Patents

Literature

43 results about "Thin film flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

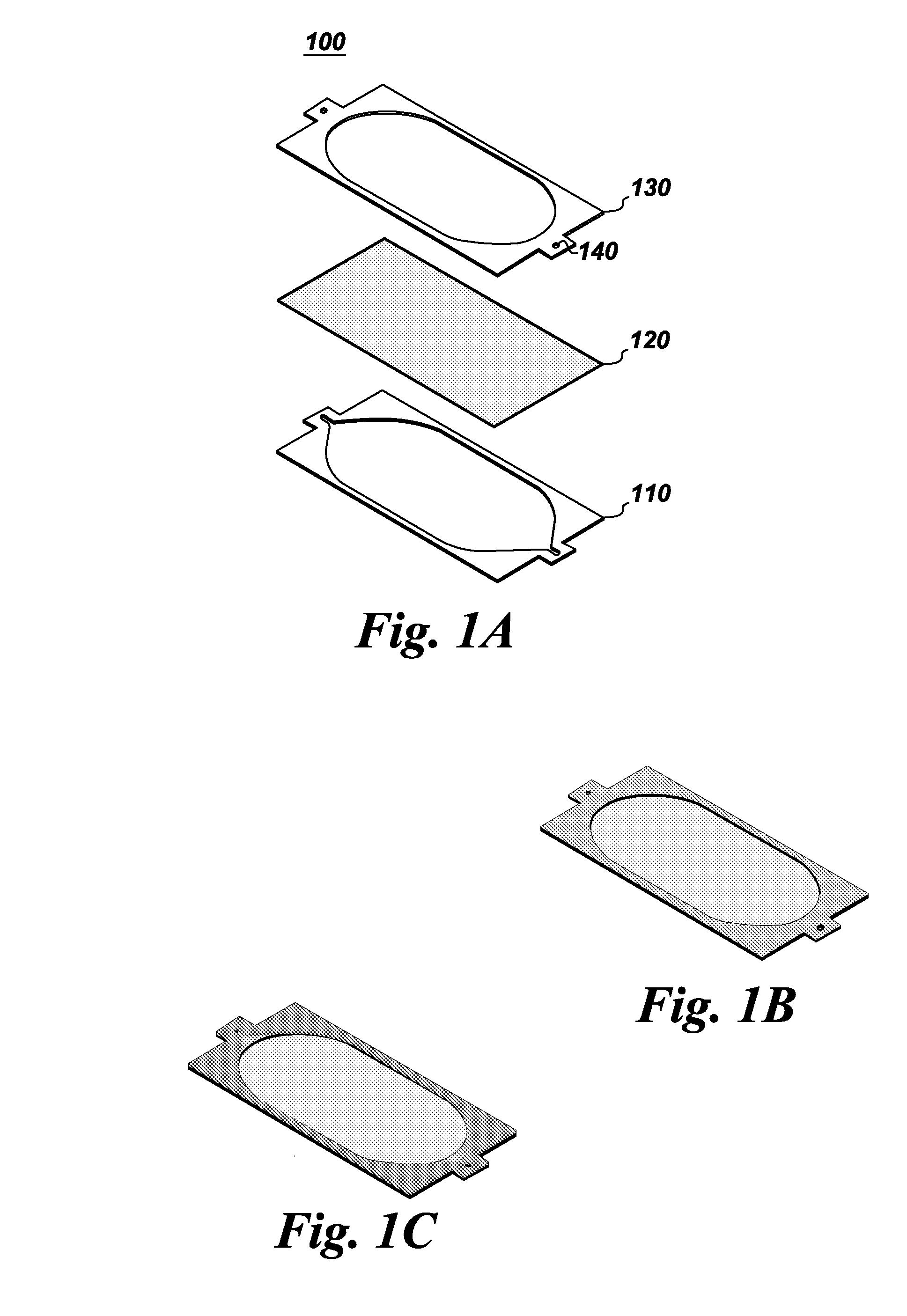

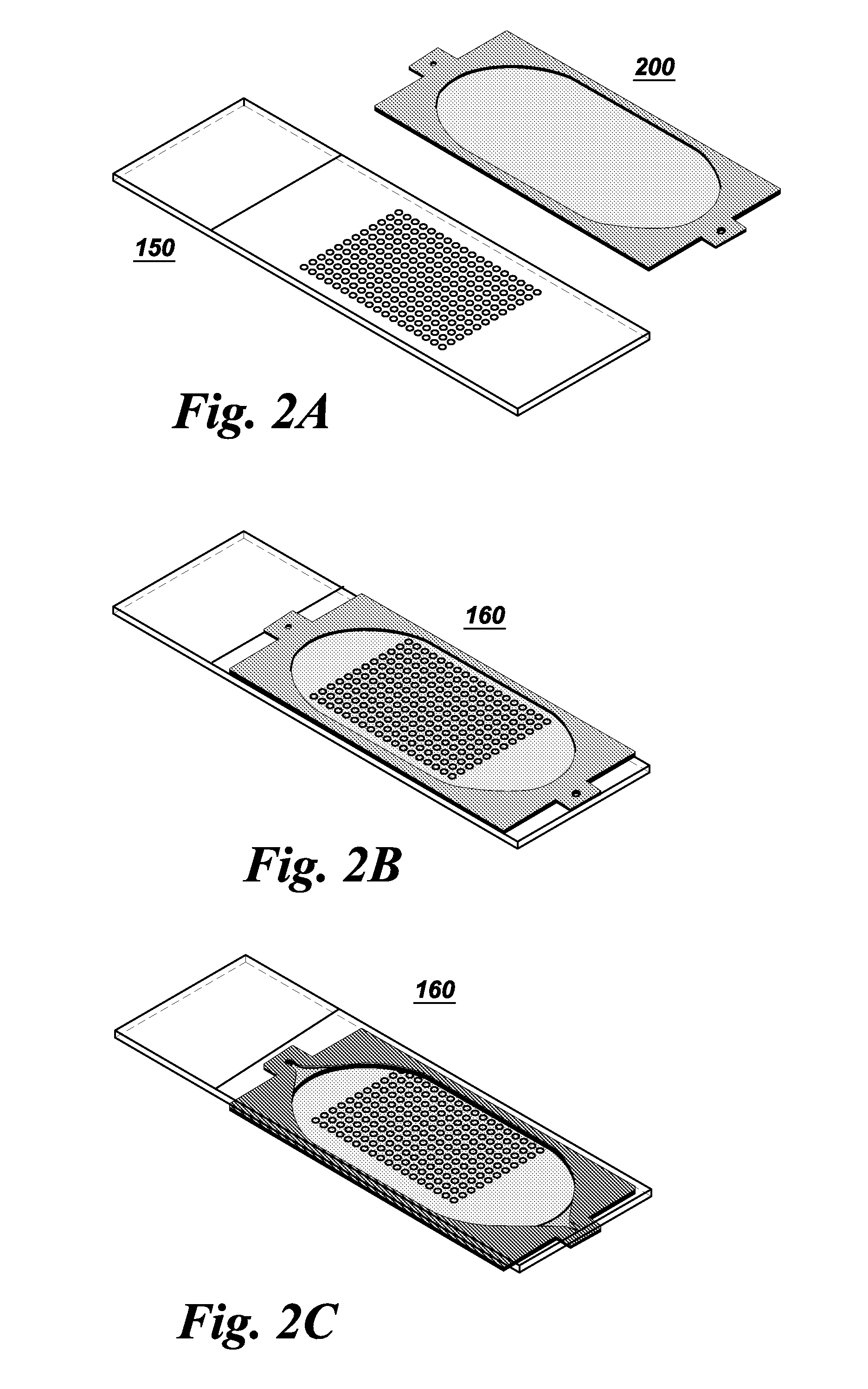

Microfluidic flow cell assemblies and method of use

ActiveUS20140248618A1Wide rangeBioreactor/fermenter combinationsBiological substance pretreatmentsStainingFlow cell

A microfluidic flow cell subassembly, which may be assembled into a flow cell having fluidic connections outside of the main substrate, is described for encapsulating a sample to allow for subsequent controlled delivery of reagents to the sample, such as multiplexed in situ biomarker staining and analysis. The fluidic connectors are thin film fluidic connectors capable of connecting to a fluid delivery system. The subassembly may be sealed against a solid support to form a flow cell. Methods of use are also disclosed.

Owner:LEICA MICROSYSTEMS CMS GMBH

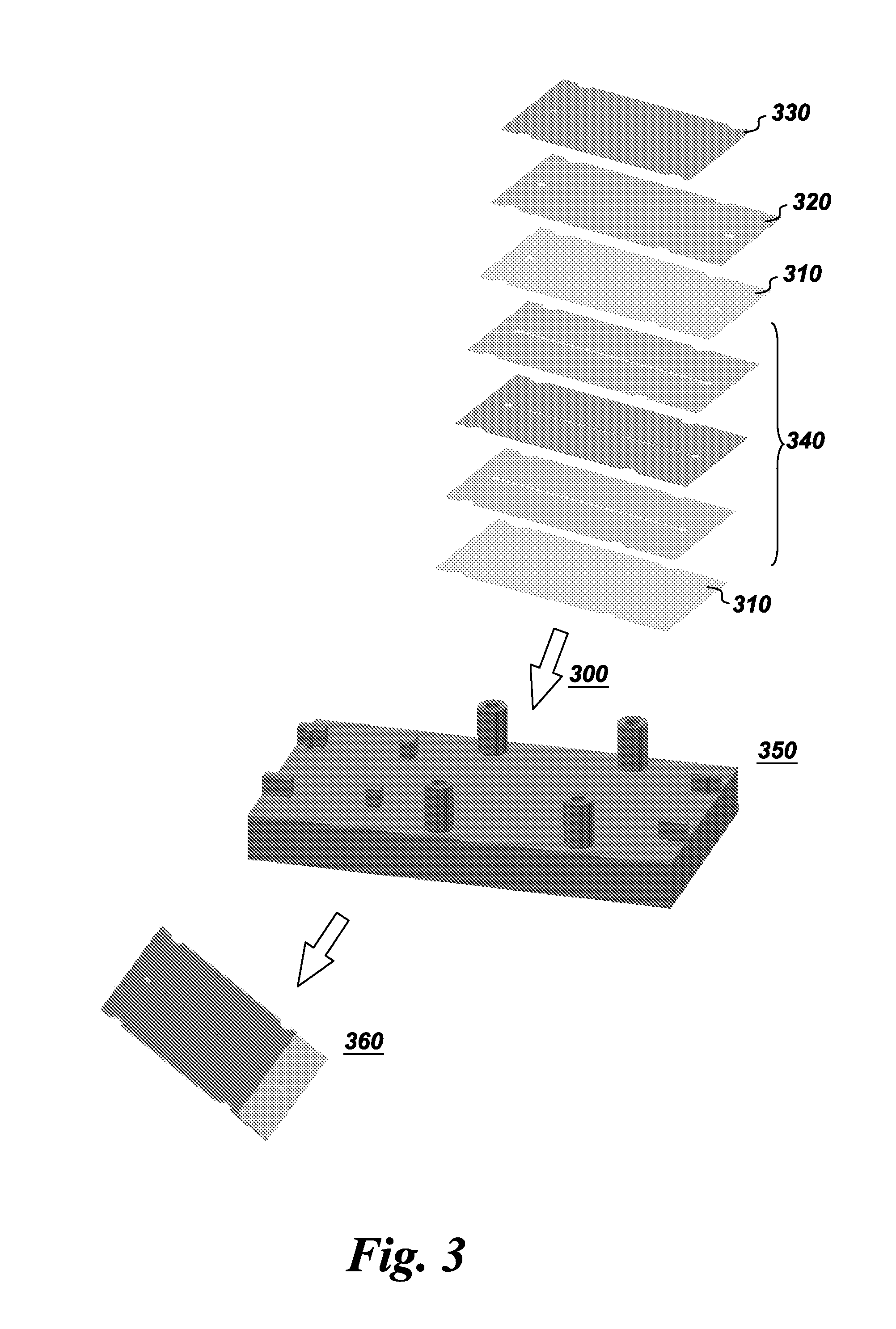

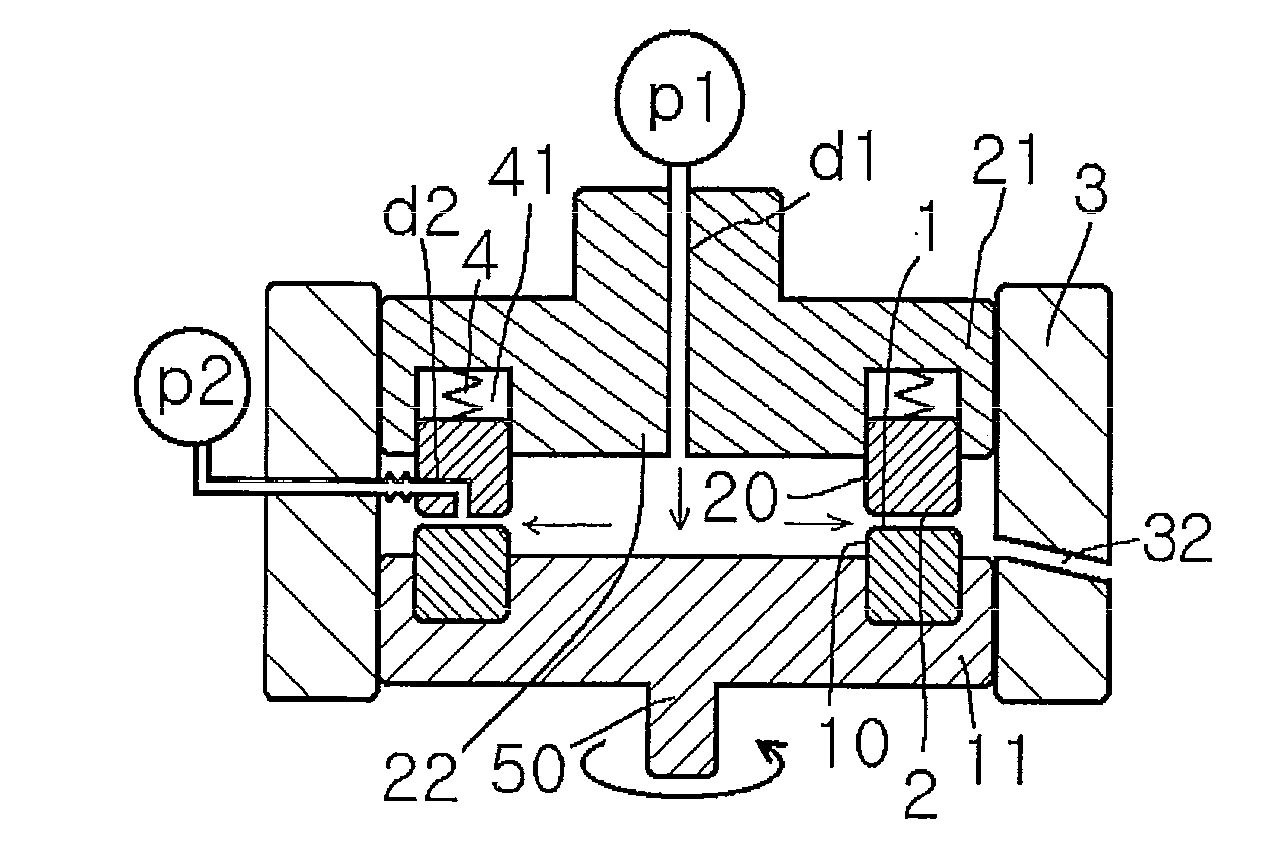

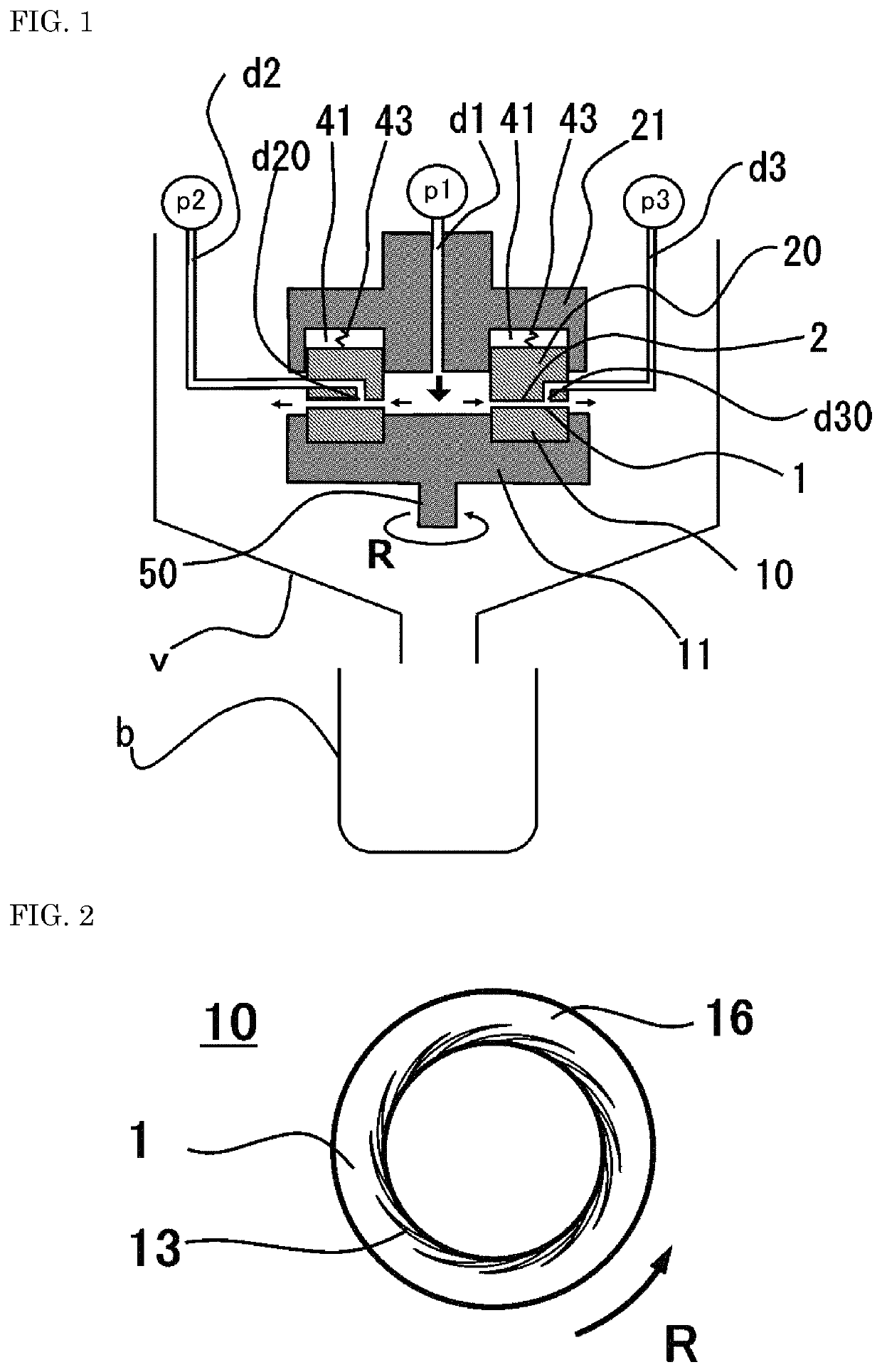

Method for producing microparticles and the microparticles

ActiveUS20100215958A1Good redispersibilityLow costPowder deliveryAntiviralsProduction rateEngineering

It is an object of the present invention to provide a method for producing microparticles, which can produce monodispersed microparticles, causes no clogging with a product due to self-dischargeability, requires no great pressure, and is excellent in productivity, wherein a fluid in which at least one kind of microparticle materials is dissolved is introduced between two processing surfaces arranged to be opposite to each other to be able to approach to and separate from each other, at least one of which rotates relative to the other, to be formed into a thin film fluid, and the thin film fluid is cooled or heated (warmed) to allow saturation solubility to change, thereby separating microparticles.

