Paste extruded insulator with air channels

a technology of extruded insulators and air channels, which is applied in the direction of insulating conductors/cables, cables, insulated conductors, etc., can solve the problems of difficult formation of large diameter ptfe insulators into large diameter insulators for wires, high cost of large diameter ptfe insulators, and inability to form structures of polyethylene, polypropylene or polyvinyl chloride, etc., to facilitate drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

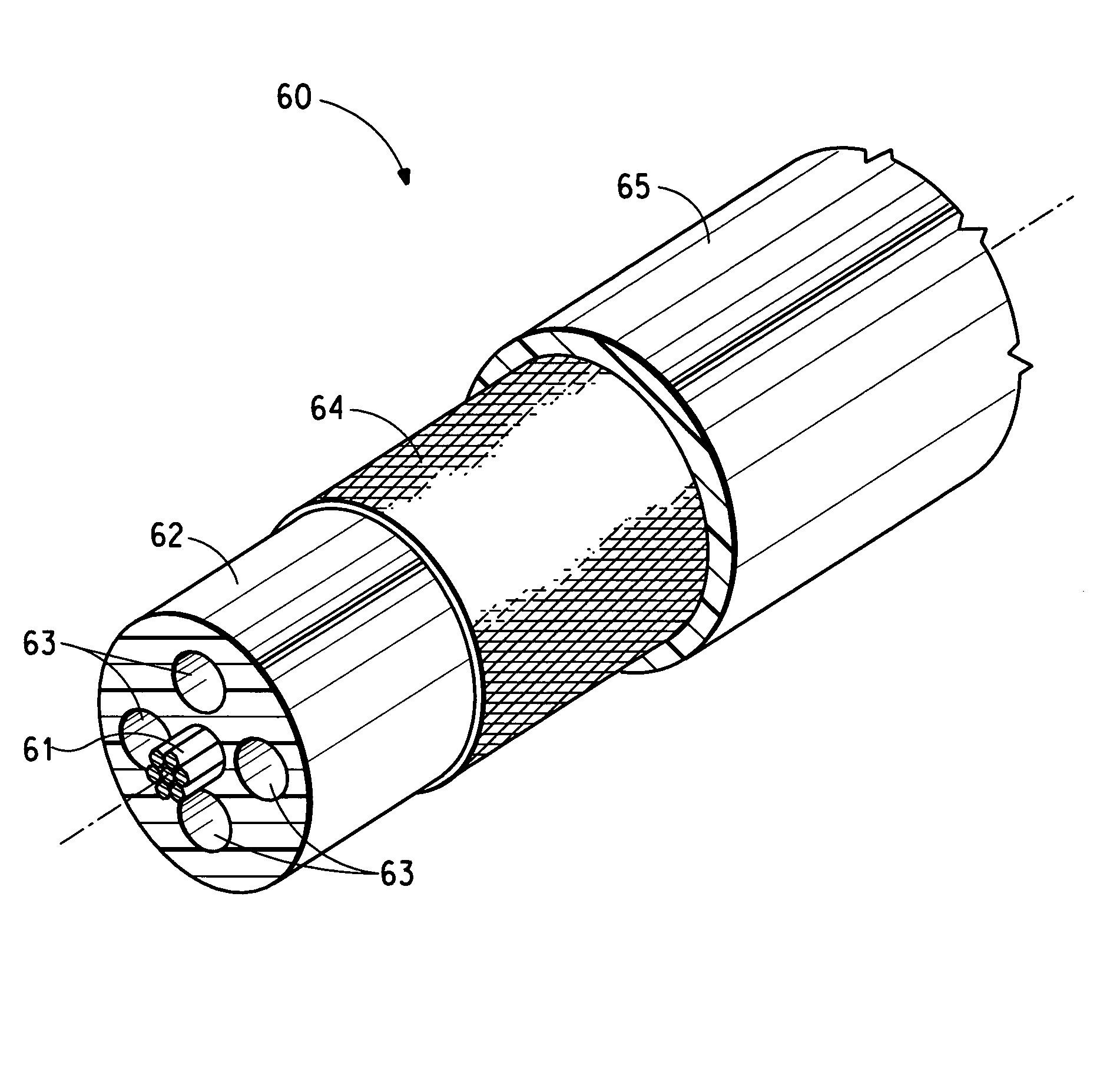

[0018] This invention relates to a process for paste extruding lubricated PTFE fine powder around a conductor forming an insulator having at least one closed continuous longitudinal air channel spaced apart from the conductor. Air channels in the insulator provide a means for aiding the removal of volatilized lubricant from the green extrudate during manufacture and for reducing the dielectric constant of the sintered product which is especially useful for high frequency communication cables.

