Patents

Literature

868results about How to "Strong and stable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

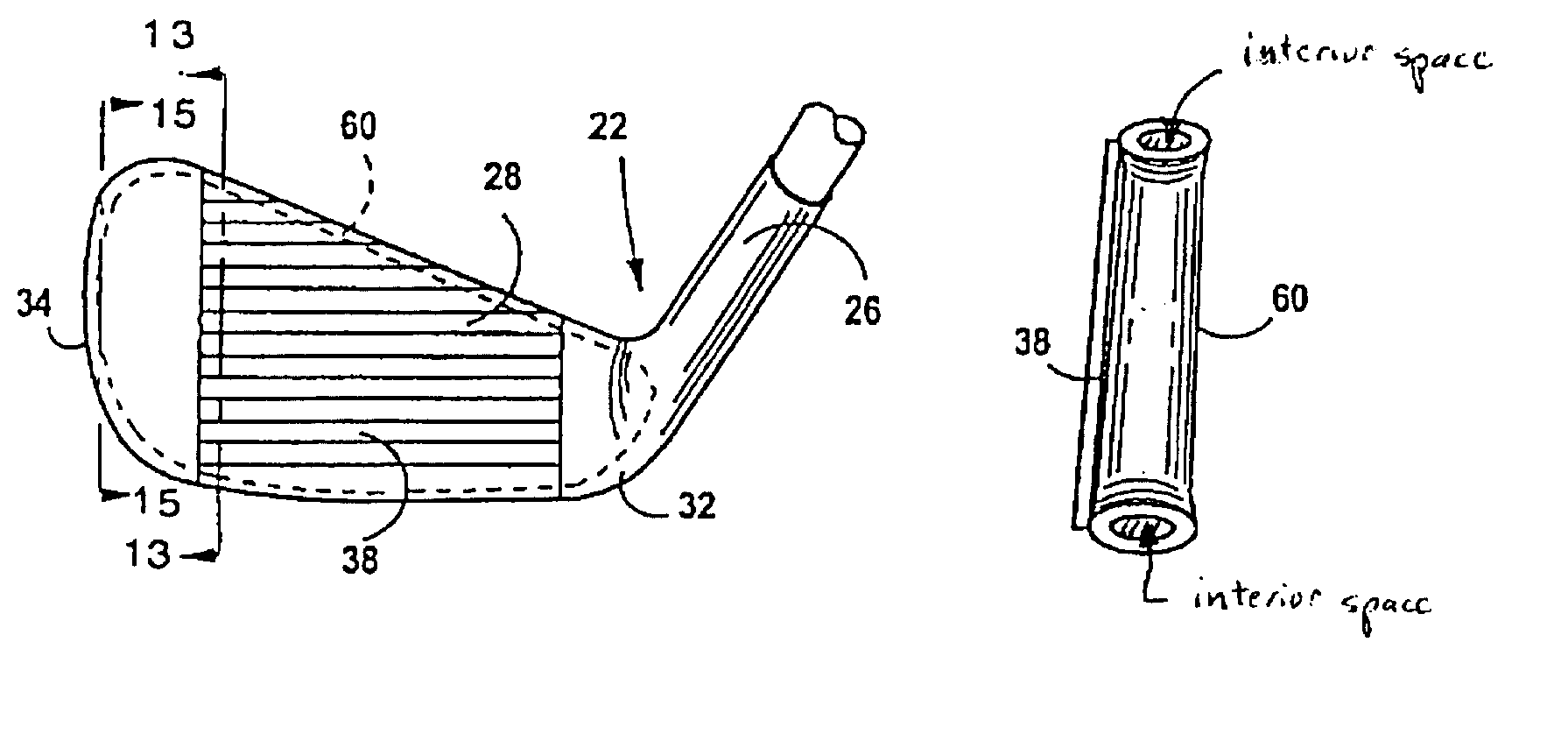

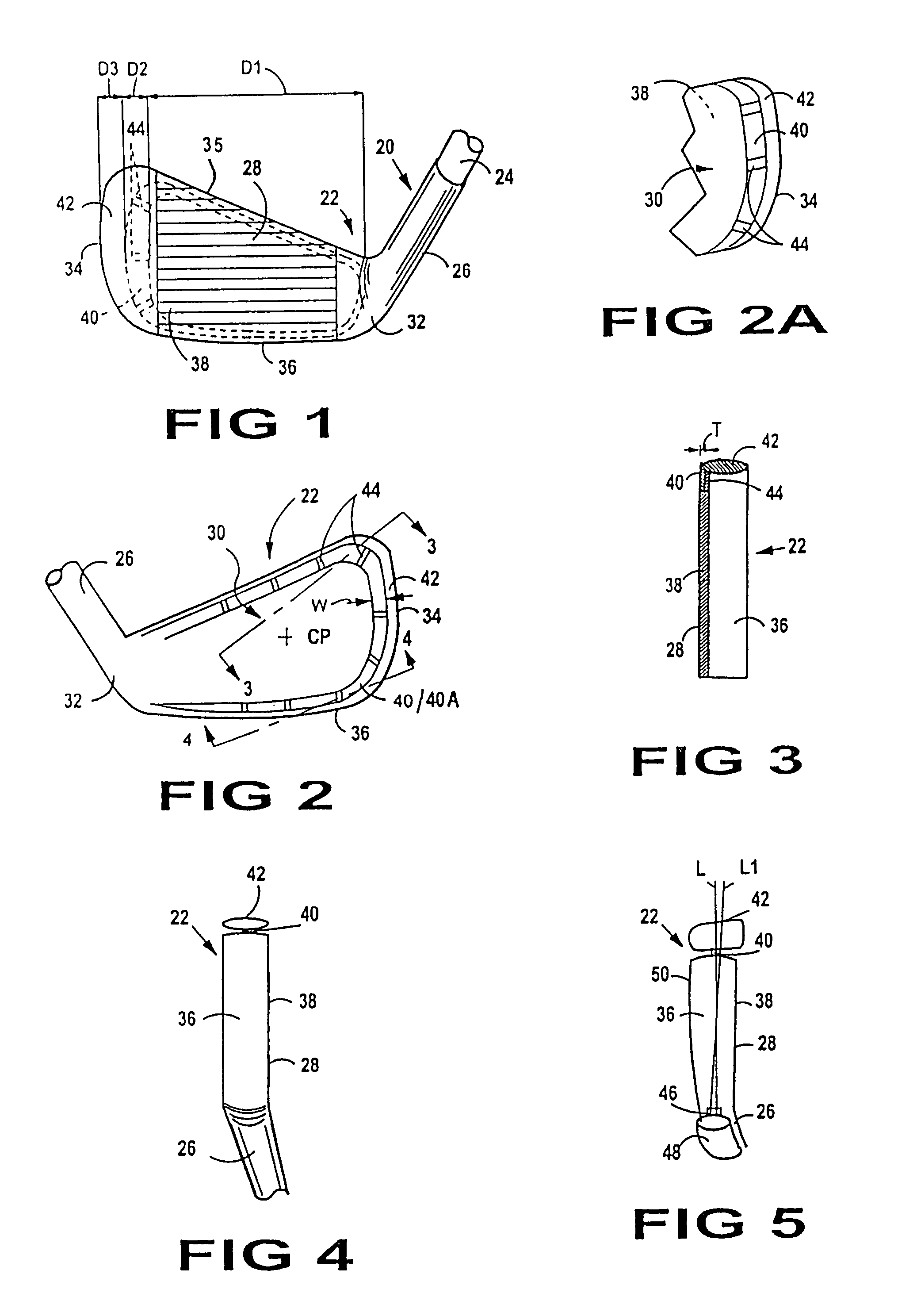

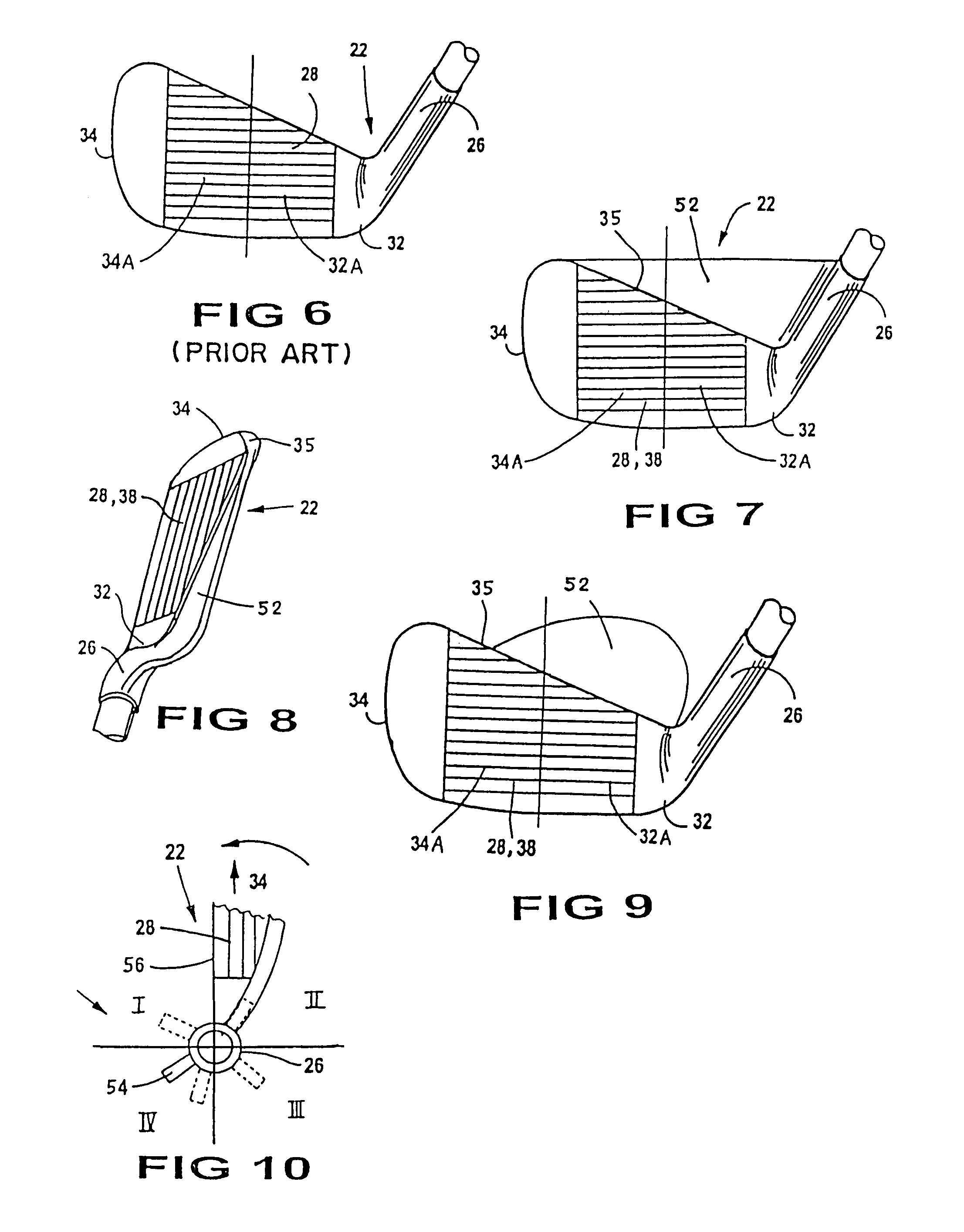

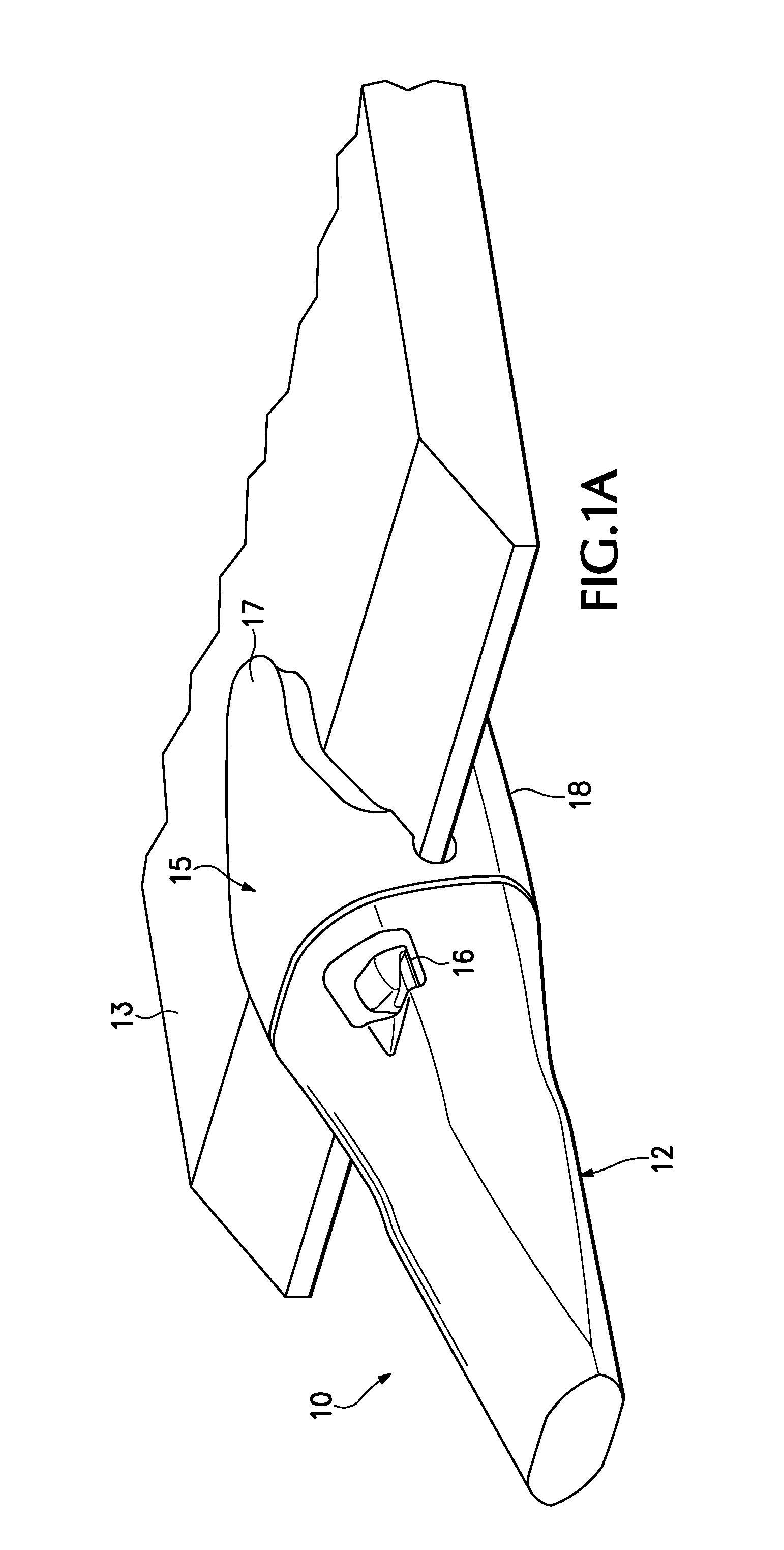

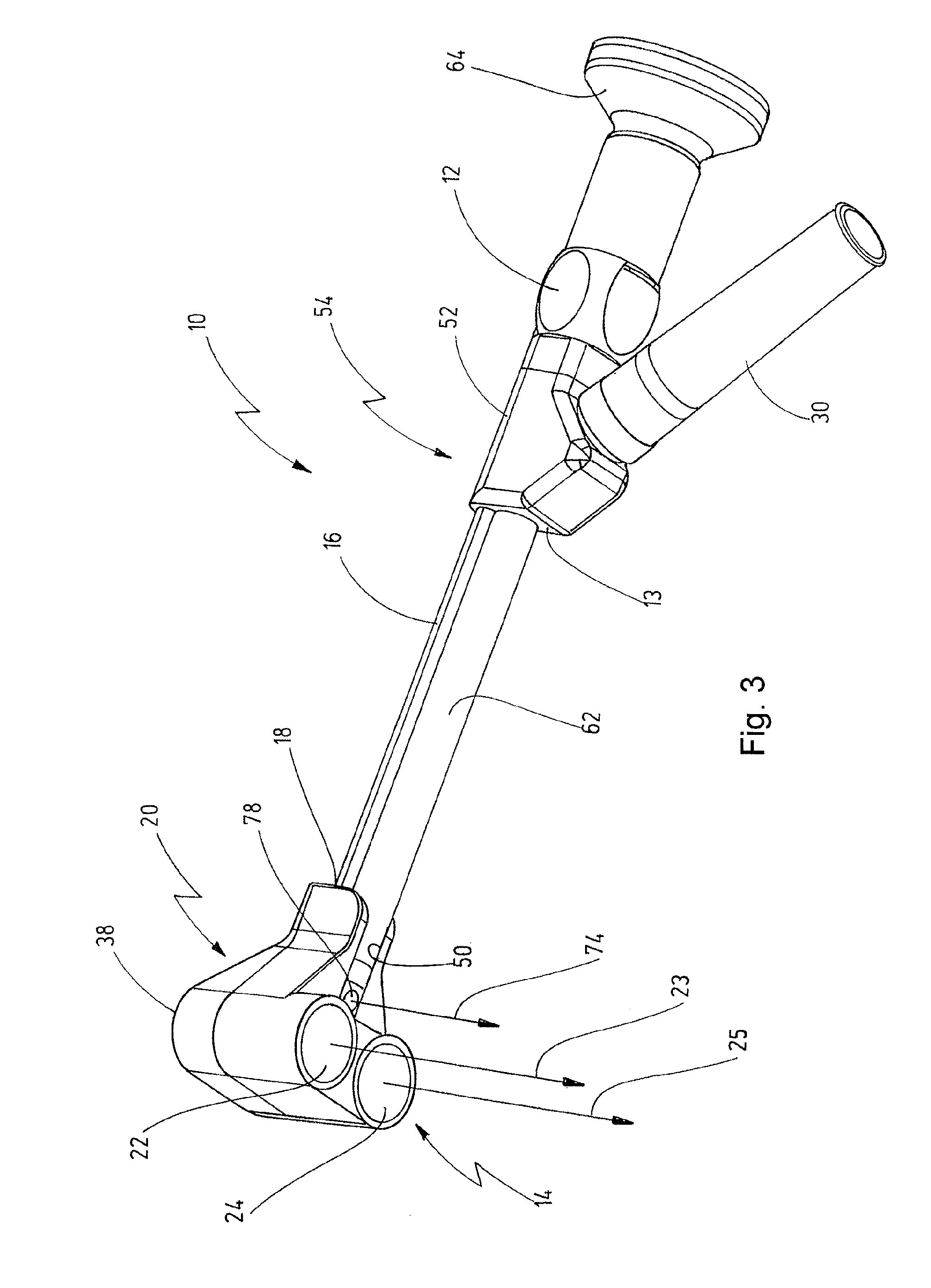

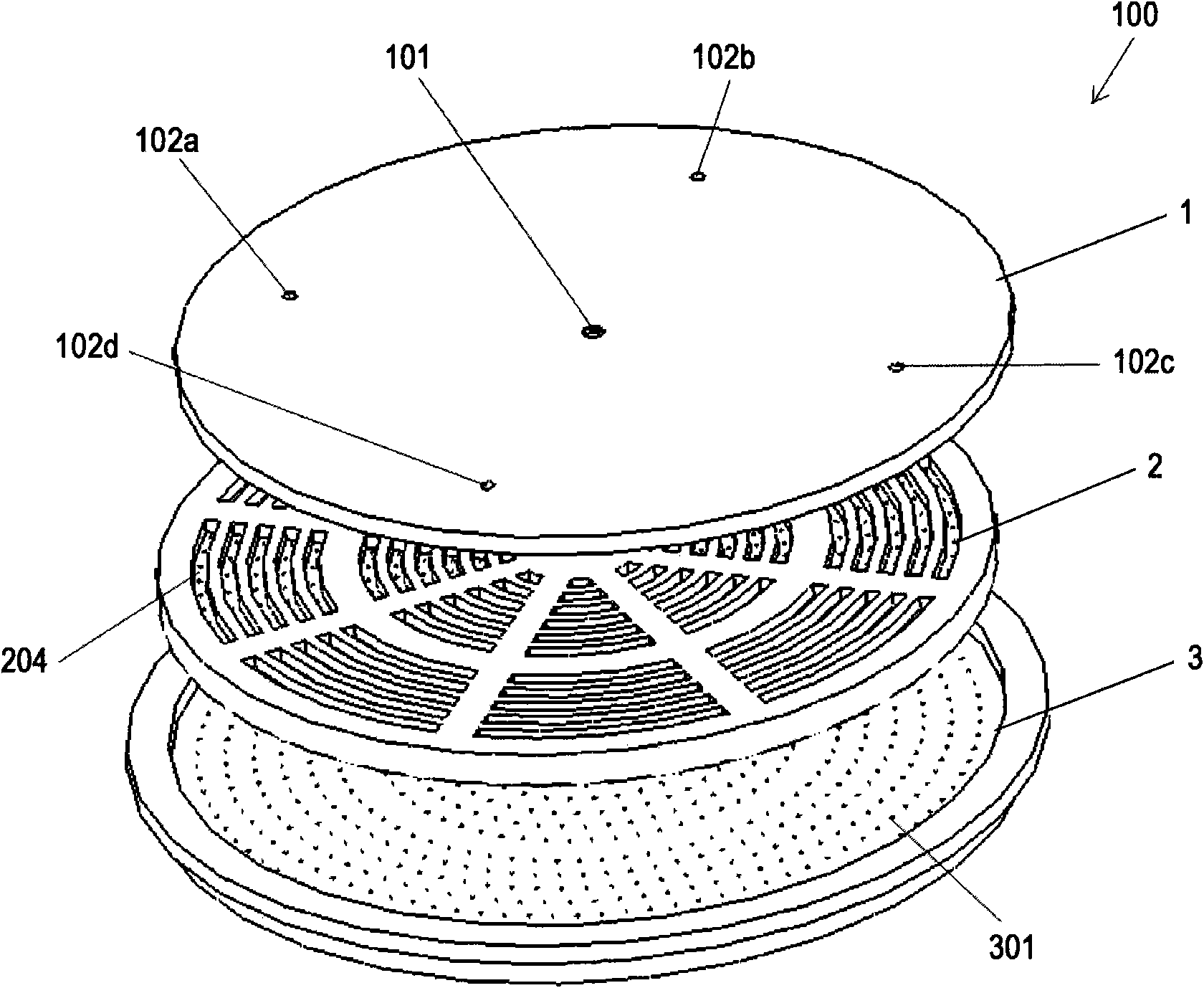

Perimeter weighted golf clubs

Improved perimeter weighted golf clubs are disclosed. The perimeter weighted golf clubs of the present invention are provided with improved structures for distributing the weight at the perimeter of the club head. In one embodiment, the club is an iron-type golf club having a club head that includes a weighted perimeter portion and a tubular frame that is located outboard of and behind at least a portion of the hitting surface.

Owner:PELICAN GOLF

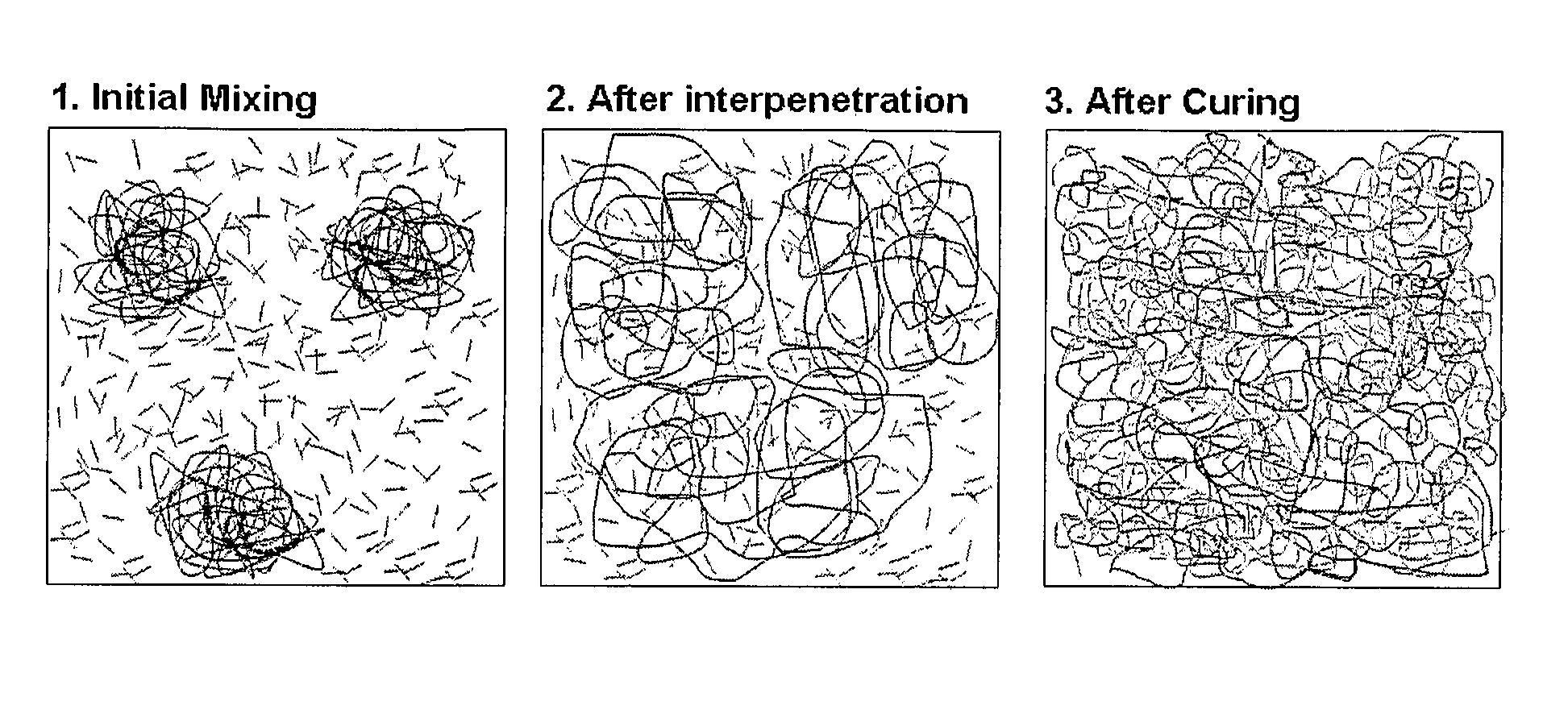

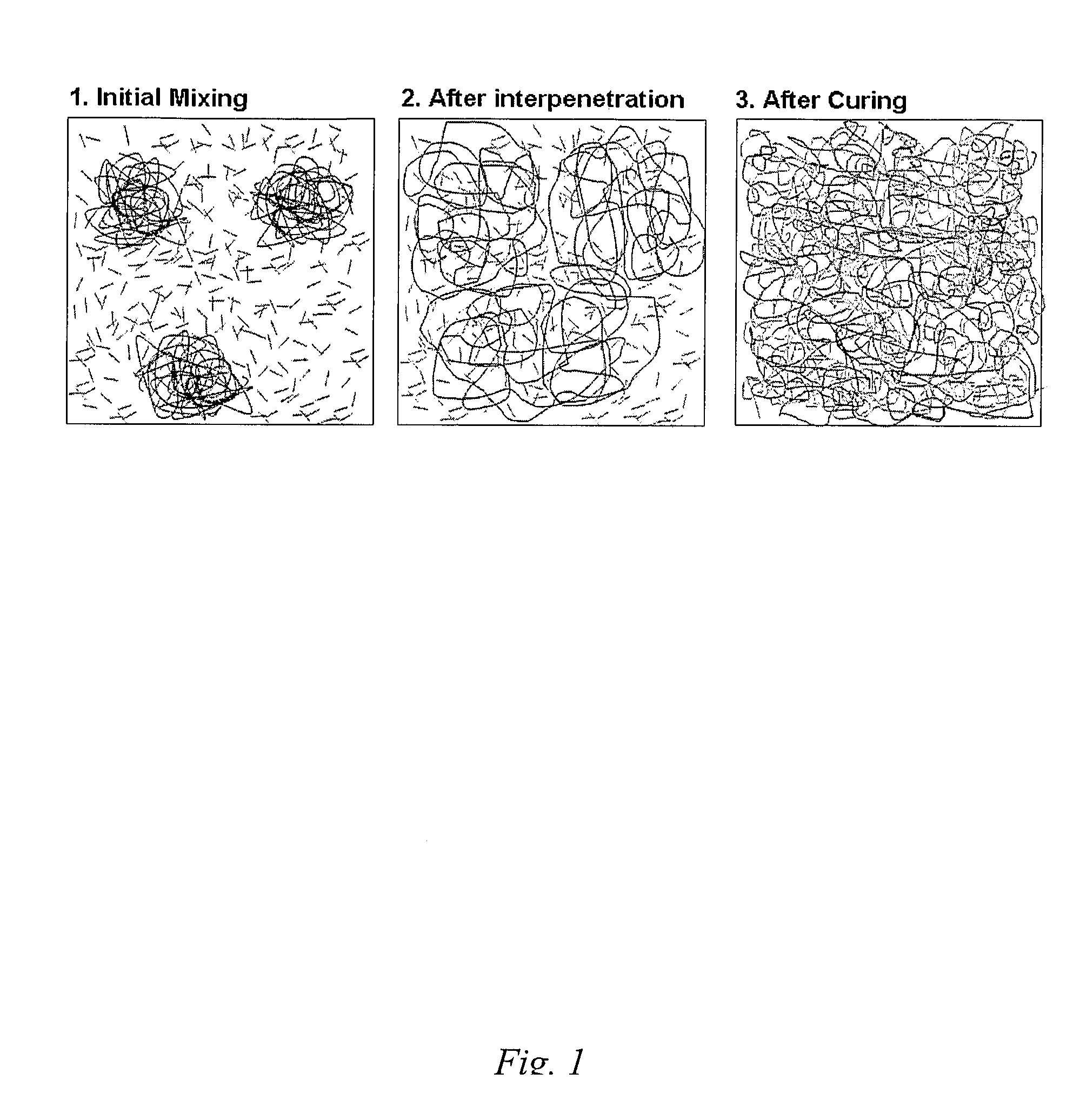

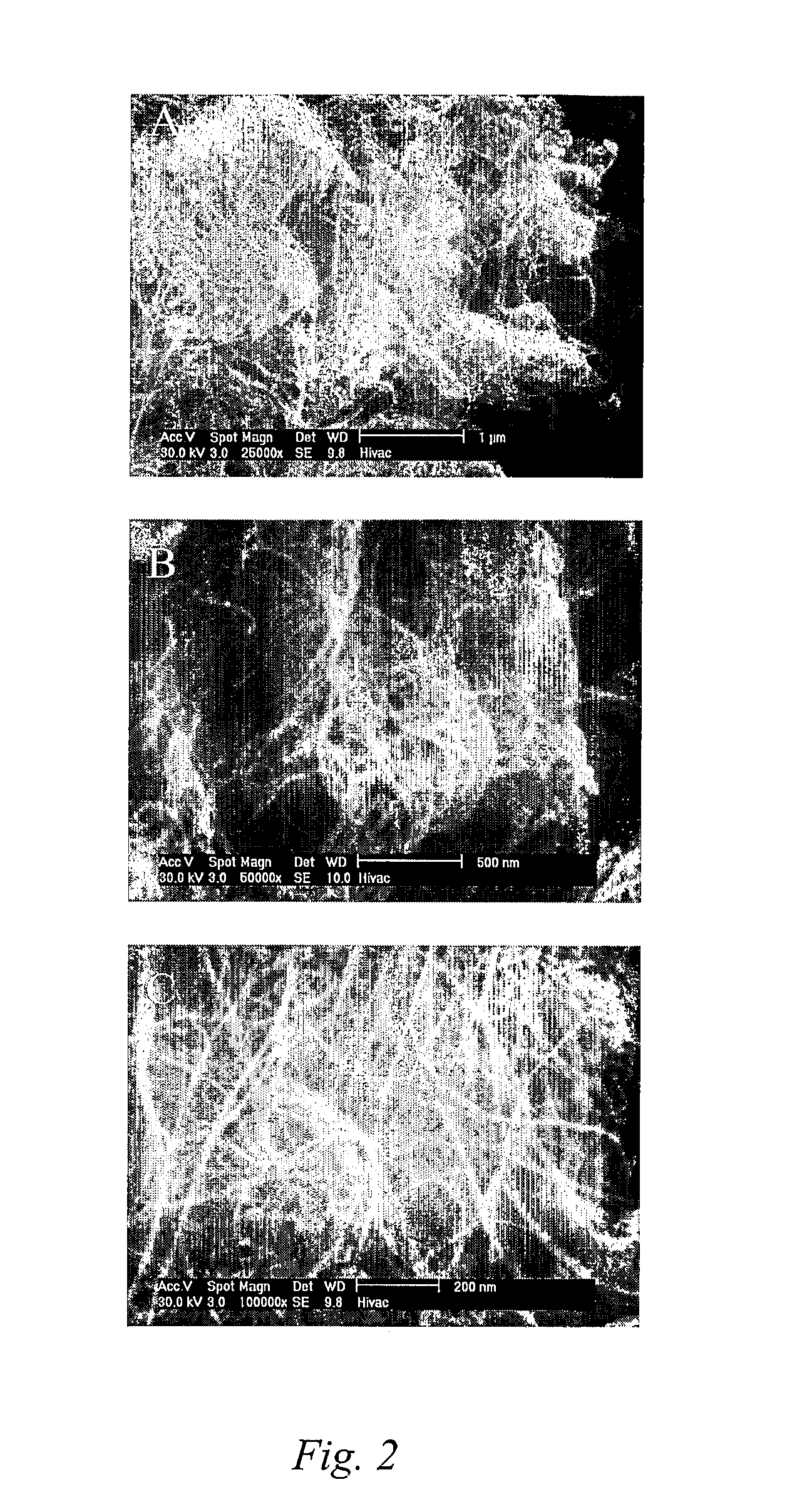

Polymer / Carbon-Nanotube Interpenetrating Networks and Process for Making Same

ActiveUS20080048364A1Improve propertiesHigh strengthPigmenting treatmentMaterial nanotechnologyCross-linkConductive polymer composite

The present invention is directed to new methods for combining, processing, and modifying existing materials, resulting in novel products with enhanced mechanical, electrical and electronic properties. The present invention provides for polymer / carbon nanotube composites with increased strength and toughness; beneficial for lighter and / or stronger structural components for terrestrial and aerospace applications, electrically and thermally conductive polymer composites, and electrostatic dissipative materials. Such composites rely on a molecular interpenetration between entangled single-wall carbon nanotubes (SWNTs) and cross-linked polymers to a degree not possible with previous processes.

