Patents

Literature

198 results about "Abnormal growths" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Abnormal Growth. Growing is a big part of your child’s life, from tracking height with pencil ticks on the wall to a shopping trip to replace outgrown clothing. Growth refers to the physical and developmental milestones that most children will reach at certain ages.

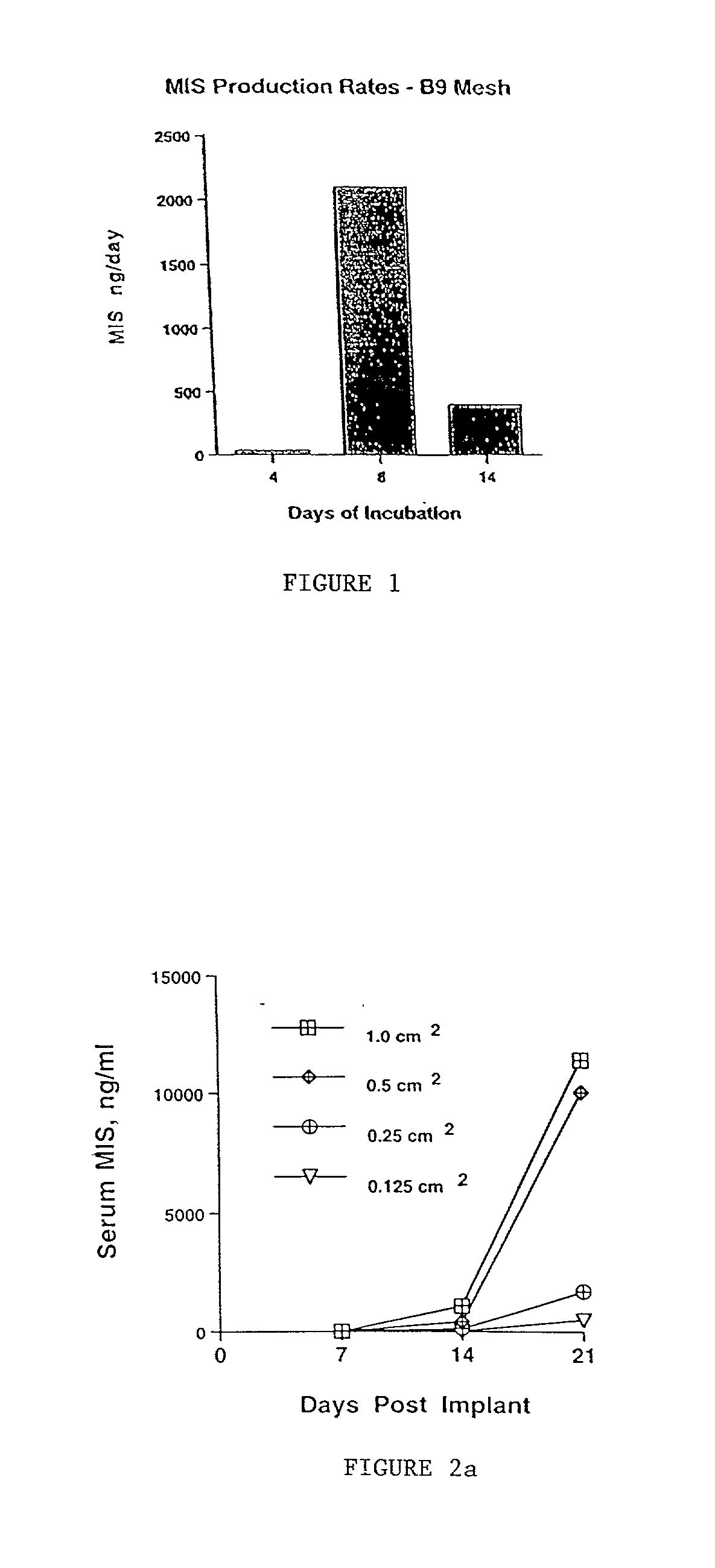

Delivery of therapeutic biologicals from implantable tissue matrices

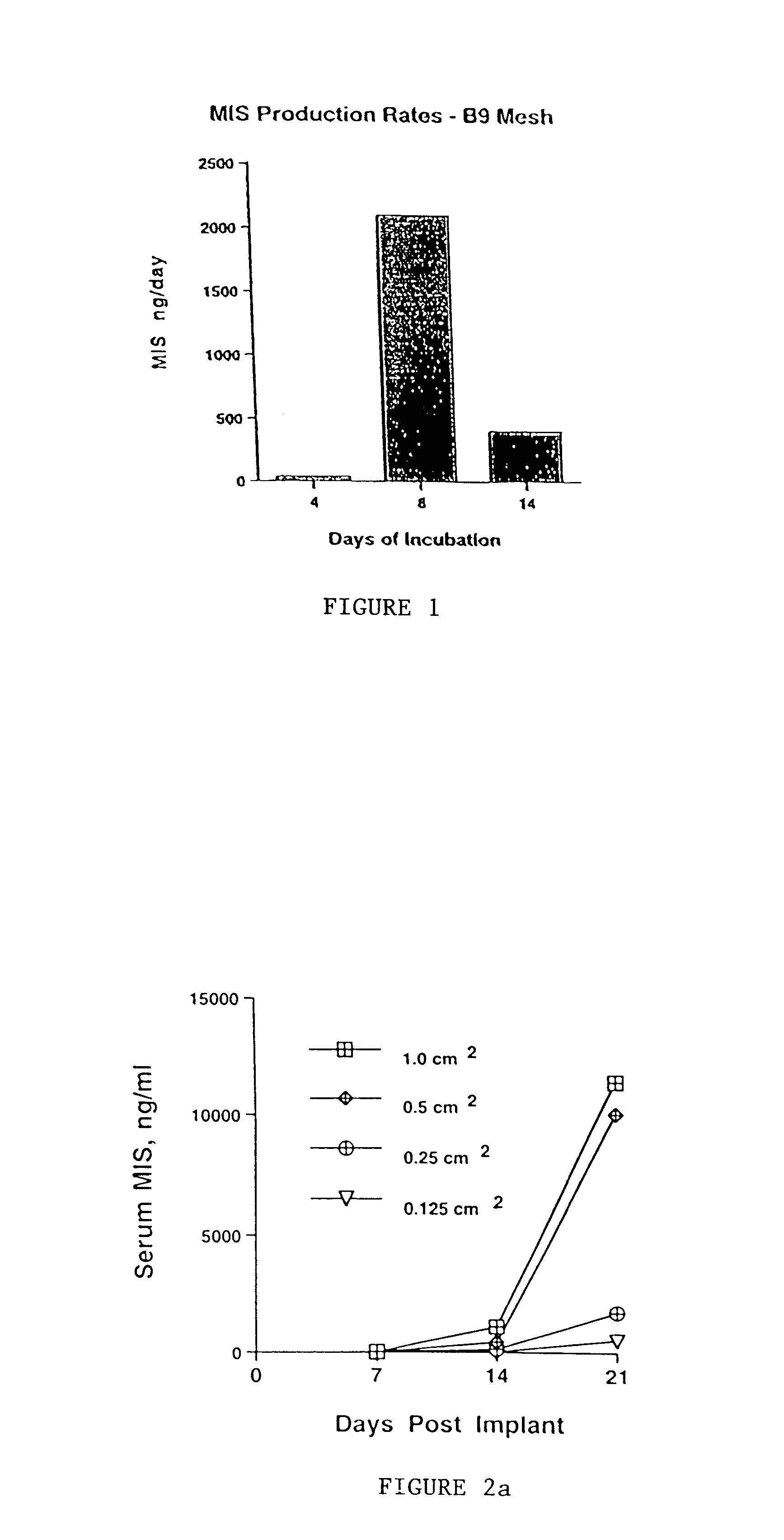

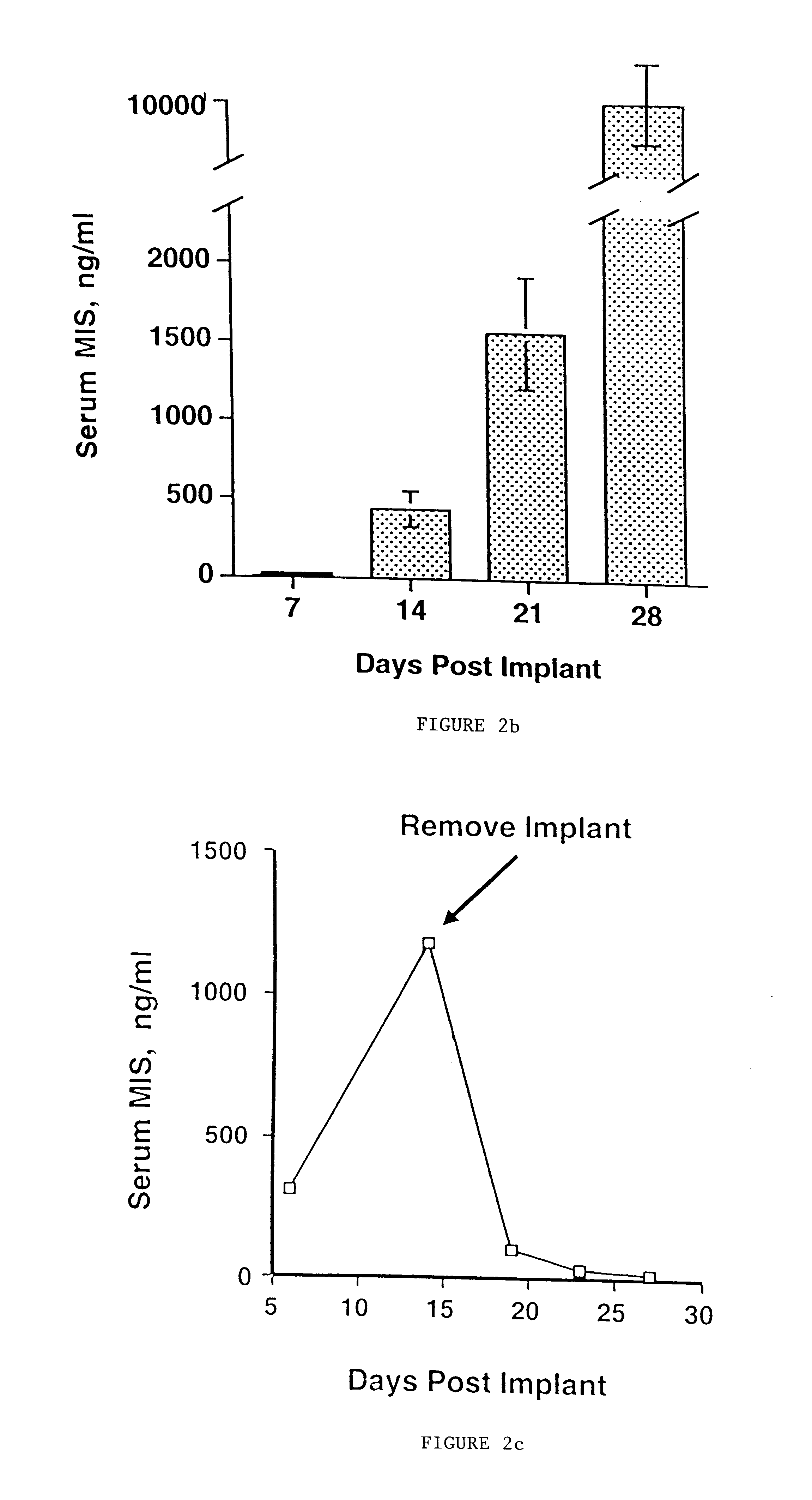

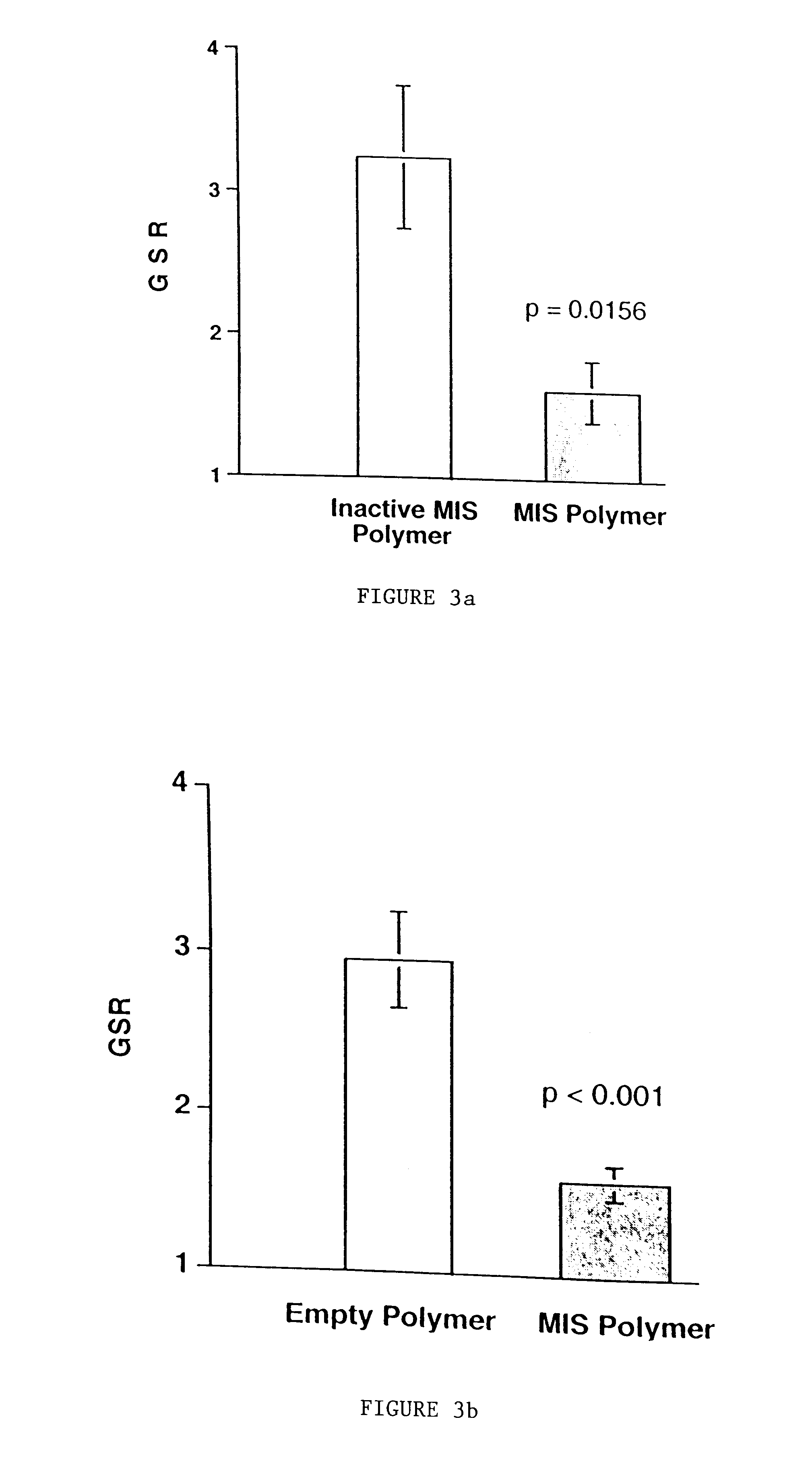

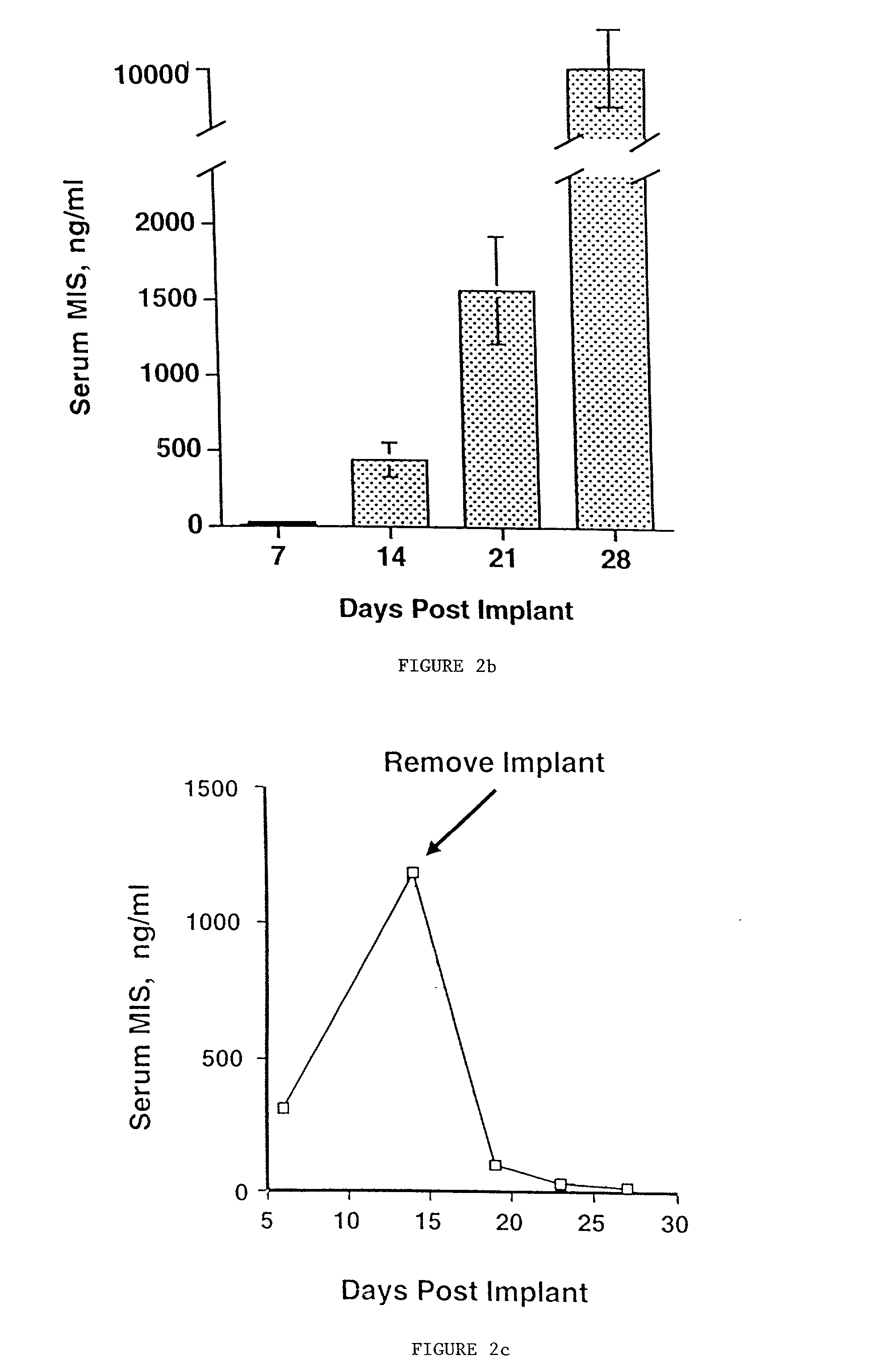

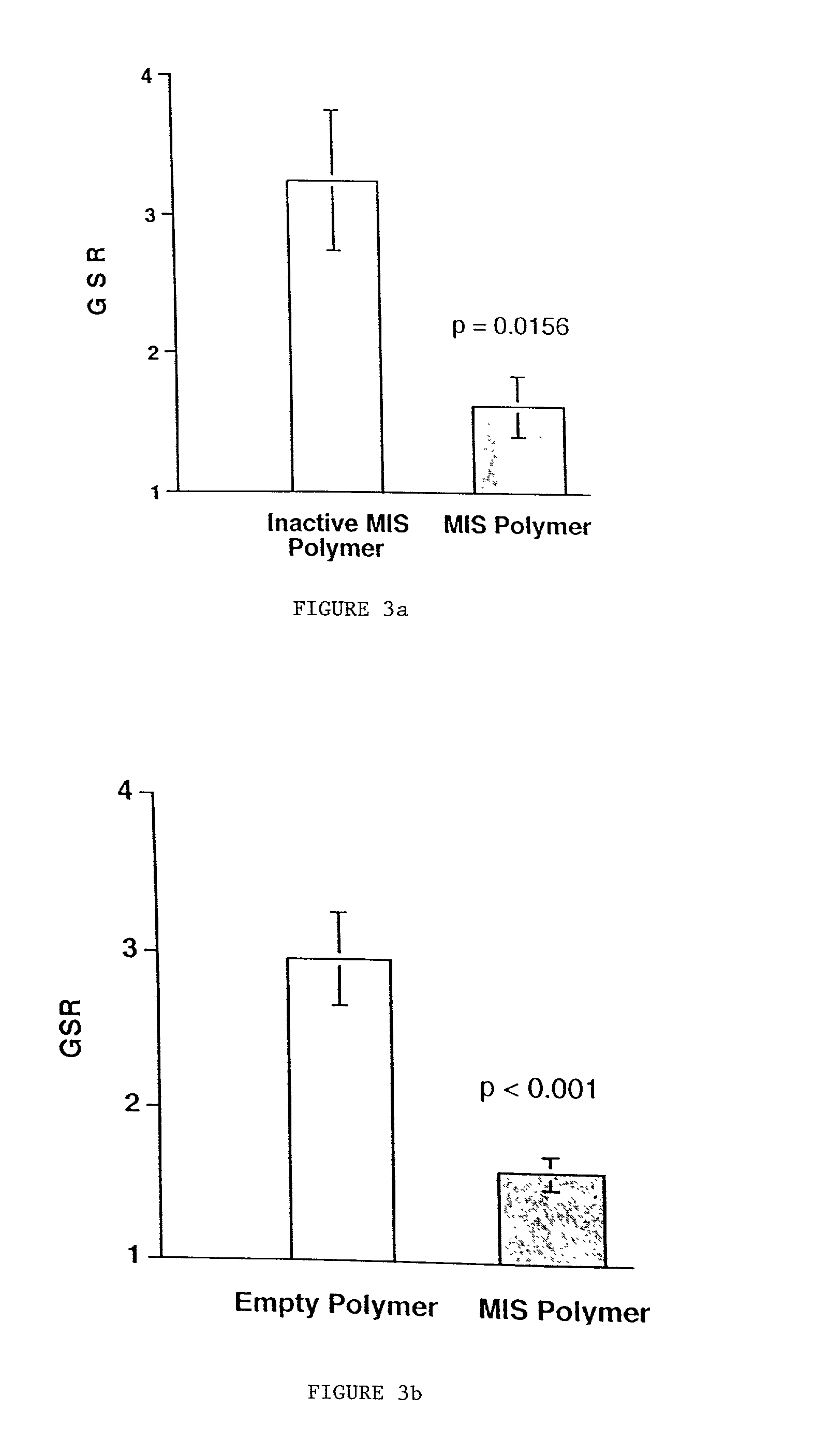

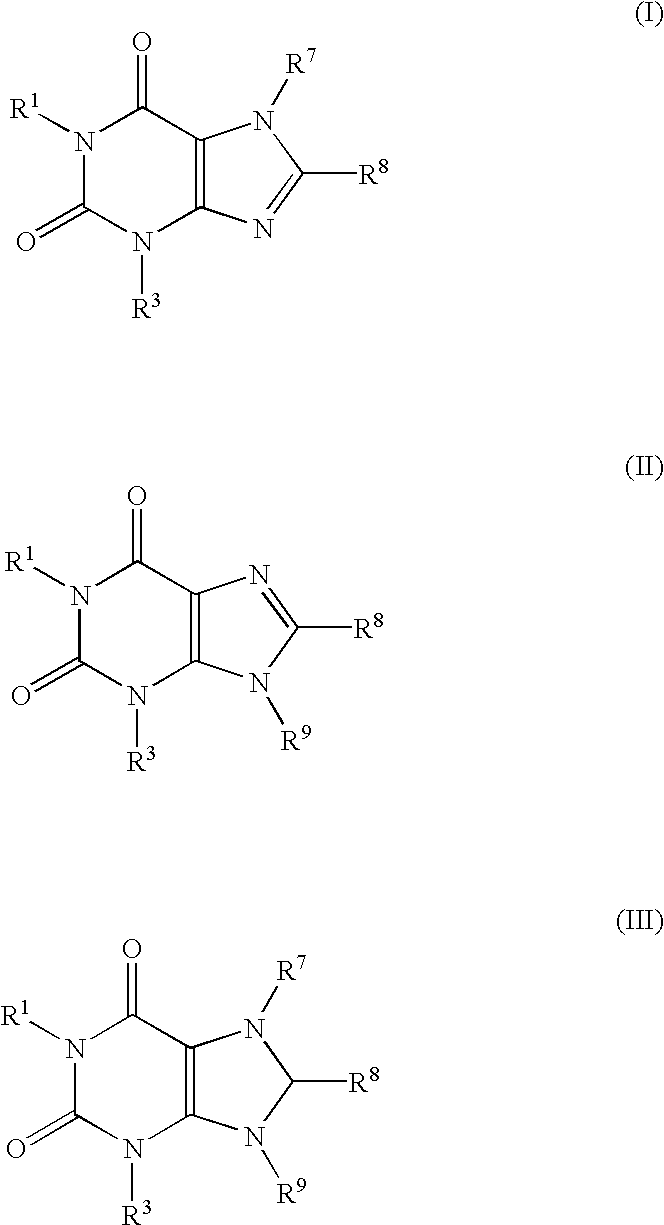

