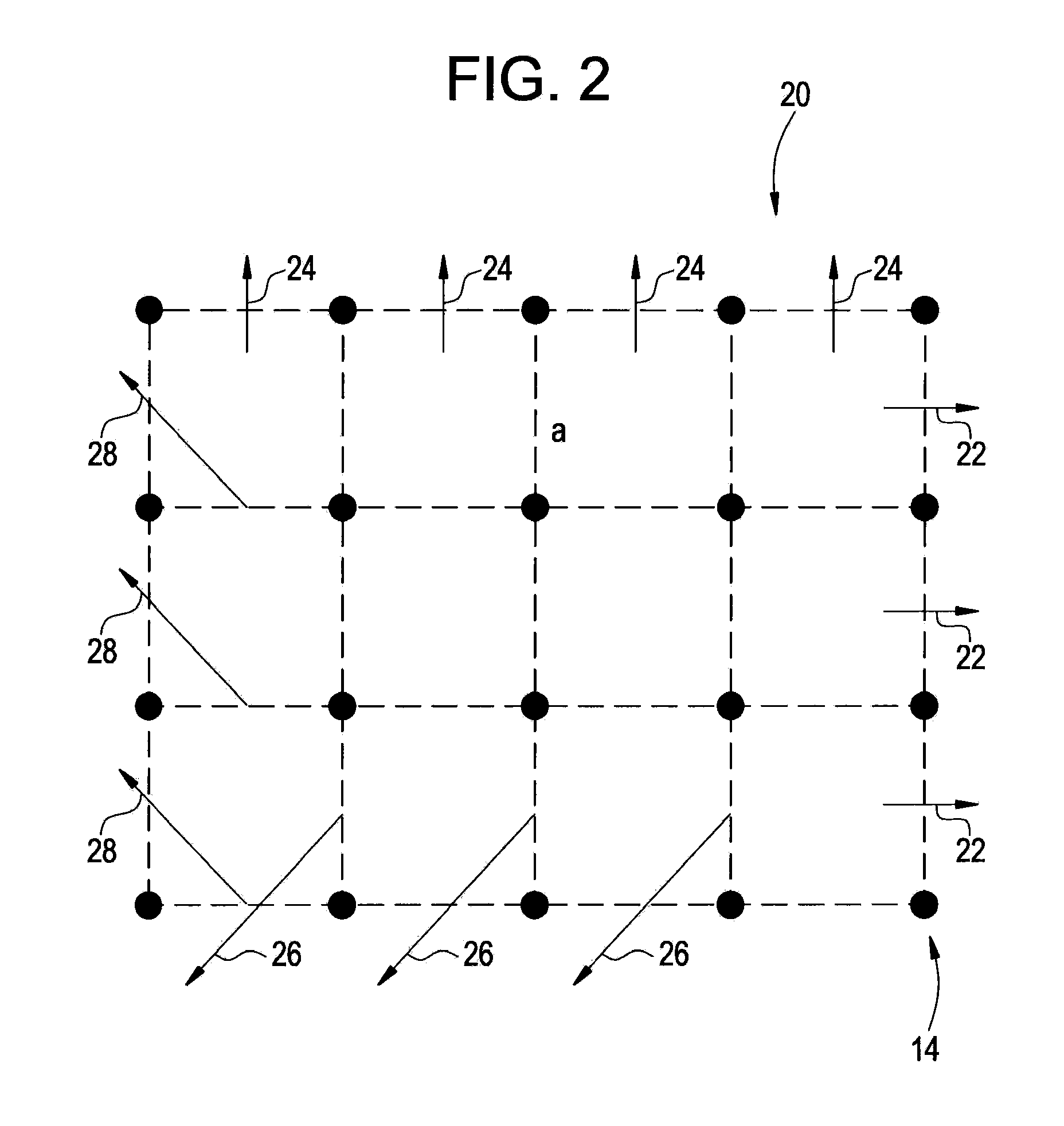

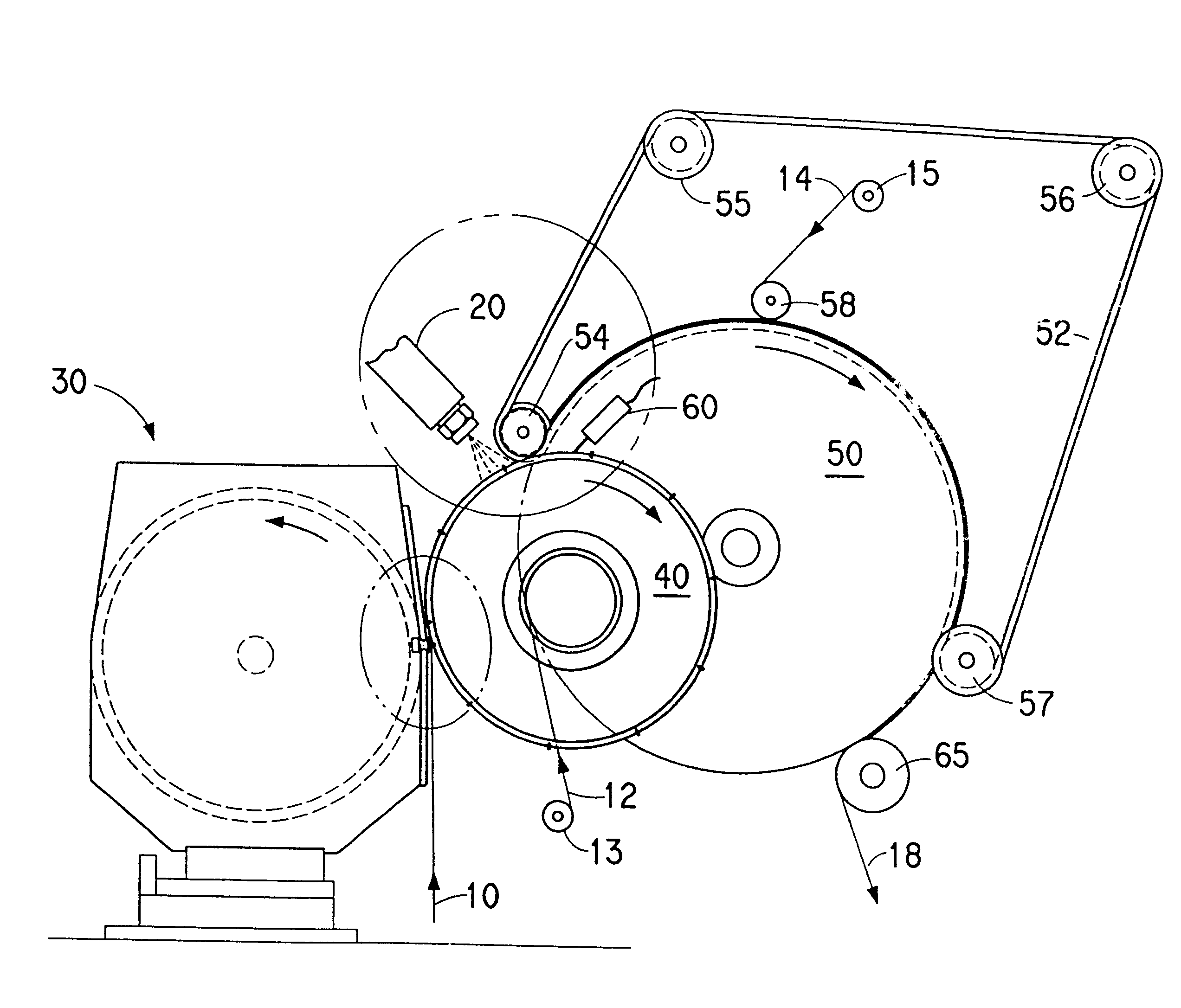

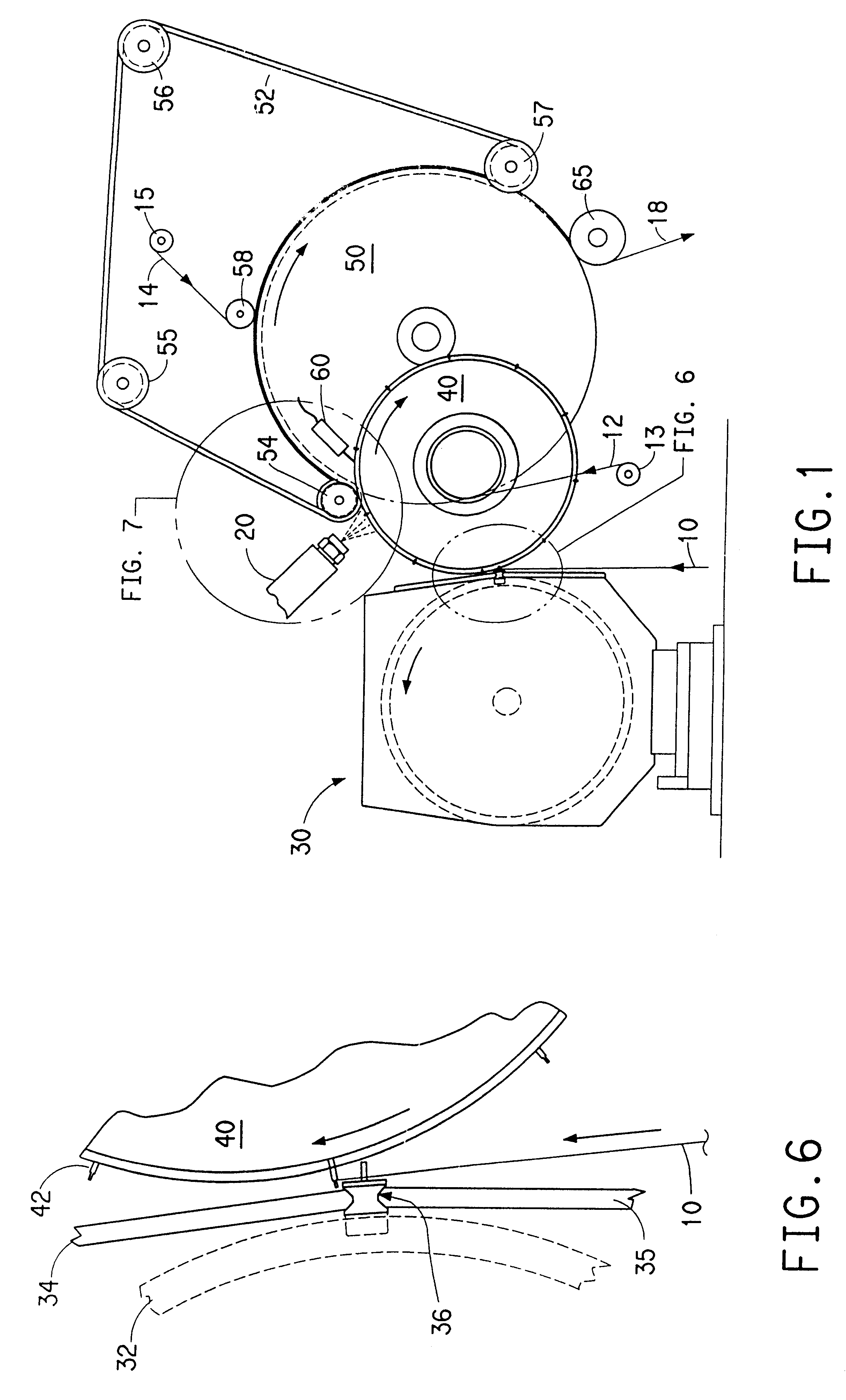

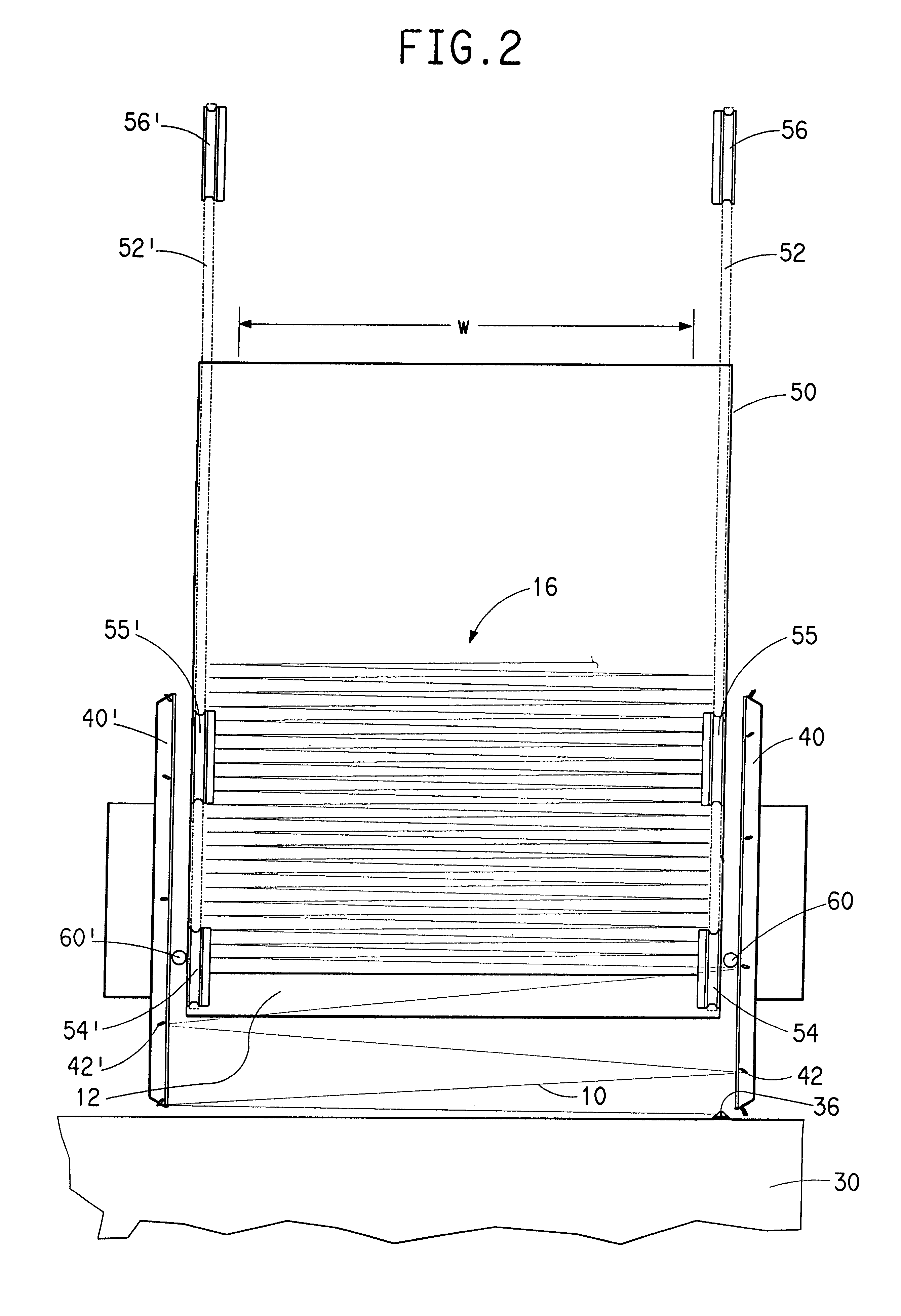

Method of Manufacture of Composite Laminates, an Assembly Therefor, and Related Articles

A method is described for making a composite laminate formed by curing a stacked structure comprising at least two layers of strips of fibrous material impregnated with resin, wherein the strips in adjacent layers have different directional orientations. An apparatus is provided for simultaneously separating a band of fibrous material impregnated with resin into strips and depositing the strips between adjacent pin rows of a pinmat to form the stacked structure.