Owner:RICE UNIV

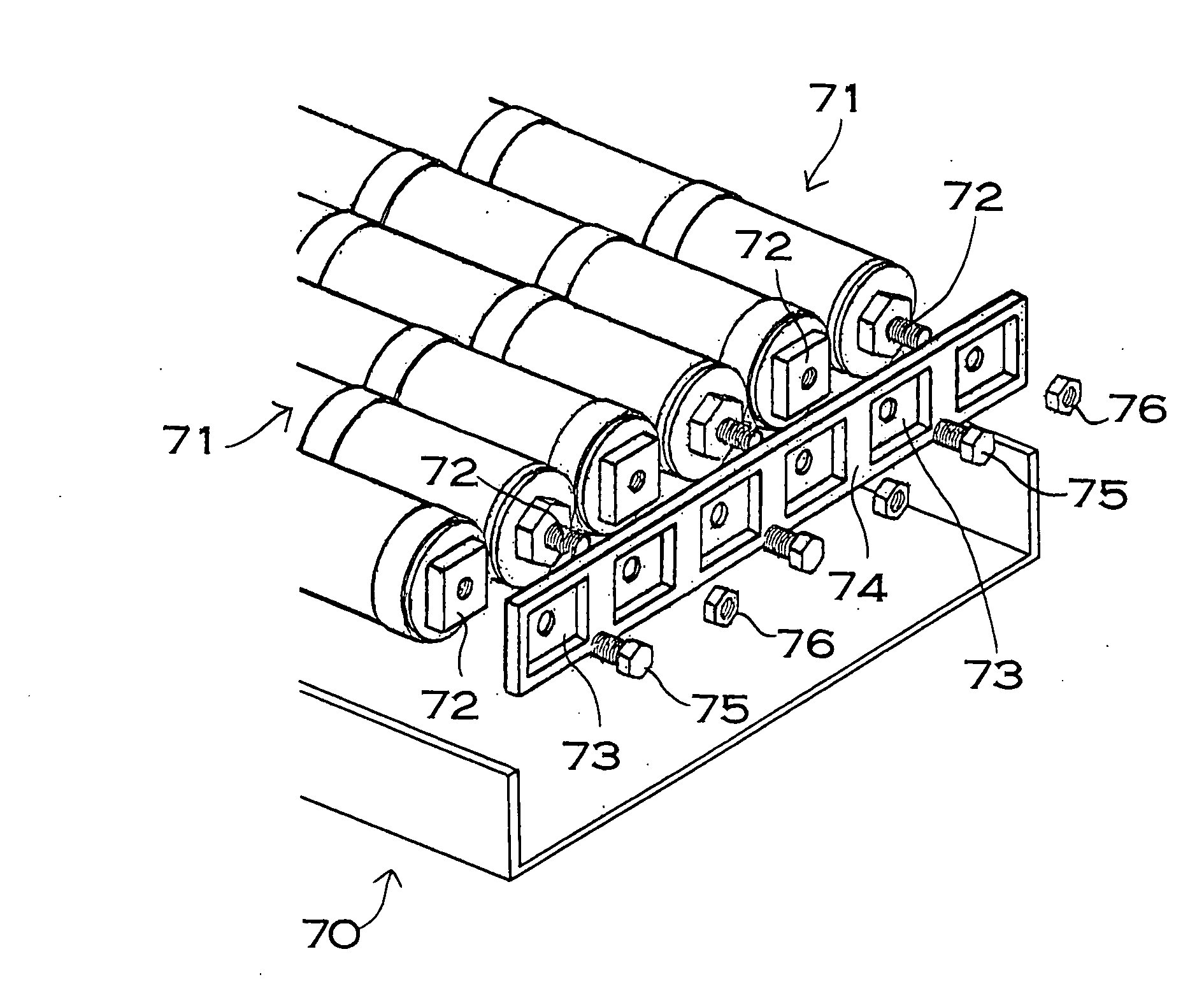

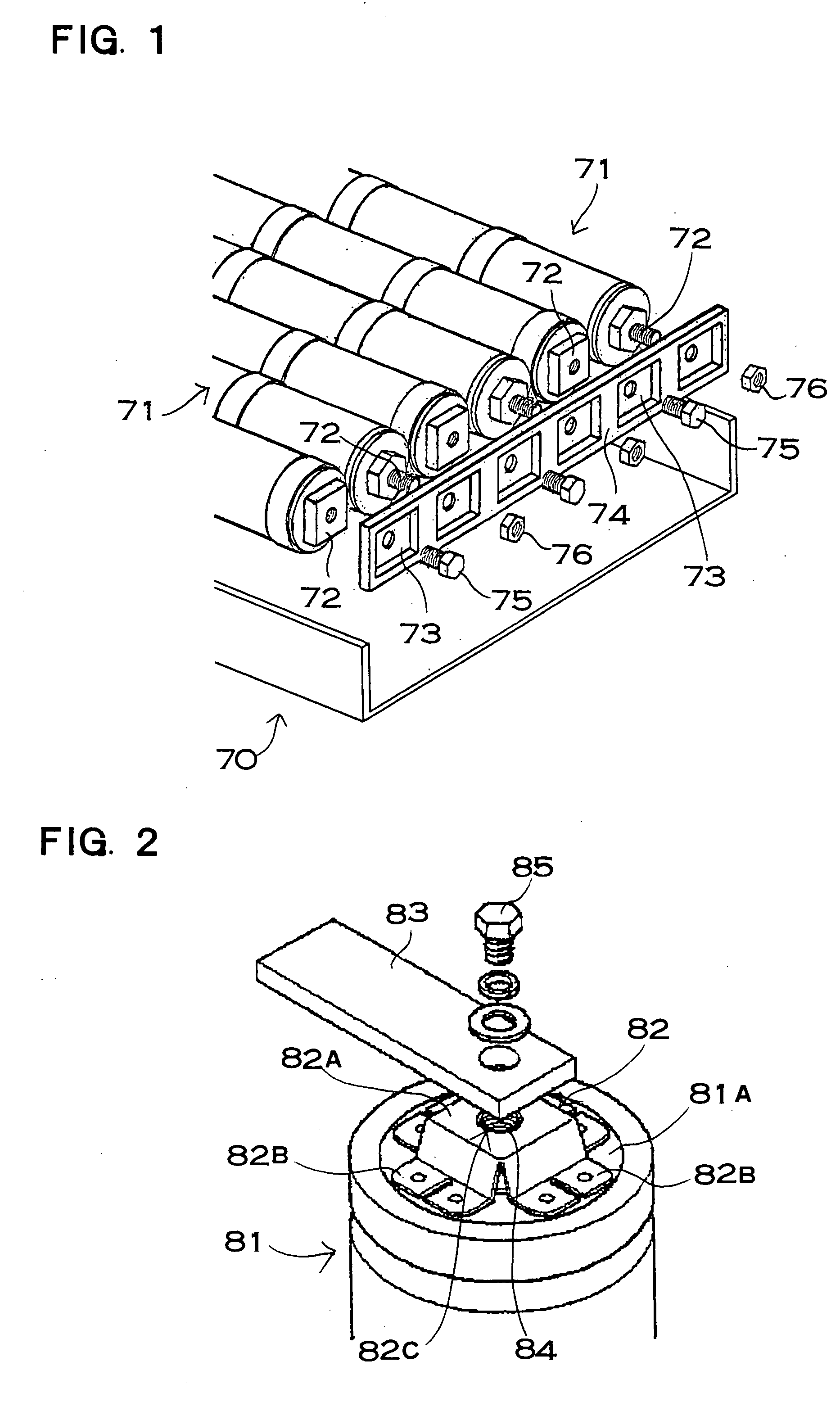

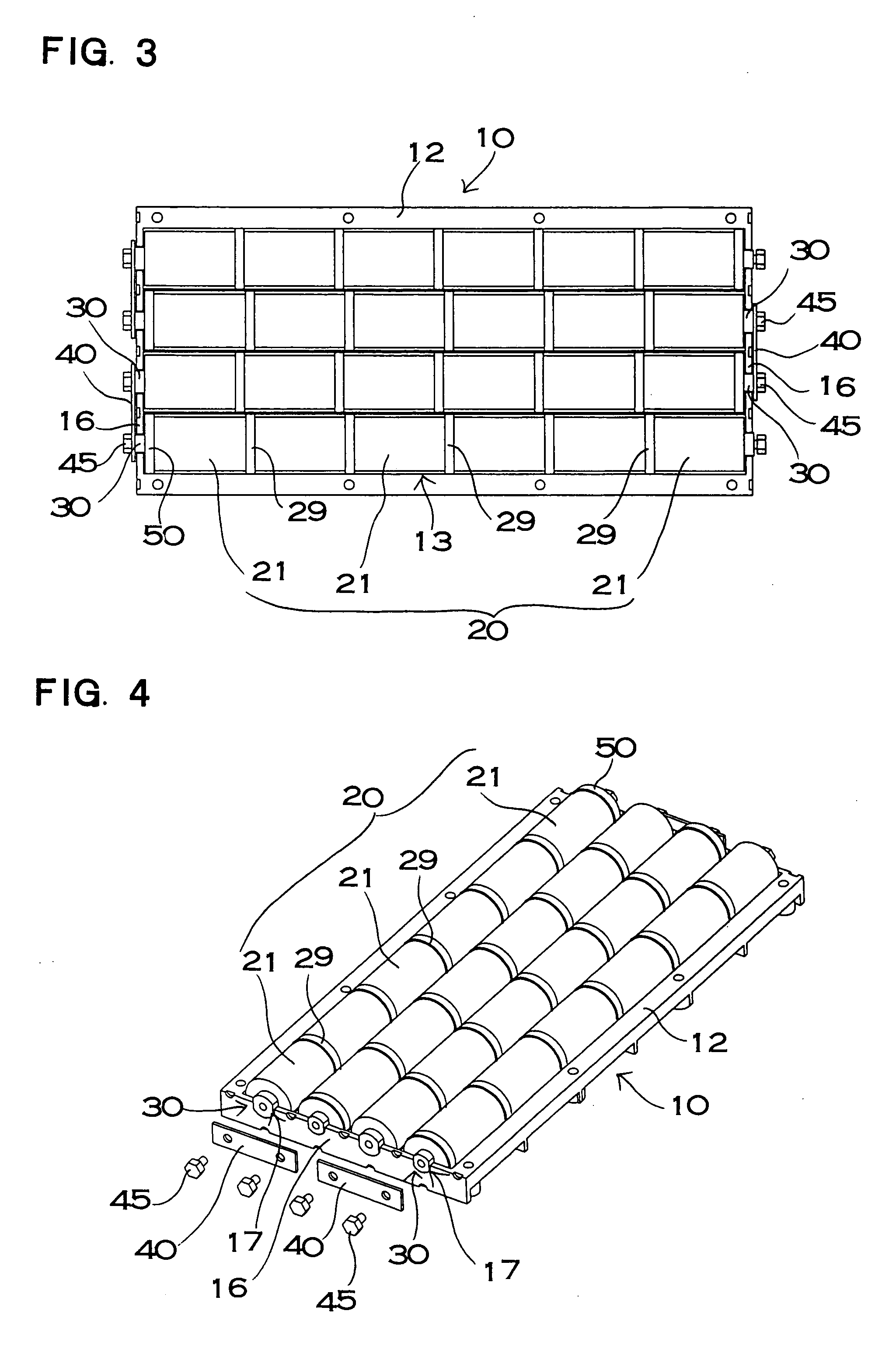

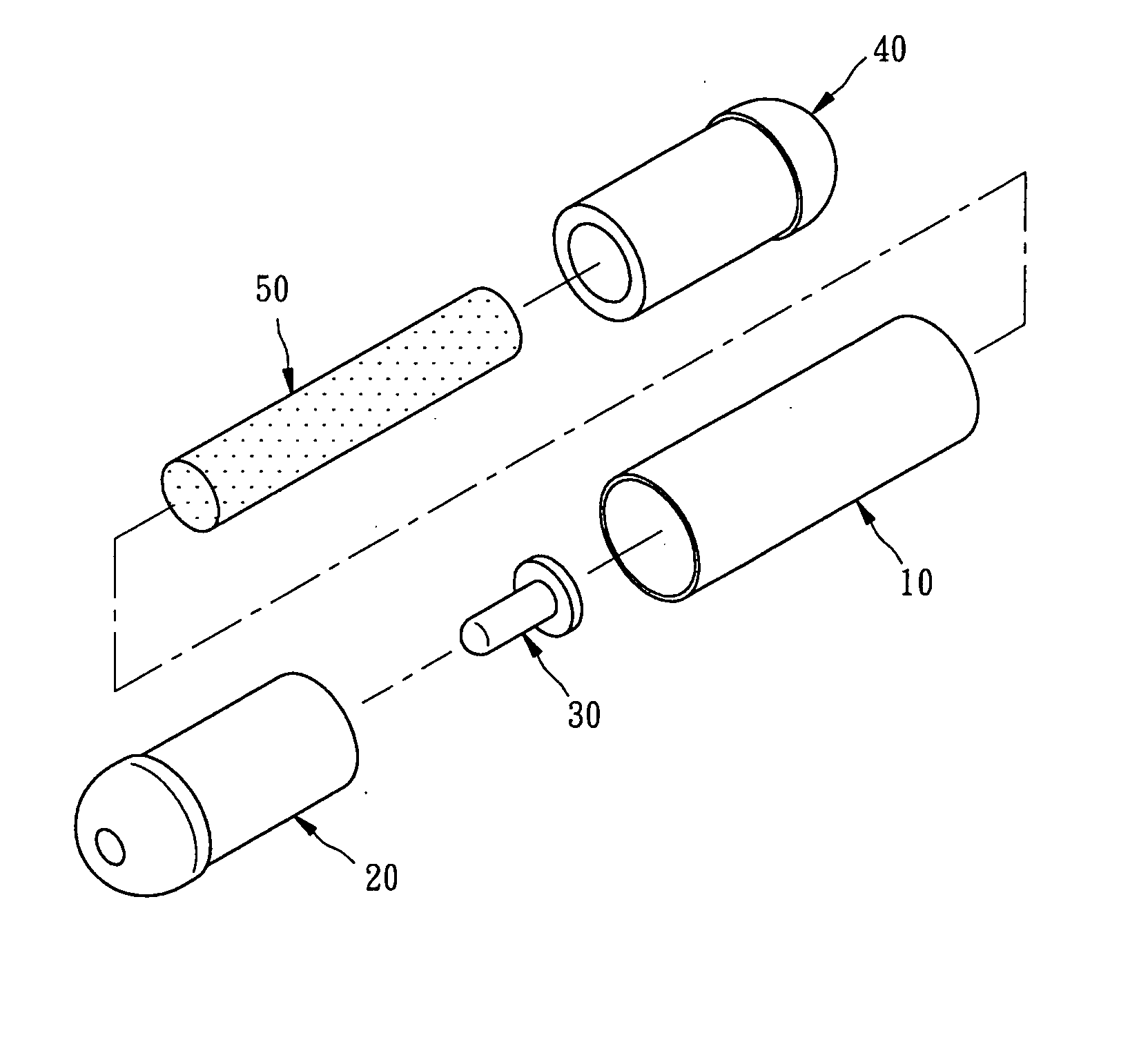

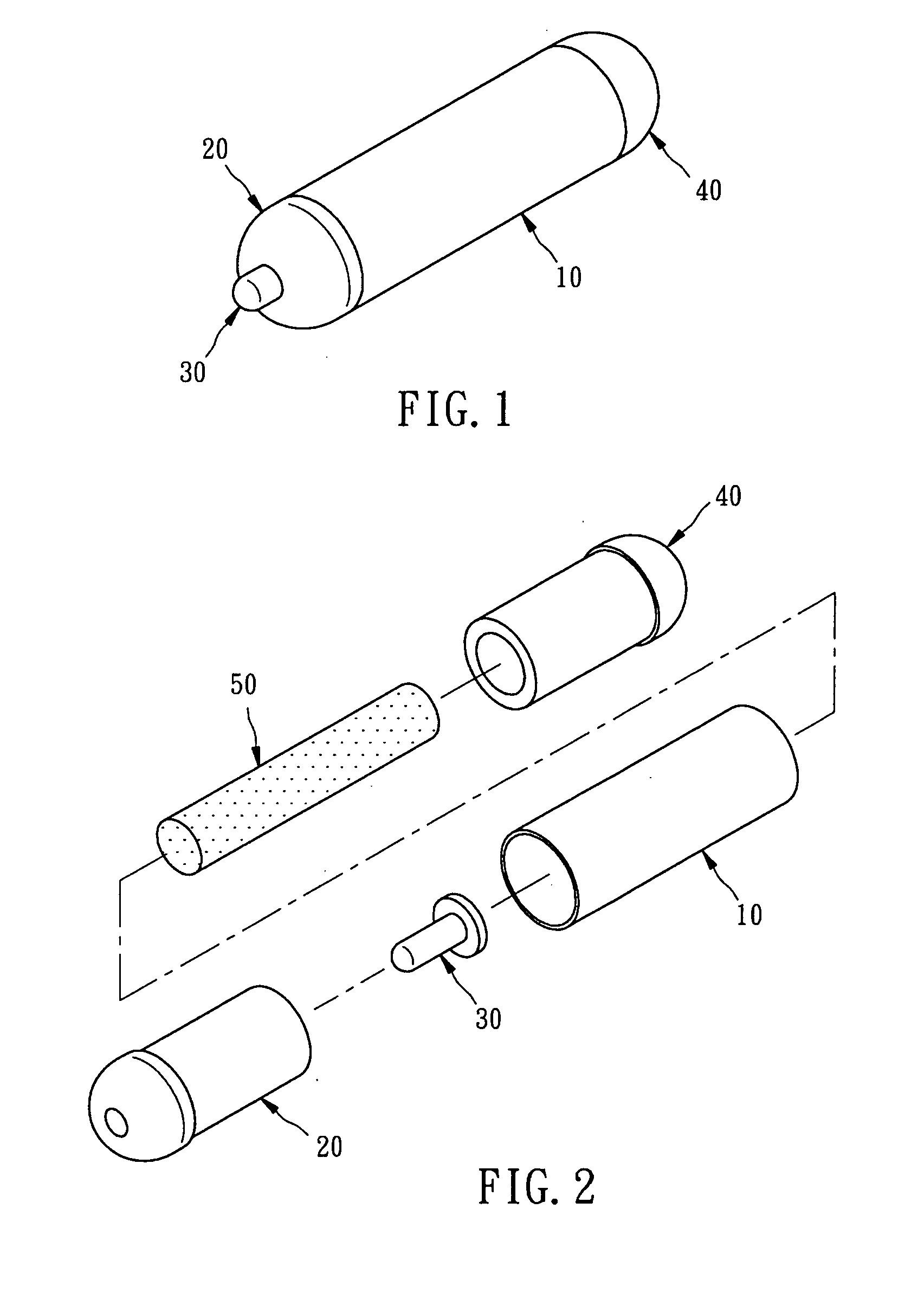

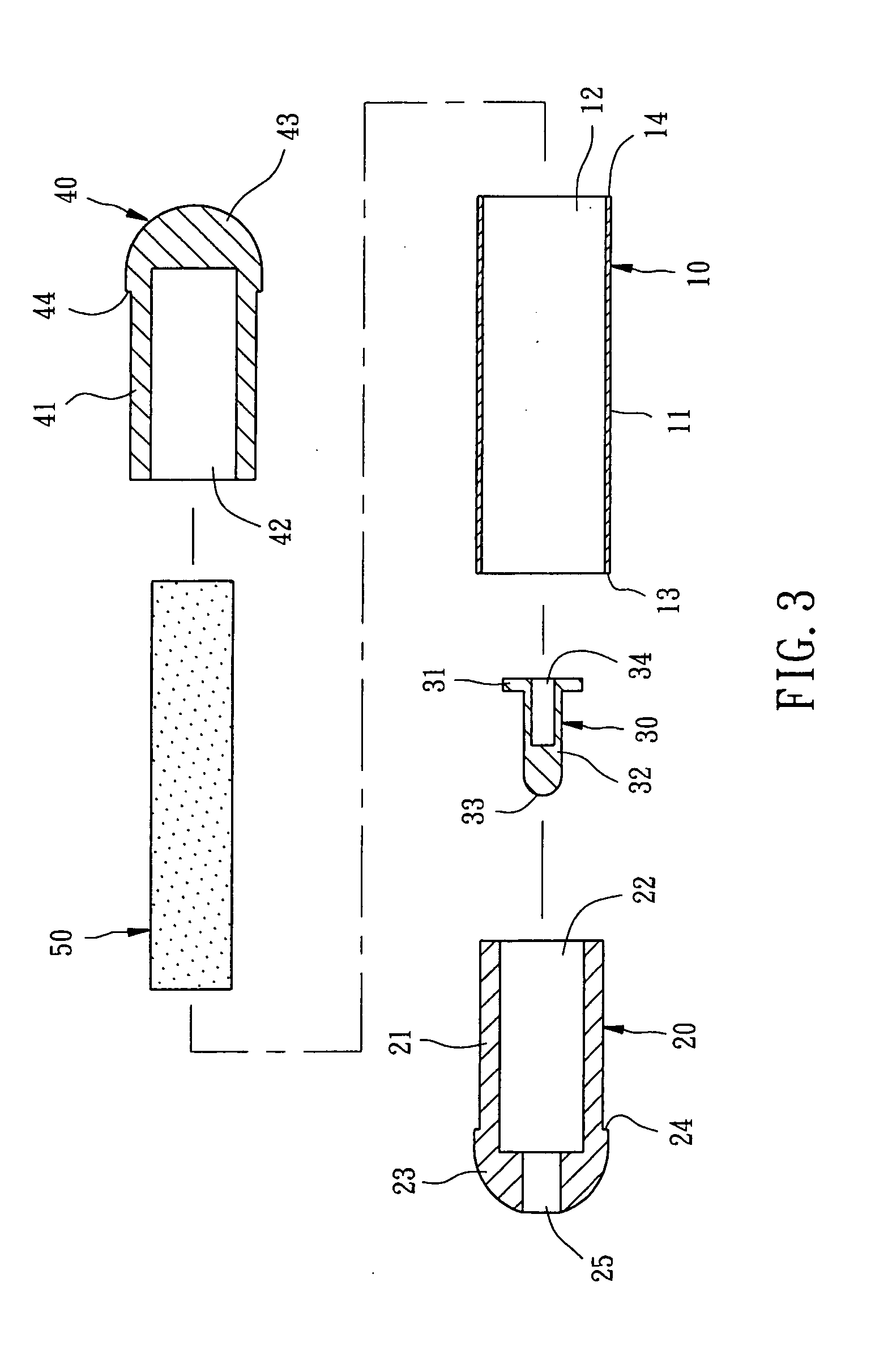

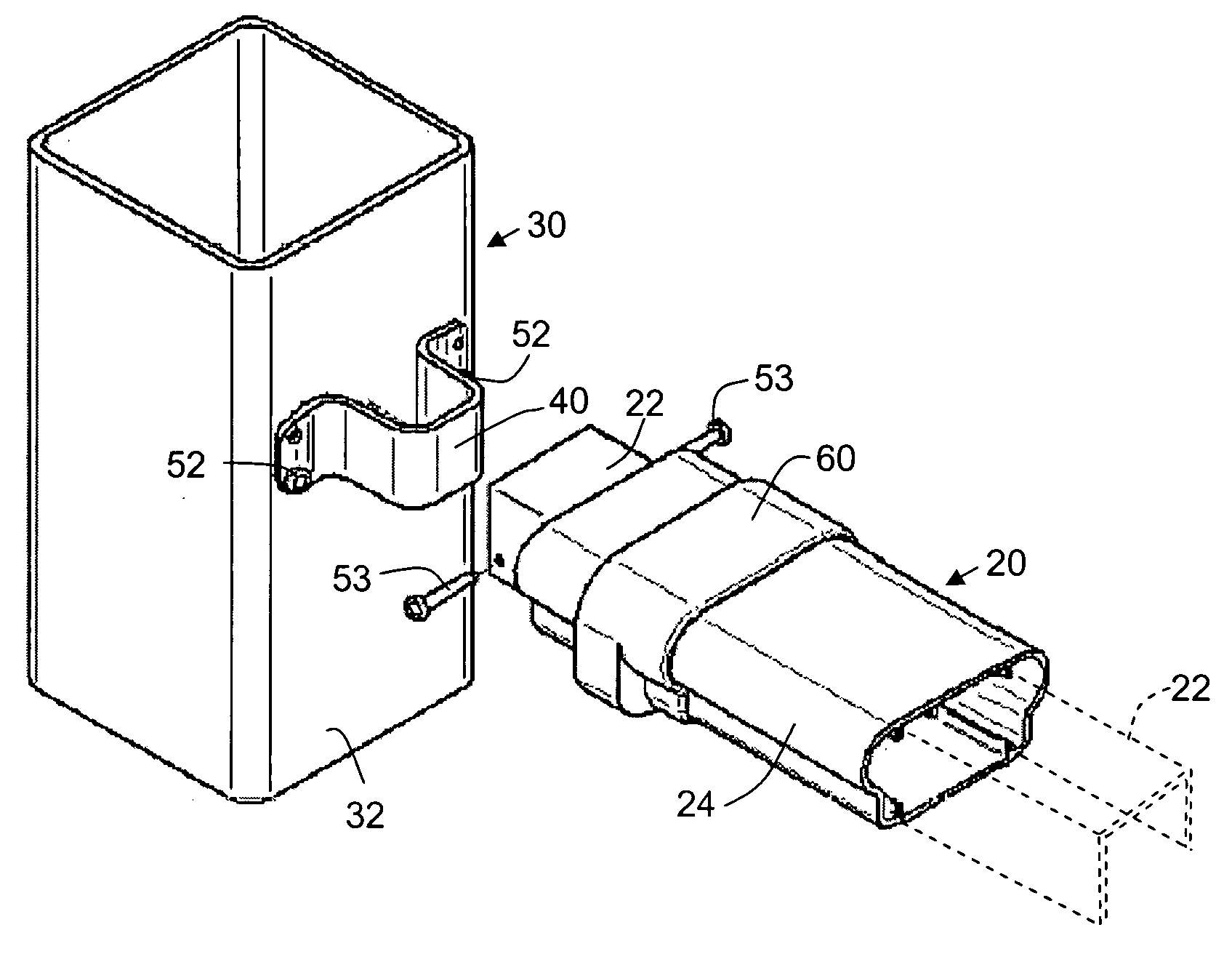

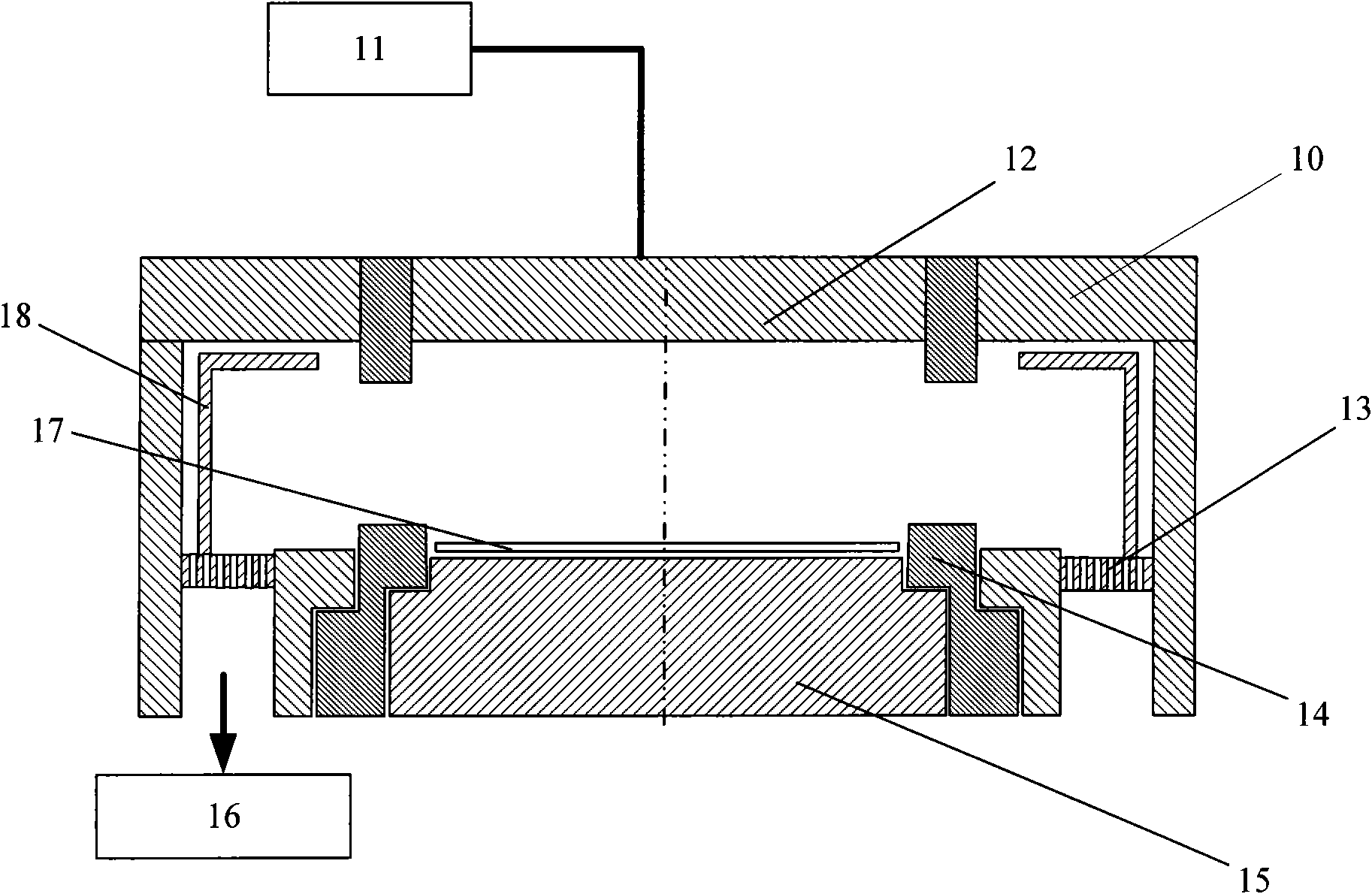

Power device

ActiveUS20060105624A1Inexpensively mass-producedHigh torqueCoupling device connectionsElectrically conductive connectionsEngineeringSurface plate

A power device includes a battery module for fixing a connecting terminal to an end and a bus bar connected to the connecting terminal of the battery module. The connecting terminal includes a fixing plate portion fixed to the end of the cell, an outer cylindrical portion protruded cylindrically from the fixing plate portion, an end face plate portion closing a tip surface of the outer cylindrical portion, and an inner cylindrical portion protruded from the end face plate portion toward the fixing plate portion. The connecting terminal is provided with a female screw on an internal surface of the inner cylindrical portion and a setscrew penetrating through the bus bar is screwed toward the female screw, and the bus bar is fixed to the connecting terminal through the setscrew.

Owner:SANYO ELECTRIC CO LTD

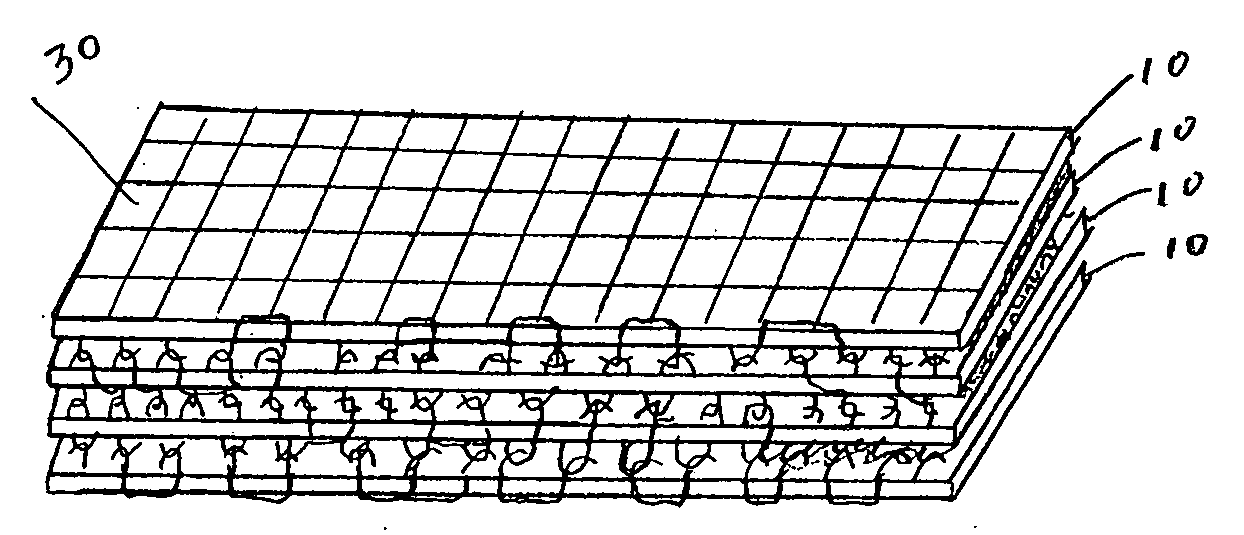

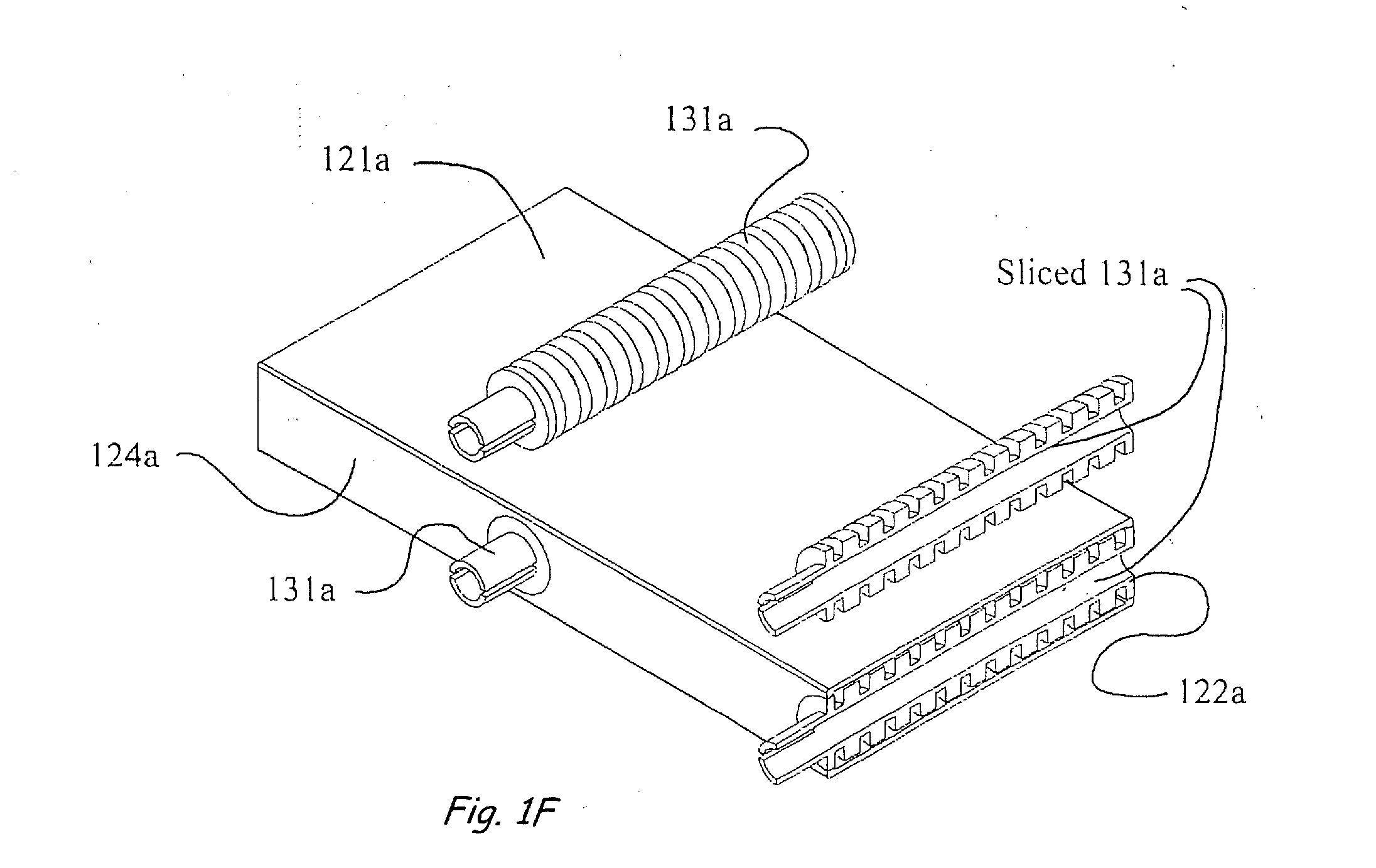

Fiber Products, Prepregs, Composites and Method of Producing Same

InactiveUS20080193709A1Increase strength and interface strengthIncreased strengthSlide fastenersLayered productsFastenerYarn

The present invention is to provide methods to increase composite interlaminate strength and interface strength, and make 3D fibers products, prepregs and composites, by using trans-interface and / or trans-fiber products such as trans-plies, strands and / or yarns fastening components selected from the group comprising of hooks and loops (velcro), hooks and hooks, zipper heads, fish hook shape hooks, staples, arrow heads, forks and mushroom heads. One ply of fibers has one or multiple of the above fasteners on at least one side. Lay-up the plies with said fastening components on its one or two sides to obtain a 3D fiber products with those fastening components locked together. The plies can be separated if need re-lay-up. A thread or a yarn have the fastening components around 0-360 degree on its surface. Lay the threads together or intercross each other to get a 3D fiber products. In those 3D fiber products, two parts of the fastening components lock each other if they meet and engage. A 3D composite can be made using the 3D fiber products.One fiber ply with the fasteners on its at least one side, is impregnated or protruded with matrix materials, a piece of the prepreg with the fasteners prepreg with the fasteners are made. Lay and press the prepreg together fastening components will lock each other if they meet and engage. In most of production processes, the matrix materials might soften and meld, and the fastening components will further interlock each other. So a 3D composite structure is made by the said 3D prepregs. Those fastening components may stay just partially or fully in matrix at matrix surface. The fastening components increase the interface strength when two matrix materials meet just by crossing interface even if they are not locked and without fiber products in matrix.