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

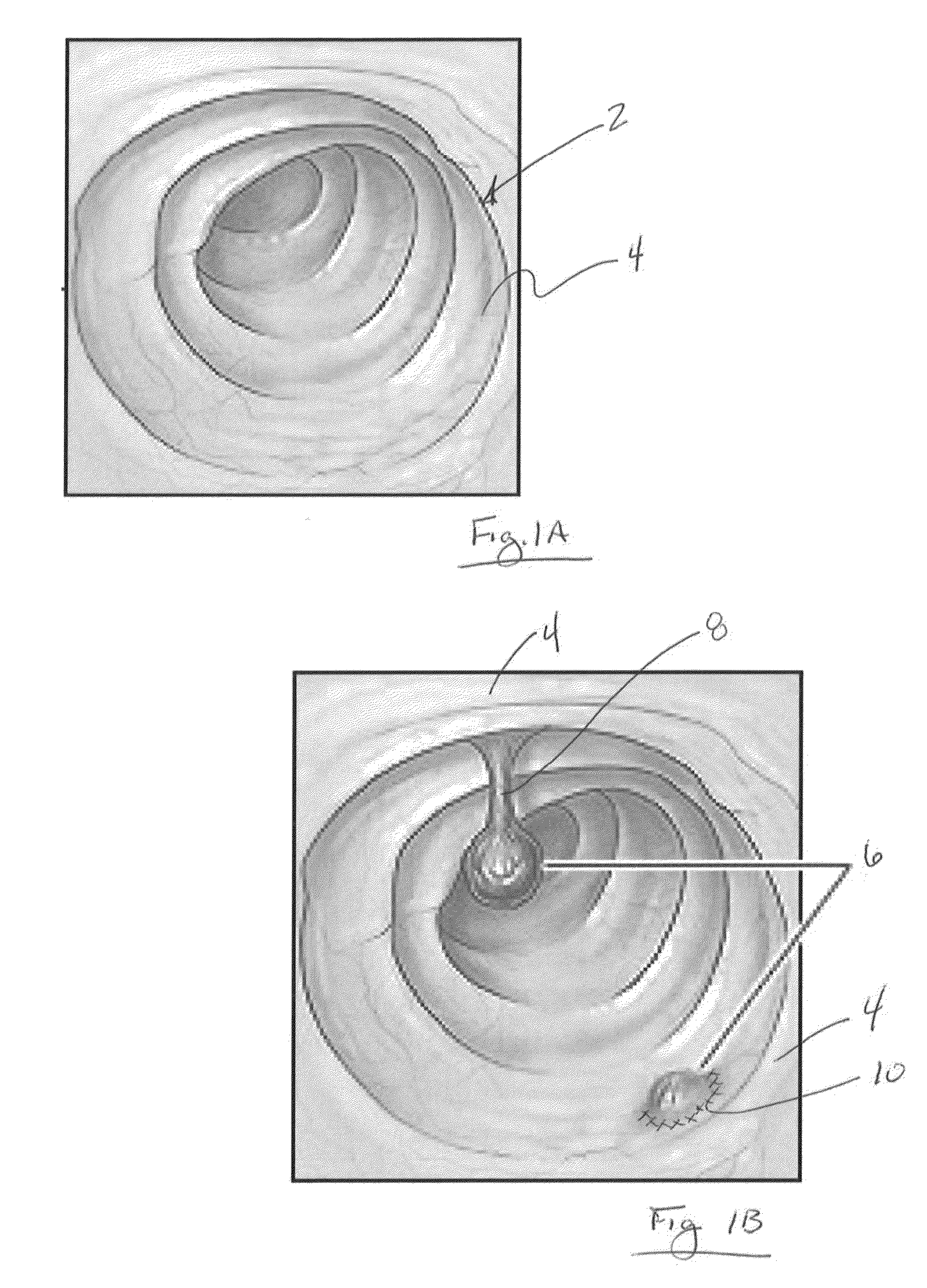

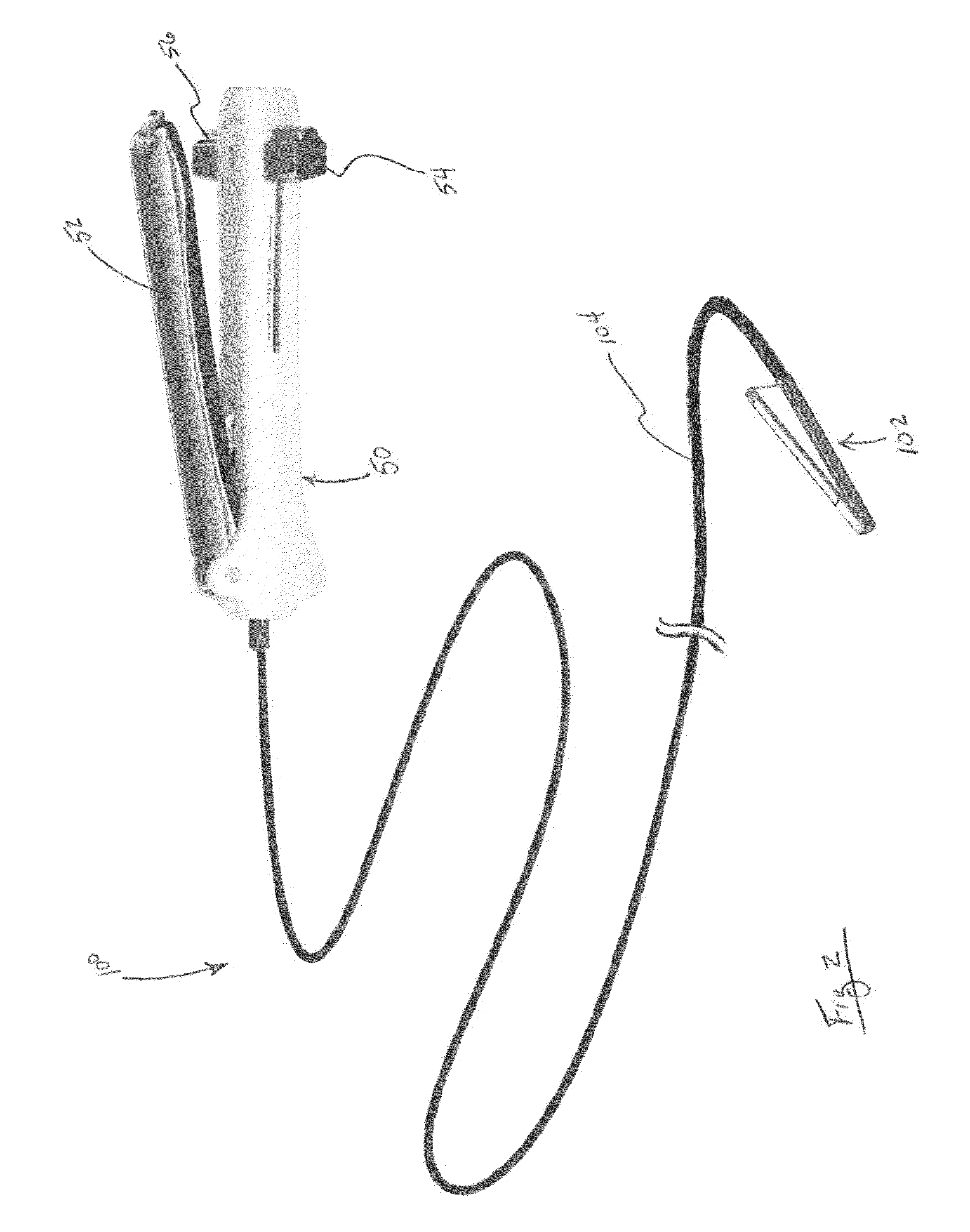

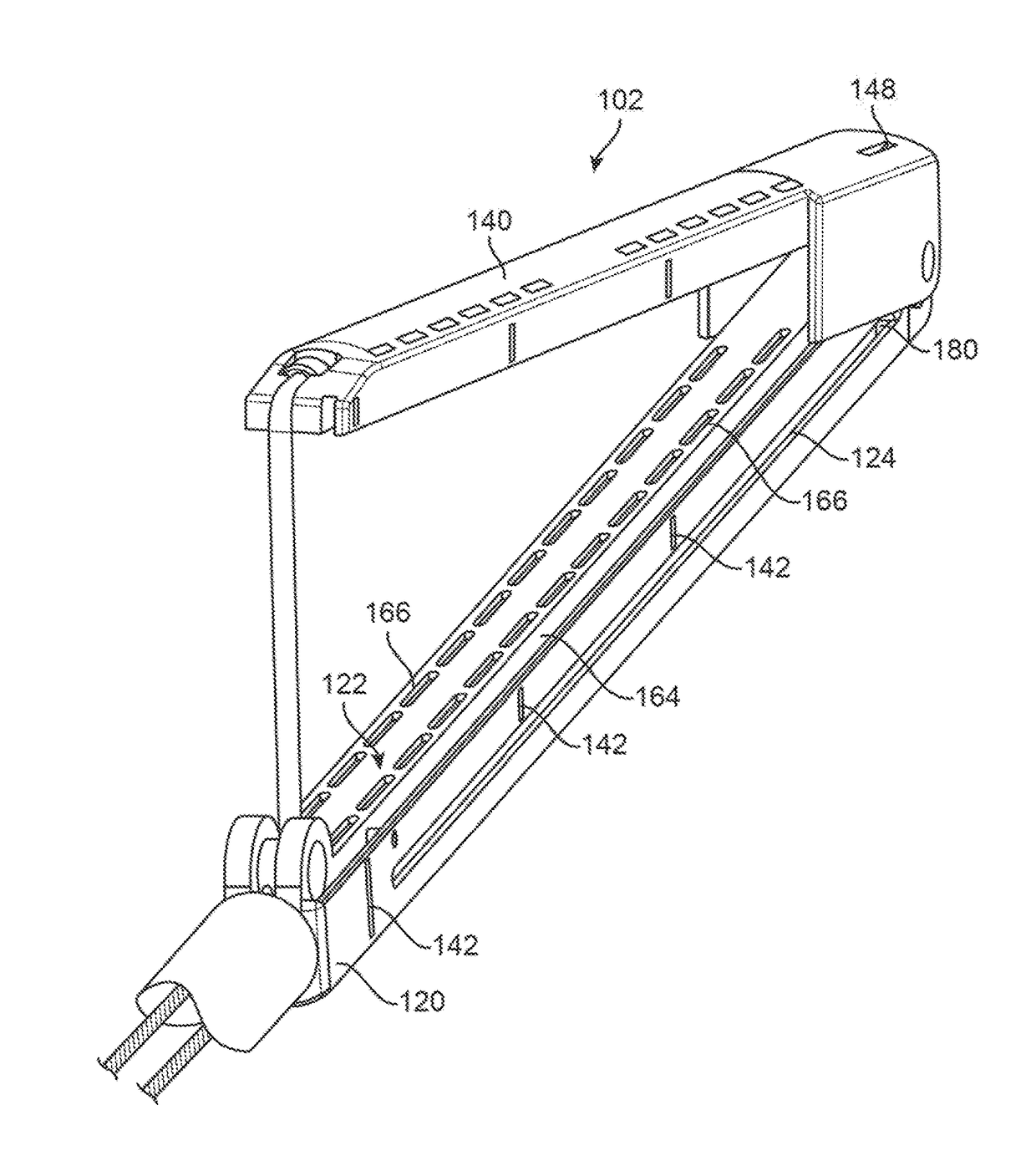

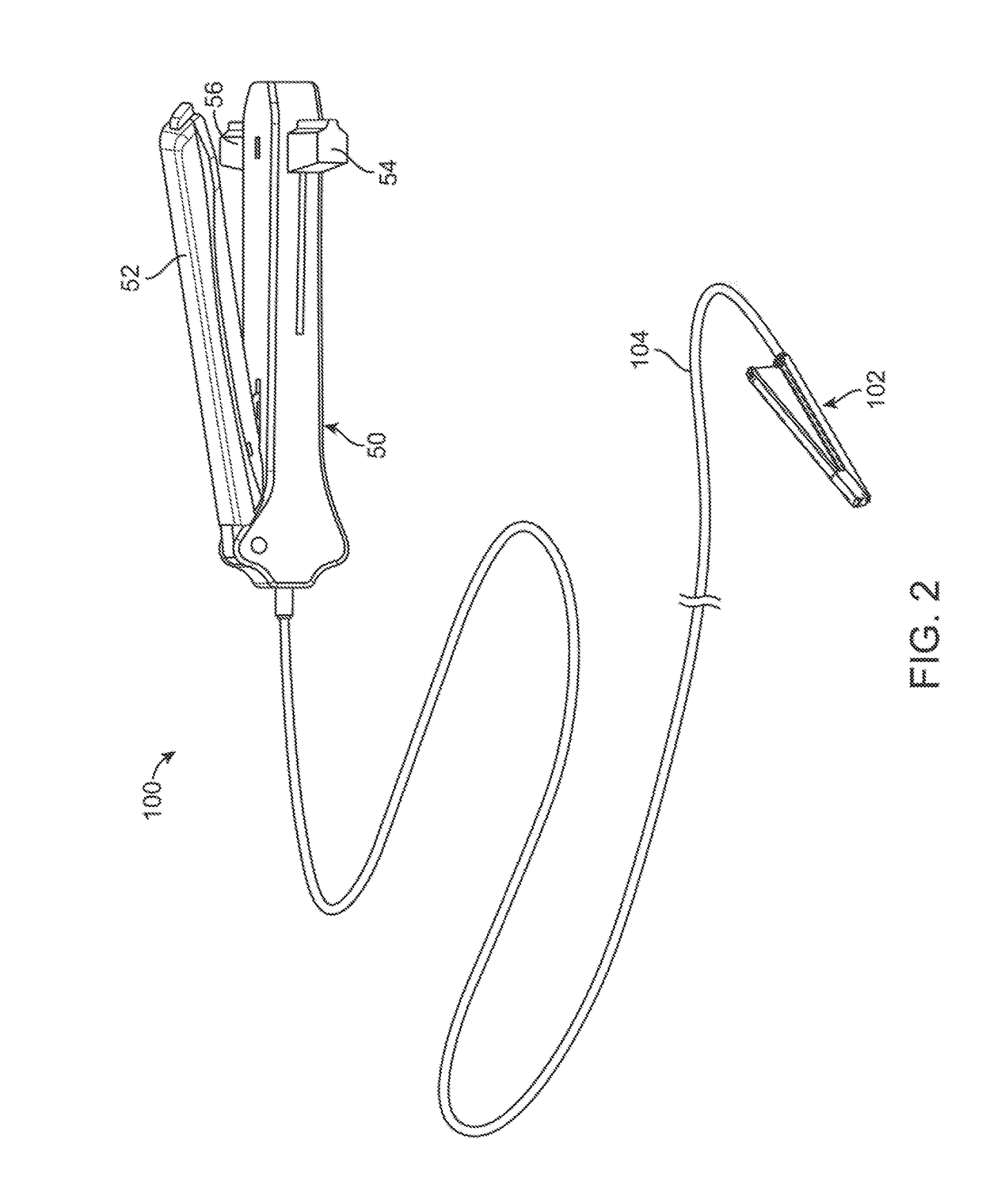

Tissue removal and closure device

ActiveUS20160262750A1Prevent movementAvoid elevationDiagnosticsSurgical staplesAbnormal tissue growthCyst

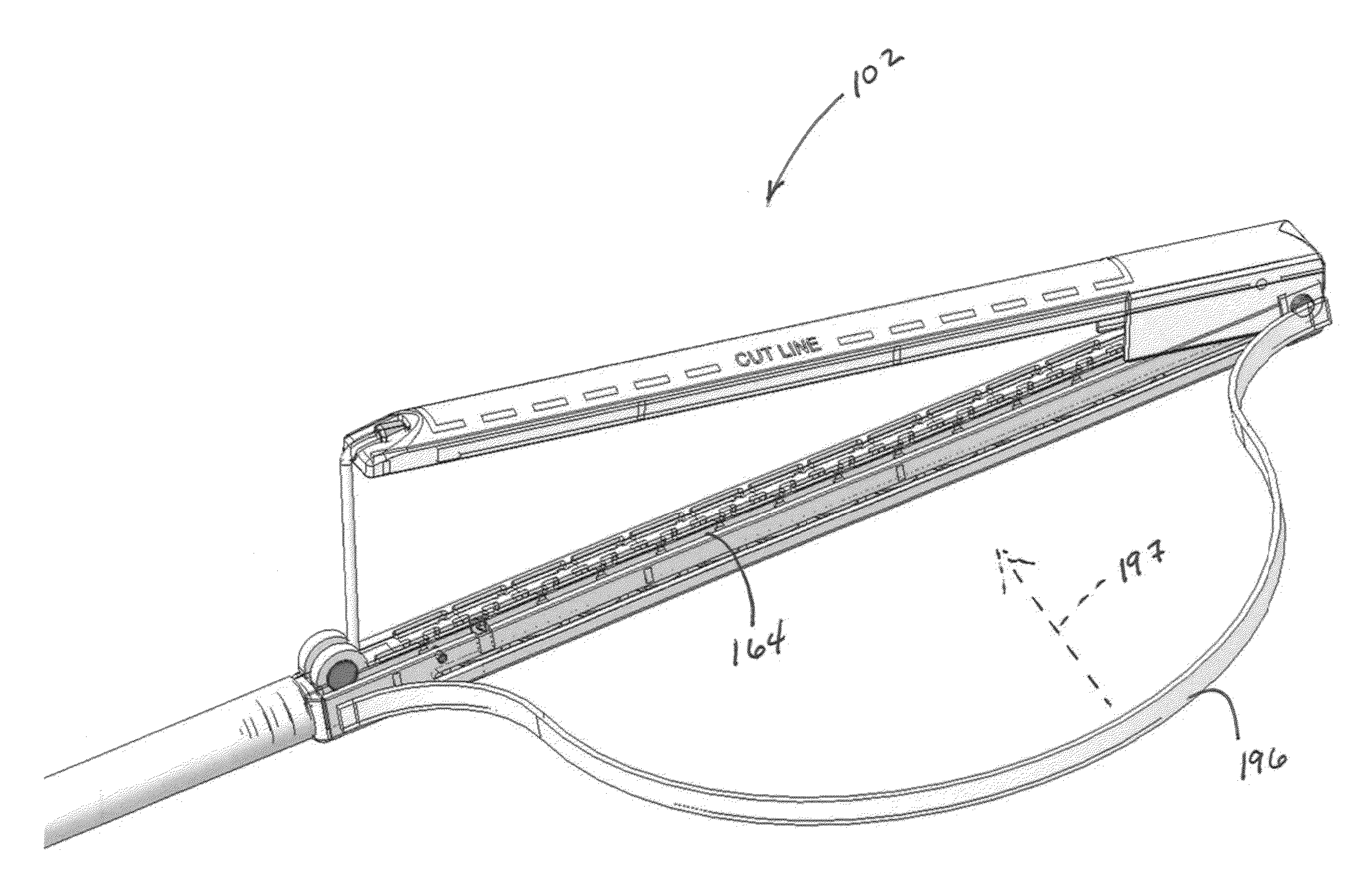

Methods and devices described herein facilitate improved treatment of body organs and relates to surgical instruments, useful in endoscopic, laparoscopic and / or open surgical procedures to effectively remove a suspect region of tissue such as a polyp, abnormal growth, cyst, tumor, lesion, or other abnormality from a base tissue structure.

