Fluorine-containing thin film tape casting preparing method

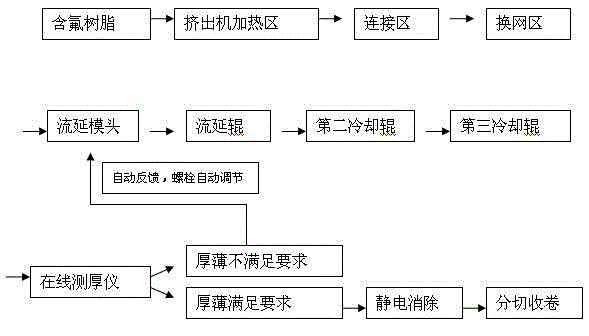

A film casting and thin film technology, which is applied in the preparation of ETFE) casting method, PFA, and fluorine-containing film (FEP), can solve the problems of large film thickness deviation and poor flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

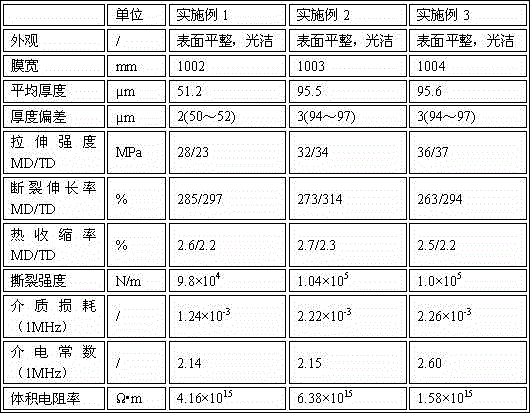

Embodiment 1

[0025] Put the FEP resin through a single-screw extruder with a diameter of 75mm and L / D = 25, flow out through a casting die (the width of the die is 1200 mm), and then shape it through a casting roll and a cooling roll, and finally draw and cut it. rolls to obtain a film of desired thickness. Among them, the screw and barrel of the extruder, the runners in the connecting area, the runners in the screen changing area and the runners in the casting die are all made of nickel alloy.

[0026] The temperature in the first zone of the extruder is set to 260°C;

[0027] The temperature in the second zone of the extruder is set to 310°C;

[0028] The temperature in the third zone of the extruder is set to 325°C;

[0029] The temperature of the junction zone is maintained at about 325°C;

[0030] The temperature in the screen changing area is kept at about 325°C;

[0031] The temperature of the casting die is maintained at about 330°C;

[0032] The temperature of the first tempe...

Embodiment 2

[0037] Put the PFA resin through a single-screw extruder with a diameter of 75mm and L / D = 25, flow out through a casting die (the width of the die is 1200 mm), and then pass through a casting roll and a cooling roll for shaping, and finally draw, cut and collect rolls to obtain a film of desired thickness. Among them, the screw and barrel of the extruder, the runners in the connecting area, the runners in the screen changing area and the runners in the casting die are all made of nickel alloy.

[0038] The temperature of the first zone of the extruder is set to be maintained at about 305°C;

[0039] The temperature in the second zone of the extruder is set to be maintained at about 350°C;

[0040] The temperature of the extruder three zone is set to maintain at about 380°C;

[0041] The temperature of the connection zone is maintained at about 380°C;

[0042] The temperature in the screen changing area is kept at about 380°C;

[0043] The temperature of the casting die is...

Embodiment 3

[0049] Put the ETFE resin through a single-screw extruder with a diameter of 75mm and L / D = 25, flow out through a casting die (the width of the die is 1200 mm), and then pass through a casting roll and a cooling roll for shaping, and finally traction, cutting and harvesting rolls to obtain a film of desired thickness. Among them, the screw and barrel of the extruder, the runners in the connecting area, the runners in the screen changing area and the runners in the casting die are all made of nickel alloy.

[0050] The temperature in the first zone of the extruder is set to 260°C;

[0051] The temperature in the second zone of the extruder is set to 320°C;

[0052] The temperature in the third zone of the extruder is set to 340°C;

[0053] The temperature of the connection zone is maintained at about 340°C;

[0054] The temperature in the screen changing area is kept at about 340°C;

[0055] The temperature of the casting die is maintained at about 340°C;

[0056] The tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com