Owner:M TECHN

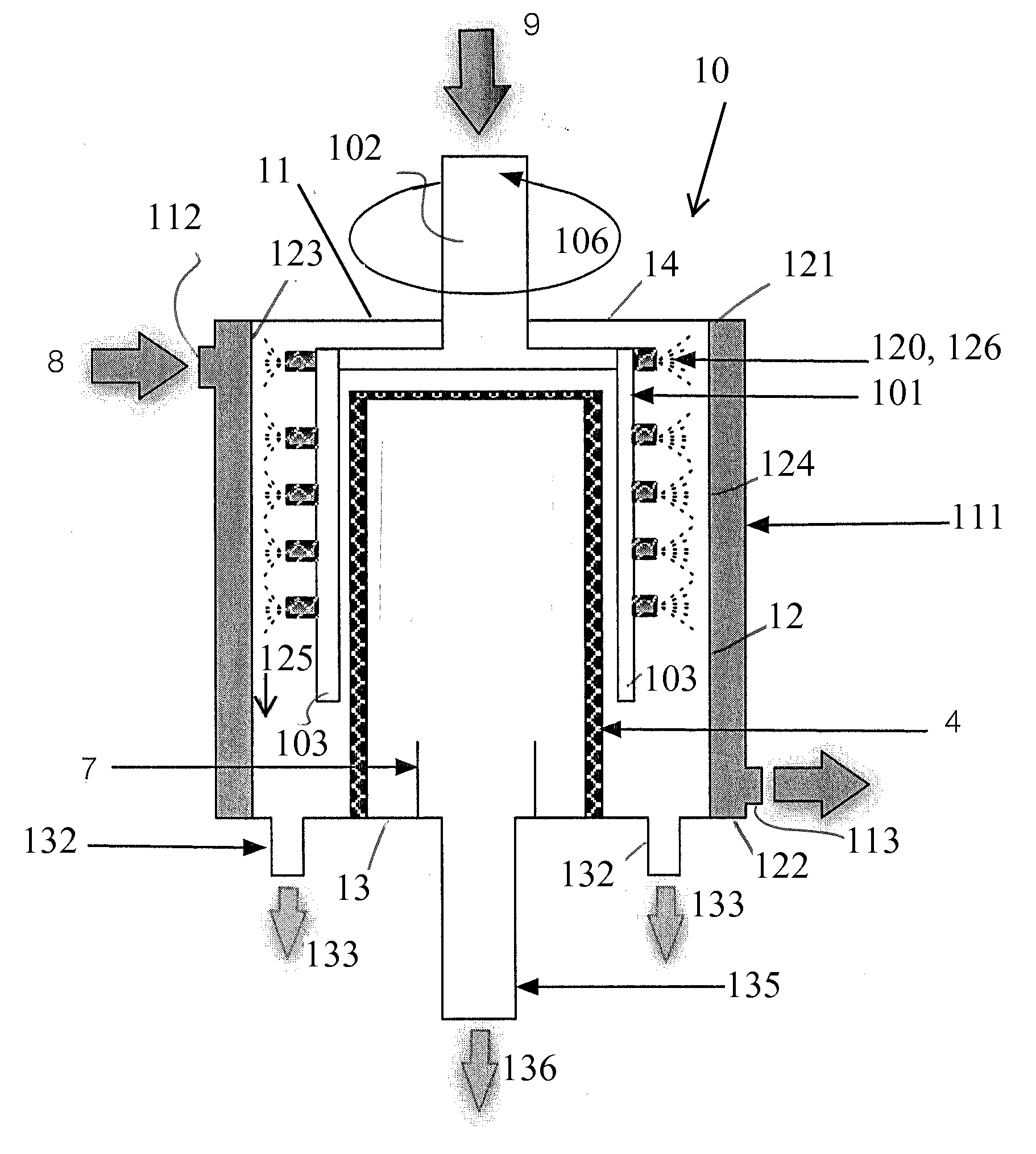

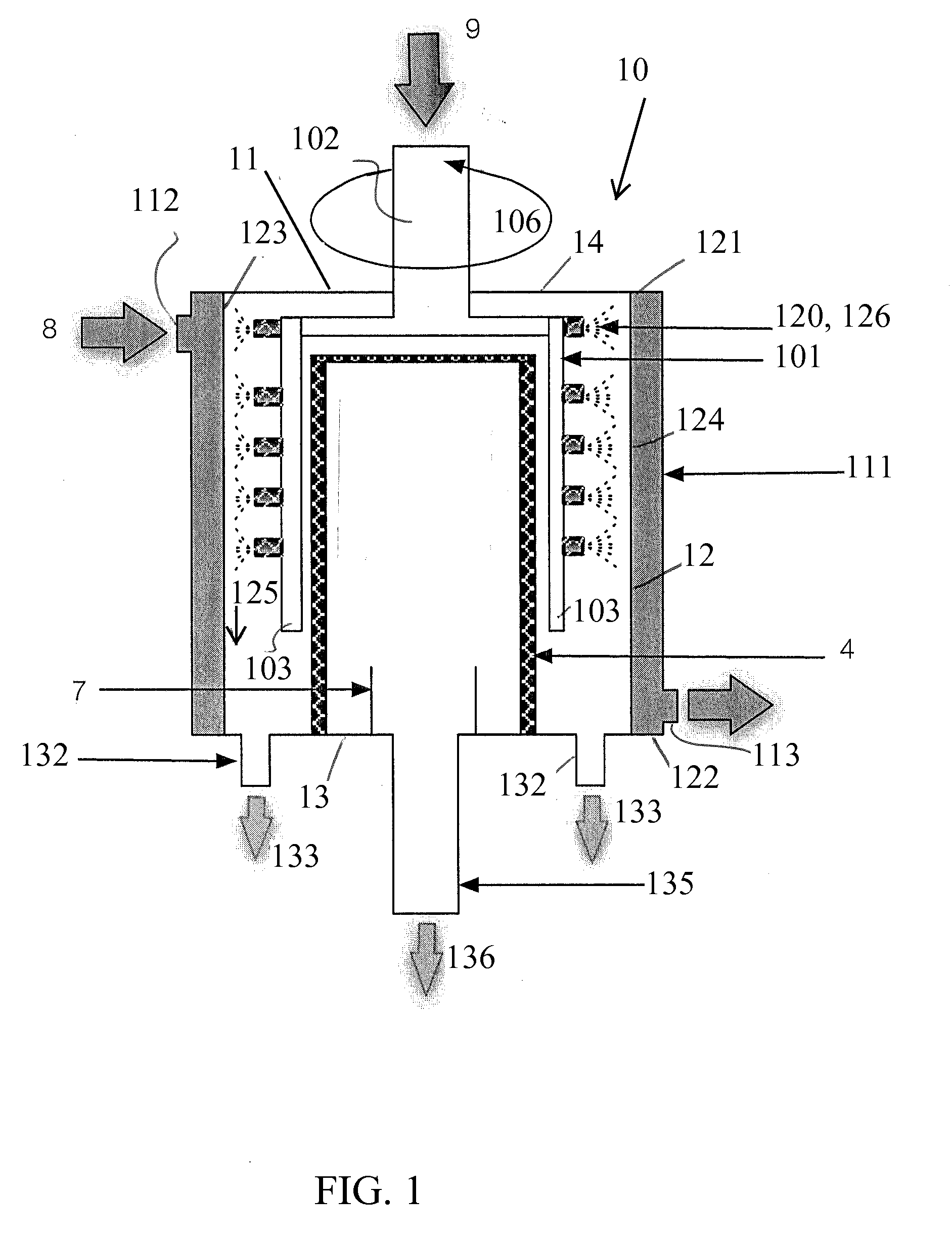

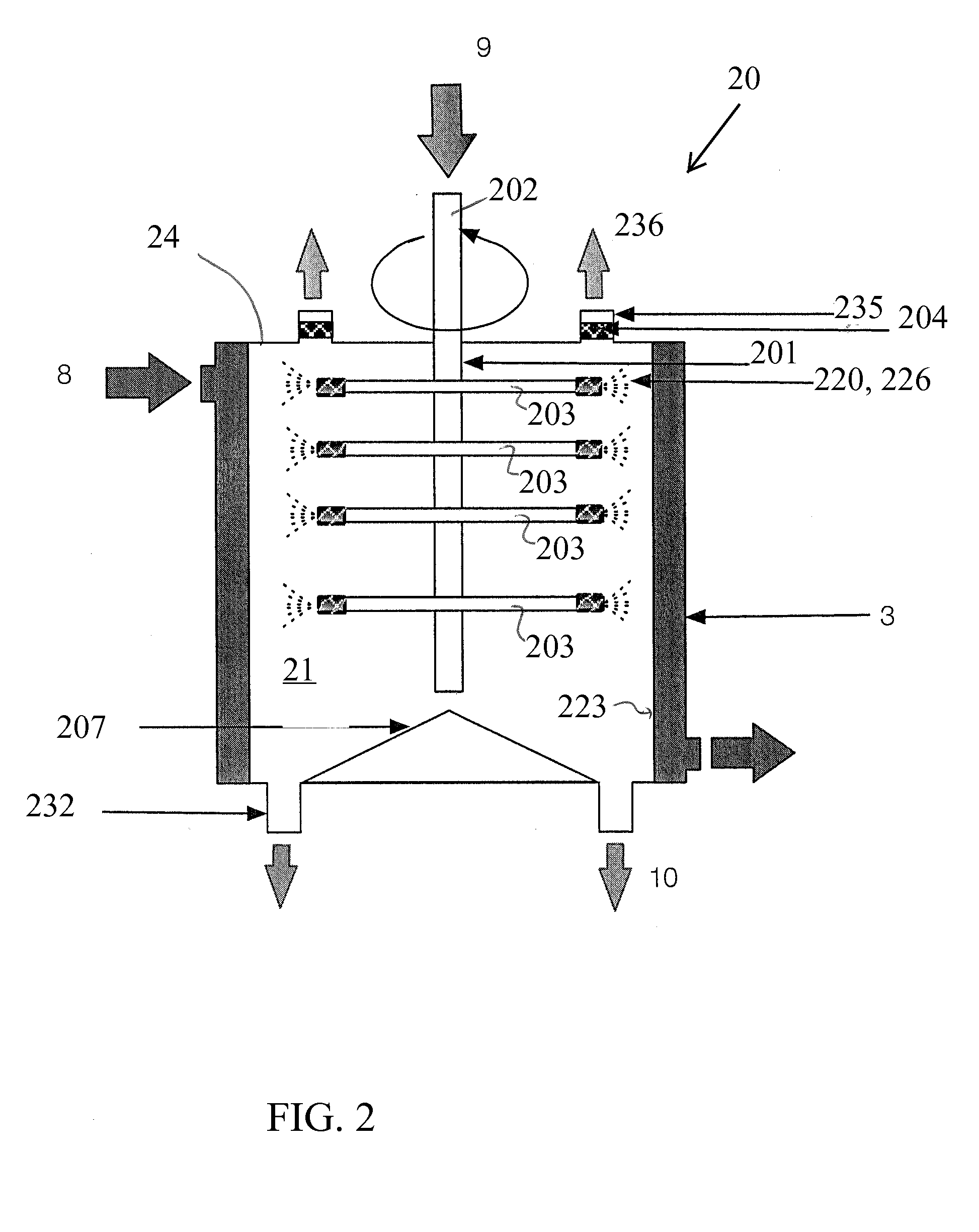

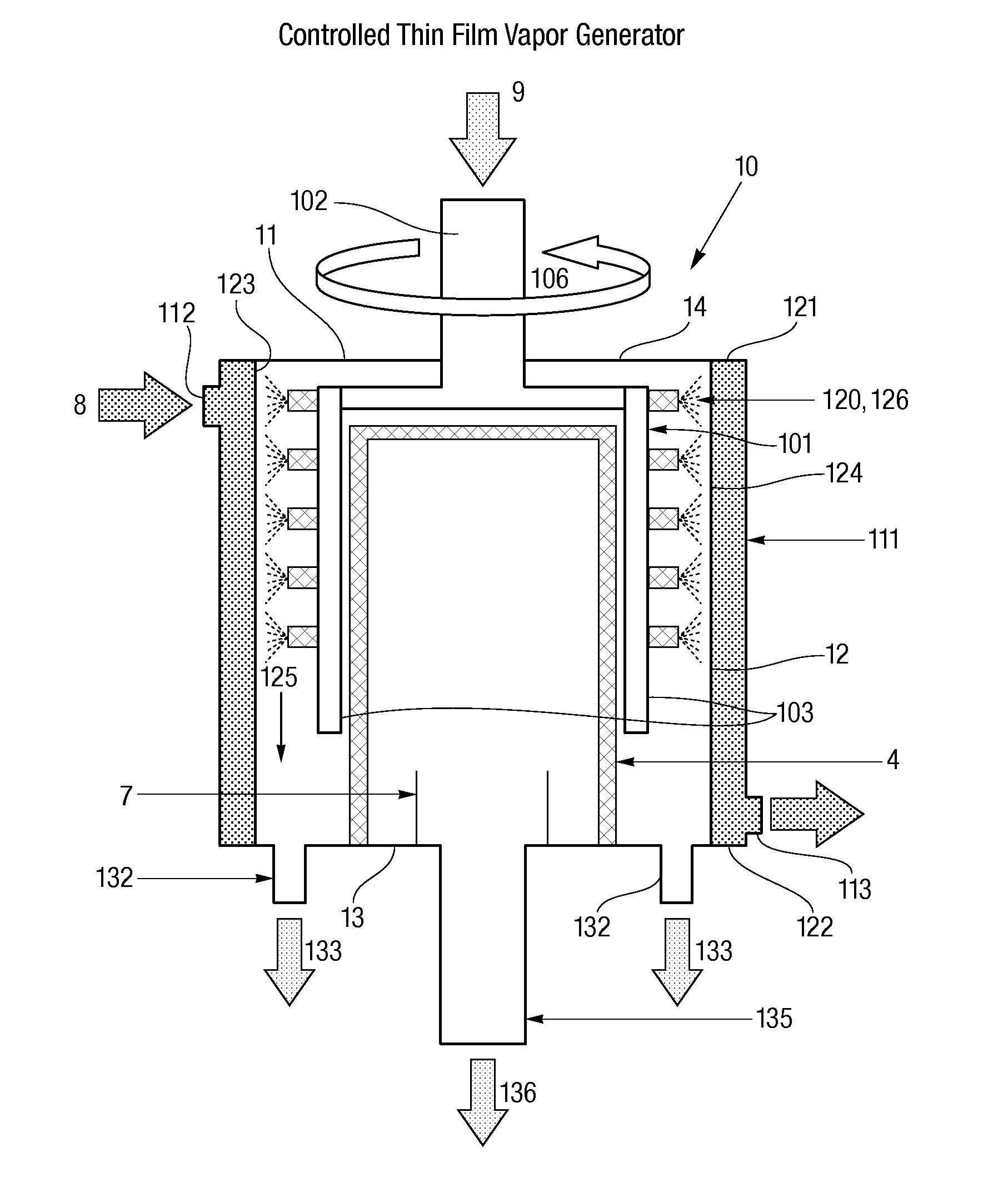

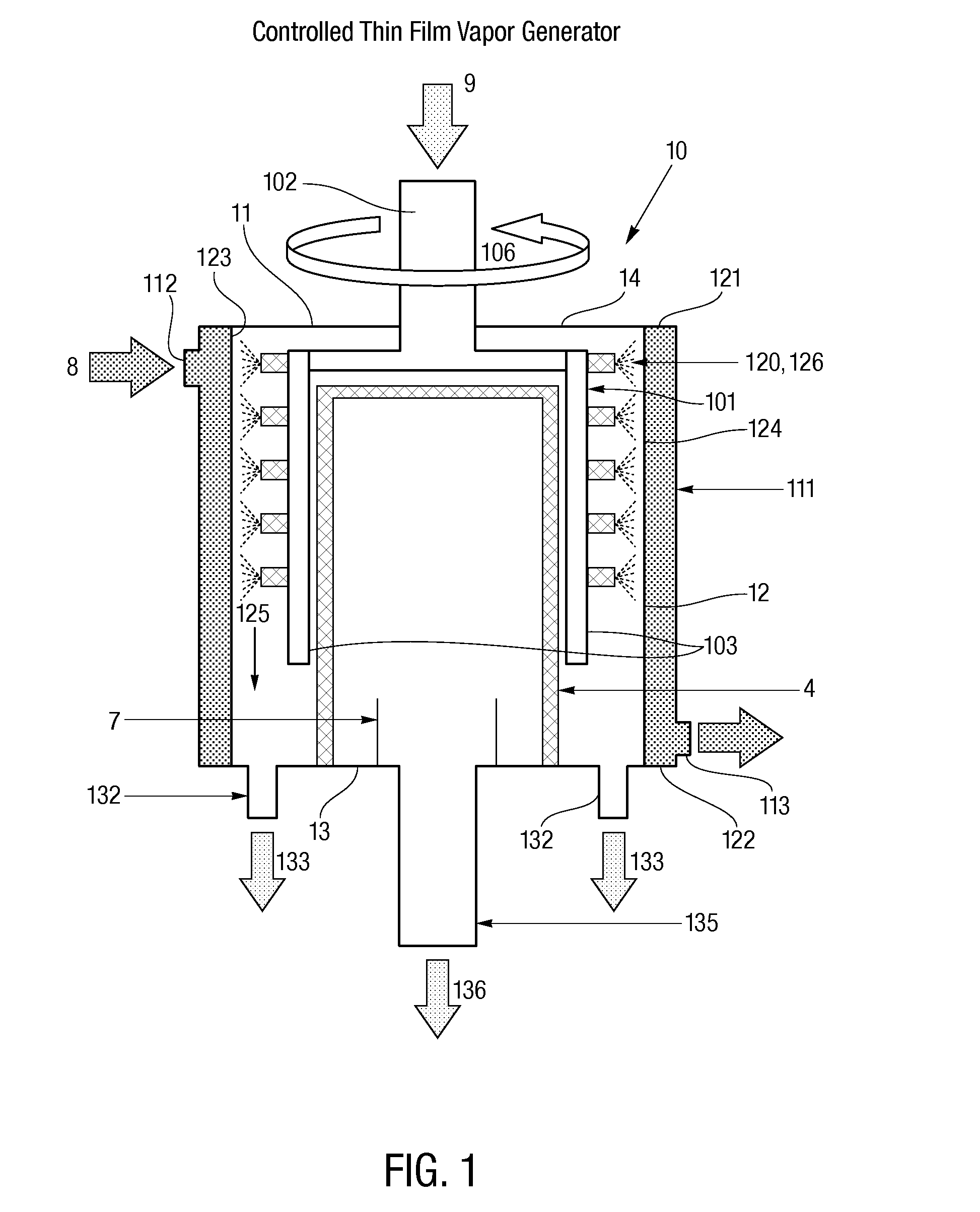

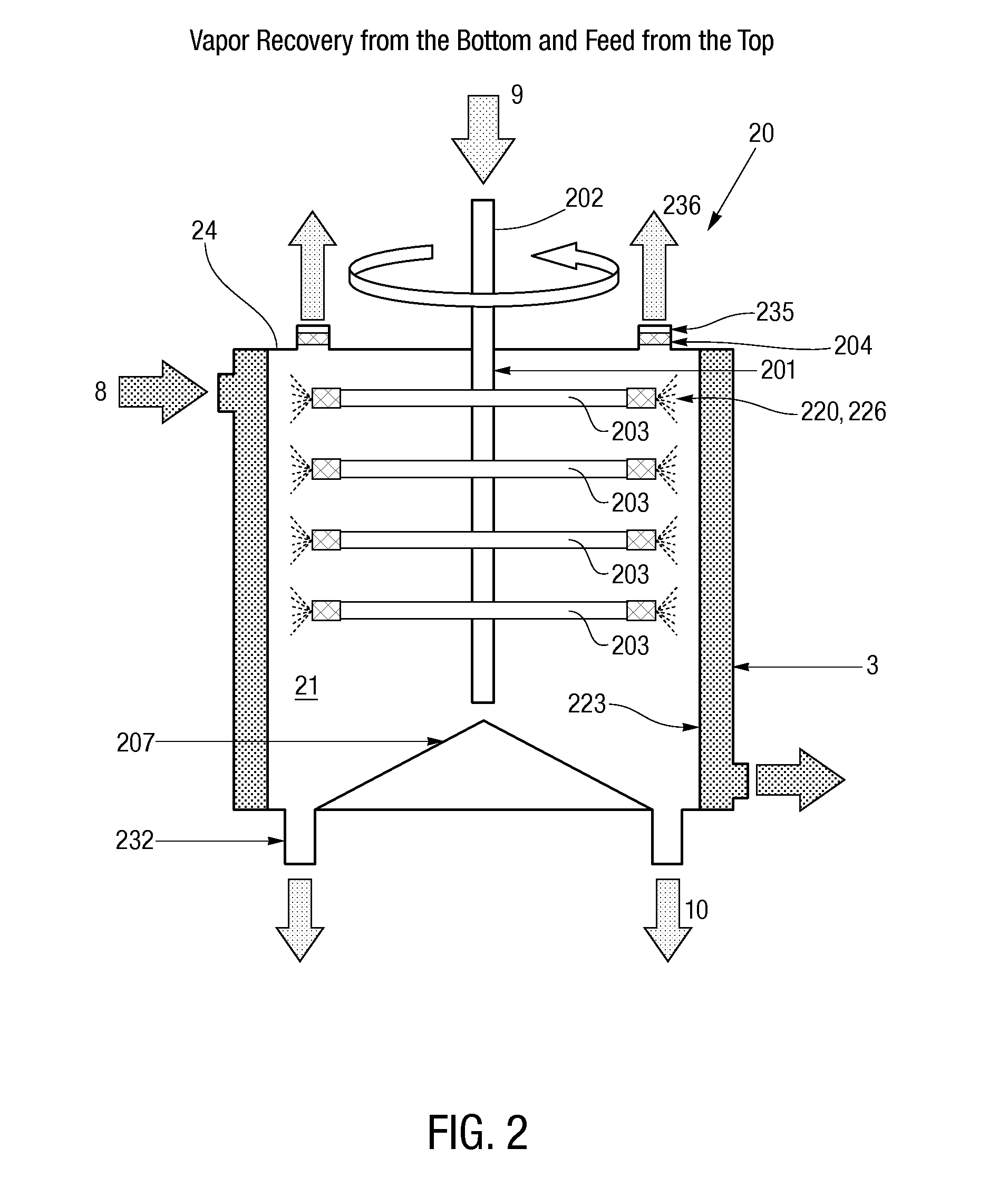

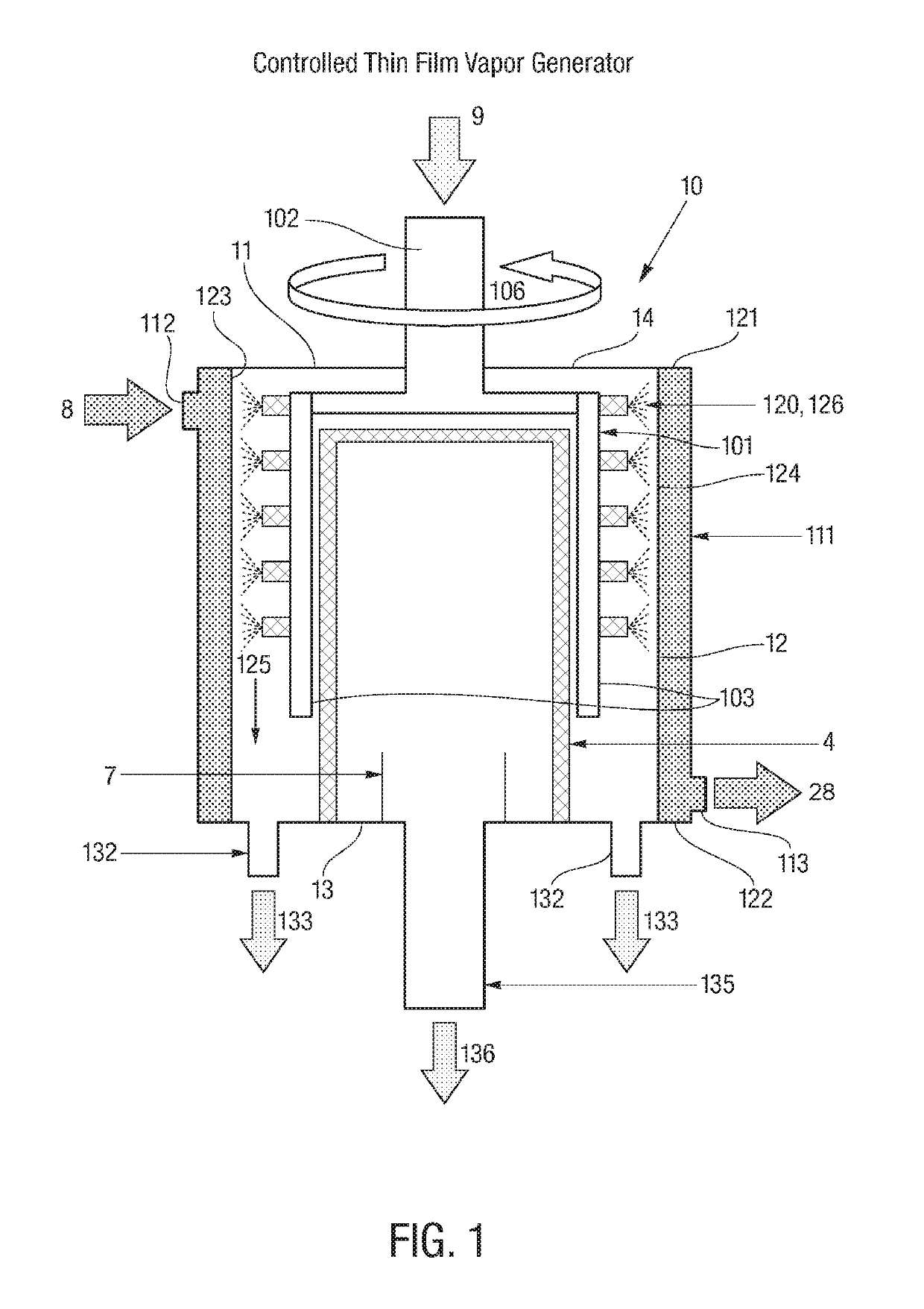

Controlled Thin Film Vapor Generator for Liquid Volume Reduction

InactiveUS20140367244A1Minimize energy consumptionIncrease heatWaste water treatment from quariesAuxillariesFirst pathwayControl manner

A reactor comprising a vessel; a fluid dispensing system having a plurality of ports arranged lengthwise along the inner surface of the vessel to distribute the fluid thereon in a controlled manner to maintain substantially uniform thin film flow along the length of the inner surface; and an outlet for removing vapor. A system comprising a fluid source; a first vessel; a heat exchanger for preheating the fluid; a first pathway for directing a preheating fluid from the first vessel to the heat exchanger; and a second pathway for directing preheated fluid toward the first vessel for processing. A method comprising introducing a fluid; distributing the fluid in a controlled manner to form a substantially uniform thin film flow an inner surface of a vessel; evaporating fluid; and removing vapor. A method comprising introducing a fluid; processing the fluid; directing processed fluid into another vessel; and further processing the fluid.

Owner:R3 FUSION

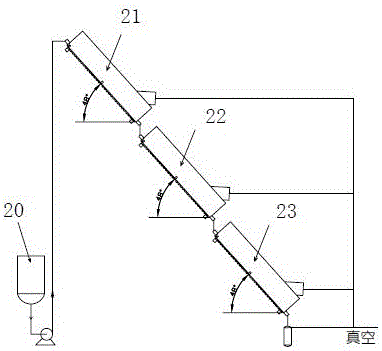

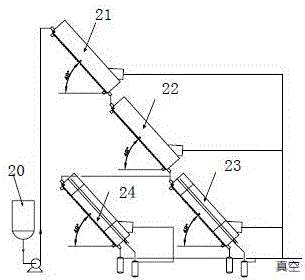

Continuous growth method of thin films at high temperature and under vacuum conditions

The invention belongs to the field of thin film growth or thin film preparation, and particularly relates to the fields or similar devices of thin film preparation performed by using methods of deposition or jet plating and the like on a substrate. The invention provides a continuous growth method of thin films at a high temperature and under vacuum conditions, which solves the problem of prolonging the growth cycle caused by long air sucking and release time and slow heating / cooling speed and the like when thin films grow in a single cavity. When a batch of thin films flows out of the final end of a three-cavity assembly line, a batch of substrates flows in the initial end of the assembly line to carry out thin film growth, thereby avoiding the time consumption and energy consumption for repeated air sucking and release and heating / cooling. In addition, the size of a stainless steel cavity used in the invention is easily expanded, so that the stainless steel cavity can accommodate large-sized and multi-layered substrates, thereby greatly improving the output of thin films growing in a single batch.

Owner:CHANGZHOU TANWEI NANO TECH

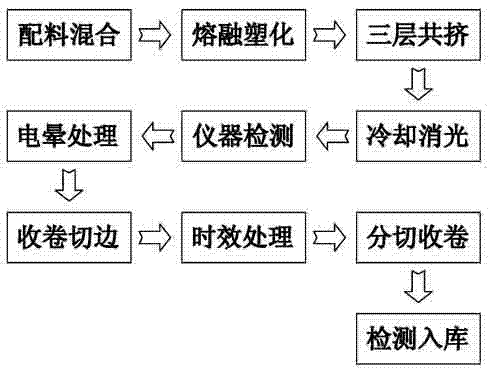

Low-gram-weight and high-performance PE (Poly Ethylene) embossing film and manufacturing technology thereof

ActiveCN103481610AReduce coefficient of frictionEliminate adhesionSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

A low-gram-weight and high-performance PE embossing film is characterized in that the embossing film comprises three layers of films formed through co-extrusion; the surface of the embossing film is subjected to corona treatment; the components and the weight percentage of the three film layers are as follows: a first layer comprises the components in percentage by weight as follows: 85%-95% of m LLDPE (linear low density polyethylene) and 5%-15% of color masterbatch; a second layer comprises the components in percentage by weight as follows: 85%-95% of HDPE (high-density polyethylene) and 5%-15% of color masterbatch; and a third layer comprises the components in percentage by weight as follows: 83%-93% of LDPE (low-density polyethylene), 5%-15% of color masterbatch and 1%-2% of a slipping agent. According to the low-gram-weight and high-performance PE embossing film, the material of the slipping agent in a certain proportion is added to the formula and subjected to co-mixing with the LDPE, the friction coefficient of the film surface is reduced, the adhesion problem among films is eliminated, and the texture is more smooth; good co-mixing and plasticizing effects of the materials are guaranteed by the aid of a three-layer co-extrusion casting technology, and the problems that the co-mixing effect of a conventional single-layer co-extrusion technology is poor, and the plasticizing is not good are solved; and the die head gap is controlled through the system and the flow of a molten plastic fluid is controlled through a metering pump, so that the film casting stable linear extrusion is realized.