Owner:AESCULAP AG

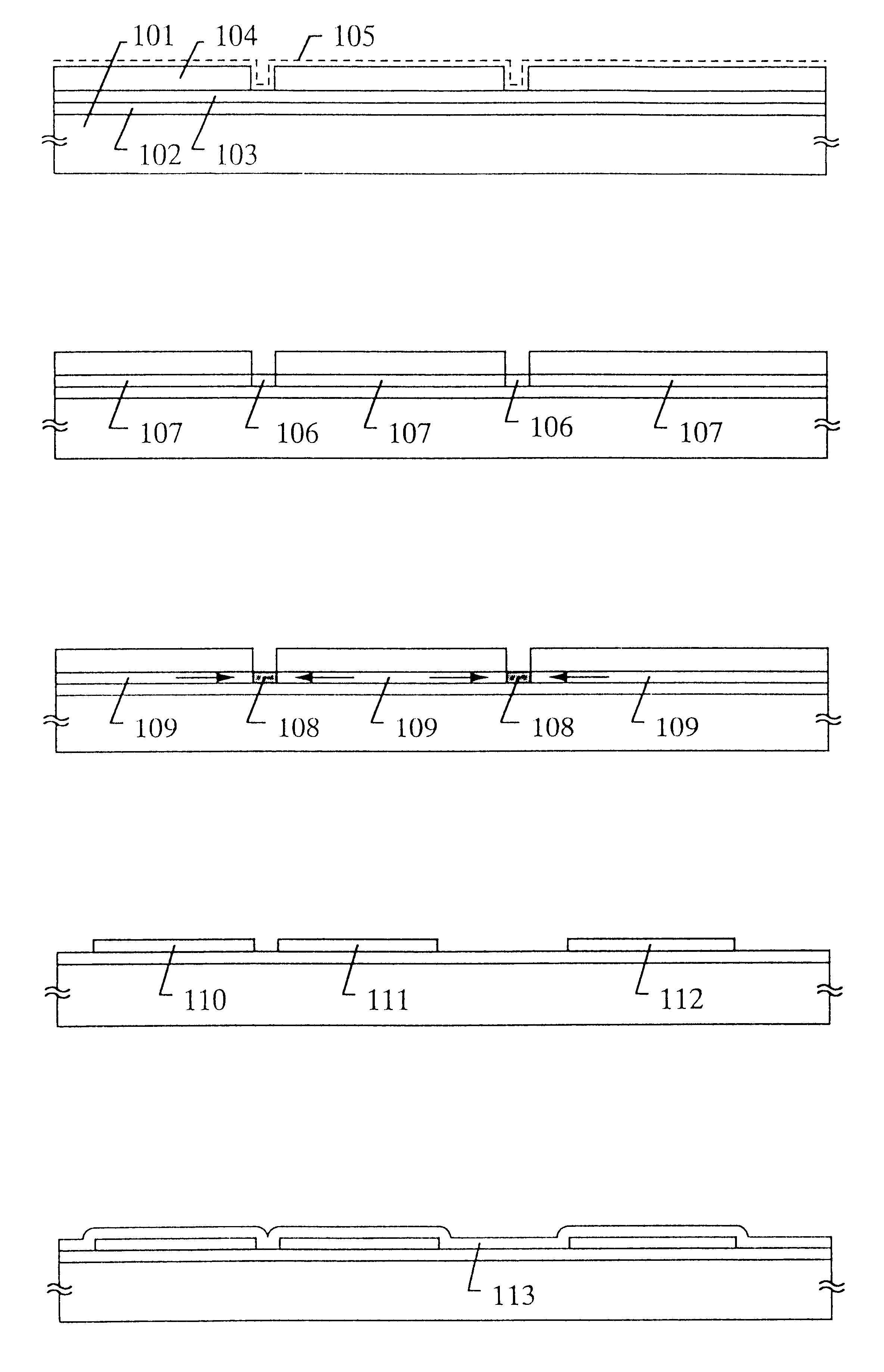

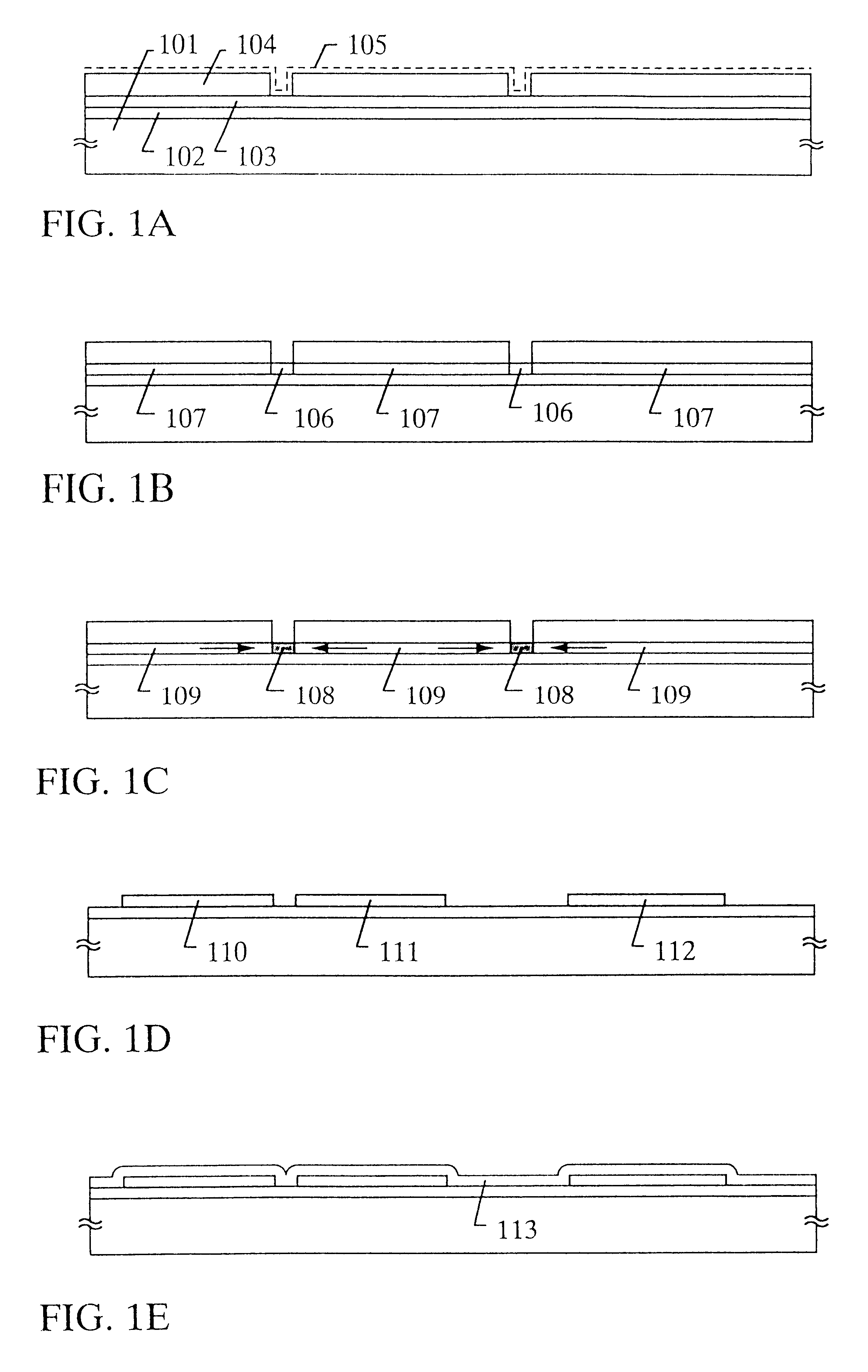

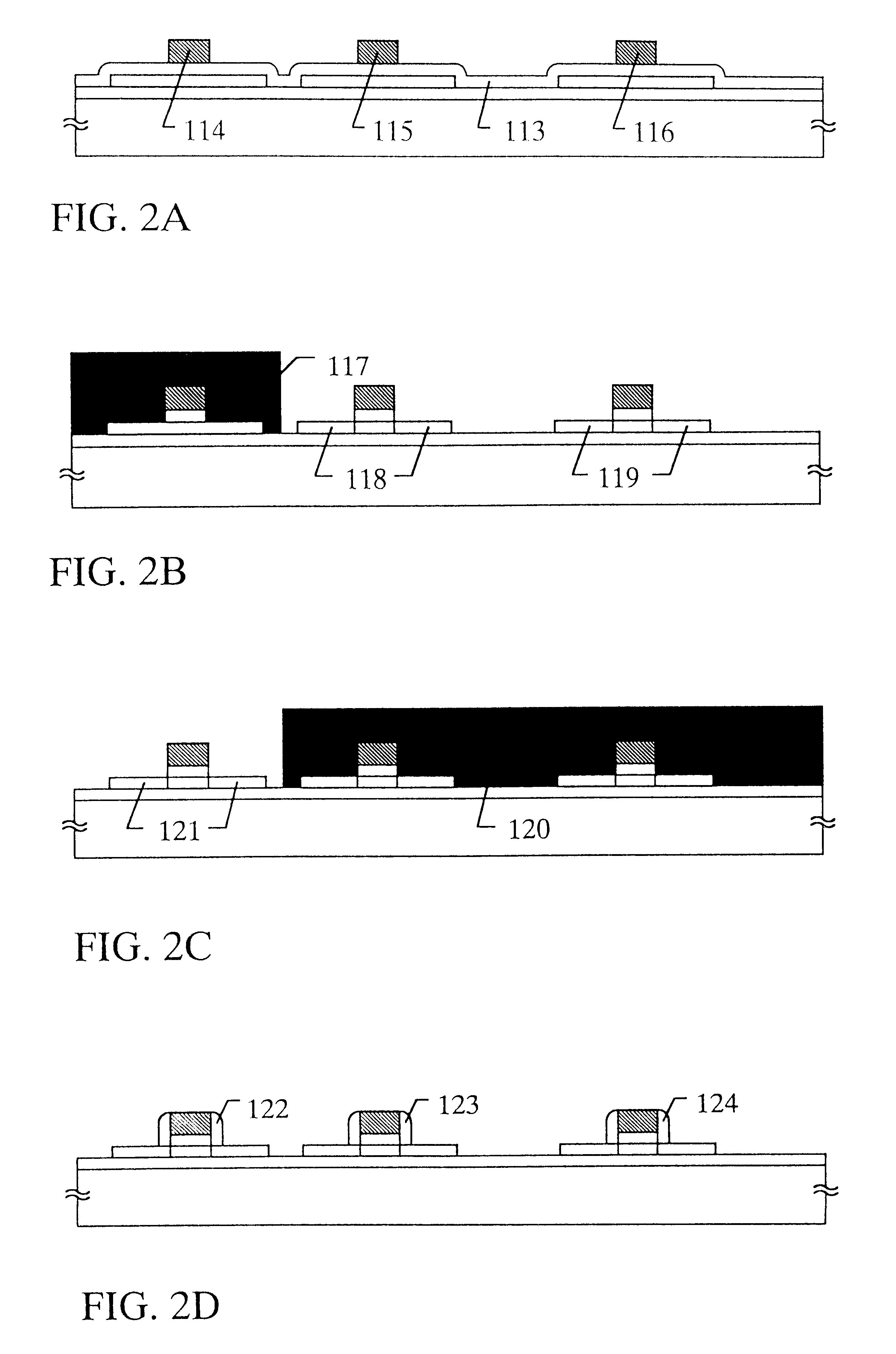

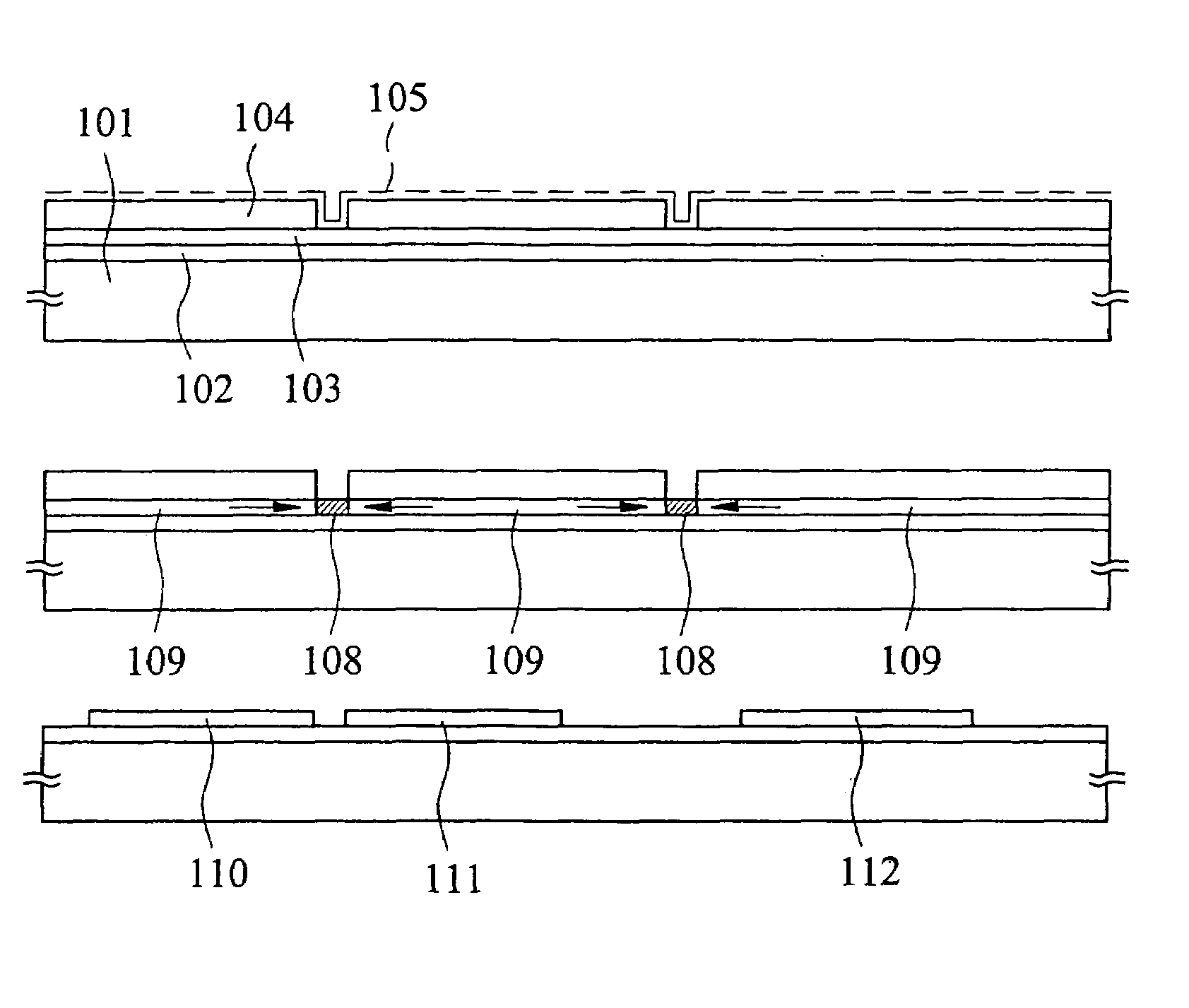

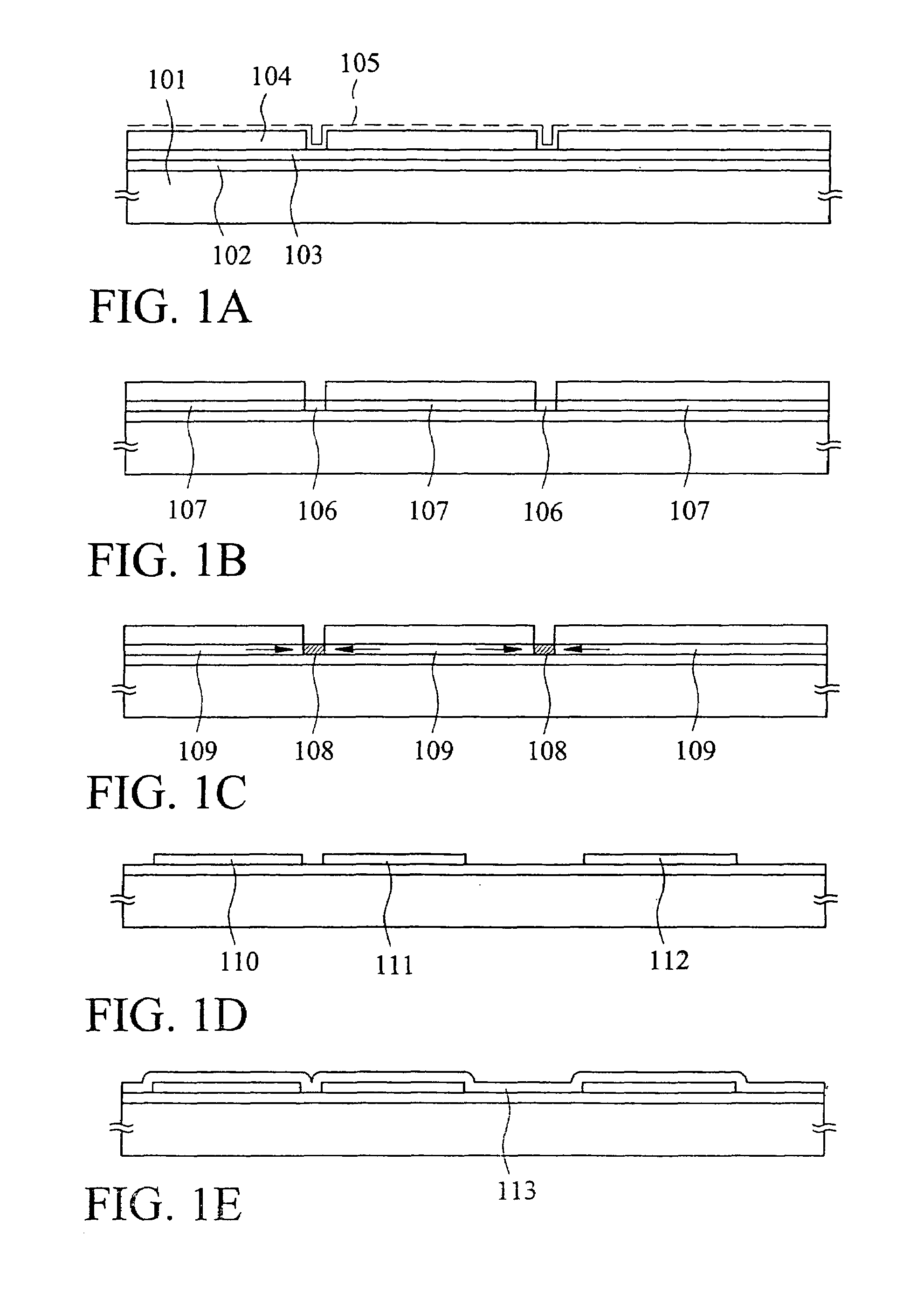

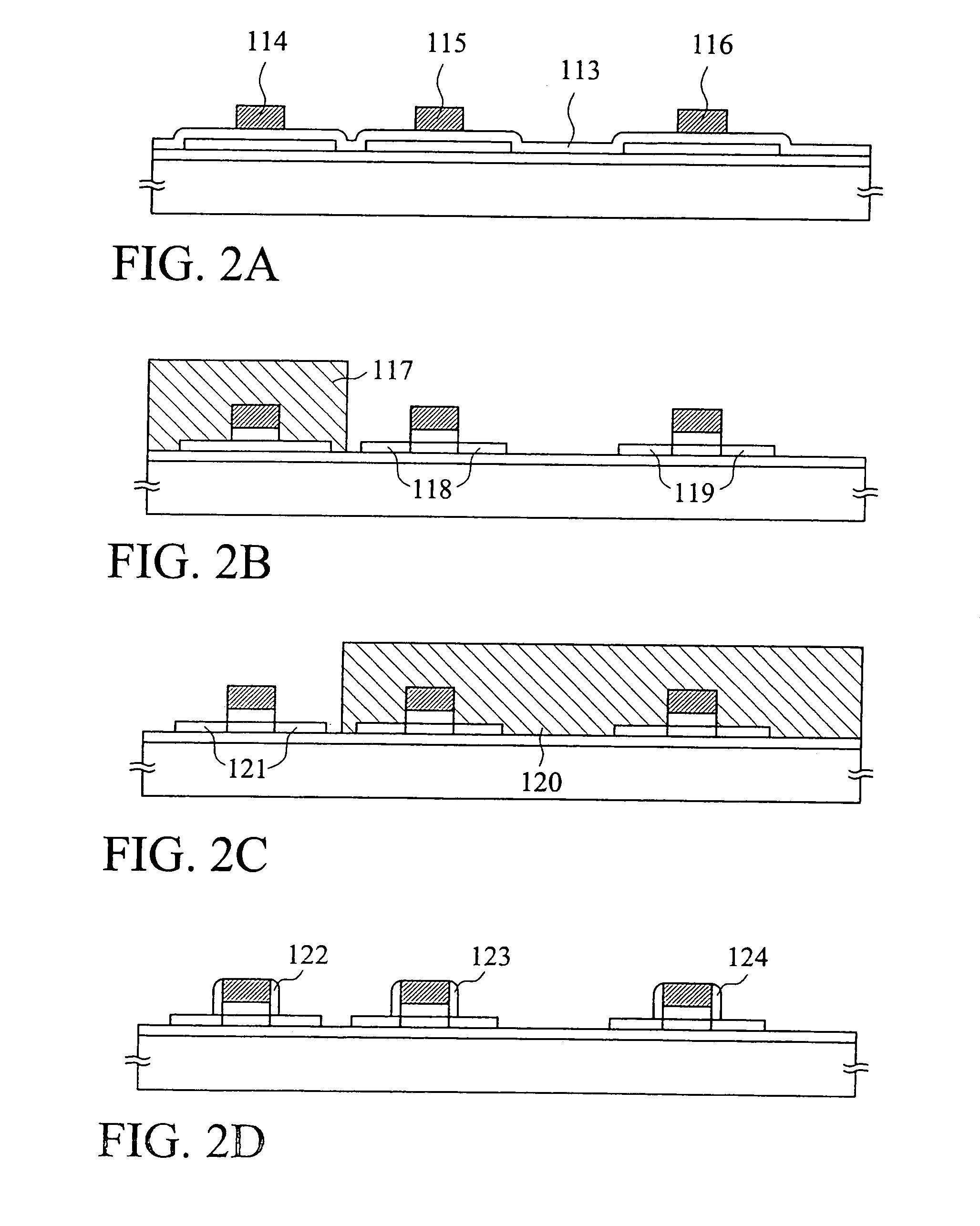

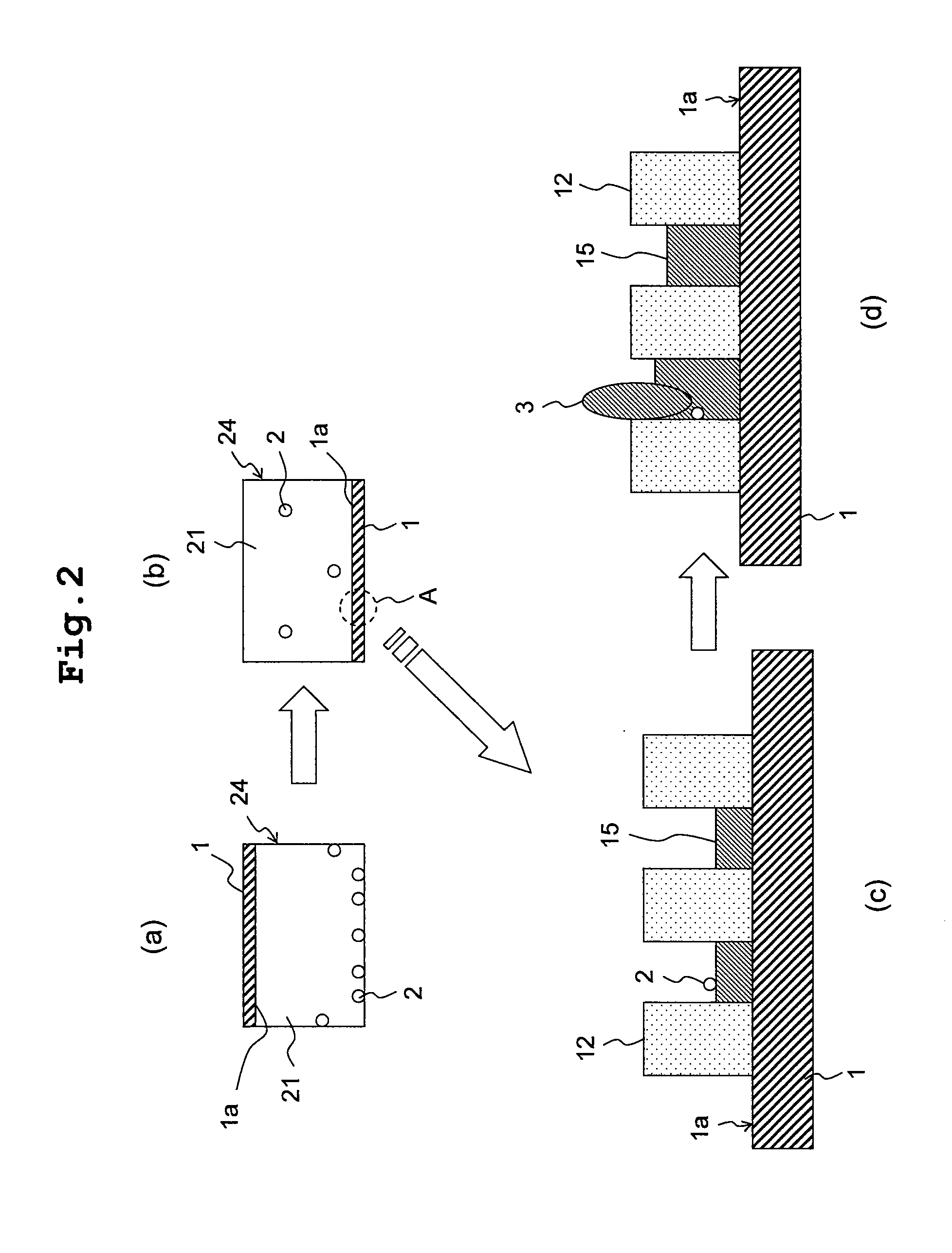

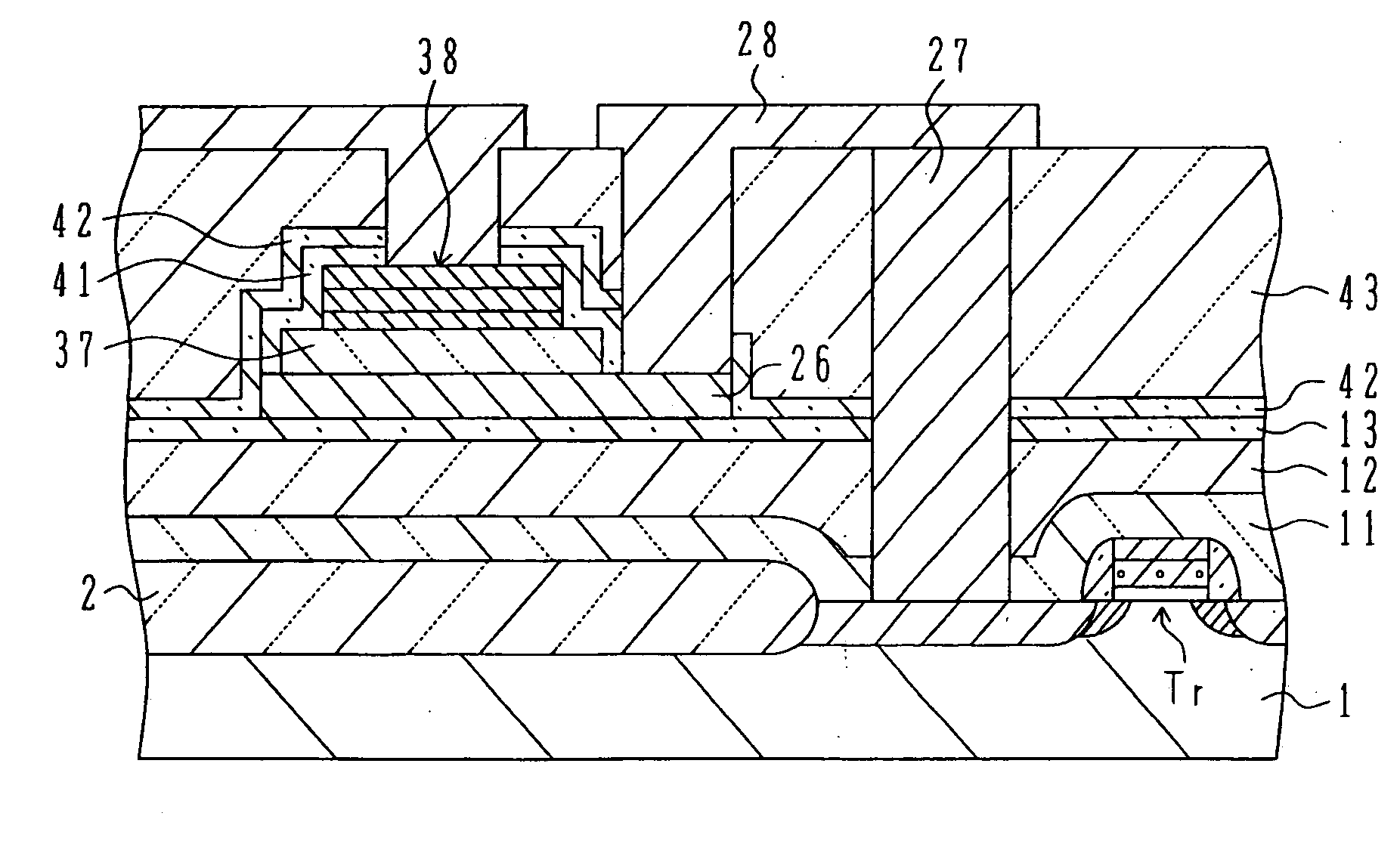

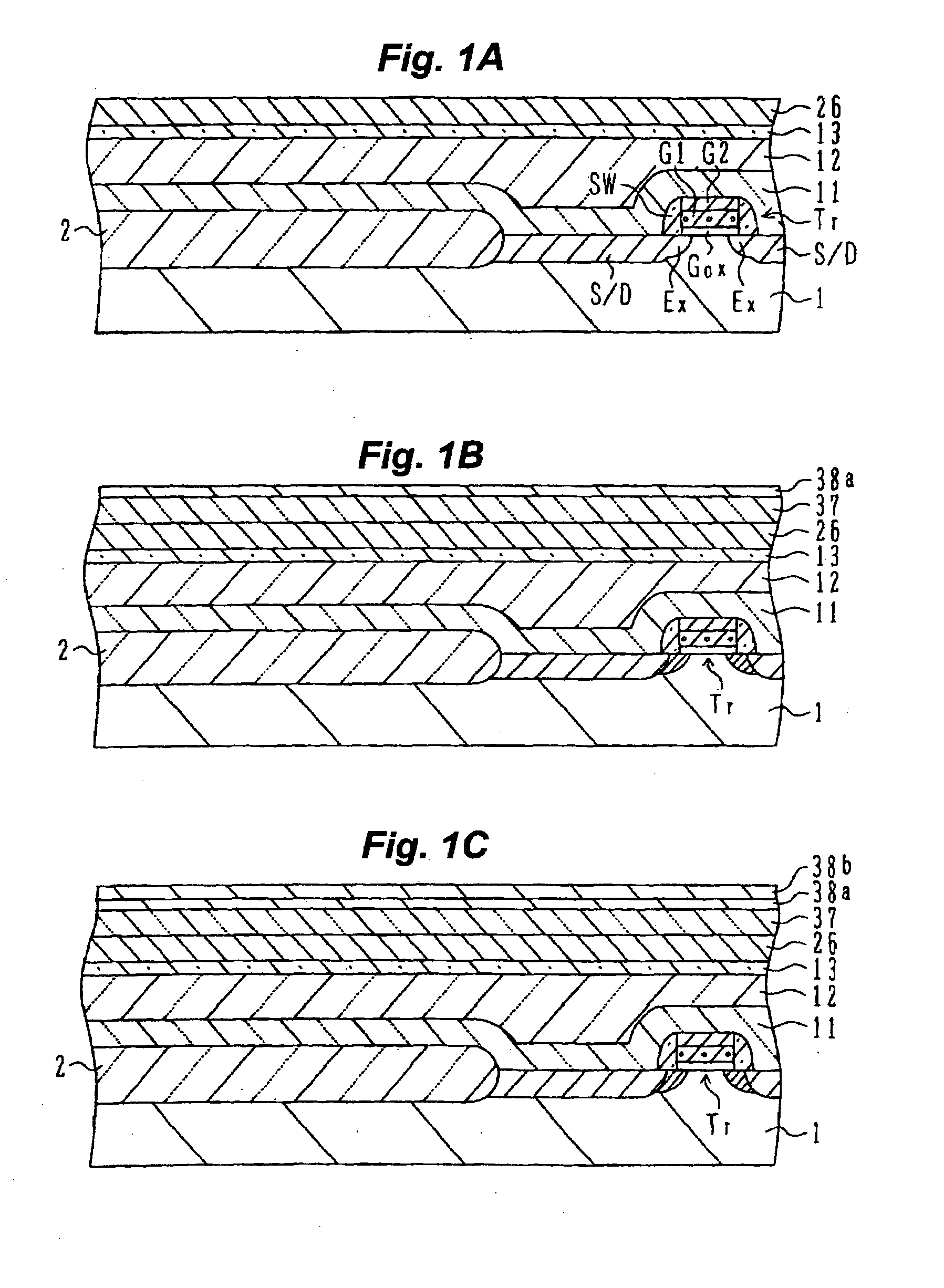

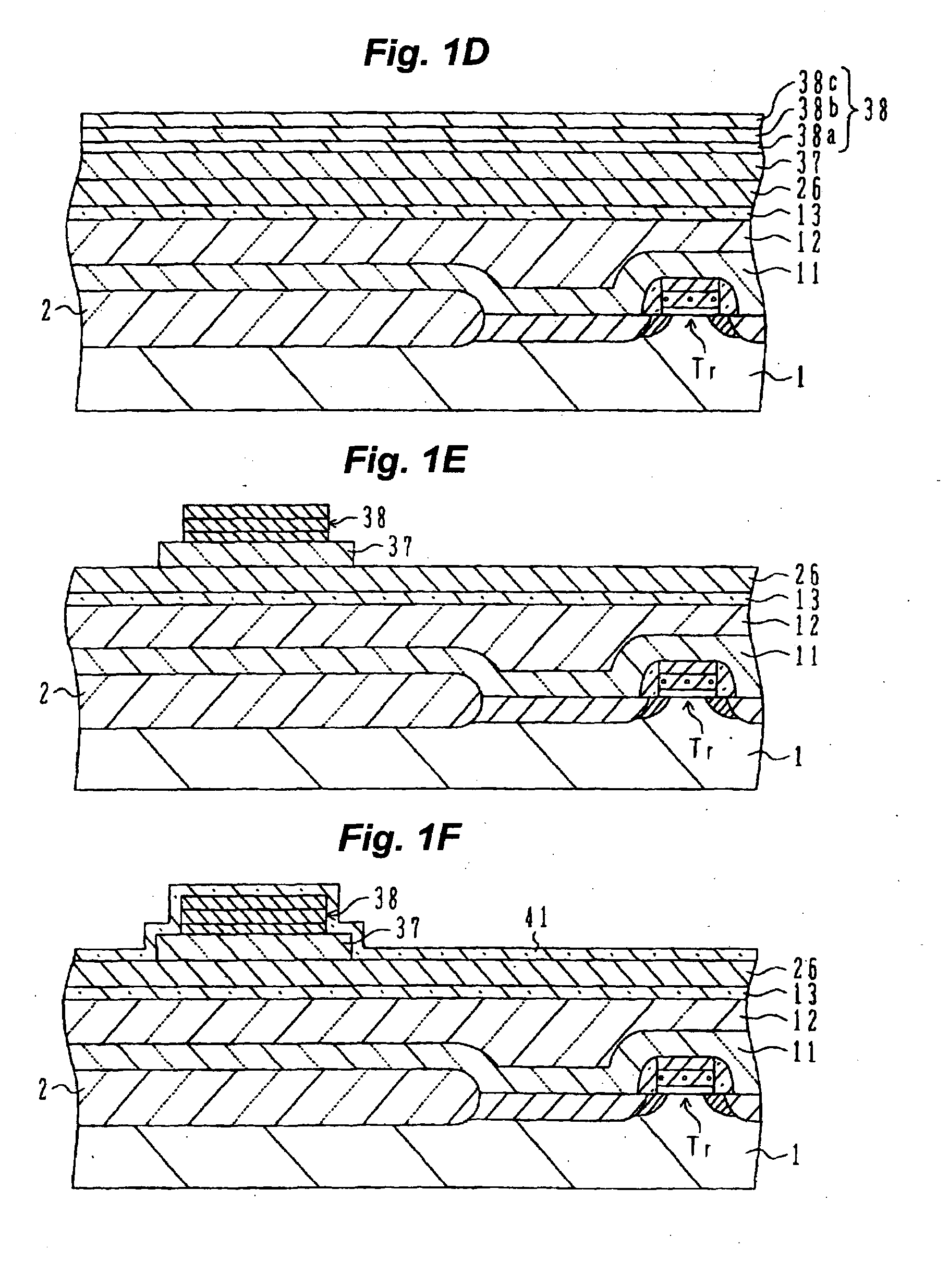

Introducing catalytic and gettering elements with a single mask when manufacturing a thin film semiconductor device

InactiveUS6348368B1TransistorSemiconductor/solid-state device manufacturingAbnormal growthsDevice material

In a method of manufacturing a semiconductor device, after a lateral growth region 107 is formed by using a catalytic element 105 for facilitating crystallization of silicon, the catalytic element is gettered into a phosphorus added region 108 by a heat treatment. Thereafter, a gate insulating film 113 is formed to cover active layers 110 to 112 formed, and in this state, a thermal oxidation step is carried out. By this, the characteristics of an interface between the active layers and the gate insulating film can be improved while abnormal growth of a metal oxide is prevented.

