Preparation method for Ti(C,N)-based cermet with high-entropy alloy bonder phase

A high-entropy alloy and cermet technology, which is used in the preparation of cermet materials and the preparation of high-entropy alloy binder phase Ti-based cermets, can solve the problems of content reduction and hard phase grain growth, and achieve thermal insulation. Short time, fast heating rate, and the effect of maintaining the composition and structure of high-entropy alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

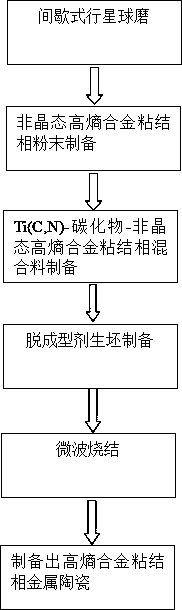

Method used

Image

Examples

example 1

[0018] Example 1: Prepare a high-entropy alloy binder phase Ti(C,N)-based cermet according to the following steps:

[0019] (1) Preparation of amorphous high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Co:Ni:Fe:Cu:Mn=1:1:1:1:0.3; Planetary ball mill, the ball milling speed is 300r / min, the ball-to-material ratio of the ball mill is 10:1, using WC-6Co balls with a diameter of 5mm, the ball milling medium is absolute ethanol, and the amount added is 15% of the total weight of the binder phase powder , the ball milling process is filled with 0.03MPa argon gas for protection, the ball milling time is 72 hours, the ball milling is 4 hours intermittently for 20 minutes, after the ball milling is finished, it is filtered with a 400 mesh screen, dried at 92 ° C, and passed through a 100 mesh screen;

[0020] (2) Preparation of Ti(C,N)-carbide-amorphous high-entropy alloy binder phase mixture: Weigh Ti(C,N), carbide and amorphous high-entrop...

example 2

[0023] Example 2: Prepare a high-entropy alloy binder phase Ti(C,N)-based cermet according to the following steps:

[0024](1) Preparation of amorphous high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Co:Ni:Fe:Cu:Mn=1:1:1:1:1; Planetary ball mill, the ball milling speed is 380r / min, the ball-to-material ratio of the ball mill is 10:1, using WC-6Co balls with a diameter of 5mm, the ball milling medium is absolute ethanol, and the amount added is 20% of the total weight of the binder phase powder , the ball milling process is filled with 0.03MPa argon gas for protection, the ball milling time is 110 hours, the ball milling is 5 hours intermittently for 20 minutes, after the ball milling is finished, it is filtered with a 400-mesh screen, dried at 98°C, and passed through a 100-mesh sieve;

[0025] (2) Preparation of Ti(C,N)-carbide-amorphous high-entropy alloy binder phase mixture: Weigh Ti(C,N), carbide and amorphous high-entropy all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com