Patents

Literature

238results about "Cable insulation construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

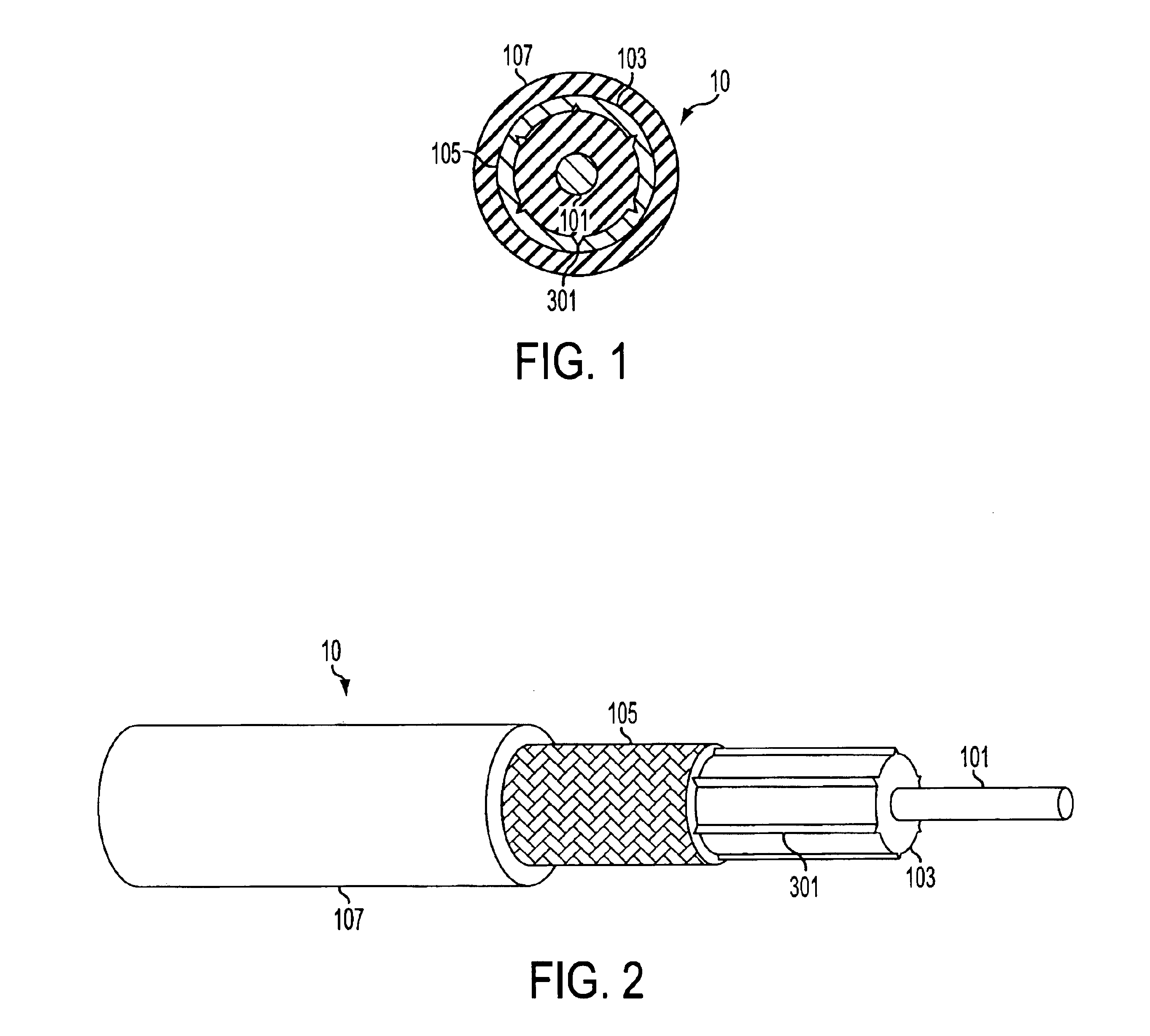

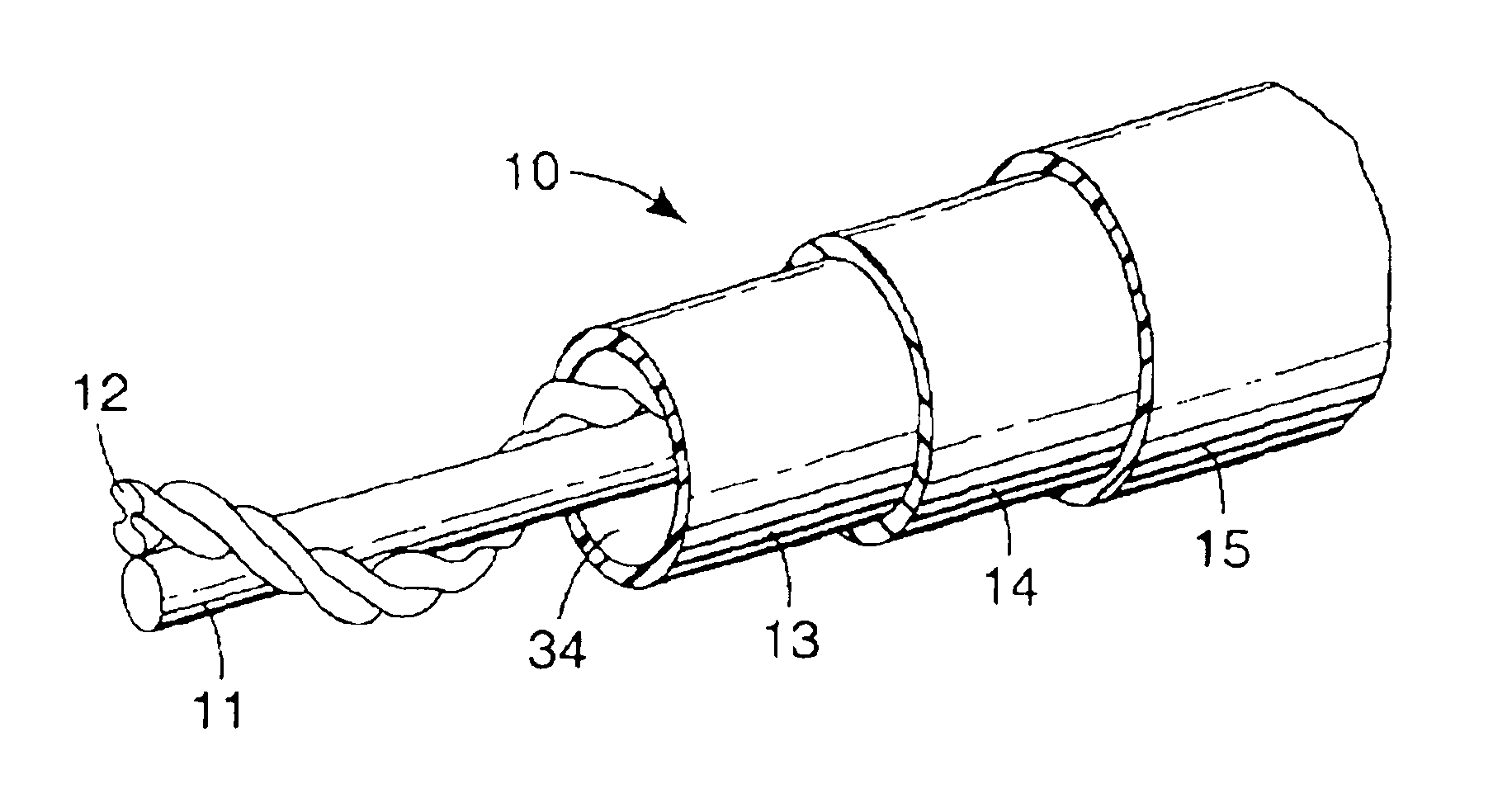

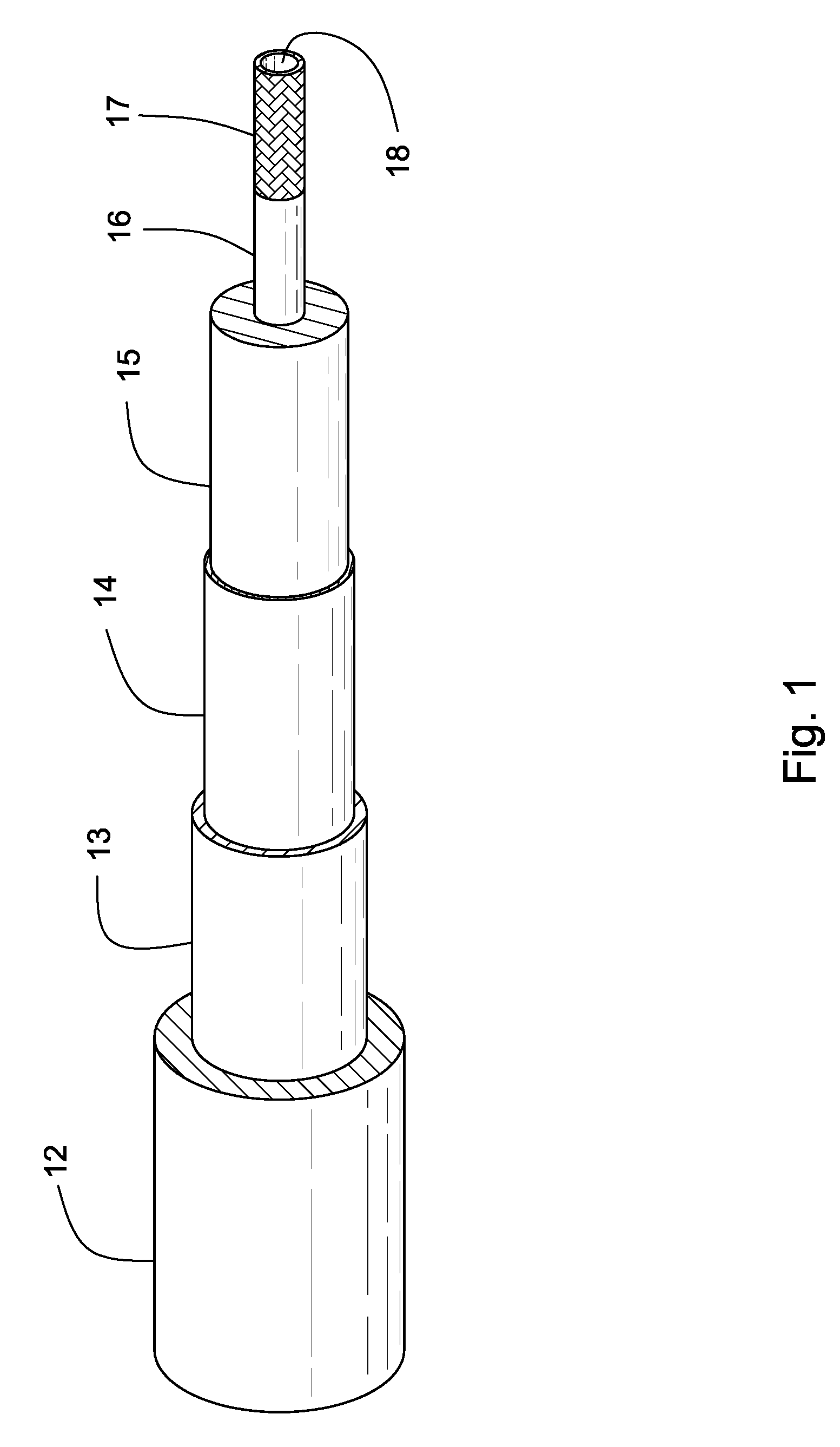

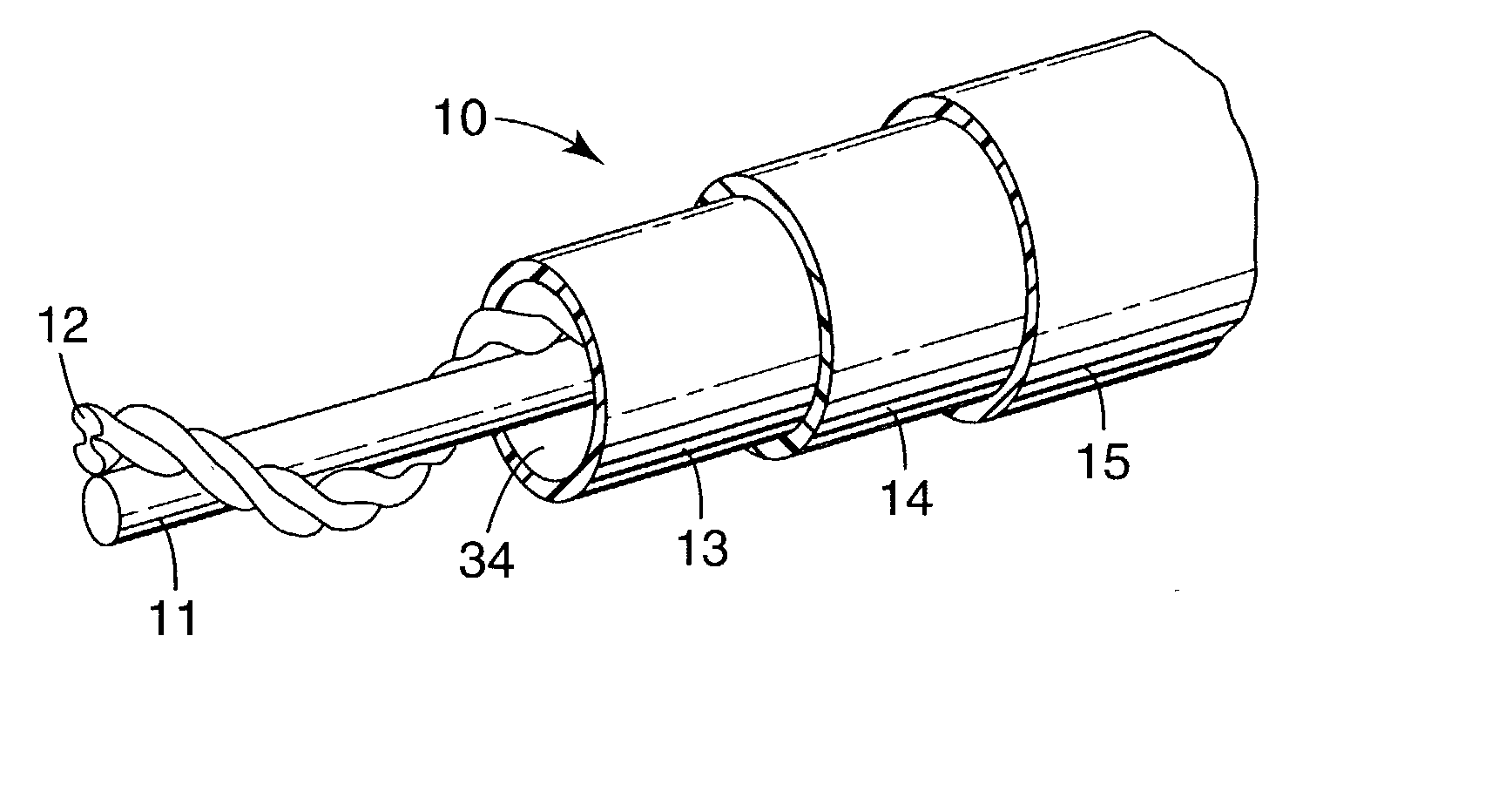

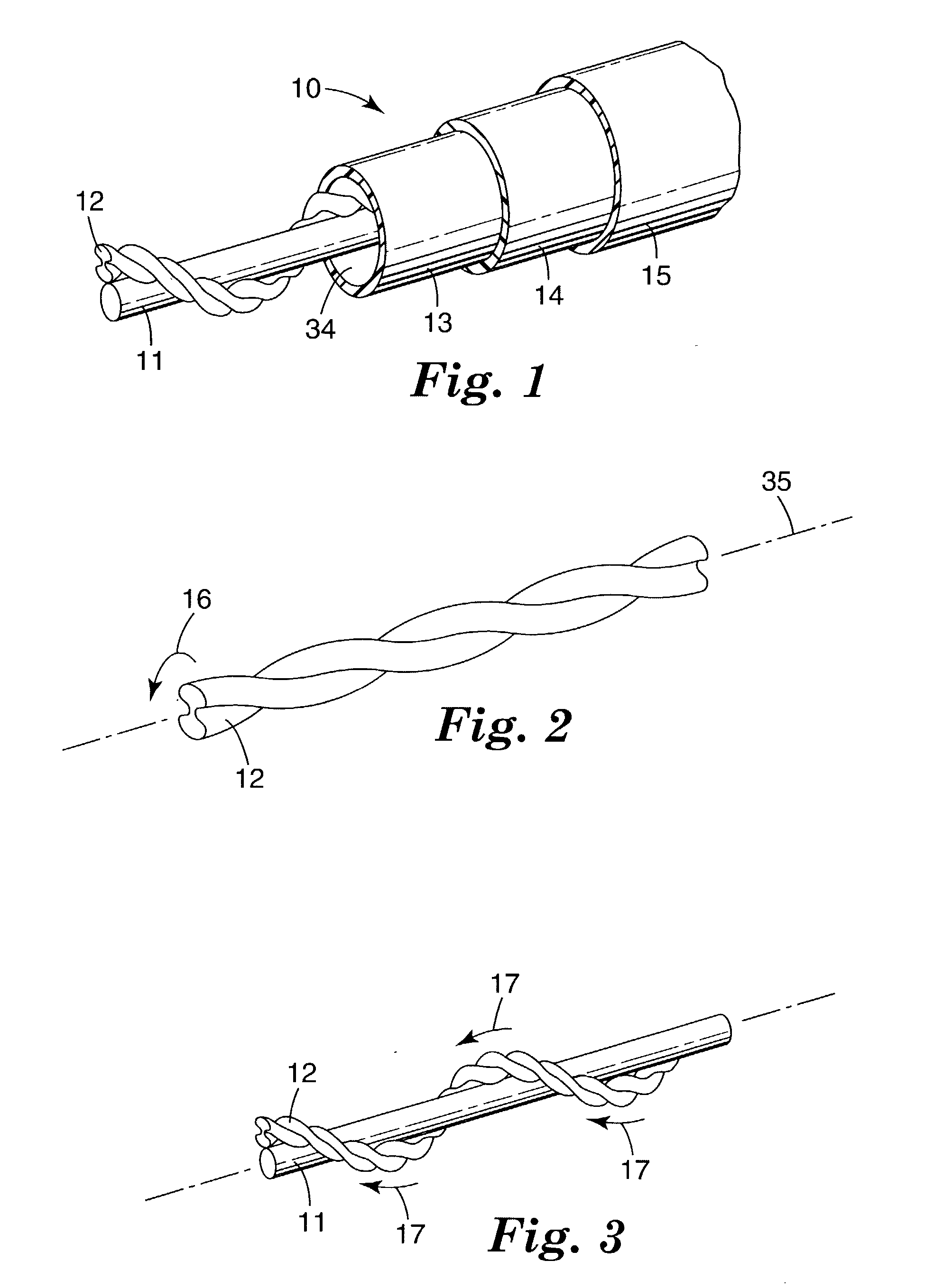

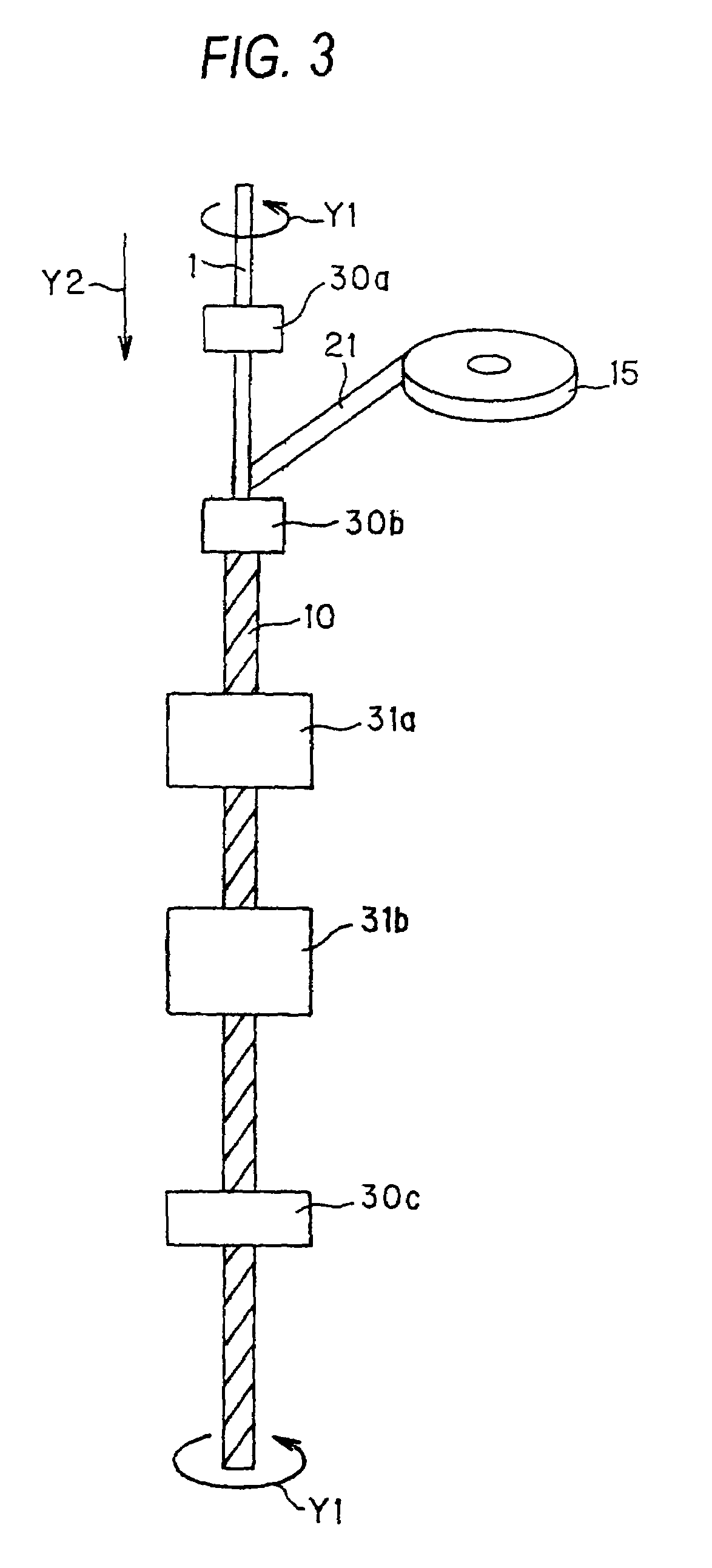

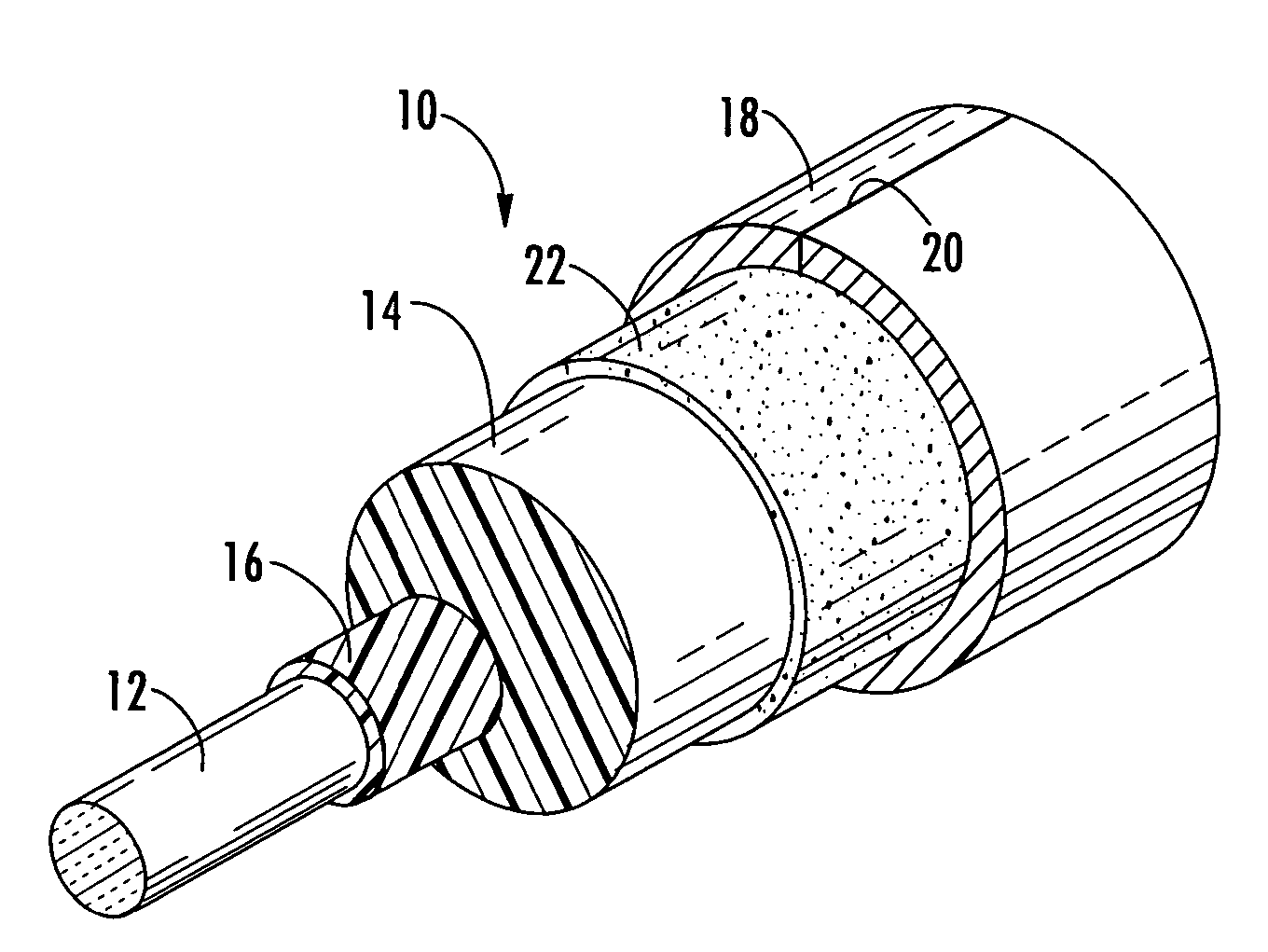

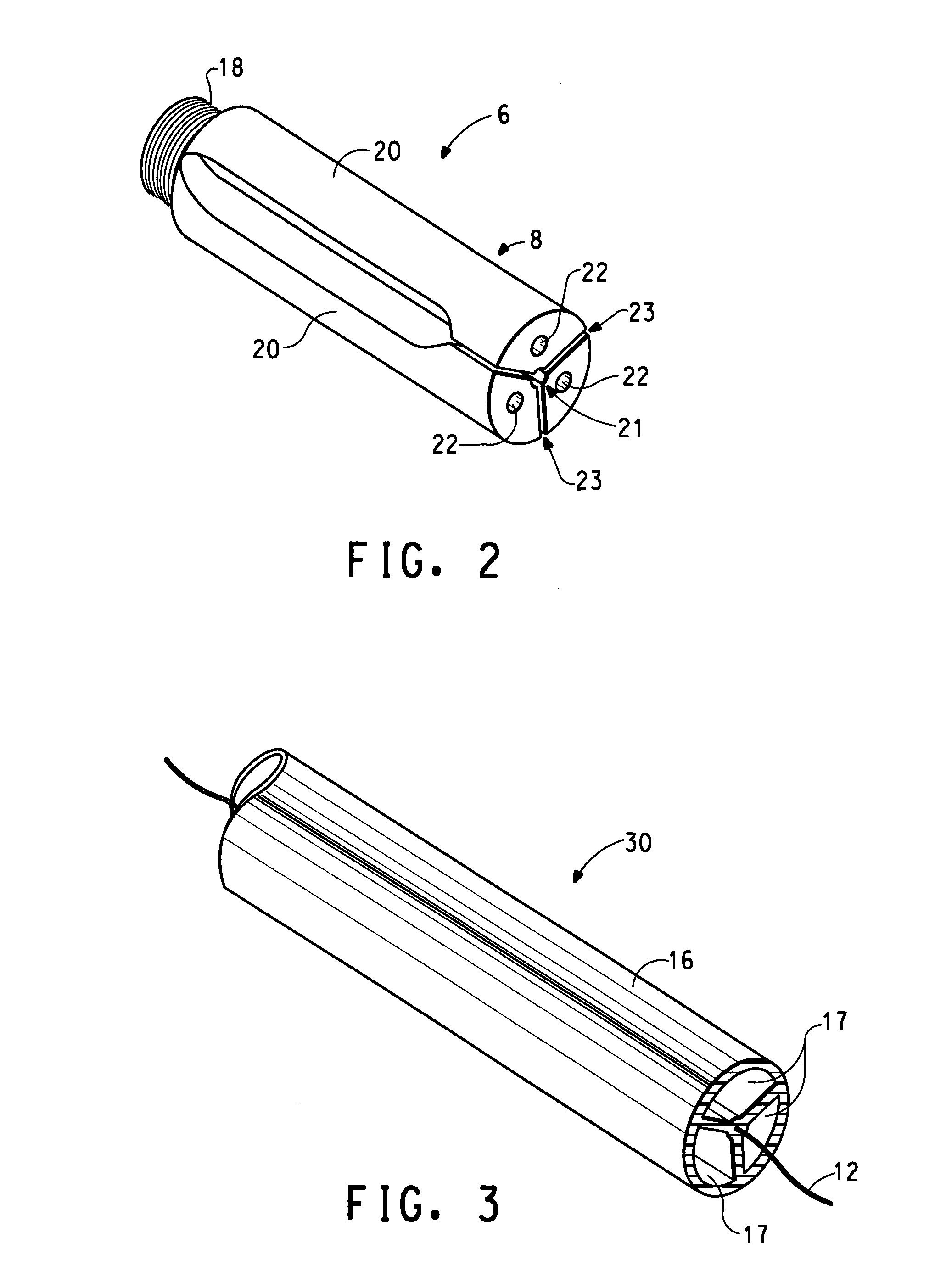

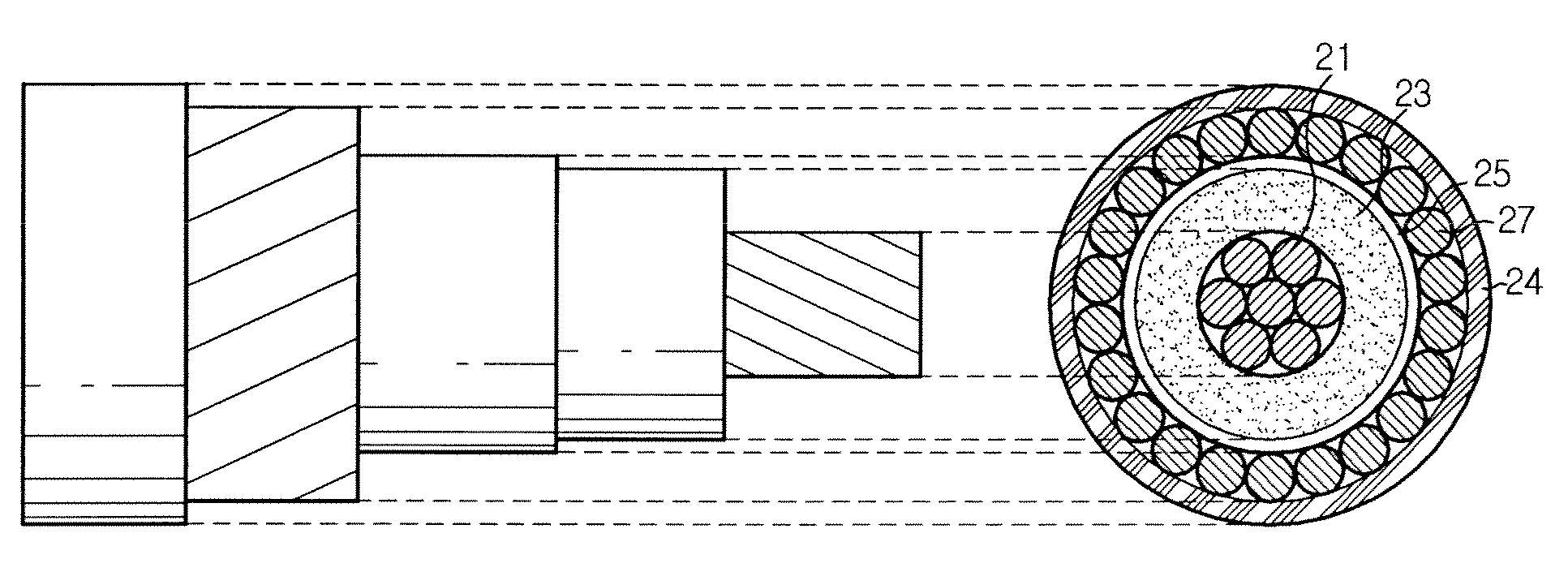

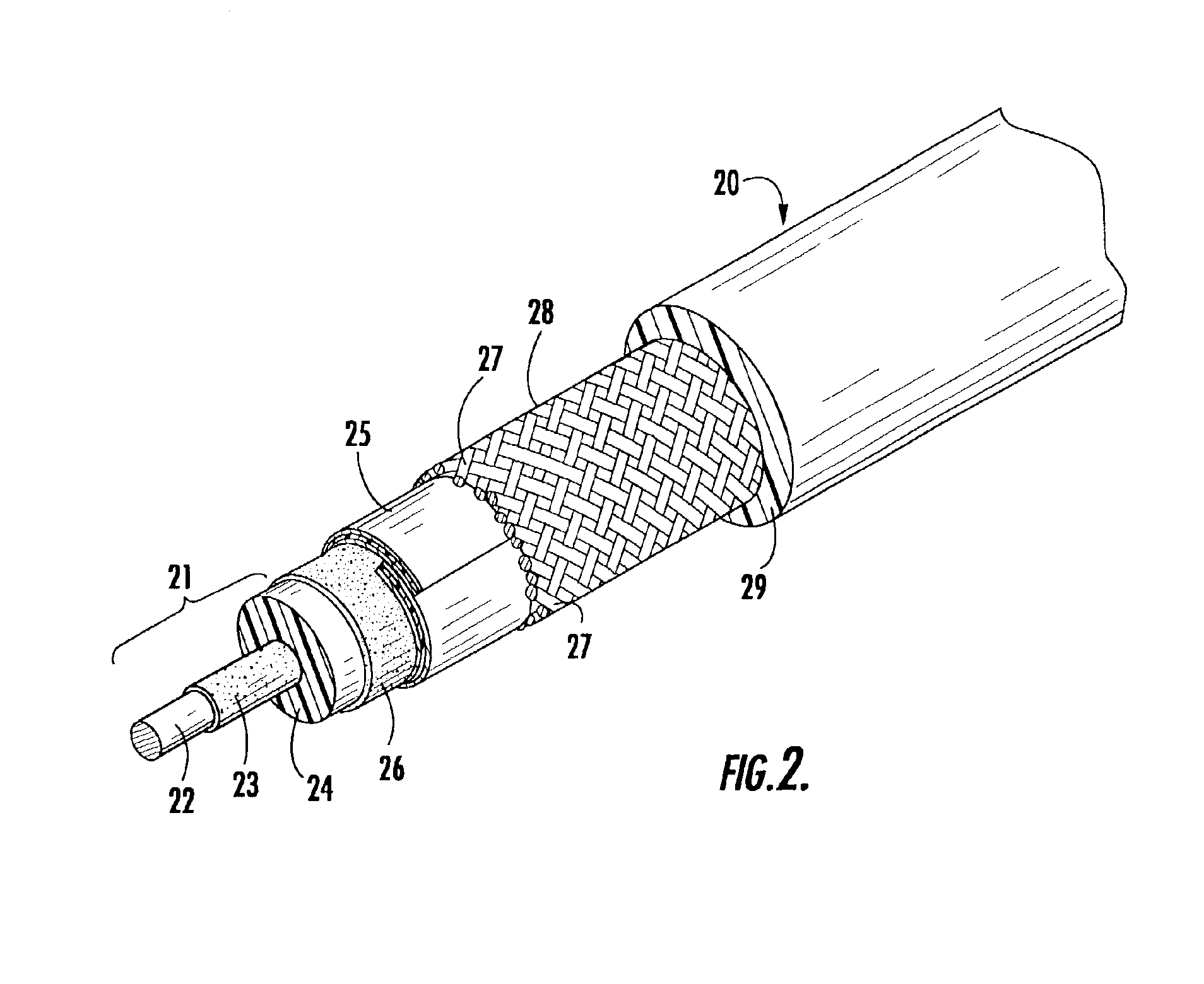

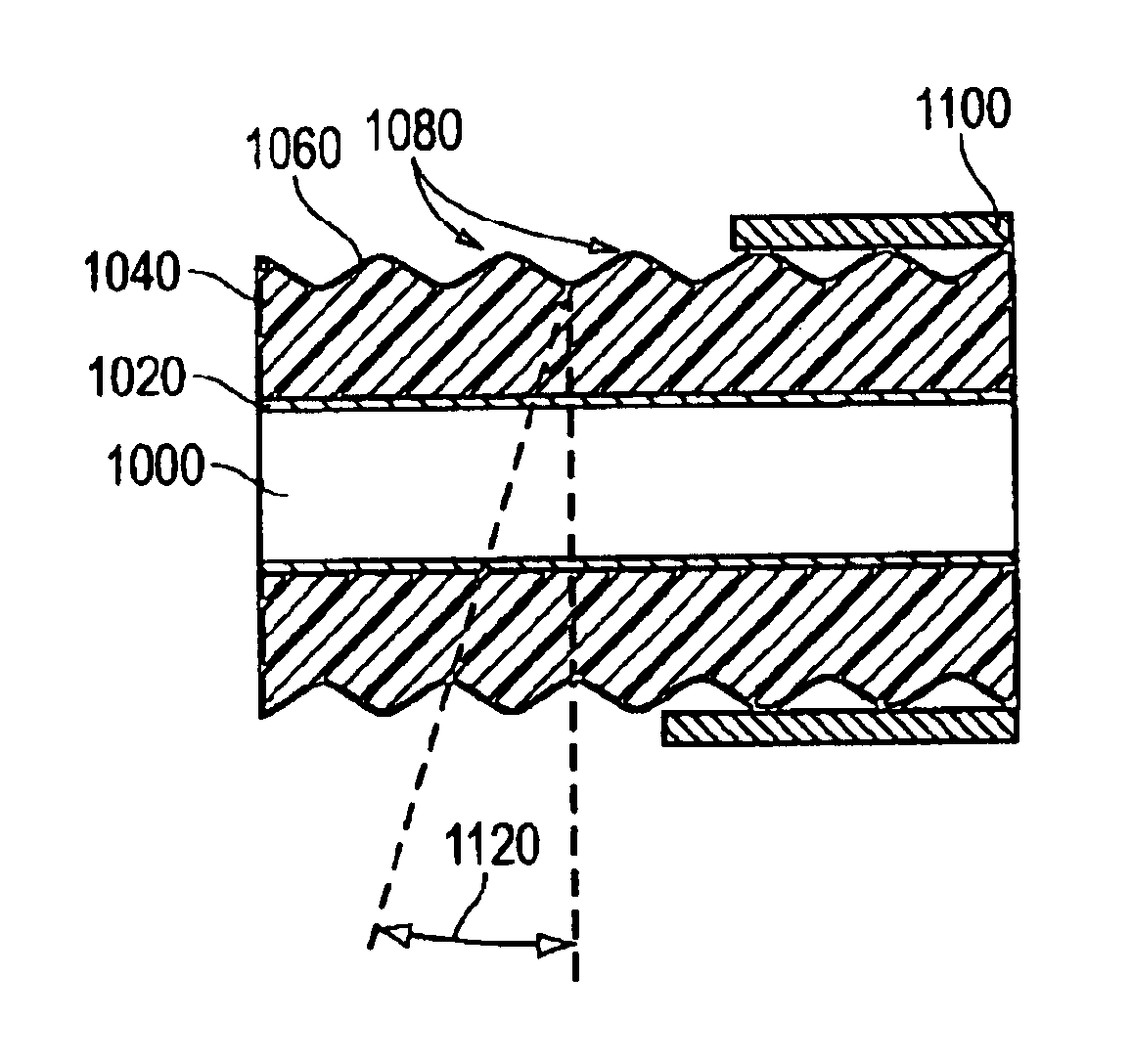

Load-Resistant Coaxial Transmission Line

ActiveUS20050067159A1Improve conductivityLow constantDrilling rodsCable insulation constructionDielectricElectricity