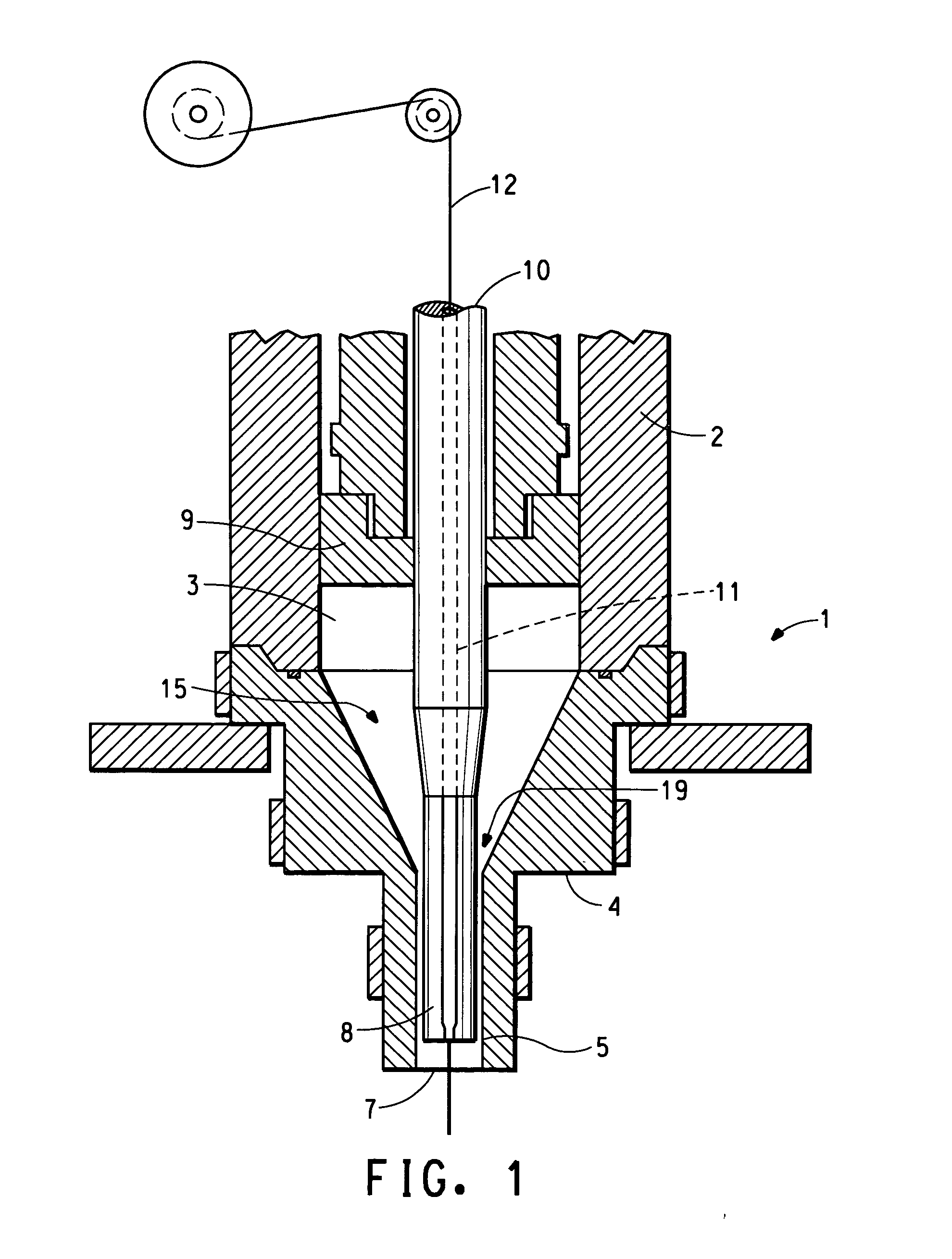

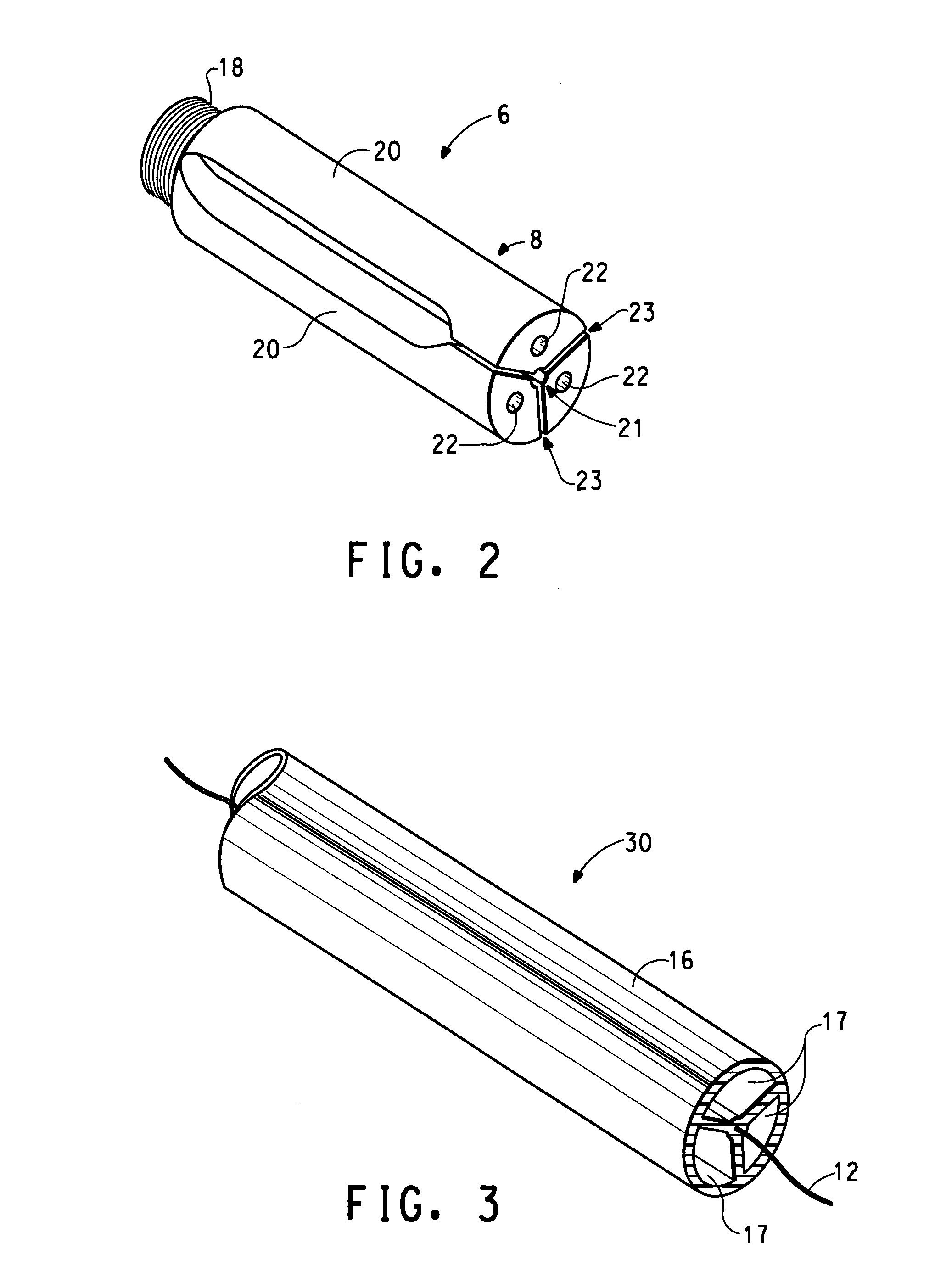

[0019] The process of paste extrusion of lubricated PTFE fine powder may be understood with reference to FIG. 1 wherein there is shown an extrusion device 1 having a barrel 2 and a die 4. Inside device 1 there is defined a chamber 3 for supplying lubricated PTFE which leads to extrusion orifice 5. Positioned within the chamber is mandrel 10 for shaping the PTFE and positioned within orifice 5 is at least one channel-forming member 8. The die and the mandrel cause chamber 3 to converge in the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com