Owner:SEMICON ENERGY LAB CO LTD

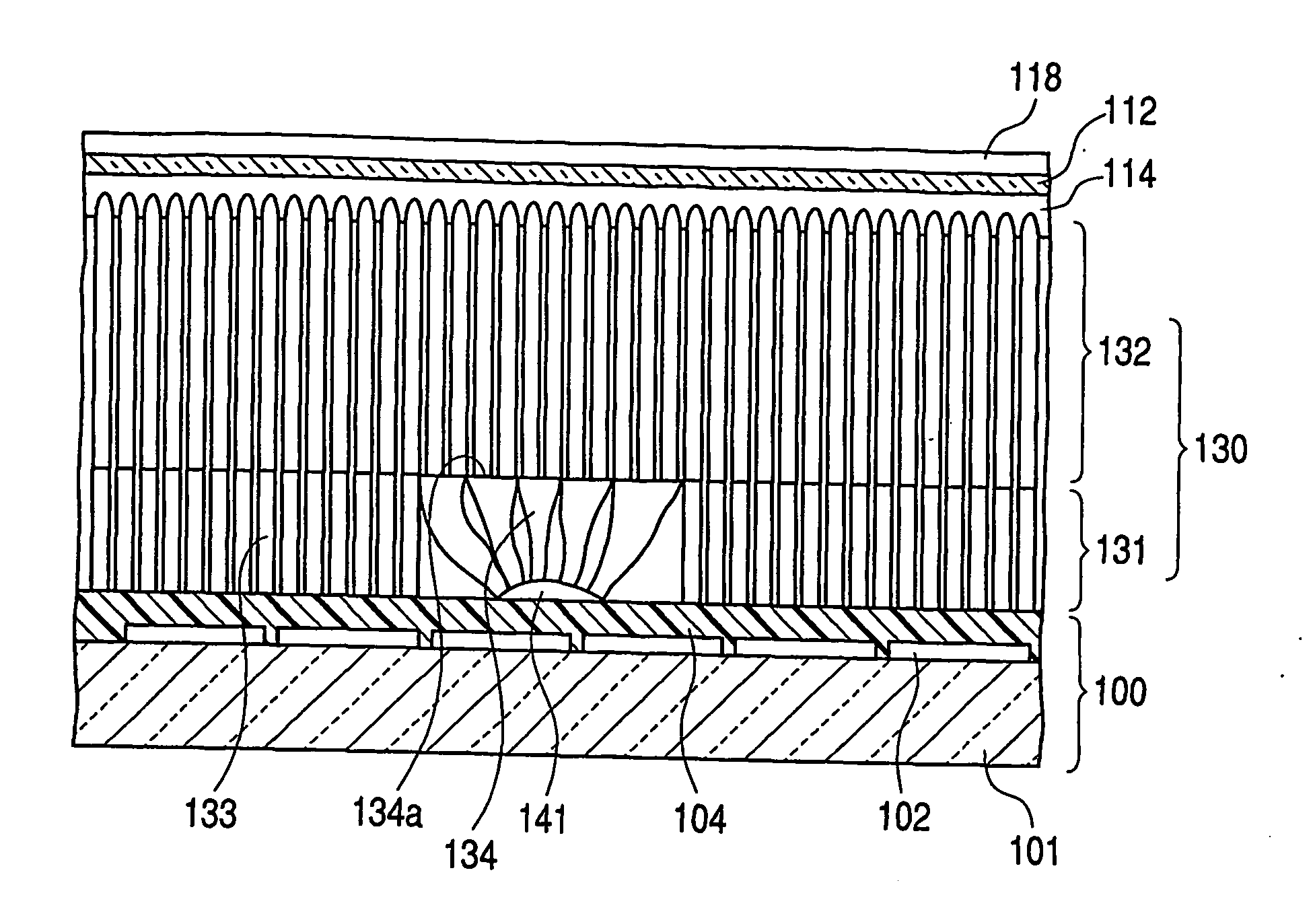

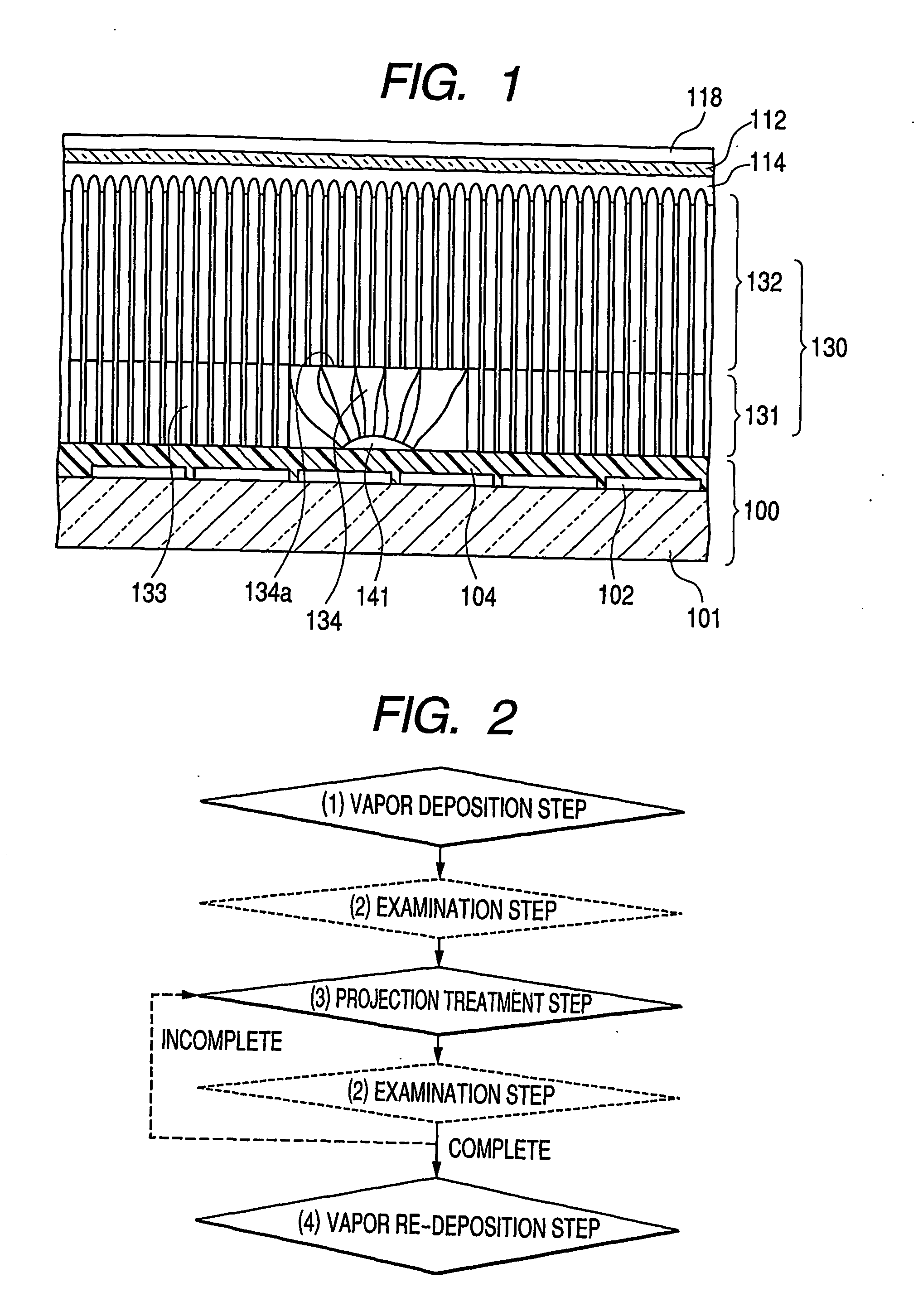

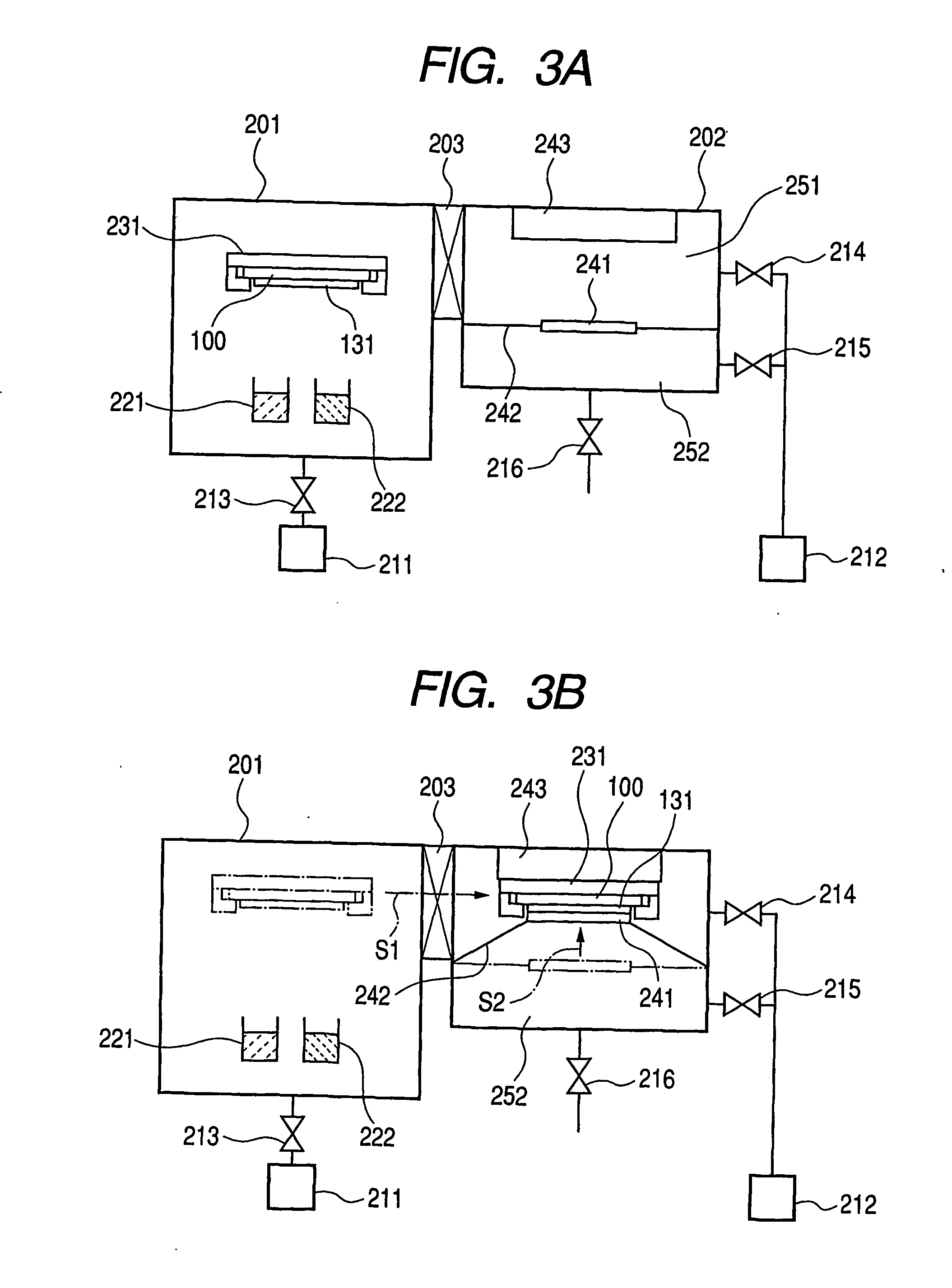

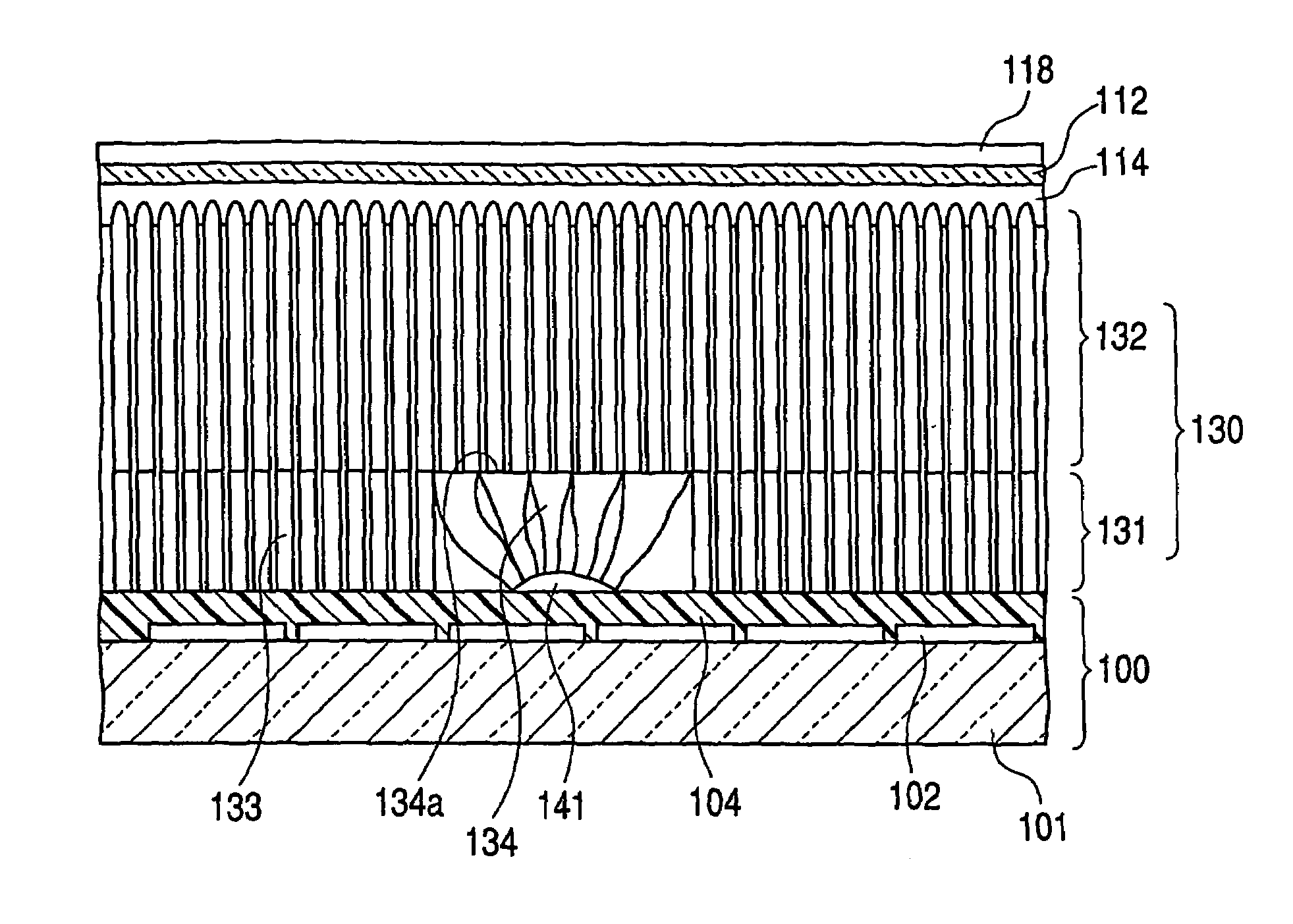

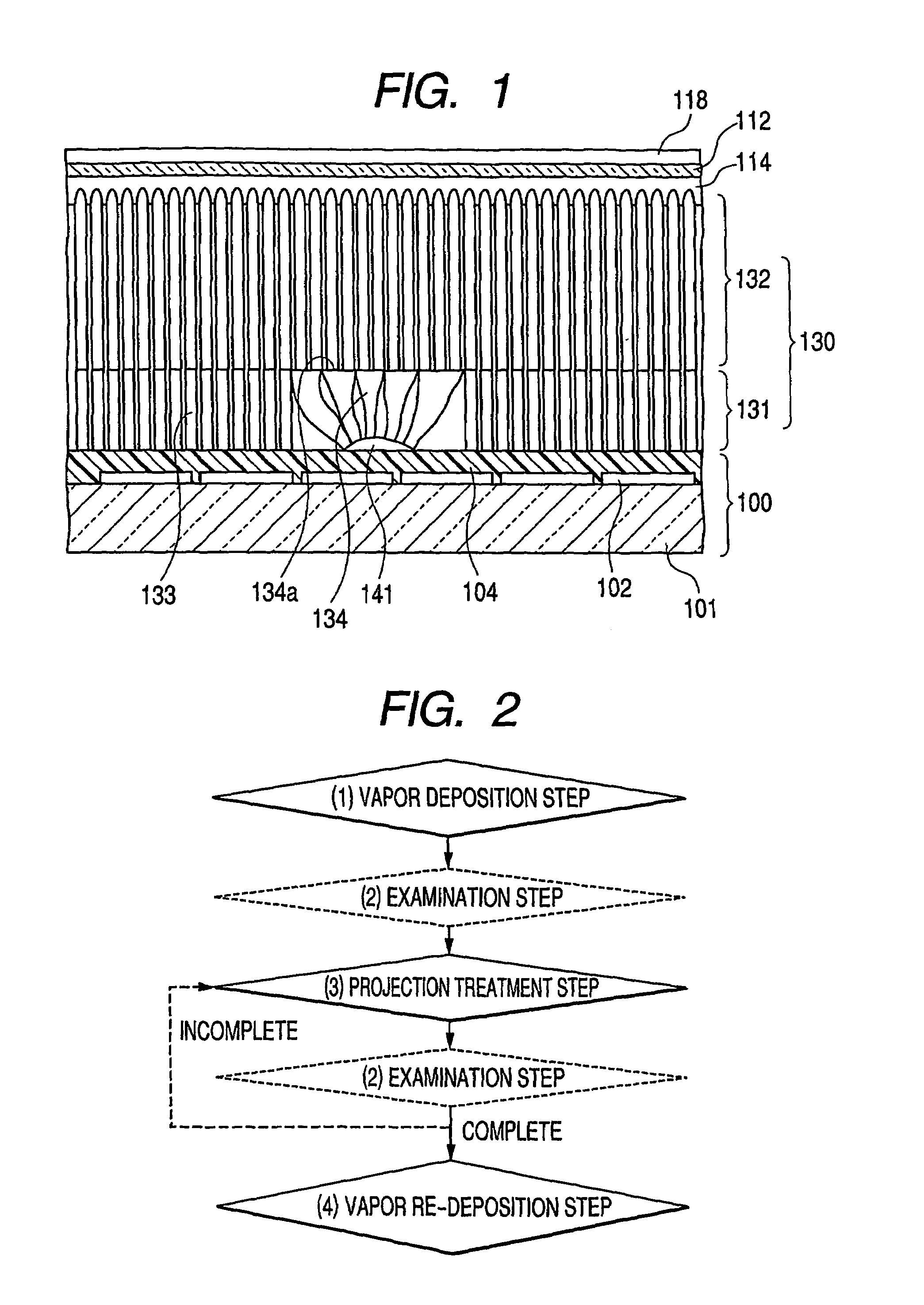

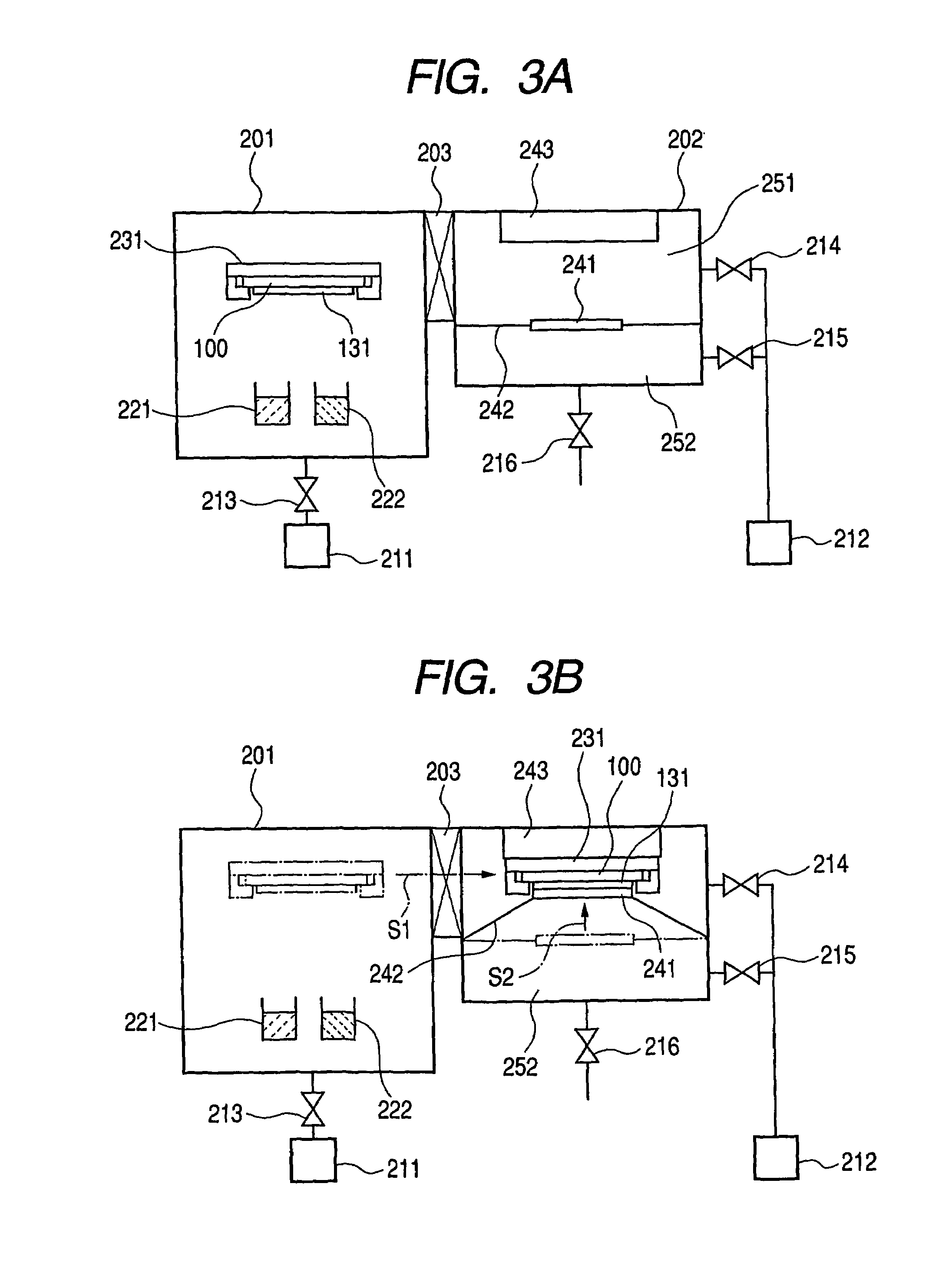

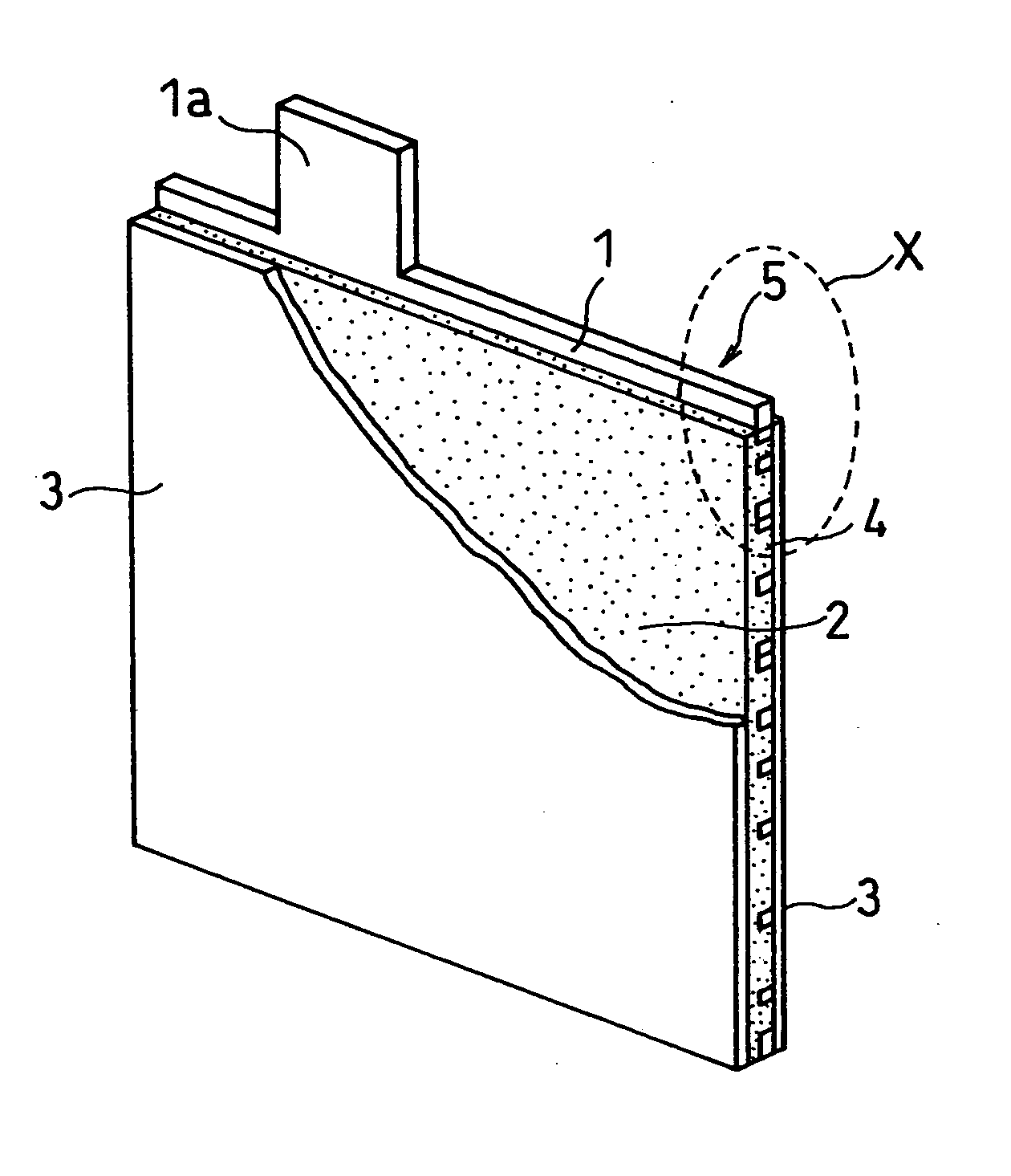

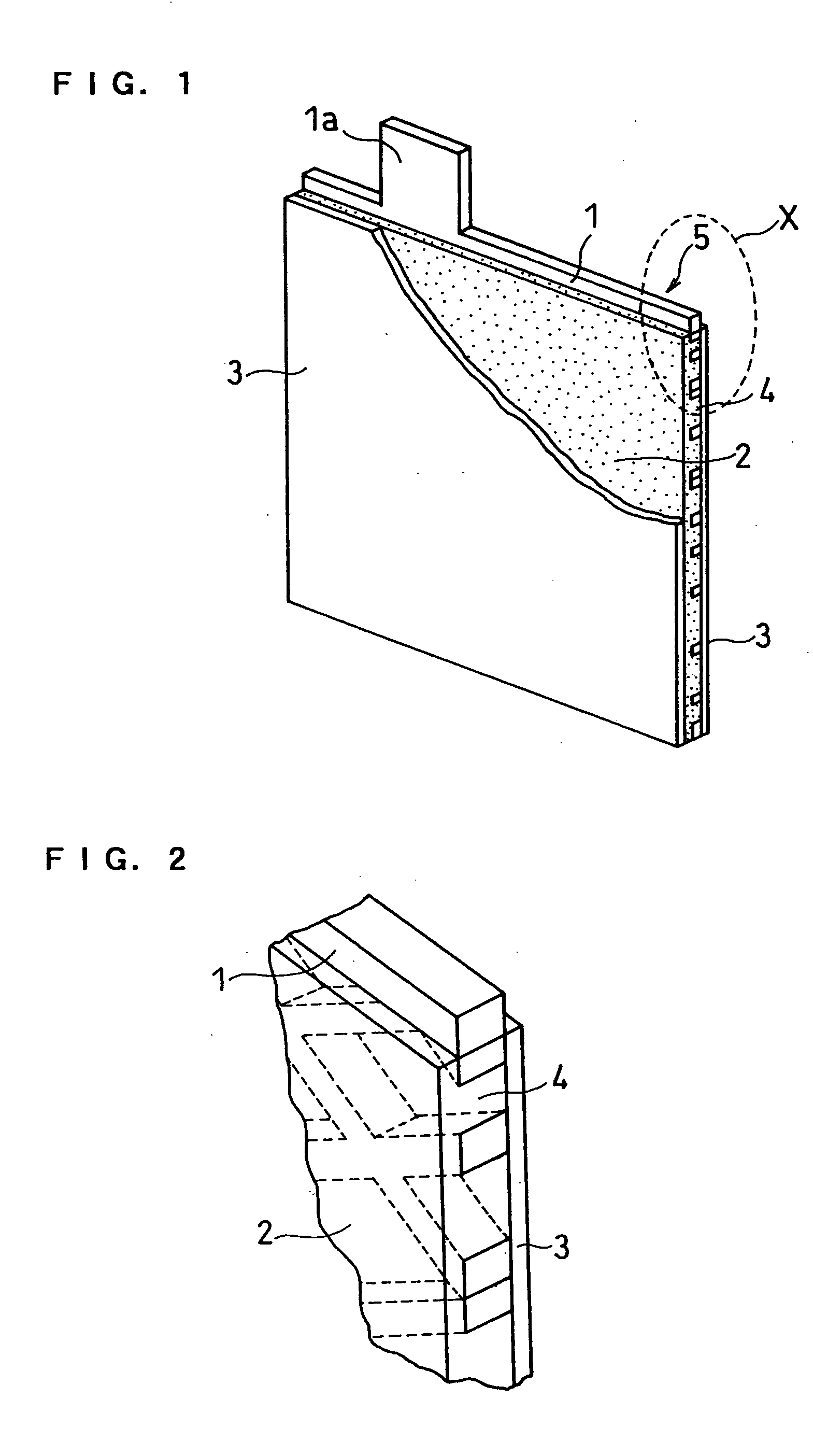

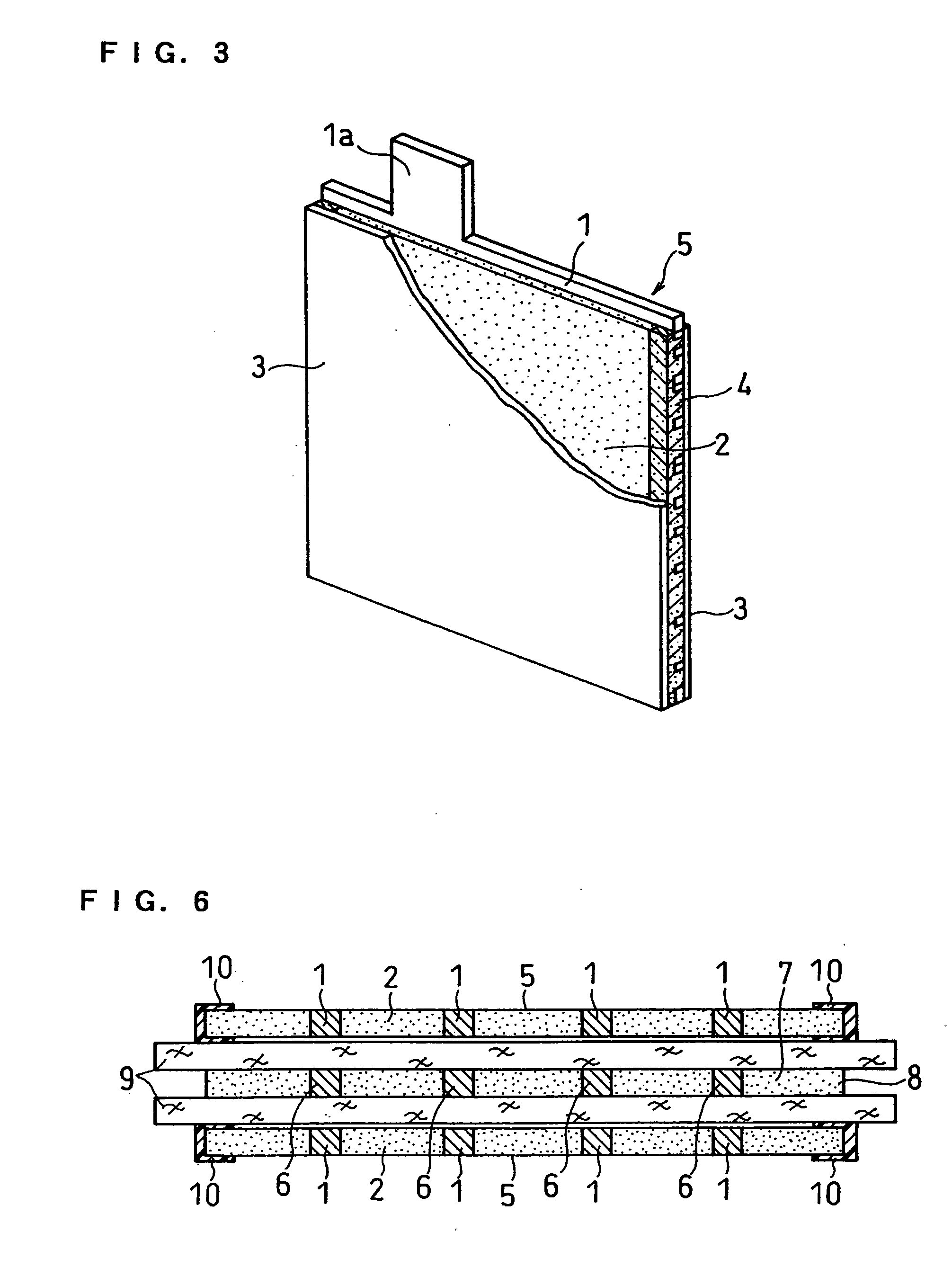

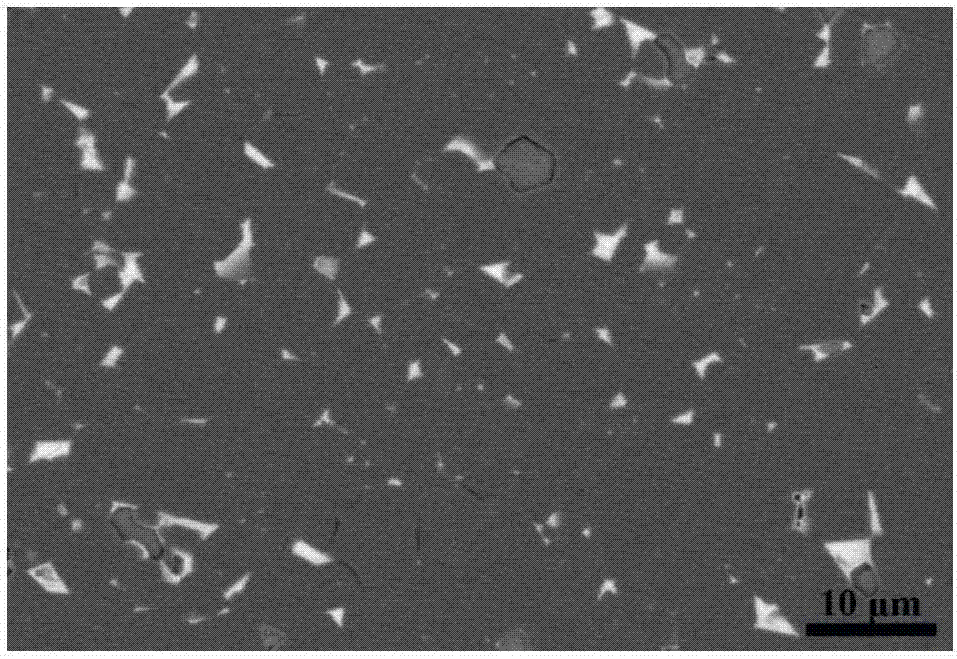

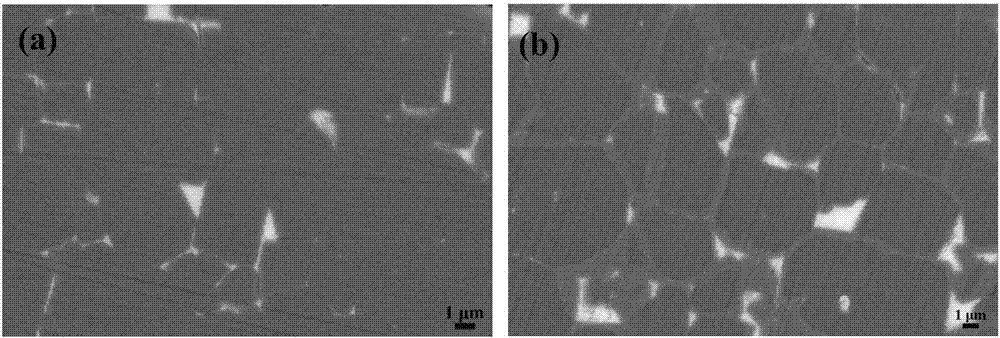

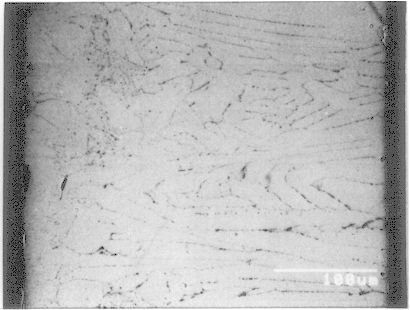

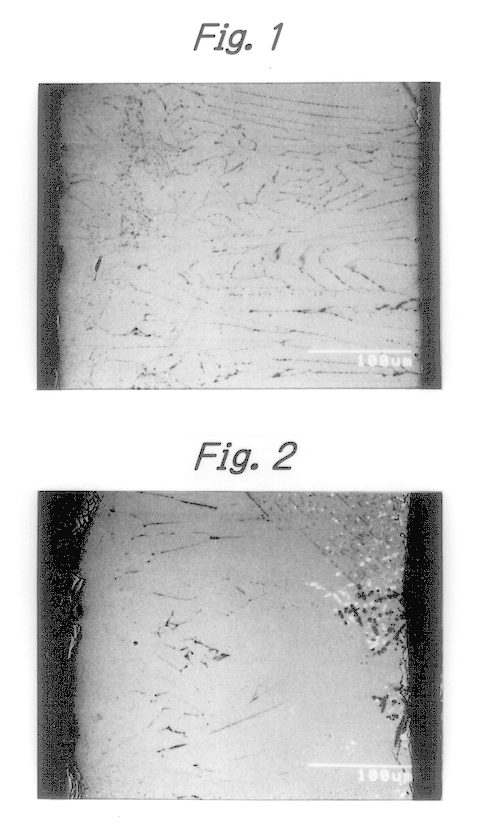

Radiation detection device, scintillator panel, method of making the same, making apparatus, and radiation image pick-up system

