Sensor magnet holder, motor having the holder incorporated therein, and method of manufacturing the motor

一种传感器、保持器的技术,应用在制造电动发电机、电动组件、机电装置等方向,能够解决蜗轮的润滑脂流到霍尔传感器的基板侧、传感器磁体停止的转矩不足等问题,达到不易裂纹、提高耐移动能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

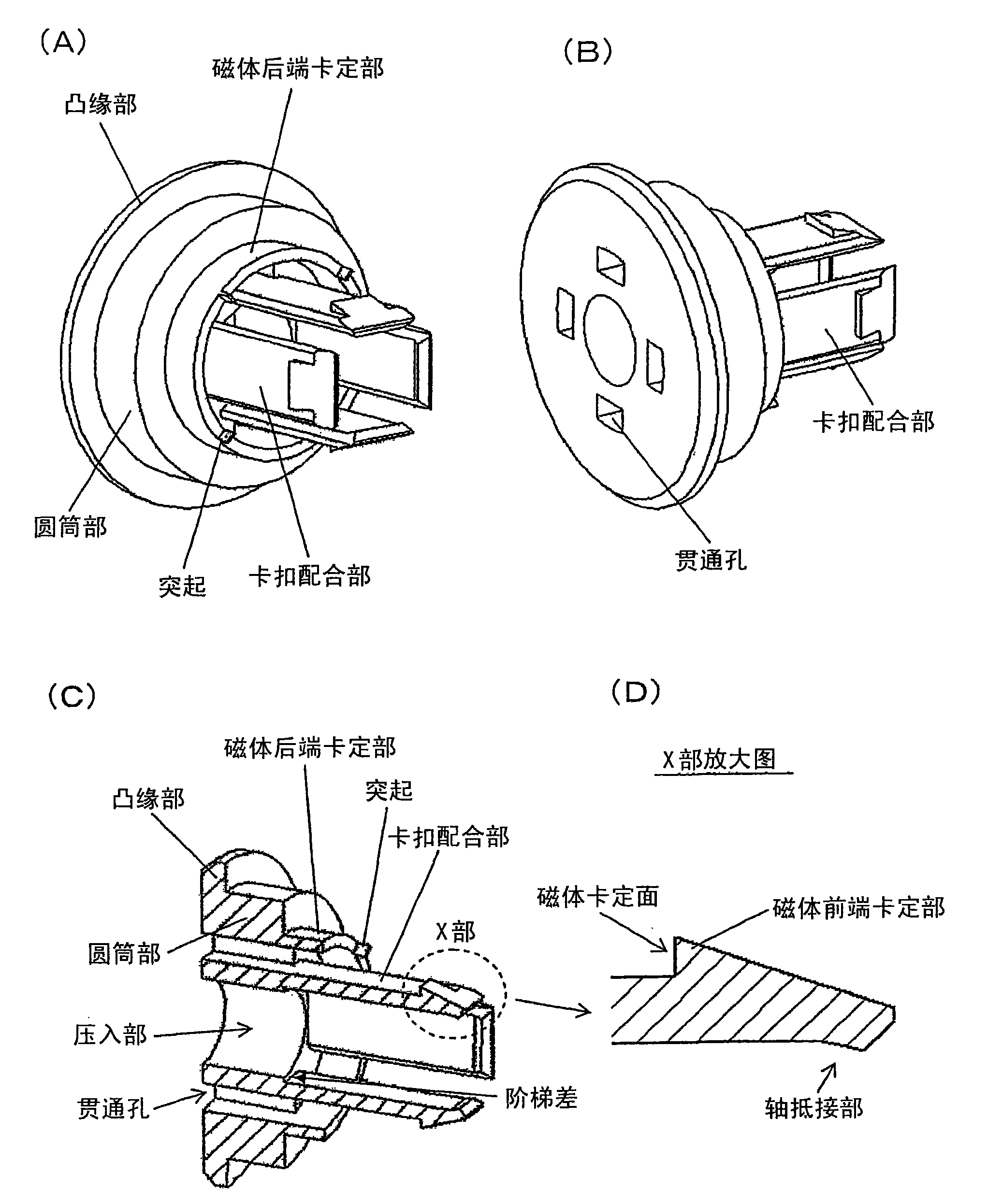

[0031] Hereinafter, the present invention will be described based on examples. The technology of the present invention, which positions and fixes the sensor magnet to a predetermined position on the shaft, can be applied to a brushless motor or a motor equipped with a worm gear reducer that needs to detect the rotation speed and rotation position as described above in the prior art. All small motors, but the following is an example for the case of motors equipped with worm gear reducers.