Owner:FOSHAN HUAHAN SANITARY MATERIAL

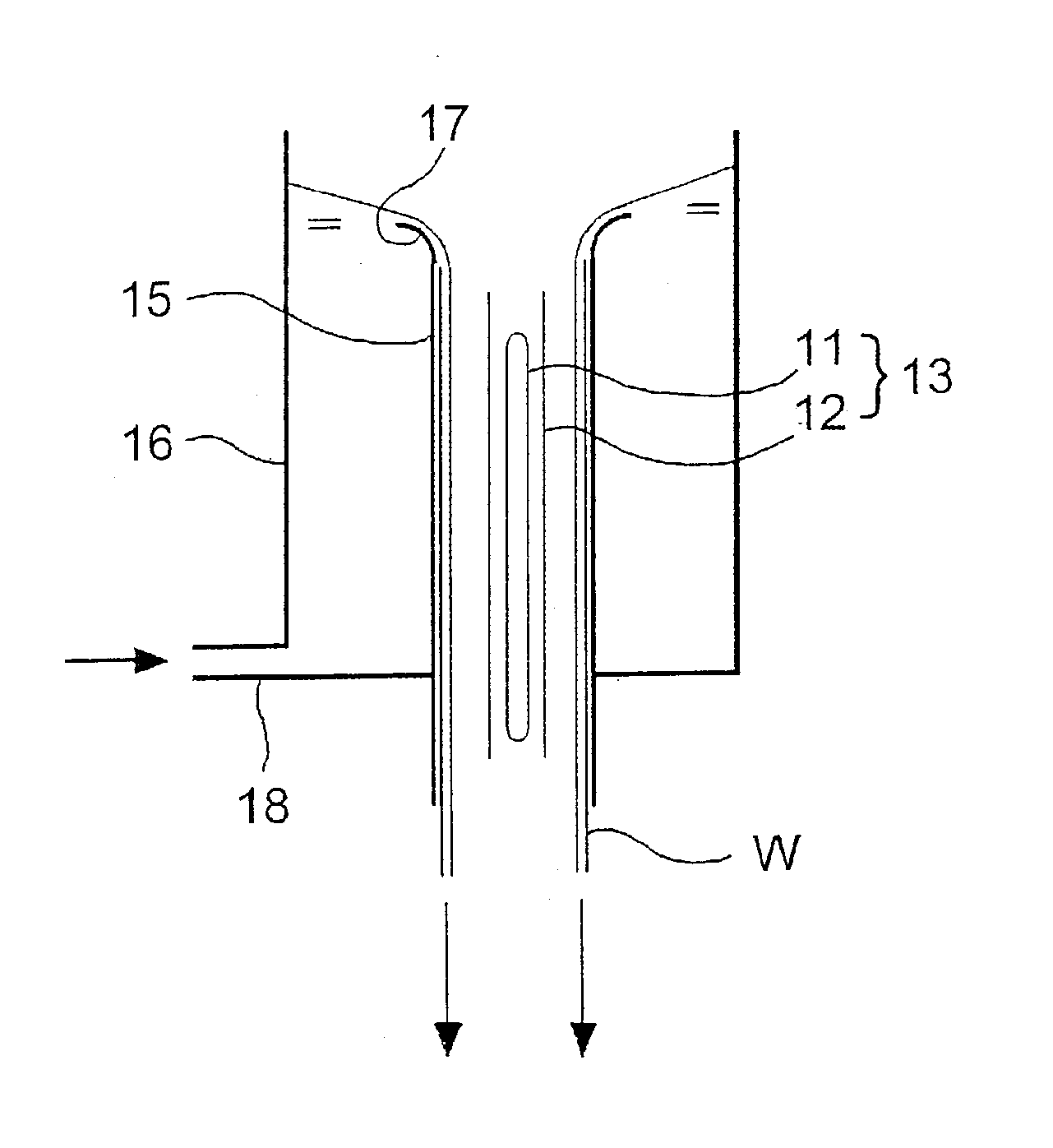

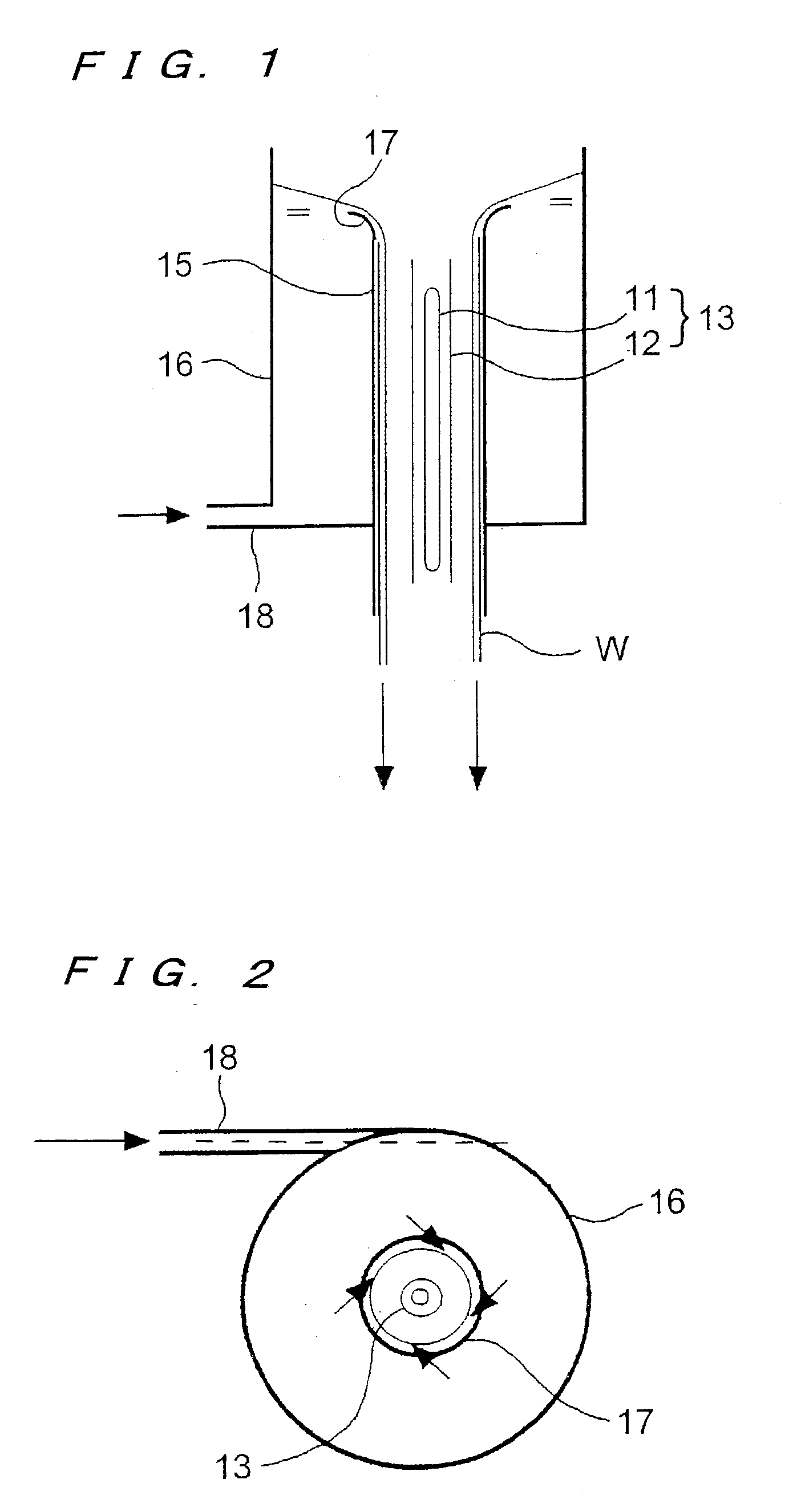

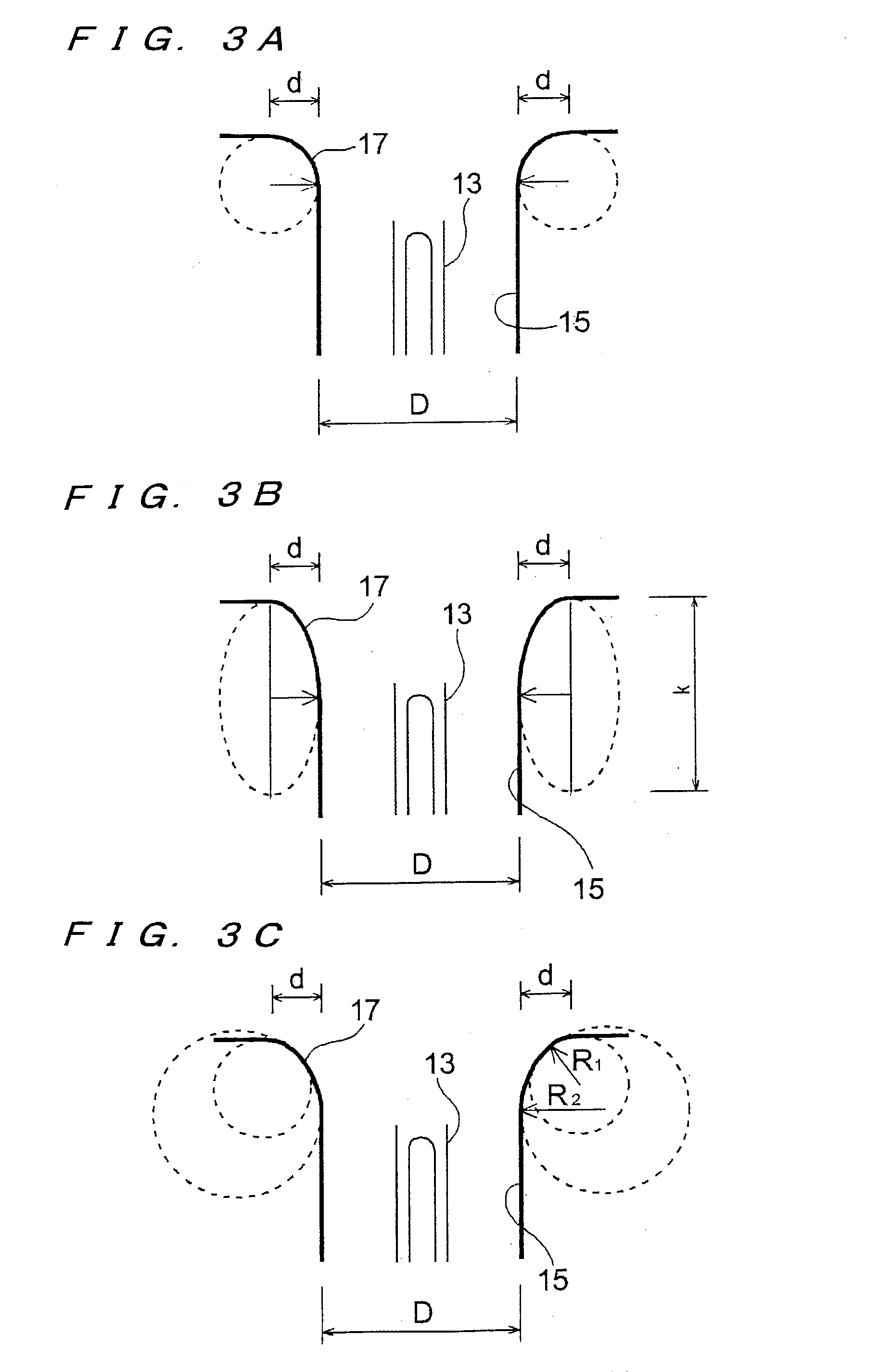

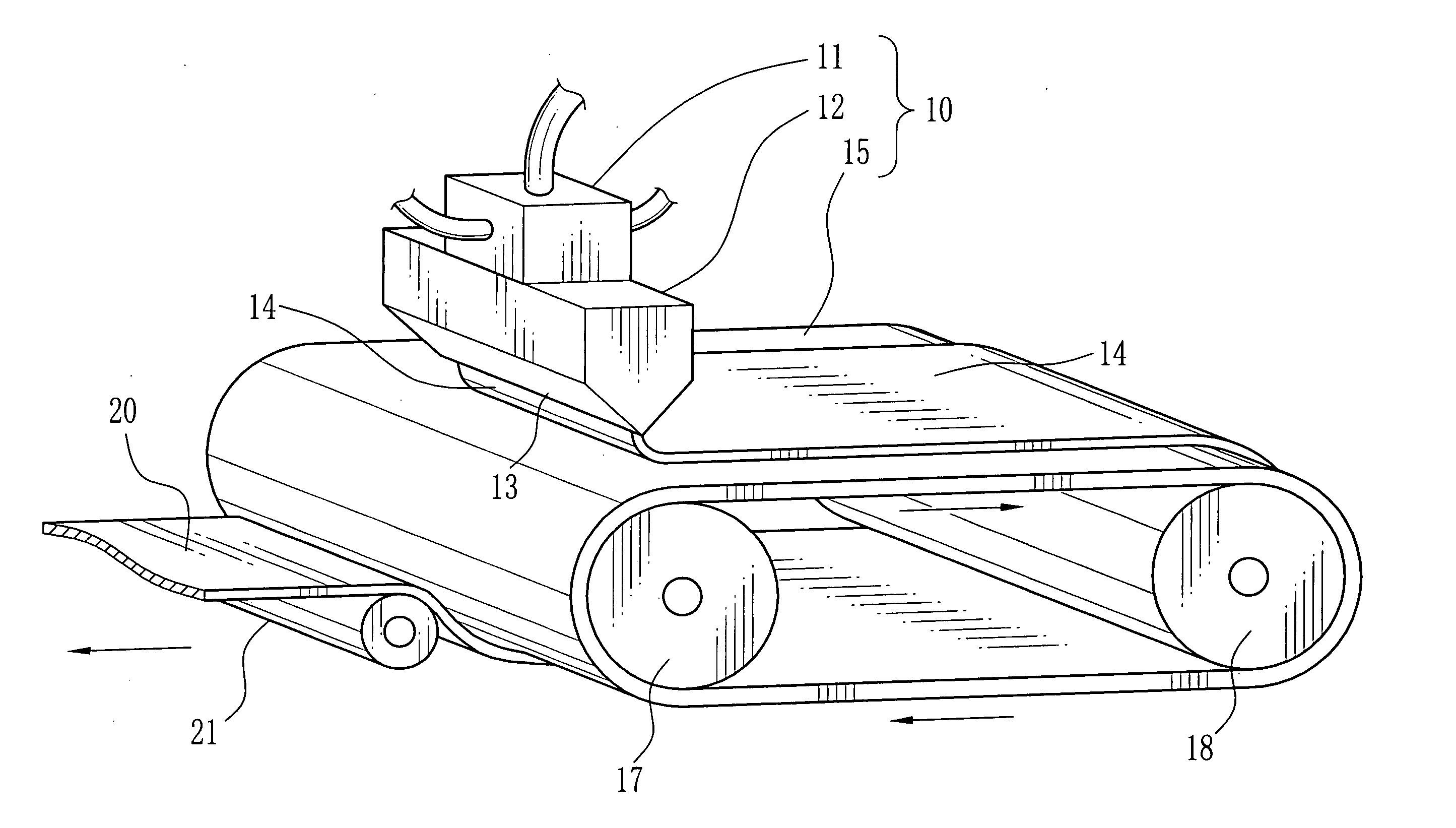

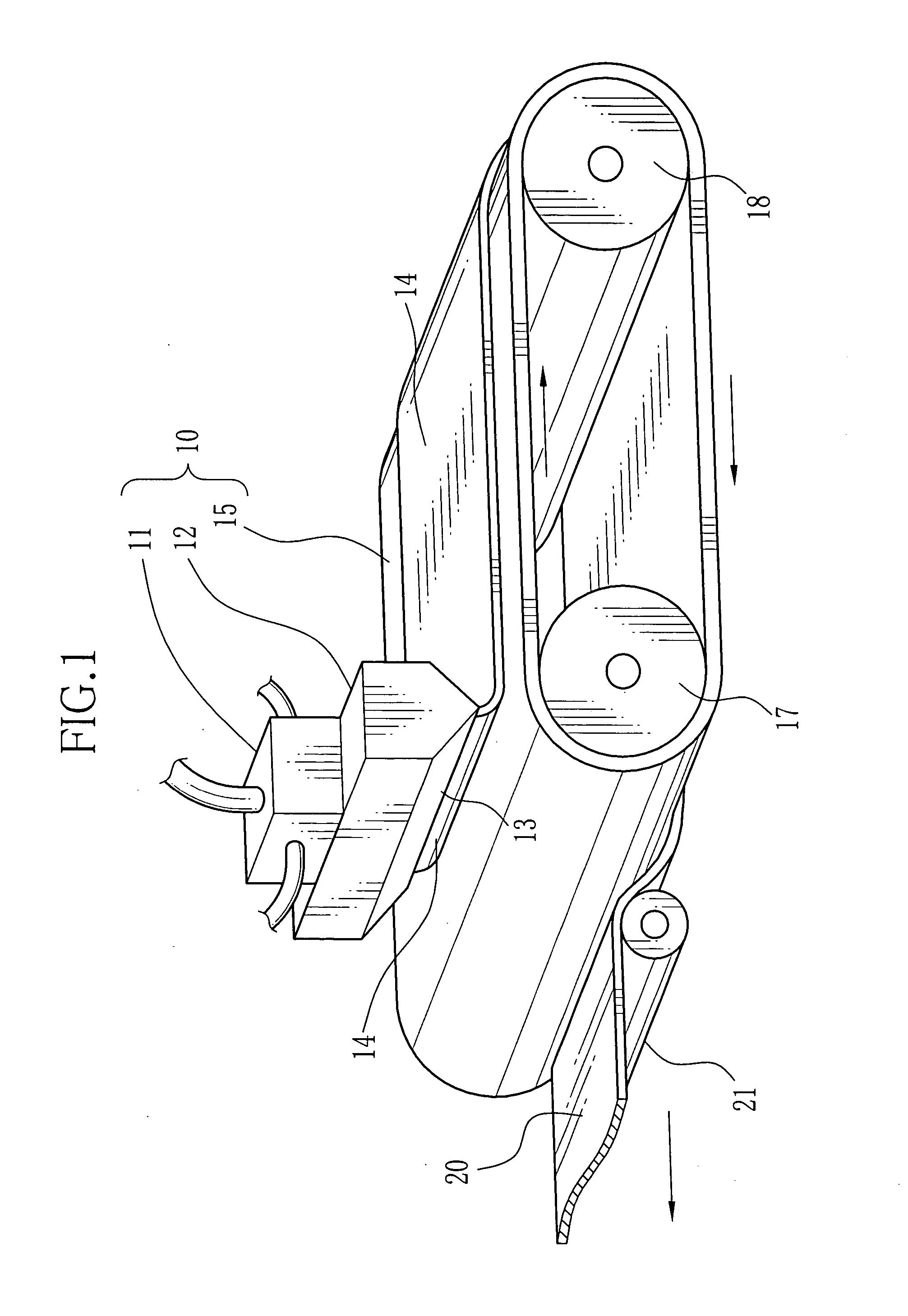

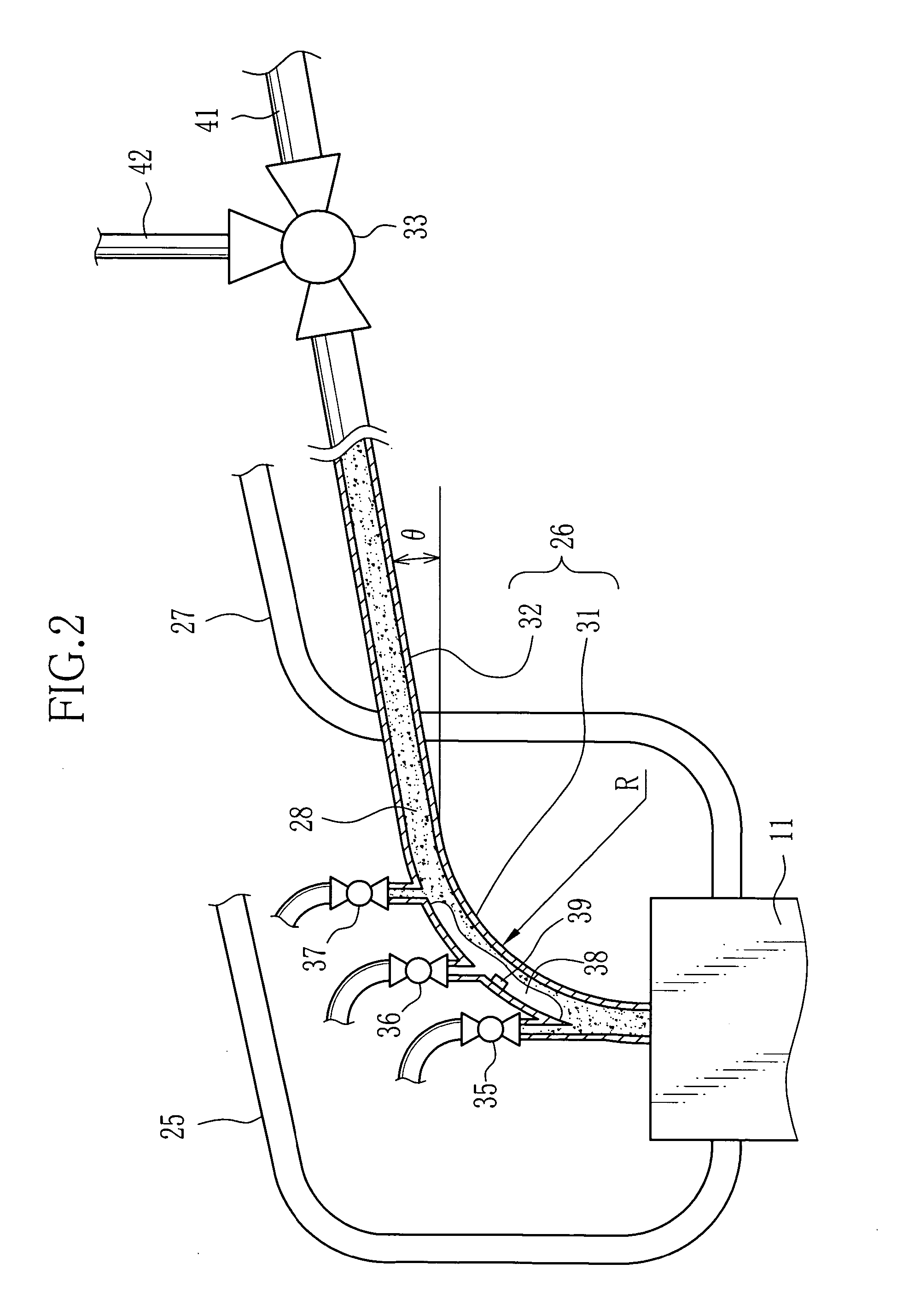

Method and apparatus for electromagnetic irradiation of liquid

InactiveUS20030141457A1Increase volumeUniform thicknessWater/sewage treatment by centrifugal separationWater/sewage treatment by irradiationEngineeringElectromagnetic radiation

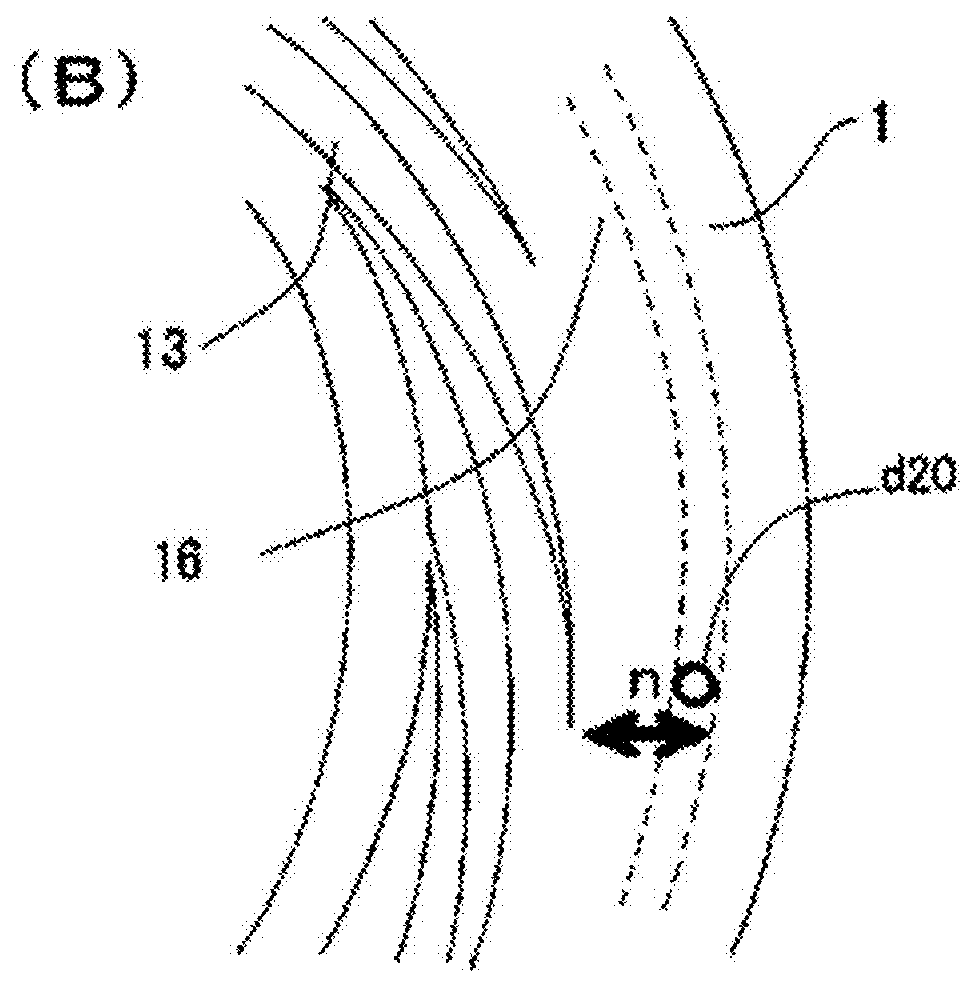

An electromagnetic wave applying apparatus according to the present invention has an electromagnetic wave source (13) such as an ultraviolet lamp or the like, a cylinder (15) surrounding the electromagnetic wave source, a liquid retention tank (16) disposed around the cylinder, and an inlet portion (17) for introducing a liquid overflow from the liquid retention tank as a thin film flowing down an inner wall surface of the cylinder, which is irradiated with an electromagnetic wave from the ultraviolet lamp (11). The electromagnetic wave applying apparatus also has swirling flow forming means for causing the liquid introduced from the inlet portion (17) onto the inner wall surface of the cylinder to flow as a swirling flow down the inner wall surface. The electromagnetic wave applying apparatus allows a large amount of liquid to be stably treated by the application of an electromagnetic wave without causing the electromagnetic wave source such as an ultraviolet lamp or the like to be contaminated.

Owner:EBARA ENG SERVICE

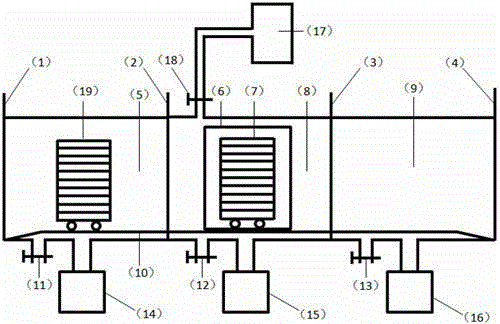

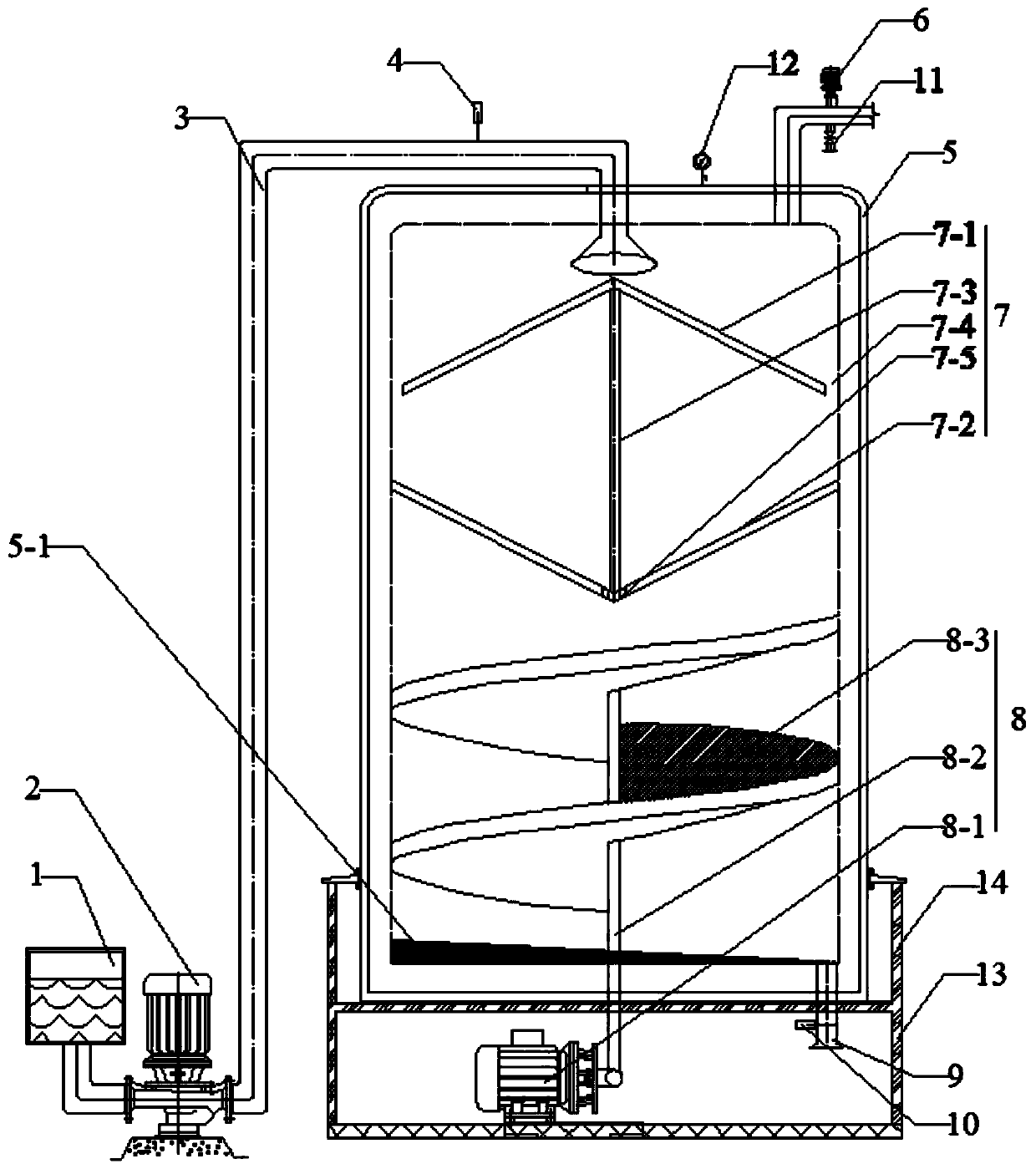

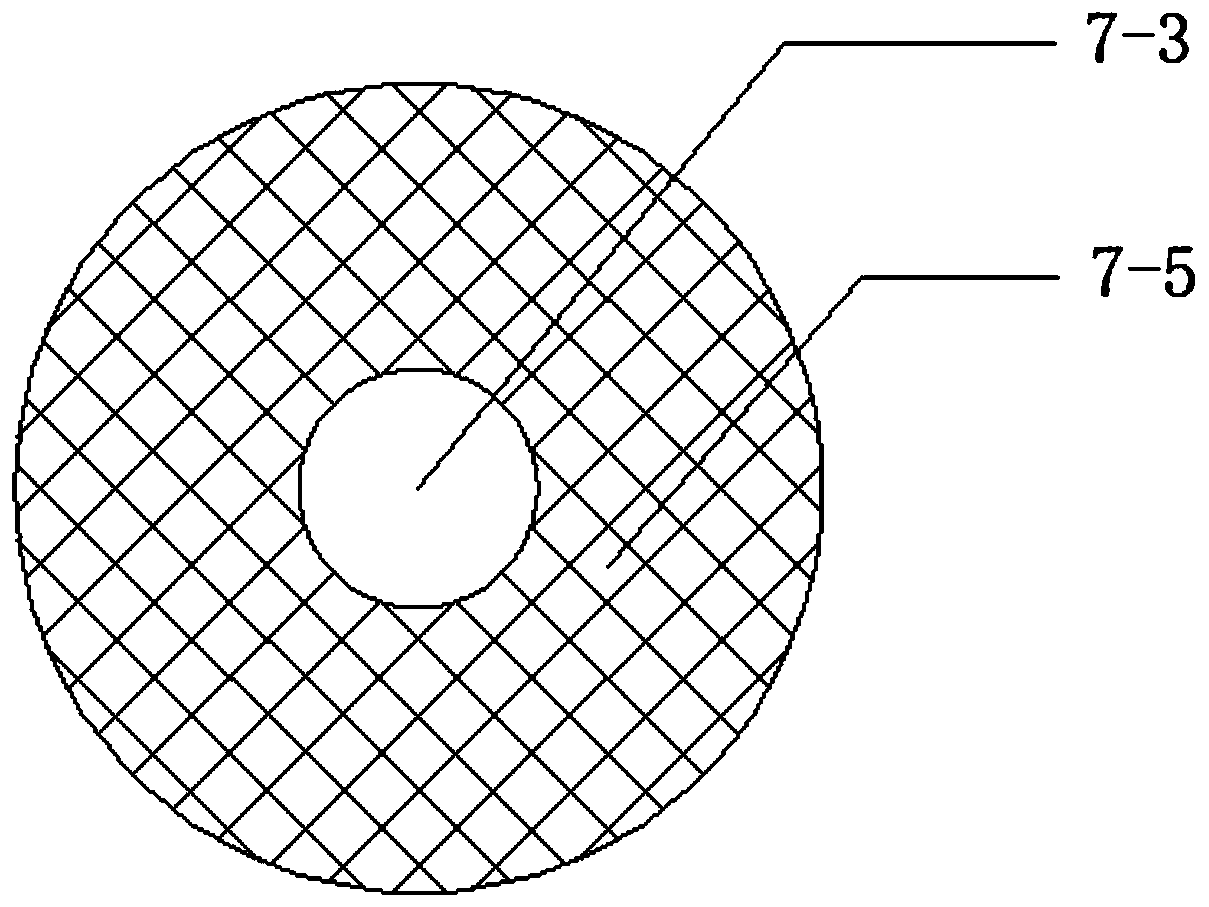

Vacuum defoaming device and defoaming method for high-viscosity liquid

PendingCN110141889ASpeed up film formationSpeed up the flowLiquid degasificationEngineeringThin film flow

The invention discloses a vacuum defoaming device and a defoaming method for high-viscosity liquid. The vacuum defoaming device is provided with two opposite defoaming baffles and a large-area spiralplate; so high-viscosity liquid is always in the state of a thin-film flow layer, which allows the surface area and the surface tension of the high-viscosity liquid to be greatly increased and bubblesto be effectively eliminated; and the low-speed rotation of the spiral plate accelerates the film formation speed and the flowing speed of the high-viscosity liquid, and the rotational shear force generated by the spiral plate can also eliminate bubbles. The defoaming method of the invention adopts multiple defoaming manners, and performs efficient and stable defoaming through a combination of acertain degree of vacuum, the rotating speed of the spiral plate and the flow control of feed and discharge flow valves. According to a technical scheme described in the invention, the vacuum defoaming device has the advantages of simple structure, simple operation, low energy consumption, low cost, high defoaming efficiency and the like, is suitable for defoaming of high-viscosity liquid, and canprotect high-viscosity liquid from the adverse impact of high temperature, defoaming agent and the like.