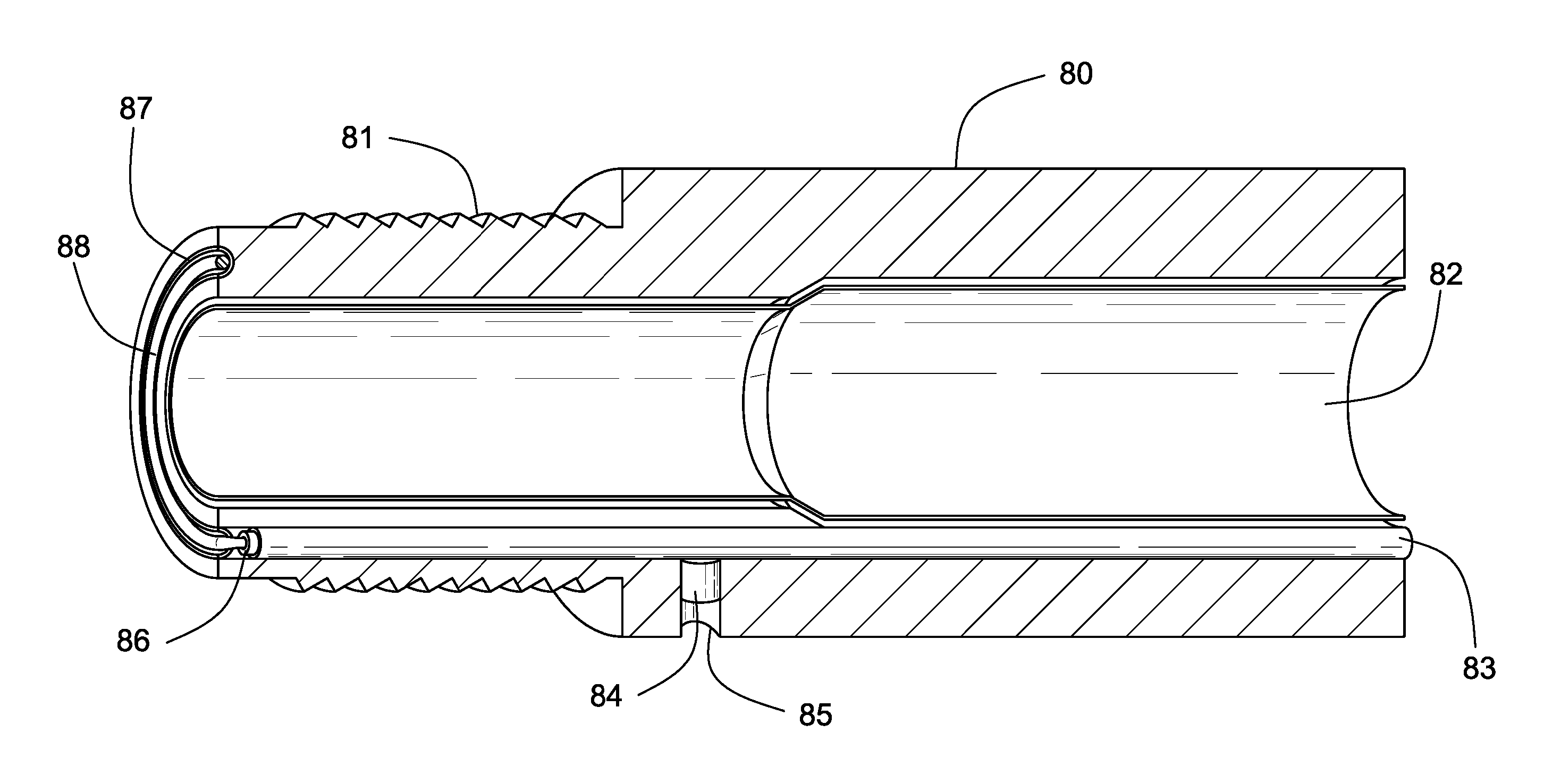

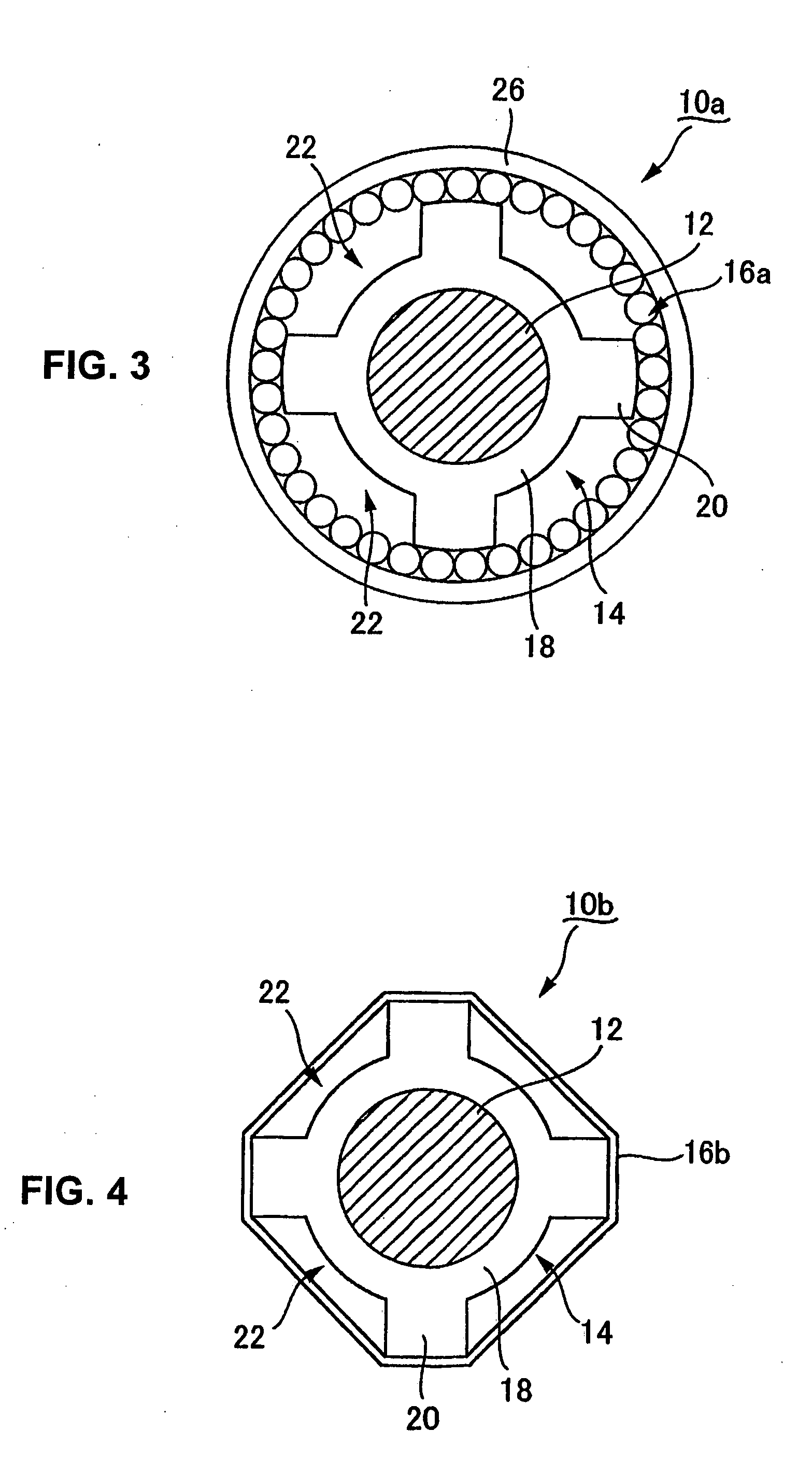

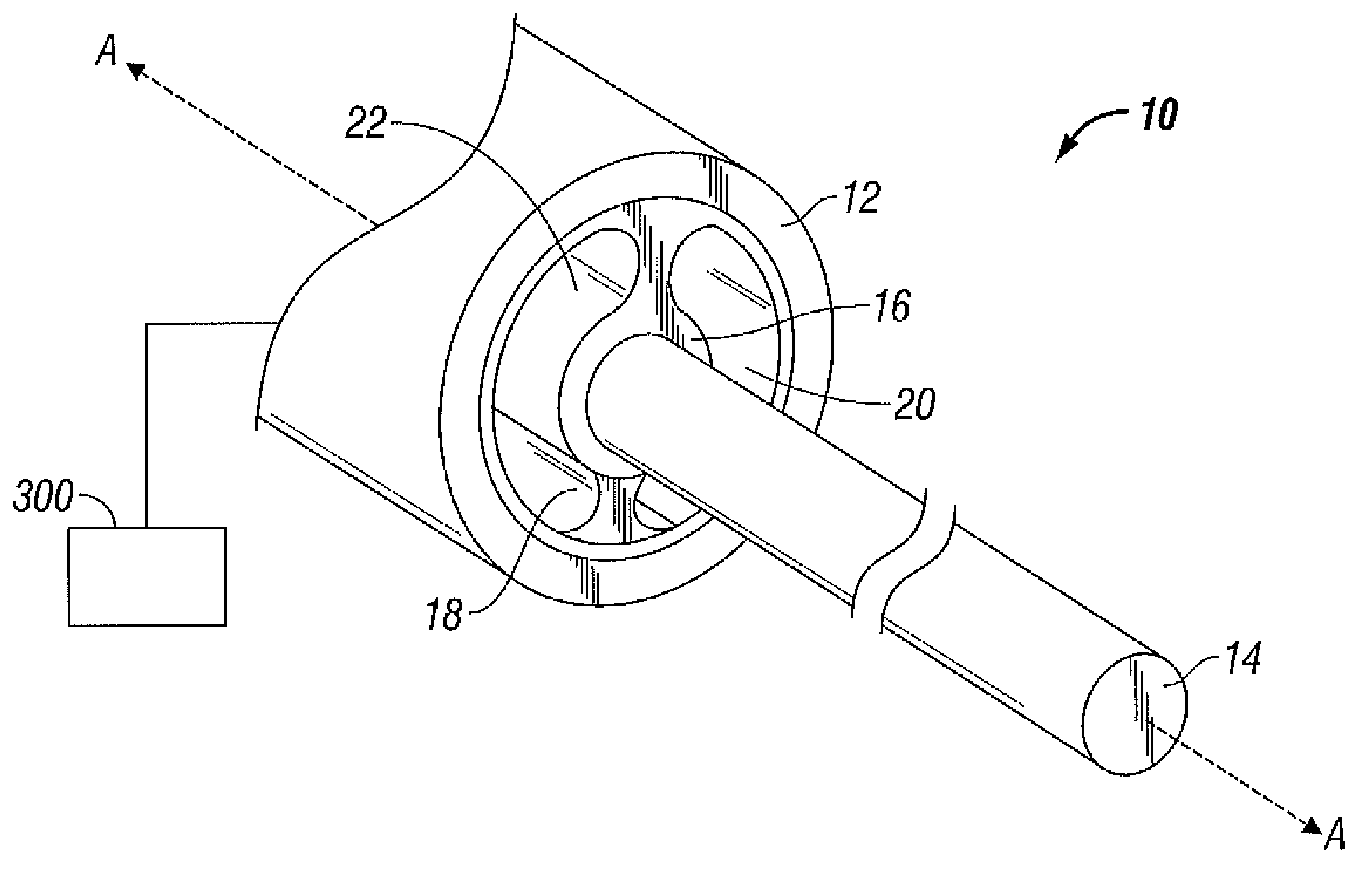

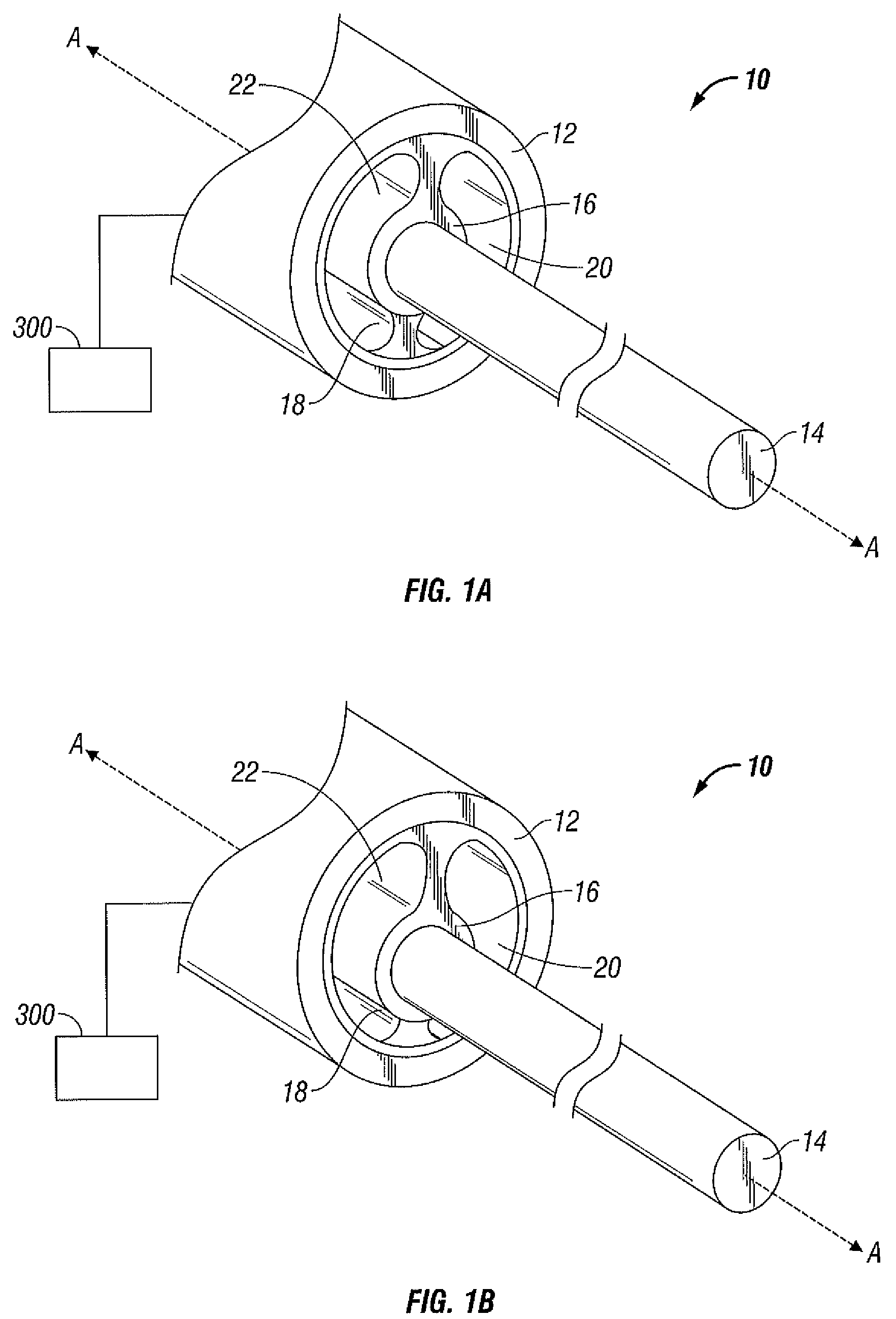

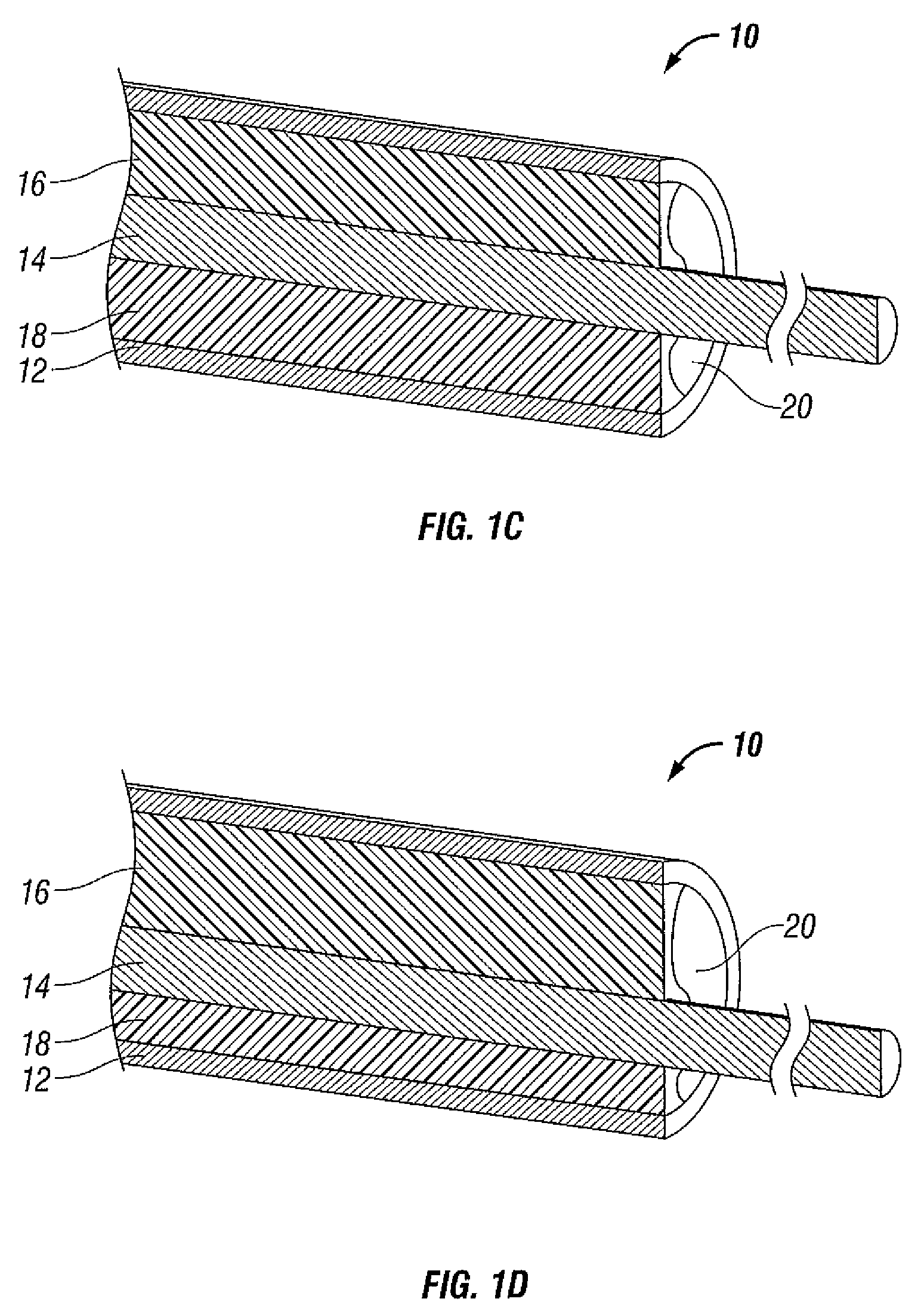

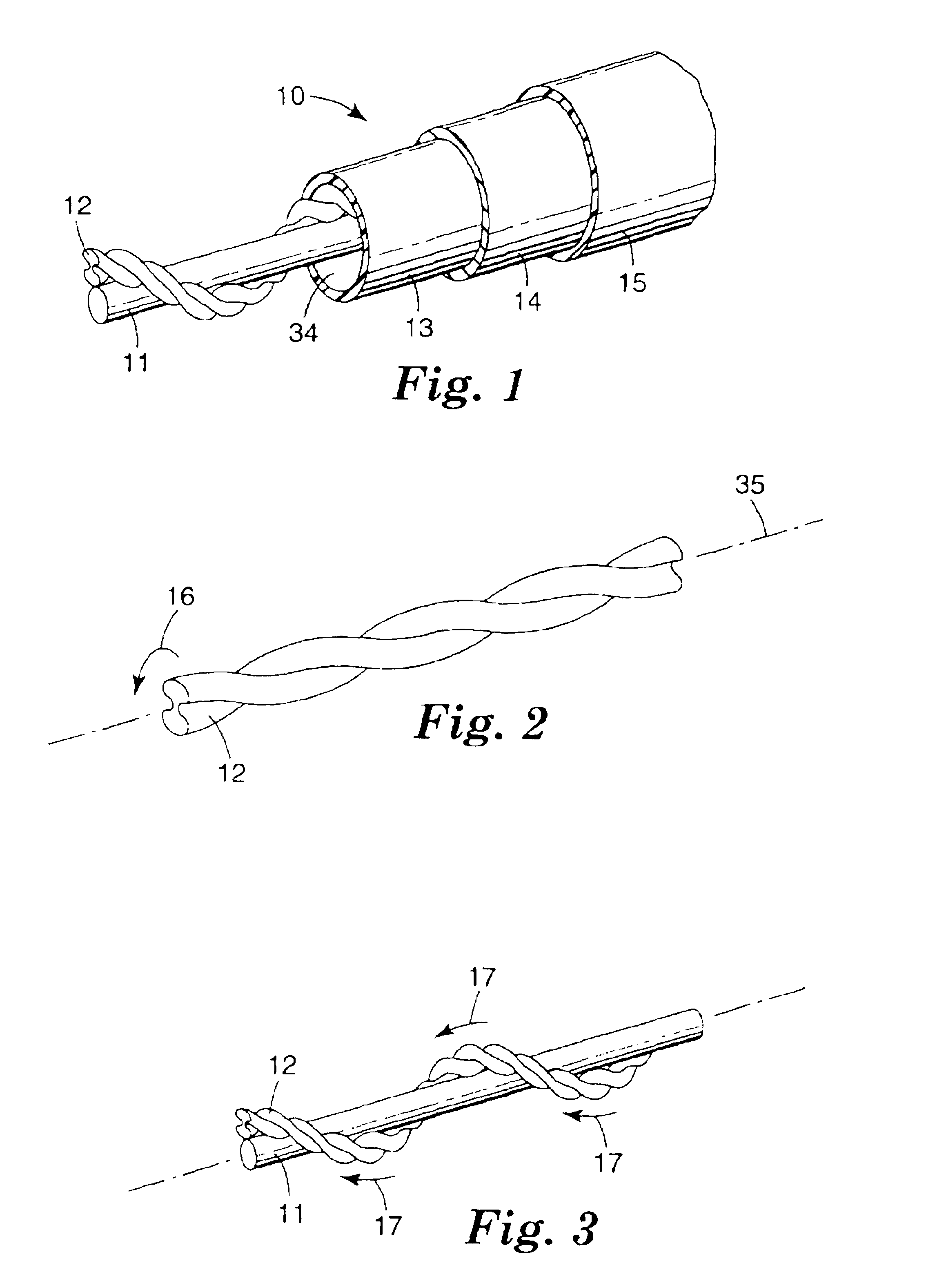

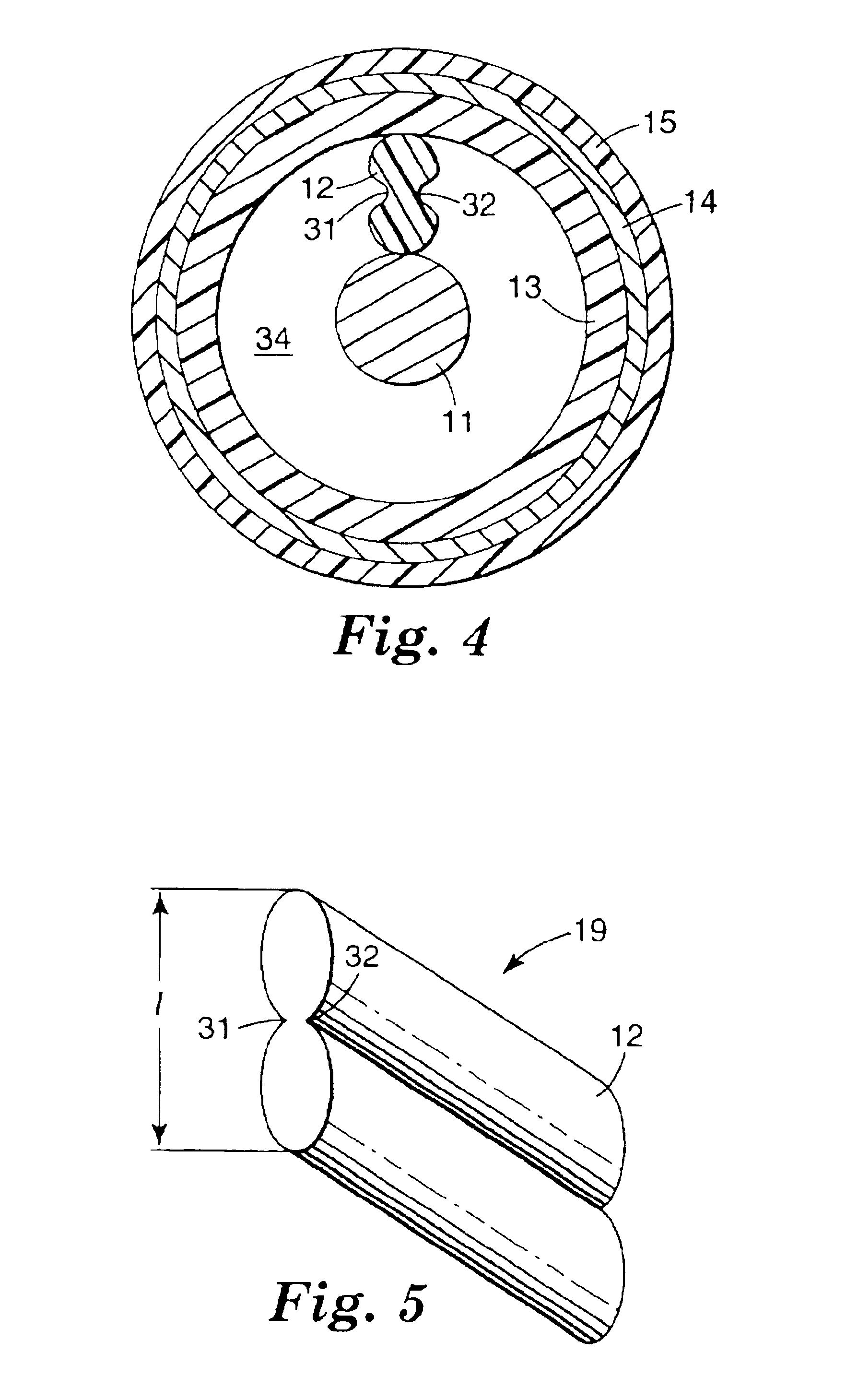

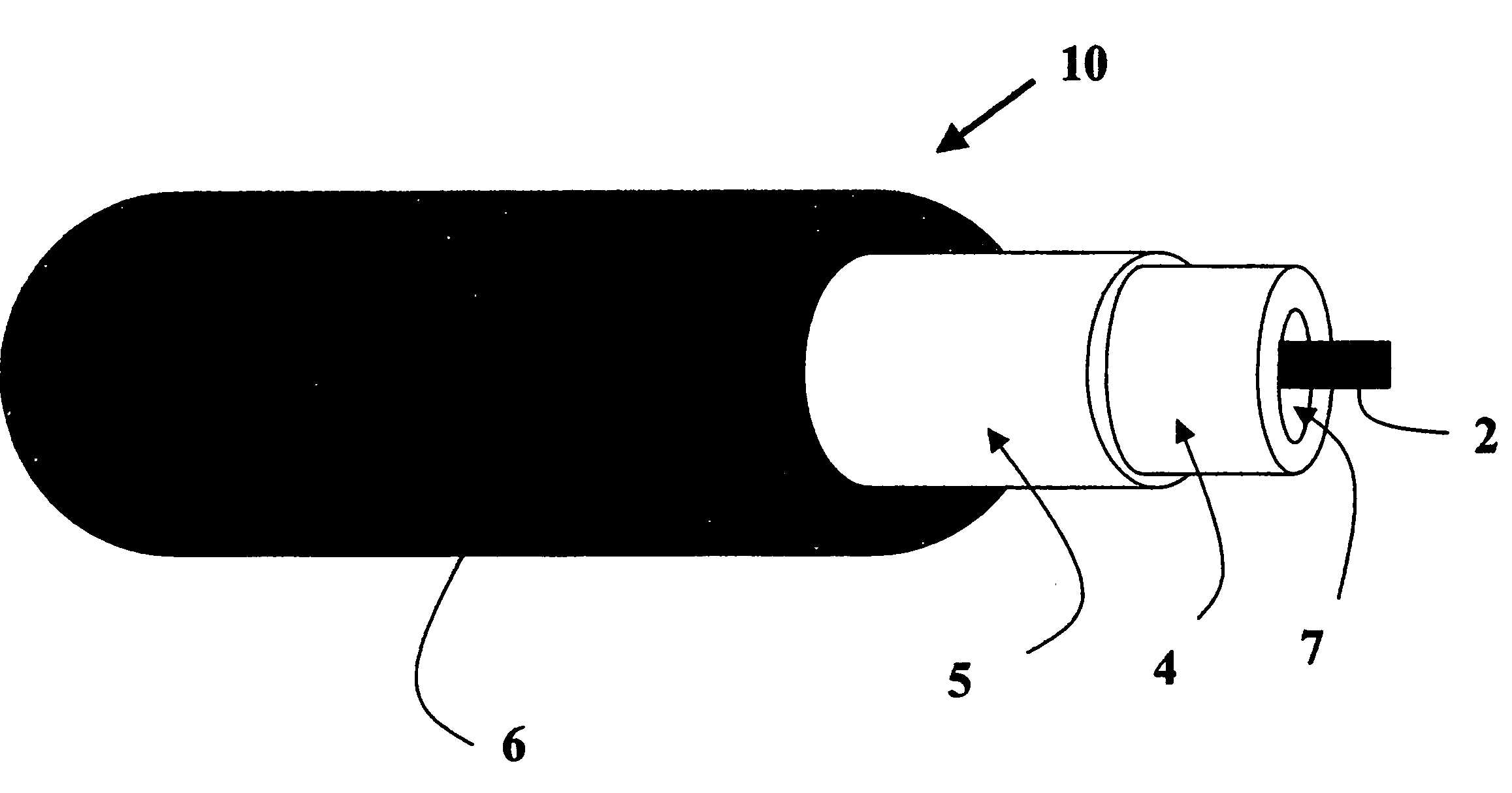

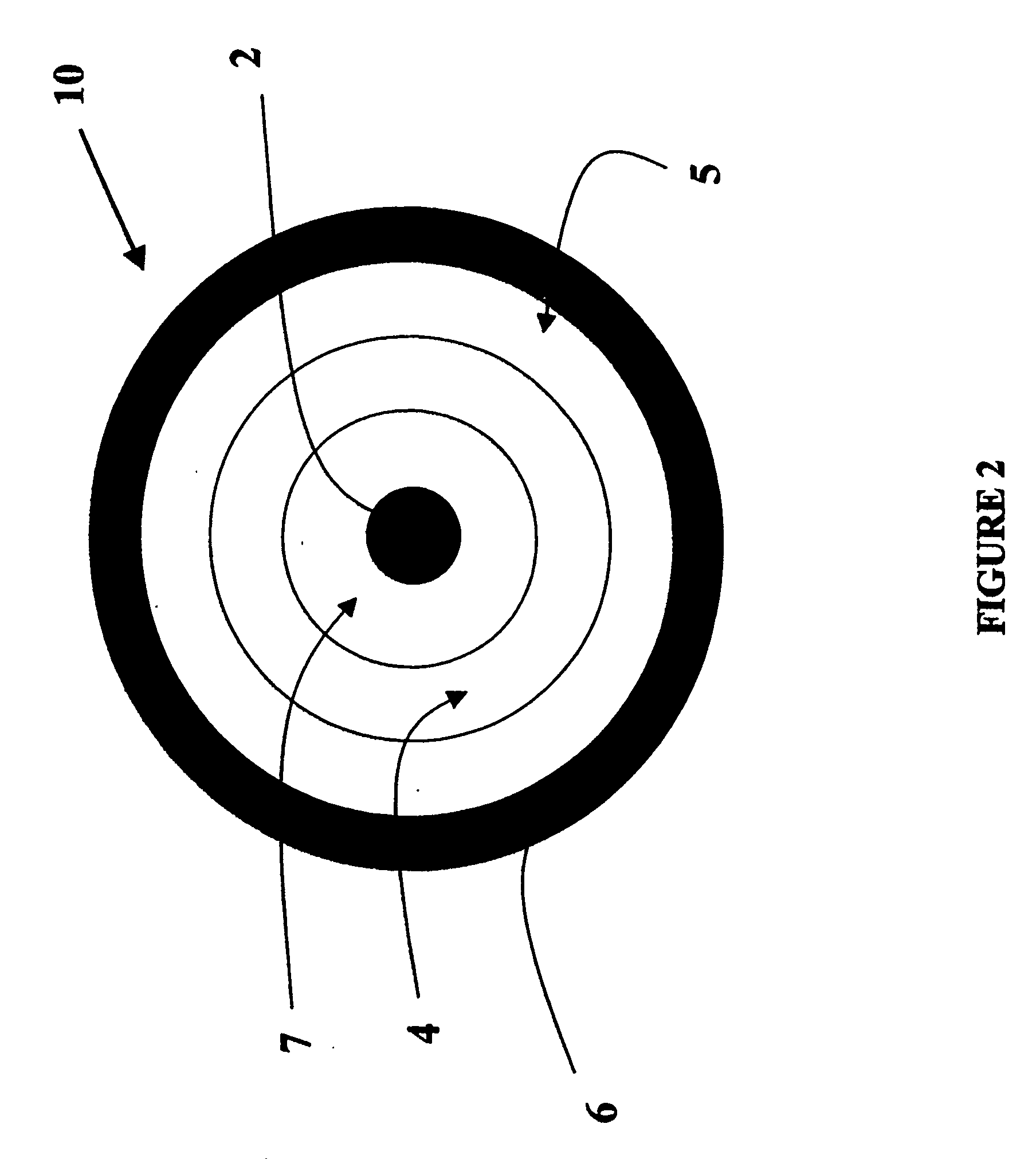

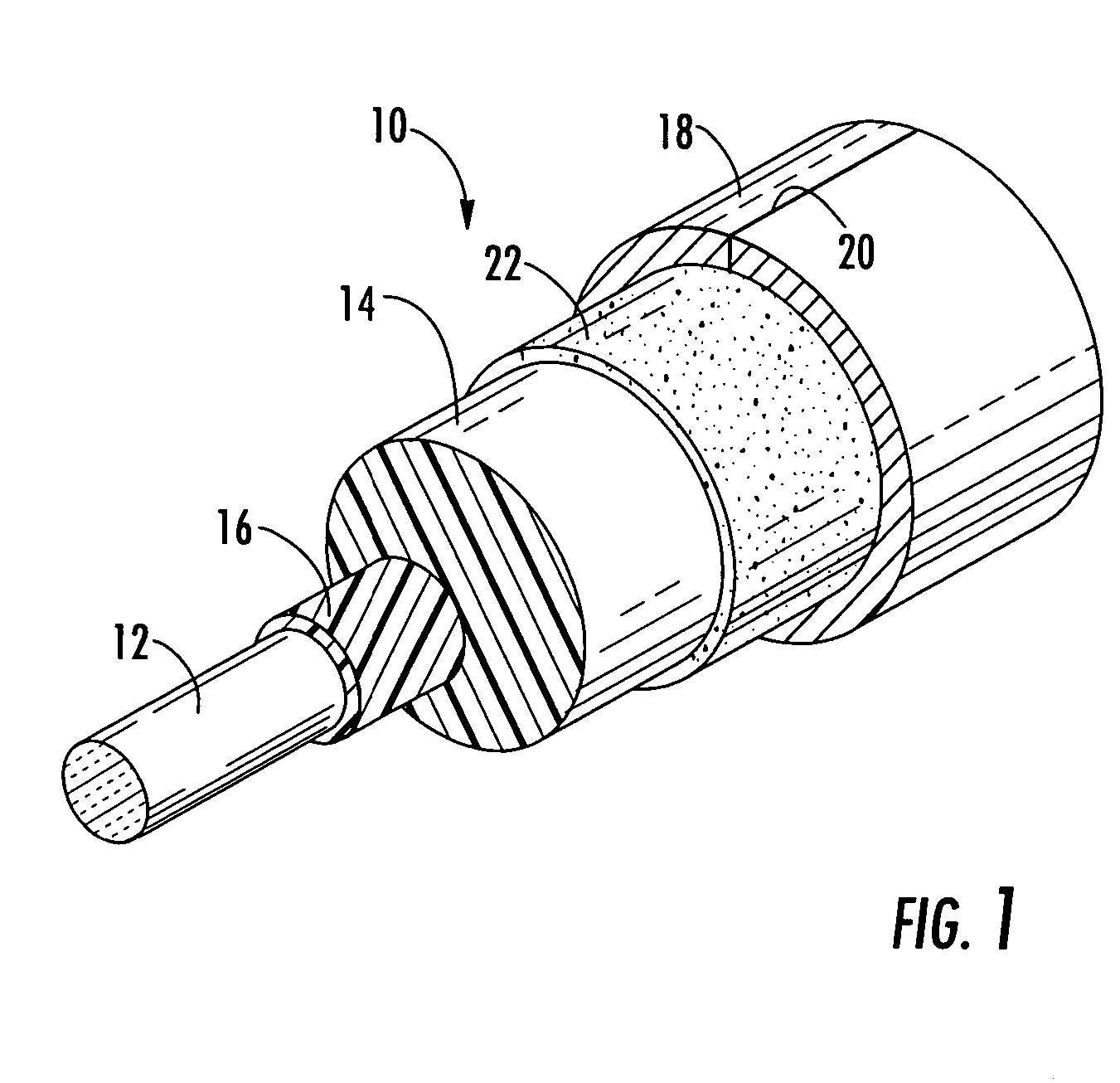

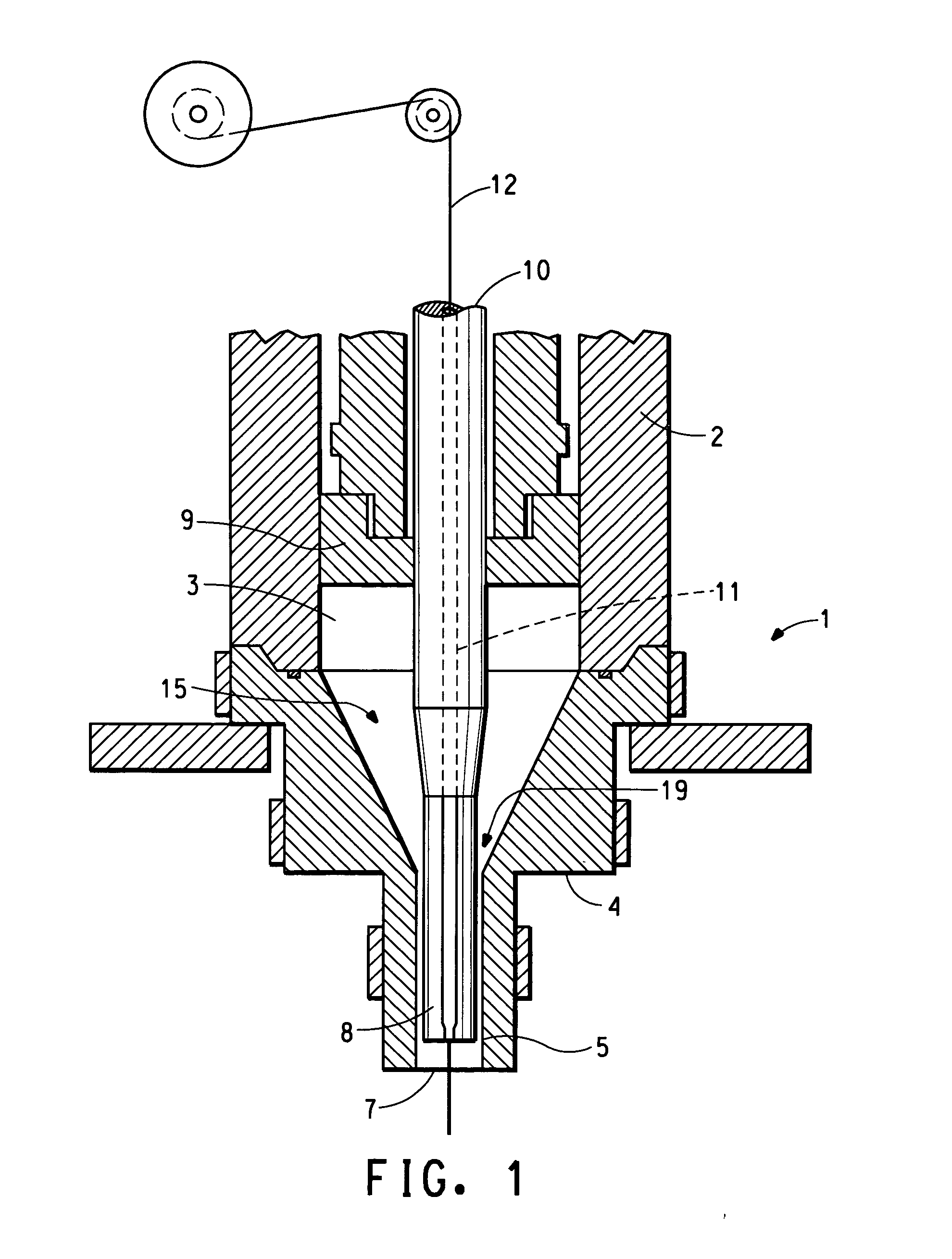

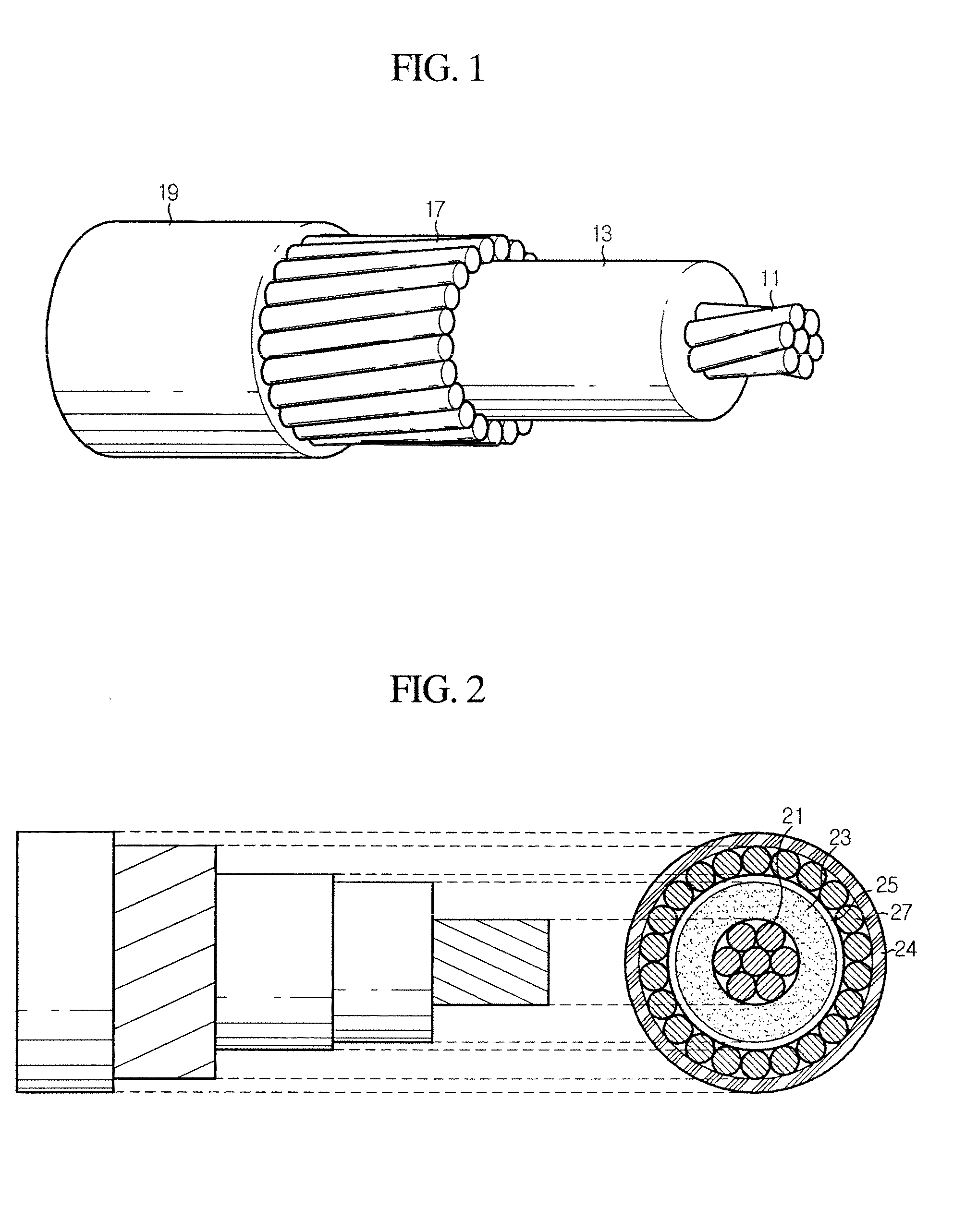

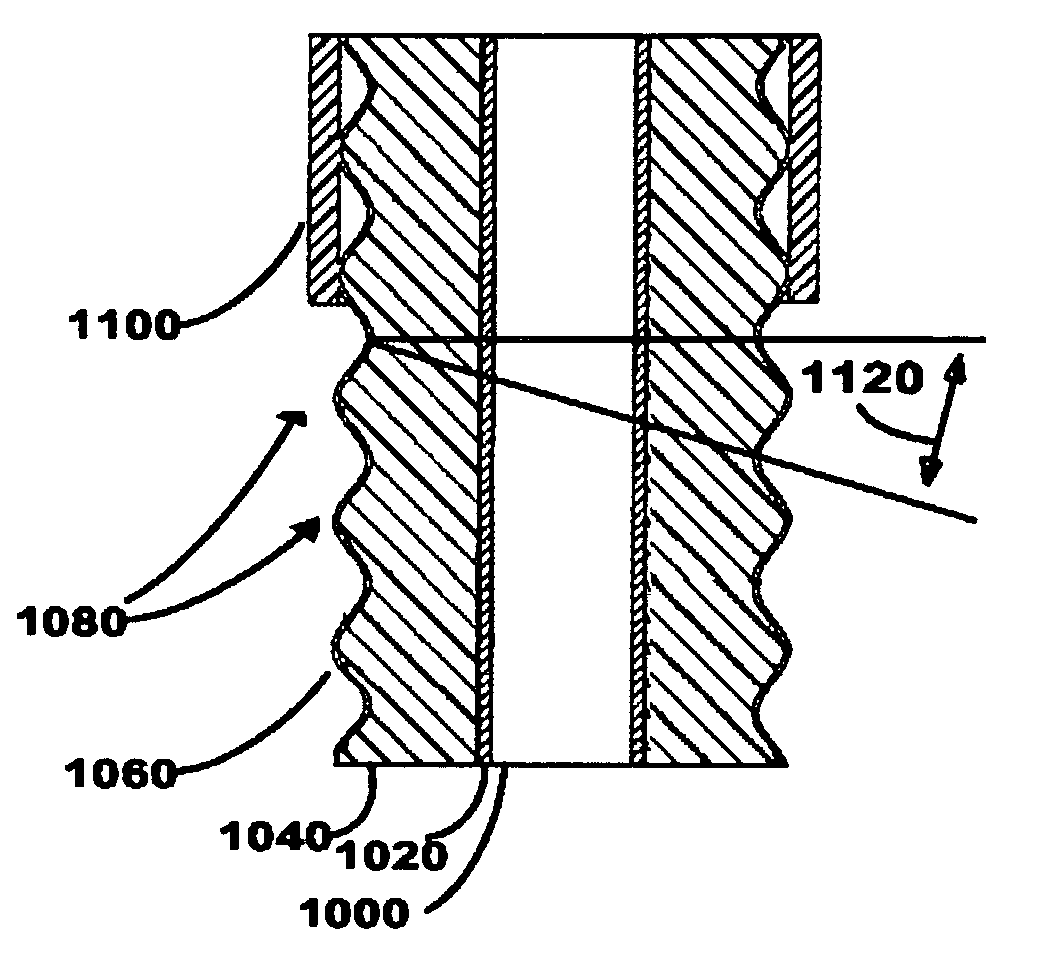

A transmission line for downhole tools that make up all or part of a tool string for drilling and production of oil, gas, and geothermal wells that can withstand the dynamic gravitational forces and other accelerations associated with downhole excavations. The transmission line comprises a metal tube, or outer conductor, that houses a coaxial wire inner conductor. A non-metallic dielectric material is interposed between the inner and outer conductors. The outer and inner conductors and the dielectric are sufficiently compressed together so that independent motion between them is abated. Compression of the components of the transmission line may be achieved by drawing the transmission through one or more dies in order to draw down the outer conductor onto the dielectric, or by expanding the inner conductor against the dielectric using a mandrel or hydraulic pressure. Non-metallic bead segments may be used in aid of the compression necessary to resist the dynamic forces and accelerations of drilling.

