Manufacturing method of semi-flexible coaxial cable shielding layer

A technology of semi-flexible coaxial cable and manufacturing method, which is applied in the manufacture of coaxial cable, cable/conductor manufacturing, circuits, etc., can solve the problems of inability to achieve braiding density, tin layer is easy to fall off, reducing cable shielding efficiency, etc. The tin is flat and uniform, and the effect of tin immersion is convenient.

Inactive Publication Date: 2010-10-06

杭州奥达线缆科技有限公司

View PDF4 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problems that the existing semi-flexible coaxial cable shielding layer cannot achieve 100% braiding density, the gaps at the intersection points increase the difficulty of tin dipping, and at the same time, the tin layer is easy to fall off after repeated bending, which reduces the cable shielding efficiency. A method for manufacturing a semi-flexible coaxial cable shielding layer that can achieve 100% braiding density, is uniform and easy to soak in tin, and the tin layer is not easy to fall off after repeated bending

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

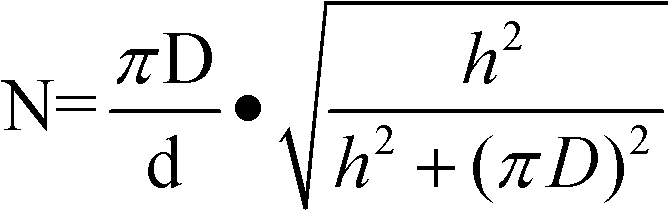

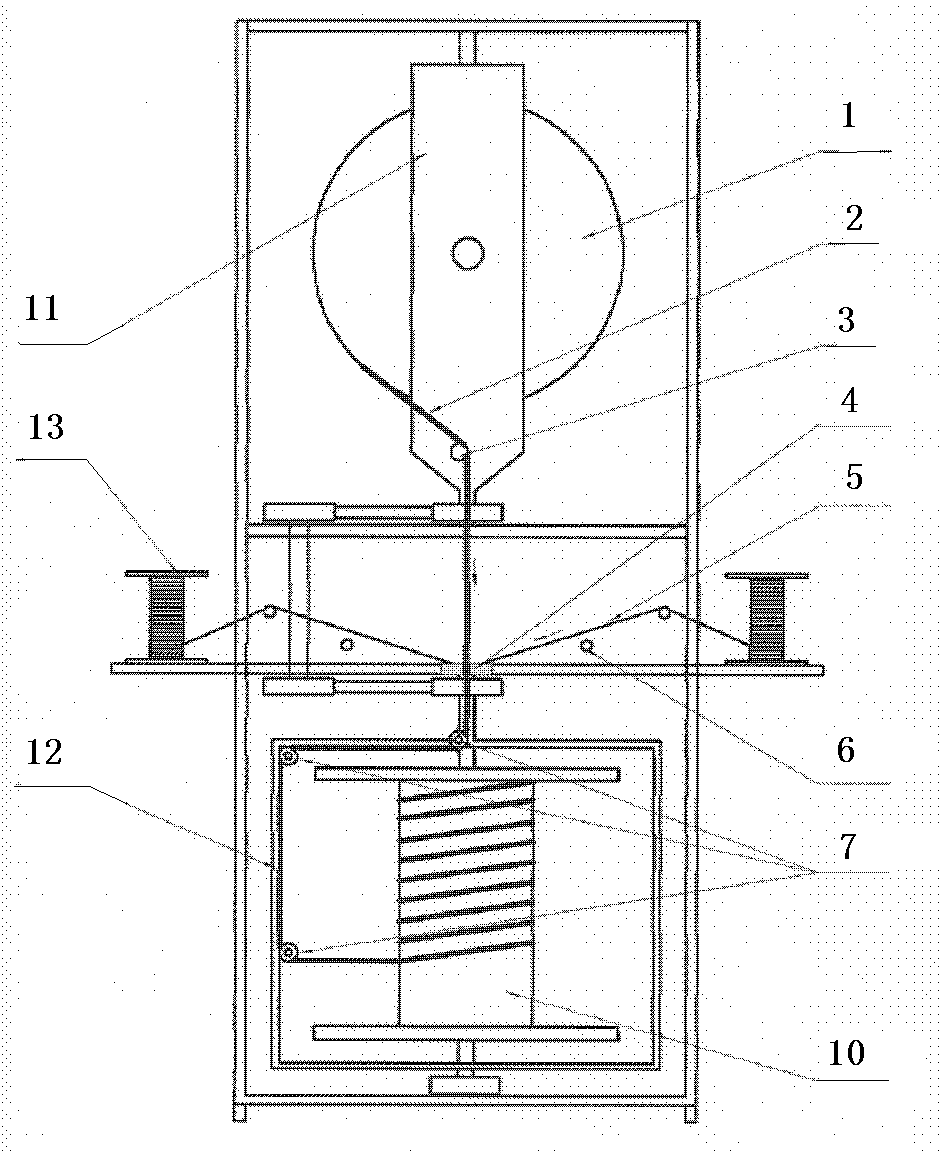

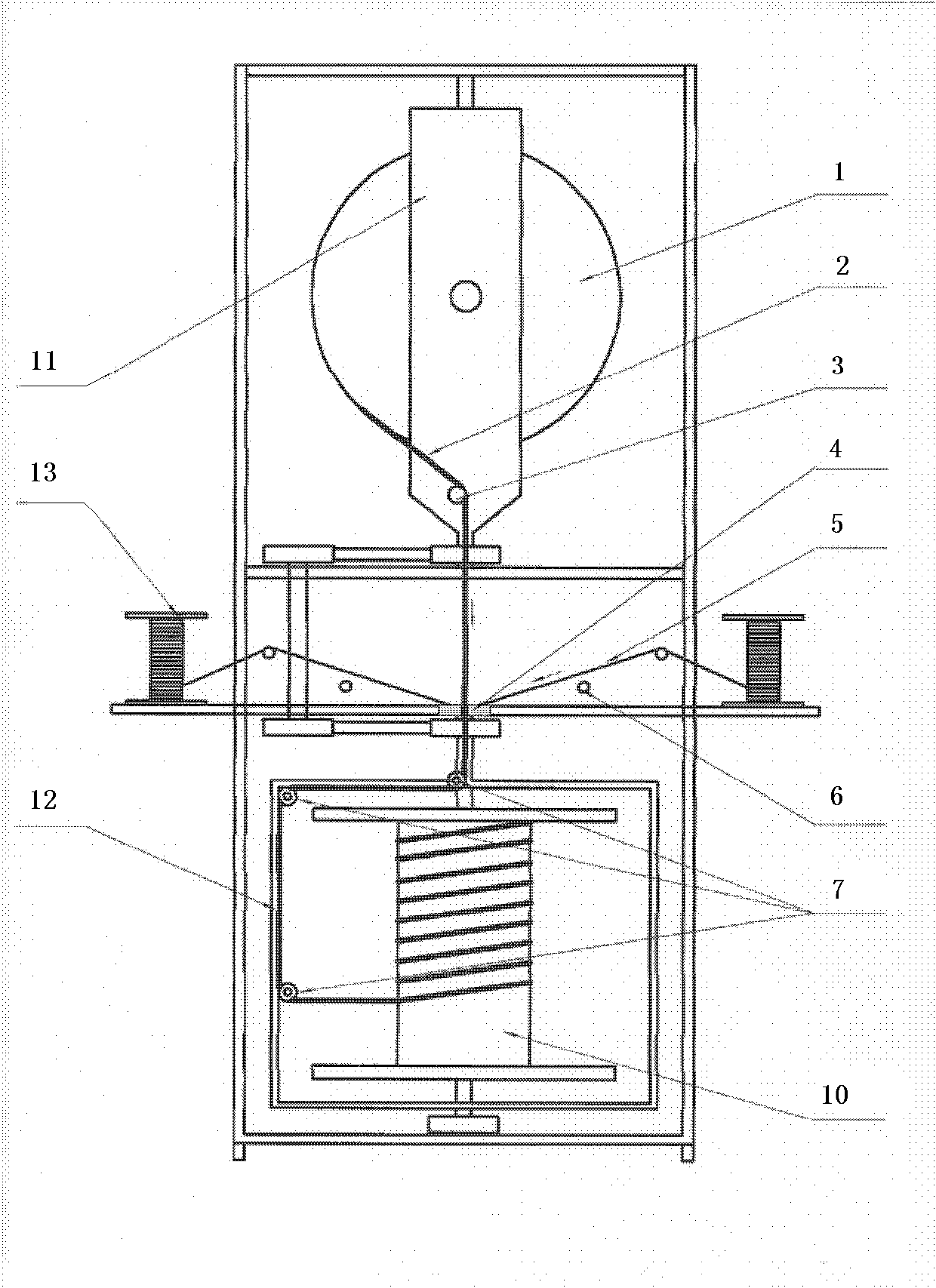

The invention relates to a manufacturing method of a semi-flexible coaxial cable shielding layer. A semi-flexible coaxial cable comprises an inner conductor, an insulating layer, a shielding layer and a jacket layer, and the semi-flexible coaxial cable shielding layer is manufactured through unidirectionally winding a metal wire on an insulating ore and then carrying out dip soldering. The manufacturing method concretely comprises the following steps of: (1) setting winding parameters of the metal wire; (2) installing a pay-off spool on which the semi-flexible coaxial cable insulating core is wound, and arranging the insulating