Owner:SUZHOU SUNMUN TECH CO LTD

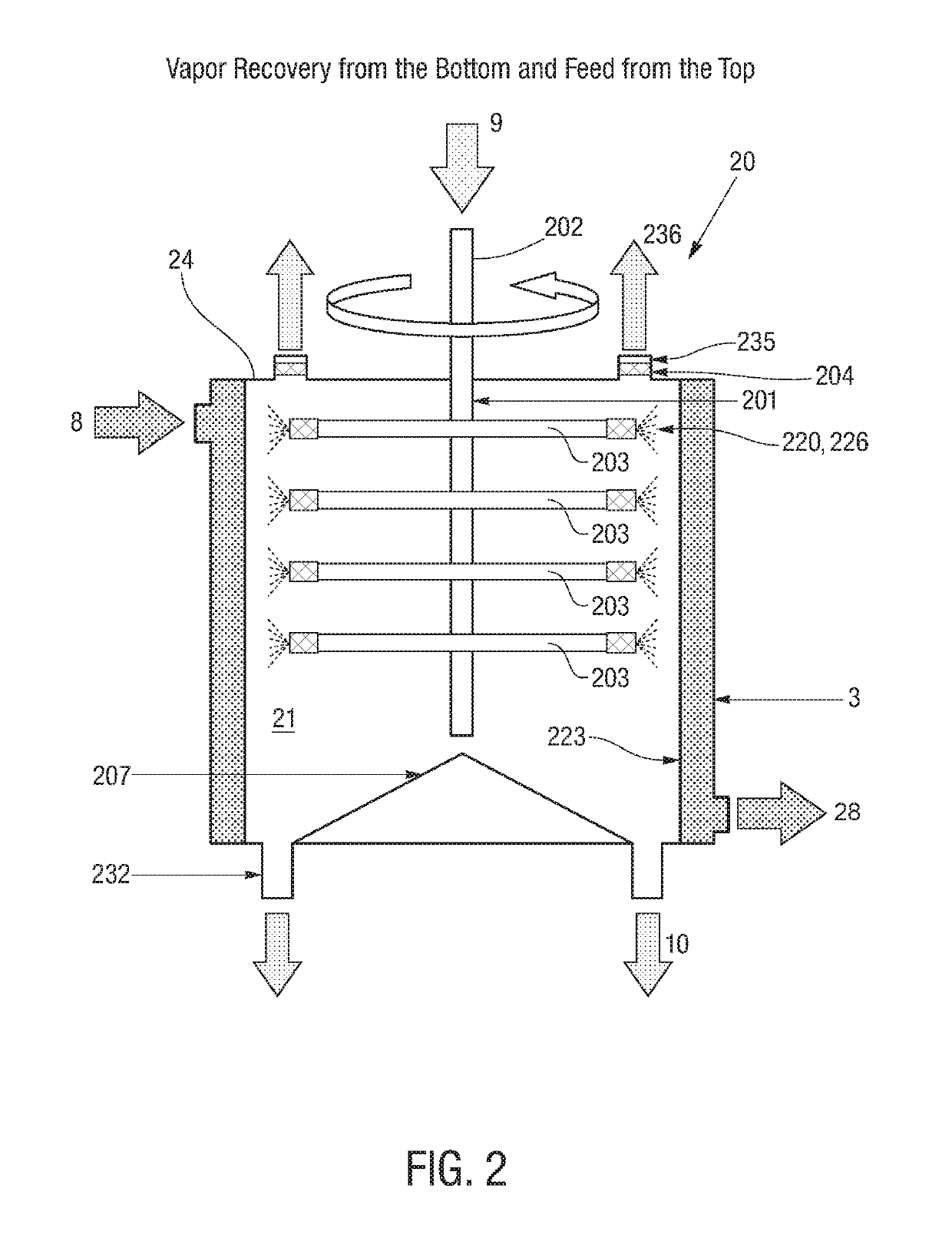

Controlled Thin Film Vapor Generator for Liquid Volume Reduction

ActiveUS20160271514A1Increase surface areaEasy to processWaste water treatment from quariesGeneral water supply conservationControl mannerEngineering

A reactor comprising a plurality of vessels, each having a heat exchange surface for processing a fluid as a thin film flow, the vessels arranged in a concentric manner; a plurality of annular spaces situated between the vessels; and a pathway for directing a heat exchange fluid from one vessel to an adjacent vessel for creating a temperature differential between the heat exchange surfaces and the fluid being processed. A system comprising a fluid source, a reactor, and a vapor outlet and a processed fluid outlet through generated vapor and processed fluid are directed out of the reactor, respectively. A method comprising providing a plurality of concentrically arranged surfaces in spaced relation, distributing a fluid to be processed against the surfaces in a controlled manner to form a substantially uniform thin film flow thereon, and evaporating at least a portion of the fluid being processed along the plurality of surfaces.

Owner:R3 FUSION

Molecular distillation deacidification method and equipment for edible oil

PendingCN106693428AImprove sealingReduce productionFatty-oils/fats refiningMolecular distillationChemical physicsDistillation

The invention discloses a molecular distillation deacidification method and equipment for edible oil. A molecular distillation system adopts single molecular distillation equipment or is formed by connecting multiple stages of molecular distillation equipment in series or parallel or in a series and parallel combination way; the positions of the multiple stages of molecular distillation equipment are disposed horizontally or vertically or in a horizontal and vertical combination manner; the edible oil to be distilled enters the molecular distillation system, so as to enter the single molecular distillation equipment or enter the molecular distillation stage I, the molecular distillation stage II and the molecular distillation stage n; the edible oil to be distilled enters the molecular distillation equipment from the top end, and is subjected to primary uniform distribution through a distribution pipe pore or / and slotted plate so as to be uniformly distributed to the upper part of the heating surface of the equipment to form a uniform thin film flowing from top to bottom; the edible oil to be distilled is at least uniformly distributed again through a distribution slotted plate or a screen hole so as to be uniformly distributed to the heating surface of the equipment to the bottom; when the molecular distillation system adopts multiple stages, the molecular distillation stage I is used for removing water retained in the edible oil, and the molecular distillation stages II and n are used for removing all types of free fatty acids.