Owner:HAN NANLIN

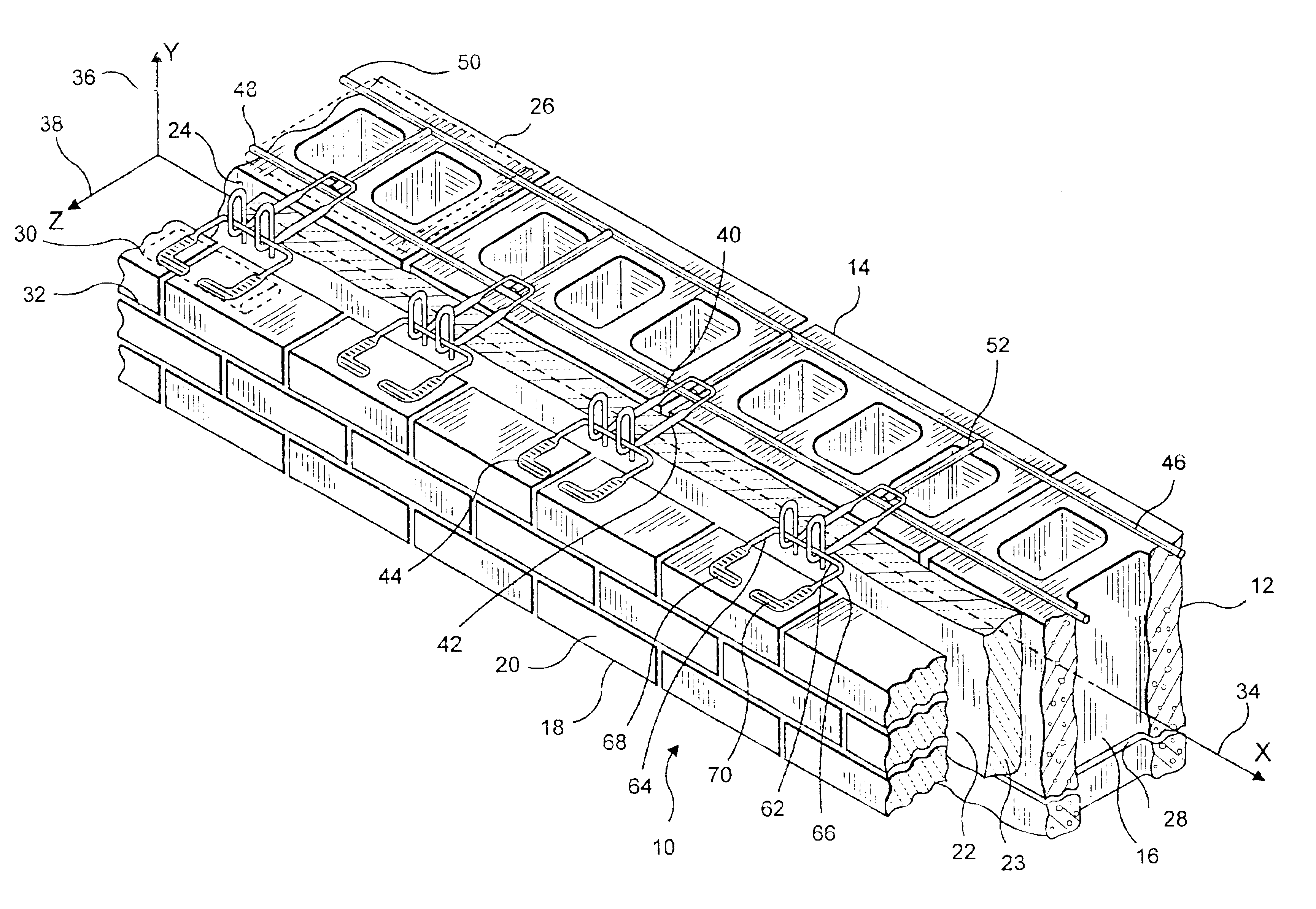

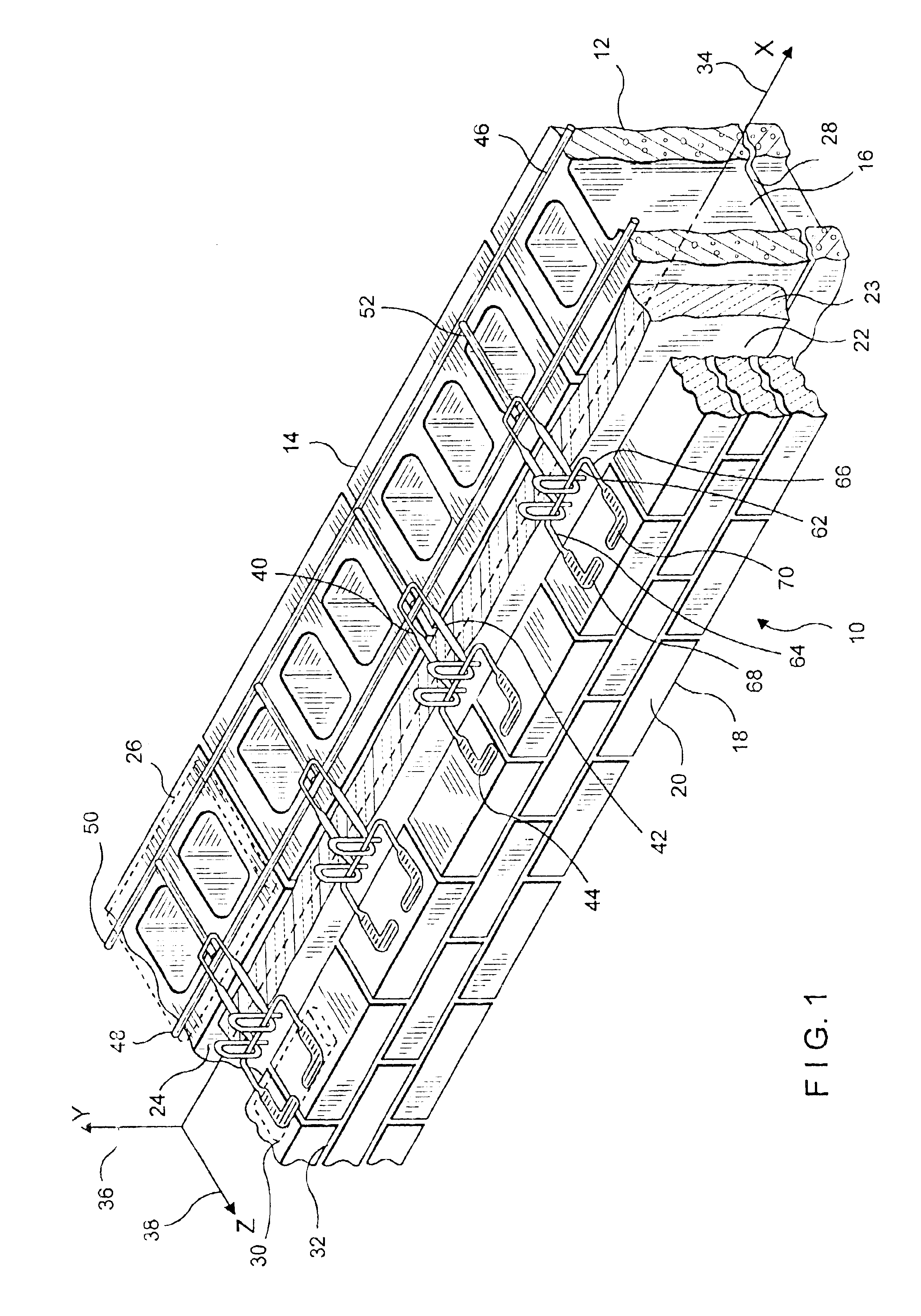

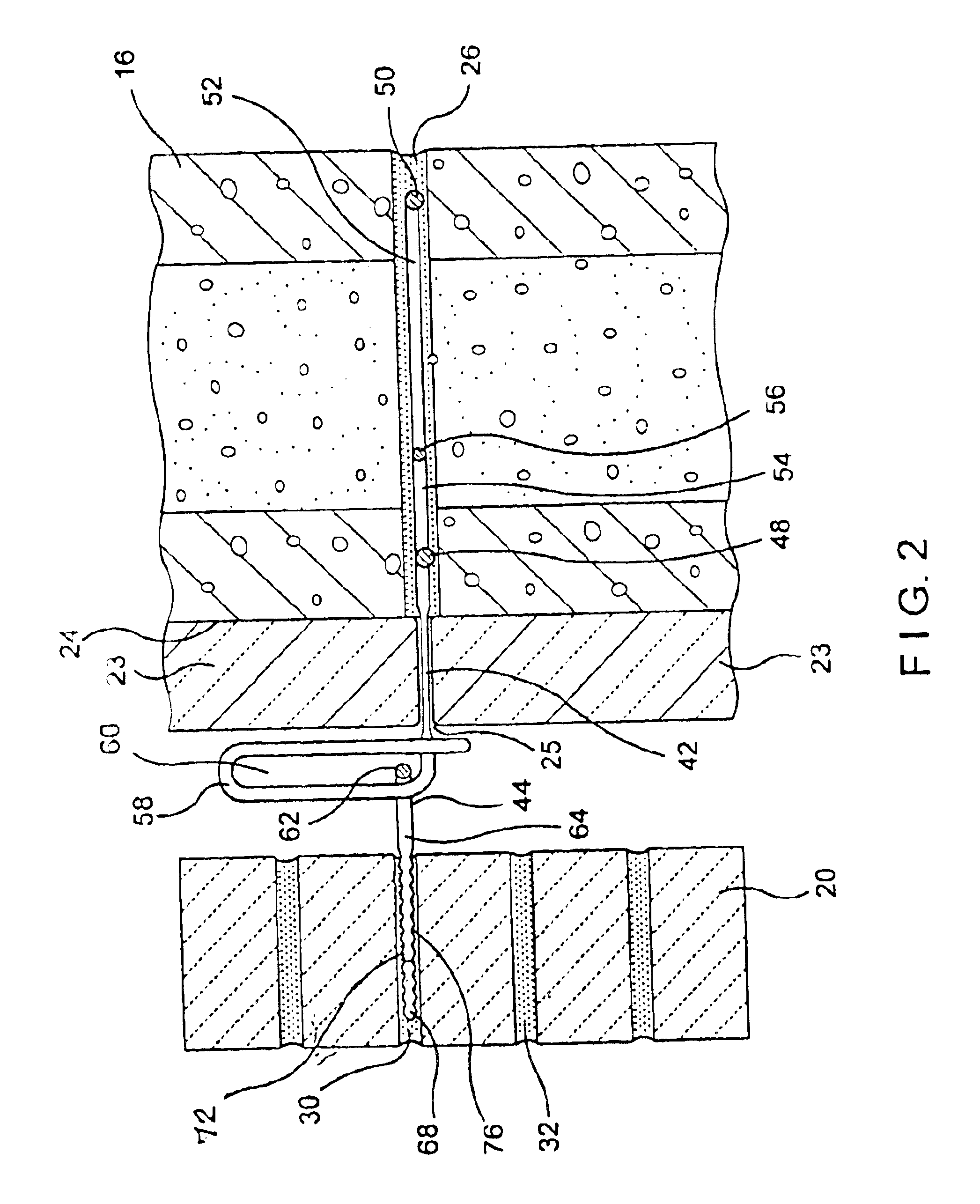

True-joint anchoring systems for cavity walls

InactiveUS6851239B1Improve evenlyReadily maintained verticalityStrutsConstruction materialMetal alloySingle plate

A high-span anchoring system is described for a cavity wall incorporating a wall reinforcement combined with a wall tie which together serve a wall construct having a larger-than-normal cavity. Further the various embodiments combine wire formatives which are compressively reduced in height by the cold-working thereof. Among the embodiments is a veneer anchoring system with a low-profile wall tie for use in a heavily insulated wall. The compressively reduced in height wall anchors protrude into the cavity through the seams, between insulation strips, which seams seal thereabout and maintain the integrity of the insulation by minimizing air leakage. Further, the eye wires extend across the insulation into the cavity between the wythes, and each accommodates the threading thereinto of a wire facing anchor or wall tie with either a pintle inserted through the eye or the open end of the veneer tie. The veneer tie is then positioned so that the insertion end is embedded in the facing wall. The close control of overall heights permits the mortar of the bed joints to flow over and about the wall reinforcement and wall tie combination inserted in the inner wythe and insertion end of the wall in the outer wythe. Because the wire formatives hereof employ extra strong material and benefit from the cold-working of the metal alloys, the high-span anchoring system meets the unusual requirements demanded thereof.

Owner:HOHMANN & BARNARD INC

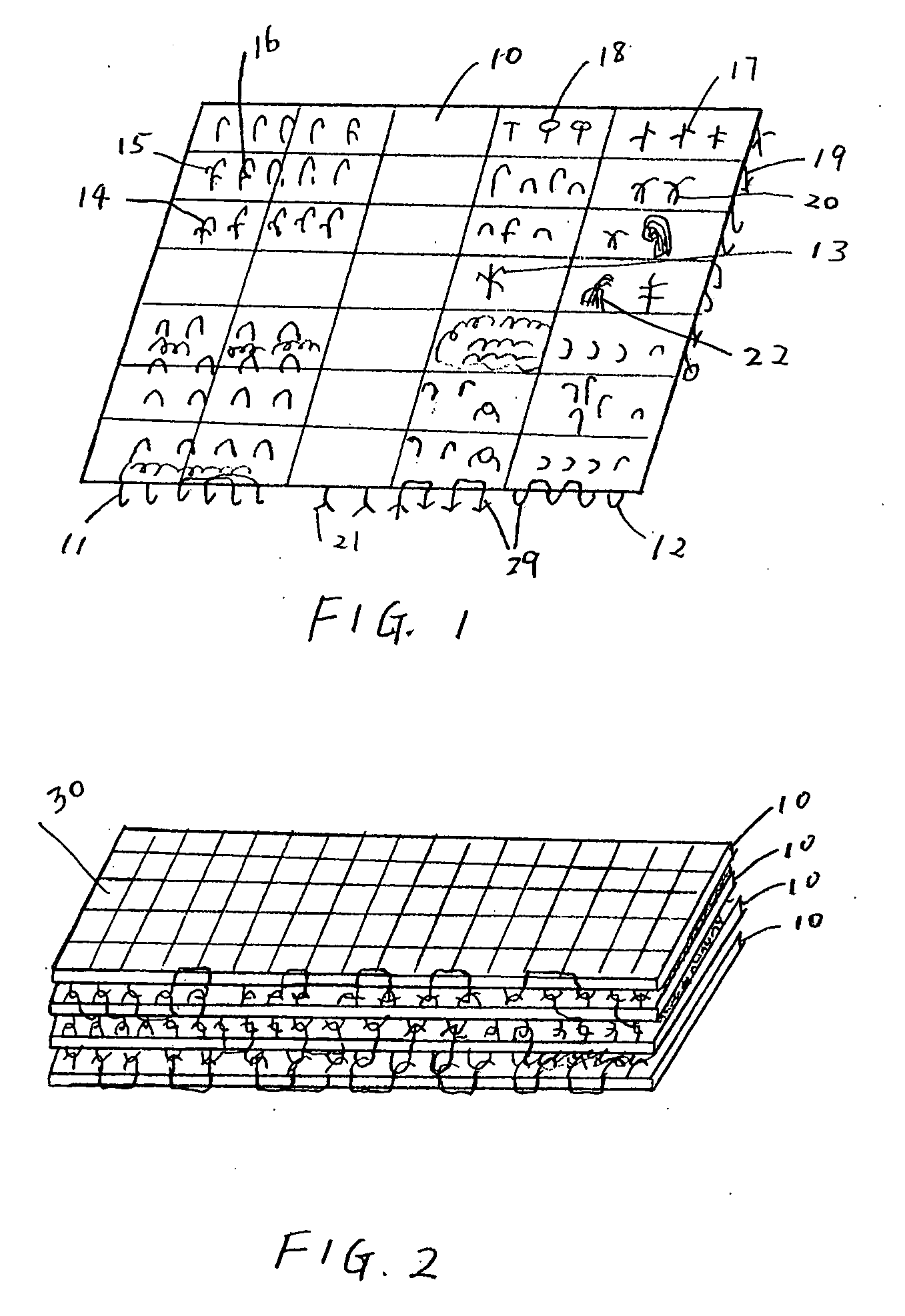

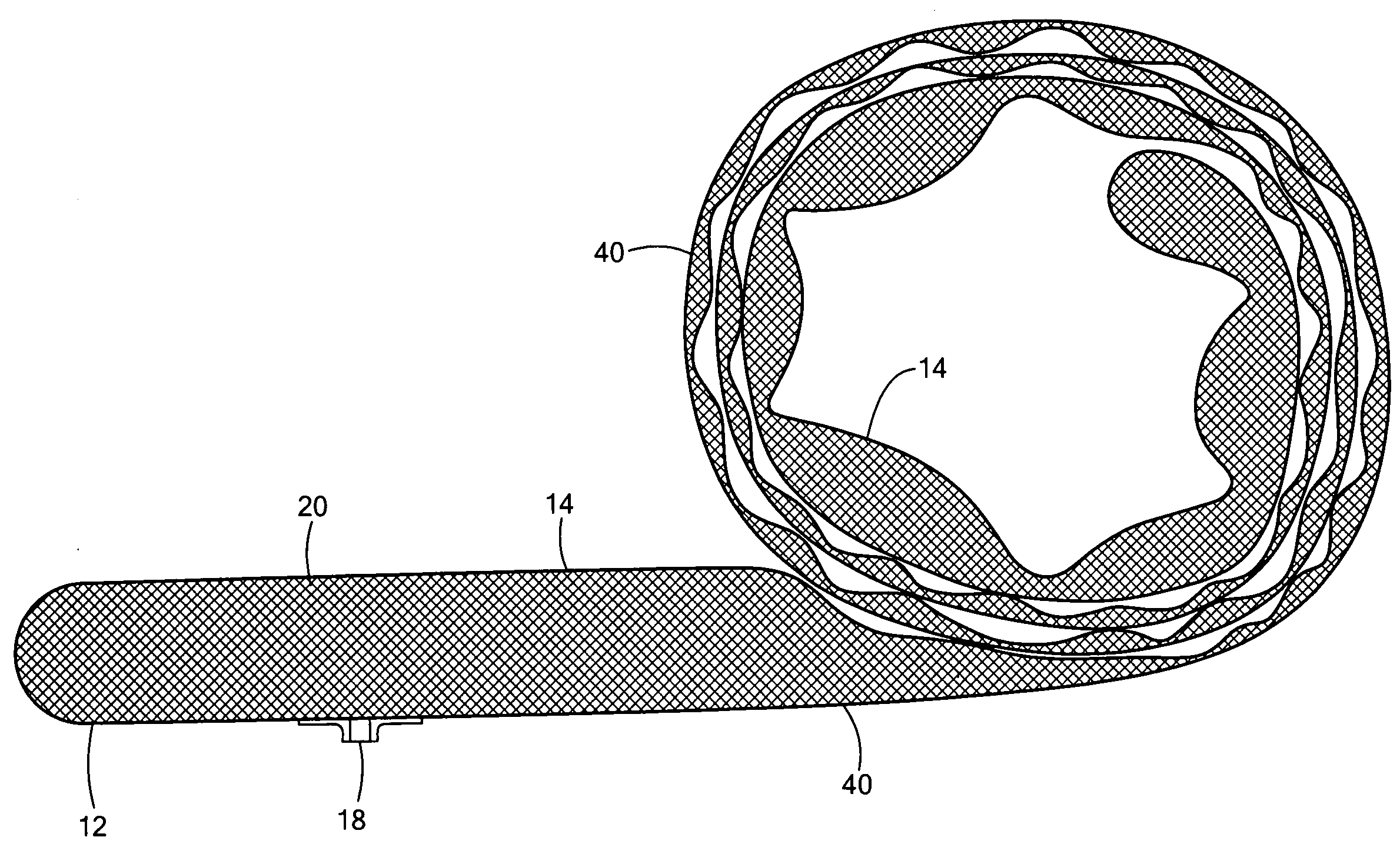

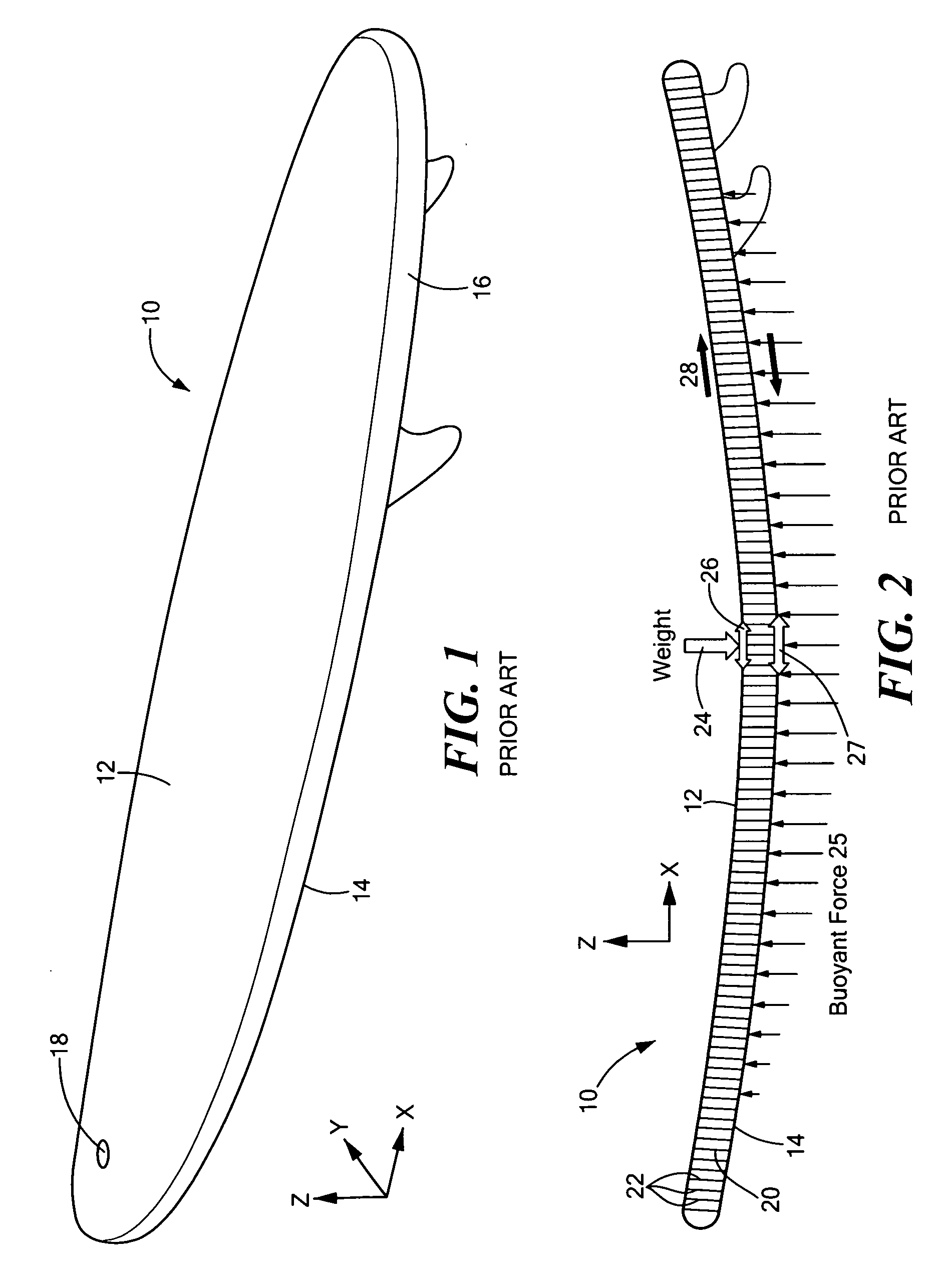

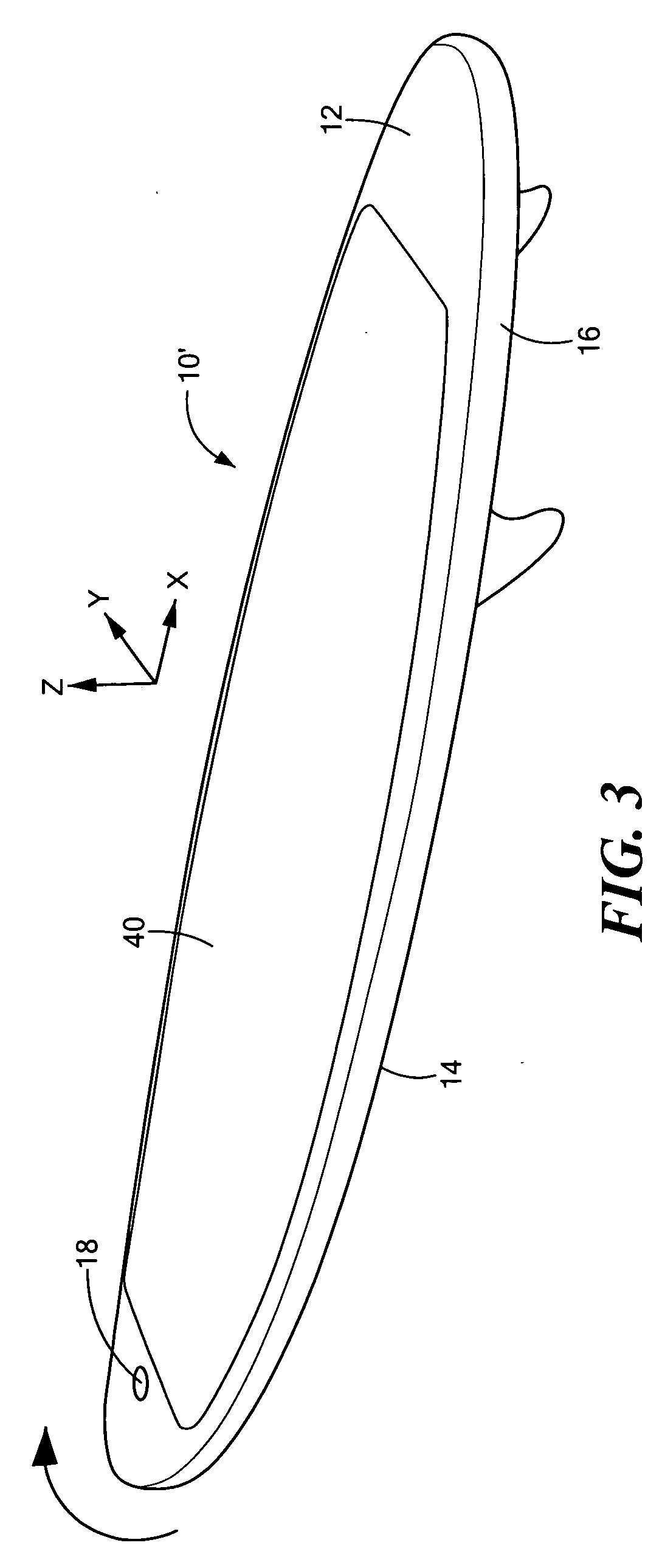

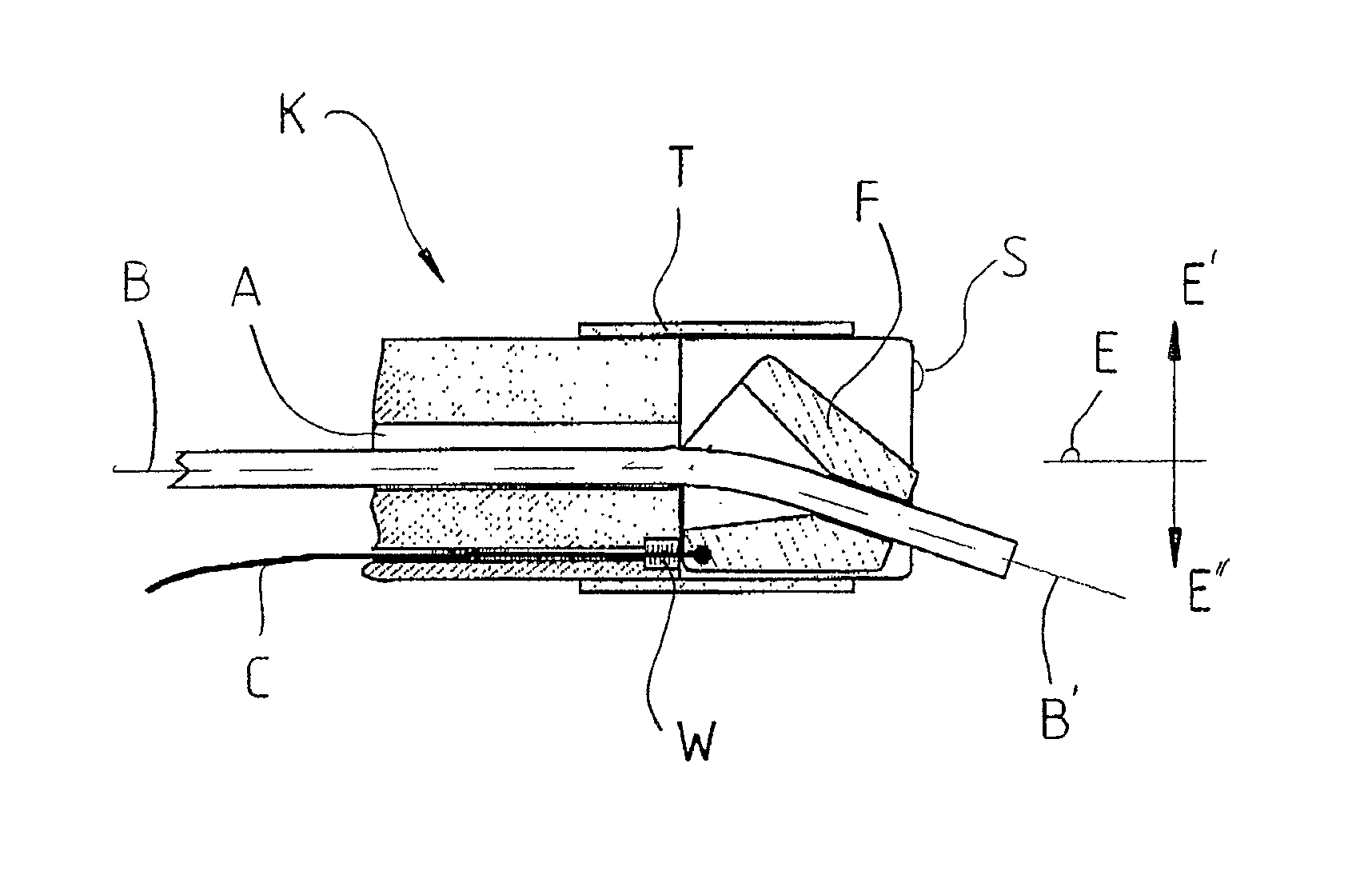

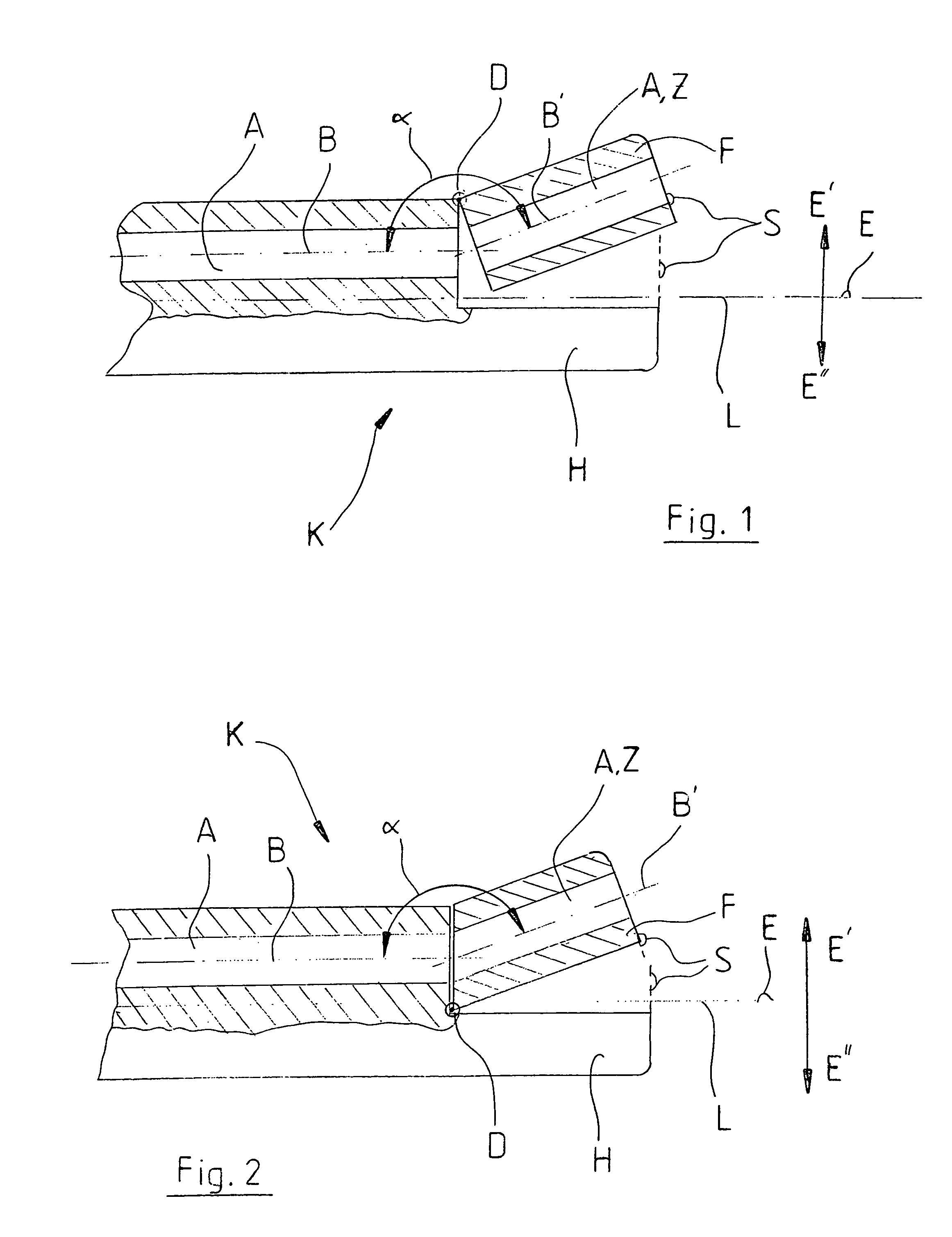

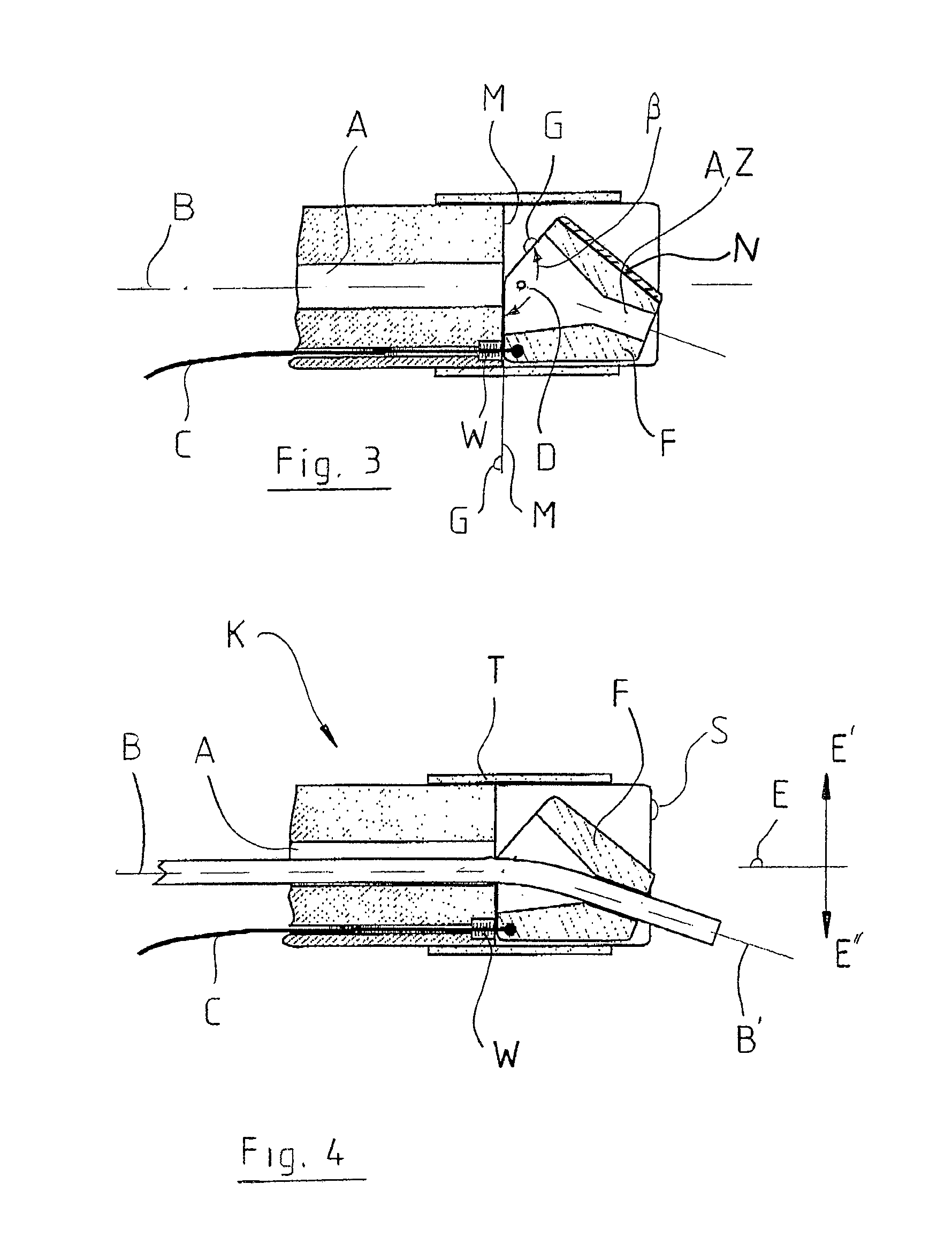

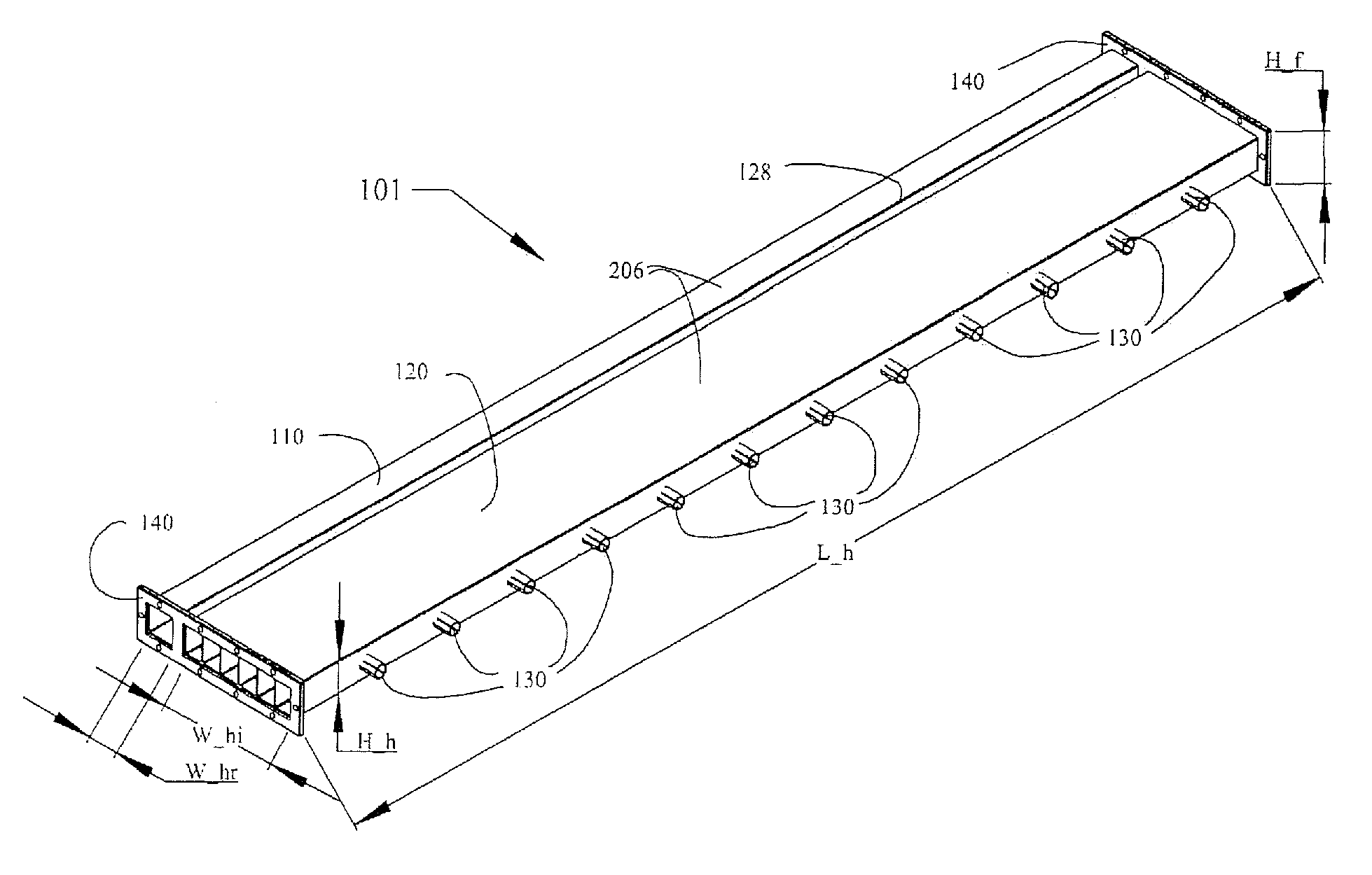

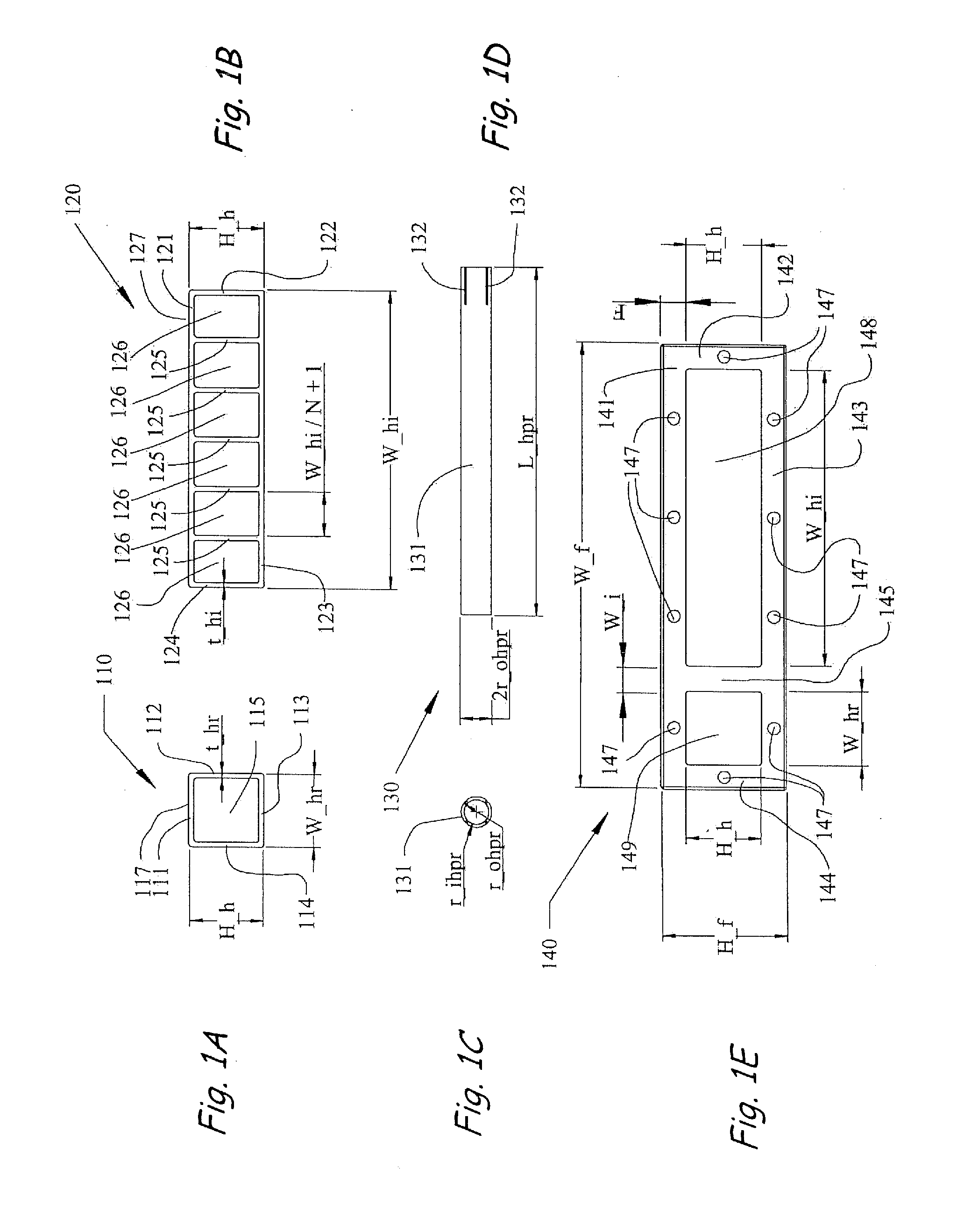

Roll-up inflatable beam structure

InactiveUS20090049757A1Strong and stable structureGood withstands buckling loadWaterborne vesselsWater sport boardsNuclear engineeringGas pressure

A sandwich beam including in one example first and second spaced walls, a core configured to maintain a predetermined spacing between the walls when the core is filled with pressurized gas and to resist shear when the beam is loaded in bending and a port for filling the core with gas biasing both walls in tension. The tension tends to increase in the second wall and decrease and cause a compression load in the first wall in response to a sufficiently large applied bending load. A compression element is fixed only with respect to the first wall and is configured (a) to support the compression load so that the beam is stronger at a given gas pressure and (b) to flex sufficiently to allow the beam to be rolled up when the gas is emptied from the core via the port.