Owner:GENERAL ELECTRIC CO

Integrated sensor cable for ranging

Owner:SENSTAR STELLAR CORP

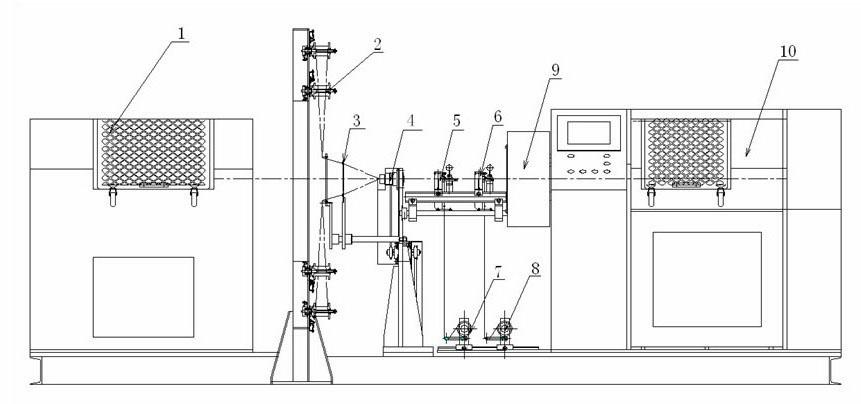

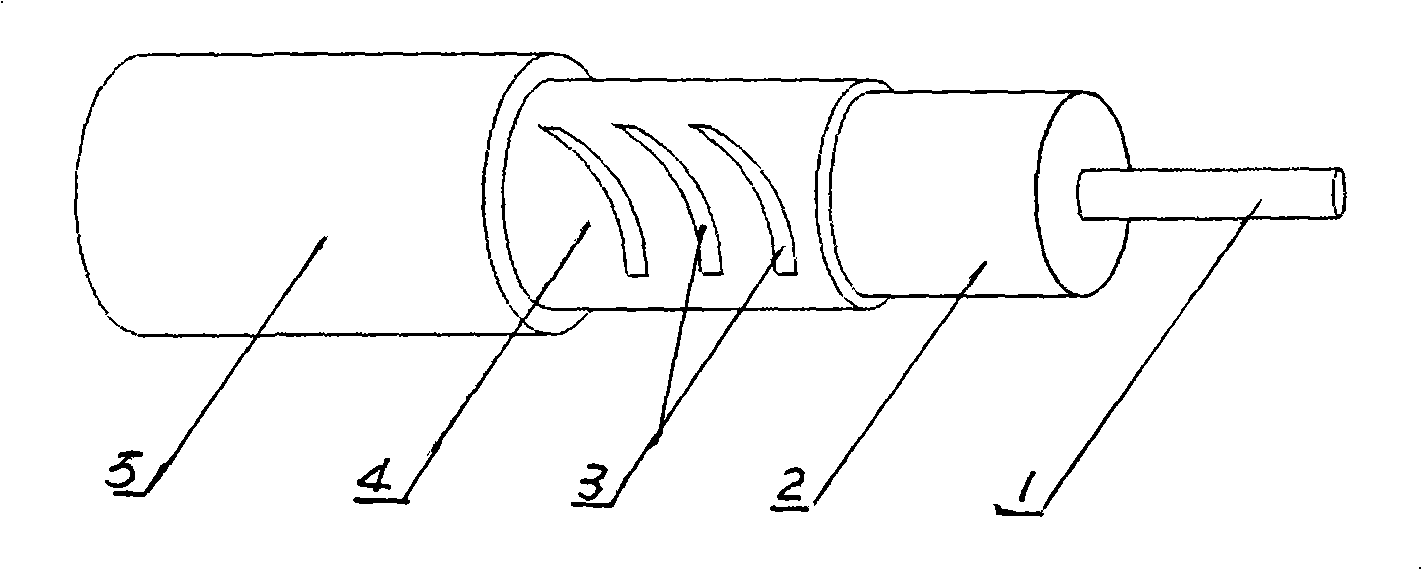

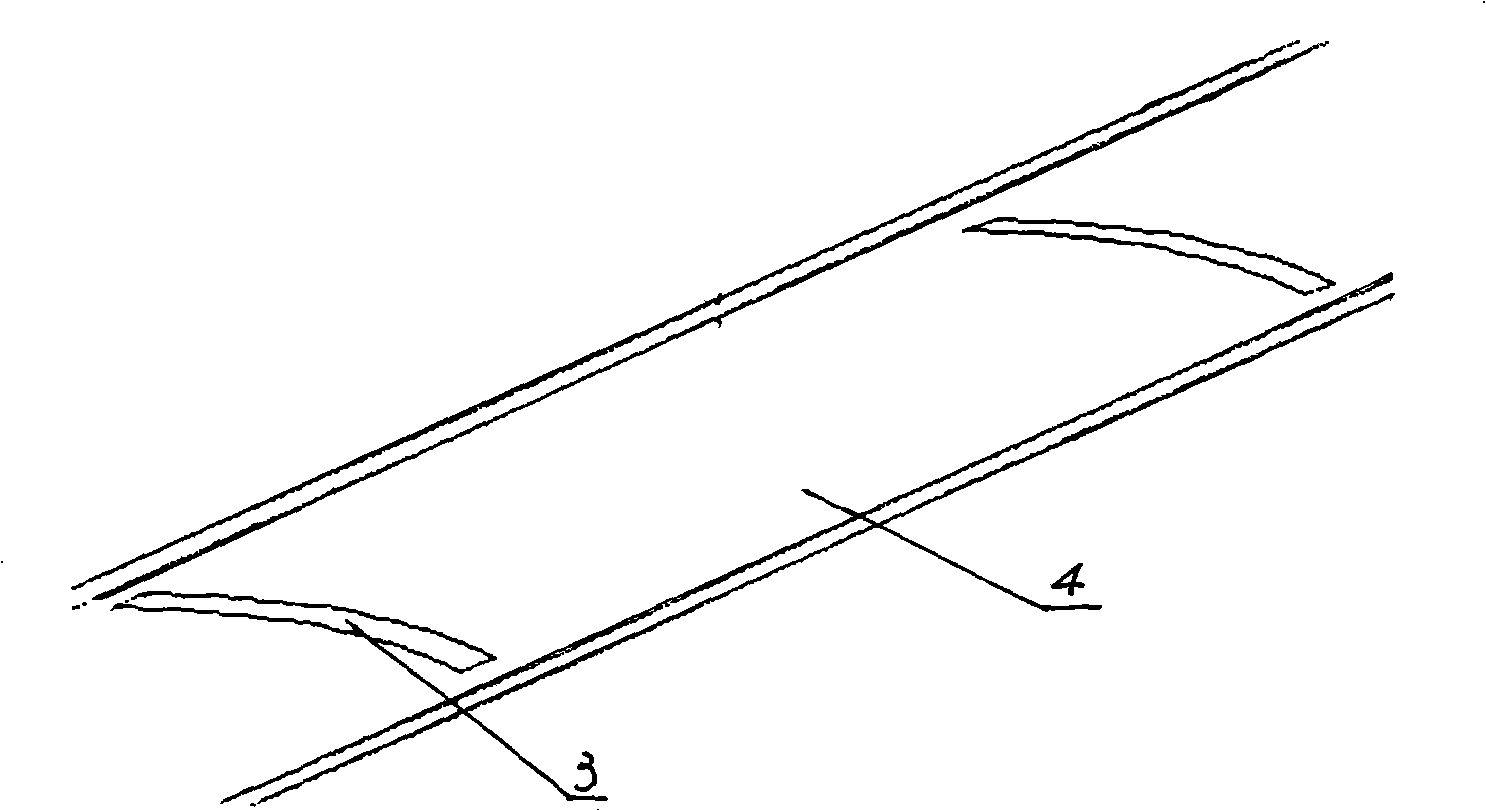

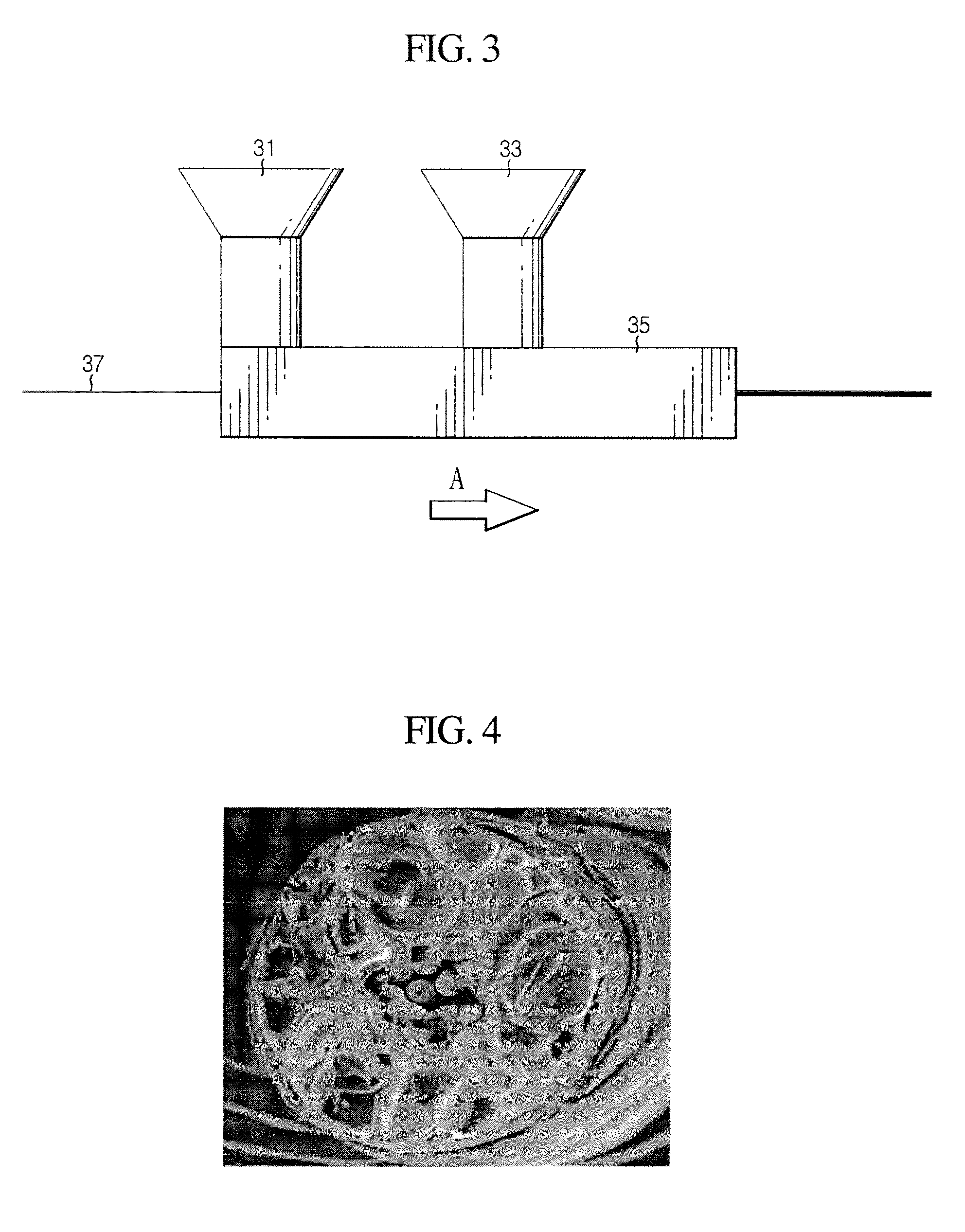

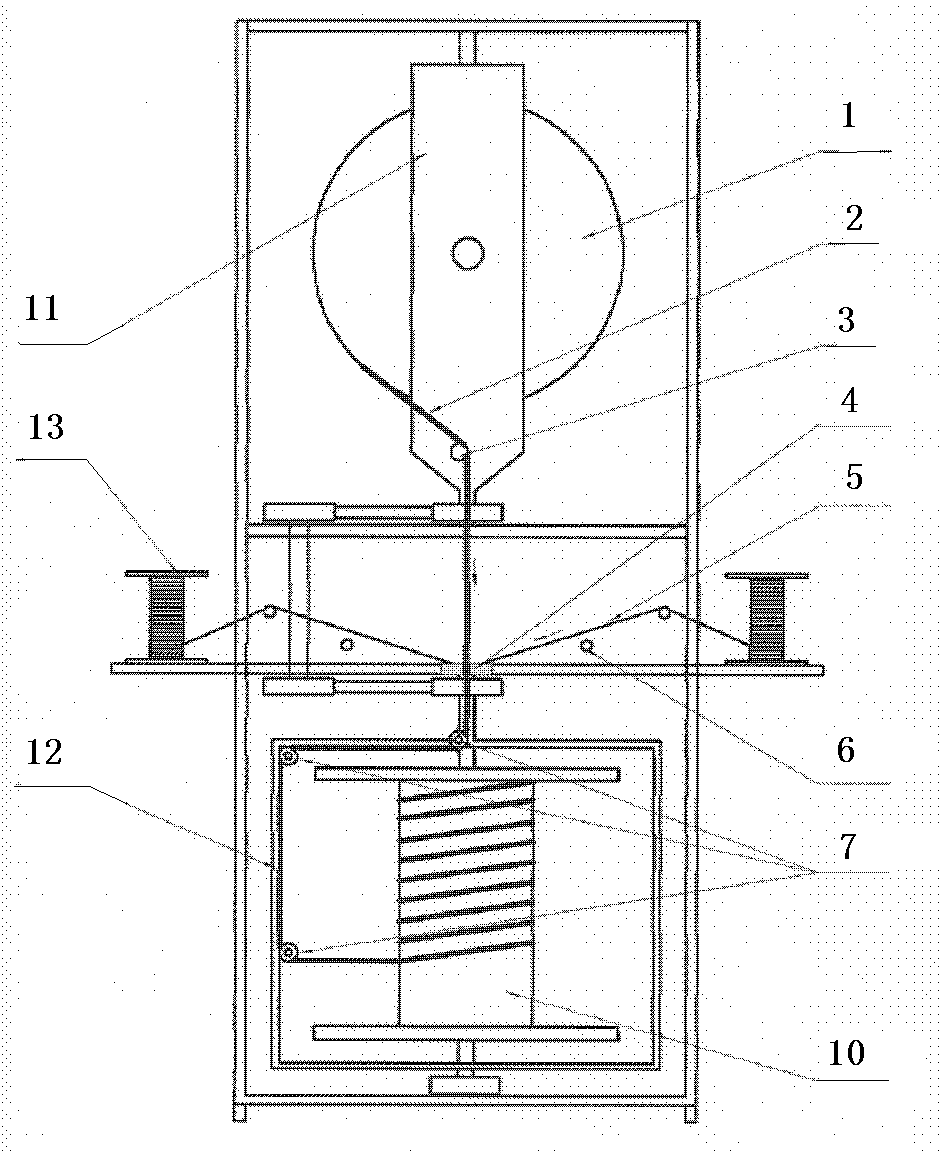

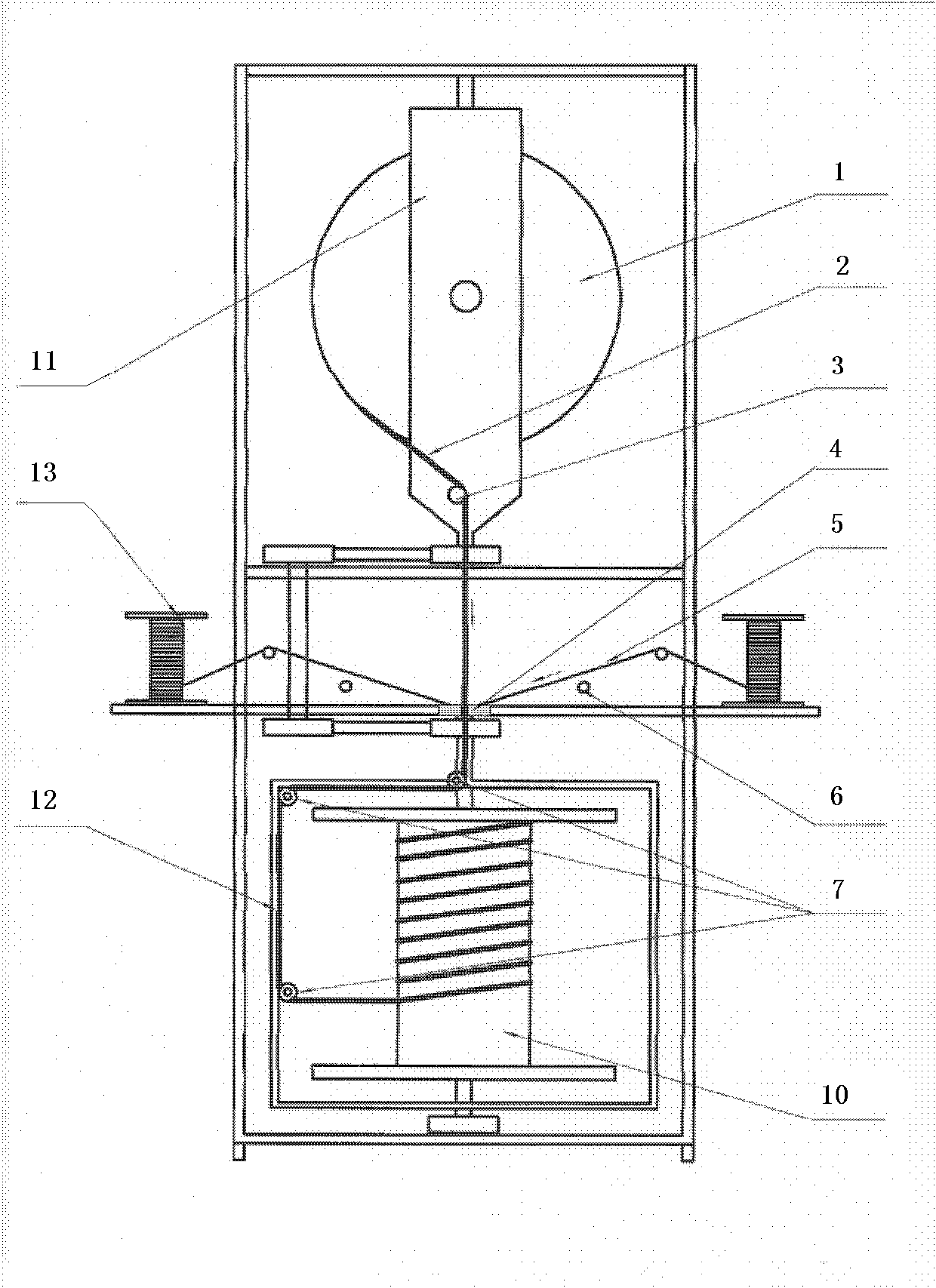

Horizontal winding machine

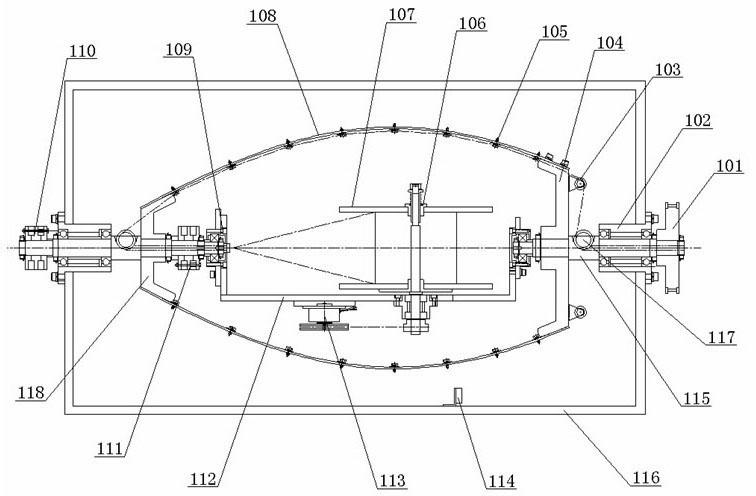

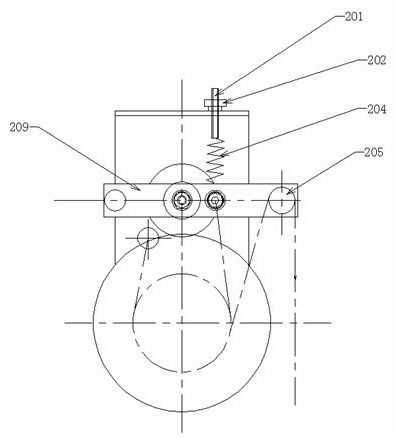

ActiveCN102136324ALarge operating spaceEasy to operateManufacturing co-axial cablesInsulating conductors/cablesWinding machineCoaxial cable

The invention relates to equipment for producing cables and wires, in particular to a winding machine for winding and belting during ultra-thin coaxial cable production. The horizontal winding machine comprises a backtwist unwinding machine (1), a tessellation line unwinding machine (2), an incoming line division board (3), a die hole (4), a conductor belting device (5), an insulation belting device (6), a leading machine (9) and a recoiling machine (10) which are arranged sequentially in the horizontal direction; the central lines of the backtwist unwinding machine (1), the tessellation line unwinding machine (2), the incoming line division board (3), the die hole (4), the conductor belting device (5), the insulation belting device (6), the leading machine (9) and the recoiling machine (10) are positioned on the same horizontal line; a first belt uncoiling device (7) is arranged below the conductor belting device (5); and a second belt uncoiling device (8) is arranged below the insulation belting device (6). The horizontal winding machine has the advantages of stably unwinding tessellation lines, finishing two working procedures of slantways belting and winding simultaneously, along with convenient operation, adjustable winding distance and high production efficiency.

Owner:SHENYU COMM TECH

Guarded coaxial cable assembly

ActiveUS8308505B2Line/current collector detailsTwo pole connectionsCoaxial cableMechanical engineering

Owner:HOLLAND ELECTRONICS

Methods of manufacturing electrical cables

ActiveUS7934311B2Increase coverageEliminate spaceLine/current collector detailsPower cables with screens/conductive layersElectrical conductorPolymer insulation

Owner:SCHLUMBERGER TECH CORP

Coaxial cable

ActiveUS20080251274A1Great shield effectivenessSuitable for low-cost mass productionCable conductor constructionPower cables with screens/conductive layersCoaxial cableCarbon nanotube

A coaxial cable (10) includes at least one conducting wire (110), at least one insulating layer (120) coating a respective conducting wire (110), at least one shielding layer (130) surrounding the at least one insulating layer (120), and a single sheath (140) wrapping the at least one shielding layer (130). The shielding layer (130) is a carbon nanotube film.

