Catalyst material as well as preparation method and application thereof

A catalytic material and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of inability to achieve perovskite catalyst specific surface area, limited oxide types, and poor hydrophobic durability. and other problems, to achieve the effect of improving catalytic performance, conducive to durability, and small steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

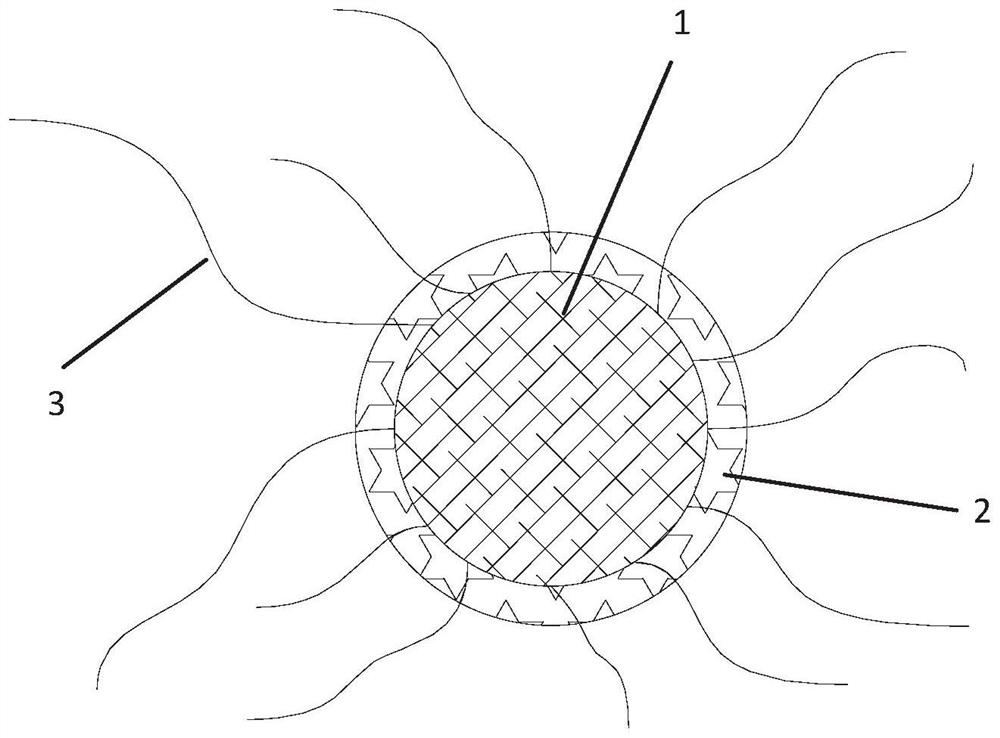

[0041] The embodiment of the present application also provides a preparation method for the above-mentioned catalyst material, including: providing a perovskite catalyst material; hydrophobically modifying the perovskite catalyst material with a hydrophobic component to obtain a perovskite-coated hydrophobic component A hydrophobically modified composite material with a core-shell structure; providing a multi-element metal oxide sol; mixing the hydrophobically-modified composite material and the multi-element metal oxide sol evenly, and applying the obtained slurry on a carrier, and then sintering at a high temperature to produce obtain the catalyst material.

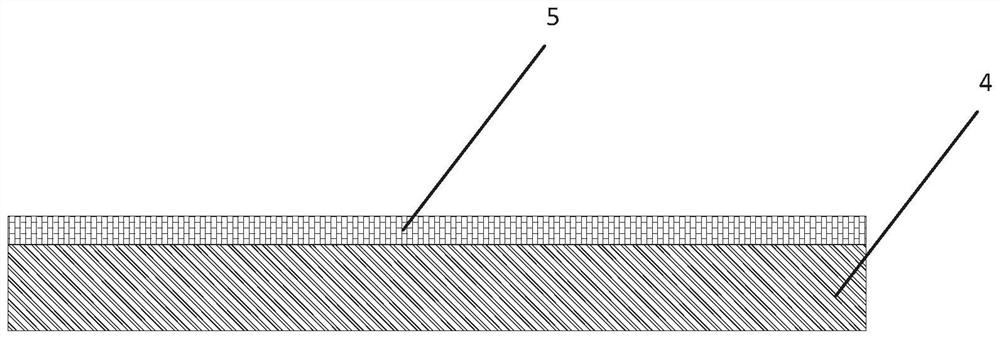

[0042] figure 2 A schematic cross-sectional view showing the surface local structure of the above-mentioned catalyst material, wherein the effective catalytic component 5 includes a core-shell structure composed of multiple cores and shell layers and a multi-element metal oxide, and the effective catalytic component 5 ...

Embodiment 1

[0073] Perovskite catalytic materials (LaCo y Fe (1-y) o 3 ) preparation

[0074] Preparation using citric acid complexation. Weigh the precursors of La, Co and Fe in proportion, add them to water, add a certain amount of citric acid and stir evenly, and keep a certain temperature under stirring to react, then dry the reaction product, and sinter at high temperature after drying to obtain the catalytic material (LaCo y Fe (1-y) o 3 ).

[0075] Among them, the precursors of La, Co, and Fe are nitrates or acetates of the corresponding metals; the molar ratio of La element: (Co+Fe) element is 1:1.1; the molar ratio of Co element: Fe element is 1:0.2 The amount of citric acid is 1.1 times the number of moles of metal elements, the reaction temperature is 50°C, and the reaction time is 2h; the drying temperature is 120°C, and the drying time is 3h; the sintering temperature is 800°C, and the sintering time is 3h.

Embodiment 2

[0077] Perovskite catalytic materials (LaCo y Fe (1-y) o 3 ) hydrophobic modification

[0078] Put the perovskite catalytic material provided in Example 1 into acetone, ultrasonically disperse, and drop the hydrophobic component into the perovskite dispersion, control the amount of the hydrophobic component, continue stirring, and add acetic acid as a catalyst A condensation reaction between the hydrophobic component and the hydroxyl group on the surface of the perovskite catalytic material can obtain a hydrophobically modified composite material with a core-shell structure coated with the hydrophobically modified component.

[0079] Among them, the hydrophobic component is a fluorine-containing compound, specifically heptadecafluorodecyltrimethoxysilane, heptadecafluorodecyltriethoxysilane, tridecafluorooctyltriethoxysilane (PFOTES, the same below), One or more combinations of fluorine-containing polysilsesquioxane; the mass ratio of perovskite catalyst:hydrophobic compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com