Method for preparing NiO@SiO2@TiO2 coaxial three-layer nano cable

A nano-cable, coaxial electrospinning technology, used in the manufacture of coaxial cables, spinning solution preparation, filament/wire forming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

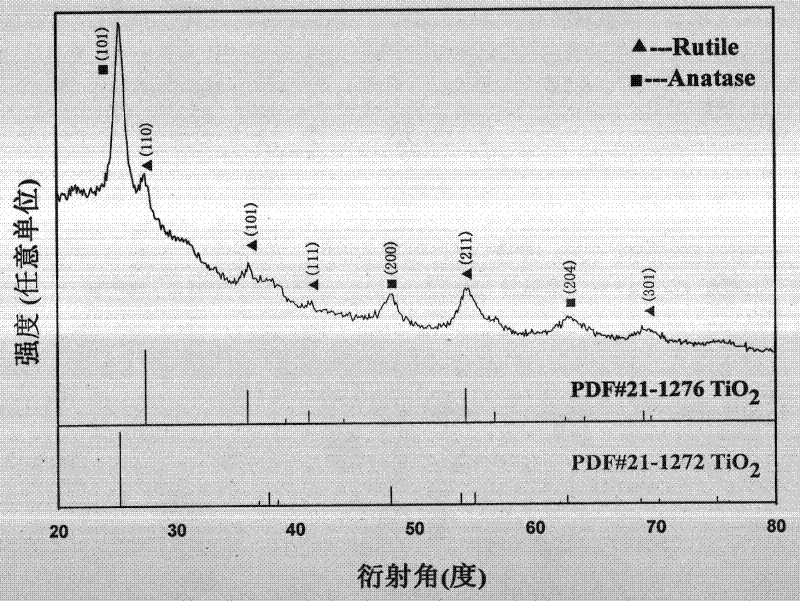

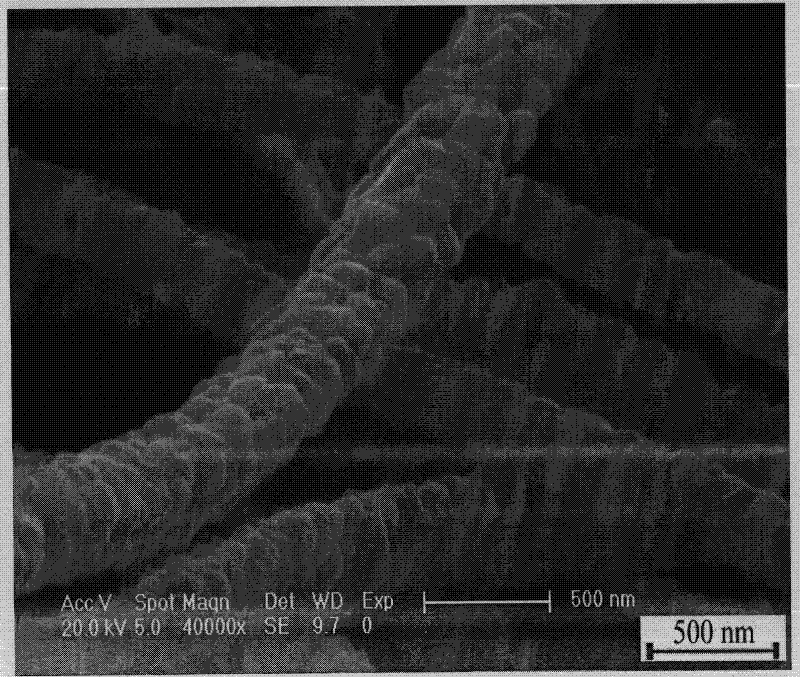

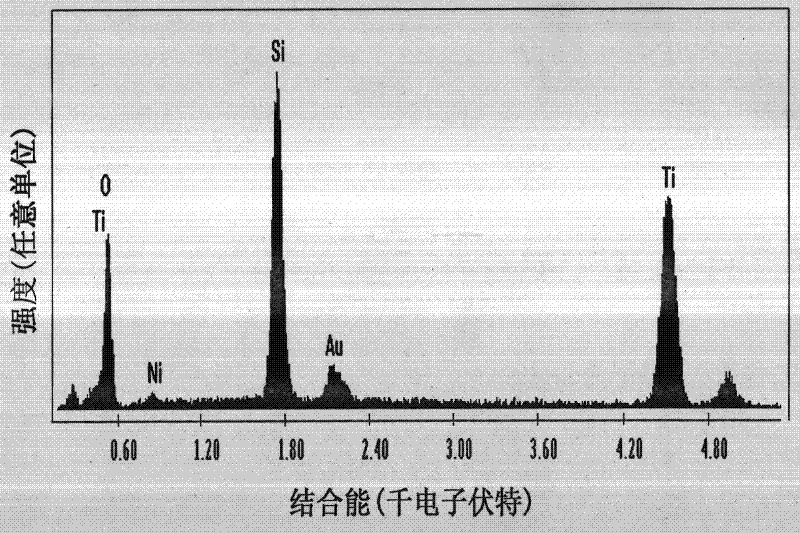

[0019] Embodiment: nickel acetate tetrahydrate Ni(CH 3 COO) 2 4H 2 O and polyvinylpyrrolidone PVP (molecular weight: 90,000) were added to N, N-dimethylformamide DMF, magnetically stirred at room temperature for 6 hours, and left to stand for 3 hours to form a core spinning solution. The mass percent of each substance is: Ni(CH 3 COO) 2 4H 2 O is 7%, PVP is 11%, DMF is 82%; the (C 2 h 5 O) 4 Si and PVP added to CH 3 CH 2 In OH, under room temperature magnetic stirring 6h, and leave standstill 3h, namely form the middle layer spinning solution, the mass percent of each material in the middle layer spinning solution is: (C 2 h 5 O) 4 Si is 31%, PVP is 17%, CH 3 CH 2 OH is 52%; Butyl titanate Ti(OC 4 h 9 ) 4 , PVP and glacial acetic acid CH 3 Add COOH to absolute ethanol CH 3 CH 2 OH, magnetically stirred at room temperature for 6 hours, and left to stand for 3 hours to form a shell spinning solution. The mass percentage of each substance in the shell spinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com