Patents

Literature

84 results about "Rotational shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

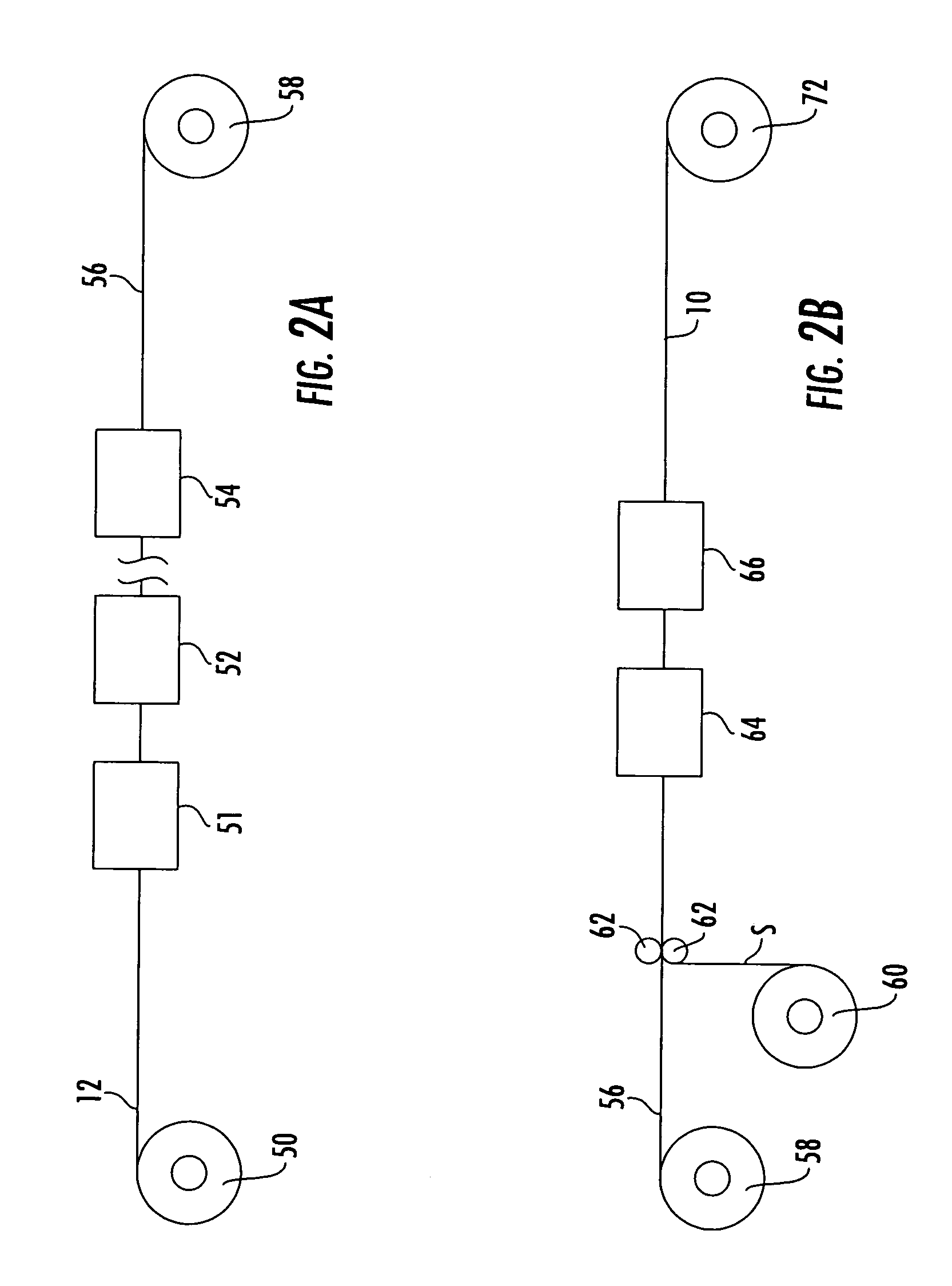

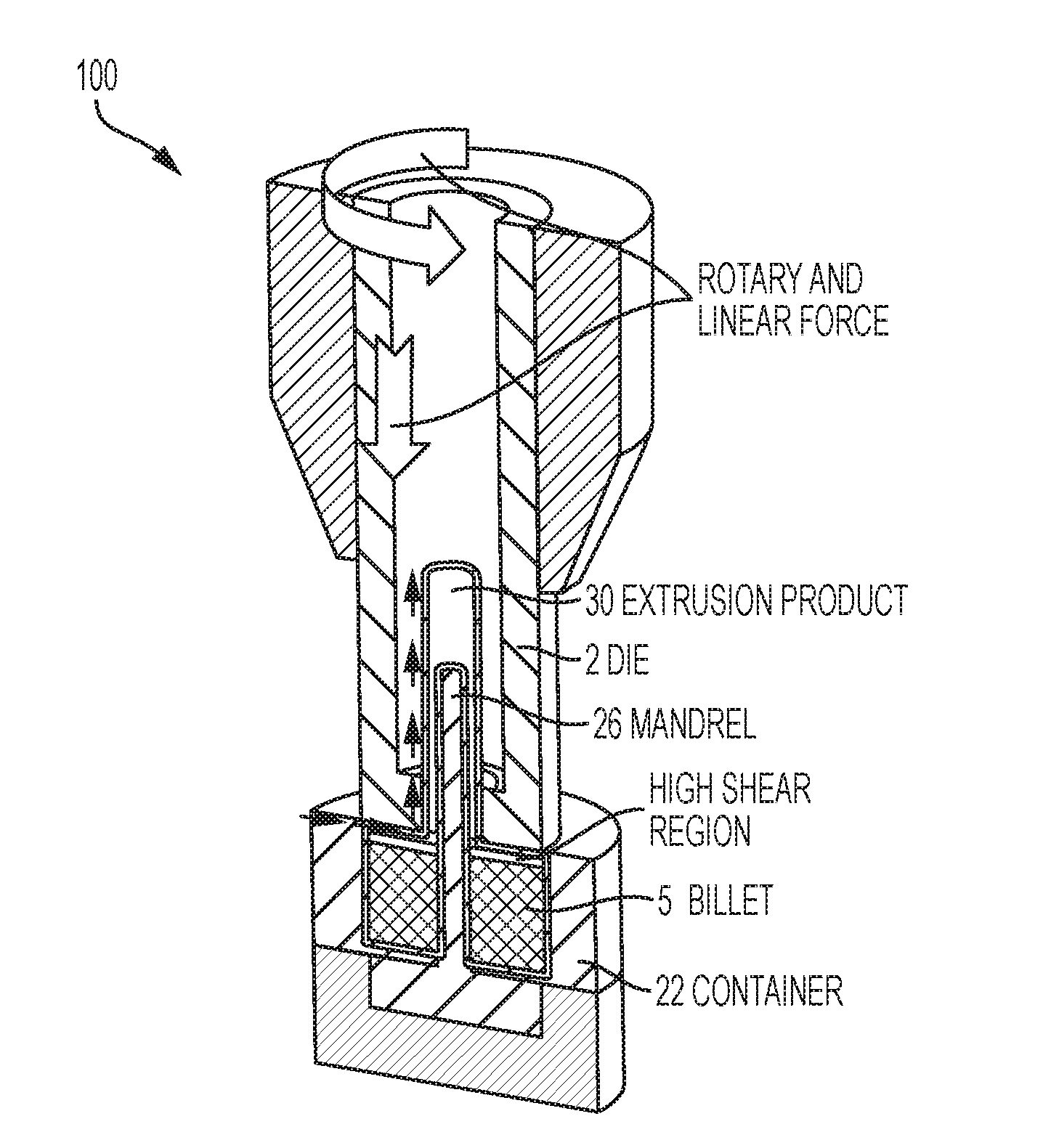

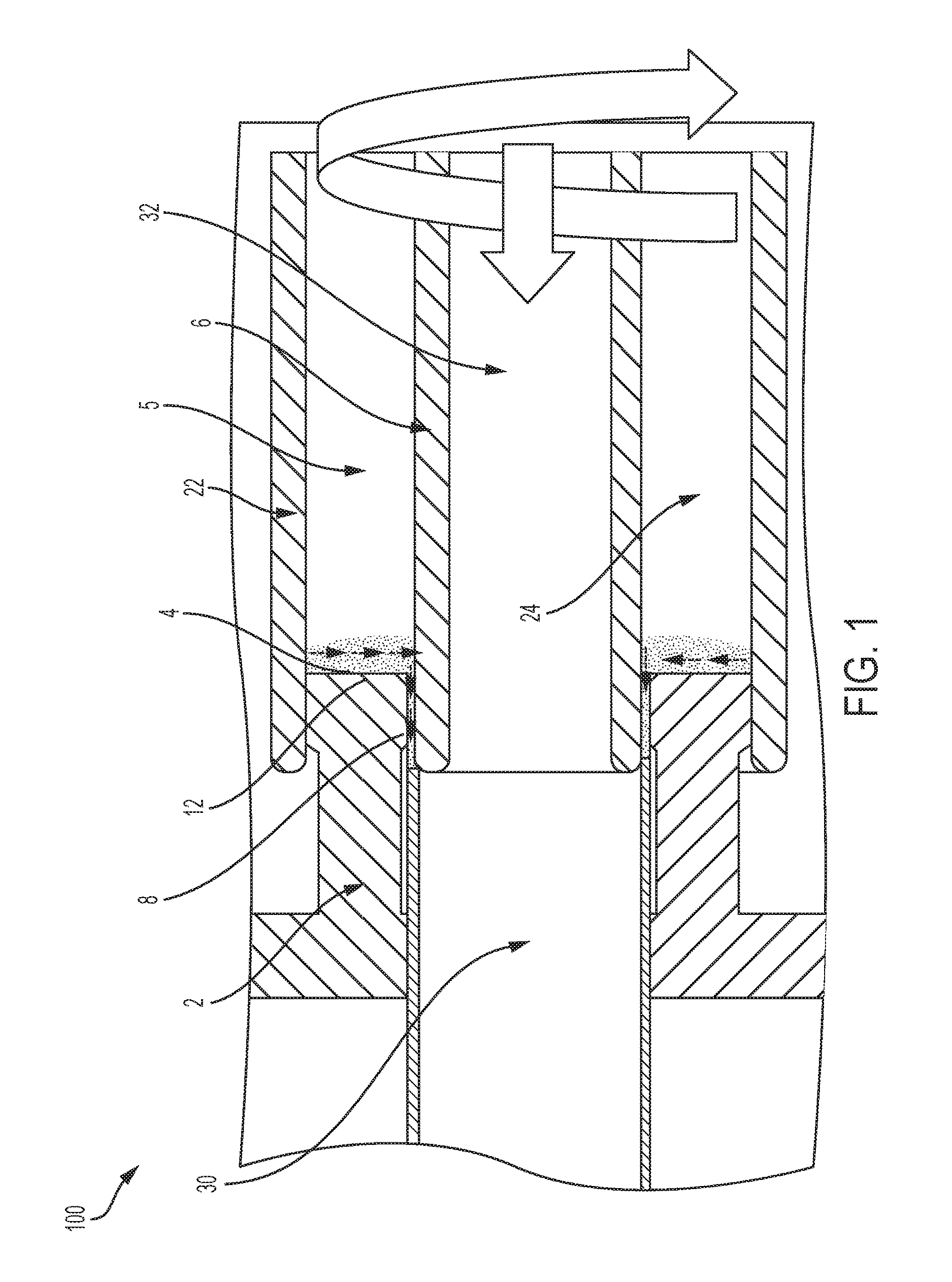

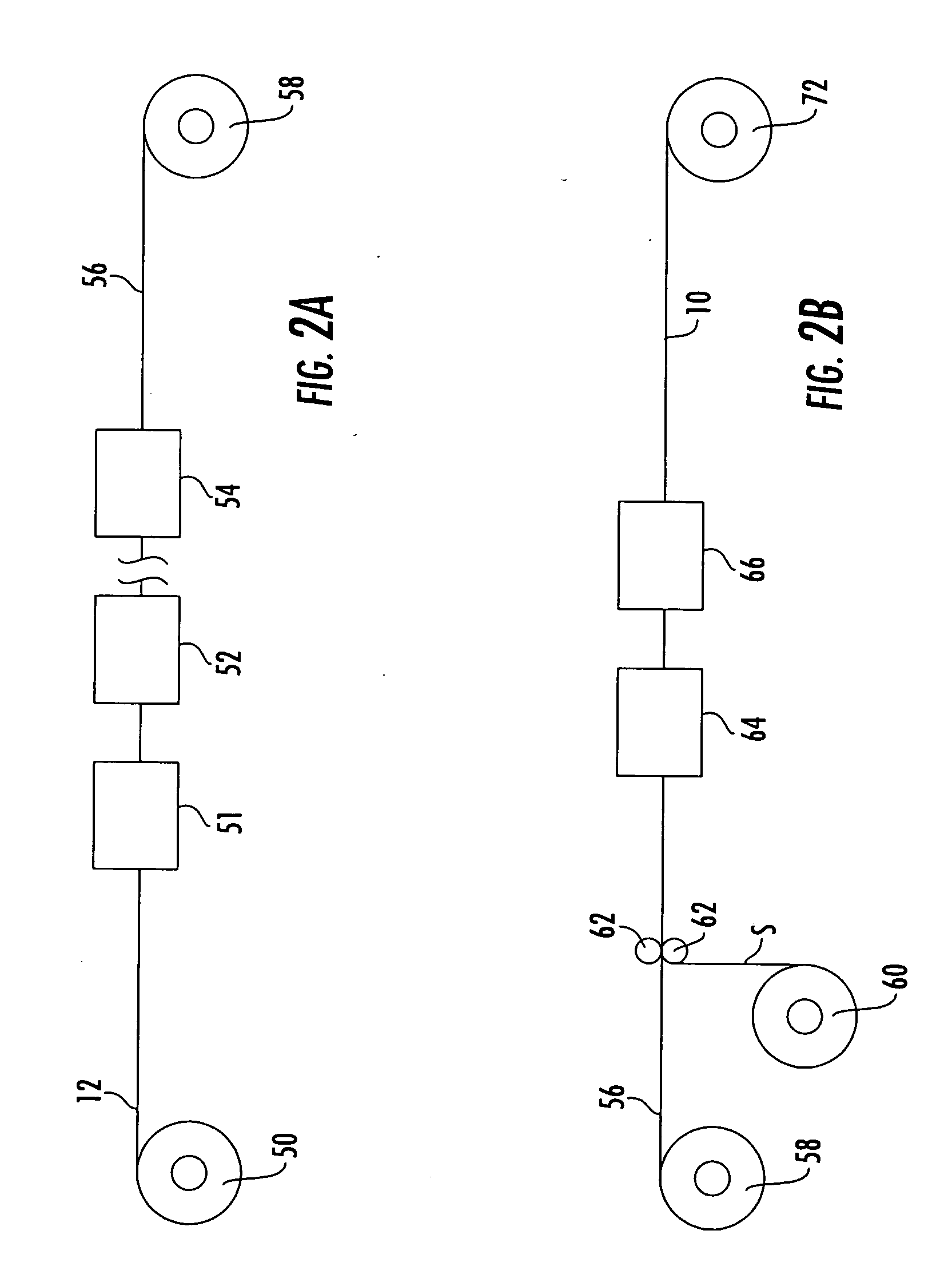

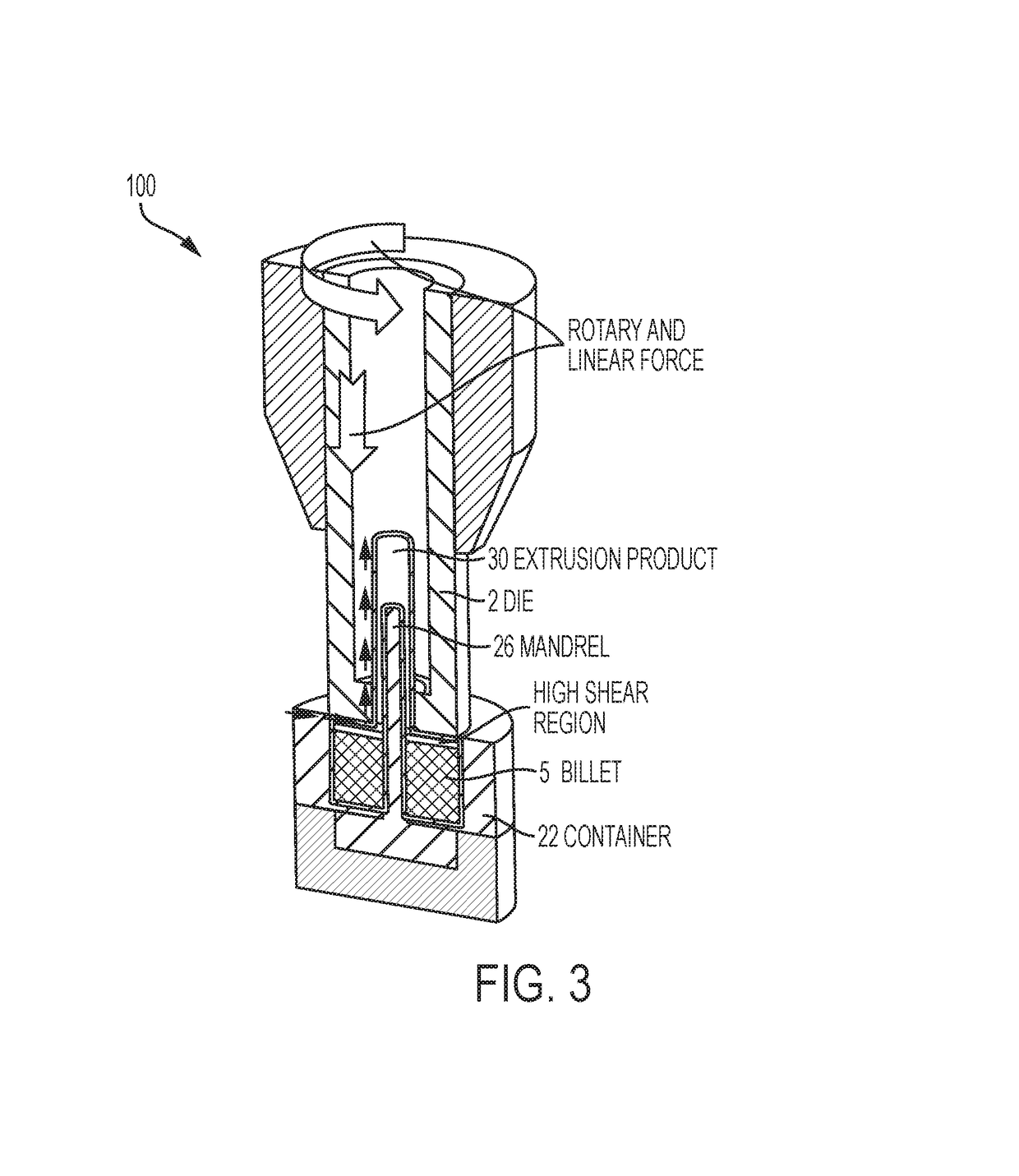

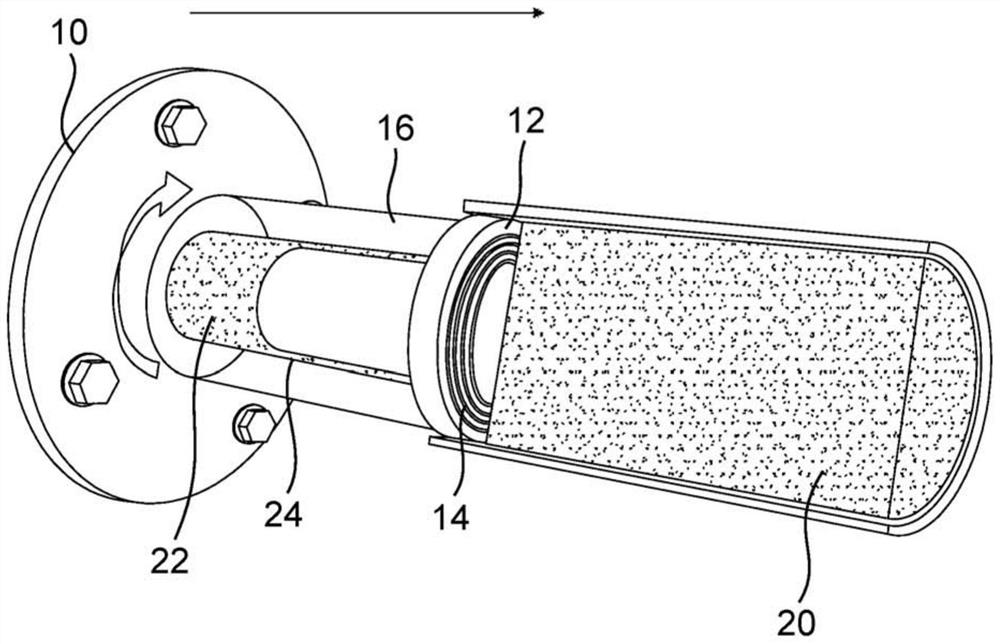

System and process for formation of extrusion structures

InactiveUS20140283574A1Improve performanceImprove propertiesExtrusion containersExtrusion mandrelsEngineeringMechanical engineering

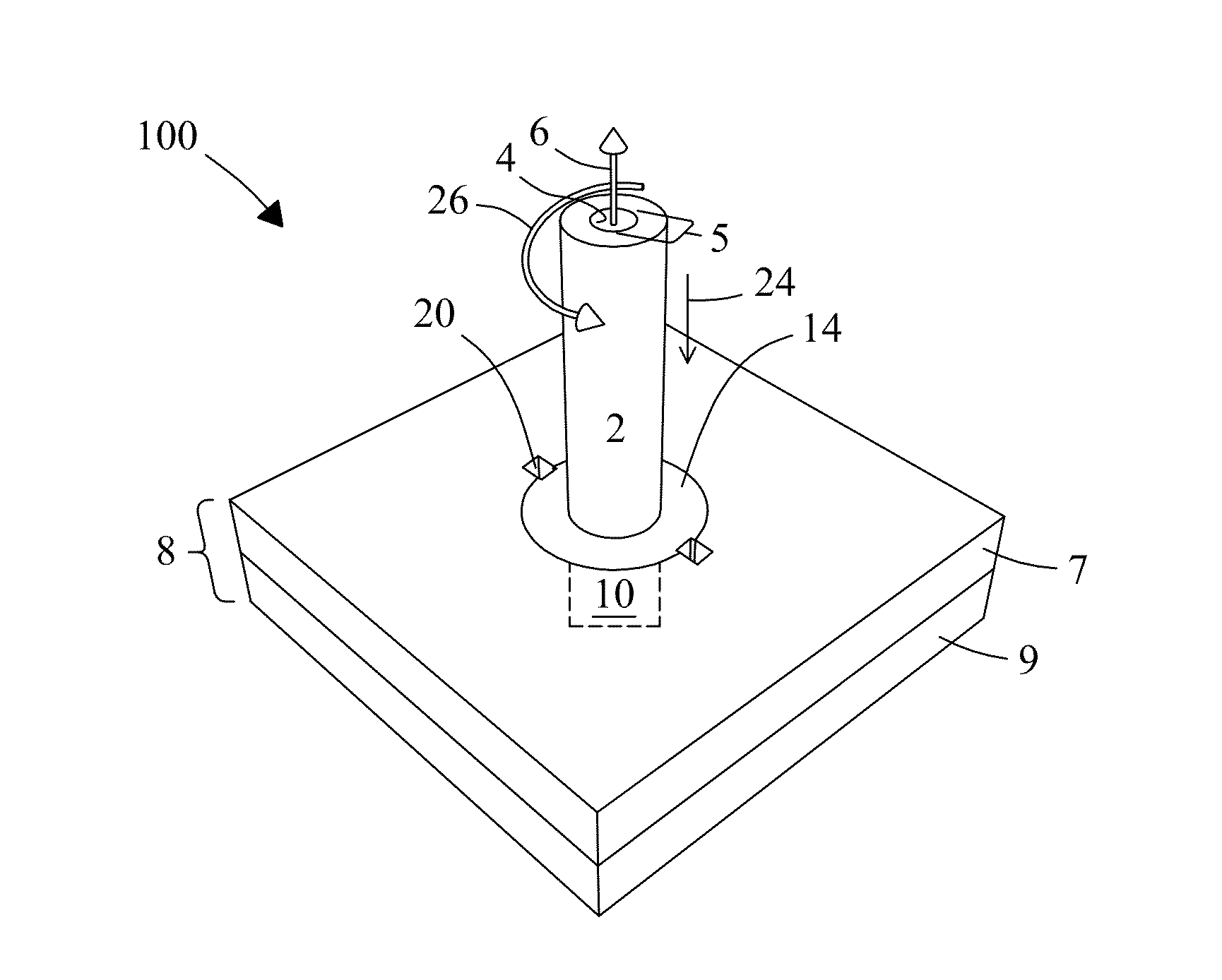

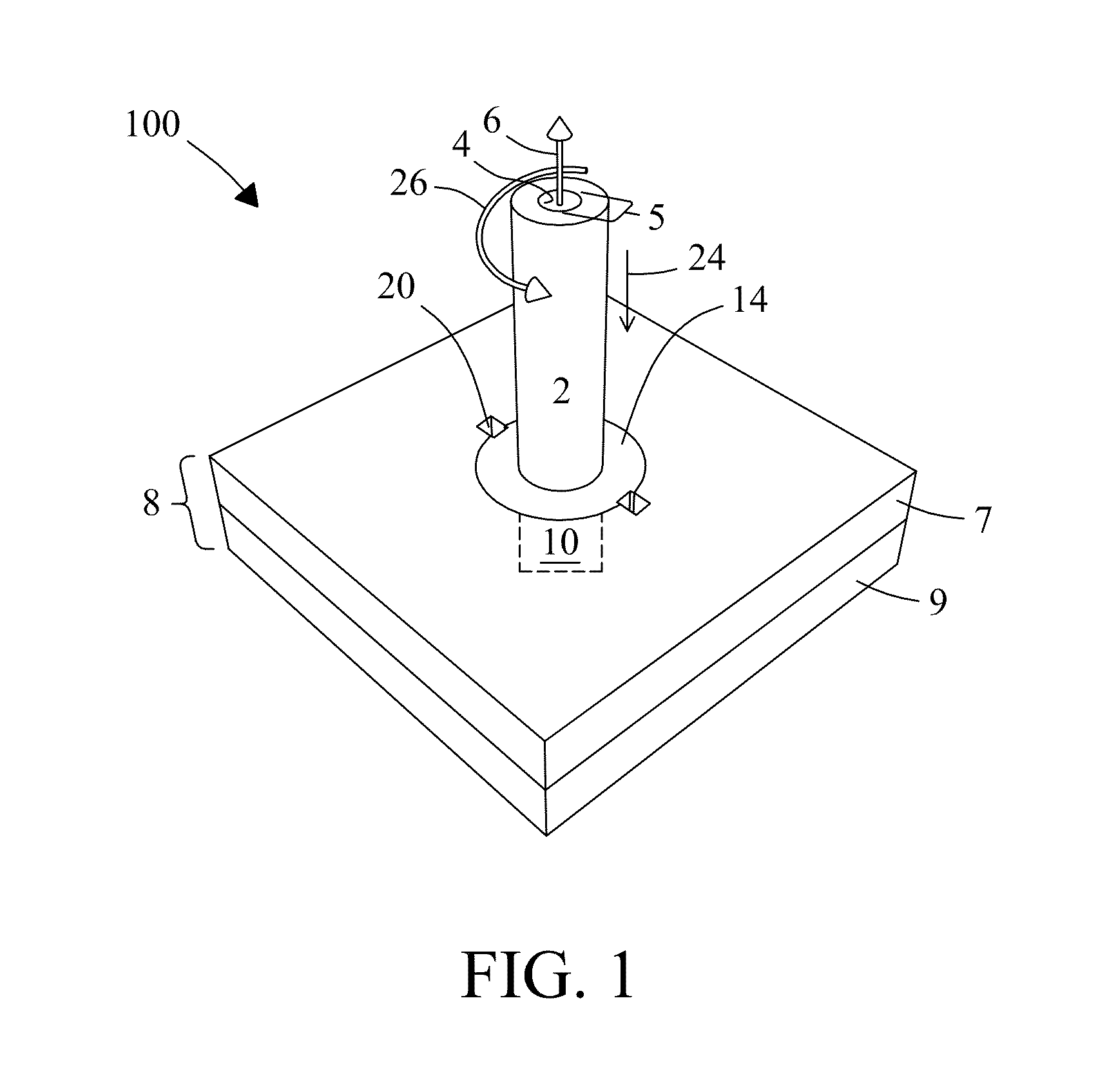

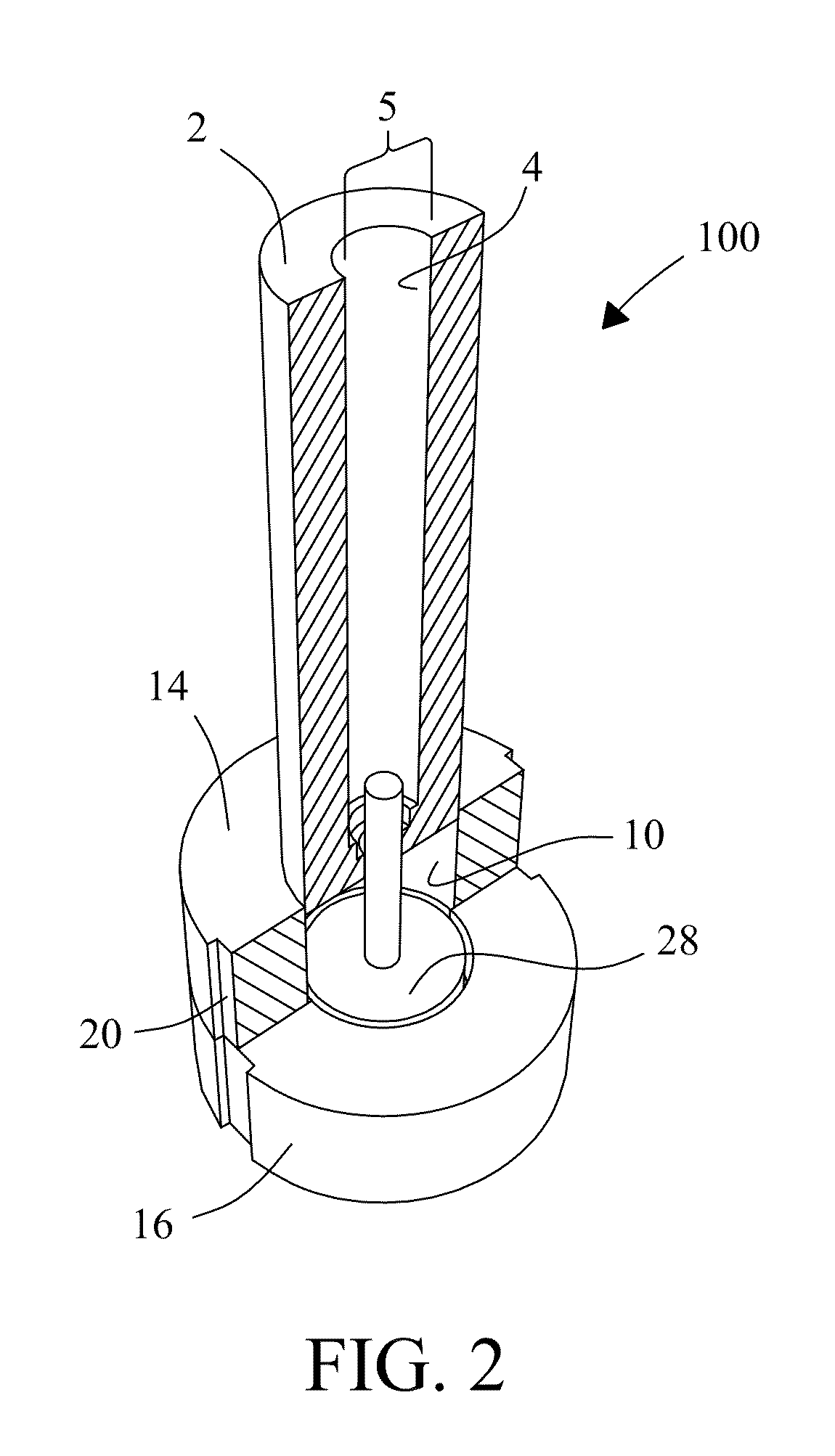

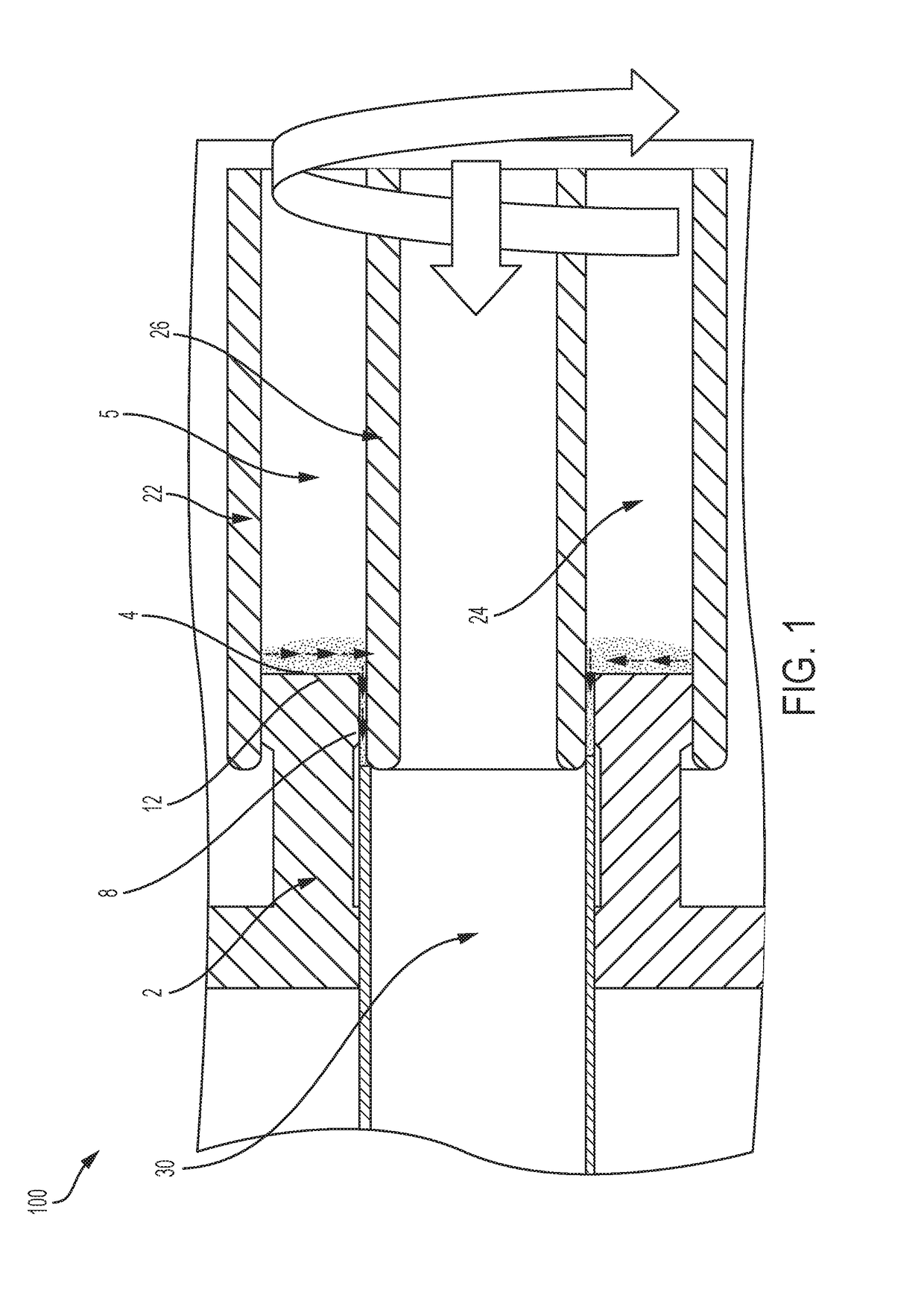

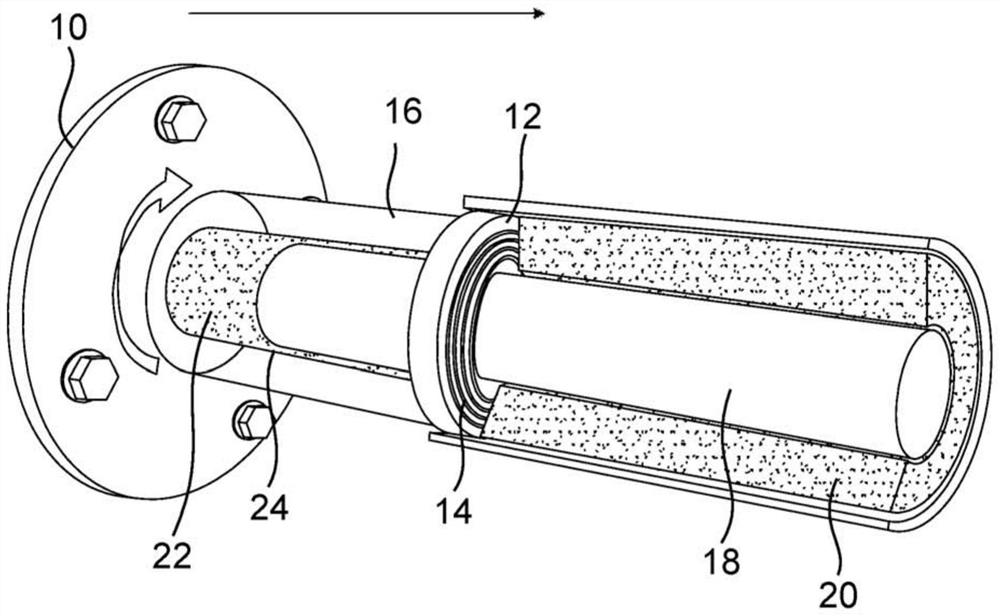

An extrusion apparatus and process are disclosed that produce high-performance extrusion structures. The extrusion apparatus includes a shear tool that applies a rotational shear force and an axial extrusion force to the face of a billet material that plasticizes the billet material. Plasticized material is extruded through an extrusion die along the length of the inner bore of the shear tool which yields hollow and solid extrusion structures. The process refines the microstructures of the extrusion structures and extrusion materials.

