Zigzag folding mechanism suitable for plastic bag processing

A plastic bag and organ technology, which is applied in bag making operations, paper/cardboard containers, containers, etc., can solve problems such as troublesome production, and achieve the effect of simple structure, easy manufacturing and saving production space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

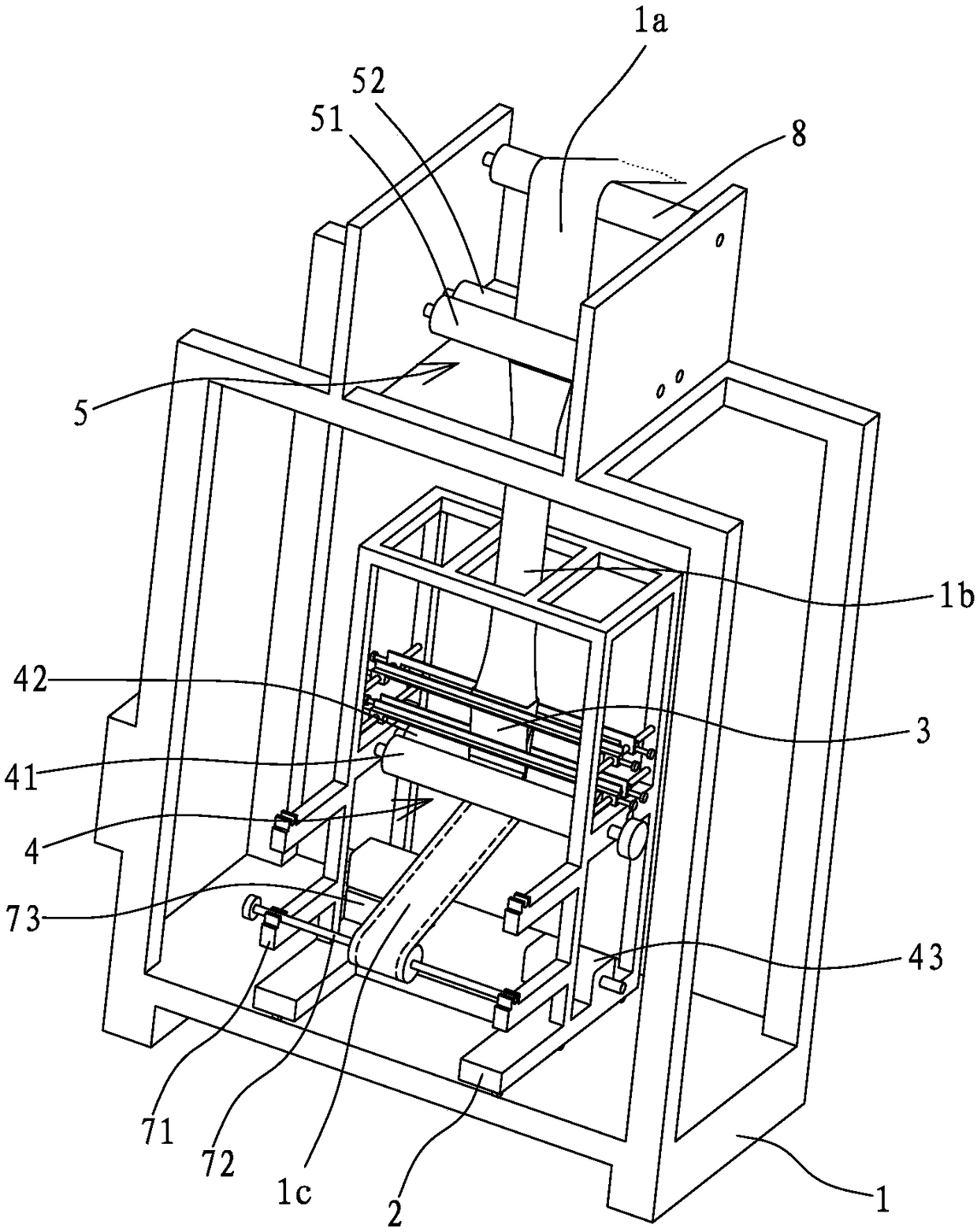

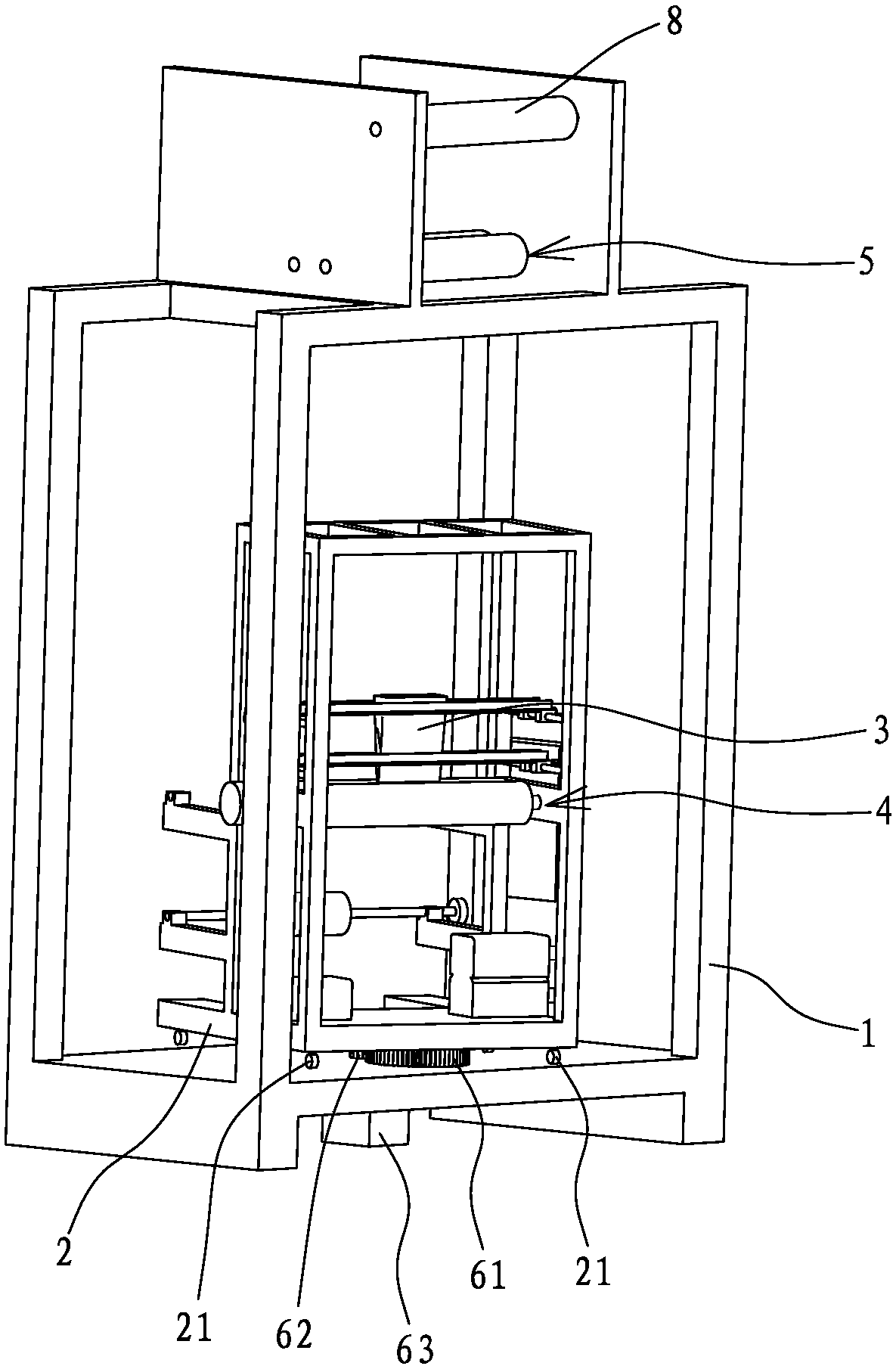