Owner:INTELLISERV

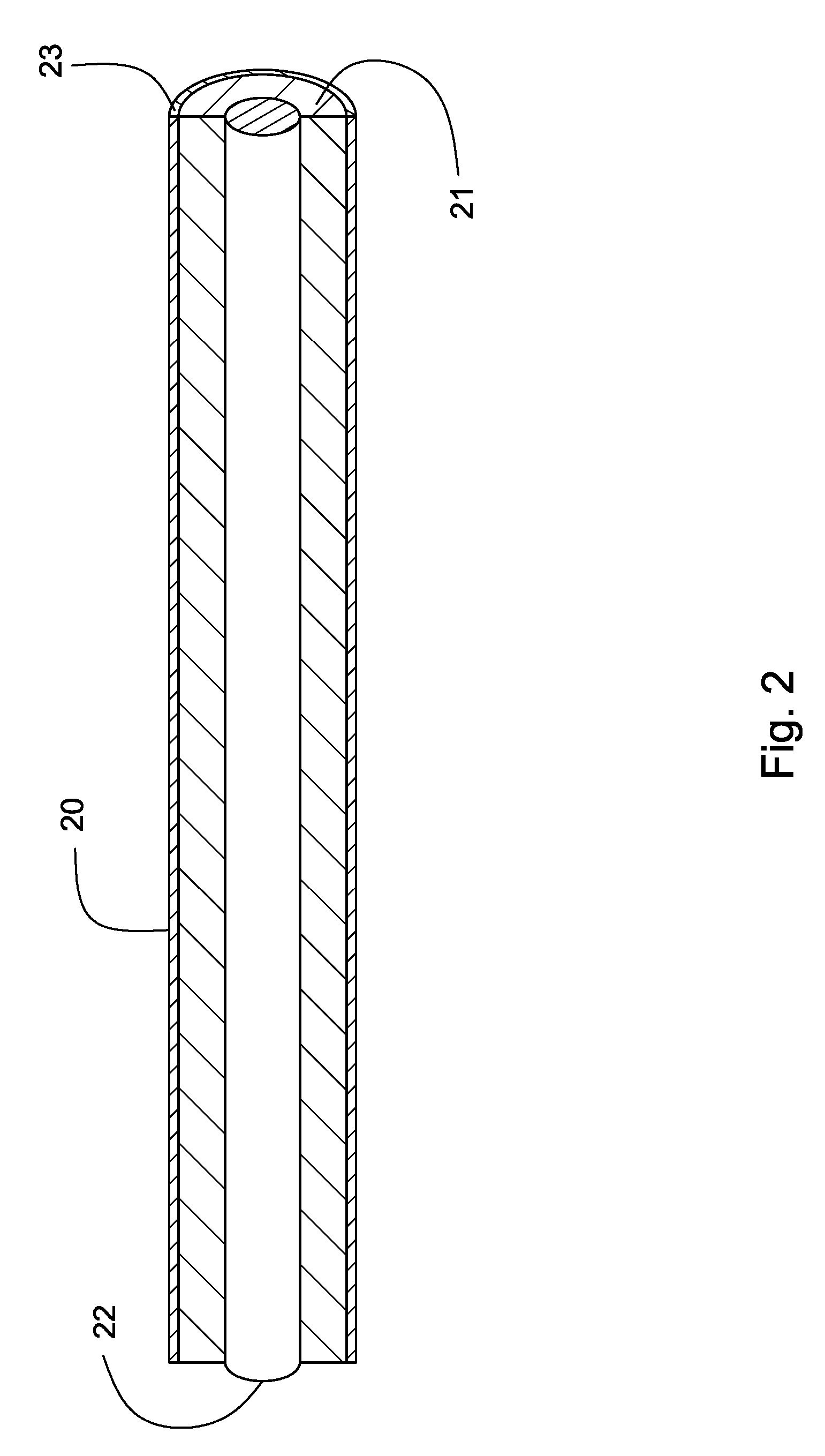

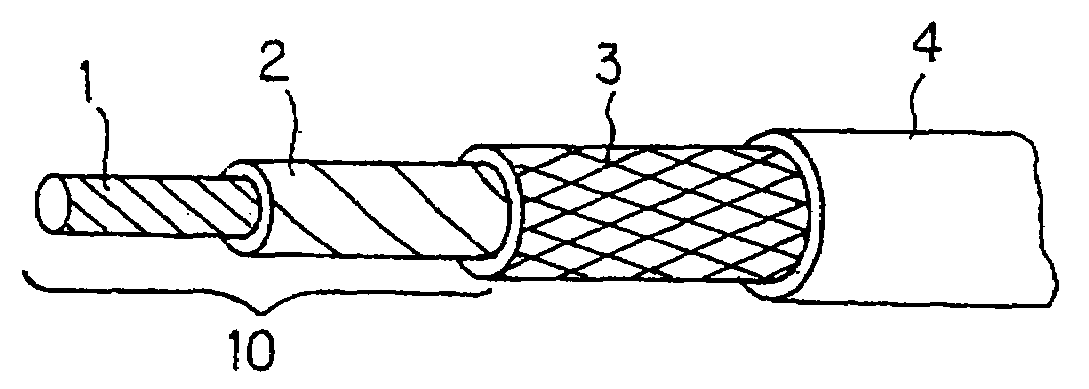

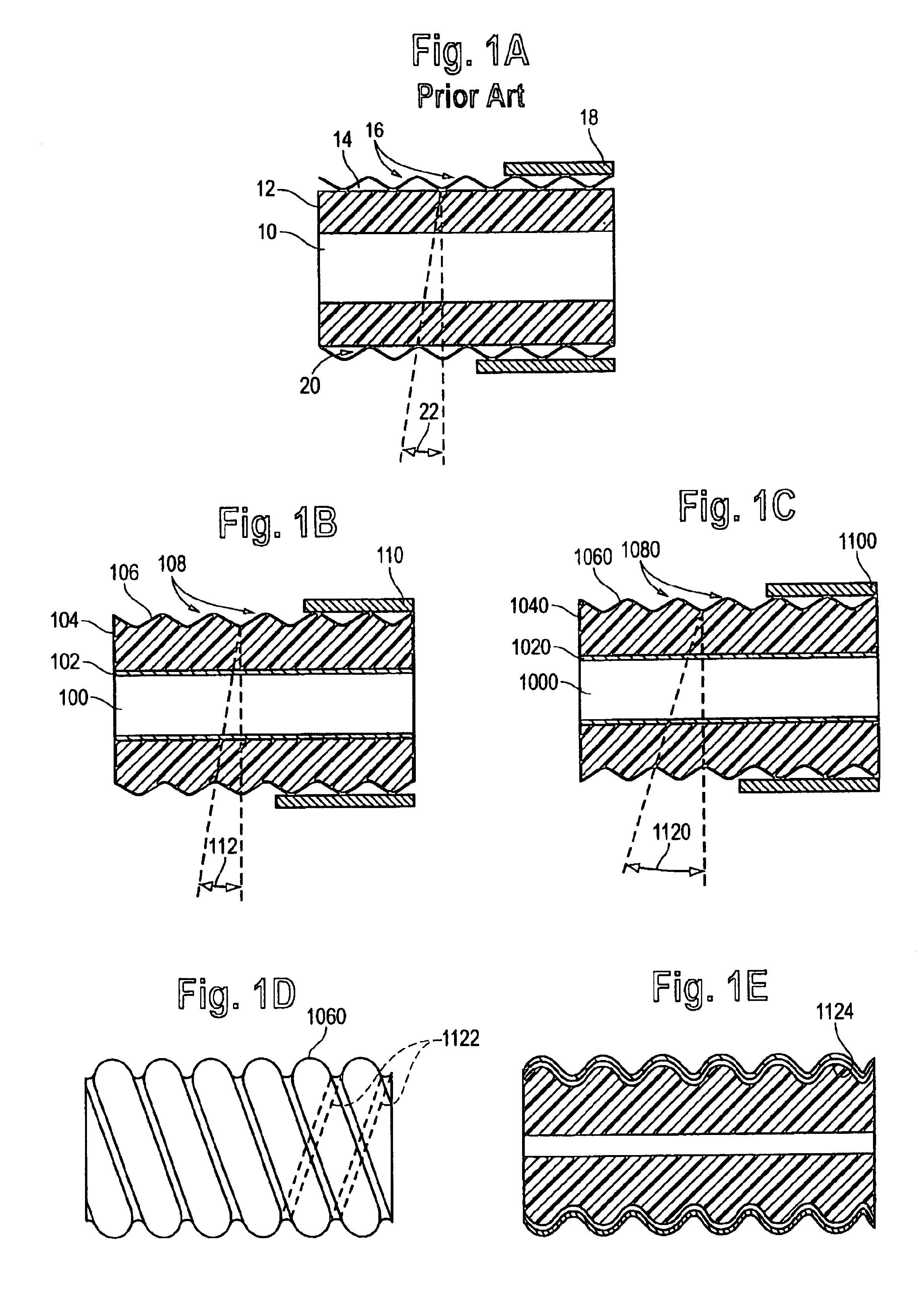

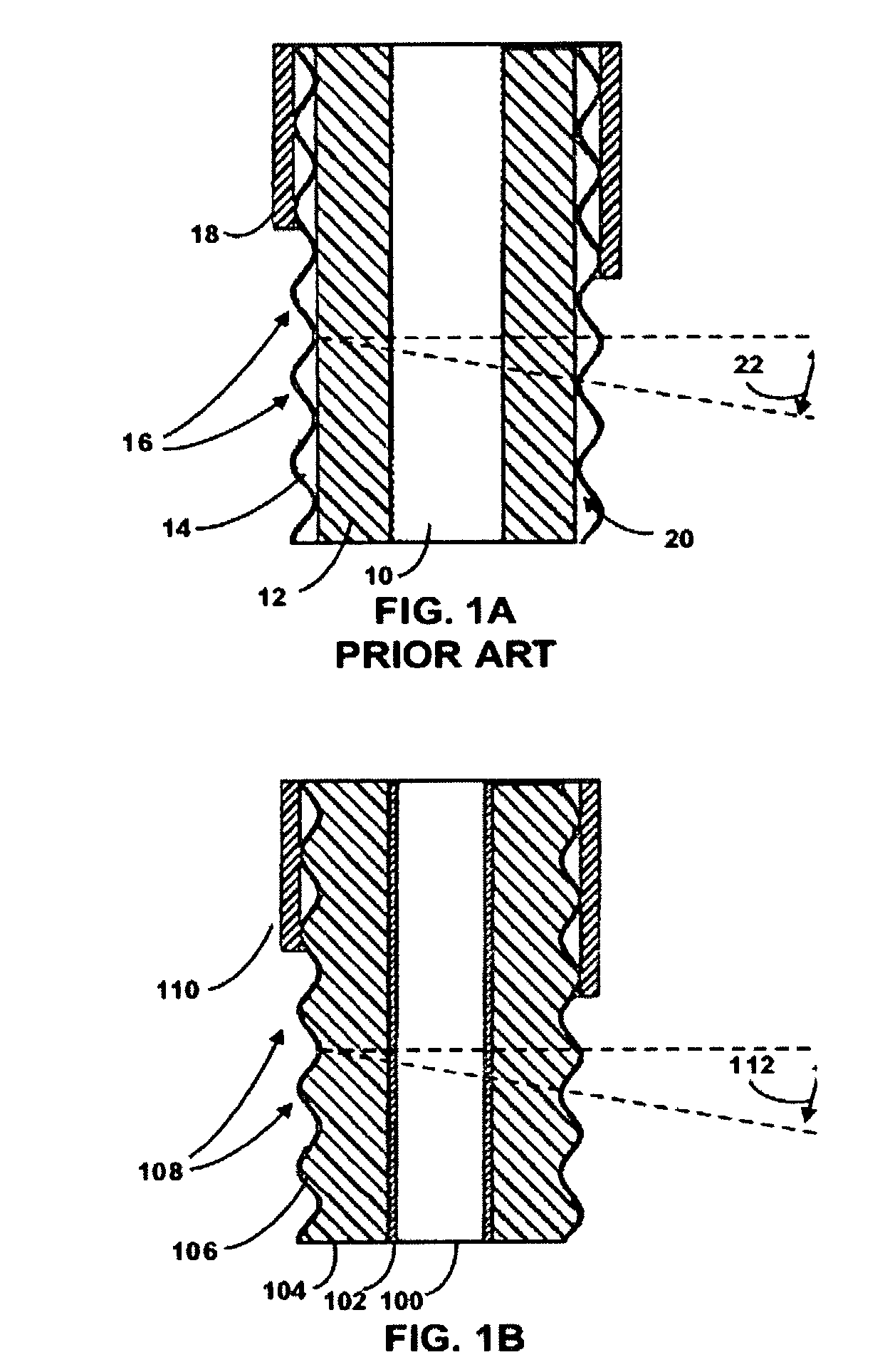

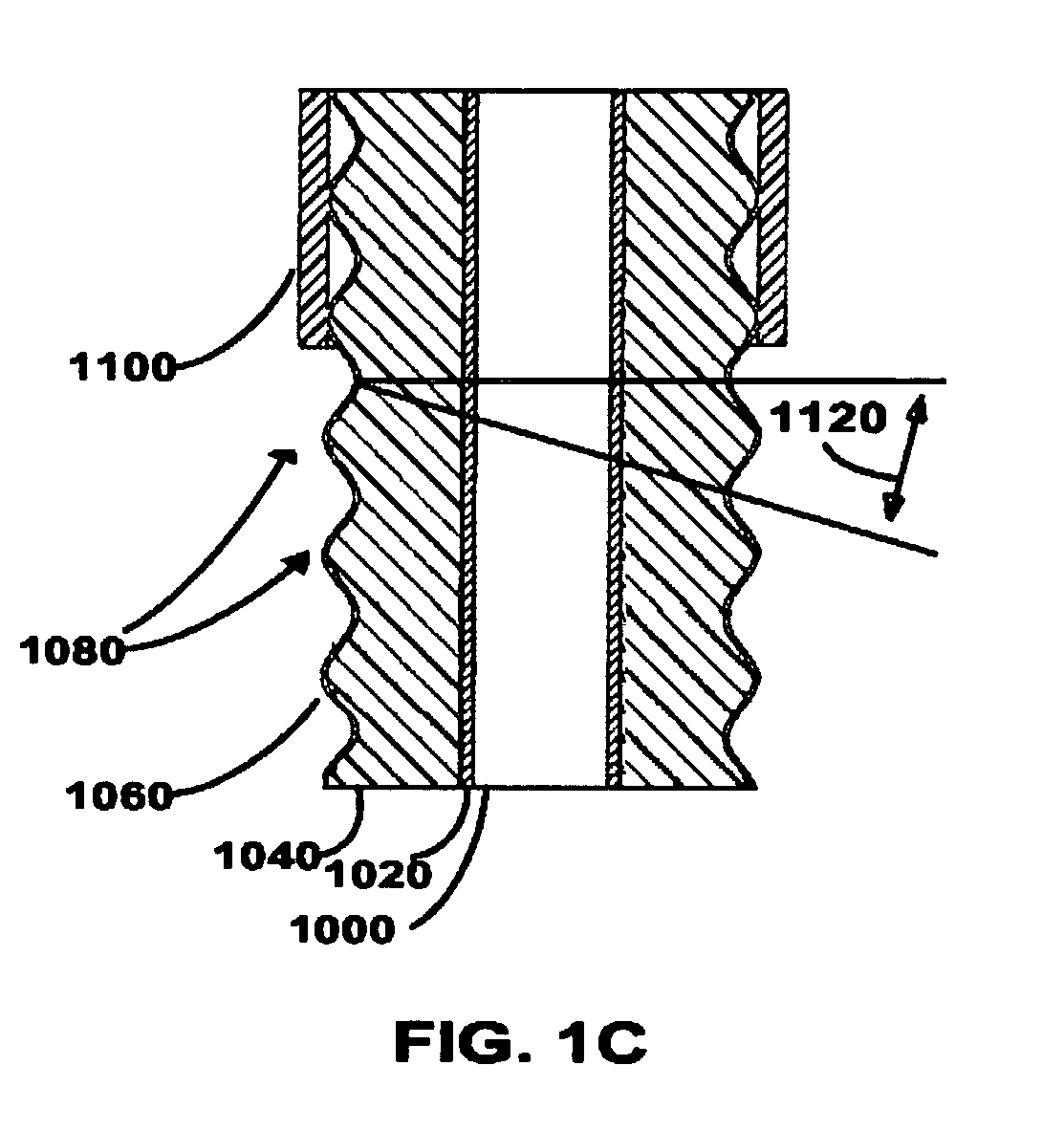

Serrated cable core

InactiveUS6815617B1Cable insulation constructionPower cables with screens/conductive layersContact forceEngineering

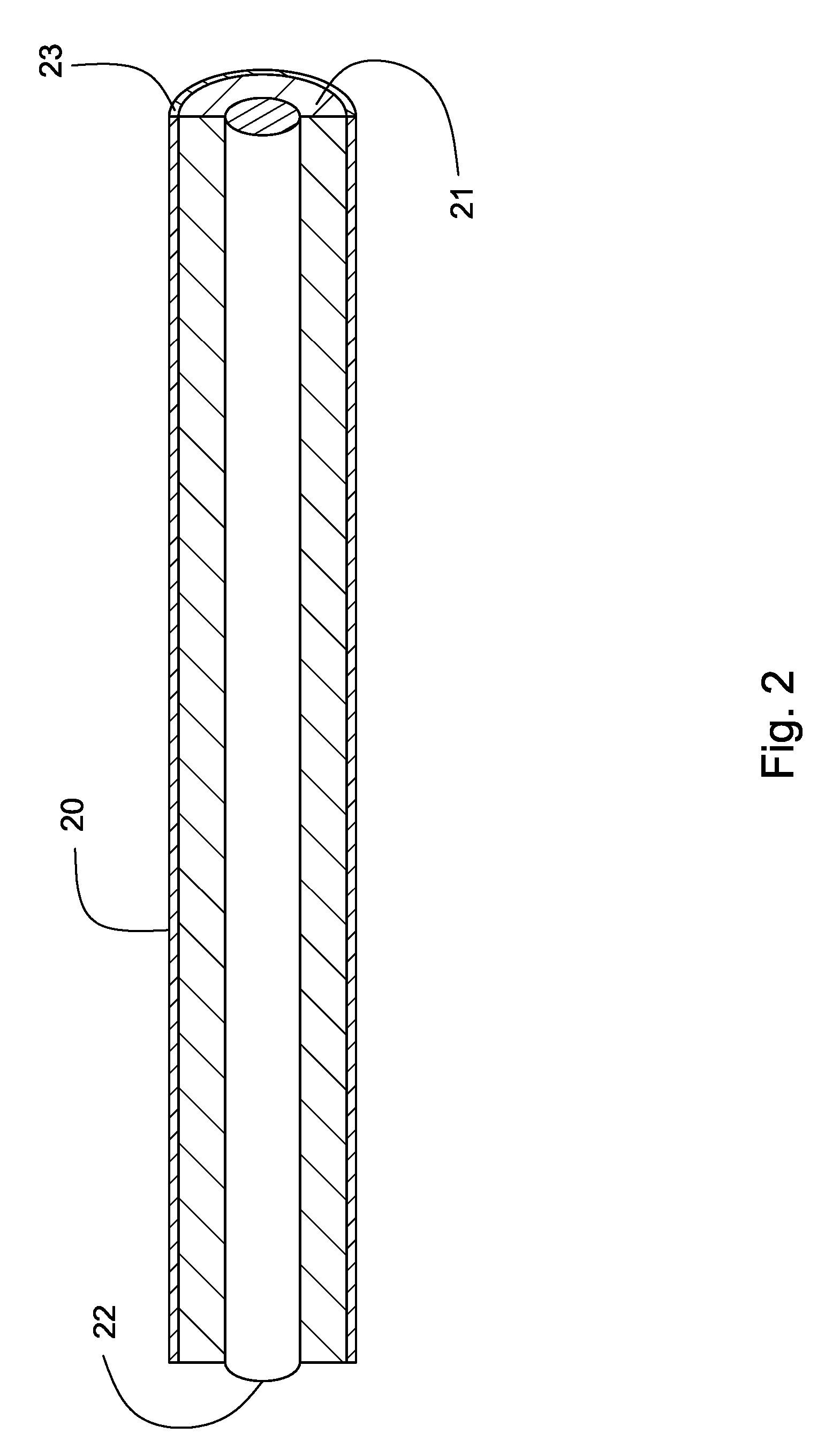

An axially arranged cable, such as a coaxial, triaxial, twinaxial, or armored cable which includes at least one serration on an insulative or conductive layer internal thereto and methods of manufacturing the same. These serrations may appear on insulators or inner jackets and are in physical contact with conductive layers such as shields which axially surround the insulative layers. The serrations generally increase the contact force between the insulative layers and the conductiver layers to help prevent separation of the cable core during stripping of the axial cable.

Owner:BELDEN TECHNOLOGY INC

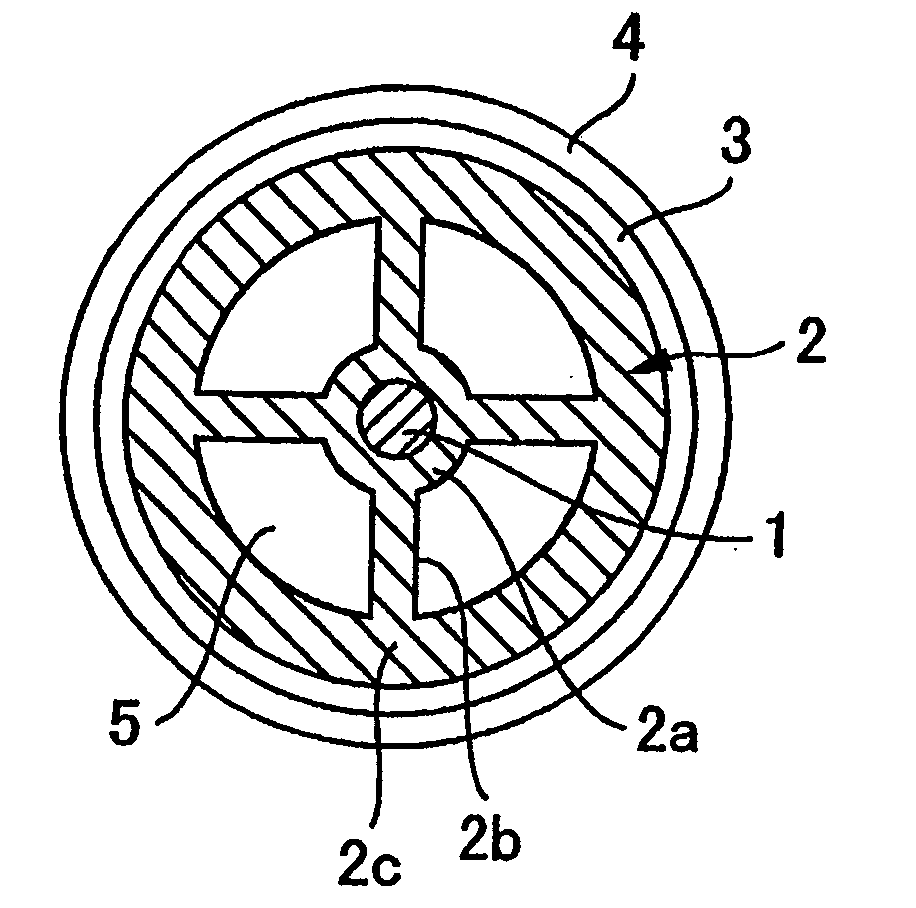

Thin-diameter coaxial cable and method of producing the same

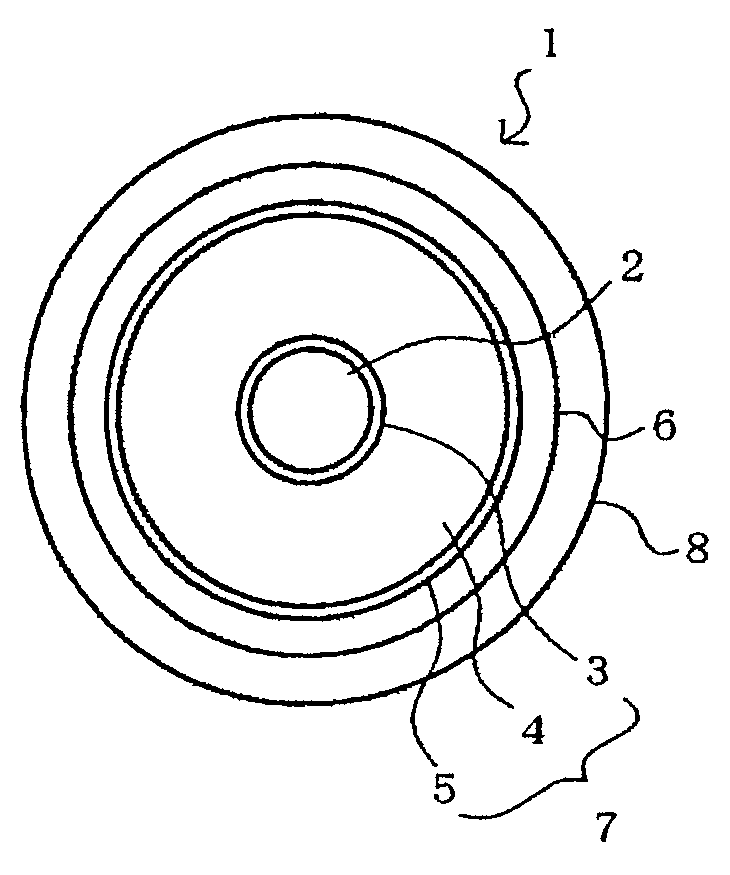

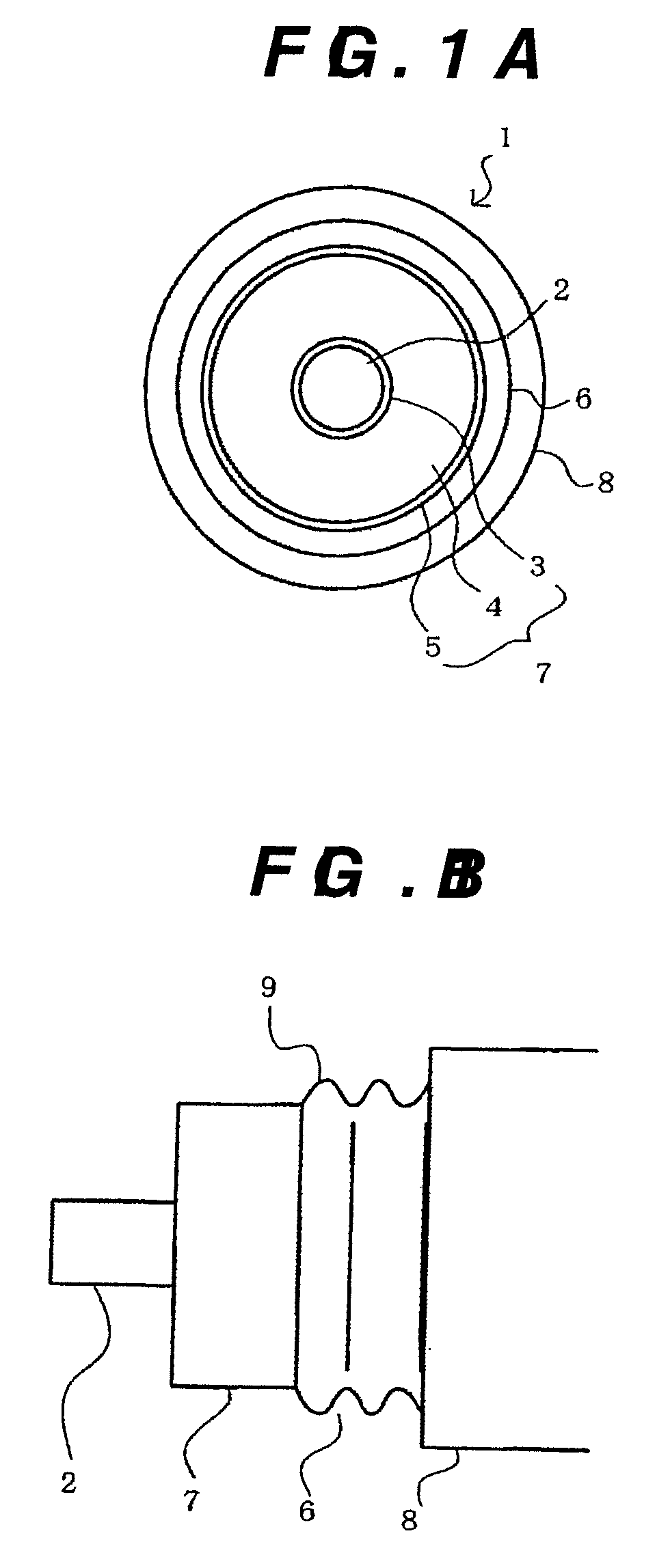

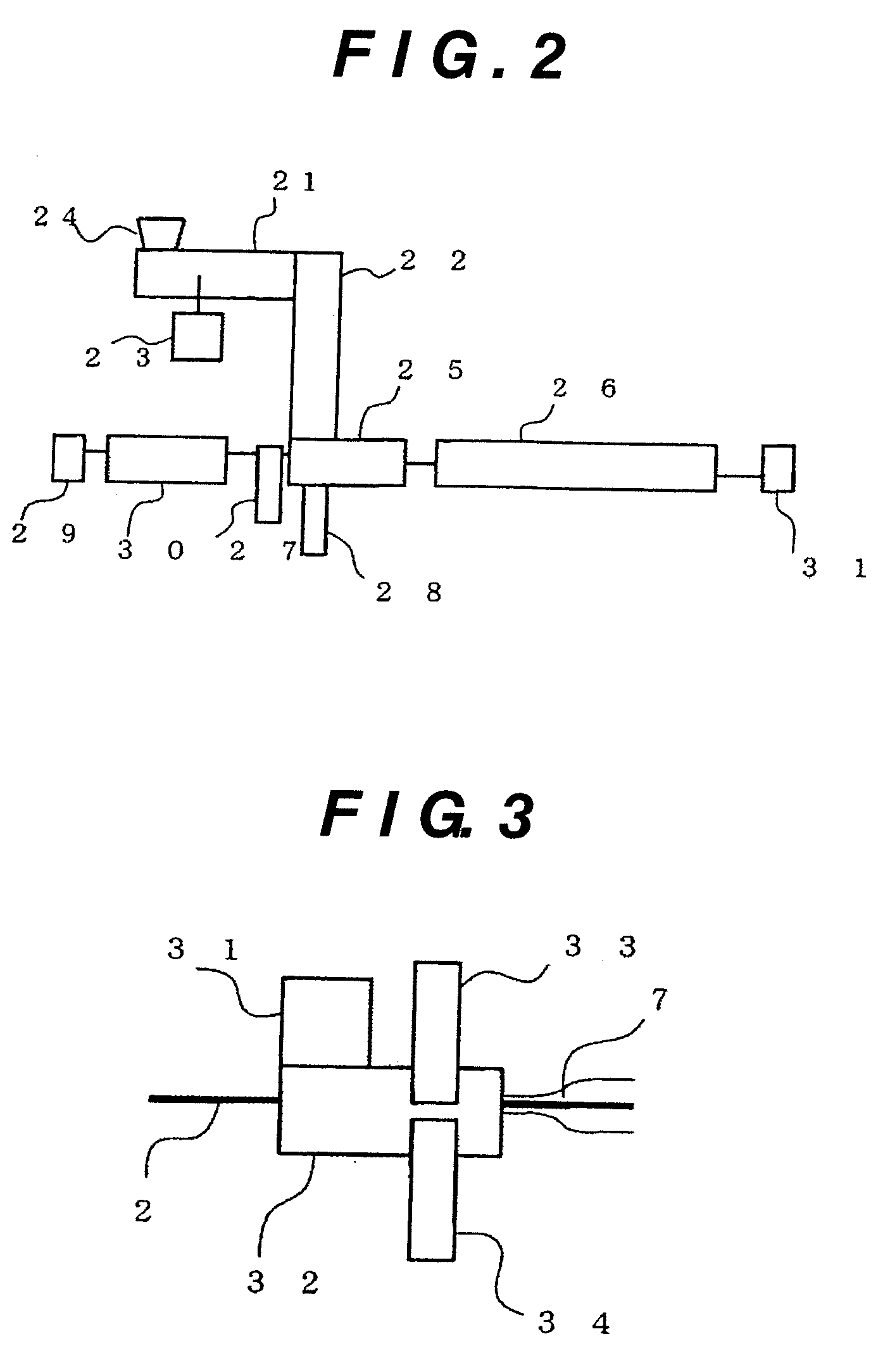

InactiveUS20050230145A1Increase in sizeHigh geometric accuracyCable insulation constructionInsulated cablesElectrical conductorCoaxial cable

A small-diameter coaxial cable comprises a central conductor, an insulated covering layer arranged on the outer periphery of the central conductor and having air gaps continuous along the longitudinal direction and an outer conductor layer arranged on the outer periphery of the insulated covering layer. The insulated covering layer includes an inner annular portion covering the outer periphery of the central conductor, a plurality of coupling portions extending outward from the inner annular portion and an outer annular portion connecting the outer peripheral edges of the coupling portions to each other. Air gaps defined along the peripheral direction by the coupling portions are formed on the inner side of the insulated covering layer.

Owner:UBE NITTO KASEI CO LTD

Thermally tuned coaxial cable for microwave antennas

ActiveUS7642451B2Cable insulation constructionPower cables with screens/conductive layersCoaxial cableMicrowave

A coaxial cable, including an outer conductor and an inner conductor adapted to connect to an energy source for treating tissue and first and second dielectric materials disposed between the inner conductor and the outer conductor which position the inner conductor relative to the outer conductor in general concentric relation thereto. The first dielectric material has a first coefficient of thermal expansion and the second dielectric material has a second coefficient of thermal expansion different from the first coefficient of thermal expansion.

Owner:TYCO HEALTHCARE GRP LP

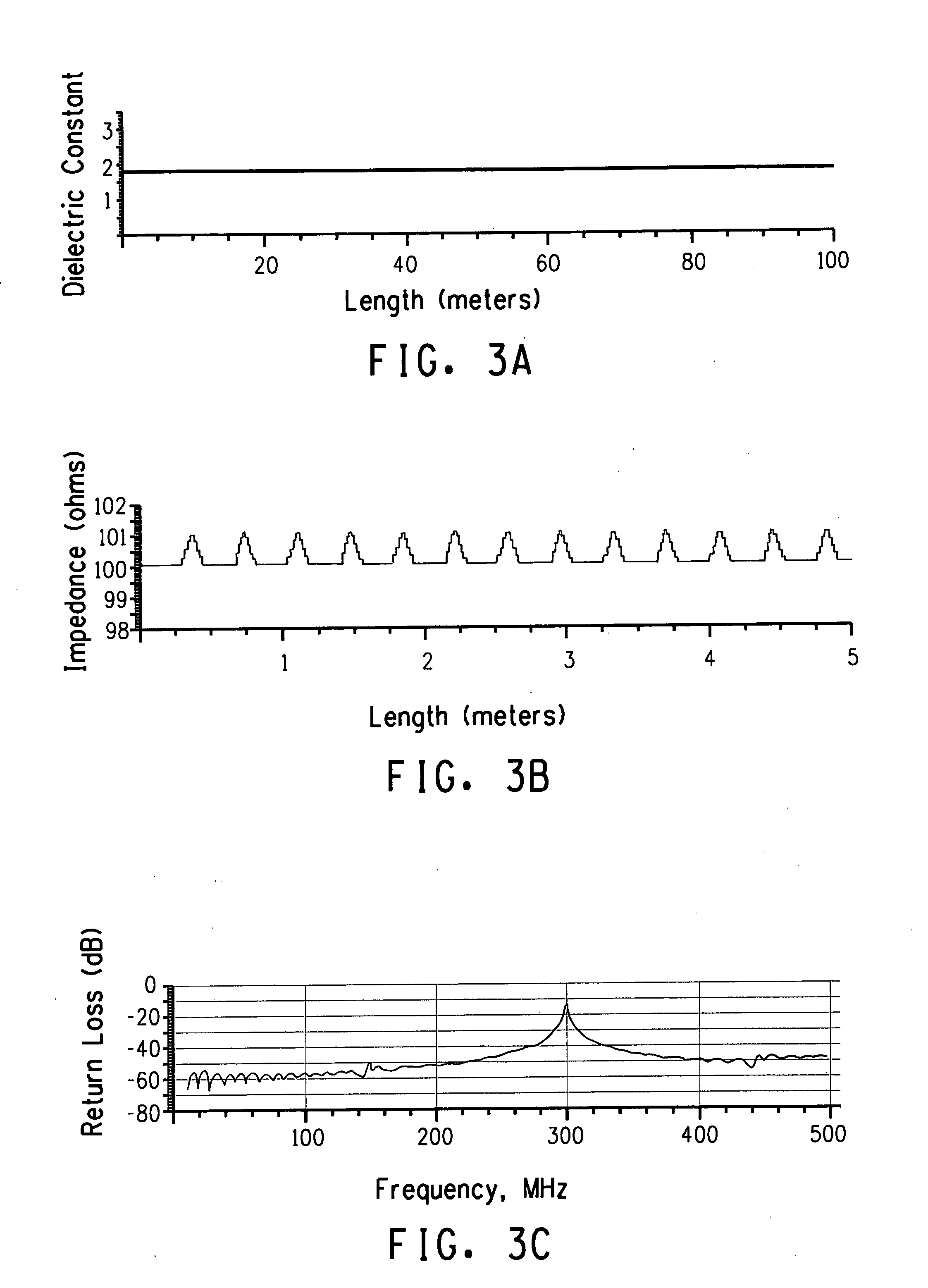

Periodic Variation of Velocity of Propagation to Reduce Additive Distortion Along Cable Length

A communications cable is provided that reduces the additive distortion of intended information encoded as electromagnetic energy that propagates longitudinally along the cable by varying the propagation velocity along its length. The additive distortion is reduced by varying the propagation periodically at a frequency that is lower than the highest frequency at which said electromagnetic energy propagates along said cable.

