A preparation method of high-entropy alloy binder phase ti(c,n)-based cermet

A high-entropy alloy and cermet technology is used in the preparation of cermet materials and the preparation of high-entropy alloy binder phase Ti-based cermets, which can solve the problems of hard phase grain growth and content reduction, and achieve thermal insulation. Short time, maintain relative content, inhibit diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

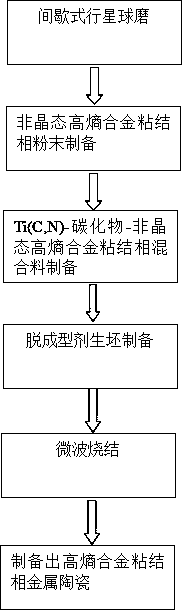

Image

Examples

example 1

[0018] Example 1: Prepare a high-entropy alloy binder phase Ti(C,N)-based cermet according to the following steps:

[0019] (1) Preparation of amorphous high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Co:Ni:Fe:Cu:Mn=1:1:1:1:0.3; Planetary ball mill, the ball milling speed is 300r / min, the ball-to-material ratio of the ball mill is 10:1, using WC-6Co balls with a diameter of 5mm, the ball milling medium is absolute ethanol, and the amount added is 15% of the total weight of the binder phase powder , the ball milling process is filled with 0.03MPa argon gas for protection, the ball milling time is 72 hours, the ball milling is 4 hours intermittently for 20 minutes, after the ball milling is finished, it is filtered with a 400 mesh screen, dried at 92 ° C, and passed through a 100 mesh screen;

[0020] (2) Preparation of Ti(C,N)-carbide-amorphous high-entropy alloy binder phase mixture: Weigh Ti(C,N), carbide and amorphous high-entrop...

example 2

[0023] Example 2: Prepare a high-entropy alloy binder phase Ti(C,N)-based cermet according to the following steps:

[0024](1) Preparation of amorphous high-entropy alloy powder: Weigh various raw material powders, according to atomic percentage Co:Ni:Fe:Cu:Mn=1:1:1:1:1; Planetary ball mill, the ball milling speed is 380r / min, the ball-to-material ratio of the ball mill is 10:1, using WC-6Co balls with a diameter of 5mm, the ball milling medium is absolute ethanol, and the amount added is 20% of the total weight of the binder phase powder , the ball milling process is filled with 0.03MPa argon gas for protection, the ball milling time is 110 hours, the ball milling is 5 hours intermittently for 20 minutes, after the ball milling is finished, it is filtered with a 400-mesh screen, dried at 98°C, and passed through a 100-mesh sieve;

[0025] (2) Preparation of Ti(C,N)-carbide-amorphous high-entropy alloy binder phase mixture: Weigh Ti(C,N), carbide and amorphous high-entropy all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com