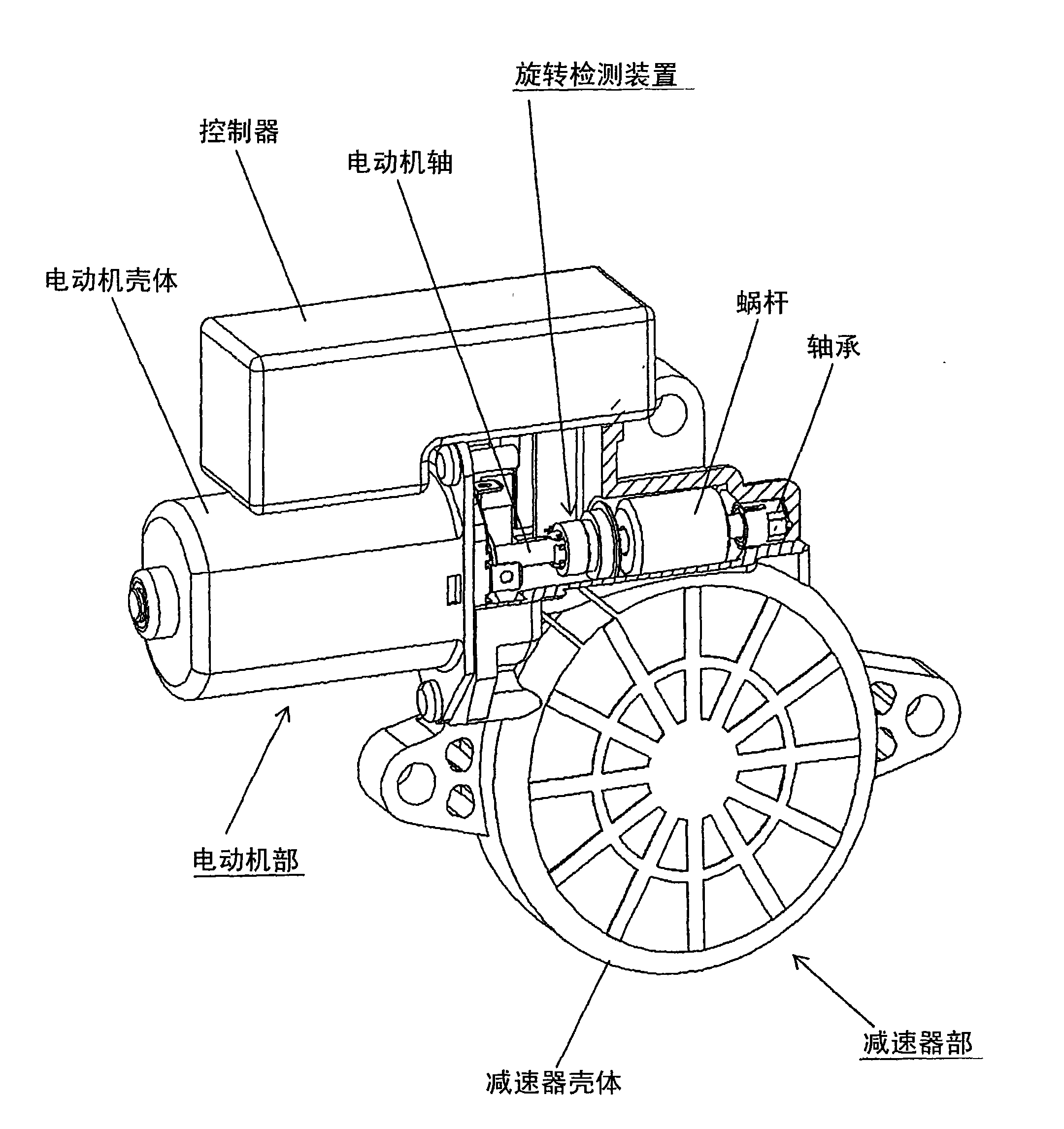

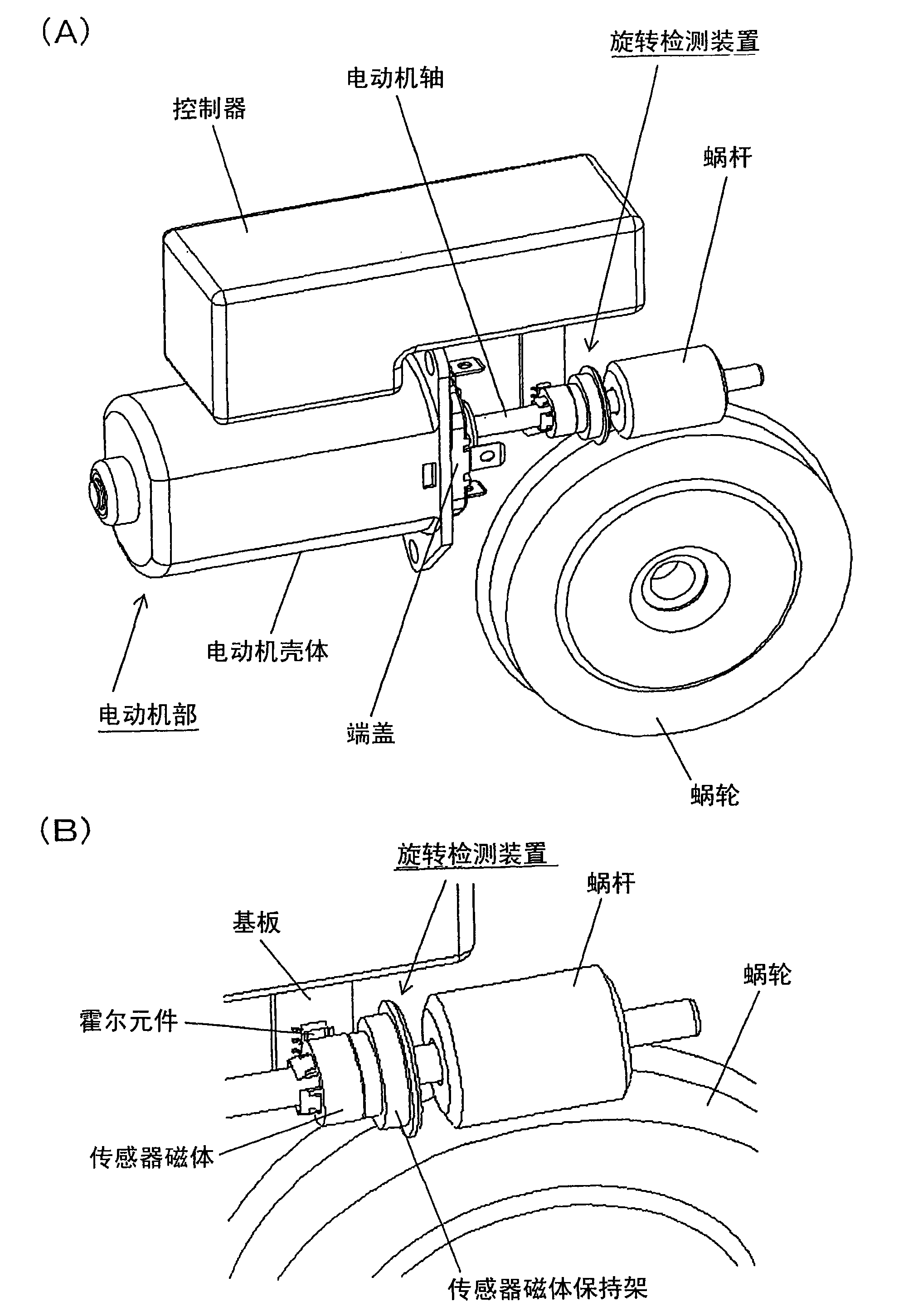

[0032] figure 1 It is a perspective view partially showing the overall structure of the electric motor with the worm gear reducer including the rotation detection device in cross-section. figure 2 (A) is a perspective view showing the rotation detection device in a state where the reduction gear case and the like are removed, and (B) is a perspective view showing a part of the rotation detection device enlarged. The speed reducer section and the controller controlling them are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com