Owner:饶攀

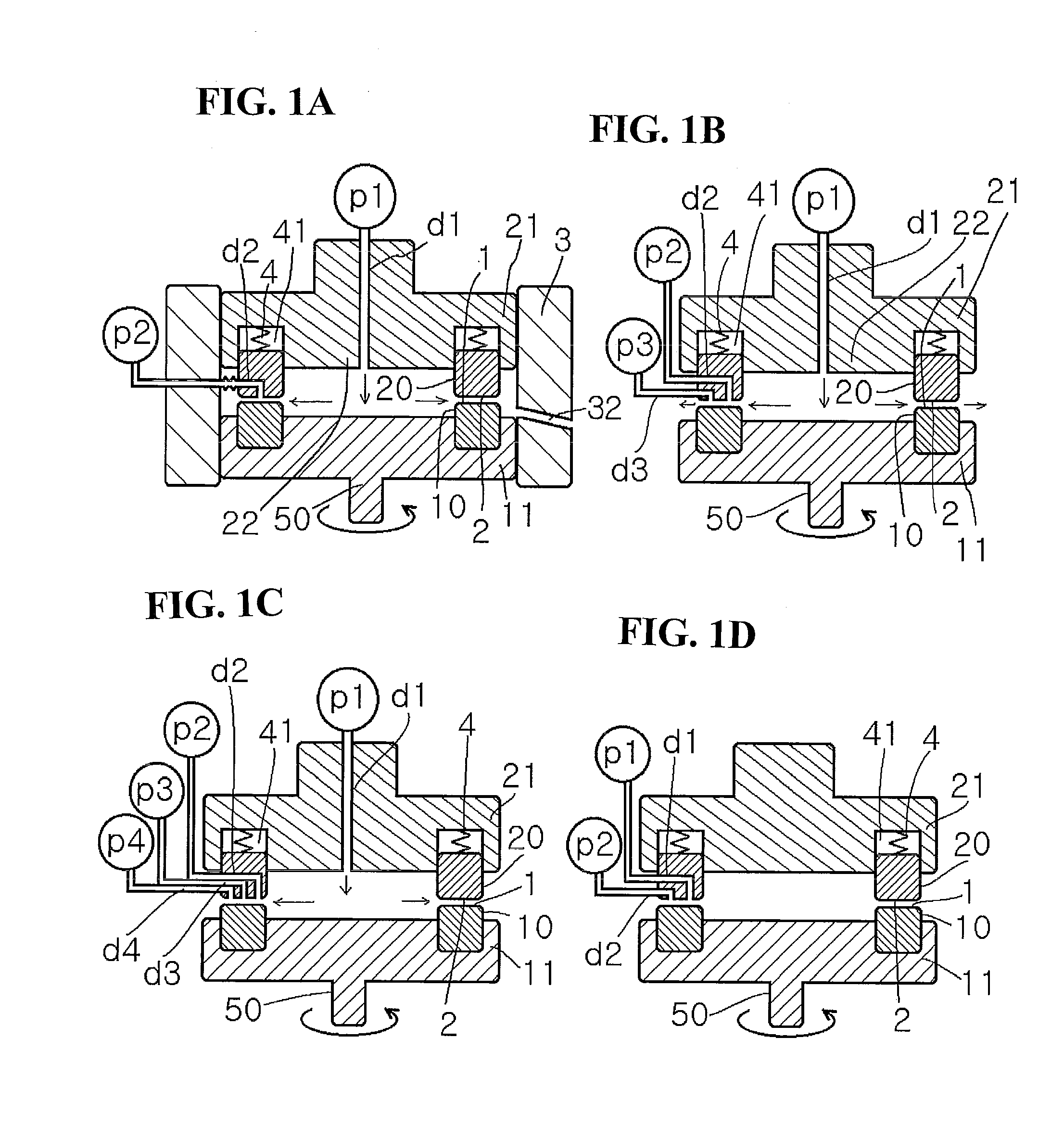

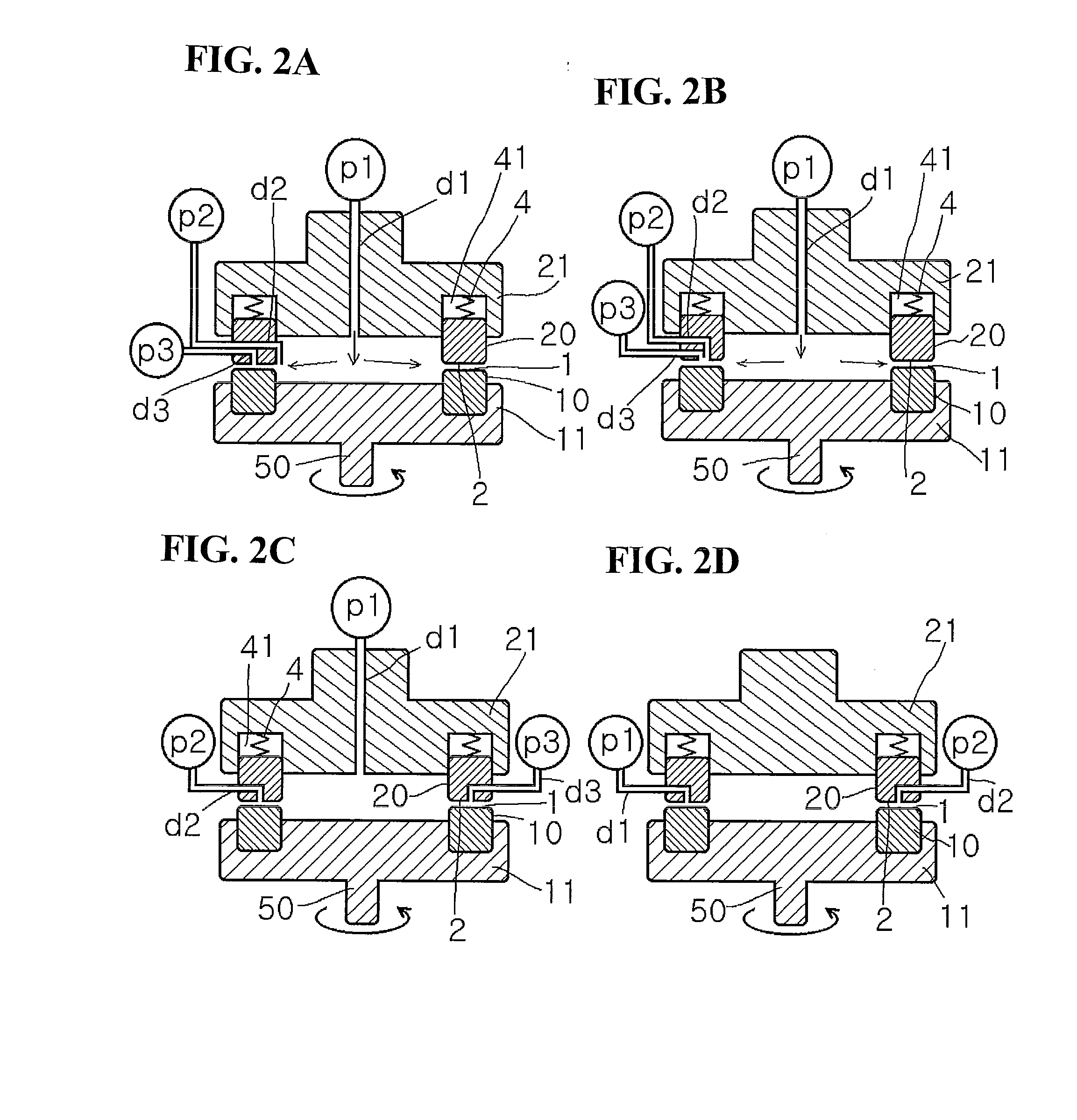

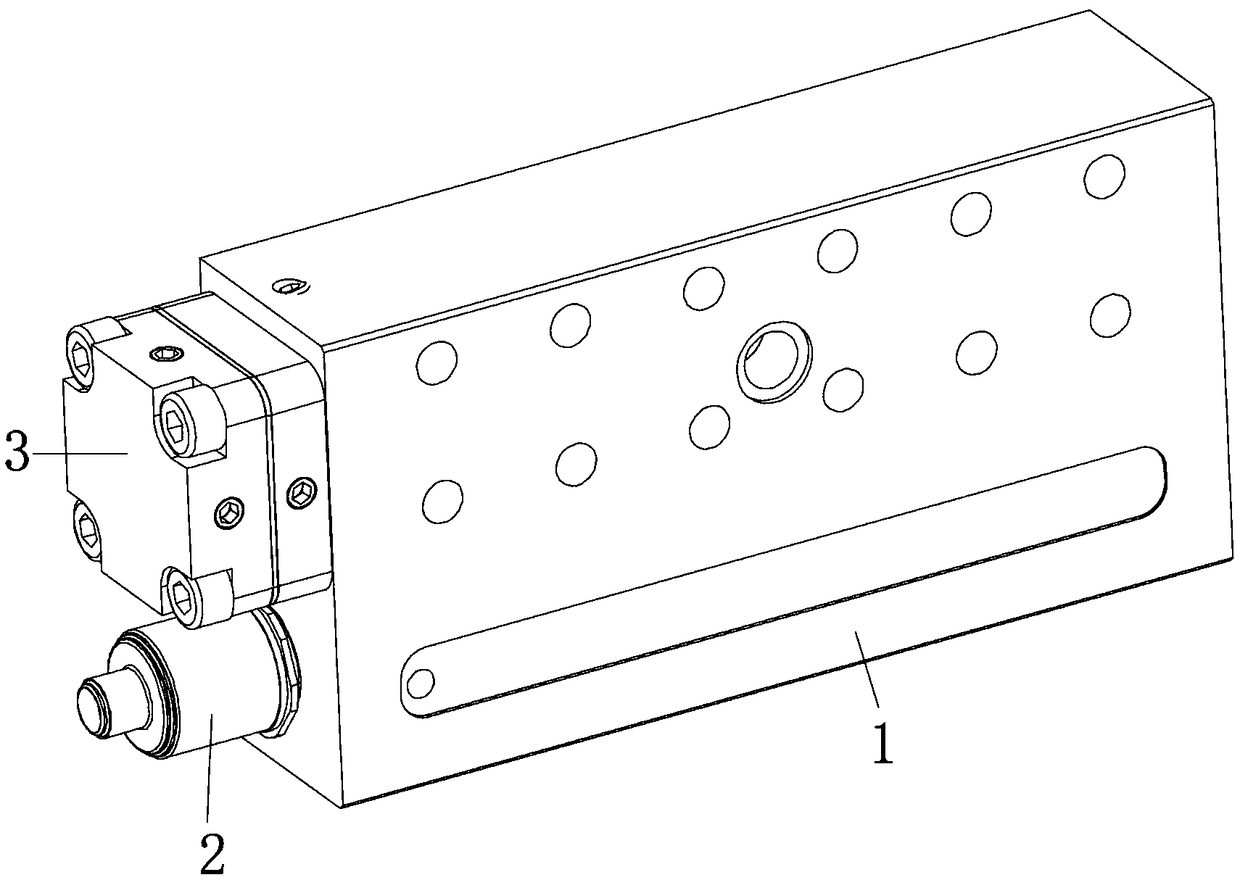

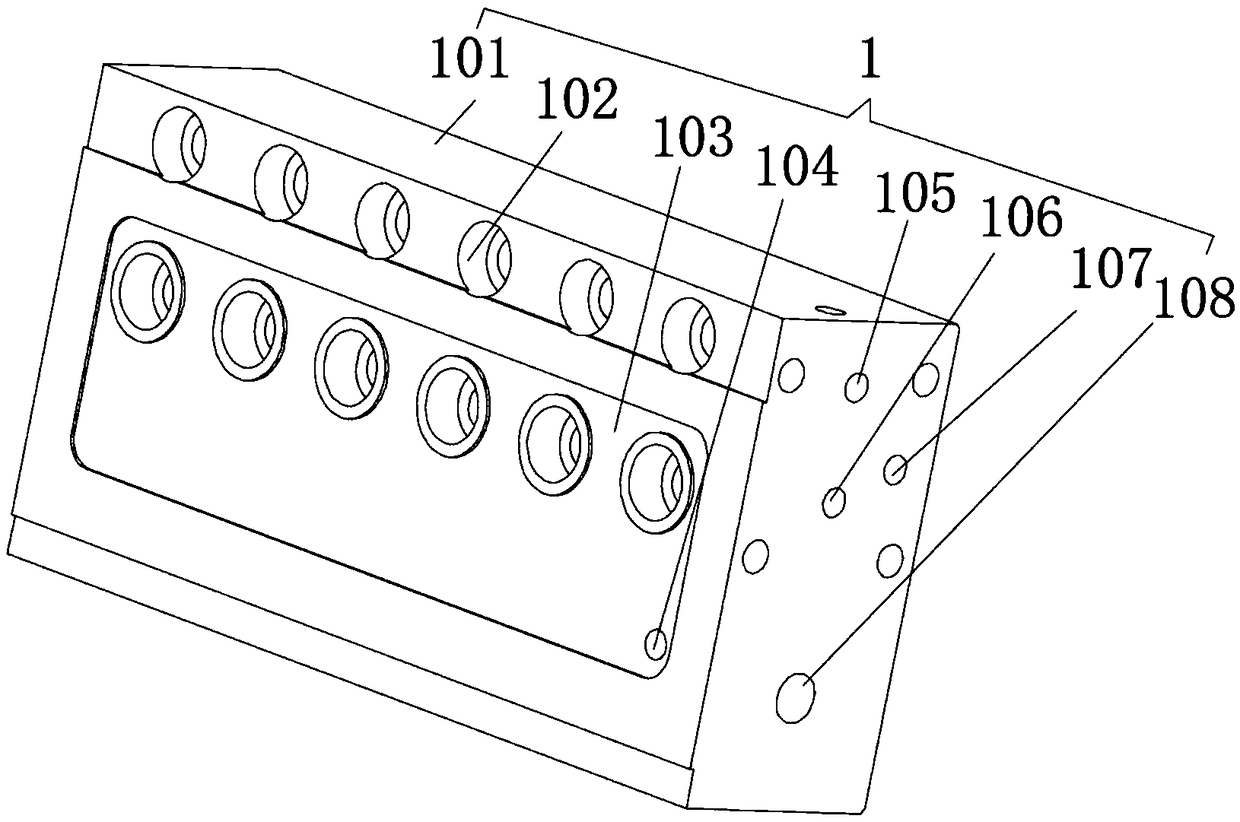

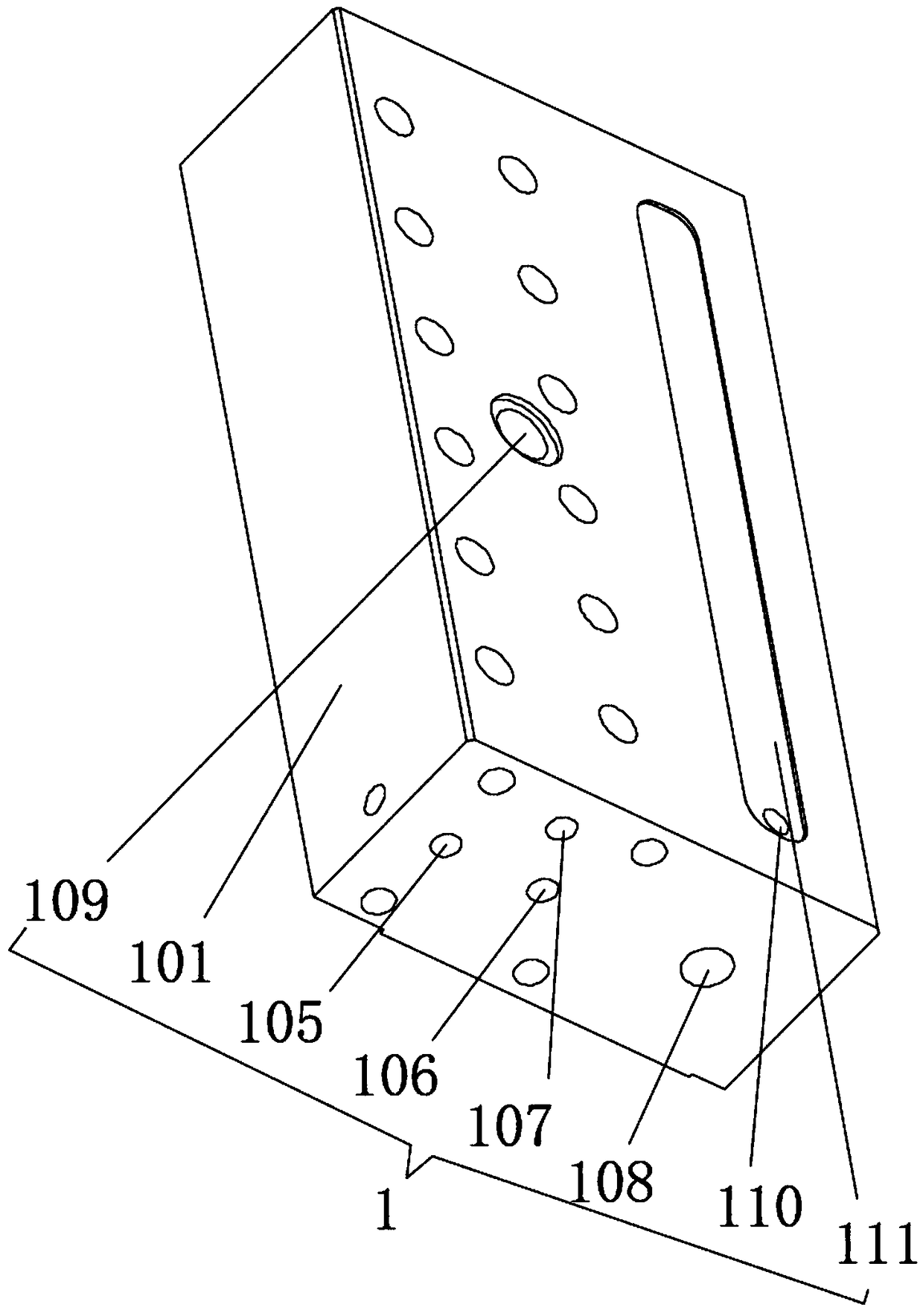

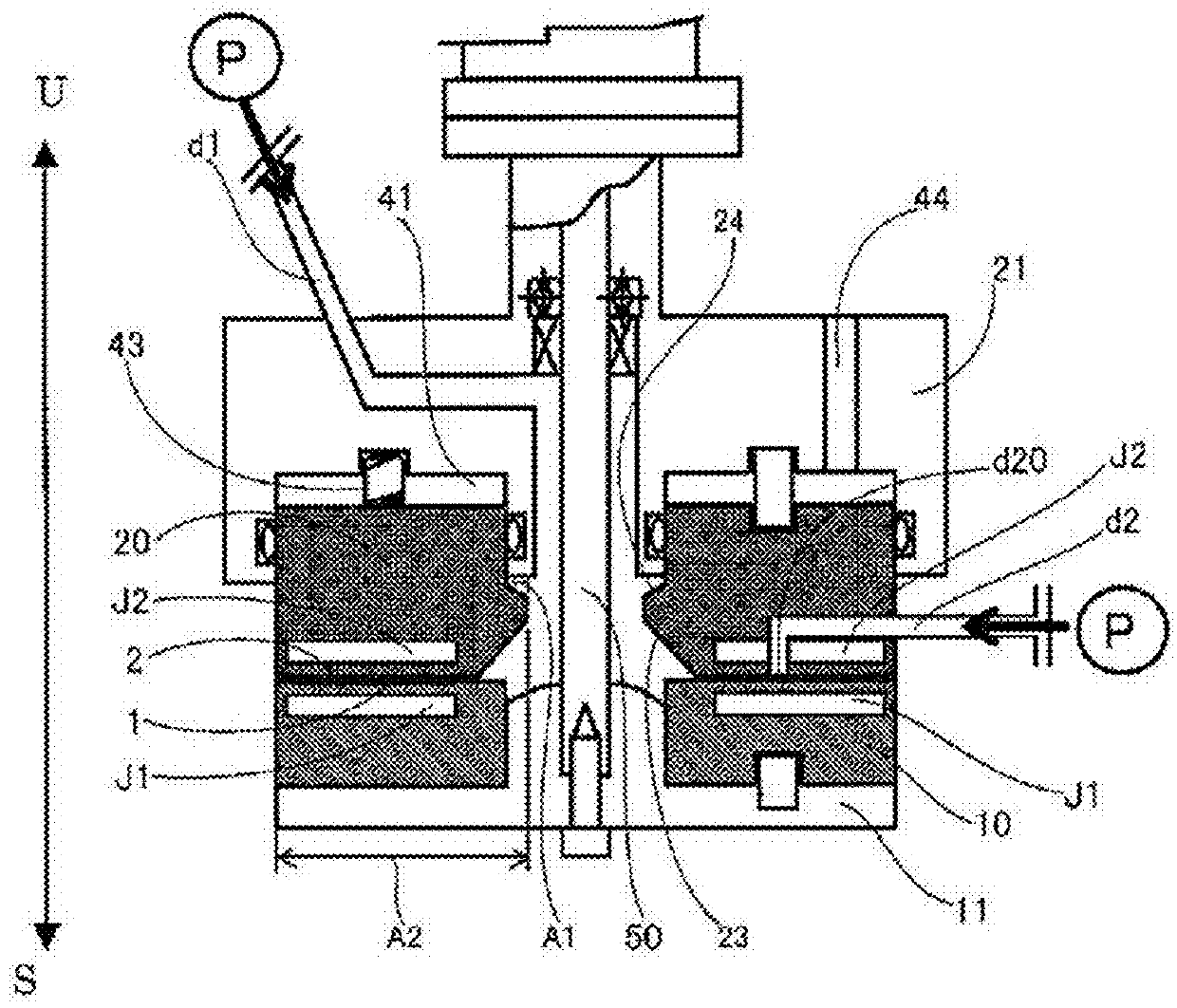

Hydrostatic guideway block integrating flow feedback device and pressure sensor

PendingCN108942275ASame stiffnessSame characteristicsMeasurement/indication equipmentsLarge fixed membersEngineeringThin film flow

The invention discloses a hydrostatic guideway block integrating a flow feedback device and a pressure sensor. The hydrostatic guideway block comprises a two-cavity sliding block, the pressure sensorand the thin film flow feedback device, wherein the two-cavity sliding block comprises a sliding block body; a screw-joint fixed hole is formed in the sliding block body; a lifting cavity is arrangedon the left side of the sliding block body; and a pressure maintaining cavity is arranged on the right side of the sliding block body. According to the device, the pressure change trend can be detected by utilizing the pressure sensor, and the installation positions of the two-cavity sliding block and a support plate are re-adjusted, so that the installation accuracy is ensured; and the device isfurther integrated with the thin film flow feedback device, and the flows in an upper oil cavity and a lower oil cavity are automatically adjusted, so that a completely installed hydrostatic guidewayis ensured to have the same oil film rigidity and characteristics on various parts; and in addition, the position of a throttle formed by an elastic thin film sheet is close to the positions of the lifting cavity and the pressure maintaining cavity, so that an oil circuit can be effectively shortened, and the dynamic rigidity is ensured.

Owner:HAIXI (FUJIAN) INST CHINA ACAD OF MASCH SCI&TECH GRP

Film casting apparatus, protective film of polarizing plate, and polarizing plate

InactiveUS20050058739A1Easy to startImprove productivityConfectioneryPolarising elementsTectorial membraneComing out

A pipe for supplying a dope to a co-casting die consists of a goose neck portion connected to a feed block of the co-casting die, and a straight pipe portion connected to the goose neck portion. The goose neck portion has a radius of curvature of 50 mm to 400 mm, and the straight pipe portion forms an angle of 0 to 20 degrees to the horizontal plane. Venting valves are opened up at the beginning of dope feeding, and are closed to some extent as the dope comes out. After the air is completely vented out, the venting valves are completely closed. Thereby, an air collection is completely let out from the pipe, a plastic web discharged from die lips of the co-casting die would not contain any air bubbles, it is prevented that the web splashes to put on the die lips, causing steaks on the produced film.

Owner:FUJIFILM CORP

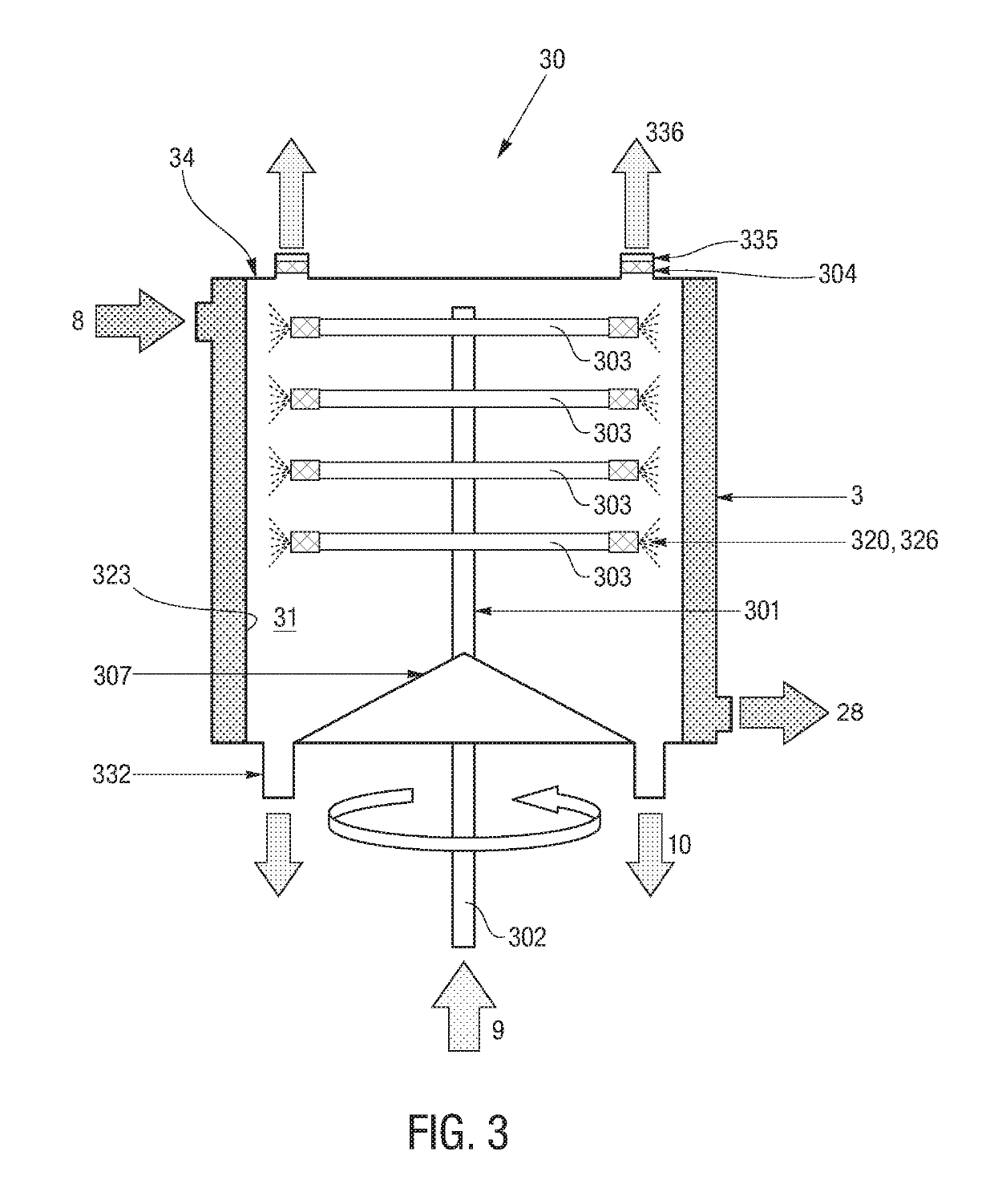

Controlled thin film vapor generator for liquid volume reduction

InactiveUS10350508B2Easy to processIncrease surface areaWaste water treatment from quariesGeneral water supply conservationControl mannerEngineering

Owner:R3 FUSION

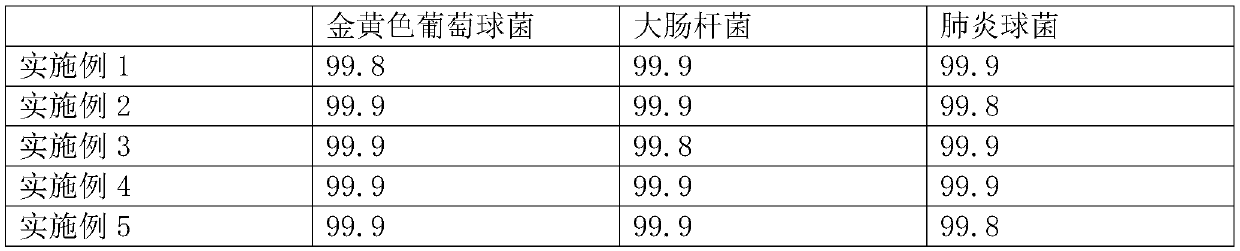

Film for antibacterial packaging bag and preparation method thereof

InactiveCN111410785AReduce manufacturing costImprove antibacterial propertiesFlexible coversWrappersLow-density polyethylenePolymer science

The invention relates to the field of packaging bags, in particular to a film for an antibacterial packaging bag and a preparation method of the film. The film for the antibacterial packaging bag is prepared by mixing the following components in parts by mass: 10-15 parts of low-density polyethylene; 35 to 45 parts of high density polyethylene; 5 to 10 parts of maleic anhydride grafted polyethylene; 10 to 18 parts of thermoplastic polyurethane elastic rubber; 3-6 parts of a filler; and 8-12 parts of a nano zinc oxide-chitosan composite antibacterial agent. The preparation method of the film for the antibacterial packaging bag comprises the steps of preparation of the nano zinc oxide-chitosan composite antibacterial agent, film extrusion, film casting, film cutting and the like. The film islow in production cost, good in antibacterial effect, non-toxic, convenient and fast to use and capable of being used for manufacturing food packaging bags.

Owner:深圳市海轩威包装有限公司

Automatic production line of solar cell panel packaging films

ActiveCN113500757AEnsure bonding strengthEnsure anti-aging propertiesFinal product manufactureSemiconductor/solid-state device manufacturingWinding machineProduction line

The invention discloses an automatic production line of solar cell panel packaging films. The automatic production line comprises a screw extruder, a film casting machine, a thickness gauge, a traction machine and a film winding machine, the screw extruder is connected with the film casting machine through a melt connector, the thickness gauge is arranged on the rear side of the film casting machine, and a rubber film bracket is arranged between the thickness gauge and the traction machine. The film winding machine is arranged on the rear side of the traction machine. Division is achieved in the screw extruder through a spiral rib plate to form a spiral water cavity and a spiral water channel, and flow guide spiral sheets are arranged on a water conveying pipe. Semiconductor refrigeration cylinders are arranged on the inner cylinder walls of roller outer cylinders of a rubber roller and a pattern roller which conduct opposite rolling, and a flexible roller sleeve and an end face cam structure are arranged on the outer cylinder of the rubber roller in a sleeving mode. Automatic winding is driven through a driving device on a winding machine frame to form a wound product, and a fly-cutter cut-off mechanism, a pressing swing arm mechanism and a spare shaft pressing mechanism are further movably supported on the winding machine frame. The production line not only can achieve continuous production and is high in efficiency, but also is good in rubber film uniformity and high in product quality.

Owner:CHINA GWELL MASCH CO LTD

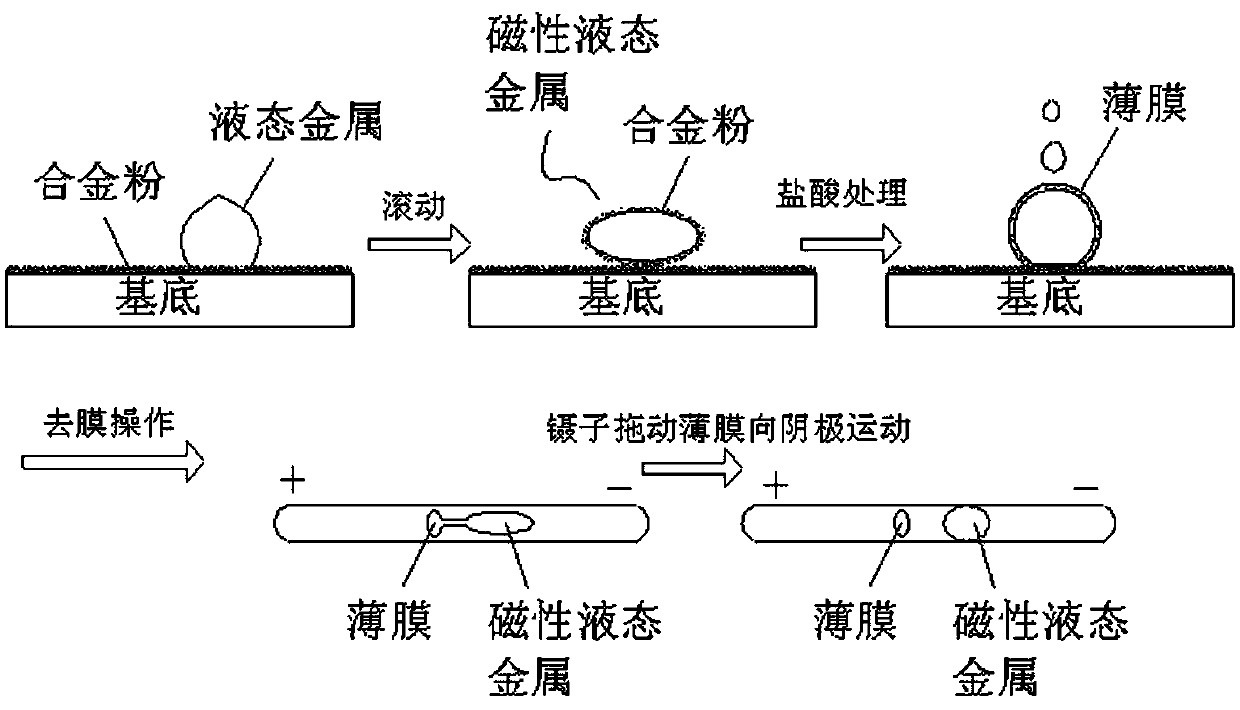

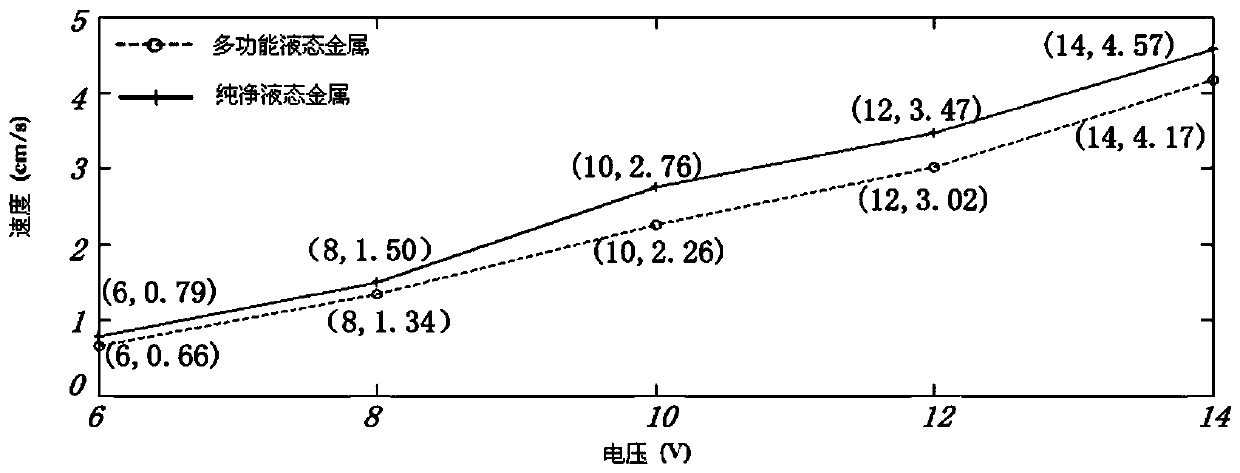

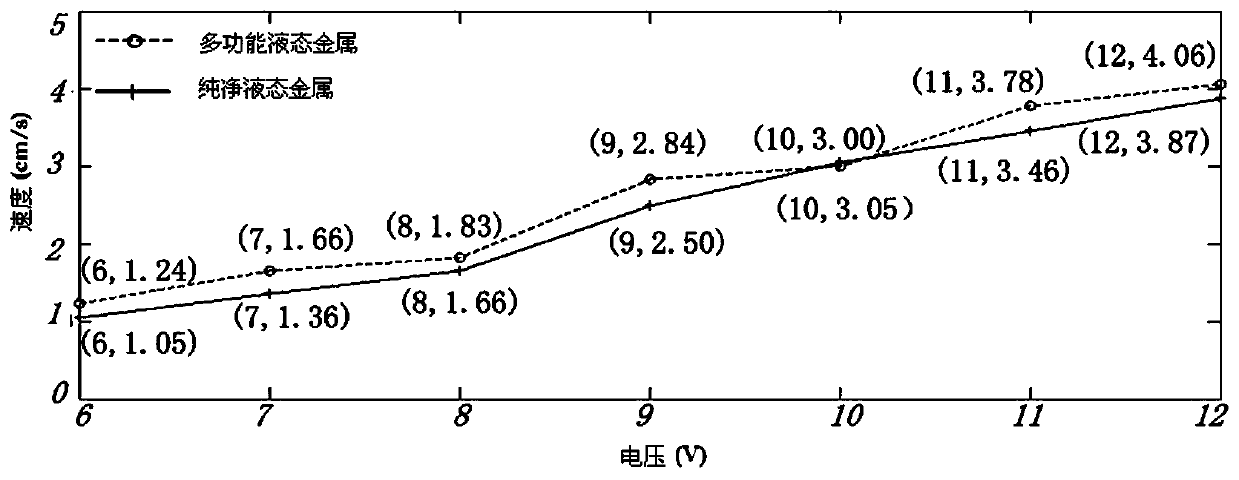

A kind of multifunctional liquid metal and preparation method thereof

ActiveCN109003773BEasy to driveA new way to add driversMagnetic liquidsInductances/transformers/magnets manufactureThin membraneLiquid metal

Owner:SUZHOU UNIV

Solid silver-copper alloy having mainly a non-eutectic structure not containing a eutectic at room temperature

ActiveUS10006105B2Suppress oxidation susceptibilitySuppress migration of silverMaterial nanotechnologyTransportation and packagingRoom temperatureSilver ion

The present invention addresses the problem of providing a novel, solid silver-copper alloy. Provided is a solid silver-copper alloy in which the concentration of copper contained in the silver-copper alloy is 0.1-99.94 wt %, and which has, as the principal constituent thereof, a non-eutectic structure which does not contain a eutectic when the solid silver-copper alloy is at room temperature. This silver-copper alloy can be produced by mixing a fluid containing silver ions and copper ions with a fluid containing a reducing agent, and separating silver-copper alloy particles therefrom. It is preferable to mix the fluid containing the silver ions and copper ions with the fluid containing the reducing agent in a thin-film fluid formed between processing surfaces arranged so as to face one another, capable of approaching toward and separating from one another, and capable of having at least one surface rotate relative to the other. The diameter of the particles of the silver-copper alloy is preferably 50 nm or less. This solid silver-metal alloy may also be a solid alloy comprising one or more types of other metals in addition to silver and copper.

Owner:M TECH CO LTD

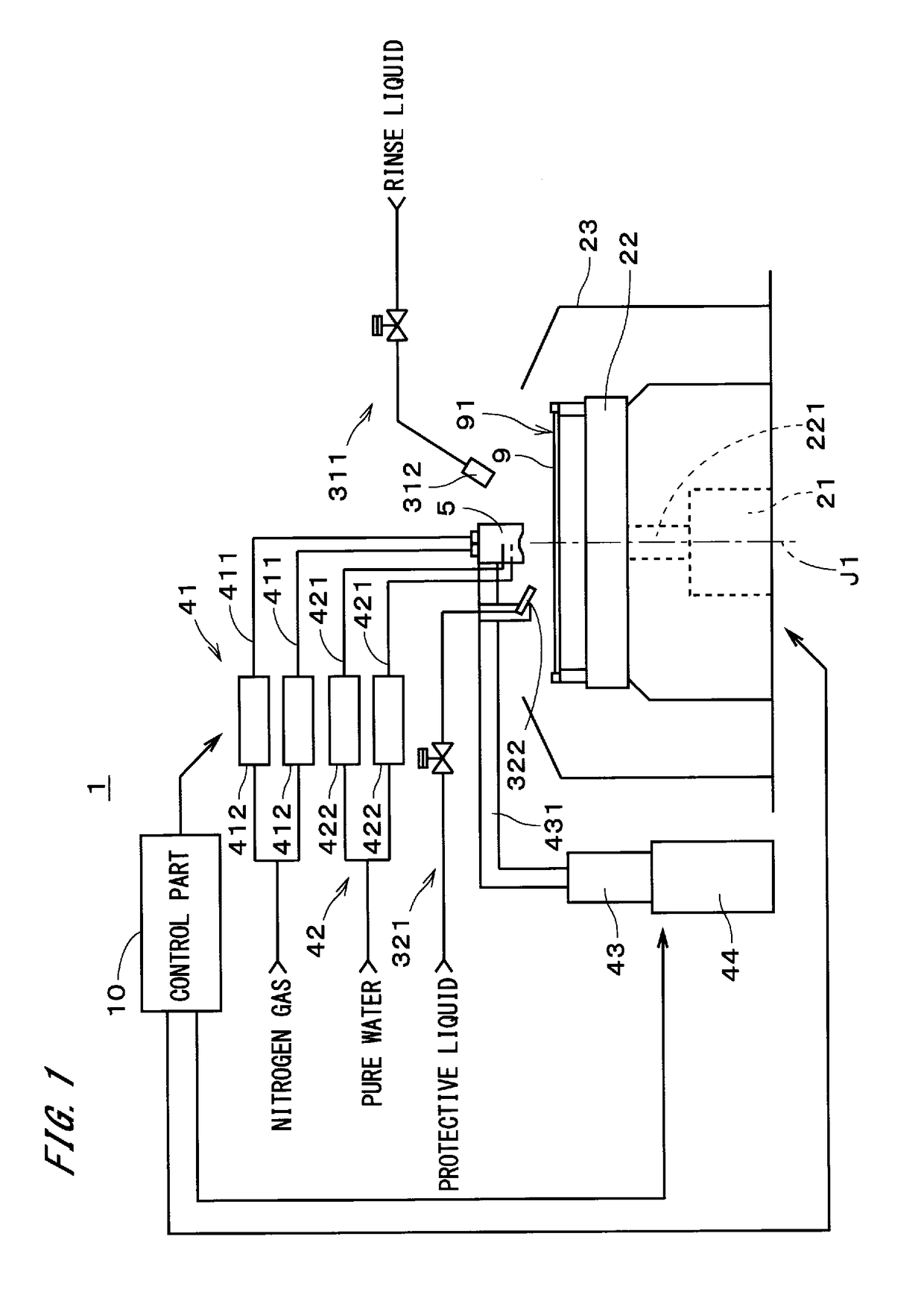

Arrangement and method for disturbance correction for imaging flow measuring processes