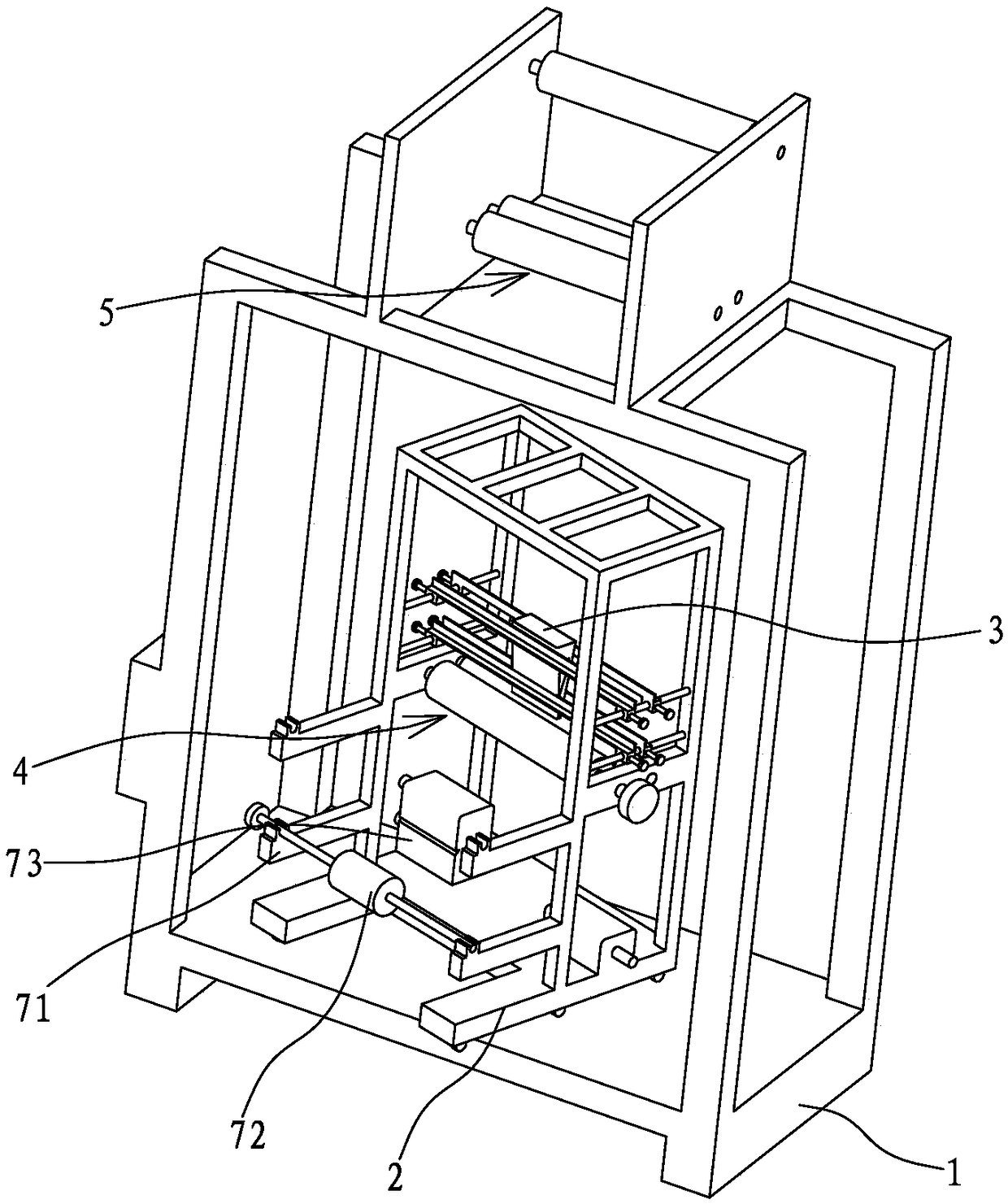

[0023] Such as Figure 1 to Figure 5 A folding organ mechanism suitable for plastic bag processing is shown, including a bottom frame 1, on which a turret 2 capable of rotating relative to the bottom frame 1 is provided, and on the turret 2, there is a blower The expanded plastic film 1b passes through the bellows 3 to fold the plastic film into a bellows. The bottom frame 1 is located above the bellows 3 and is provided with a plastic film raw material 1a for external input to pass through and flow to the bellows. 3, the first roller set 5 includes the first left and right rollers 51, 52 that are attached to each other, and the first left and right rollers 51, 52 will pass between the left and right rollers The plastic film is tightly pressed so that the plastic film layers are sealed at the first left and right rollers 51 and 52. The turret 2 is located on the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com