Owner:EI DU PONT DE NEMOURS & CO

High propagation speed coaxial and twinaxial cable

InactiveUS6849799B2Low dielectric constantReduce morbidityCable insulation constructionInsulated cablesElectrical conductorEngineering

Owner:3M INNOVATIVE PROPERTIES CO

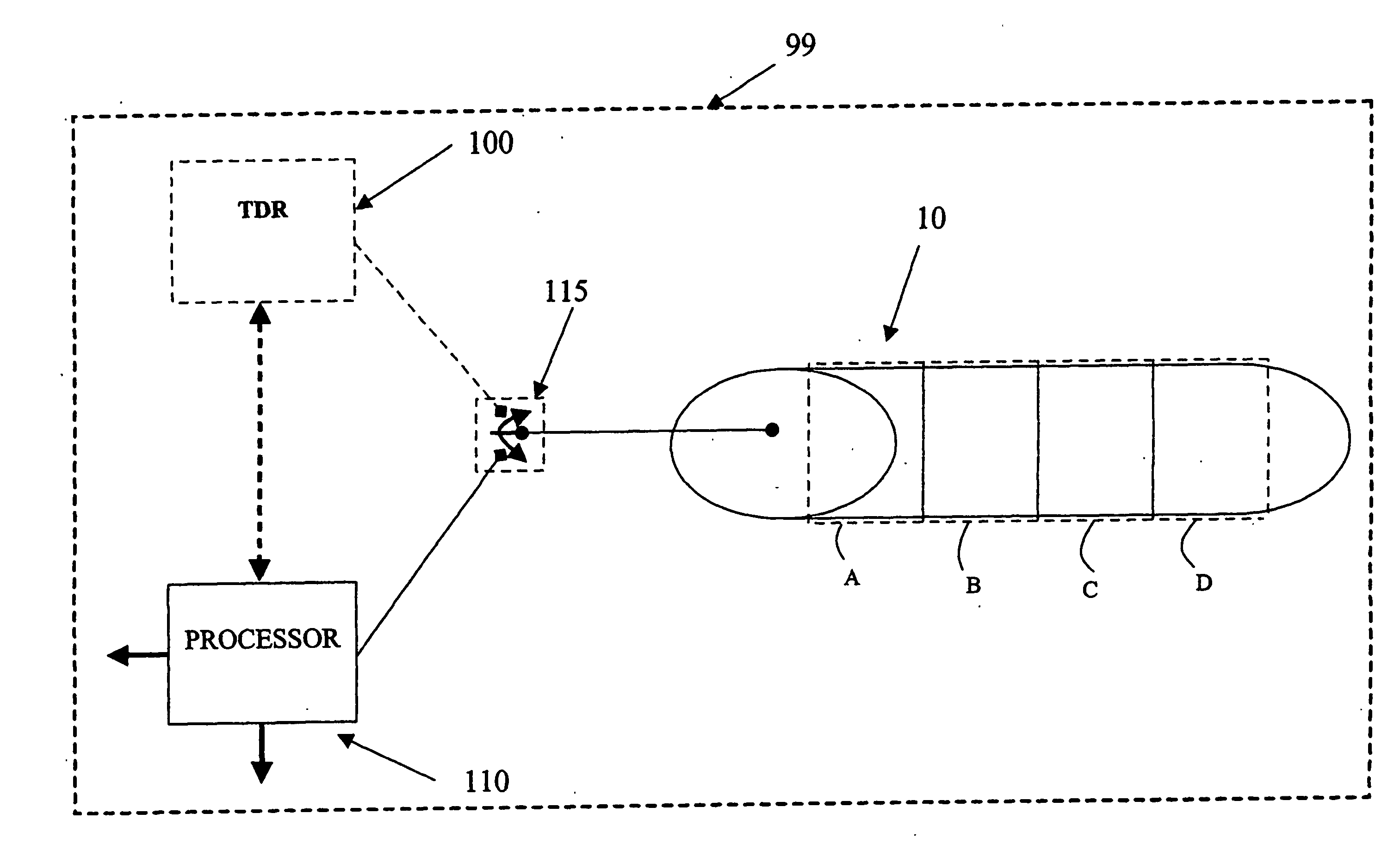

Triboelectric, ranging, or dual use security sensor cable and method of manufacturing same

InactiveUS7479878B2Easy constructionReadily availableCable insulation constructionInsulated cablesElectrical conductorTerminal voltage

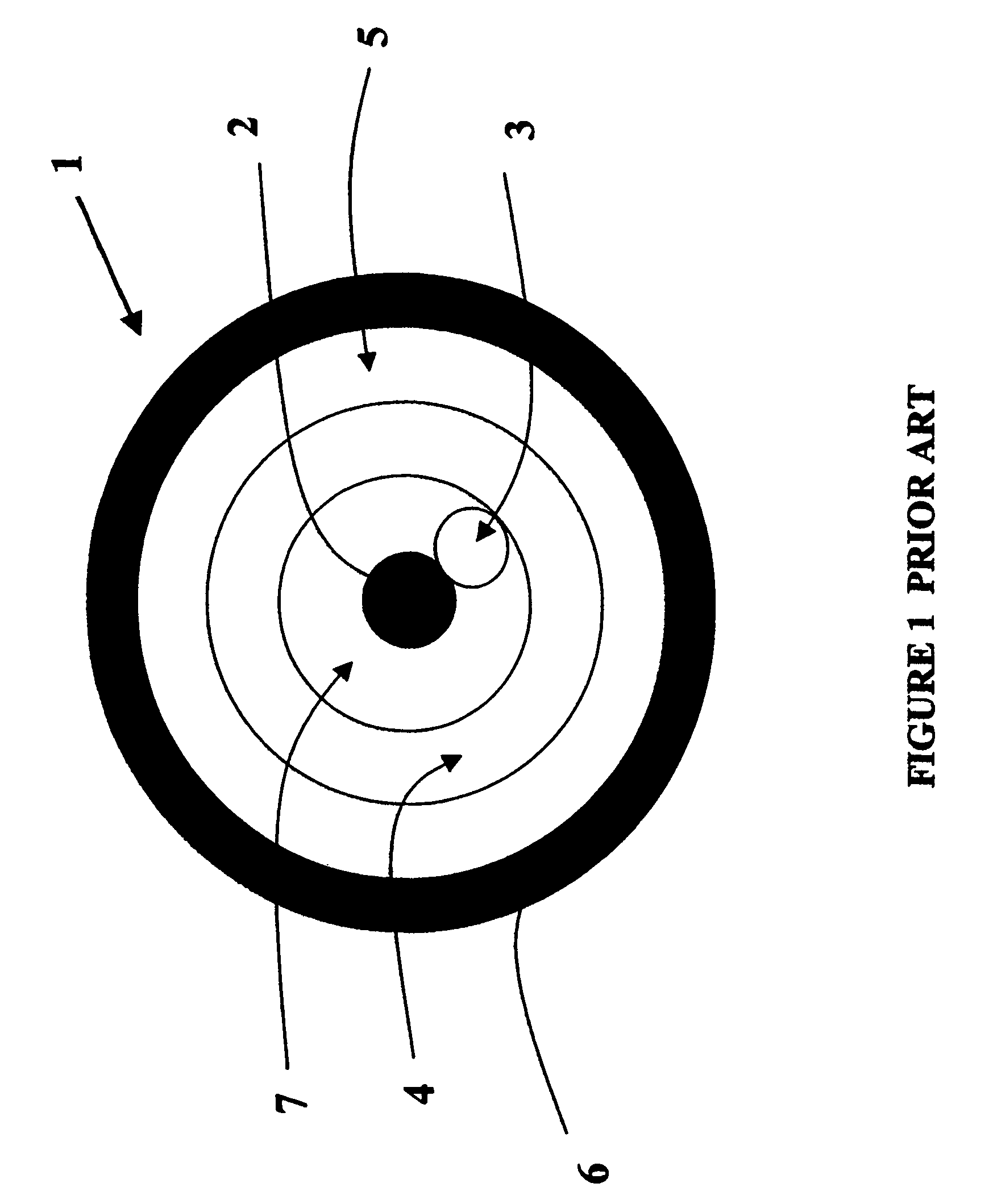

The present invention provides an inexpensive security sensor cable, a method for manufacturing of same and an overall security system for using that sensor cable. The sensor cable consists of a central conductor, an air separator, a polyethylene dielectric tube, an outer conductor and an outer protective jacket. The central conductor is loosely centered in the coaxial cable and thus freely movable relative to the dielectric tube. The sensor cable has application either in a passive sensing system or in an active ranging sensing system to determine the location of an intrusion along the cable. For the passive sensing function, when the center conductor moves, it contacts a suitable dielectric material from the triboelectric series, such as polyethylene, which can be processed to produce a charge transfer by triboelectric effect that is measurable as a terminal voltage. In an active system, the central conductor moves within the dielectric in response to a vibration to provide an impedance change that can be sensed. Conventional radio grade cable may be modified in its construction by removing its dielectric thread to manufacture the sensor cable, thus enabling the center conductor to move freely in the air gap within the dielectric tube. An inexpensive method of manufacturing sensor cable is provided as the cable parts are readily available. Such a sensor cable is advantageous in that the passive triboelectric properties of the cable, in response to a disturbance, can provide a larger voltage response over prior art cables.

Owner:SENSTAR CORP

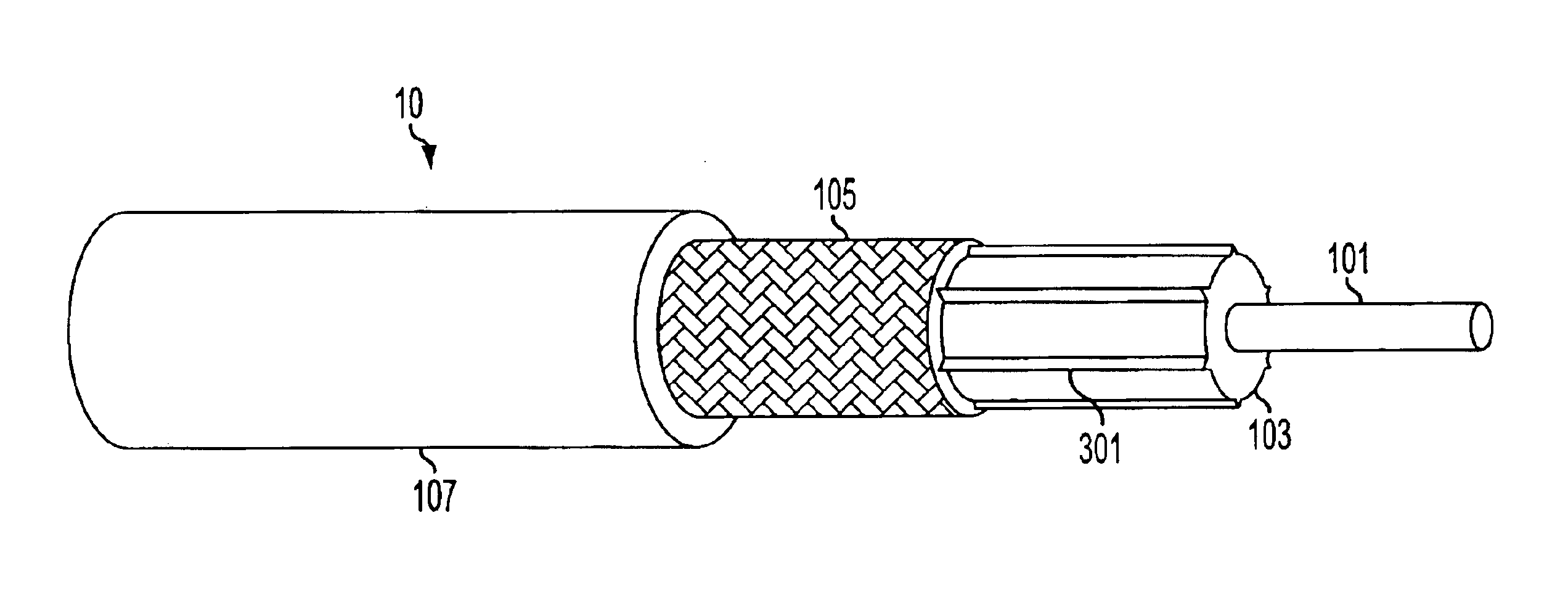

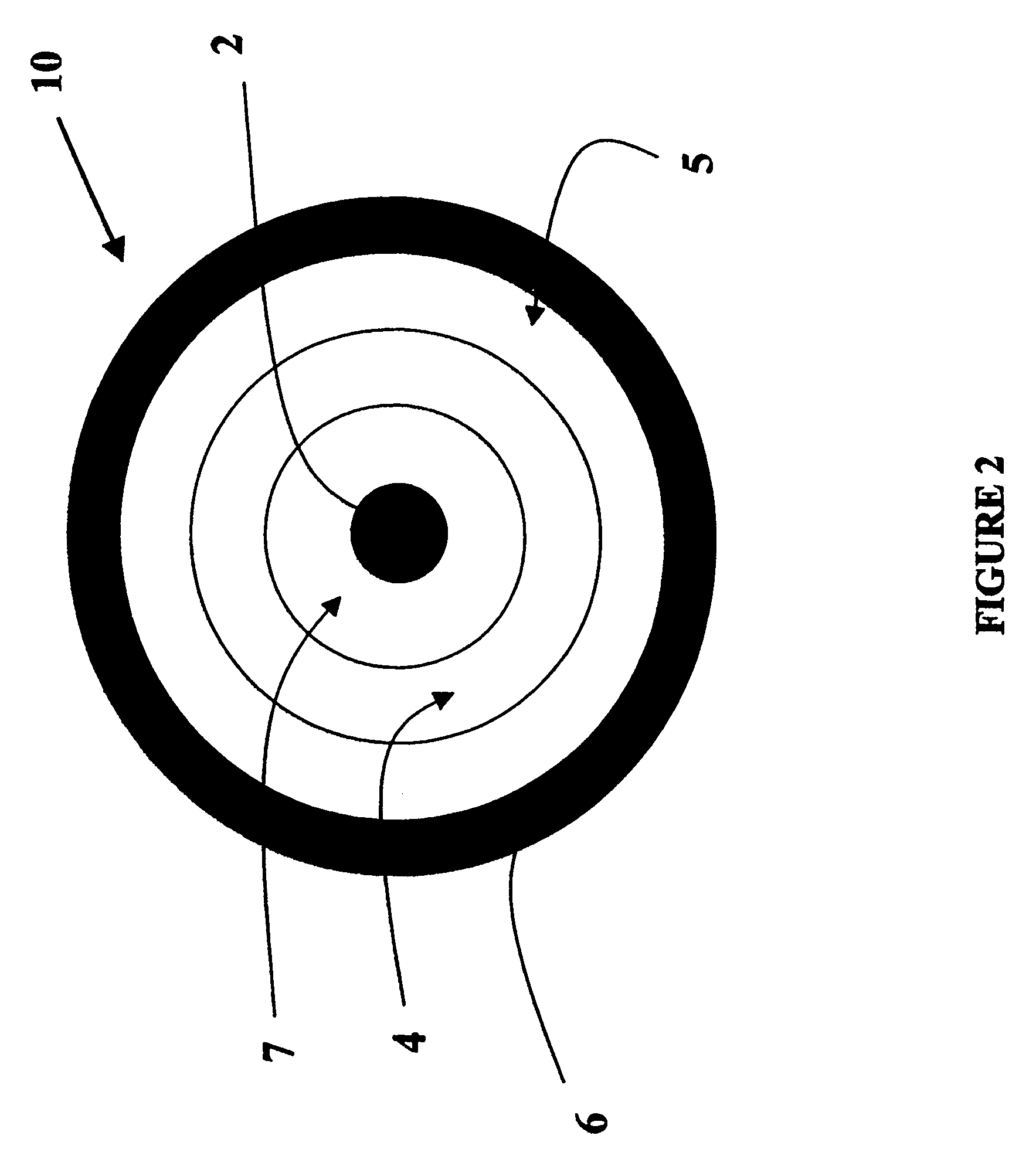

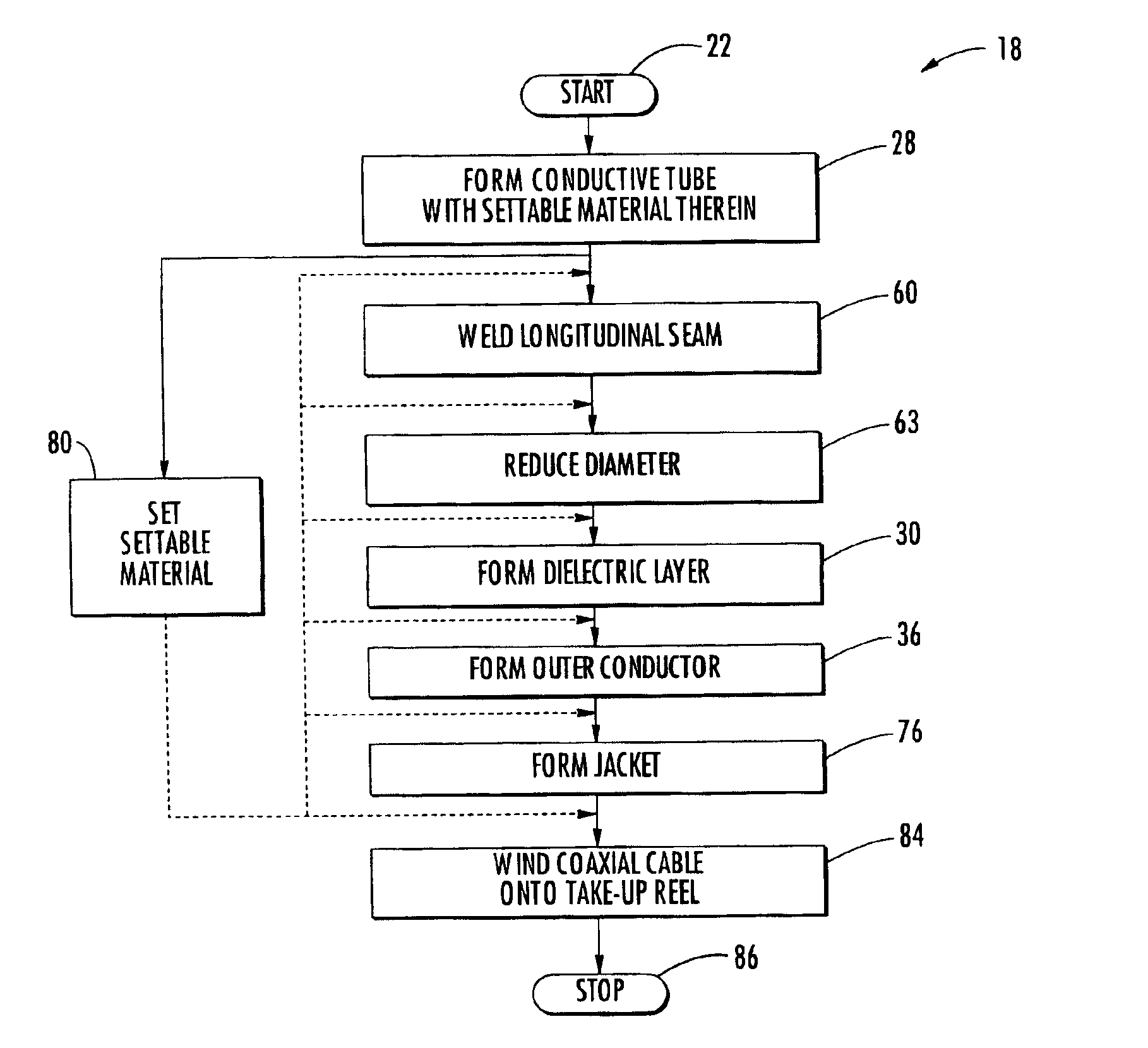

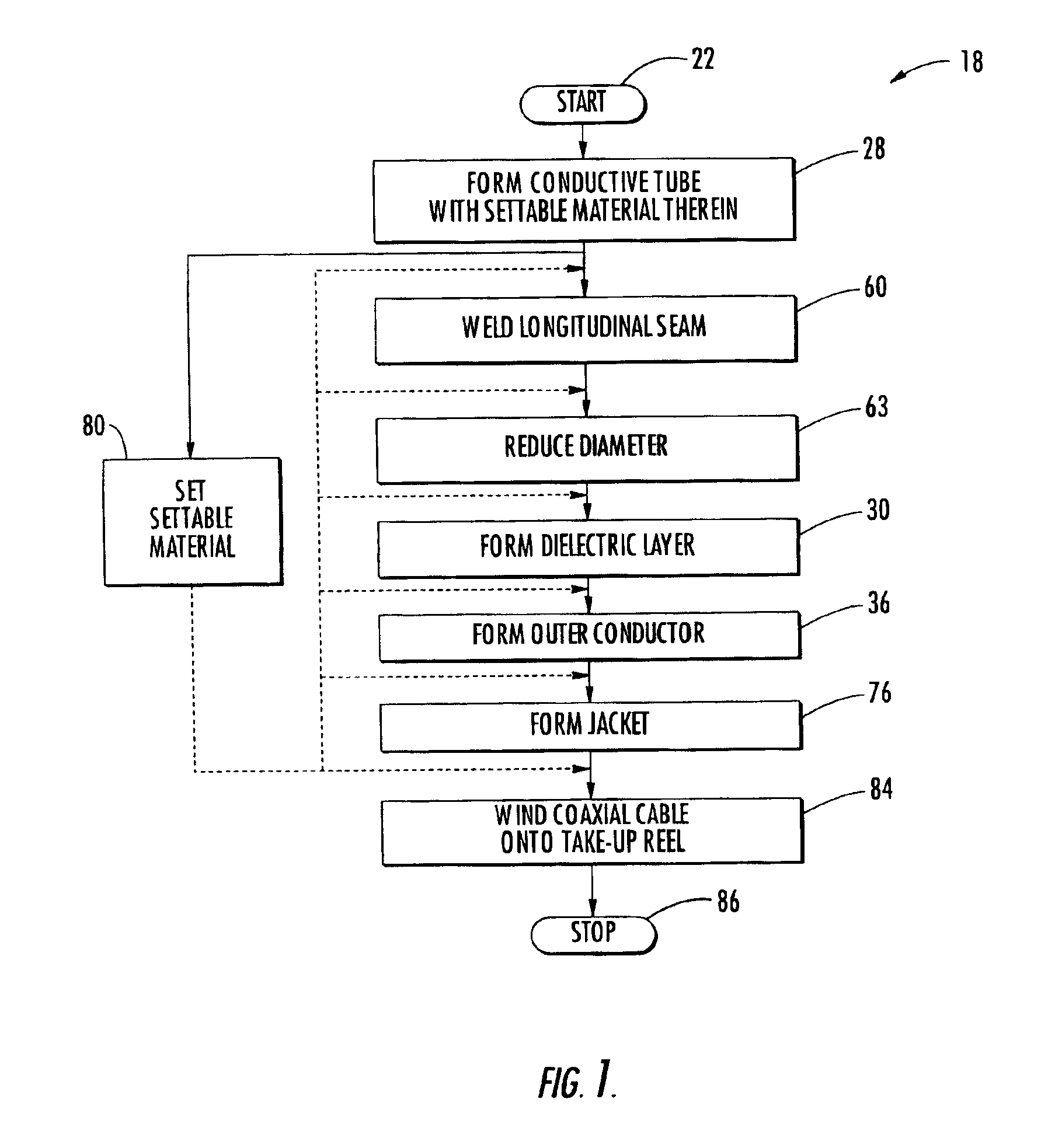

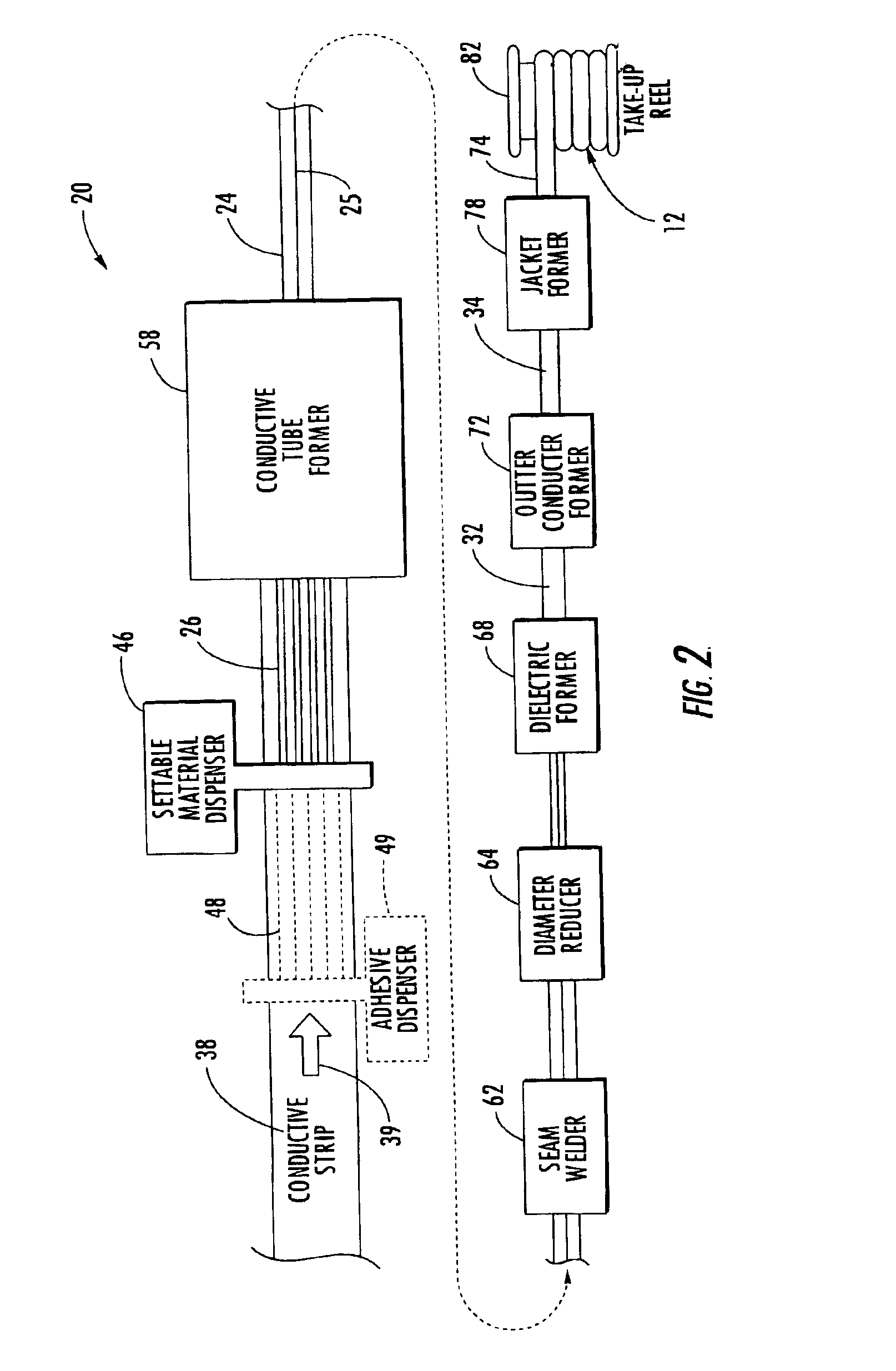

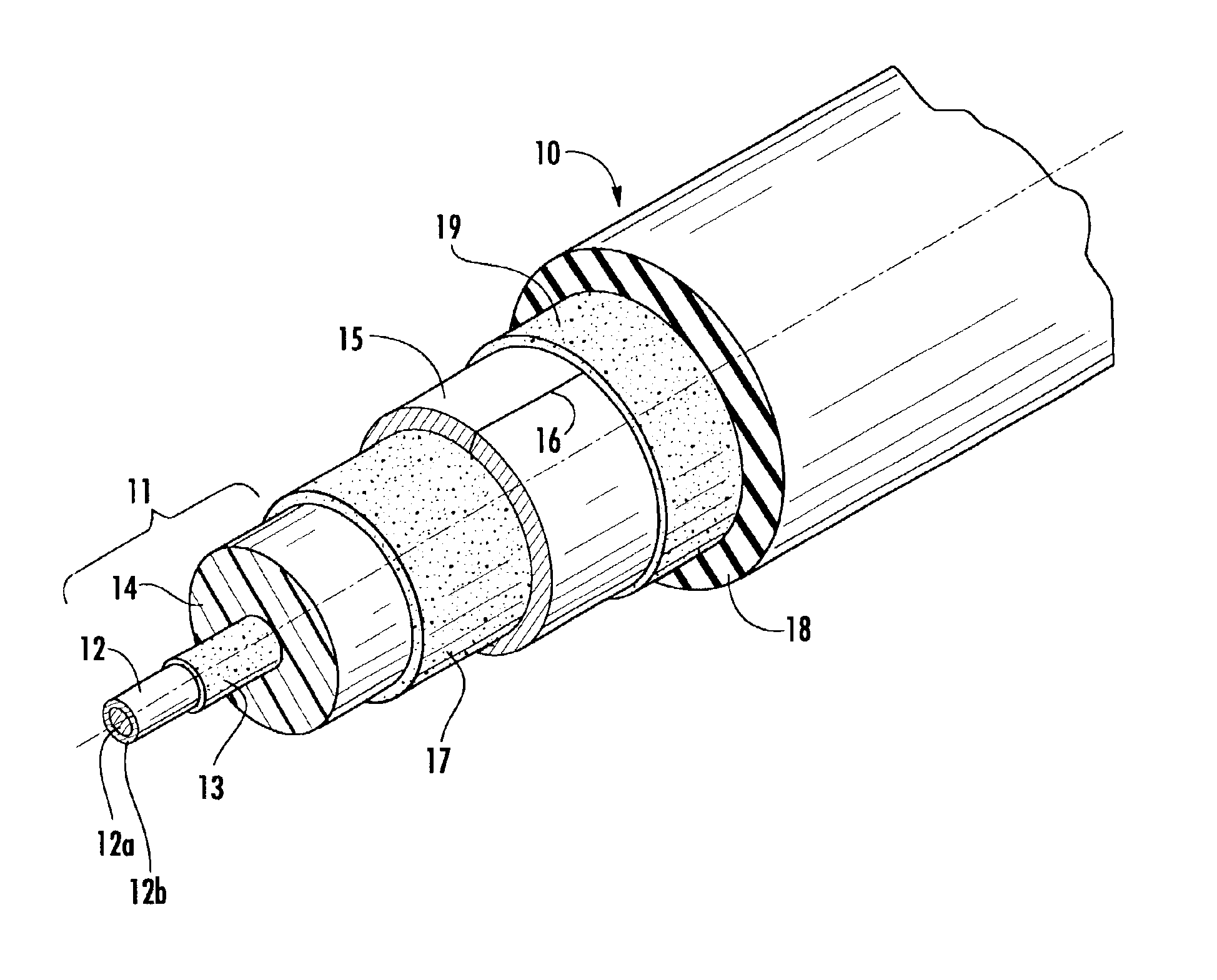

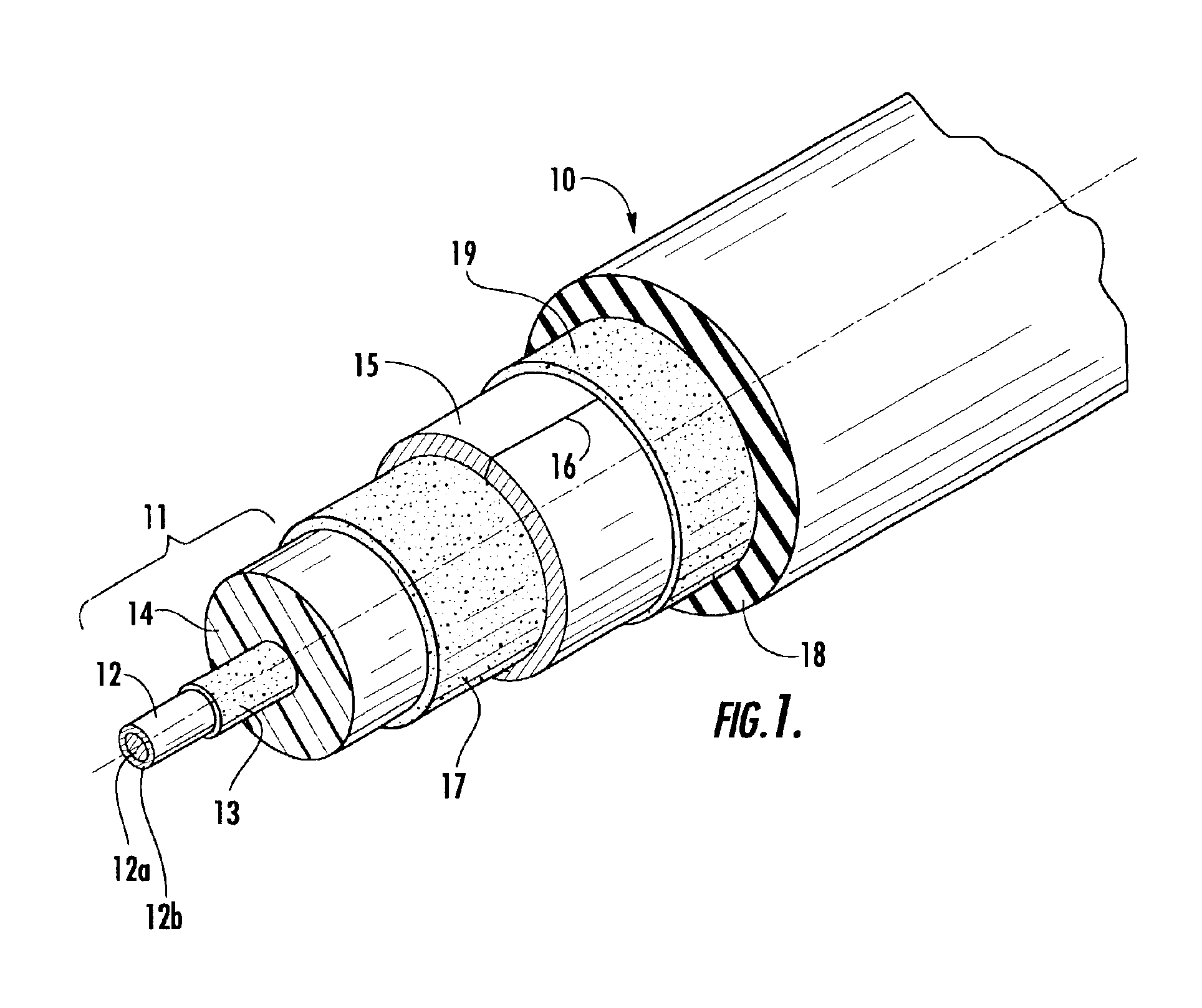

Method and apparatus for manufacturing coaxial cable with composite inner conductor

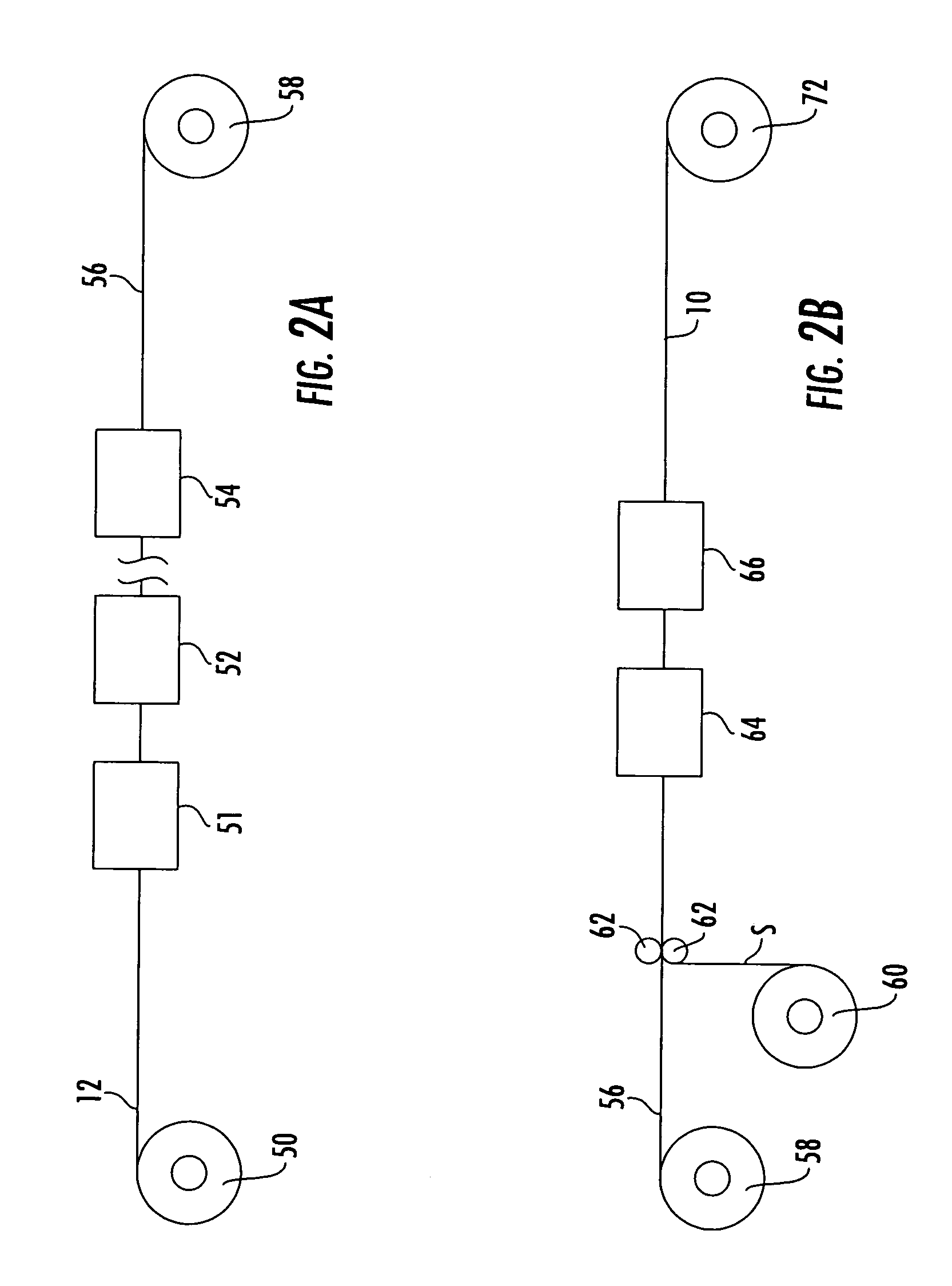

InactiveUS6915564B2Efficient preparationLow costLine/current collector detailsCable conductor constructionElectrical conductorCoaxial cable

A method of making a coaxial cable includes forming a conductive tube and setting a settable material therein to define an inner conductor. Forming may include advancing a conductive strip and bending it into a tube having a longitudinal seam. The settable material may be dispensed onto the conductive strip continuously with the forming. Alternately, the settable material may be dispensed onto the conductive strip prior to advancing. The dispensing may use a puller cord as the settable material or carrying some or all of the settable material. The method may further include forming a dielectric layer surrounding the inner conductor, and forming an outer conductor surrounding the dielectric layer.