Owner:BATTELLE MEMORIAL INST

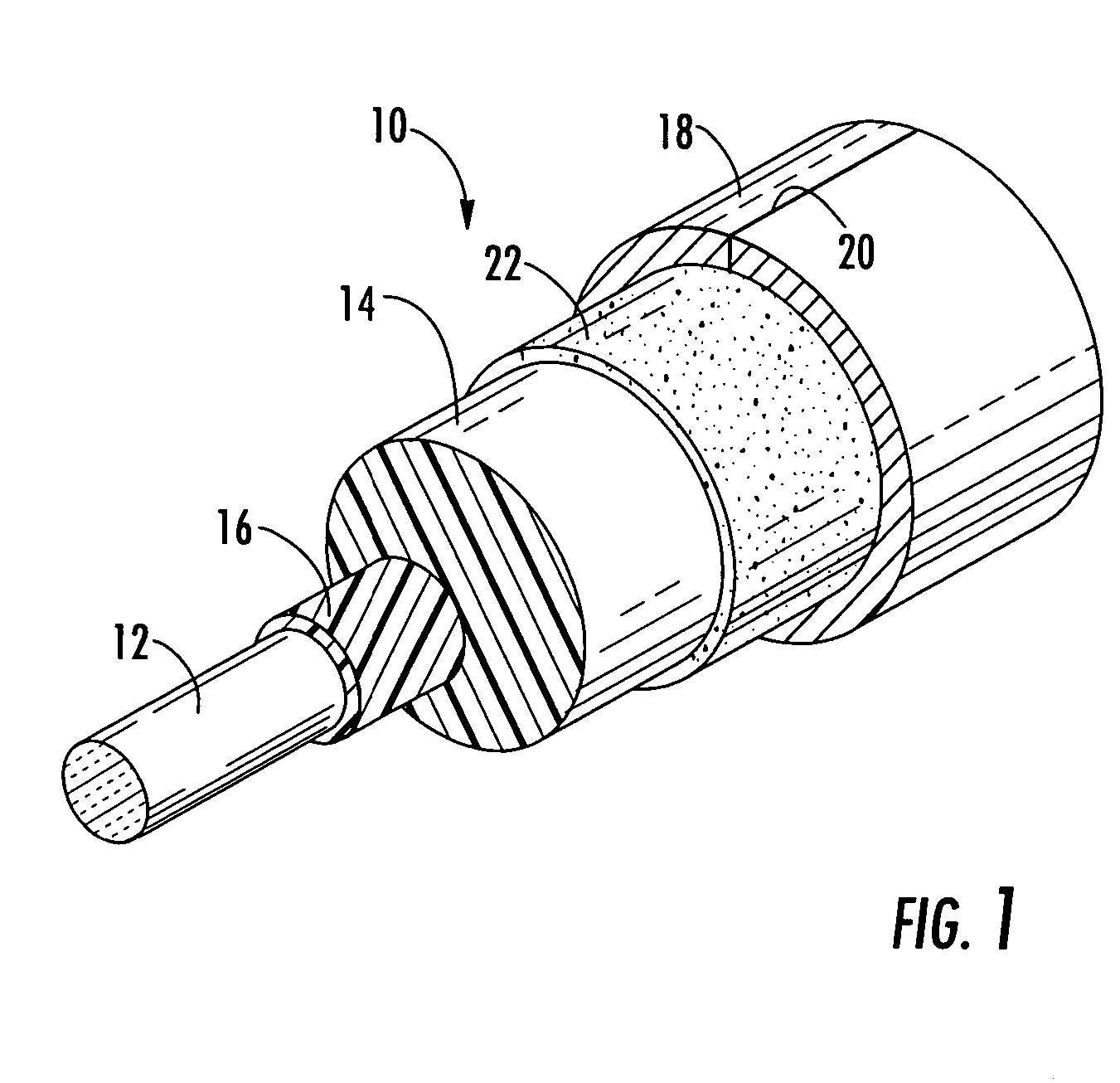

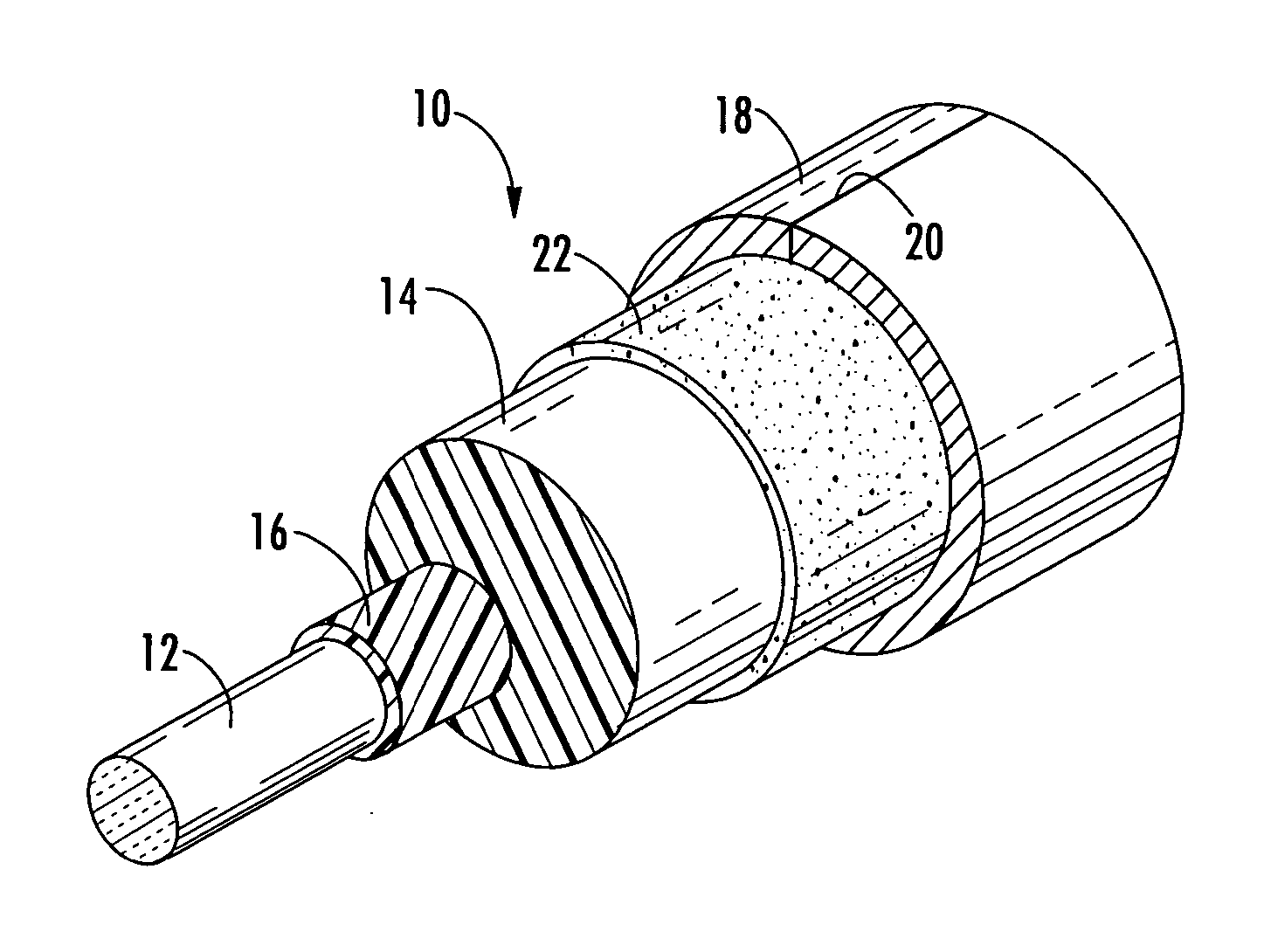

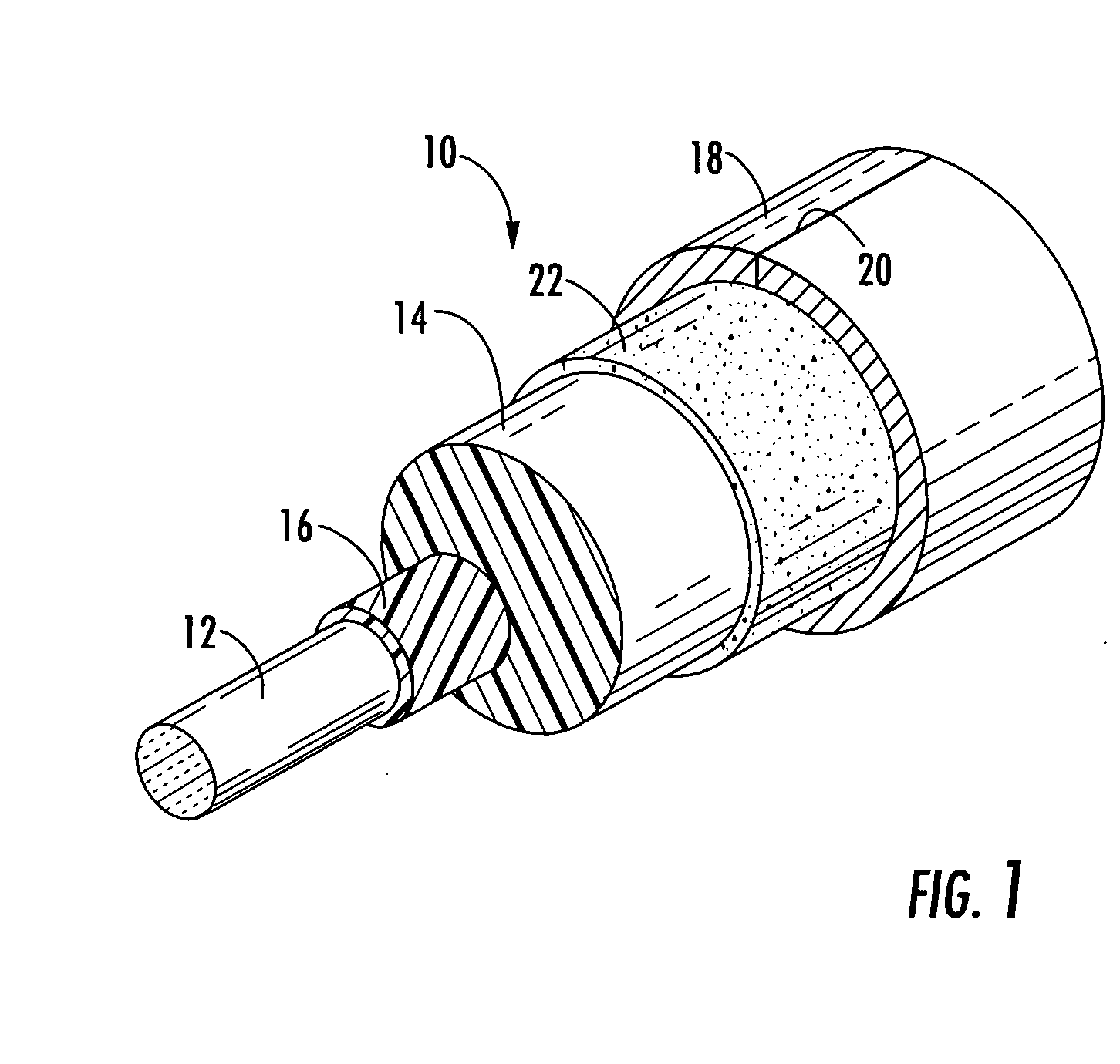

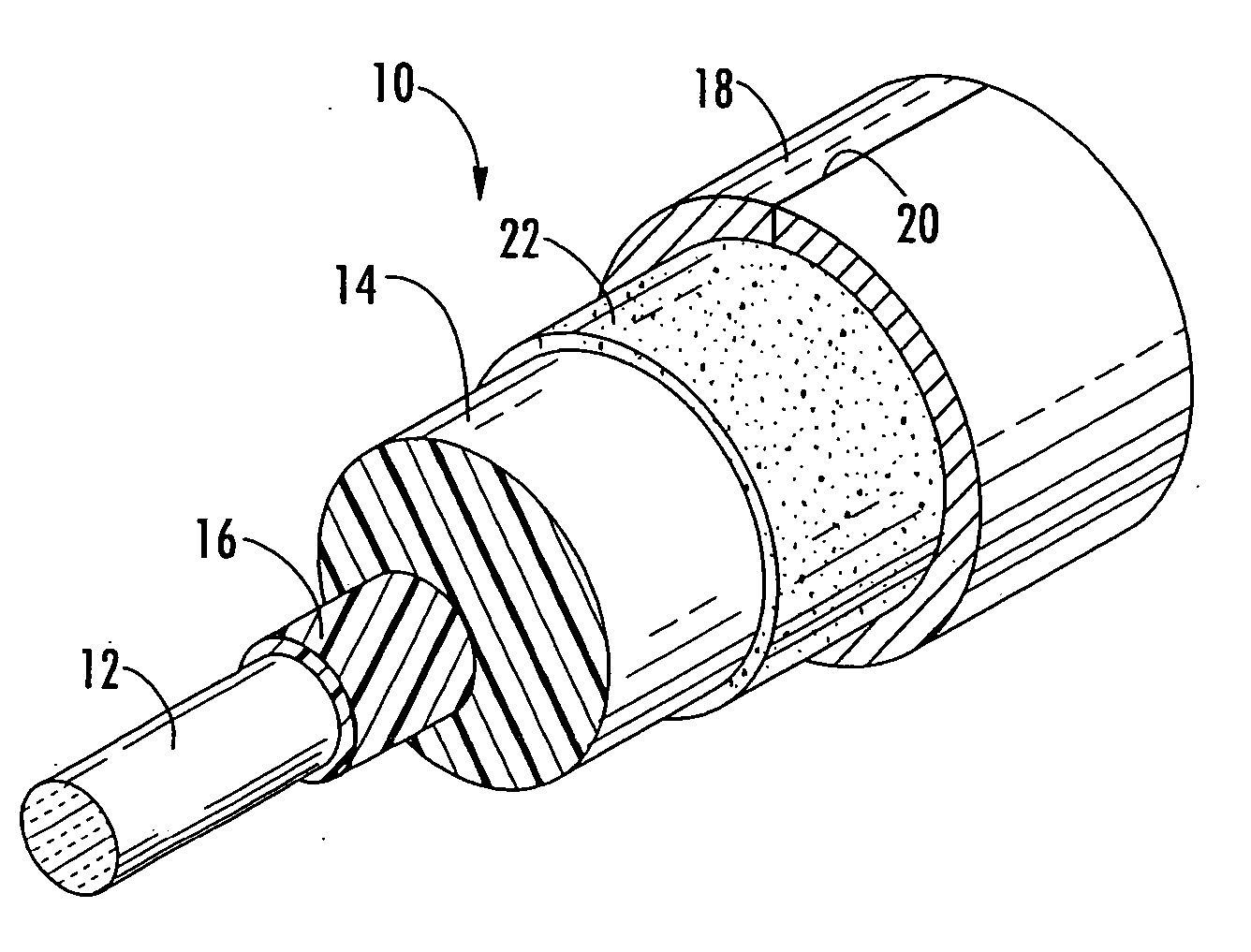

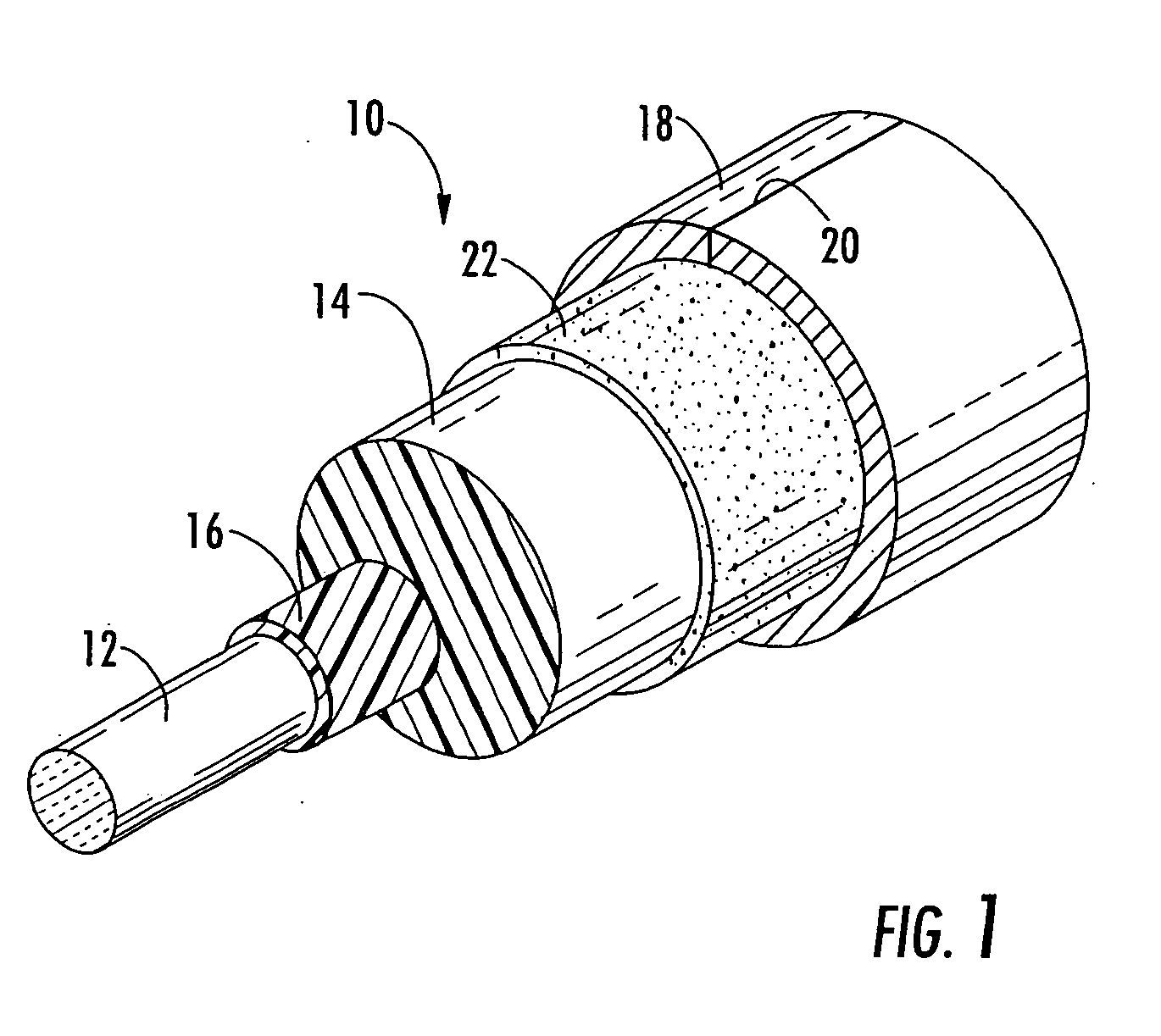

Coaxial cable with strippable center conductor precoat

ActiveUS7022918B2Easy to disassembleEasy to operateCable insulation constructionPower cables with screens/conductive layersAdhesion forceBond interface

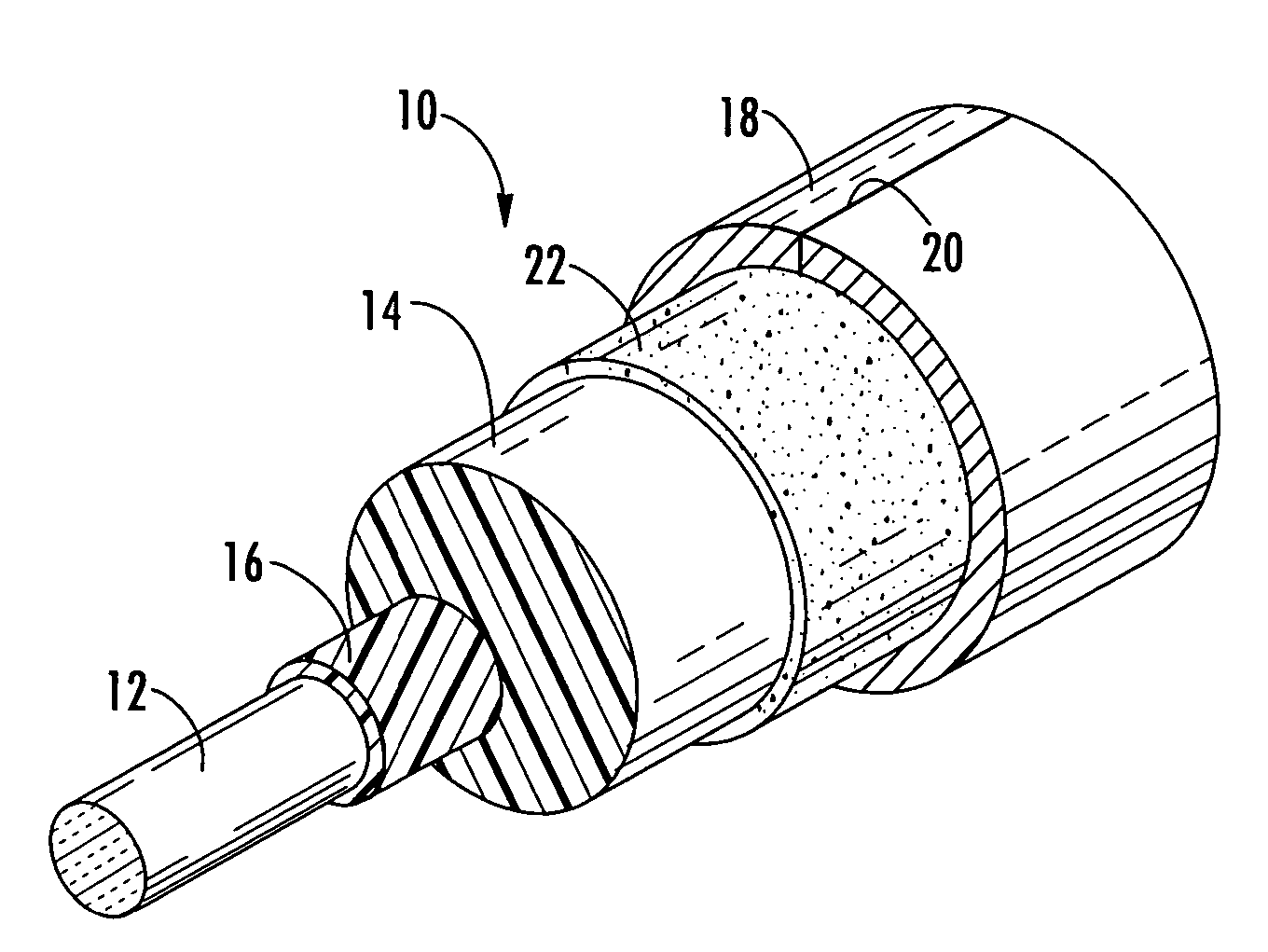

A coaxial cable is provided with a specially prepared precoat layer that facilitates removal of the precoat layer when the end of the cable is cored in preparation for receiving a connector. The cable includes an inner conductor; a foam polyolefin dielectric layer surrounding the inner conductor; an outer conductor surrounding said dielectric layer; and a precoat layer disposed between the inner conductor and the dielectric layer. The precoat layer forms a first bond interface with the inner conductor and a second bond interface with the dielectric layer, wherein the ratio of the axial shear adhesion force of the first (“A”) bond to the axial shear adhesive force of the second (“B”) bond is less than 1, and wherein the ratio of the axial shear adhesion force of the “A” bond formed by the precoat layer between the inner conductor to the dielectric layer to the rotational shear adhesion force of the bond is 5 or greater.

Owner:COMMSCOPE INC

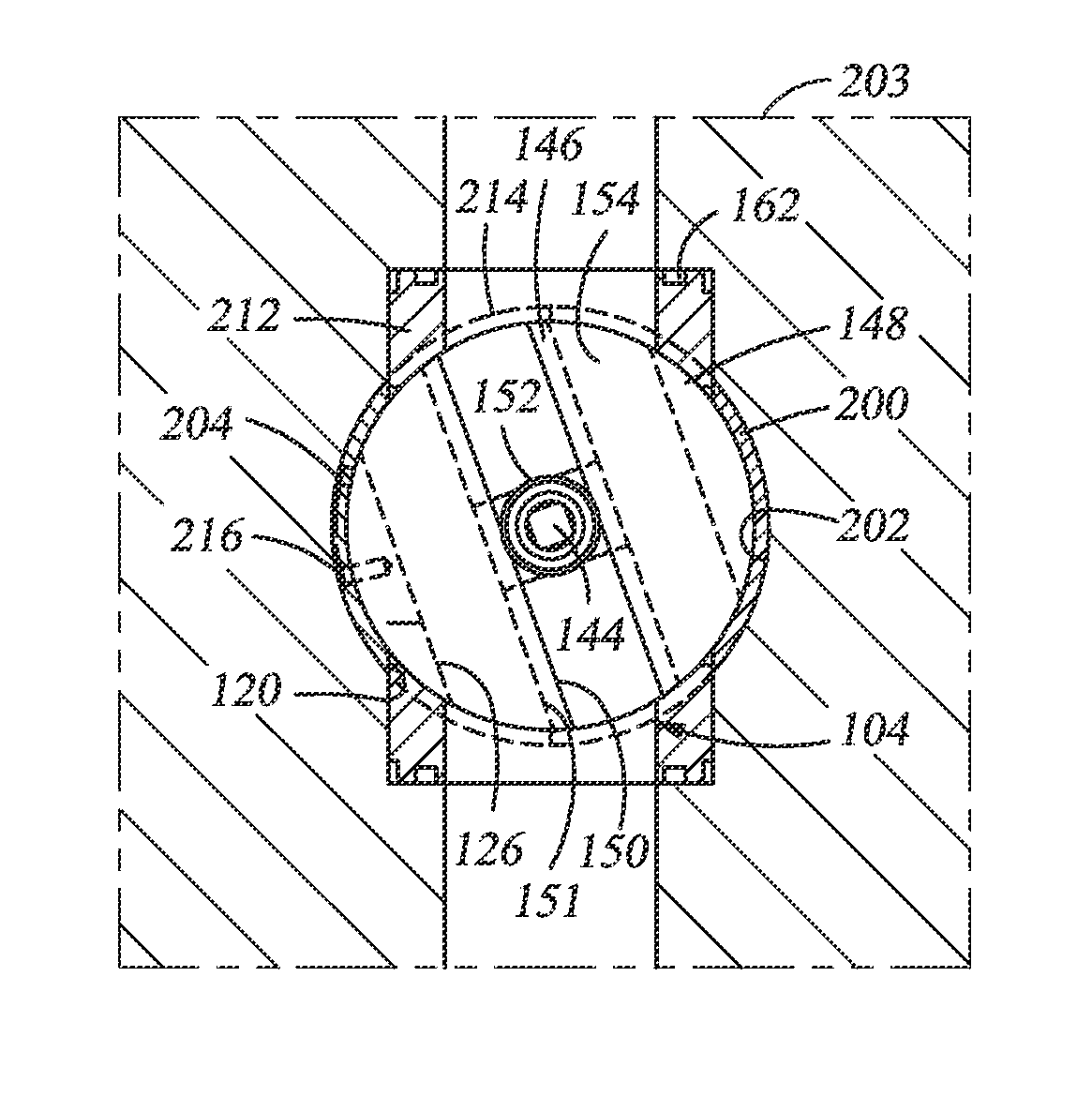

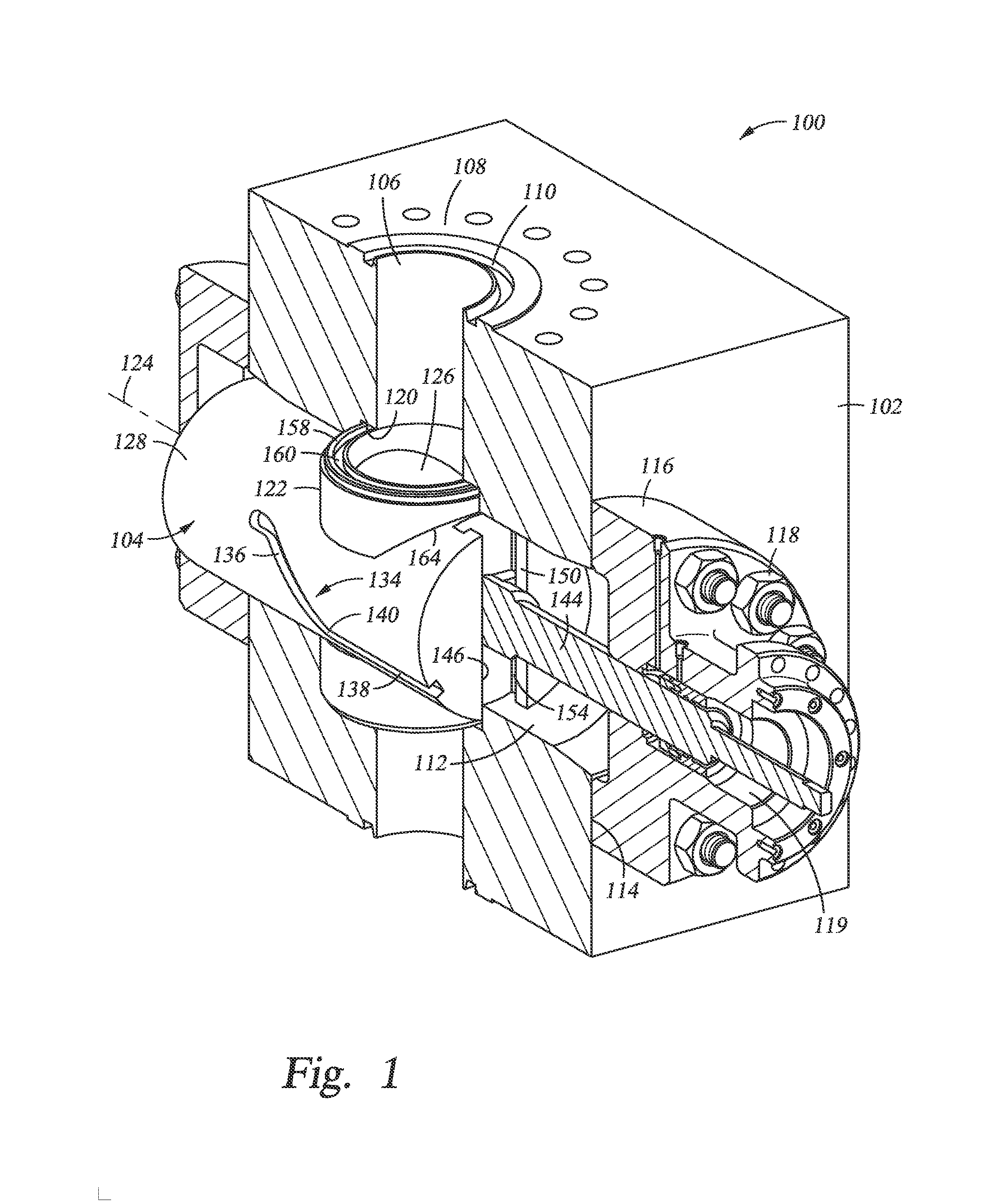

Rotational shear valve

ActiveUS20130327536A1Reduce cleaningRemove and reduce likelihood of damagePlug valvesOperating means/releasing devices for valvesEngineeringGate valve

A rotating gate valve can be used to shear cables or tubing as it closes to obstruct flow. In embodiments, a valve body can have a flow passage and a lateral bore that is transverse to the flow passage. The gate can have a generally cylindrical shape and can rotate about the axis of the gate as it moves laterally to close a flow passage. The lateral and rotational movement can shear articles such as, for example, cables and tubing that extend through the flow passage.