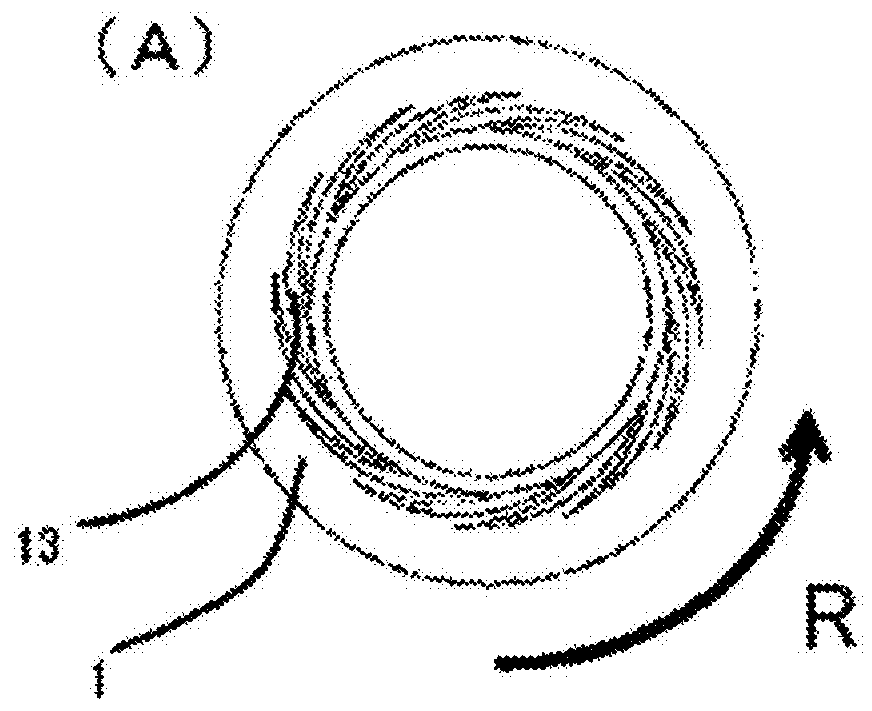

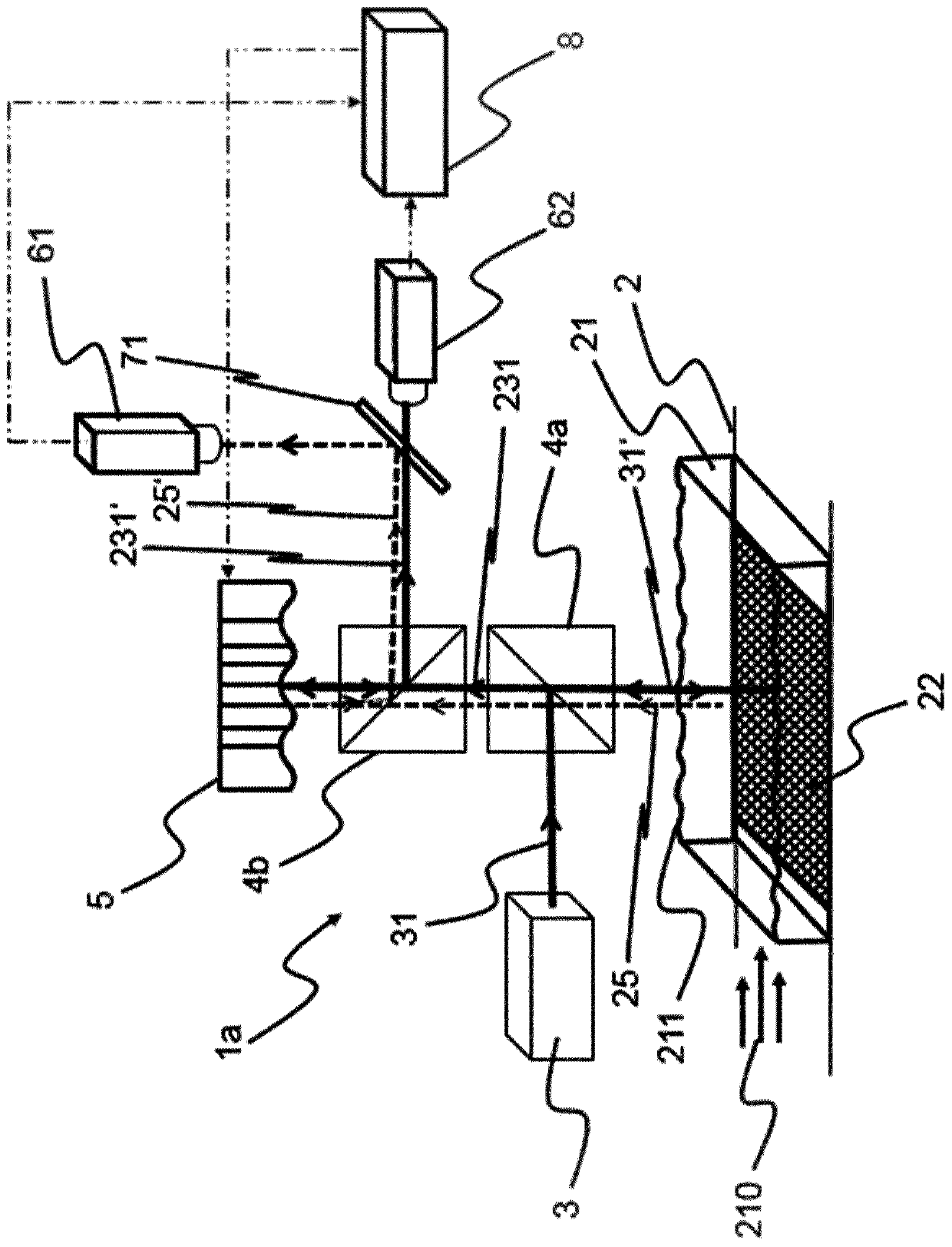

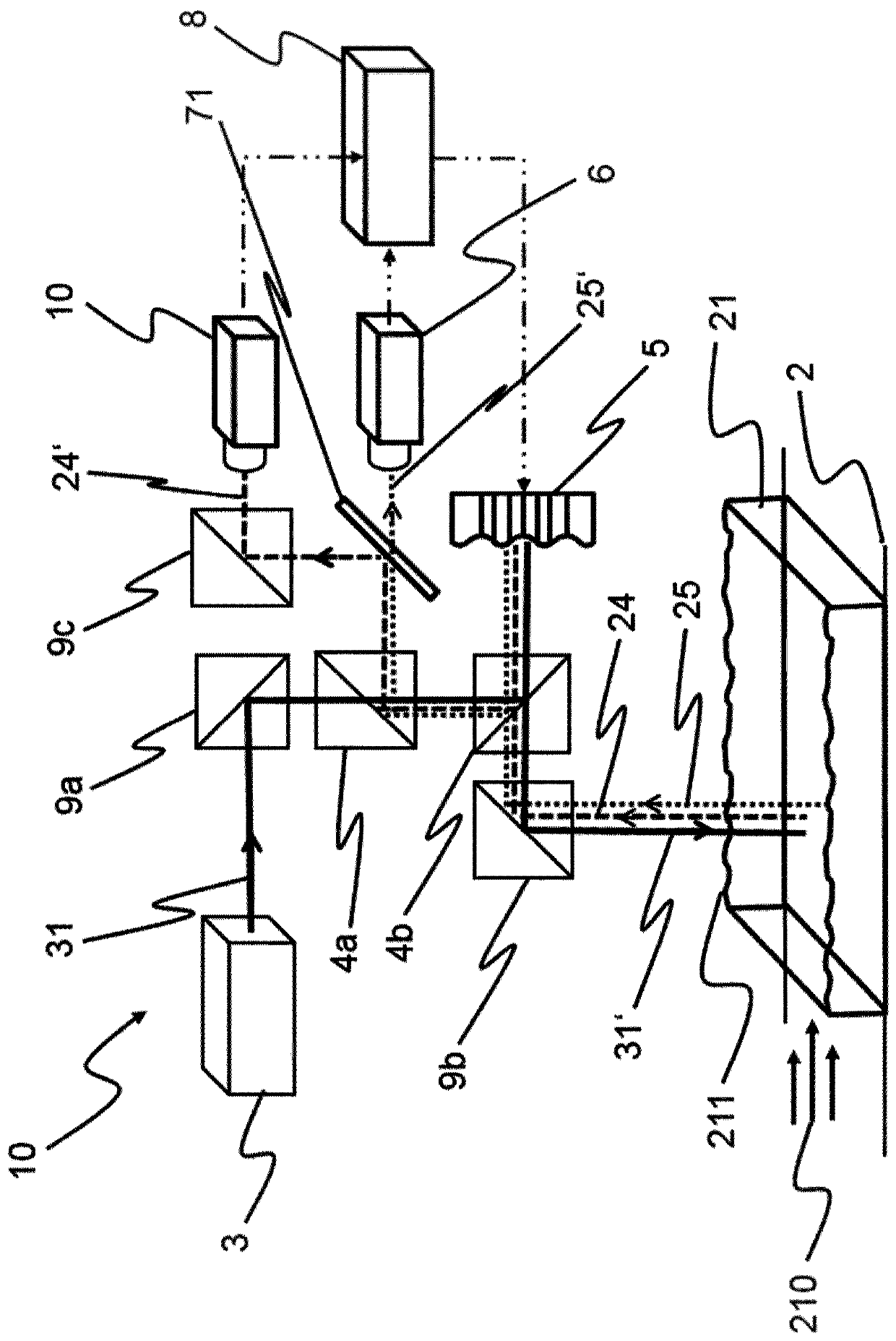

ActiveCN110914736AReal-time operationHigh frequency of responseVolume/mass flow measurementMaterial analysis by optical meansElectrolysisRefractive index

A generally time-varying boundary surface between multiple flowing fluids with different refractive indices, for example the boundary surface between water and air with a free water surface, represents an optical disturbance. Optical flow measuring processes that take place through the boundary surface are influenced by this disturbance, which leads to significant measurement deviations or even completely prevents measurement. The invention contributes to solving this technical measurement problem by proposing arrangements (1, 1a, 1') and processes for the instantaneous, hardware-based correction of the optical disturbances caused by a fluctuating boundary surface (211). For this purpose, a wavefront modulator (5) is introduced into the beam of the optical measuring process and, by means of a feedback control, actively compensates for the optical disturbance that is caused. The invention makes it possible to perform optical flow measurements through a fluctuating boundary surface. It is at the same time not restricted to a single flow measuring process but can be implemented in all known imaging processes. The invention can be used in a large number of technical applications. To bementioned by way of example are: liquid-air boundary surfaces, for example in water channels with an open surface; film flows, for example in chemical process engineering for cooling, cleaning or distillation; liquid jets with the surface fluctuating on all sides; measurements in levitated drops or drops adhering on an opaque underlying surface or gas bubbles occurring in liquids. The invention is also suitable for the correction of disturbances due to temperature gradients in combustion processes, pressure gradients, for example in the case of pressure surges, or concentration gradients, forexample in the case of electrolytic processes.

Owner:DRESDEN UNIVERSITY OF TECHNOLOGY

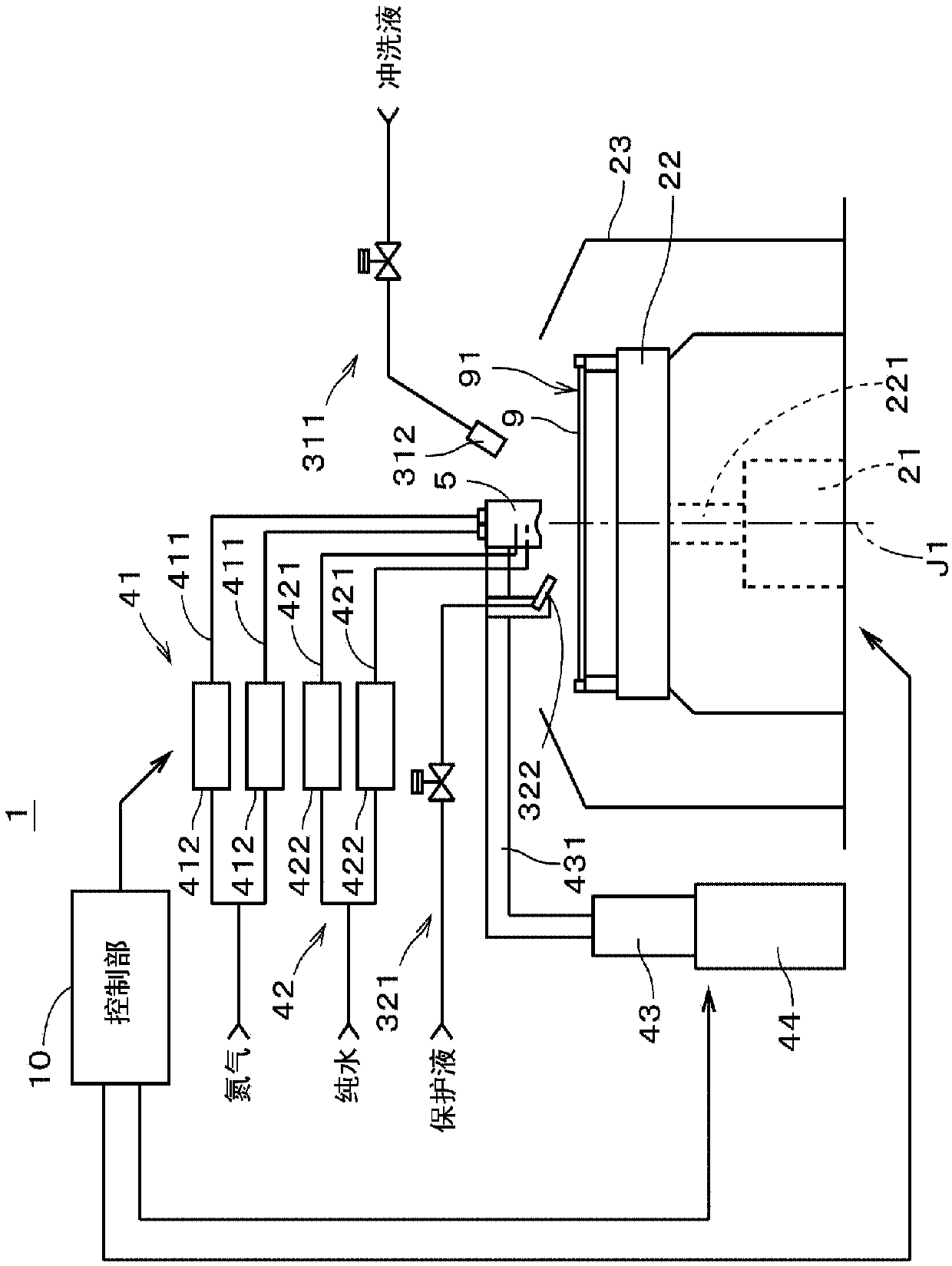

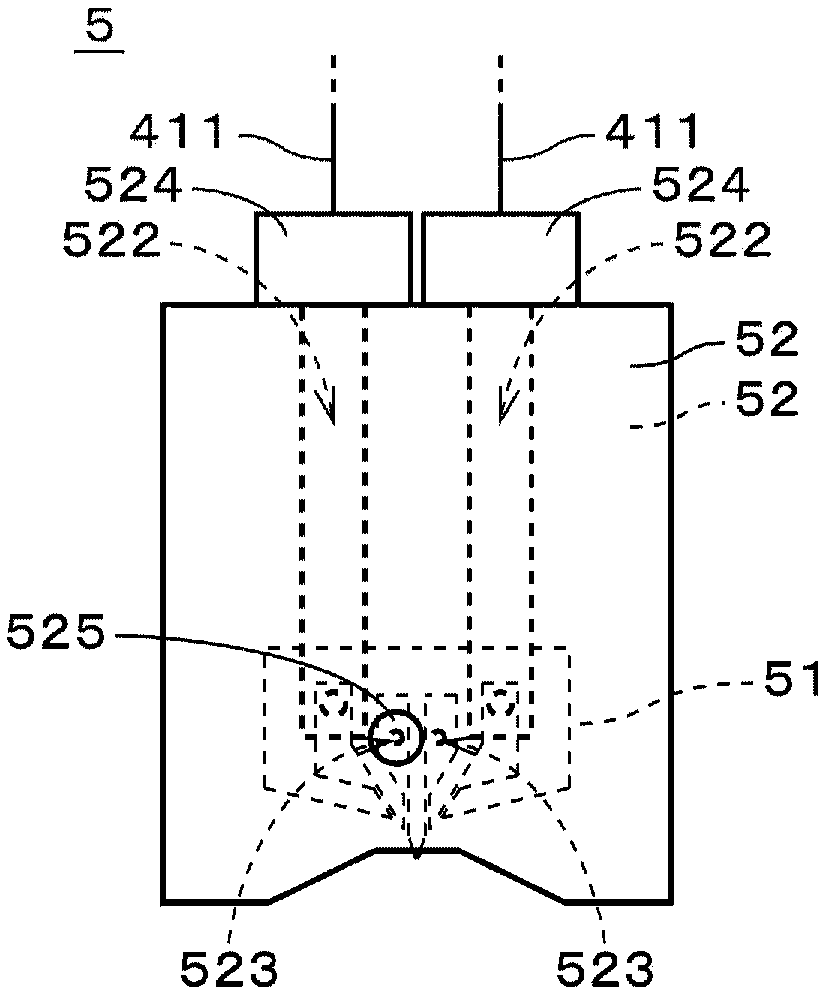

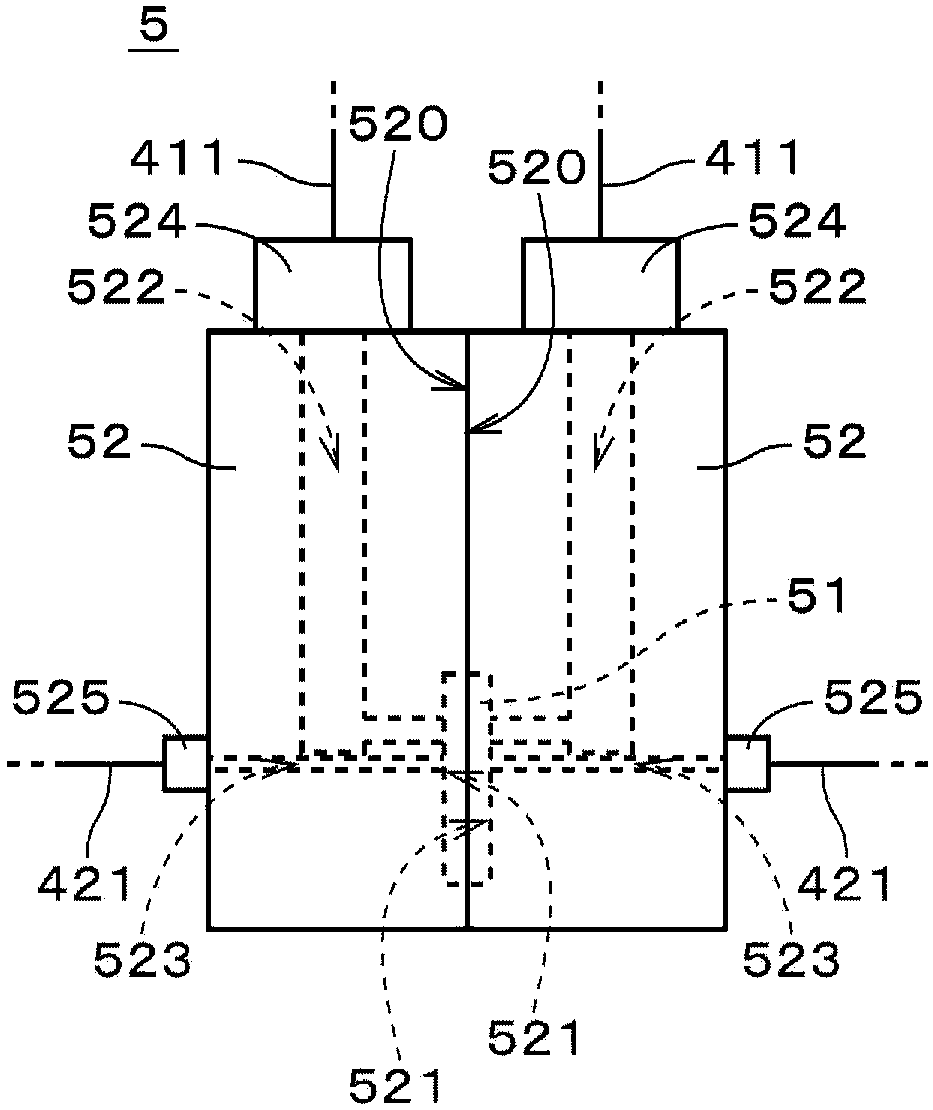

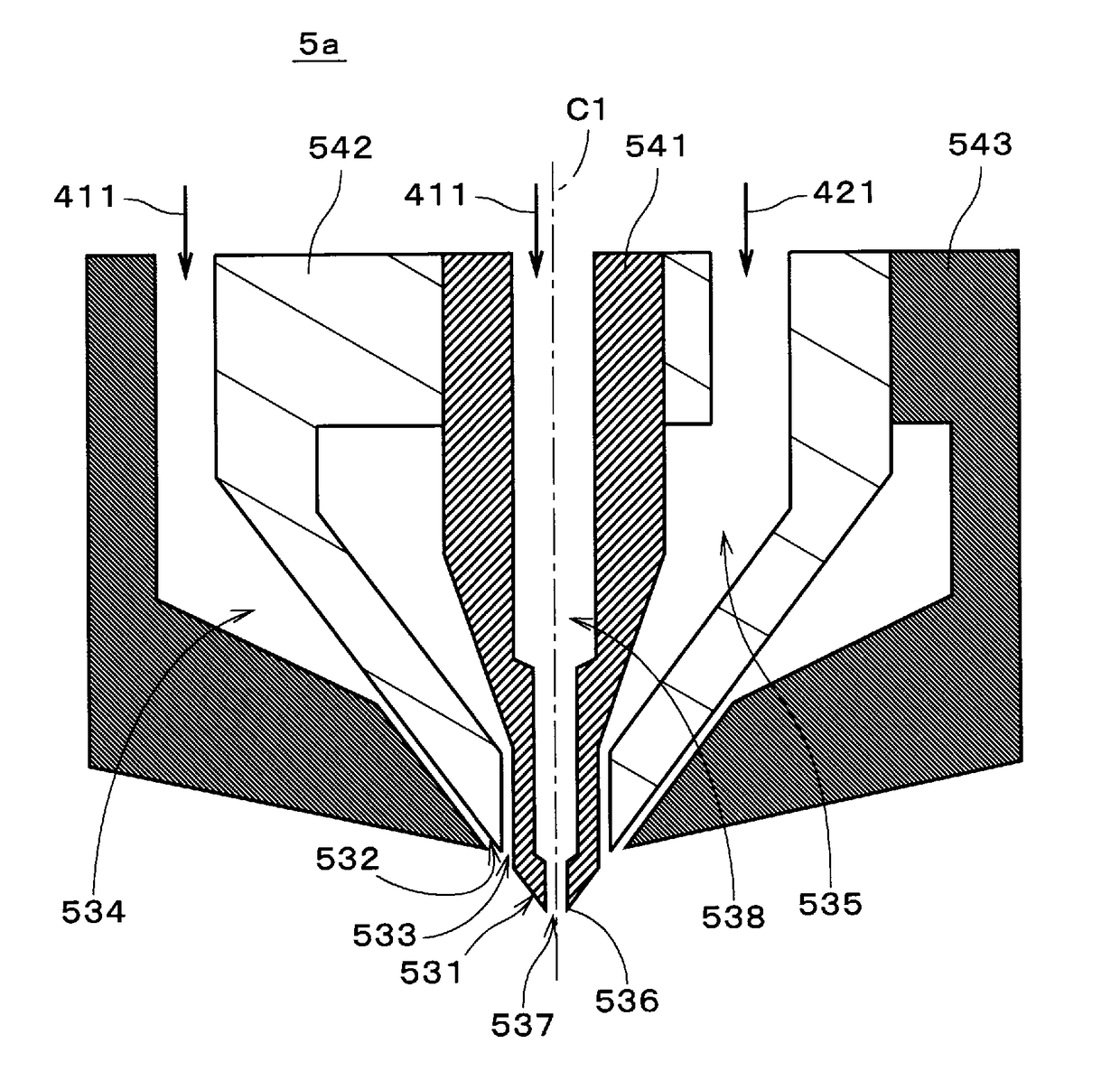

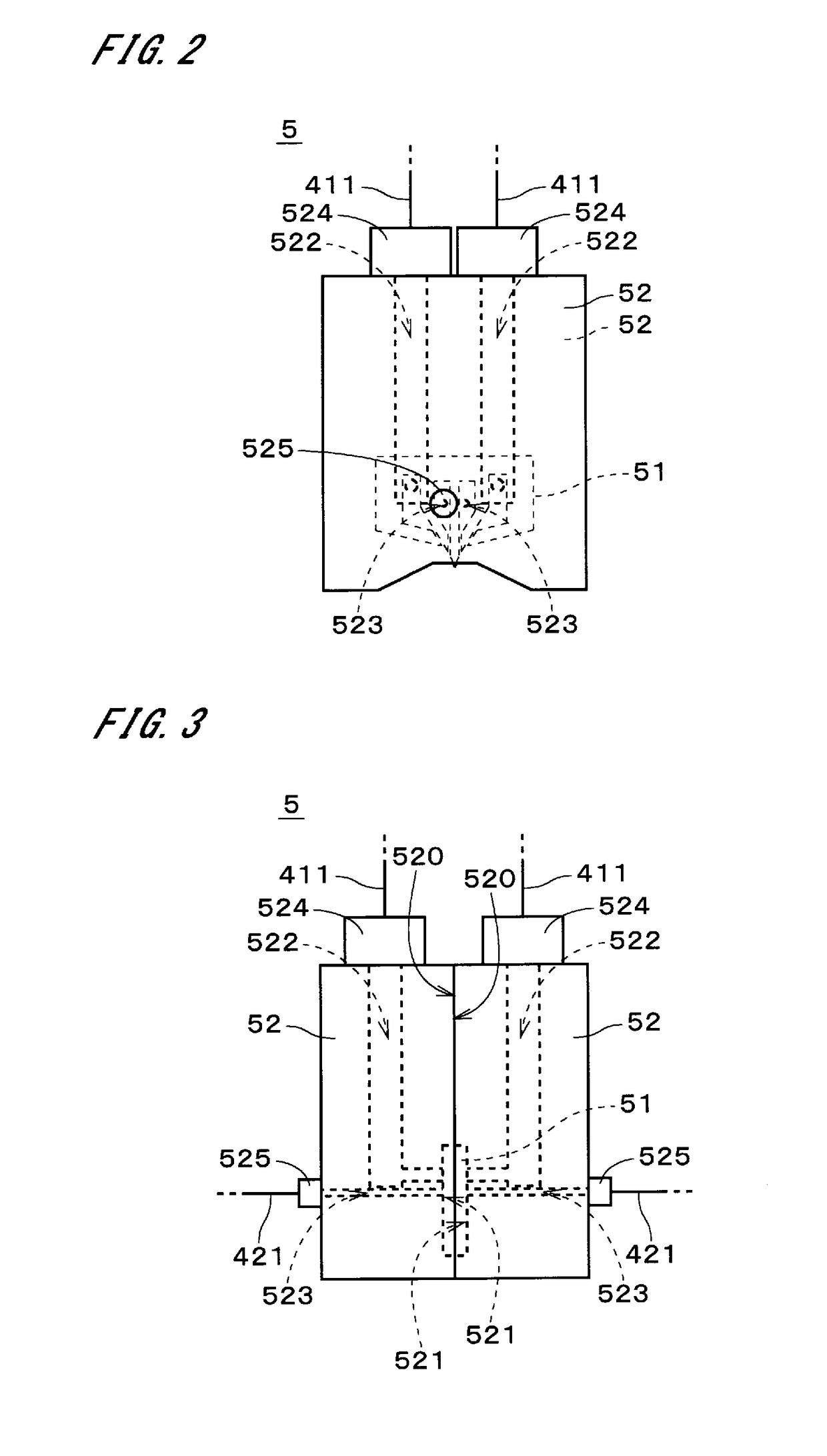

Substrate treatment apparatus

InactiveCN107615457ASemiconductor/solid-state device manufacturingCleaning using gasesEngineeringProduct gas

A substrate treatment apparatus is provided with: a substrate rotating mechanism that rotates a substrate; a nozzle section that jets droplets of a treatment liquid toward a main surface of the substrate; and a nozzle moving mechanism that moves the nozzle section in the direction along the main surface. The nozzle section is provided with two guide surfaces (511), two gas jetting ports (512), andtwo treatment liquid supply ports (513). Through the gas jetting ports, a gas is jetted along the guide surfaces, and gas flows are formed along the guide surfaces. The treatment liquid supply portsare provided in the guide surfaces, and through each of the treatment liquid supply ports, the treatment liquid is supplied between each of the gas flows and each of the guide surfaces. In the nozzlesection, when one of the two gas jetting ports is considered as a first gas jetting port which forms a gas flow that carries, as a thin film flow, the treatment liquid to a lower end edge (516) of theguide surfaces, the other gas jetting port is considered as a second gas jetting port that forms a gas flow that collides with the treatment liquid scattered from the lower end edge. Consequently, the substrate can be suitably treated by jetting a plurality of droplets having a uniform diameter.