Owner:COMMSCOPE INC

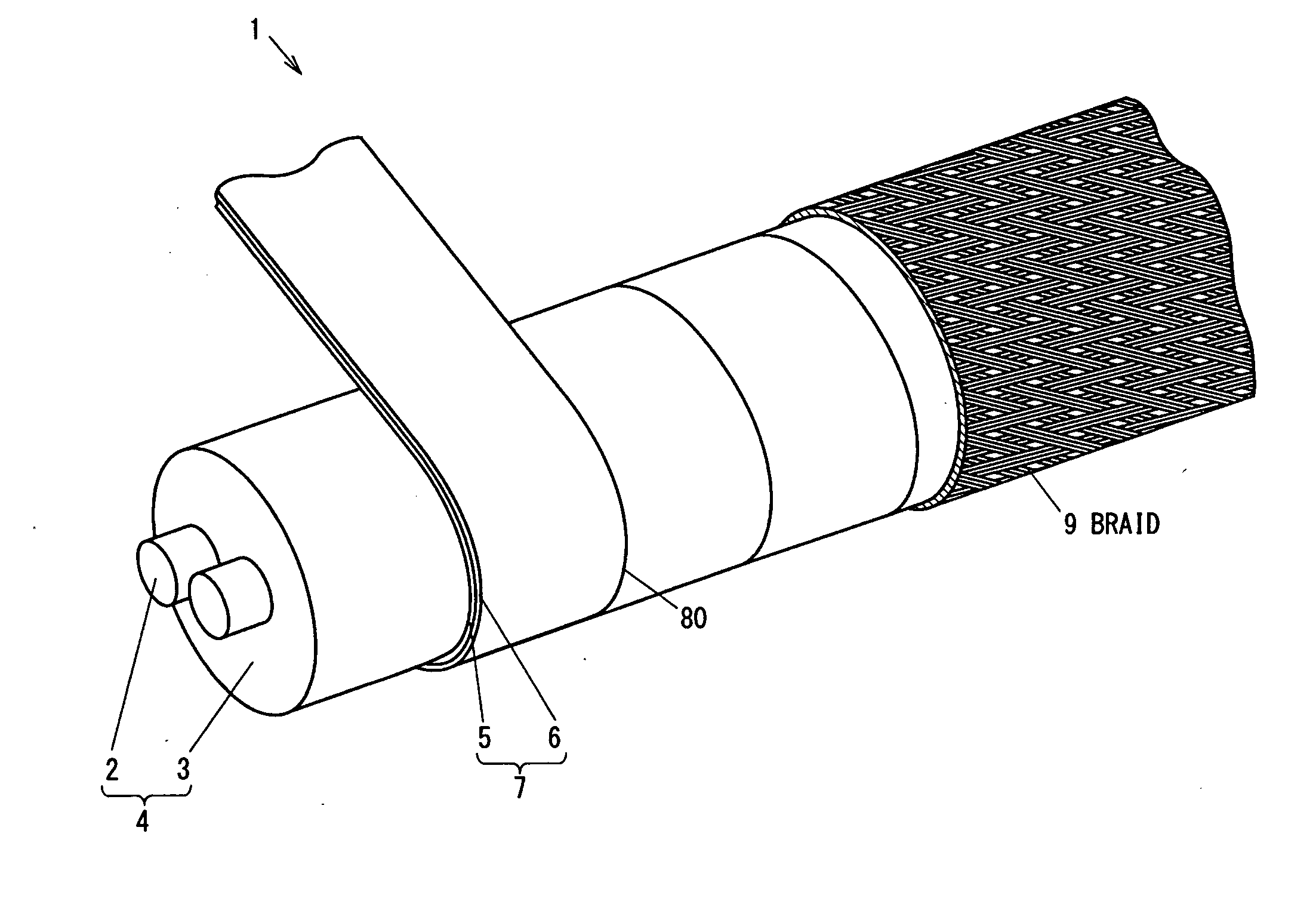

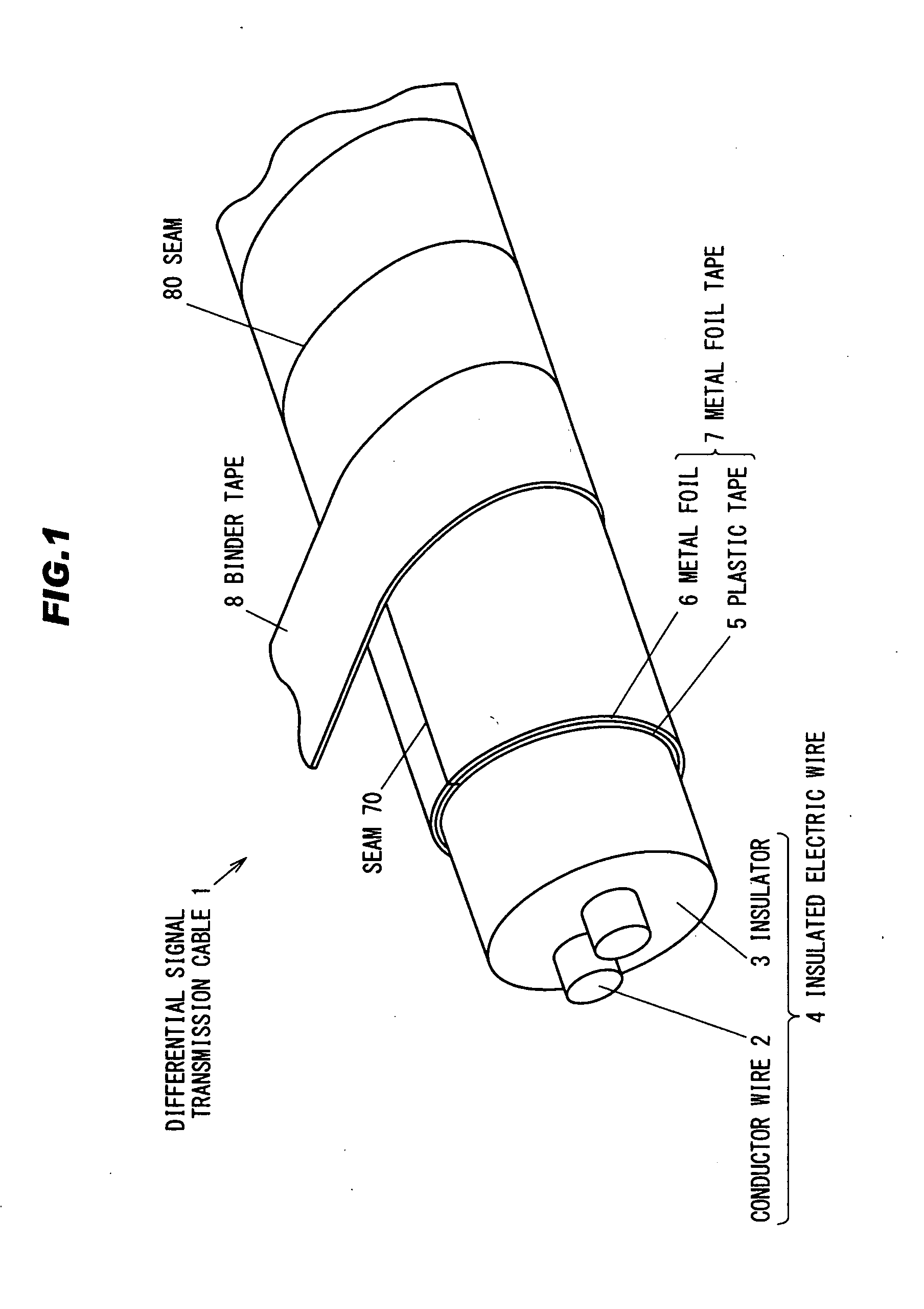

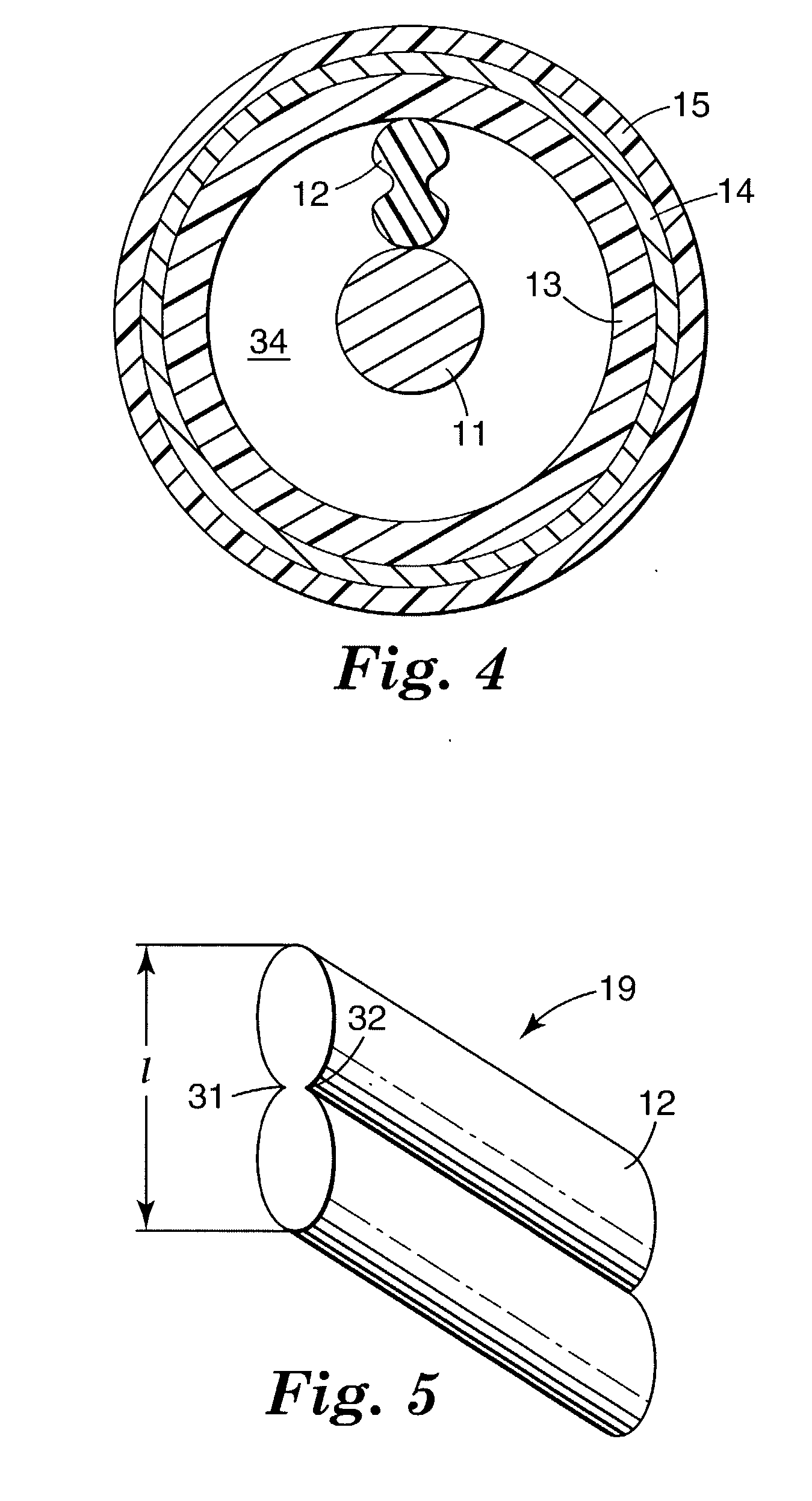

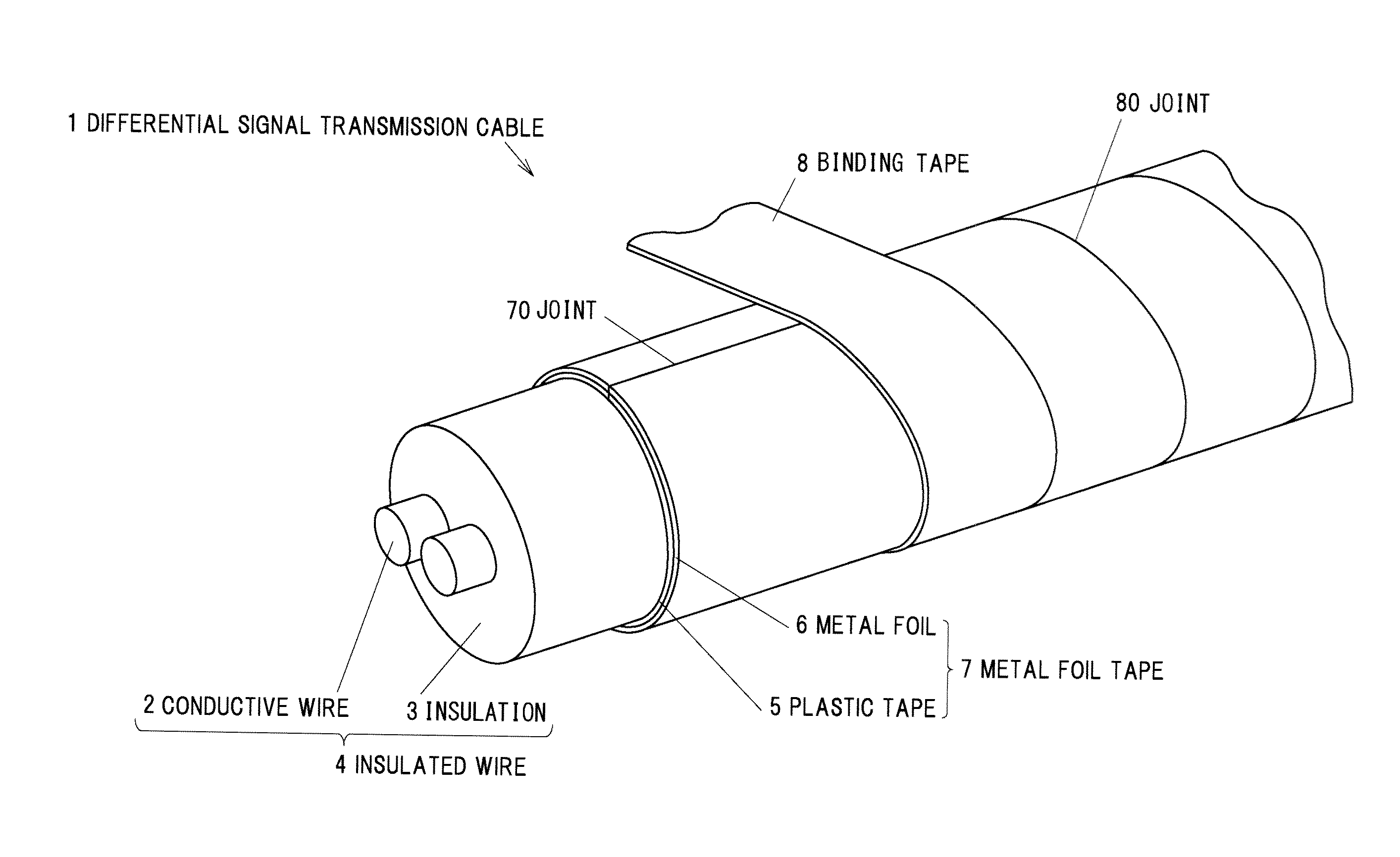

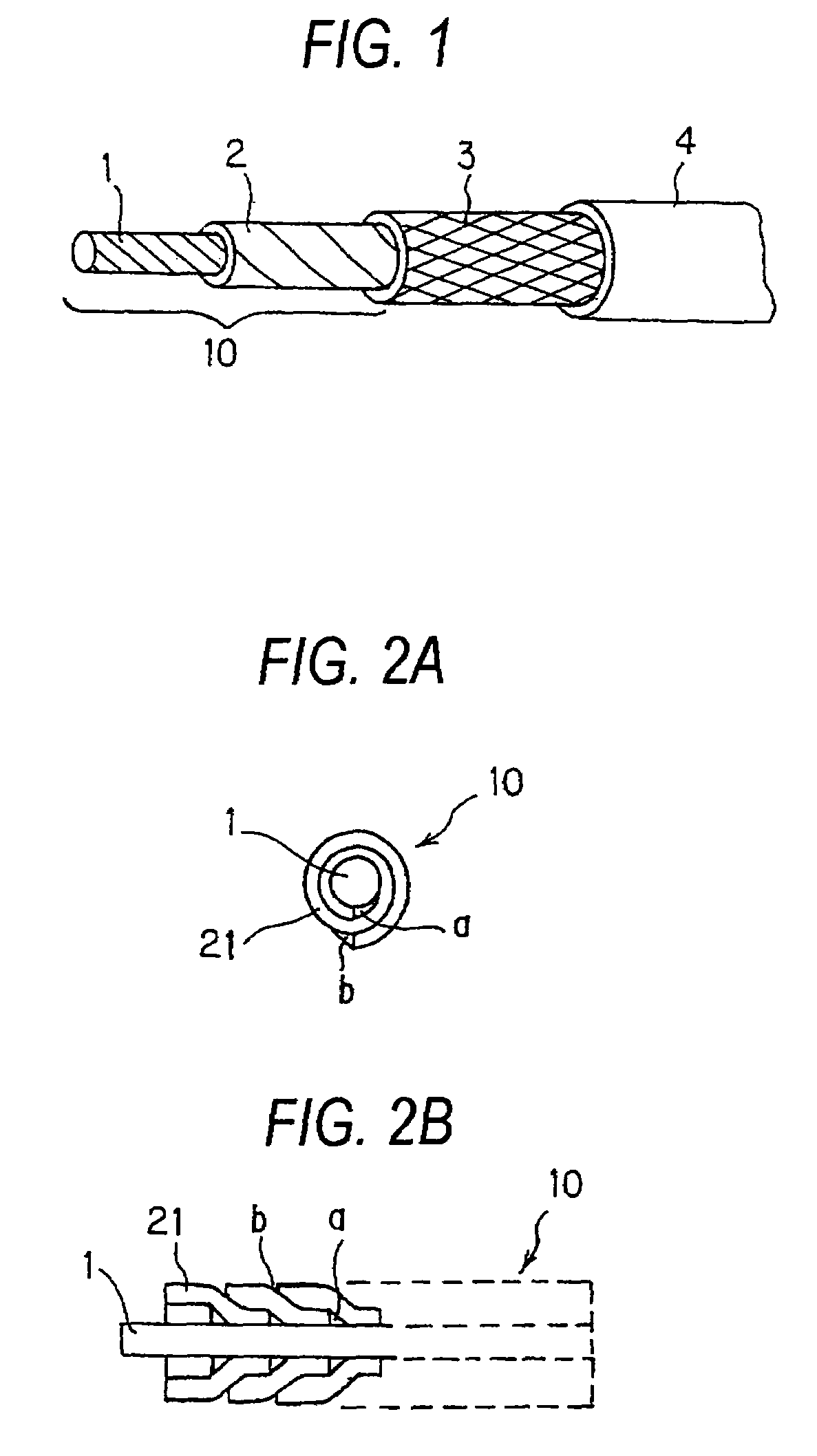

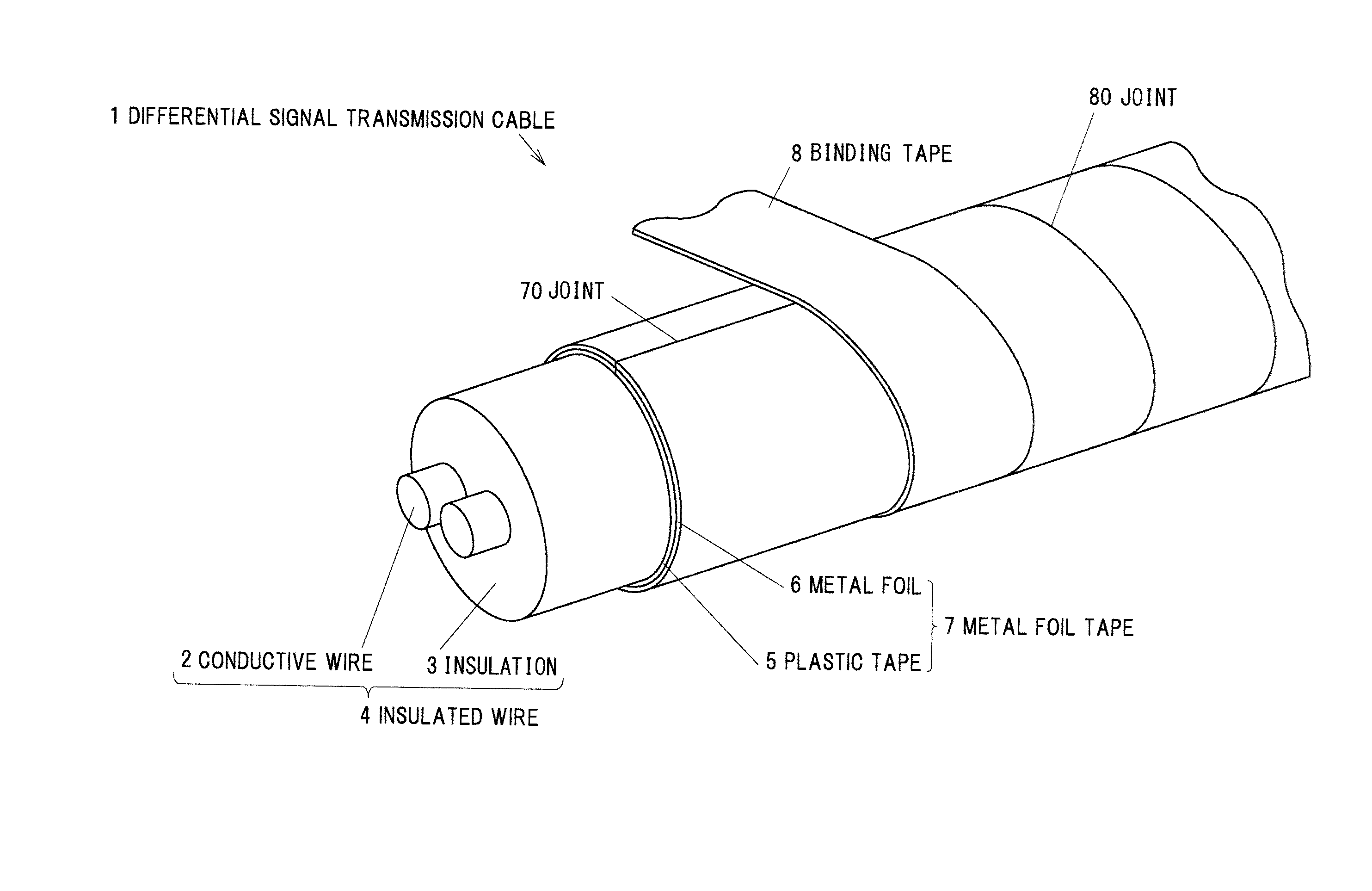

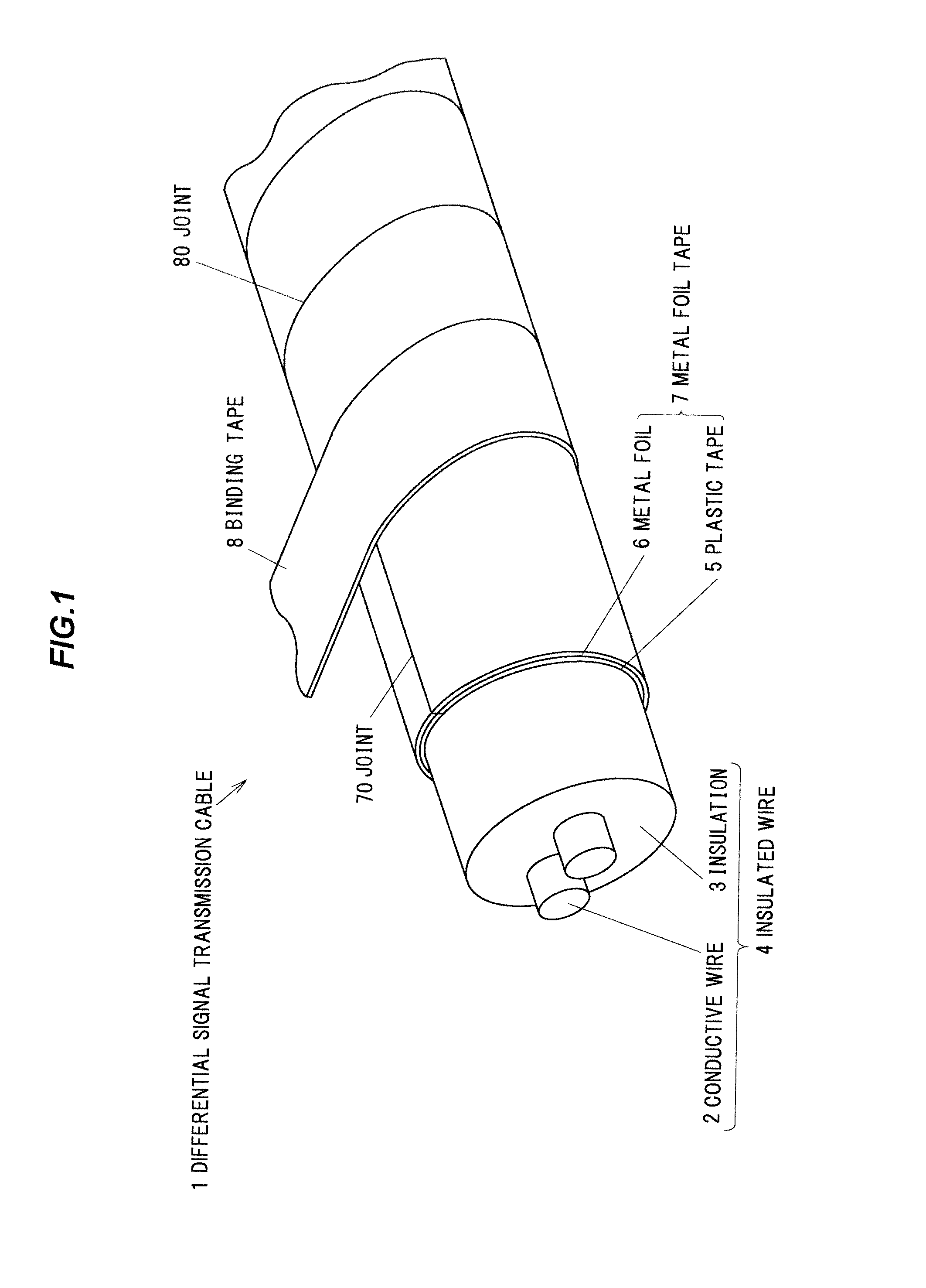

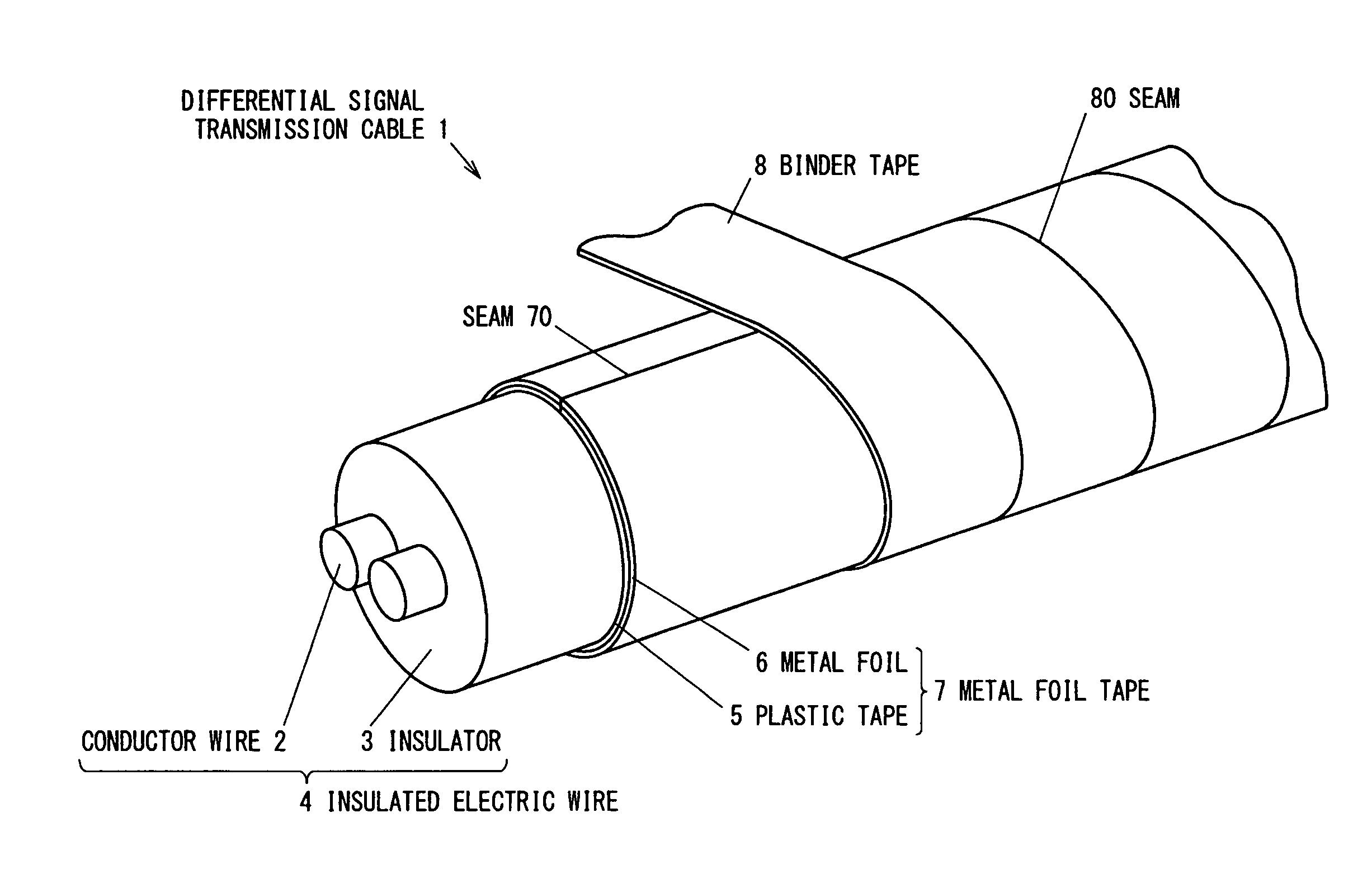

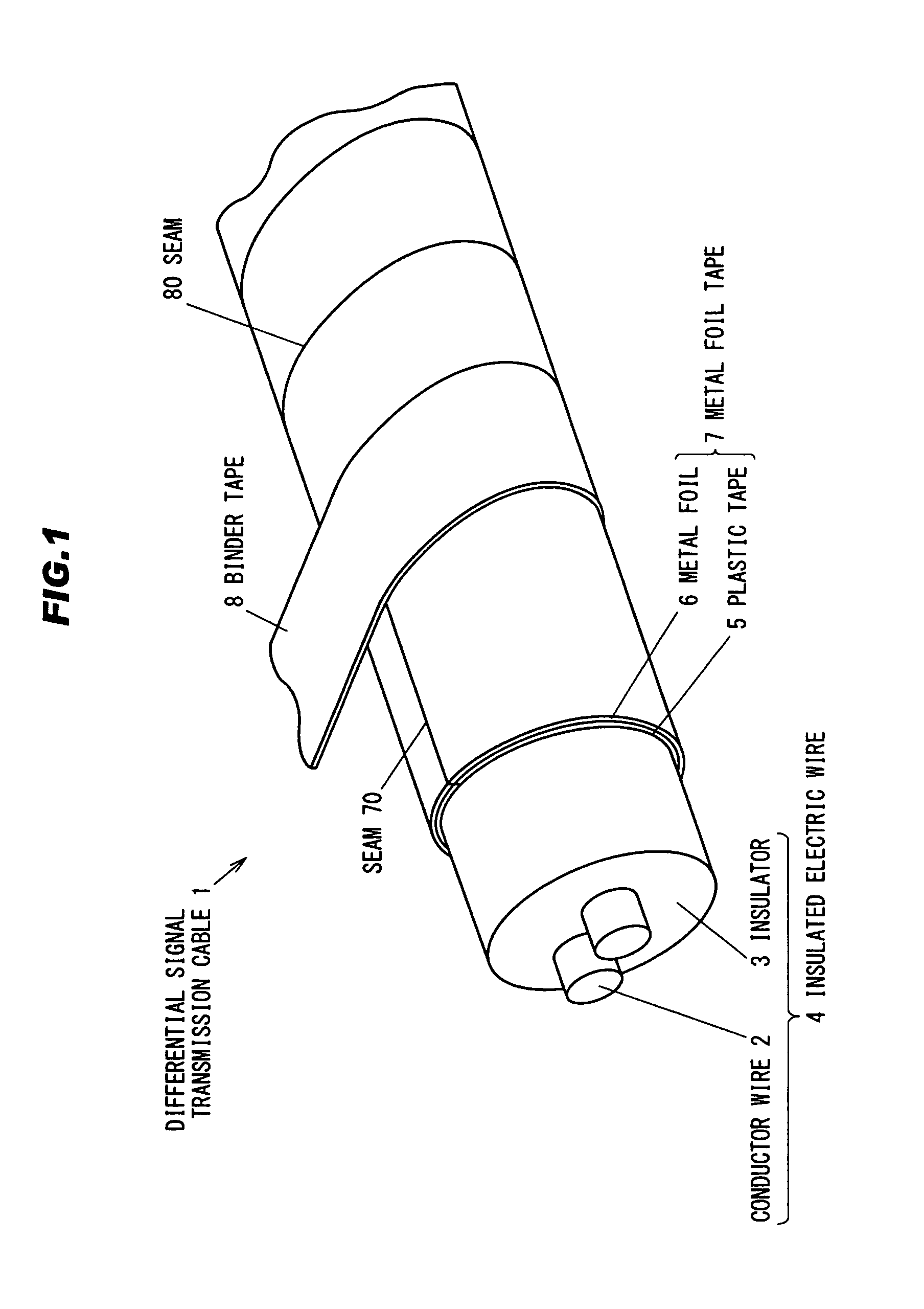

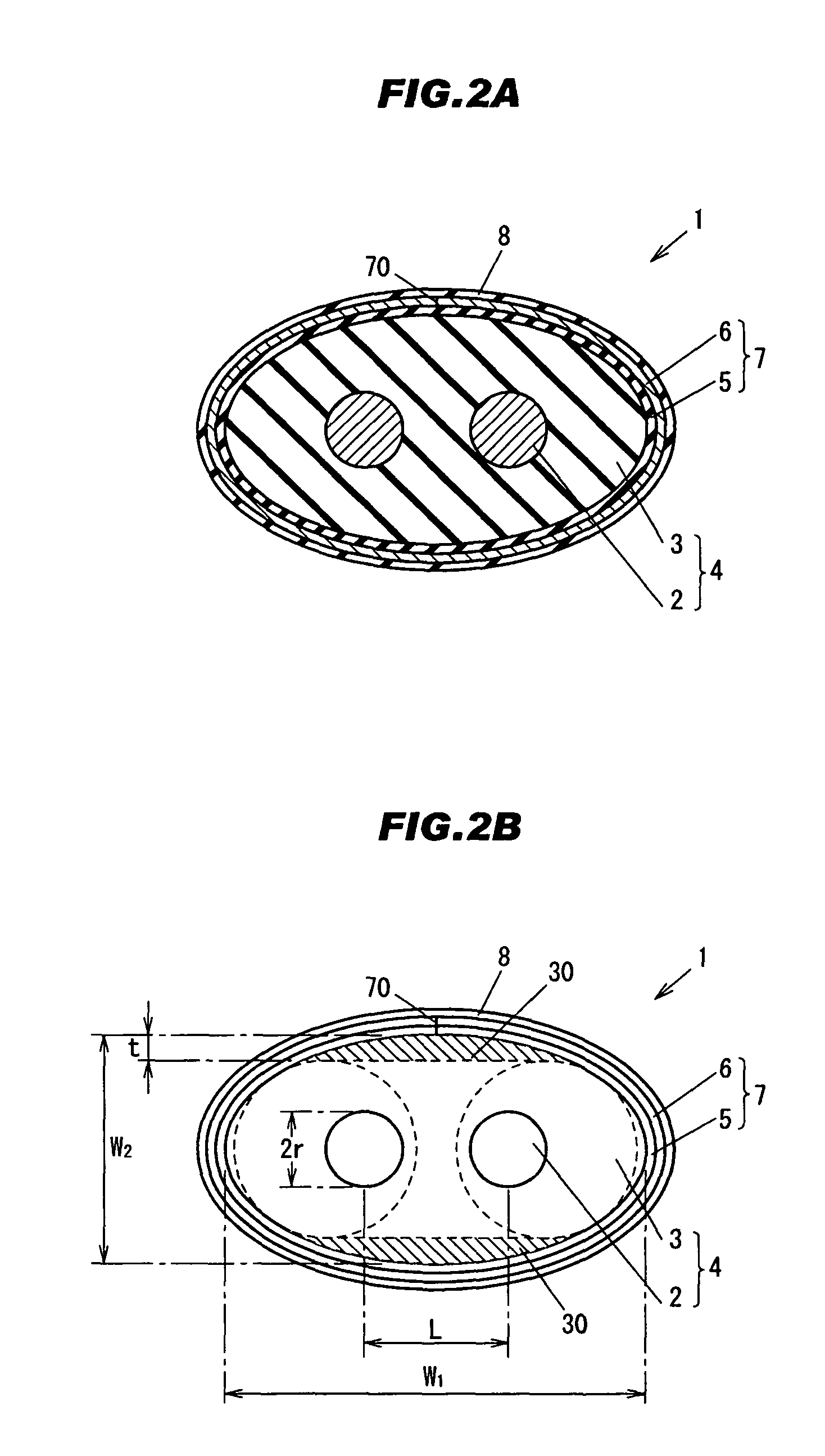

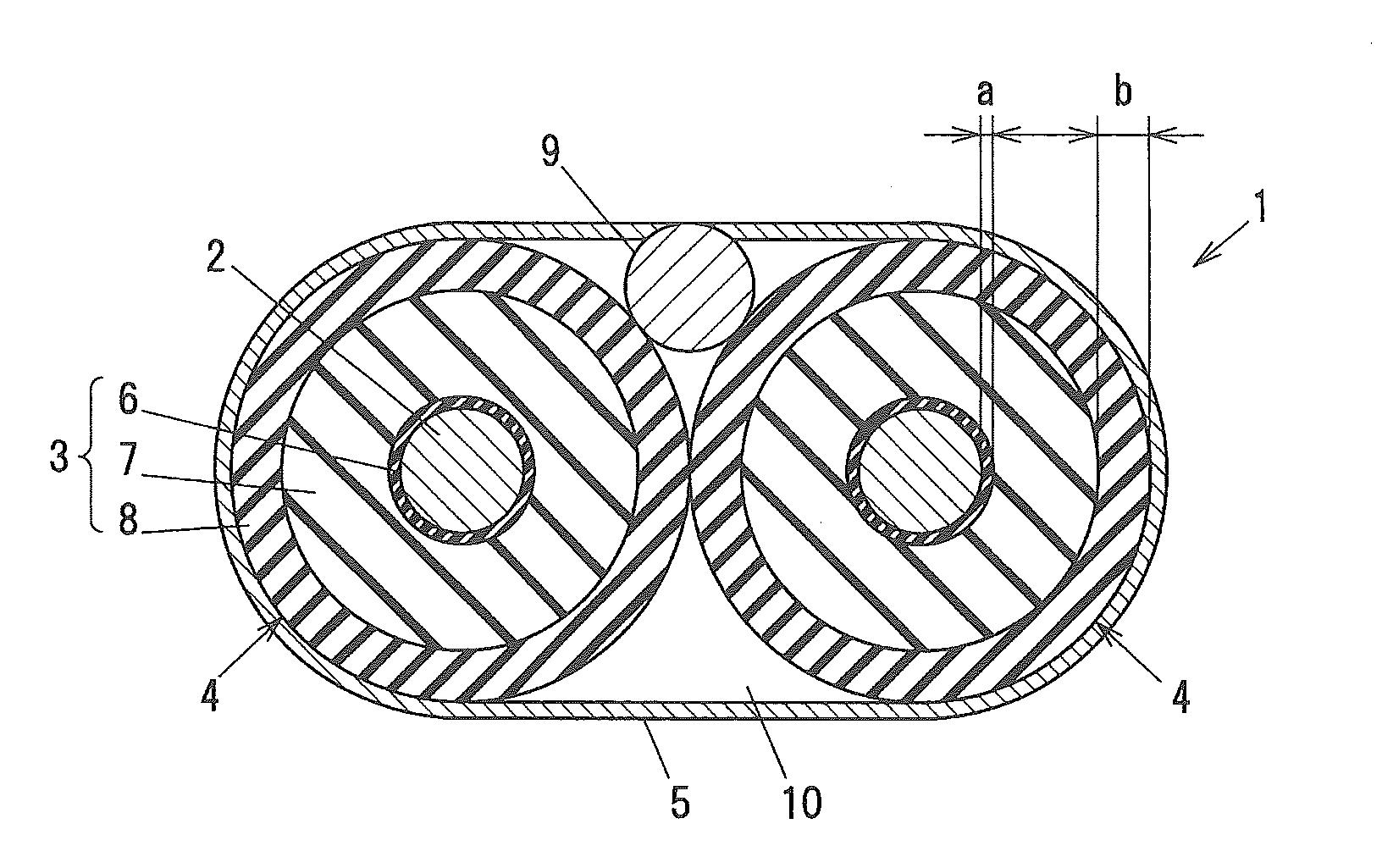

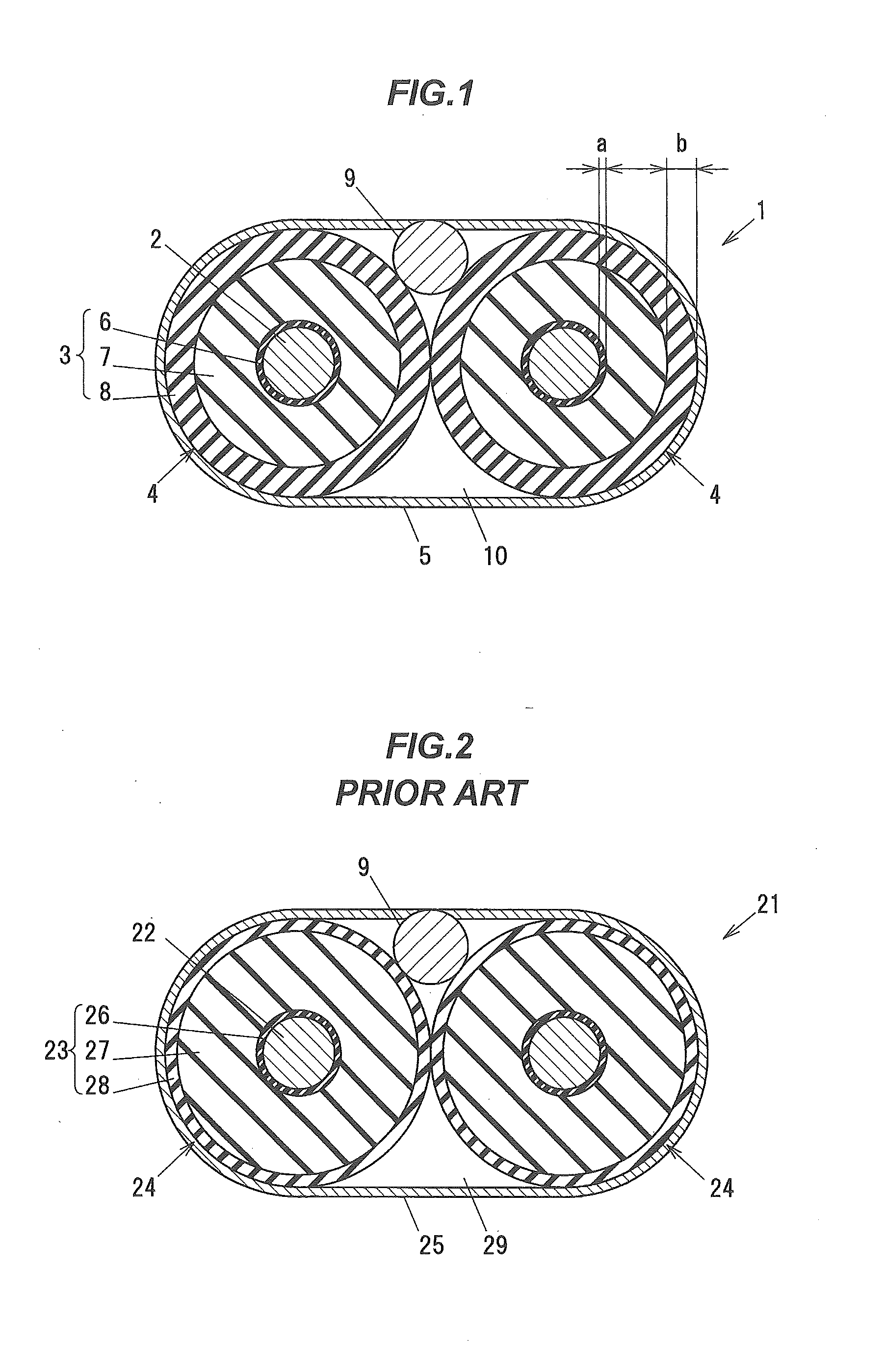

Differential signal transmission cable

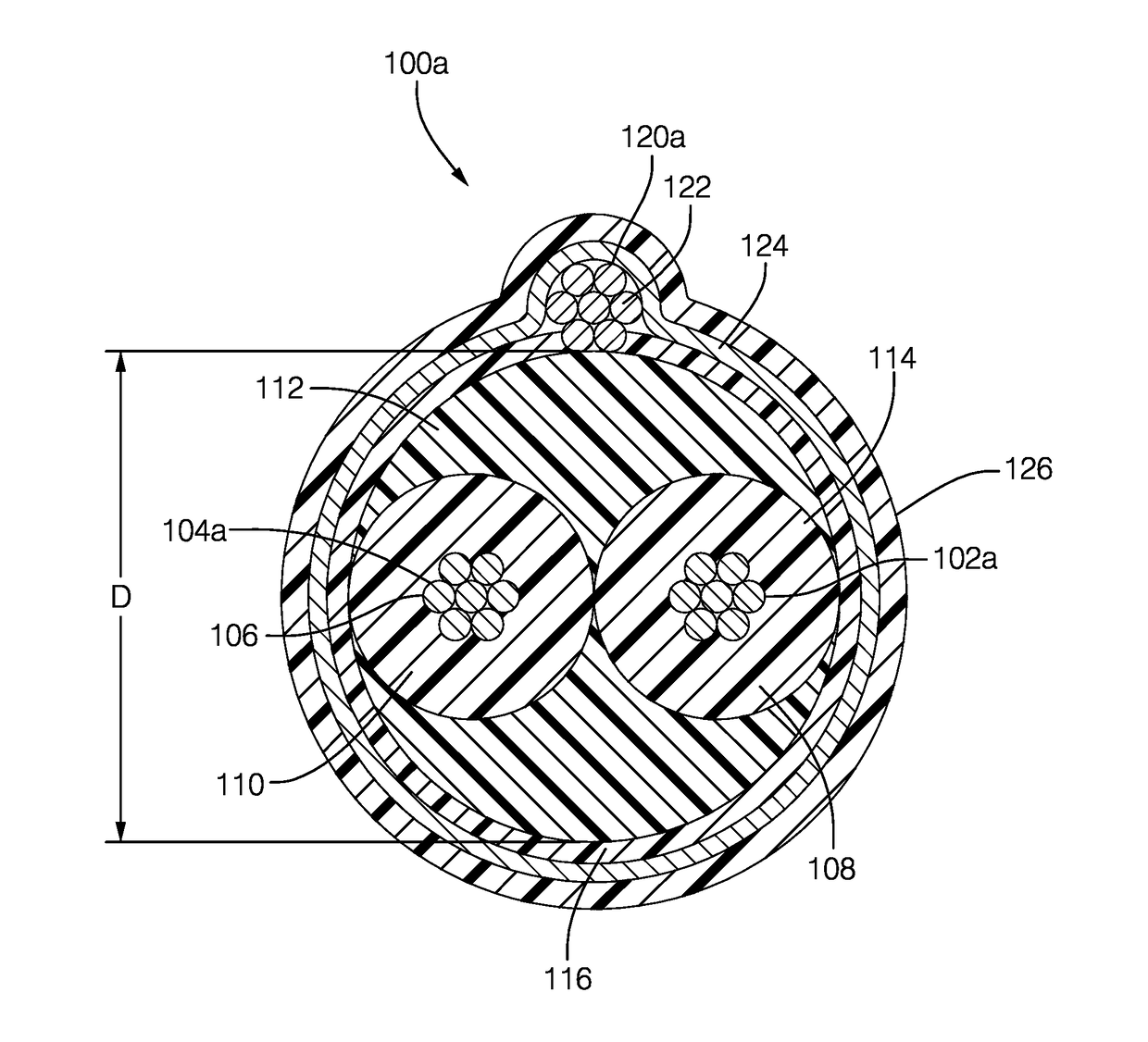

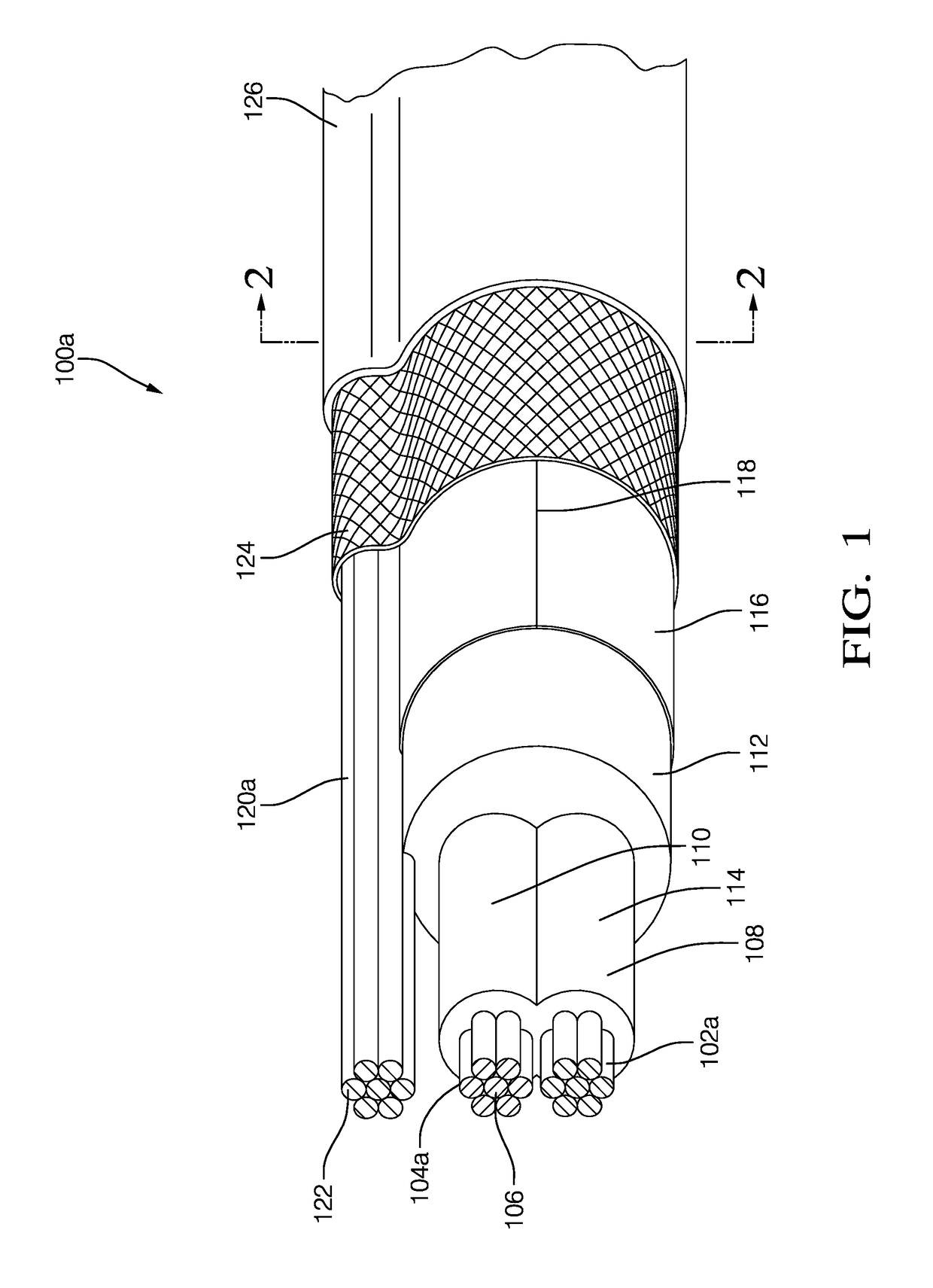

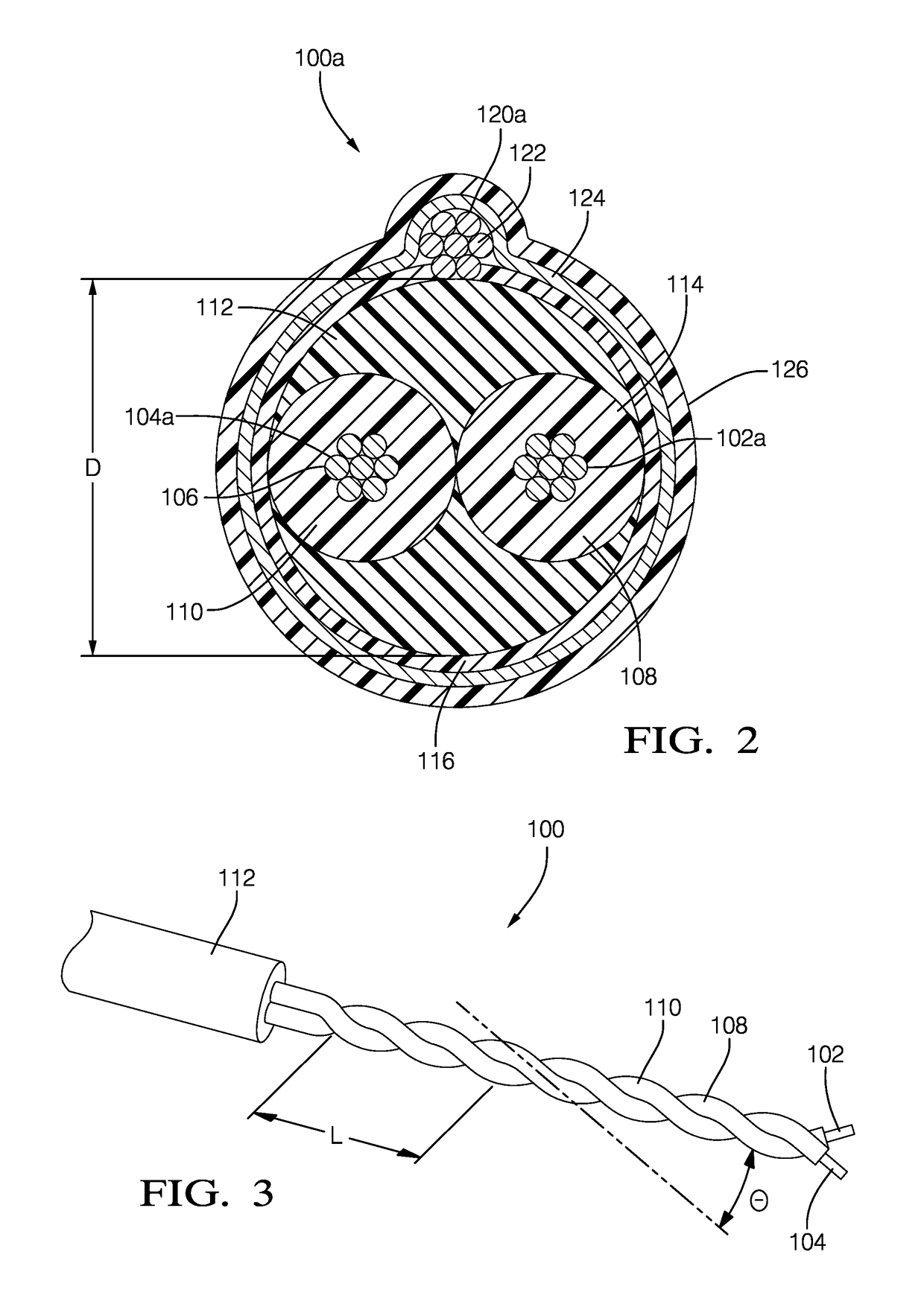

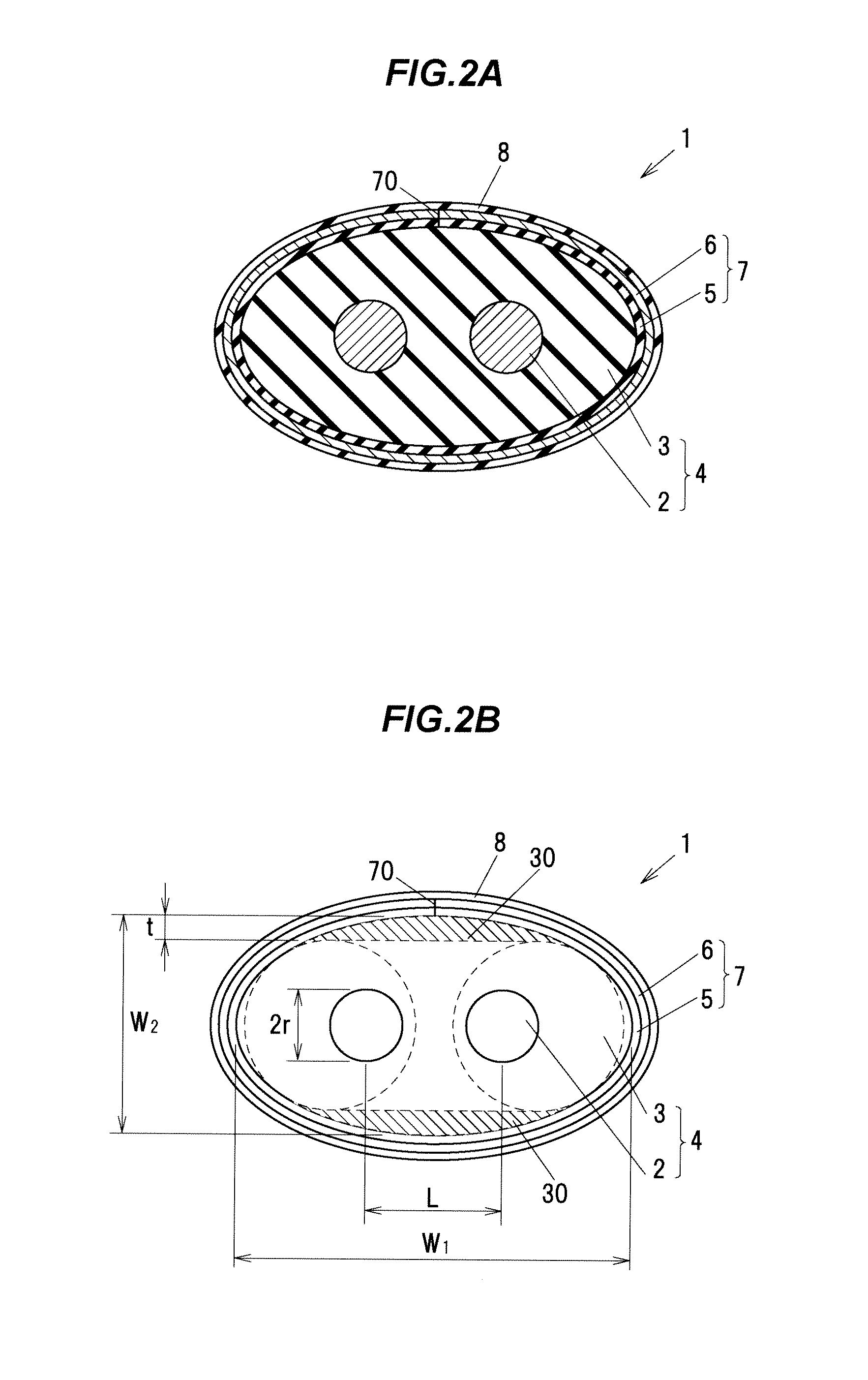

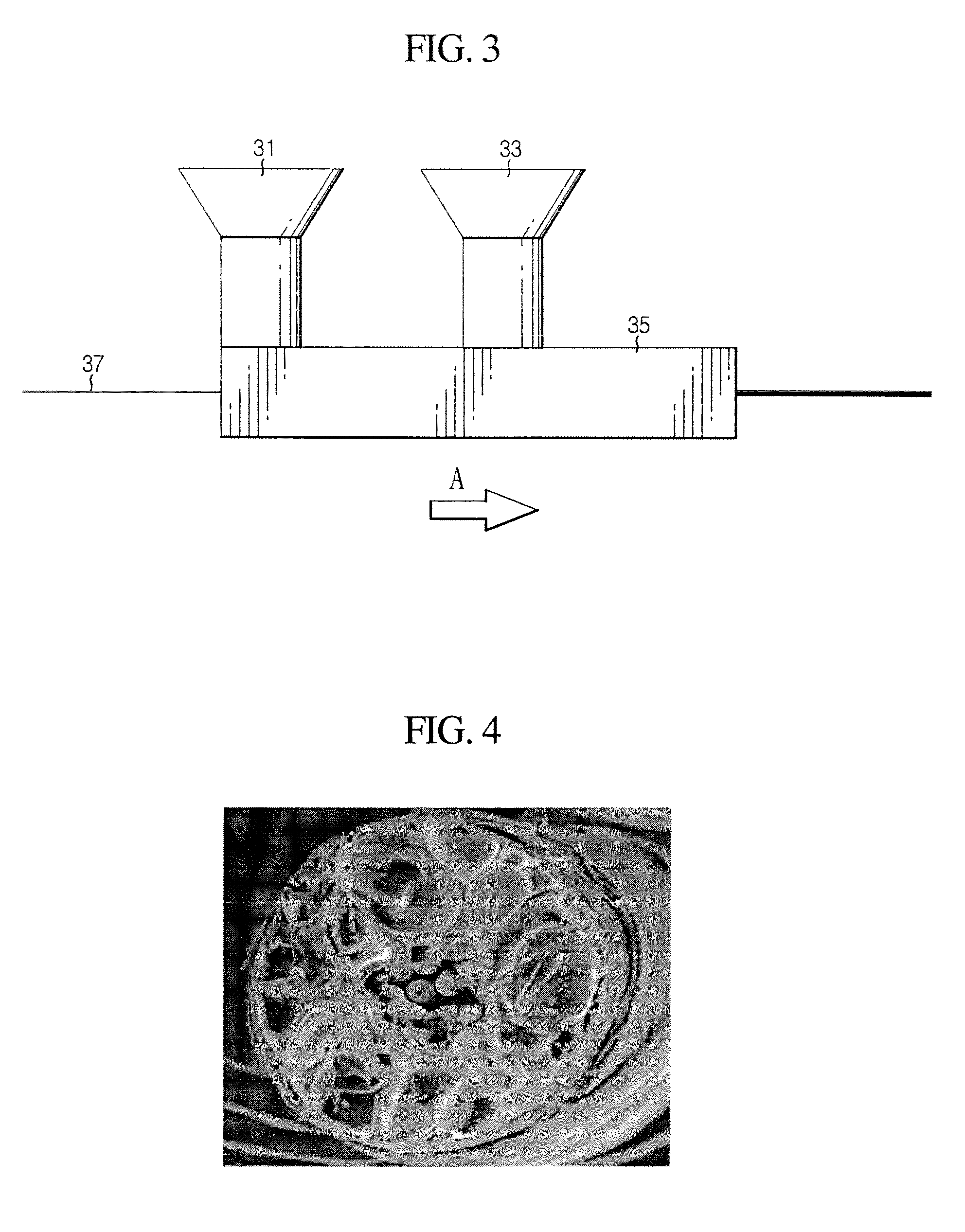

ActiveUS20120186850A1Suppression skewSuppress the skew and the differential modeCable insulation constructionPower cables with screens/conductive layersElectrical conductorDifferential signaling

A differential signal transmission cable has a pair of conductors arranged to be distant from each other and parallel to each other, an insulator covering the pair of conductors, and a shield conductor wound around the insulator. The insulator has an outer periphery shape of a transversal cross section in that a plurality of curved lines with different curvature radiuses are combined. The shield conductor has an inner periphery shape of a transversal cross section in that the plurality of curved lines are combined in accordance with the outer periphery shape of the insulator.

Owner:HITACHI METALS LTD

Load-resistant coaxial transmission line

A transmission line for downhole tools that make up all or part of a tool string for drilling and production of oil, gas, and geothermal wells that can withstand the dynamic gravitational forces and other accelerations associated with downhole excavations. The transmission line has a metal tube, or outer conductor, that houses a coaxial wire inner conductor. A non-metallic dielectric material is interposed between the inner and outer conductors. The outer and inner conductors and the dielectric are sufficiently compressed together so that independent motion between them is abated. Compression of the components of the transmission line may be achieved by drawing the transmission through one or more dies in order to draw down the outer conductor onto the dielectric, or by expanding the inner conductor against the dielectric using a mandrel or hydraulic pressure. Non-metallic bead segments may be used in aid of the compression necessary to resist the dynamic forces and accelerations of drilling.

Owner:INTELLISERV LLC

Triboelectric, Ranging, or Dual Use Security Sensor Cable and Method of Manufacturing Same