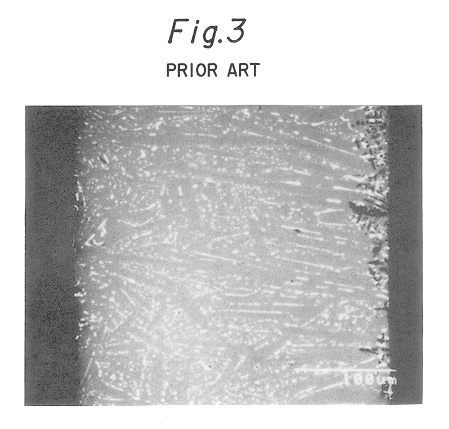

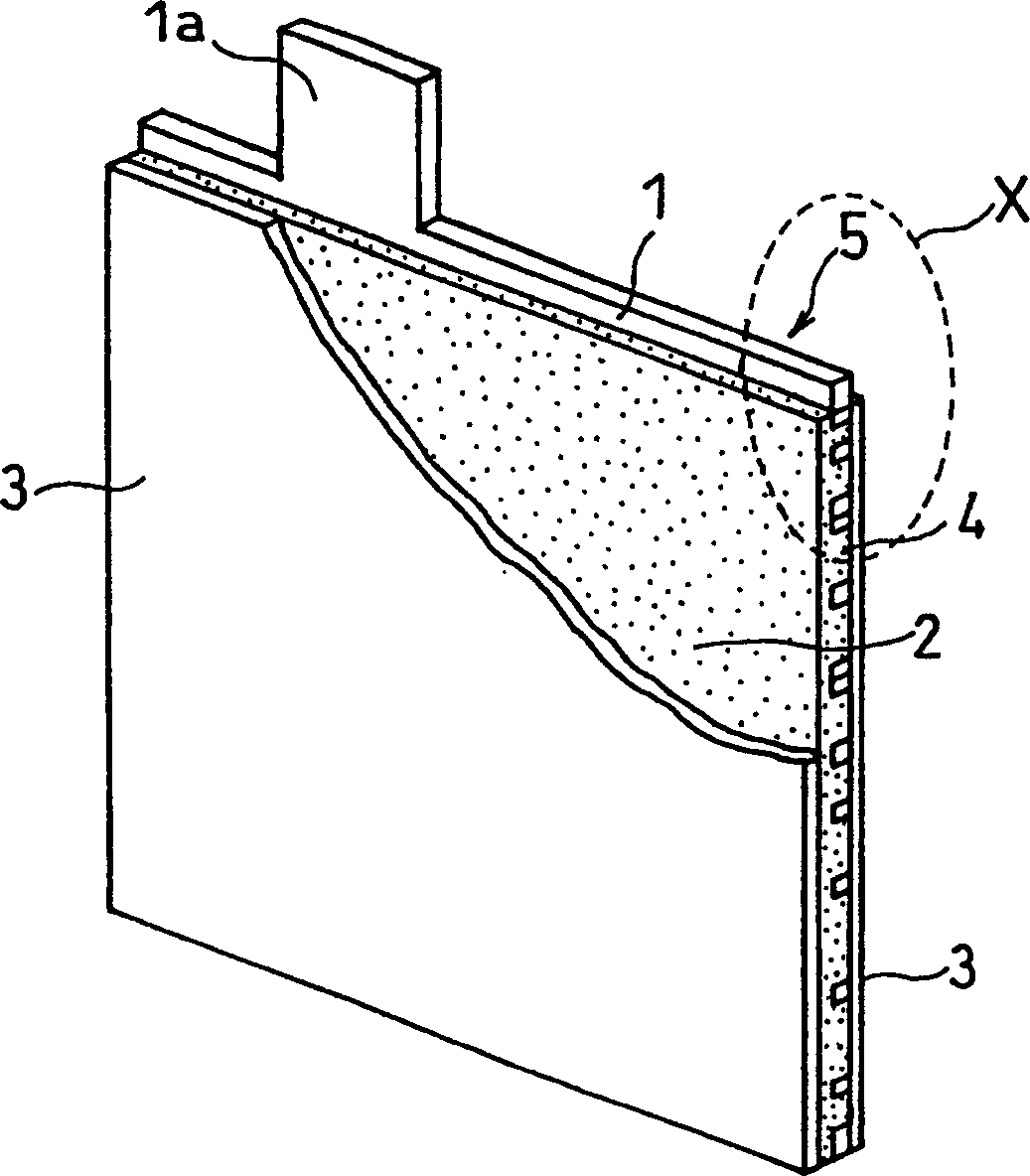

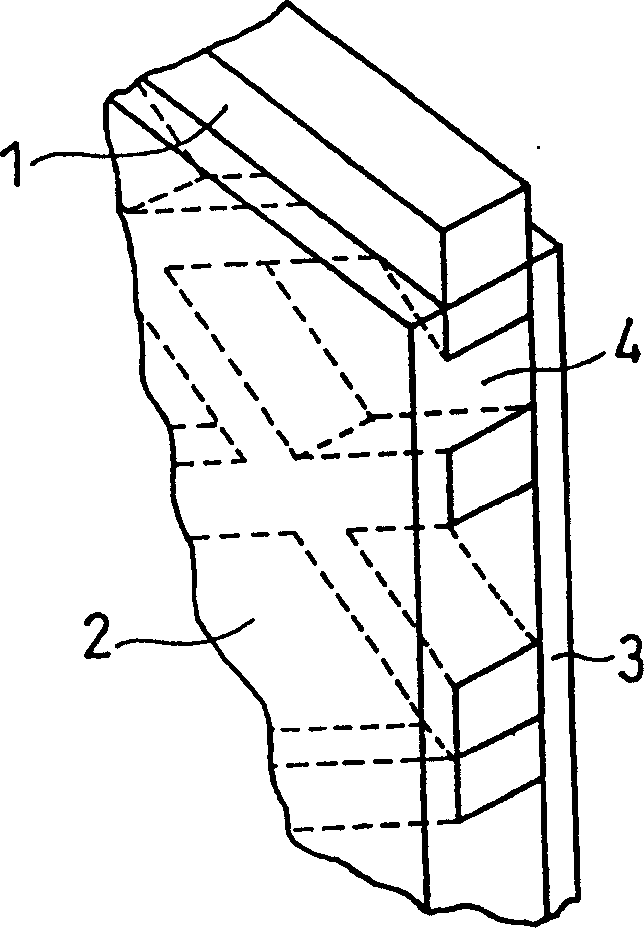

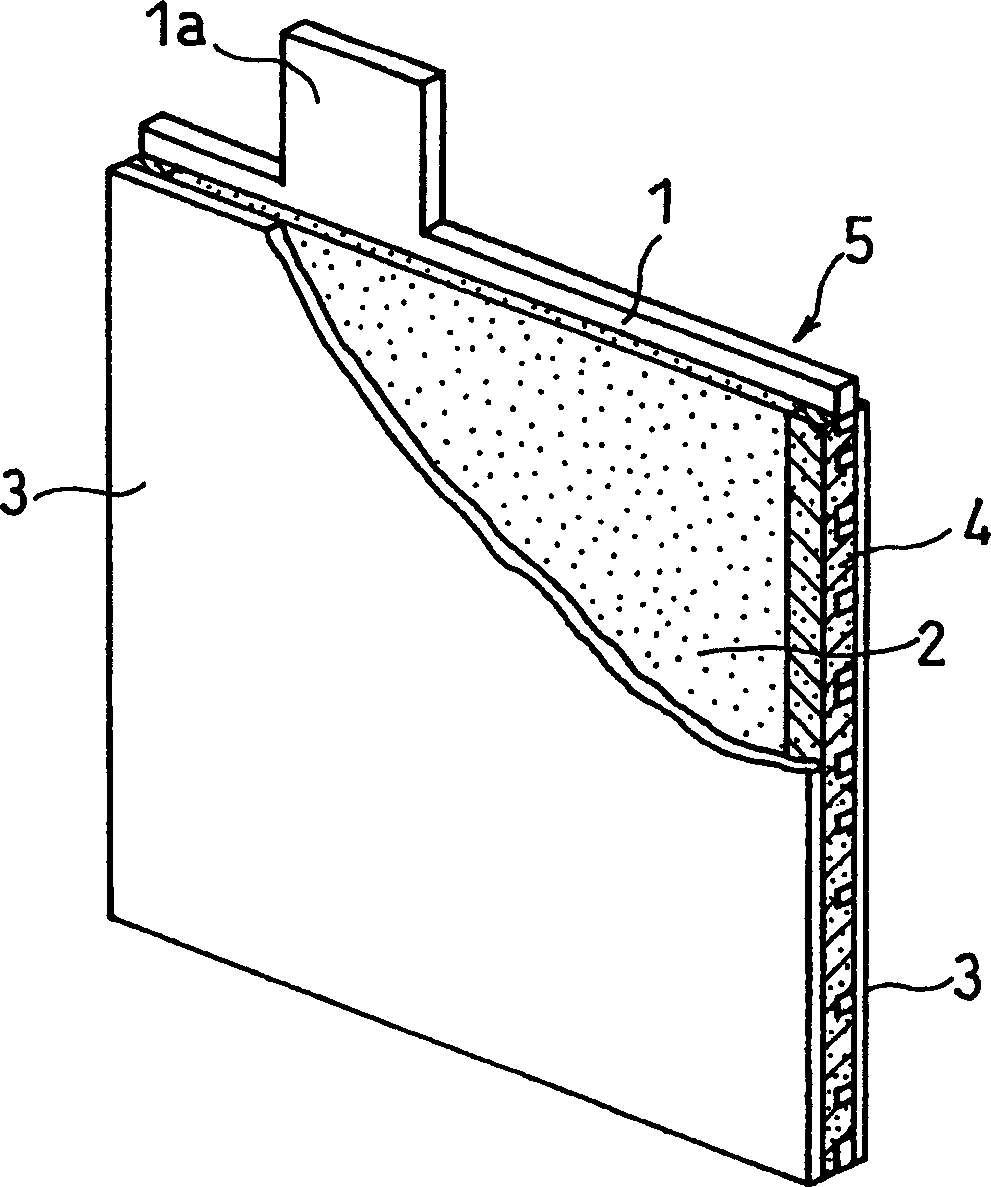

InactiveUS20070051896A1Quality improvementSolid-state devicesMaterial analysis by optical meansAbnormal growthsCrystal structure

There are provided a scintillator (130) comprising a structure in which a plurality of scintillator layers (131, 132, 135) having columnar crystal structures are stacked with, and a radiation detection device using the scintillator. There are also provided a scintillator (130) comprising a structure in which a plurality of scintillator layers (131, 132, 135) and light-transmitting intermediate layers (138, 139) disposed among the plurality of scintillator layers (131, 132, 135) are alternately stacked with, and a radiation detection device using the scintillator. Accordingly, it is possible to control the scintillator layer in such a manner as to reduce irregularities on the surface of the scintillator layer, and reduce an abnormal growth portion such as a splash existing inside the scintillator layer. Therefore, a radiation detection device can be obtained which has high reliability, high resolution, and small correction error of a digital image.

Owner:CANON KK

Combination therapy of hedgehog inhibitors, radiation and chemotherapeutic agents

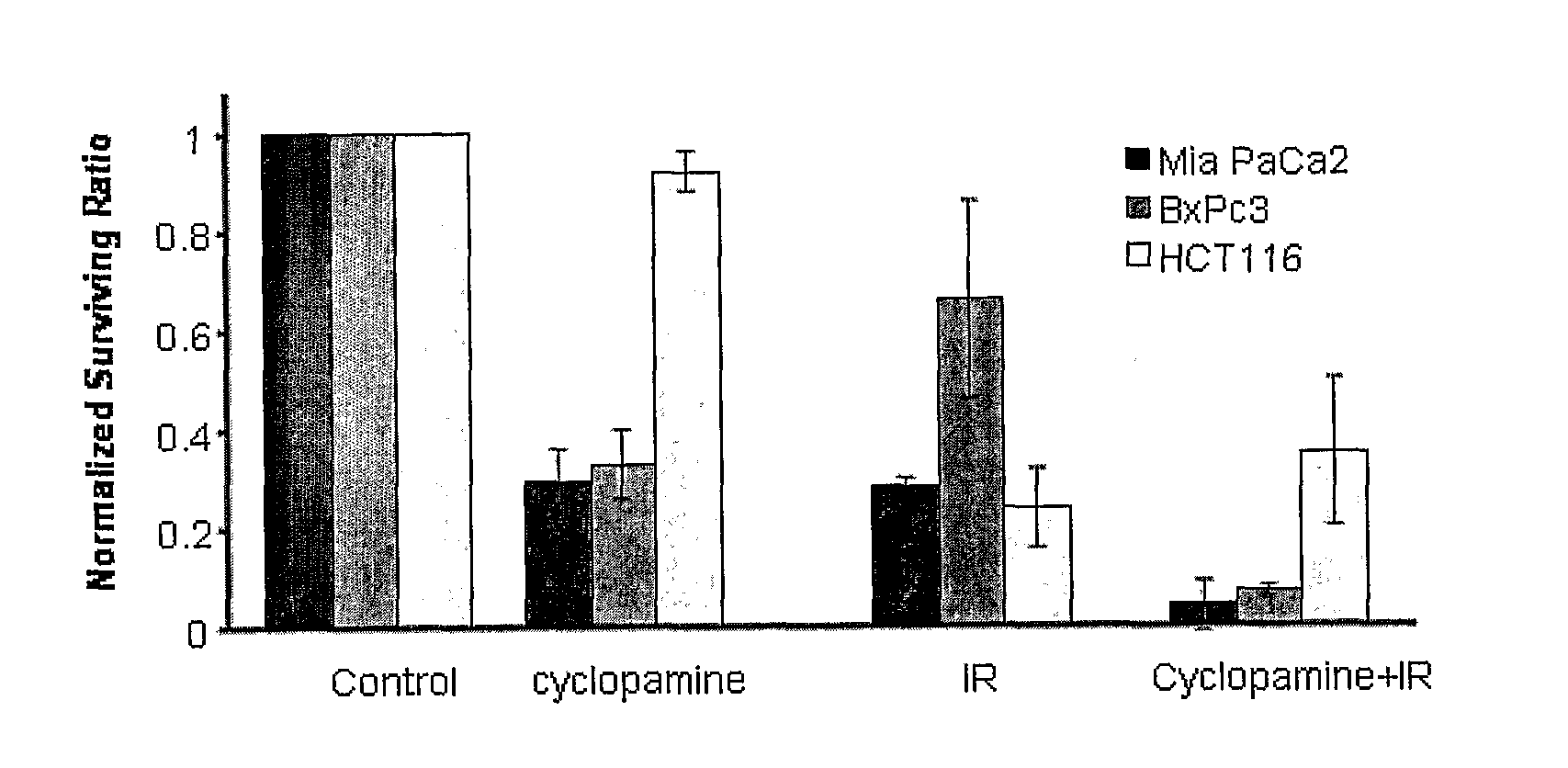

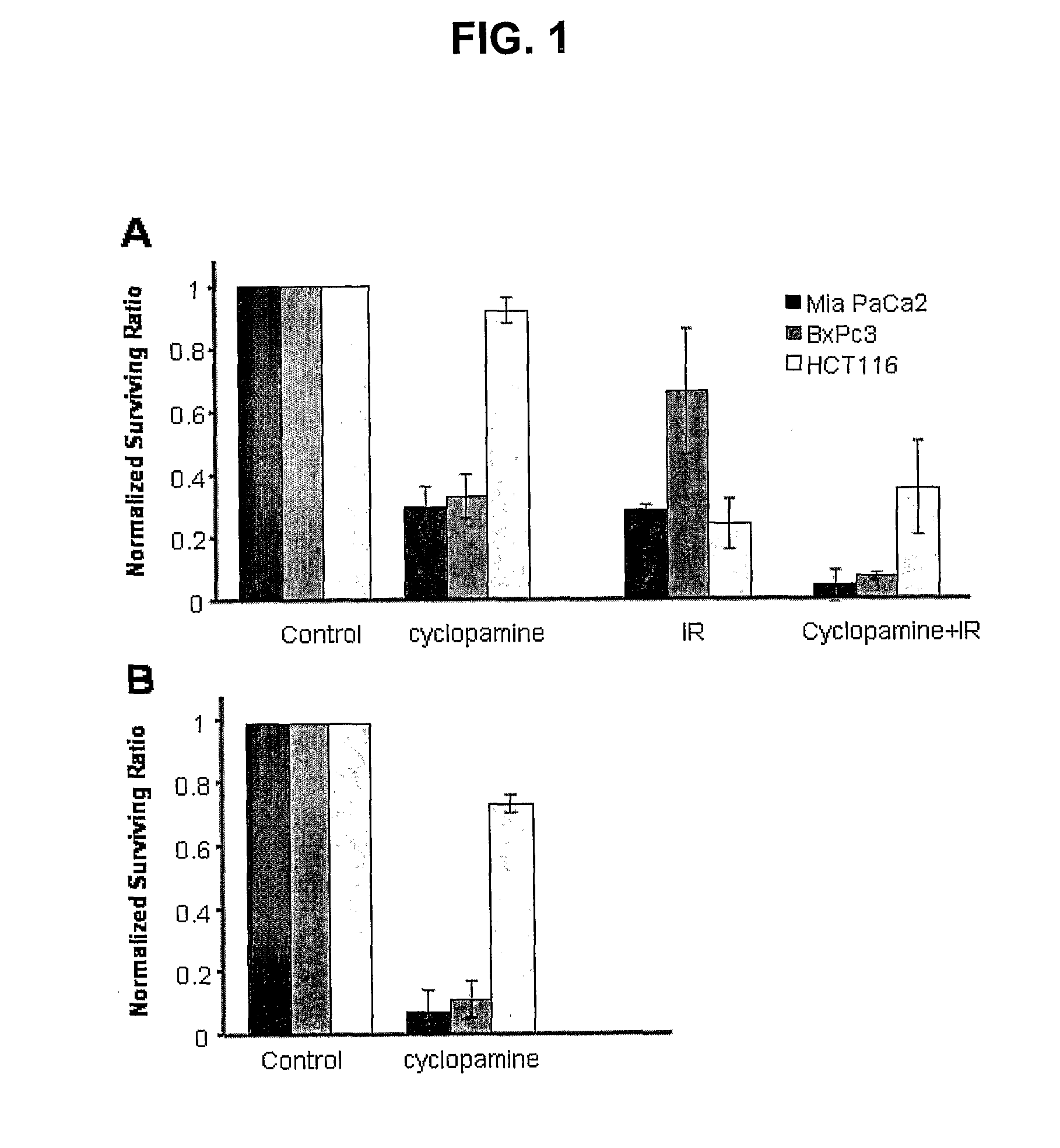

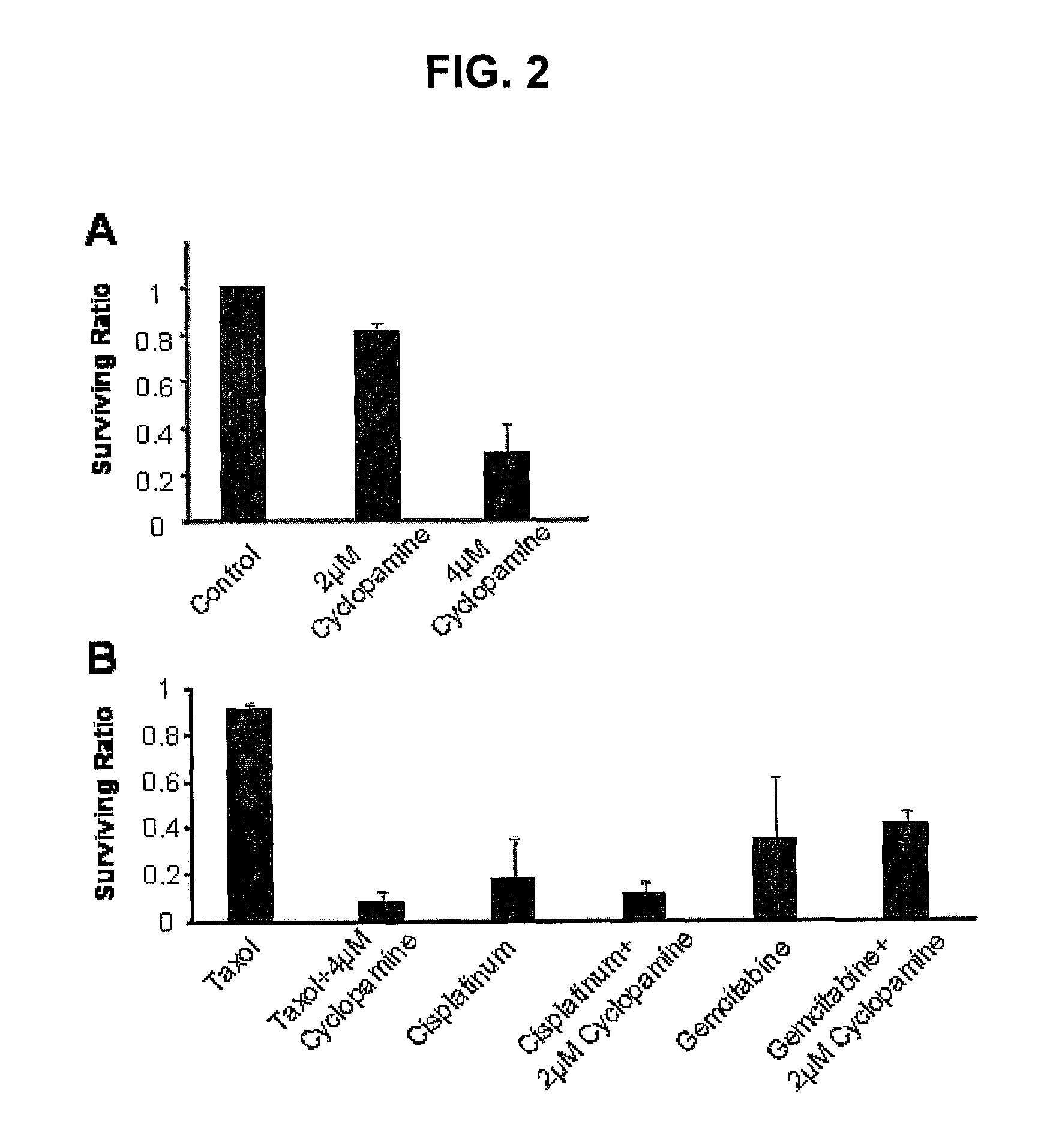

InactiveUS20070281040A1Increased apoptosisIncrease percentageHeavy metal active ingredientsBiocideAbnormal growthsCancer cell

The present invention relates to therapeutic combinations and methods of inhibiting the proliferation of cancerous cells, the abnormal growth of cells, and tumor cell growth using the combination of a hedgehog inhibitor with chemotherapy and / or radiation therapy. The present invention also relates to methods of enhancing the antiproliferative effect of chemotherapy and / or radiation therapy in a mammalian cancer patient undergoing either chemotherapy or radiation or a combination of radiation and chemotherapy by co-administering a therapeutically amount of a hedgehog inhibitor, concurrently or sequentially, with the chemotherapy and / or radiation therapy.

Owner:UNIVERSITY OF CHICAGO

Delivery of therapeutic biologicals from implantable tissue matrices

InactiveUS20020031500A1Many of effectMany of inconveniencePowder deliveryBiocideProgenitorActive agent

Normal cells, such as fibroblasts or other tissue or organ cell types, are genetically engineered to express biologically active, therapeutic agents, such as proteins that are normally produced in small amounts, for example, MIS, or other members of the TGF-beta family Herceptin(TM), interferons, andanti-angiogenic factors. These cells are seeded into a matrix for implantation into the patient to be treated. Cells may also be engineered to include a lethal gene, so that implanted cells can be destroyed once treatment is completed. Cells can be implanted in a variety of different matrices. In a preferred embodiment, these matrices are implantable and biodegradable over a period of time equal to or less than the expected period of treatment, when cells engraft to form a functional tissue producing the desired biologically active agent. Implantation may be ectopic or in some cases orthotopic. Representative cell types include tissue specific cells, progenitor cells, and stem cells. Matrices can be formed of synthetic or natural materials, by chemical coupling at the time of implantation, using standard techniques for formation of fibrous matrices from polymeric fibers, and using micromachining or microfabrication techniques. These devices and strategies are used as delivery systems via standard or minimally invasive implantation techniques for any number of parenterally deliverable recombinant proteins, particularly those that are difficult to produce in large amounts and / or active forms using conventional methods of purification, for the treatment of a variety of conditions that produce abnormal growth, including treatment of malignant and benign neoplasias, vascular malformations (hemangiomas), inflammatory conditions, keloid formation, abdominal or plural adhesions, endometriosis, congenital or endocrine abnormalities, and other conditions that can produce abnormal growth such as infection. Efficacy of treatment with the therapeutic biologicals is detected by determining specific criteria, for example, cessation of cell proliferation, regression of abnormal tissue, or cell death, or expression of genes or proteins reflecting the above.