Owner:VETCO GRAY U K

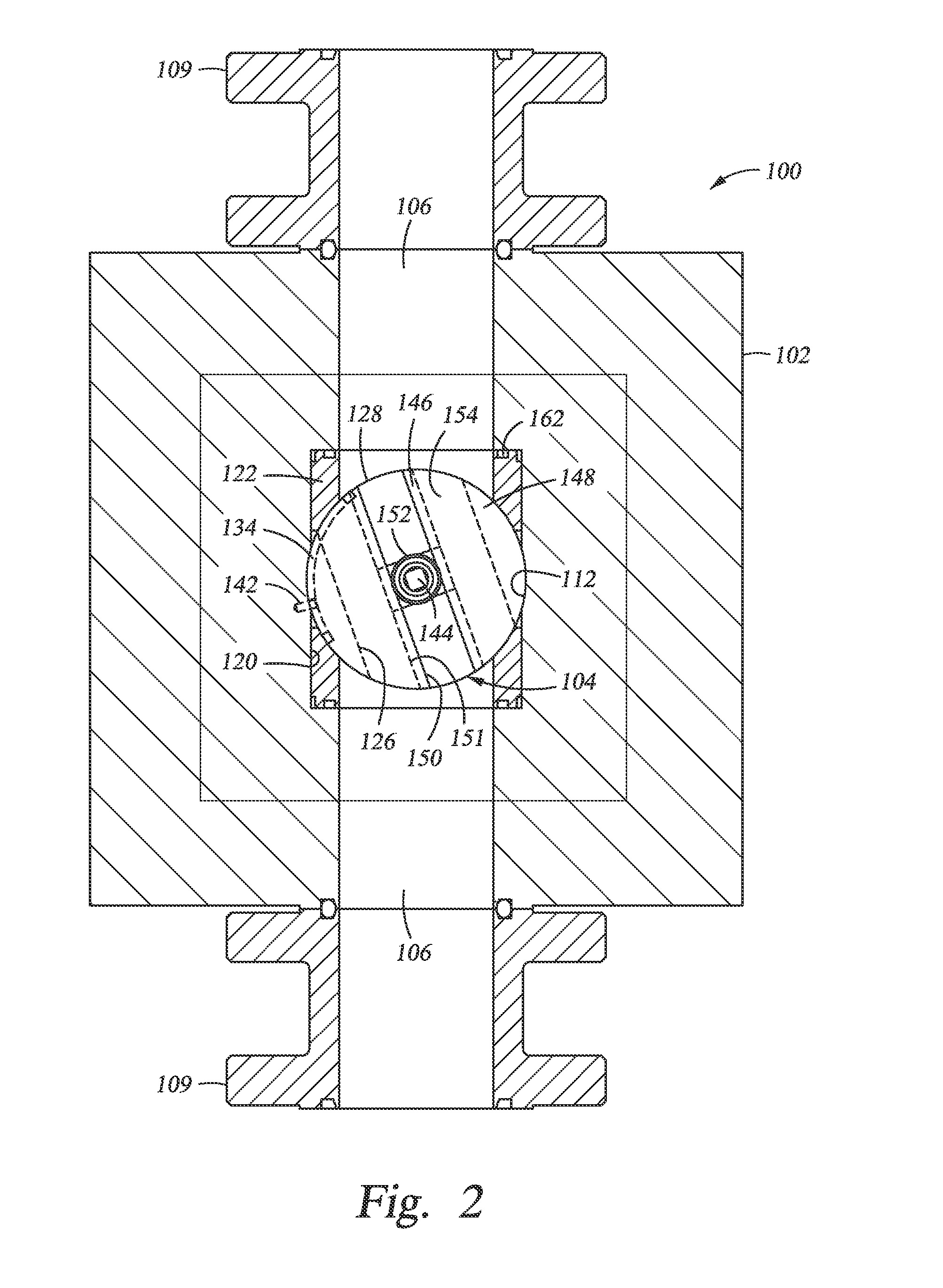

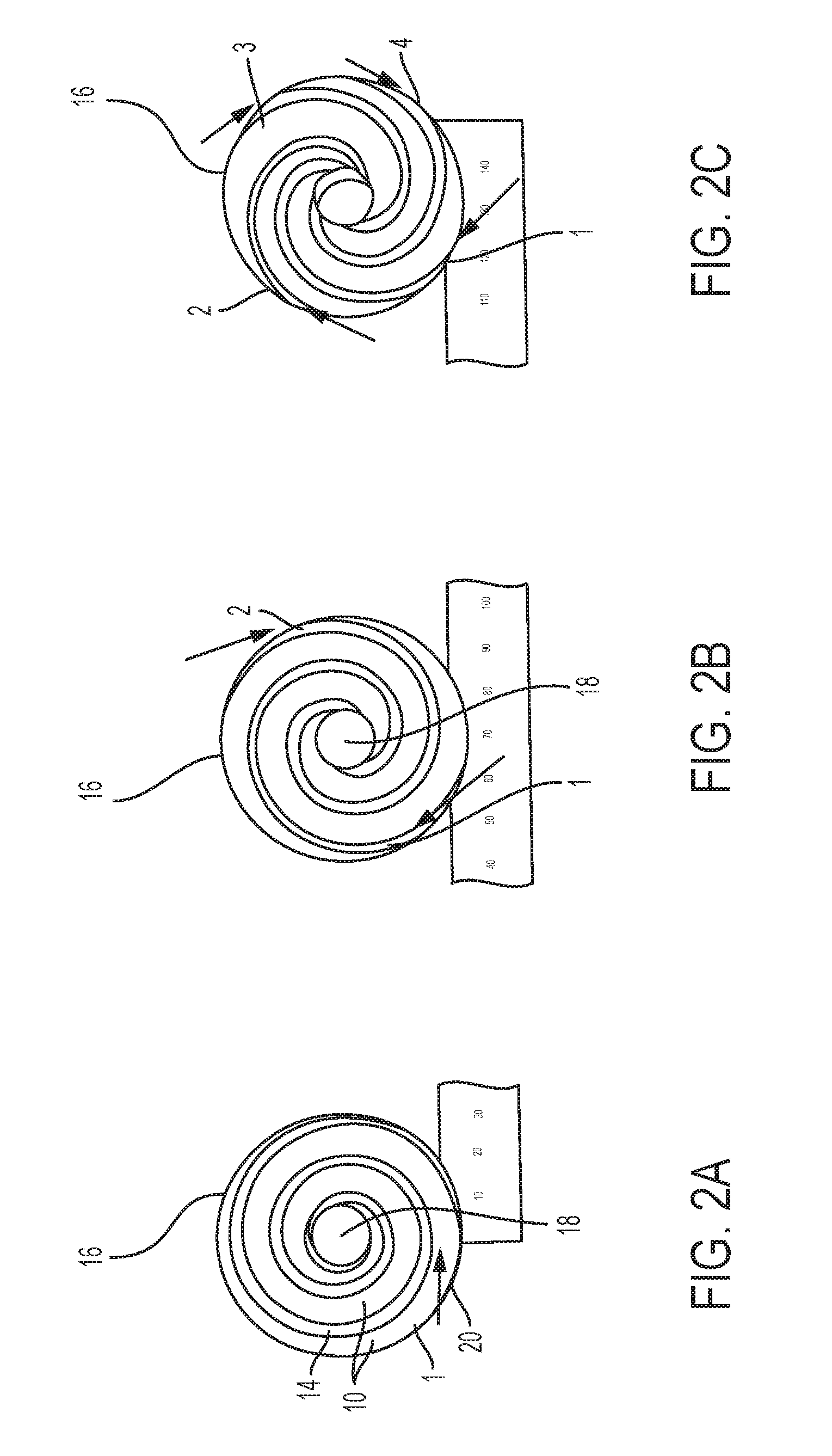

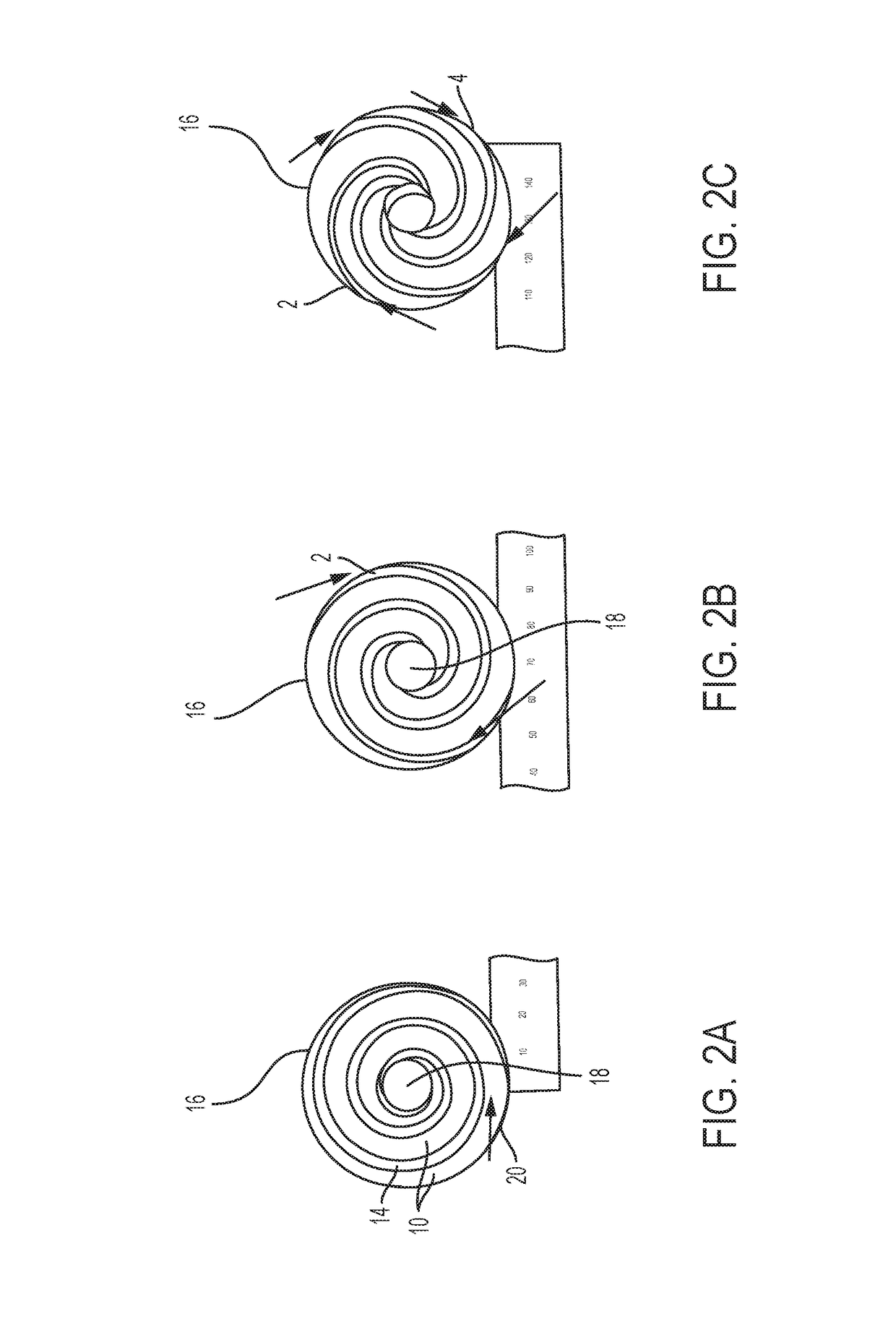

System and process for formation of extrusion products

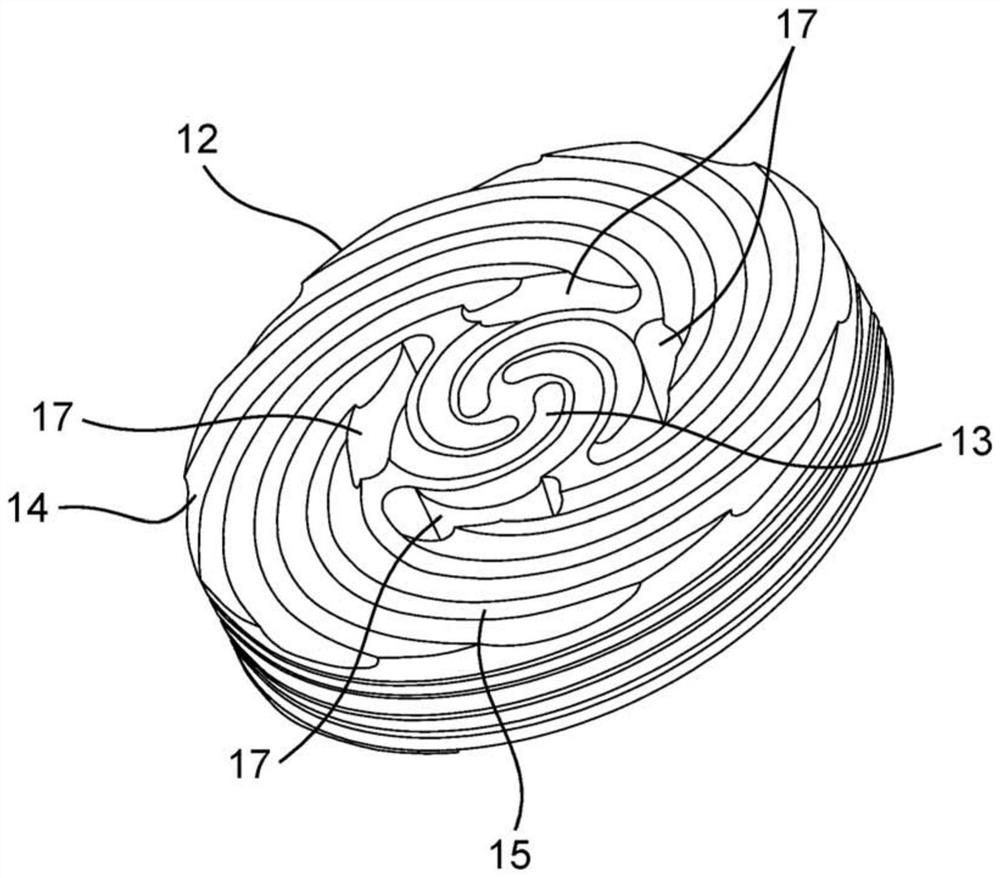

Devices and processes for performing shear-assisted extrusion include a rotatable extrusion die with a scroll face configured to draw plasticized material from an outer edge of a billet generally perpendicularly toward an extrusion orifice while the extrusion die assembly simultaneously applies a rotational shear and axial extrusion force to the billet.

Owner:BATTELLE MEMORIAL INST

Coaxial cable with strippable center conductor precoat

ActiveUS20050056453A1Easy to disassembleEasy to operateCable insulation constructionPower cables with screens/conductive layersAdhesion forceBond interface

Owner:COMMSCOPE INC

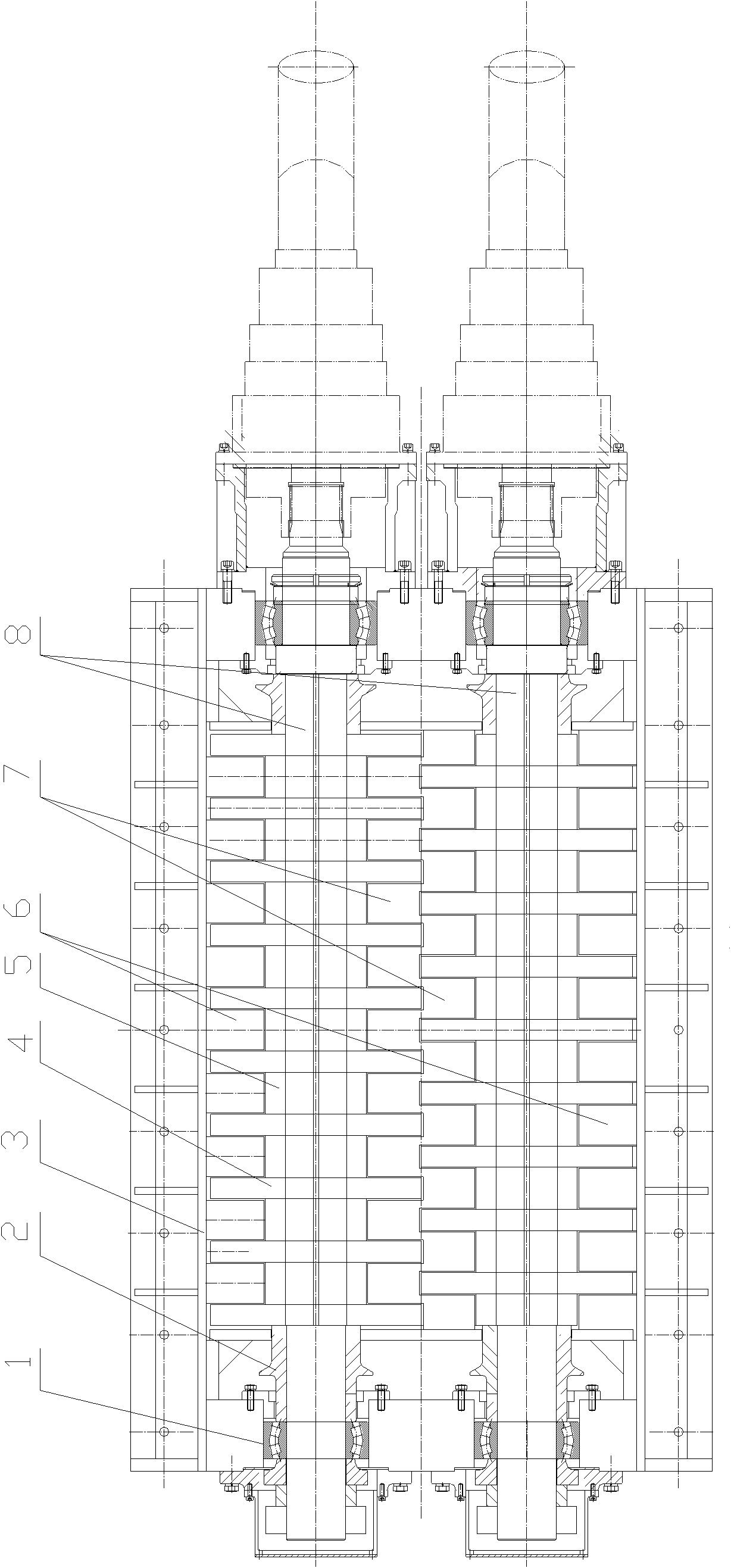

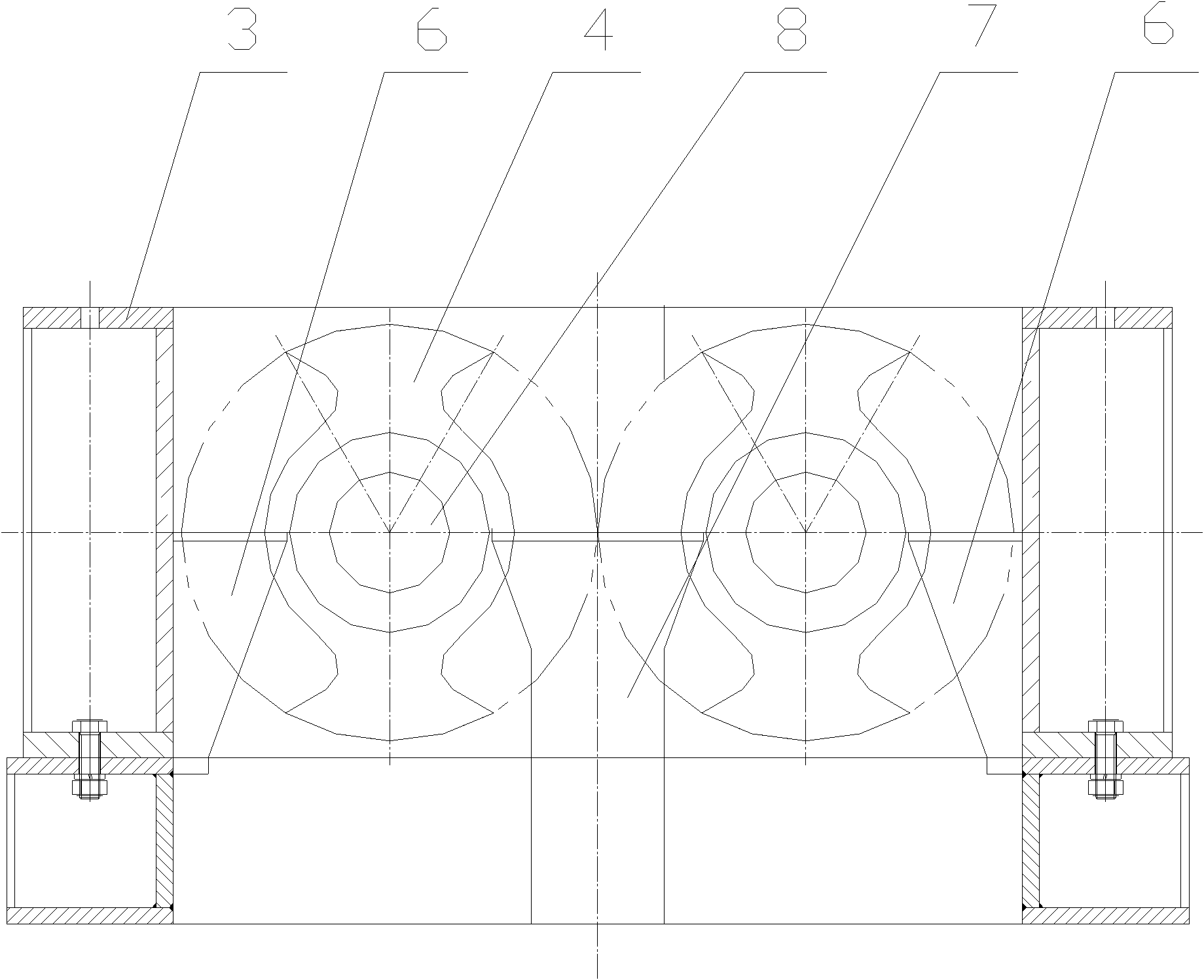

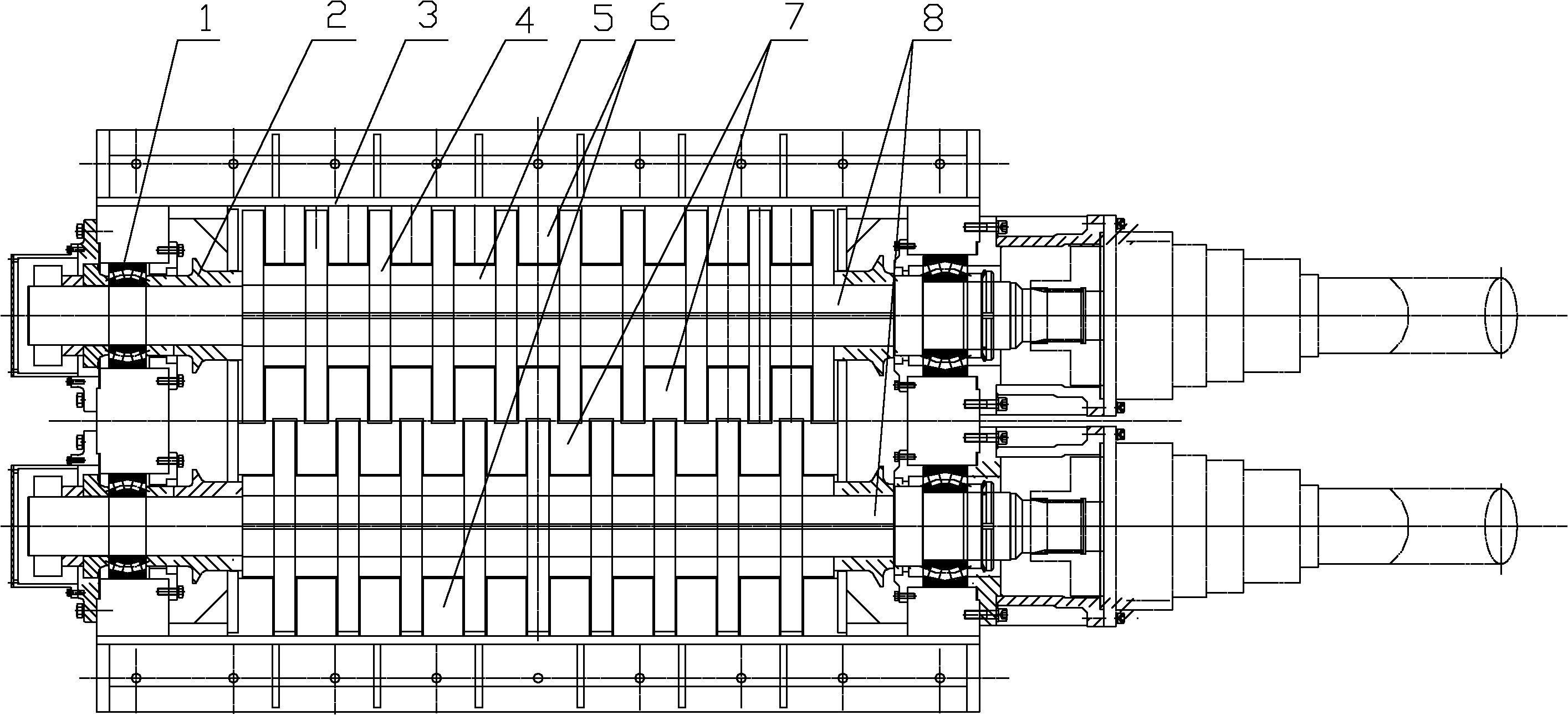

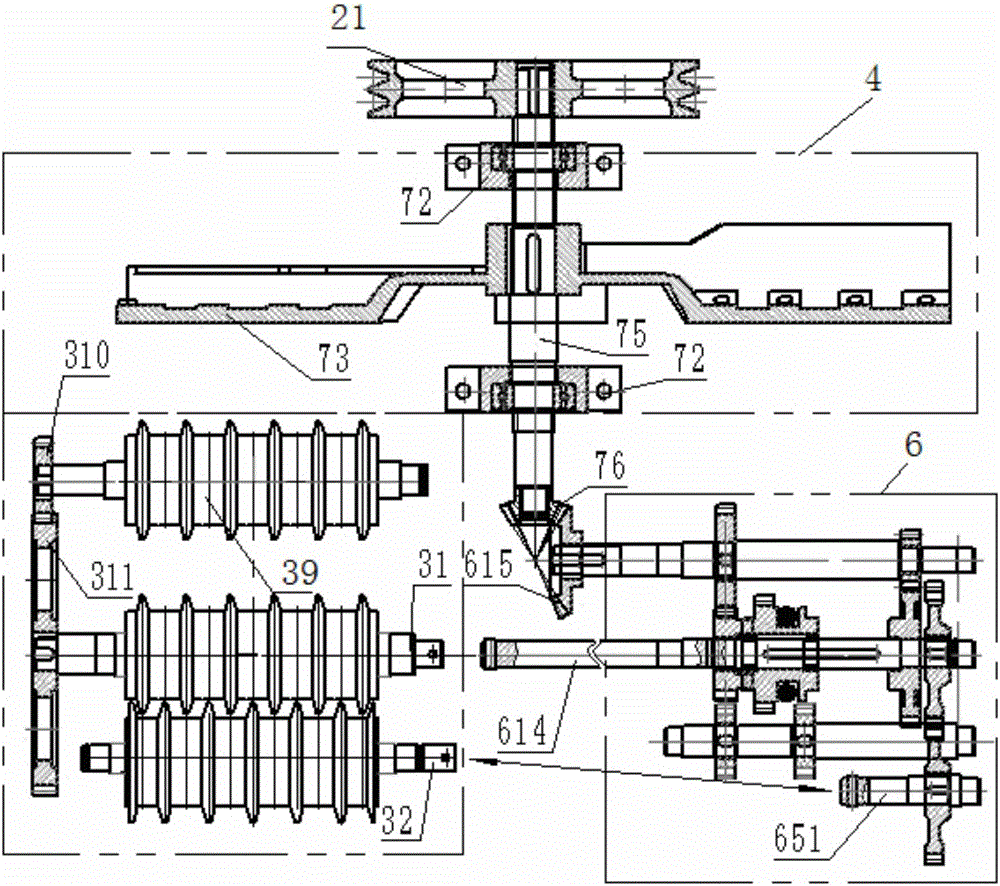

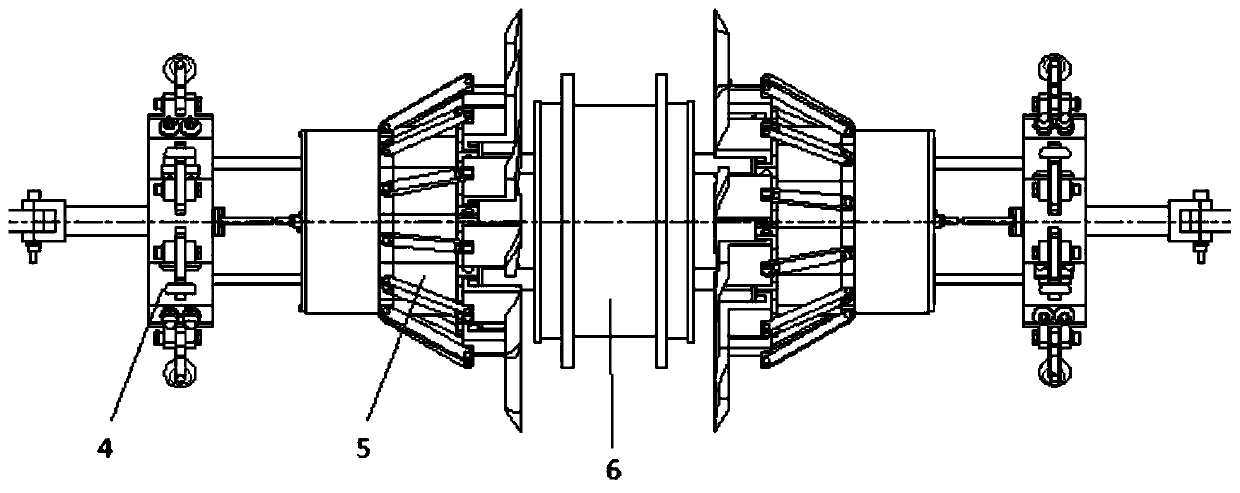

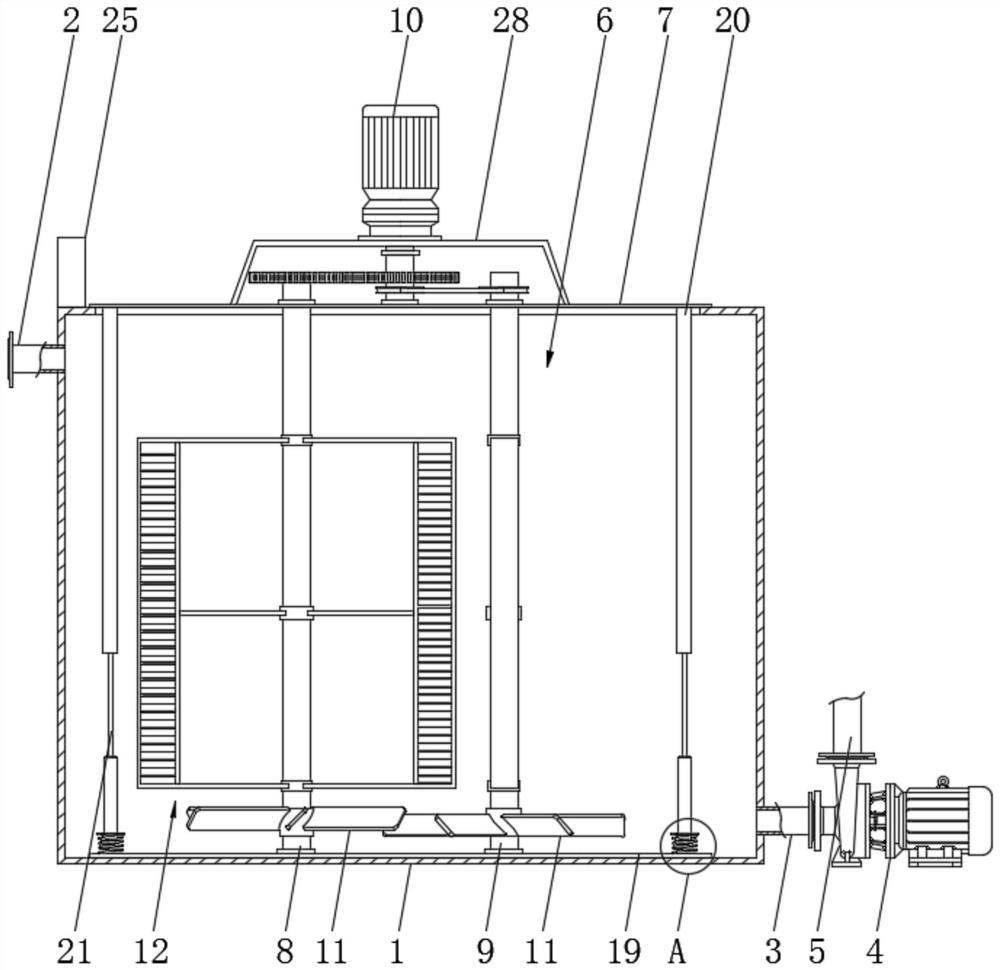

Rotational shear type double-shaft single crusher for solid waste

InactiveCN101987308AImprove crushing efficiencyIncrease productivityGrain treatmentsEngineeringCrusher

The invention discloses a rotational shear type double-shaft single crusher for solid waste. The crusher comprises a box and two mutually parallel main shafts, wherein the main shafts are installed in the box; a plurality of crushing knives are installed on each main shaft; the center lines of the two main shafts are in the same horizontal plane; a plurality of fixed knives in staggered arrangement with the crushing knives are respectively installed on the two sides and middle part of the box body; and a driving device is connected with each main shaft. In the invention, two power units for respectively driving the main shafts to carry out the crushing work, each main shaft can independently complete the material crushing function, and each main shaft can both forwardly rotate and reversely rotate for crushing, so the crushing efficiency is high; because both forward rotation and reverse rotation are for carrying out the crushing work, when the external resistance is so large that the material can not be crushed, the main shafts automatically reversely rotate for crushing without shutting down or plugging, so the production efficiency is high; and the gaps between the fixed knives and the crushing knives can be adjusted to ensure the best shearing state.

