Process for preparing titanium-silicon molecular sieve/nano-carbon fiber fiber composite catalyst

A technology of titanium-silicon molecular sieve and nano-carbon fiber, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effects of improved filtration performance, simple preparation process, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 1 g of TS-1 for industrial use, 1 g of CNF and 50 ml of distilled water into a 150 ml three-necked flask, and stir at 500 rpm for 24 hours to obtain a mixture.

[0028] Filter the mixture and dry it at 120°C for 12 hours to obtain the mixed TS-1 / CNF composite catalyst of the present invention, which is ready for use.

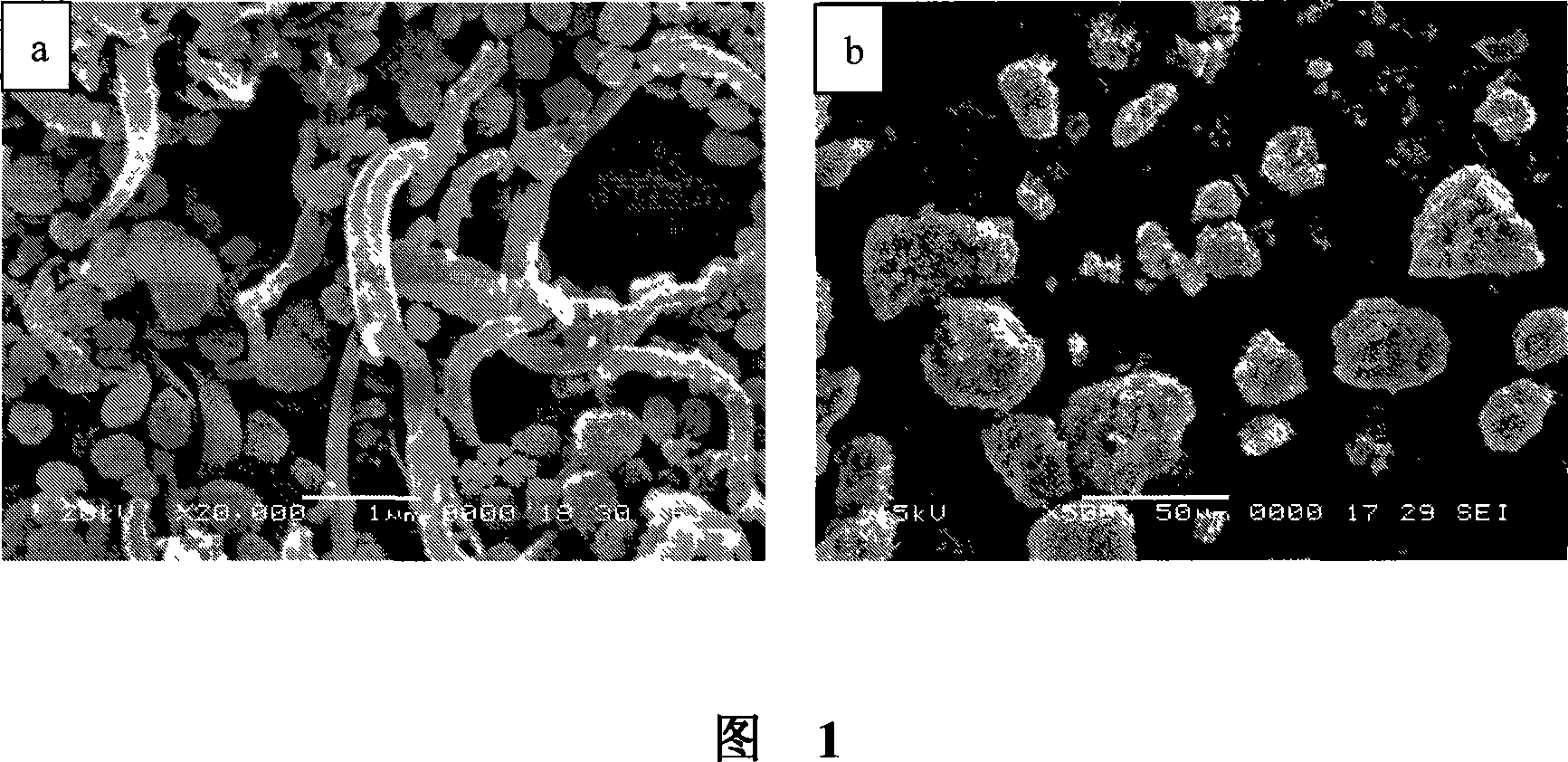

[0029] Wherein: the weight percent of the titanium silicon molecular sieve TS-1 is 50.0%, and the carbon nanofiber is 50.0%. The particle size of the titanium-silicon molecular sieve is less than or equal to 150nm, and the particle size range of the composite catalyst is 5-50 μm. The scanning electron microscope photo is shown in Figure 1.

Embodiment 2

[0031] Add 1 g of TS-1 for industrial use, 4 g of CNF and 50 ml of distilled water into a 150 ml three-necked flask, and stir at 500 rpm for 24 hours to obtain a mixture.

[0032]Filter the mixture and dry it at 120°C for 12 hours to obtain the mixed TS-1 / CNF composite catalyst of the present invention, which is ready for use.

[0033] Wherein: the weight percent of the titanium silicon molecular sieve TS-1 is 20.0%, and the carbon nanofiber is 80.0%. The particle size of the titanium-silicon molecular sieve is 100-300 nm, and the particle size range of the composite catalyst is 5-80 μm.

Embodiment 3

[0035] Add 2 g of TS-1 for industrial use, 1 g of CNF and 50 ml of distilled water into a 150 ml three-necked flask, and stir at 500 rpm for 24 hours to obtain a mixture.

[0036] Filter the mixture and dry it at 120°C for 12 hours to obtain the mixed TS-1 / CNF composite catalyst of the present invention, which is ready for use.

[0037] Wherein: the weight percent of titanium silicon molecular sieve TS-1 is 66.7%, and the carbon nanofiber is 33.3%. The particle size of the titanium-silicon molecular sieve is 100-500 nm, and the particle size range of the composite catalyst is 1-80 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com