Owner:TSINGHUA UNIV +1

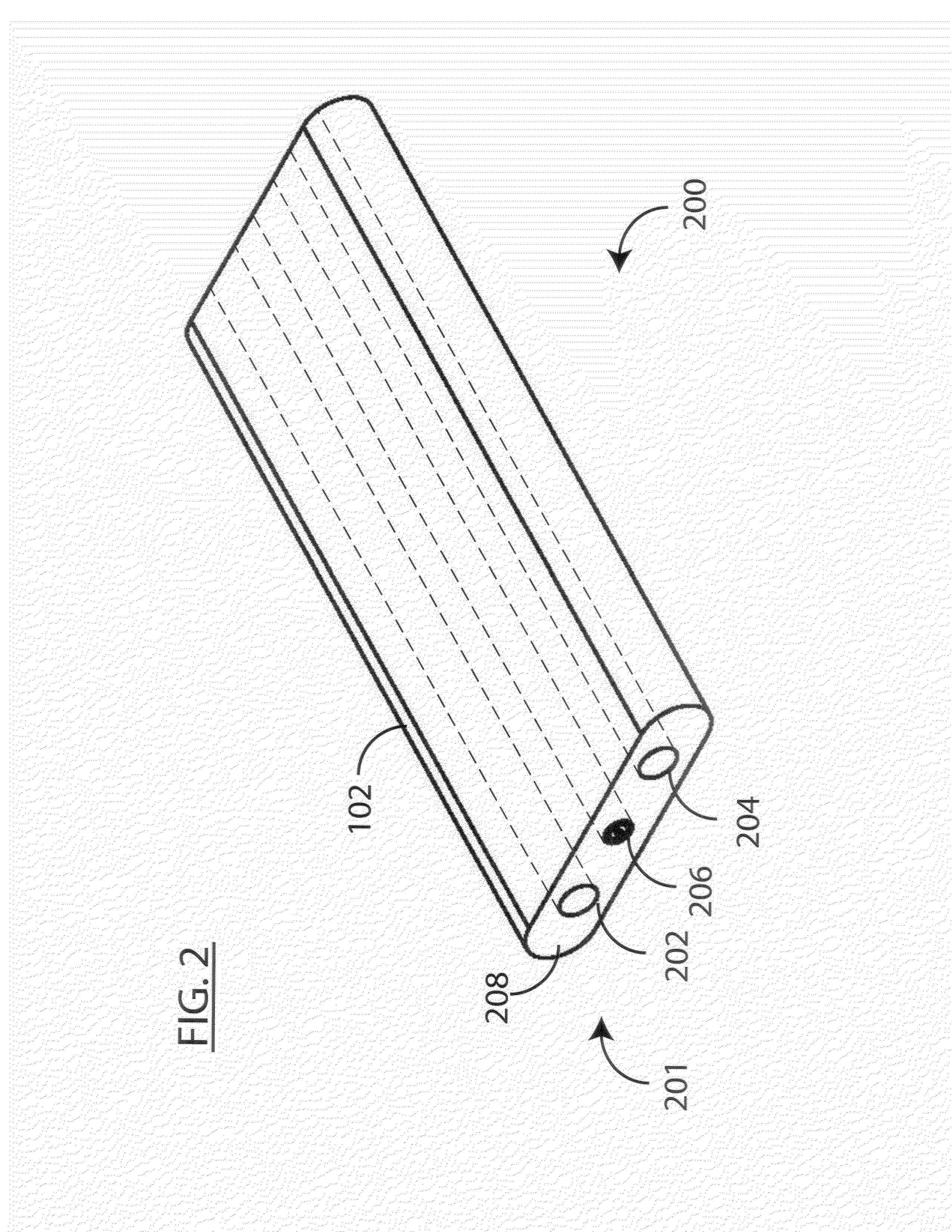

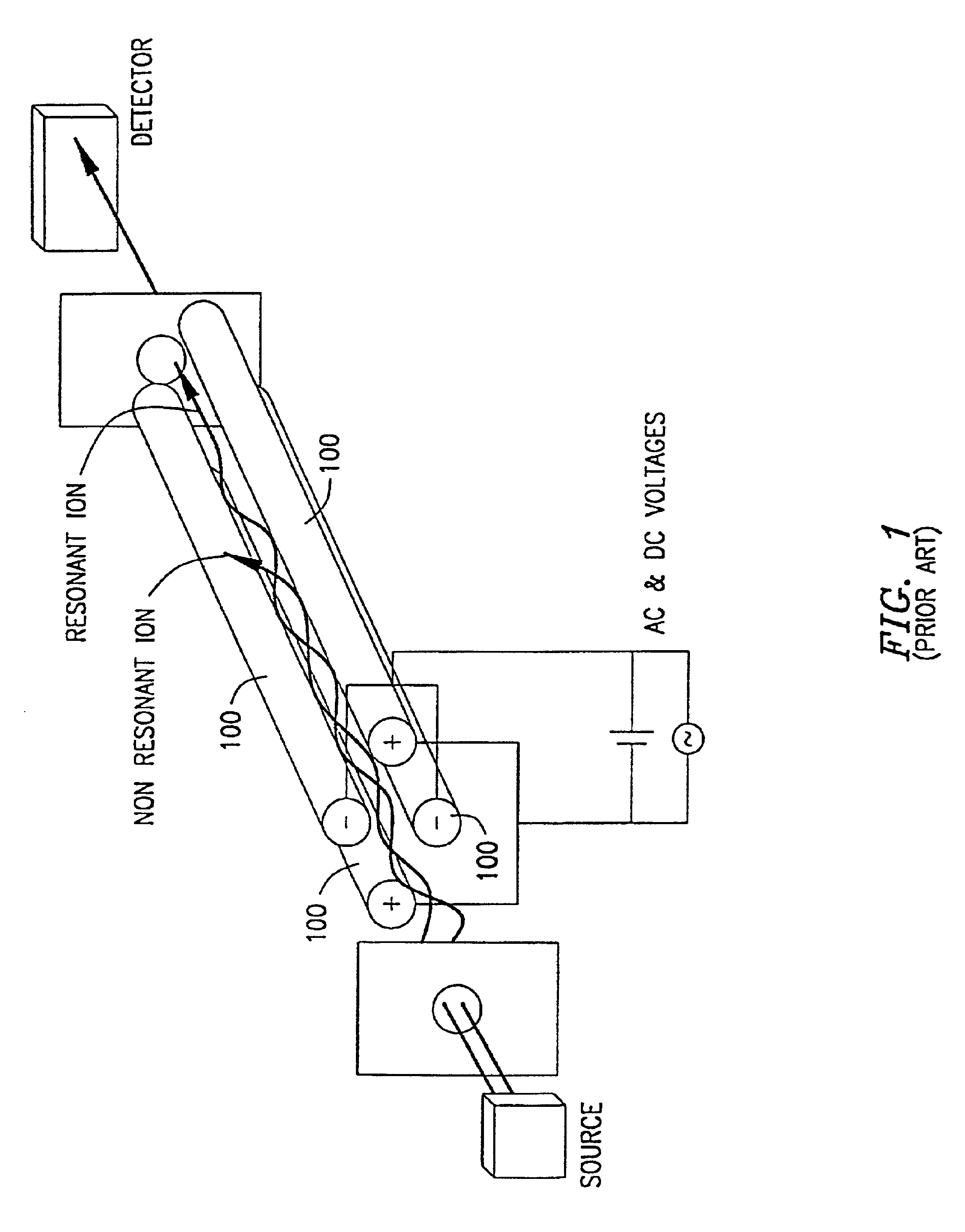

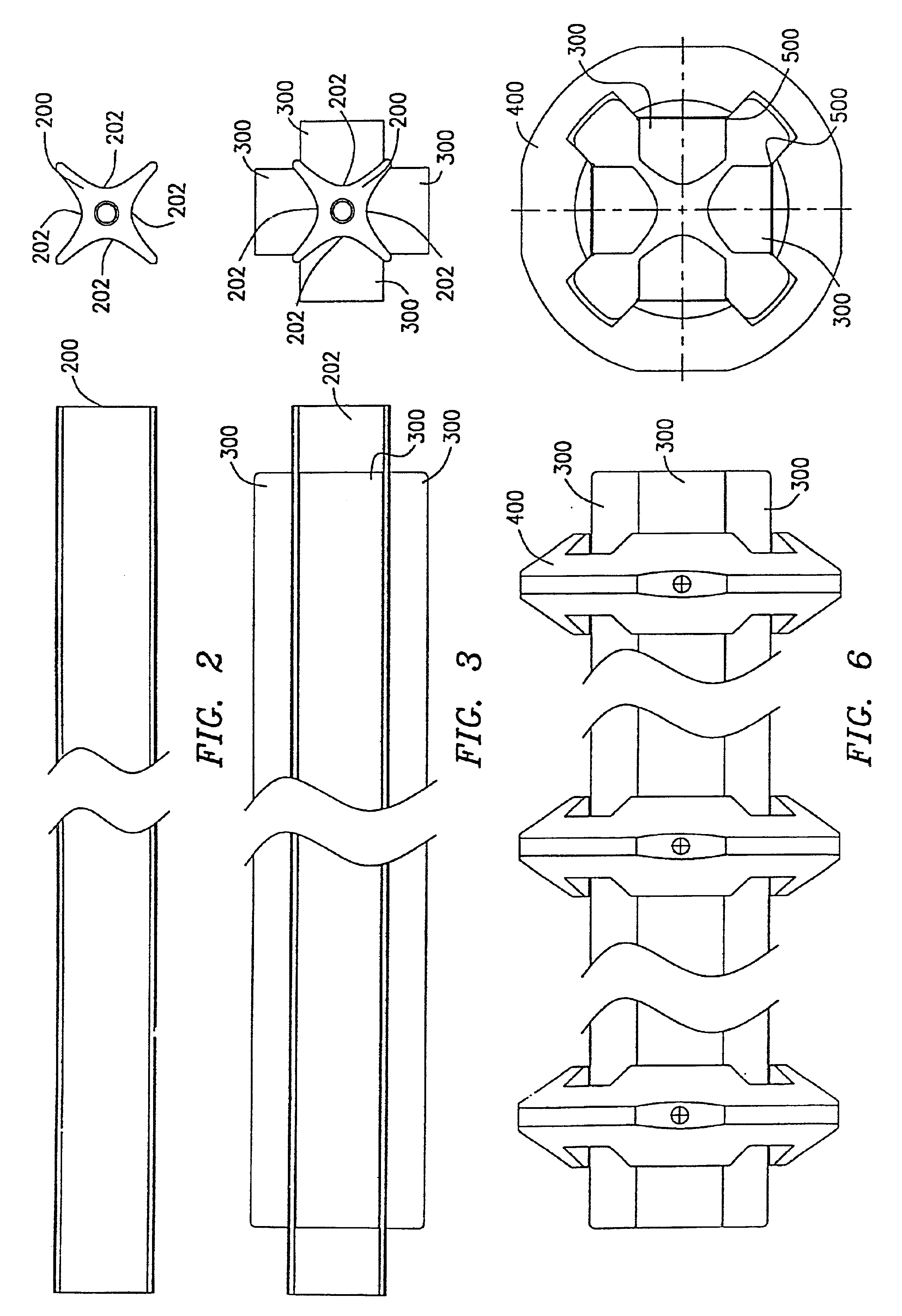

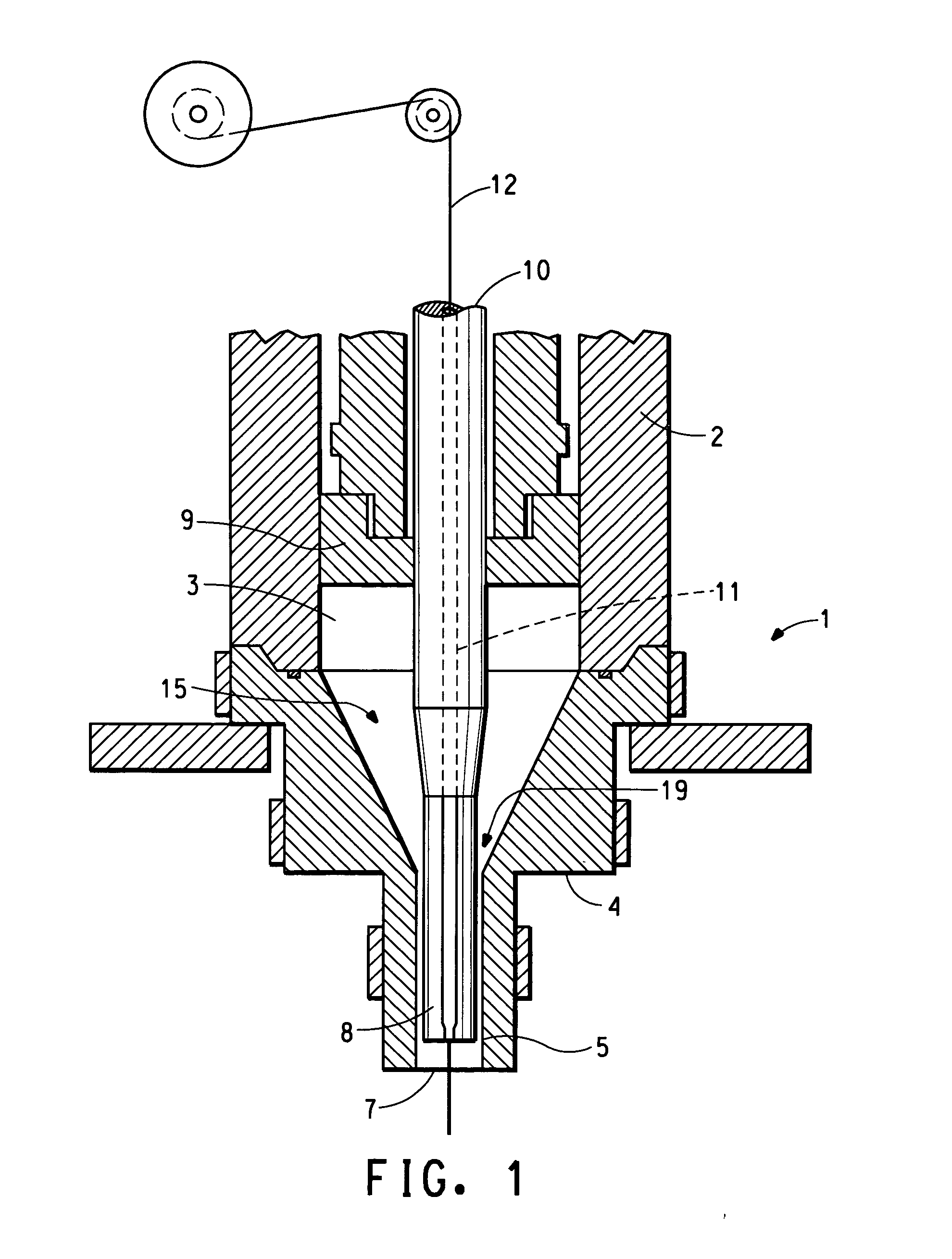

Manufacturing precision multipole guides and filters

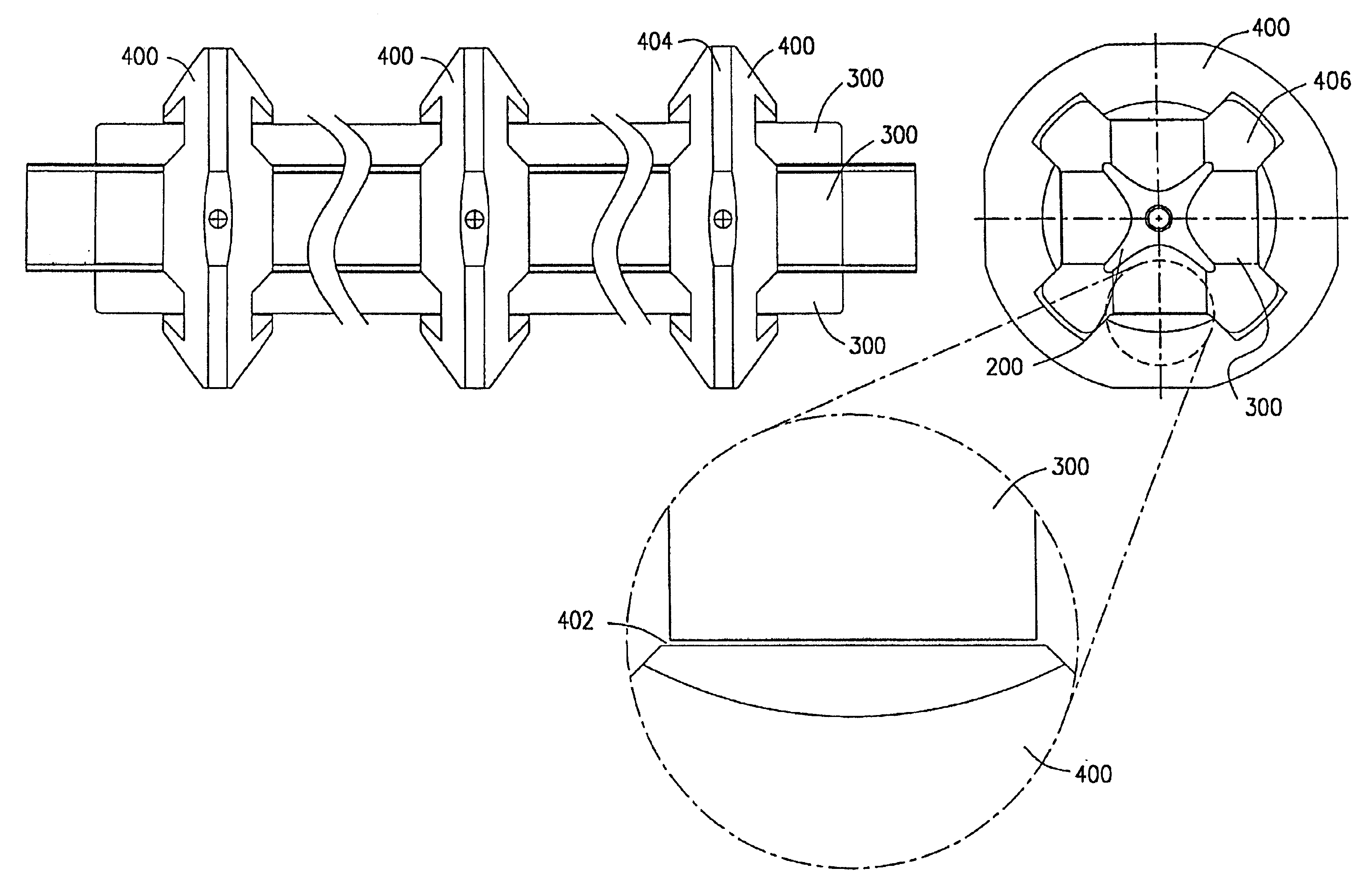

InactiveUS6926783B2Precise positioningImprove accuracyAdhesive processesStability-of-path spectrometersResidual gas analyzerParticle beam

A method for manufacturing a multipole assembly for use in mass spectrometers, residual gas analyzers, mass filters, ion containment apparatus and particle beam accelerators. A precision mandrel tool is utilized for positioning a plurality of electrode rods in position during the manufacturing process. The electrode rods are placed on the mandrel. At least one insulator is positioned about the mandrel-rod assembly such that the mandrel-rod assembly psses through the insulator. The rods are tightly clamped to the mandrel and adhesive is placed in a gap established between each rod and the insulator. The adhesive is cured such that it acts both as a rigid bond between the insulator and each rod, as well as a precision spacer for positioning each rod in a precision position after the mandrel is removed from the assembly.

Owner:AGILENT TECH INC

Broad band radiation type leak coaxial cable for subway and its production method

ActiveCN101404350AUniformly foamed poresUniform field strengthCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsInsulation layerElectrical conductor

The invention relates to a broadband radial pattern leaky coaxial cable used for subway and a manufacturing method thereof, and the leaky coaxial cable has the double functions of transmission line of information and duplexer. The structure of the leaky coaxial cable consists of an inner conductor, an insulation layer, an outer conductor and a jacket, wherein, the inner conductor is externally covered with the insulation layer which is externally covered with the outer conductor that is externally sheathed with the jacket, and the insulation layer that covers on the surface of the inner conductor adopts nitrogen or carbon dioxide physical foam to form a foamed polyethylene