Owner:天津百利阳光环保设备有限公司

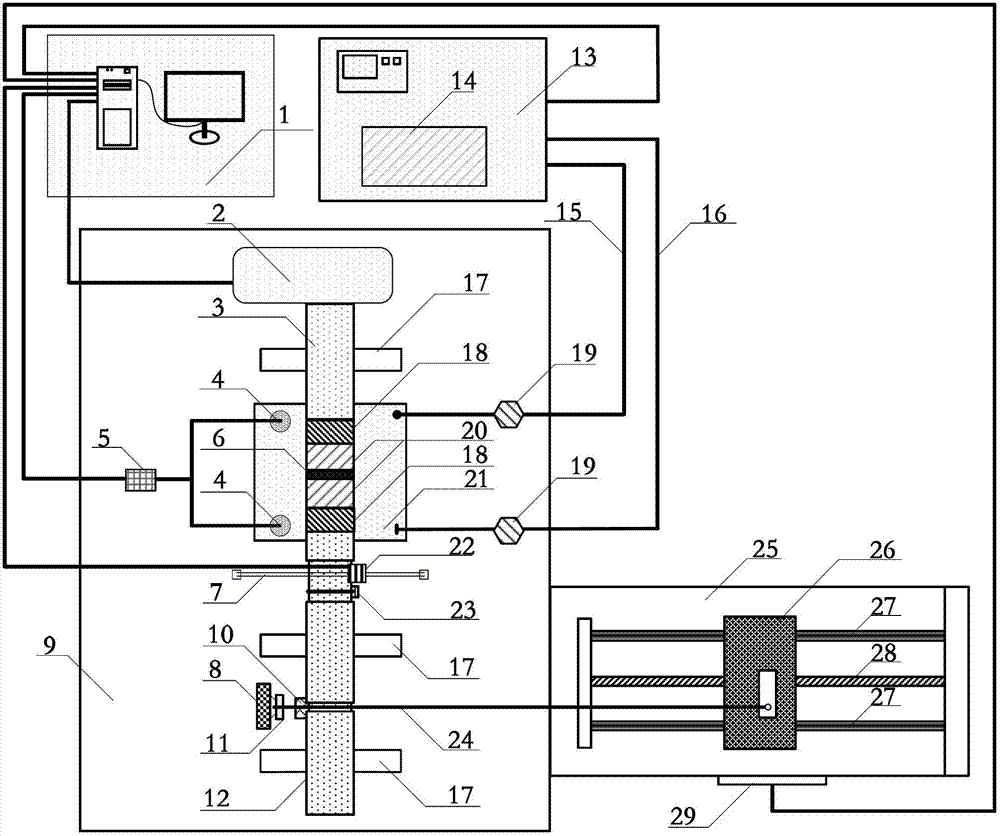

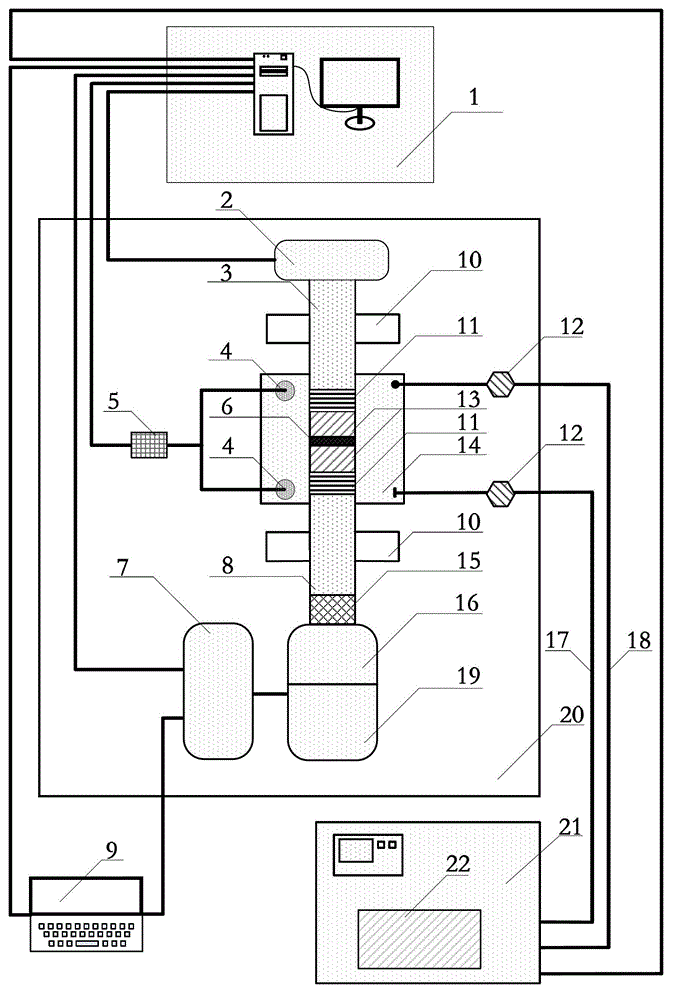

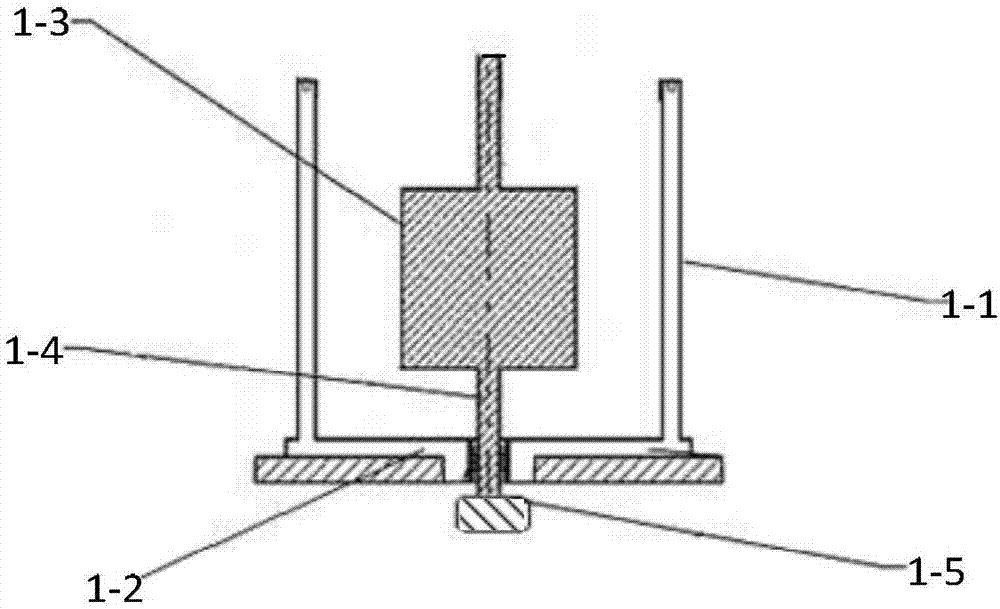

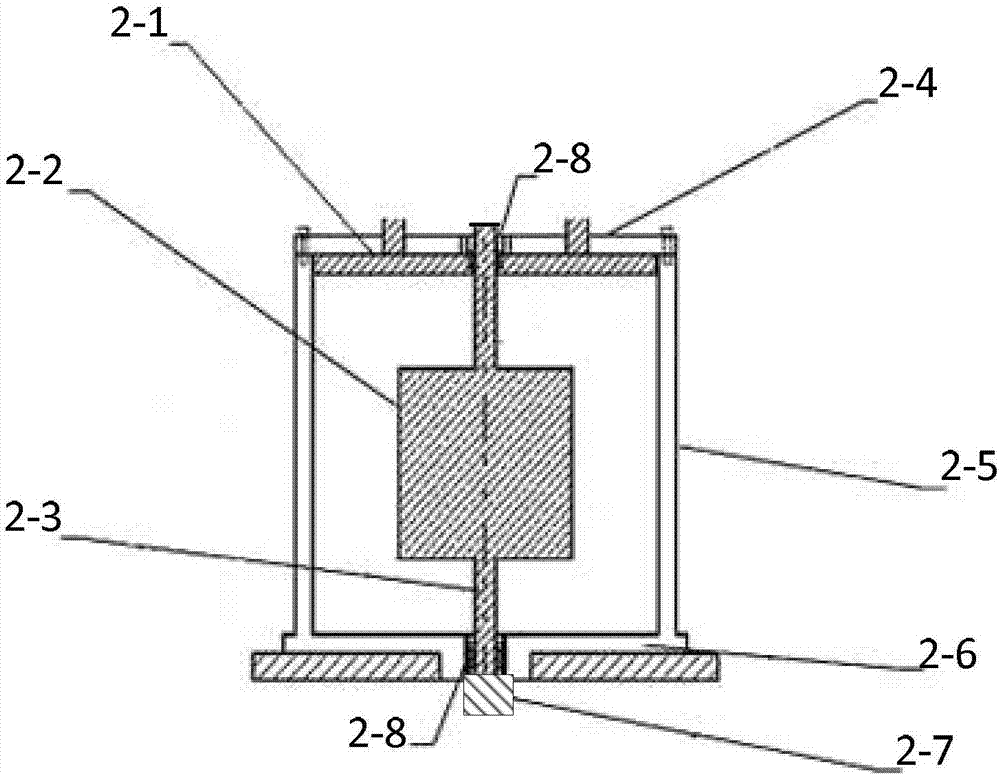

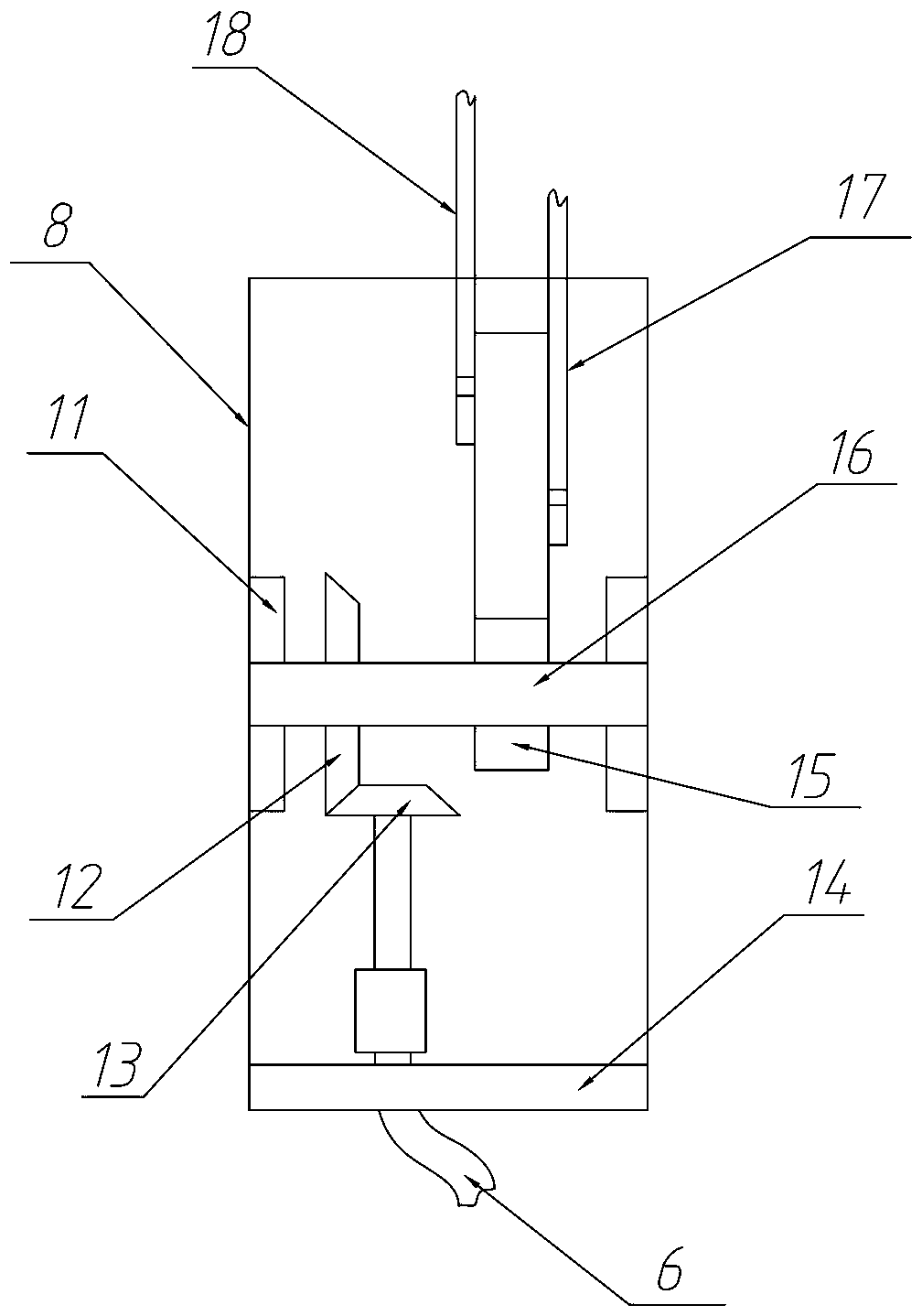

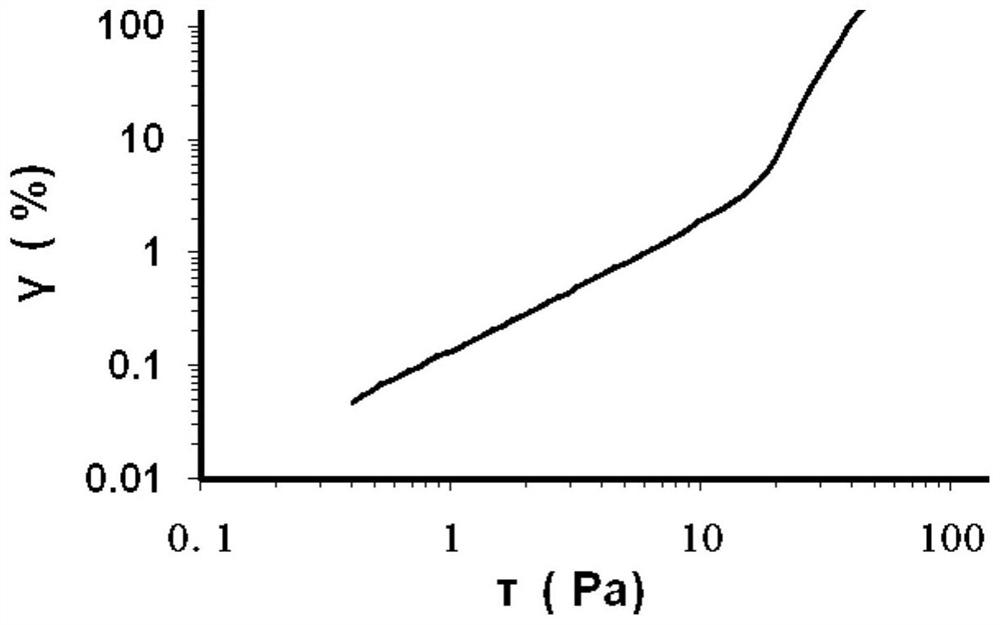

Test device and test method for asphalt rotational shear creep and repeated creep recovery

InactiveCN103207120AMaterial strength using repeated/pulsating forcesComputer control systemTemperature control

The invention belongs to the field of asphalt mechanical performance tests and particularly relates to a test device and a test method for asphalt rotational shear creep and repeated creep recovery. The device comprises a test platform, a test specimen, a temperature control system, a loading system and a computer control system. The computer control system automatically controls maintenance temperature and creep test temperature of the test specimen through the temperature control system. Simultaneously, the computer control system further controls the loading system to complete asphalt rotational shear creep and repeated creep recovery of the asphalt test specimen. The device is applicable to testing creep and repeated creep recovery performance of asphalt cements such as common asphalt, SBS (styrene butadiene styrene block copolymer) modified asphalt, rubber asphalt and other polymer modified asphalt under rotational shear and temperature-control environments.

Owner:DALIAN UNIV OF TECH

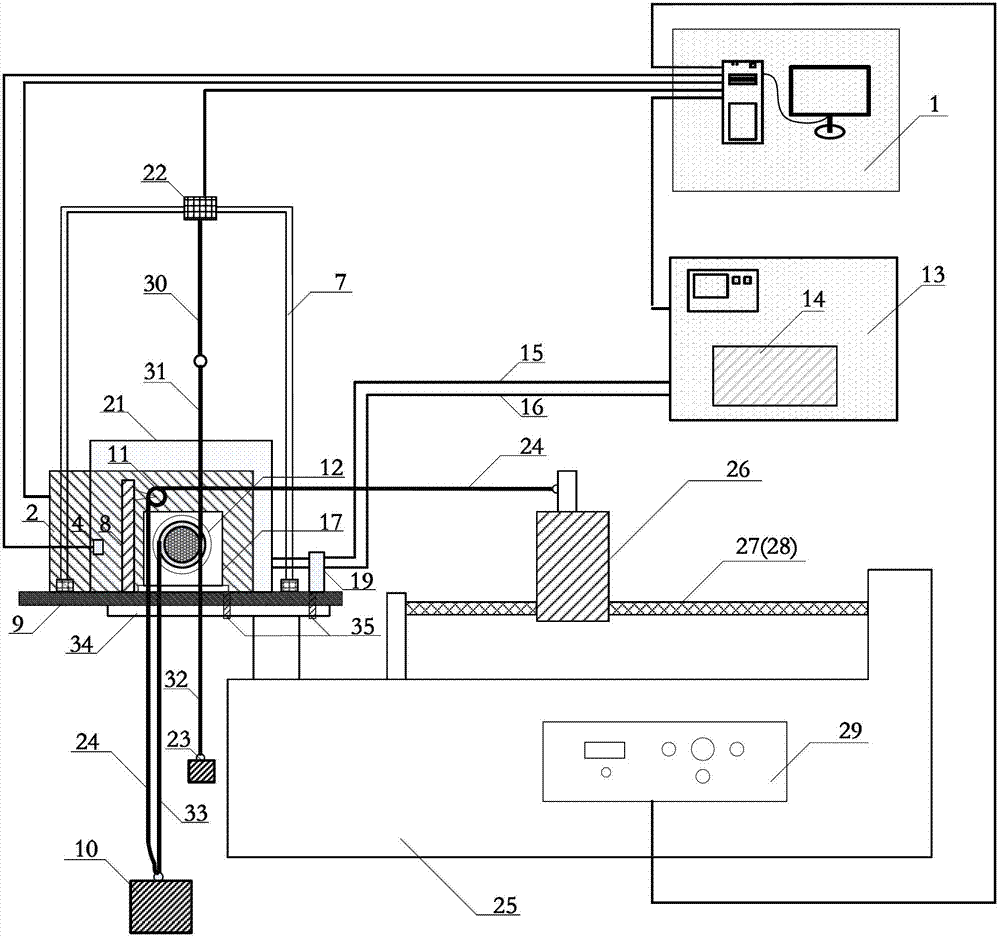

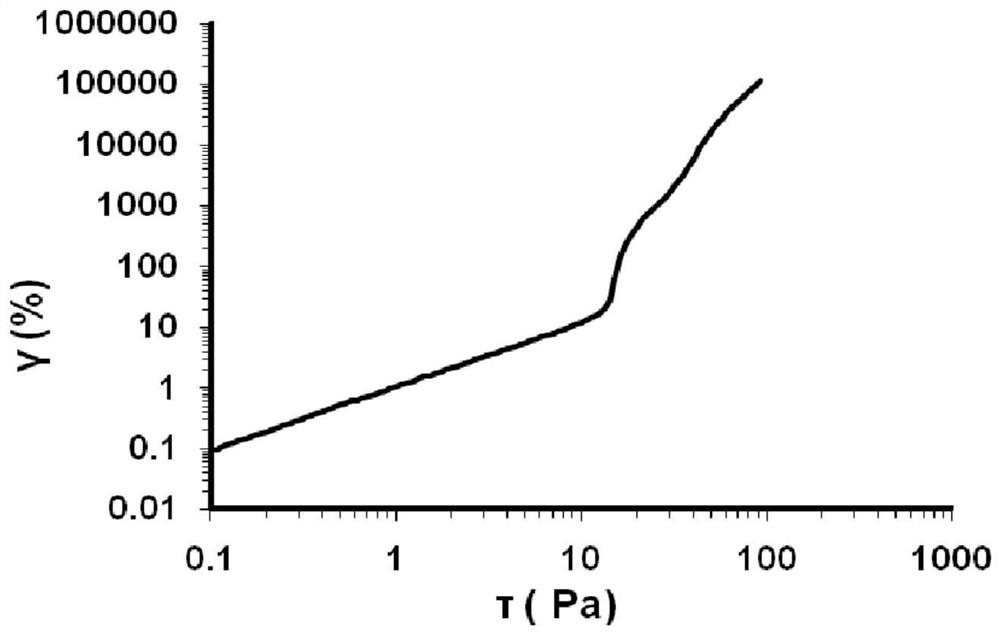

Pitch rotational shear oscillation fatigue rupture experimental device and method

InactiveCN103149099AMaterial strength using steady shearing forcesComputer control systemTemperature control

The invention discloses a pitch rotational shear oscillation fatigue rupture experimental device and a method and belongs to the field of pitch material tests. The pitch rotational shear oscillation fatigue rupture experimental device is composed of an experimental device, a loading system, a temperature control system and a computer control system. The computer control system is capable of controlling the temperature control system to conserve pitch test specimen and control temperatures of an experimental process. In the experimental process, the computer control computer is capable of controlling the loading system to carry out dynamic rotation shear load to the pitch test specimen. The pitch rotational shear oscillation fatigue rupture experimental device is capable of automatically controlling temperatures, big in stress than range and has multiple oscillation function. The pitch rotational shear oscillation fatigue rupture experimental device can also be suitable for determining asphalt cement complex shear modulus (G*) and phase angles (8).

Owner:DALIAN UNIV OF TECH

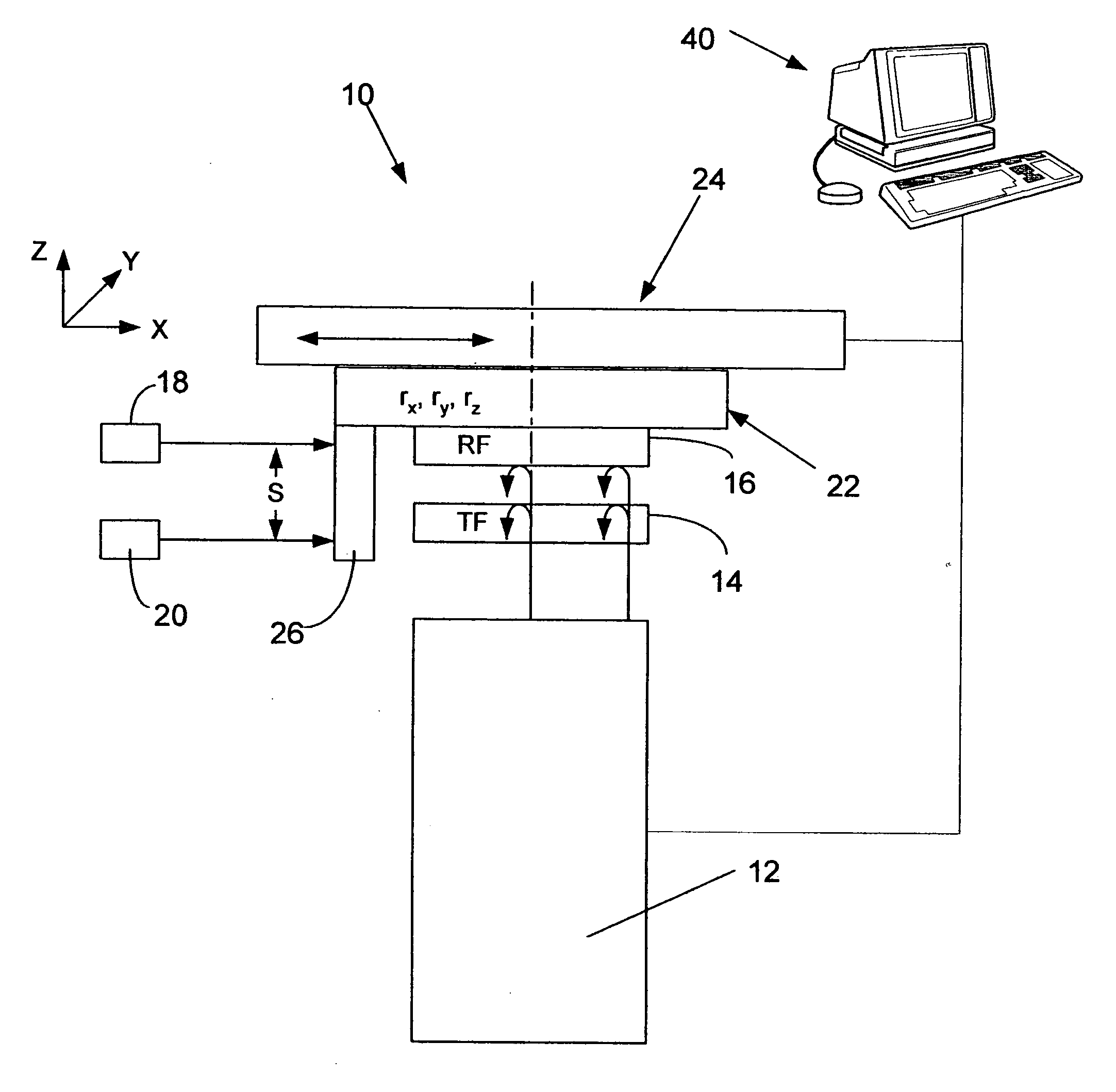

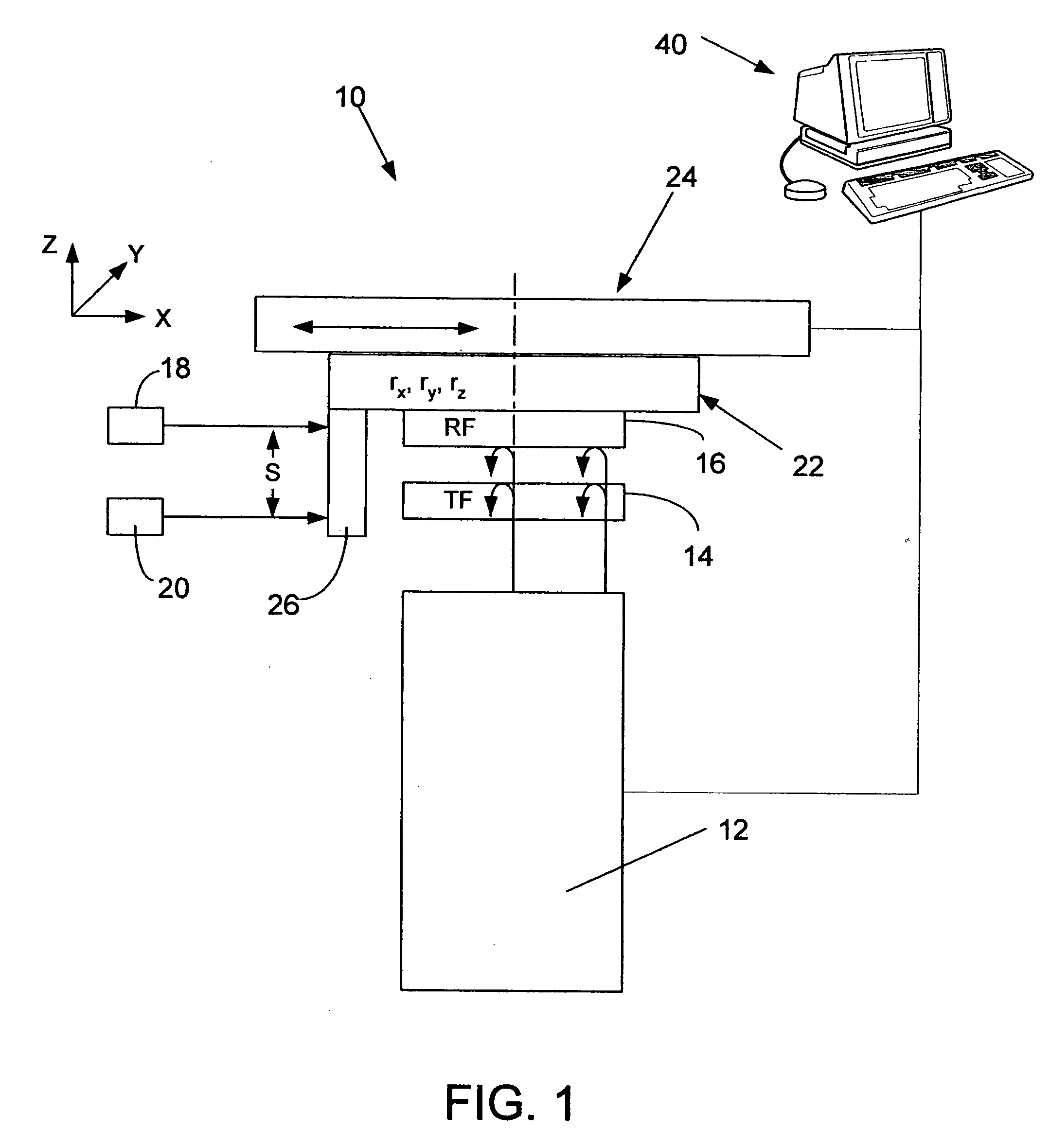

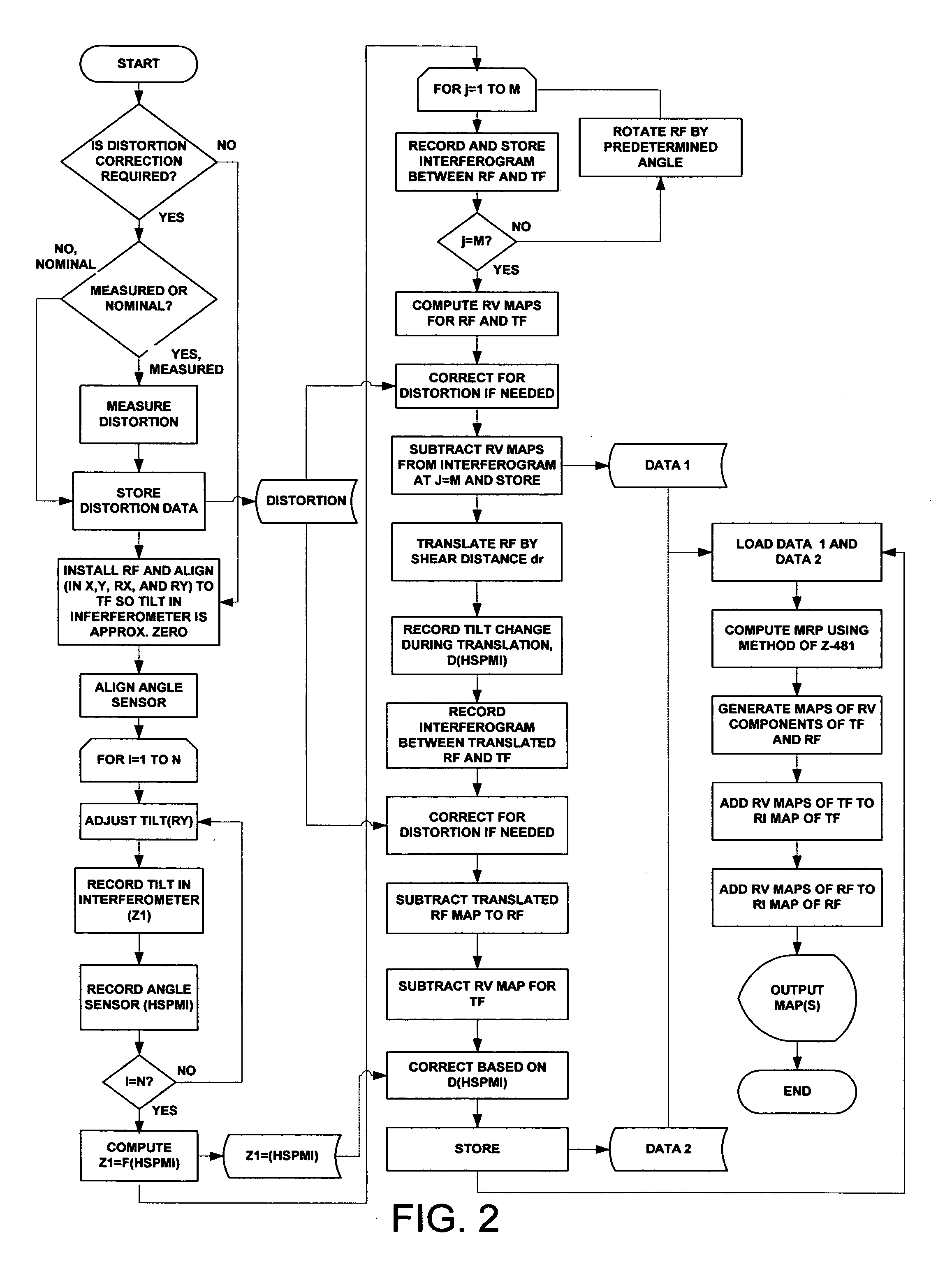

Method and apparatus for tilt corrected lateral shear in a lateral shear plus rotational shear absolute flat test

A Fizeau or other interferometer is used to provide high resolution, in-situ calibration of an external angle measurement system such as widely spaced high stability plane mirror interferometers (HSPMIs)). The calibrated measurement system then measures mechanical tilt during shearing. The tilt data is used to correct the sheared data, preferably before computation of the rotationally invariant (RI) terms. Altematively, the data may be used to compute the spurious quadratic term and correct after integration.