Owner:THE GENERAL HOSPITAL CORP

Screening method

Owner:THEIALIFE SCI LTD

Tissue removal and closure device

Methods and devices described herein facilitate improved treatment of body organs and relates to surgical instruments, useful in endoscopic, laparoscopic and / or open surgical procedures to effectively remove a suspect region of tissue such as a polyp, abnormal growth, cyst, tumor, lesion, or other abnormality from a base tissue structure.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

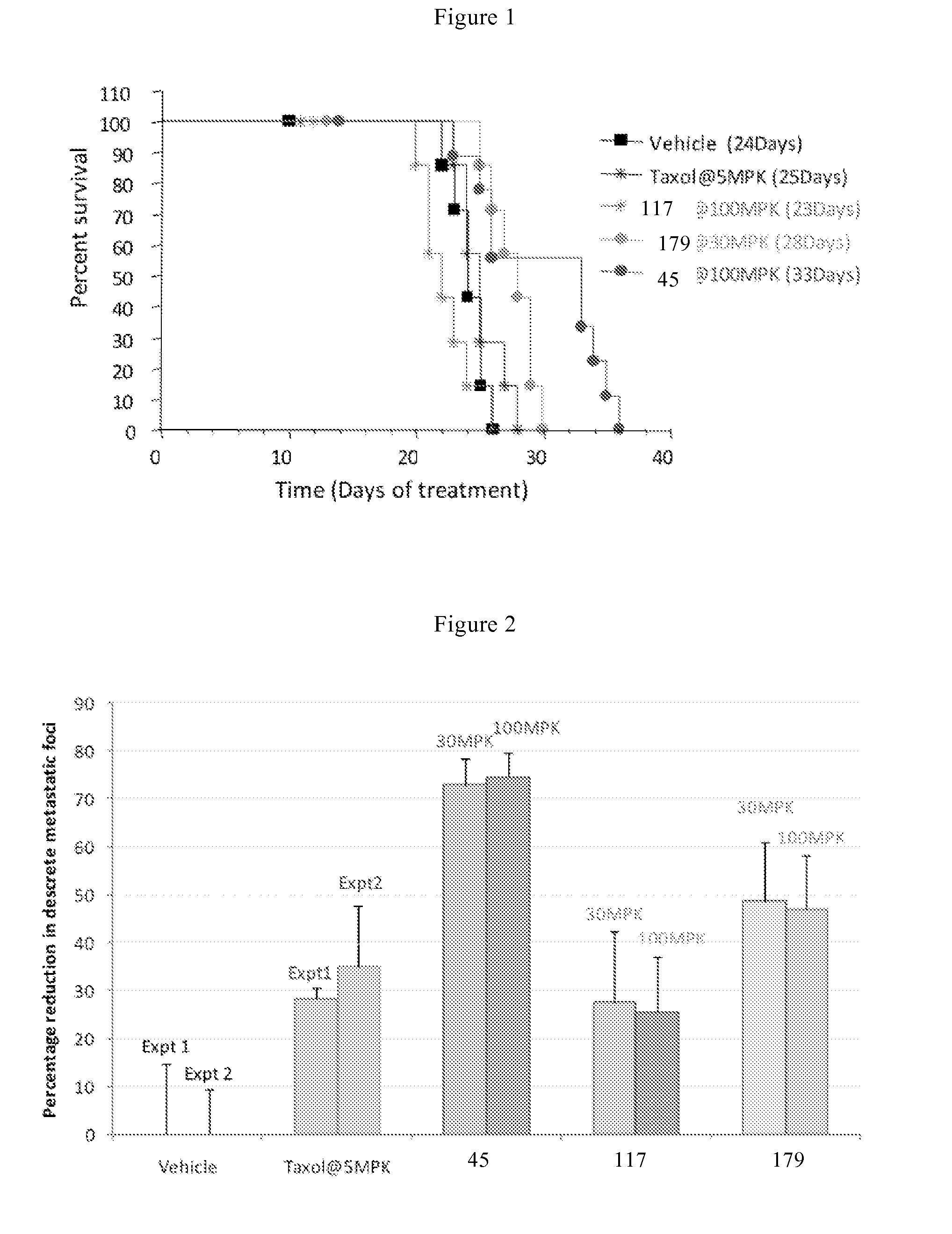

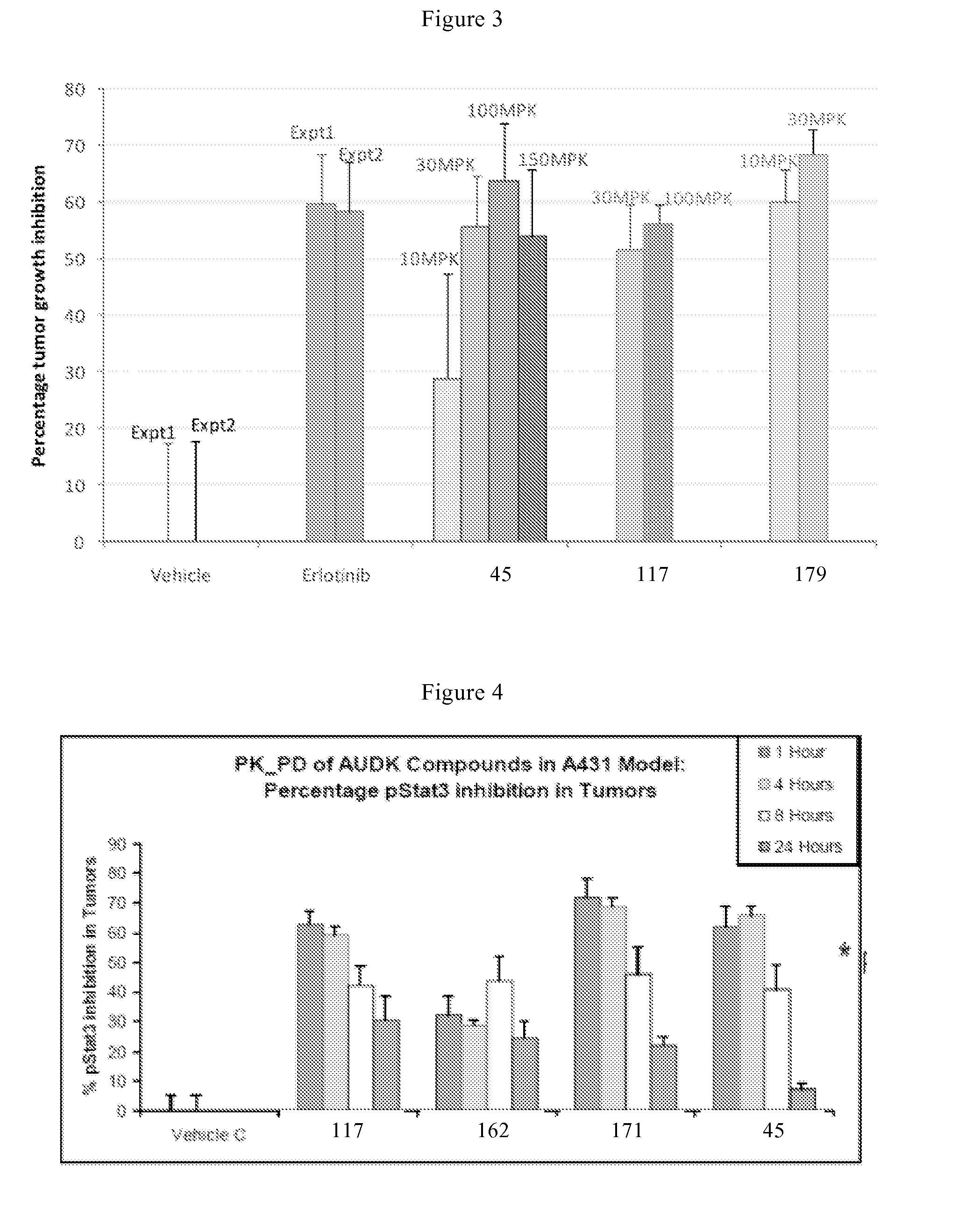

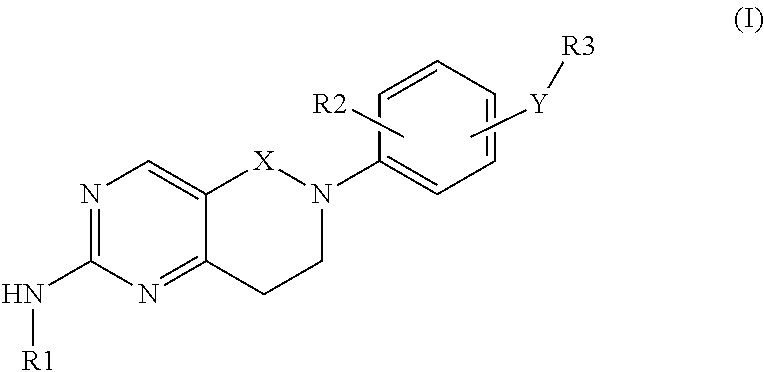

Bicyclic compounds and their uses as dual c-SRC / JAK inhibitors

Owner:AURIGENE DISCOVERY TECH +1

Radiation detection device, scintillator panel, method of making the same, making apparatus, and radiation image pick-up system

InactiveUS7315027B2Quality improvementSolid-state devicesMaterial analysis by optical meansAbnormal growthsImage resolution

There are provided a scintillator (130) comprising a structure in which a plurality of scintillator layers (131, 132, 135) having columnar crystal structures are stacked with, and a radiation detection device using the scintillator. There are also provided a scintillator (130) comprising a structure in which a plurality of scintillator layers (131, 132, 135) and light-transmitting intermediate layers (138, 139) disposed among the plurality of scintillator layers (131, 132, 135) are alternately stacked with, and a radiation detection device using the scintillator. Accordingly, it is possible to control the scintillator layer in such a manner as to reduce irregularities on the surface of the scintillator layer, and reduce an abnormal growth portion such as a splash existing inside the scintillator layer. Therefore, a radiation detection device can be obtained which has high reliability, high resolution, and small correction error of a digital image.

Owner:CANON KK

Medical heating device and method with self-limiting electrical heating element

ActiveUS20110166563A1Avoid heatSuture equipmentsStapling toolsSelf limitingElectrical resistance and conductance

A medical heating device is based on an electrical heater formed out of a self-limiting conductive material, such as a conductive polymer or ceramic. An electrical resistance that gradually changes with temperature characterizes the material such that heat production from electrical current through the material varies with temperature. A thermally insulating jacket contains the self-limiting heater element, which can be coupled to an electrical power supply. A probe thermally coupled to the heater extends outward from the jacket. The self-limiting medical heating device can be used by touching the end of the probe to target tissue, such as skin, adipose tissue, nerves, glands, vascular tissue, or abnormal growths or tumors to effect the desired treatment, typically by thermally ablating, cutting, or shrinking the target tissue where touched by the probe or in the vicinity therein.

Owner:CURO MEDICAL

Lead storage battery

InactiveUS20040115530A1Avoid separationImprove acid resistanceFinal product manufactureElectrode carriers/collectorsAbnormal growthsEngineering

The present invention relates to a lead-acid battery Comprising a positive and a negative electrode, each having a current collector comprising an expanded grid, characterized in that at least one of the positive electrode and the negative electrode contains an organic binder in an active material layer at an edge portion thereof. This makes it possible to suppress an internal short circuit resulting from the separation or abnormal growth of an active material due to repeated charge / discharge, thereby remarkably prolonging the cycle life of a lead-acid battery.

Owner:PANASONIC CORP

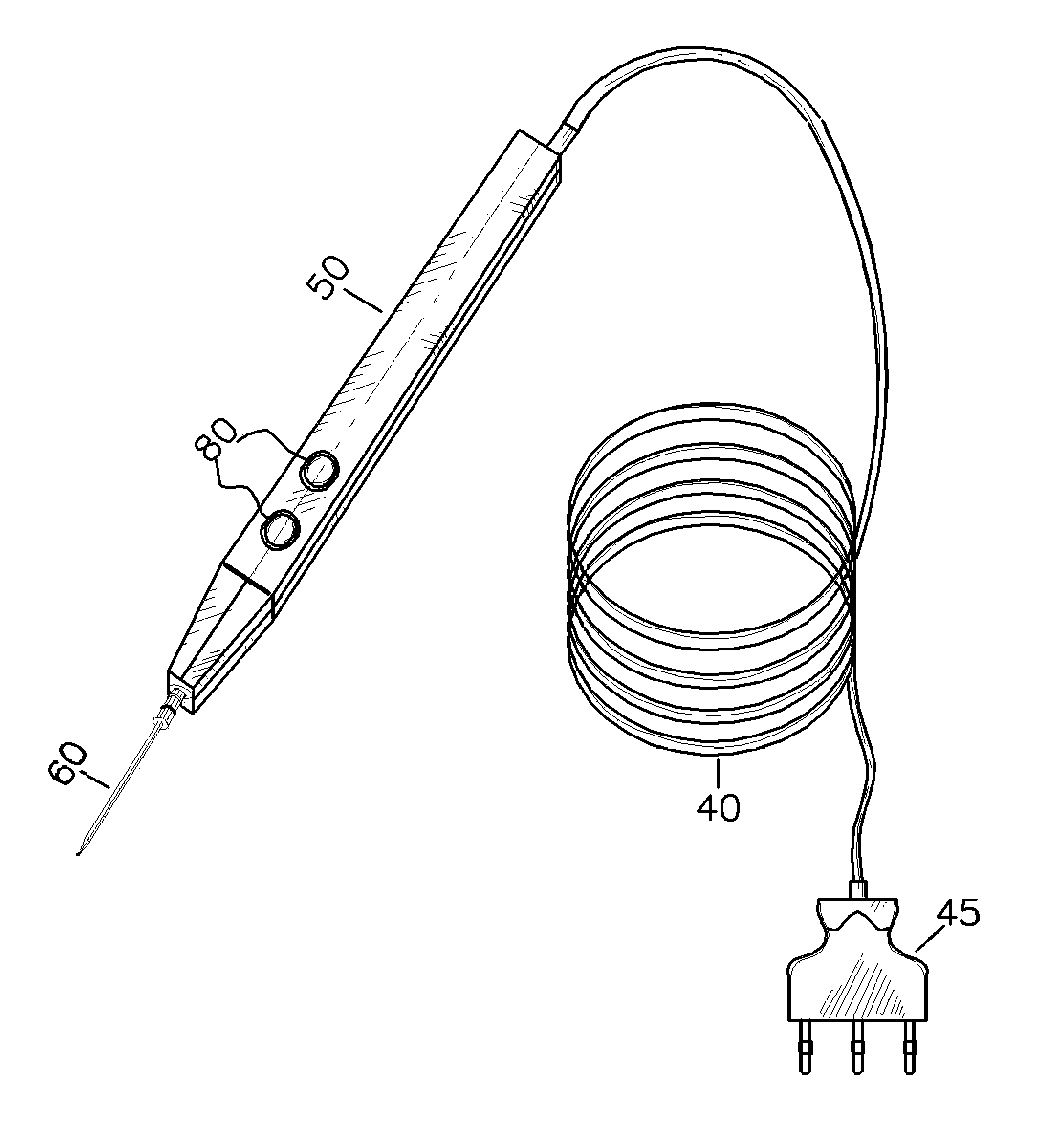

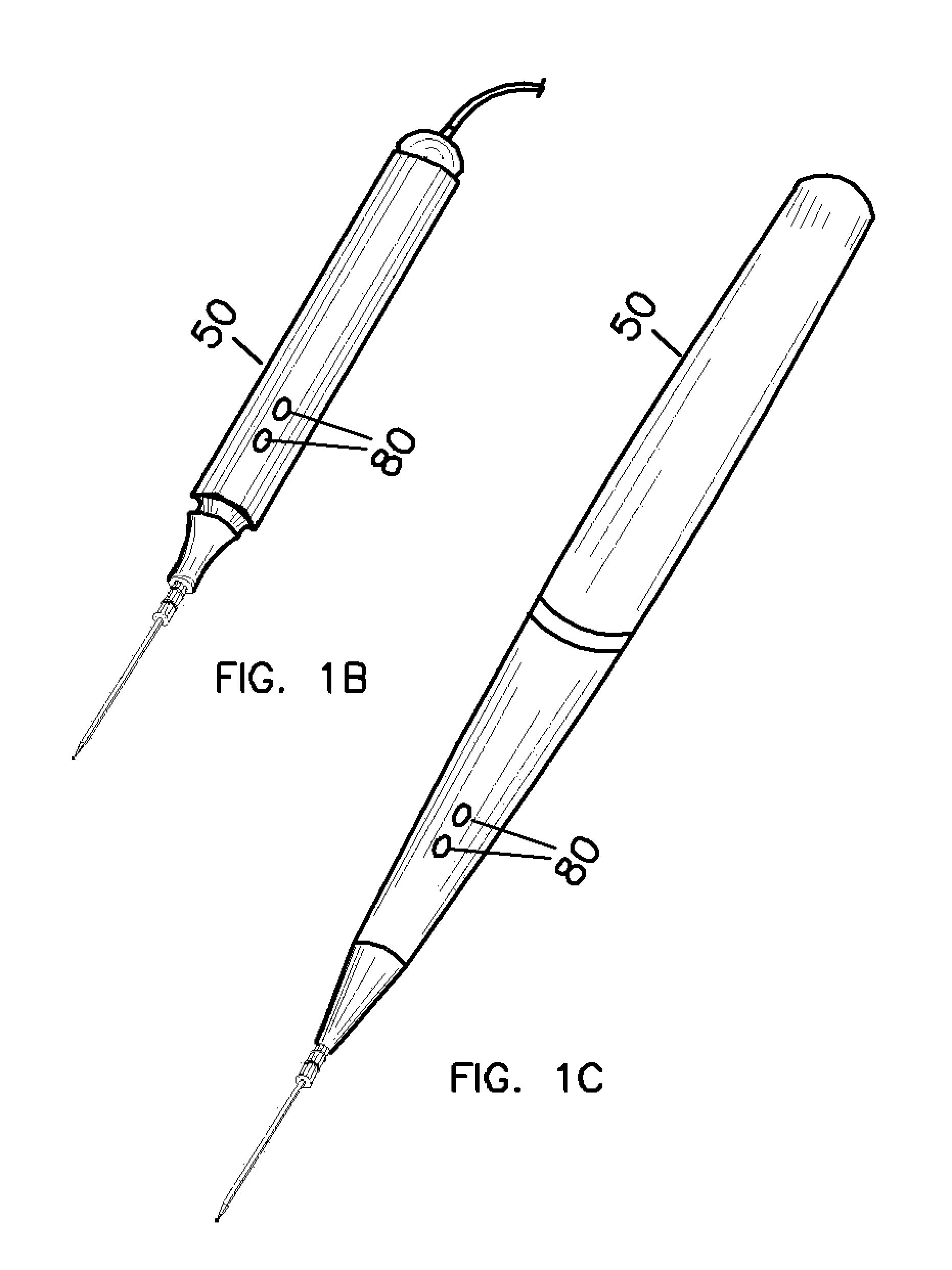

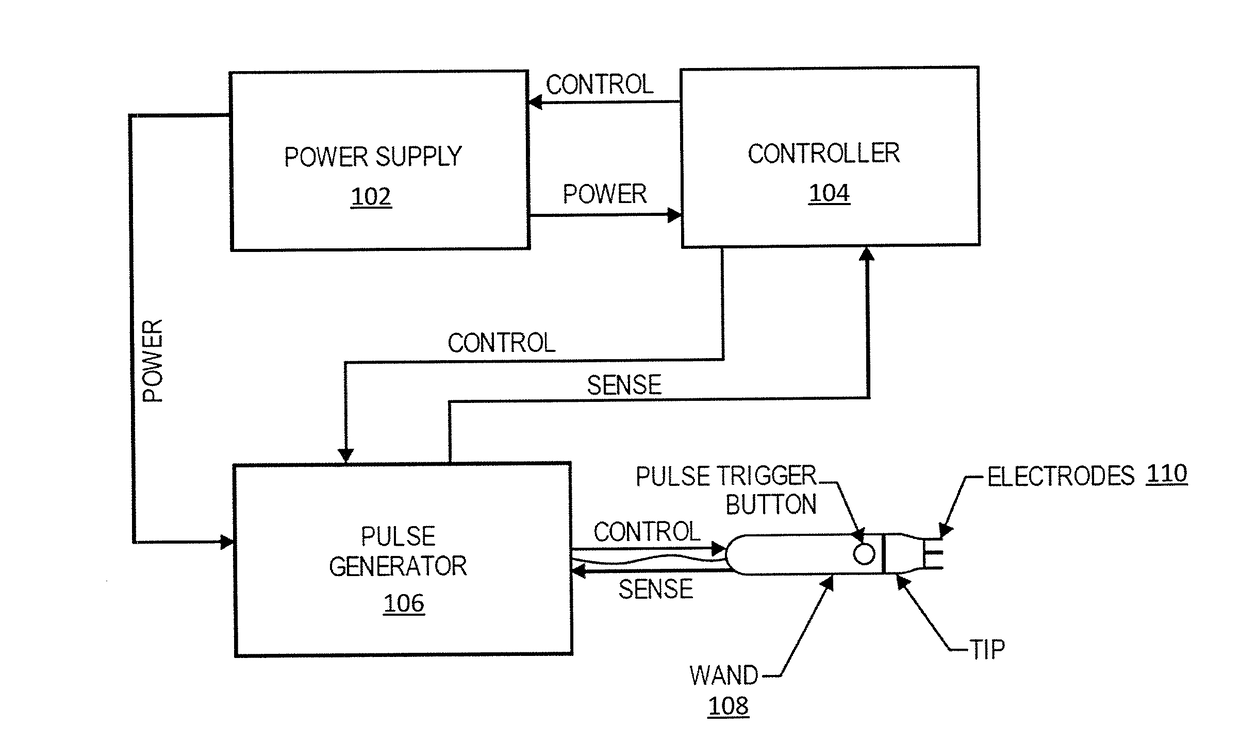

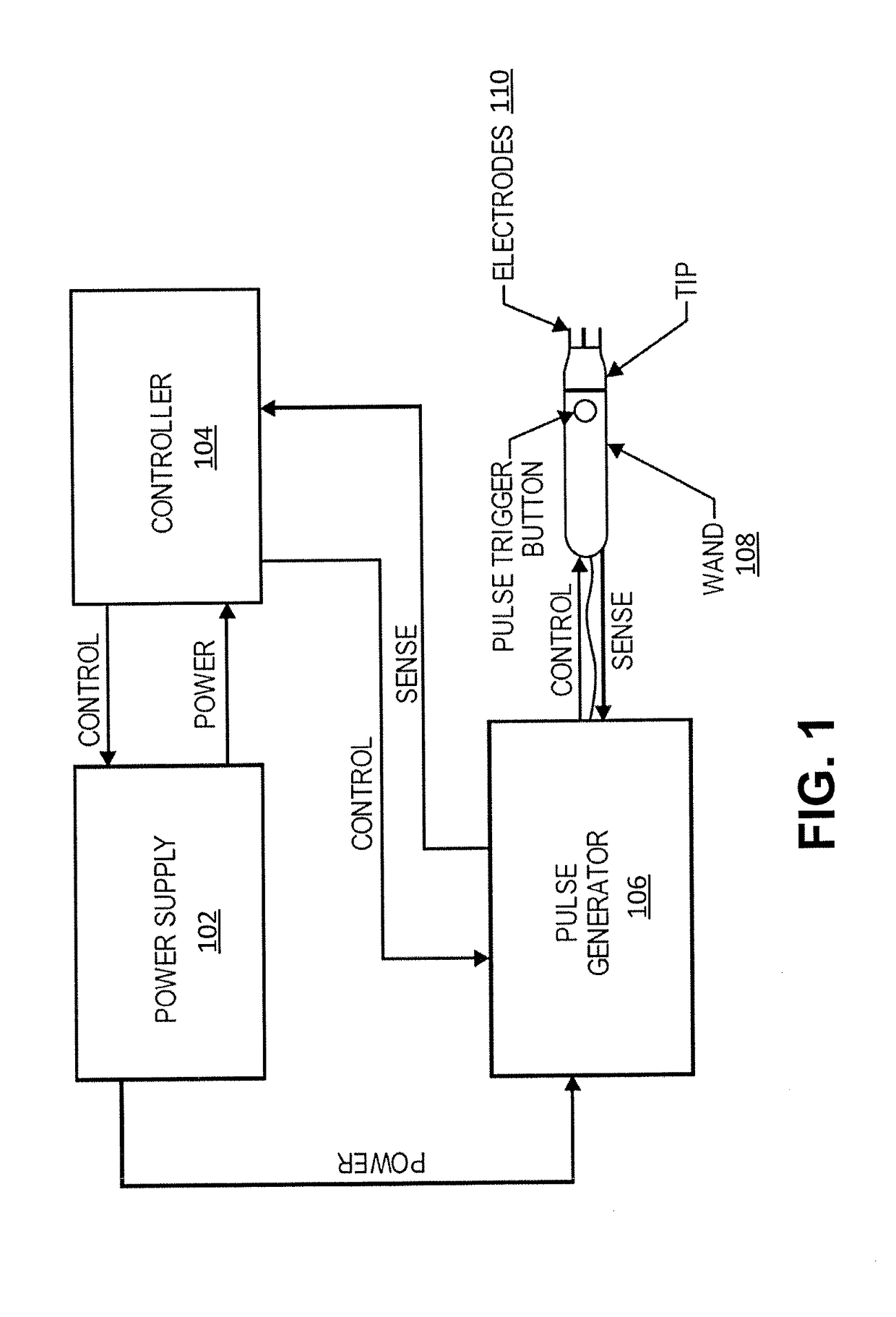

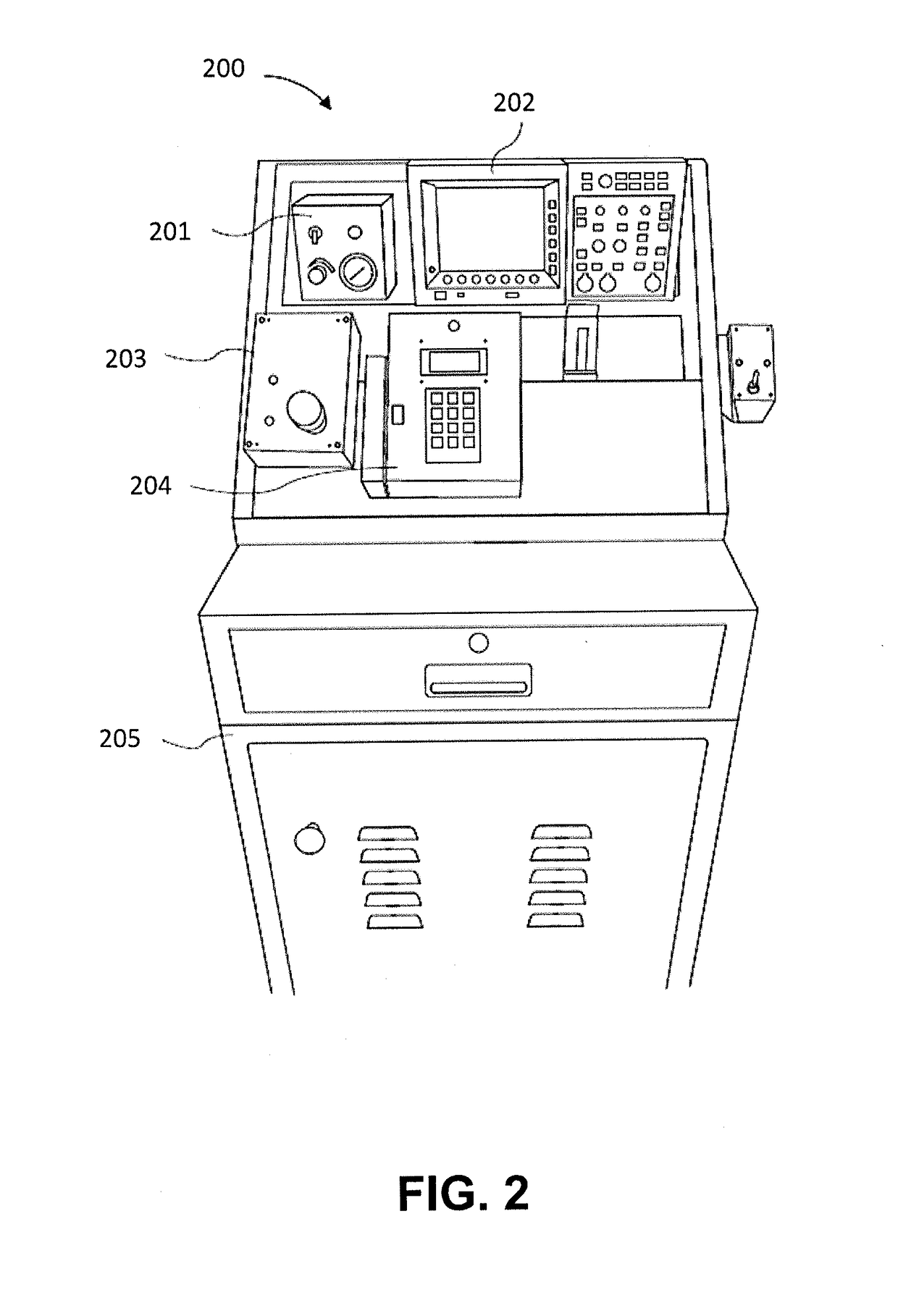

Methods and devices for treatment of tumors with nano-pulse stimulation

InactiveUS20180154142A1ProductionInhibit productionSurgical needlesControlling energy of instrumentDiseaseRegulatory T cell

Disclosed herein are methods and devices for stimulating an immune response to a disease in a subject, which involves passing sub-microsecond long pulses of electric fields having an amplitude between 5 kV / cm and 68 kV / cm through an abnormal growth of a subject sufficient to suppress myeloid-derived suppressor cell (MDSC) or regulatory T cell (Treg) production, increase adenosine triphosphate (ATP) or high mobility group box 1 (HMGB1) production, or stimulate dendritic cell activation in the subject.

Owner:OLD DOMINION UNIVERSITY RESEARCH FOUNDATION

Method of manufacturing a semiconductor device

InactiveUS7166500B2Improve performanceExcellent electrical propertiesTransistorSemiconductor/solid-state device manufacturingAbnormal growthsEngineering

In a method of manufacturing a semiconductor device, after a lateral growth region 107 is formed by using a catalytic element for facilitating crystallization of silicon, the catalytic element is gettered into a phosphorus added region 108 by a heat treatment. Thereafter, a gate insulating film 113 is formed to cover active layers 110 to 112 formed, and in this state, a thermal oxidation step is carried out. By this, the characteristics of an interface between the active layers and the gate insulating film can be improved while abnormal growth of a metal oxide is prevented.