insulation layer; cambered slotted holes are opened on a clutch gold belt of the outer conductor covered outside the insulation layer. The manufacturing method comprises the steps: (1) a spiral wrinkle inner conductor is manufactured by longitudinal covering welding and embossing by using a copper strip; (2) the nitrogen or the carbon dioxide are adopted to be injected into the smelted polyvinyl plastics, and then the physical foamed polyethylene insulation layer is formed on the surface of the inner conductor by extrusion and cladding; (3) the slotted holes broken out by the clutch gold belt of the outer conductor are the cambered slotted holes; (4) the clutch gold belt of the outer conductor is covered on the insulation layer longitudinally, and the surface of the clutch gold belt of the outer conductor is crowded and covered with the jacket.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

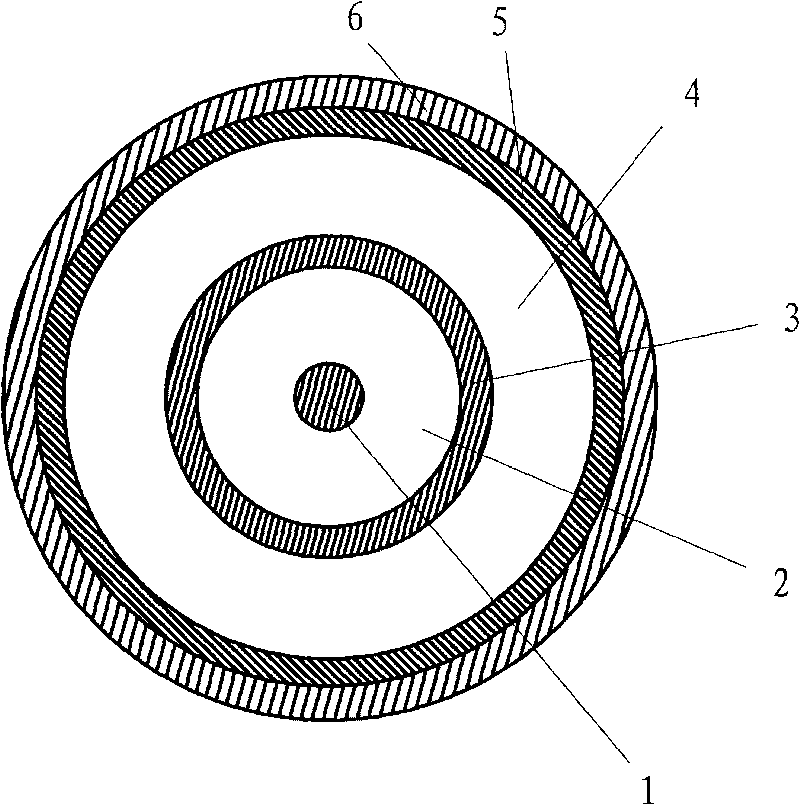

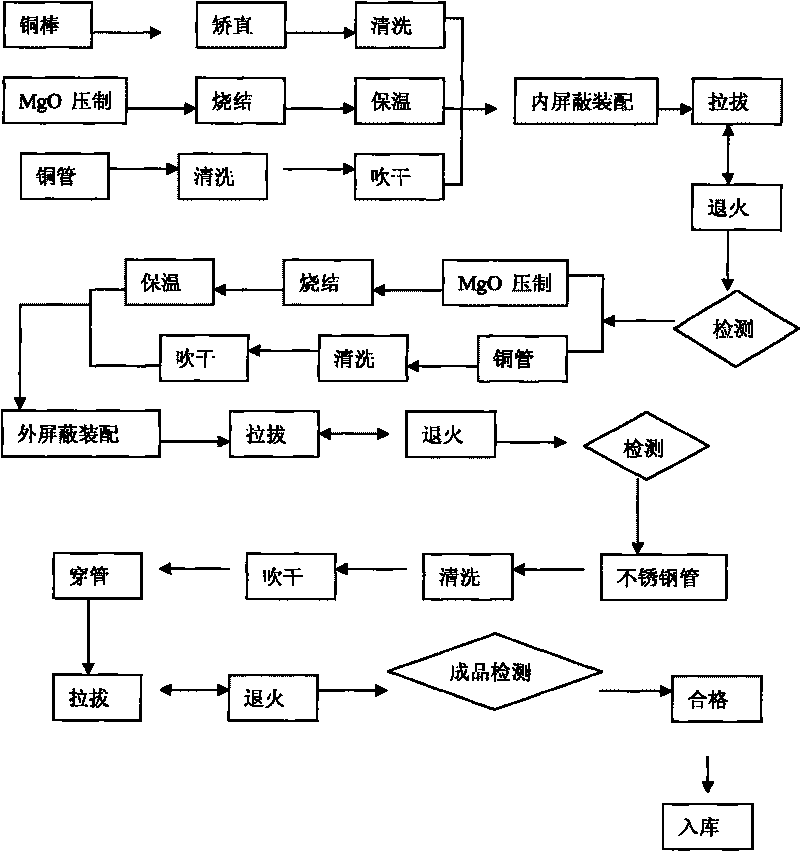

Double-shielded mineral-insulated cable and manufacturing method thereof

ActiveCN101673598AHigh temperature resistantOxidation resistantCoaxial cables/analogue cablesInsulated cablesAviationSilicon dioxide

The invention relates to a double-shielded mineral-insulated cable which is mainly applied to the fields of high-frequency signal transmission in occasions with high ambient temperature and high radiation, such as the communication fields of metallurgy, medical treatment, aerospace, military and the like. The double-shielded mineral-insulated cable comprises an inner conductor, an insulating medium, an outer conductor, an insulating medium and a protective sleeve in sequence from inside to outside, and is characterized in that the insulating medium is magnesium oxide, aluminum oxide or silicondioxide. Compared with the existing double-shielded cable, the double-shielded mineral-insulated cable has the advantages of longer service life and wider use range; in addition, the double-shieldedmineral-insulated cable has excellent performance, has little interference to transmitted signals and can be used for the communication fields of metallurgy, medical treatment, aerospace, military andthe like.