Owner:ZYGO CORPORATION

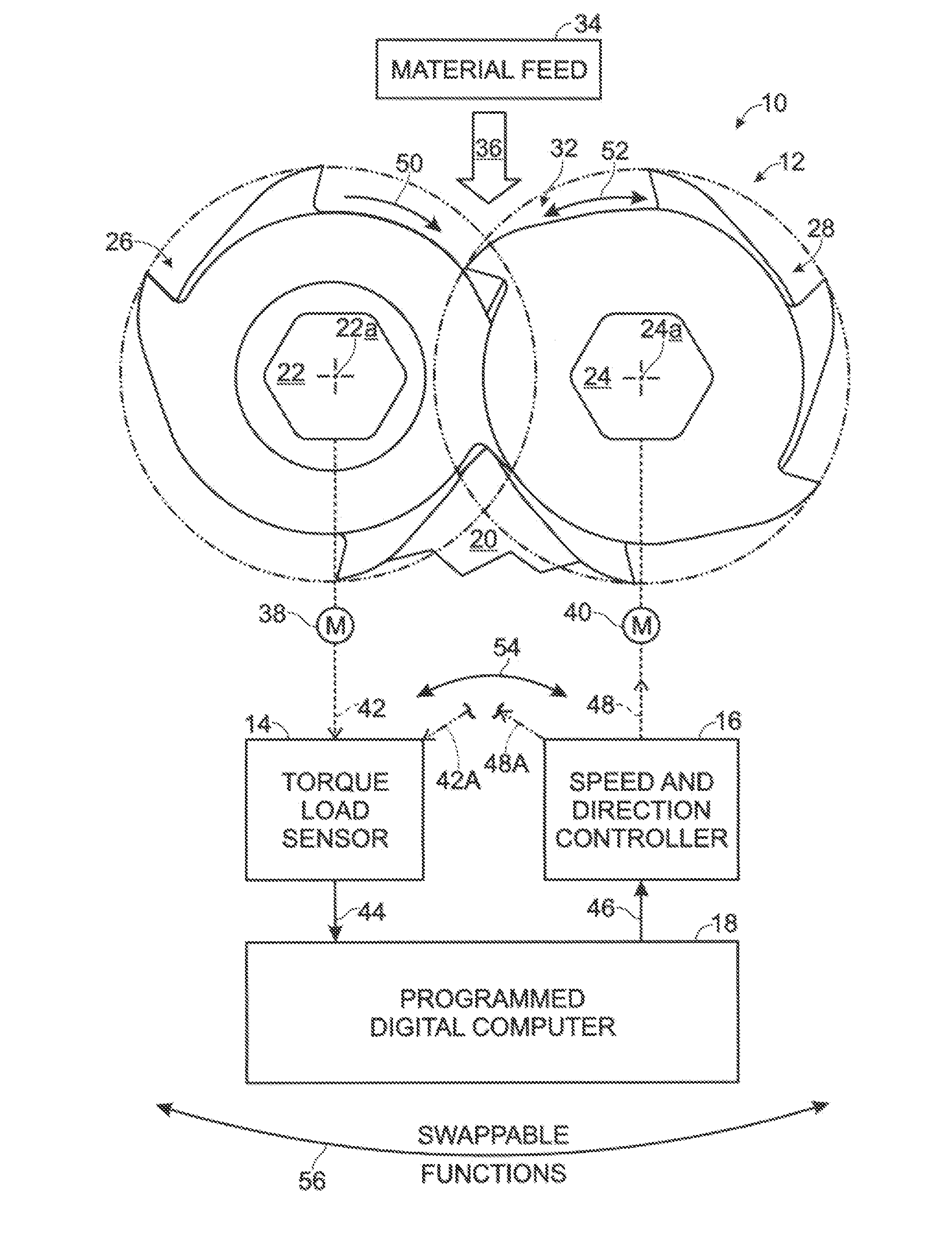

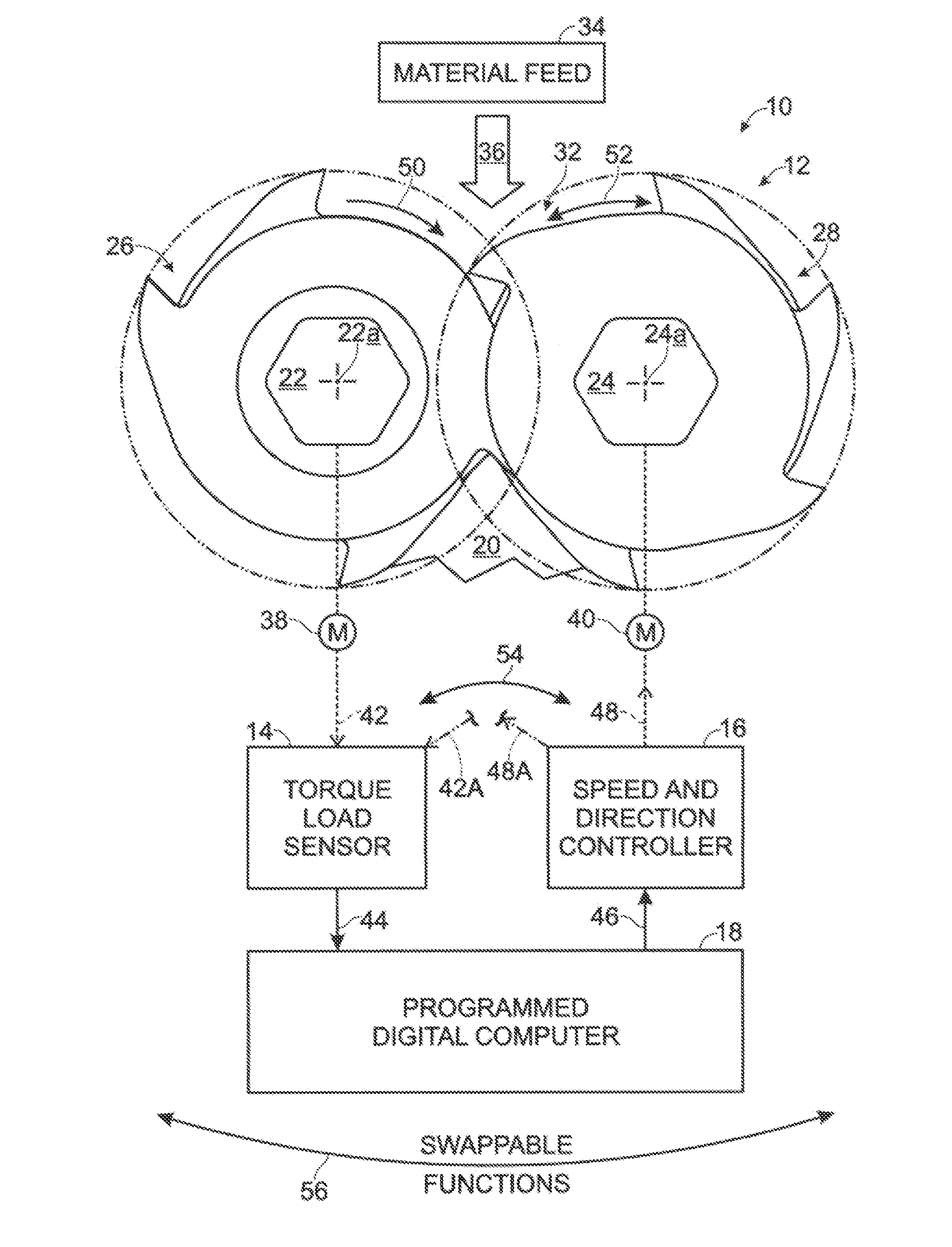

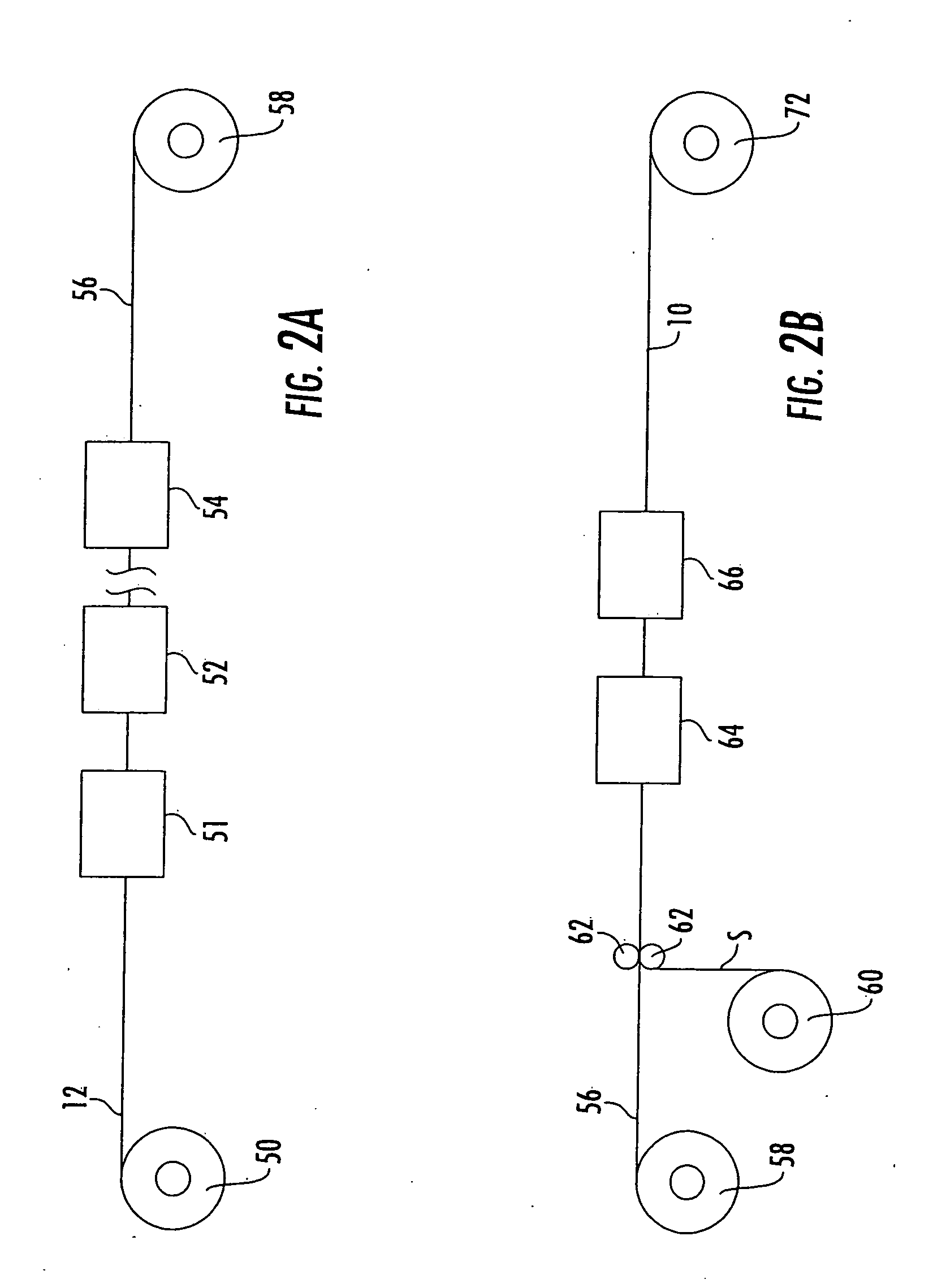

Controlled feed-rate shredding

ActiveUS20120175443A1Effective monitoringEfficient implementationCocoaGrain treatmentsEngineeringSystem structure

A method, and method-implementing system structure, for metering the flow of material through the shredding zone in a rotary shear shredder, which zone is defined, at least in part, by confrontingly rotating knives that are carried on a pair of adjacent, power-driven, nominally matched-motion counter-rotating shafts. The method includes holding the speed and rotational direction of one of the shafts essentially constant while selectively varying, in a manner variably differentiating the relative rotational motions of the two shafts, the speed, and under certain circumstances also the direction, of rotation solely of the other shaft.

Owner:SSI SHREDDING SYST

System and process for formation of extrusion products

Devices and processes for performing shear-assisted extrusion include a rotatable extrusion die with a scroll face configured to draw plasticized material from an outer edge of a billet generally perpendicularly toward an extrusion orifice while the extrusion die assembly simultaneously applies a rotational shear and axial extrusion force to the billet.

Owner:BATTELLE MEMORIAL INST

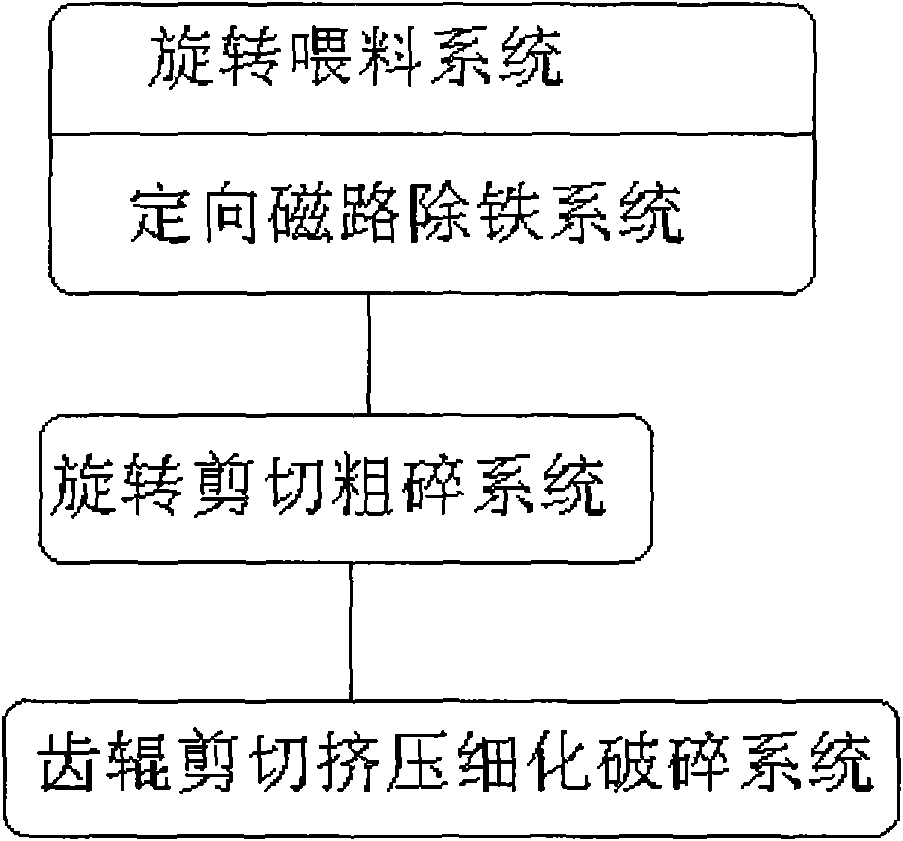

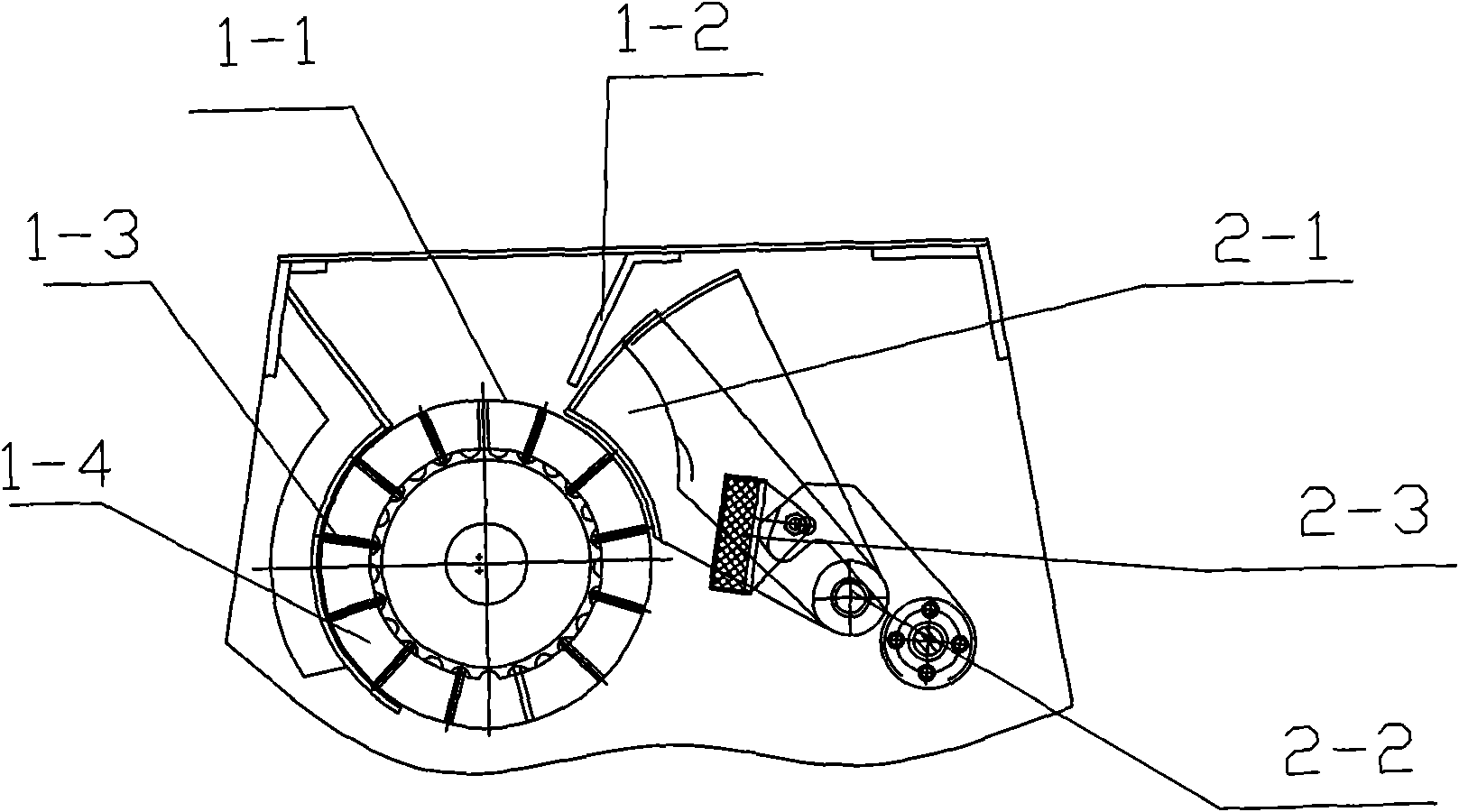

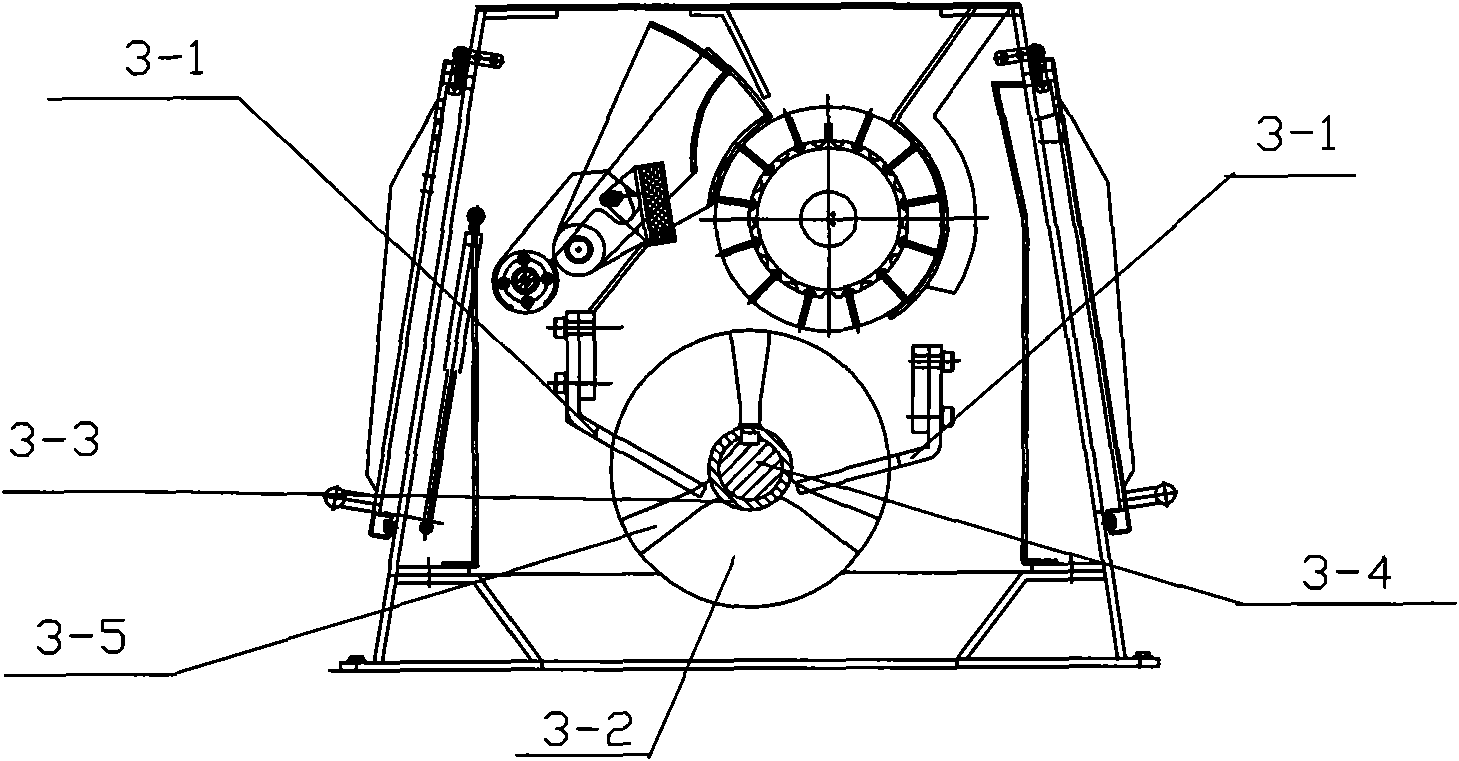

Novel shear crusher and application thereof

InactiveCN101653744AEfficient removalUnique broken effectMagnetic separationGrain treatmentsGranularityEngineering

The invention discloses a novel shear crusher and an application thereof. The crusher comprises a rotary feeding system, an orientating magnetic circuit iron-removing system, a rotary cutting coarse-crush system and a rod-toothed crushing knapping system. The orientating magnetic circuit iron-removing system is fixedly disposed on the rotary feeding system. The rotary cutting coarse-crush system is disposed on the lower part of the rotary feeding system. The rod-toothed crushing knapping system is connected to the lower part of the rotary cutting coarse-crush system. The invention is applied to knapping dregs of beans, with special effect, uniform granularity of knapped dregs of beans, low fines content, large output, low energy consumption, simple operation, and convenient maintenance. The invention has the function of a tractor serving multiple purposes.

Owner:佛罗斯机械设备技术(北京)有限公司

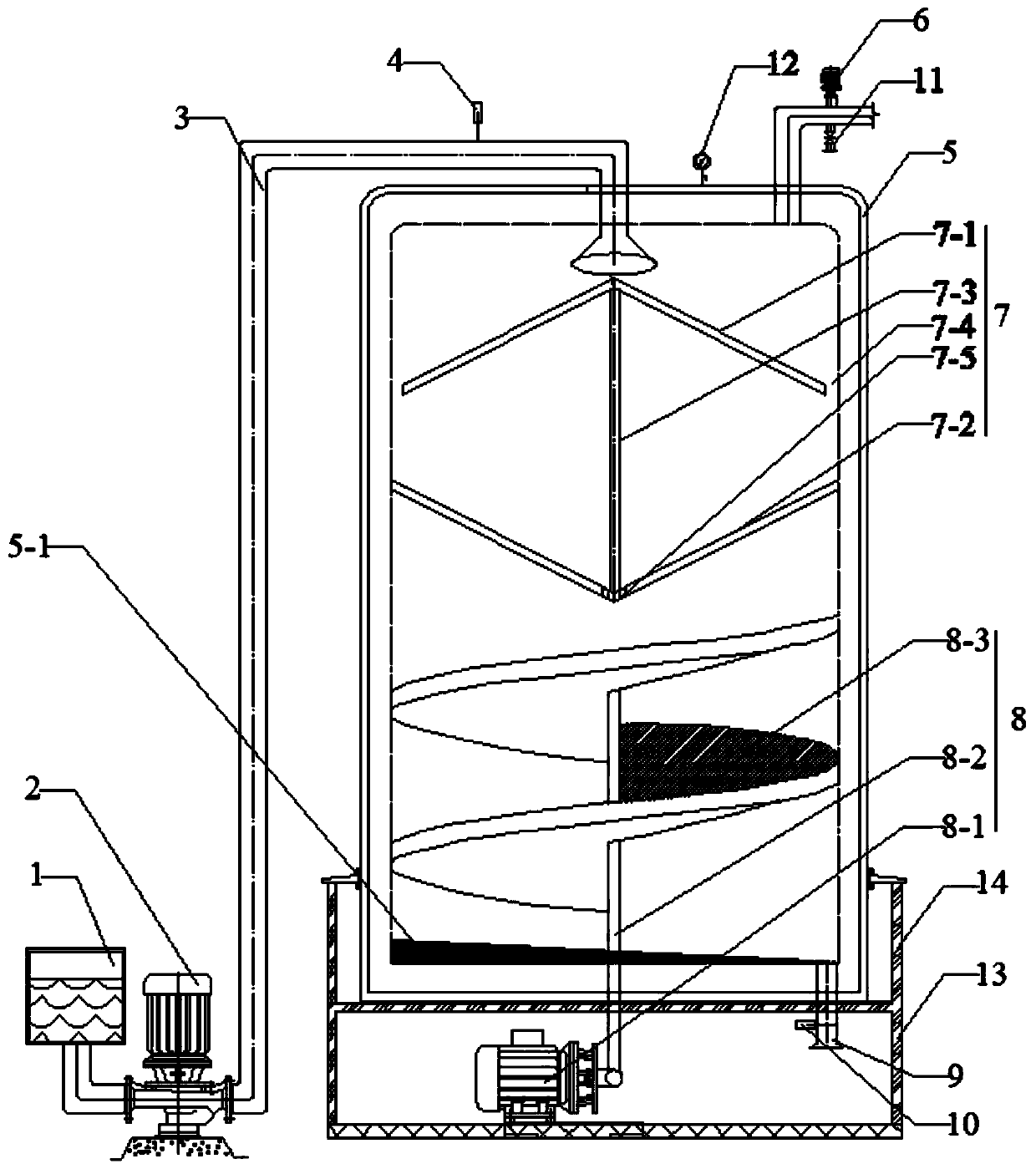

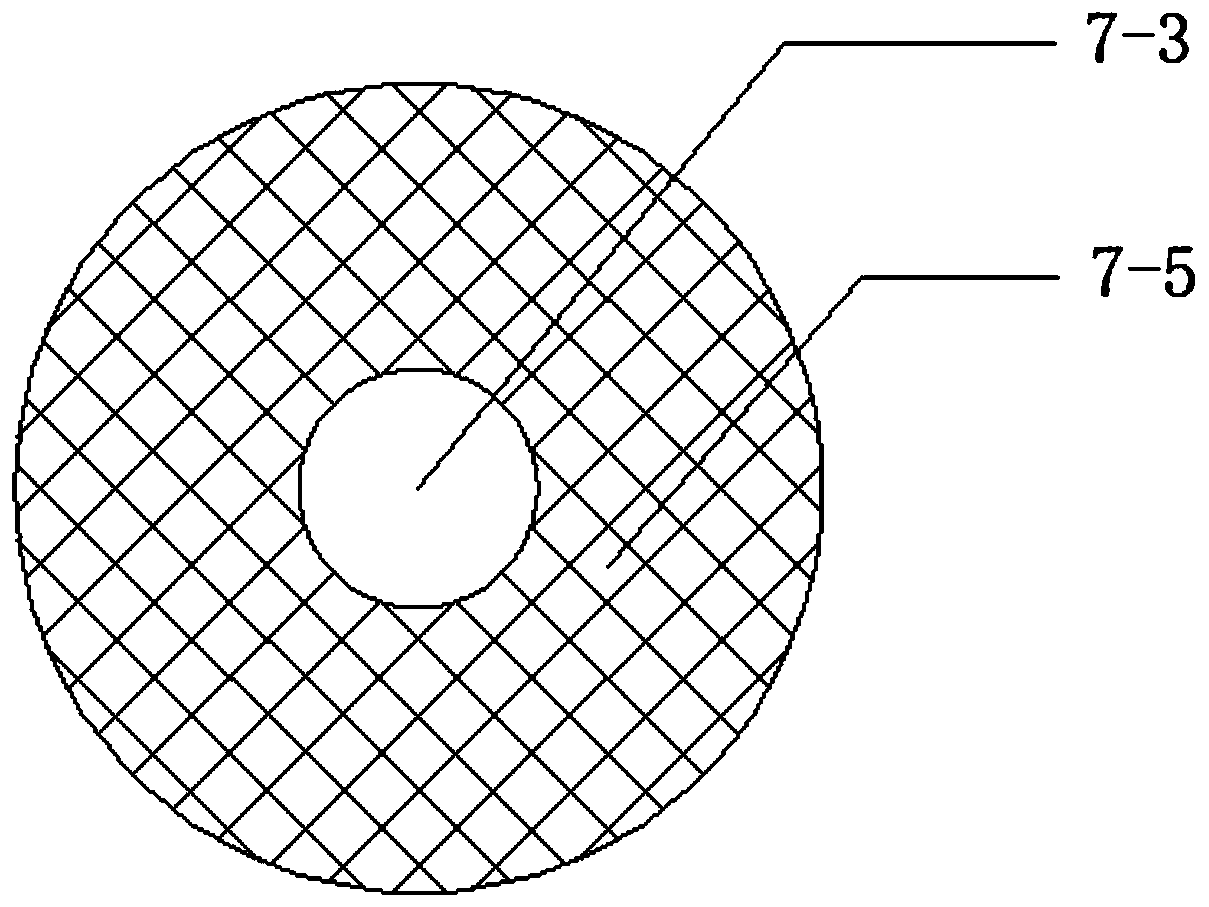

Vacuum defoaming device and defoaming method for high-viscosity liquid

PendingCN110141889ASpeed up film formationSpeed up the flowLiquid degasificationEngineeringThin film flow

The invention discloses a vacuum defoaming device and a defoaming method for high-viscosity liquid. The vacuum defoaming device is provided with two opposite defoaming baffles and a large-area spiralplate; so high-viscosity liquid is always in the state of a thin-film flow layer, which allows the surface area and the surface tension of the high-viscosity liquid to be greatly increased and bubblesto be effectively eliminated; and the low-speed rotation of the spiral plate accelerates the film formation speed and the flowing speed of the high-viscosity liquid, and the rotational shear force generated by the spiral plate can also eliminate bubbles. The defoaming method of the invention adopts multiple defoaming manners, and performs efficient and stable defoaming through a combination of acertain degree of vacuum, the rotating speed of the spiral plate and the flow control of feed and discharge flow valves. According to a technical scheme described in the invention, the vacuum defoaming device has the advantages of simple structure, simple operation, low energy consumption, low cost, high defoaming efficiency and the like, is suitable for defoaming of high-viscosity liquid, and canprotect high-viscosity liquid from the adverse impact of high temperature, defoaming agent and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

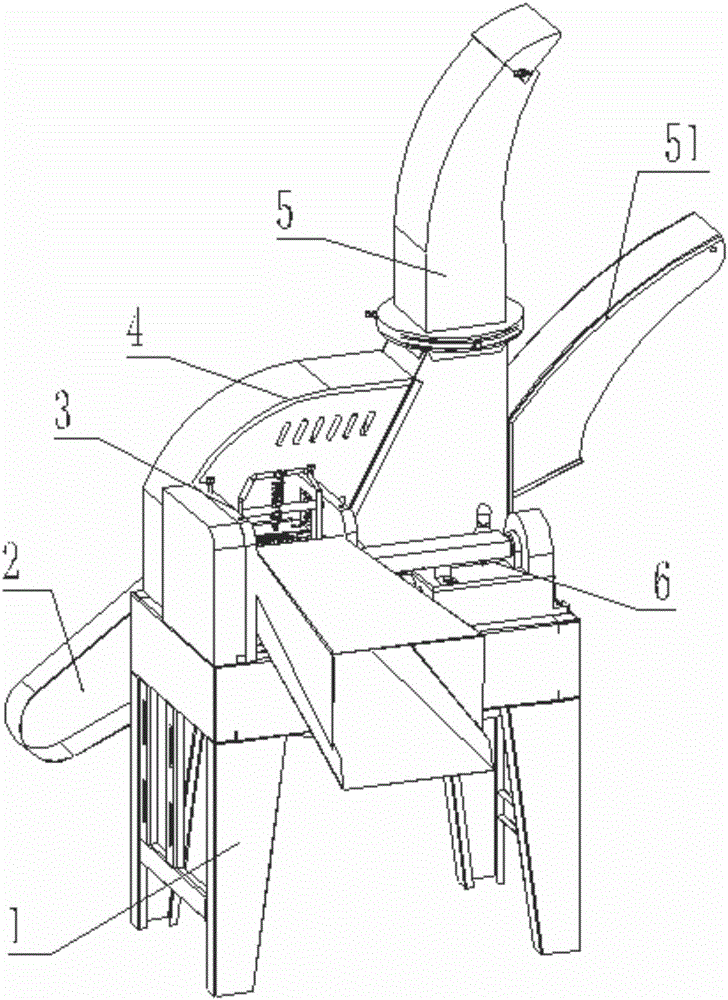

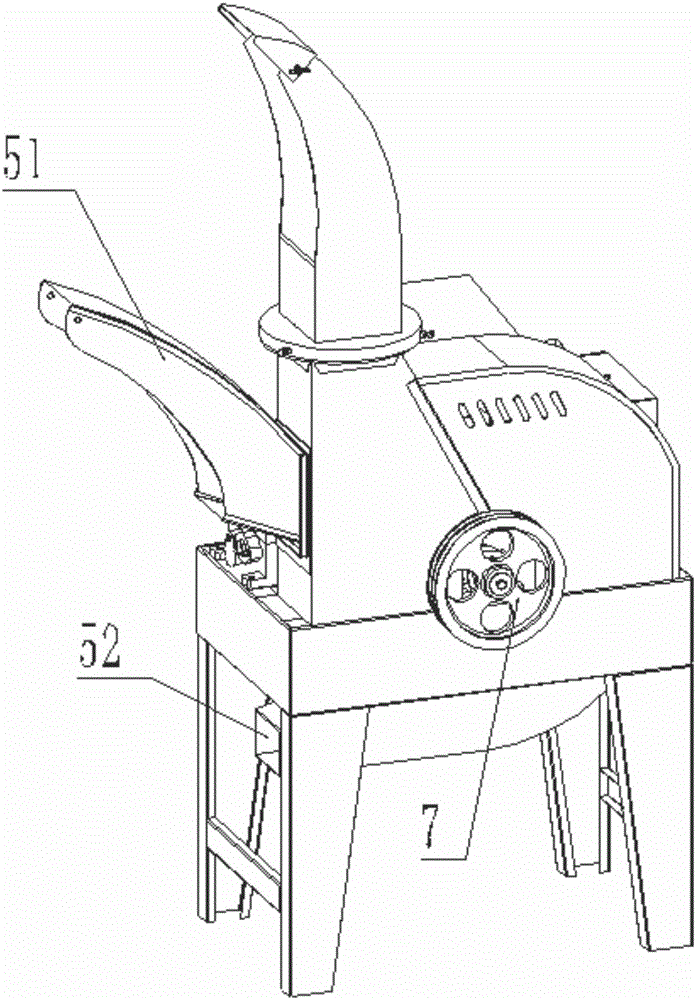

Biomass crushing cut-off machine

ActiveCN105797822AIncrease usageImprove processing efficiencyGrain treatmentsEngineeringMechanical engineering

The invention relates to the field of agricultural machinery, in particular to a biomass crushing cut-off machine with an auxiliary cutting piece arranged in a feeding device. The biomass crushing cut-off machine comprises a driving device, the feeding device, a work chamber and a main shaft assembly. The feeding device, the driving device and the main shaft assembly are all arranged on the work chamber. Biomass enters the work chamber through the feeding device and conducts rotational shear through the main shaft assembly. The main shaft assembly is driven by the driving device to rotate. The work chamber is provided with a discharging outlet. A conveying mechanism and an auxiliary cutting mechanism are arranged inside the feeding device. The biomass is conveyed through the conveying mechanism to enter the auxiliary cutting mechanism after entering the feeding device, and then conducts auxiliary cutting through the auxiliary cutting mechanism. By means of the biomass crushing cut-off machine, the biomass can be crushed or torn or subject to other pretreatments before being cut, hence, processing efficiency is improved, and the utilization rate of processed biomass feed is increased.