Owner:SEMICON ENERGY LAB CO LTD

Preparation method of nanometer ceramic bonder type superhard material grinding wheel

InactiveCN104802104AEvenly distributedSmall shrinkageGrinding devicesStress concentrationSuperhard material

The invention relates to a one-step preparation method of a nanometer ceramic bond type superhard material grinding wheel. The preparation method comprises the following steps of using water-soluble nitrate or chlorate, a superhard material abrasive and a perforating agent corresponding to a to-be-prepared ceramic powder as raw materials; dissolving the raw materials, monomers or a crosslinking agent into water, and adding an initiating agent and a catalyst so as to polymerize a nanometer three-dimensional space network and form a gel under the condition of constant temperature of 20 to 80 DEG C; in the gel drying process, precipitating the water-soluble nitrate or chlorate, and forming nanometer grains by the limiting of the three-dimensional space network; uniformly distributing the superhard material abrasive into a base body of the ceramic bond, and adding one or multiple organic matters with better water solubility and lower melting point, so as to obviously reduce the shrinkage of the gel in the low-temperature drying process, early melt or decompose in the dry gel sintering process, and gradually release the stress concentration. By adopting the quick sintering technique, the preparation method has the advantages that the problem of abnormal growth of the nanometer ceramic bond in the subsequent sintering process is solved, and the nanometer ceramic bond type superhard material grinding wheel with good property can be prepared.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for preparing high-performance sintered Nd-Fe-B magnet by using two-step grain boundary diffusion technique

InactiveCN107256795AIncrease profitAvoid abnormal growthSolid state diffusion coatingInductances/transformers/magnets manufactureRare earthAlloy

The invention discloses a method for preparing a high-performance sintered Nd-Fe-B magnet by using the two-step grain boundary diffusion technique, and belongs to the field of rare earth permanent magnetic materials. The method includes: laying a low-melting-point alloy diffusion source R1-R2-TM thin band on a surface of a clean commercial sintered Nd-Fe-B magnet, wherein the R1 is randomly selected from La, Ce, Pr, and Nd, the R2 is selected from at least one of Dy and Tb, and the TM is selected from at least one of Cu, Al, Ti, Zn, Co, Ni, and Fe; performing heat treatment at the temperature of 650-800 DEG C for 6-24 hours, and allowing Tb / Dy to diffuse toward the inner part of the magnet along a grain boundary; performing heat treatment at the temperature of 850-950 DEG C for 1-4 hours, allowing the Tb / Dy enriched in a grain boundary phase to diffuse toward a surface layer of grains, and forming a Tb / Dy-rich shell structure; performing annealing at the temperature of 450-550 DEG C for 1.5-2.5 hours, and further adjusting a boundary structure; and finally acquiring the high-performance sintered Nd-Fe-B magnet. The advantages of the method are that the Tb / Dy is fully used to reinforce a grain surface transition layer so as to improve the coercivity; the time of the high temperature heat treatment is shortened, and energy can be saved; abnormal growth of grains can be avoided; and the method is suitable for thick magnets.

Owner:UNIV OF SCI & TECH BEIJING

Method for extracting astaxanthin from haematococcus pluvialis

ActiveCN103787941AReduce the possibility of oxidative degradationImprove extraction qualityOrganic chemistryAbnormal growthsFrond

The invention provides a method for extracting astaxanthin from haematococcus pluvialis, and belongs to the technical fields of bioprocess technology and chemical technology. The method comprises the following steps: completing the selection of raw materials through abnormal growth of cells of the selected haematococcus pluvialis, dilution of high-density algae cells and light induction, carrying out wall-breaking treatment on frond by using an ultrahigh pressure extractive technology, then extracting, eluting, concentrating, saponifying and centrifuging, thus obtaining the astaxanthin. The method has the advantages that the consumption of an organic solvent is little, an extraction agent can be circularly utilized, the environmental pollution is little, the production cost is low, the recovery rate is high, few impurities exist, the possibility of oxidative degradation of the astaxanthin is reduced, and the extraction quality of the astaxanthin is improved.

Owner:QINGDAO KEHAI BIOLOGICAL

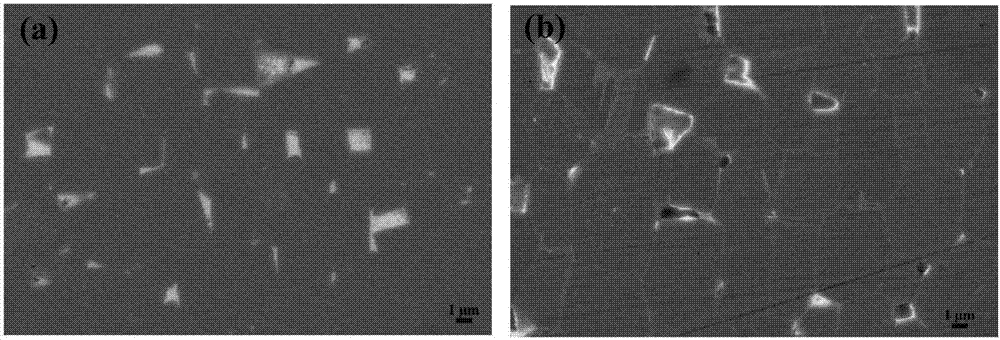

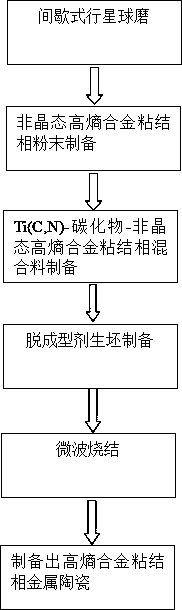

Preparation method for Ti(C,N)-based cermet with high-entropy alloy bonder phase

ActiveCN109022990AGood for maintaining relative contentKeep the relative contentWear resistantHigh entropy alloys

The invention discloses a preparation method for a Ti(C,N)-based cermet with a high-entropy alloy binder phase. The preparation method is characterized in that firstly, an amorphous high-entropy alloybinder phase powder with Co:Ni:Fe:Cu:Mn = 1:1:1:1:(0.3-1) is prepared by using an intermittent planetary ball mill; then, the amorphous high-entropy alloy binder phase powder is mixed with a hard phase powder by using a drum-type ball mill, and the prepared mixture is still in an amorphous state; lastly, microwave sintering at 1400-1450 DEG C is performed to allow the amorphous high-entropy alloybonder phase in the cermet to be crystallized, a transition process from the amorphous state to the crystalline state and the hysteretic element diffusion effect of the high-entropy alloy restrain the dissolution of the hard phase into the binder phase, and the binder phase of the cermet is the single-phase high-entropy alloy with a face-centered cubic structure; and thus, the cermet with the high-entropy alloy bonder phase is prepared. The preparation method overcomes the problem that during the existing preparation process of a cermet with a high-entropy alloy binder phase, a Ti(C,N) hard phase dissolves in a bonder phase, so that the relative content decreases and the grains of the hard phase are prone to abnormal growth, and finally insufficient mechanical properties of a hard alloy are caused. The preparation method can be used in cutting tools, wear-resistant parts and other fields.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

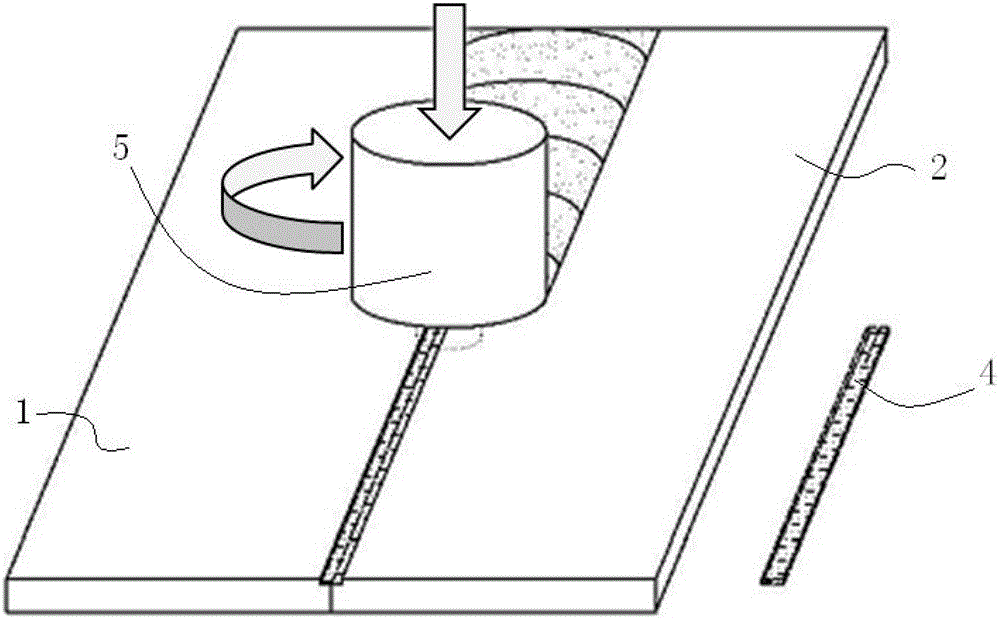

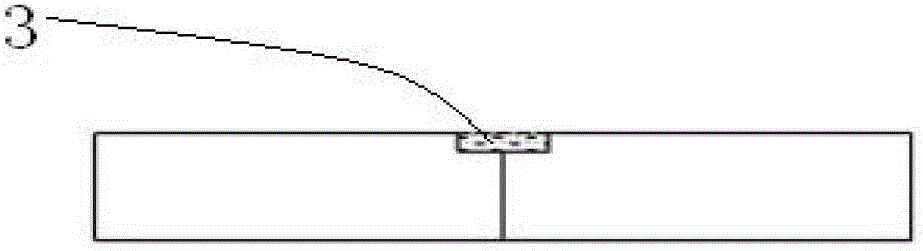

Friction stir welding method

InactiveCN102717181AImprove mechanical propertiesImprove stabilityNon-electric welding apparatusAluminideFriction stir welding

The invention discloses a friction stir welding method. The method is used for welding a joint by realizing dispersive distribution of in-situ authigenic metal aluminide nanoparticles with high volume fraction and residual elementary metal powder welding flux particles in a nugget area via friction stir welding by the aid of in-situ reaction. In the structure of the aluminum plate welded joint prepared by the friction stir welding method, the in-situ authigenic metal aluminide nanoparticles with the high volume fraction and the residual elementary metal powder welding flux particles are distributed in the nugget area in a dispersive manner and are used as small-size reinforced phases, the comprehensive mechanical performance of the welded joint is improved, a crystal boundary also can be pinned, abnormal growth of crystal particles in the nugget area is suppressed, and accordingly the stability of a fine-crystal structure of the nugget area is improved.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of WC-Co hard alloy with in-situ addition of rare earth oxide crystal grain refiner

ActiveCN104831098AAchieve molecular level distributionThe process is simple and easy to controlRare earthAlloy

The invention discloses a preparation method of WC-Co hard alloy with in-situ addition of a rare earth oxide crystal grain refiner. The method includes following steps: (1) according to proportion, dissolving a soluble salt compound containing cobalt and rare earth in water and preparing cobalt oxide sol-gel doped with the rare earth oxide through a sol-gel method; (2) adding the sol or the gel to original powder with WC as a main component with fully mixing to obtain a mixture; (3) drying the mixture; (4) reducing the mixture with hydrogen; (5) adding wax to the reduced mixture; (6) performing compression moulding forming; and (7) sintering a product. In the invention, a problem of abnormal growth of crystal grain due to non-uniform addition of the rare earth oxides in the prior art, especially, a problem of the growth of crystal grain of cobalt, can be avoided, thereby achieving molecular-grade dispersed distribution of the rare earth oxides in the crystal grain of cobalt and meanwhile achieving inhibition on growth of the crystal grain of WC. Compared with a convention method, the preparation method is high in product purity, is controllable in chemical components and can enable the rare earth oxides to disperse uniformly. The hard alloy is fine in crystal grain and is increased in hardness by 1 HRA, in bending strength by more than 10% and in impact toughness by 30%.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method of integral special-shaped heavy forging made of austenitic stainless steel

ActiveCN103350173AImprove surface qualityImprove hot workabilitySS - Stainless steelArgon oxygen decarburization

The invention discloses a production method of an integral special-shaped heavy forging made of austenitic stainless steel, and belongs to the technical field of stainless steel machining. The process comprises the following steps of smelting which combines an electric furnace, AOD (argon oxygen decarburization) and electroslag remelting, hammer cogging, upsetting, stretching, remelting heating and forging, heat treatment, machining, cold bending or hot bending machining, heat treatment and the like. Electroslag ingot surface quality is improved through surface grinding, and an electroslag ingot casting-state structure is broken through hammer cogging, so that the hot-working character of billet steel is improved, the electroslag ingot is restrained from hammer cogging, and conditions are provided for following large-deformation upsetting and stretching. The steel ingot crystal grain size is refined through repeated large-deformation upsetting and stretching processes, recrystallized grains are restrained from abnormal growth through controlling of last flame path remelting heating temperature, forging deformation and final heat treatment process, coarse crystals and mixed crystals are avoided, the forging structure is refined, and the crystal grain size reaches a 4.0 grade or high.

Owner:CENT IRON & STEEL RES INST

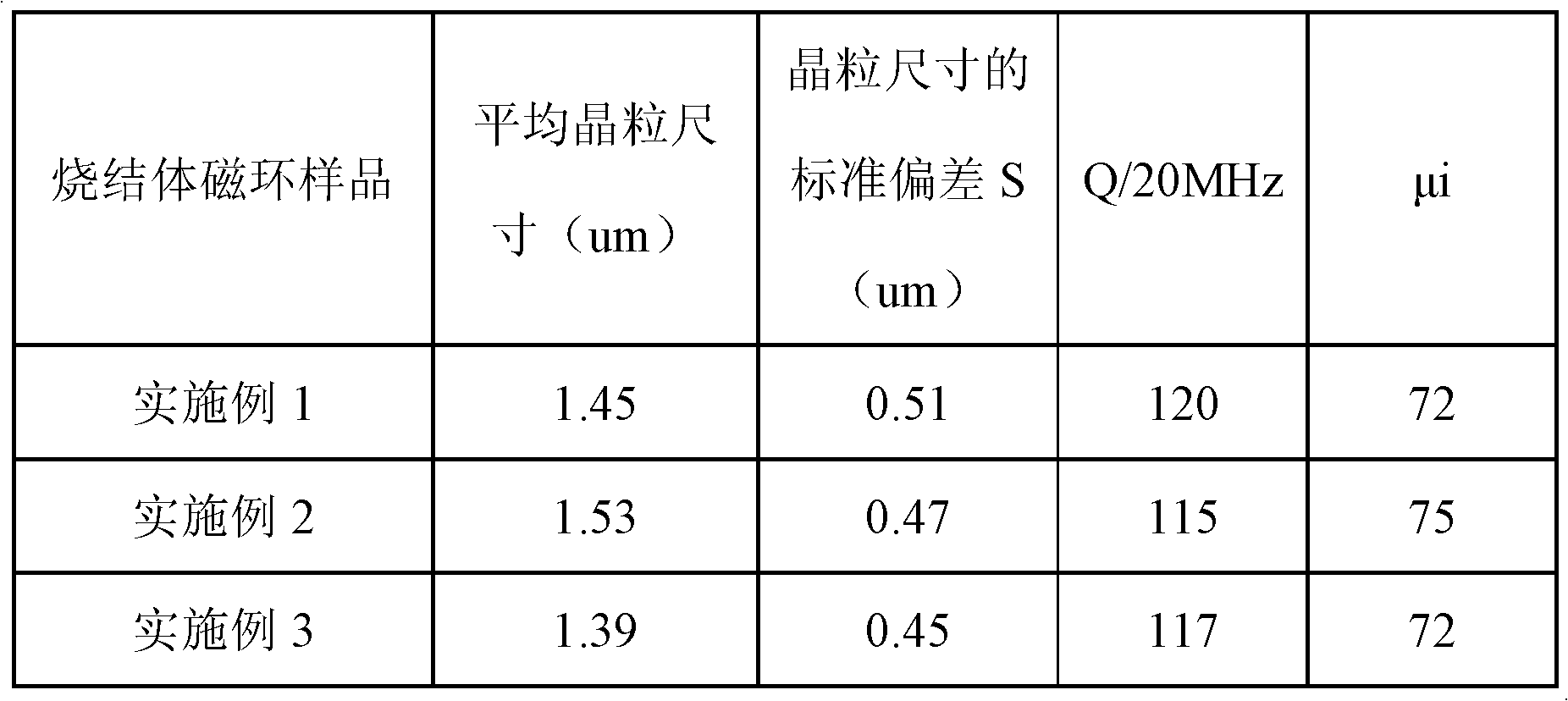

NiCuZu ferrite material and preparation method thereof

The invention discloses a NiCuZu ferrite material and a preparation method thereof. The technical problem to be solved is how to improve the Q value and initial permeability of the NiCuZu ferrite material under 20MHz and ensure that the abnormal growth of crystalline grains cannot easily take place. The invention adopts the following technical scheme: according to mole percentage, the main components of the NiCuZu ferrite material include 47.5 to 49.5 mol percent of Fe2O3, 14.5 to 20.5 mol percent of ZnO, 7.3 to 9.3 mol percent of of CuO and the balance of NiO, and the NiCuZu ferrite material is also added with sintering aid Bi2O3 accounting for 0.2 to 0.6 percent by weight of the weight of the main components and additive Co2O3 accounting for 0.1 to 0.5 percent by weight of the weight of the main components. The invention also provides the preparation method for the NiCuZu ferrite material. The abnormal growth of crystalline grains cannot easily take place, the initial permeability Mu i is between 70 and 100, and the Q value under 20MHz reaches 100 or more.

Owner:SHENZHEN SUNLORD ELECTRONICS

Manufacturing method of semiconductor integrated device

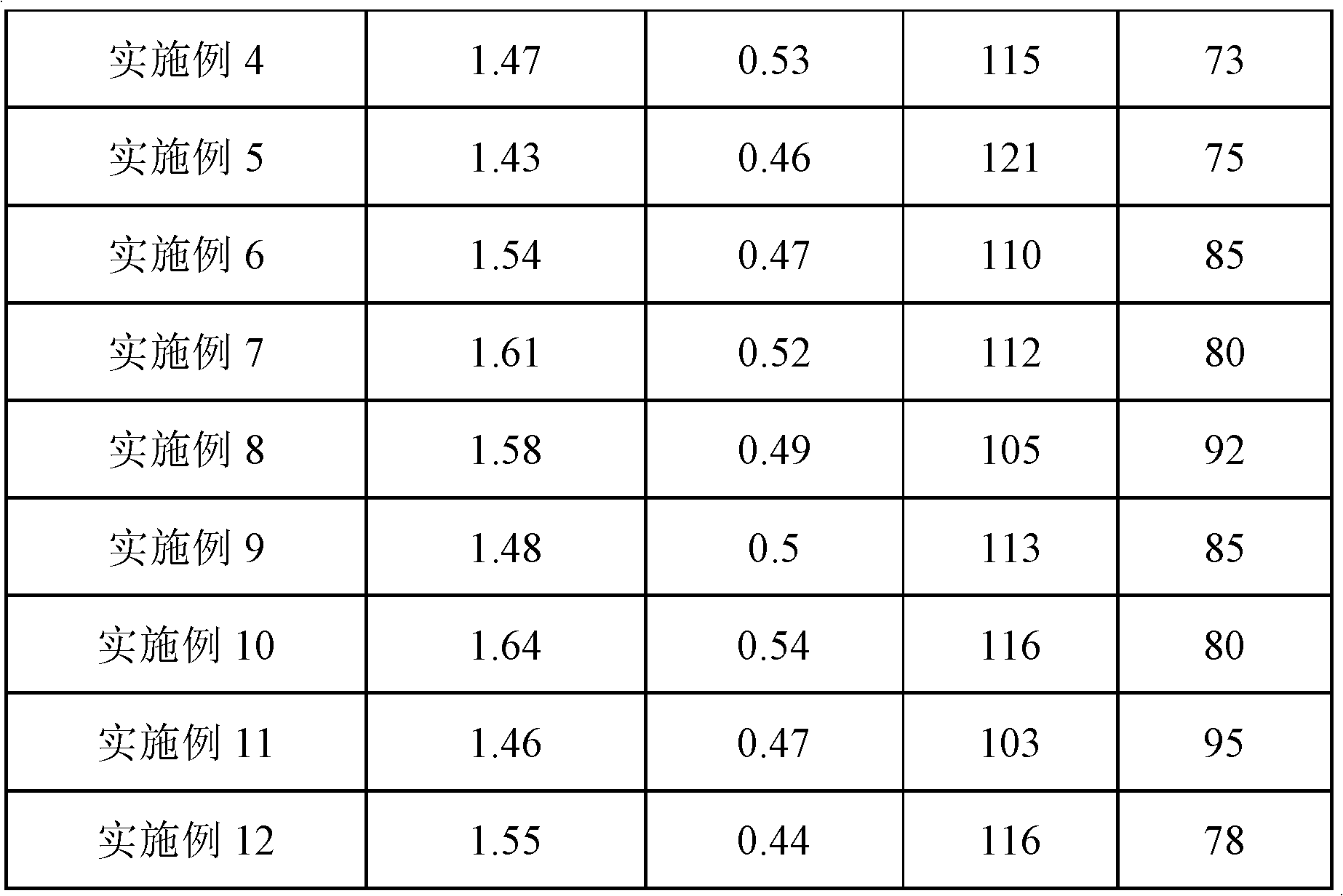

InactiveUS20090117730A1Avoid abnormal growthHighly uniform thicknessCellsAnodisationAbnormal growthsEngineering

Manufacture of semiconductor products such as LCD driver requires a bump plating step for forming a gold bump electrode having a size of from about 15 to 20 μm. This bump plating step is performed by electroplating with a predetermined plating solution, but projections intermittently appear on the bump electrode during a mass production process. In the invention, abnormal growth of projections over the gold bump electrode is prevented by adding, prior to the gold bump plating step, a step of circulating and stirring a plating solution while erecting a plating cup and efficiently dissolving / discharging a precipitate. This step is performed for each wafer to be treated.