InactiveUS20080024297A1Easy constructionReadily availableCable insulation constructionInsulated cablesElectrical conductorTerminal voltage

The present invention provides an inexpensive security sensor cable, a method for manufacturing of same and an overall security system for using that sensor cable. The sensor cable consists of a central conductor, an air separator, a polyethylene dielectric tube, an outer conductor and an outer protective jacket. The central conductor is loosely centered in the coaxial cable and thus freely movable relative to the dielectric tube. The sensor cable has application either in a passive sensing system or in an active ranging sensing system to determine the location of an intrusion along the cable. For the passive sensing function, when the center conductor moves, it contacts a suitable dielectric material from the triboelectric series, such as polyethylene, which can be processed to produce a charge transfer by triboelectric effect that is measurable as a terminal voltage. In an active system, the central conductor moves within the dielectric in response to a vibration to provide an impedance change that can be sensed. Conventional radio grade cable may be modified in its construction by removing its dielectric thread to manufacture the sensor cable, thus enabling the center conductor to move freely in the air gap within the dielectric tube. An inexpensive method of manufacturing sensor cable is provided as the cable parts are readily available. Such a sensor cable is advantageous in that the passive triboelectric properties of the cable, in response to a disturbance, can provide a larger voltage response over prior art cables.

Owner:SENSTAR CORP

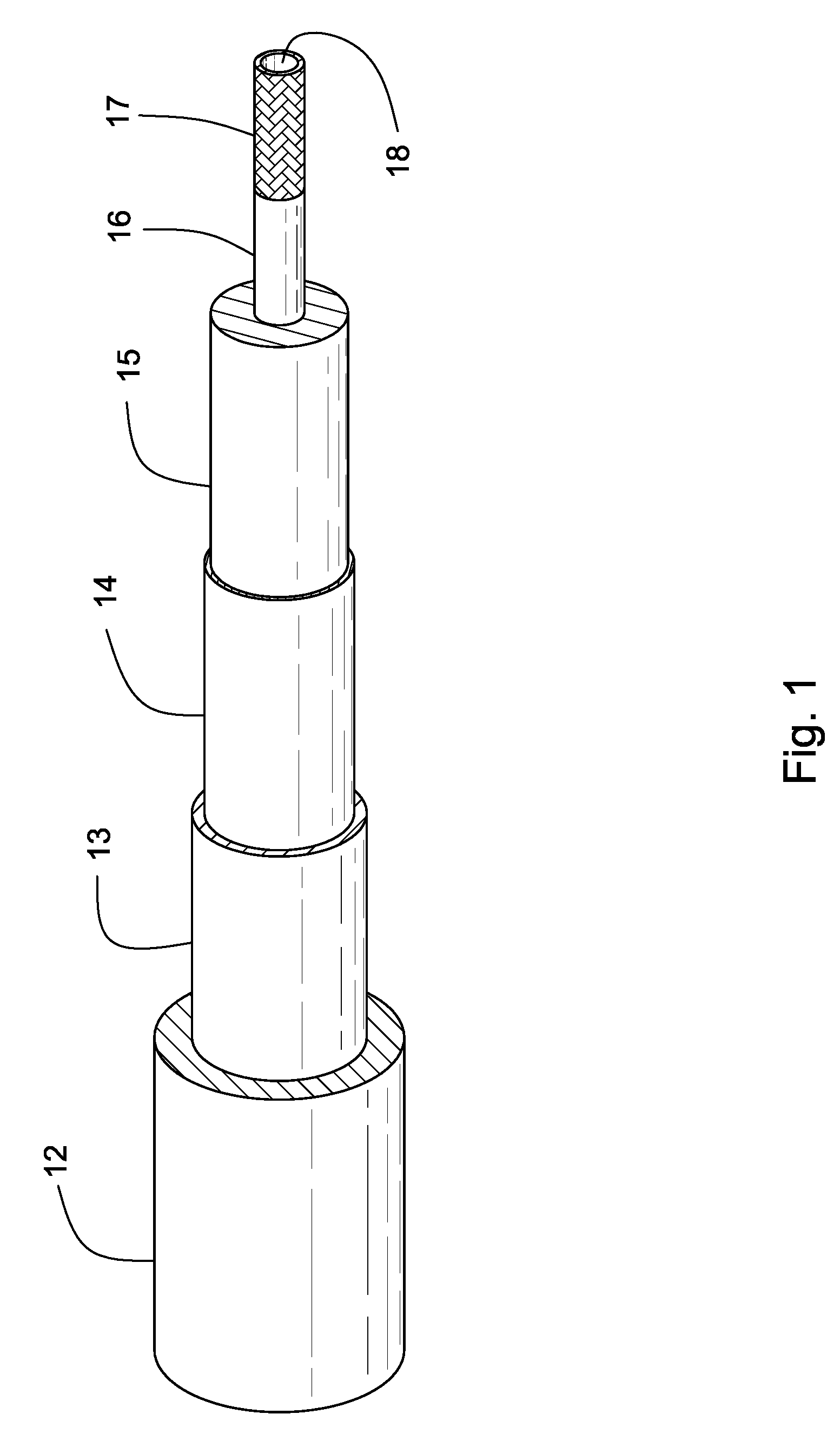

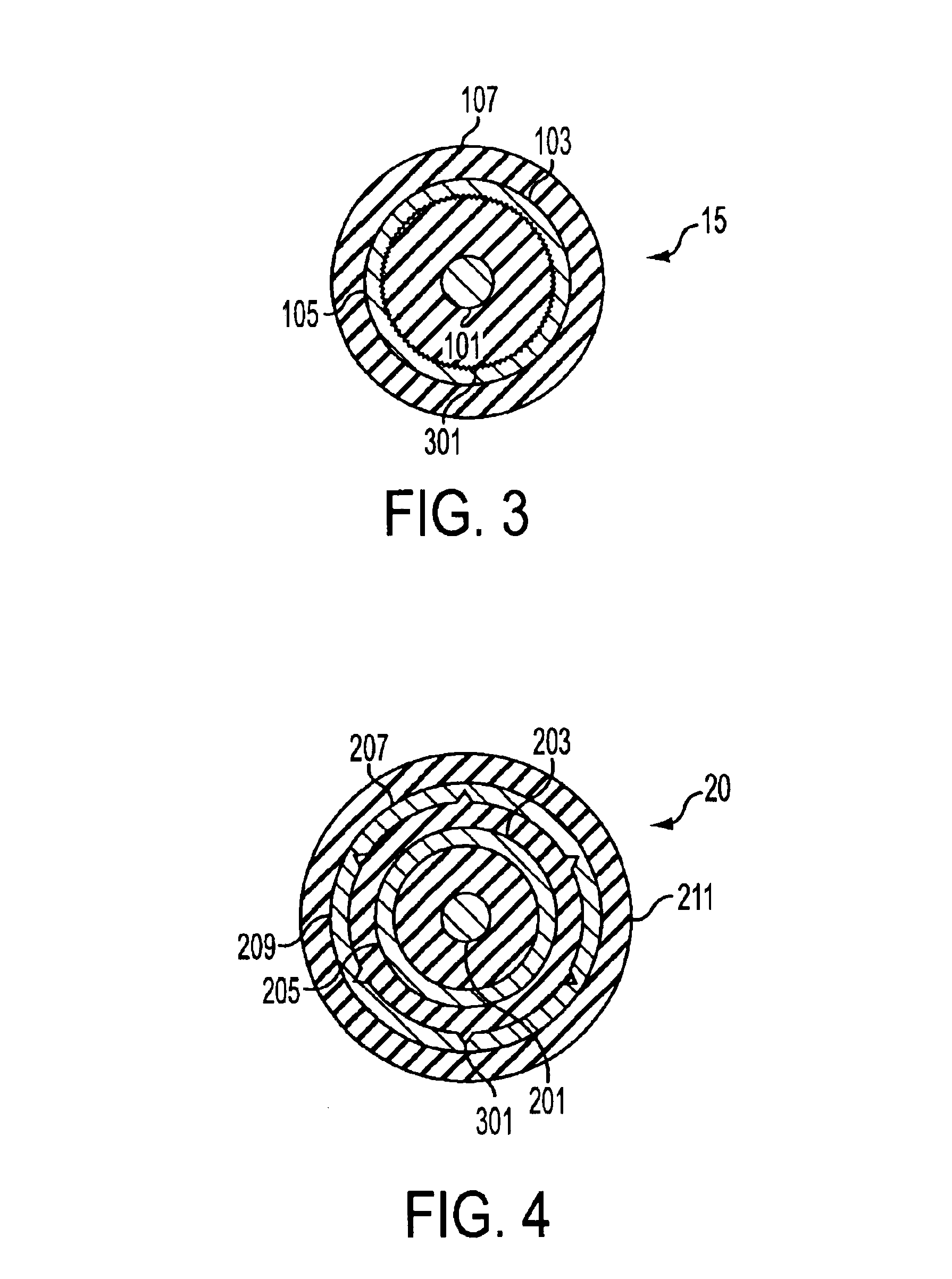

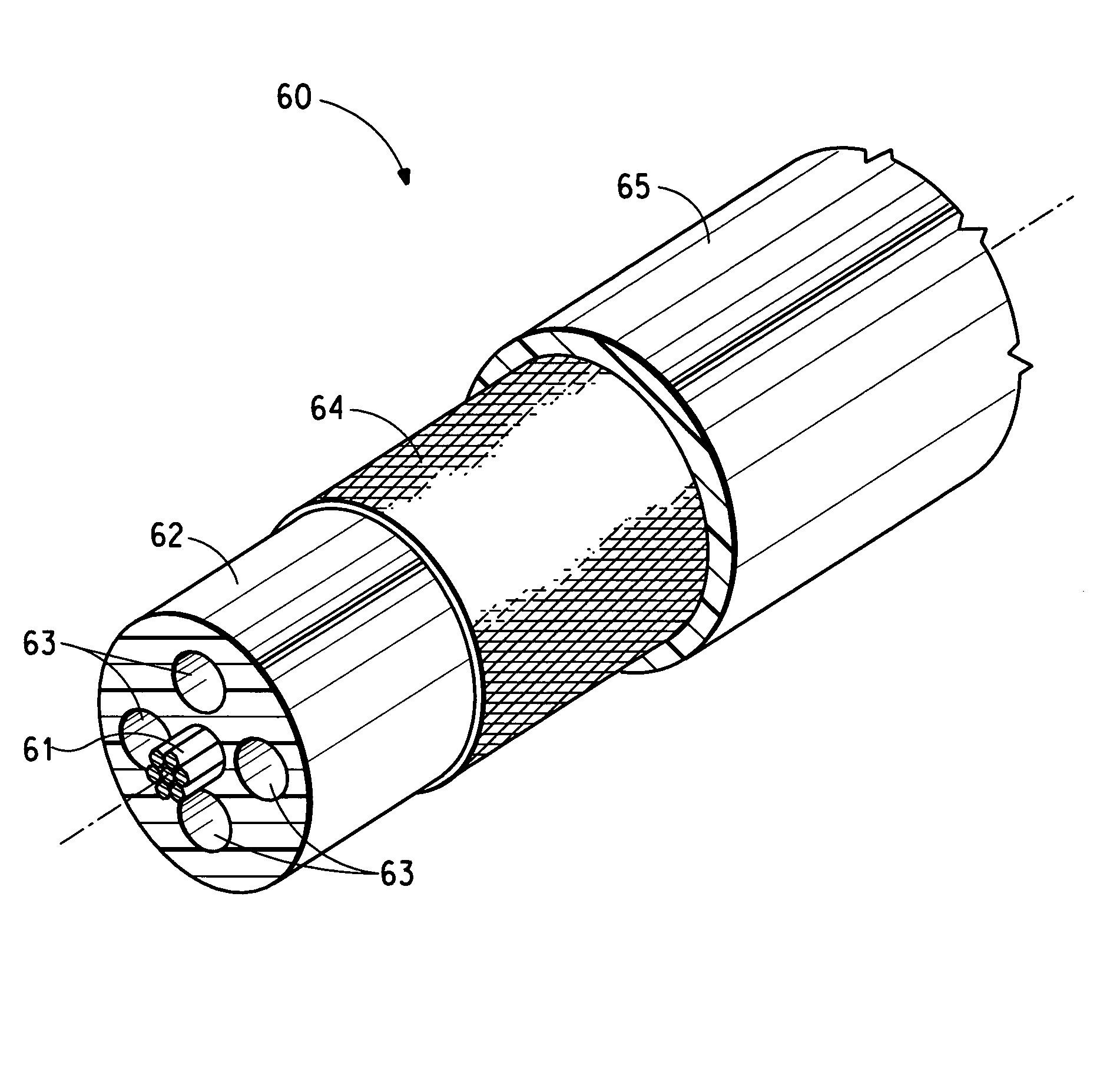

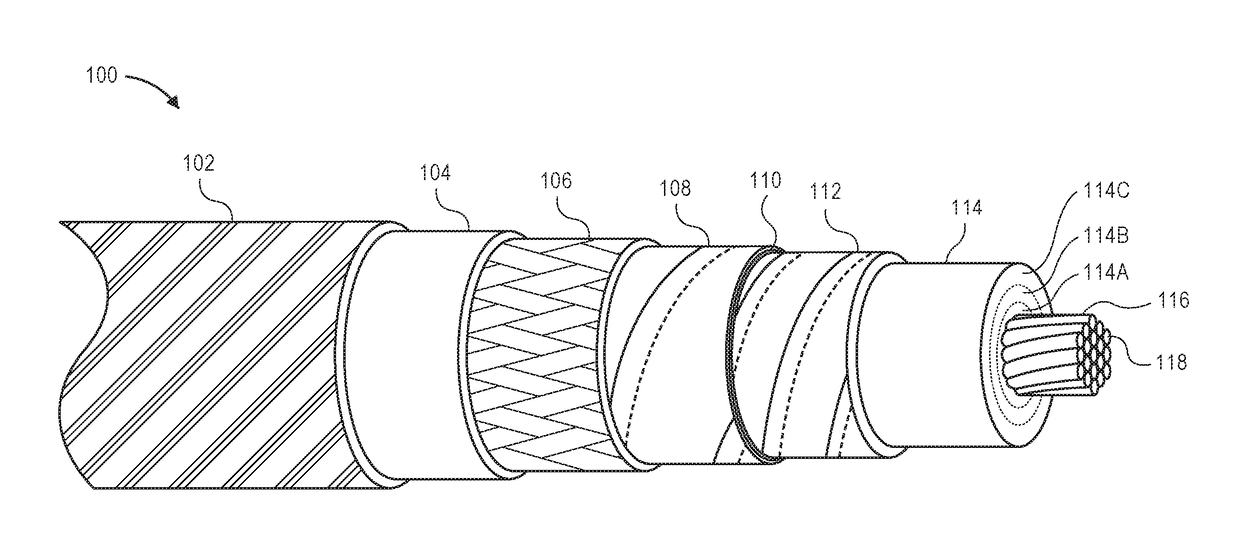

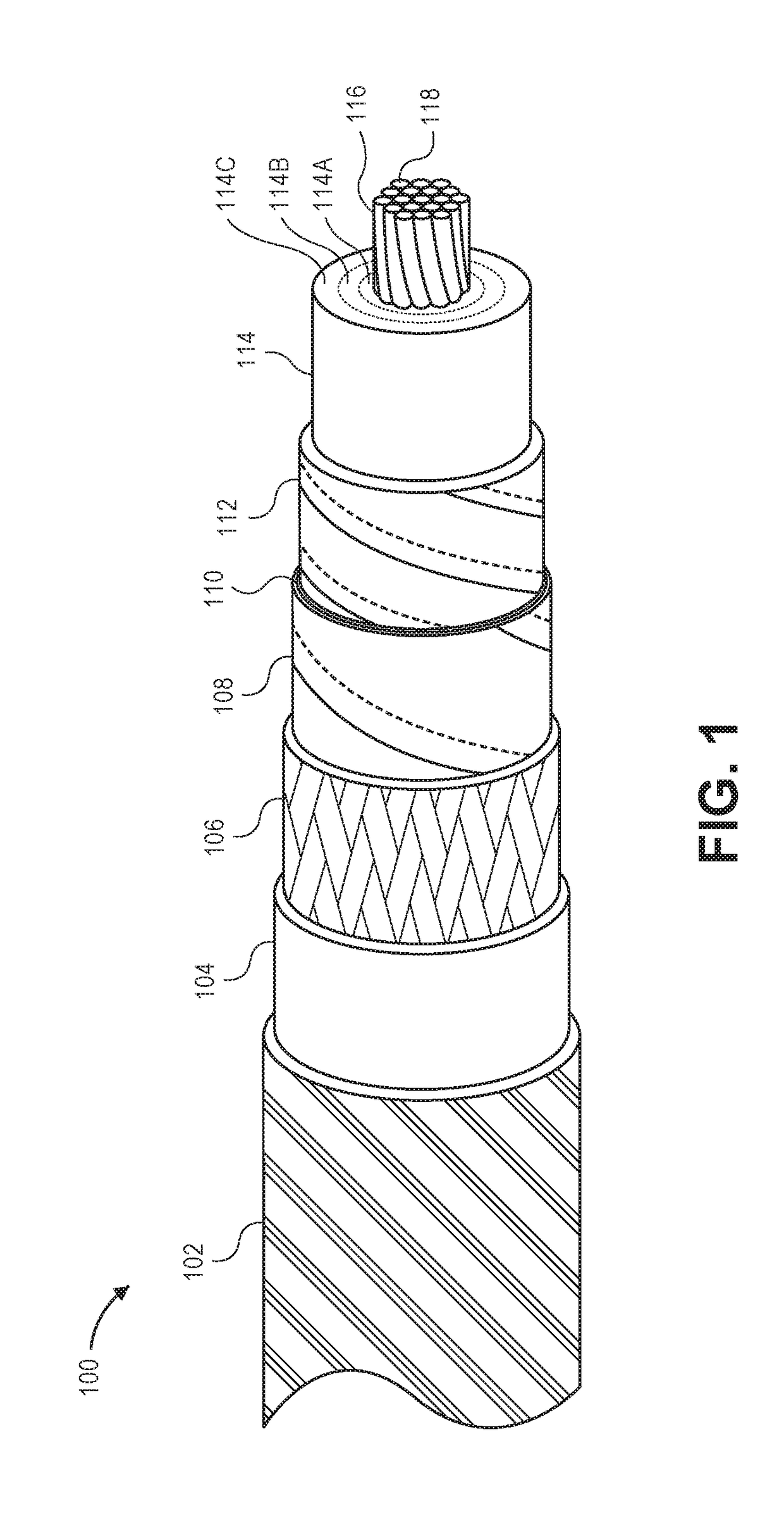

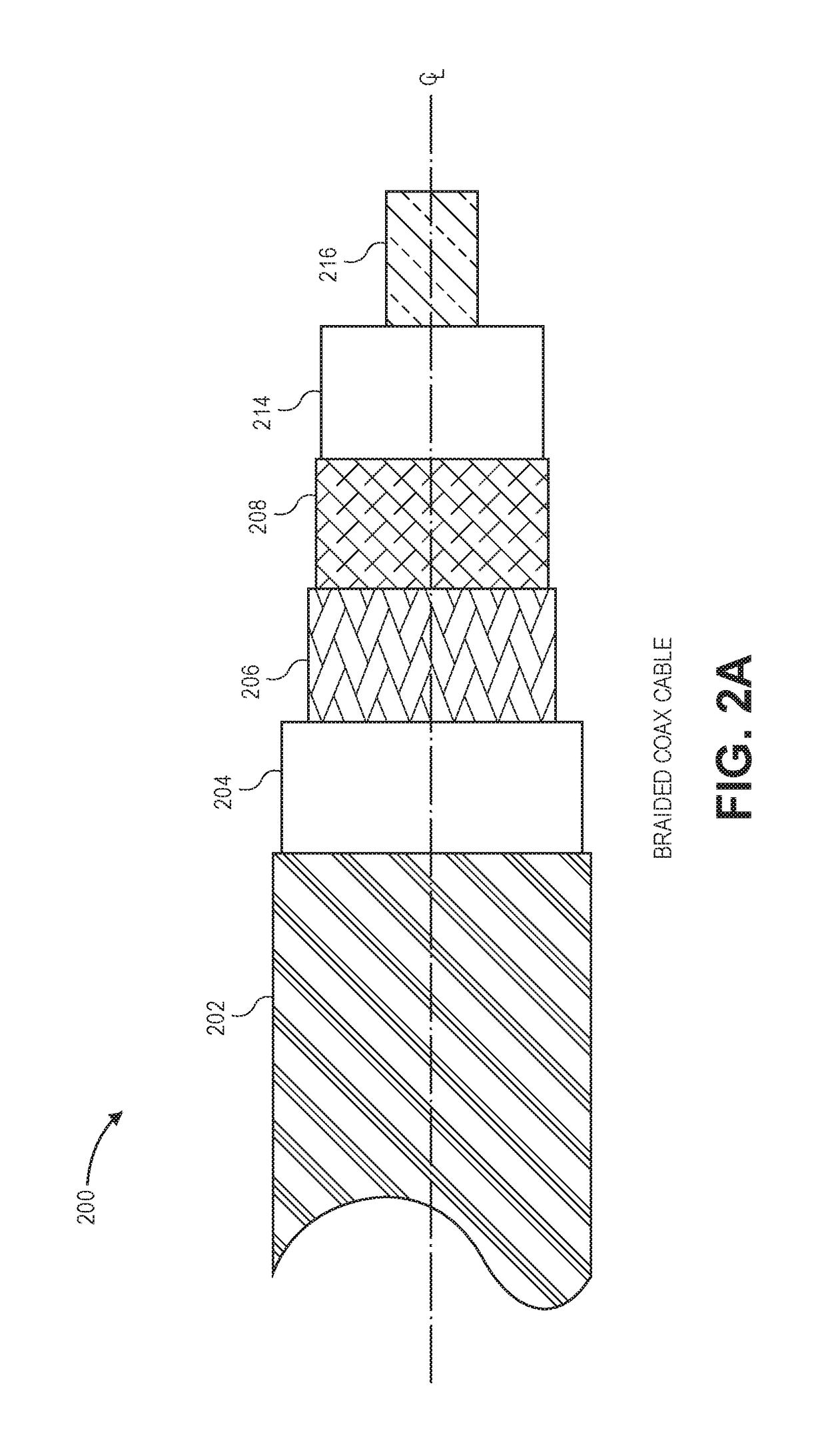

Multi-axial electrically conductive cable with multi-layered core and method of manufacture and use

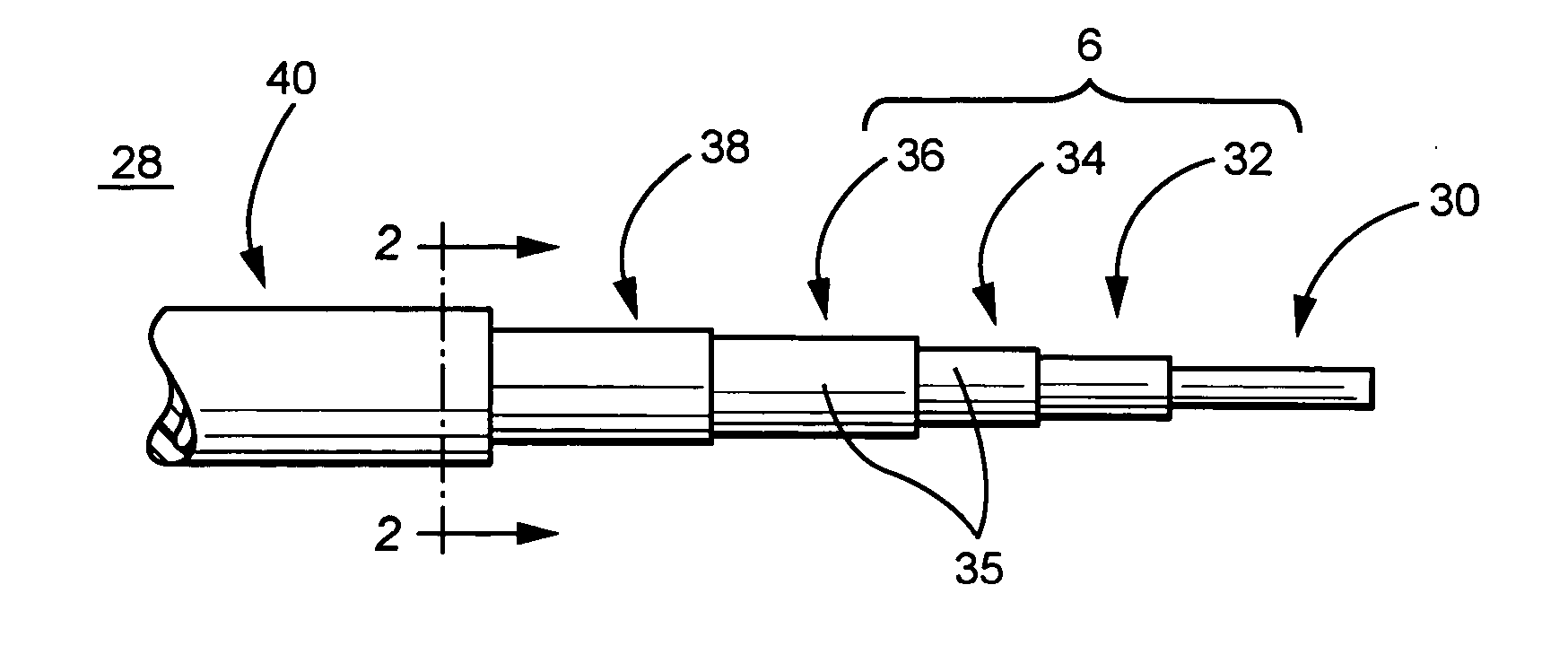

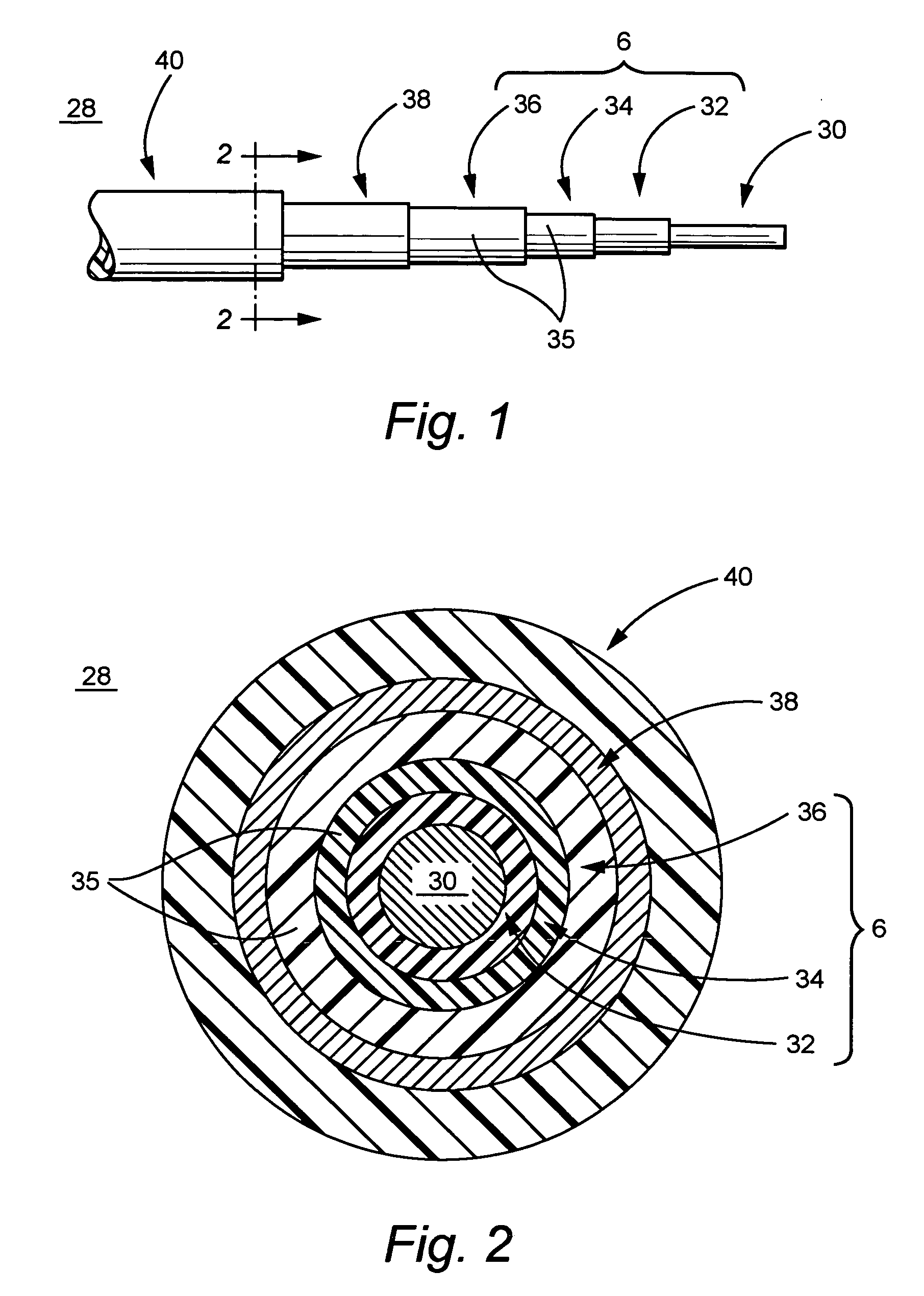

InactiveUS20060011376A1Line/current collector detailsTwo pole connectionsElectrical connectionEngineering

A multi-axial electrically conductive cable having a multi-layered core. The multi-layered core comprises one layer of insulating dielectric material and at least one additional layer of insulating dielectric material. The multiple layers of the core are separable and allow the multi-axial electrically conductive cable to be utilized in several electrical connections of varying impedances and different sized connections.