Owner:马千茹

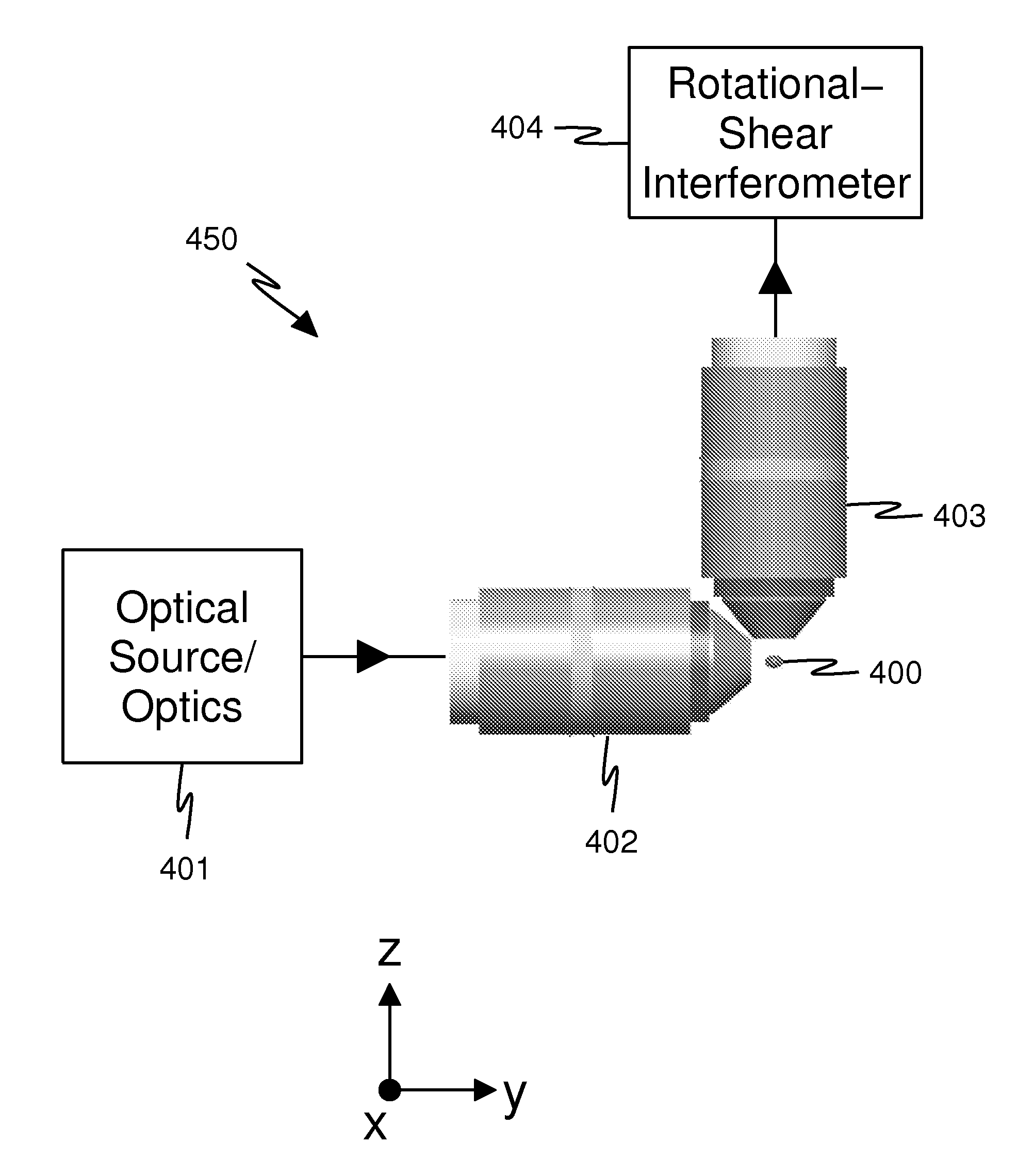

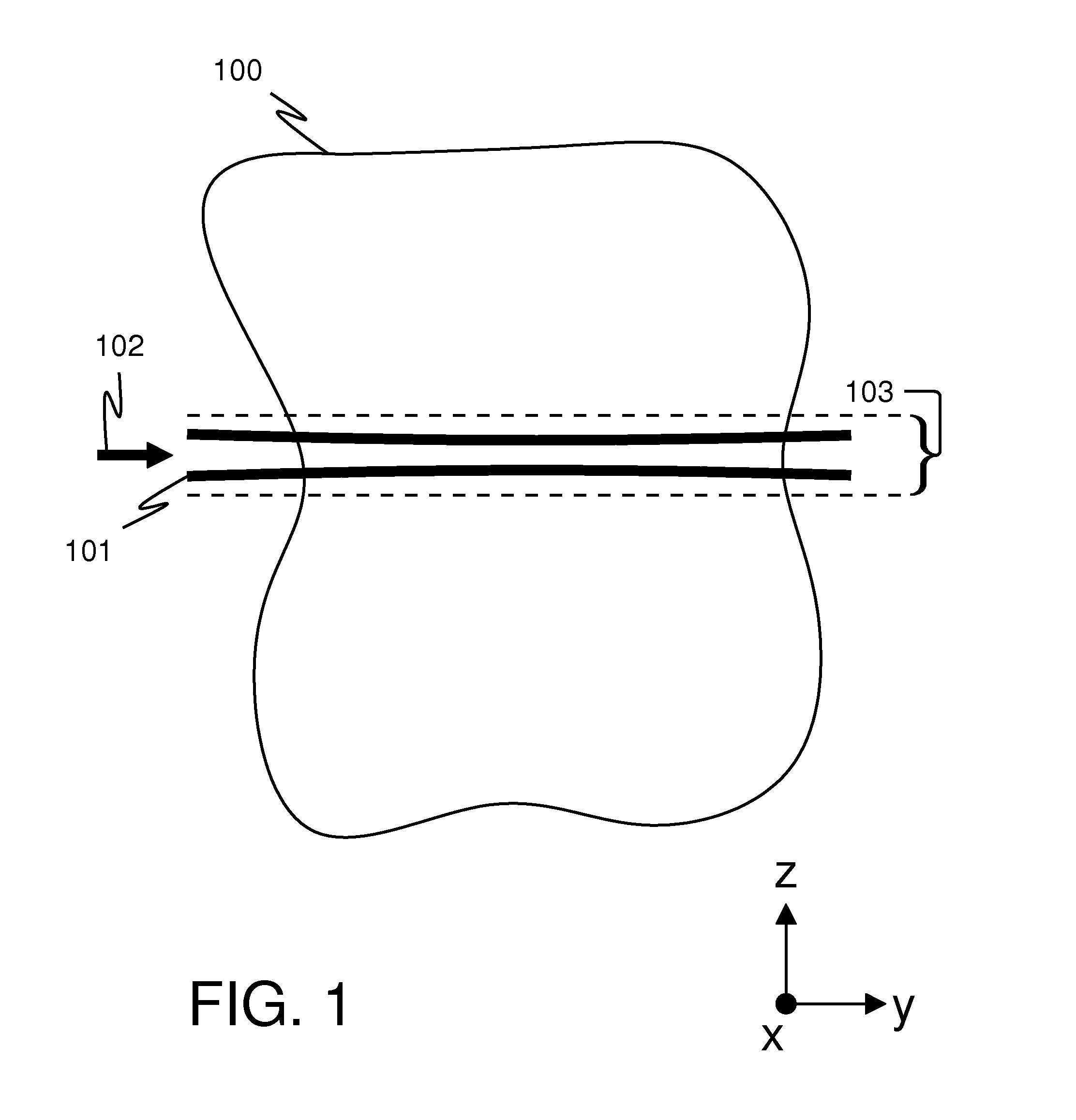

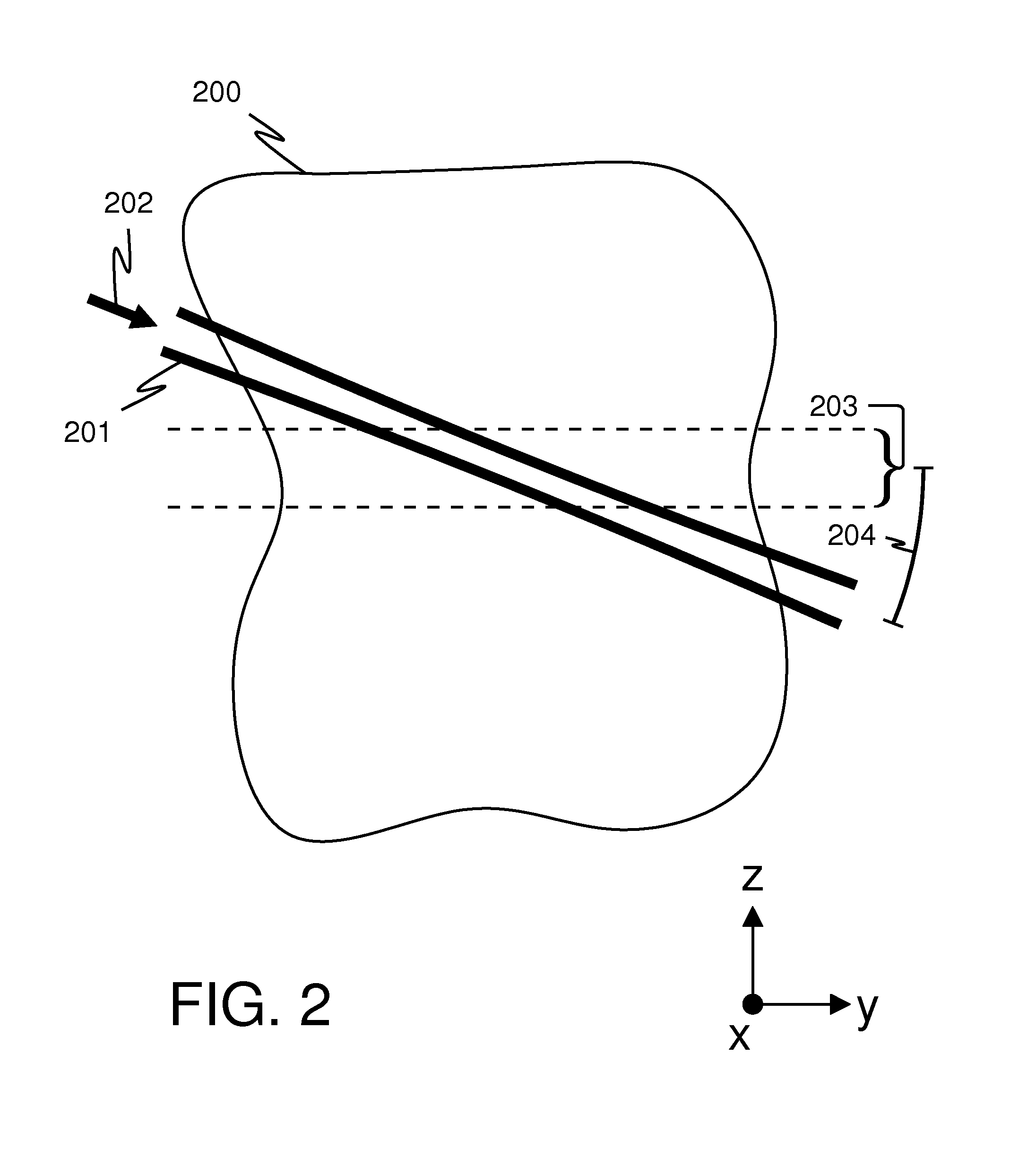

Lightsheet microscopy with rotational-shear interferometry

Devices and methods for lightsheet microscopy using rotational-shear interferometry are provided. Advantages include improved lateral spatial resolution and easier alignment.

Owner:WAYNE LEONARD RODENHAUSEN

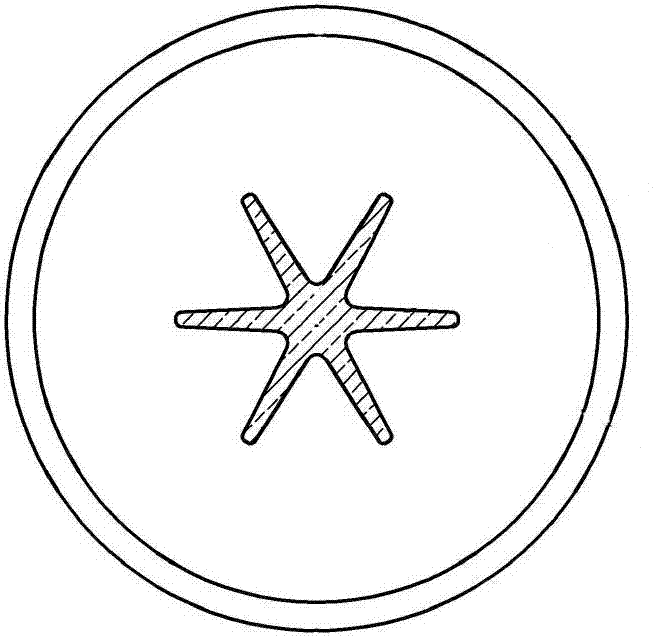

Shear test device and method for shear test by device

PendingCN107063894AEven by forceMeet the test requirements of wide granularity levelMaterial strength using steady shearing forcesTest sampleClassical mechanics

The application discloses a shear test device. The shear device comprises a test container and a rotary shear loading device; the test container is used for holding a to-be-tested sample and at least comprises a bottom plate and a side wall; the bottom plate of the test container is provided with an axial hole for placing a shear plate rotating shaft; the rotary shear loading device comprises a shear plate and a torque applying device, wherein the shear plate is installed on the axial hole of the bottom plate of the test container through the shear plate rotating shaft and can rotate around the shear plate rotating shaft; the torque applying device is used for driving the shear plate to rotate around the shear plate rotating shaft and realizing the rotating shear of the to-be-tested sample held in the test container. The shear test device and method have the advantages of realizing fixed area of a shear face, uniform stress of the shear face, and unlimited shearing displacement during the shear test process, and meeting the testing requirement of wide particle size of the test sample.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

In-situ detection shearing device of loess hole

ActiveCN110646299APrecise determination of shear strengthMaterial strength using steady shearing forcesSoil scienceMeasurement test

The invention discloses an in-situ detection shearing device of a loess hole. The in-situ detection shearing device comprises a motion carrier, a shearing part and an air bag carrier, wherein the motor carrier drives the shearing part and the air bag carrier to climb a wall and walk, the loess shearing tool is borne by the shearing part, the shearing part is used for driving the shearing tool to rotate and cut after the motor carrier reaches a detection position, the air bag carrier is connected with the shearing part and comprises a main air bag carrier and a side air bag carrier, the main air bag carrier bears a main air bag and is used for solidifying hole soil, the side air bag carrier bears a side air bag, and the motion carrier and the side air bag are jointly used for measuring a shearing force. In the shearing force, in-situ measurement test of soil shear strength can be performed in a loess underground pipeline, and soil shear strength at different soil layer positions can beaccurately measured.

Owner:CHANGAN UNIV

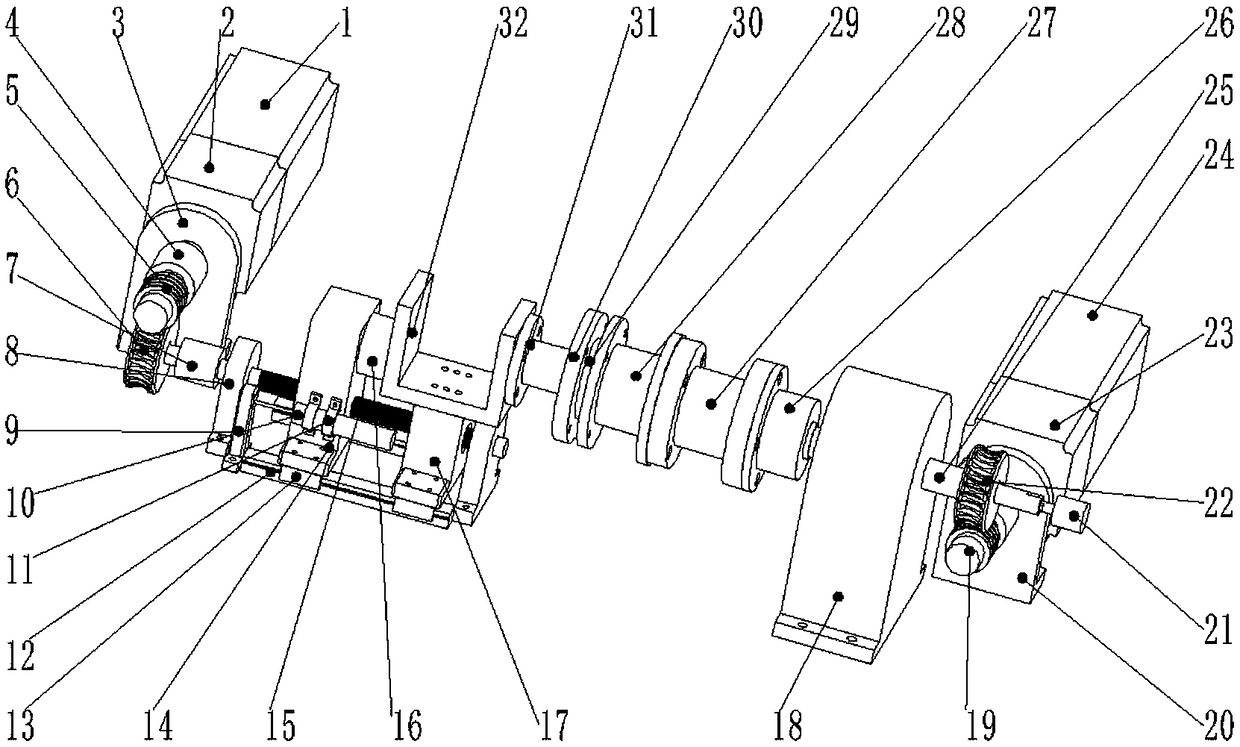

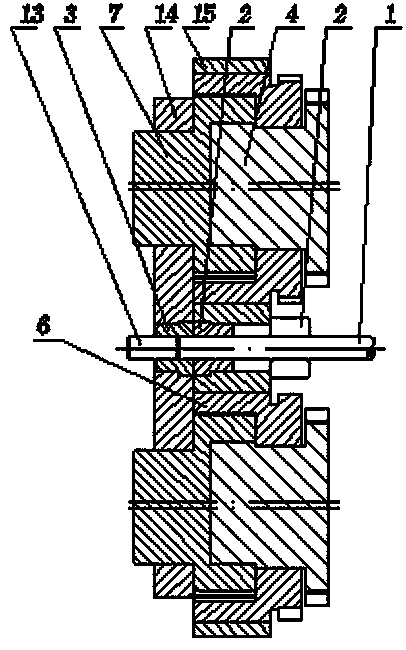

Bidirectional shear test device for metal plates

ActiveCN109283067AEasy to testConstant ratioMaterial strength using steady shearing forcesMotor driveLow speed

The invention discloses a bidirectional shear test device for metal plates, comprising a servo motor, a speed reduction mechanism, a measuring instrument, a tension and compression shearing mechanismand a rotary shearing mechanism, wherein the servo motor supplies power to the whole device to drive the operation of the whole device; the speed reduction mechanism is configured to convert the high-speed motor rotation into low-speed shearing motion; the measuring instrument is configured to measure the force and deformation generated during the test; and the tension and compression shearing mechanism and the rotary shearing mechanism are the actuators of the entire test device in order to achieve shear deformation in both directions of the bidirectional shear test piece. The motor drive canrealize the constant tension, compression shear deformation and rotational shear deformation at any ratio during bidirectional shearing, and improve the reliability of the test results. The forward and reverse shearing of the metal plates can be realized by the forward and reverse rotation of the drive system to obtain a more comprehensive study of material properties.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

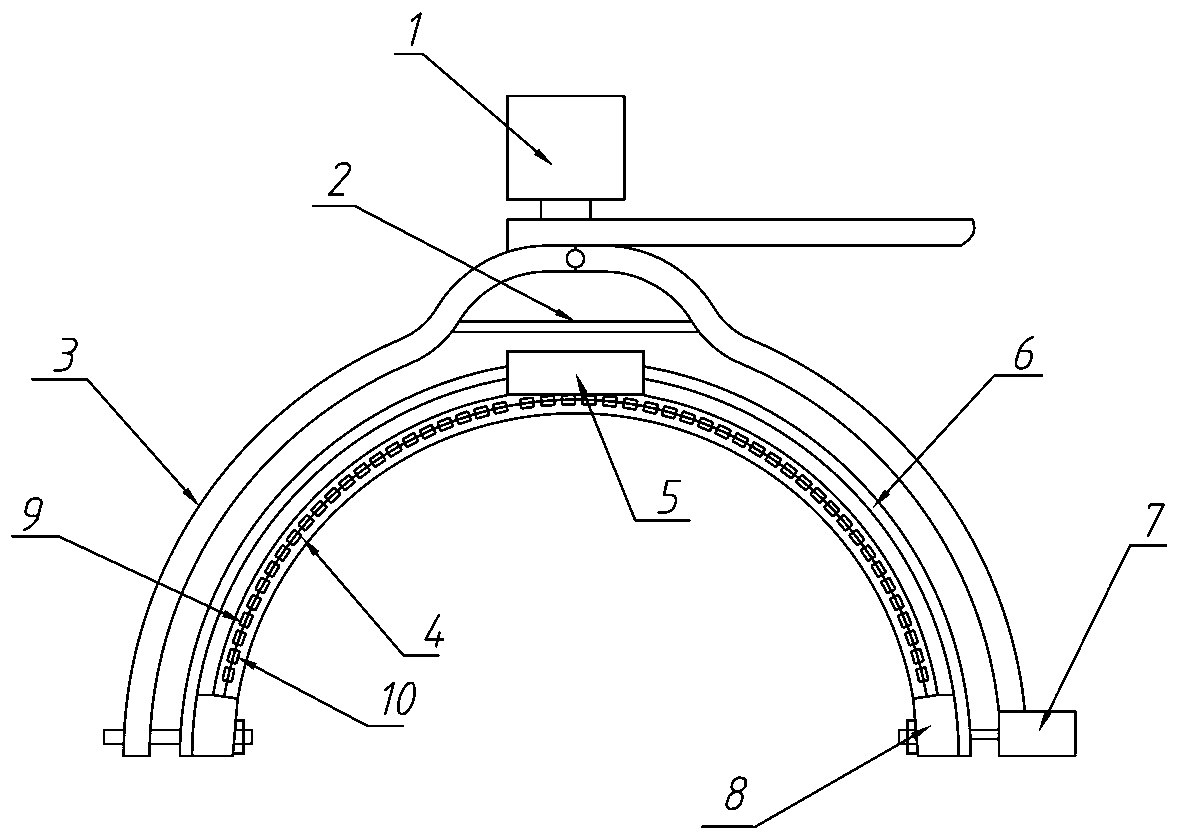

Arc hedgerow cutter

InactiveCN107852994ASimple structureEasy to operateHedge trimming apparatusVertical planeMotor drive

The arc hedge knife of the present invention relates to the field of garden pruning equipment, in particular to an arc hedge knife, comprising a shearing knife body and two arc-shaped knife rests, and the two arc-shaped knife rests are rotatably connected to form a semicircular knife rest. The two ends of the semicircular knife rest are connected to the two ends of the shearing knife body in rotation, and the semicircular knife rest is provided with a through-axis motor, and the two output ends of the through-axis motor are connected to the shear through a flexible shaft. The two ends of the cutter body are connected; the present invention has simple structure, convenient operation, rapid trimming and accurate positioning. The two ends of the semicircular knife holder are respectively connected to the two ends of the shearing cutter body in rotation, and are driven by a vertical rotating motor. The shearing knife body rotates in the vertical plane, and the shearing knife body is rotated to the horizontal plane to facilitate positioning, so that the center of the shearing knife body is aligned with the center of the ball tree, and combined with the horizontal rotation motor, the shearing knife body can be positioned in the horizontal plane. It can rotate in the horizontal plane and can also rotate in the vertical plane to improve the pruning efficiency and the pruning effect is good.

Owner:闫永健

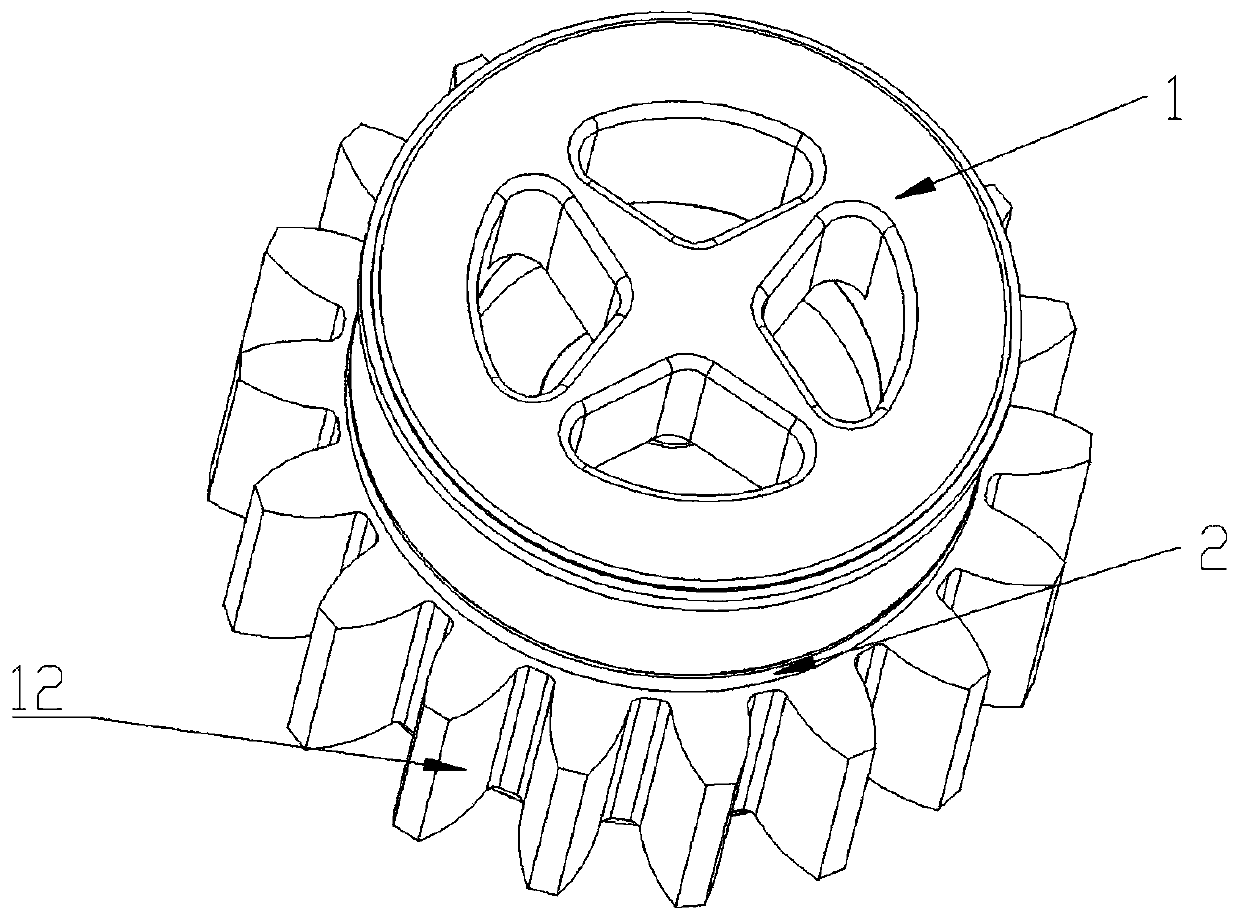

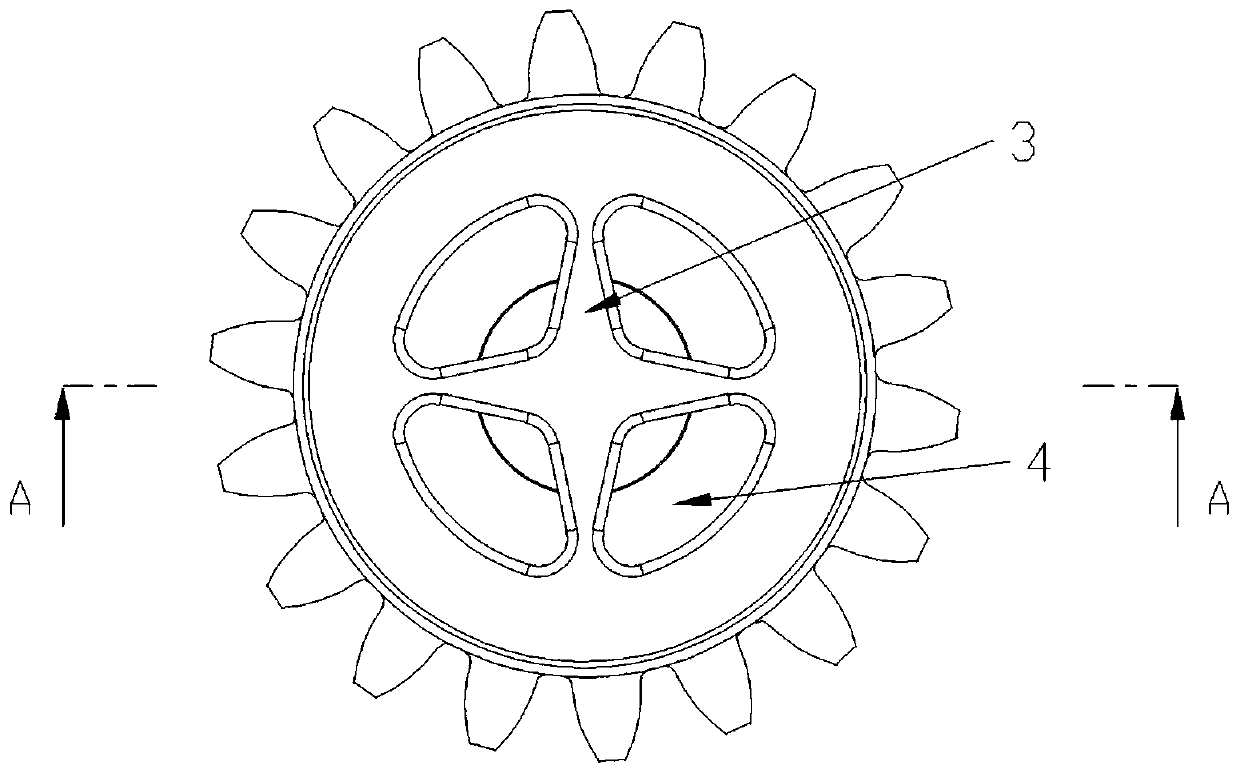

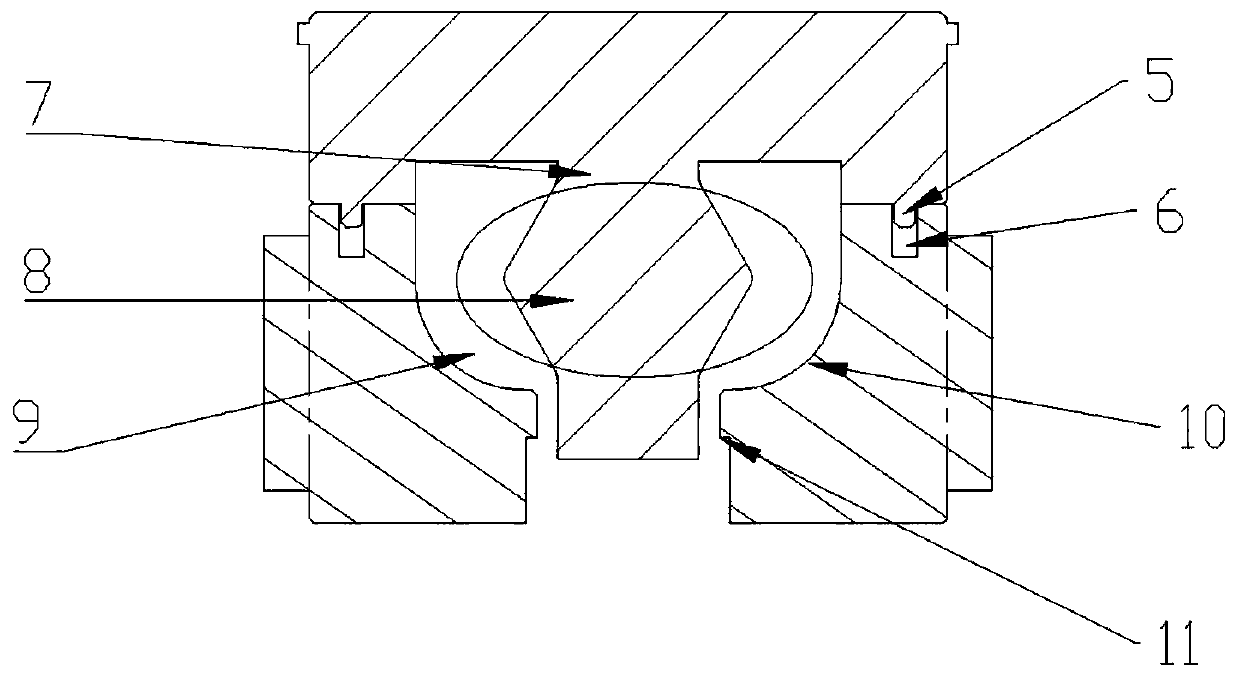

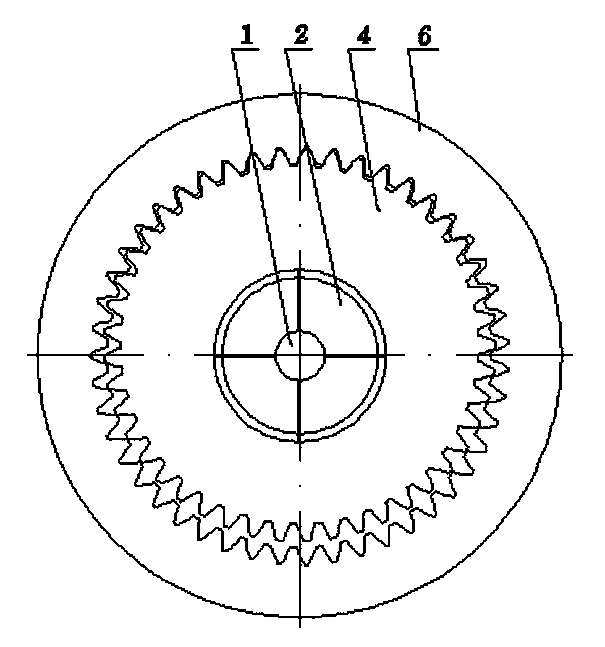

Aluminum pipe extrusion die with rotary shearing force

The invention discloses an aluminum pipe extrusion die with rotary shearing force. The die comprises an upper die body. A die core is arranged in the center of the lower end face of the upper die body; a double-cone body is arranged in the middle of the die core; the double-cone body is divided into an upper cone body and a lower cone body; the upper cone body and the lower cone body are containedin a welding chamber; the lower die body is arranged right under the upper die body; and a cylindrical straight gear is arranged on the outer side of the lower die body. The die is simple in structure; die repairing and die changing are convenient; the gear of the lower die is engaged by an external gear and is driven to rotate; the surface of the upper cone body in the middle of the upper die core can achieve a flow guide effect, so that the aluminum material can rotate more sufficiently in the welding chamber formed by the lower die and the upper die; the aluminum material is sheared and deformed in the rotating process, so that grains of the aluminum material are further refined; and the aluminum material is welded after rotating, and the mechanical property of an extruded aluminum pipe is improved, so that the quality of the aluminum pipe is improved.

