Substrate treatment apparatus

A substrate processing device and technology for substrates, which are applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of large-scale cleaning nozzles, prolonged cleaning time, and reduced cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

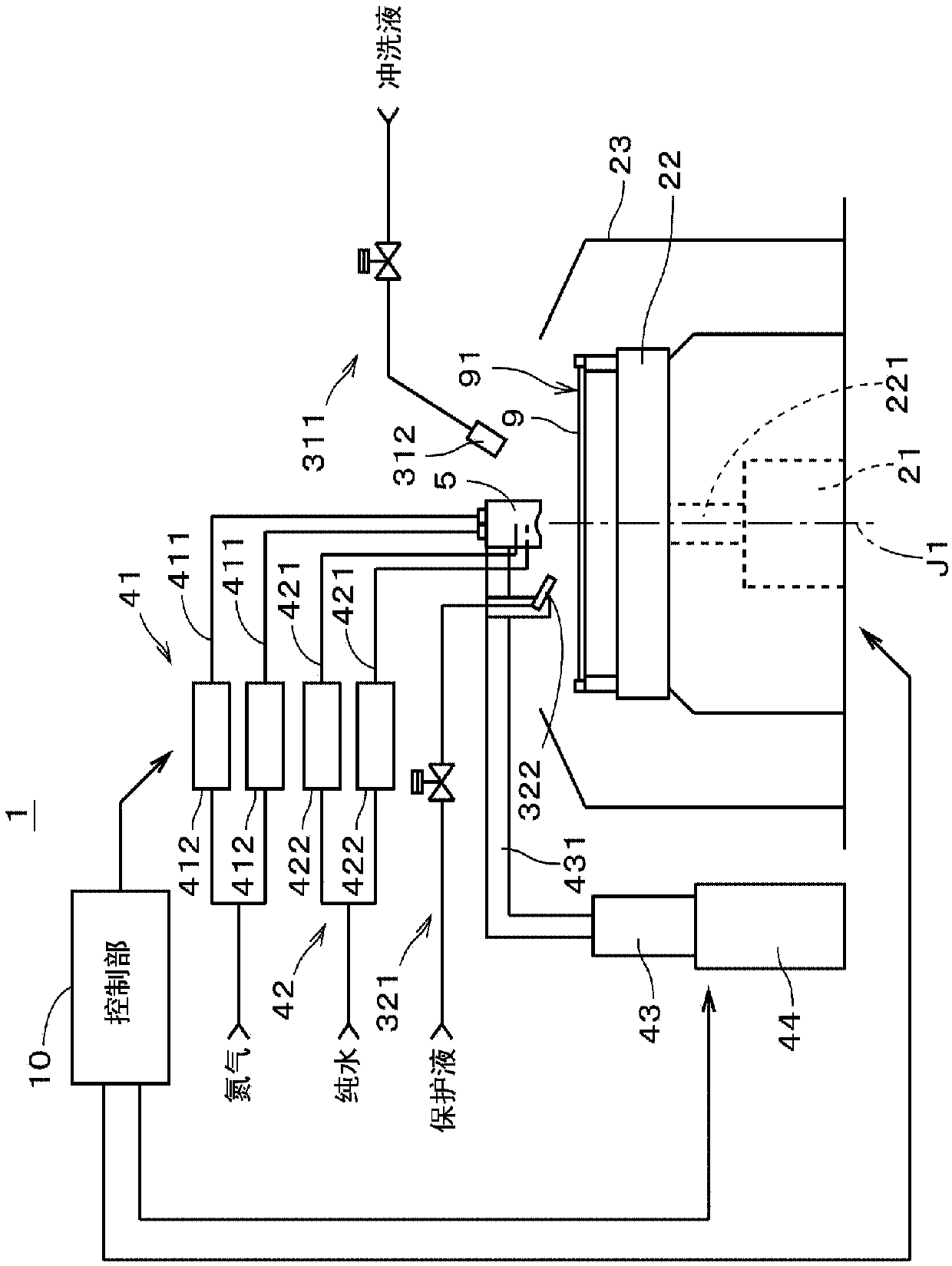

[0037] figure 1 It is a figure which shows the structure of the substrate processing apparatus 1 which concerns on 1st Embodiment of this invention. Each component in the substrate processing apparatus 1 is controlled by the control unit 10 . The substrate processing apparatus 1 includes a spin jig 22 as a substrate holding unit, a spin motor 21 as a substrate rotation mechanism, and a cover 23 surrounding the spin jig 22 . The substrate 9 is placed on the rotary jig 22 . The rotary jig 22 clamps the substrate 9 by bringing a plurality of pinching members into contact with the peripheral edge of the substrate 9 . As a result, the substrate 9 is held in a horizontal posture by the rotating jig 22 . In the following description, main surface 91 of substrate 9 facing upward is referred to as "upper surface 91". Fine patterns are formed on the upper surface 91 .

[0038] A shaft 221 extending in the vertical direction (vertical direction) is connected to the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com