Friction stir welding method

A technology of friction stir and welding method, which is applied in the field of stirring, and can solve the problems of reducing the strength of materials in the nugget area, reducing superplasticity, and affecting the appearance of the surface, so as to inhibit the abnormal growth of grains, improve stability, and improve comprehensive mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

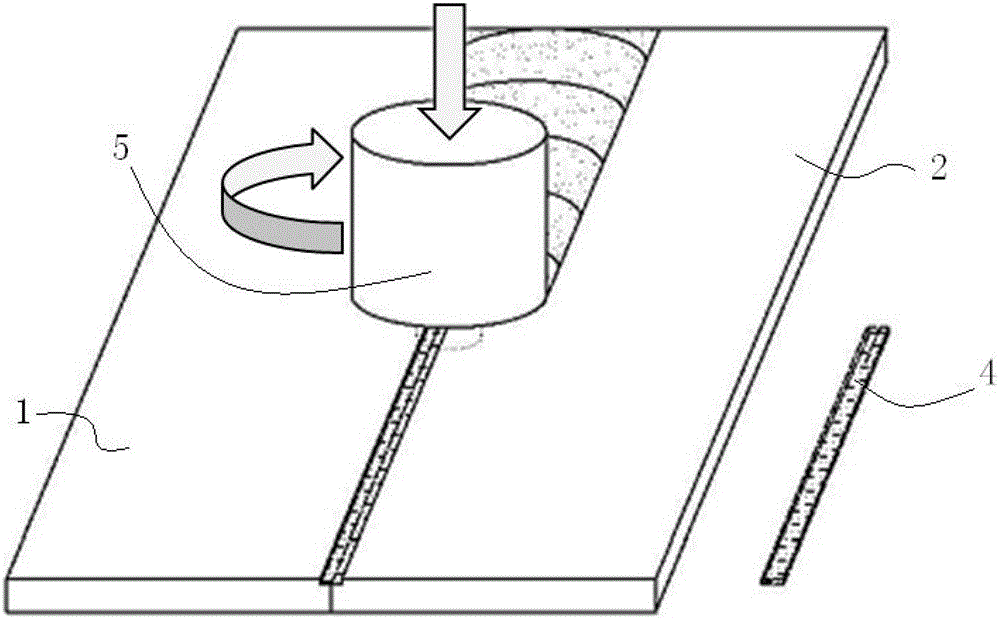

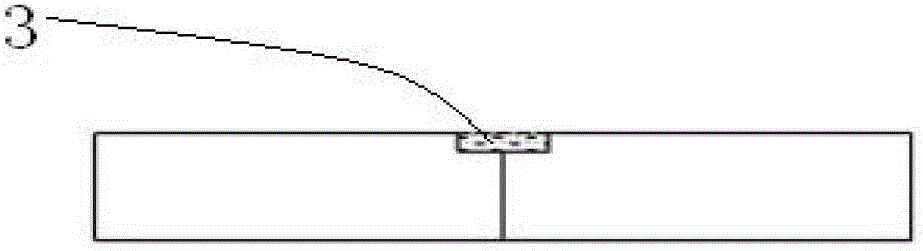

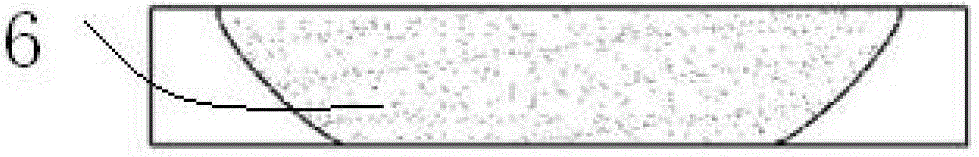

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, groove 3 is made near the bonding surfaces of 1060-H24 pure aluminum plates 1 and 2 with a thickness of 2.7 mm, the cross-sectional size is 1 mm × 0.5 mm, and the thickness direction of the aluminum plate is 0.5 mm to form a processing area; The aluminum plates 1 and 2 to be welded are docked along the groove direction, placed on the friction stir welding machine tool, and fixed with a clamp; the elemental metal solder pure titanium powder 4 to be reacted with the Al matrix in situ to generate Al3Ti nanoparticles is filled into the groove 3, compacted and flush with the surface of pure aluminum plates 1 and 2; the average particle size of pure titanium powder is about 30 μm; use the stirring head 5 matching the size of the processing area to perform 4 passes on aluminum plates 1 and 2 Friction stir welding treatment, the welding joint 6 with 5%~15% volume fraction of in-situ self-generated Al3Ti nanoparticles ...

Embodiment 2

[0022] Embodiment 2: In embodiment 1, other types of aluminum alloy plates 1 and 2 can also be used, such as pure aluminum plates such as 1050 or high-strength aluminum alloy plates such as AA5083; the mixed solder of metal aluminum powder and titanium powder can also be used; The forward speed of the stirring head 5 is 20~50mm / min, the rotation speed of the stirring head 5 is 1200~1500rpm, 4~8 times of friction stir welding can obtain in situ self-generated Al3Ti nanoparticles and simple substance with a high volume fraction in the weld nugget area. Solder joint 6 with dispersed Ti powder solder particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com