Owner:DAINIPPON SCREEN MTG CO LTD

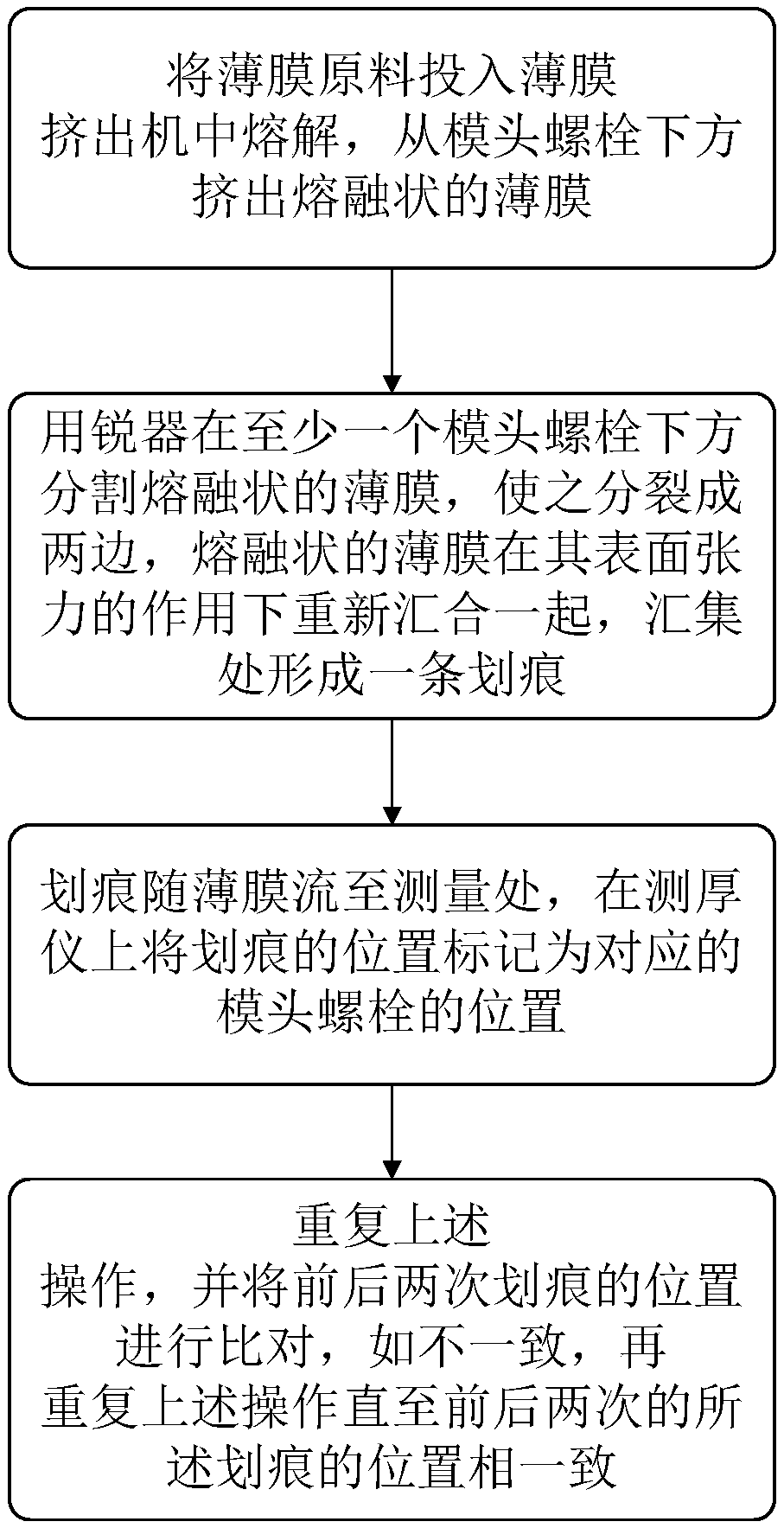

Method for aligning die head bolt

The invention is applicable to the field of film extruders, and provides a method for aligning a die head bolt. The method comprises the steps that 1, a thin film raw material is put into a film extruder for melting, and a molten film is extruded below the die head bolt; 2, the molten film is segmented below at least one die head bolt through a sharp instrument so that the film is split into two sides, the molten film is integrated again under the action of surface tension, and a scratch is formed at the combined position; and 3, the scratch flows to a measuring position along with the moltenfilm, and the position of the scratch is marked as the position corresponding to the die head bolt on a thickness gauge. According to the method, the film is torn by the sharp instrument, and the molten film below the die head bolt is identified, so that the film can correspond to the die head bolt through identification when the film moves to the measuring position, and the die head bolt is aligned.

Owner:湖北江升新材料有限公司

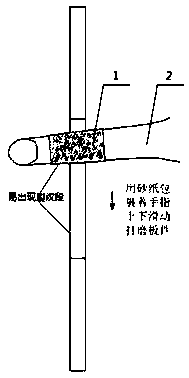

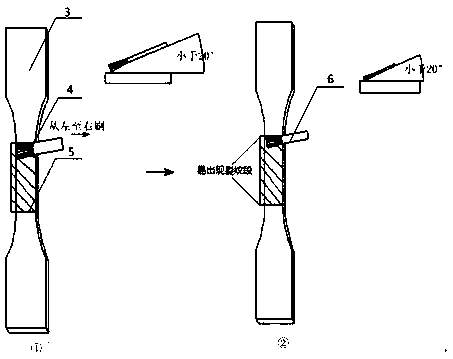

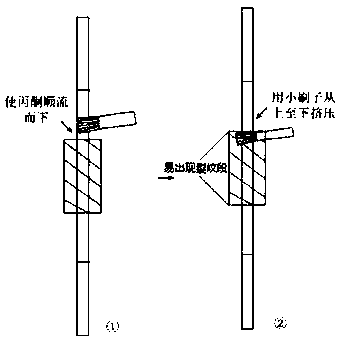

An Experimental Method for Obtaining Fatigue Small Cracks in Sheet Metal Parts Using Cellulose Acetate Film Replicas

ActiveCN108375514BIncrease success rateImprove accuracyPreparing sample for investigationOptically investigating flaws/contaminationCellulosePolymer science

The invention discloses an experimental method using cellulose acetate film replication to acquire fatigue small crack condition of sheet metal and relates to the field of mechanical structure fatigue. The experimental method includes: during front-back replication, adopting a big hairbrush for quick brushing to enable a film to be pasted on the sheet metal at a time, and using a small hairbrush to dip acetone to remove bubbles from left to right, wherein the moving direction of the hairbrush is perpendicular to a load bearing direction of the sheet metal, and the moving direction of the hairbrush and the surface of the sheet metal form 20 degrees; during replication of the side face of the sheet metal, adopting the small hairbrush to dip acetone, enabling the hairbrush to contact with thesheet metal above the film to enable the acetone to flow down the film and to enable the film to be pasted on the side face of the sheet metal, and pressing the hairbrush to squeeze out the bubbles in the film; during extracting of the film from the front and the back, using a finger to poke the film exposed on the outer side repeatedly to enable the film to slowly expand; during extracting of the film from the side face, using the hairbrush to slightly brush to enable the film to warp up, and using a finger to poke the film exposed on the outer side repeatedly to enable the film to expand. By using the experimental method, replication success rate is increased, and experimental accuracy is improved.

Owner:BEIJING UNIV OF TECH

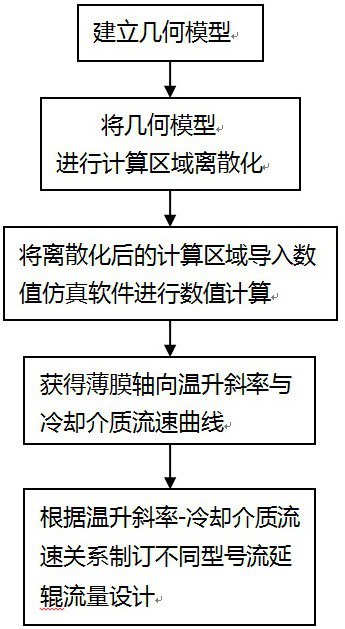

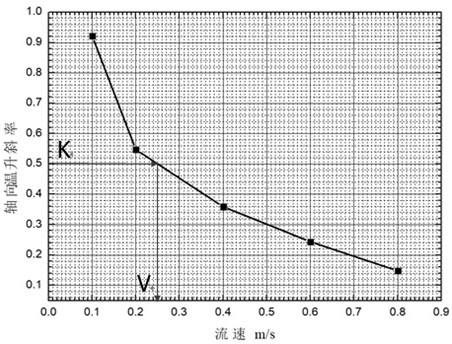

Flow design method of casting roller

ActiveCN112440416AMeet flow parametersFast and accurate operationDesign optimisation/simulationFlat articlesGeometric modelingEngineering

The invention discloses a flow design method of a casting roller. The method comprises the following steps of firstly, respectively establishing geometric models of a casting film, the casting rollerand a cooling medium; secondly, discretizing a calculation region of the geometric models, importing the discretized calculation region into numerical simulation software, setting boundary conditions / physical property parameters, and performing numerical iterative calculation to obtain three-dimensional temperature field distribution characteristics of the casting roller, the casting film, the cooling medium; then, extracting axial temperature rise information of the casting film, and drawing an axial temperature rise curve of the film; and finally obtaining a relation curve of 'axial temperature rise slope - cooling medium flow velocity ' of the film, and conducting calculation according to a flow calculation formula to obtain flow Q meeting design requirements. According to the flow design method of the casting roller, the flow design of the casting roller can be quickly realized, and flow parameters meeting the design requirements are obtained. Specifically, the corresponding relation between the axial temperature rise slope and the flow velocity of the casting roller is obtained in a modeling simulation mode, the relation is substituted into a flow calculation formula, the flowrequired by the casting roller is obtained, and the method is rapid and accurate.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Substrate processing apparatus

InactiveUS20180151394A1Uniform particle sizeAppropriately processedSemiconductor/solid-state device manufacturingCleaning using gasesSputteringEngineering

A substrate processing apparatus includes a substrate rotating mechanism for rotating a substrate, a nozzle part for discharging droplets of a processing liquid toward a main surface of the substrate, and a nozzle moving mechanism for moving the nozzle part in a direction along the main surface. The nozzle part includes two guide surfaces (511), two gas ejection ports (512), and two processing liquid supply ports (513). The gas ejection port ejects gas along the guide surface, to thereby form a gas flow flowing along the guide surface. The processing liquid supply port is provided in the guide surface, for supplying the processing liquid to between the gas flow and the guide surface. In the nozzle part, assuming that one of the two gas ejection ports is regarded as a first gas ejection port for forming a gas flow which carries the processing liquid as a thin film flow to a lower end edge (516) of the guide surface, the other is a second gas ejection port for forming a gas flow which collides with the processing liquid spattering from the lower end edge. With this configuration, it is possible to discharge a lot of droplets having a uniform particle diameter and thereby appropriately process a substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

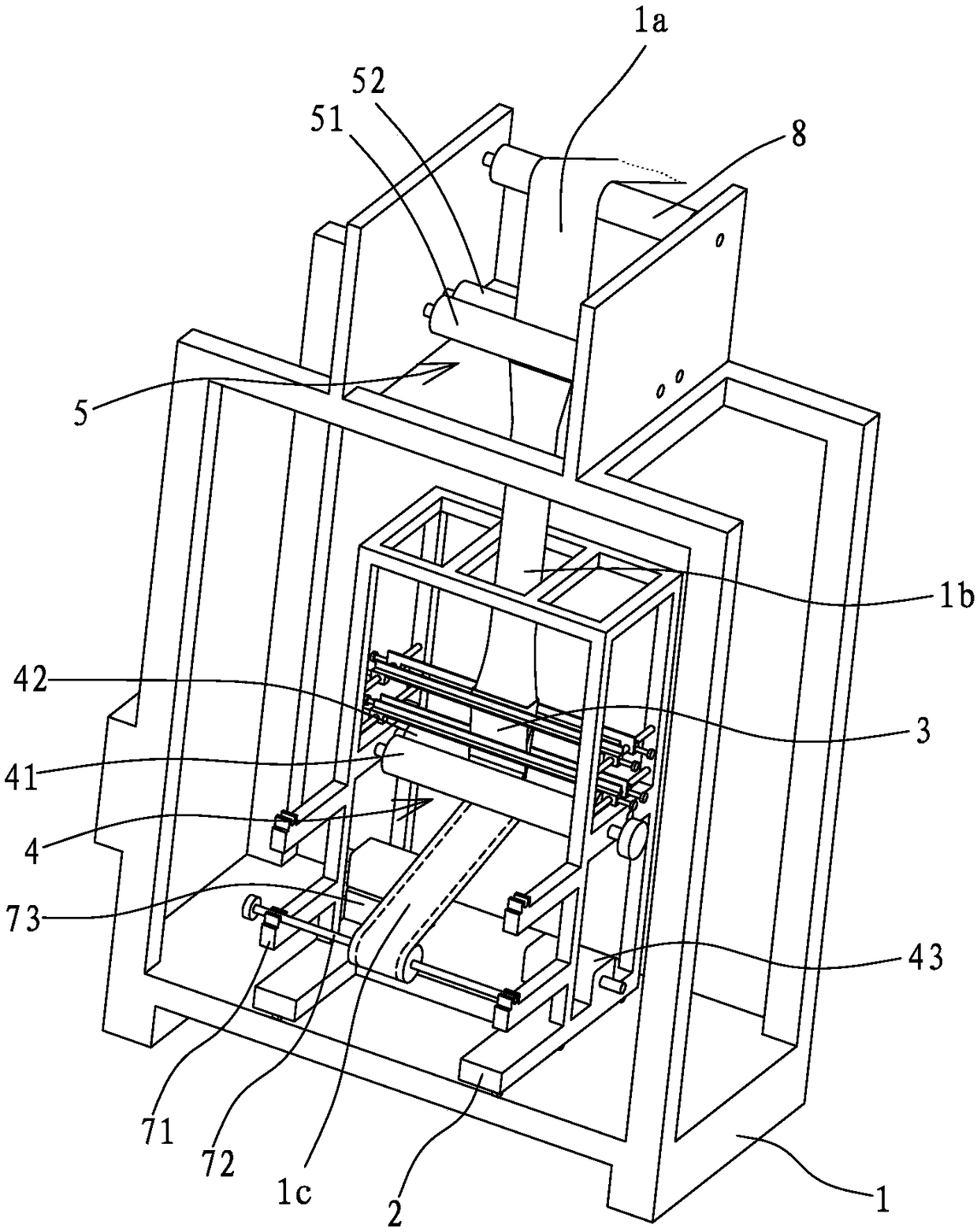

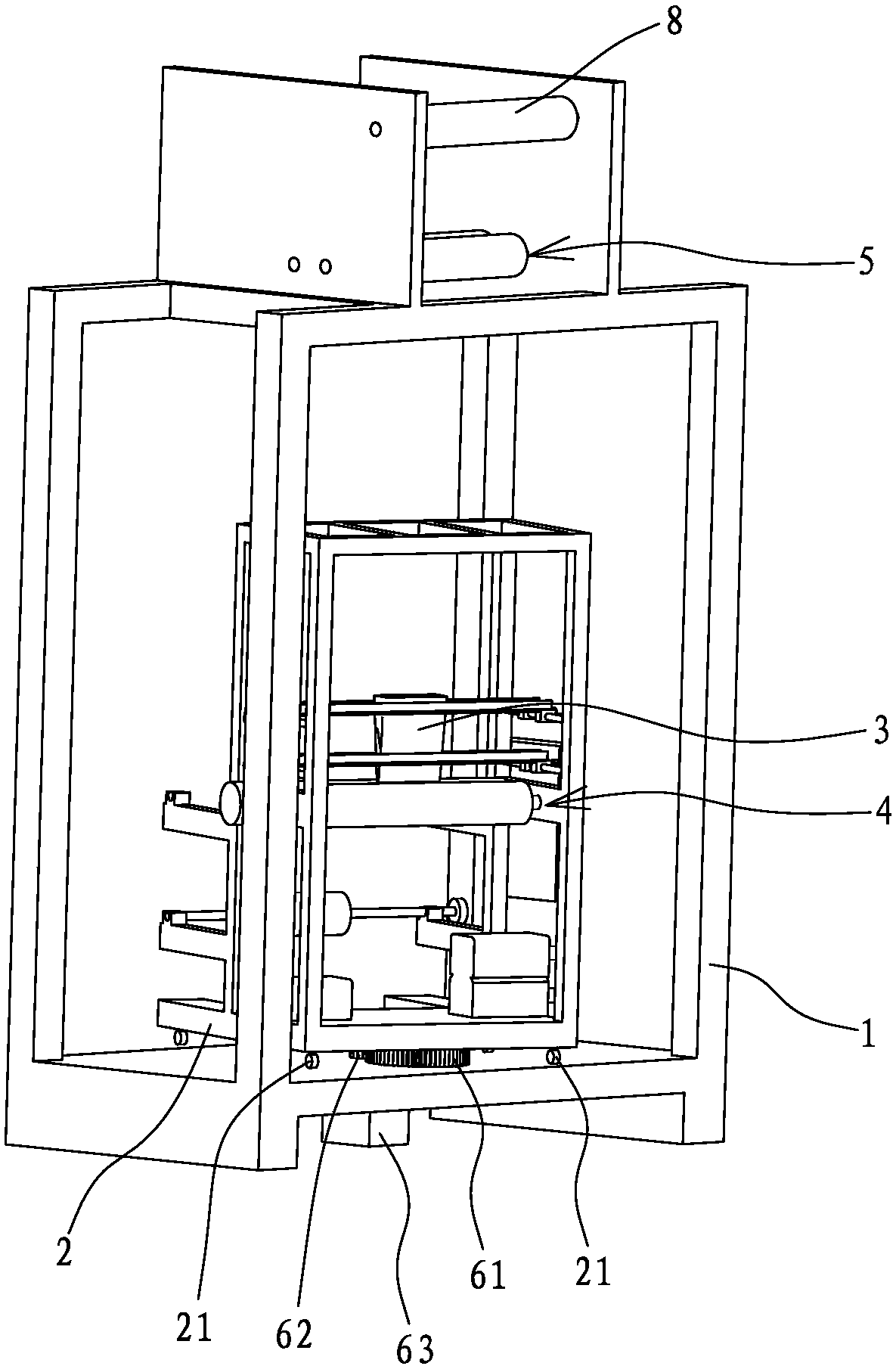

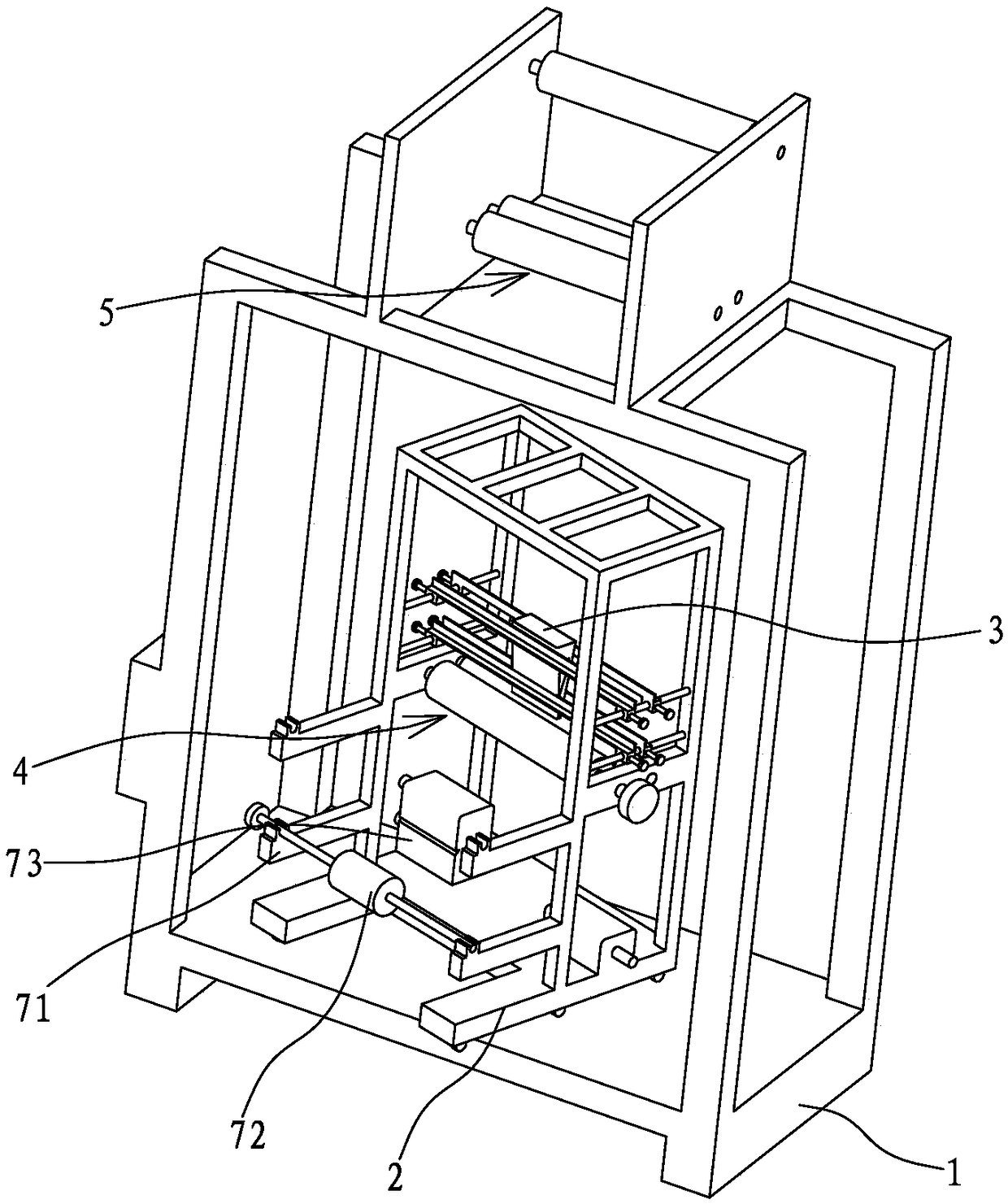

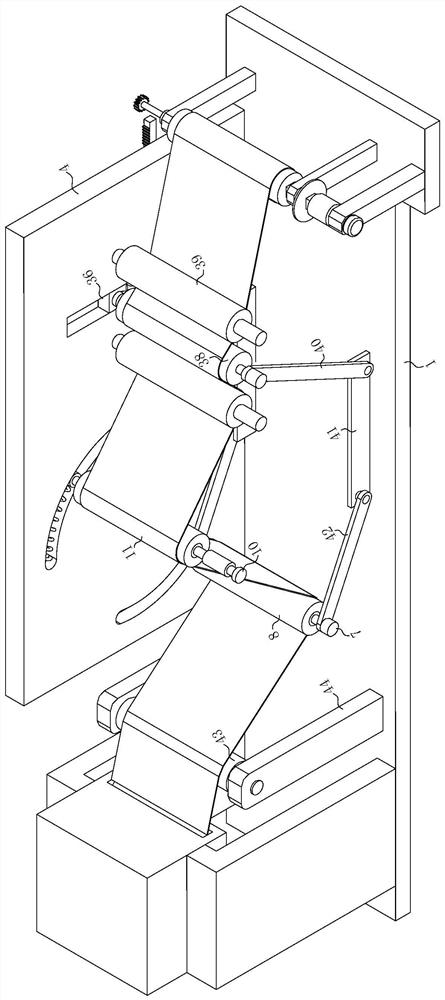

Zigzag folding mechanism suitable for plastic bag processing

PendingCN108582880ACompact structureSave production spaceBag making operationsPaper-makingThin film flowPlastic bag

The invention discloses a zigzag folding mechanism suitable for plastic bag processing. The zigzag folding mechanism comprises a bottom frame; a rotating frame which can rotate relative to the bottomframe is arranged on the bottom frame; a zigzag folding cylinder which allows plastic thin films to penetrate through so as to conduct zigzag folding on the plastic thin films is arranged on the rotating frame; a first roller set which can allow plastic thin film raw materials to pass through is arranged on the position, above the zigzag folding cylinder, on the bottom frame; the first roller setcomprises a first left roller and a first right roller which are mutually attached and tightly press the plastic thin films passing through the position between the first left roller and the first right roller so as to enable plastic thin film layers to be sealed at the first left roller and the first right roller; a second roller set which can forwards convey the plastic thin films flowing out ofthe zigzag folding cylinder is arranged on the rotating frame; and the second roller set comprises a second left roller and a second right roller which are mutually attached, tightly press the plastic thin films passing through the position between the second left roller and the second right roller so as to enable the plastic thin film layers to be sealed at the second left roller and the secondright roller, and drive the plastic thin films to forwards move during rotating. The zigzag folding positions of the plastic thin films can be adjusted by rotating the rotating frame, and operation iseasy.

Owner:ZHONGSHAN ZHENHONG PACKAGING TECH

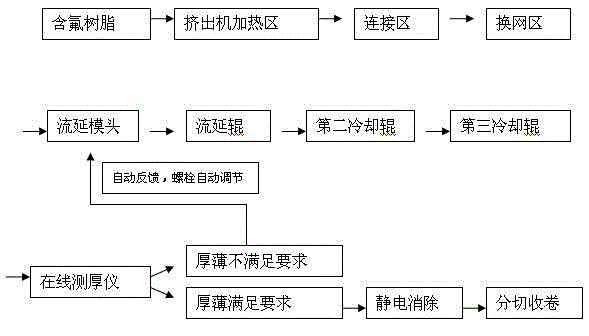

Fluorine-containing thin film tape casting preparing method

The invention relates to a preparation method of fluorine-containing film casting method, wherein the fluorine-containing resin (FEP, PFA, ETFE) is extruded by a screw to obtain a molten fluorine-containing polymer, and then extruded through a casting die to obtain a melt film, a melt film After being cooled and shaped by casting rolls and cooling rolls, and then through online thickness detection and automatic feedback information, the die head automatically adjusts the opening of the die lip to obtain a film whose thickness deviation is controlled within ±2%, and then conducts static elimination and slitting Winding, the final film has good surface smoothness, smoothness and very small thickness deviation, while maintaining other excellent physical properties of the film.

Owner:SHANGHAI PLASTICS RES INST CO LTD

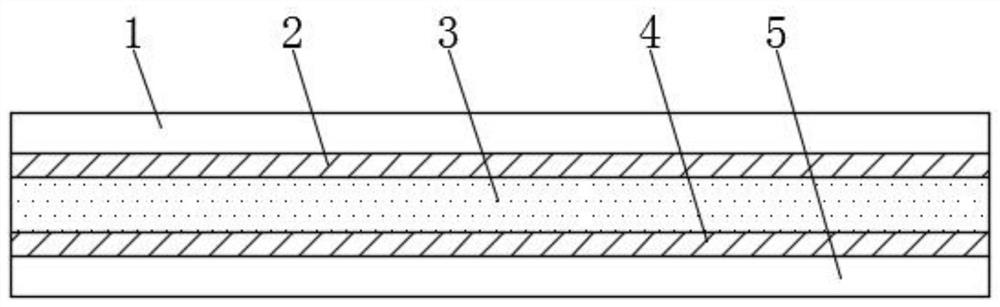

Functional multi-layer co-extruded fluororesin composite film and preparation method thereof

InactiveCN114274626AReduce processing stepsIncrease productivitySynthetic resin layered productsCoatingsComposite filmThin membrane

The invention discloses a functional multi-layer co-extrusion fluororesin composite film and a preparation method, and belongs to the field of airship skin, the functional multi-layer co-extrusion fluororesin composite film has a multi-layer structure, and comprises a first fluororesin layer, a first bonding layer, a high barrier layer, a second bonding layer and a second fluororesin layer. The protective layer and the barrier layer are integrally realized, so that the functionality of the fluororesin composite film is enhanced, the surface density of a skin material is reduced, further optimization is realized while the functions of the protective layer and the barrier layer of the airship skin are ensured, and the fluororesin composite film has the advantages of low surface density, high strength, high barrier, environment (high and low temperature, ultraviolet and the like) resistance and the like; compared with traditional airship skin preparation, compounding procedures are reduced, the process control difficulty is lowered, compared with traditional compounding of a protective layer and a blocking layer, the fluororesin composite film is more stable in structure, higher in interlayer bonding capacity and higher in reliability. The multi-layer co-extrusion fluororesin composite film fills the blank of a multi-layer co-extrusion fluororesin film casting process (two-way stretching process) in China.