Owner:FOSTER-MILLER

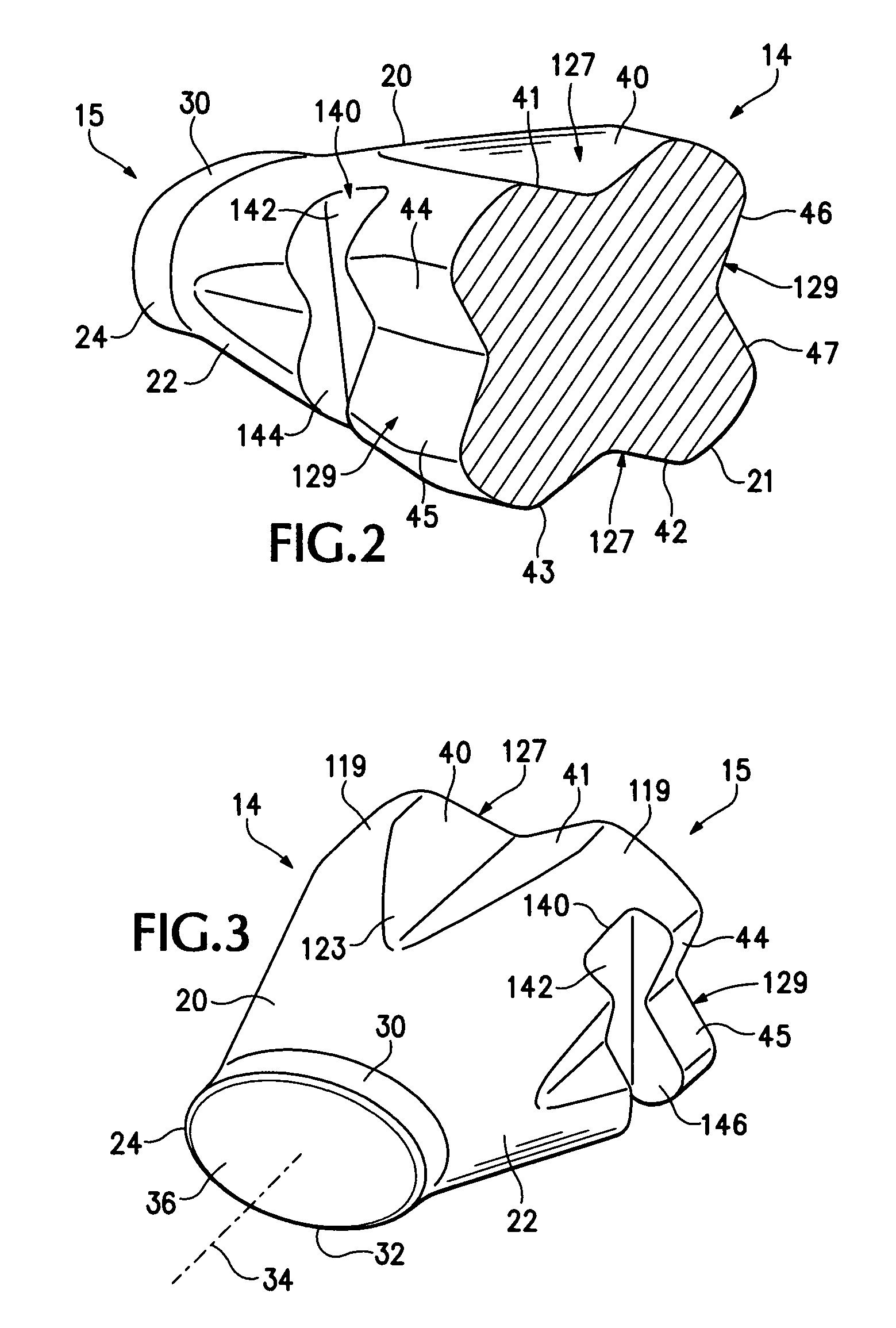

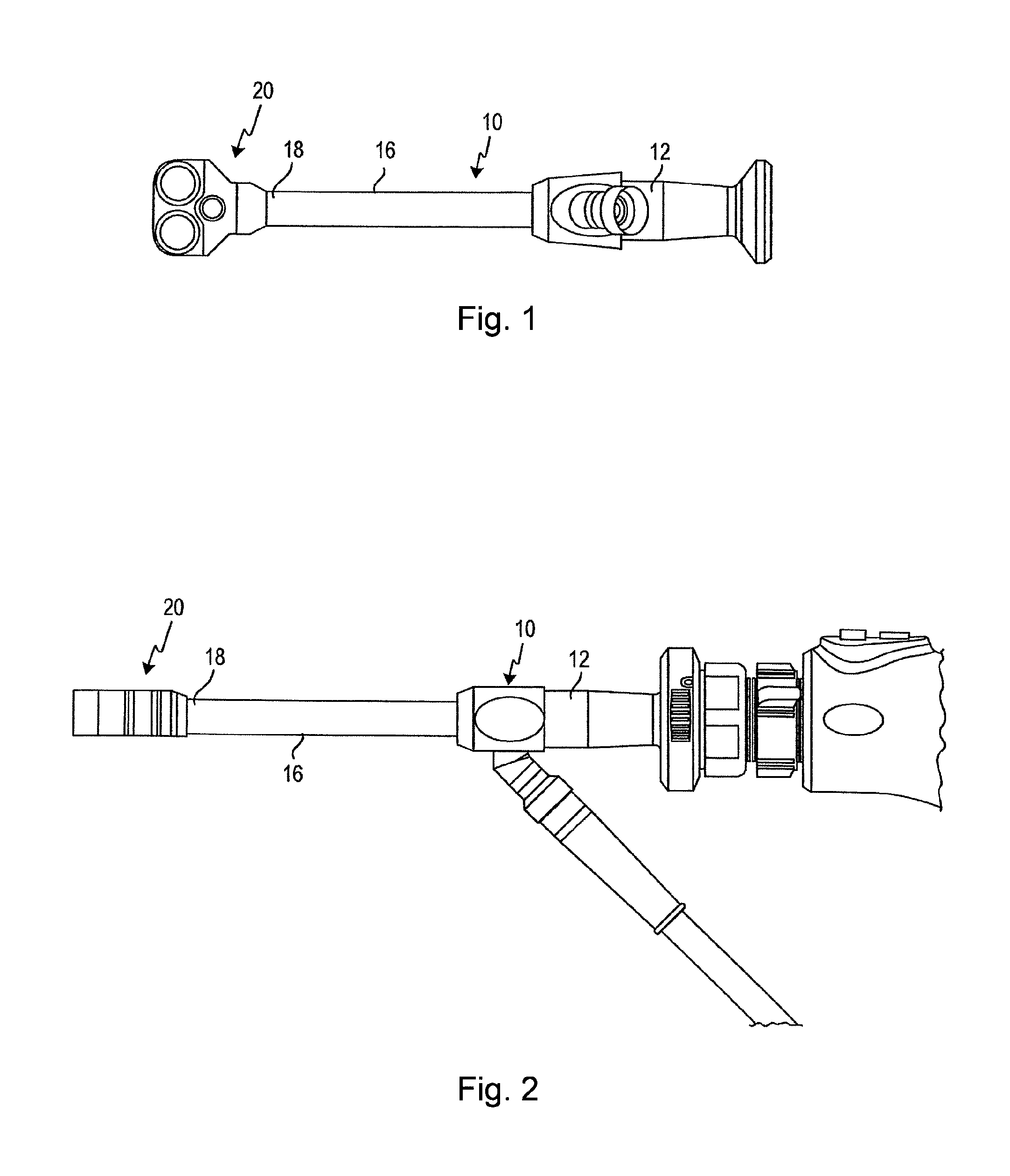

Wear assembly

ActiveUS7730651B2Reduce penetrationImprove stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

Owner:ESCO GRP LLC

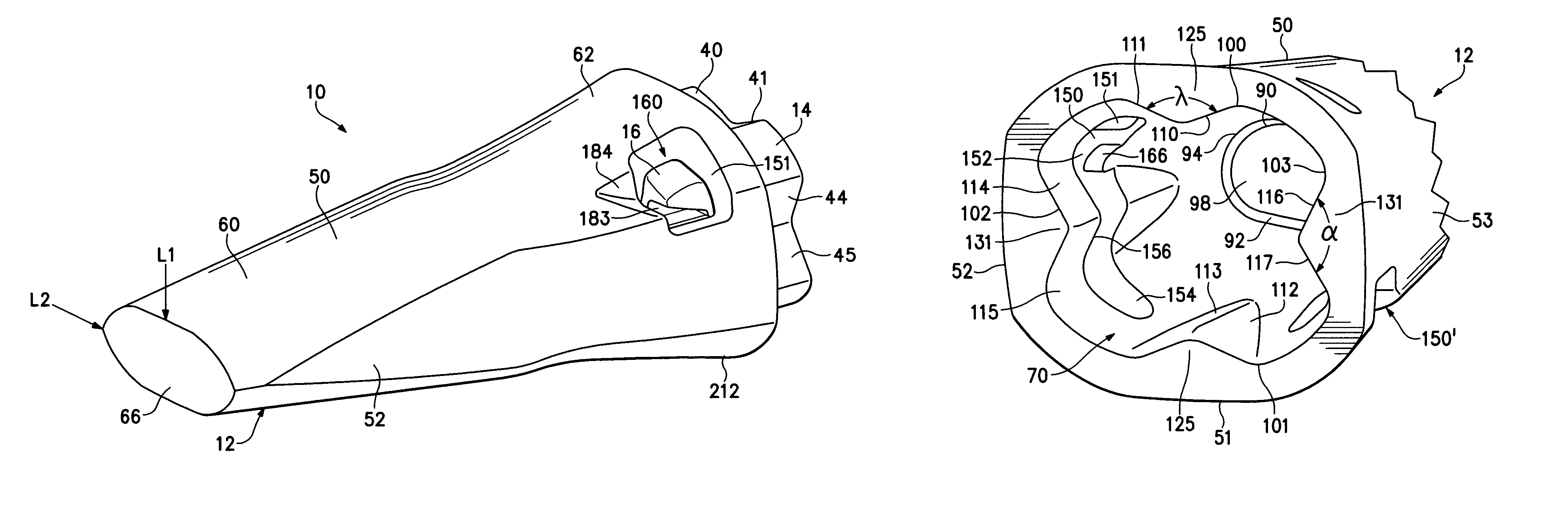

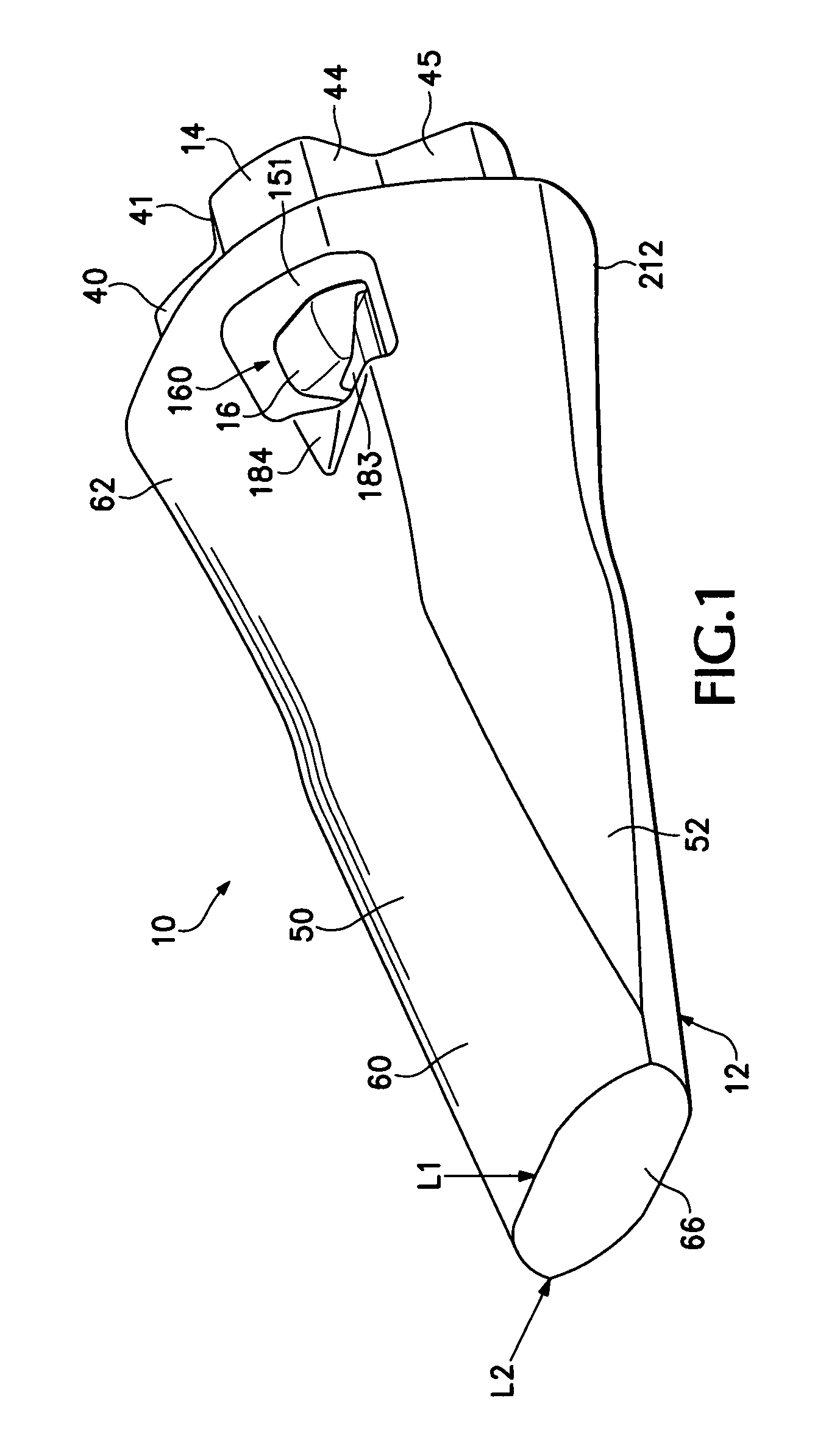

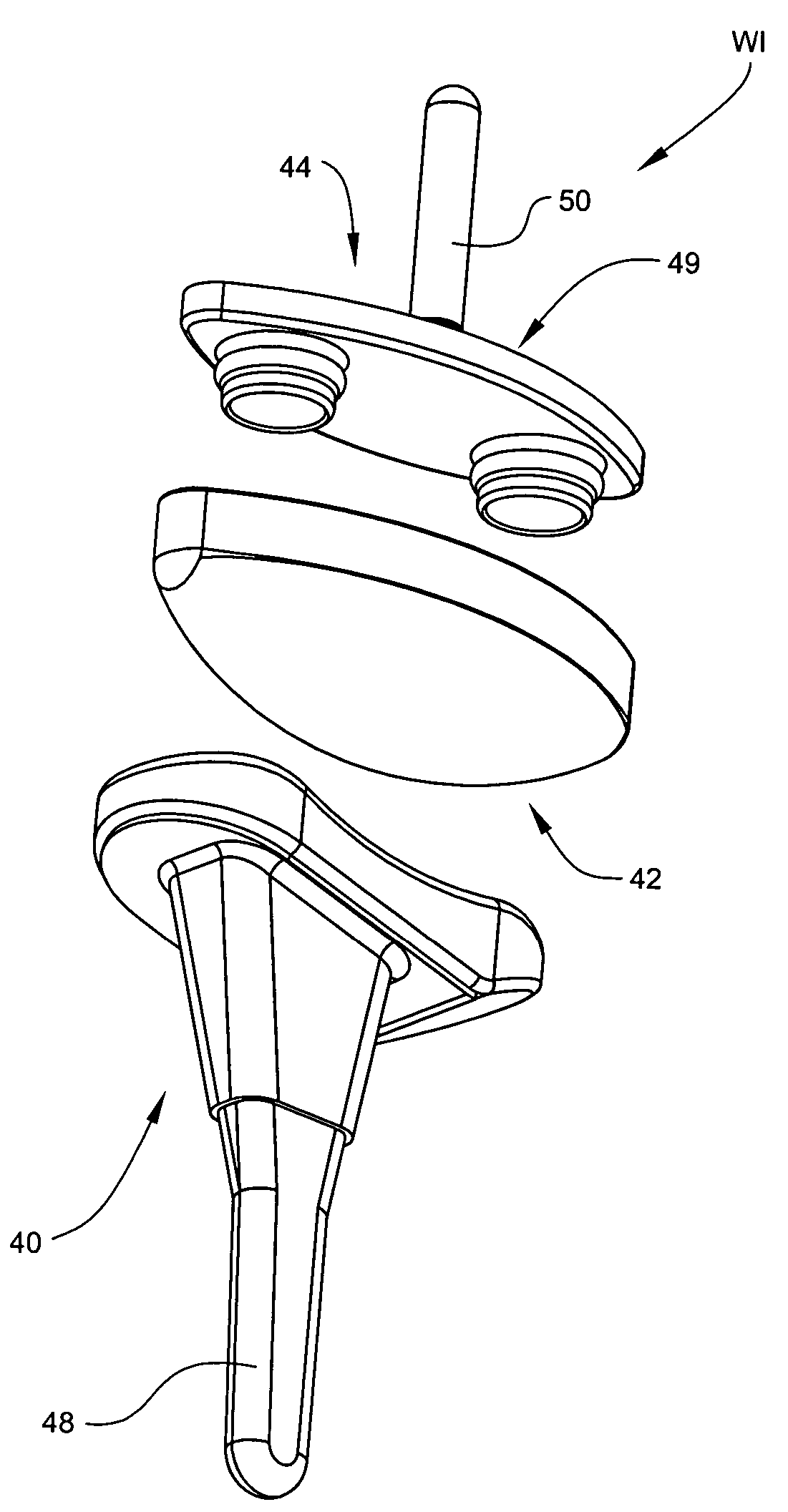

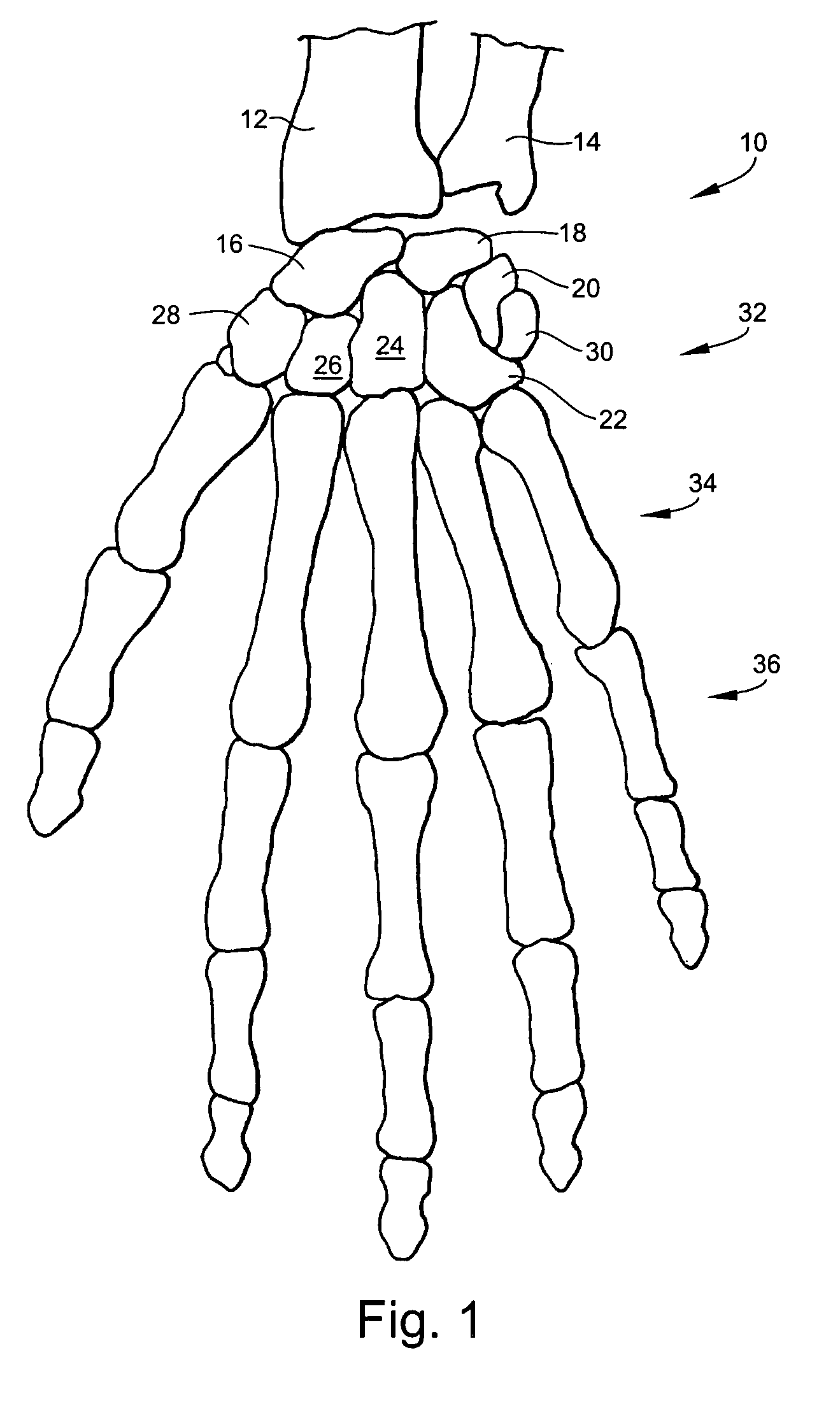

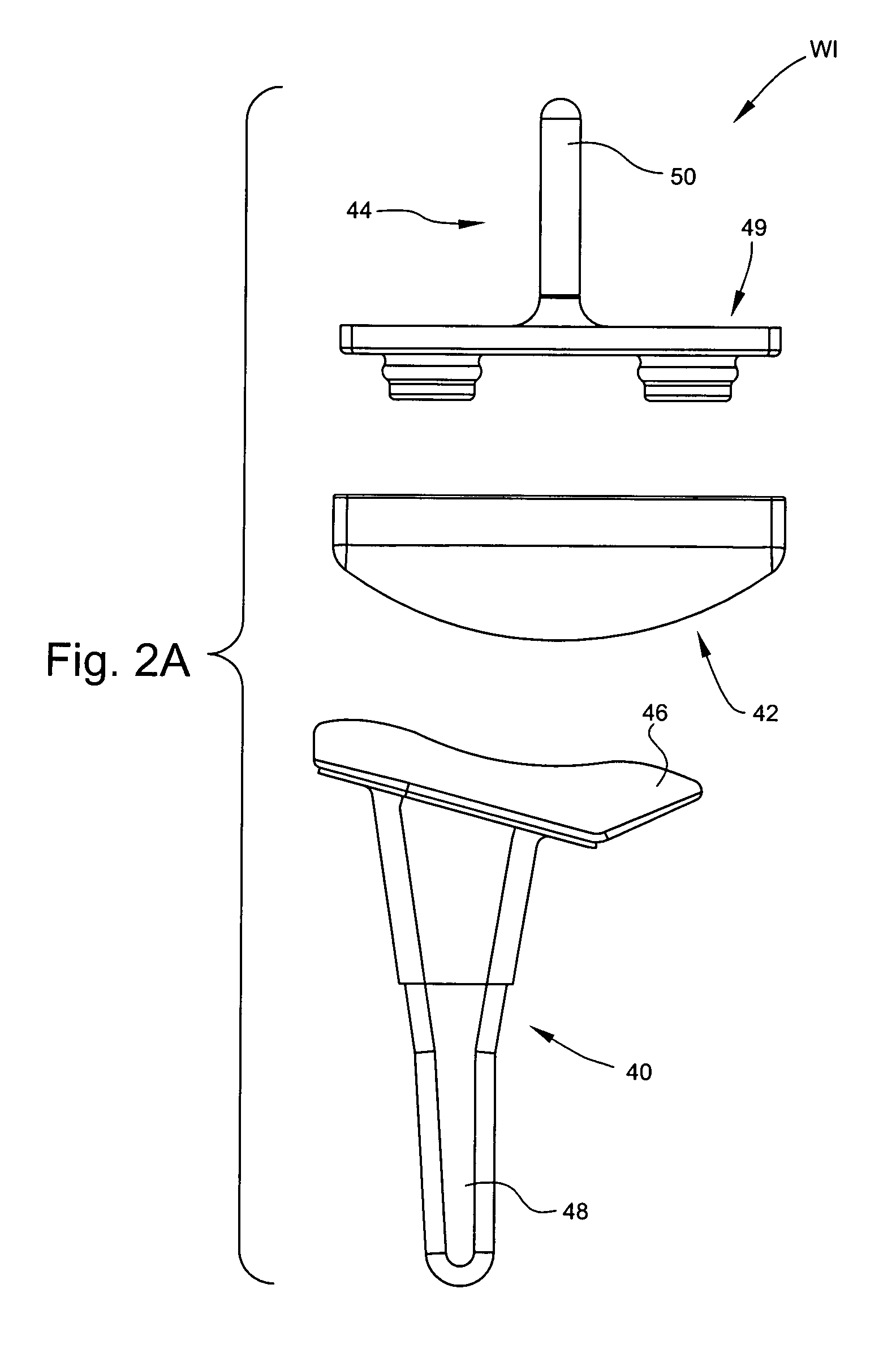

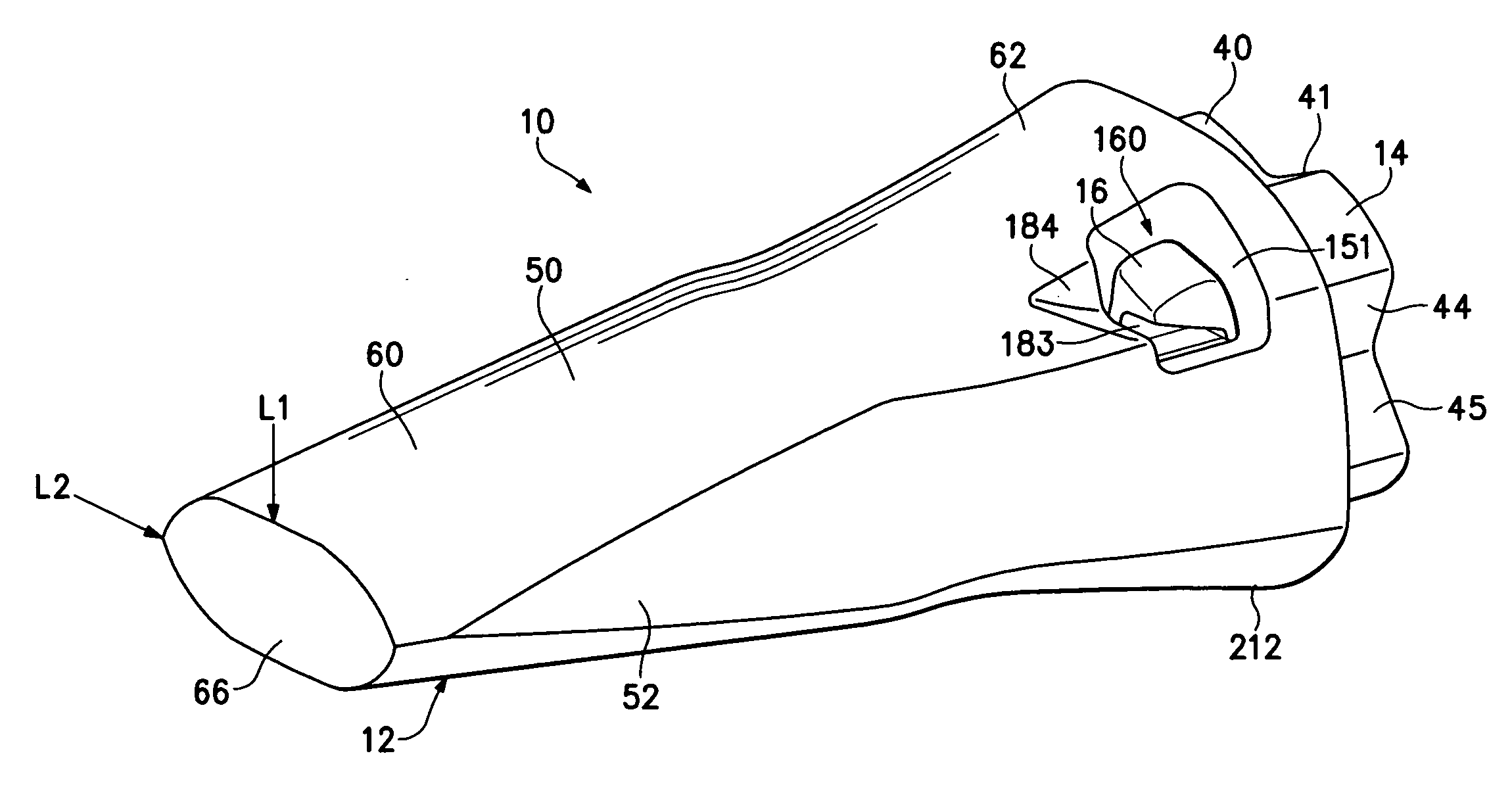

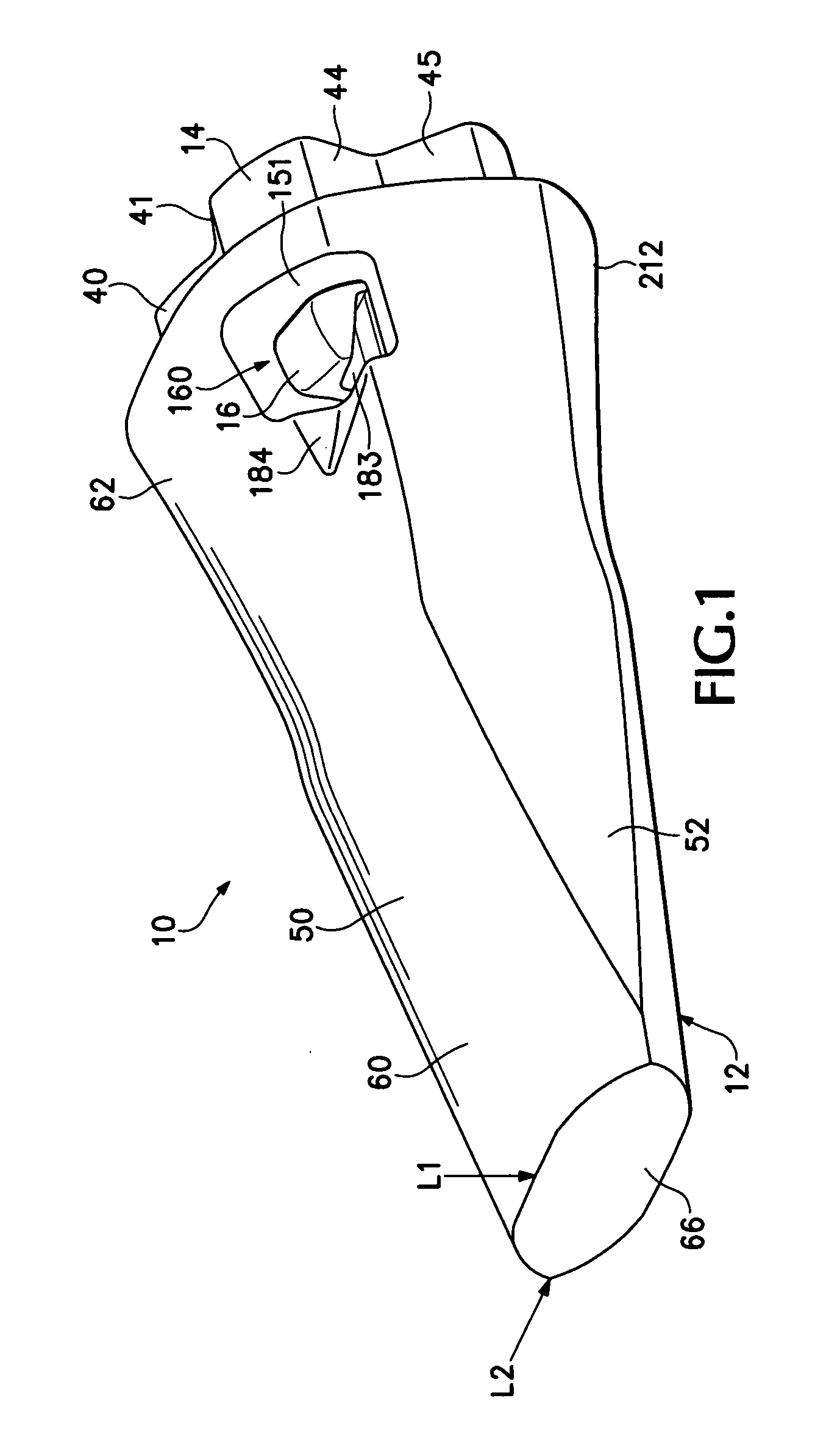

Wrist implant apparatus and method

ActiveUS7531003B2Large range of motionAcceptable flexionWrist jointsAnkle jointsProsthesisCarpal bones

Prosthetic wrist implants and methods are provided. The prosthetic wrist implant includes a radial component including a base member having an upper bearing surface and a lower surface having an elongated radial stem for fixation to a radius bone. The elongated radial stem can be in an off-center position in relation to a center of the lower surface. A carpal component is also provided including a substantially planar base member having an upper surface and a lower surface with at least one socket protrusion extending therefrom, and may further included an elongated carpal post member for fixation to one or more carpal bones. An articulating bearing component for placement between the radial and carpal components is provided and includes an upper surface defining at least one socket recess and a lower bearing surface for cooperative engagement with the upper bearing surface of the radial component. The socket protrusion of the carpal component is adapted to linearly engage the socket recess of the bearing component to desirably limit rotational and translational movement of the carpal component relative to the bearing component.