Owner:久盛电气股份有限公司

Process for making composite sheet

A process and an apparatus for high speed manufacture of a composite sheet material, which includes a cylindrical cam-driven strand-traverse guide that can loop strands around pins projecting from a pair of advancing pin conveyors which can transfer the strands to the surface of a moving sheet, are provided. When the strands are elastic, the elastic composite sheet material made by this process and apparatus are useful in elastic components of disposable diapers, adult incontinence articles and other garments.

Owner:INVISTA NORTH AMERICA R L

High accuracy foamed coaxial cable and method for manufacturing the same

InactiveUS6963032B2Exact impedanceImprove accuracyPlastic/resin/waxes insulatorsCable conductor constructionCoaxial cableElectrical conductor

Owner:HIRAKAWA HEWTECH +1

Coaxial cable with strippable center conductor precoat

ActiveUS7022918B2Easy to disassembleEasy to operateCable insulation constructionPower cables with screens/conductive layersAdhesion forceBond interface

A coaxial cable is provided with a specially prepared precoat layer that facilitates removal of the precoat layer when the end of the cable is cored in preparation for receiving a connector. The cable includes an inner conductor; a foam polyolefin dielectric layer surrounding the inner conductor; an outer conductor surrounding said dielectric layer; and a precoat layer disposed between the inner conductor and the dielectric layer. The precoat layer forms a first bond interface with the inner conductor and a second bond interface with the dielectric layer, wherein the ratio of the axial shear adhesion force of the first (“A”) bond to the axial shear adhesive force of the second (“B”) bond is less than 1, and wherein the ratio of the axial shear adhesion force of the “A” bond formed by the precoat layer between the inner conductor to the dielectric layer to the rotational shear adhesion force of the bond is 5 or greater.

Owner:COMMSCOPE INC

Paste extruded insulator with air channels

InactiveUS20050139377A1Easy to disassemblePlastic/resin/waxes insulatorsCable insulation constructionElectrical conductorEngineering

The invention provides an insulated wire having a conductor and an insulator of paste extruded PTFE fine powder around the conductor. The paste extruded insulator has at least one closed continuous longitudinal air channel spaced apart from the conductor. The invention further provides a process for forming an insulator around a conductor by paste extruding lubricated PTFE fine powder in an extrusion device comprising a die, mandrel, and at least one channel-forming member. The die and mandrel form a converging chamber leading to an extrusion orifice and the channel-forming member is positioned in the orifice. The mandrel has a central bore for supplying the conductor. Lubricated PTFE fine powder is forced through the chamber and out of the exit of the orifice as a lubricated green extrudate around the conductor forming an insulator with at least one closed longitudinal air channel spaced apart from the conductor.

Owner:EI DU PONT DE NEMOURS & CO

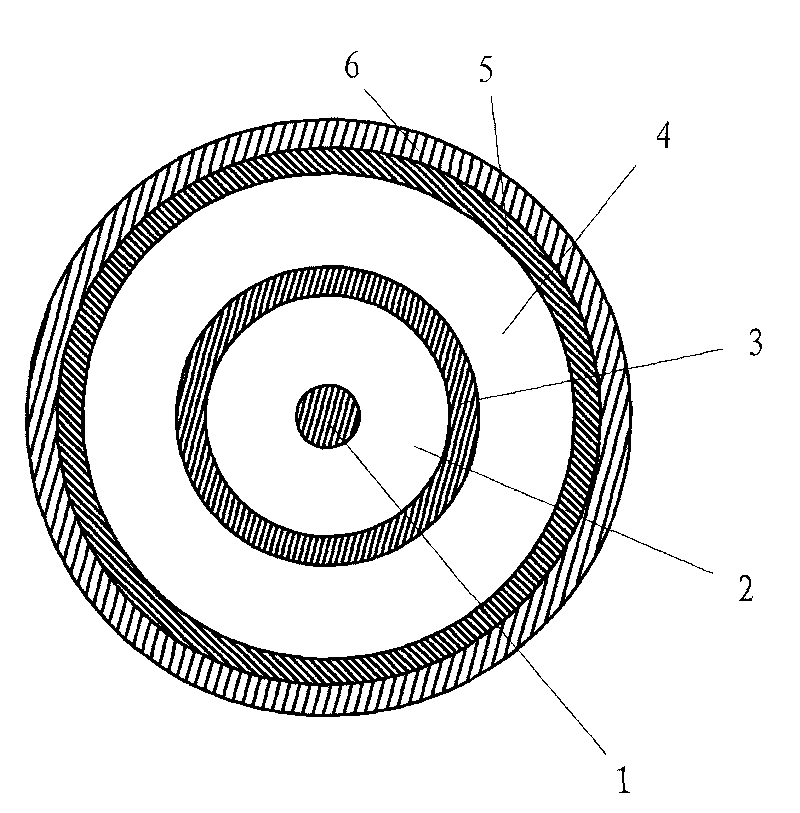

Three-coaxial mineral insulated cable and manufacturing method thereof

ActiveCN101707076AHigh temperature resistantOxidation resistantCoaxial cables/analogue cablesInsulated cablesCoaxial cableSilicon dioxide

The invention relates to a three-coaxial mineral insulated cable which is mainly applied to the field of the transmission of a high-frequency signal in an occasion with high environmental temperature and high radiation, such as the communication fields of metallurgy, medical treatment, aerospace, military affairs and the like. The three-coaxial mineral insulated cable comprises an internal conductor layer, an internal insulation dielectric layer, an internal shielding layer, an external insulation dielectric layer, an external shielding layer and a sheath layer sequentially from the inside to the outside. The three-coaxial mineral insulated cable is characterized in that the internal insulation dielectric layer and / or the external insulation dielectric layer are magnesia, alumina or silicon dioxide. Compared with the prior coaxial cable, the three-coaxial mineral insulated cable has the advantages of longer service life and more extensive use range.

Owner:久盛电气股份有限公司

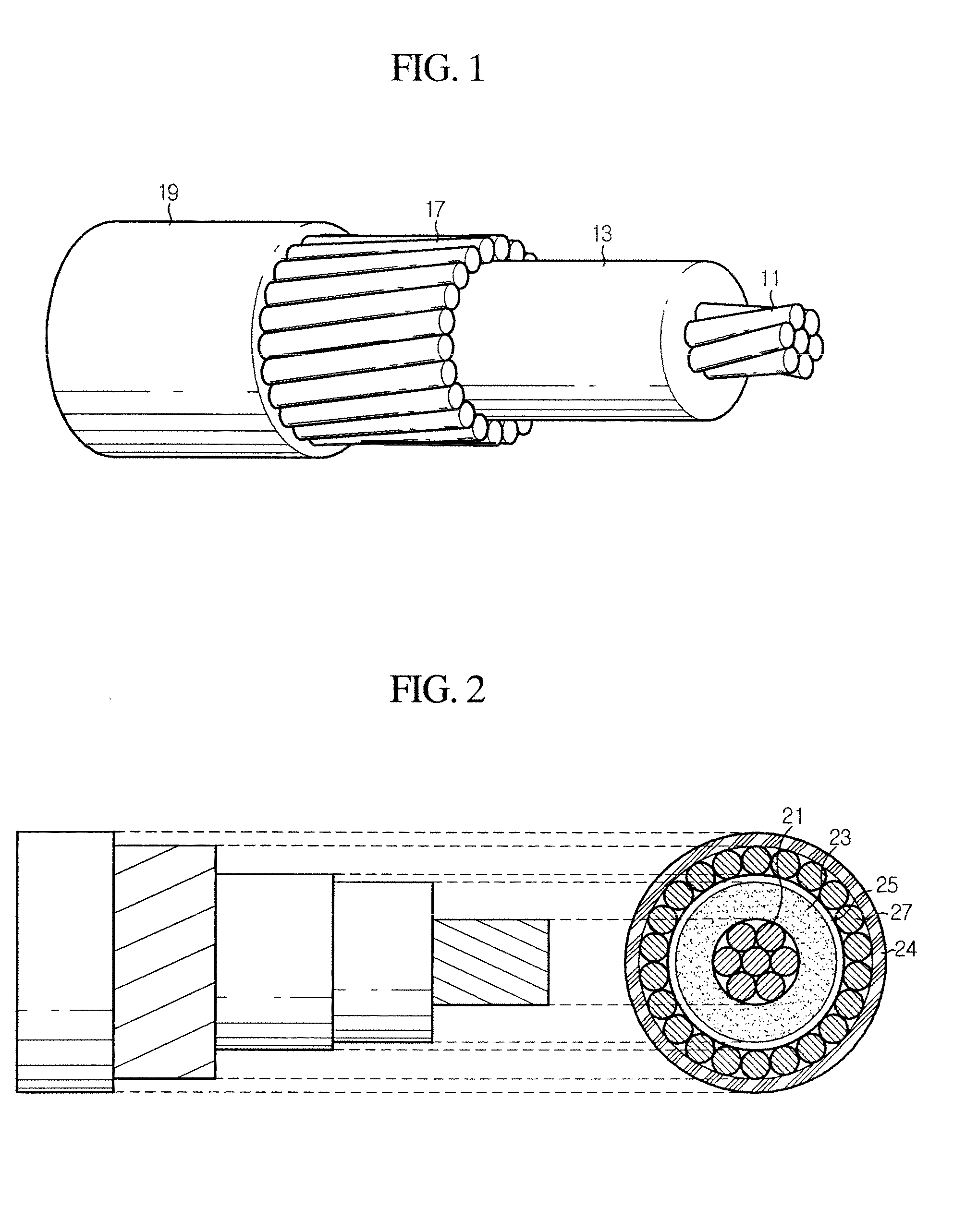

Micro CoAxial Cable

ActiveUS20080047732A1Lower melting temperatureEasy to useCable insulation constructionPower cables with screens/conductive layersAbnormal growthsElectrical conductor

A micro coaxial cable includes an inner conductor; an insulation layer having foaming cells and formed to surround the inner conductor; an over-foaming preventing layer formed to surround the insulation layer for the purpose of uniform forming of the foaming cells; a metal shield layer formed to surround the over-foaming preventing layer; and a protective coating layer formed to surround the metal shield layer. The over-foaming preventing layer restrains abnormal growth of foaming cells formed in the insulation layer such that the foaming cells are successively adjacently formed with uniform size. Due to the uniformity of foaming, the dielectric constant of the insulation layer is not locally different but uniform as a whole, thereby capable of improving transmission characteristics. In addition, the micro coaxial cable enables to transmit signals even at a high frequency transmission of GHz range, which was impossible in the prior art.

Owner:HITACHI METALS LTD

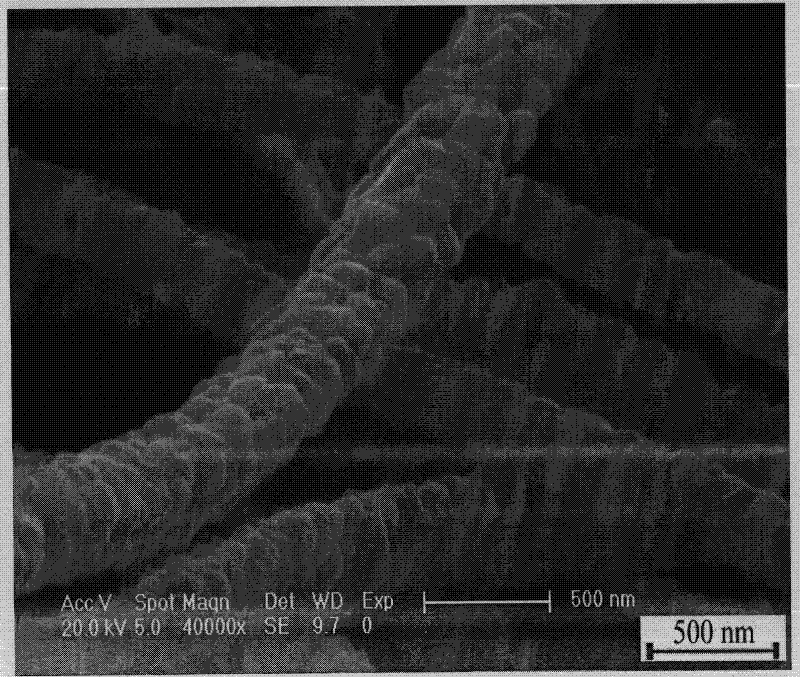

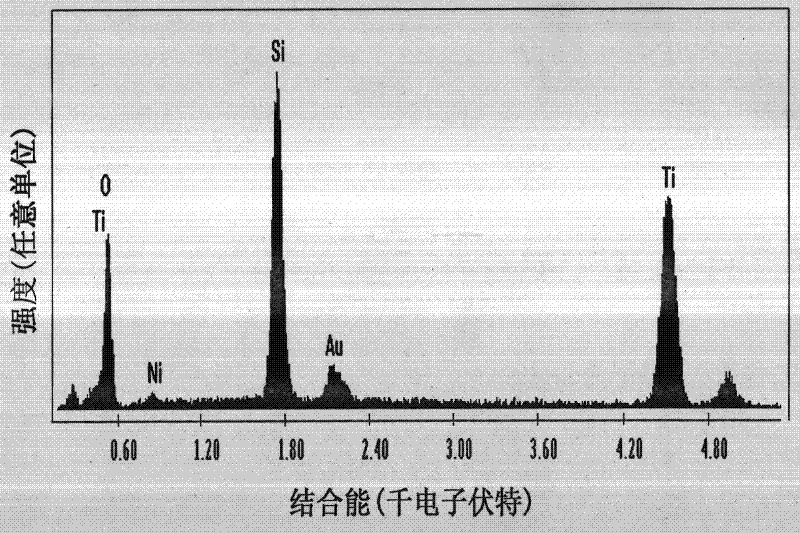

Method for preparing NiO@SiO2@TiO2 coaxial three-layer nano cable

InactiveCN102191570AFilament/thread formingConjugated artificial filamentsN dimethylformamideRelative humidity

The invention relates to a method for preparing a NiO@SiO2@TiO2 coaxial three-layer nano cable and belongs to the technical field of preparation of nano materials. The method comprises three steps of: (1) preparing spinning solution, namely adding 4-H2O nickel acetate and polyvinylpyrrolidone (PVP) into N,N-dimethylformamide (DMF) and forming core spinning solution, adding tetraethoxysilane and PVP into ethanol and forming middle spinning solution, and adding tetrabutyl titanate, PVP and glacial acetic acid into the ethanol and forming shell spinning solution; (2) preparing [Ni(CH3COO)2+PVP]@[(C2H5O)4Si+PVP]@[Ti(OC4H9)4+CH3COOH+PVP] precursor compound cable, namely adopting a coaxial electrostatic spinning technology and using a coaxial three-layer spinning nozzle under voltage of 17kV, acuring distance of 15 centimeters, room temperature of 21 to 25 DEG C, relative humidity of 50 to 62 percent; and (3) preparing the NiO@SiO2@TiO2 coaxial three-layer nano cable, namely thermally treating the precursor compound cable at a temperature rising rate of 1 DEG C per minute, preserving the temperature for 8 hours at 800 DEG C, reducing the temperature at the speed of 1 DEG C per minute to 200 DEG C and naturally cooling to room temperature so as to obtain the NiO (core) @SiO2 (middle)@TiO2 (shell) coaxial three-layer nano cable, wherein the diameter of the NiO@SiO2@TiO2 coaxial three-layer nano cable is 200 to 250 nanometers; and the length of the cable is larger than 300 microns.