core; (3) installing a metal wire coil for winding, arranging the metal wire, and winding the metal wire on the insulating core; and (4) fluxing the wound shielding wire coil, drying, carrying out dip soldering, air cooling, and connecting with a second take-up spool assembled on a second take-up stand. The shielding layer is formed by unidirectionally winding the metal wire, the dip soldering is even, uniform and easy, and the tin layer can not fall off due to the relative sliding of interwoven metal wires in bending. The production efficiency is six times higher than the weaving efficiency, and the energy consumption of the manufacturing method only accounts for 1 / 24 of that of the weaving process. In addition, 100 percent of shielding can be realized.

Description

(1) Technical field The invention relates to a manufacturing method of a semi-flexible coaxial cable shielding layer. (2) Background technology Conventional coaxial cables are composed of inner conductors, insulating layers, shielding layers, and sheath layers. Due to the incompactness of the braided structure of the shielding layer itself, when the shielding attenuation requirements are strict in the case of bending, its cable performance cannot meet the requirements for use. , in order to make up for the lack of density of the braiding layer, a coaxial cable with a metal tube as the shielding layer, that is, a semi-rigid coaxial cable, has appeared, but this type of cable has poor bending performance and cannot be mass-produced continuously. The semi-flexible coaxial cable dipped in tin again solves the problems of bending and continuous production. However, since the shielding layer of this type of cable adopts a two-way cross braiding structure, there will inevitably be ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01B13/016H01B13/26

Inventor 丁宗富

Owner 杭州奥达线缆科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com