Owner:SMITH & NEPHEW INC

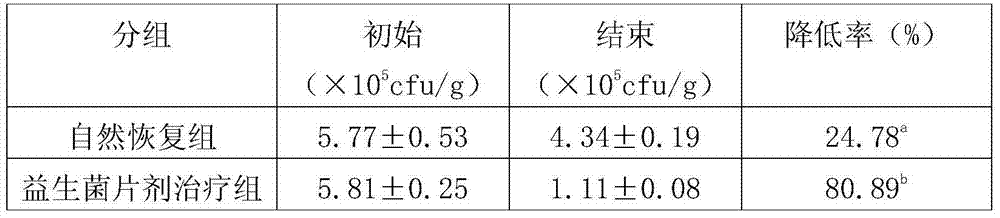

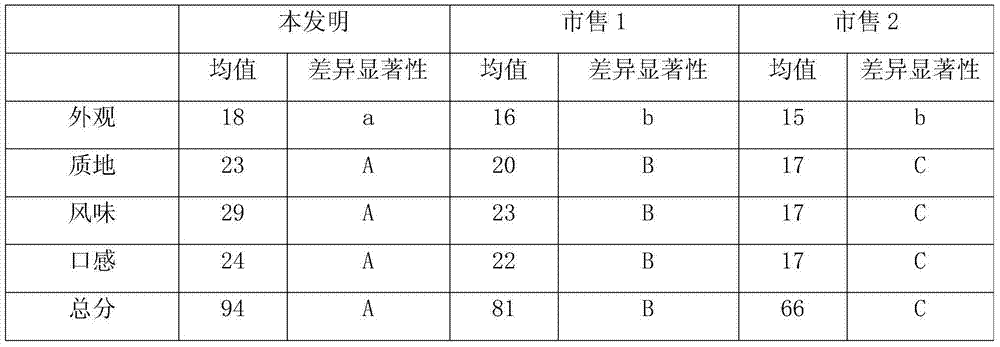

Fruit and vegetable probiotic tablet and preparation method thereof

ActiveCN104489646AHigh survival rate of live bacteriaImprove stabilityNatural extract food ingredientsFood ingredient functionsCelluloseDrug biological activity

The present invention discloses a fruit and vegetable probiotic tablet and a preparation method thereof. The fruit and vegetable probiotic tablet uses probiotic powders such as lactobacillus plantarum powder as the main raw material, and the preparation method scientifically mixes modified dietary fibers, fruit and vegetable powder, oligosaccharides, plant extracts, protein powder, tea leaf extracts and traditional Chinese medicine extracts and etc., thus improves the content of soluble celluloses which are of real significance for probiotic flora, enhances the physiological activity of celluloses, thereby increases the species of intestinal probiotic flora as well as significantly enhances the colonization ability and time of endogenous and exogenous probiotics in the human intestinal tracts, effectively inhibits the growth and reproduction of harmful intestinal bacteria, especially gram-negative bacteria, and fully regulates the composition of the intestinal probiotic flora. The prepared fruit and vegetable probiotic tablet has a high biological activity, a long human intestinal colonization time, and a significant weight loss effect, and is suitable for a wide range of people.

Owner:南京旭优食品技术有限公司

Flexible endoscope with longitudinal axial channels

InactiveUS8066631B2Improve coordinationFacilitates cleaning and replacementSurgeryEndoscopesFlexible endoscopeBiomedical engineering

Owner:KARL STORZ GMBH & CO KG

Wear assembly

ActiveUS20070193075A1Reduce penetrationImprove stabilitySoil-shifting machines/dredgersEngineeringMechanical engineering

Owner:ESCO GRP LLC

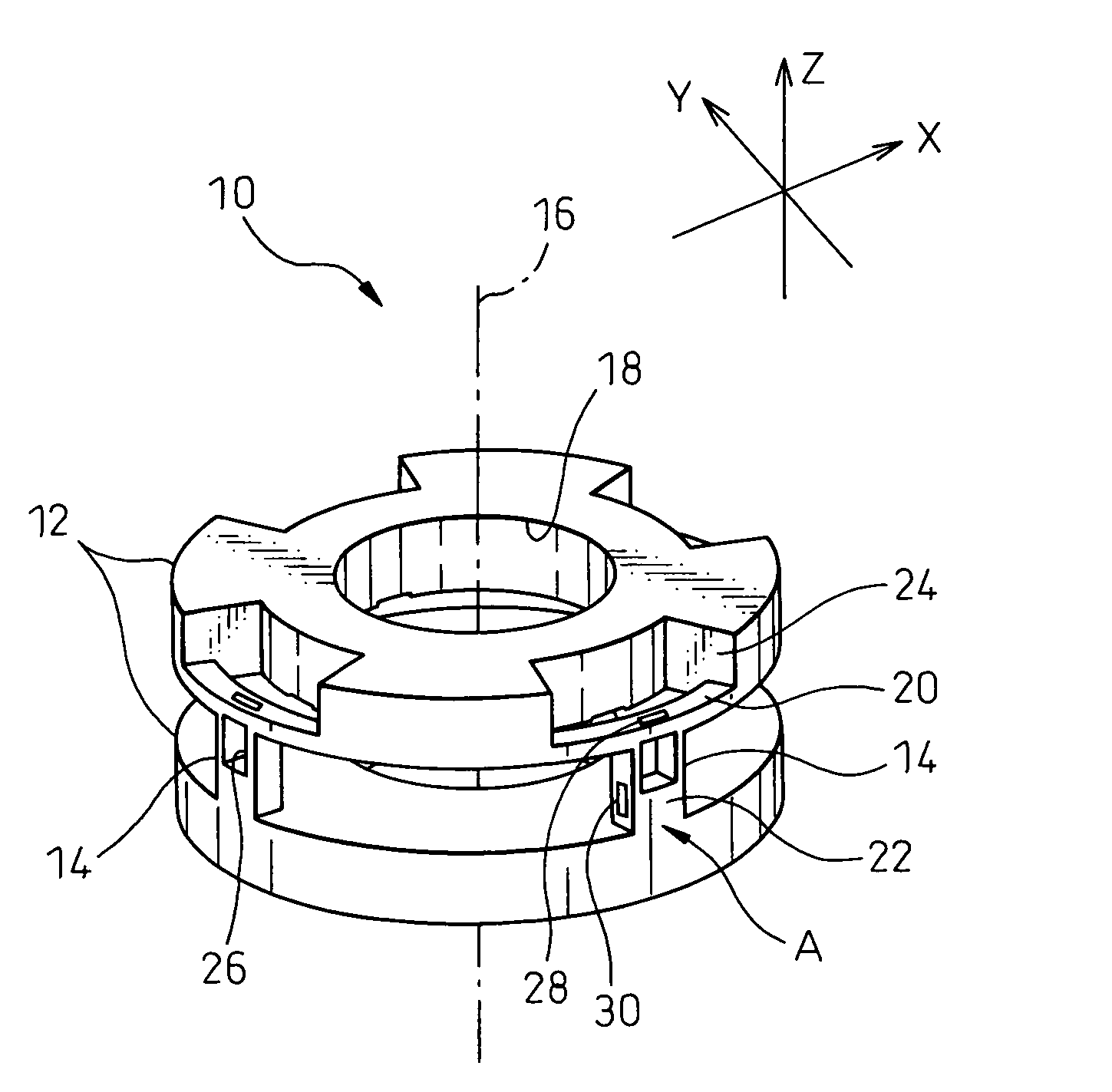

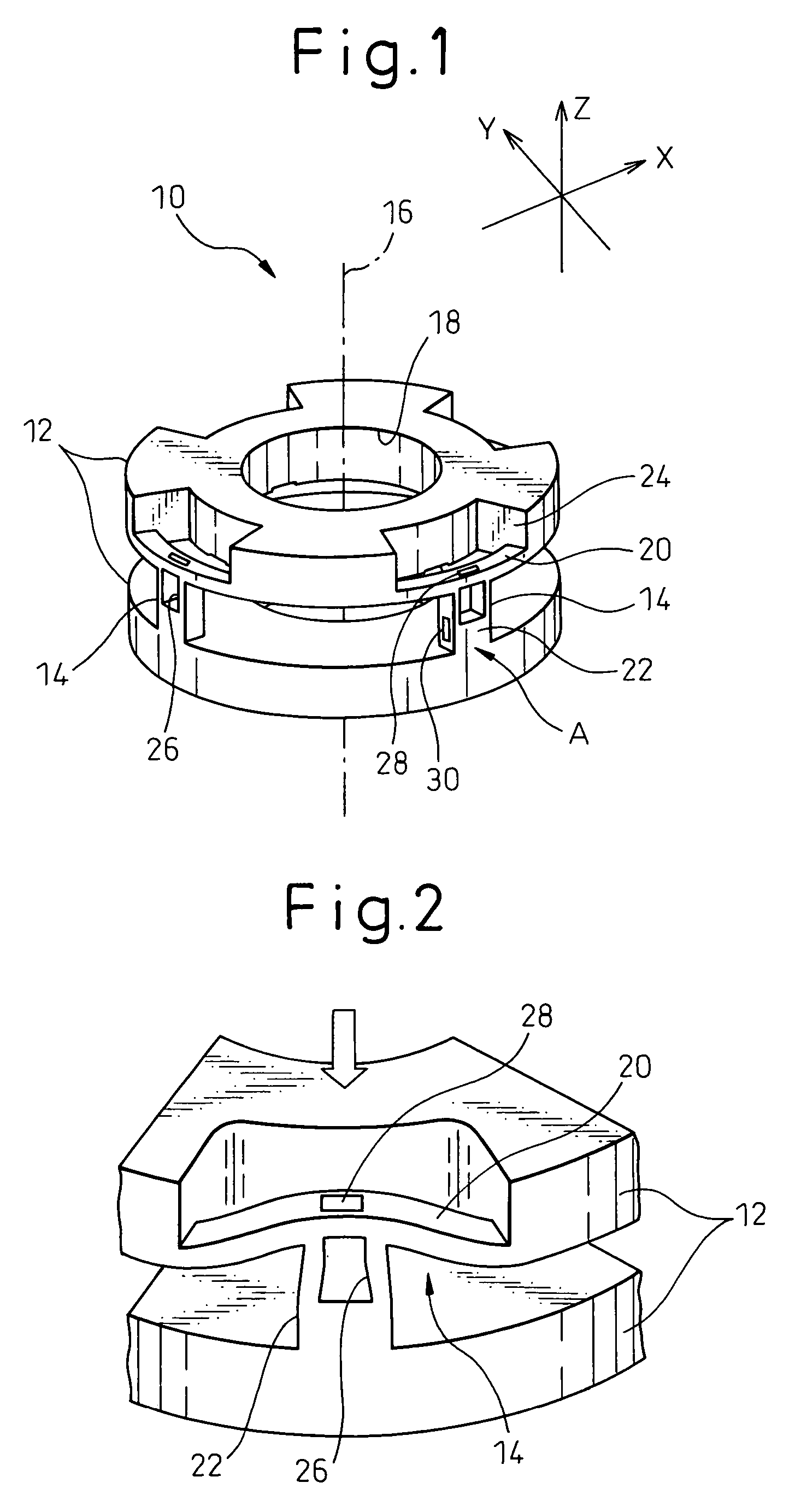

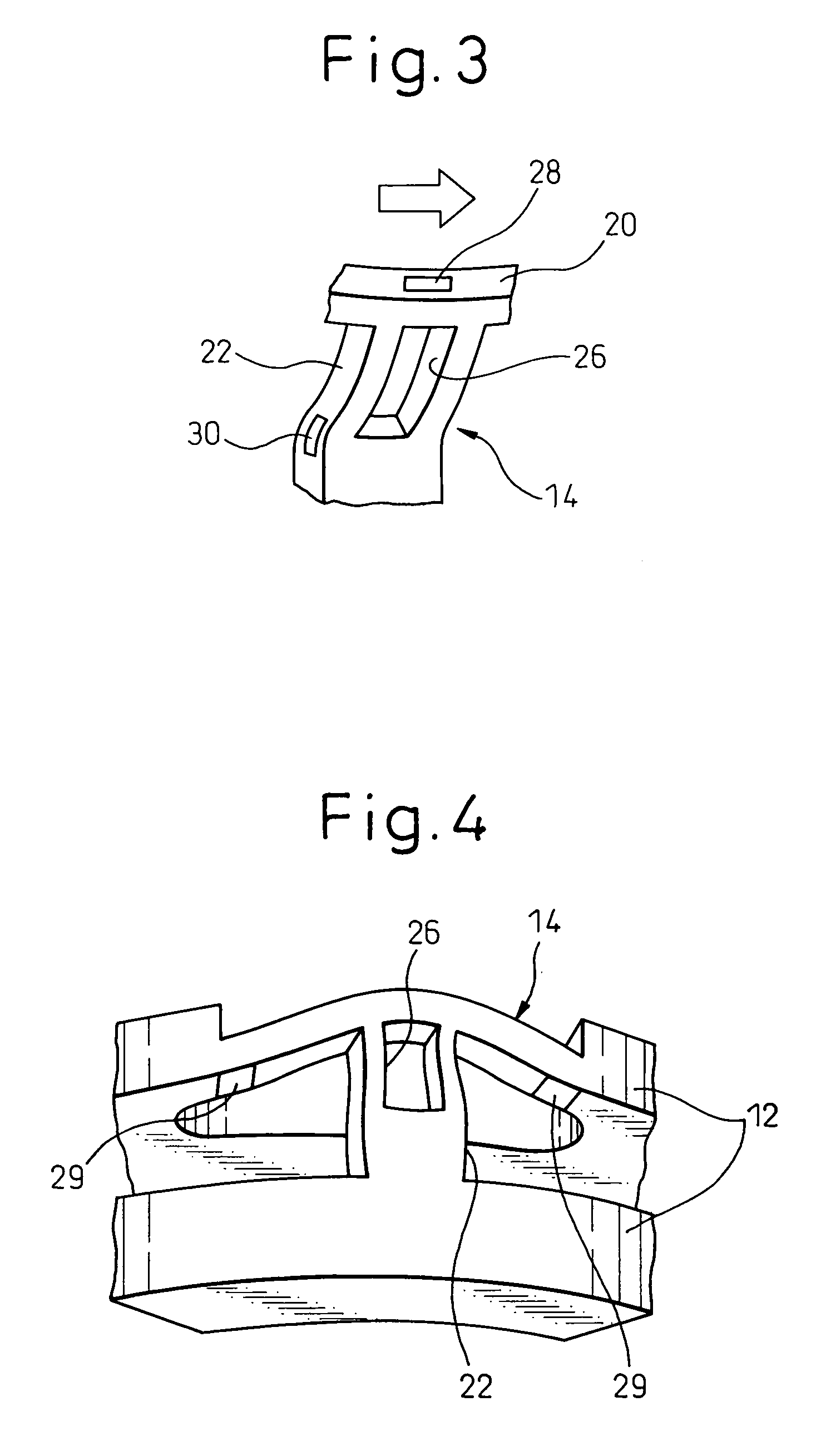

Six-axis force sensor

ActiveUS7437954B2Simple structureSimple processForce measurementTension measurementEngineeringStrain gauge

A six-axis force sensor includes a pair of members, and at least three legs scatteringly disposed between the pair of members on the periphery of the members. Each leg includes a T-shaped leg consisting of a cross beam supported at both ends thereof by one of the pair of members and extending on the periphery of the member in a circumferential direction, and a vertical beam extending from the center of the cross beam to a direction perpendicular to the cross beam and connected to the other of the pair of members. The strains on the legs are detected by first single-axis-type strain gauges and second single-axis-type strain gauges. A first single-axis-type strain gauge is attached to a surface of the cross beam facing the side opposite to the vertical beam or a surface of the cross beam facing the vertical beam, so as to be able to detect a strain generated in the cross beam in a longitudinal axis direction thereof, and a second single-axis-type strain gauge is attached to a side surface of the vertical beam facing in a circumferential direction, so as to be able to detect a strain generated in the vertical beam in a longitudinal axis direction thereof.

Owner:FANUC LTD

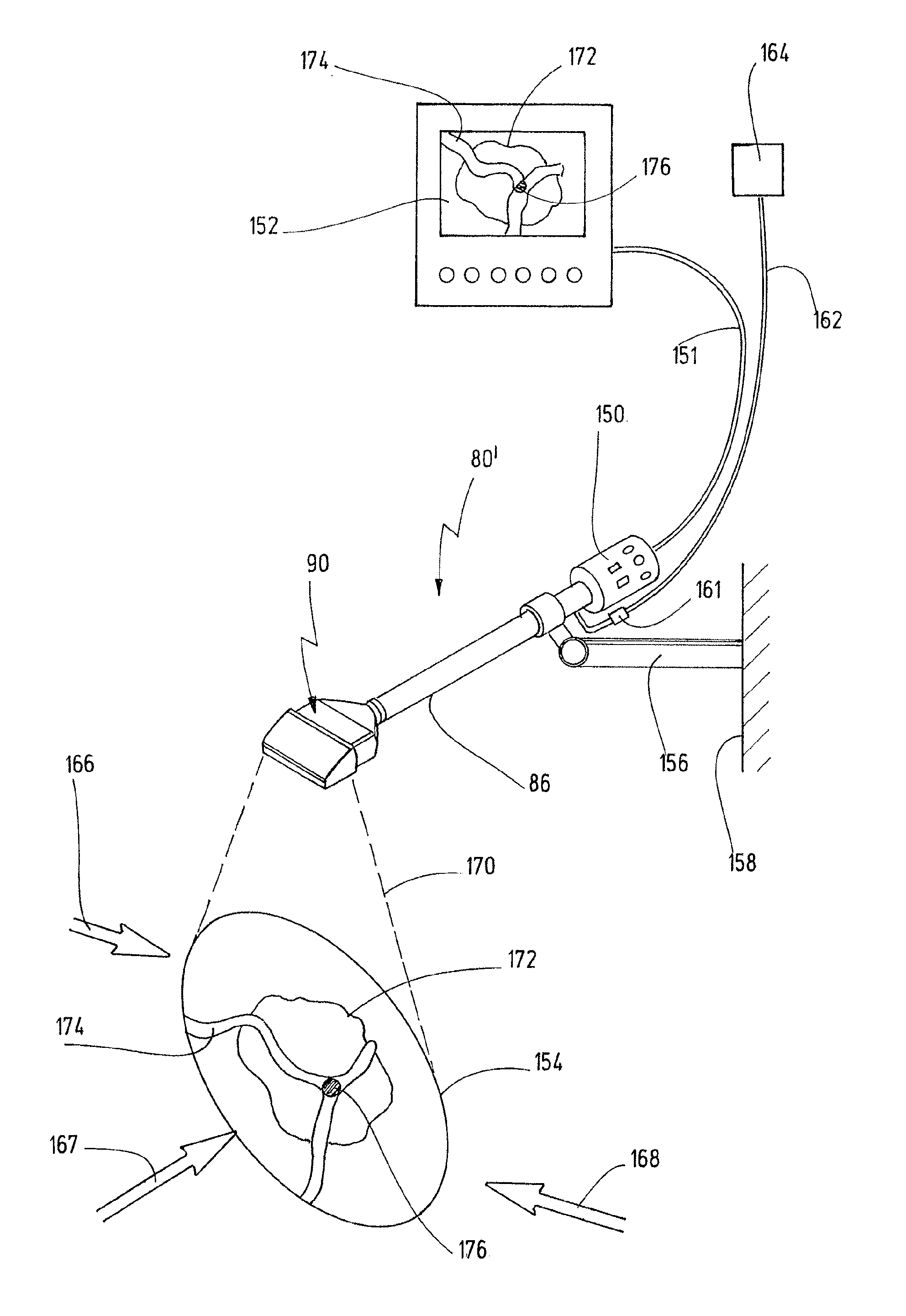

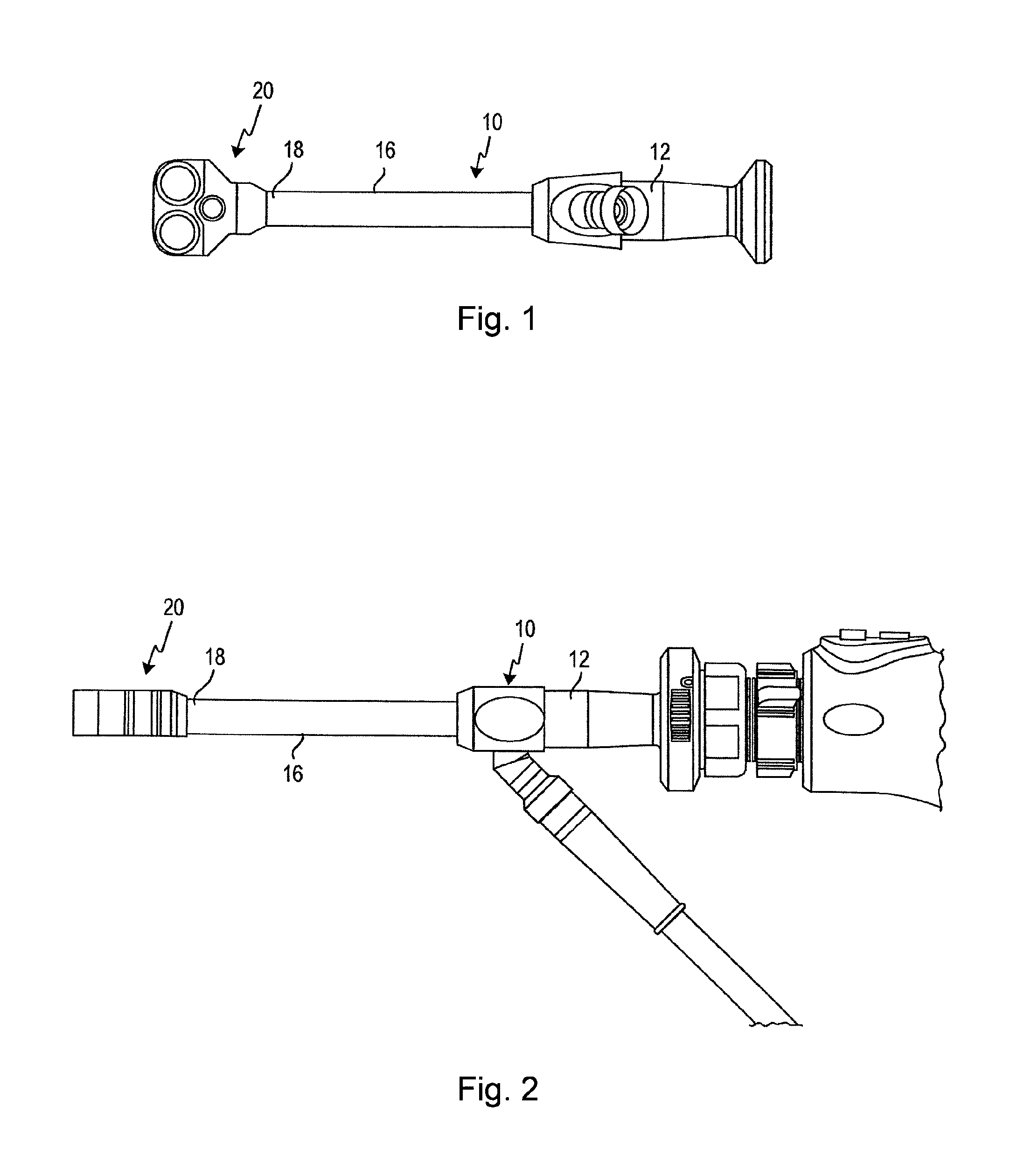

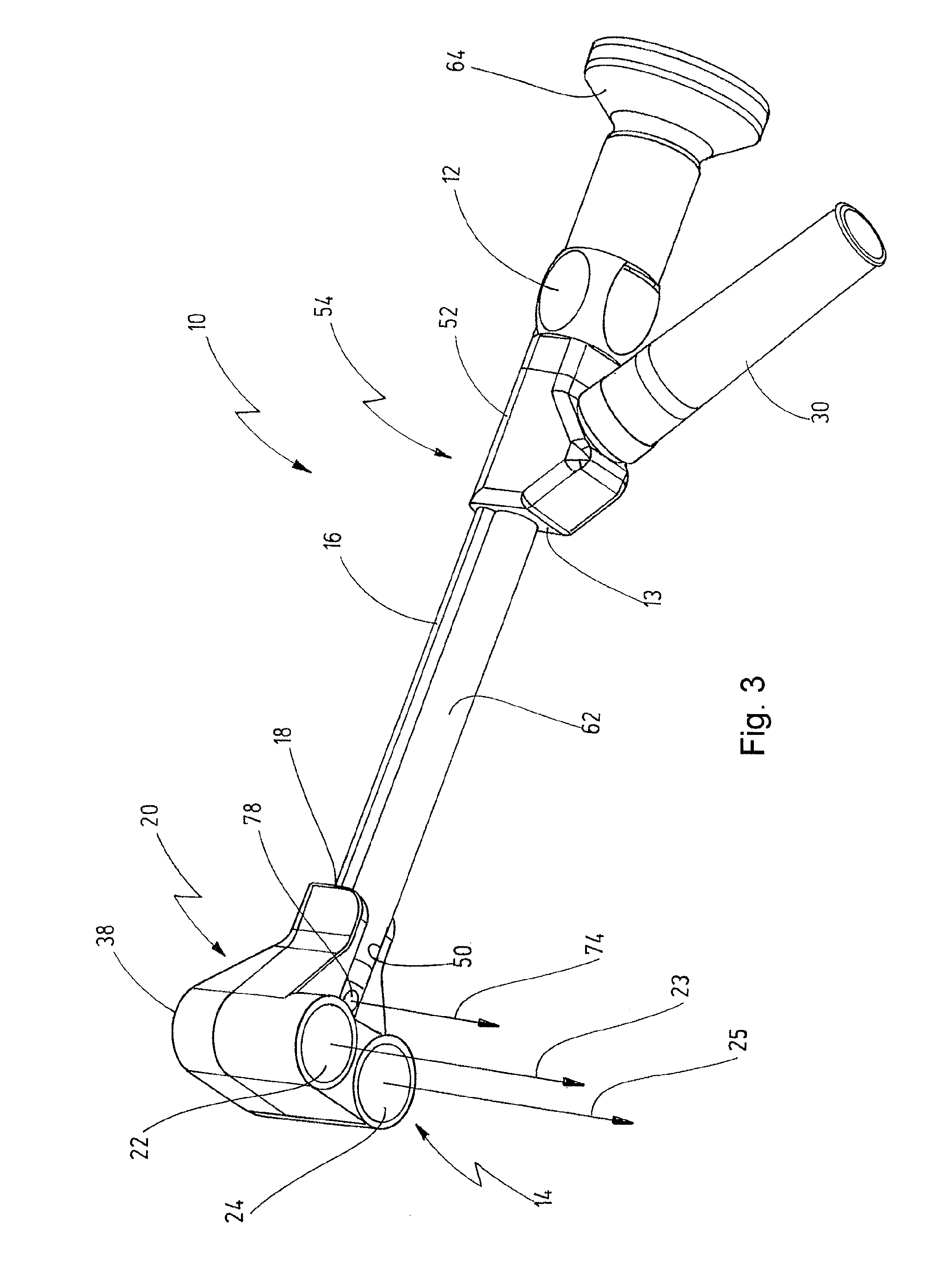

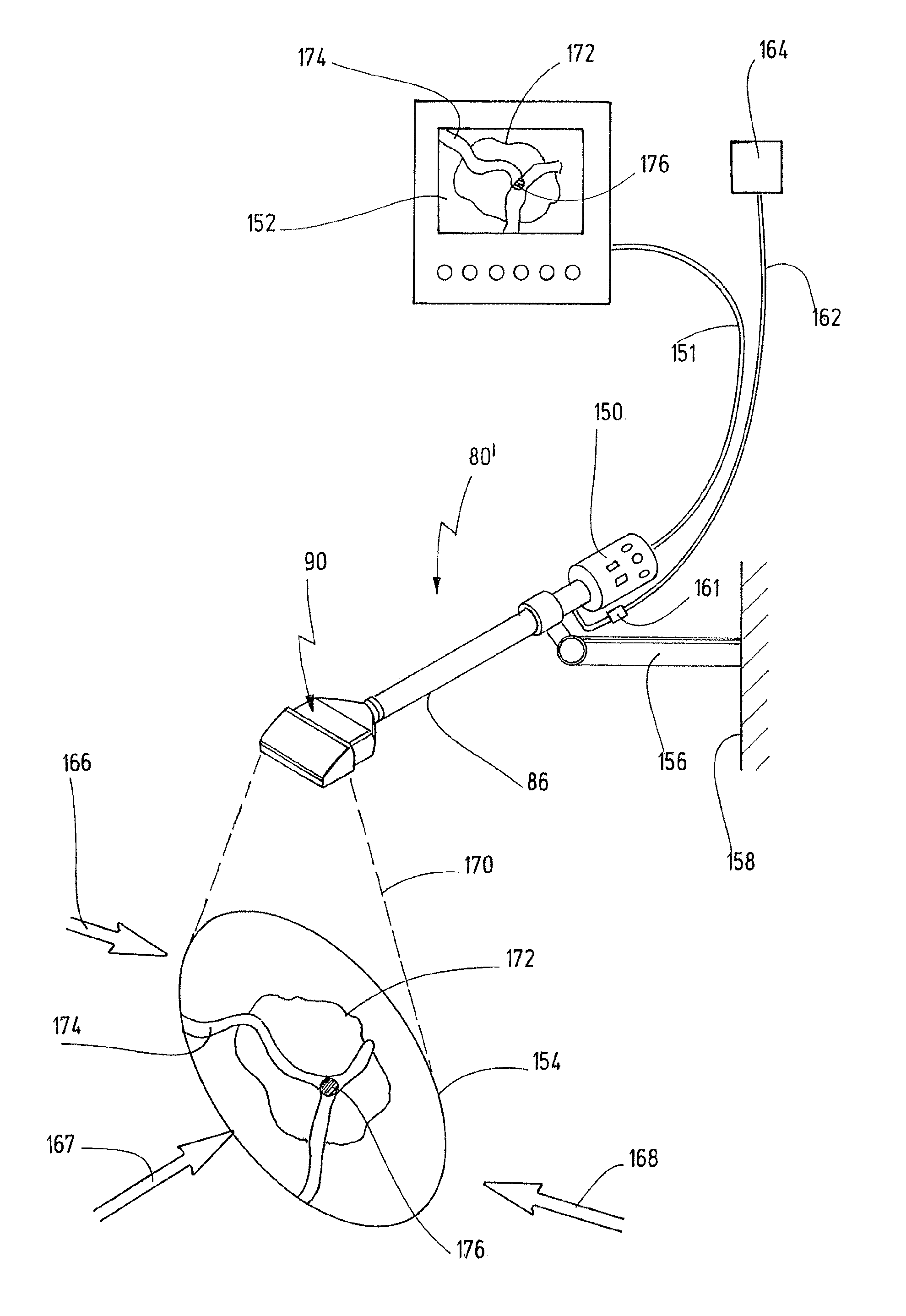

Exoscope

ActiveUS20120265023A1Strong and stable structureSufficient lightingEndoscopesSurgical field illuminationRadiation exposureObject field

An exoscope serves for observing and illuminating an object field on a patient from a position set apart from the patient's body. A lens system serves to observe the object field and an illumination serves to illuminate the object field. A distance between the lens system and the object field can be modified by a bracket. A shaft comprises on its distal end a head member that is widened in comparison to it, so that the illumination reaches into the distal-side head member. Positioned in the head member is at least one radiating illumination unit whose radiant characteristic can be adjusted in such a way that the object field can be illuminated homogeneously at all possible distances from the lens system. Supply lines for the at least one illuminating unit are positioned in the shaft.

Owner:KARL STORZ GMBH & CO KG

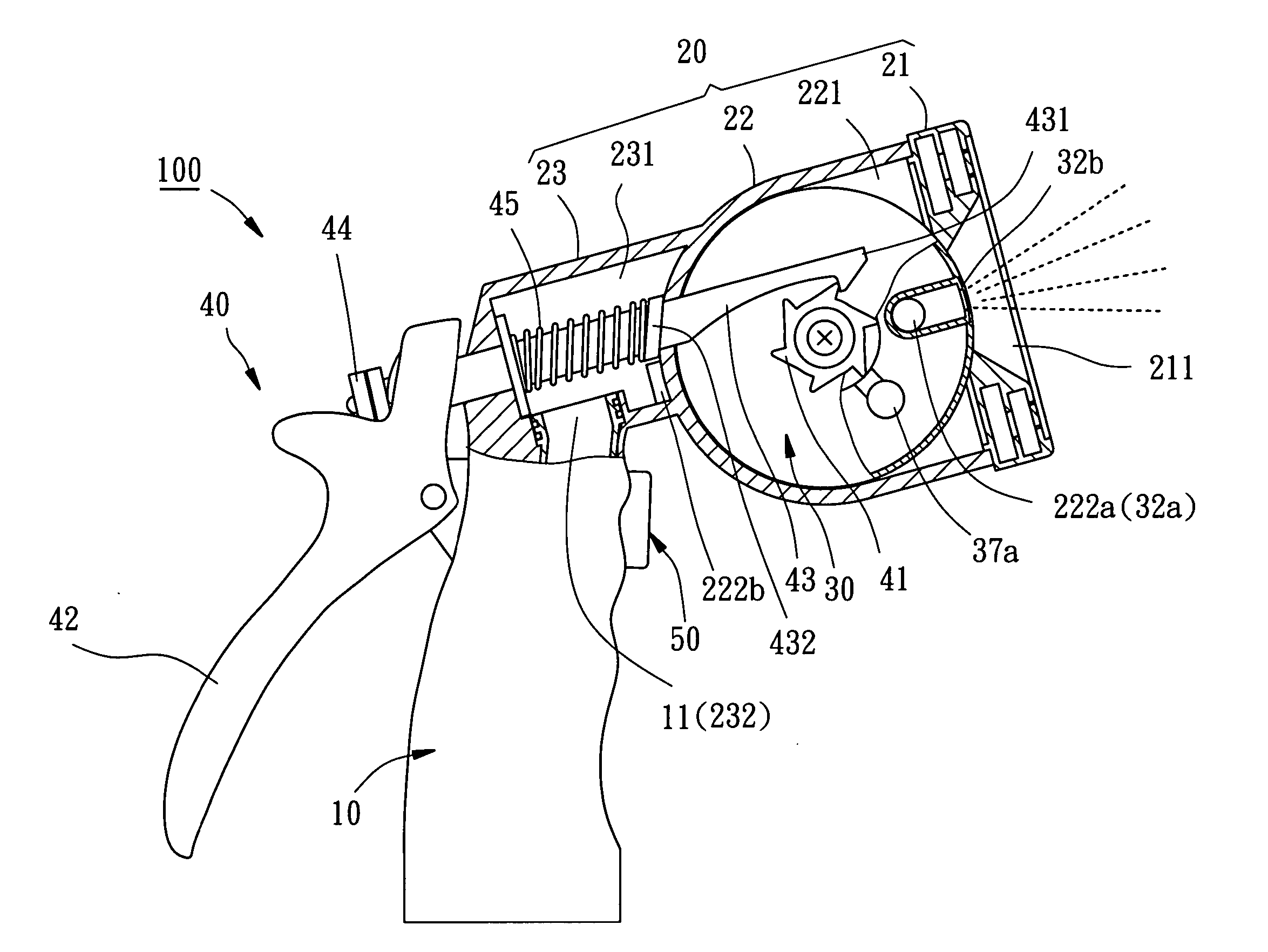

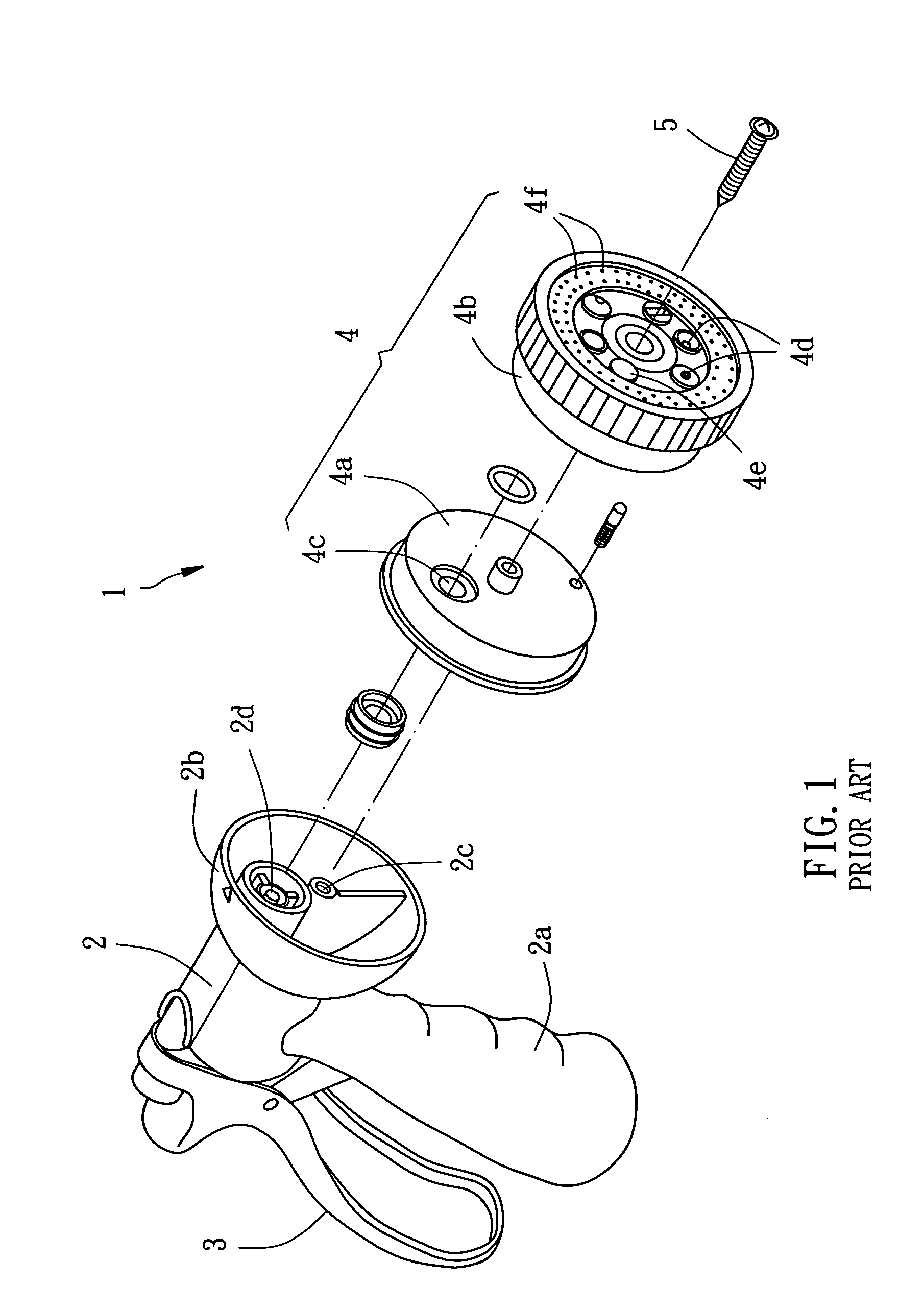

Water sprayer

InactiveUS20050258274A1Conveniently changedEasy to operateSpray nozzlesFire rescueWater wheelSprayer

A water sprayer includes a housing and a water wheel holder connected to the housing. The water wheel holder has a receiving chamber therein in communication with a water inlet in the housing, a first water outlet, and a second water outlet formed of a plurality of fine holes. A water wheel is rotatably stepwise mounted in the water wheel holder and located inside the receiving chamber. The water wheel has a plurality of primary water passages, which are selectively connectable between the water inlet and the first water outlet for guiding water from the water inlet to the first water outlet, and a secondary water passage, which is selectively connectable between the water inlet and the second water outlet for guiding water from the water inlet to the second water outlet.