Owner:CHANGCHUN UNIV OF SCI & TECH

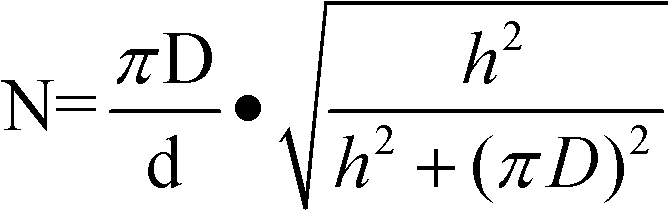

Manufacturing method of semi-flexible coaxial cable shielding layer

InactiveCN101853718AWon't fall offDip tin evenlyManufacturing co-axial cablesElectrical conductorCoaxial cable

The invention relates to a manufacturing method of a semi-flexible coaxial cable shielding layer. A semi-flexible coaxial cable comprises an inner conductor, an insulating layer, a shielding layer and a jacket layer, and the semi-flexible coaxial cable shielding layer is manufactured through unidirectionally winding a metal wire on an insulating ore and then carrying out dip soldering. The manufacturing method concretely comprises the following steps of: (1) setting winding parameters of the metal wire; (2) installing a pay-off spool on which the semi-flexible coaxial cable insulating core is wound, and arranging the insulating core; (3) installing a metal wire coil for winding, arranging the metal wire, and winding the metal wire on the insulating core; and (4) fluxing the wound shielding wire coil, drying, carrying out dip soldering, air cooling, and connecting with a second take-up spool assembled on a second take-up stand. The shielding layer is formed by unidirectionally winding the metal wire, the dip soldering is even, uniform and easy, and the tin layer can not fall off due to the relative sliding of interwoven metal wires in bending. The production efficiency is six times higher than the weaving efficiency, and the energy consumption of the manufacturing method only accounts for 1 / 24 of that of the weaving process. In addition, 100 percent of shielding can be realized.

Owner:杭州奥达线缆科技有限公司

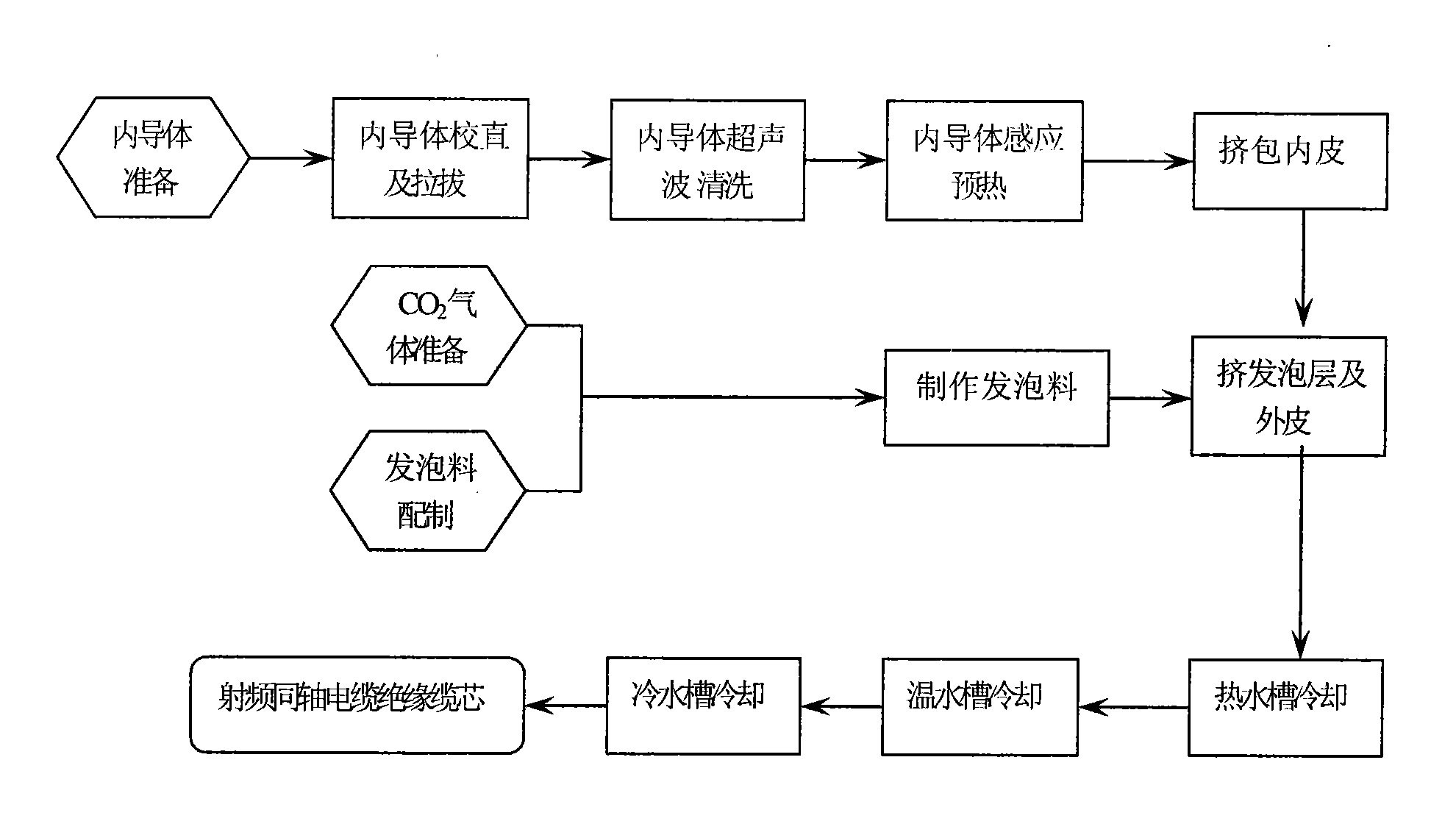

Method for making carbon dioxide physically foamed RF coaxial cable insulation cable core

ActiveCN101640083ASmall attenuationImprove performanceManufacturing co-axial cablesInsulating conductors/cablesLow-density polyethyleneElectrical conductor

The invention relates to a method for making a highly foamed carbon dioxide physically foamed RF coaxial cable insulation cable core, in particular to production technology of RF coaxial cable insulation core wire for the third generation data mobile communication 3G. The making method is as follows: (1) the inner conductor of an insulation core wire is subject to strengthening, sizing and ultrasonic cleaning and then is coated with an inner cortex through extrusion by an extruding machine after preheating; (2) foaming material is prepared, and high-density polyethylene, low-density polyethylene and nucleating agent are mixed and melted in to polymer at the high temperature of 180-220 DEG C in the extruding machine; (3) carbon dioxide foaming agent is injected into the melted polymer in the extruding machine by liquid carbon dioxide by virtue of pore gas injection needle high pressure; (4) at high temperature, molten polymer and carbon dioxide foaming agent are mixed uniformly by virtue of revolution of a screw of the extruding machine; (5) the mixture is extruded at the periphery of the inner conductor of the 3G RF coaxial cable by an extruding nose, foamed and made into the foamed insulation cable core; (6) the foamed insulation cable core is made into carbon dioxide physically foamed RF coaxial cable insulation cable core.