Owner:FUJIAN UNIV OF TECH

Method of manufacturing coaxial cable with strippable center conductor precoat

InactiveUS20060026825A1Easy to disassembleEasy to operateCable insulation constructionPower cables with screens/conductive layersAdhesion forceCoaxial cable

Owner:COMMSCOPE INC

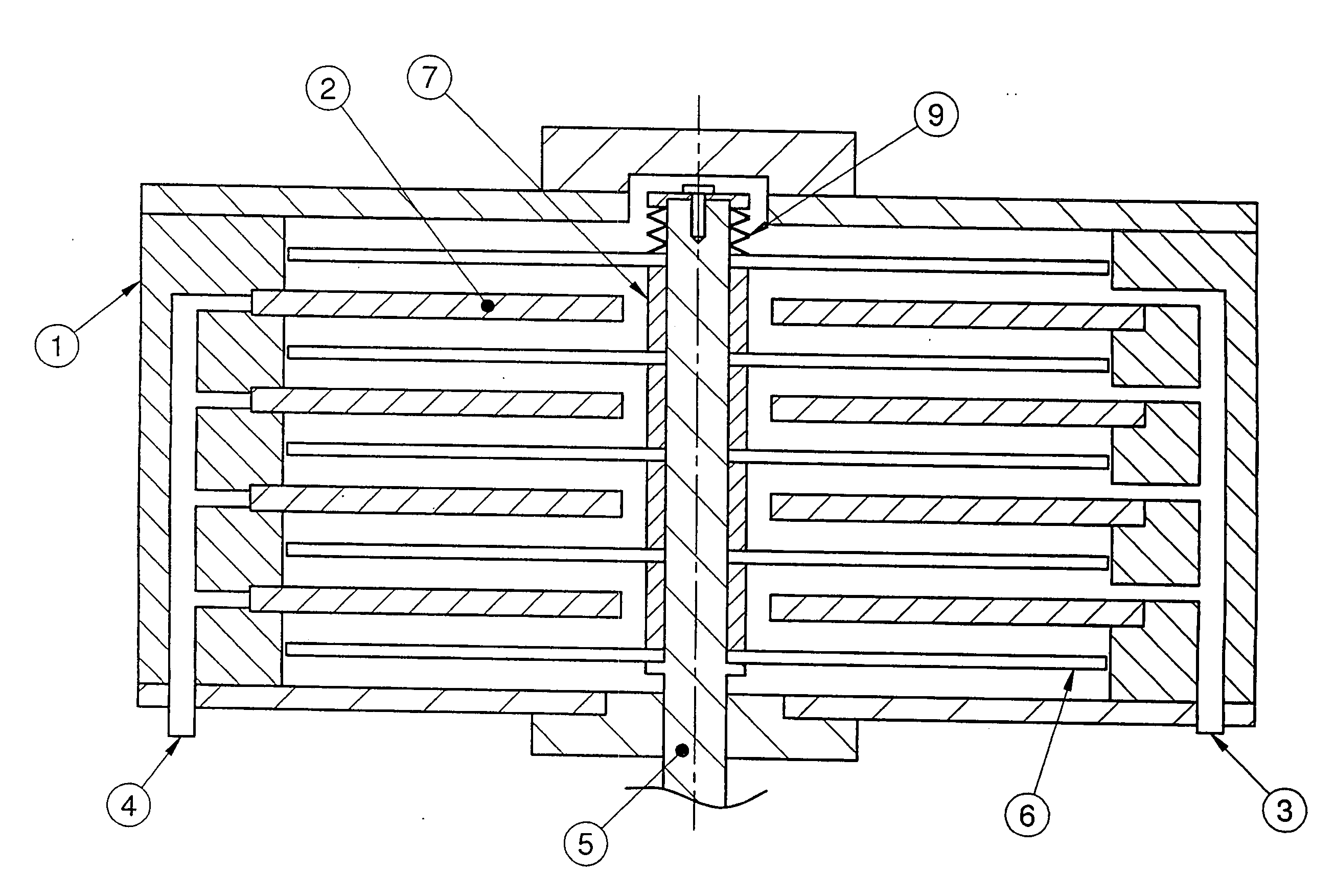

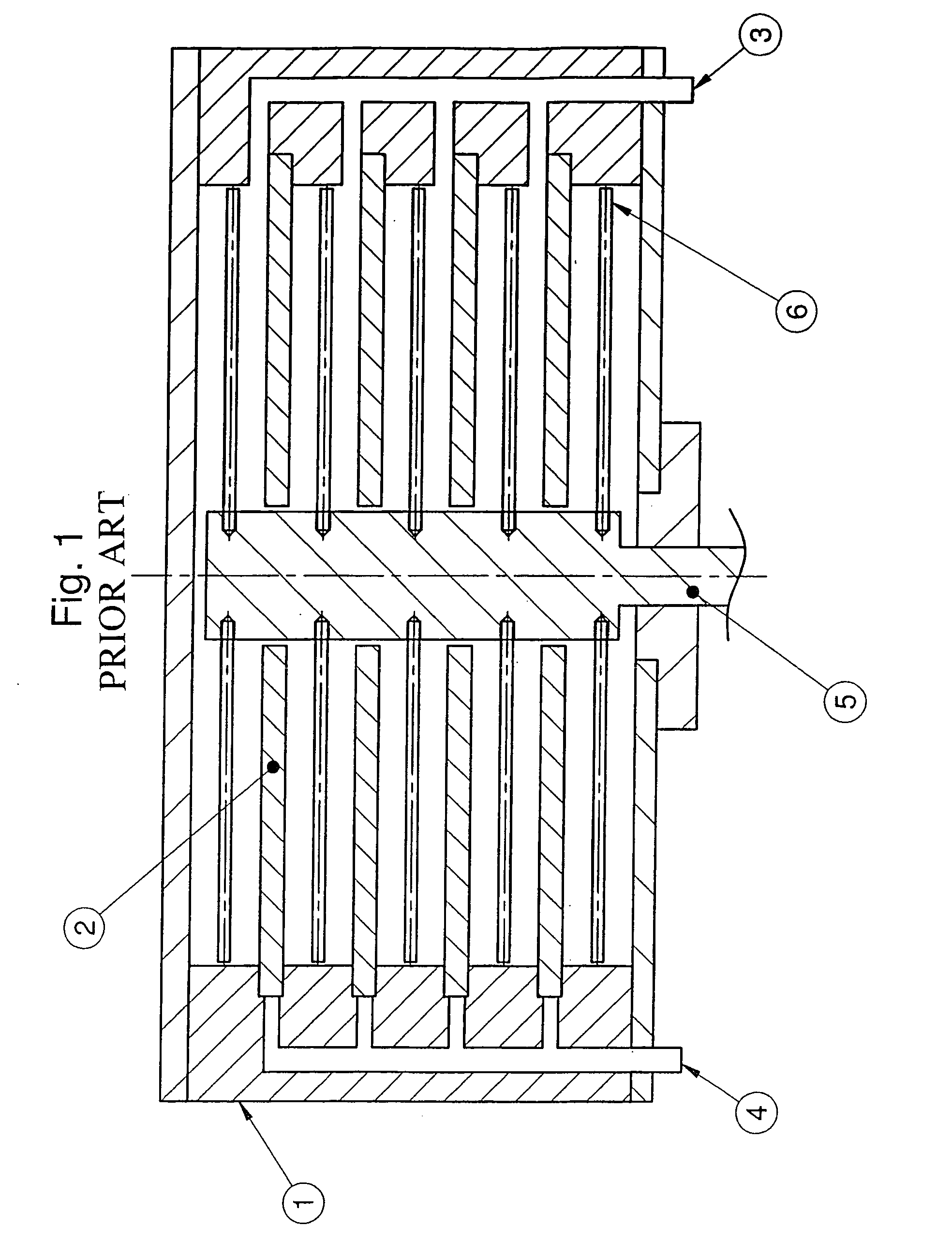

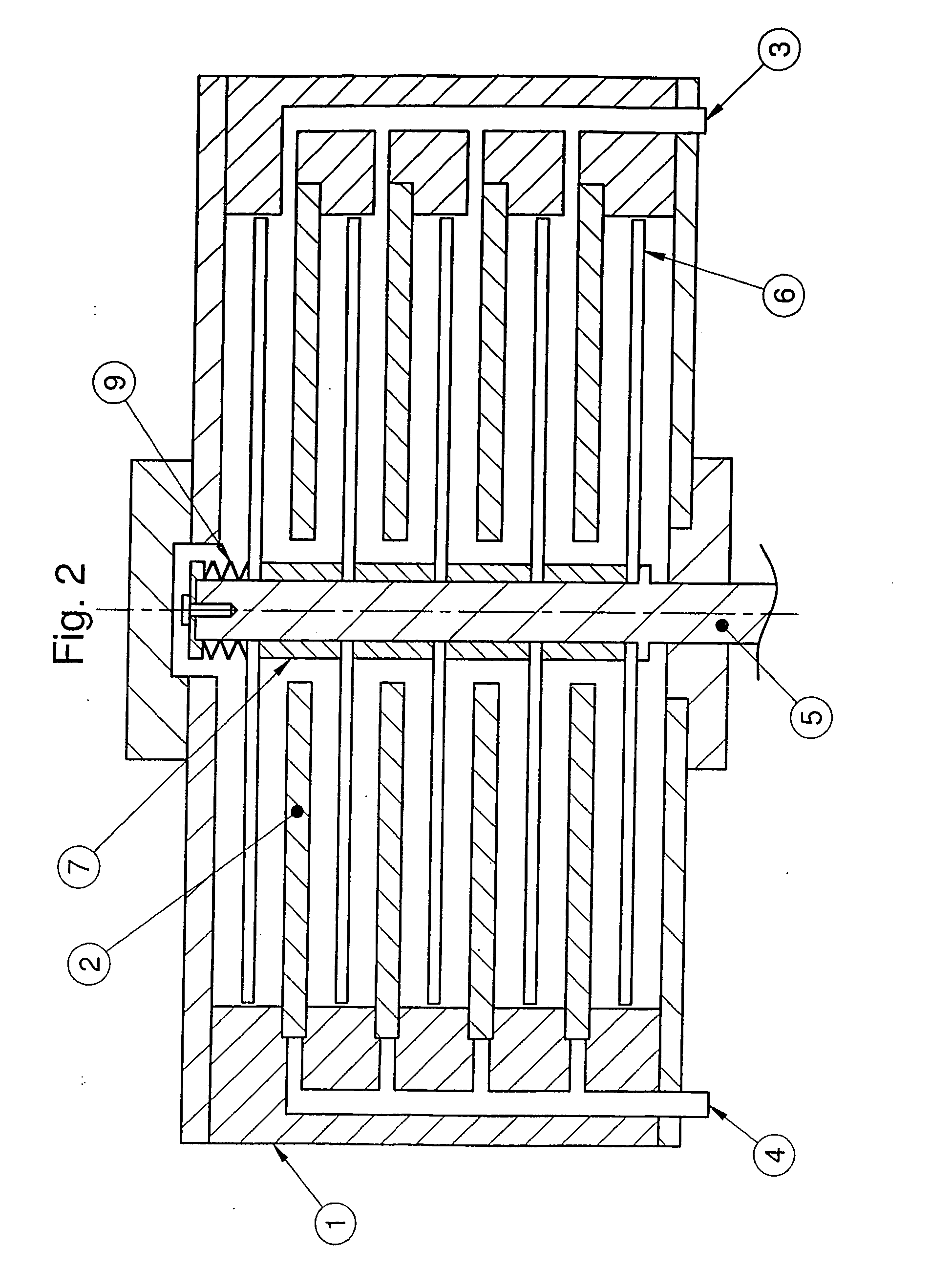

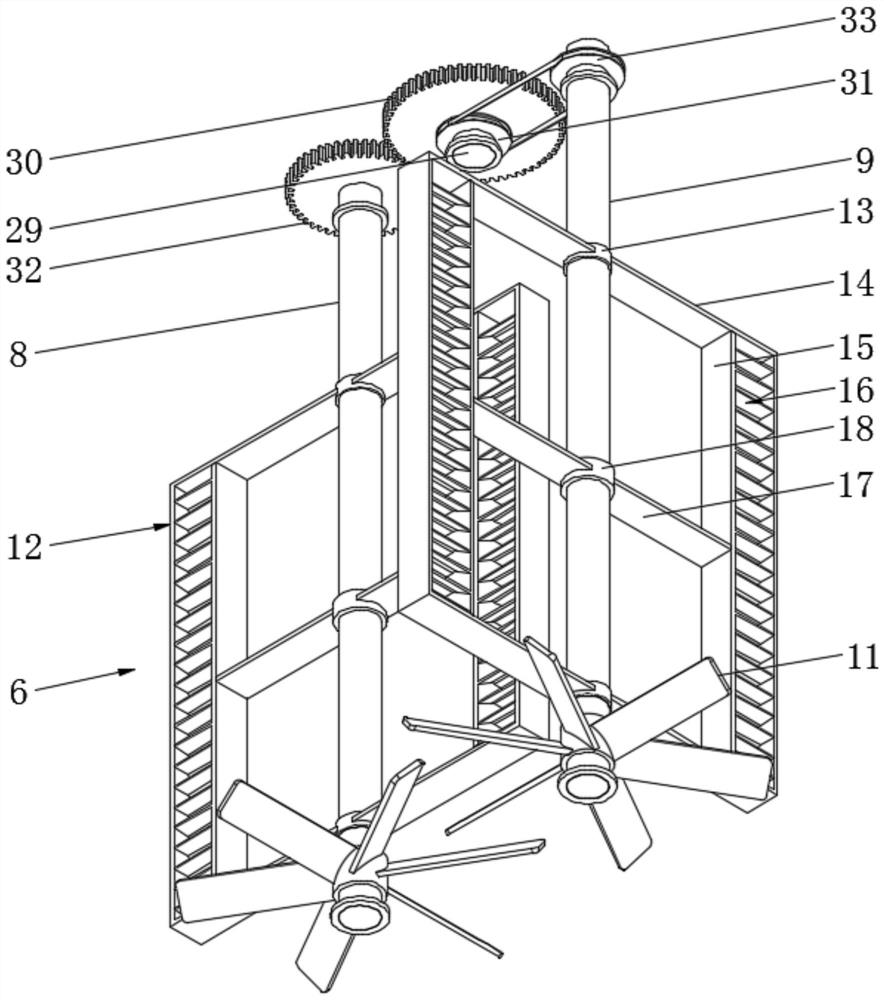

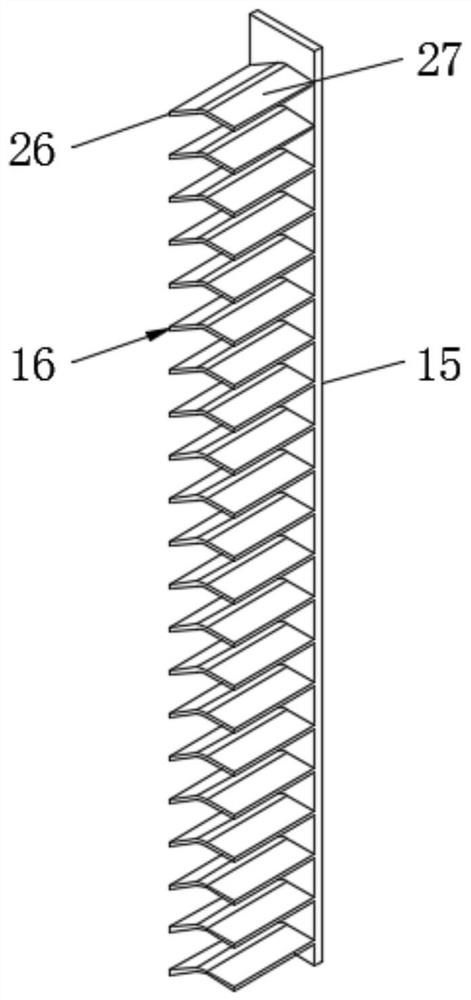

Rotational shearing filter

InactiveUS20070158260A1Increase the use of spaceEasy to useTransportation and packagingRotary stirring mixersRandom materialsDrive shaft

A rotational shearing filter is disclosed which includes a housing and several spaced-apart, stationary, coaxial, annular, hollow filter disks that are disposed therein. Several shearing elements are retained in a torsion-proof manner on a central, rotatable drive shaft which penetrates the filter disks. The shearing elements are placed next to the annular surfaces of the filter disks, which point in the axial direction of the housing, so as to keep the filter disks penetrable for filtrate that penetrates from the housing into the filter disks. In order to prevent the shearing elements and the filter elements from touching each other as a result of thermal expansion, the shearing elements that are connected to the drive shaft so as to rotate therewith are guided thereon in an axially movable manner while spacers which axially displace the shearing elements according to longitudinal modifications of the housing occurring due to thermal conditions are positioned between the shearing elements. The spacers can be arranged directly between adjacent shearing elements and can be made of a material corresponding to the thermal expansion behavior of the housing. Alternatively, the spacers can be made of a largely random material while limiting the minimum distances between the shearing elements and the filter disks or the facing housing walls.

Owner:ANDREAS KUFFERATH

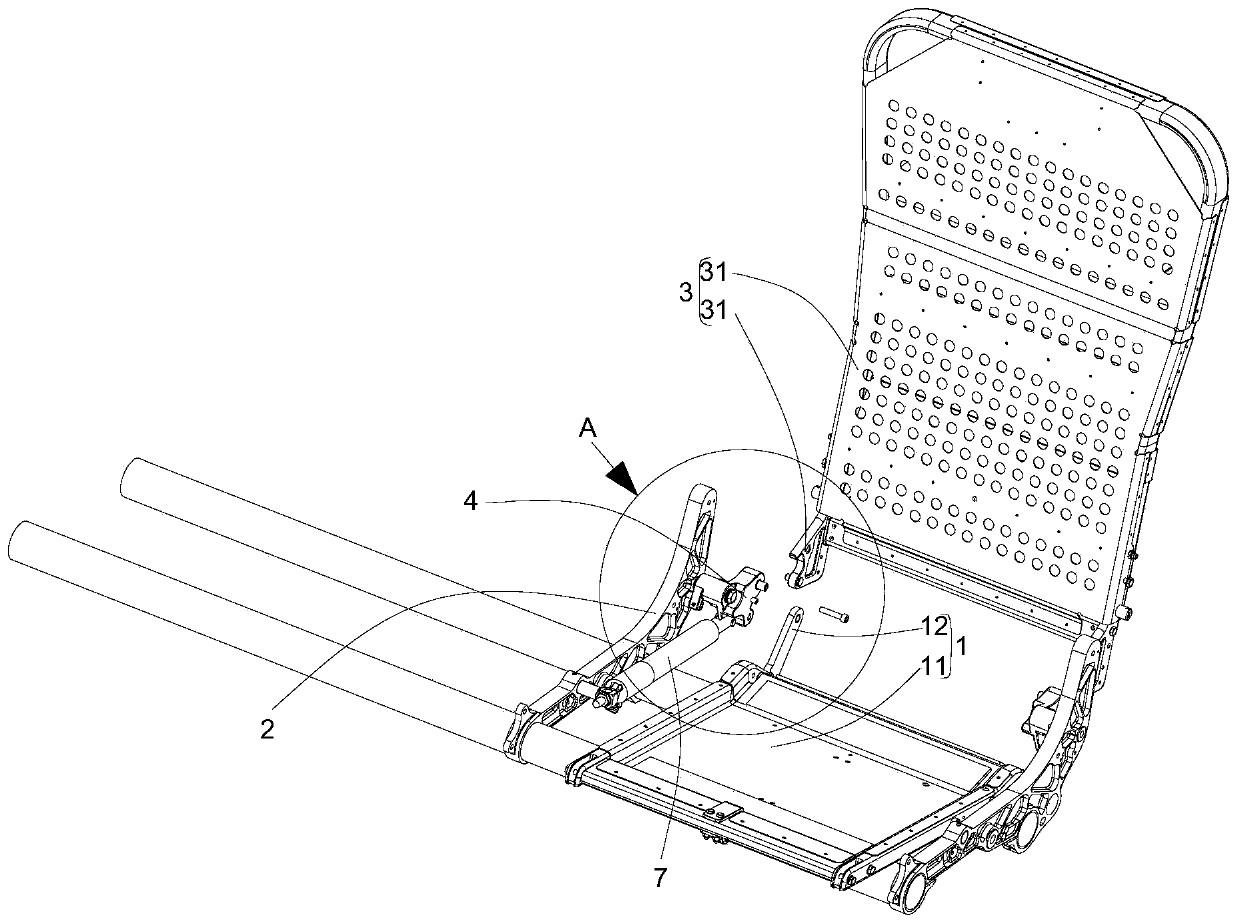

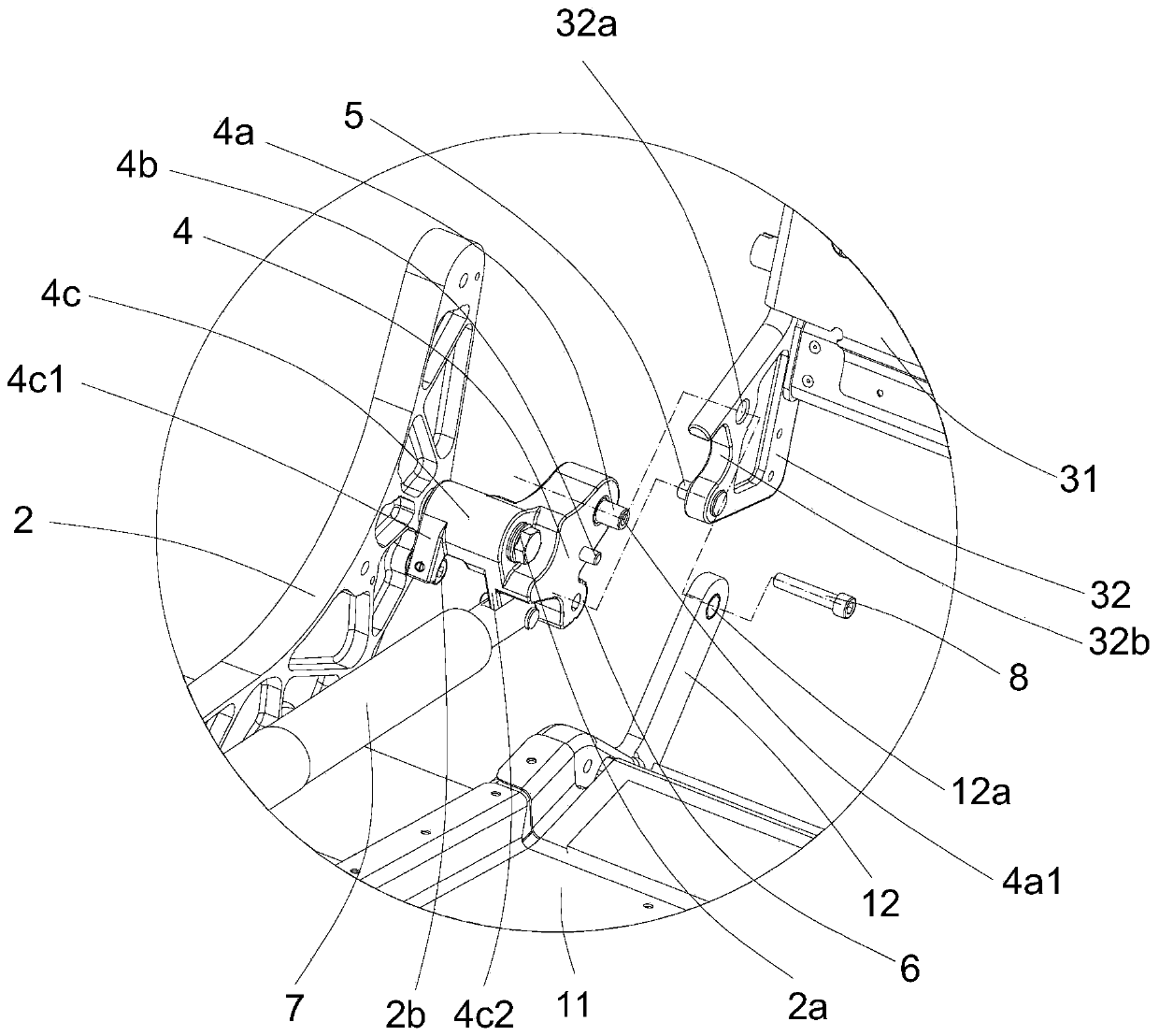

Different-axis rotary shearing energy-absorbing aero seat

The invention discloses a different-axis rotary shearing energy-absorbing aero seat which comprises a chair basin, a side plate, a backrest, a connecting plate, a shearing pin, a shearing ring and a driving mechanism. The side plate is fixed on the left side or the right side of the chair basin; the lower end of the backrest is hinged to the rear side of the chair basin, and the hinged axis of thebackrest and the chair basin is a first axis; the first end of the connecting plate is hinged to the side plate, the second end of the connecting plate is hinged to the backrest, the shearing ring isarranged at the third end of the connecting plate, and the hinged axis of the first end of the connecting plate and the side plate is a second axis; when the backrest bears large inertia and inclinesforwards, the backrest rotates relative to the side plate with the first axis as the rotating axis, in the process, the shearing ring is torn open by the shearing pin, the rotating axis of the backrest and the axis of the shearing ring are staggered through the structure, and meanwhile interference of a linkage structure on stress of the shearing ring is avoided.