Owner:HSIN YUIRS INDAL

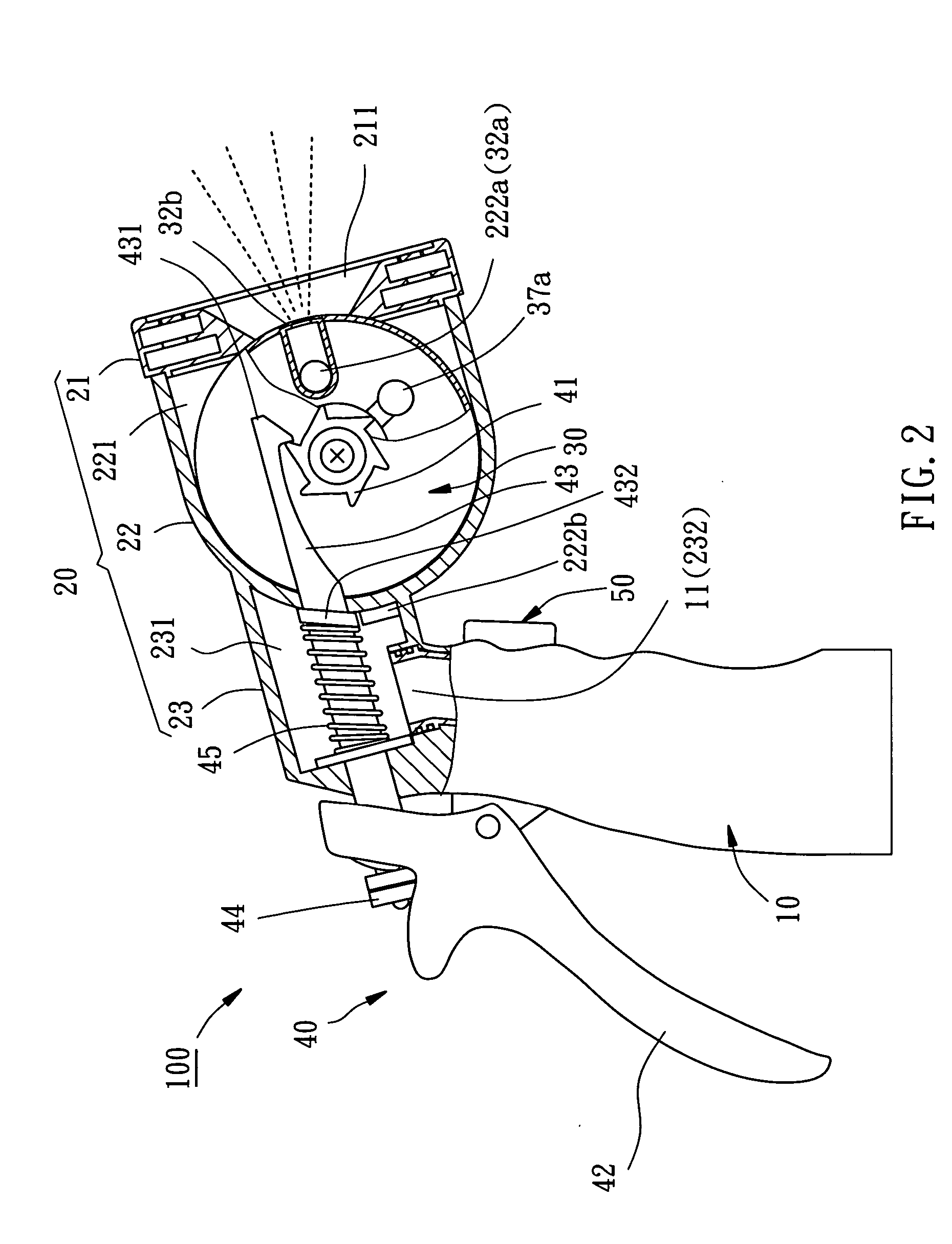

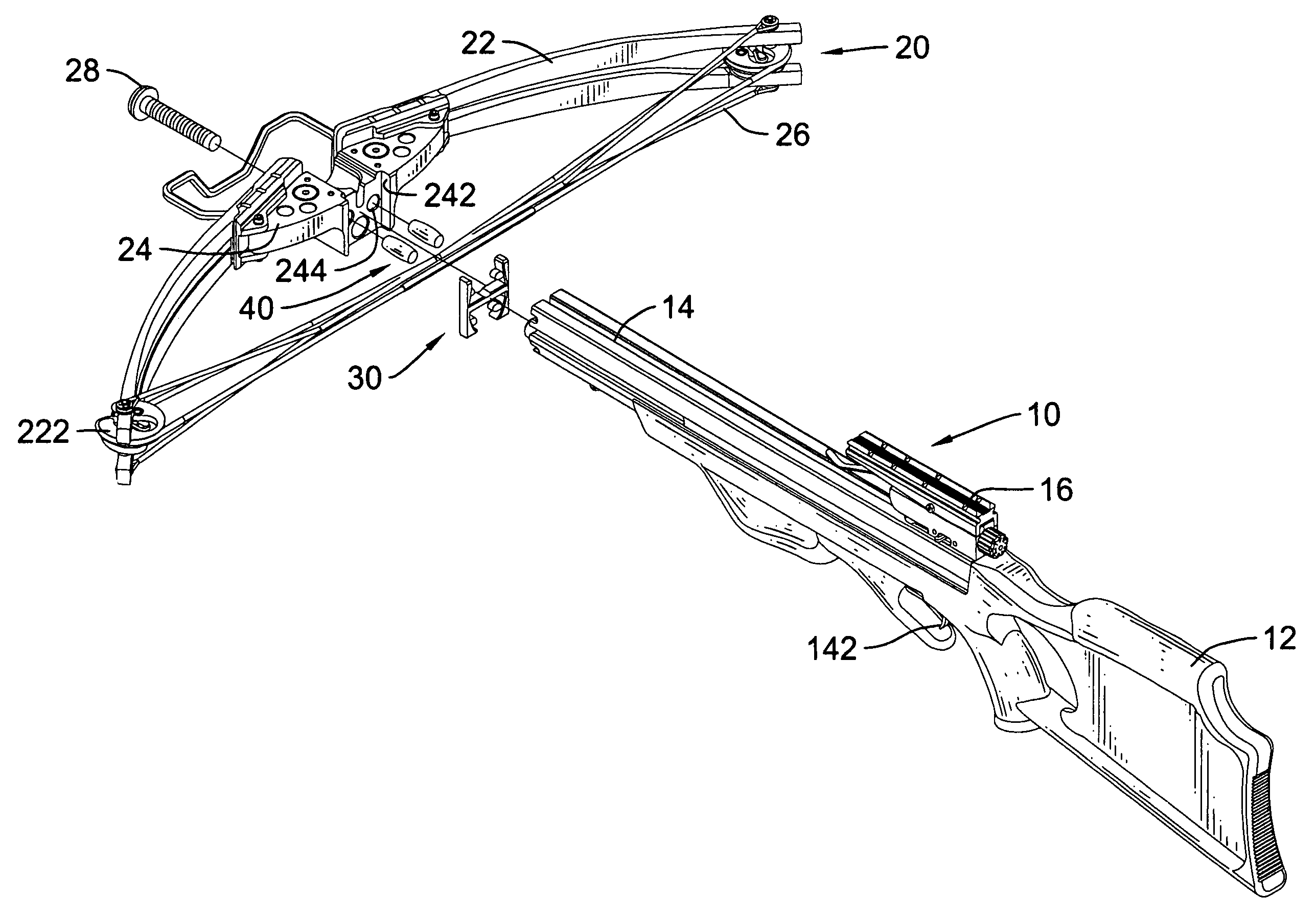

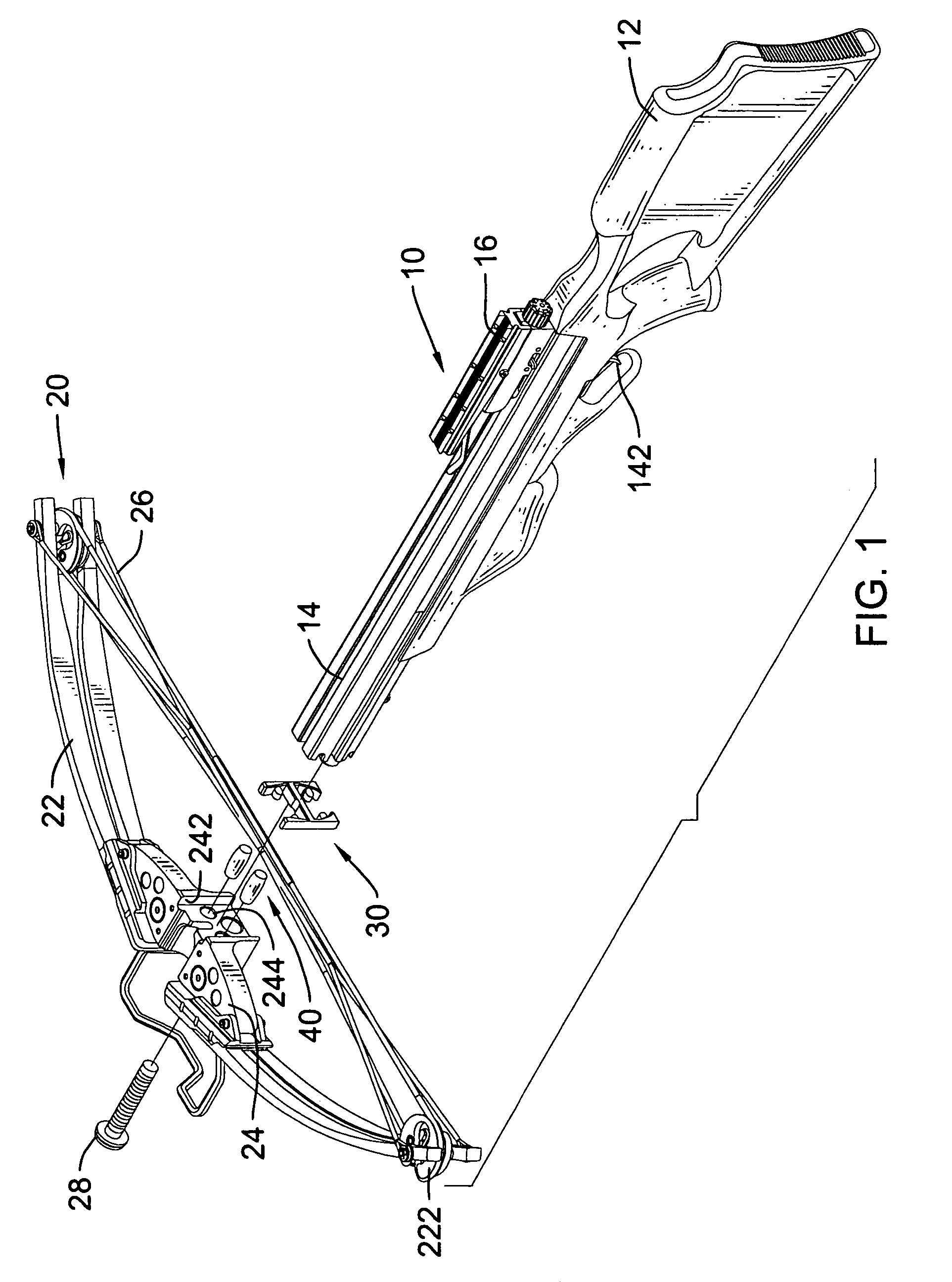

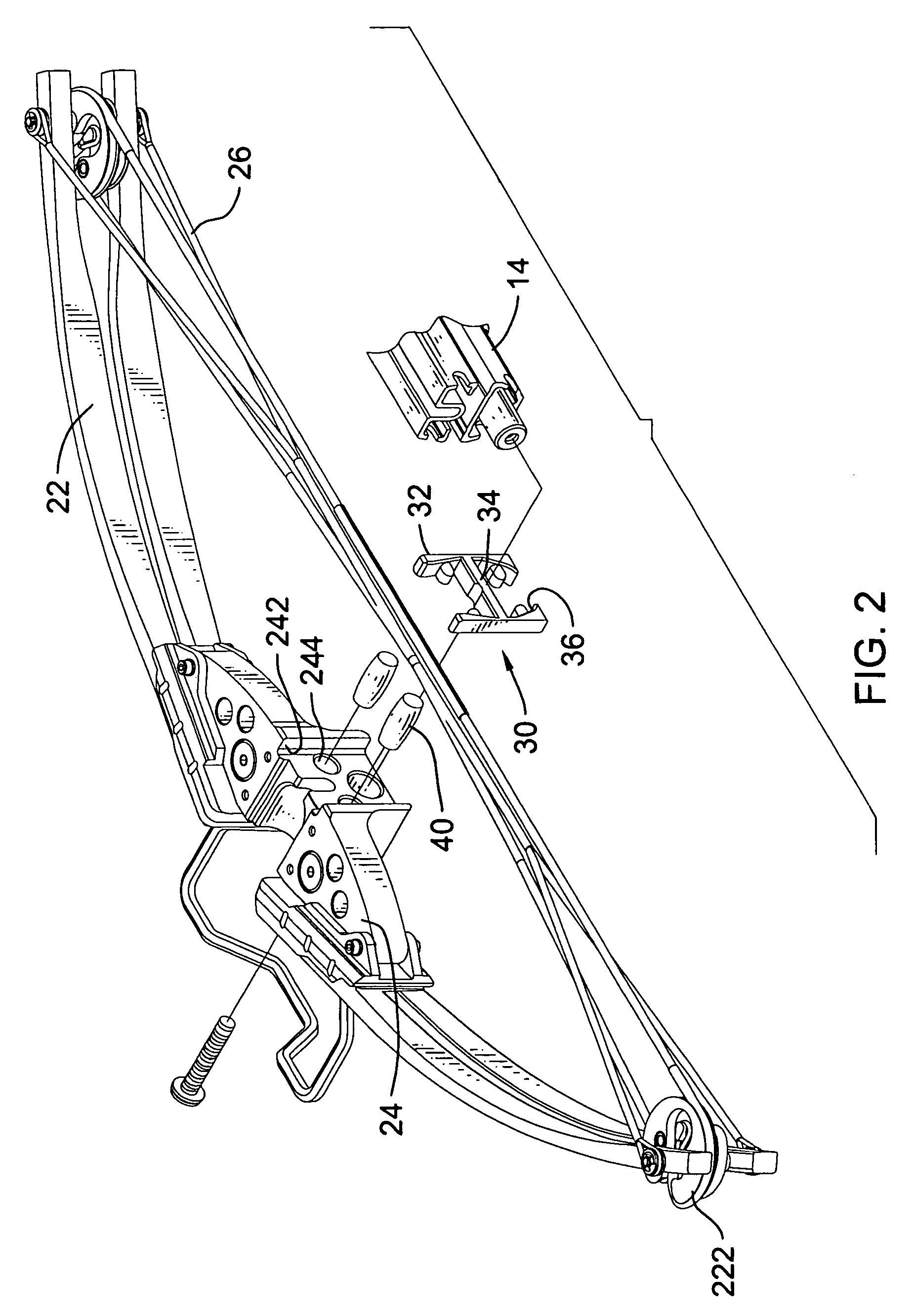

Crossbow with a vibration-damping device

ActiveUS7178514B2Strong and stable structureGood vibration reduction effectBows/crossbowsEngineeringMechanical engineering

A crossbow with a vibration-damping device has a stock assembly, a bow assembly, a bushing and at least one resilient element. The stock assembly has a front end. The bow assembly is attached to the front end of the stock assembly. The bushing is clamped between the stock assembly and the bow assembly. The at least one resilient element serves as a vibration-damping device and is clamped between the bushing and the bow assembly. By adding the resilient element, vibrations of the bow assembly are greatly reduced, and the bushing can be selectively made of rigid material to keep the structure of the crossbow sturdy.

Owner:POE LANG ENTERPRISE

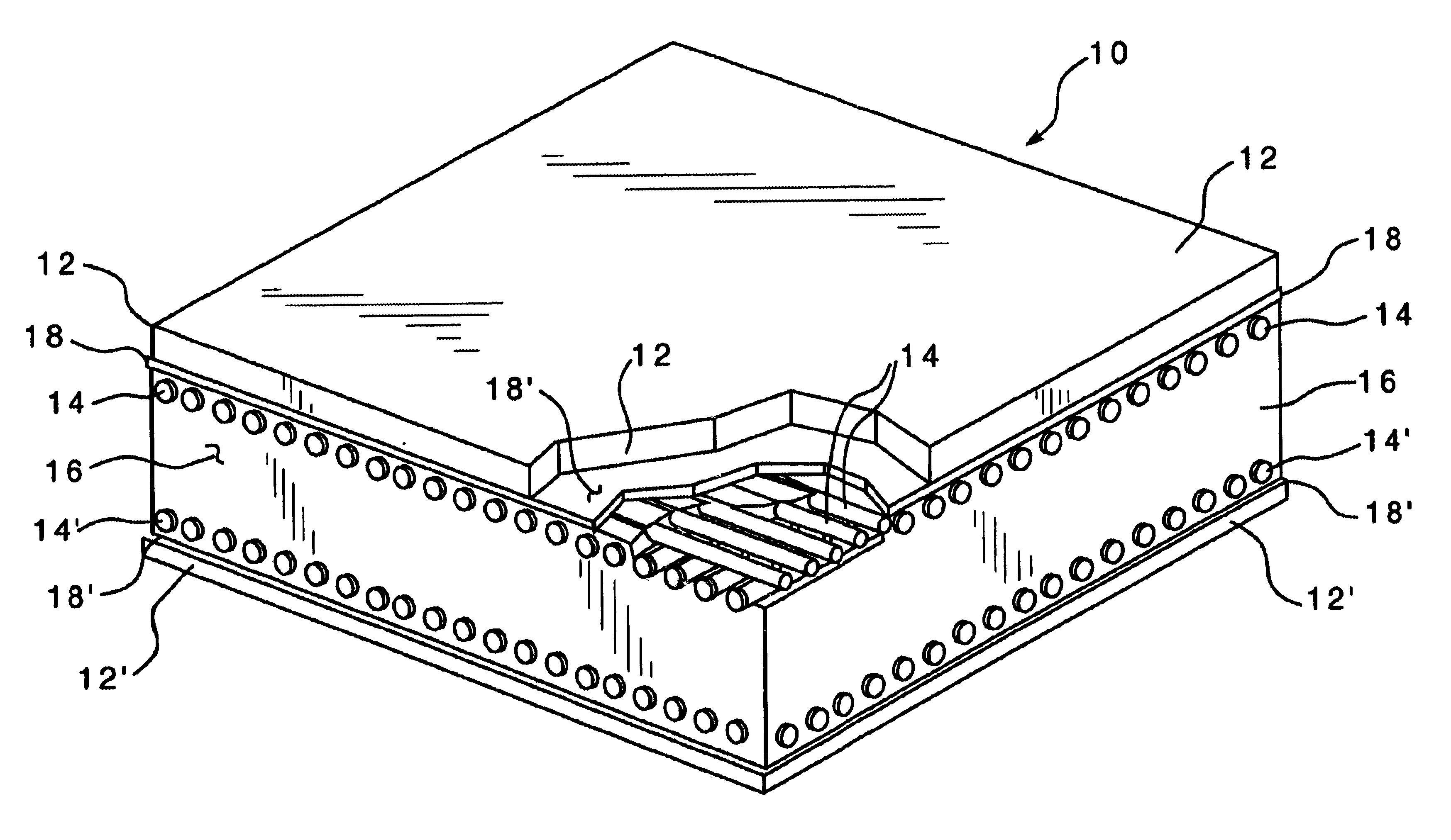

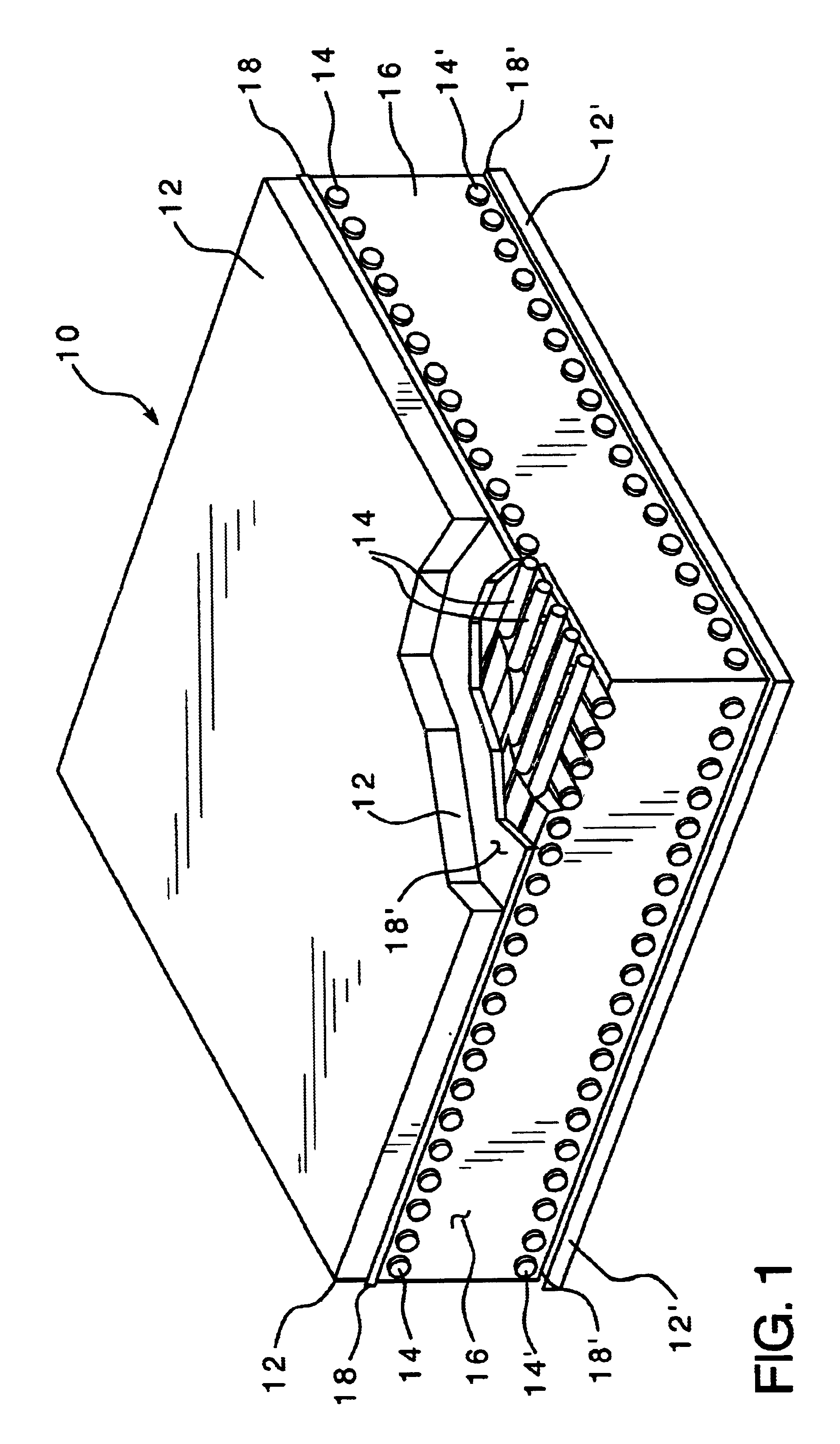

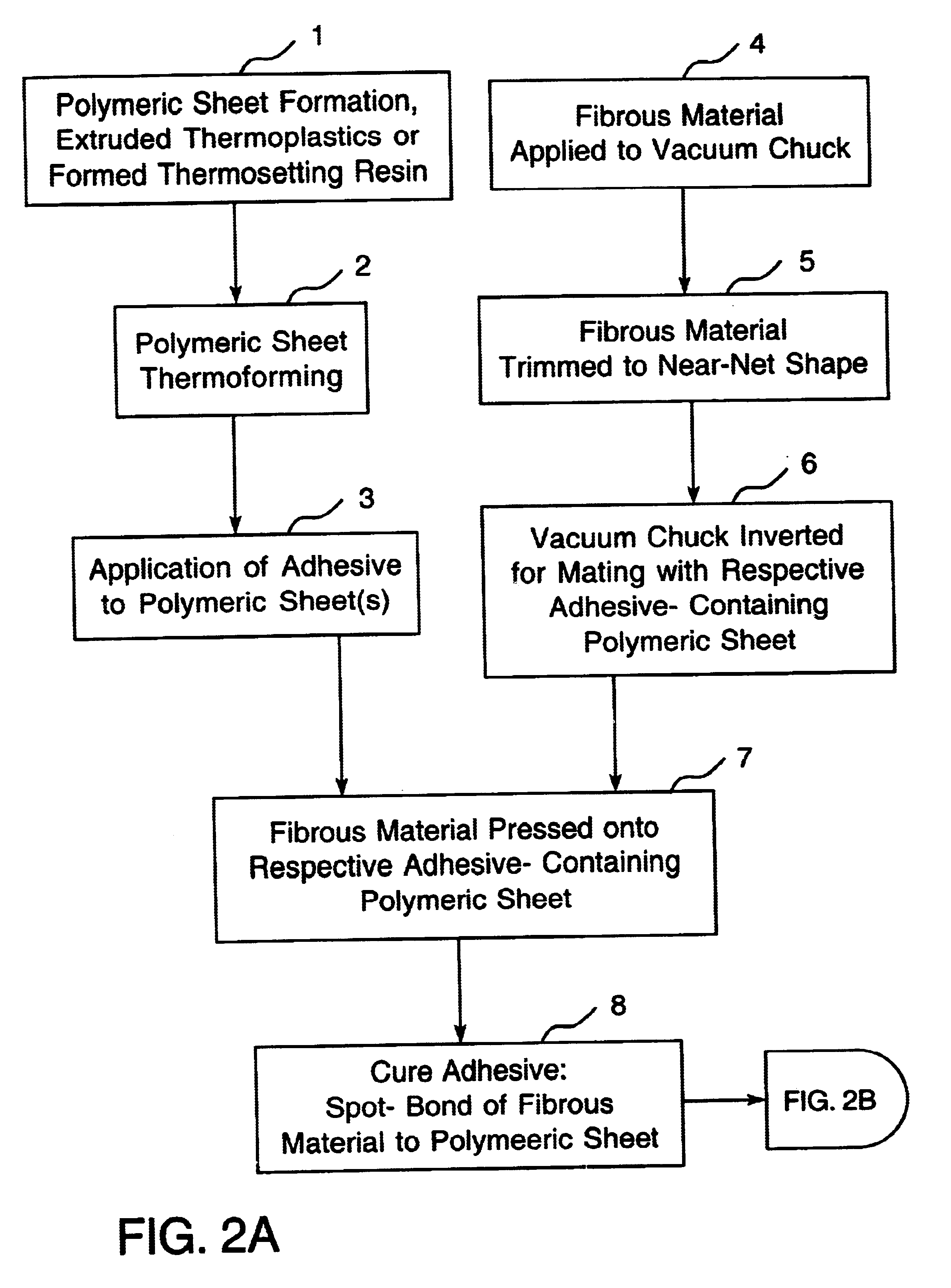

System and method of forming composite structures

InactiveUS6627018B1Large cycle timeLow viscosityLamination ancillary operationsSynthetic resin layered productsMachining processPolyresin

A system and method for forming a composite structure involves providing at least two polymeric sheets as outer layers such that a cavity is formed therebetween, adhesively bonding fibrous layers to the polymeric layers to hold the fibrous layers in place during processing, and injecting into the cavity a polymeric core material capable of exhibiting a foamed character and a resinous character. The cavity is evacuated during filling with the core material, and a blowing agent of the core material is activated upon exposure to the evacuated cavity. The core material contacting the fibrous layers is reconverted to its resinous character and forms a relative dense, resinous interface between the core and fibrous layers. Upon filling the region of the cavity between the fibrous layers, a catalytic reaction is initiated in the core. Then, each resinous interface is driven through the respective fibrous layer to impregnate the fibrous layer and form a dense, resinous layer between each fibrous layer and adjacent polymeric layer. A structural insert, such as a rigid plate adapted to receive fasteners, is embedded within the core material for attaching other devices or structures thereto.

Owner:SABIC GLOBAL TECH BV

Bioplastics

InactiveUS20120135169A1Improved propertyGood renewabilitySynthetic resin layered productsHollow wall articlesPolymer sciencePlasticizer

In a first aspect, the invention thus pertains to thermoplastic processable compositions (base compositions) comprising one or more flours, one or more polymers, optionally plasticizers, optionally fillers and optionally additives, characterized in that at least one of the polymers is present in the form of its water-redispersible polymer powder or as aqueous polymer dispersion, whereby the compositions contain less than 12% by weight of polyvinyl alcohol, based on the total amount of polymeric components of the composition.

Owner:WACKER CHEM GMBH +1

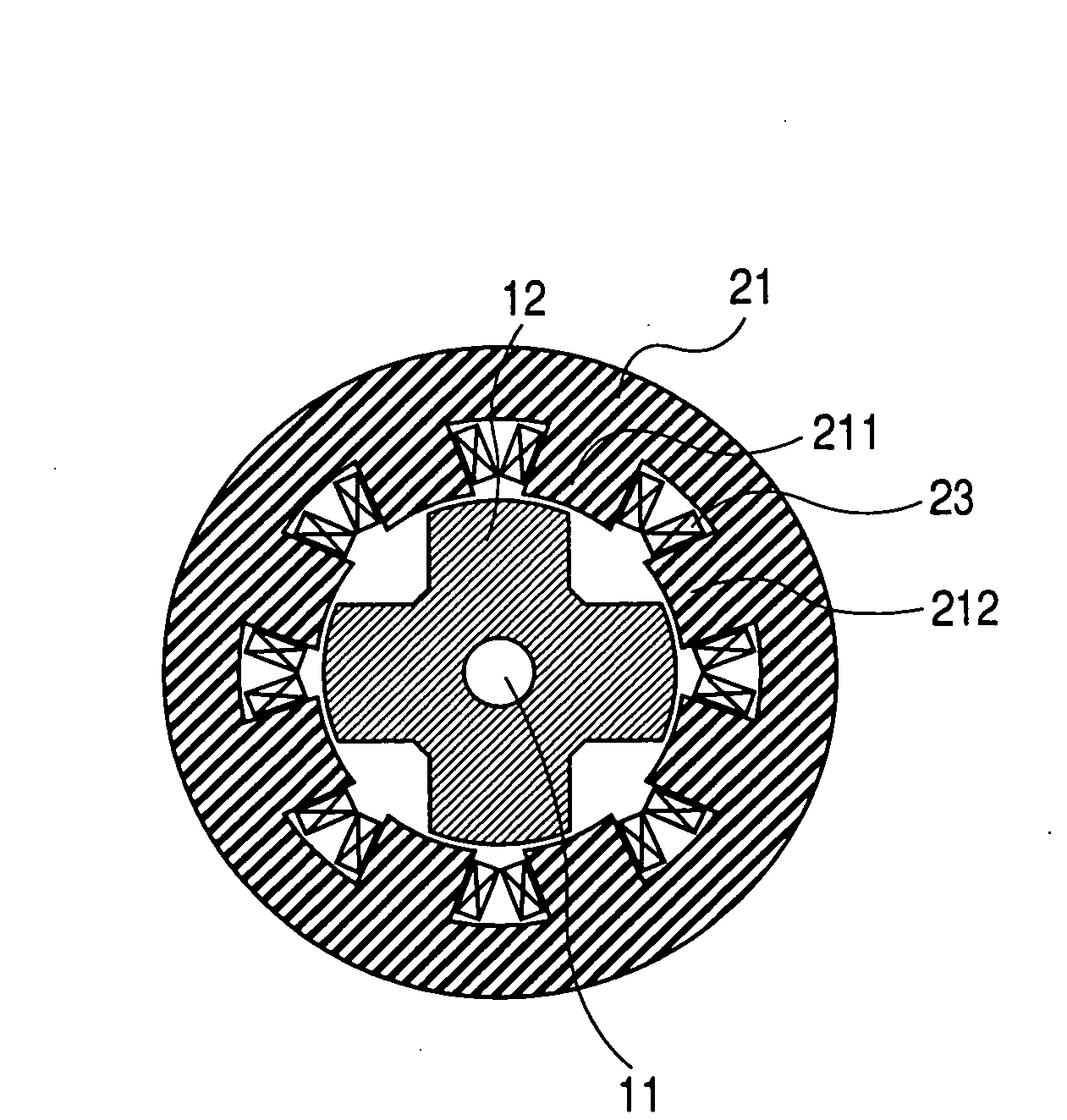

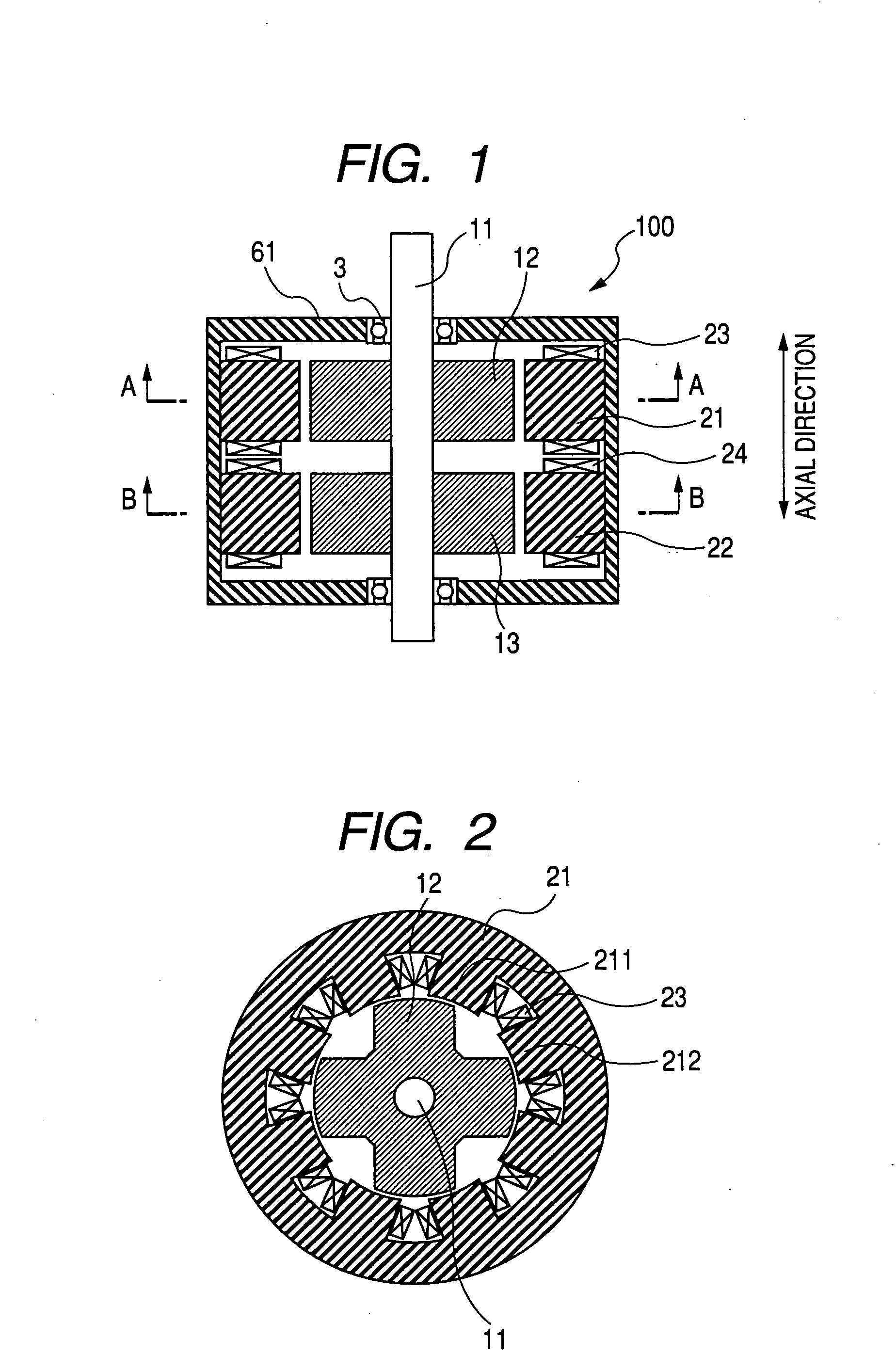

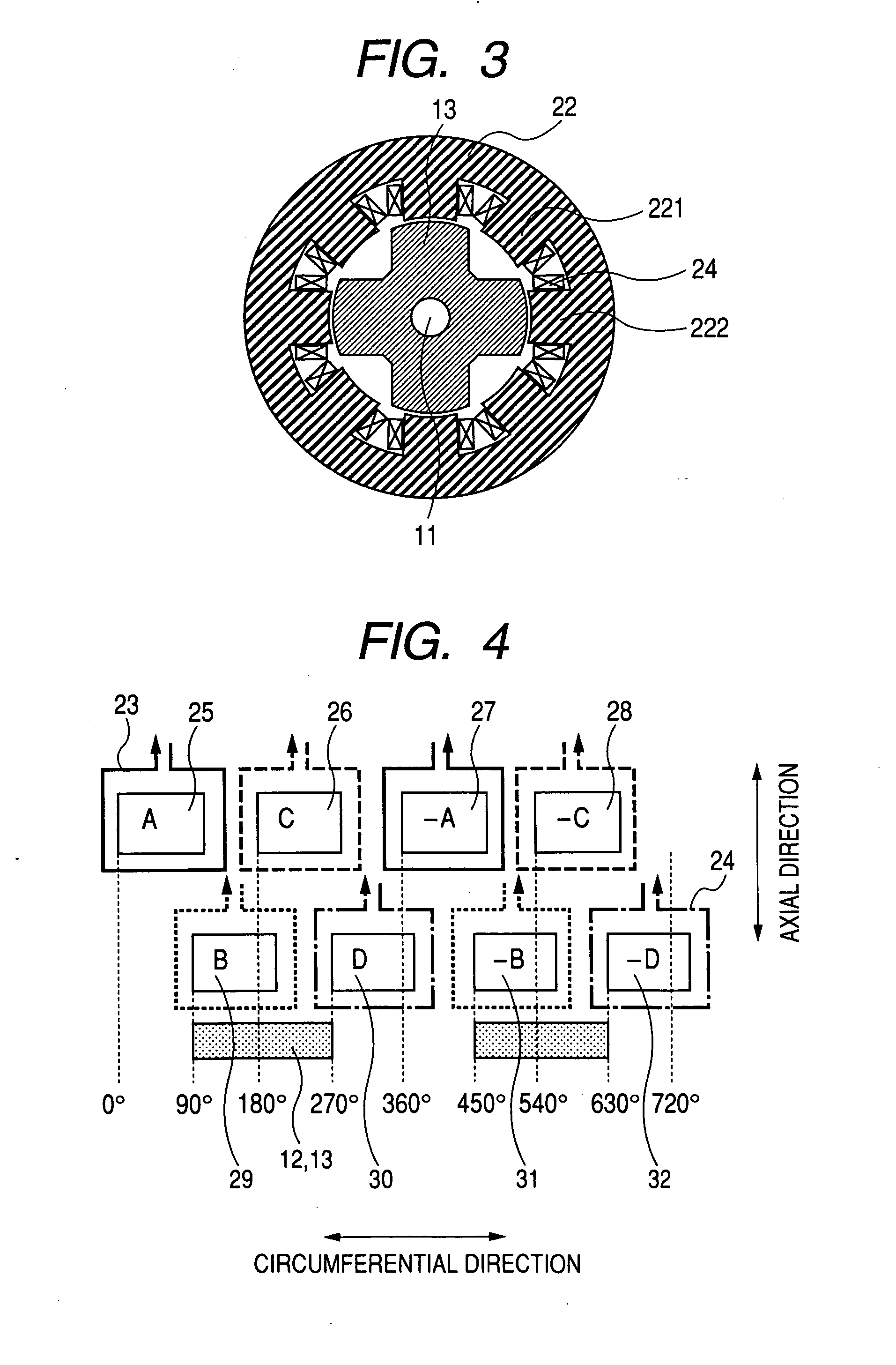

Switched reluctance motor

InactiveUS20080278010A1Reduce manufacturing costHigh magnetic flux densitySynchronous generatorsSynchronous motorsMagnetic polesReluctance motor

A switched reluctance motor has a rotor and a stator. The stator has first and second stator magnetic pole groups sequentially placed in an axial direction of the rotor. First and second stator magnetic poles in each group are alternately arranged on a same circumference. The first stator magnetic poles are placed every electrical angle 2π and reversely magnetized to each other. The second stator magnetic poles are placed every electrical angle 2π and reversely magnetized to each other. The first magnetic pole is apart from the second magnetic pole by electrical angle π. Each stator magnetic pole in the first stator magnetic pole group is apart from that in the second magnetic pole group by electrical angle π / 2 in the circumferential direction.