Owner:ZHONGTIAN RADIO FREQUENCY CABLE CO LTD

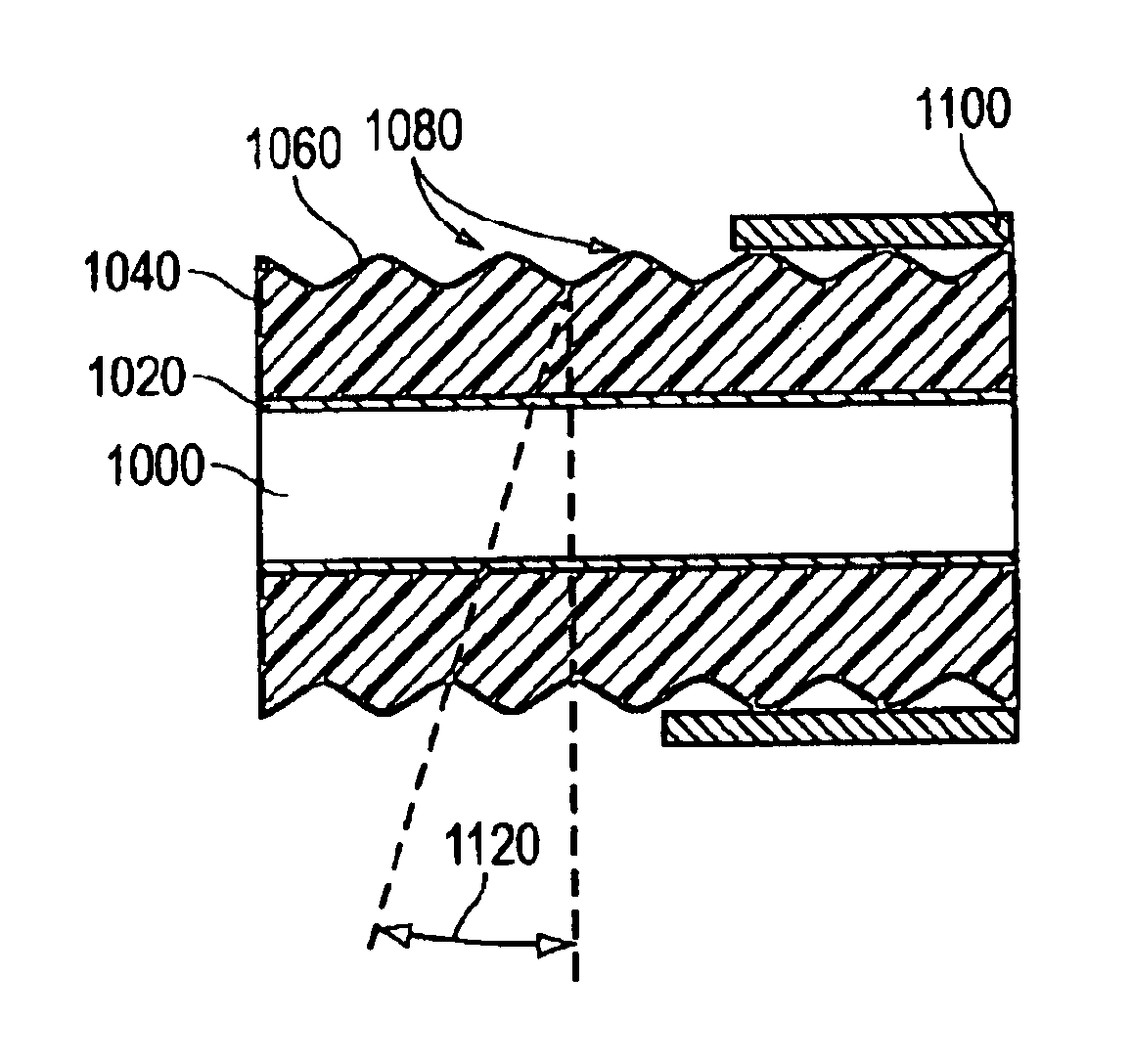

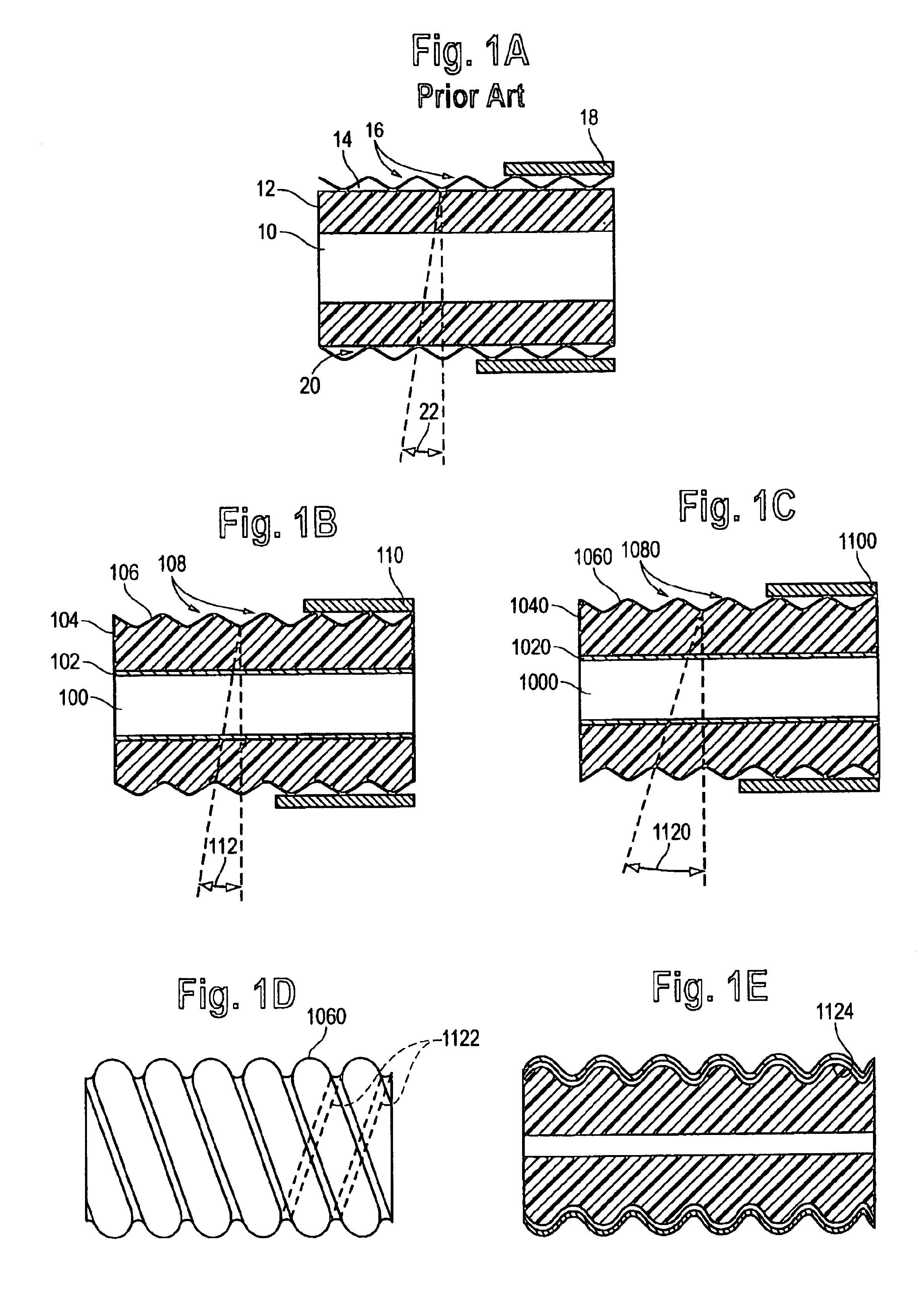

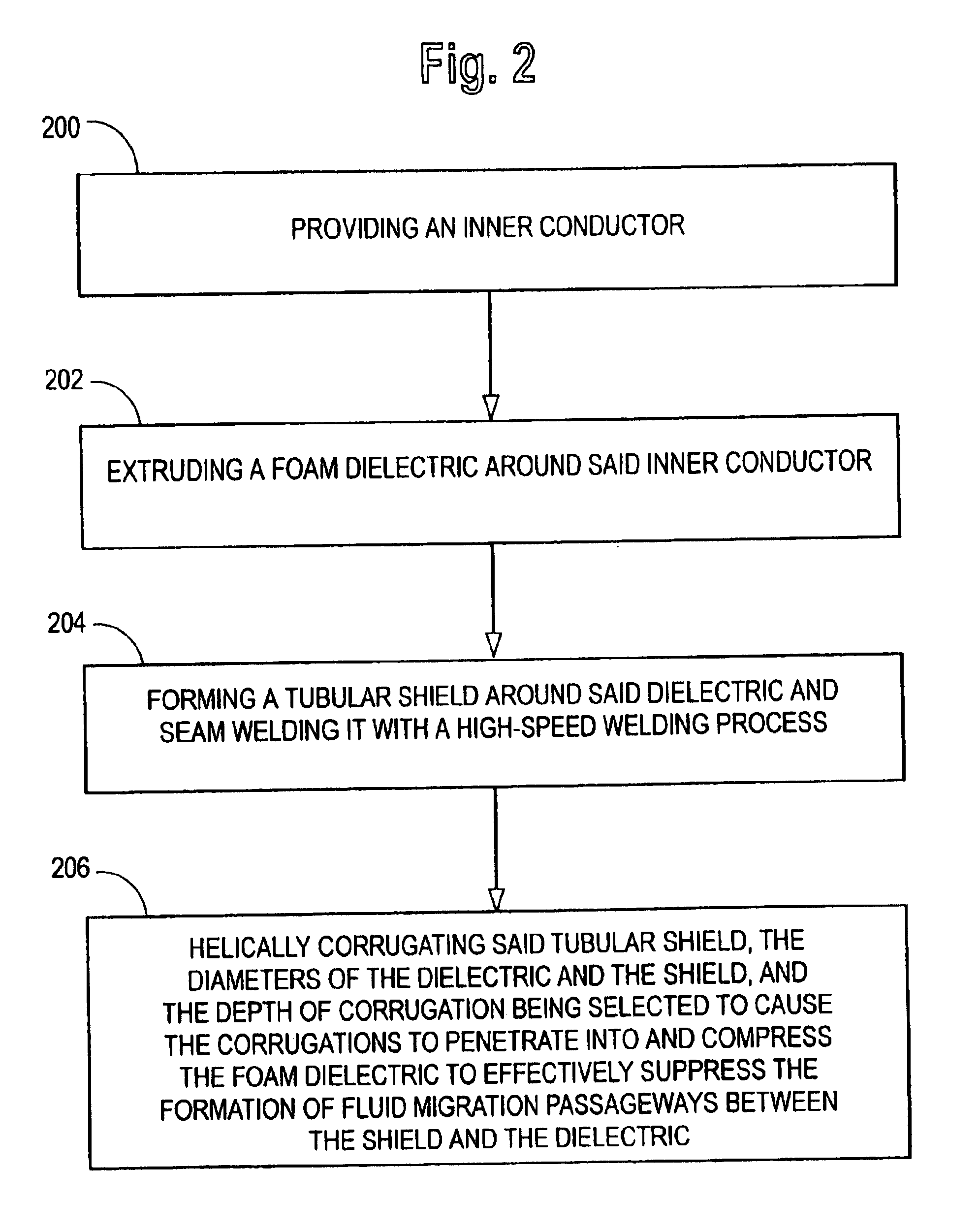

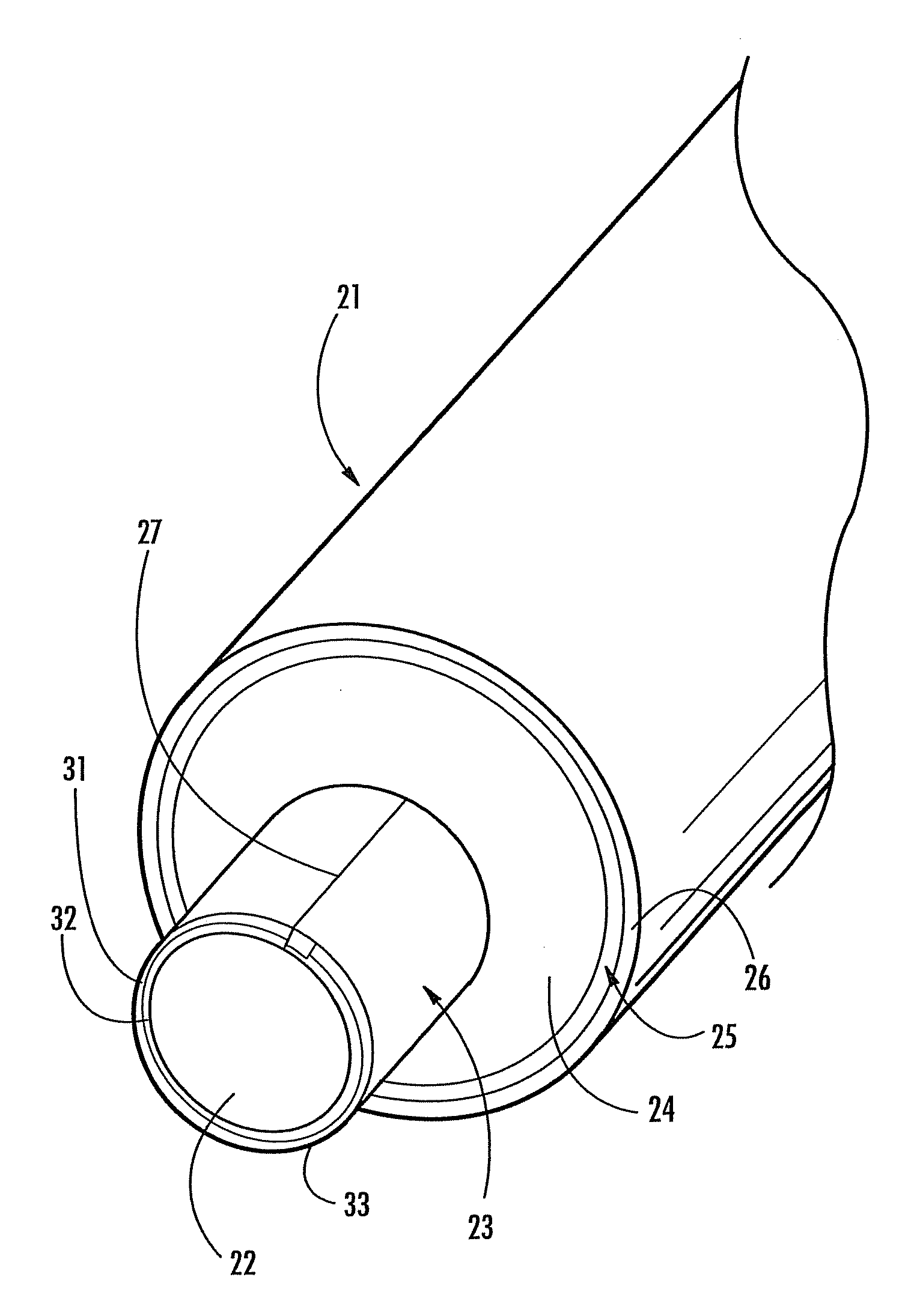

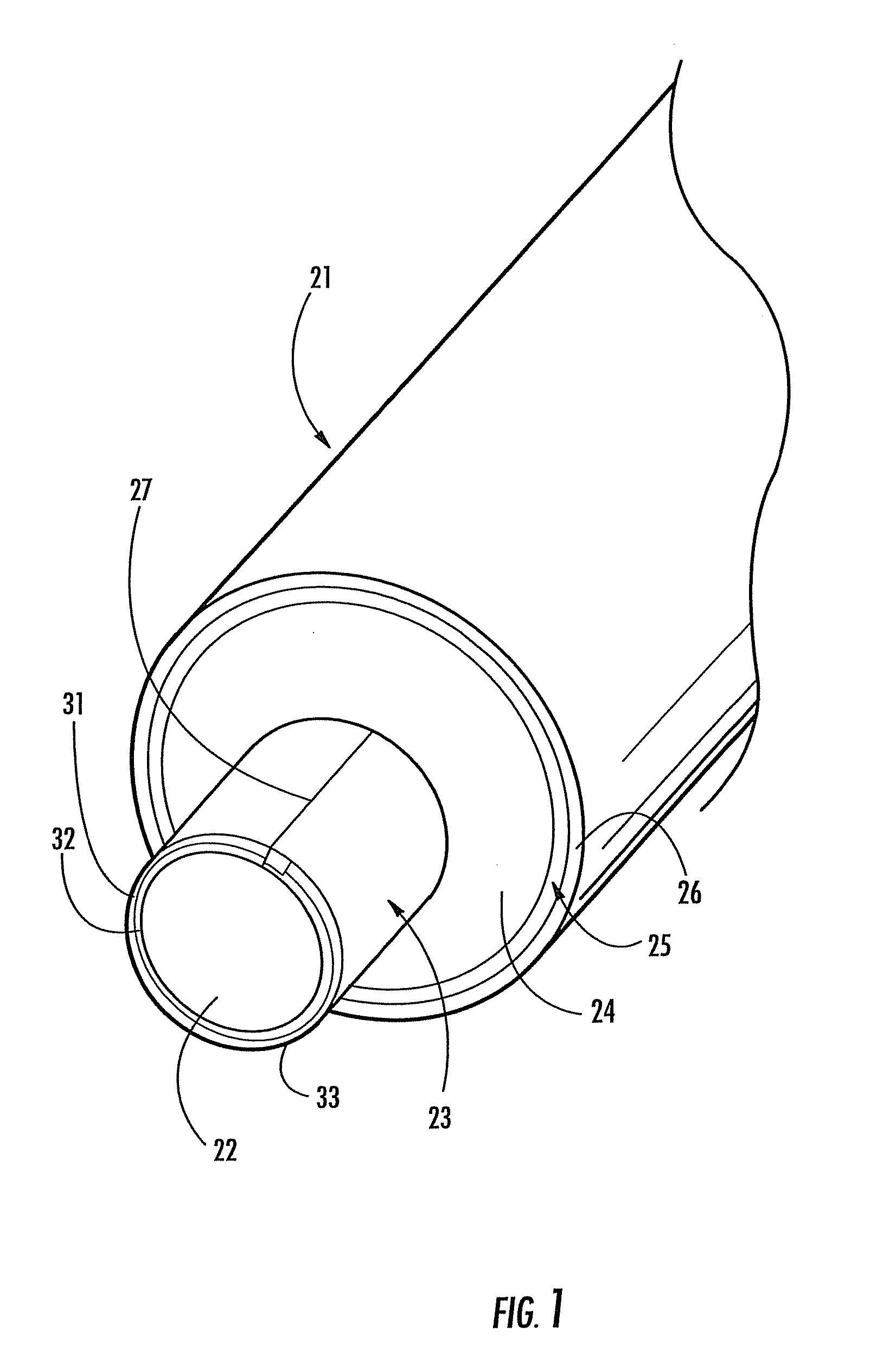

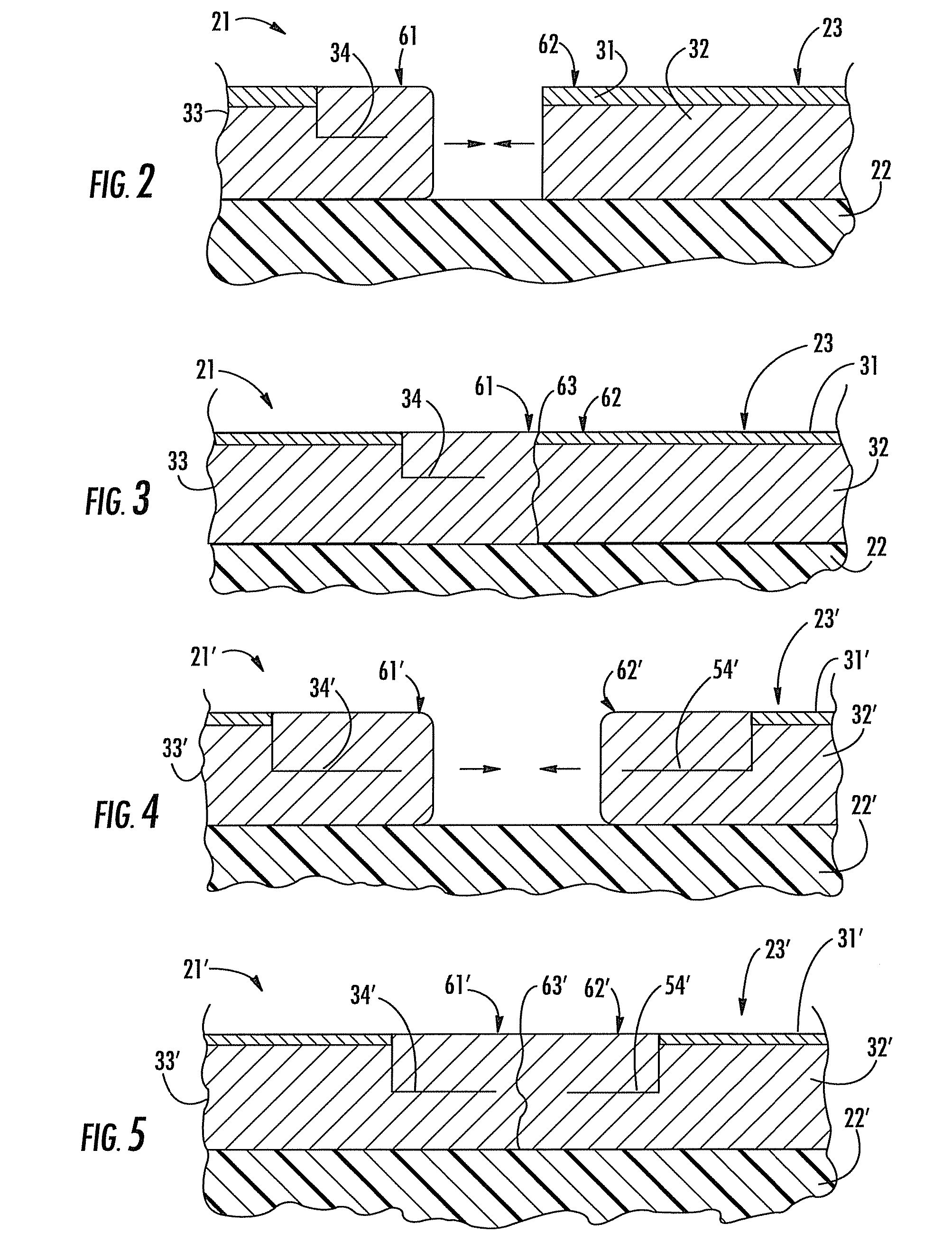

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS6693241B2Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Method of making a coaxial cable including tubular bimetallic inner layer with folded over edge portions

InactiveUS20090218027A1Line/current collector detailsCable conductor constructionElectrical conductorCoaxial cable

A method for making a coaxial cable including an inner conductor, an outer conductor, and a dielectric material layer therebetween may include forming the inner conductor by at least forming a bimetallic strip into a tubular bimetallic layer having a pair of longitudinal edge portions at a longitudinal seam. The bimetallic strip may include an inner metal layer and an outer metal layer bonded thereto and coextensive therewith. Each of the longitudinal edge portions may be folded over. The method may also include forming a welded joint between adjacent portions of the folded over longitudinal edge portions and defining surplus material at the welded joint. The method may further include removing the surplus material at the welded joint and forming the dielectric material layer surrounding the inner conductor. The method may also include forming the outer conductor surrounding the dielectric material layer.