Owner:湖北航宇嘉泰飞机设备有限公司

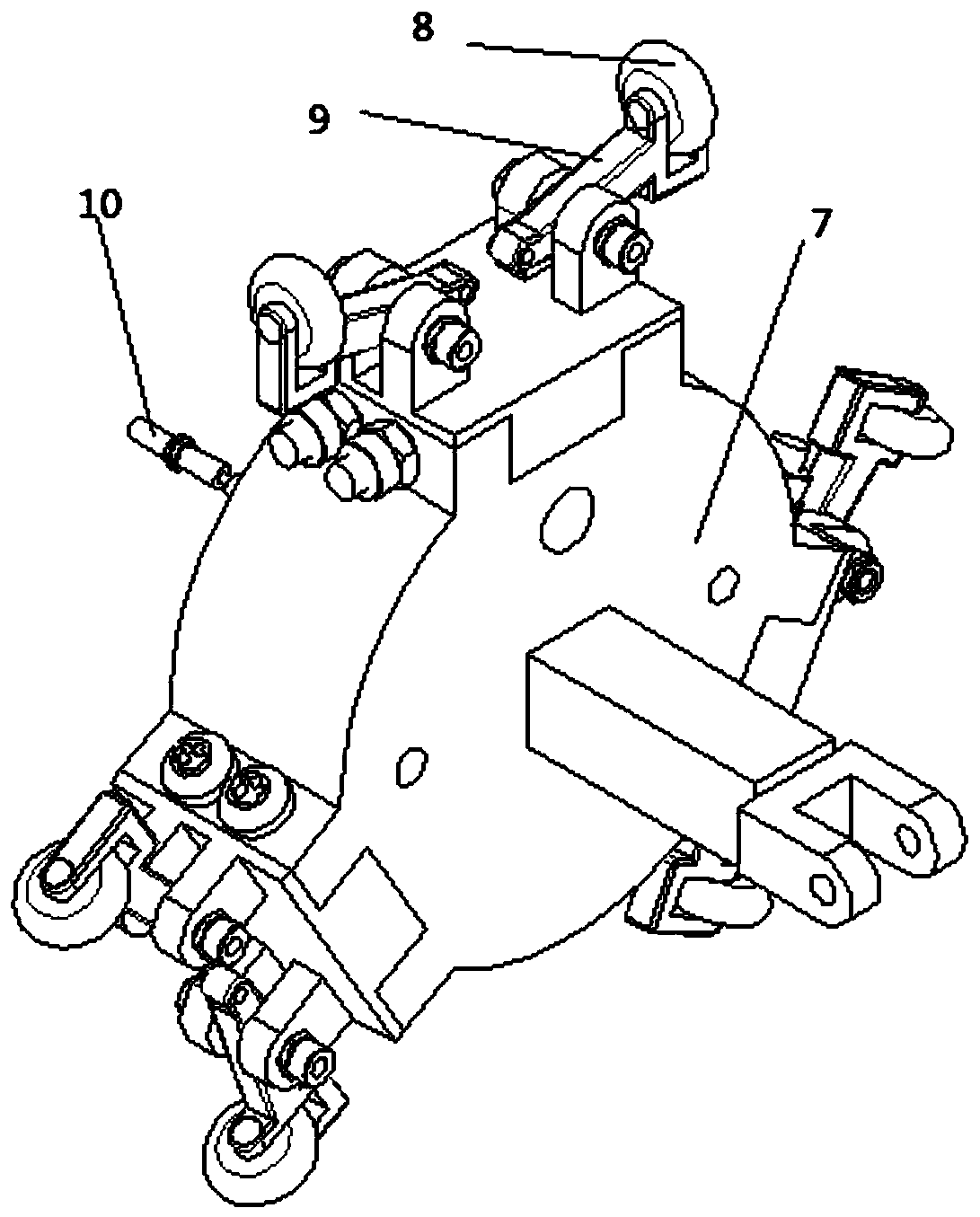

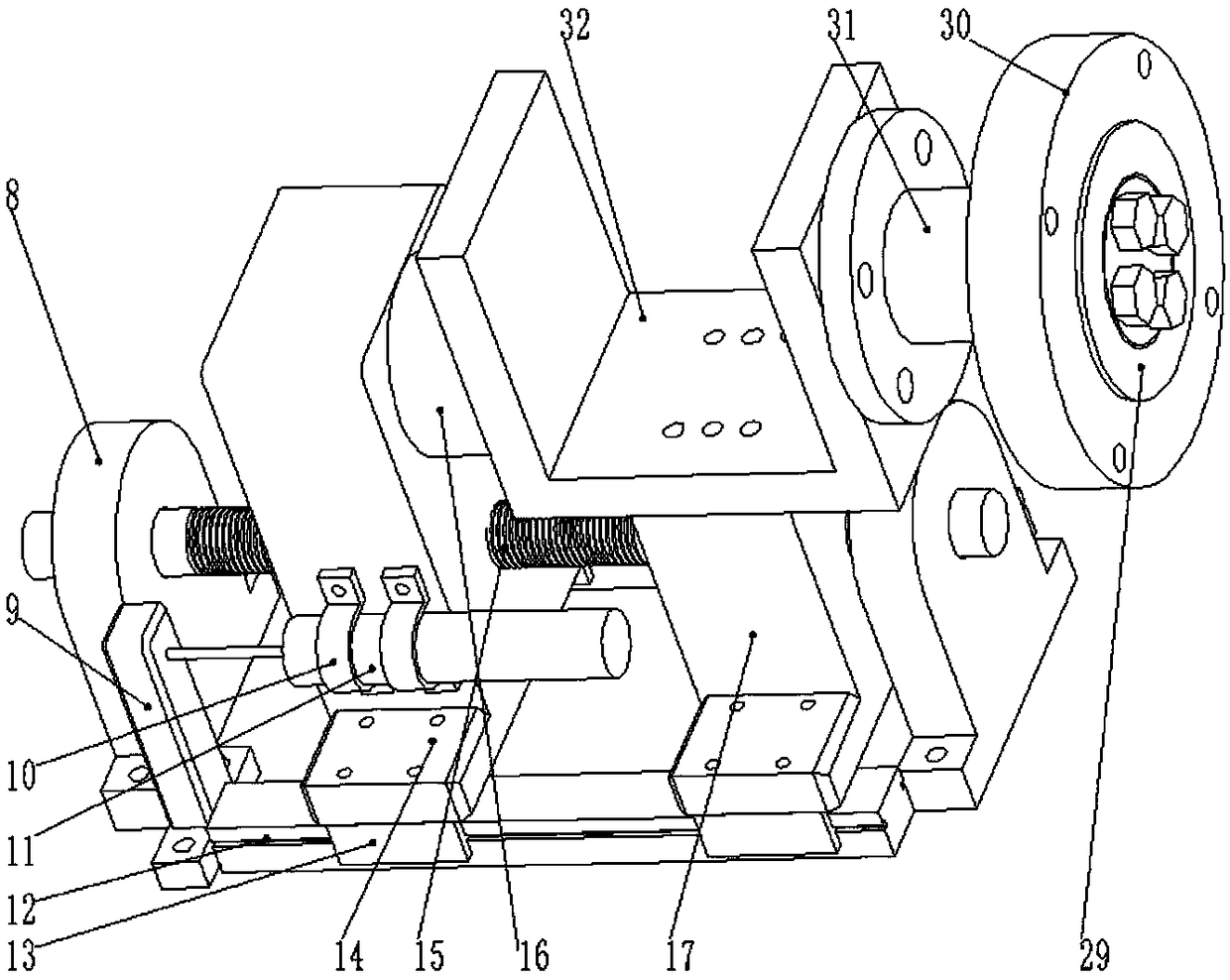

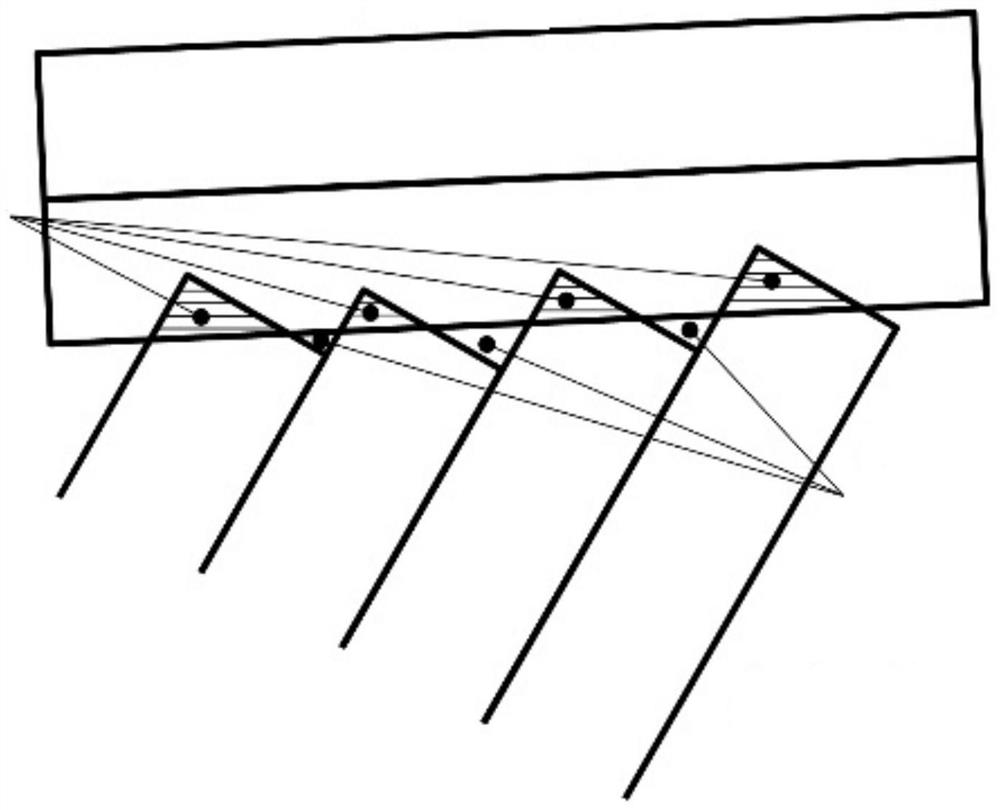

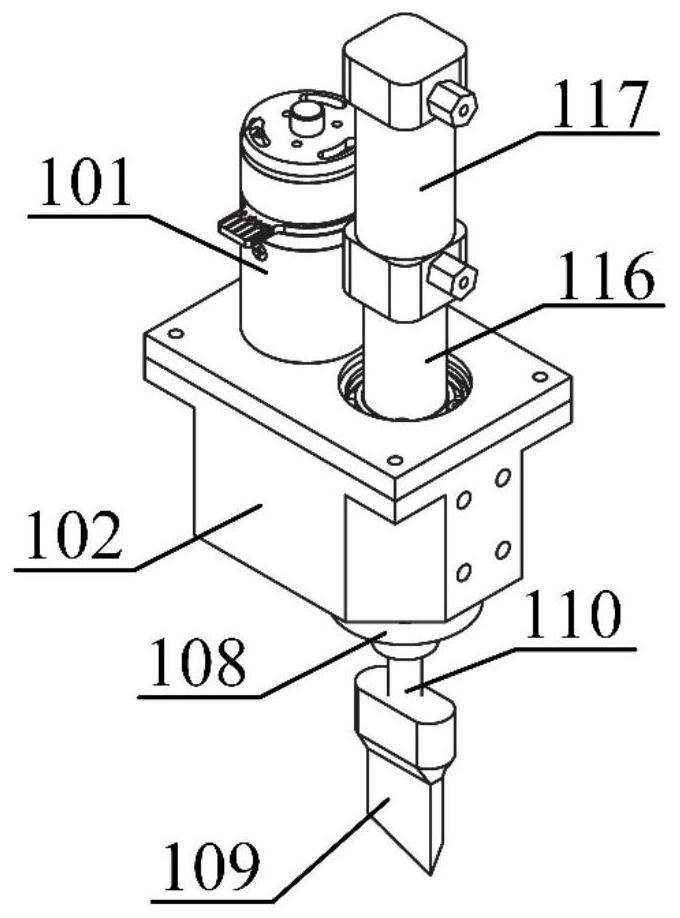

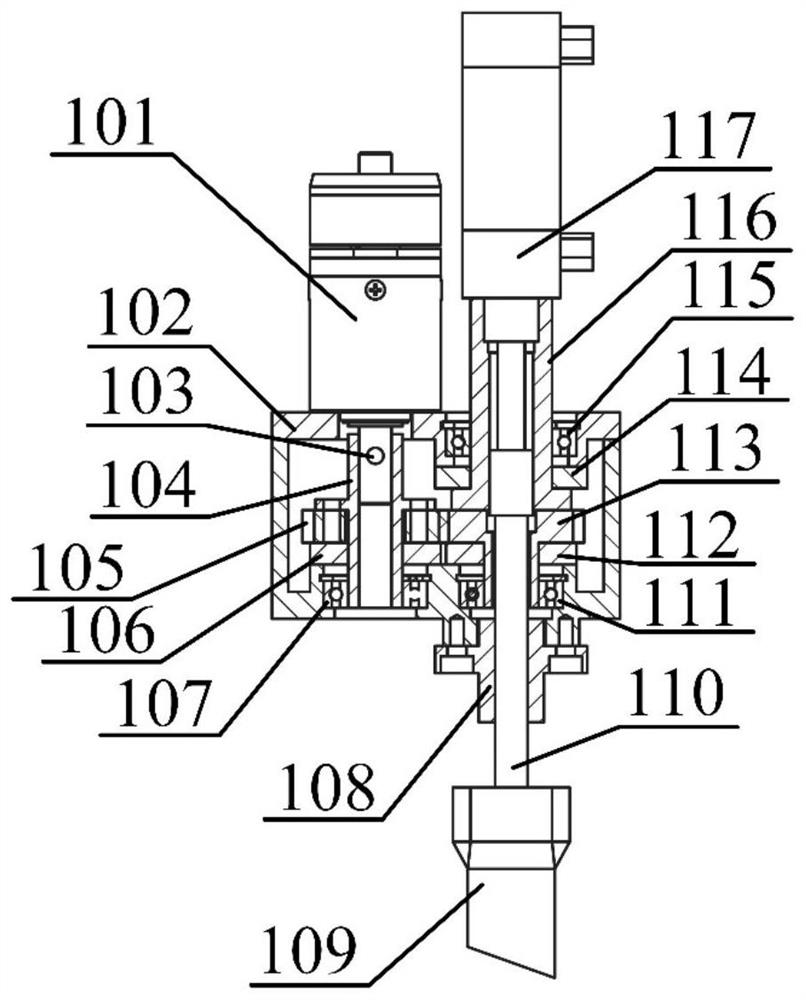

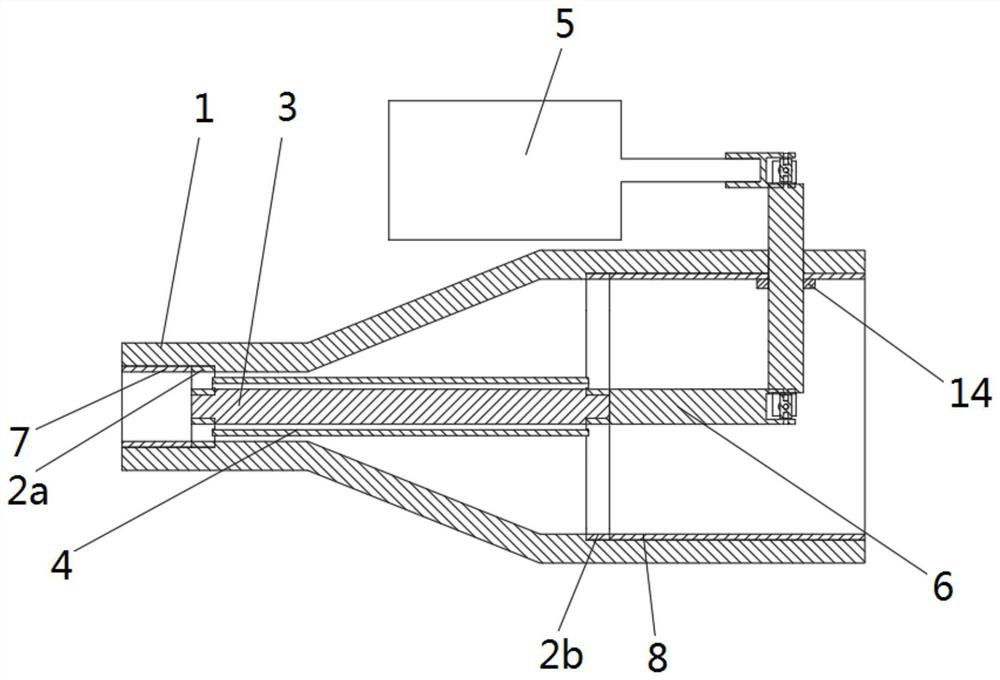

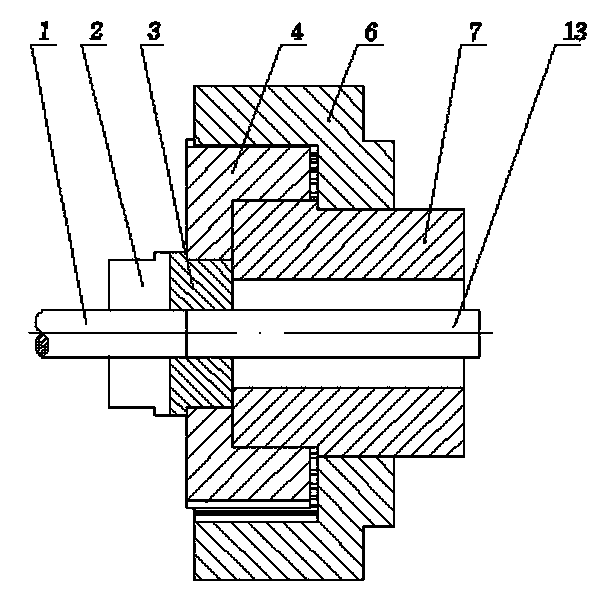

Rotary shearing mechanism and laying head for automatic fiber laying and forming

The invention relates to a rotary shearing mechanism and a laying head for automatic fiber laying and forming, and aims to solve the problem that gaps and overlapping defects exist at the boundary of a laying track. The rotary shearing mechanism comprises a motor, a machine base, a flange shaft, a driving gear, a linear guide rail, a knife rest assembly, an extended stepped shaft, a driven gear, a air cylinder sleeve and an air cylinder, and the laying head comprises a rotary shearing mechanism, a re-conveying mechanism, a clamping mechanism, a first guide roller, a jumping roller, a second guide roller, an adapter plate, a third guide roller, a charging tray, a compression roller cylinder, a compression roller and a frame body. A motor shell is installed on the machine base, the flange shaft is fixedly installed on an output shaft of the motor in a sleeved mode and connected with the driving gear, a piston rod of the air cylinder is connected with one end of the extended stepped shaft, the knife rest assembly is installed at the other end of the extended stepped shaft, the other end of the air cylinder sleeve is fixedly connected with the driven gear, and the driving gear is meshed with the driven gear. The invention belongs to the technical field of automatic molding of matrix composite materials.

Owner:HARBIN INST OF TECH

Spray flow gel and preparation method thereof

The invention relates to the technical field of hydrogel preparation, in particular to spray flow gel and a preparation method thereof.The preparation method includes the following steps of (1) addingfood natural macromolecules into deionized water and stirring at a certain temperature until the food natural macromolecules are completely swollen into a uniform solution; (2) enabling the swollen solution to form spray under the action of compressed air with certain pressure, and controlling the aperture of an outlet of a spray head to be 0.2-0.8 mm to form micron-scale liquid drops; (3) blowing with cold air with a certain temperature within the range of liquid drops to ensure that the liquid drops complete sol-gel conversion in the air; and collecting liquid drops after gel transformationby using a container with a certain temperature to obtain the spray flowing gel. The preparation method of the spray flow gel is different from a rotary shearing mode, the micron-scale small liquid drops are subjected to a gelling effect at the temperature far lower than a gel dissolving transition point through an air shearing mode, the preparation efficiency is high, and the industrial production is facilitated.

Owner:HUBEI UNIV OF TECH

Fluid feeding device with stirring function

InactiveCN112705091AIncrease the degree of mixingPrevent subsidenceShaking/oscillating/vibrating mixersTransportation and packagingSolid particleAgitator

The invention relates to the technical field of material transportation equipment, in particular to a fluid feeding device with a stirring function, which comprises a temporary storage tank, a stirring mechanism is arranged on the temporary storage tank, and the stirring mechanism comprises a mixing stirrer; the mixing stirrer comprises an axial-flow stirrer and a marginal stirrer fixedly arranged above the axial-flow stirrer, and the marginal stirrer comprises a first shaft sleeve fixedly arranged on a first stirring shaft and a second stirring shaft, a C-shaped frame blade fixedly arranged on the first shaft sleeve, an auxiliary blade fixedly arranged on the C-shaped frame blade and flow guide plates fixedly arranged on the C-shaped frame blade; and a rectangular cavity is defined by the C-shaped frame blade and the auxiliary blade, and the flow guide plates are longitudinally distributed in the rectangular cavity at equal intervals. The two axial-flow stirrers synchronously rotate in different directions to form strong vortex flow, so that solid particles in fluid are suspended between the two axial-flow stirrers, sedimentation is avoided, axial and radial flow of the fluid is promoted through rotary shearing provided by the marginal stirrer, and the mixing degree of the fluid is improved.

Owner:亢慧慧

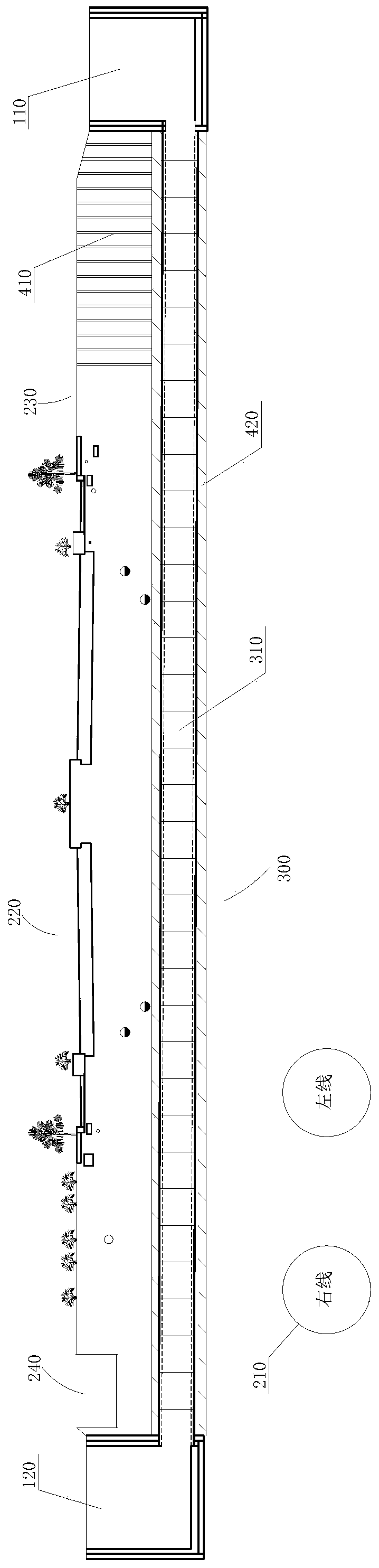

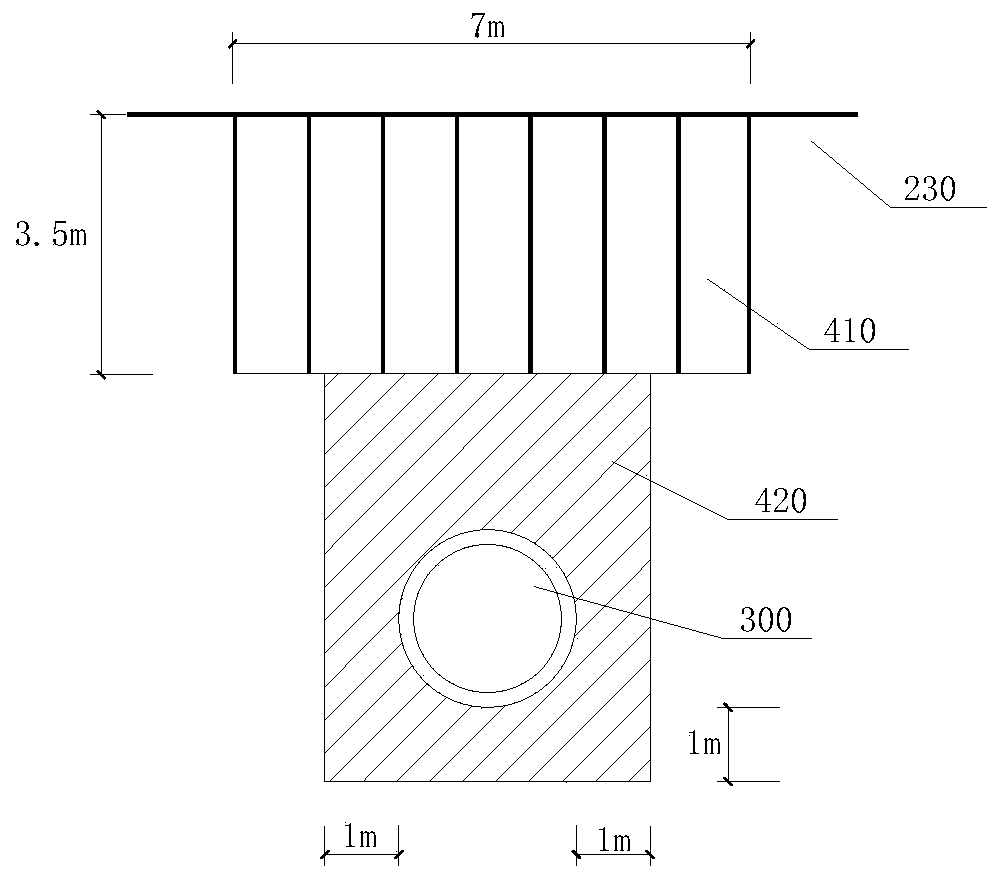

Mud water balance shield tunnelling machine and pipe jacking tunnelling construction method by applying mud water balance shield tunnelling machine

The invention discloses a mud water balance shield tunnelling machine. The mud water balance shield tunnelling machine comprises a rotatable cutter disc and a cutting mechanism, wherein the cutter disc is provided with a conical surface with the cross section decreasing gradually and a propulsion surface, and the propulsion surface is provided with a material inlet; and the cutting mechanism comprises a first cutting component and a second cutting component, the first cutting component comprises cutters arranged on the cutter disc, the cutters comprise hobbing cutters and scraping cutters, thehobbing cutters comprise the first hobbing cutters distributed on the propulsion surface and the second hobbing cutters circularly distributed on the conical surface, the scraping cutters comprise the first scraping cutters distributed to the material inlet, the second scraping cutters distributed on the propulsion surface and the third scraping cutters circularly distributed on the conical surface, and the second cutting component comprises twist legs which support the cutter disc and rotate and a disc body which forms a crushing gap with the twist legs. According to the mud water balance shield tunnelling machine and a pipe jacking tunnelling construction method by applying the mud water balance shield tunnelling machine, crushed stone obtained by cutter crushing (primary crushing) canenter a crushing bin from the material inlet and further enter the crushing gap to be subjected to secondary crushing under mutual rotational shearing between the twist legs and the disc body.

Owner:成都建工第二建筑工程有限公司

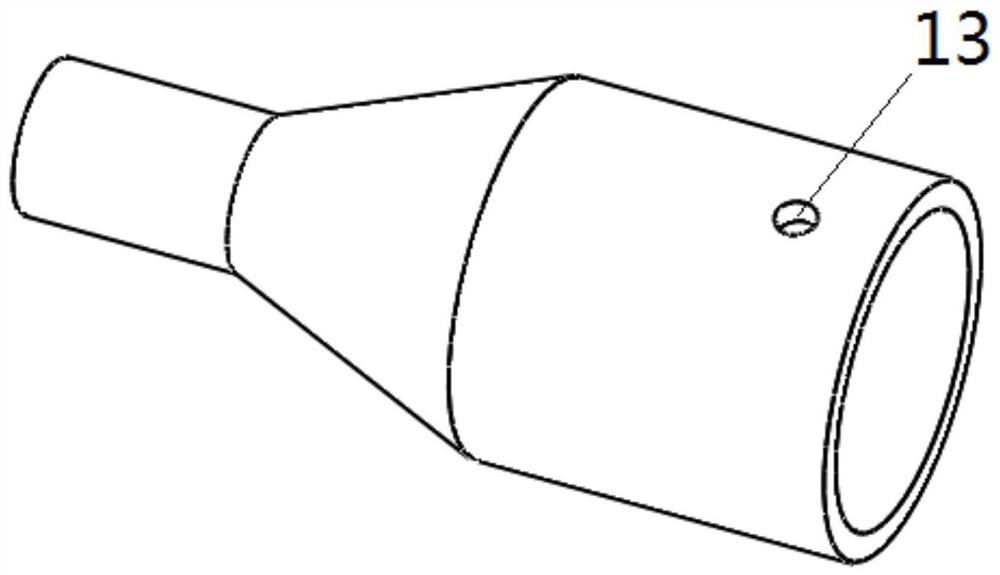

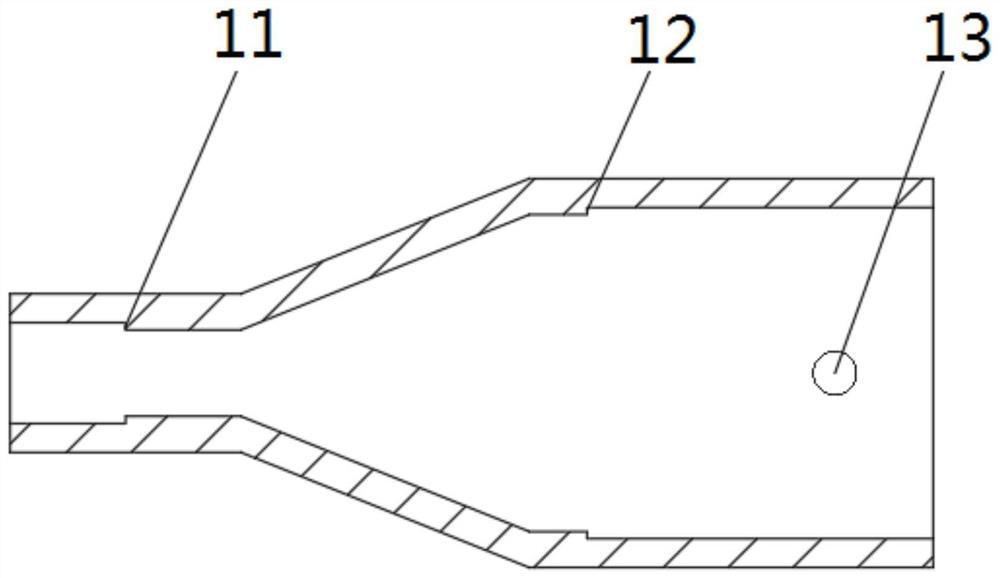

Rotary shearing cavitation nozzle

ActiveCN113333191AIncrease in sizeImprove cavitation effectMovable spraying apparatusCleaning using liquidsElectric machineryEngineering

The invention provides a rotary shearing cavitation nozzle, and belongs to the technical field of water jets. The rotary shearing cavitation nozzle comprises a nozzle main body, a first support, a second support, a central body, a rotary shearing cylinder, a driving motor and a universal shaft; the nozzle main body is of a hollow rotating body structure, and the inner diameter of the water inlet end is larger than that of the water outlet end; the first support and the second support are oppositely and rotationally mounted in the nozzle main body, and the two ends of the central body are rotationally mounted on the first support and the second support respectively; the central body is sleeved with the rotary shearing cylinder, and the two ends of the rotary shearing cylinder are fixed to the first support and the second support respectively; the output end of the driving motor is connected with the input end of the universal shaft, and the output end of the universal shaft is connected with the second support. According to the nozzle, the outside of the central body of the central body type nozzle is coaxially sleeved with the rotary shearing cylinder, and the jet flow between the rotary shearing cylinder and the central body generates a speed gradient in the radial direction due to high-speed rotation of the rotary shearing cylinder, so that the maximum principal stress in liquid becomes tension, and the liquid is severely cavitated.

Owner:WUHAN UNIV

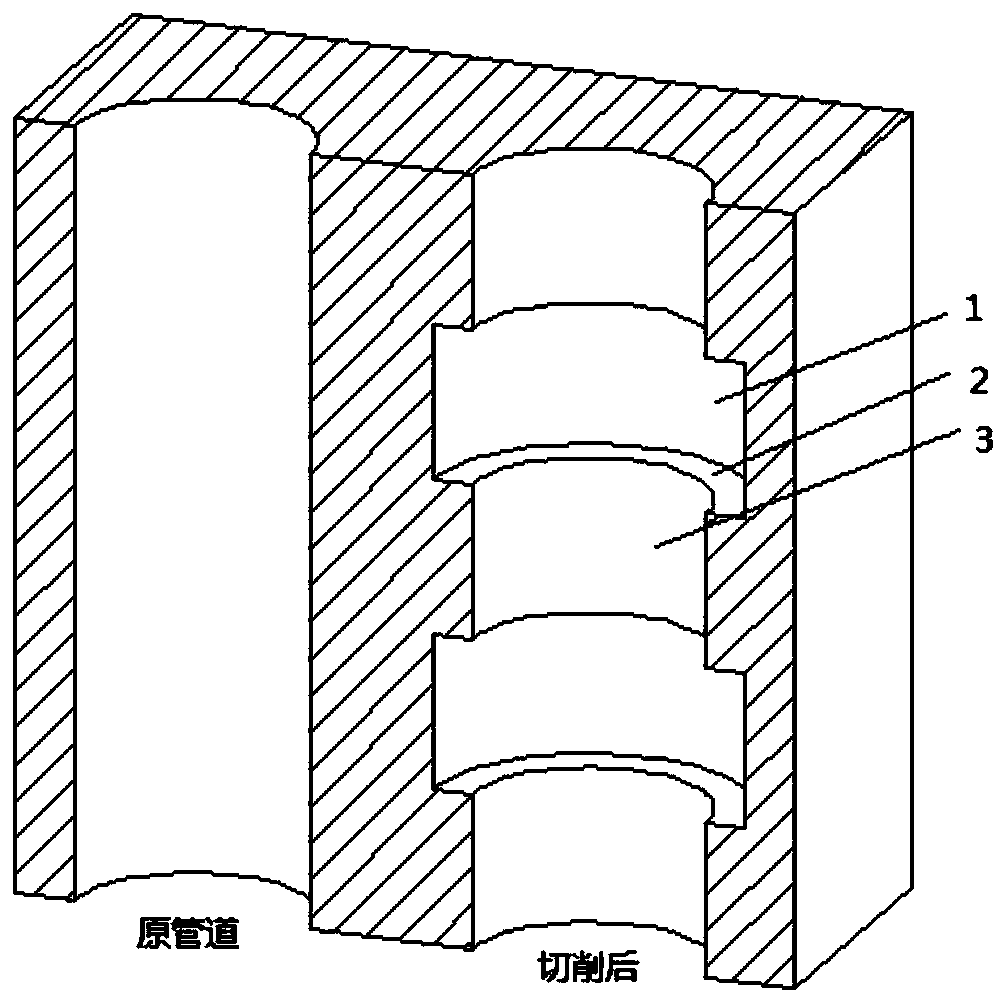

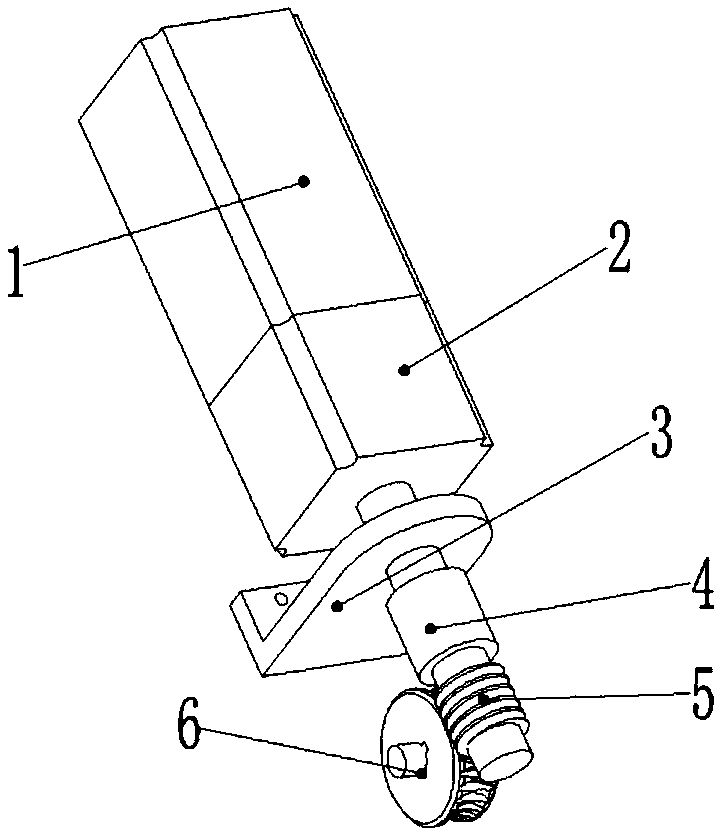

Progressive rotational shear feeding method and progressive rotational shearing machine

ActiveCN103386505ANo wasteNo out-of-round deformationShearing machinesShearing machine accessoriesEngineeringMechanical engineering

The invention discloses a progressive rotational shear feeding method and a progressive rotational shearing machine. The progressive rotational shearing machine comprises a clamping stationary knife for fixing a blank and a moving knife for shearing a feed section of the blank, and is characterized in that the clamping force of the clamping stationary knife and the moving knife is radial, and two or more than two stressed parts are availableand centrosymmetric; and the moving knife is sleeved in a dual-crankshaft mechanism or a flywheel slider mechanism, the dual-crankshaft mechanism or the flywheel slider mechanism drives the moving knife to rotate the feed section of the blank by 360 degrees and progressively shear the feed section along the radial direction. The progressive rotational shear feeding method solves the problems of the conventional cutting feeding method and shear feeding method; and the invention has the advantages that the efficiency is high, the waste of raw materials is avoided, the cost is low, the cut is flat without bevel angles or collapsed corners, the blank is not deformed, the blank with the extremely small draw ratio can be cut off, pipes and sections can be cut off and the like.

Owner:四川名钺机械设备制造有限公司

METHOD FOR FORMING HOLLOW PROFILE NON-CIRCULAR EXTRUSIONS USING SHEAR ASSISTED PROCESSING AND EXTRUSION (ShAPE)

PendingCN112512710AImprove mechanical propertiesReduce manufacturing costExtrusion diesExtrusion mandrelsEnergy absorptionPlasticulture

A process for forming extruded products using a device having a scroll face configured to apply a rotational shearing force and an axial extrusion force to the same preselected location on material wherein a combination of the rotational shearing force and the axial extrusion force upon the same location cause a portion of the material to plasticize, flow and recombine in desired configurations. This process provides for a significant number of advantages and industrial applications, including but not limited to extruding tubes used for vehicle components with 50 to 100 percent greater ductility and energy absorption over conventional extrusion technologies, while dramatically reducing manufacturing costs.

Owner:BATTELLE MEMORIAL INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com