Owner:DENSO CORP

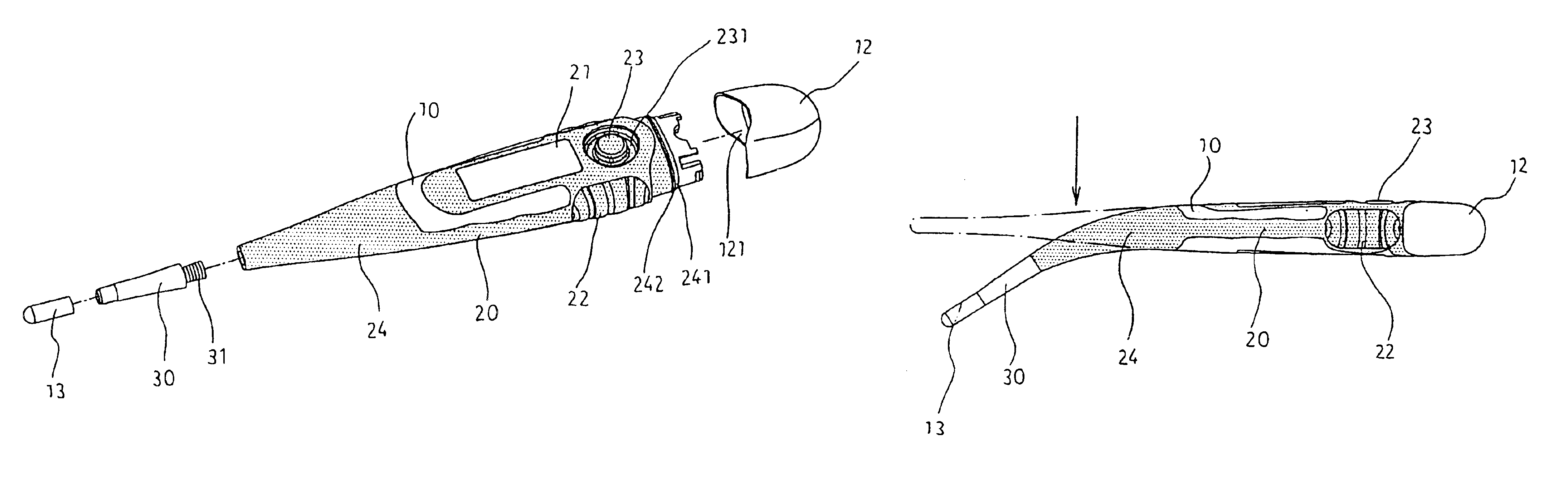

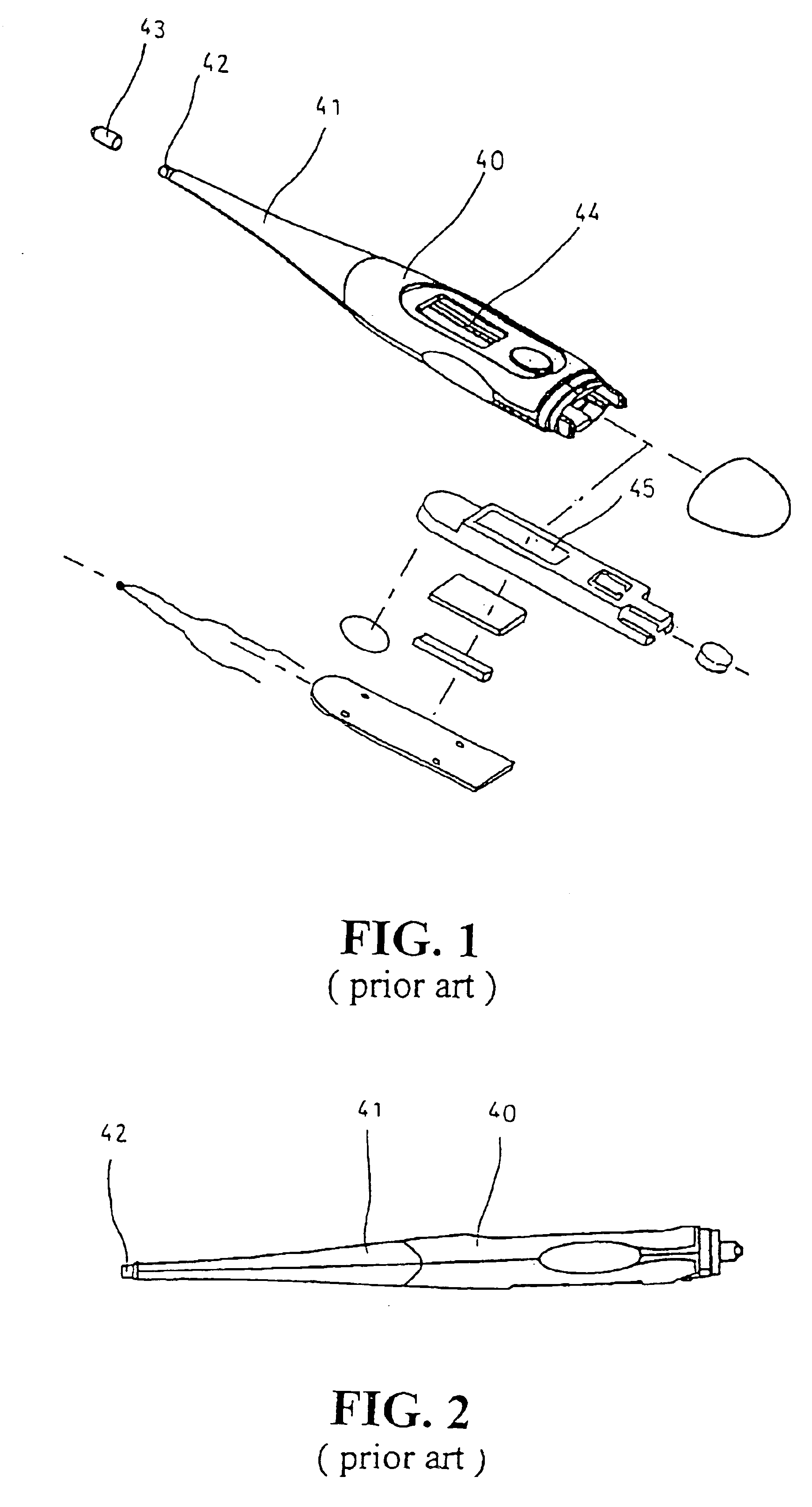

Electronic clinical thermometer

InactiveUS6854880B2Strong and stable structureImprove securityThermometer detailsThermometers using electric/magnetic elementsElectronic temperatureThermoscope

An electronic thermometer is constructed to include a casing, an electronic thermometer module mounted in the casing, a metal probe electrically connected to the electronic thermometer module for sensing the body temperature, an integrally formed flexible covering covered on the casing, and a hard stem connecting the metal probe to the distal end of the tapered front portion of the flexible covering, whereby the stress produced at the time when the measuring end is bent for measuring body temperature will be concentrated at a root portion with a larger inner diameter thereby preventing the measuring end from breaking and ensuring safety in operation. Furthermore, the flexible covering appropriately encloses the casing and has a tapered front portion protruded over the front side of the casing to a distance and has an integrally formed push button, locating flange, and embossed portions for waterproof, decoration and holding convenience thereby reducing manufacturing process and lowering the cost.

Owner:ACTHERM INC

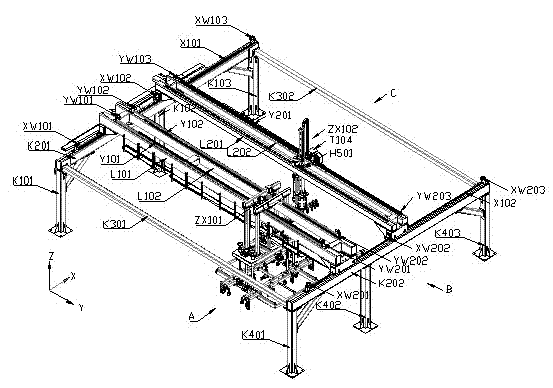

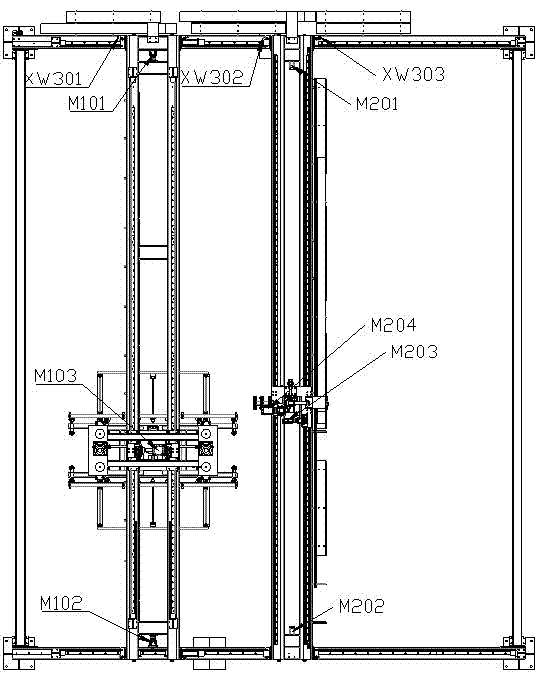

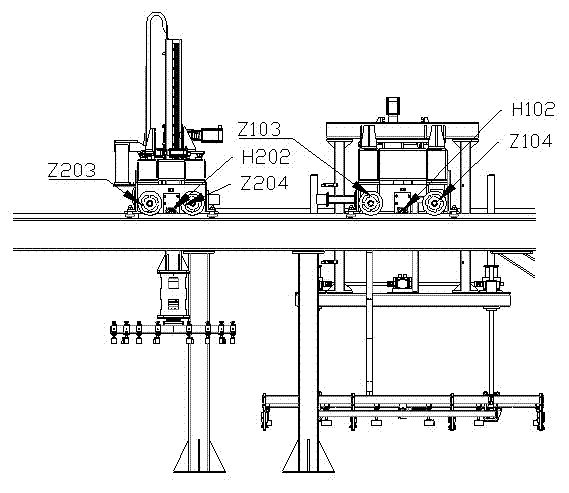

Overloaded manipulator of ten-shaft double-gantry

ActiveCN102962841ARun smoothlyReduce noiseProgramme-controlled manipulatorGripping headsManipulatorEngineering

The invention discloses an overloaded manipulator of a ten-shaft double-gantry. The overloaded manipulator comprises a rack, a first gantry and a second gantry, wherein the rack consists of supporting legs, supports, racks and limit components, wherein first, second, third and fourth supports are connected end to end to form a four-sided frame, and the supporting legs are connected with the four-sided frame in a supporting way; a first rack and first and second mechanical limit devices in an X-axis direction are arranged on the first support, and a second rack and third and fourth mechanical limit devices in the X-axis direction are arranged on the third support; the third and fourth mechanical limit devices are positioned at the two ends of the second rack, and the first and second gantries are respectively arranged on the first and third supports; the first gantry is parallel to the second gantry, and the first gantry moves in X, Y and Z-axis directions to complete the moving of overloaded plates; and the second gantry moves in X, Y and Z-axis directions to complete the moving of small plates. The overloaded manipulator provided by the invention has the advantages of smooth running, low noise, high reliability and long service life, and provides a strong guarantee for the performance of the entire overloaded manipulator.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Massage Tool

InactiveUS20080319358A1Simple assembly structureEasy to assembleDevices for pressing relfex pointsGenitals massageMassageEngineering

A massage tool includes a handle, which has a cylinder provided for holding, a barrel hole going through the cylinder; a first barrel, which has a barrel body inserted into the barrel hole of the handle, a chamber formed concaved on the barrel body, a fitting hole opened downwards from the bottom of the chamber; a toe, which has a shoulder received in the chamber of the first barrel; a second barrel, which has a barrel body inserted into the barrel hole of the handle; the massage tool which assembled via above structure is convenient for use and holding; further, the massage tool can includes a skirt, which has a skirt body mounted on the handle, the second barrel and the skirt mounted at least two fingers or a palm; and a magnet group received in the chamber of the first barrel; thereby, the invention can assembled variety of massage tool, the magnet group generating magnetic field improve human body blood circulation, and the toe or the finger to proceed pressing.

Owner:CHUEN JEOU DAY ENTERPRISE

Exoscope

ActiveUS8702602B2Strong and stable structureSufficient lightingEndoscopesSurgical field illuminationFluenceObject field

An exoscope serves for observing and illuminating an object field on a patient from a position set apart from the patient's body. A lens system serves to observe the object field and an illumination serves to illuminate the object field. A distance between the lens system and the object field can be modified by a bracket. A shaft comprises on its distal end a head member that is widened in comparison to it, so that the illumination reaches into the distal-side head member. Positioned in the head member is at least one radiating illumination unit whose radiant characteristic can be adjusted in such a way that the object field can be illuminated homogeneously at all possible distances from the lens system. Supply lines for the at least one illuminating unit are positioned in the shaft.

Owner:KARL STORZ GMBH & CO KG

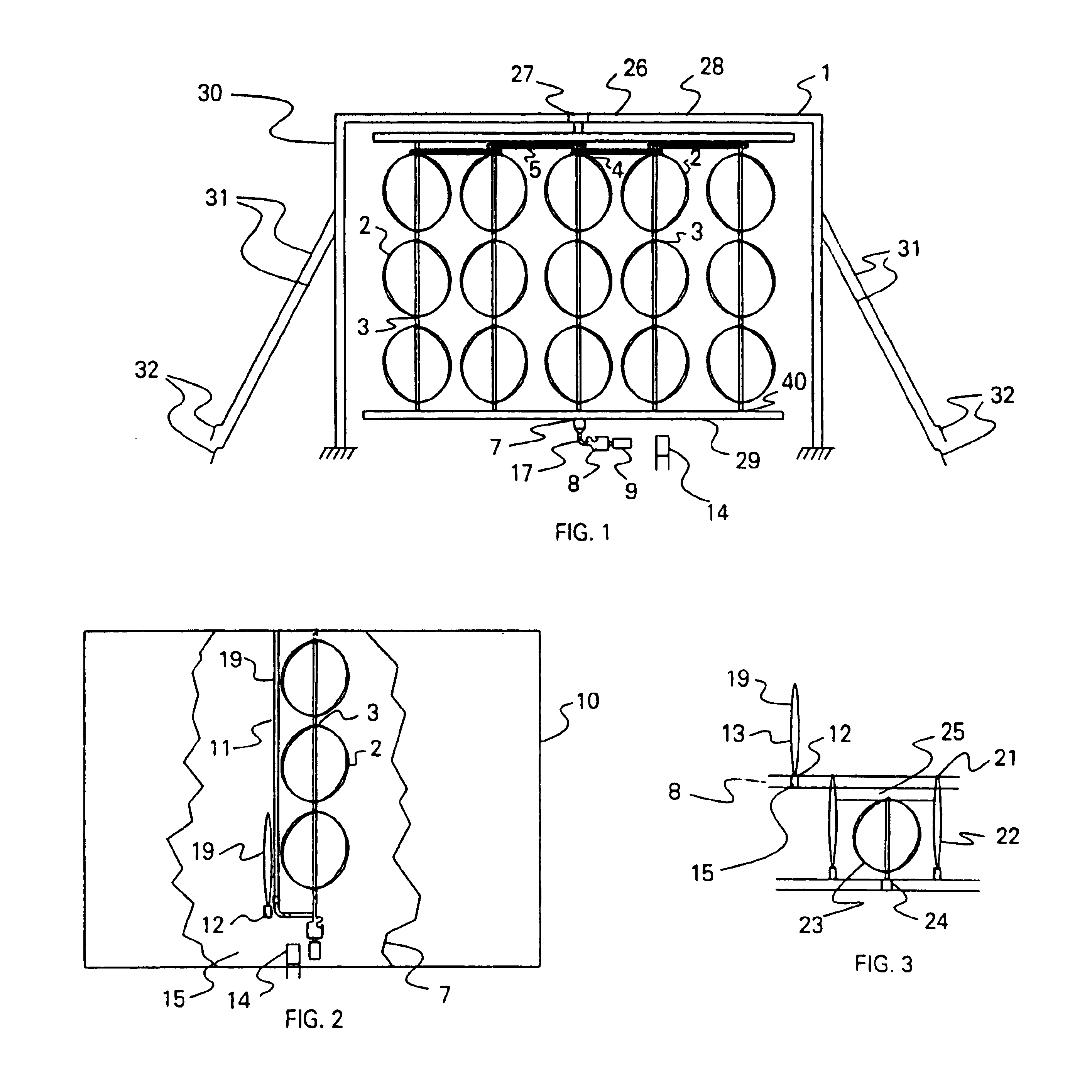

Multiaxis turbine

InactiveUS6864597B1More durableImprove stabilityWind motor combinationsMachines/enginesImpellerDiameter ratio

Multiaxis Turbine with an external upper covering, a tower structure with a plurality of vertical elongated members connected to each other with supporting horizontal elongated members, and a plurality of smaller blades on a rotation connected to a tower structure with a plurality of the rotation. A preferred embodiment includes impact impellers connected to a rotation creating a swept area with a height to diameter ratio of greater than four. A preferred embodiment includes wherein said impact impellers connected to a rotation means creating a swept area with a height to diameter ratio of greater than ten.

Owner:RICKER JONATHAN C

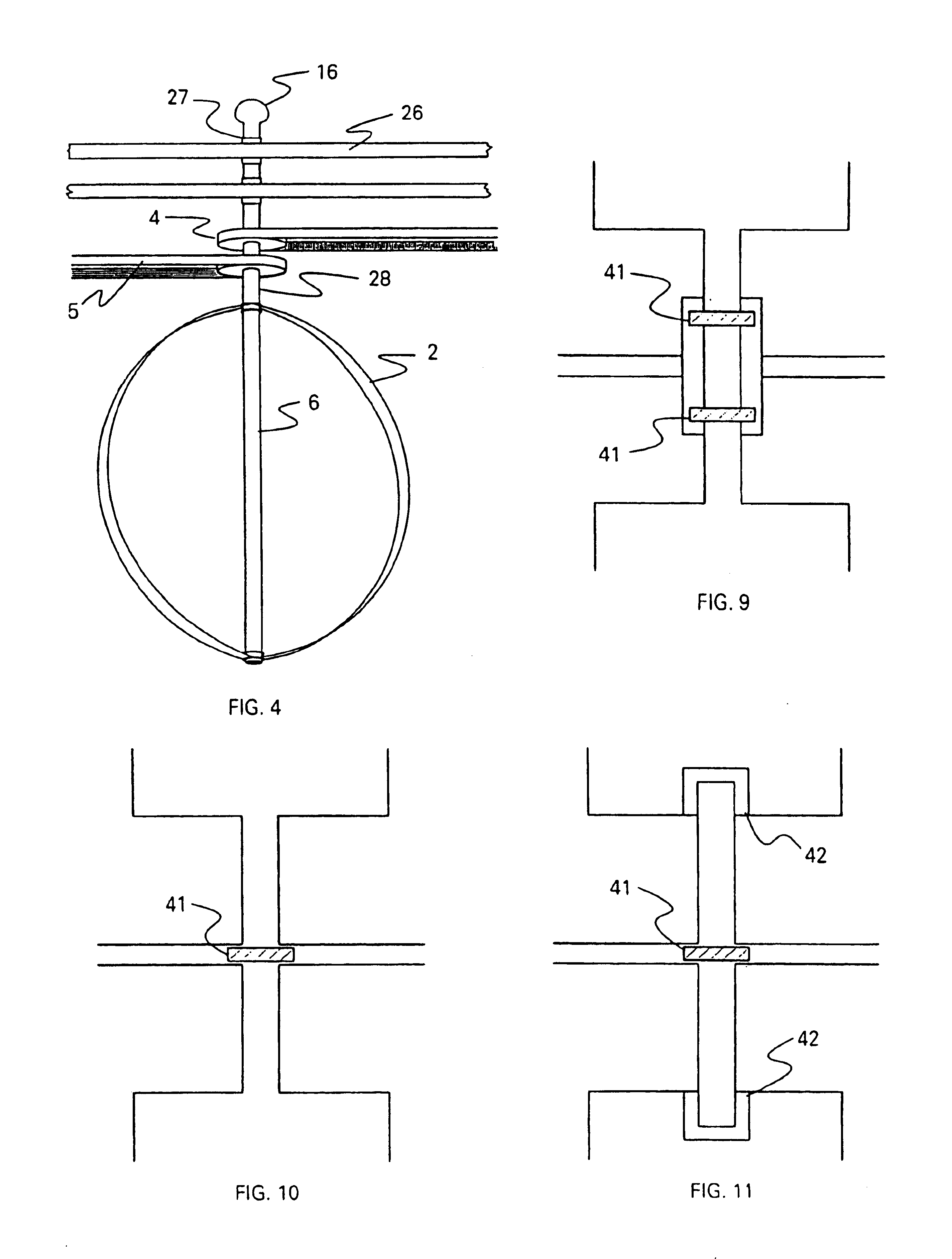

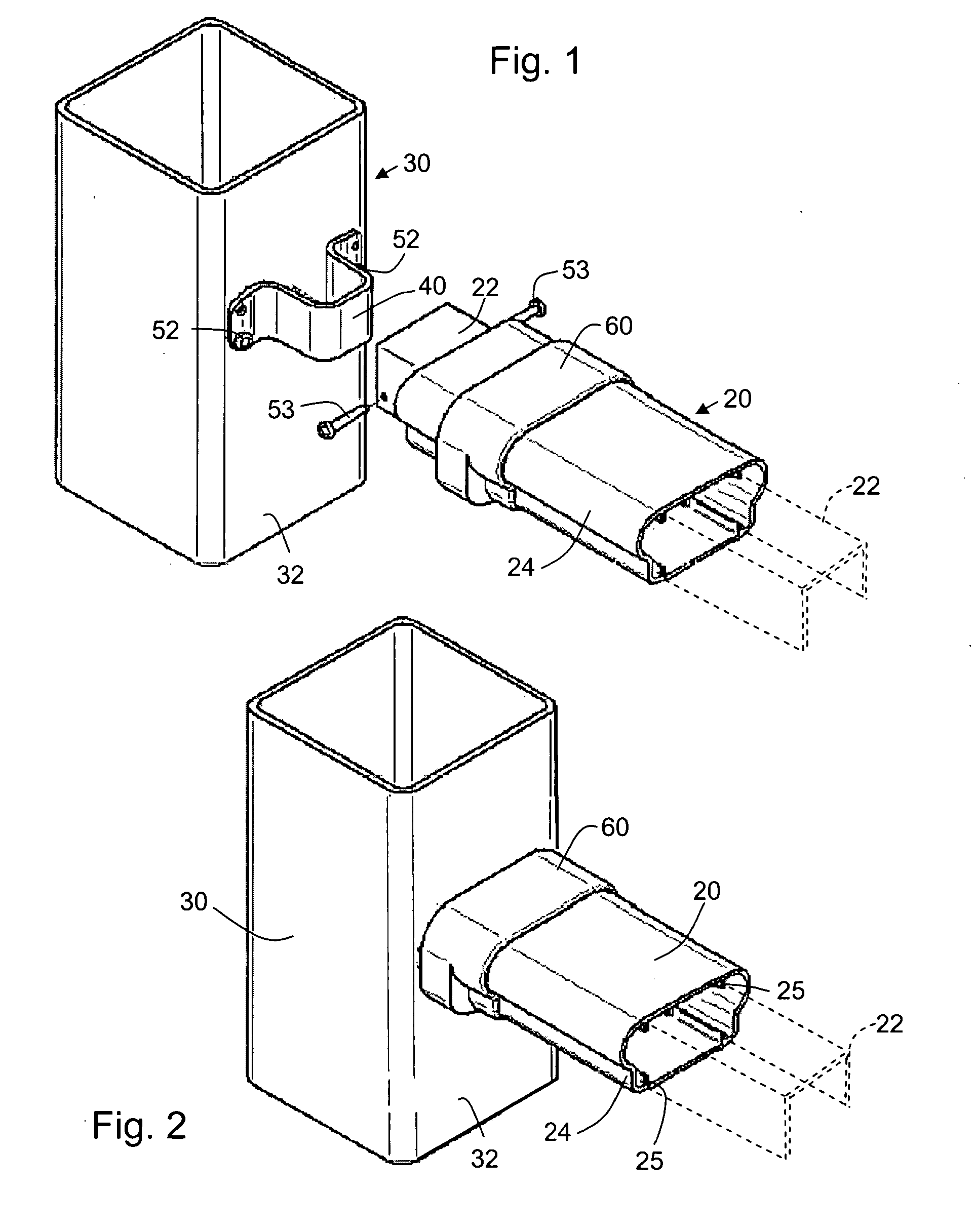

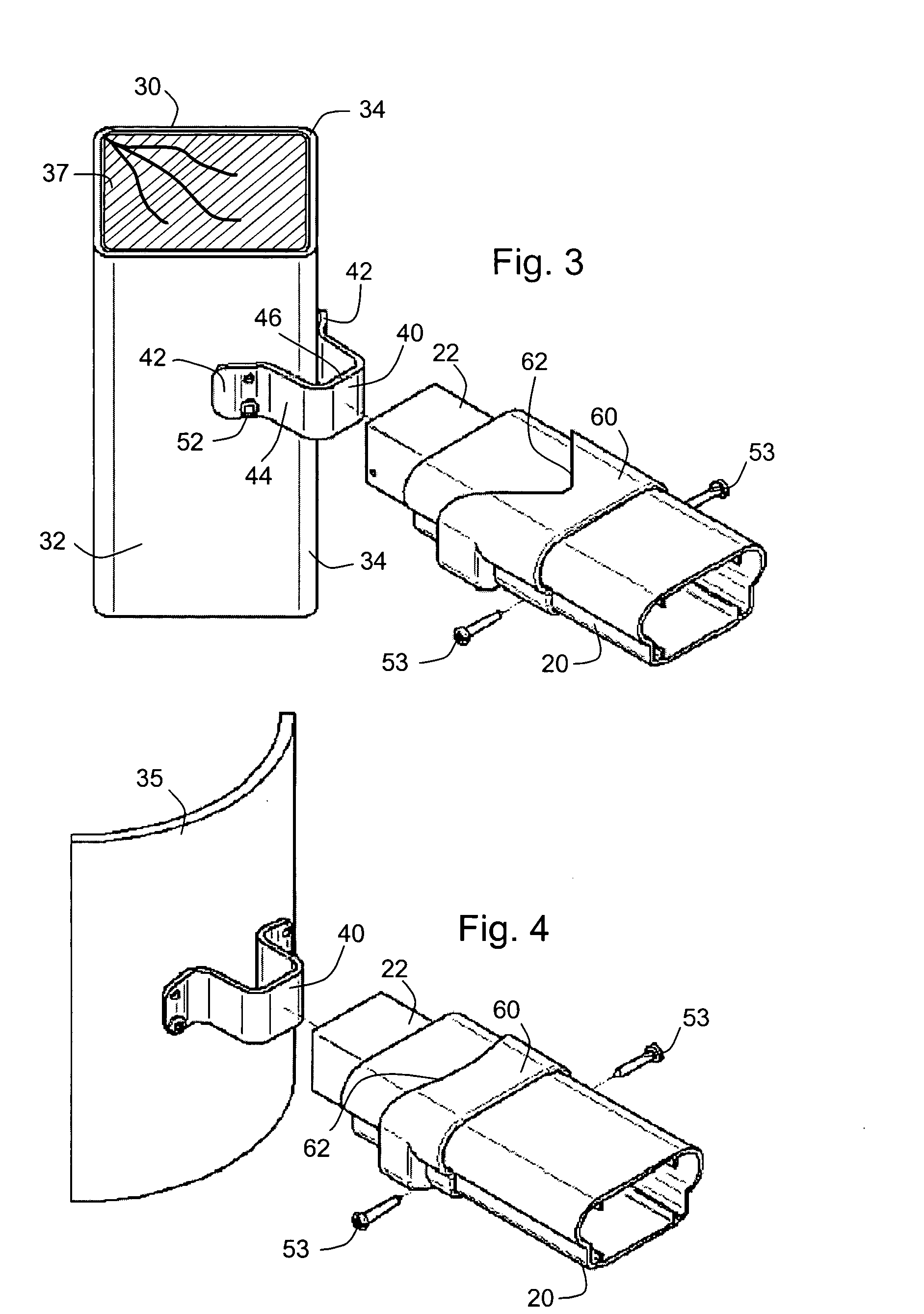

Bracket system for attaching elongated members

InactiveUS20050127346A1Easy to assembleMaintenance freeFencingCurtain suspension devicesBalusterFastener

Elongated members such as the rail and post of a baluster are attached by a U-shaped bracket strip affixed on a surface of the post and received in an end of the rail, being attached to each by fasteners. A terminal fitting forms a sleeve that is provided or is shaped during installation to conform to the surface of the post. The terminal fitting sleeve extends over the end of the rail and over the bracket, to abut against the post, concealing the end of the rail. The rail can have a flush cut load bearing internal member such as an aluminum channel or rectangular tube. A polymer outer cover forms the surface of the rail. The bracket system makes convenient, useful and structurally strong rail-to-post connections at various angles and in situations where the rail needs to meet the post at a polygonal edge.

Owner:CERTAINTEED CORP

Solar heat pipe heat exchanger

InactiveUS20120175082A1Low cost electricityLow cost heatSolar heating energySolar heat devicesEngineeringSolar energy harvesting

This invention relates to the process of collecting heat and removing heat from a heat pipe for solar energy applications. More specifically, this invention is a solar energy system that elegantly couples a heat pipe and a single header heat transfer assembly that has the capability of interchangeable operational designs using solar collector panel, solar vacuum tube, or integrated solar thermal and photovoltaic array configurations. The header assembly is structurally and thermally connected to the heat pipe by a heat pipe receiver which surrounds the condenser end of the heat pipe and plugs into the interior of the header assembly.