Owner:天津新兴东方临近空间航天科技有限公司

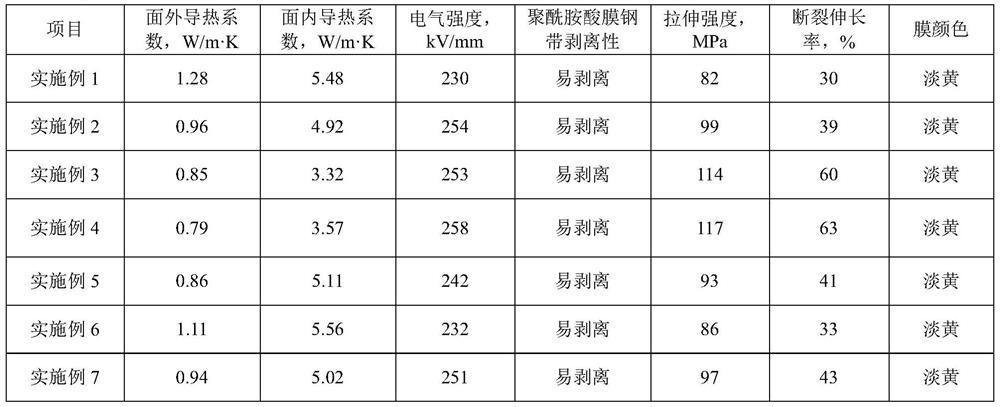

A kind of high out-of-plane thermal conductivity polyimide film and preparation method thereof

ActiveCN112480447BGood dispersionImprove the interface binding forceFlat articlesImidePolymer science

The invention discloses a polyimide film with high out-of-plane thermal conductivity and a preparation method thereof, belonging to the technical field of polyimide materials. The difference between the preparation method of the high out-of-plane thermal conductivity polyimide film of the present invention and the prior art is that the defoaming polyamic acid resin is extruded from the die lip of the die head of the film casting extrusion equipment to whereabouts In the process to the support body, the effect of the electric field is applied, and the direction of the electric field is perpendicular to the falling direction of the defoaming polyamic acid resin; when passing through the casting furnace, the orientation is upward and positive between the front roller and the rear roller. For the hot air on the back of the support, the temperature of the hot air is 150-170°C. The polyimide film prepared by the method of the present invention also has good electrical properties and mechanical properties while having high out-of-plane thermal conductivity and in-plane thermal conductivity, and simultaneously prepares a self-supporting film without adding a release agent. It can be easily and completely peeled off from the support under the premise.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

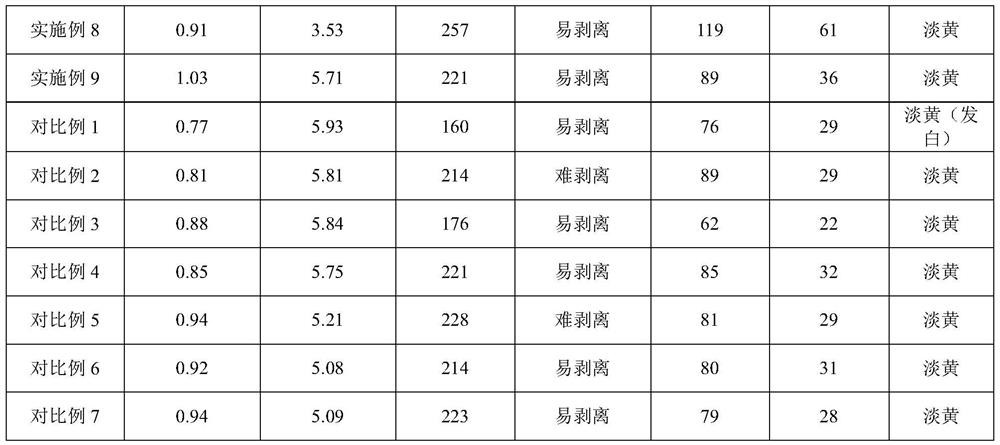

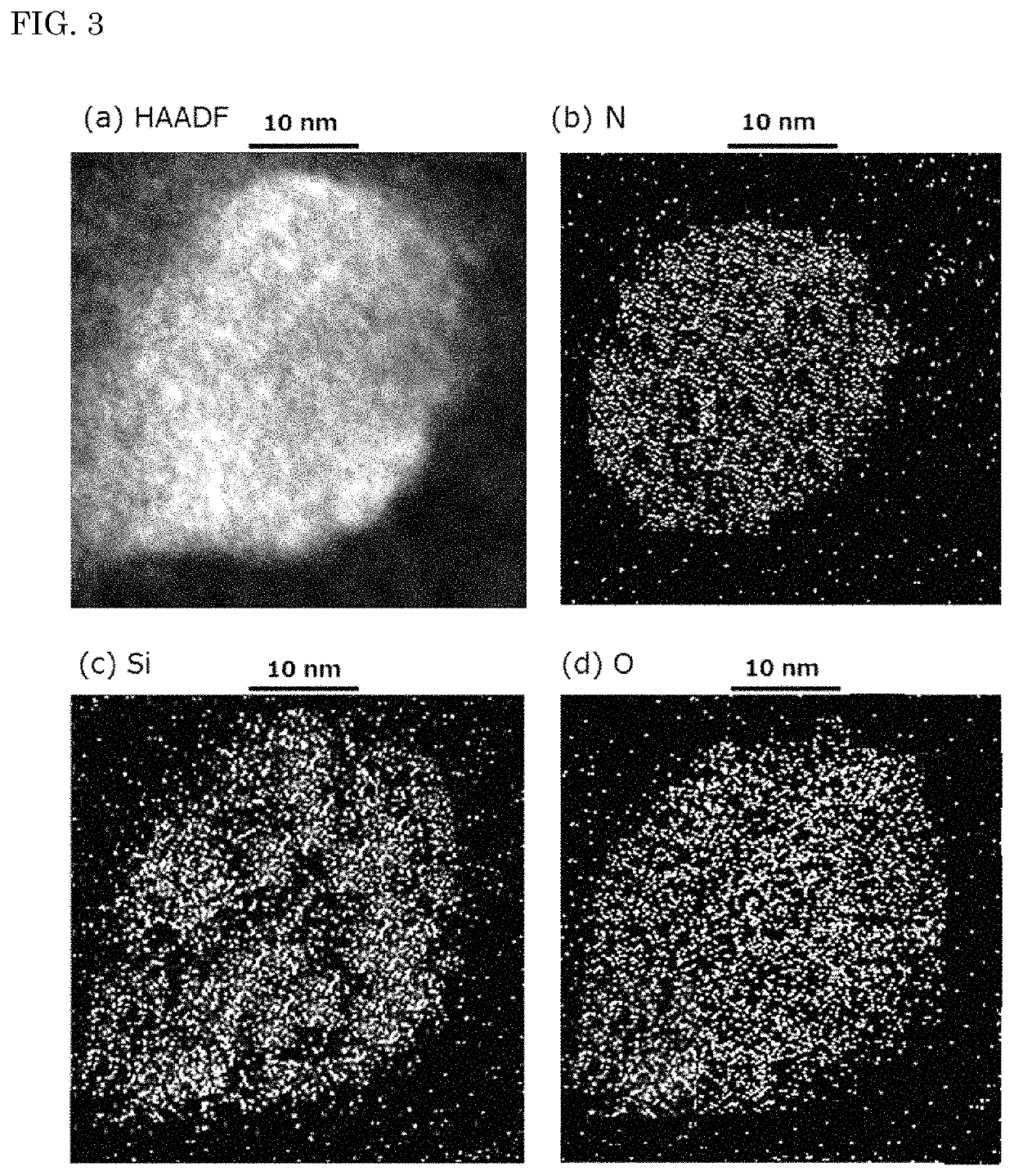

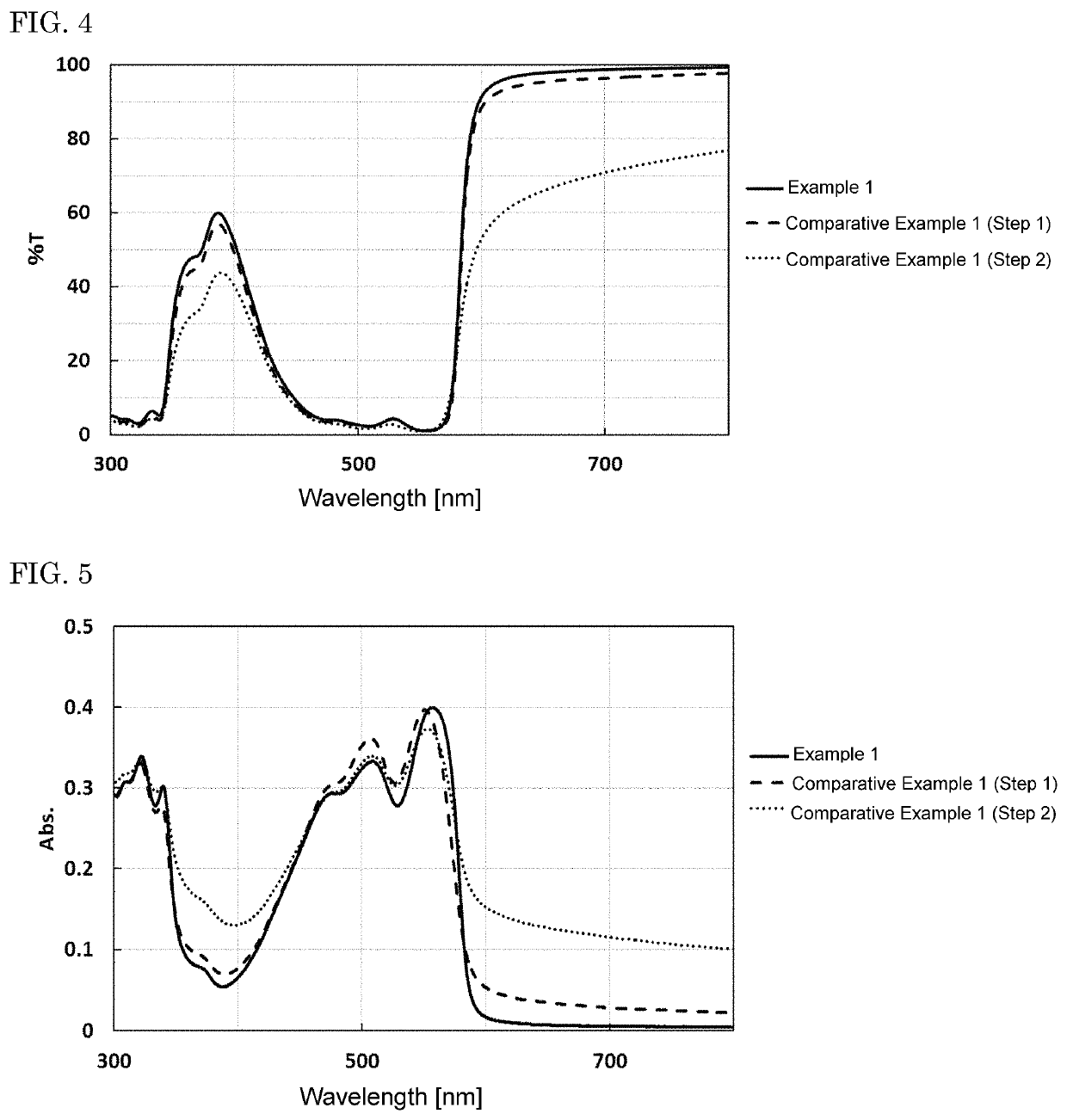

Method for producing organic pigment microparticles

ActiveUS10611915B2Suppress growth and aggregationGood solvent resistanceRotary stirring mixersTransportation and packagingPhotopigmentMicroparticle

A method of producing organic pigment microparticles includes: Step 1 of precipitating organic pigment microparticles by mixing an organic pigment raw material liquid in which an organic pigment raw material is mixed with a solvent, and a precipitation solvent for precipitating the organic pigment microparticles from the organic pigment raw material liquid in a thin film fluid formed by introducing the organic pigment raw material liquid and the precipitation solvent in a space between at least two processing surfaces which are disposed so as to face each other, being capable of approaching to and separating from each other, at least one of which rotates relatively to the other; and Step 2 of coating at least a part of the organic pigment microparticles with an oxide coating; wherein the oxide coating is optically colorless and transparent, and Step 1 and Step 2 are performed out continuously in the thin film fluid.

Owner:M TECH CO LTD

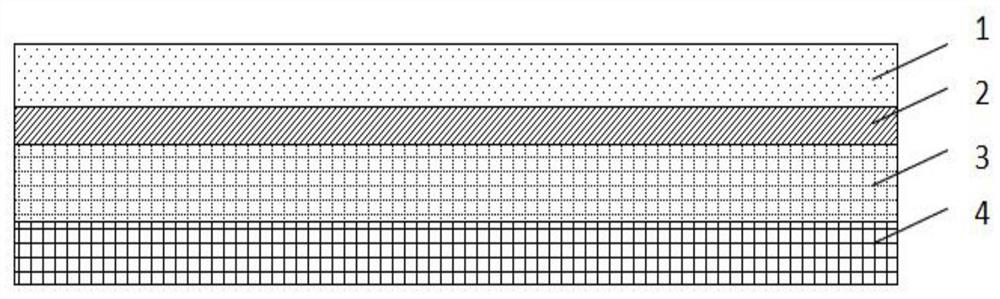

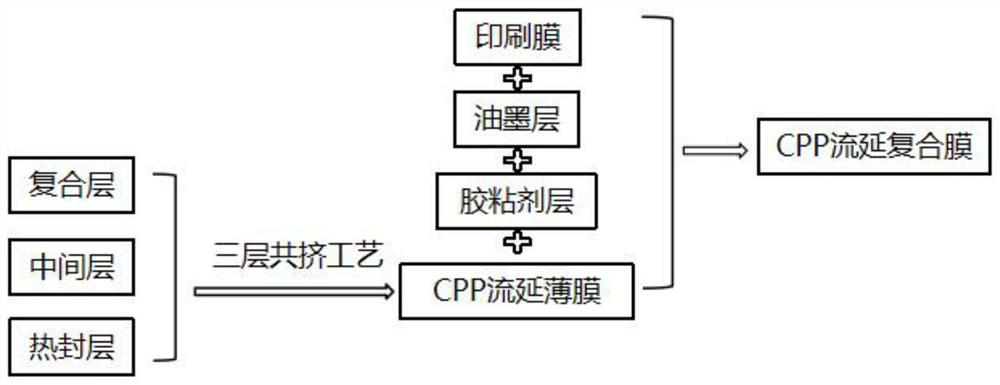

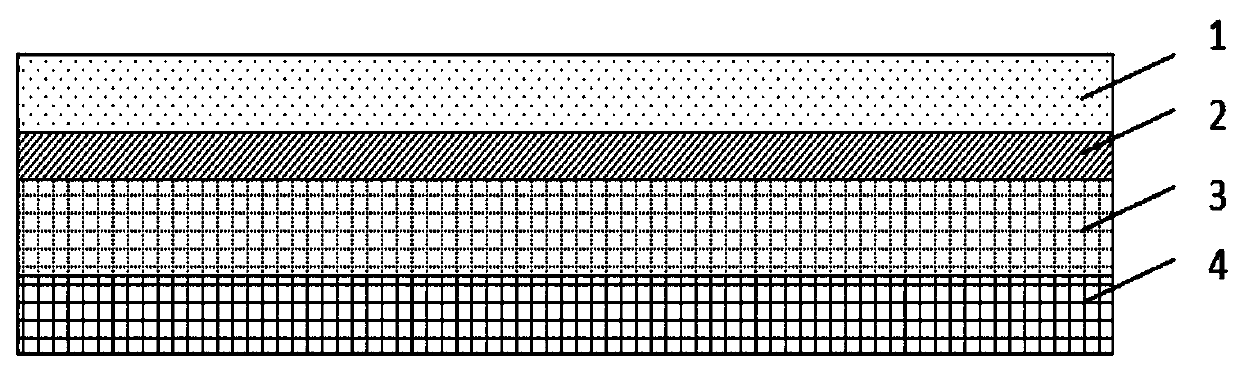

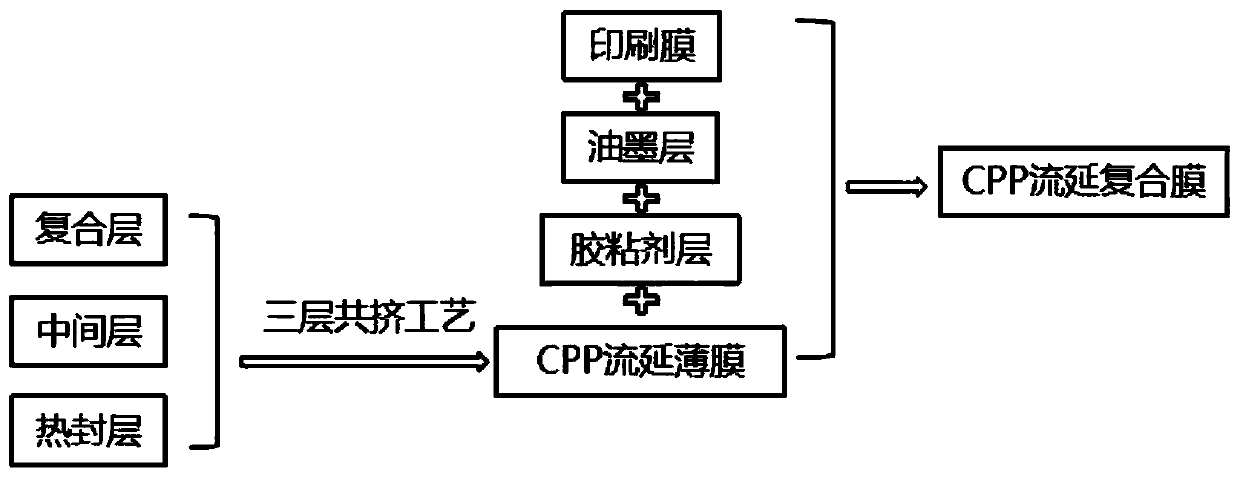

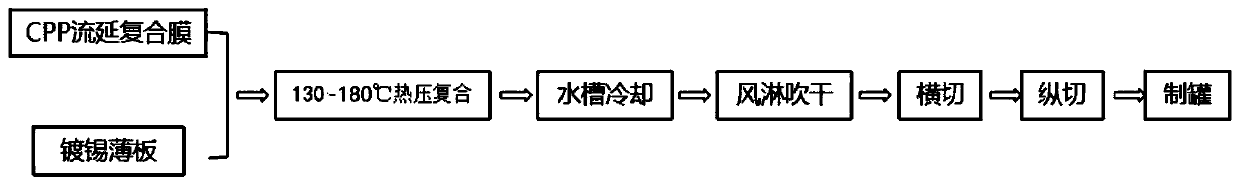

Cpp cast film, composite film, preparation method of composite film and tin-plated sheet

ActiveCN111546734BEasy to handleImprove high temperature resistancePackage recyclingSynthetic resin layered productsTinningComposite film

The invention provides a CPP cast film, a CPP cast composite film, a preparation method of the CPP cast composite film, and a tin-plated sheet heated and pressed by the CPP cast composite film, belonging to the technical field of packaging. The CPP cast film is made of a composite layer, an intermediate layer and a heat-sealing layer through a three-layer co-extrusion casting process; the printing film is printed with gravure printing ink and uniformly glued, and then heated and pressed by a laminating roller to seal the film. The CPP cast film is compounded with the printed film to obtain a composite film containing the CPP cast film. The composite film can be heat-sealed and pressed with a tin-plated sheet at 130-180°C, and the adhesive strength is greater than 5N / 15mm. The composite film is beautifully printed, and the lamination is easy to operate. It is suitable for canning and reprocessing, and is discarded by packaging. The separation and recycling of materials brings a new display effect to the iron-filled packaging. The composite product can be easily formed into cans, and the recycling and disposal of the packaging waste cans is more convenient.

Owner:HUANGSHAN NOVEL

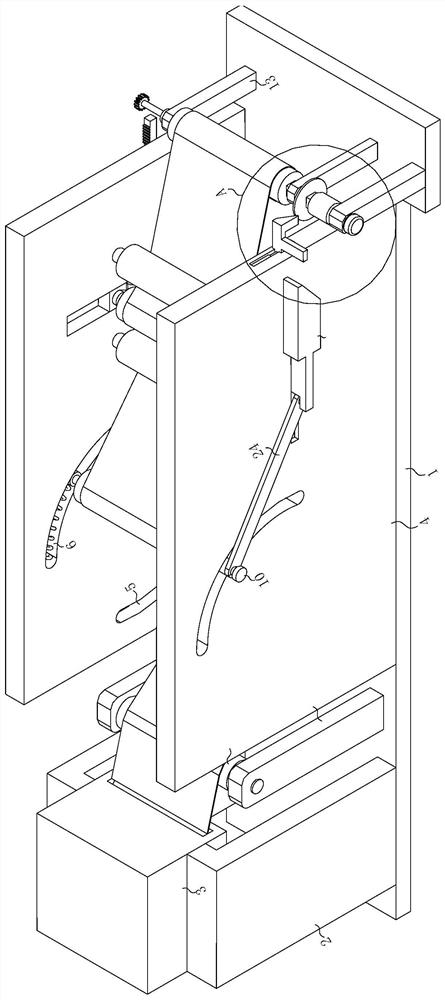

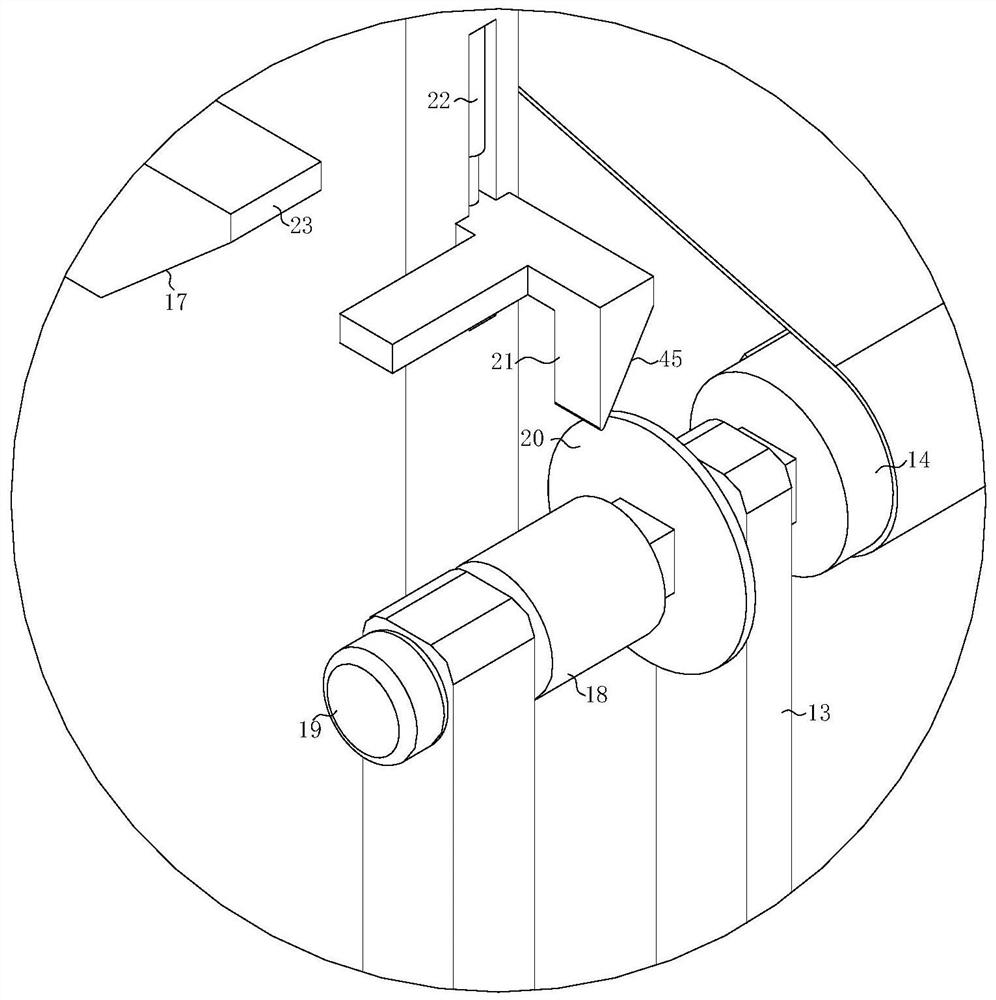

Thin film casting equipment for preparing new polymer packaging material thin film

ActiveCN113183379AEasy to rewindIncrease winding lengthFlat articlesCoatingsThin membraneThin film flow

The invention discloses thin film casting equipment for preparing a new polymer packaging material thin film in the technical field of film thin processing. The thin film casting equipment comprises a bottom plate, the front side and the rear side of the left end of the top of the bottom plate are fixedly connected with two symmetrically-arranged first mounting plates, the inner walls of the two first mounting plates are jointly and fixedly connected with a casting box, second mounting plates are symmetrically and fixedly connected to the front side and the rear side of the top of the bottom plate, first arc-shaped sliding grooves and second arc-shaped sliding grooves are formed in the left sides and the right sides of the inner walls of the two second mounting plates correspondingly, and the two first arc-shaped sliding grooves are slidably connected with first rotating shafts correspondingly. According to the thin film casting equipment, when a casting machine breaks down, protection can be carried out on the thin film, damage to the thin film can be greatly reduced, and the production quality of the thin film can be improved.

Owner:上海纽氪曼科技有限公司

CPP cast film, composite film, preparation method of composite film and tinned sheet

ActiveCN111546734AEasy to handleImprove high temperature resistancePackage recyclingSynthetic resin layered productsTinningComposite film

The invention provides a CPP cast film, a CPP cast composite film, a preparation method of the CPP cast composite film and a tinned sheet formed by heating and pressing the CPP cast composite film, and belongs to the technical field of packaging. The CPP casting film is prepared from a composite layer, a middle layer and a heat sealing layer through a three-layer co-extrusion casting process, andthe composite film containing the CPP cast film is formed by printing ink on the printing film in an intaglio printing manner, uniformly gluing, and heating and laminating through a laminating rollerto compound the CPP cast film and the printing film together, thereby obtaining the composite film containing the CPP cast film. The composite film can be subjected to heat-seal press fit with a tinned sheet at 130-180 DEG C, and the bonding strength is larger than 5 N / 15 mm. The composite film is exquisite in printing, convenient to coat, suitable for can making and reprocessing and capable of bringing a new display effect to iron can packaging through separation and recycling of packaging waste; the compounded products are easy to make cans and form, and packaging waste can bodies are more convenient to recycle and process.

Owner:HUANGSHAN NOVEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com