Composite material core used for enhanced cable, preparation process thereof and enhanced cable

A composite core and preparation process technology, which is applied in cable/conductor manufacturing, insulated cables, cables, etc. The protective film is easy to be worn or damaged, so as to achieve the effect of designability, good applicability and increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

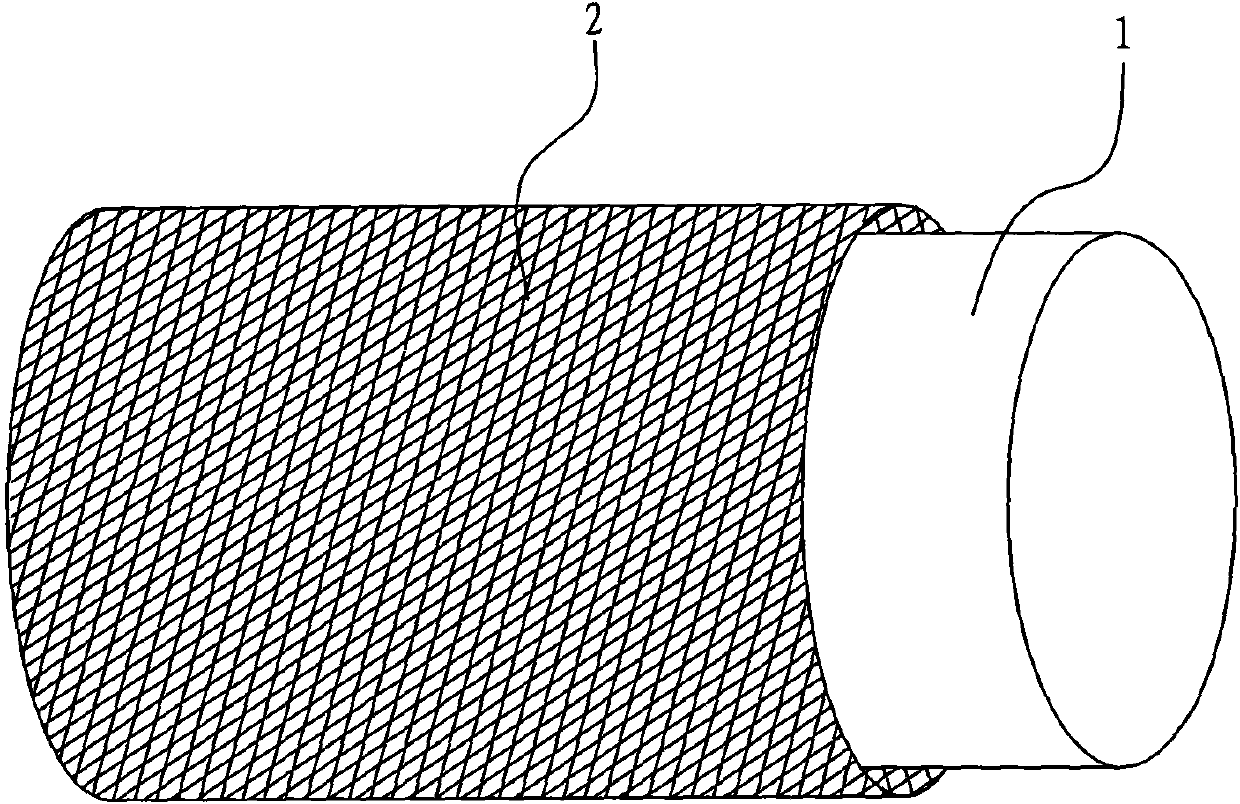

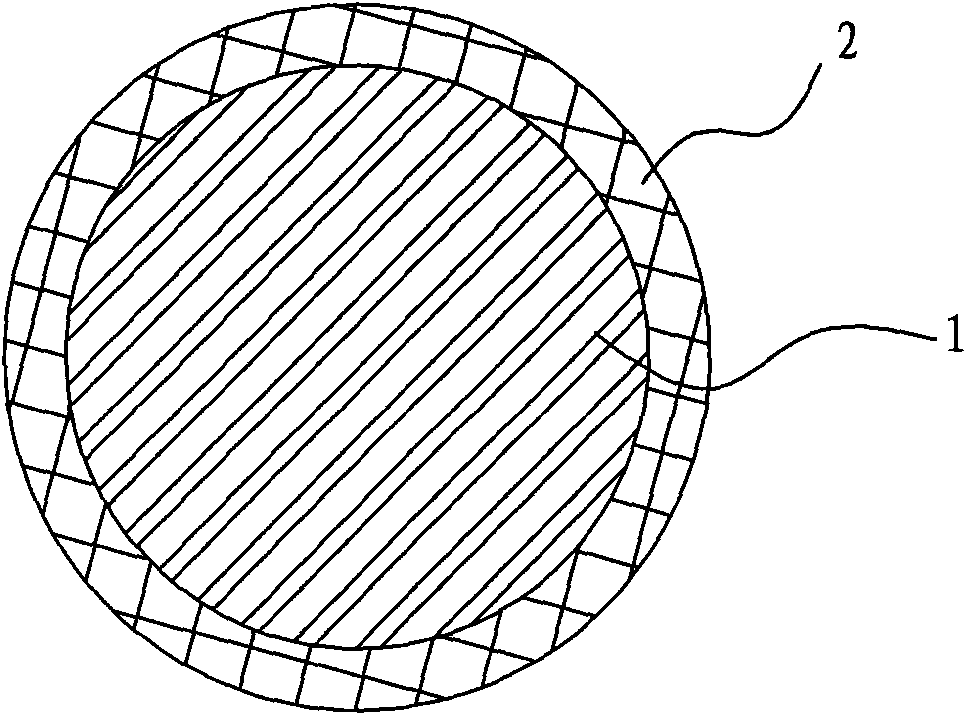

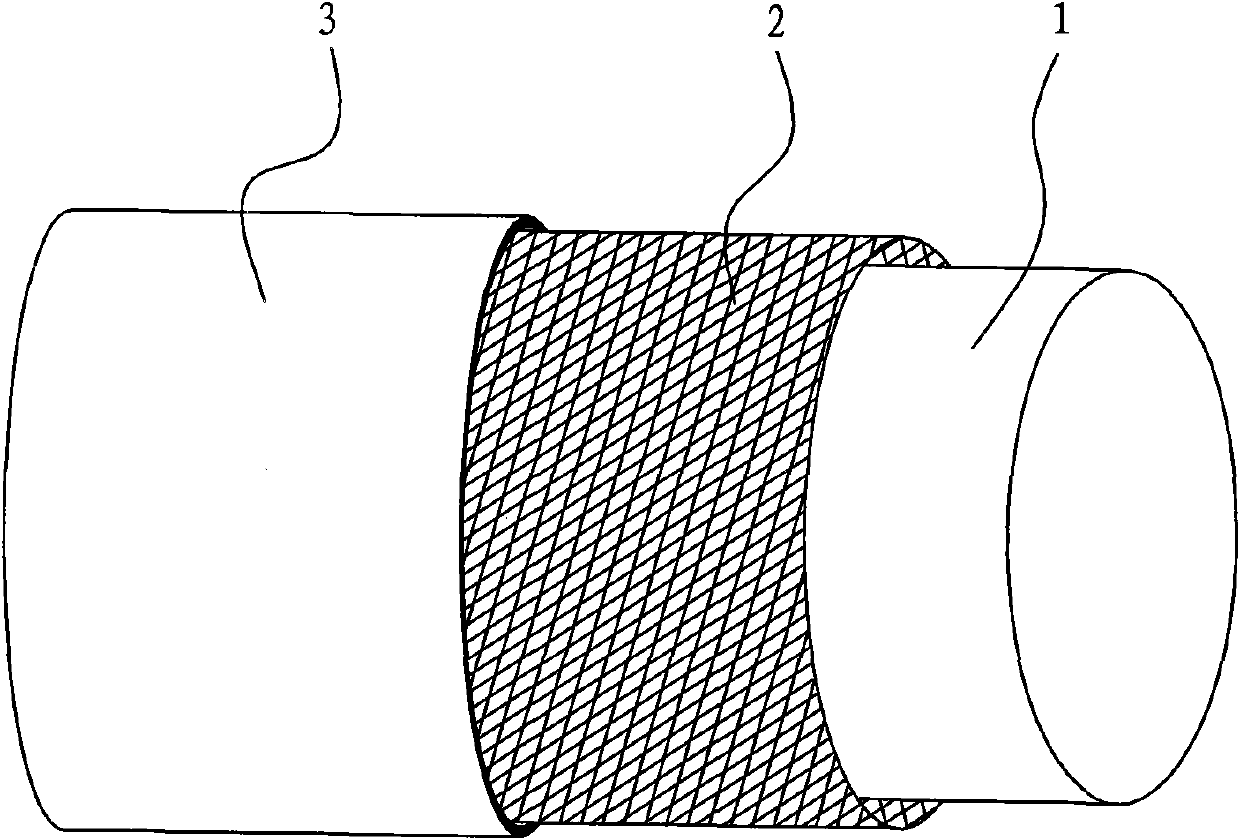

[0070] Embodiment 1: The cross-sectional area of the inner layer 1 is about 50 square millimeters, and the cross-sectional area of the outer layer 2 is about 20 square millimeters. The inner core 1 uses 60 12K carbon fibers with a fiber diameter of 7 microns; the outer layer 2 uses E glass fibers, braided with 16 bundles of glass fibers, and each bundle of glass fibers is 400Tex; a 16-spindle horizontal braiding machine is used; thermosetting resin Epoxy resin is selected, the glass transition temperature Tg is about 125°C, acid anhydride is used as curing agent, and imidazole is used as accelerator. Proportion of epoxy resin glue: epoxy resin: