A kind of preparation method of high-entropy alloy binder phase tungsten-based high specific gravity alloy

A high-entropy alloy and binder phase technology, which is applied in the preparation of high-entropy alloy binder phase tungsten-based high-gravity alloys and the preparation of high-gravity alloys, can solve the problem of W hard phase grain growth and relative content reduction, etc. problem, to achieve the effect of short holding time, fast heating speed and inhibiting diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

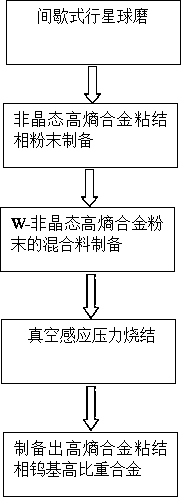

Method used

Image

Examples

example 1

[0016] Example 1: Prepare high-entropy alloy binder phase tungsten-based high specific gravity alloy according to the following steps:

[0017] (1) Preparation of amorphous high-entropy alloy binder phase powder: Weigh various raw material powders, according to atomic percentage Cu:Co:Cr:Fe:Ni=0.5:1:1:1:1; The raw material powder is stirred and ball milled, the ball milling speed is 500r / min, the ball-to-material ratio of the ball mill is 5:1, WC-Co balls with a diameter of 4mm are used, the ball milling medium is absolute ethanol, and the amount added is the total weight of the binder phase powder 18% of 18%, filled with 0.03MPa argon gas for protection during the ball milling process, the ball milling time is 4 hours, the ball milling time is 1 hour, and the ball milling is intermittent for 11 minutes.

[0018] (2) Preparation of mixture of W-amorphous high-entropy alloy powder: take W powder and amorphous high-entropy alloy powder by weight percentage, amorphous high-entrop...

example 2

[0020] Example 2: Prepare high-entropy alloy binder phase tungsten-based high specific gravity alloy according to the following steps:

[0021] (1) Preparation of amorphous high-entropy alloy binder phase powder: Weigh various raw material powders, according to atomic percentage Cu:Co:Cr:Fe:Ni=1.5:1:1:1:1; The raw material powder is stirred and ball milled, the ball milling speed is 570r / min, the ball-to-material ratio of the ball mill is 5:1, WC-Co balls with a diameter of 4mm are used, the ball milling medium is absolute ethanol, and the amount added is the total weight of the binder phase powder 16% of 0.03MPa argon gas for protection during the ball milling process, the ball milling time is 5h, the ball milling time is 1h, and the ball milling interval is 15min. After the ball milling, use a 400-mesh screen to filter, dry at 98°C, and pass through a 100-mesh sieve;

[0022] (2) Preparation of mixture of W-amorphous high-entropy alloy powder: take W powder and amorphous hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com