Owner:GENERAL ELECTRIC CO

Shielded cable assembly

InactiveUS20170110222A1Electrically conductive connectionsPlastic/resin/waxes insulatorsShielded cableElectrical conductor

A wire cable assembly capable of transmitting signals at speeds of 5 Gigabits per second over a single pair or conductors. The cable has a characteristic impedance of 95 Ohms and can support transmission data according to either USB 3.0 or HDMI 1.3 performance specifications. The wire cable includes a pair of conductors, a shield surrounding the conductors, and a dielectric structure configured to maintain a first predetermined spacing between the conductors and a second predetermined spacing between said the conductors said shield. The shield includes an inner shield conductor enclosing the dielectric structure, a ground conductor external to the inner shield conductor, extending generally parallel to the pair of conductors, an outer shield conductor enclosing the inner shield conductor and the ground conductor.

Owner:APTIV TECH LTD

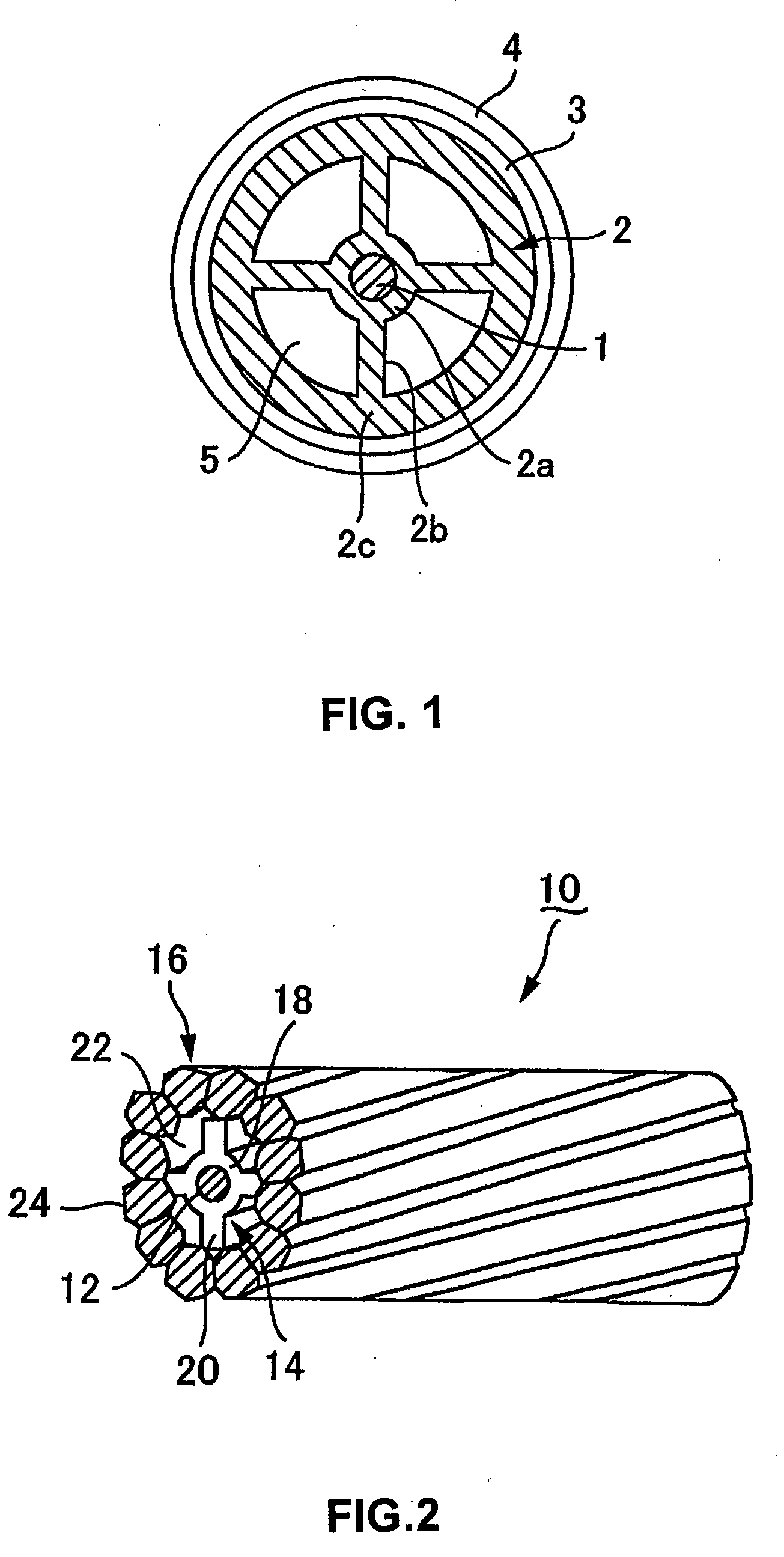

High propagation speed coaxial and twinaxial cable

The amount of air dielectric in air core coaxial and twinaxial cables is increased by spacer structures installed between the center conductor and the outer shield which have provision for air voids or pockets running lengthwise. The extra air space provides lower effective dielectric constant for the cable. In one embodiment, a single-element extruded spacer is formed with air cavities or voids that run continuously throughout the length of the spacer. Several spacer "profiles" or cross-sections are disclosed that place less solid dielectric mass in proximity to the center conductor. The result is a greater volume of air dielectric, and hence a lowered cable dielectric constant. In a further embodiment the spacer is a circular cross-sectioned element consisting of a central dielectric strength member surrounded with foamed material. Strength strands such as Kevlar(R) may be added to the spacer.

Owner:3M INNOVATIVE PROPERTIES CO

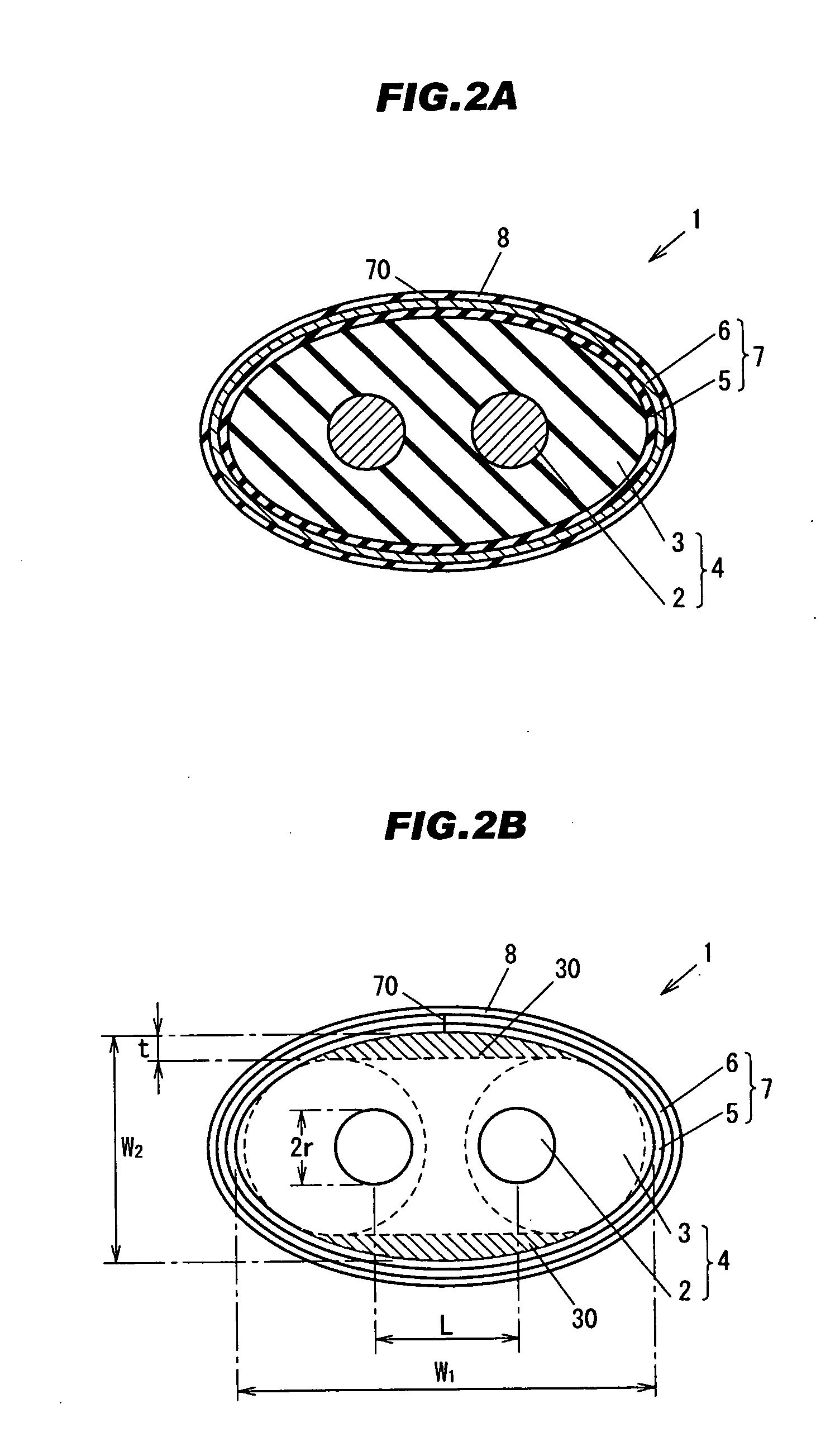

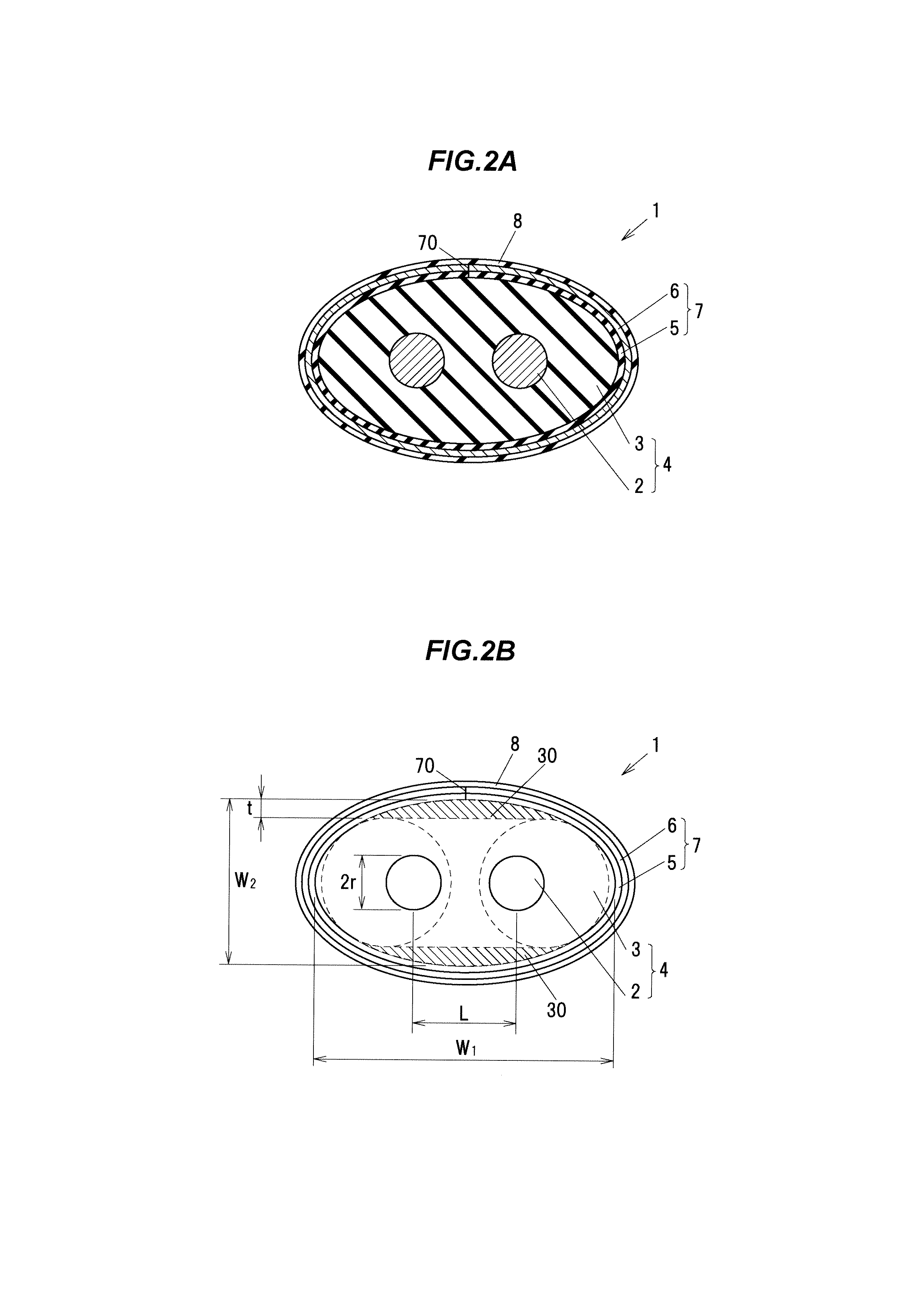

Differential signal transmission cable

ActiveUS8546691B2Improve skewElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorEllipse

A differential signal transmission cable includes a pair of differential signal lines arranged in parallel to each other, an insulation for bundle-covering the pair of differential signal lines, and a shield conductor wound around an outer periphery of the insulation. The insulation is configured such that an outer circumference thereof in a cross section perpendicular to a longitudinal direction thereof has an oval shape formed with a continuous convex arc-curve. The oval shape has a width in a first direction along the arrangement direction of the pair of differential signal lines being larger than a width in a second direction orthogonal to the first direction.

Owner:HITACHI CABLE

High accuracy foamed coaxial cable and method for manufacturing the same

InactiveUS6963032B2Exact impedanceImprove accuracyPlastic/resin/waxes insulatorsCable conductor constructionCoaxial cableElectrical conductor

Owner:HIRAKAWA HEWTECH +1

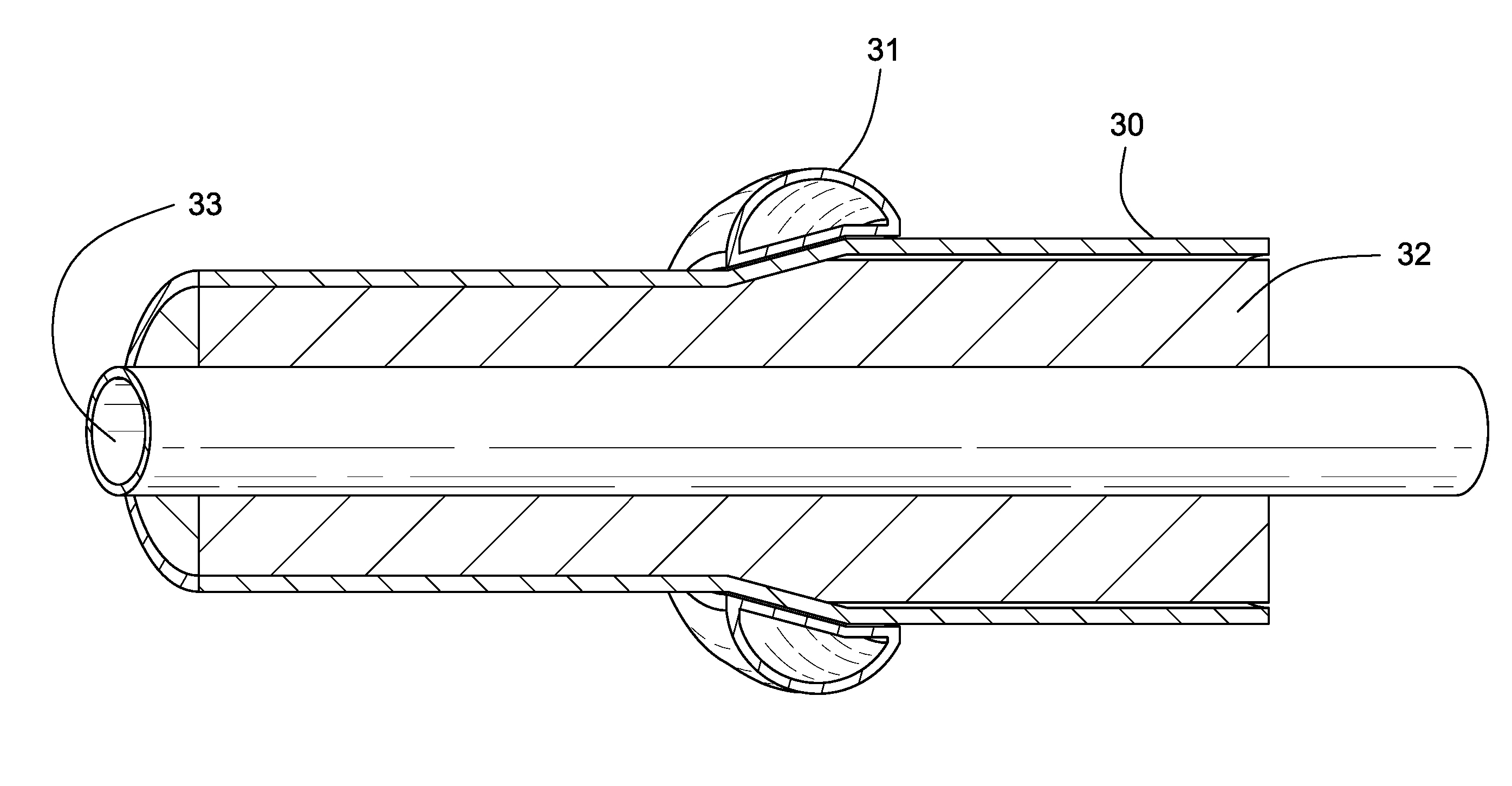

Differential signal transmission cable

ActiveUS20130175081A1Prevent looseningImprove skewElectrically conductive connectionsMagnetic/electric field screeningElectrical conductorElectric cables

A differential signal transmission cable includes a pair of differential signal lines arranged in parallel to each other, an insulation for bundle-covering the pair of differential signal lines, and a shield conductor wound around an outer periphery of the insulation The insulation is configured such that an outer circumference thereof in a cross section perpendicular to a longitudinal direction thereof has an oval shape formed with a continuous convex arc-curve The oval shape has a width in a first direction along the arrangement direction of the pair of differential signal lines being larger than a width in a second direction orthogonal to the first direction

Owner:HITACHI CABLE

Coaxial cable with strippable center conductor precoat

ActiveUS7022918B2Easy to disassembleEasy to operateCable insulation constructionPower cables with screens/conductive layersAdhesion forceBond interface

A coaxial cable is provided with a specially prepared precoat layer that facilitates removal of the precoat layer when the end of the cable is cored in preparation for receiving a connector. The cable includes an inner conductor; a foam polyolefin dielectric layer surrounding the inner conductor; an outer conductor surrounding said dielectric layer; and a precoat layer disposed between the inner conductor and the dielectric layer. The precoat layer forms a first bond interface with the inner conductor and a second bond interface with the dielectric layer, wherein the ratio of the axial shear adhesion force of the first (“A”) bond to the axial shear adhesive force of the second (“B”) bond is less than 1, and wherein the ratio of the axial shear adhesion force of the “A” bond formed by the precoat layer between the inner conductor to the dielectric layer to the rotational shear adhesion force of the bond is 5 or greater.

Owner:COMMSCOPE INC

Paste extruded insulator with air channels

InactiveUS20050139377A1Easy to disassemblePlastic/resin/waxes insulatorsCable insulation constructionElectrical conductorEngineering

The invention provides an insulated wire having a conductor and an insulator of paste extruded PTFE fine powder around the conductor. The paste extruded insulator has at least one closed continuous longitudinal air channel spaced apart from the conductor. The invention further provides a process for forming an insulator around a conductor by paste extruding lubricated PTFE fine powder in an extrusion device comprising a die, mandrel, and at least one channel-forming member. The die and mandrel form a converging chamber leading to an extrusion orifice and the channel-forming member is positioned in the orifice. The mandrel has a central bore for supplying the conductor. Lubricated PTFE fine powder is forced through the chamber and out of the exit of the orifice as a lubricated green extrudate around the conductor forming an insulator with at least one closed longitudinal air channel spaced apart from the conductor.

Owner:EI DU PONT DE NEMOURS & CO

Thin coaxial cable and method for its manufacture

InactiveUS6953888B2Thin layerPlastic/resin/waxes insulatorsCable insulation constructionCoaxial cableInsulated glazing

A thin coaxial cable is provided comprising an inner conductor; an outer conductor being an electroplated conductive metal layer; a thin electrically insulating layer made of a polymeric enamel resin or of glass of at most approximately 15 μm thickness separating said inner and said outer conductor; said insulating glass or polymeric enamel resin layer is coated with a layer of an adhesion promoting primer material or said insulating polymeric enamel resin layer is coated with a layer of ABS resin, and an electroless plated metal layer is deposited between said primer or ABS resin layer and said electroplated conductive metal layer.

Owner:LIVSHITZ DANIEL +1

Differential signal transmission cable

ActiveUS8575488B2Suppress the skew and the differential modeCable insulation constructionPower cables with screens/conductive layersElectrical conductorDifferential signaling

A differential signal transmission cable has a pair of conductors arranged to be distant from each other and parallel to each other, an insulator covering the pair of conductors, and a shield conductor wound around the insulator. The insulator has an outer periphery shape of a transversal cross section in that a plurality of curved lines with different curvature radiuses are combined. The shield conductor has an inner periphery shape of a transversal cross section in that the plurality of curved lines are combined in accordance with the outer periphery shape of the insulator.

Owner:HITACHI METALS LTD

Micro CoAxial Cable

ActiveUS20080047732A1Lower melting temperatureEasy to useCable insulation constructionPower cables with screens/conductive layersAbnormal growthsElectrical conductor

A micro coaxial cable includes an inner conductor; an insulation layer having foaming cells and formed to surround the inner conductor; an over-foaming preventing layer formed to surround the insulation layer for the purpose of uniform forming of the foaming cells; a metal shield layer formed to surround the over-foaming preventing layer; and a protective coating layer formed to surround the metal shield layer. The over-foaming preventing layer restrains abnormal growth of foaming cells formed in the insulation layer such that the foaming cells are successively adjacently formed with uniform size. Due to the uniformity of foaming, the dielectric constant of the insulation layer is not locally different but uniform as a whole, thereby capable of improving transmission characteristics. In addition, the micro coaxial cable enables to transmit signals even at a high frequency transmission of GHz range, which was impossible in the prior art.

Owner:HITACHI METALS LTD

Cable with foamed plastic insulation comprising and ultra-high die swell ratio polymeric material

InactiveUS6858805B2Improve bindingImproved stress crack resistancePlastic/resin/waxes insulatorsCable insulation constructionUltrasound attenuationCrack resistance

An electrical communications element having a foamed plastic insultation extruded about a conductor with said insulation including at least one component with more than 20% by weight of an ultra-high die swell ratio polymer (UHDSRP), preferably around 15% by weight. The UHDSRP is defined as greater than 55% die swell ratio and more preferably greater than 65% die swell ratio. The insulation also preferably includes at least a second component with a high degree of stress crack resistance, such that the combination of (minimally) these polymers will yield an insulation layer that has a unique combination of physical propeties yielding a high degree of foaming, small uniform cell structure, characteristically lower attenuation, and stress crack resistance capable of withstanding greater than 100 hours at 100° C. while coiled at a stress level of 1 times the insulation outside diameter without failure (cracking).

Owner:COMMSCOPE INC

Fire resistant coaxial cable and manufacturing technique

Fire-resistant coaxial cables are described as well as methods to manufacture them. The dielectric between the coax cable's central conductor and outer coaxial conductor ceramify under high heat, such as those specified by common fire test standards (e.g., 1850° F. / 1010° C. for two hours). The dielectric can be composed of ceramifiable silicone rubber, such as that having a polysiloxane matrix with inorganic flux and refractory particles. Because thick layers of uncured ceramifiable silicone rubber deform under their own weight when curing, multiple thinner layers are coated and serially cured in order to build up the required thickness. A sacrificial sheath mold is used to hold each layer of uncured ceramifiable silicone rubber in place around the central conductor while curing. The outer conductor can be a metal foil, metal braid, and / or corrugated metal. Another layer of extruded ceramifiable silicone dielectric or an outer wrap of ceramic fiber yarn surrounds the outer conductor and continues to insulate it from the outside if a low smoke zero halogen jacket burns away. Methods of testing and installation are described.

Owner:AMERICAN FIRE WIRE INC

Differential signal transmission cable and multipair differential signal transmission cable

InactiveUS20140305676A1Deterioration in transmission can be suppressedCable insulation constructionPower cables with screens/conductive layersElectrical conductorInsulation layer

A differential signal transmission cable includes two core wires arranged in parallel, each of the two core wires having an insulation layer on an outer periphery of a conductor; and an outer conductor provided so as to cover the two core wires all together. The insulation layer includes sequentially an inner skin layer of a non-foamed resin, a foam layer of a foamed resin, and an outer skin layer of a non-foamed resin on the outer periphery of the conductor. The outer skin layer has a higher relative permittivity than the inner skin layer. The multipair differential signal transmission includes a plurality of differential signal transmission cables and a protective jacket provided around the plurality of differential signal transmission cables.

Owner:HITACHI METALS LTD

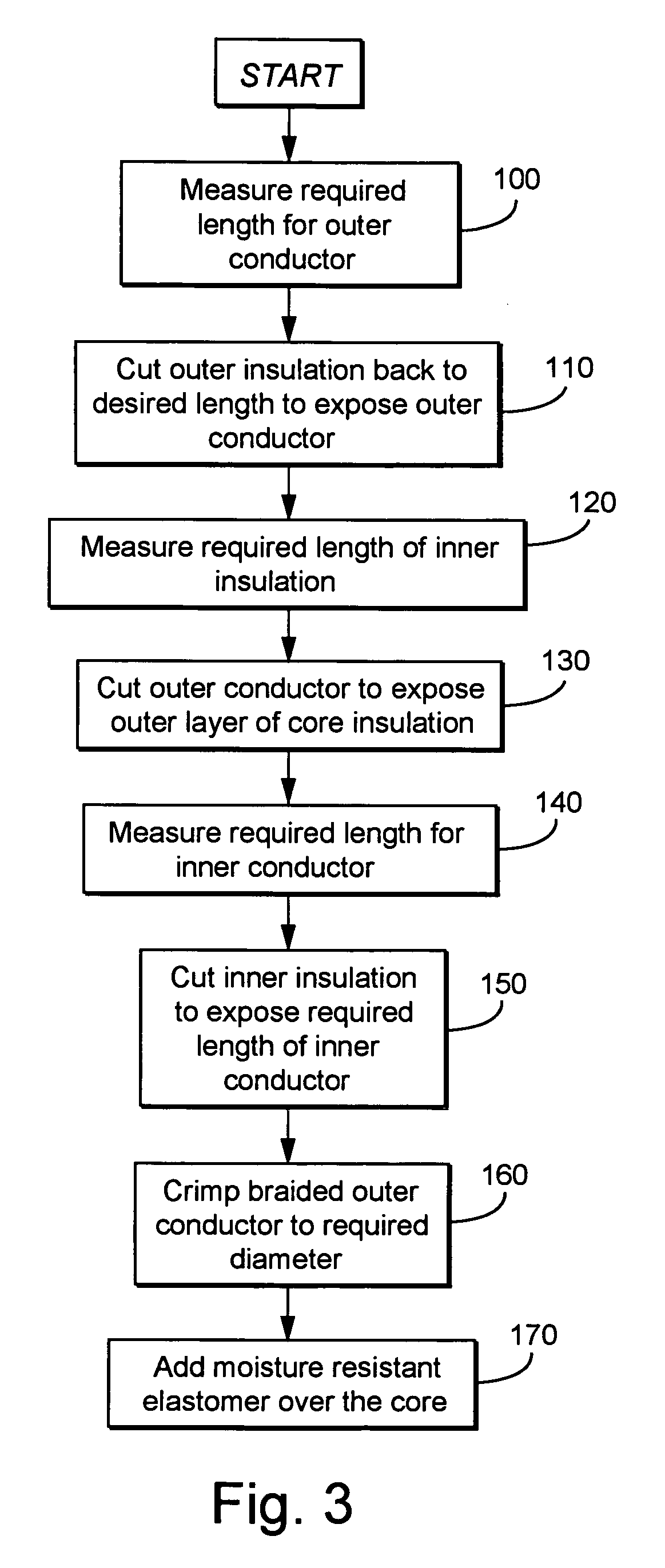

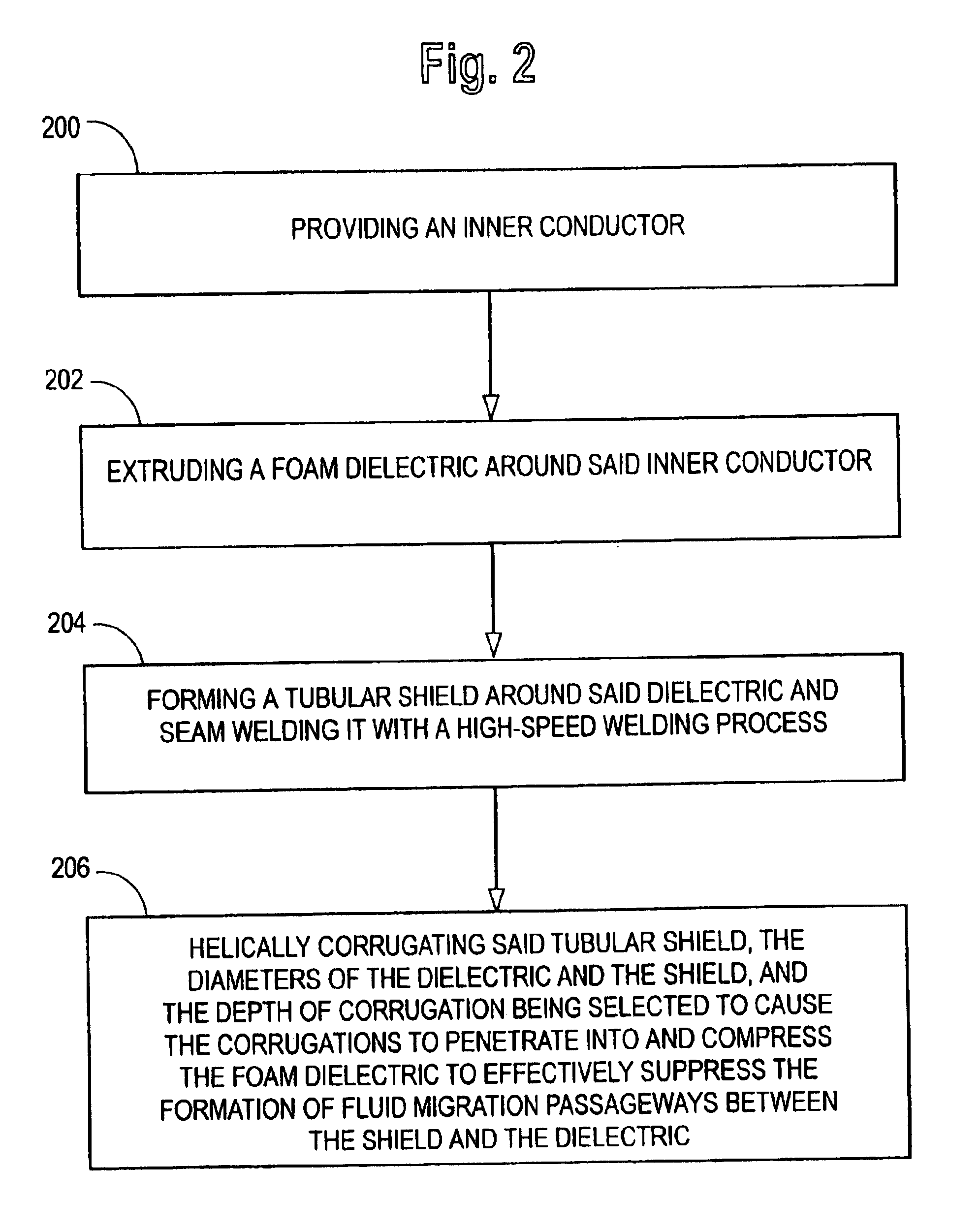

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS6693241B2Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