methyltetrahydrophthalic anhydride: 1-methylimidazole: zinc stearate = 100:80:2:2. The sum of the weight of the carbon fiber in the inner core 1 and the E-glass fiber in the outer layer 2 accounts for about 50% of the total weight of the composite core.

[0071] The specific production steps are as follows:

[0072] 60 rolls of ca...

Embodiment 2

[0074] Embodiment 2: The cross-sectional area of the inner layer 1 is about 29 square millimeters, and the cross-sectional area of the outer layer 2 is about 2.6 square millimeters. The inner core 1 uses 46 12K carbon fibers with a fiber diameter of 7 microns; the outer layer 2 uses E glass fibers, braided with 24 bundles of glass fibers, and each bundle of glass fibers is 120 two strands; a 24-spindle horizontal braiding machine is used 7 ; The thermosetting resin is epoxy resin, the glass transition temperature Tg is about 160 ℃, acid anhydride is used as curing agent, and imidazole is used as accelerator. Proportion of epoxy resin glue: epoxy resin: methyltetrahydrophthalic anhydride: 1-methylimidazole: zinc stearate = 100:80:1.5:2. The sum of the weight of the carbon fiber in the inner core 1 and the E-glass fiber in the outer layer 2 accounts for about 75% of the total weight of the composite core.

[0075] The specific production steps are as follows:

[0076] 46 r...

Embodiment 3

[0078] Embodiment 3: The cross-sectional area of the inner core 1 is about 74 square millimeters, and the cross-sectional area of the outer layer 2 is about 52 square millimeters. Inner core 1 uses 100 12K carbon fibers with a fiber diameter of 7 microns, and 50 800Tex basalt fibers with a fiber diameter of 9 microns. The inner core 1 uses carbon fibers and basalt fibers in a mixed arrangement; the outer layer 2 uses two horizontal braiding machines 7 weaving, the first weaving machine 7 is 24 spindles, the second weaving machine 7 is 16 spindles, the 24-spindle braiding machine 7 is woven with 24 bundles of E glass fibers, and each bundle of glass fibers is 400Tex; the 16-spindle braiding machine 7 It is braided with 16 bundles of aramid fibers, and each bundle of aramid fibers is made of Kevlar49; the thermosetting resin is made of epoxy resin, the glass transition temperature Tg is about 190°C, and acid anhydride is used as a curing agent, and imidazole is used as an acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com