Owner:RENESAS ELECTRONICS CORP

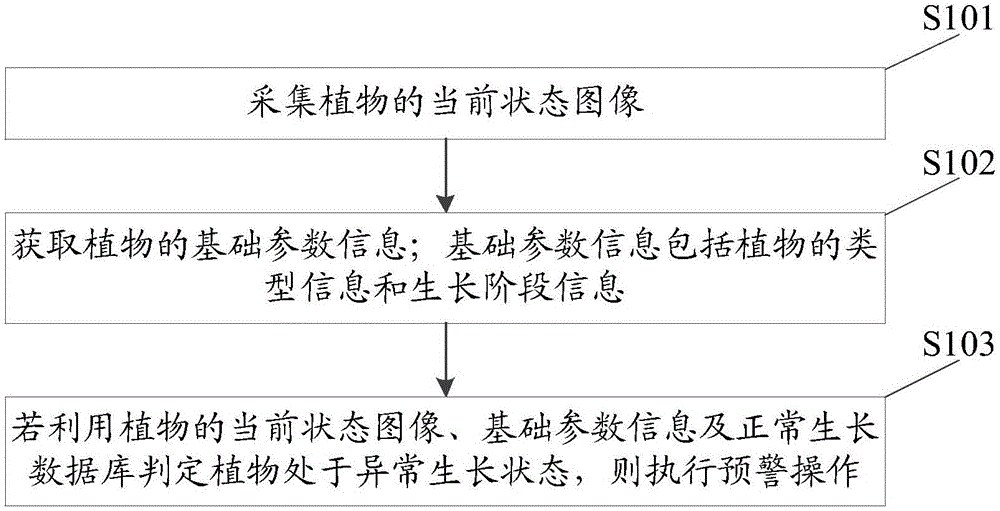

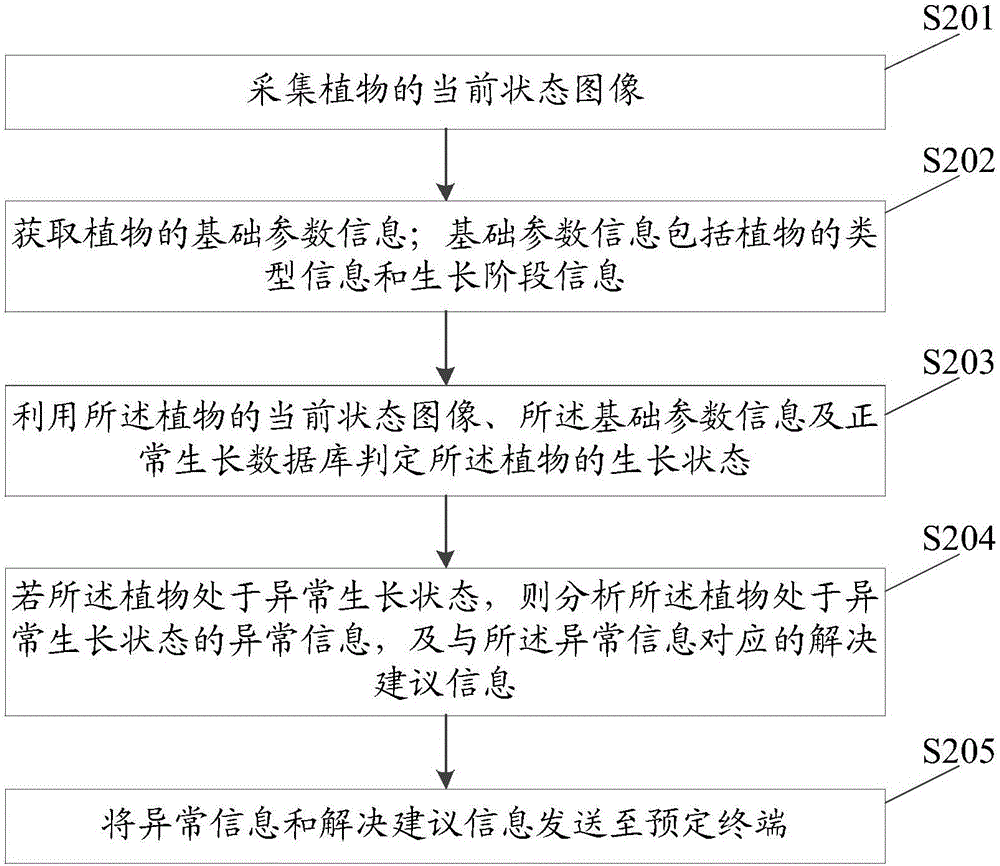

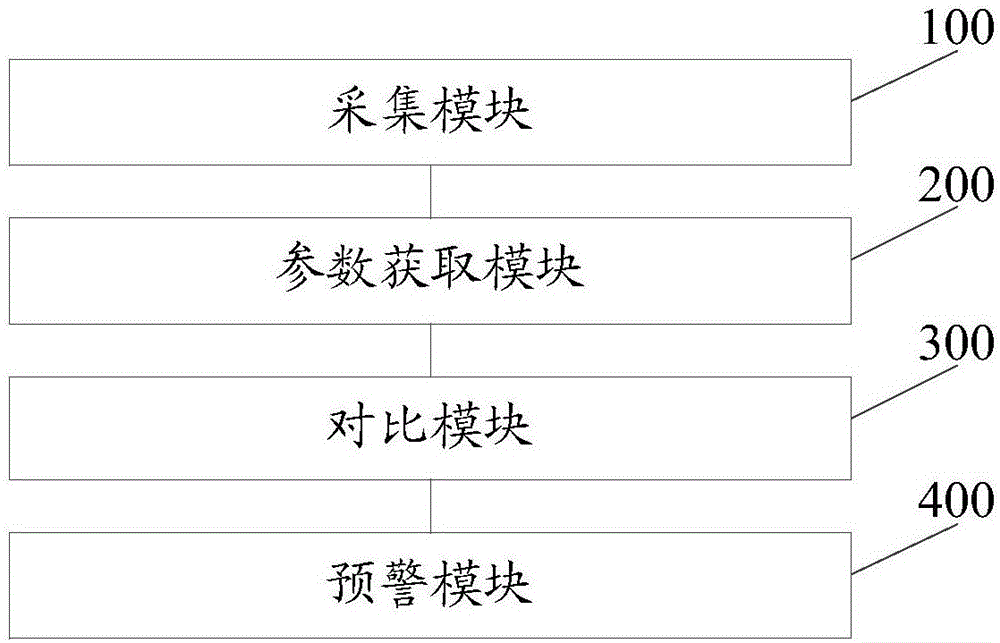

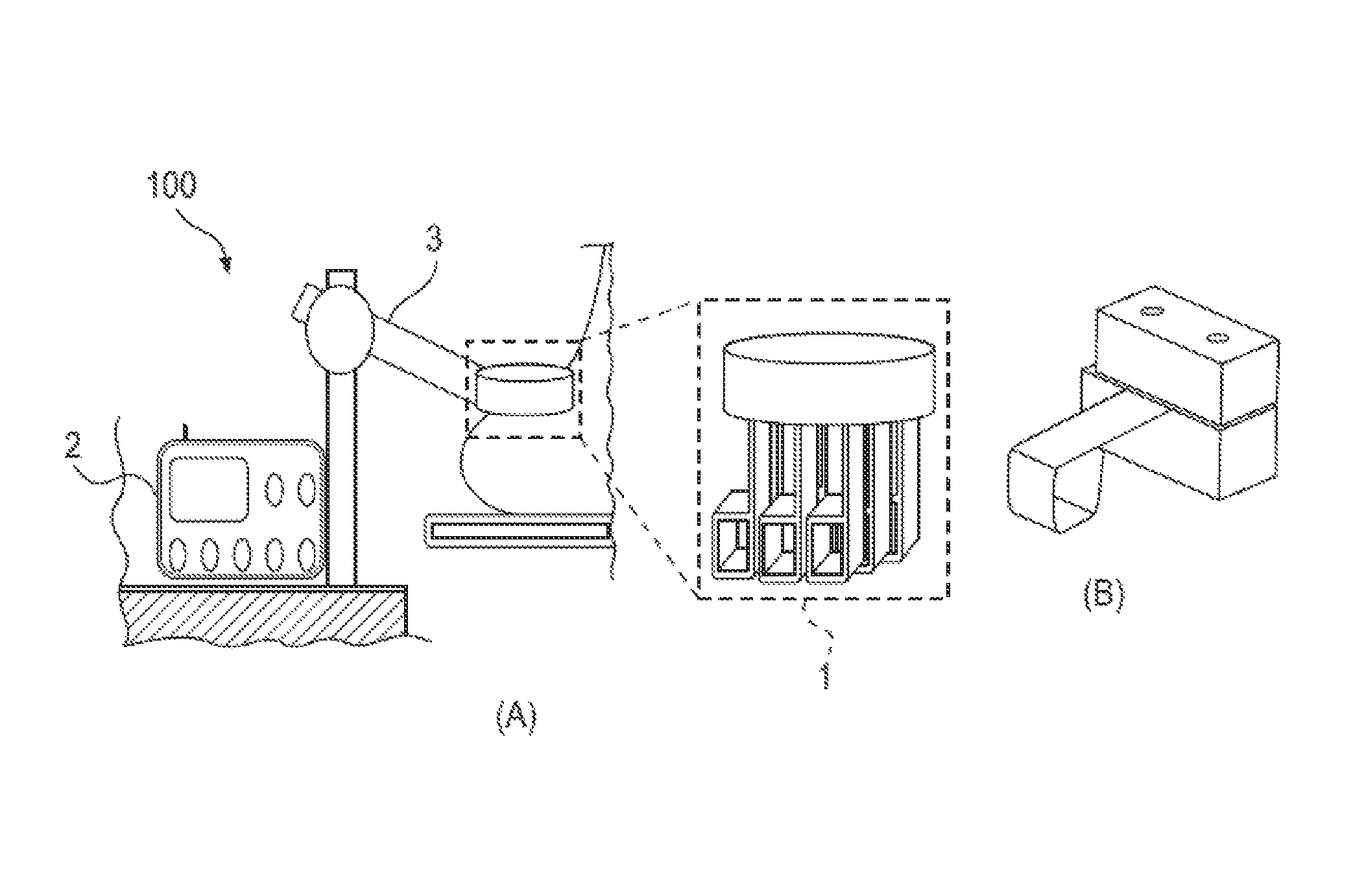

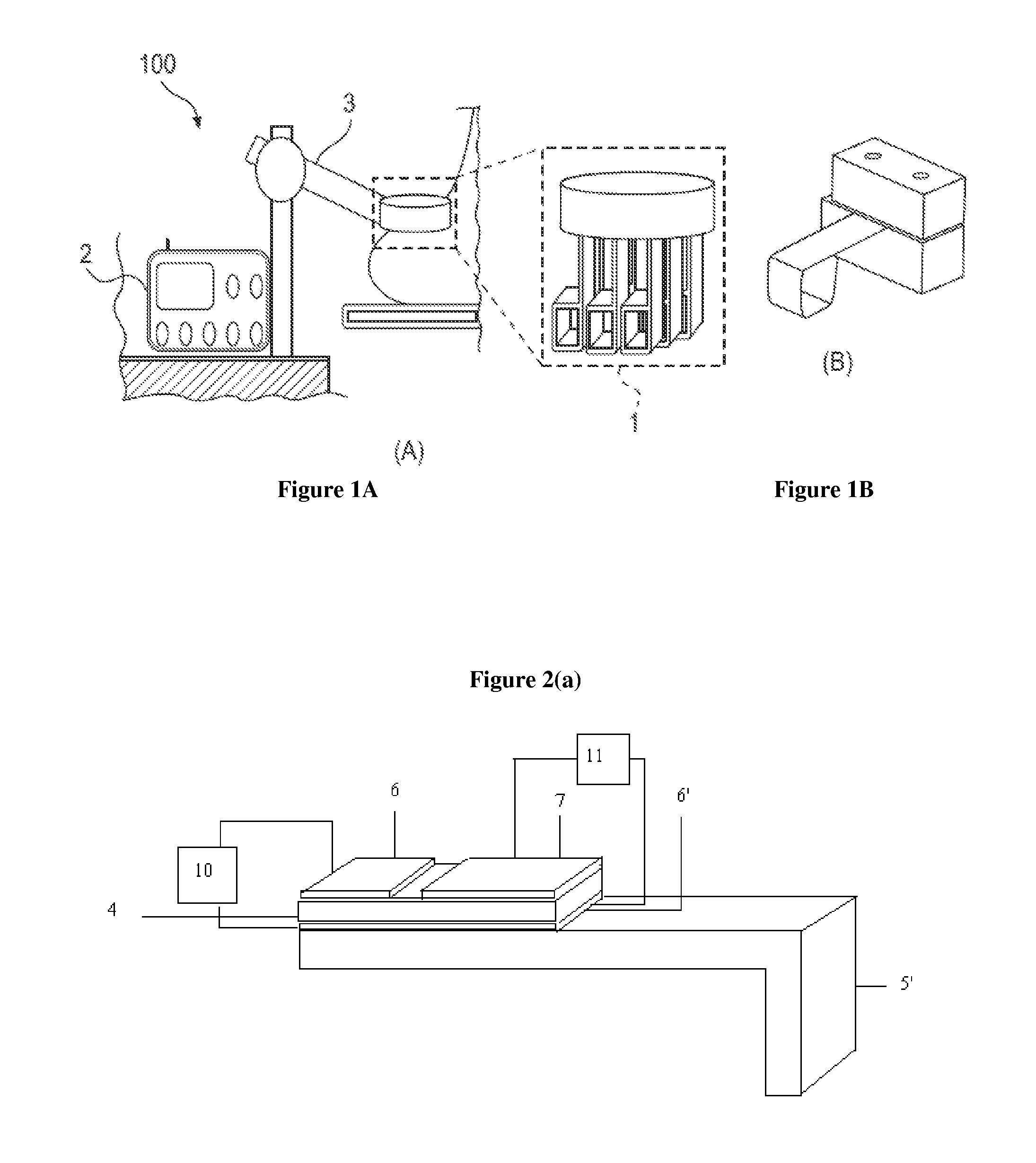

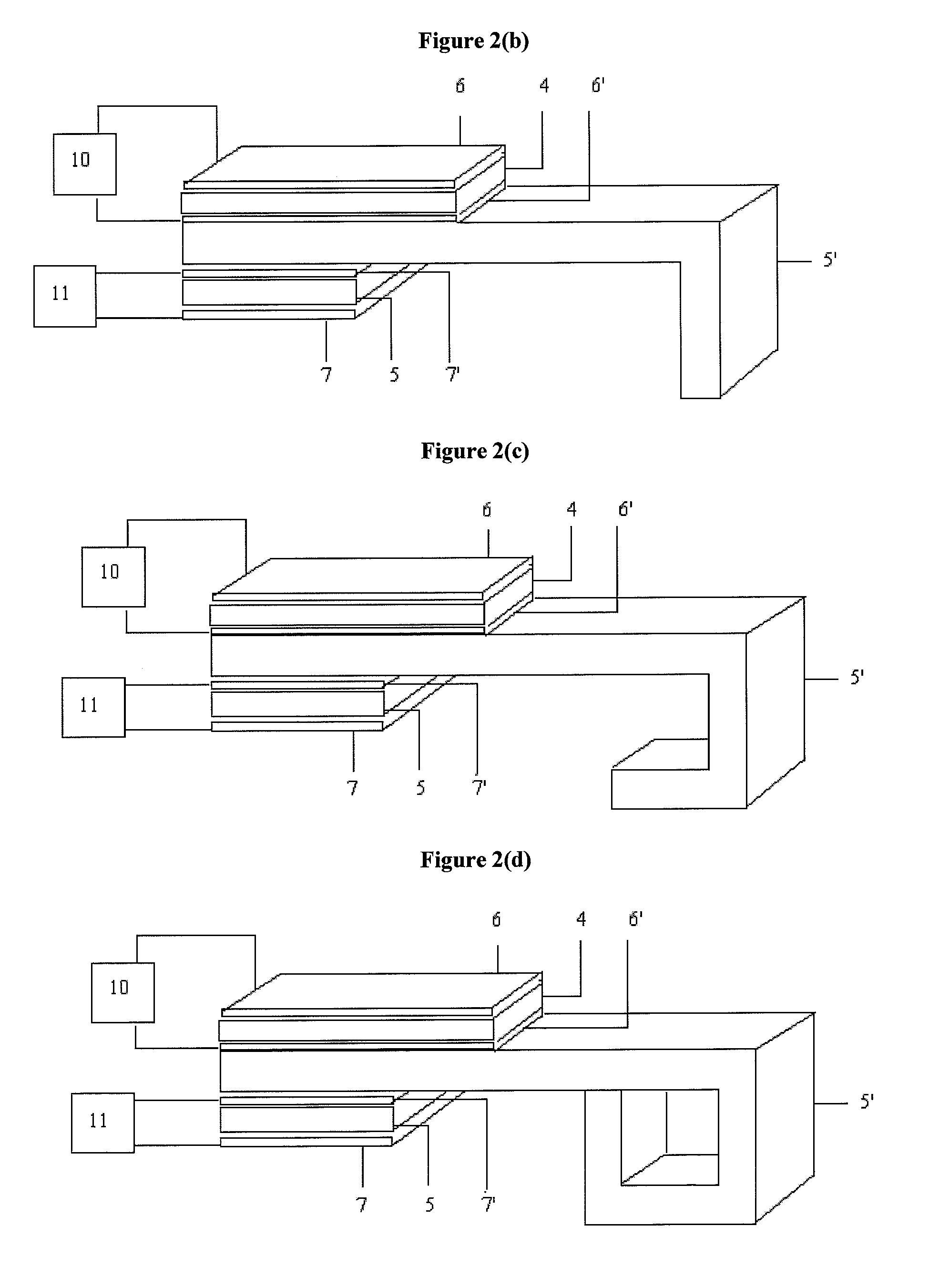

Method and device for monitoring plant growth status based on greenhouse environment

InactiveCN106645155AImprove timelinessSimplify monitoring operationsInvestigation of vegetal materialAbnormal growthsGrowth plant

The invention discloses a method for monitoring plant growth status based on a greenhouse environment. The method comprises the steps of acquiring the current status image of a plant, and acquiring the basic parameter information of the plant, wherein the basic parameter information comprises type information and growth stage information of the plant; if the plant is judged to be in an abnormal growth status according to the current status image and the basic parameter information of the plant as well as a normal growth database, performing early warning operation. Therefore, according to the scheme, the current growth status of the plant can be determined by comparing the current status image of the plant with data stored in the normal growth database, so that early warning can be performed in time, the monitoring operation is simplified, and the timeliness of the problem solving is improved. The invention also discloses a device for monitoring the plant growth status based on the greenhouse environment; the device also can realize the technical effects in the same way.

Owner:SHENZHEN SPRINGWOODS HLDG CO LTD

Bridging connection method for curing greatly-damaged tree

The invention discloses a bridging therapeutic method for seriously damaged trees which means that the technical principles of grafting and regeneration are utilized to engraft and communicate with the damaged part caused by insect pest or band girdle of trees, and then the branches or bark of the same trees are taken as a cion to cure the damaged part by means of bridge connection to make the tree grow normally. The method can avoid the abnormal growth or life lost of the grand tree or noble tree caused by the damage of phloem. The method of operation is that firstly, the cion is made ready according to the damaged shape of the tree, and then partial dry and decayed xylem and phloem of the damaged part are taken out to make the interface of the fresh and undamaged xylem and phloem reveal, the edges of the two ends of the cion are cut into a wedge shape dovetailing with the interface and then are closely pressed on the damaged part of the tree; the plastic cloth or parchment paper is used to bind up the damaged part; finally, the ligature is taken out after the callus outgrows and becomes firm. The invention has a survival rate up to as much as more than 95 percent, and has characteristic of simple and convenient manipulation.

Owner:GUIZHOU INST OF PRATACULTURE

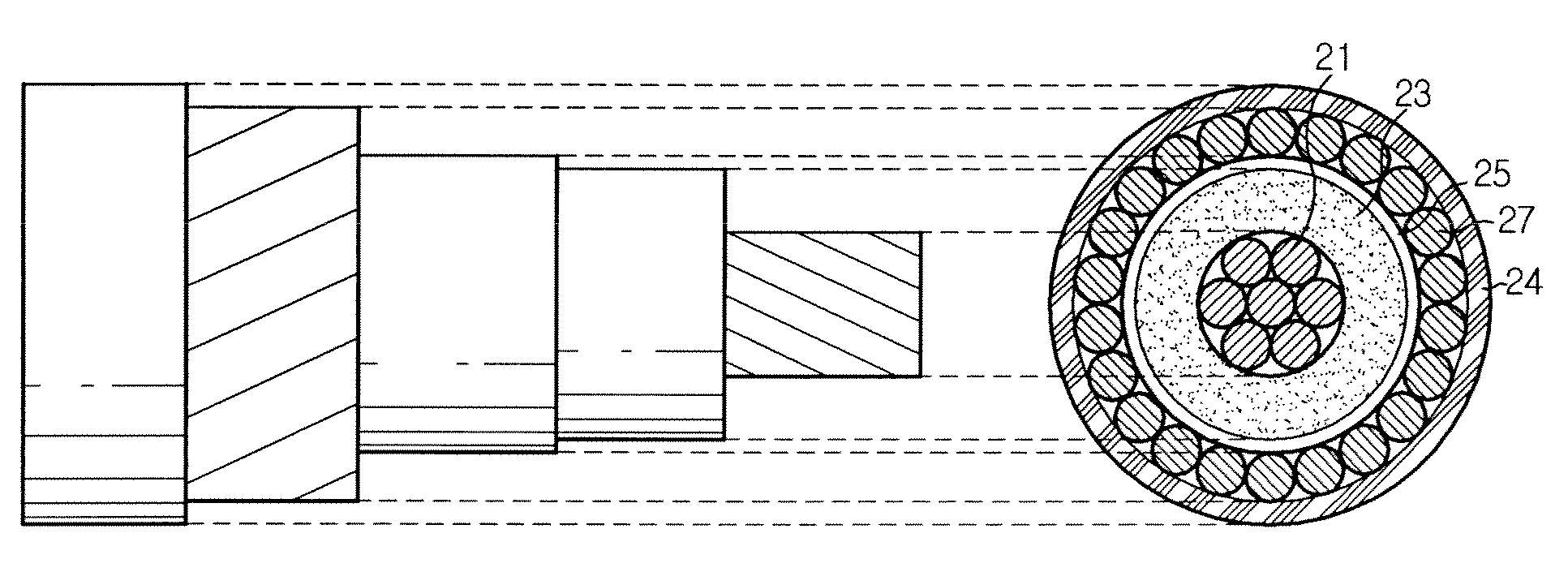

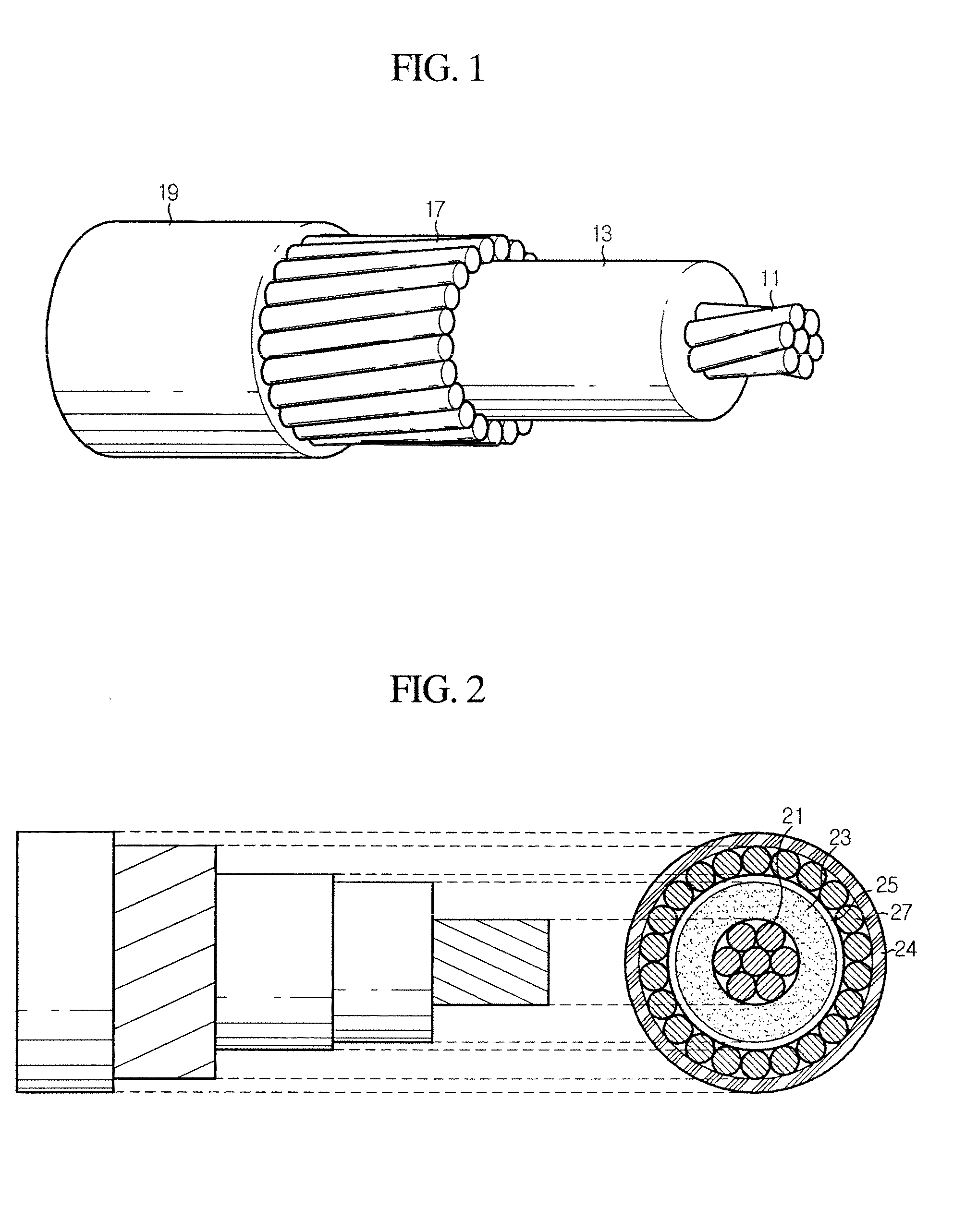

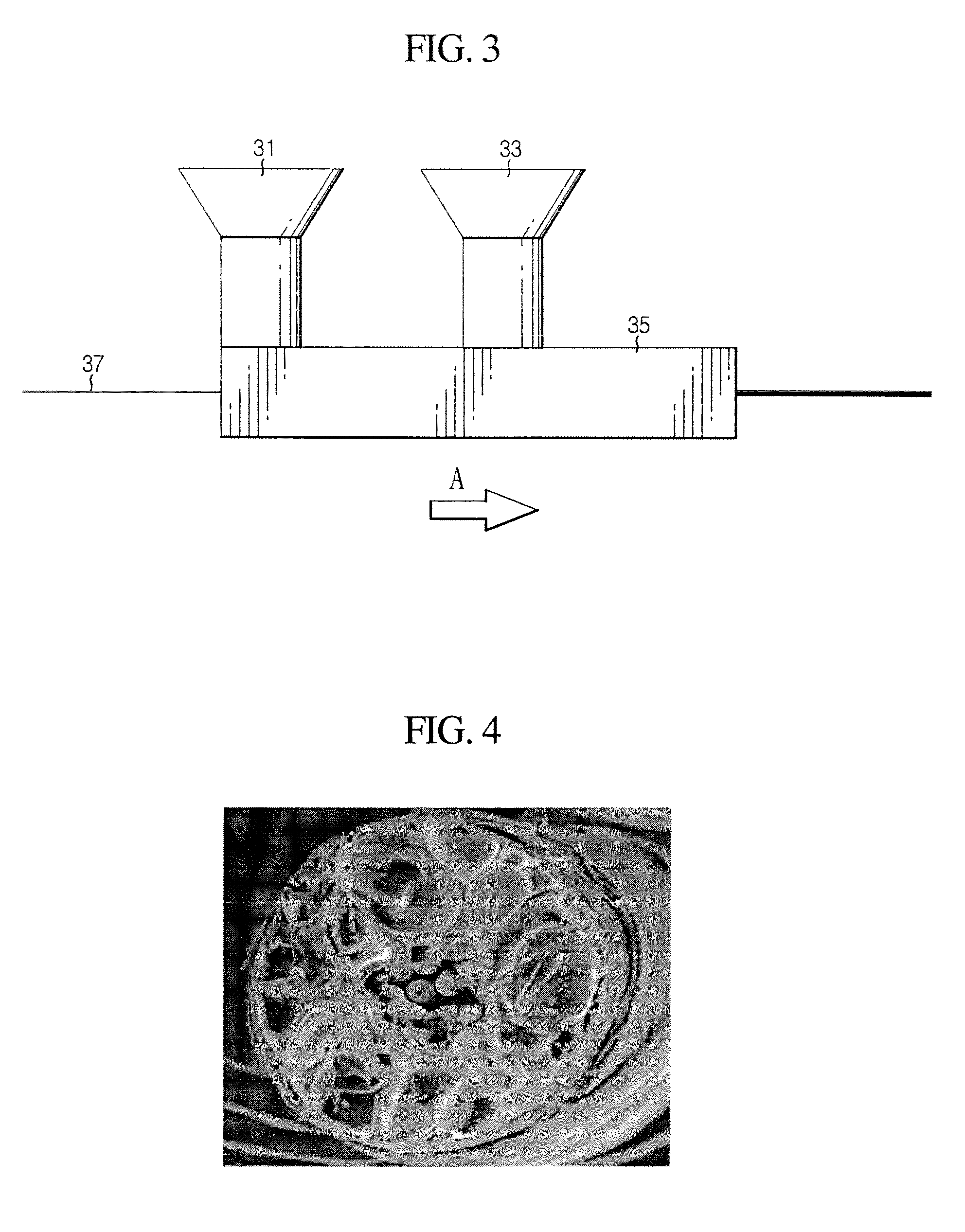

Micro CoAxial Cable

ActiveUS20080047732A1Lower melting temperatureEasy to useCable insulation constructionPower cables with screens/conductive layersAbnormal growthsElectrical conductor

A micro coaxial cable includes an inner conductor; an insulation layer having foaming cells and formed to surround the inner conductor; an over-foaming preventing layer formed to surround the insulation layer for the purpose of uniform forming of the foaming cells; a metal shield layer formed to surround the over-foaming preventing layer; and a protective coating layer formed to surround the metal shield layer. The over-foaming preventing layer restrains abnormal growth of foaming cells formed in the insulation layer such that the foaming cells are successively adjacently formed with uniform size. Due to the uniformity of foaming, the dielectric constant of the insulation layer is not locally different but uniform as a whole, thereby capable of improving transmission characteristics. In addition, the micro coaxial cable enables to transmit signals even at a high frequency transmission of GHz range, which was impossible in the prior art.

Owner:HITACHI METALS LTD

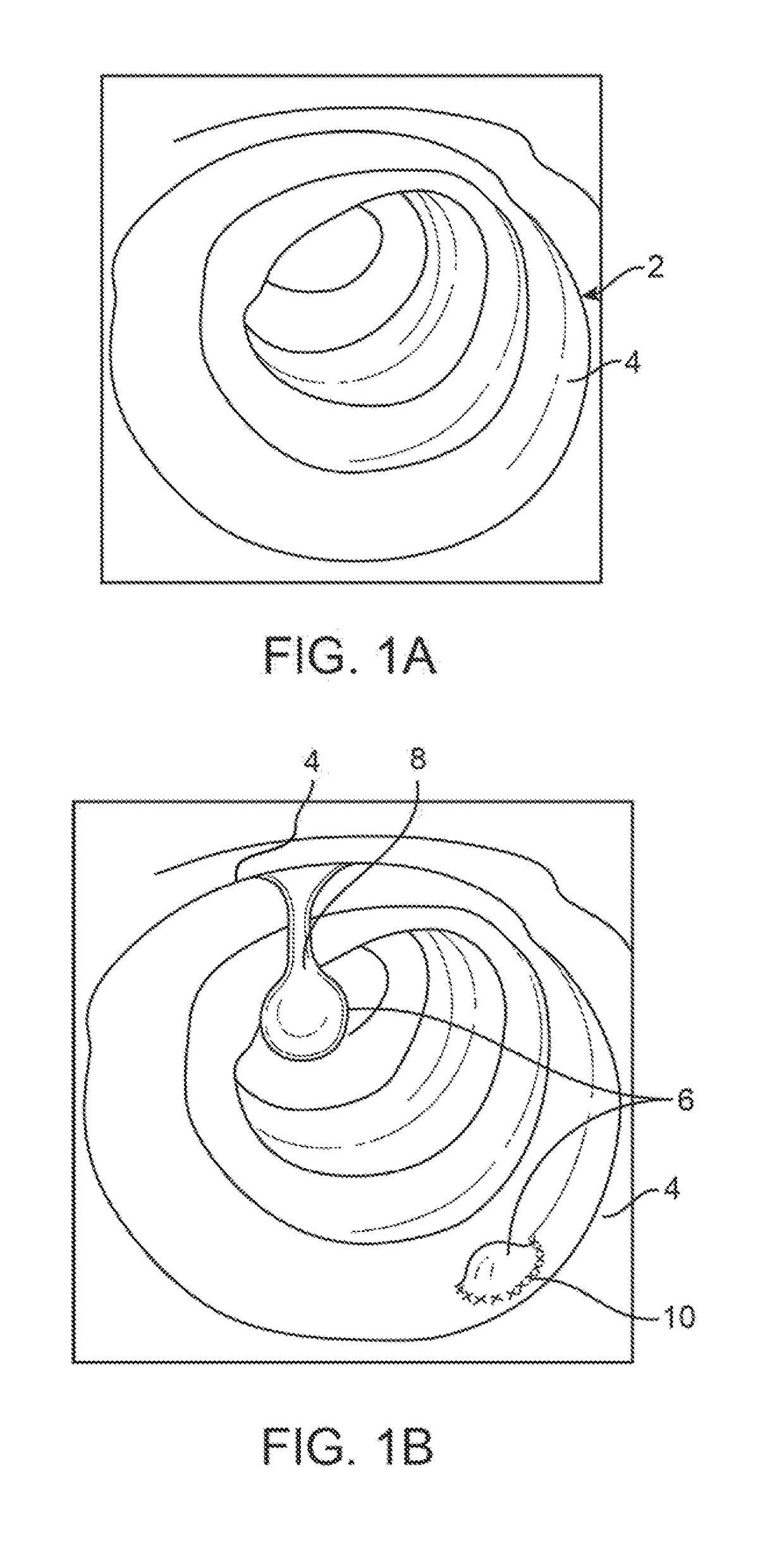

System and method for evaluating tissue

ActiveUS8562546B2Less readMinimization requirementsUltrasonic/sonic/infrasonic diagnosticsMaterial analysis using sonic/ultrasonic/infrasonic wavesAbnormal growthsShear modulus

The present invention provides a sensor system for measuring an elastic modulus and a shear modulus and a method for using the sensor system to evaluate a tissue by determining the presence of and / or characterizing abnormal growths. The method involves applying a set of forces of different magnitudes to one or more locations of tissue, detecting the corresponding displacements due to said applied forces, determining the forces acting on those locations of tissue which are a combination of forces from the applied voltages and the countering forces from tissue deformation, obtaining the elastic modulus and / or shear modulus for a plurality of locations, and determining abnormal growth invasiveness, malignancy or the presence of a tumor from said elastic and / or shear moduli.

Owner:DREXEL UNIV

Alloy for use in preparation of R-T-B-based sintered magnet and process for preparing R-T-B-based sintered magnet

InactiveUS6444048B1Oxidation during the production of the sintered magnet can, therefore, be suppressedInorganic material magnetismAbnormal growthsBinary alloy

Processes for the preparation of a sintered alloy comprising R2Fe14B as a magnetic phase constituting a main phase include a binary alloy process wherein a main phase alloy having a lower R content than the above phase is mixed with a grain boundary phase alloy rich in R component and serving as a liquid phase in the sintering in order to prepare a mixture to be used as the starting material. The conventional main phase alloy has a structure comprising the R2Fe14B phase and, in addition, a large amount of an easily oxidizable lamella R-rich phase and a harmful dendrite alpha phase. On the other hand, the main phase alloy of the invention has a low dendrite a phase content and a low lamella R-rich phase and contains a lamella alpha Fe phase. This contributes to excellent oxidation resistance and improved properties of the magnet. The preparation of a sintered magnet by mixing the main phase alloy with the grain boundary phase alloy by the binary alloy method can reduce abnormal growth of crystal grains.

Owner:SHOWA DENKO KK

Lead accumulator

InactiveCN1503994AInhibit sheddingNo damage to output characteristicsFinal product manufactureElectrode carriers/collectorsAbnormal growthsEngineering

The present invention relates to a lead-acid battery Comprising a positive and a negative electrode, each having a current collector comprising an expanded grid, characterized in that at least one of the positive electrode and the negative electrode contains an organic binder in an active material layer at an edge portion thereof. This makes it possible to suppress an internal short circuit resulting from the separation or abnormal growth of an active material due to repeated charge / discharge, thereby remarkably prolonging the cycle life of a lead-acid battery.

Owner:PANASONIC CORP

Semiconductor device including ferroelectric capacitor

InactiveUS20080035970A1Suppress abnormal growthSuppress generationSolid-state devicesSemiconductor/solid-state device manufacturingAbnormal growthsDevice material

A semiconductor device includes a ferroelectric capacitor formed above the lower interlevel insulating film covering a MOS transistor formed on a semiconductor substrate, including lamination of a lower electrode, an oxide ferroelectric film, a first upper electrode made of conductive oxide having a stoichiometric composition AOx1 and an actual composition AOx2, a second upper electrode made of conductive oxide having a stoichiometric composition BOy1 and an actual composition BOy2, where y2 / y1>x2 / x1, and a third upper electrode having a composition containing metal of the platinum group; and a multilayer wiring structure formed above the lower ferroelectric capacitor, and including interlevel insulating films and wirings. Abnormal growth and oxygen vacancies can be prevented which may occur when the upper electrode of the ferroelectric capacitor is made of a conductive oxide film having a low oxidation degree and a conductive oxide film having a high oxidation degree.

Owner:FUJITSU SEMICON MEMORY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com