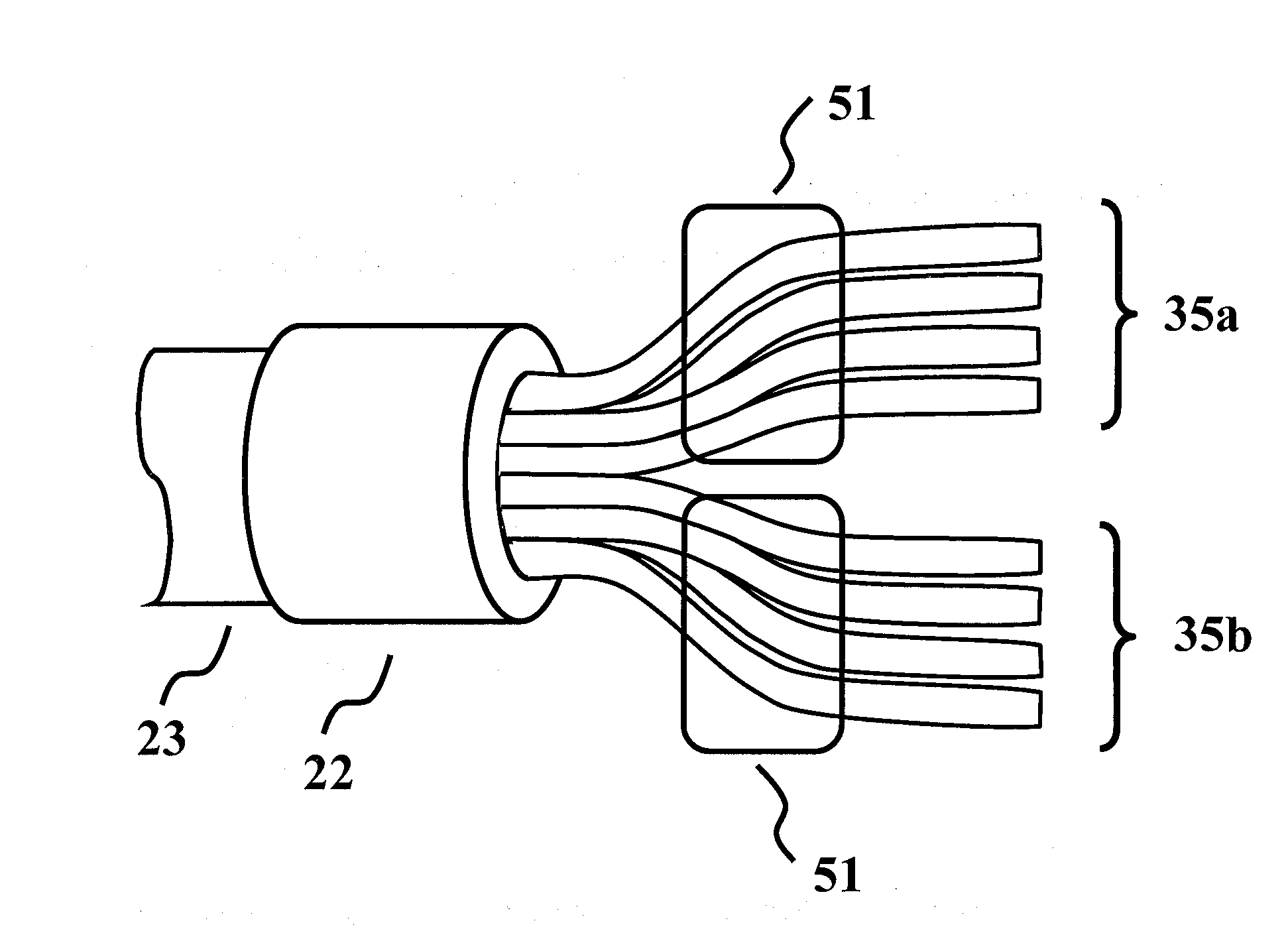

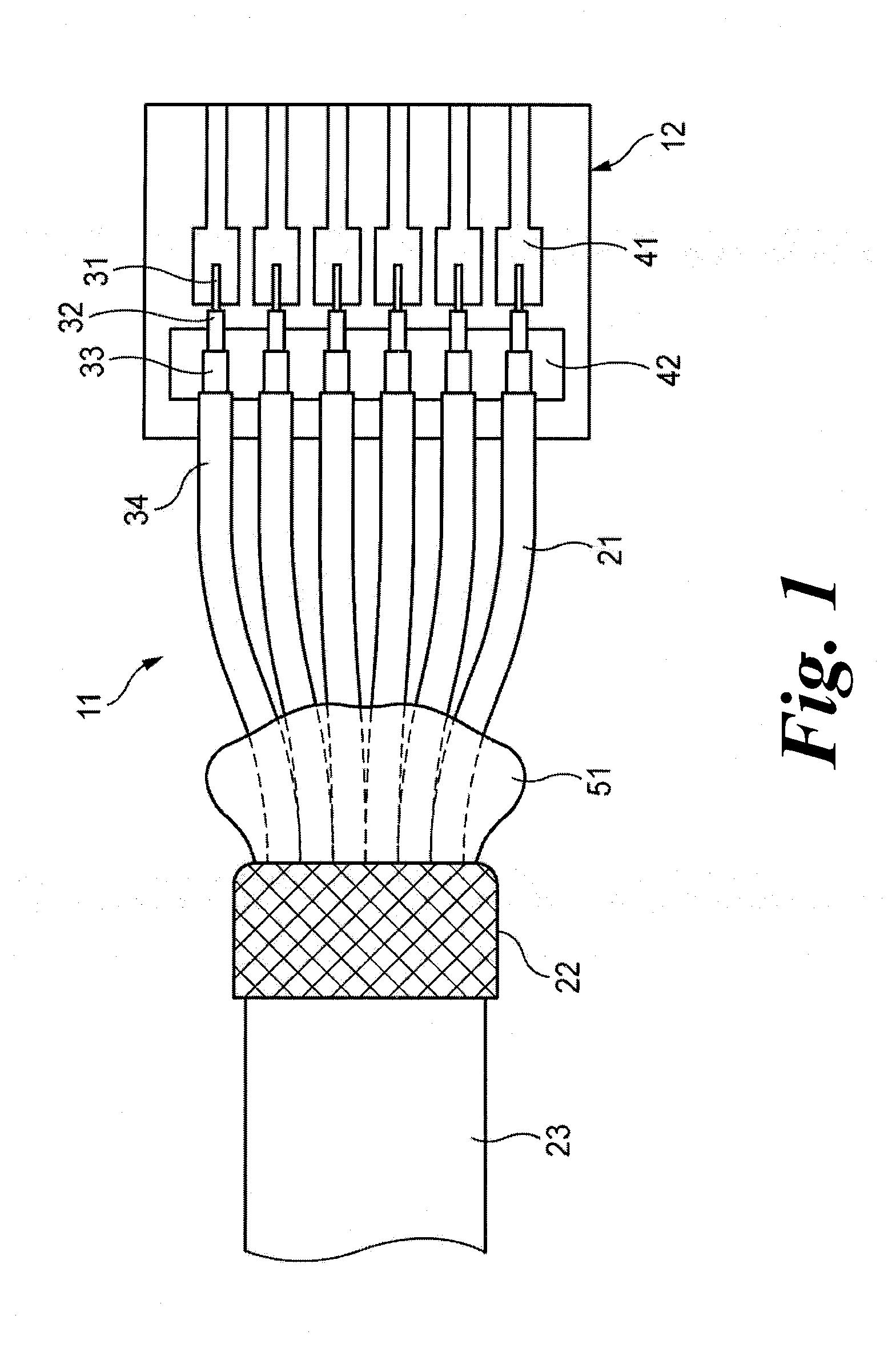

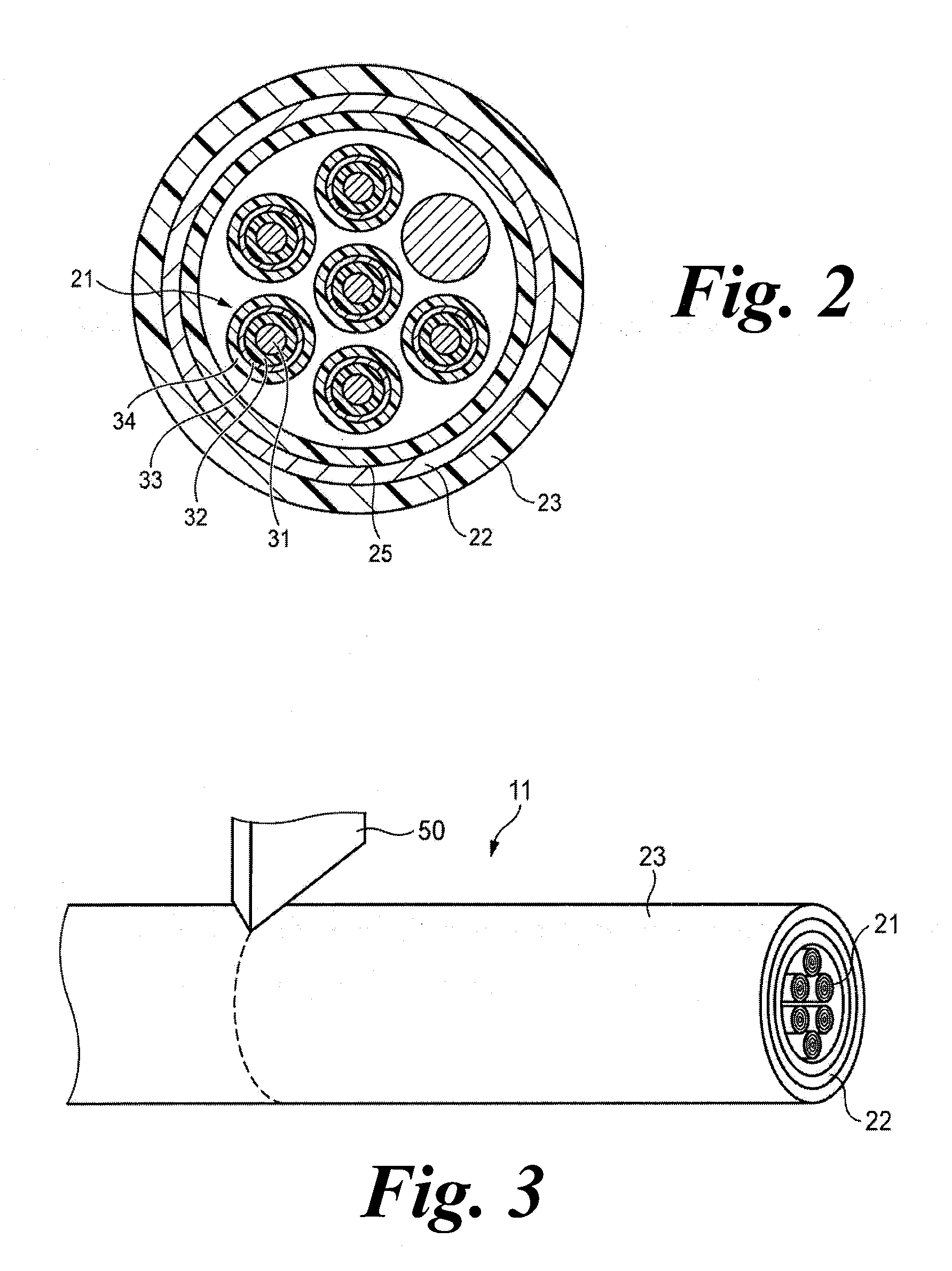

Multi-core cable and aligning method therefor

ActiveUS20130333943A1Good adhesionReduced restoring forceLamination ancillary operationsCable insulation constructionMulticore cableElectrical conductor

Owner:SUMITOMO ELECTRIC IND LTD

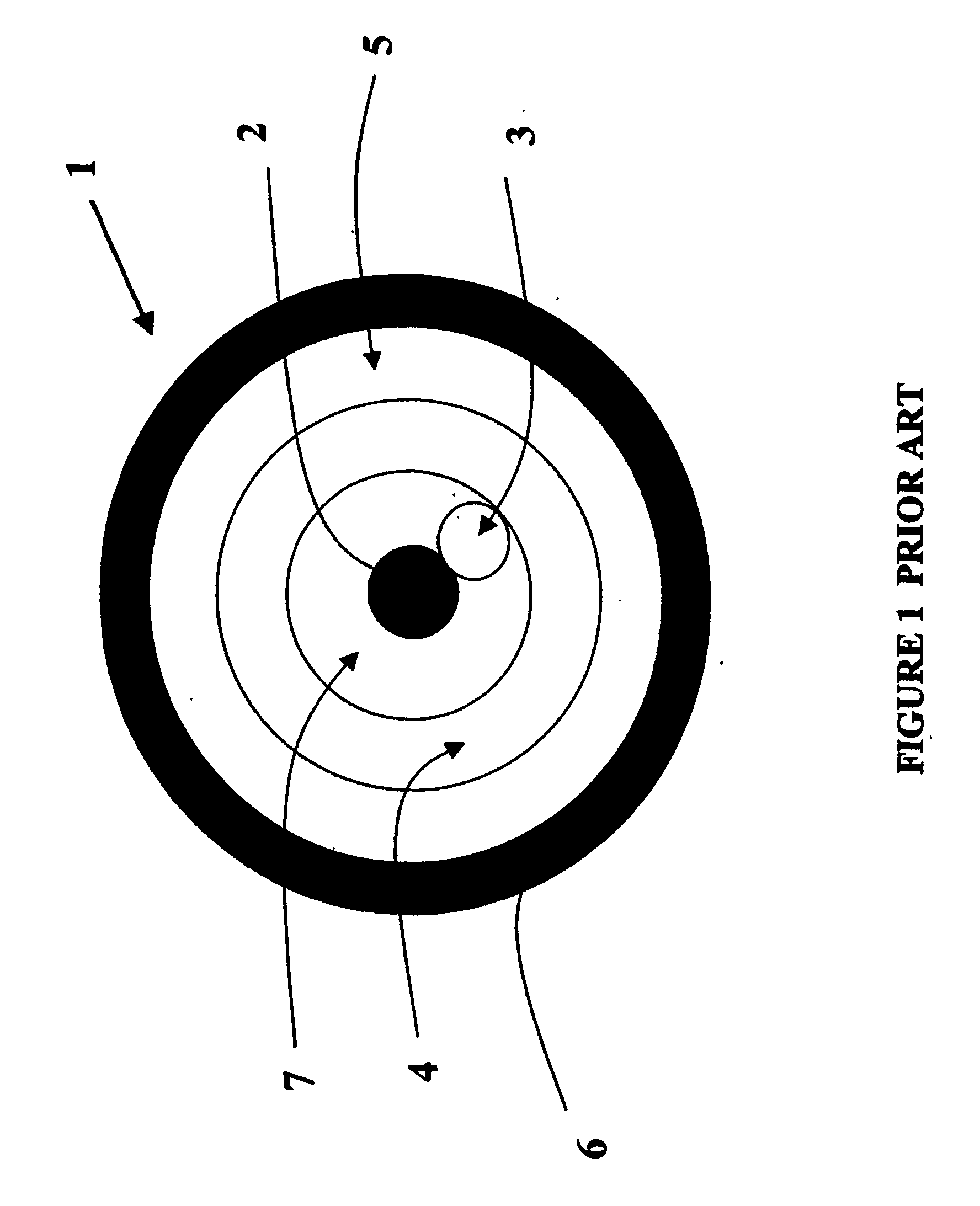

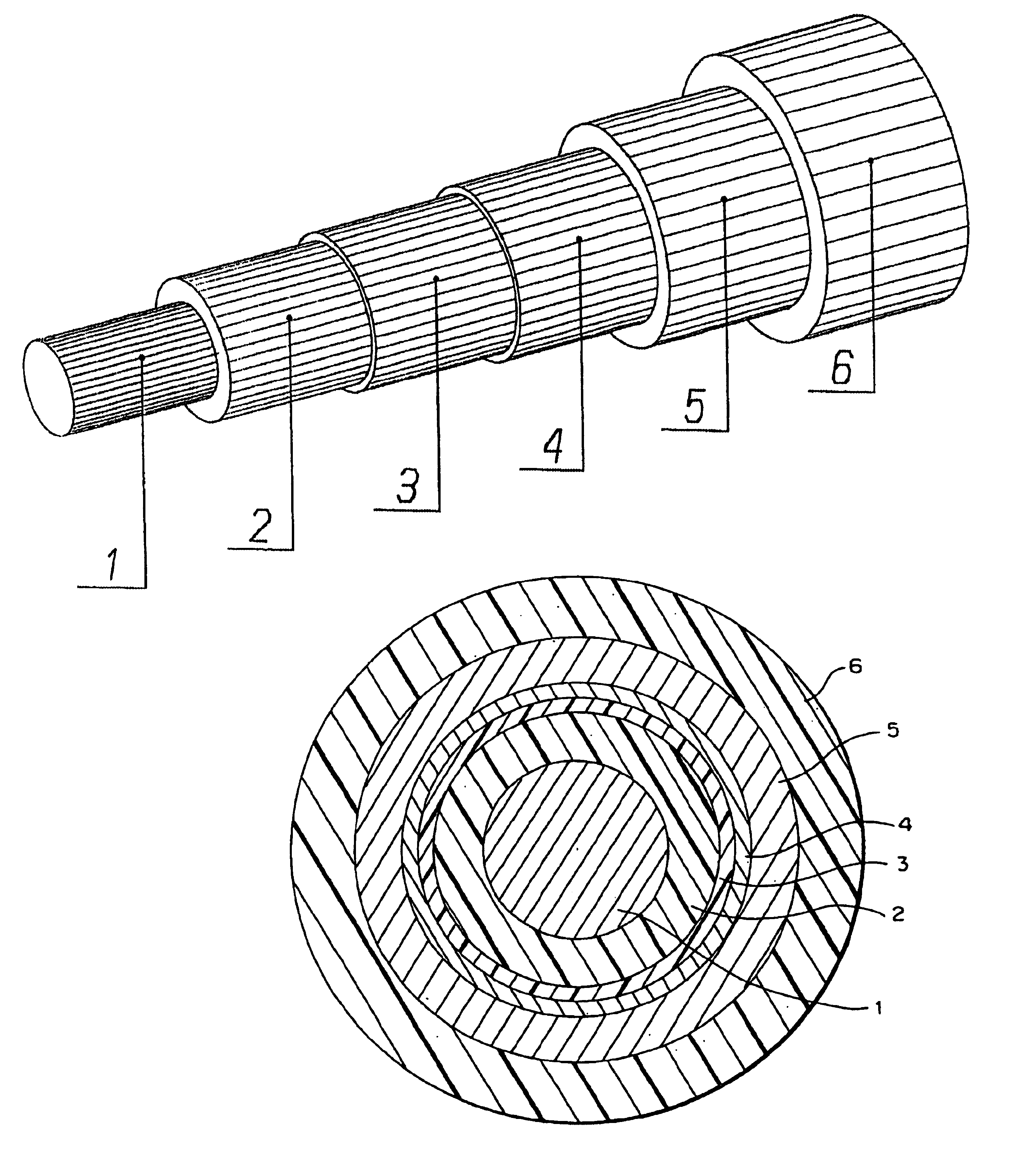

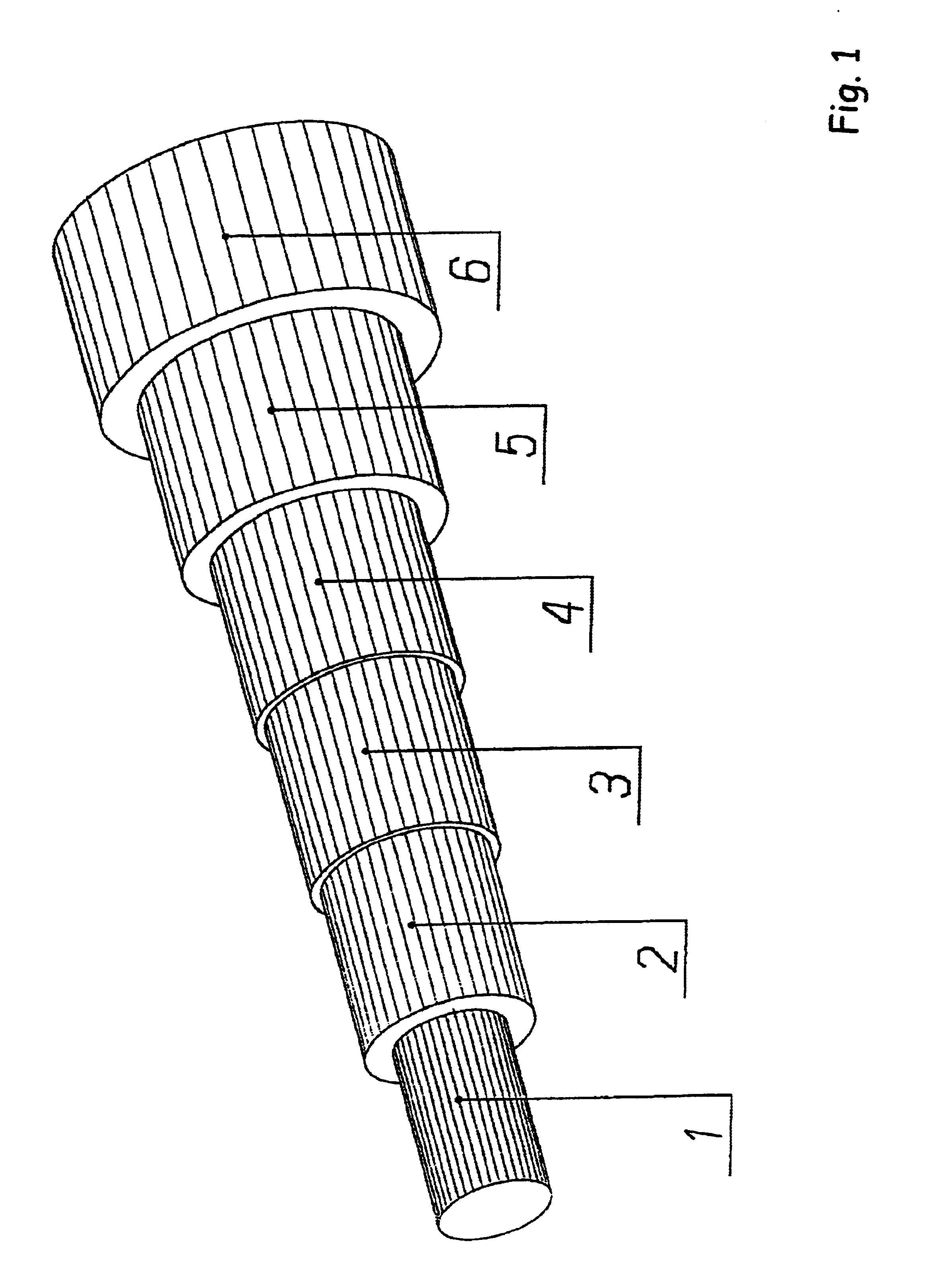

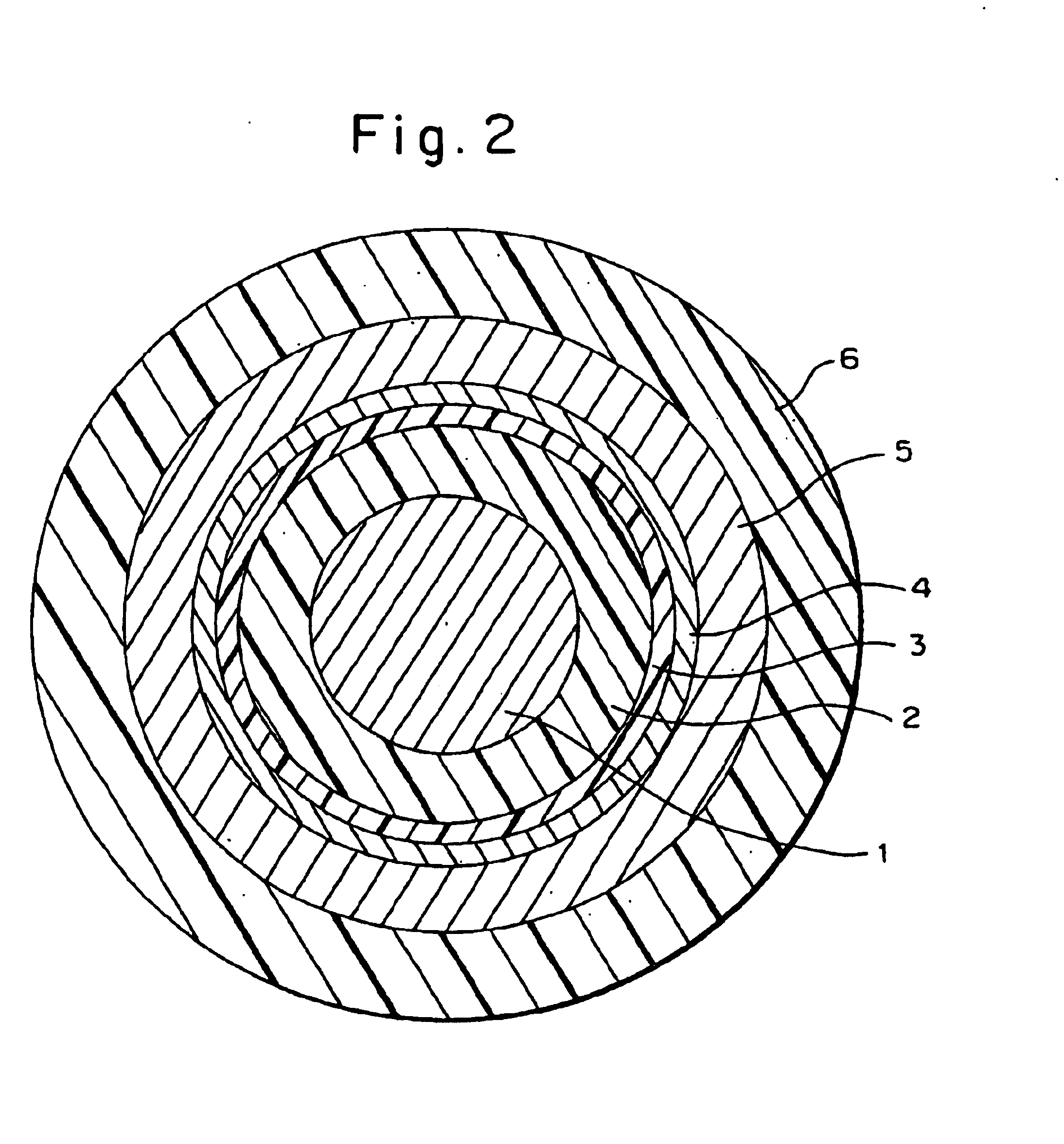

High-frequency coaxial cable

InactiveUS20090151970A1Lower voltage stand wave ratioReduce the amount presentCable insulation constructionInsulated cablesUltrasound attenuationElectrical conductor

In a high-frequency coaxial cable (1), an internal solid layer (3), an insulation layer (4) made of a foam resin, an external solid layer (5), and an external conductor (6) are provided on the periphery of an internal conductor (2) in this order. The external solid layer (5) has a dielectric dissipation factor of 1.0×10−4 or less at 2 GHz. Thereby, the voltage standing-wave ratio and the attenuation of the high-frequency coaxial cable (1) are reduced.

Owner:HITACHI METALS LTD

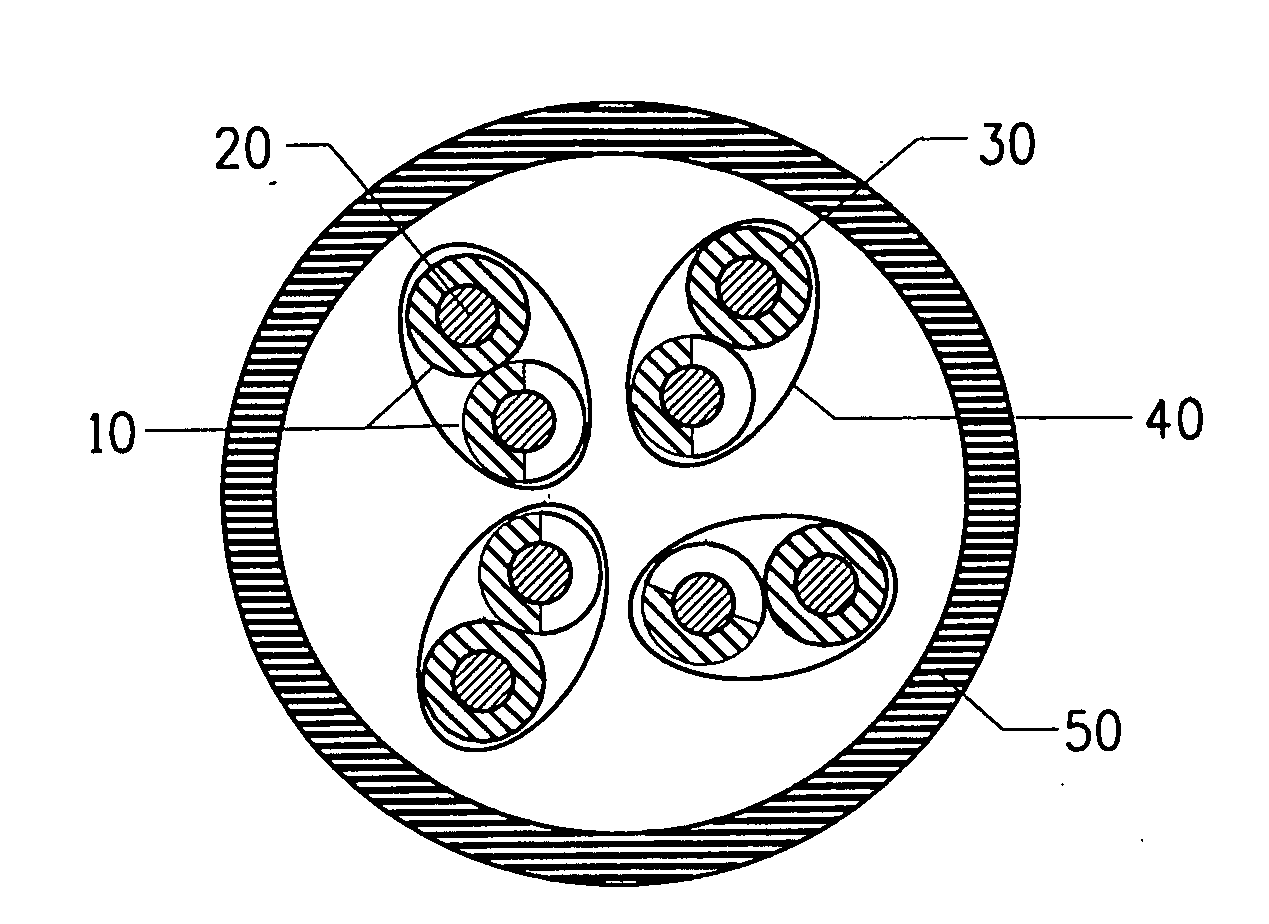

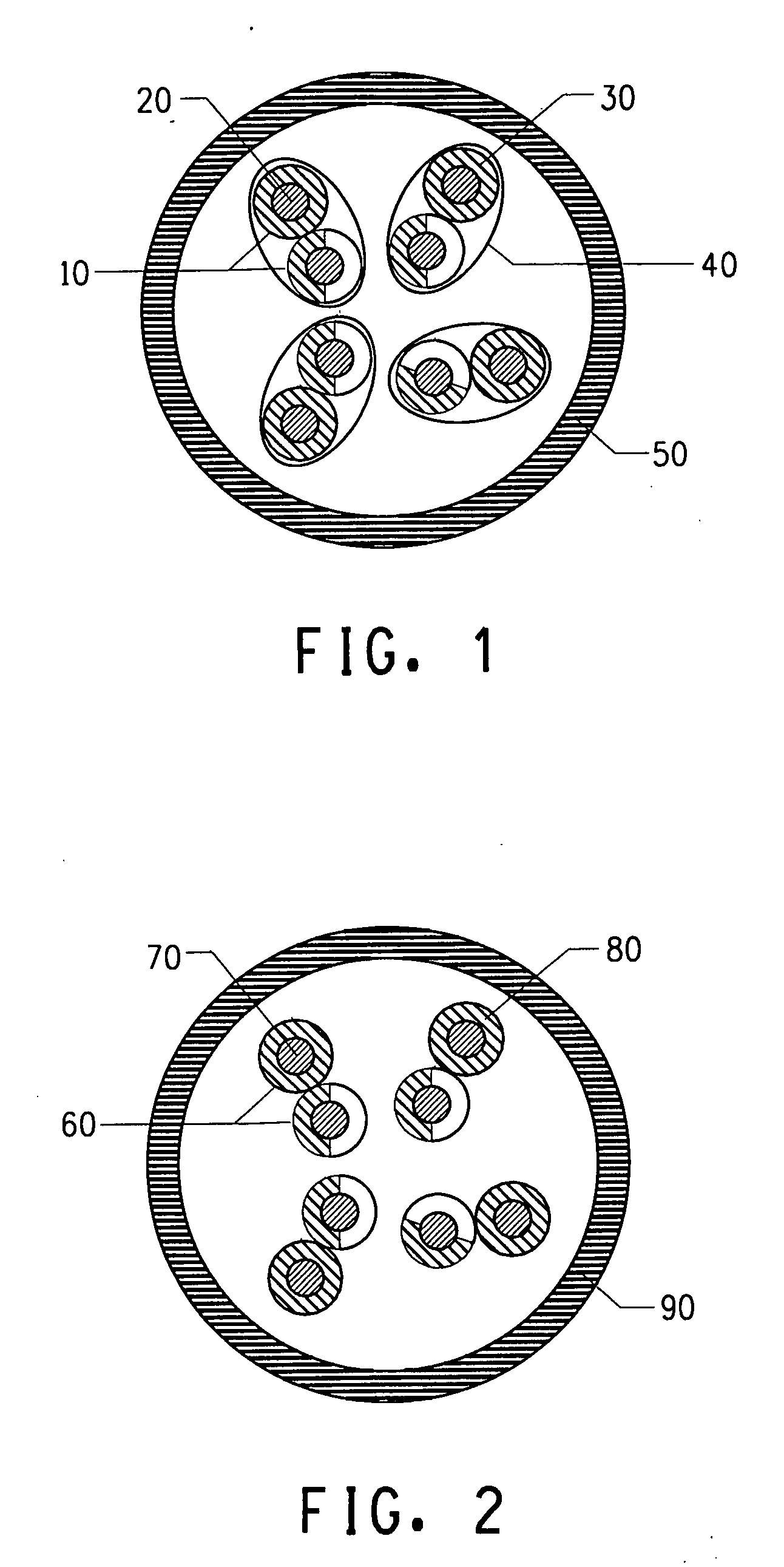

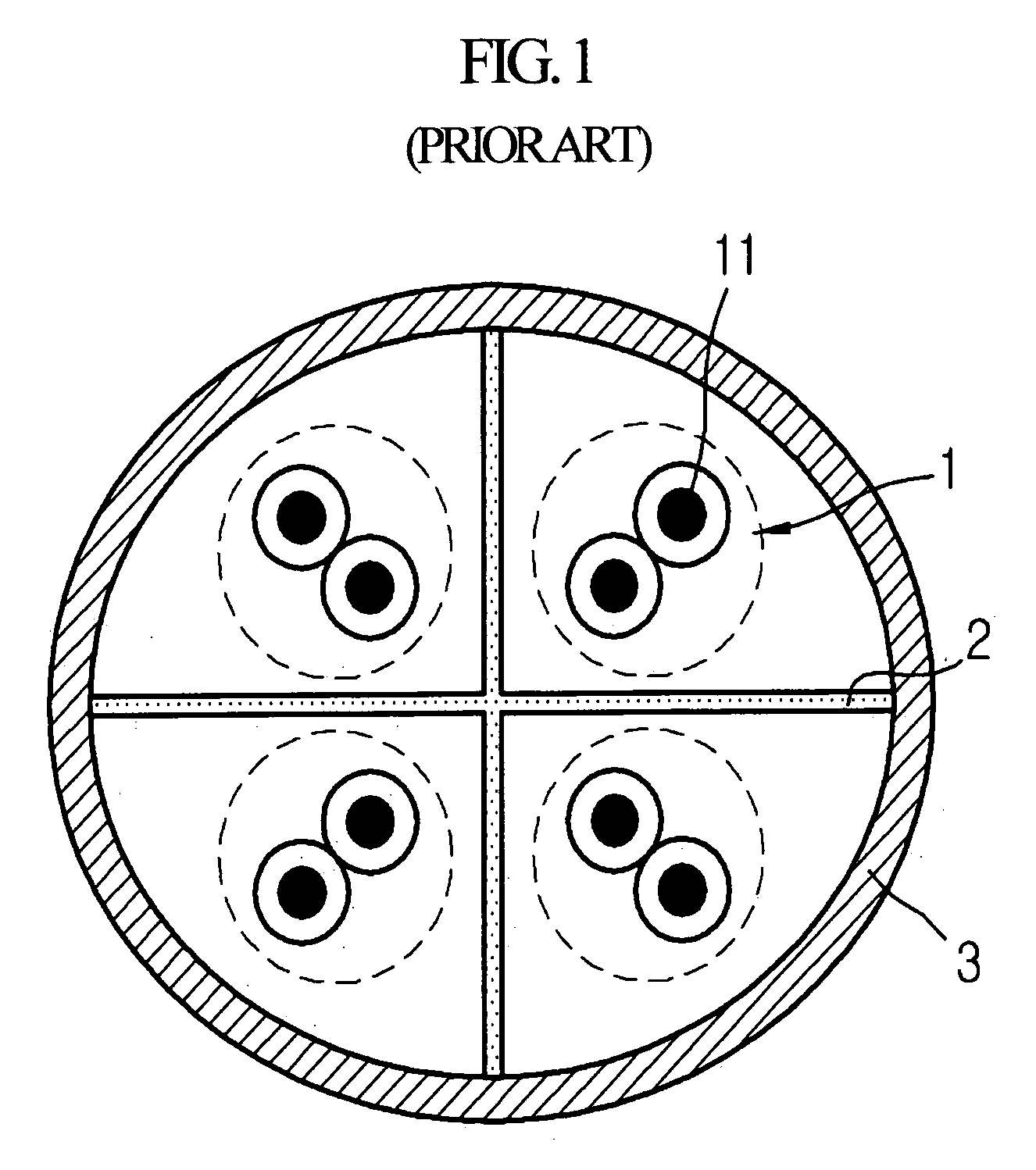

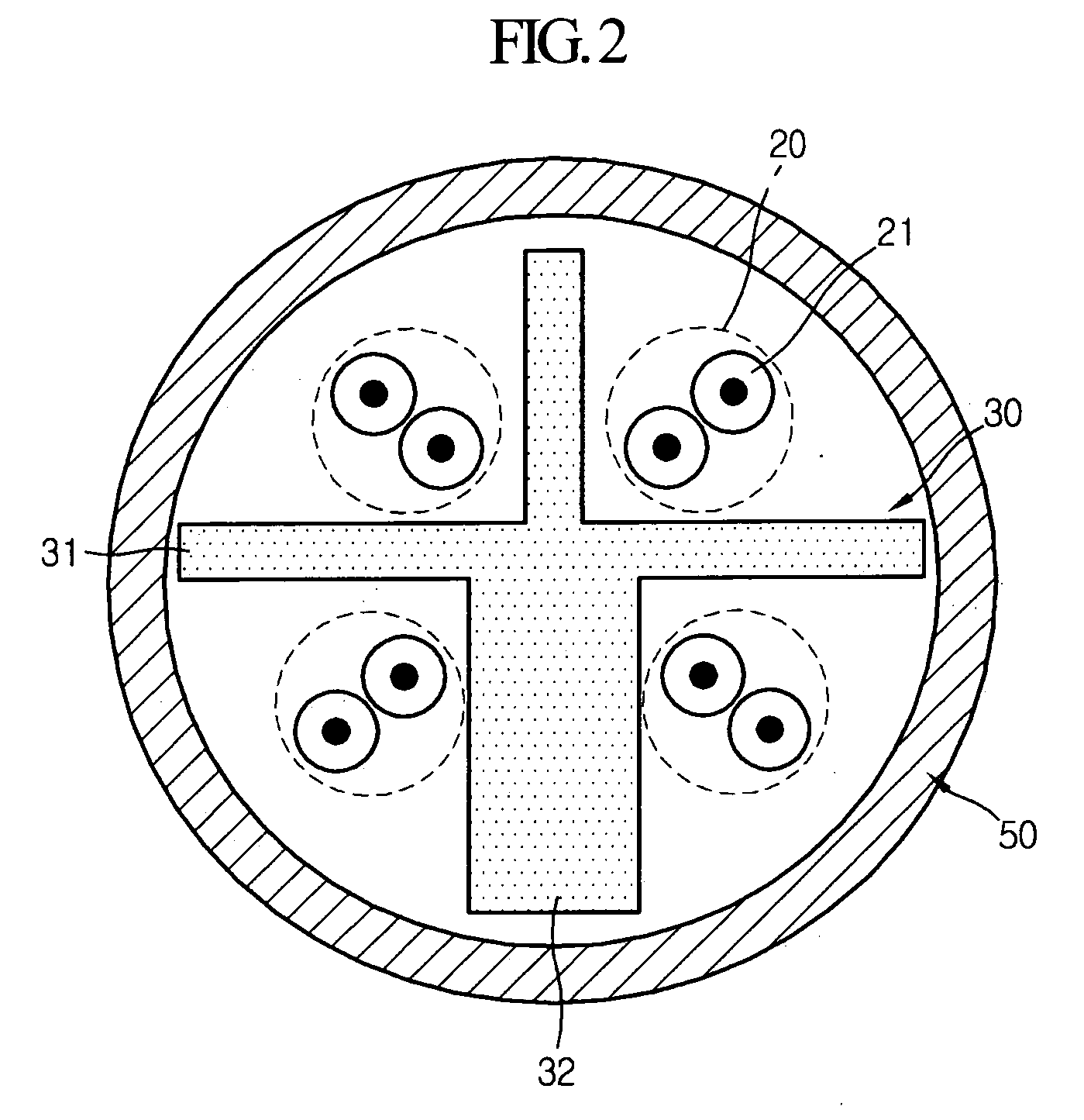

Asymmetrical separator and communication cable having the same

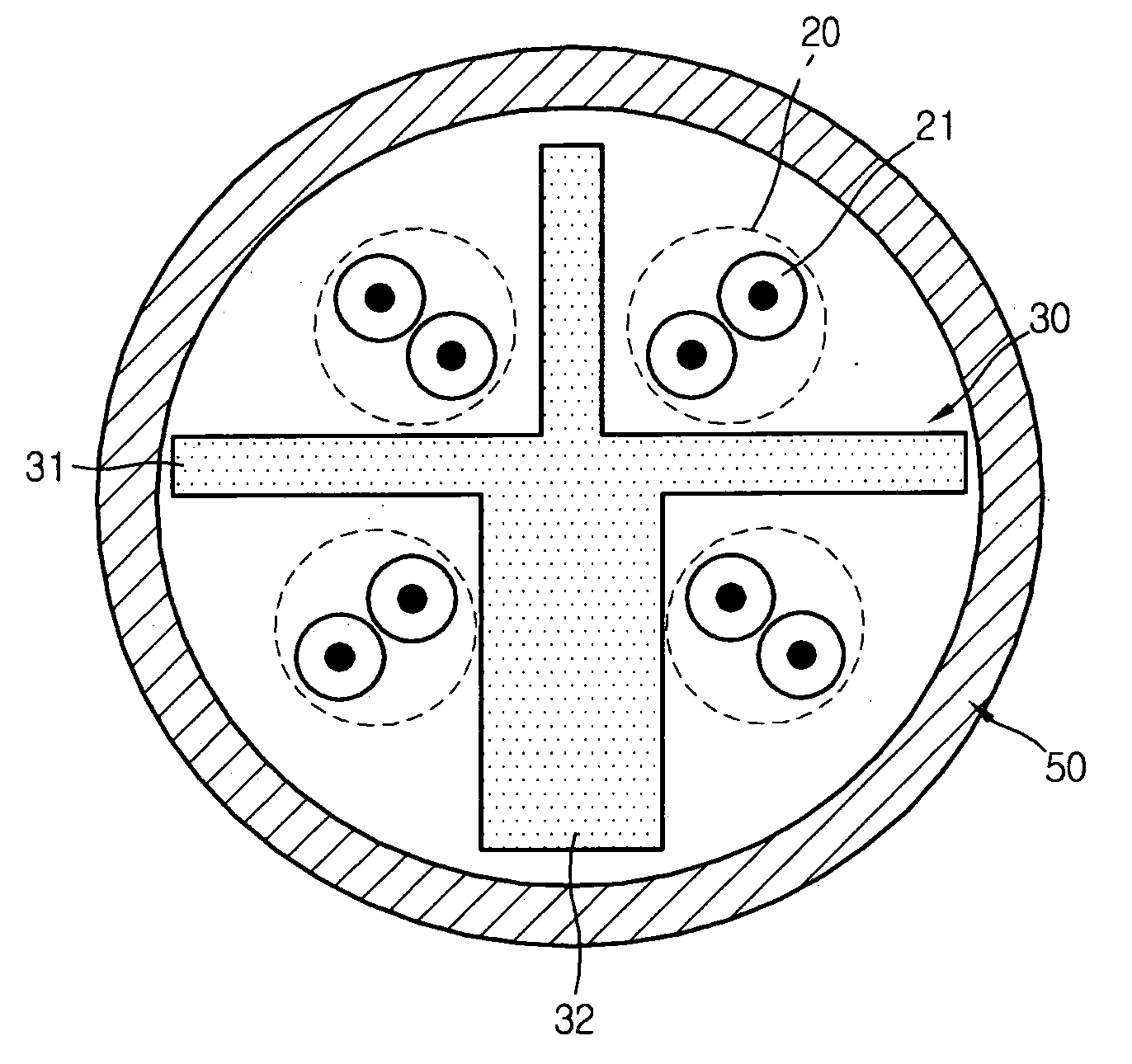

InactiveUS20070044995A1Cable insulation constructionInsulated cablesCrosstalkElectrical and Electronics engineering

A separator for a communication cable includes a plurality of barriers formed in a radial direction so that at least two pair units, in each of which at least two insulation-coated wires are spirally twisted, are received in spaces formed by the barriers one by one so as to separate the pair units from each other. At least one of the barriers has a relatively greater thickness than the other barriers. Thus, a communication cable having the separator may prevent PSNEXT (Power Sum Near and Crosstalk) caused by interference between adjacent wires when a high frequency signal is transmitted through the wires.

Owner:LG CABLE LTD (KR)

Low-cost, high performance, moisture-blocking, coaxial cable and manufacturing method

InactiveUS20030201115A1Low costCable insulation constructionPower cables with screens/conductive layersDielectricShielded cable

A helical corrugated coaxial cable possesses low cost of manufacture comparable to that of braided shield coaxial cable, electrical performance comparable to solid tubular shielded cable, flexibility of helical and annular corrugated cable, and fluid blockage comparable to annular shielded cable. The cable has an inner conductor surrounded by a foam dielectric insulator. A tubular shield surrounds the dielectric and has helical corrugations penetrating into and compressing the foam dielectric to effectively suppress the formation of fluid migration air gaps or passageways between the shield and the dielectric. The shield is preferably composed of aluminum or aluminum alloy. Alternatively, the shield may be annularly corrugated for improved water blocking performance. The manufacturing process employs high speed welding and multi-lead corrugating operations to reduce cost.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com