Owner:KMETOVICZ RONALD E +1

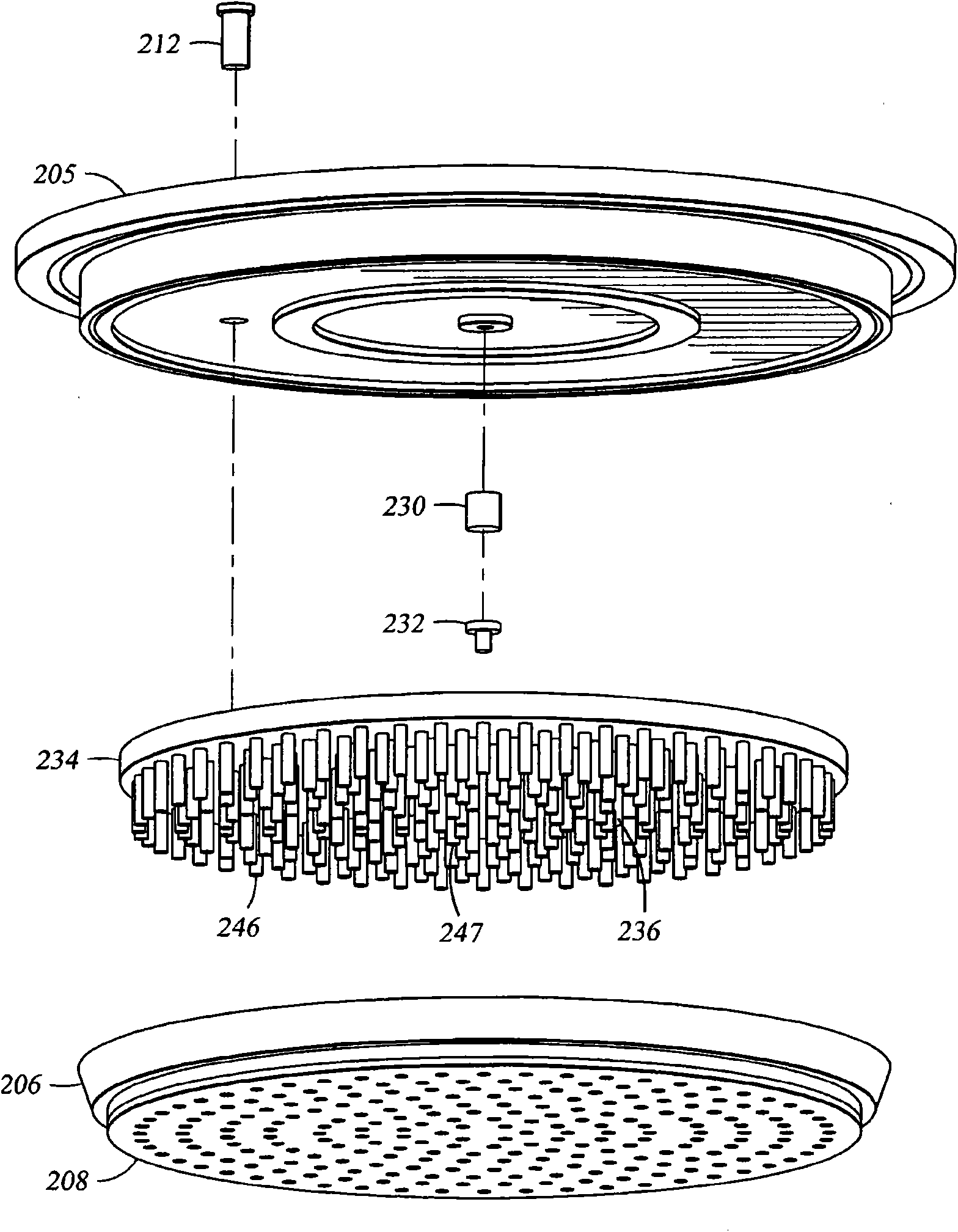

Gas distributor and semiconductor processing equipment applying same

ActiveCN101556904AEasy to processSimple and fast processingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingProduct gasEngineering

The invention discloses a gas distributor comprising a supporting plate, a spoiler and a spray header electrode which are sequentially cascaded from top to bottom. The back of the supporting plate is provided with a first supporting table and supporting plate flow guide bosses, and a supporting plate groove is disposed between every two adjacent supporting plate flow guide bosses. The front face of the spoiler is provided with a second supporting table and spoiler grooves, and a spoiler flow guide boss is disposed between every two adjacent spoiler grooves; the width and the depth of the grooves are both larger than those of the corresponding flow guide bosses so that the flow guide bosses can be embedded into the corresponding grooves and when the first supporting table is in contact with the second supporting table, and a certain gap is remained between the flow guide bosses and the corresponding grooves so as to transfer and distribute gas. In addition, the invention also discloses semiconductor processing equipment applying the gas distributor. The gas distributor and the semiconductor processing equipment not only can relatively evenly distribute gas inside a reaction chamber, but also have the advantages of convenient processing, no easy damage, and the like.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

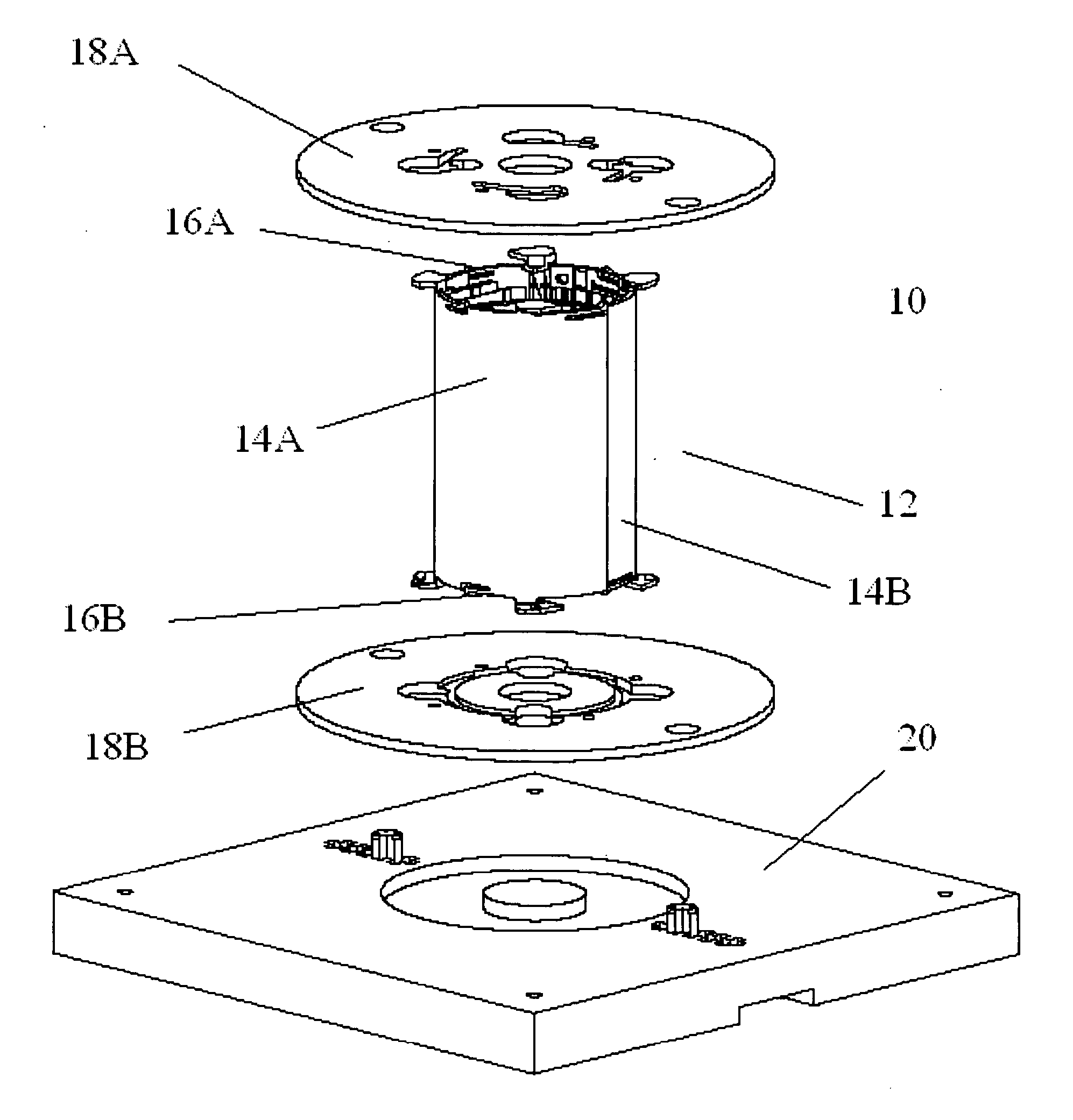

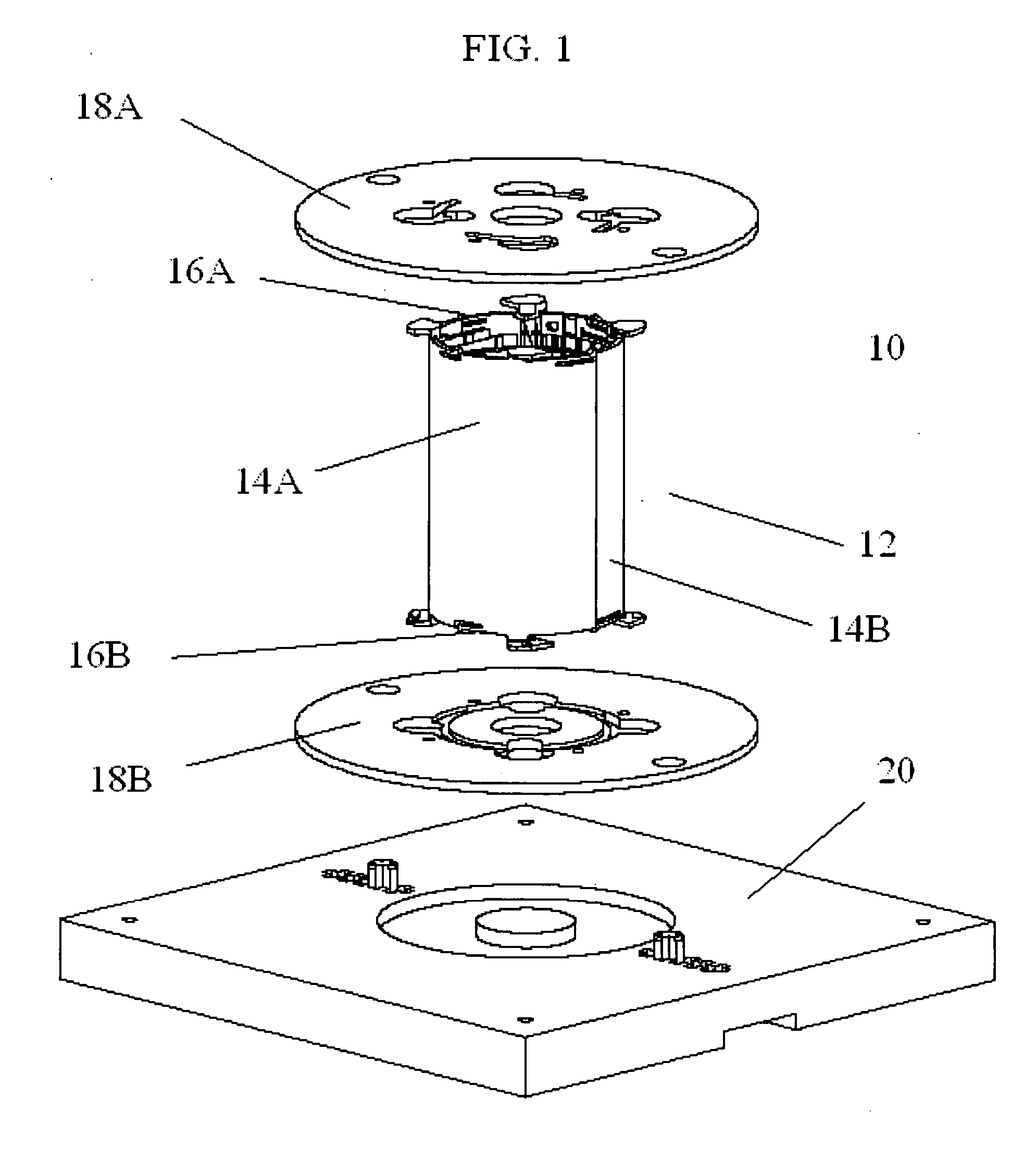

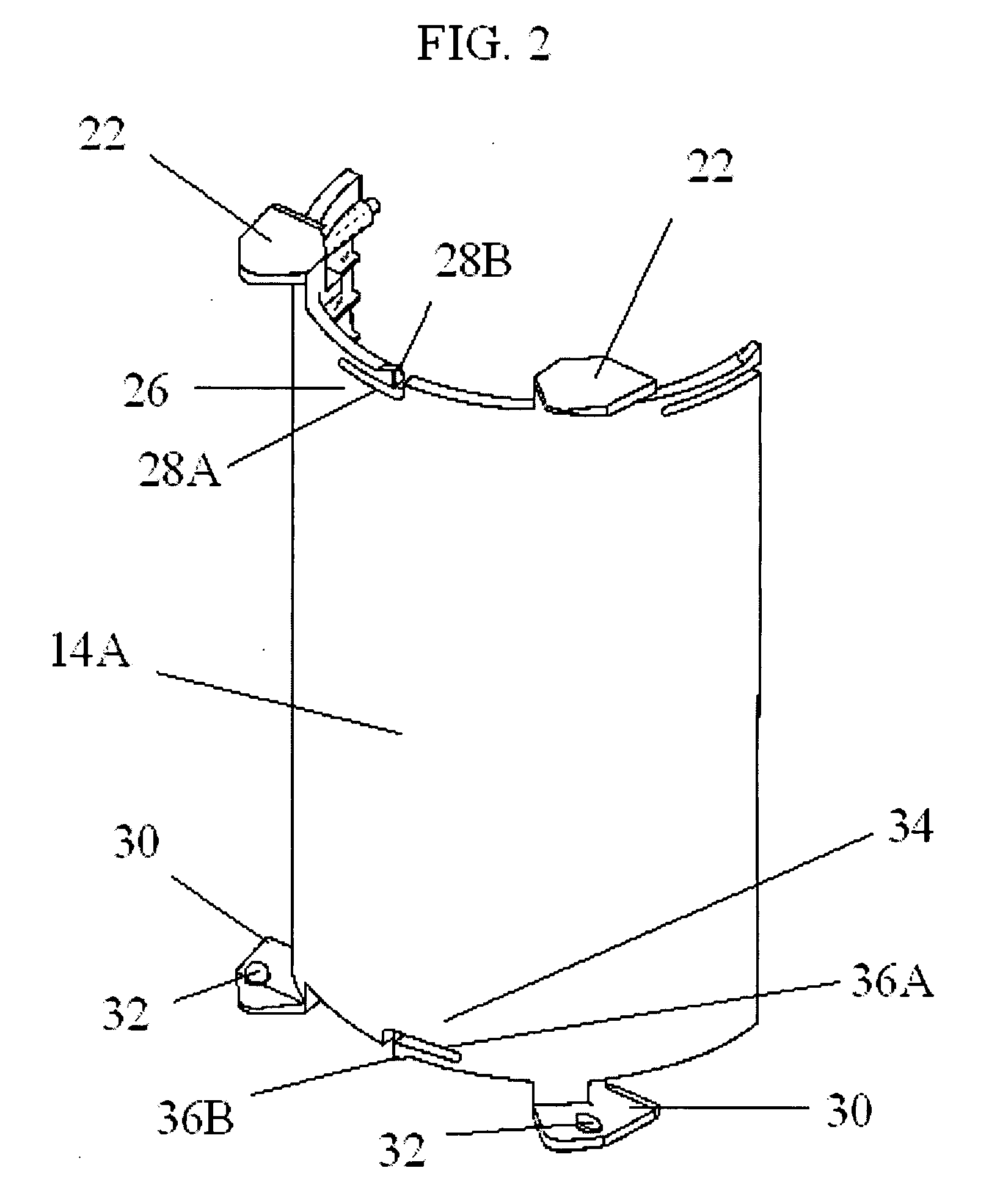

Storage and transport device for flexible material and method of making same

InactiveUS20070262192A1Easy and fast assemblyStrong and stable structureLocking mechanismEngineering

A storage and transport device for flexible material that allows for easy assembly by an individual, wherein the device includes a cylindrical core made of two identical tube portions which include several locking mechanism to join the tube portions, and a first flange connected to the top of the cylindrical core and a second flange connected to the bottom of the cylindrical core, wherein flexible material is wound or unwound around the core.

Owner:DERENDAL THADDEUS J

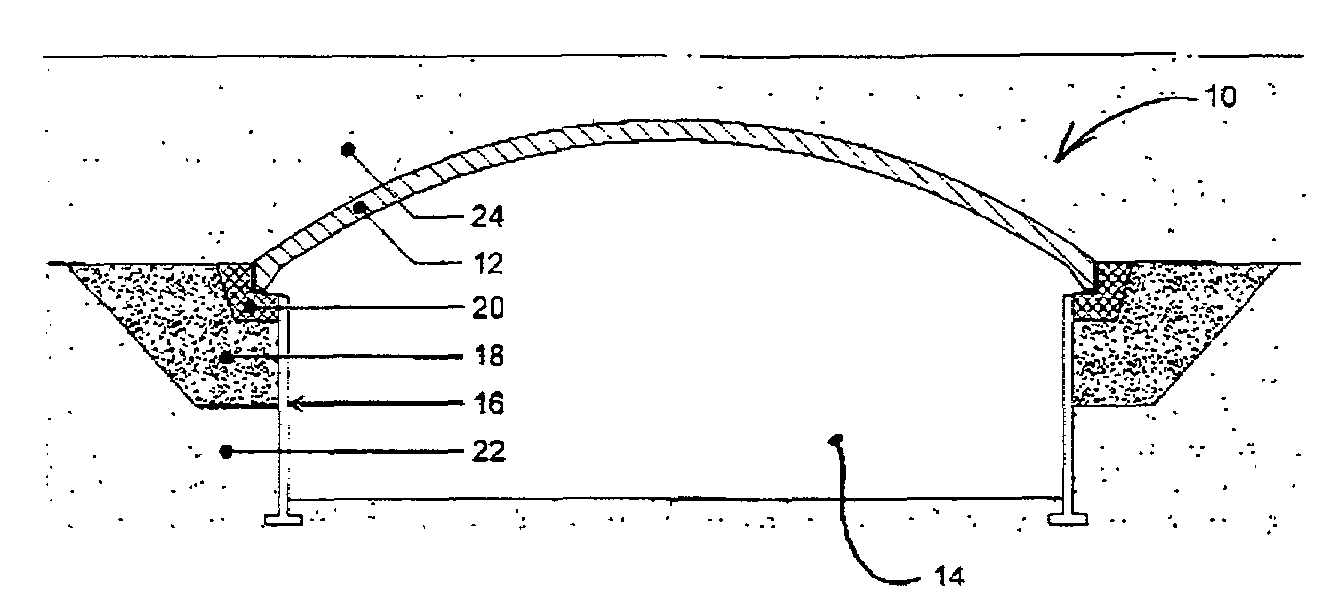

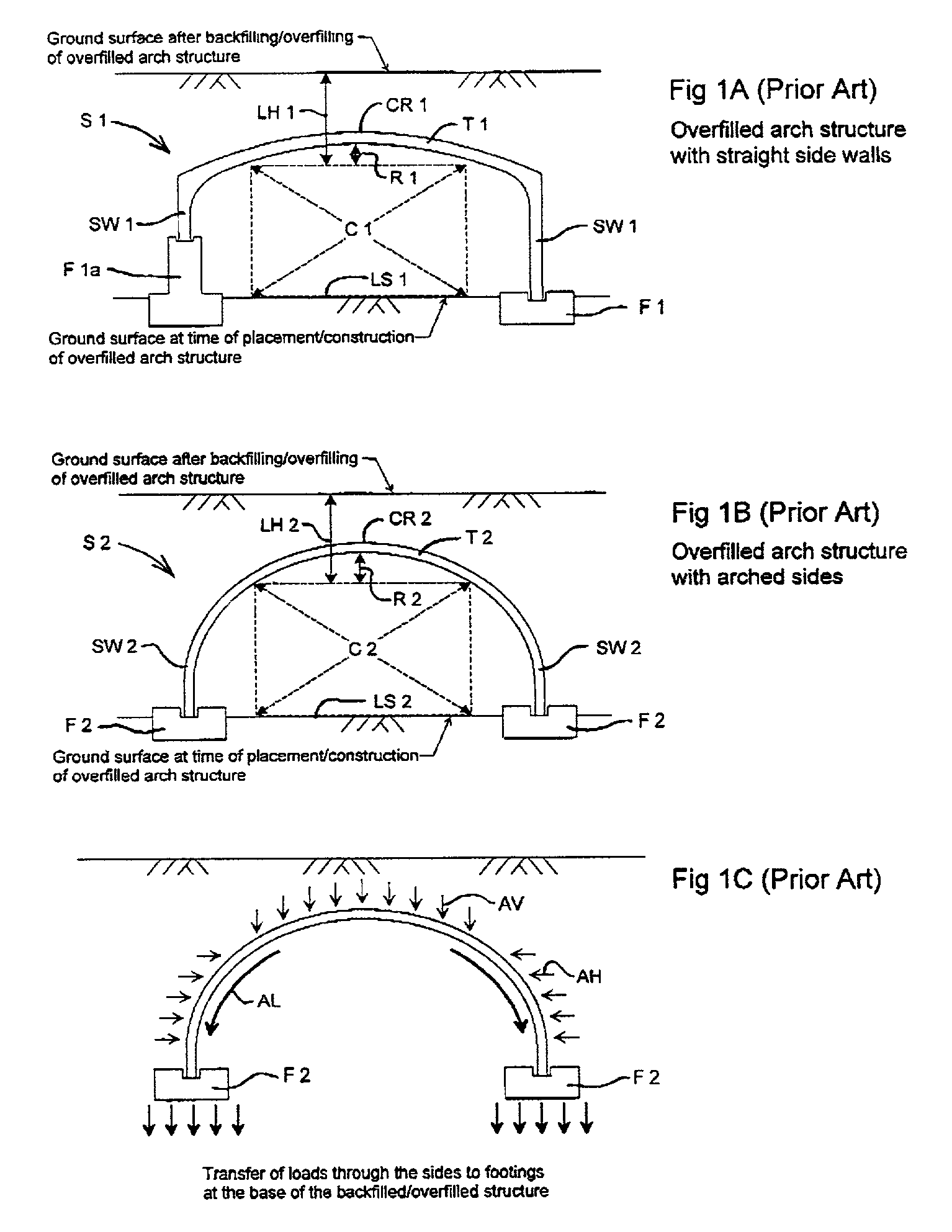

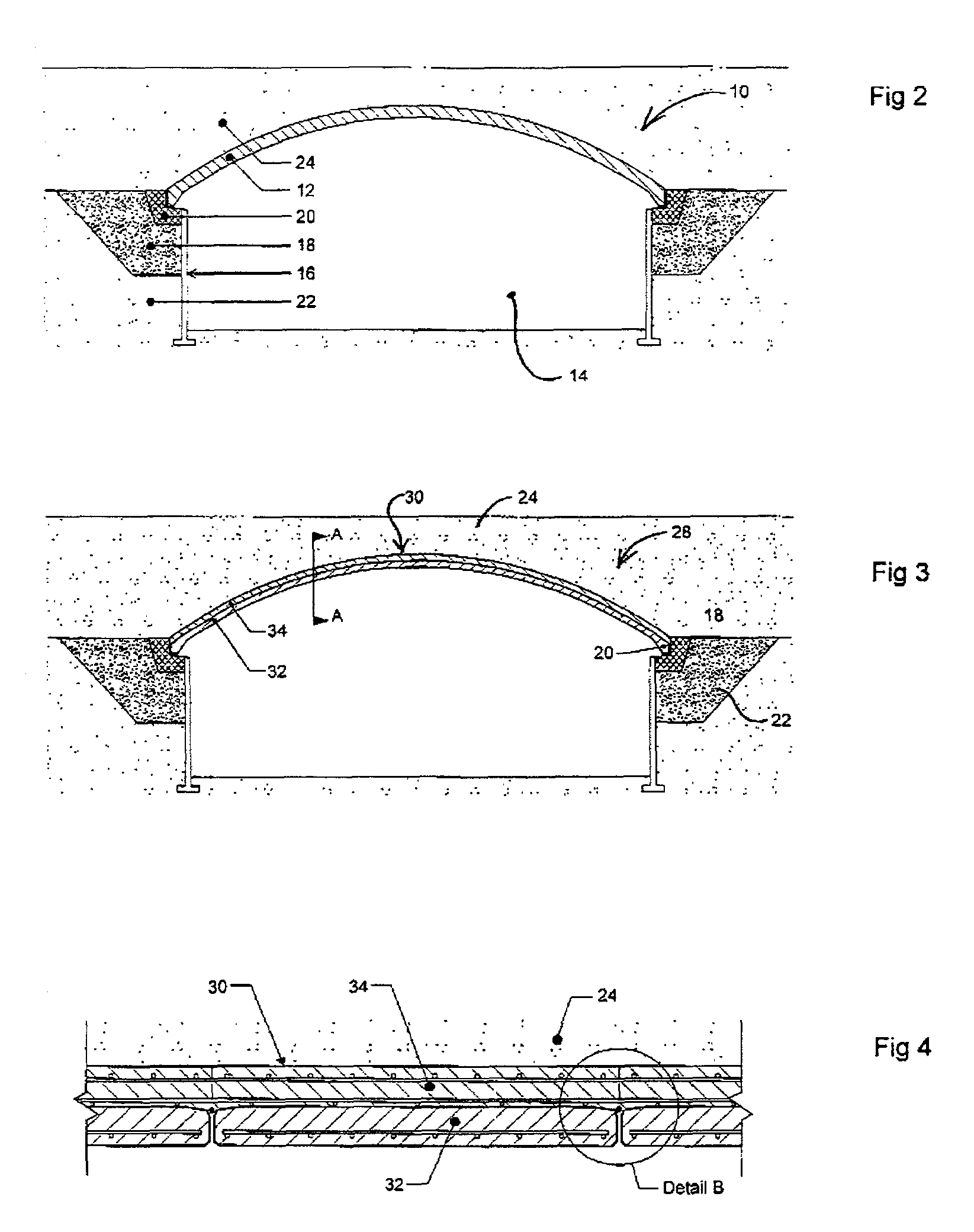

Composite overfilled arch system

InactiveUS7305798B1Enhanced advantageEfficiently and effectively accommodatedGround-workArched structuresPre stressArch bridge

An overfilled arch bridge system includes a composite arch which has a precast layer and a cast-in-place layer. The system further includes means for reducing bending moments within the overfilled arch. The means include customizing the arch end geometry and prestressing the arch prior to or during loading. The system can be used in connection with the overfilled arch system disclosed in co-pending patent application titled “Top Arch Overfilled System” filed by the same inventor on Mar. 22, 2002.

Owner:CONTECH ENGINEERED SOLUTIONS

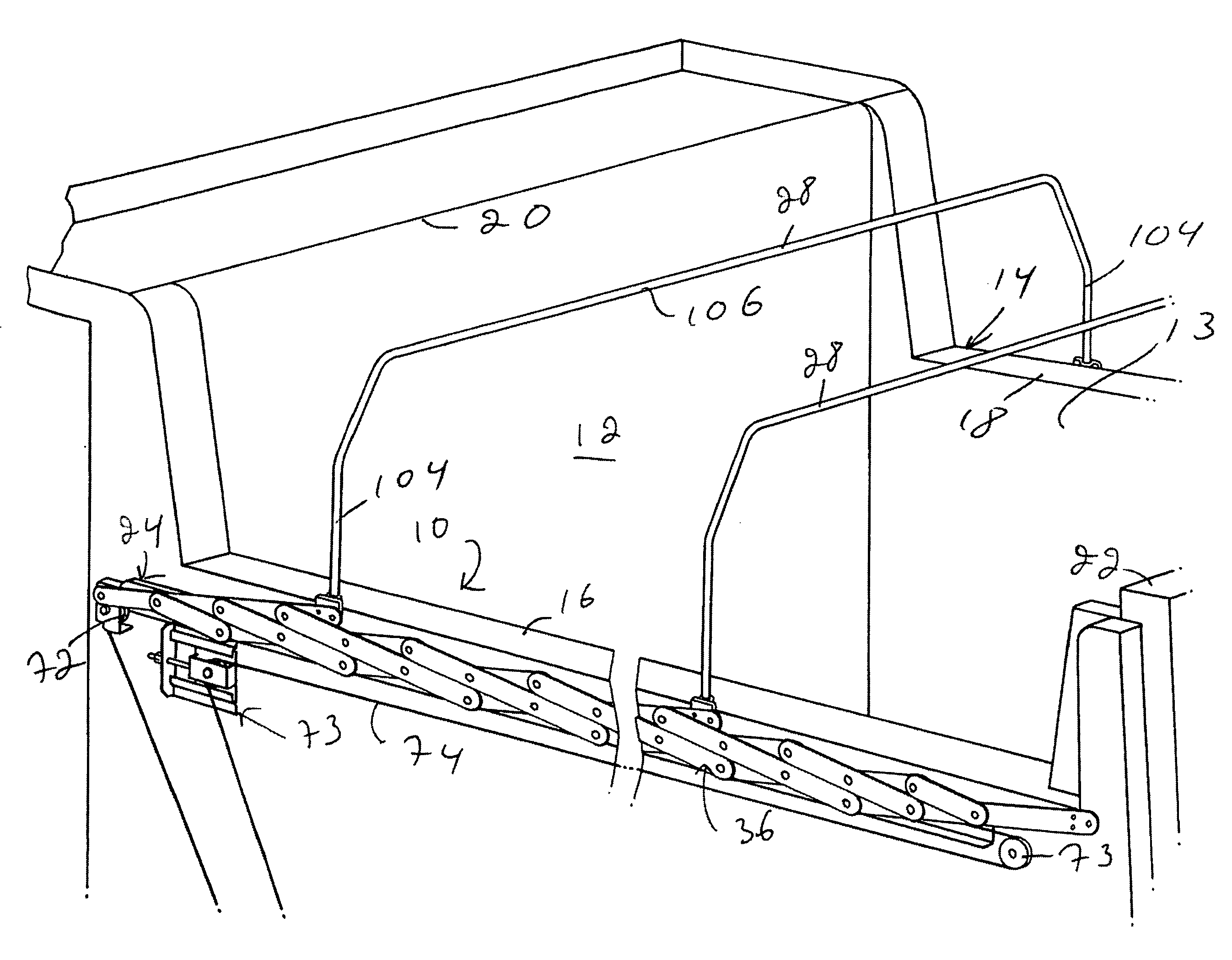

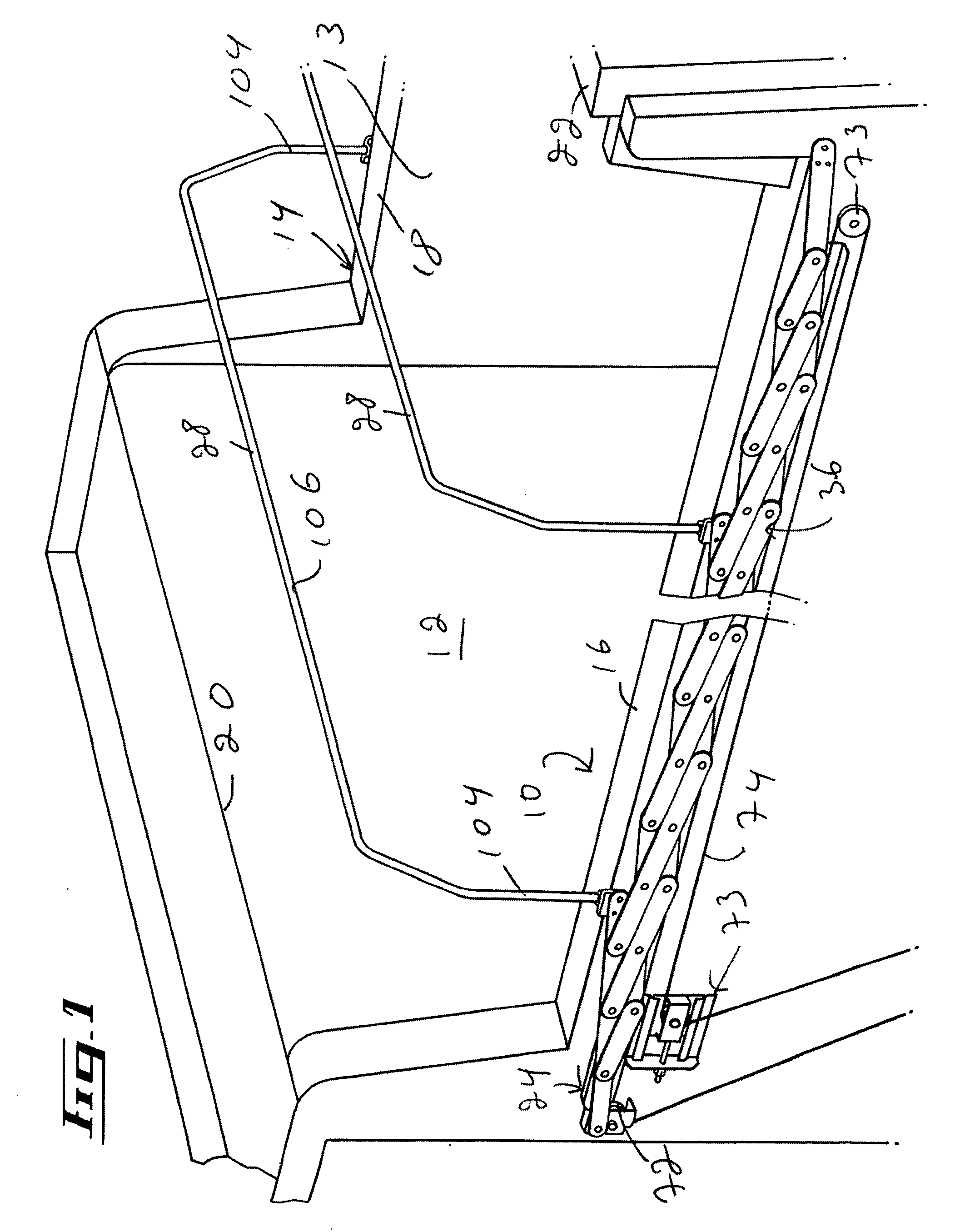

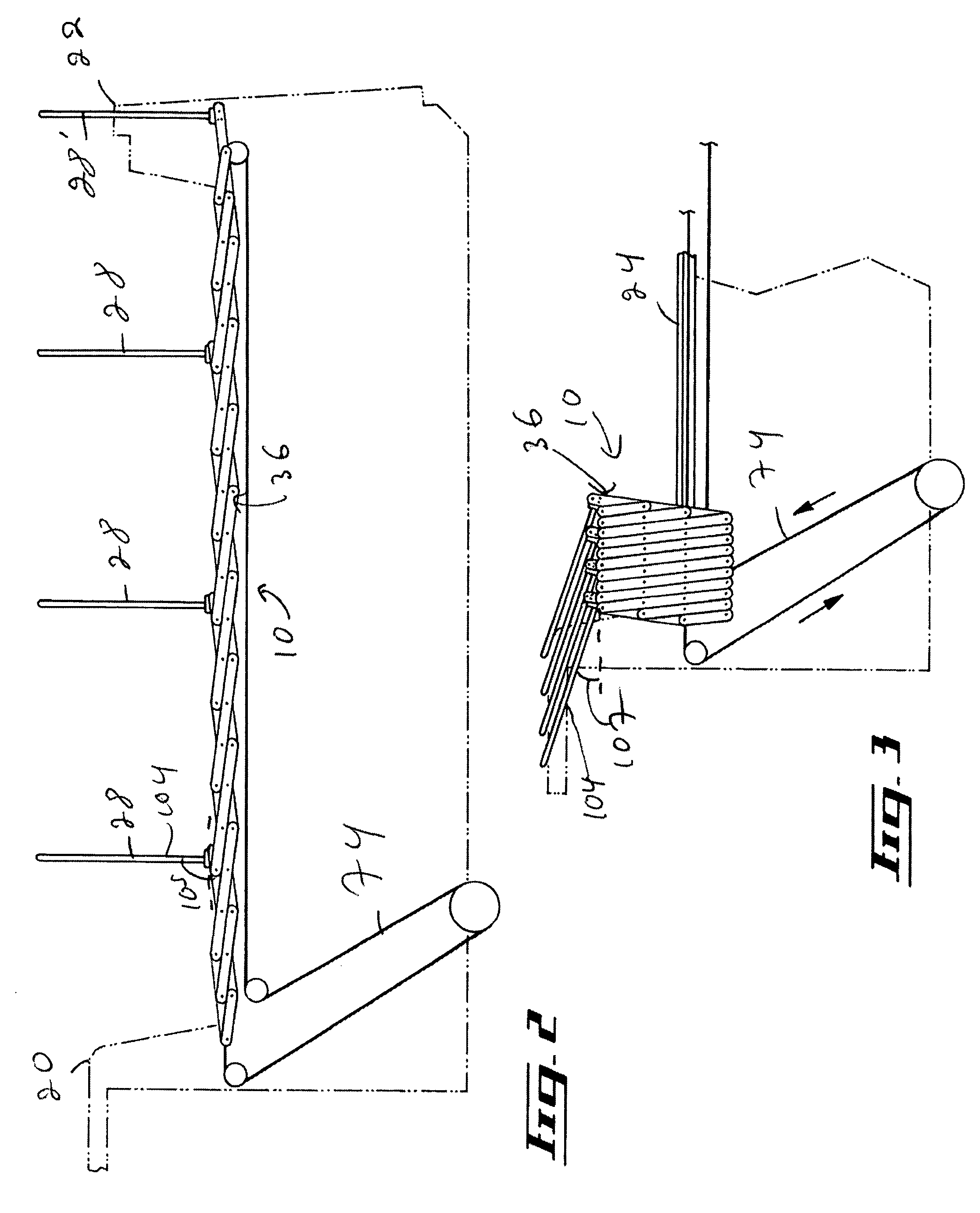

Device for manipulating a tarpaulin

InactiveUS20080290686A1Easy to disassembleEasy accessVehicle with living accommodationSuperstructure subunitsMechanical engineeringEngineering

A device for manipulating a tarpaulin so as to selectively cover and uncover a top aperture of a container. The top aperture defines an aperture peripheral edge, the aperture peripheral edge including two substantially opposed substantially longitudinal segments. The tarpaulin is configurable between an extended configuration and a retracted configuration. In the extended configuration, the tarpaulin substantially covers the top aperture. In the retracted configuration, the tarpaulin is substantially retracted from the top aperture. The device includes an elongated guiding component defining a guiding component longitudinal axis. The guiding component is securable to the container so as to extend at least partially along at least one of the longitudinal segments. A tarpaulin mounting component is usable for attaching the tarpaulin thereto. A link, mechanically coupled to the guiding component, is longitudinally movable therealong between a link proximal position and a link distal position. The tarpaulin mounting component is operatively coupled to the link in a manner such that when the link is in the link proximal position, and the tarpaulin is attached to the tarpaulin mounting component, the tarpaulin is in the retracted configuration. When the link is in the link distal position and the tarpaulin is attached to the tarpaulin mounting component, the tarpaulin is in the extended configuration.

Owner:ROYER REAL

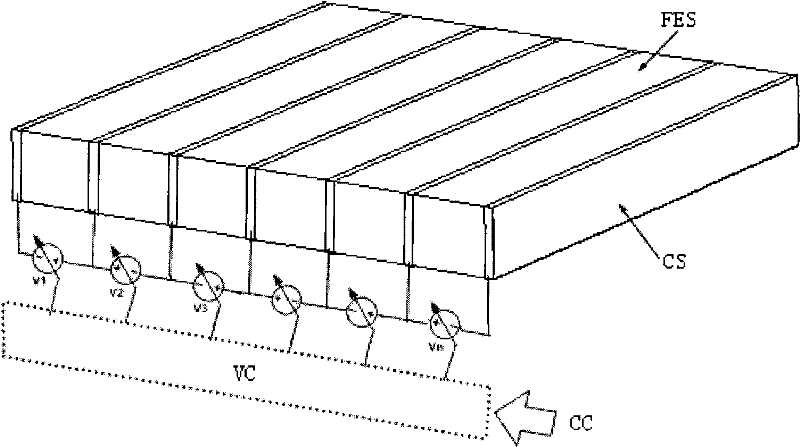

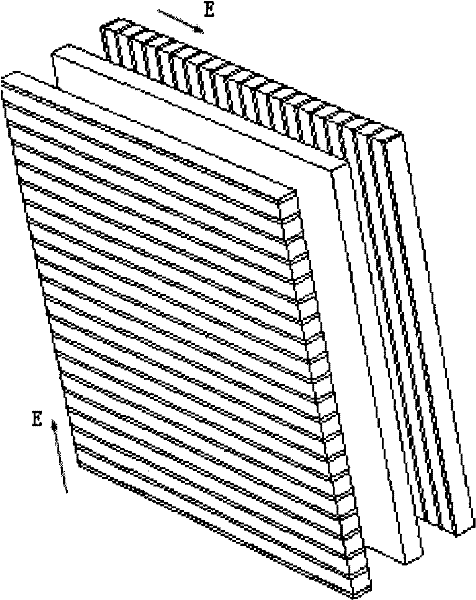

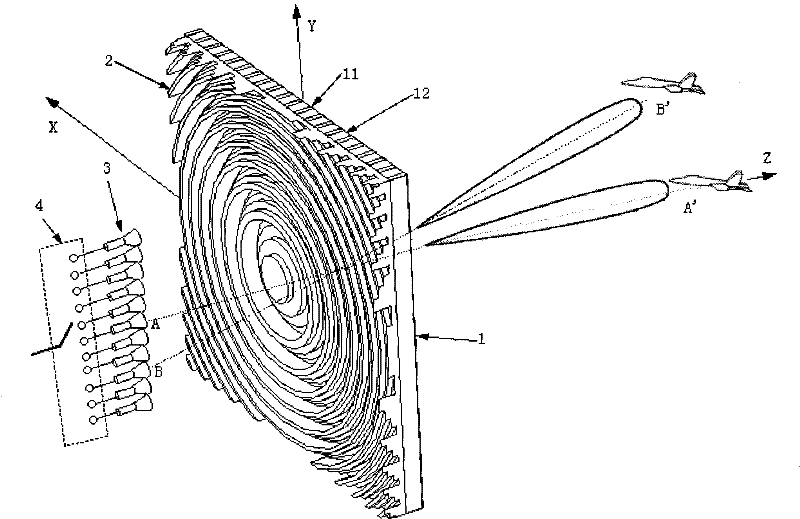

Two-dimensional electric scanning lens antenna

The invention provides a two-dimensional electric scanning lens antenna which has stable and compact structure and is used for scanning radar. The antenna comprises a ferroelectric lens antenna and a one-dimensional linear array feed source, wherein the ferroelectric lens antenna comprises conductor plane plates, ferroelectric dielectric plates are clamped among adjoining conductor plane plates, the ferroelectric lens antenna is provide with a binary diffraction lens, the binary diffraction lens is positioned between the one-dimensional linear array feed source and the ferroelectric lens antenna, the one-dimensional linear array feed source is connected with a N channels selecting switch, and the polarization direction of an electromagnetic wave which is transmitted or received by the one-dimensional linear array feed source is perpendicular to the direction of the long edges of the conductor plane plates. The antenna realizes the two-dimensional electric scanning through the N channels selecting switch and an N voltages control system; and compared with a scanning system which consists of two pieces of PELs, a scanning control part is simpler. A BDL is a plane structure, thereby not only effectively reducing the weight and the profile of the antenna, but also being capable of being wirelessly connected with an FEL of the plane structure, and being good for obtaining a stable and compact structure.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com