Owner:COMMSCOPE TECH LLC

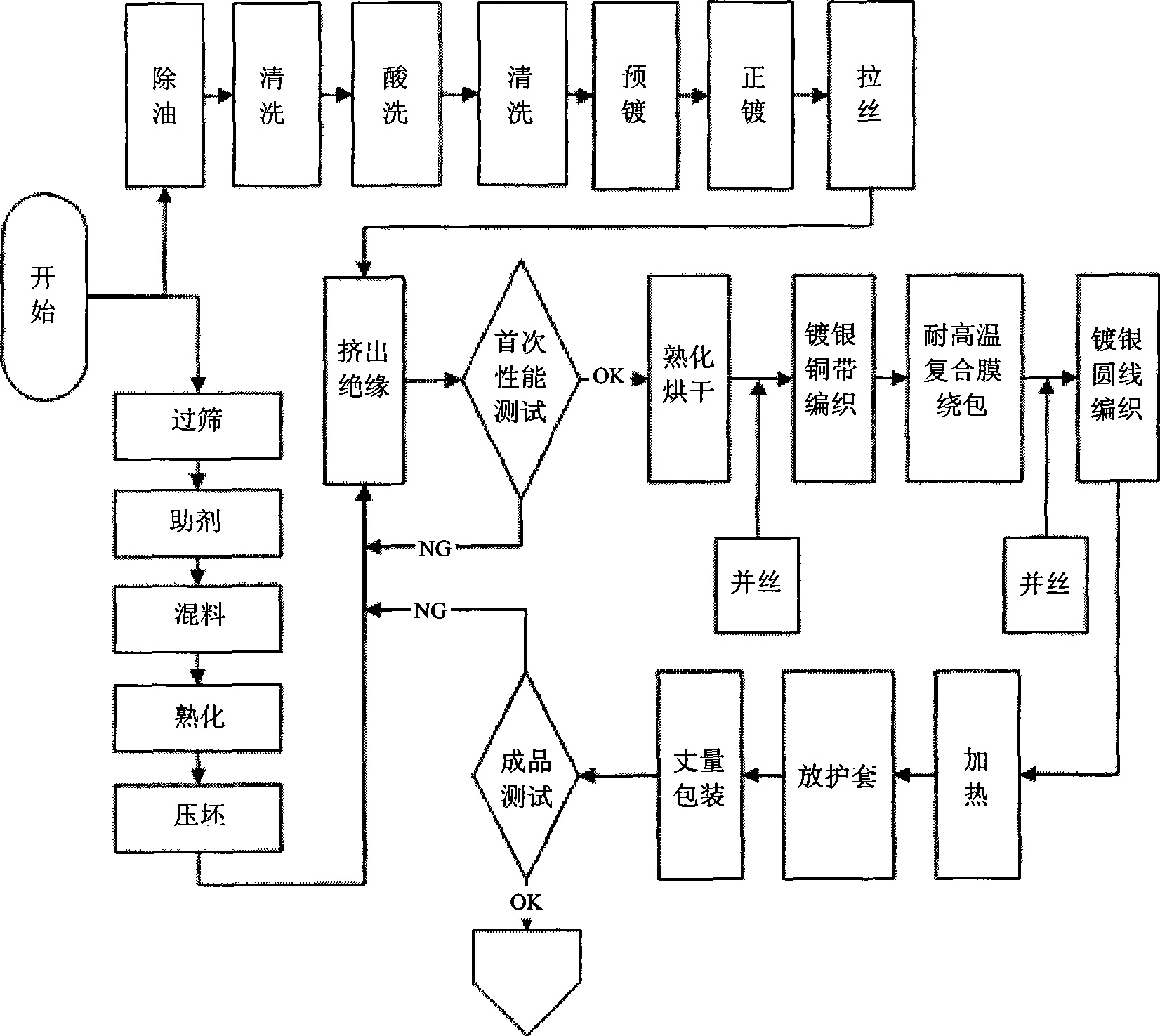

Low-loss phase-stable coaxial cable and manufacture method thereof

ActiveCN101447256AReduce lossStable structureCoaxial cables/analogue cablesWaveguidesComposite filmElectrical conductor

The invention relates to a low-loss phase-stable coaxial cable and a manufacture method thereof. The low-loss phase-stable coaxial cable comprises, sequentially arranged from inside to outside, an inner conductor, an intermediate insulation layer, an outer conductor and an outer sheath, wherein the inner conductor includes a base material containing Ag-Cu alloy and an Ag coating layer. In the preferred scheme, the Ag-Cu alloy contains Cu 99% and Ag 1%. The outer conductor includes, sequentially arranged from inside to outside, an alloy strip layer, a metal composite film layer, and an Ag wire braid layer, which are respectively wrapped by an alloy strip, a metal composite film strip and a flat Ag wire braid strip. The intermediate insulation layer is made of a foamed polytetrafluoroethylene material with the dielectric constant of 1.65 to 1.73. The low-loss phase-stable coaxial cable can lower the transmission loss of coaxial cables so as to reduce the signal attenuation in the transmission process, and can improve the mechanical phase stability of the coaxial cables.

Owner:KINGSIGNAL TECHNOLOGY CO LTD

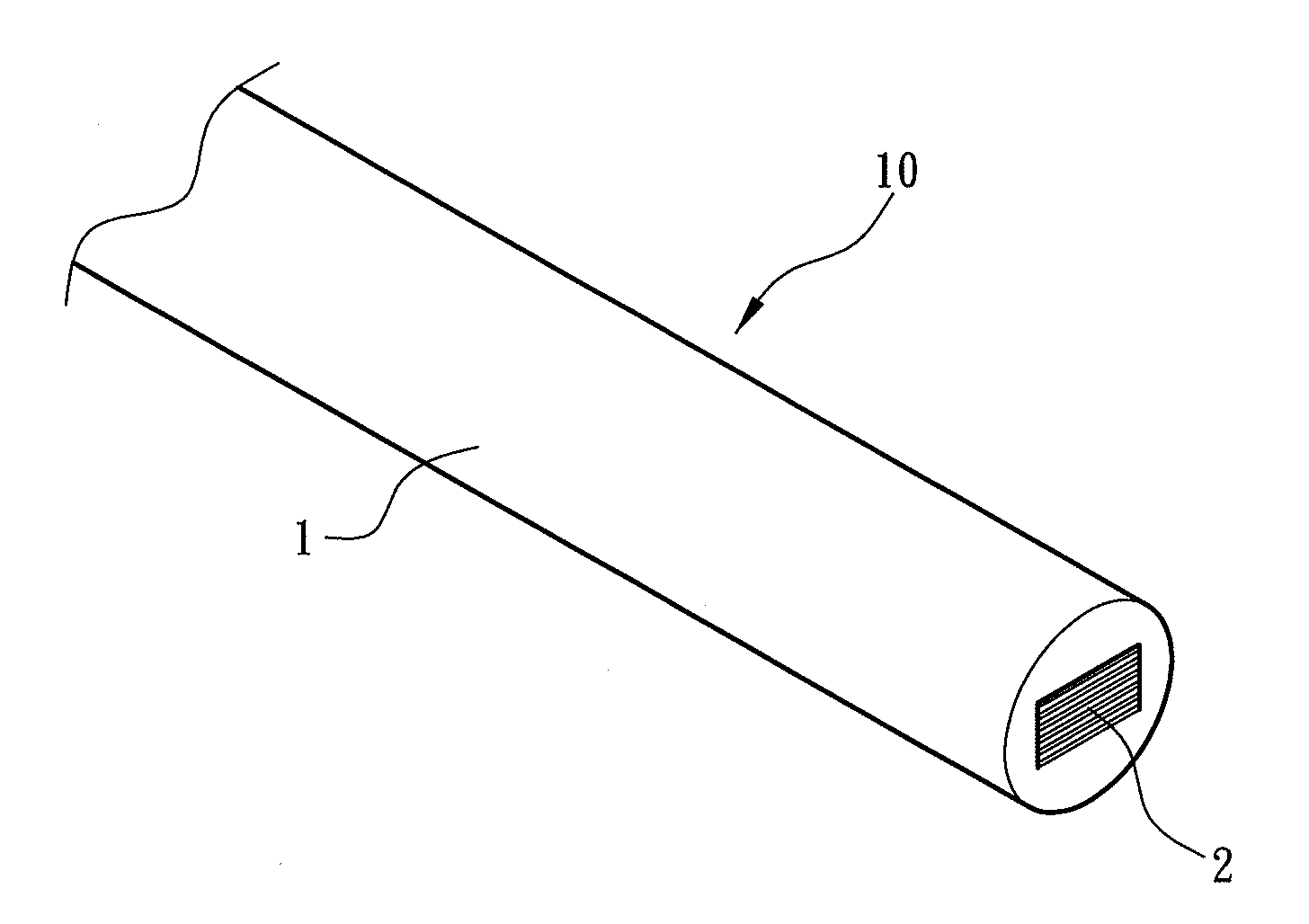

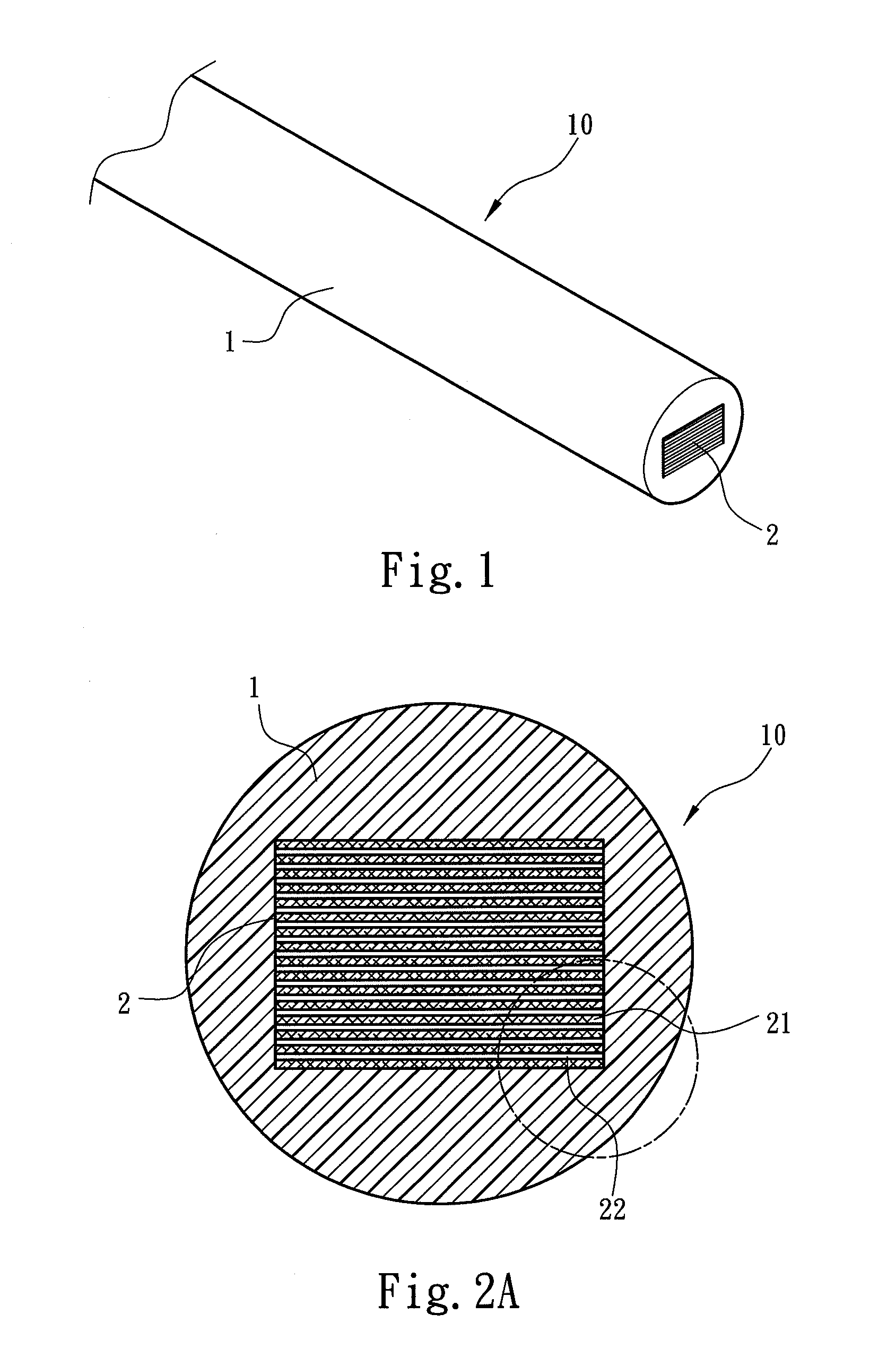

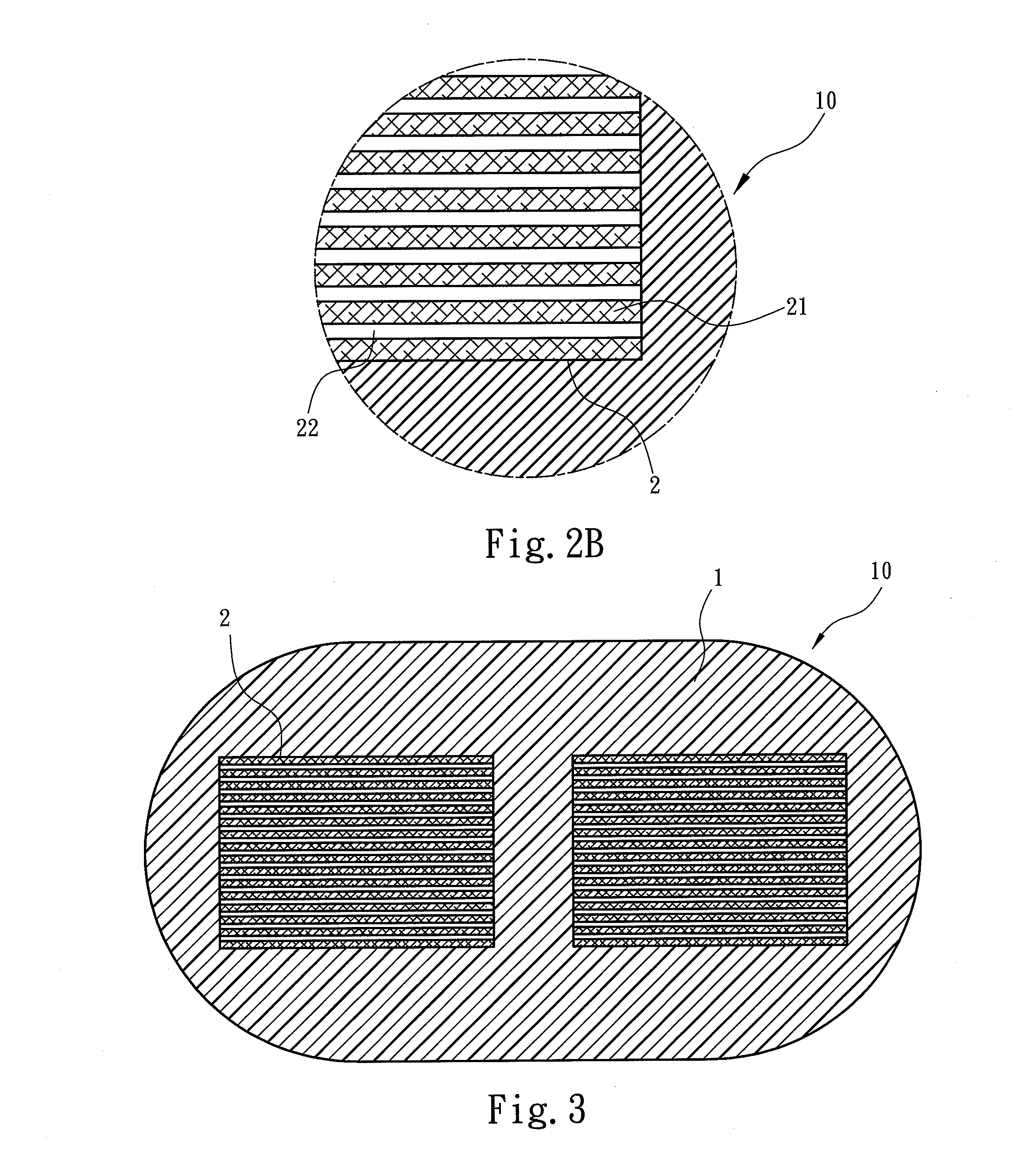

Conducting wire structure and method of manufacturing a conducting wire core

InactiveUS20110155417A1Area maximizationImprove conductivityStrip/foil conductorsFlat/ribbon cablesElectrical conductorInsulation layer

A conducting wire structure and a method of manufacturing a conducting wire core, the conducting wire comprises at least one core and an insulation skin encasing the core. The core is formed by stacking a plurality of flattened conductors with flattened cross sections interposed by an insulation layer. The insulation layer bonds two neighboring flattened conductors to form the core in an integrated manner. The flattened conductors can conduct an identical electric signal. Thus the surface area of the flattened conductors can transmit electric power or signal to maximize conductive area of one core. The method of manufacturing a core includes: providing a plurality of flattened conductors with flattened cross sections through a conductor flattened fabrication means; coating an insulation layer on the surface of the flattened conductors through a coating means; and stacking the flattened conductors coaxially to form a core. Thus conductive surface area can be maximized.

Owner:INNOTRANS TECH

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201115A1Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com